Remote Automation Solutions Gas Control Manager Program User Manual (FloBoss 107) Manuals & Guides

Page 1

Part D301749X012

August 2016

Gas Control Manager Program User

Manual (for FloBoss™ 107)

Remote Automation Solutions

Page 2

Gas Control Manager Program User Manual (FB107)

Page

Revision

All Pages

August-2016

Initial release

August-2014

Revision Tracking Sheet

August 2016

This manual may be revised periodically to incorporate new or updated information. The revision date of each

page appears at the bottom of the page opposite the page number. A change in revision date to any page also

changes the date of the manual that appears on the front cover. Listed below is the revision date of each page (if

applicable):

ii Revised Aug-16

Page 3

Gas Control Manager Program User Manual (FB107)

Contents

Chapter 1 – Introduction 1

1.1. Scope and Organization ................................................................................................................. 1

1.2. Product Overview ........................................................................................................................... 1

1.2.1. EFM Applicatio n s ............................................................................................................. 2

1.2.2. Cause and Effect .............................................................................................................. 2

1.2.3. Flow Summation............................................................................................................... 2

1.3. Program Requirements .................................................................................................................. 2

Chapter 2 – Installation 5

2.1. Installing the License Key ............................................................................................................... 5

2.2. Downloading the Program .............................................................................................................. 6

Chapter 3 – Configuration 11

3.1. EFM Applicatio n s .......................................................................................................................... 11

3.1.1. Run Switching – Run Switch Tab: Station Settings ....................................................... 12

3.1.2. Run Switching – Run Switch Tab: Tube Settings .......................................................... 17

3.1.3. Run Switching – Run Switch Operate Tab ..................................................................... 20

3.1.4. Run Switching – Proportional Output Tab ...................................................................... 21

3.1.5. Run Switching – Total Accum Tab ................................................................................. 22

3.1.6. About Open and Close DO ............................................................................................ 23

3.2. Cause and Effect .......................................................................................................................... 23

3.2.1. Effect Configuration Settings .......................................................................................... 25

3.2.2. Cause Configuration Settings ........................................................................................ 27

3.2.3. Cause and Effect Operate Display ................................................................................. 32

3.2.4. Configuration Examples ................................................................................................. 33

3.3. Flow Summation ........................................................................................................................... 41

3.3.1. Flow Sum ....................................................................................................................... 42

3.3.2. Examples ........................................................................................................................ 44

Chapter 4 – Reference 46

4.1. Point Type 22: Cause Configuration ............................................................................................ 47

4.2. Point Type 23: Effect Configuration .............................................................................................. 53

4.3. Point Type 35: Run Switching ...................................................................................................... 56

4.4. Point Type 36: Flow Sum ............................................................................................................. 66

Appendix A – Sample Cause and Effect Diagram 69

Revised Aug-16 iii

Page 4

Gas Control Manager Program User Manual (FB107)

[This page is intentionally left blank.]

iv Revised Aug-16

Page 5

Chapter 1 – Introduction

Gas Control Manager Program User Manual (FB107)

Caution

When implementing control using this product, observe best industry

practices as suggested by applicabl e and appropriate environmental,

health, and safety organizations. While this product can be used as A

safety component in a system, it is NOT intended o r designed to be the

ONLY safety mechanism in that system.

This chapter describes the structure of this manual and presents an

overview and installation instructions of the Gas Control Manager

Program for the FloBoss 107 (FB107).

1.1. Scope and Organization

This document is the user manual for the Gas Control Manager Program

for use in the FB107.

This manual describes how to download and configure this program

(referred to as the “Gas Control Manager Program” or “the program”

throughout the rest of this manual). You access and configure this program

using ROCLINK™ 800 Configuration Software (version 2.20 or greater)

loaded on a personal computer (PC) running Windows XP (with Service

Pack 3), Windows Vista™ (32-bit), Windows 7 (32-bit and 64-bit), or

Windows 8 (32-bit and 64-bit).

The sections in this manual provide information in a sequence appropriate

for first-time users. Once you become familiar with the procedures and the

software running in a FB107, the manual becomes a reference tool.

This manual has the following major sections:

Chapter 1 – Introduction

Chapter 2 – Installation

Chapter 3 – Configuration

Chapter 4 – Reference

This manual assumes that you are familiar with the FB107 and its

configuration. For more information, refer to the following manuals:

FloBoss 107 Flow Manager Instruction Manual (D301232X012)

ROCLINK 800 Configuration Software User Manual (for FB107)

1.2. Product Overview

The Gas Control Manager Program has two major components: EFM

Applications and Cause and Effect. This manual describes both

components, as well as an additional feature, Flow Summation.

(D301249X012)

Revised Aug-16 1

Page 6

Gas Control Manager Program User Manual (FB107)

1.2.1. EFM Applications

The Gas Control Manager program enables you to configure the FB107 to

perform common gas measurement (EFM) functions, including station

emergency shutdown, output of a 4-20 mA signal proportional to an input

or calculation, reset total meter accumulators for volume/energy, and run

switching. Normally, you would have to write a series FSTs to accomplish

these tasks; the program simplified the management of these and other

EFM-related tasks.

