Remote Automation Solutions Guide: DeltaV Export Configuration Tool Reference Guide-OpenEnterprise v2.83 Manuals & Guides

Page 1

OpenEnterprise DeltaV Export Configuration Tool

D301682X412

Reference Guide

March 2012

OpenEnterprise

TM

DeltaV

TM

Export Configuration Tool Reference Guide

v2.83

The DeltaV Export Configuration Tool is an OpenEnterprise component that enables you to configure

and export a control strategy file that can be imported to a DeltaV Virtual Controller. That makes

OpenEnterprise SCADA data available to the DeltaV community.

In this context, an RTU is a Remote Terminal Unit that is also a process controller (typically a

ControlWave

View and select the remote signals that you want to export to DeltaV

Create a corresponding control strategy module fi le (.FHX) for a DeltaV Virtual Controller

Confi gure the OPC Mirror to pass the selected signal data from OpenEnterprise to the Virtual Controller

™

or ROC™ device). The configuration tool enables you to:

Page 2

OpenEnterprise DeltaV Export Configuration Tool

Table of Contents

1. DeltaV Export Confi guration Tool ......................... 1

1.1 DeltaV RTU Connect .................................. 3

2. How-to Guide ...................................................... 3

2.1 How to Open the Confi guration Tool ......... 3

2.1.1 From the Start Button ................... 3

2.2.2 Command Line Parameters .......... 3

2.2 How to Create Alarm Associations ............. 3

2.3 How to Search for Signals ........................... 3

2.3.1 Work with Rule Sets ...................... 4

2.3.2 Use Aliases in Searches ................. 4

2.4 How to Create the DeltaV Control Strategy 5

2.4.1 How to Modify Default Control

Strategy Areas and Module Names

2.4.2 How to Modify Signal Names ........ 6

2.5 How to Confi gure the PI Server .................. 6

3. Knowledge Base ................................................... 7

3.1 DeltaV Plant ............................................... 7

3.2 ProPlus Workstation .................................. 8

3.3 Operator Workstation ................................ 8

3.4 Application Station .................................... 8

3.5 DeltaV Controller ....................................... 8

3.6 Virtual Controller ....................................... 8

3.7 Remote Controllers .................................... 9

3.8 Plantwide Event Historian .......................... 9

3.9 PI Historian ................................................ 9

3.10 OpenEnterprise ......................................... 9

3.11 OPC Data Access ........................................ 9

3.12 PI Client ..................................................... 10

3.13 DeltaV RTU Connect .................................. 10

3.13.1 DeltaV RTU Connect ..................... 10

3.13.2 Real Time Integration ................... 10

3.13.3 Historical Integration .................... 13

3.13.4 Alarm and Event Integration ......... 22

4. User Interface ....................................................... 24

4.1 Menu Bar ................................................... 25

4.2.1 File Menu ...................................... 25

4.2.2 View Menu ................................... 25

4.3.3 Tools Menu ................................... 25

4.4.4 Help Menu .................................... 26

4.2 Tool Bar ..................................................... 26

4.2.1 Import Rule Set ............................. 26

4.2.2 Export Rule Set ............................. 26

6

March 2012

4.3 Search Criteria Controls ............................. 26

4.3.1 Device Name ................................ 27

4.3.2 Signal Name ................................. 27

4.3.3 Description ................................... 27

4.3.4 Match Case ................................... 27

4.3.5 Instance ....................................... 27

4.3.6 Base ............................................. 27

4.3.7 Extension ..................................... 27

4.3.8 Attribute ...................................... 27

4.3.9 Search for Signals ......................... 27

4.3.10 Add Rule Set ................................. 27

4.3.11 Using Aliases in Rule Sets .............. 28

4.3.12 Modify Rule Set ............................ 28

4.4 Rule Sets Pane ........................................... 28

4.4.1 Delete Rule Set ............................. 28

4.4.2 Search using Rule Sets .................. 28

4.5 Search List Pane ......................................... 29

4.5.1 Background Colors ....................... 29

4.5.2 Selecting Signals ........................... 30

4.5.3 Dragging Signals .......................... 31

4.5.4 Show New Signals Only ................. 31

4.5.5 Hide Dragged Items ..................... 31

4.5.6 Signals Found ............................... 31

4.5.7 Data Service ................................. 31

4.5.8 Signal Properties Dialog ................ 31

4.6 DeltaV Pane ............................................... 32

4.6.1 Name Change Buttons .................. 33

4.6.2 Export Button ............................... 33

4.6.3 Adding Areas ................................ 35

4.6.4 Adding Modules ........................... 35

4.6.5 Deleting Signals ............................ 37

4.6.6 Performance Issues ....................... 37

4.6.7 Gateway Export Tool Settings ....... 37

4.7 Status Pane ................................................ 37

4.8 Properties Dialog ....................................... 38

4.8.1 General Page ................................ 38

4.8.2 Tag Format Page ........................... 40

4.8.3 Alarm Association Page ................ 43

4.8.4 OPC Mirror Page ........................... 47

4.8.5 Historical Backfi ll .......................... 48

5. Index .................................................................... 52

2 www.EmersonProcess.com/Remote

Page 3

March 2012

OpenEnterprise DeltaV Export Configuration Tool

1.1 DeltaV RTU Connect

DeltaV RTU Connect is an integrated software suite, centering around the OpenEnterprise SCADA application, that

enables data from remote RTUs to be passed into a DeltaV plant. It is installed onto a DeltaV Application Station.

2. How-to Guide

This is a high level list of tasks required to confi gure the Export Confi guration Tool. Some tasks link to topics which break the

tasks down into smaller units.

1. How to Open the Export Confi guration Tool

2. How to Create alarm associations

3. How to Search for signals from the RTU Connect

4. How to Create and Export the DeltaV control strategy

5. How to Confi gure the PI Server

Note: For instructions on how to confi gure a DeltaV RTU Connect application station, please see document number D301690x412

entitled “DeltaV RTU Connect - Getting Started”. This will be available on the installation media or from the Emerson public web site.

2.1 How to Open the Configuration Tool

2.1.1 From the Start Button

This opens the Export Confi guration Tool with default settings applied from the OpenEnterprise settings fi le.

1. Select Start > All Programs > OpenEnterprise > Toolbox.

2. Double click on the Gateway Export tool within the Toolbox.

2.1.2 Command Line Parameters

The command line parameters can be used to vary how the Export Confi guration Tool opens. They may be

applied directly from the command line or as command line parameters to the task in the Session Manager.

–s: Database service

–u: Username

–p: Password

–n: Devicename - inserts the devicename into the devicename text box on startup

2.2 How to Create Alarm Associations

1. Select Tools > Properties from the menu bar.

2. Select the Alarm Association page from the left pane of the Properties dialog.

3. Create your alarm associations - for more information see the Alarm Association topic.

2.3 How to Search for Signals

1. Using the DeltaV Export Confi guration Tool interface, create your search criteria, then view the signals.

See the Search Criteria Controls topic for more information on creating search criteria.

See the Search List Pane topic for information on the search list itself.

2. Defi ne other rule sets if required See the Working with rule sets topic for more information.

3. Use aliases in rule sets to fi ne tune your searches. See the How to use Aliases in Searches topic for instructions.

www.EmersonProcess.com/Remote 3

Page 4

OpenEnterprise DeltaV Export Configuration Tool

2.3.1 How to Work with Rule Sets

1. See the Rule Sets Pane topic for more information on working with rule sets.

2. See the Tool Bar topic for more information on exporting and importing rule sets.

2.3.2 How to use Aliases in Searches

It is possible to create rules that contain aliases in order to refi ne searches for tags. Aliases can be defi ned within

the Device name, Instance, Base, Extension, and Attribute fi elds. This is an example of one way aliases can be

created and used.

1. Create the fi rst rule set using an alias and one other real value in the search criteria controls.

a. Type the alias by enclosing it in double pipe characters - e.g., ||BASE||.

b. Add an actual value in at least one other fi eld.

c. Click the button highlighted in red to add the defi ned search to the confi gured rule sets.

March 2012

2. Change the real value to another valid value and create a second rule set.

a. Leave the ||BASE|| alias there.

b. Change the Attribute alias.

c. Add the new search to the rule sets.

3. Create a third rule set.

a. Leave the ||BASE|| alias there.

b. Change the Attribute alias again.

c. Add the fi nal search to the rule sets.

4 www.EmersonProcess.com/Remote

Page 5

March 2012

OpenEnterprise DeltaV Export Configuration Tool

4. Finally, give the alias a value in the search criteria and use the rule sets to fi nd the tags of interest.

2.4 How to Create the DeltaV Control Strategy

Having got to this stage, you should already have searched for and created a list of signals that you are interested in

exporting to DeltaV. See the How to Search for Signals section for instructions.

1. Before you begin, decide if you want to modify the default names for control strategy areas and modules. See the How

to Modify Default Control Strategy Areas and Module Names topic for more information.