1.2.2. Cause and Effect

The program supports 16 causes and 8 effects, enabling you to perform

logical operations without writing FSTs. Typically, a cause monitors a

selected point that the program logically evaluates against a setpoint you

define. Any tripped cause linked to an effect forces the action defined in

that effect. The design of the configuration screens enables you to

configure this logic using a Cause & Effect matrix. In many cases you can

input the effects and causes line by line through the entire matrix. Each

cause configuration screen and effect configuration screen applies to a tag

line in your Cause & Effect matrix.

1.2.3. Flow Summation

An additional feature of the Gas Control Management program is the

ability to sum station values, totalizing any selected meter runs into flow

or volume results for station 1 or 2. You can then place volume and energy

results into softpoint tables or access those values directly through their

TLPs. Resettable total station accumulators are available according to the

totalization selections as well for station 1 or 2.

Station Total Accumulators for volume and energy accumulate selected

meter runs as totalized amount until you manually reset the accumulators.

The point parameters used accumulate to a huge number, and (for all

practical purposes) will never reach a roll-over point.

1.3. Program Requirements

You download the Gas Control Manager Program to the Flash and RAM

memory on the FB107 with firmware version 1.60 (or greater). Download

and configure the program using ROCLINK 800 Configuration software

version 2.20 (or greater).

The downloadable program is:

File Name

Target Unit/

Version

User Defined

Points (UDP)

Flash Used

(in bytes)

DRAM Used

(in bytes)

ROCLINK 800

Version

Display

Number

GasControlMgr_

v305_02_1.bin

2 Revised Aug-16

FB107 1.60 22, 23, 35, 36 40260 16384 2.20

21, 22, 23,

35, 36

Page 7

Gas Control Manager Program User Manual (FB107)

Note: You must connect a PC to the FloBoss’s LOI port before starting

the download.

For information on viewing the memory allocation of user programs, refer

to the ROCLINK 800 Configuration Software User Manual (for FB107)

(D301249X012).

Revised Aug-16 3

Page 8

Gas Control Manager Program User Manual (FB107)

[This page is intentionally left blank.]

4 Revised Aug-16

Page 9

Chapter 2 – Installation

This section provides instructions for installing the Gas Control Manager

Program into the FB107. Read Section 1.3 of this manual for program

requirements.

Note: The program and license key can be installed in any order. The

manual shows the installation of the license key first.

2.1. Installing the License Key

A license key is required to use the Gas Control Manager Program. To

install a USB key-based license on the FB107:

1. Insert the USB license key in a USB port on your PC.

2. Select Utilities > License Key Administrator > Transfer Between

Device and Key from the ROCLINK 800 menu bar. The Transfer

Licenses Between a Device and a Key screen displays.

Gas Control Manager Program User Manual (FB107)

Figure 1. Transfer Licenses Between a Device and a Key

Note: This screen has three sections. The upper portion (Licenses on

Device) shows any software licenses installed on the FB107. The

middle portion (Licenses on Key) shows software licenses on the

license key. The lower portion of the screen (License Key Event

Log) provides a rolling log of the last eight events related to this

license key.

Revised Aug-16 5

Page 10

Gas Control Manager Program User Manual (FB107)

3. Select the key-based license you want to transfer to the FB107 (Read

Only Port, as shown in Figure 1).

4. Click Move to Device. ROCLINK moves one instance of the license

from the key to the FB107 and updates the screen.

Note: An FB107 can hold up to six different licenses, although you

can install only one instance of each license on the FB107.

When you click Move to Device, ROCLINK 800 moves only

one instance of the license onto the FB107 and automatically

decreases the license quantity on the USB key by one.

5. Verify the license name displays in the Licenses on Device section of

the screen. Proceed to Section 2.2 to download the user program.

2.2. Downloading the Program

This section provides instructions for installing the user program into

FloBoss memory.

Note: Connect a PC to the FloBoss’s LOI port before starting the

download.

To download the user program:

Figure 2. License Installed

1. Start and logon to ROCLINK 800.

2. Select ROC > Direct Co n nect to connect to the FloBoss unit.

6 Revised Aug-16

Page 11

Gas Control Manager Program User Manual (FB107)

3. Select Utilities > User Program Administrator from the ROCLINK

menu bar. The User Program Administrator screen displays (see

Figure 3):

Figure 3. User Program Administrator

4. Click Browse in the Download User Program File frame. The Select

User Program File screen displays (see Figure 4).

5. Select the path and user program file to download from the CD-ROM.

(Program files are typically located in the Program Files folder on the

CD-ROM). As Figure 4 shows, the screen lists all valid user program

files with the .BIN extension:

Figure 4. Select User Program File

Revised Aug-16 7

Page 12

Gas Control Manager Program User Manual (FB107)

6. Click Open to select the program file. The User Program

Administrator screen displays. As shown in , note that the Download

User Program File frame identifies the selected program and that the

Download & Start button is active:

Figure 5. User Program Administrator

7. Click Download & Start to begin loading the selected program. The

following message displays:

Figure 6. Confirm Download

Note: For the FB107, ROCLINK 800 assigns program positions

based on memory allocations.