2. Also before you begin, consider how you will convert your OpenEnterprise tag names so that the DeltaV 16 character

limit is not broken. See the Tag Format Page for further information.

3. Add Area and Module nodes to your control strategy using the DeltaV Pane. See the DeltaV Pane topic for more

information.

4. Select the required signals and drag them from the Search List pane to the DeltaV pane. For more information see the

Search List Pane topic.

5. Check the status pane to see if there are any signal names that need to be changed. See the Status Pane topic for more

information.

www.EmersonProcess.com/Remote 5

Page 6

OpenEnterprise DeltaV Export Configuration Tool

6. Modify or shorten signal names. See the How to Modify Signal Names topic for more information.

7. If there is no further warning about tagnames in the Status Pane, click the [Export] button at the top of the DeltaV pane.

See the DeltaV Pane topic for more information on the [Export] button. This will export the .FHX fi le using the fi le name

and location confi gured on the General Properties Page.

8. From the DeltaV ProPlus workstation download this control strategy fi le to the virtual controller on the DeltaV RTU

Connect machine.

2.4.1 How to Modify Default Control Strategy Areas and Module Names

1. Select Tools > Properties from the Export Confi guration Tool menu bar.

2. Select the Tag Format page. The Area / Module name format section at the bottom of this page contains input

fi elds to change these default names. See the Tag Format topic for more information.

2.4.2 How to Modify Signal Names

1. If you have many signals to change and you can live with a shortened format being applied to all tagnames:

a. Select Tools > Properties from the Export Confi guration Tool menu bar.

b. Use the tag format page of the properties dialog to make the necessary changes.

c. When you have fi nished making the changes, click the [OK] button at the bottom of the Tag Format page,

and you have the choice of applying the name changes immediately. See the Tag Format topic for more

information.

2. If you only have a small number of tag names to change:

a. Use the left and right buttons in the DeltaV explorer view. These will be highlighted if any tag names

require a name change.

b. On pressing the right button the next signal requiring a name change will be highlighted for modifi cation.

c. he left and right arrow keys can also be used instead of the buttons. This particular method is useful if

you want to modify only the tagnames that require changing (rather than forcing tagname changes to be

applied to all signals). See the DeltaV Pane topic for more information.

March 2012

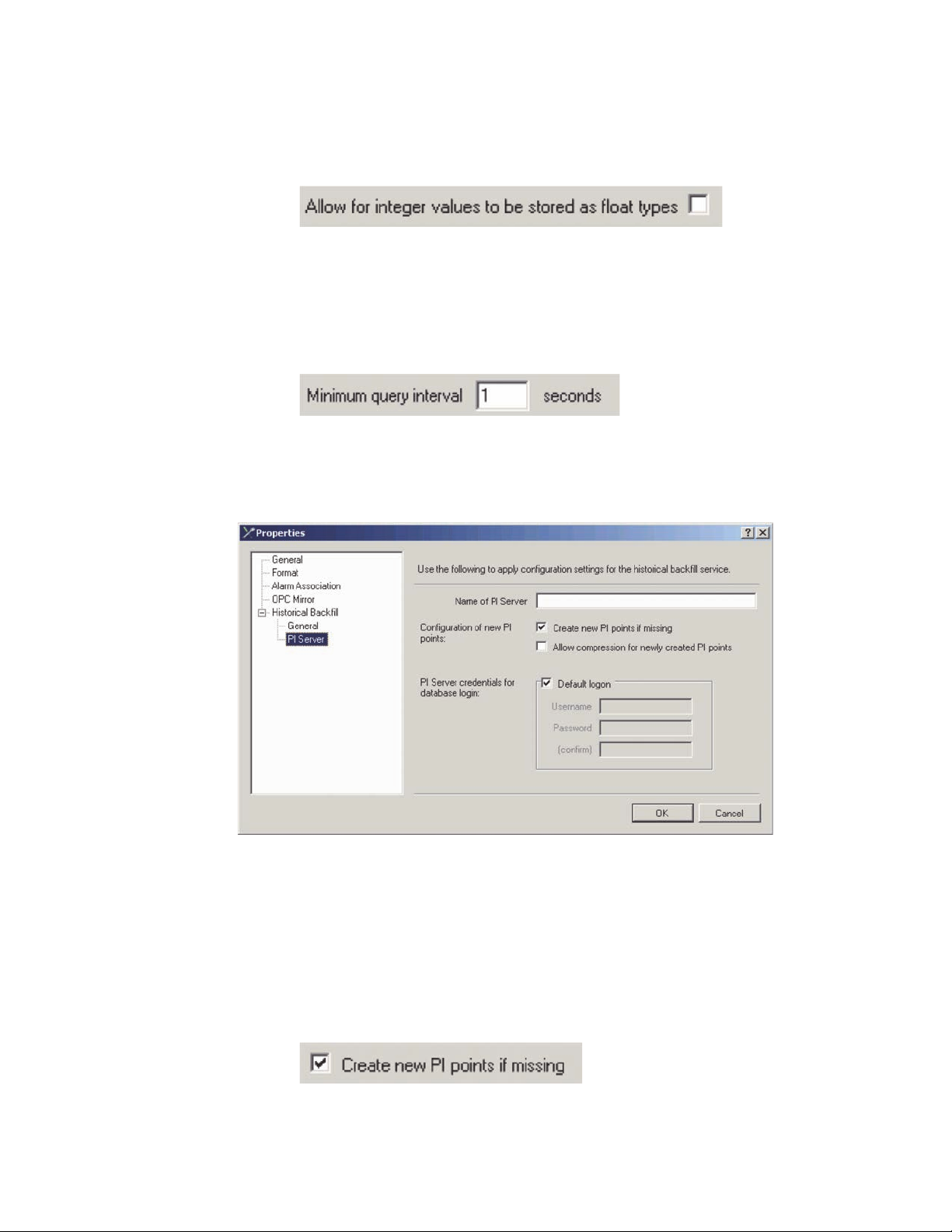

2.5 How to Configure the PI Server

1. Open the property pages by selecting Tools | Properties from the Export Confi guration Tool menu bar.

2. Select the Historical Backfi ll pages.

3. On the General Historical Backfi ll page you can change the way the RTU Connect handles historical streaming to the PI

database. See the Historical Backfi ll General Page topic for more details.

4. On the PI Server page you can specify the name of the PI Server (unless you’re using the default PI server). You can also

confi gure how the RTU Connect should handle new PI points when streaming the data and modify PI Server logon

credentials if necessary. See the Historical Backfi ll PI Server Page topic for more details.

6 www.EmersonProcess.com/Remote

Page 7

March 2012

OpenEnterprise DeltaV Export Configuration Tool

3. Knowledge Base

The aim of this section is to help you to understand how the DeltaV RTU Connect integrates remote RTU data collected by

OpenEnterprise into DeltaV systems.

A diagrammatic representation of DeltaV RTU Connect integration is shown below. The headings below it will explain each

element of the diagram.

3.1 DeltaV Plant

The RTU Connect enables RTU data to be integrated into a DeltaV system using the following DeltaV components:

An application station running OpenEnterprise which is collecting data from RTUs.

A DeltaV virtual controller which makes the data from the RTUs available to the DeltaV system.

A second application station running the PI historical database and the Plantwide Event Historian to provide historical

signal and alarm-event data from the RTUs.

www.EmersonProcess.com/Remote 7

Page 8

OpenEnterprise DeltaV Export Configuration Tool

3.2 ProPlus Workstation

The ProfessionPLUS (or ProPlus) workstation is used to provide a single administrative point of entry, allowing

for access to all aspects of a DeltaV integrated solution (including third party applications).

The ProPlus workstation also contains the central DeltaV confi guration database. A ProPlus workstation is a

requirement of every DeltaV network. There can be only one ProPlus workstation per system.

3.3 Operator Workstation

A DeltaV operator workstation provides standard plant operational capability. This includes the use of control

displays, real-time and historical trending capabilities and the ability to view and process alarms.

3.4 Application Station

As part of the DeltaV suite a user can confi gure a desktop or server to host a DeltaV application station. The

application station is used to integrate DeltaV and other applications into the enterprise. A single system

can host up to 20 application stations, each with their own virtual controller.

The DeltaV RTU Connect is installed onto a DeltaV application station. Typically, the OpenEnterprise part of the RTU

Connect will be installed on one application station and the Plantwide Event Historian and PI Historian are installed on a

separate application station.

March 2012

3.5 DeltaV Controller

A plug and play controller that executes control logic based on the process signals derived from the

I / O subsystem and provides communication to the rest of the DeltaV control system for operator

interaction and data collection.

The controller’s primary function is to execute control modules that are designed to meet the specifi c control requirements

of the plant. These control modules use process signals from the controller’s I / O subsystem and provide communication of

process data to the rest of the DeltaV control system for operator interaction and data collection.