8. Click Yes to begin the download. During the download, the program

performs a warm start, creates an event in the event log, and—when

the download completes—displays the following message:

8 Revised Aug-16

Page 13

Gas Control Manager Program User Manual (FB107)

Figure 7. ROCLINK 800 Download Confirmation

9. Click OK. The User Program Administrator screen displays (see

Figure 8). Note that:

The User Programs Installed in Device frame identifies the loaded

program.

The Status field indicates that the program is running.

Figure 8. User Program Administrator

10. Click Close and proceed to Chapter 3 to configure the program.

Note: Installing a user program without a license key allows you only

to view the program screens (that is, the program outputs no

data). Installing the license key enables the program to read

from the meter and output data.

Revised Aug-16 9

Page 14

Gas Control Manager Program User Manual (FB107)

[This page is intentionally left blank.]

10 Revised Aug-16

Page 15

Chapter 3 – Configuration

After you download and start the Gas Control Manager Program,

configure the program using ROCLINK 800 software. To do this, use the

program-specific Gas Control Manager Program screen.

Gas Control Manager Program User Manual (FB107)

Figure 9. ROCLINK 800

3.1. EFM Applications

Once you have successfully loaded the Gas Control Manager program into

the FloBoss, you can access the Gas Control Manager screens. To start the

EFM Applications:

1. Double-click an FB107 device or click the D ir ect C on n ect icon in the

toolbar.

2. The device window opens. Select User Program > Gas Control Mgr

in the ROCLINK configuration tree.

3. Double-click Display #35, Run Switching.

4. You will see a display for each station. Double-click a station to see

the Run Switching window for that station.

Revised Aug-16 11

Page 16

Gas Control Manager Program User Manual (FB107)

Figure 10. Run Switch tab – Run Switching screen

The Run Switch tab is divided into two main sections: Station

Configuration and Tube Configuration:

Station Configuration. Use this section to configure global settings

that affect all tubes in the station. Two run switching stations are

available.

Tube Configuration. Use this section to configure switching for up to

four runs. You define your input and output points, set high and low

points, and choose when to open and close runs.

3.1.1. Run Switching – Run Switch Tab: Stati on S ett ings

Use this section to configure global settings that affect all tubes in the

station. Two run switching stations are available.

12 Revised Aug-16

Page 17

Gas Control Manager Program User Manual (FB107)

Field

Description

Figure 11. Station settings of the Run Switch tab

1. Review the values in the following fields:

Station Tag

Status

Status

Message

Display

Use this field to name your station. The default value is

Station1.

The first number reflects the total number of runs (flow

tubes) that the program believes is currently open. The

next four fields show the status of each of the four tubes.

The values are 1 (open) or 0 (closed). The blue box

frames the tube that is in focus or control.

Provides information for the following run switching

conditions:

0 = Status OK

1 = Station ESD

2 = PV Type Not Selected

3 = Invalid Open DO Type

4 = Invalid Open DO Param

5 = Invalid Close DO Type

6 = Invalid Close DO Param

7 = Invalid Open DI Type

8 = Invalid Open DI Param

9 = Invalid Close DI Type

10 = Invalid Close DI Param

11 = Illegal Flow Tube 1

12 = Illegal Flow Tube 2

13 = Illegal Flow Tube 3

14 = Illegal Flow Tube 4

15 = Illegal DI Tube 1

16 = Illegal DI Tube 2

17 = Illegal DI Tube 3

18 = Illegal DI Tube 4

Revised Aug-16 13

Delays

Use the Spike and Settling delays to set how long the

system waits before taking action.

Page 18

Gas Control Manager Program User Manual (FB107)

Field

Description

Spike Delay

Settling Delay

Switch Mode

Sets, in seconds, a delay time. The program examines

this field whenever a run’s Input TLP value goes above

or below its high or low set point. The condition must

remain in effect for the number of seconds specified in

this field before any run-switching executes. The delay

provides a filter for the process variables. The Spike

Delay time is also used when switching down to a lower

tube that has been closed or up from a lower tube that

will be closed (this happens when “Leave Open After

Opening Next Tube” is unchecked). Before the program

closes that tube, it must see flow (a PV value greater

than the PV Cutoff Value) for the tube just opened, for

the amount of time specified in the Spike Delay.

Maximum value is 255 seconds.

Sets, in seconds, a delay time. This delay goes into

effect immediately after a run switches. During the delay,

the new focus run remains in focus, so no comparisons

occur for any more possible switching. This allows

process conditions to stabilize after the previous change

before any more decisions are made. Maximum value is

255 seconds.

Indicates how the tubes are monitored.