3.6 Virtual Controller

This is an IEC 61-1131 emulated DeltaV controller (in effect a soft programmable logic controller). The DeltaV

Export Confi guration Tool creates a control strategy fi le (an .FHX fi le) that contains references to the remote

RTU signals. The control strategy is then downloaded to the virtual controller from the DeltaV system.

The control strategy contains input signal tags which can be arranged by the Export Confi guration Tool within alarm

function blocks, linking process signals with their alarm limits.

8 www.EmersonProcess.com/Remote

Page 9

March 2012

The virtual controller inputs are connected to the OpenEnterprise OPC Data Access server via the OPC Mirror in order to

receive real-time data from the DeltaV RTU Connect.

In this way the virtual controller pushes data from the RTU Connect into the DeltaV network to emulate passed through

real-time data and alarms from remote controllers.

3.7 Remote Controllers

These are remote ControlWave or ROC controllers that are being integrated into the DeltaV system

through the DeltaV RTU Connect.

3.8 Plantwide Event Historian

The Plantwide Event Historian (PEH) captures, stores and displays event data for an entire plant. It records

plant event information from any OPC alarm and event server, including the OpenEnterprise OPC Alarm and

Event server, and stores that information in a Microsoft SQL Server database.

For more details on how the RTU Connect integrates alarm and event data into DeltaV see the Alarm and Event Integration

topic.

3.9 PI Historian

The PI Historian is a standard enterprise database developed by OSIsoft™ that allows for an embedded, centralized

alternative to the native DeltaV continuous historian. The PI Historian can be installed onto an application station and

embedded into a DeltaV system.

OpenEnterprise DeltaV Export Configuration Tool

The DeltaV RTU Connect streams historical backfi ll data via the PI client to the PI historian. DeltaV operator workstations

are confi gured to request historical data from the PI Historian rather than the DeltaV continuous historian.

For more details on how the RTU Connect integrates signal history into DeltaV, see the Historical Integration topic.

3.10 OpenEnterprise

OpenEnterprise is an industrial strength SCADA (Supervisory Control and Data Acquisition) system.

OpenEnterprise collects data from Remote Telemetry Units (RTUs) using direct low level communications

programs and serves the data to clients, normally through standard OPC and ODBC application interfaces.

Typical systems include a processing plant (for instance a well head, pipeline or water processing plant)

connected to ControlWave or ROC RTUs and communication systems to transmit the data back to the OpenEnterprise

server database.

3.11 OPC Data Access

OPC Data Access is a group of standards that provides specifi cations for communicating real-

time data from automation controllers. Real-time data is streamed from the DeltaV RTU Connect

through to DeltaV by means of the OPC Mirror application.

For more information on how the DeltaV RTU Connect integrates real time data into DeltaV through OCP Data Access, see

the Real Time Integration topic.

www.EmersonProcess.com/Remote 9

Page 10

OpenEnterprise DeltaV Export Configuration Tool

3.12 PI Client

The Historical Export Application uses the PI SDK to stream historical data from OpenEnterprise to the PI

Historian.

For more information on how the DeltaV RTU Connect integrates historical data into DeltaV through the

Historical Export Application, see the Historical Integration topic.

3.13 DeltaV RTU Connect

3.13.1 DeltaV RTU Connect

The DeltaV RTU Connect is a suite of software components that when installed together or separately onto DeltaV

Application Station nodes within a DeltaV system make it possible to integrate real-time, alarm-event and historical

data from remote ControlWave and ROC devices into that DeltaV system:

1. Real Time Integration

2. Historical Integration

3. Alarm and Event Integration

3.13.2 Real Time Integration

In order to allow for the provision of real-time logged data, the DeltaV RTU Connect uses OPC Data Access

connectivity.

March 2012

10 www.EmersonProcess.com/Remote

Page 11

March 2012

OpenEnterprise DeltaV Export Configuration Tool

3.13.2.1 The DeltaV Export Configuration Tool

The DeltaV Export Confi guration Tool allows you to select the remote RTU tags that you want to integrate

into the DeltaV system. You can then export these tags to a control strategy module fi le (.FHX), which

DeltaV downloads to a virtual controller module.

The Export Confi guration Tool also sends mapping information from your selected signals to the OPC

Mirror, which enables the OpenEnterprise OPC server and the DeltaV OPC servers to pass the signal data

between themselves. The DeltaV OPC server then pushes the RTU data to the virtual controller and it

becomes integrated into the DeltaV system.

The Export Confi guration Tool also allows you to confi gure historical integration via the PI Historian.

3.13.2.2 The OPC Mirror

The OPC Mirror is able to create a channel that streams data between two OPC servers. This channel is

called a “pipe”. The confi guration required for the OPC Mirror to form a pipe is:

1. The program id of the OpenEnterprise OPC server (let’s call this A)

2. The program id of the DeltaV OPC server (let’s call this B)

3. The direction of the piping

a. From A to B

b. From B to A

c. Both ways (this is the option used)

4. A map of the required signal data.

This is all done automatically when you export an .FHX fi le using the DeltaV Export Confi guration Tool.

The Export Confi guration Tool confi gures the OPC Mirror at the same time that it exports the .FHX fi le.

The only thing you will need to do regarding the OPC Mirror itself is to provide a DeltaV administrator

name and password when you install it onto the DeltaV RTU Connect application station. The Export

Confi guration Tool will do the rest.

3.13.2.2 The OpenEnterprise OPC Server

The OpenEnterprise OPC Data Access server makes data from the OpenEnterprise database available to

OPC clients. Its program id is BristolBabcock.BristolOPCServer.

3.13.2.4 The DeltaV OPC Server

The DeltaV OPC server makes data from the RTU Connect available to the DeltaV virtual controller on

the application station, which in turn makes it available to the rest of the DeltaV system. Its program id is

OPC.DeltaV.1.

3.13.2.5 Virtual Controller

This is an IEC 61-1131 emulated DeltaV controller (in effect a soft programmable logic controller). The

DeltaV Export Confi guration Tool creates a control strategy fi le (an .FHX fi le) that contains references to

the remote RTU signals. The control strategy is then downloaded to the virtual controller from the DeltaV

system.

www.EmersonProcess.com/Remote 11

Page 12

OpenEnterprise DeltaV Export Configuration Tool

The control strategy contains input signal tags which can be arranged by the Export Confi guration Tool

within alarm function blocks, linking process signals with their alarm limits.

The virtual controller inputs are connected to the OpenEnterprise OPC Data Access server via the OPC

Mirror in order to receive real-time data from the DeltaV RTU Connect.

In this way the virtual controller pushes data from the RTU Connect into the DeltaV network to emulate

passed through real-time data and alarms from remote controllers.

March 2012

3.13.2.6 OpenEnterprise

OpenEnterprise is an industrial strength SCADA (Supervisory Control and Data Acquisition) system.

OpenEnterprise collects data from Remote Telemetry Units (RTUs) using direct low level communications

programs and serves the data to clients, normally through standard OPC and ODBC application

interfaces.

Typical systems include a processing plant (for instance a well head, pipeline or water processing plant)

connected to ControlWave or ROC RTUs and communication systems to transmit the data back to the

OpenEnterprise server database.

3.13.2.7 Remote Device Interfaces (RDIs)

OpenEnterprise communicates with ControlWave and ROC RTUs using a set of device drivers called

Remote Device Interfaces (RDIs). Collected data can consist of current values, history and alarm and

event data.

3.13.2.7.1 The ControlWave RDI

The ControlWave RDI is also known as the NW3000 RDI since the original family of Bristol

devices were known by the name Network 3000.

The ControlWave RDI (Remote Device Interface) is installed as part of OpenEnterprise. It is

a communications program that enables OpenEnterprise to communicate with and collect

data from ControlWave RTUs.

™

12 www.EmersonProcess.com/Remote

Page 13

March 2012

The ControWave RDI’s confi guration program is the NW3000 Setup Tool, which utilizes two

other programs:

The NW3000 Signal Builder inserts, modifi es and deletes signals from the database

The Template Builder creates polling templates from those signals for effi cient data

The ControlWave RDI requires OpenBSI to be installed on the same machine along with the

ControlWave control strategy fi les and network defi nition.

3.13.2.7.2 The ROC RDI

The ROC RDI (Remote Device Interface) is also installed as part of OpenEnterprise. It is a

communications program that enables OpenEnterprise to communicate with and collect

data from ROC and FloBoss

ROC RDI is has its own confi guration tool which enables you to add ROC devices and points to

the database and schedule data collection.

3.13.2.8 Polling of RTUs

The frequency of real-time updates through the OPC Mirror will be restricted by the rate at which

OpenEnterprise is able to collect the data. In many cases where only a dial-up connection exists, this may

be once a day, and / or on demand. At that time, the RTU Gateway will obtain historical signal data from

the RTUs and stream it to DeltaV.

collection.

OpenEnterprise DeltaV Export Configuration Tool

™

RTUs.

3.13.3 Historical Integration

There are two methods available for getting historical data from the RTU Connect. It is intended and

recommended that most systems use both methods, so that no data is lost:

1. Data pass through. Data is passed directly from the Gateway’s virtual controller via the PI OPC server to the PI

database.