Monitor All

Monitor Last

Opened

Monitors all passed switch points. For

example, if all four tubes had been

opened, choosing this option causes

the system to monitor the switch points

in all four tubes.

Monitors only the switch point that was

last activated. For example, if all four

tubes had been opened, choosing this

option causes the system to monitor

the switch points in tube 4 only.

Solenoid

Mode

14 Revised Aug-16

Selects a method for controlling the run switching valve

activations. The selected mode applies to all valves, and

impacts status messages that notify whether relevant

selections for digital outputs and digital inputs have been

made. Valid values are:

Single

Solenoid

Latch

The Open DO selection is defined for

each valve used which opens and

closes the valve by energizing or deenergizing a solenoid. The Open and

Close DI selections can be defined and

monitored to verify valve travel if

needed.

Page 19

Gas Control Manager Program User Manual (FB107)

Field

Description

Dual Solenoid

Latch

Dual Solenoid

Latch with DI

Reset

Dual Solenoid

Momentary

The Open DO selection defines the

output signal to open the valve. The

program will hold this state until a

signal to close is issued. The Close DO

selection will define the output signal to

close the valve. One or the other

solenoids will always be on. The Open

and Close DI selections can be defined

and monitored to verify valve travel if

needed.

In this mode the outputs behave as a

Dual Solenoid Latch, but the solenoid

resets or releases after the valve

travels and the valve DI limit switches

detect that valve position.

In this mode, selections are made for

an open and close DO that turn on

momentarily while the valve travels and

then turn off. The FloBoss Point I/O

Time On setting for that DO determines

the duration of the momentary pulse.

The Open and Close DI selections can

be defined and monitored to verify

valve travel if needed.

Focus Run

Verification

PV Cutoff

Value

Verifies the focus (control) tube by continually monitoring

the verification method of each enabled tube. The

highest number tube that is verified to be flowing is set as

the focus tube. This feedback causes the proper DO

state to be asserted to establish proper focus. Valid

values are:

Disable

PV Flow

Sensing

DI State

Defines a threshold for a valid flow sensing condition

using the low flow cutoff value. The program also uses

this value to establish a valid flow for the Action On

Failure mode Illegal PV Flow.

No Run Verification

Compares Input PV to the PV Cutof f

Value to determine whether a flow

condition exists for that tube. The

highest number tube that is flowing

becomes the focus tube.

Examines the state of the digital inputs

for each tube to determine the focus

tube. The highest number tube with its

digital inputs indicating “valve open”

becomes the focus tube. If these DI

points are “Undefined,” this evaluation

is not made.

Revised Aug-16 15

Page 20

Gas Control Manager Program User Manual (FB107)

Field

Description

Station ESD

ESD TLP

Action On

Failure

Configures the Emergency Shutdown feature. If you

leave this field “Undefined” the ESD is not activated. This

feature can also be used for routine station shut-in. When

tripped, an ESD closes all run switching valves to provide

positive shut-in. A Set conditi on is logge d to the alar m

log. The program restores the run switching function

when the ESD condition clears, and sends a Clear

condition to the alarm log.

Defines the TLP the program monitors for emergency

shutdown.

Verifies tube flowing conditions or DI states relative to the

focus tube depending on the selected Failure Type.

Various actions are possible based on the selection. No

evaluations are made until after the Failure Delay counter

to allow run switching to stabilize before applying any

actions are applied. Valid values are:

Type:

None

Type:

Illegal PV Flow

Type:

Illegal DI State

Action:

Status Only

Action:

Alarm Log

Action:

Disable Tube &

Alarm Log

Disables any failure evaluation.

Evaluates valid tube flow by using the

PV Cutoff Value in the Focus Run

Verification section, which determines

if a tube is actually open or closed.

Uses digital input states to determine

if a tube is actually open or closed.

Generates a status message code to

indicate a Failure condition.

Sends a Failure condition to the alarm

log that contains the status message

code number.

Disables the tube where the Failure

condition is identified and logs that

tube as OFF in the alarm log. If this

tube was not the last tube enabled,

run switching skips the disabled tube

and uses the next tube for control.

16 Revised Aug-16

Failure Delay

(Sec)

All Action On Failures are performed after the Settling

Delay plus the Failure Delay setting in seconds.

Maximum value is 255 seconds.

2. Click Apply to save your changes.

3. Proceed to Section 3.1.2, Run Switching – Run Switch Tab: Tube

Settings.

Focus Run Verification methods can be used to assure the run switching

program’s focus tube is what is actually happening. An example of this is

a valve with momentary solenoids that do not change state when the

output is pulsed. If this were to occur, the program would switch focus and

lose sight of the actual valve states. This may be most useful for dual

Page 21

Gas Control Manager Program User Manual (FB107)

solenoids that do not hold their states such as Momentary or DI Reset

modes.

An example of what happens in the event of a valve switch failure: Tube 3

has just pulsed to close because of low DP. Ordinarily tube 2 becomes the

focus run. But as long as flow is still sensed in tube 3, it remains the focus

run. After the settling time expires (default 30 seconds), if tube 3 still has

low DP, the program will pulse to close tube 3 again and wait another

settling period.