2. Use the Gateway Historical Export application to export historical data directly to the PI database.

Method 1 above is good where OpenEnterprise can poll the remote controllers at relatively short intervals.

Method 2 provides a historical backfi ll service to the PI historical database if the connection to the remote

controllers is lost. If OpenEnterprise cannot poll the remote controllers at short intervals, this will be the main

method of integrating historical data.

www.EmersonProcess.com/Remote 13

Page 14

OpenEnterprise DeltaV Export Configuration Tool

3.13.3.1 Historical Data Pass Through

Real time signal updates are collected from the Gateway’s virtual controller by the PI OPC server and

inserted as historical samples directly into the PI database.

March 2012

3.13.3.1.1 OpenEnterprise

OpenEnterprise is an industrial strength SCADA (Supervisory Control and Data Acquisition)

system.

OpenEnterprise collects data from Remote Telemetry Units (RTUs) using direct low level

communications programs and serves the data to clients, normally through standard OPC

and ODBC application interfaces.

Typical systems include a processing plant (for instance a well head, pipeline or water

processing plant) connected to ControlWave or ROC RTUs and communication systems to

transmit the data back to the OpenEnterprise server database.

3.13.3.1.2 The OpenEnterprise OPC Server

The OpenEnterprise OPC Data Access server makes data from the OpenEnterprise database

available to OPC clients. Its program id is BristolBabcock.BristolOPCServer.

14 www.EmersonProcess.com/Remote

Page 15

March 2012

OpenEnterprise DeltaV Export Configuration Tool

3.13.3.1.3 OPC Mirror

The OPC Mirror is able to create a channel that streams data between two OPC servers. This

channel is called a “pipe”. The confi guration required for the OPC Mirror to form a pipe is:

1. The program id of the Bristol OPC server (let’s call this A)

2. The program id of the DeltaV OPC server (let’s call this B)

3. The direction of the piping

a. From A to B

b. From B to A

c. Both ways (this is the option used)

4. A map of the required signal data.

This is all done automatically when you export an .FHX fi le using the DeltaV Export

Confi guration Tool. The Export Confi guration Tool confi gures the OPC Mirror at the same

time that it exports the .FHX fi le.

The only thing you will need to do regarding the OPC Mirror itself is to provide a DeltaV

administrator name and password when you install it onto the DeltaV RTU Connect

application station. The Export Confi guration Tool will do the rest.

3.13.3.1.4 DeltaV OPC Server

The DeltaV OPC server makes data from the RTU Connect available to the DeltaV virtual

controller on the application station, which in turn makes it available to the rest of the DeltaV

system. Its program id is OPC.DeltaV.1.

3.13.3.1.5 Virtual Controller

This is an IEC 61-1131 emulated DeltaV controller (in effect a soft programmable logic

controller). The DeltaV Export Confi guration Tool creates a control strategy fi le (an .FHX fi le)

that contains references to the remote RTU signals. The control strategy is then downloaded

to the virtual controller from the DeltaV system.

The control strategy contains input signal tags which can be arranged by the Export

Confi guration Tool within alarm function blocks, linking process signals with their alarm

limits.

www.EmersonProcess.com/Remote 15

Page 16

OpenEnterprise DeltaV Export Configuration Tool

The virtual controller inputs are connected to the OpenEnterprise OPC Data Access server via

the OPC Mirror in order to receive real-time data from the DeltaV RTU Connect. In this way

the virtual controller pushes data from the RTU Connect into the DeltaV network to emulate

passed through real-time data and alarms from remote controllers.

3.13.3.1.6 PI OPC Interface

The DeltaV OPC server makes data from the RTU Connect available to the DeltaV virtual

controller on the application station, which in turn makes it available to the rest of the DeltaV

system. Its program id is OPC.DeltaV.1.

3.13.3.1.7 EntHist Confi guration File

The PI database uses ‘PI points’ to store tag information in the pipoint table, each point

mapping across to a single DeltaV tag.

In order to confi gure these automatically, the PI historian sources tag information from the

EntHist confi guration fi le, created in the DeltaV fi le system.

This is a standard XML fi le containing details of which tags have been confi gured for historical

data logging.

The EntHist fi le can only be created when the following has been done:

March 2012

1. The PI historian must be enabled within DeltaV to be the historical data source

2. Signals must have been exported from the Export Confi guration Tool, and downloaded to

the Gateway’s virtual controller.

DeltaV will then create the EntHist confi guration fi le for the PI historian, and the PI OPC

Interface will begin passing data through for the tags confi gured in the EntHist fi le.

3.13.3.1.8 PI Historian

The PI Historian is a standard enterprise database developed by OSIsoft that allows for an

embedded, centralized alternative to the native DeltaV continuous historian. The PI Historian

can be installed onto an application station and embedded into a DeltaV system.

The DeltaV RTU Connect streams historical backfi ll data via the PI client to the PI historian.

DeltaV operator workstations are confi gured to request historical data from the PI Historian

rather than the DeltaV continuous historian.

3.13.3.1.9 Remote Device Interfaces (RDIs)

OpenEnterprise communicates with ControlWave and ROC RTUs using a set of device drivers

called Remote Device Interfaces (RDIs). Collected data can consist of current values, history

and alarm and event data.

3.13.3.1.9.1 The ControlWave RDI

The ControlWave RDI is also known as the NW3000 RDI since the original family

of Bristol devices were known by the name Network 3000.

The ControlWave RDI (Remote Device Interface) is installed as part of

OpenEnterprise. It is a communications program that enables OpenEnterprise

to communicate with and collect data from ControlWave RTUs.

16 www.EmersonProcess.com/Remote

Page 17

March 2012

OpenEnterprise DeltaV Export Configuration Tool

The ControWave RDI’s confi guration program is the NW3000 Setup Tool, which

utilizes two other programs:

The NW3000 Signal Builder inserts, modifi es, and deletes signals from the

database.

The Template Builder creates polling templates from those signals for

effi cient data collection.

The ControlWave RDI requires OpenBSI to be installed on the same machine

along with the ControlWave control strategy fi les and network defi nition.

3.13.3.1.9.2 The ROC RDI

The ROC RDI (Remote Device Interface) is also installed as part of

OpenEnterprise. It is a communications program that enables OpenEnterprise

to communicate with and collect data from ROC and FloBoss RTUs.

ROC RDI is has its own confi guration tool which enables you to add ROC devices

and points to the database and schedule data collection.

3.13.3.1.10 Polling of RTUs

The frequency of real-time updates through the OPC Mirror will be restricted by the rate

at which OpenEnterprise is able to collect the data. In many cases where only a dial-up

connection exists, this may be once a day, and / or on demand. At that time, the RTU

Gateway will obtain historical signal data from the RTUs and stream it to DeltaV.

3.13.3.1.11 OpenEnterprise Historical Backfi ll

When OpenEnterprise polls remote RTUs for their data, it can also request historical data that

has been stored in the RTUs from the last time the data was polled.

This data is then retrospectively backfi lled into the OpenEnterprise history tables, so no

historical data is lost between polls.

This is important, because some systems are so remote that a connection can only be made

once a day or on a one-shot basis. Even systems with a permanent connection can experience

connection breakdown from time to time, but historical backfi ll guarantees that no data is

lost.

In order to utilize the backfi ll service there are three areas of confi guration required across the

system:

1. A historical stream must be confi gured within the device.

a. For ROC devices, you should use ROCLink

storage within a history segment. For further help consult the ROCLink 800

documentation.

b. For ControlWave devices, you need to confi gure an Archive module to store the

required signal values historically. For further help consult the ControlWave Designer

or ACCOL documentation.

™

800 to confi gure signals for historical

www.EmersonProcess.com/Remote 17

Page 18

OpenEnterprise DeltaV Export Configuration Tool

2. OpenEnterprise must be confi gured to collect the historical data.

a. For ROC devices, this can be achieved using the ROC confi guration tool. For further

help, consult the ROC Confi guration Tool Reference Guide (document number

D301654x412).

b. For ControlWave devices you need to set up NW3000 Archiving. For further help,

consult the NW3000 Archiving Overview (document number D301506x412) and

NW3000 Archive Confi guration (document number D301505x412) Reference Guides.

3. DeltaV must be confi gured to use the embedded PI Historian. For further help see the

DeltaV documentation.

3.13.3.2 Historical Backfill Integration

Historical signal data from the DeltaV RTU Connect is imported to the DeltaV system by means of the

Historical Export application.

March 2012

3.13.3.2.1 The DeltaV Export Confi guration Tool

The DeltaV Export Confi guration Tool allows you to select the remote RTU tags that you want

to integrate into the DeltaV system. You can then export these tags to a control strategy

module fi le (.FHX), which DeltaV downloads to a virtual controller module.