3.1.2. Run Switching – Run Switch Tab: Tube S e t t ings

Use this section to configure switching for up to four runs. You define

your input and output points, set high and low points, and choose when to

open and close runs.

In the Run Switching section, you can configure switching for up to four

runs, using various types of input and output points. The program supports

both non-latching and latching (such as Versa® Valve or Magna-Latch)

solenoids and has configurable high and low switch points, and the option

of closing the previous run when opening another.

Figure 12. Station settings of the Run Switch tab

Notice that the Run 1 configuration has no Lo SwitchPt field. This is

because the Lo SwitchPt field triggers a run to be closed and closing Run

1 would result in no flow at the station. Conversely, notice that the Run 4

configuration has no Hi SwitchPt or Leave Open fields. This is because

there is no Run 5 to be opened after Run 4.

1. Review the values in the following fields:

Revised Aug-16 17

Page 22

Gas Control Manager Program User Manual (FB107)

Field

Description

Tag

Enabled

Input PV TLP

A 10-character field that identifies the meters that

makes up the run-switching scheme. This tag is

useful for documentation purposes (screen prints,

etc.).

Select this checkbox to enable a run for the runswitching scheme. You must enable at least two runs

in order to do run-switching. If only one of the four

runs is enabled, no action is done. The left-most run

(Run 1) is the primary run (open during lowest/all flow

conditions). The focus starts on the left and moves to

the right. Normally, at least Run 1 and Run 2 would

be enabled to do run-switching with two meters.

However, the program allows you to skip runs (taken

out of service) so the run-switching functionality is still

valid even with Run 1 disabled (as long as you have

enabled two or more other runs).

Specifies the points in the FB107 that are defined as

variable inputs to the run-switching function. For

orifice measurement, these are typically differential

pressures (DPs) which are the “Meter Input”

parameter used in flow calculations. For linear

measurement, actual uncorrected flow is typically

selected. If you leave this field “Undefined” the

program displays a PV Type Not Selected status

message. The field shown as PV displays the current

value of the selected Input PV.

Open DO TLP

Close DO TLP

Energize to

Open

Specifies the points in the FB107 that are wired to the

valve solenoids. These should be digital output points.

They can be wired to either non-latching solenoids

(energized/de-energized) or latching solenoids (such

as Versa Valves or Magna-Latches). All enabled

tubes must use an Open DO with the exception of the

base tube (the first enabled tube), which is optional. If

the base tube has no actuated switching valve, the

DO will be “Undefined”.

Specifies the points in the FB107 that are wired to the

valve solenoids. These are the digital output points.

They can be wired to either non-latching solenoids

(energized/de-energized) or latching solenoids (such

as Versa Valves or Magna-Latches). If the single

solenoid mode is selected (such that a single solenoid

both opens and closes the valve), or the base tube

has no actuated switching valve, then the Close DO

TLP is unused, and is left “Undefined”.

For more information about open and close DO, refer

to Section 3.1.6. About Open and Close DO.

Energizes the Open DO to open the valve and open

the run. If this box is not selected, the program turns

off the Open DO to open the valve.

18 Revised Aug-16

Page 23

Gas Control Manager Program User Manual (FB107)

Field

Description

Open DI TLP

Close DI TLP

Lo Switch Pt

Selects the Open DI from available points on the

FB107. The TLP automatically uses the STATU S

parameter regardless of what parameter is selected.

This selection is mandatory only for the Solenoid

Mode Dual Solenoid Latch – DI Reset. Otherwise the

point can be used for monitoring purposes or left as

“Undefined” if the valve has no limit switches.

Selects the Close DI from available points on the

FB107. The TLP automatically uses the STATUS

parameter regardless of what parameter is selected.

This selection is mandatory only for the Solenoid

Mode Dual Solenoid Latch – DI Reset. Otherwise the

point can be used for monitoring purposes or left as

“Undefined” if the valve has no limit switches.

Indicates the low value that the program compares to

the value of the Input TLP for each run. In the runswitching function the right-most (furthest to the right)

run open is the focus run. When the value of the focus

run’s “Input TLP” is less than or equal to its low set

point for a certain amount of time (spike delay), the

run closes. When using “Monitor All Passed

SwitchPts,” if any of the runs is below its low set point,

the focus run closes and focus shifts to the next

enabled run to the left.

Note: The units of this field are actual Engineering

Units (not percentages).

Hi Switch Pt

Leave Open

After Opening

Next Tube

Indicates the high value that the program compares to

the value of the Input TLP for each run. In the runswitching function the right-most (furthest to the right)

run open is the focus run. When the value of the focus

run’s “Input TLP” is greater than or equal to its high

set point for a certain amount of time (spike delay),

the next enabled run to the right opens. When using

“Monitor All Passed SwitchPts,” if any of the runs is

above its high set point, the next enabled run to the

right of focus opens and focus shifts to that run.

Notice that Run4 has no “Hi Switch Pt” field as there

is no openable run to its right (all available runs are

already open).

Note: The units of this field are actual Engineering

Units (not percentages).

Select this checkbox if, during expansion, each run

remains open when focus shifts to the next enabled

run to the right. If you do not select this checkbox,

each run opens only when it is the focus run (there is

only one run open at all times). When a run loses

focus it remains open while monitoring the new focus

run (to either the left or right). When flow is detected

on the new focus run (Input TLP value is greater than

one, for the spike delay time), the previous focus

closes.

Revised Aug-16 19

2. Click Apply to save your changes.

Page 24

Gas Control Manager Program User Manual (FB107)

Field

Description

3. Proceed to Section 3.1.3, Run Switching – Run Switch Operate Tab.

3.1.3. Run Switching – Run Switch Operate Ta b

Use this tab to view information about the stations.

Figure 13. Run Switching screen – Run Switch Operate tab

1. Review the values in the following fields:

ESD SetPt

ESD Status

Status This read-only section shows the status of the Focus

Settling

Input Spike

Establishes the set point which triggers the ESD.

When the setpoint matches the TLP defined, an ESD

occurs, shutting all available runs configured in Run

Switching.

Provides information for the run switching conditions.

The code number is available in Run Switching

parameter 81.

Run and Runs Open.

Sets Settling Run Switch Delay. Values are shown in

seconds.

Sets Spike Delay for all inputs. Values are shown in

seconds.

20 Revised Aug-16

Page 25

Gas Control Manager Program User Manual (FB107)

Field

Description

Prev Opened

Trail Run

Lo Switch Pt

Hi Switch Pt

Indicates the setting time (in seconds) that both valves

are open during the transition period between tubes.

This feature applies only if you have disabled the

Leave Open After Opening Next Tube option on the

Run Switch tab.

Indicates the low value that the program compares to

the value of the Input TLP for each run.

Note: The units of this field are actual Engineering

Units (not percentages).

Indicates the high value that the program compares to

the value of the Input TLP for each run.

Note: The units of this field are actual Engineering

Units (not percentages).