The Export Confi guration Tool also sends mapping information from your selected signals to

the OPC Mirror, which enables the OpenEnterprise OPC server and the DeltaV OPC servers to

pass the signal data between themselves. The DeltaV OPC server then pushes the RTU data to

the virtual controller and it becomes integrated into the DeltaV system.

The Export Confi guration Tool also allows you to confi gure historical integration via the PI

Historian.

18 www.EmersonProcess.com/Remote

Page 19

March 2012

OpenEnterprise DeltaV Export Configuration Tool

3.13.3.2.2 The Gateway Historical Export Application

This is a server application that runs as part of the OpenEnterprise session. It streams

historical data from OpenEnterprise to the embedded PI Historical database that resides on a

DeltaV application station.

For more information, see the Gateway Historical Export application topic.

3.13.3.2.3 PI Client

The Historical Export Application uses the PI SDK to create a PI client which streams historical

data from OpenEnterprise to the PI historian.

The Emerson RTU Gateway streams historical backfi ll data via the PI client to the PI historian.

DeltaV operator workstations are confi gured to request historical data from the PI Historian

rather than the DeltaV continuous historian.

3.13.3.2.4 OpenEnterprise

OpenEnterprise is an industrial strength SCADA (Supervisory Control and Data Acquisition)

system.

OpenEnterprise collects data from Remote Telemetry Units (RTUs) using direct low-level

communications programs and serves the data to clients, normally through standard OPC

and ODBC application interfaces.

Typical systems include a processing plant (for instance a well head, pipeline or water

processing plant) connected to ControlWave or ROC RTUs and communication systems to

transmit the data back to the OpenEnterprise server database.

3.13.3.2.5 Remote Device Interfaces (RDIs)

OpenEnterprise communicates with ControlWave and ROC RTUs using a set of device drivers

called Remote Device Interfaces (RDIs). Collected data can consist of current values, history

and alarm and event data.

3.13.3.2.5.1 The ControlWave RDI

The ControlWave RDI is also known as the NW3000 RDI since the original family

of Bristol devices were known by the name Network 3000.

The ControlWave RDI (Remote Device Interface) is installed as part of

OpenEnterprise. It is a communications program that enables OpenEnterprise

to communicate with and collect data from ControlWave RTUs.

The ControWave RDI’s confi guration program is the NW3000 Setup Tool, which

utilizes two other programs:

The NW3000 Signal Builder inserts, modifi es, and deletes signals from the

database.

The Template Builder creates polling templates from those signals for

effi cient data collection.

The ControlWave RDI requires OpenBSI to be installed on the same machine

along with the ControlWave control strategy fi les and network defi nition.

www.EmersonProcess.com/Remote 19

Page 20

OpenEnterprise DeltaV Export Configuration Tool

3.13.3.2.5.2 The ROC RDI

The ROC RDI (Remote Device Interface) is also installed as part of

OpenEnterprise. It is a communications program that enables OpenEnterprise

to communicate with and collect data from ROC and FloBoss RTUs.

ROC RDI is has its own confi guration tool which enables you to add ROC devices

and points to the database and schedule data collection.

3.13.3.2.6 Polling of RTUs

The frequency of real-time updates through the OPC Mirror will be restricted by the rate

at which OpenEnterprise is able to collect the data. In many cases where only a dial-up

connection exists, this may be once a day, and / or on demand. At that time, the RTU

Gateway will obtain historical signal data from the RTUs and stream it to DeltaV.

3.13.3.2.7 OpenEnterprise Historical Backfi ll

When OpenEnterprise polls remote RTUs for their data, it can also request historical data that

has been stored in the RTUs from the last time the data was polled.

This data is then retrospectively backfi lled into the OpenEnterprise history tables, so no

historical data is lost between polls.

March 2012

This is important, because some systems are so remote that a connection can only be made

once a day or on a one-shot basis. Even systems with a permanent connection can experience

connection breakdown from time to time, but historical backfi ll guarantees that no data is

lost.

In order to utilize the backfi ll service there are three areas of confi guration required across the

system:

1. A historical stream must be confi gured within the device.

a. For ROC devices, you should use ROCLink 800 to confi gure signals for historical storage

within a history segment. For further help consult the ROCLink 800 documentation.

b. For ControlWave devices, you need to confi gure an Archive module to store the

required signal values historically. For further help consult the ControlWave Designer

or ACCOL documentation.

2. OpenEnterprise must be confi gured to collect the historical data.

a. For ROC devices, this can be achieved using the ROC confi guration tool. For further

help, consult the ROC Confi guration Tool Reference Guide (document number

D301654x412).

b. For ControlWave devices you need to set up NW3000 Archiving. For further help,

consult the NW3000 Archiving Overview (document number D301506x412) and

NW3000 Archive Confi guration (document number D301505x412) Reference Guides.

3. DeltaV must be confi gured to use the embedded PI Historian. For further help see the

DeltaV documentation.

20 www.EmersonProcess.com/Remote

Page 21

March 2012

OpenEnterprise DeltaV Export Configuration Tool

3.13.3.3 The Gateway Historical Export Application

The Gateway Historical Export Application instantiates an active query on the historicalexportrecord

table in OpenEnterprise. Any new records in this table will trigger the application to begin streaming the

updates to the PI Server.

If OpenEnterprise loses connection to the remote controllers, then when a connection is reestablished,

OpenEnterprise will collect historical data from the remote controllers and insert it into the relevant

historical tables. The historical records are transferred to the historicalexportrecord table, and the

Gateway Historical Export Application will be triggered to begin streaming these updates to the PI Server.

The export process will then either insert this data into PI, update existing data by replacing duplicates, or

ignore duplicate data altogether. DeltaV will then be able to access historical data in PI using its suite of

analysis tools (trending, etc.).

There will be a delay between timestamp values logged by DeltaV and those logged by OpenEnterprise.

Thus, when replacing duplicate records, a method is used to correlate those records which belong to the

same logged timestamp . This is done by comparing incoming records with existing records and allowing

for a small tolerance in the timestamp value, which by default will be 1 second. This allows any new

records to be up to 1 second either side of the currently logged timestamp, to be considered the same

logged record. You can change this value on the Historical Backfi ll General properties page.

The PI server can be confi gured to work with UTC timestamps. This is done when confi guring the scan

class in the PI OPC interface. The scan class is used to determine how often PI will collect data, and has an

optional fl ag to set the logged occurrence time to UTC.

Therefore if the PI OPC interface has been confi gured for DST, the PI Backfi ll service will adjust timestamps

from OpenEnterprise before inserting / updating into PI . In order to utilize this, you must confi gure the

timestamp UTC logging fl ag within the service.

www.EmersonProcess.com/Remote 21

Page 22

OpenEnterprise DeltaV Export Configuration Tool

3.13.4 Alarm and Event Integration

Alarm and event data from the DeltaV RTU Connect is streamed from the Bristol Alarm and Event OPC server to the

Plantwide Event Historian running on an application station, where it becomes available to the DeltaV system.

March 2012

3.13.4.1 Plantwide Event Historian (PEH)

The Plantwide Event Historian is installed on a separate DeltaV application station. It records plant event

information from the OpenEnterprise OPC Alarm and Events server, and stores it in a Microsoft SQL Server

database.

3.13.4.2 PEH Events Manager

The Events Manager receives the events data from the PEH OPC server and inserts the data into the SQL

Server database. Each event stored contains the name of the Alarm and Event OPC server, the time stamp

of the event, the type of event, the description of the event, as well as many other standard attributes

that are communicated by the Alarm and Event OPC server.

3.13.4.3 PEH Diagnostic Server

The Plantwide Event Historian Diagnostics Server collects the status of the Events Manager, the MSMQ,

the PEH OPC Servers and the OPC Alarms & Events servers. You are then able to view and use this data for

diagnostic purposes using the PEH Diagnostic Tool.

3.13.4.4 MSMQ

The Plantwide Event Historian uses Microsoft Message Queue (MSMQ) for communicating between the

Plantwide Event Historian OPC Server and the SQL Server database.

The MSMQ has a sending end and a receiving end. The sending end of the MSMQ is incorporated into the

PEH OPC Server; the receiving end of the MSMQ is incorporated into the PEH Events Manager.

If there is a communications failure between the sending end and the receiving end of the MSMQ,

the MSMQ buffers the event data on the sending end and delivers it to the receiving end when the

communications are restored, ensuring no data is lost.

22 www.EmersonProcess.com/Remote

Page 23

March 2012

OpenEnterprise DeltaV Export Configuration Tool

3.13.4.5 PEH OPC Server

The PEH OPC server should be installed on the DeltaV RTU Connect computer. The PEH OPC server

communicates with the OpenEnterprise OPC Alarms & Events server through the standard OPC COM

(Component Object Model) interface.

The PEH OPC server then forwards the event data to the PEH Events Manager, which inserts the event

data to the PEH SQL Server database.

3.13.4.6 OpenEnterprise Alarm and Event OPC Server

The OpenEnterprise OPC Alarm and Event server serves alarm and event data from the OpenEnterprise

database to the PEH OPC server, which then passes this data through to the PEH Event Manager. The PEH

Event Manager then inserts the data into the PEH database.

The program id of the OpenEnterprise Alarm and Event OPC server is:

BristolBabcock.BristolOPCEventServer.

3.13.4.7 OpenEnterprise

OpenEnterprise is an industrial strength SCADA (Supervisory Control and Data Acquisition) system.

OpenEnterprise collects data from Remote Telemetry Units (RTUs) using direct low level communications

programs and serves the data to clients, normally through standard OPC and ODBC application

interfaces.

Typical systems include a processing plant (for instance a well head, pipeline or water processing plant)

connected to ControlWave or ROC RTUs and communication systems to transmit the data back to the

OpenEnterprise server database.

3.13.4.8 Remote Device Interfaces (RDIs)

OpenEnterprise communicates with ControlWave and ROC RTUs using a set of device drivers called

Remote Device Interfaces (RDIs). Collected data can consist of current values, history and alarm and

event data.

3.13.4.8.1 The ControlWave RDI

The ControlWave RDI is also known as the NW3000 RDI since the original family of Bristol

devices were known by the name Network 3000.

The ControlWave RDI (Remote Device Interface) is installed as part of OpenEnterprise. It is

a communications program that enables OpenEnterprise to communicate with and collect

data from ControlWave RTUs.

The ControWave RDI’s confi guration program is the NW3000 Setup Tool, which utilizes two

other programs:

The NW3000 Signal Builder inserts, modifi es, and deletes signals from the database

The Template Builder creates polling templates from those signals for effi cient data

collection.

The ControlWave RDI requires OpenBSI to be installed on the same machine along with the

ControlWave control strategy fi les and network defi nition.

www.EmersonProcess.com/Remote 23

Page 24

OpenEnterprise DeltaV Export Configuration Tool

3.13.4.8.2 The ROC RDI

The ROC RDI (Remote Device Interface) is also installed as part of OpenEnterprise. It is a

communications program that enables OpenEnterprise to communicate with and collect

data from ROC and FloBoss RTUs.

ROC RDI is has its own confi guration tool which enables you to add ROC devices and points to

the database and schedule data collection.

3.13.4.9 Polling of RTUs

The frequency of real-time updates through the OPC Mirror will be restricted by the rate at which

OpenEnterprise is able to collect the data. In many cases where only a dial-up connection exists, this may

be once a day, and / or on demand. At that time, the RTU Gateway will obtain historical signal data from

the RTUs and stream it to DeltaV.

4. User Interface

The DeltaV Export Confi guration Tool enables you to confi gure the remote RTU tags that you want to integrate into the DeltaV

system.

This section provides you with a detailed description of the DeltaV Export Confi guration Tool user interface.

March 2012

24 www.EmersonProcess.com/Remote

Page 25

March 2012

4.1 Menu Bar

OpenEnterprise DeltaV Export Configuration Tool

There are four menus available on the menu bar.

4.1.1 File Menu

The fi le menu enables you to import and export confi gured rule sets. These are saved in XML format. For more

information on rule sets, see the Rule Sets Pane topic.

4.1.2 View Menu

4.1.2.1 Show Search

When checked, the user interface displays the search criteria controls. When unchecked, the search criteria

controls are removed, and the search list is extended upwards.

4.1.2.2 Show Status

When checked, the user interface displays the status pane. When unchecked, the status pane is removed,

and the DeltaV Explorer pane is extended downwards.

4.1.3 Tools Menu

The Tools menu contains only the Properties... item, which opens the Properties dialog.

www.EmersonProcess.com/Remote 25

Page 26

OpenEnterprise DeltaV Export Configuration Tool

4.1.4 Help Menu

There are two options under the Help menu.

4.1.4.1 Help

This option opens the Help fi le for the Emerson Remote Integration Tool (Export Confi guration Tool).

4.1.4.2 About

This opens the About box for the Export Confi guration Tool.

4.2 Tool Bar

There are two buttons on the tool bar that enable you to import and export rule sets (i.e., search criteria).

4.2.1 Import Rule Set

Selecting this button allows you to import a previously saved rule set. It opens a fi le selection dialog that

enables you to fi nd the saved rule set. It is the same as selecting the File > Import Rule Set menu.

4.2.2 Export Rule Set

Selecting this button allows you to export a rule set that you have confi gured. It opens a fi le selection

dialog that enables you to fi nd a location where rule set will be saved. It is the same as selecting the File >

Export Rule Set menu.

March 2012

4.3 Search Criteria Controls

This section contains input fi elds that enable you to create search criteria for signals that you want to ntegrate into DeltaV.

The fi elds represent attributes belonging to the signal tables within the OpenEnterprise database. A set of search criteria is

known as a rule set. A rule set can be used to represent an asset type or RTU type for repeat exports.

Each fi eld can contain text and the wildcard asterisk (*), which fi nds all signals that contain the text prior to or after the

wildcard. A percent character (%) can be used as an alternative to (*) and is treated identically.

For instance “ROC*” in the Device name fi eld will fi nd all signals beginning with “ROC1” such as “ROC10”, “ROC21”, etc.. If

you type “*AIN*” into the Signal name fi eld, the search will fi nd all signals that have the sub string “AIN” within their name

such as “ROC1:AIN.1.EU”, “ROC12:AIN.3.CALRAW1”, “FB107:AIN.3.EU”, etc..

26 www.EmersonProcess.com/Remote

Page 27

March 2012

OpenEnterprise DeltaV Export Configuration Tool

The explanation of each fi eld and button available here is given in the headings below the image.

4.3.1 Device name

Text typed here will fi lter the signal search using the “devicename” attribute.

4.3.2 Signal name

Text typed here will fi lter the signal search using the signal name.

4.3.3 Description

Text typed here will fi lter the signal search using the “description” attribute.

4.3.4 Match case

If this box is unchecked (default setting), the signal search will not be case sensitive. If it is checked, the search will be

case sensitive.

4.3.5 Instance

Text typed here will fi lter the signal search using the “instance” attribute.

4.3.6 Base

Text typed here will fi lter the signal search using the “base” attribute.

4.3.7 Extension

Text typed here will fi lter the signal search using the “extension” attribute.

4.3.8 Attribute

Text typed here will fi lter the signal search using the “attribute” attribute.

4.3.9 Search for Signals

Select this button to start a signal search based on the criteria that you provided.

4.3.10 Add Rule Set

A rule set is a particular search criteria confi guration. If you have created a new search criteria confi guration,

you can add it to the other rule sets by selecting this button.

The search criteria in a single rule set works on a logical AND basis. Multiple rule sets work on an OR basis.

www.EmersonProcess.com/Remote 27

Page 28

OpenEnterprise DeltaV Export Configuration Tool

4.3.11 Using Aliases in Rule Sets

It is possible to use aliases in rule sets to provide fi ner tuning when searching for tags of interest. See the How to use

Aliases in Searches topic for details.

4.3.12 Modify Rule Set

If you have modifi ed an existing rule set in the search criteria, you can update this rule by selecting this

button. The corresponding rule set in the rule sets pane will be updated.

4.4 Rule Sets Pane

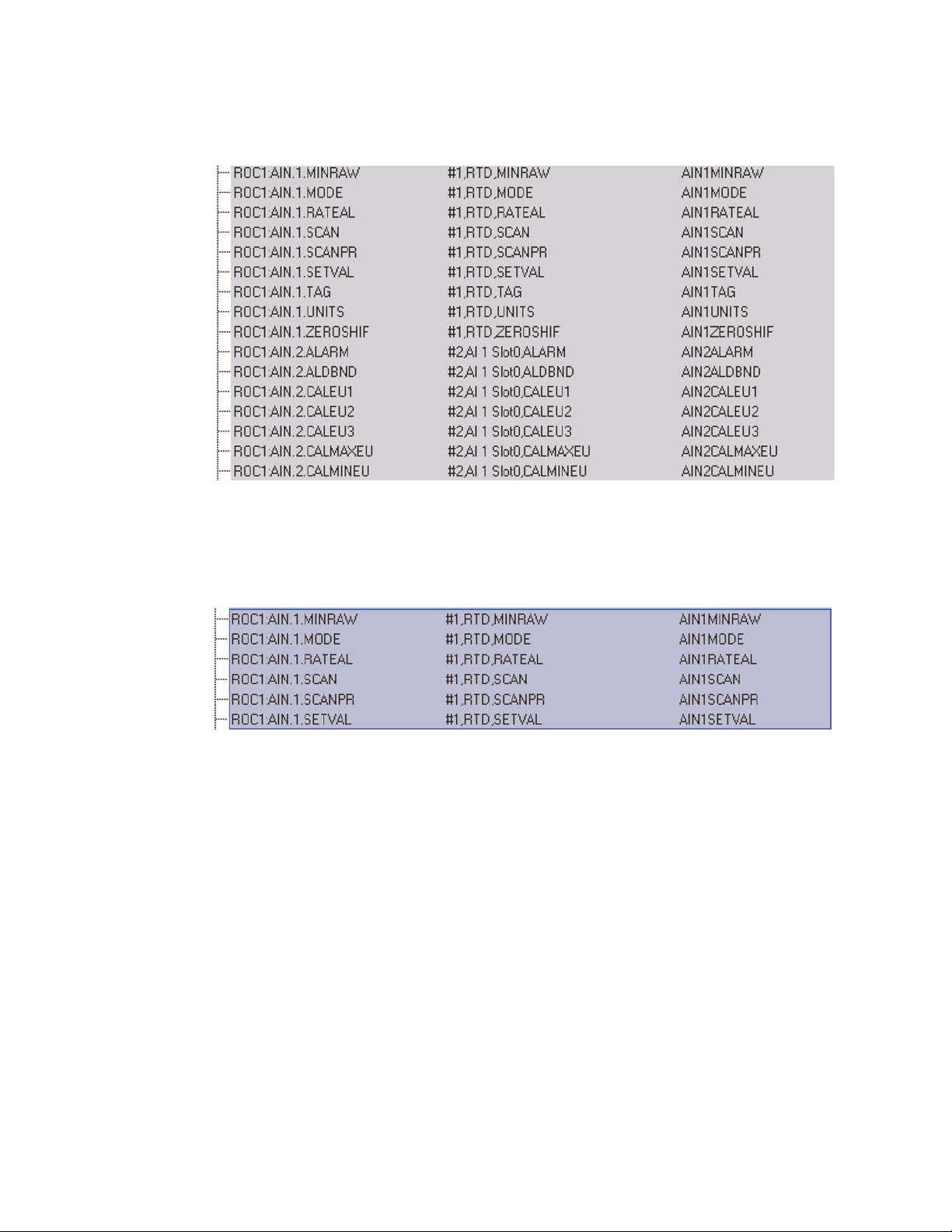

A rule set is a particular set of search criteria that has been saved. You can save a rule set by clicking the Add Rule Set button

on the search criteria controls section of the user interface. A saved rule set is listed in the Rule sets pane, shown in the

example below.

March 2012

4.4.1 Delete Rule Set

Click this button to delete a selected rule set.

4.4.2 Search using Rule Sets

Click this button to begin a signal search using a combination of all rule sets in the rule set pane. Rule sets are

strung together by an OR condition, so the query can be potentially widened out.

28 www.EmersonProcess.com/Remote

Page 29

March 2012

4.5 Search List Pane

Click the search button immediately above this pane and the list is populated with OpenEnterprise signals that

match the search criteria. They are then available for export into DeltaV. This is a two-stage process.

1. The signals must be dragged over into the DeltaV pane.

2. The signals can then be exported by clicking the [Export] button above the DeltaV pane.

OpenEnterprise DeltaV Export Configuration Tool

4.5.1 Background Colors

The background color of the signals will show their status. The default colors are:

1. Blue: Signals already dragged

This color denotes signals that are currently in the DeltaV pane. They may also have been exported previously. If

an export takes place now, they will continue to be in the DeltaV system.

www.EmersonProcess.com/Remote 29

Page 30

OpenEnterprise DeltaV Export Configuration Tool

2. Gray: Signals already exported

This color denotes signals that were previously exported to DeltaV, but no longer exist in the DeltaV pane. If an

export takes place now, these signals will no longer be in the DeltaV system.

March 2012

3. Darker Blue with a line around: Signals selected for dragging

Signals with this color have been selected for dragging across to the DeltaV pane.

See the Selecting Signals section below to view keyboard options that are available when selecting signals.

4.5.2 Selecting Signals

Signals can be selected in many ways, from a single signal to multiple signals. There are two ways of selecting

multiple signals.

4.5.2.1 Selecting a Single Signal

Just left click with the mouse on the signal.

4.5.2.2 Selecting a Single Block of Signals

You begin selecting a continuous block of signals by clicking with the left mouse button on the fi rst signal,

then holding the [Shift] key. Then click with the left mouse button on the last signal in the block.

4.5.2.3 Selecting Multiple Blocks of Signals

First, select the fi rst block of signals as described above, then hold the [Ctrl] key down on your keyboard

and select the fi rst signal in the next block. Now stop holding the [Ctrl] key and hold instead the [Shift] key.

Then select the last signal in the new block.

30 www.EmersonProcess.com/Remote

Page 31

March 2012

OpenEnterprise DeltaV Export Configuration Tool

4.5.2.4 Selecting All Signals

You can instantly select all of the signals in the signal list by keeping the [Ctrl] key on the keyboard held

down as you press the A (or a) key.

See the Dragging Signals section below to see keyboard shortcuts that are available when dragging signals.

4.5.3 Dragging Signals

Once you have selected a single or a single block of signals, you can literally drag them over to the DeltaV pane with

the mouse. Hold the left mouse button down as you do this.

However there is a keyboard combination that will do this for you. When you have selected the signals you want,

hold the [Ctrl] and D keys down to move them automatically over to the DeltaV pane.

4.5.4 Show New Signals Only

Check this box if you want the search list pane to only show signals that have not been exported over to the DeltaV

pane.

This could be helpful if you have already exported a large number of signal tags (e.g., in excess of 3000), since the

processing required to display such a large number of tags may cause a noticeable delay in updating the search list.

4.5.5 Hide Dragged Items

Check this box if you want items that have already been dragged over to the DeltaV pane to be hidden from the

search list.

If you have deleted an object from the DeltaV pane that has already been dragged and exported, it will now show in

the search list as an item that has previously been exported, but not yet dragged.

4.5.6 Signals Found

This label will display the total number of signals found using the search criteria.

4.5.7 Data Service

This label displays the data service that the DeltaV Export Confi guration Tool is connected to.

4.5.8 Signal Properties Dialog

Double click any individual signal entry within the search summary panel to view its details in the Signal Properties

dialog.

On this dialog there is a “Disable historical export” check box, which enables you to specify whether historical

logging of the selected signal should be enabled / disabled.

By default, each signal is enabled for historical logging. This parameter is stored as the “disablehistoricalexport”

attribute within the signal table of the OpenEnterprise database.

www.EmersonProcess.com/Remote 31

Page 32

OpenEnterprise DeltaV Export Configuration Tool

You can also modify the signal’s description from here.

4.6 DeltaV Pane

This pane provides a view which corresponds to what you would see in DeltaV explorer. It defi nes a control strategy with

plant areas, modules and signals / alarms.

March 2012

You populate it by selecting signals from the search list and drag / drop these to any relevant node within this view to create

your control strategy for the DeltaV Virtual Controller. When a signal is dragged over into the DeltaV explorer view it will

reformat its signal name to a prescribed format. This articular format can be confi gured on the Tag Format property page.

The control strategy will then be exported to an .FHX fi le, which will be read by the Virtual Controller. If the Status Pane

informs you that you need to change some DeltaV tag names, the names will be updated automatically as you change

them, whether you do it one by one using the signal locator buttons at the top of the pane or whether you use the Tag

Format and Alarm Association pages of the Properties dialog.

32 www.EmersonProcess.com/Remote

Page 33

March 2012

OpenEnterprise DeltaV Export Configuration Tool

4.6.1 Name Change Buttons

When the Export Confi guration Tool detects that you have drag / dropped signals that have names that are above

the 16 character limit imposed by DeltaV, two things happen:

1. The Name Change buttons become enabled.

2. The Status Pane will inform you if any signals require a name change.

You can change the names one at a time by clicking on the Name Change buttons, or using the left and right

cursor keys on the keyboard to scroll up and down the DeltaV explorer pane. Only tags requiring a name change

are selected each time you click a button or a cursor key, as seen in the example below. You can then change the

name of the selected signal.

4.6.2 Export Button

When you select the [Export] button at the top of the DeltaV pane, the Export Confi guration Tool

will create an .FHX fi le that will be recognized as a control strategy fi le by DeltaV.

www.EmersonProcess.com/Remote 33

Page 34

OpenEnterprise DeltaV Export Configuration Tool

If there are tag names that exceed the 16 character limit, have illegal characters or are duplicated, you will see this

warning:

Just click the [OK] button and make the changes indicated, then try to export again.

4.6.2.1 Use the Default .FHX Filename or Change

If there are no signals requiring a change, you will see the Save As dialog. You can change both the fi le name

and the destination using this dialog before fi nally saving.

The default fi lename will already be in the File name fi eld. This is confi gured on the General page of the

Properties dialog.

March 2012

4.6.2.2 Warning Messages

Note that when an import into DeltaV occurs, a couple of warning messages may appear. This is normal

operation and is nothing to worry about.

The fi rst message says “WARNING: No SCHEMA block was found at the head of this import fi le”. This

message occurs when .FHX header information is not included in the .FHX export. This is intentional,

because it allows us to produce fi les which are not associated with specifi c DeltaV versions.

The second message says “Warning: the imported index (1) for Plant Area ‘<PlantArea>’ is different from the

existing index (0). The existing index will be used.” This message appears if you added an Area into DeltaV

Explorer and then used the Export Confi guration Tool to import a new area. The Export Confi guration Tool

has no knowledge of the area already confi gured in DeltaV, so the warning message is generated. Again, this

is nothing to worry about.

When closing the tool, the following messagebox will appear if signals have been dragged or deleted or

name changes made and an export has not taken place.

If you do not want to lose your changes, select [No] and click the Export button before closing.

34 www.EmersonProcess.com/Remote

Page 35

March 2012

OpenEnterprise DeltaV Export Configuration Tool

4.6.2.3 DeltaV Alarm Names

When an .FHX has been exported and viewed in DeltaV Control Designer, each alarm confi gured will have

it’s own associated internal alarm name. In order to maintain a unique set of internal alarms, each is given a

unique generic name, which is non-confi gurable.

4.6.3 Adding Areas

When you right click with the mouse on the main Control Strategies node, a context menu appears.

4.6.3.1 Add an Area

Select this option to add a new plant area to the control strategy. The new area will be given the name

confi gured on the Tag Format page of the Properties dialog.

4.6.3.2 Expand all

Expands the currently selected node. The option is grayed out if the node is already expanded.

4.6.3.3 Collapse all

Collapses the currently selected node. The option is greyed out if the node is already collapsed.

4.6.3.4 Export

Exports the current control strategy to an .FHX fi le.

4.6.4 Adding Modules

When you right click with the mouse on any Plant Area node, a context menu appears.

4.6.4.1 Add a Module

Select this option to add a new module to the control strategy. The new module will be given the name

confi gured on the Tag Format page of the Properties dialog.

www.EmersonProcess.com/Remote 35

Page 36

OpenEnterprise DeltaV Export Configuration Tool

4.6.4.2 DeltaV Module Naming Conventions

A list of reserved DeltaV module naming rules is provided below. Failure to observe these rules will cause the

.FHX fi le export to fail. The Export Confi guration Tool will test for conformance with all rules listed below

except for the DeltaV reserved names.

Names must be alphanumeric.

Names cannot exceed 16 characters.

Names must contain at least one alpha character.

Names should not match any of the function block names in the system. This includes default function

block names, user-defi ned names and function block template names. Using the same names for

modules and function blocks may prevent the system from successfully browsing to parameter names

under some circumstances.

Names can contain $, -, or _.

Names cannot be any of the following reserved DeltaV names:

__$TEST$__

BATCH

BHIST

CHIST

COMM

CONF

CONT

DELTAV

IO1

JOUR

NVM

OPC

OPCMIRROR

OPER

PHIST

PRI

PVXIO

REDU

March 2012

4.6.4.3 Expand all

Exp

ands the currently selected node. The option is greyed out if the node is already expanded.

4.6.4.4 Collapse all

Collapses the currently selected node. The option is greyed out if the node is already collapsed.

4.6.4.5 Delete

Deletes the currently selected plant area along with any modules and signals that may already belong to it. A

warning will appear before the deletion takes place, with an option to abort.

4.6.4.6 Rename

Renames the currently selected plant area.

36 www.EmersonProcess.com/Remote

Page 37

March 2012

OpenEnterprise DeltaV Export Configuration Tool

4.6.5 Deleting Signals

If you right click with the mouse on any signal in the DeltaV window, a context menu allows you to delete that signal

from the list.

4.6.6 Performance Issues

If the tool has been confi gured to export a large number of signals (between 3 and 5000), there will be a noticeable

delay at startup. This is due to the signals being loaded into the DeltaV Explorer view.

4.6.7 Gateway Export Tool Settings

The DeltaV Export Confi guration Tool assumes defaults, according to restrictions applied by DeltaV for the

maximum number of areas, modules per area, input blocks per module that can be created for export, as well as

the maximum number of characters allowed in the tag name. For projects not requiring export of an .FHX fi le, these

restrictions can be modifi ed using the Settings Editor. For further help on this see the Gateway Export Key topic in

the Settings Editor documentation.

4.7 Status Pane

The Status Pane will inform you of:

1. The number of signals currently requiring a name change before export. You will need to change the names of these

signals before you export to an .FHX fi le.

2. The number of alarm blocks that require a name change. As with signals, you will have to rename any alarm blocks that

need a name change before you can export the confi guration.

3. The number of areas that are currently confi gured for exporting to an .FHX fi le.

4. The number of modules that are currently confi gured for exporting to an .FHX fi le.

5. The number of signals that are currently confi gured for exporting to an .FHX fi le. There is currently a 5000 tag limit on

exports.

6. The number of alarm blocks that are currently confi gured for exporting to an .FHX fi le.

7. The number of OPC Mirror links that are currently confi gured for exporting to an .FHX fi le.

www.EmersonProcess.com/Remote 37

Page 38

OpenEnterprise DeltaV Export Configuration Tool

4.8 Properties Dialog

The Properties dialog has selectable options in the left pane that change the confi guration items that are displayed in the

right pane.

4.8.1 General Page

The General page enables you to confi gure the Application Station name and also a default .FHX fi le name and

location. It also allows you to change the colors used in the search list for signals that have been exported or dragged

into the virtual controller pane already.

March 2012

38 www.EmersonProcess.com/Remote

Page 39

March 2012

OpenEnterprise DeltaV Export Configuration Tool

4.8.1.1 Application station node name

Enter the name of the DeltaV application station that the RTU Connect is installed on.

4.8.1.2 Default filename

Type a default name for any exported .FHX fi les that you create.

4.8.1.3 Default output location

Use the small ellipsis button [...] to the right of this fi eld to browse for a suitable location for your .FHX fi les.

4.8.1.4 Removed from Export Color

This image below shows the default background color that will be given to signals in the search list that were

included in the last export, but currently are not in the DeltaV list. You can change this color by clicking on

the colored button. A palette dialog will load, enabling you to select a different color.

A signal with the exported color is shown in the example below. This means that this signal was exported last

time, but it has subsequently been deleted from the DeltaV pane. If you export now, this signal will not be in

the DeltaV export. To include it in any subsequent DeltaV export, you will have to drag it over to the DeltaV

pane again.

4.8.1.5 Exported Color

This control shows the default background color that will be given to signals in the search list pane that are

currently also in the DeltaV pane. You can change the color by clicking on the colored button. A palette

dialog will load, enabling you to select a different color.

A signal with the exported color is shown in the example below:

www.EmersonProcess.com/Remote 39

Page 40

OpenEnterprise DeltaV Export Configuration Tool

Note, the exported color can mean that the signal has just been dragged over to the DeltaV pane, but has

not yet been exported, or that it is already in the DeltaV pane from the last time an export took place. If it

remains in this state, it will also be exported to DeltaV again this time.

If you exported this signal last time you exported to DeltaV and have not subsequently removed it from the

DeltaV pane, it will show up as if it had been dragged. The dragged color takes precedence, because it shows

clearly what signals will be exported when the [Export] button is next selected.

4.8.2 Tag Format Page

The Tag Format page enables you to determine how signal names from OpenEnterprise will be modifi ed before

being exported to the DeltaV virtual controller view pane.

March 2012

4.8.2.1 Tag buttons

This row of buttons can be used to modify the signal name that is exported to the virtual controller module

pane (this is how the signal will appear in DeltaV Explorer). To use them, position the cursor along the

Signals / Alarms or Alarm Block input text fi elds and then click the tag alias button that you want to appear

in the string that gets exported.

This enables you to quickly build up a pattern that you want to use for exporting signals and alarms. In the

example below, the cursor was placed at the beginning of the Signals / Alarms fi eld, and then the Device

button was selected.

40 www.EmersonProcess.com/Remote

Page 41

March 2012

OpenEnterprise DeltaV Export Configuration Tool

4.8.2.1.1 OpenEnterprise Signal Naming Convention

OpenEnterprise signals are created with sections that may or may not be used. The sections

are <Device>, <Instance>, <Base>, <Extension>, and <Attribute>. The general rule is that the

<Device> name must appear fi rst, followed by a colon, then one or more of the other sections

may appear, separated by a dot. Each signal name must be unique. An example would be:

In the example above the following conventions are applied:

Device name = ROC1 (meaning ROC device number 1)

Base = AIN (meaning the signal refers to a ROC Analog Input point)

Extension = 2 (meaning the 2nd Analog Input in the ROC1 device)

Attribute = EU (meaning this signal represents the EU parameter of the specifi c Analog

Input point)

4.8.2.1.2 DeltaV Signal Names

DeltaV signal names are limited to 16 characters, whereas OpenEnterprise signal names may be

much longer. It is a good idea to bear this in mind when confi guring ROC or ControlWave RTUs

that need to export data to a DeltaV system. Try to make the signal names as short as possible

without losing any information.

Also, full stops may not be used in DeltaV signal names, so they may be replaced with an