2. Click Apply to save your changes.

3. Proceed to Section 3.1.4, Run Switching – Proportional Output Tab.

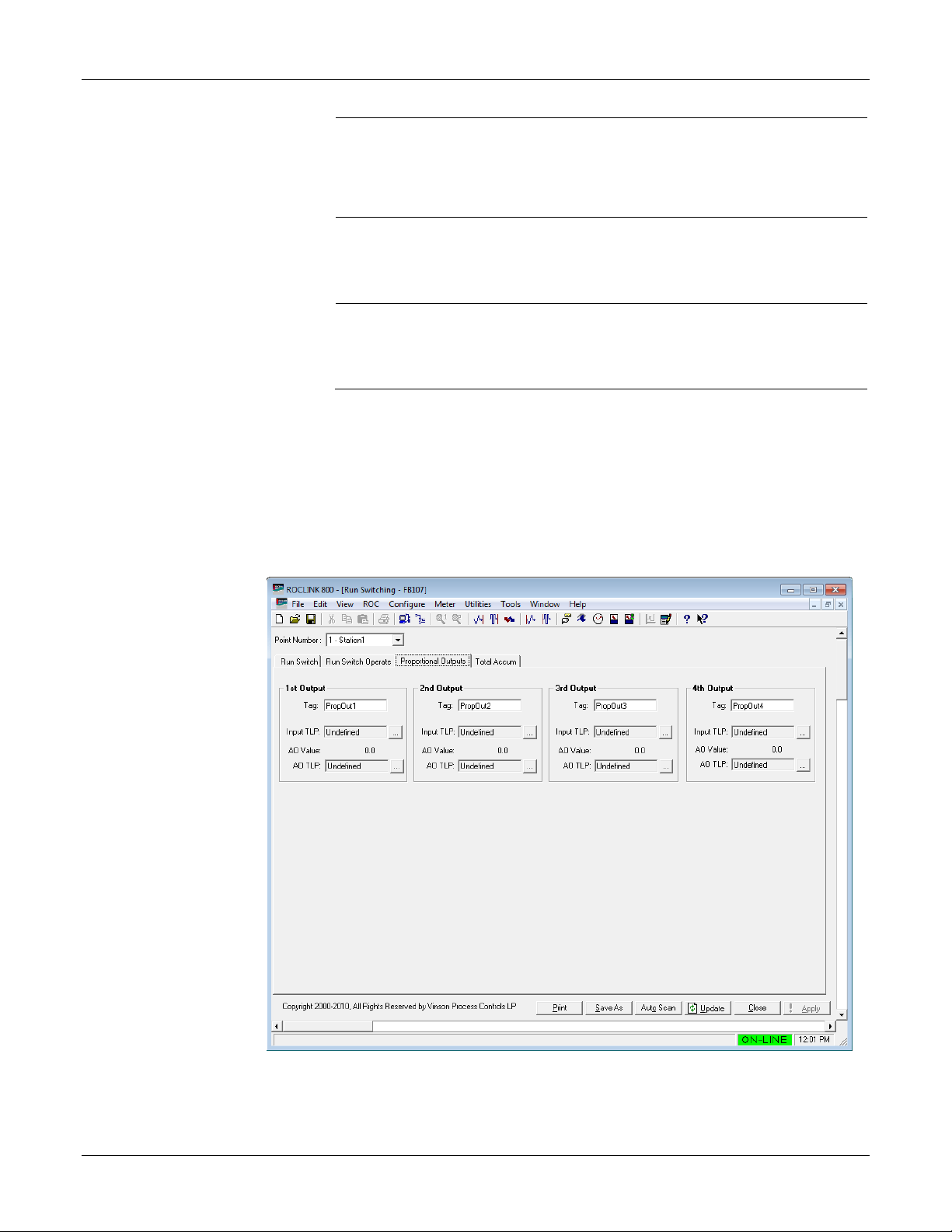

3.1.4. Run Switching – Proporti ona l Out put Ta b

Eight proportional outputs are available that send selected inputs points to

analog outputs. Station 1 contains the 1

contains the 5

th

to 8th output.

st

to 4th Output, while Station 2

Revised Aug-16 21

Figure 14. Run Switching screen – Proportional Outputs tab

1. Review the values in the following fields:

Page 26

Gas Control Manager Program User Manual (FB107)

Field

Description

Tag

Input TLP

AO Valu e

AO TLP

Use this field to name your output.

Selects the Input from available points on the ROC.

Shows the AO Value for the selected Output.

Selects the AO from available points on the ROC.

2. Click Apply to save your changes.

3. Proceed to Section 3.1.5, Run Switching – Total Accum Tab.

3.1.5. Run Switching – Total Accum Tab

The program provides four sets of resettable total accumulators for each

meter’s volume and energy. Unlike the total accumulator points in the

base FB107 (that roll over at a value of 1,000,000), this accumulator is

based on a huge data type that practically never rolls over unless manually

reset. All resets log to the event log. A station level reset from the Flow

Sum section reset these meter level accumulators that are associated with

that station.

22 Revised Aug-16

Figure 15. Run Switching screen – Total Accum tab

Page 27

Gas Control Manager Program User Manual (FB107)

Field

Description

1. Review the values in the following fields:

Volume (MCF)

Energy

(MMBTU)

Reset

2. Click Apply to save your changes.

3. Proceed to Section 3.1.6, About Open and Close DO.

This read-only field shows the Run Total Volume

Accum for the selected meter.

This read-only field shows the Run Total Volume

Energy for the selected meter.

Click to reset the value of the selected meter.

3.1.6. About Open and Close DO

The selected Solenoid Mode determines the DO parameter, so correct

selection of Status or Mode is not important. For testing purposes without

any physical I/O, FST MISC 1 to 4 Parameters are legitimate selections.

When using the Solenoid Mode Dual Solenoid Momentary, you configure

the pulse DO Time On delay in seconds using the ROCLINK I/O Discrete

Output screen’s General tab:

3.2. Cause and Effect

Revised Aug-16 23

Figure 16. Discrete Output window

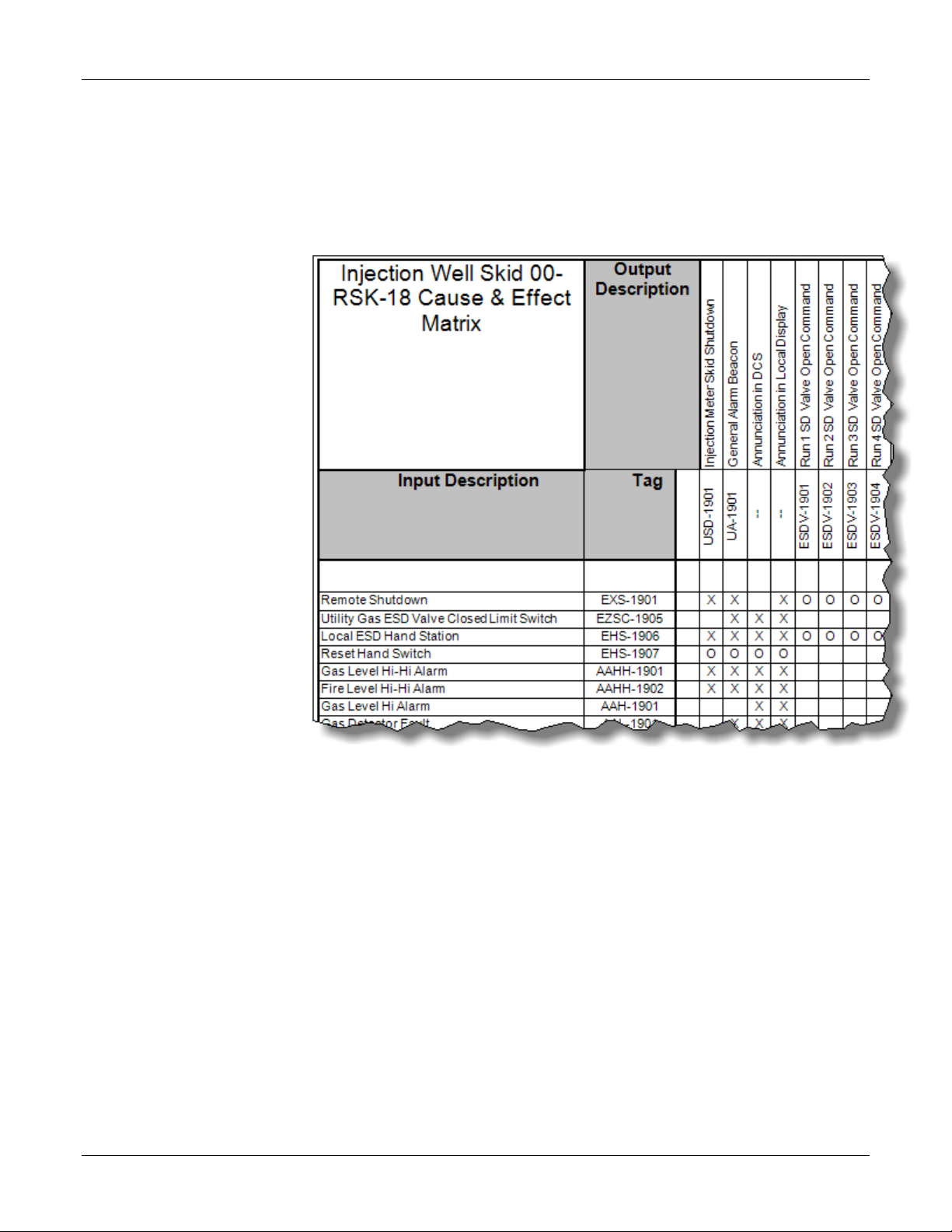

Before you begin configuring causes and effects, a little planning is

helpful. You may have up to eight effects triggered by one or more of the

Page 28

Gas Control Manager Program User Manual (FB107)

sixteen causes. For this reason, it is best to plan your effects first, and then

decide what triggers those effects.

You may wish to use a chart such as the one pictured below as a handy

way to organize your information. The effects are located across the top of

the table in columns, and the causes are listed down the left side of the

table for easy reference:

Figure 17. Cause and Effect sample matrix

Appendix A provides a full sample matrix. Use the sample or make your

own design.

To start the Cause and Effect Program:

1. Double-click a FB107 or click the Direct Connect icon in the toolbar.

2. The device window opens. Click User Program > Gas Control Mgr

in the ROCLINK configuration tree.

3. Double-click Display #23, Effect Configuration.

4. A display appears for each effect point. Double-click an effect point to

see the Effect Configuration window for that station.

Each effect represents a particular action that occurs when the causes that

are linked to it are tripped or cleared. The Value When Active is the value

the program applies to the selected PtDef when the effect is active (1 =

24 Revised Aug-16

Page 29

Gas Control Manager Program User Manual (FB107)

Field

Description

Yes). The Value When Inactive is the value that the program applies to the

selected PtDef when the effect is not active (0 = No). The output state is

written either one time only or continuously based on the Assert Effect

Continuously selection. Writing one time to the output can be useful for

operations such as setting a discrete output momentary parameter for a

resettable output.

The Effect Configuration screen displays for the effect you have chosen.

The screen has three main sections:

Effect Configuration. Use this area to name your effect, define the

point and define the active and inactive states that will be applied.

Effect Usage. Use this area to define an effect to be a normal output or

hardware/software input reset point.

Effect Status. This area is informational.

3.2.1. Effect Configuration Se t t ings

Use this screen to configure the Effect Configuration settings..

Revised Aug-16 25

Figure 18. Effects Configuration screen

1. Review the values in the following fields:

Effect Tag

Use this field to name your effect with up to 10

characters. The default value is Effect 1.

Page 30

Gas Control Manager Program User Manual (FB107)

Field

Description

Enable Effect

PtDef

Tag and

CurValue

Value When

Active

Value When

Inactive

Force Value

When

Inactive

Select this checkbox to process the effect. If you leave

this checkbox blank, the program ignores the effect,

even when a cause should activate it (that is, one or

more causes that list the effect are true).

Indicates the controlled FB107 data point (TLP).

Shows the current name “PtDef” field whenever the

effect is activated by one or more true causes.

The user-specified (or dynamic) value that is sent to

the TLP defined in the “PtDef” field whenever the effect

is actuated by one or more true causes.

The user-specified (or dynamic) value that is sent to

the TLP defined in the Effect PtDef field whenever the

effect is un-activated as a result of no true cause. If the

Force Value When Inactive is unchecked, the TLP

defined in the Effect PtDef field is not controlled when

the effect is un-activated.

Writes the value in the Value When Inactive field to the

TLP defined in the PtDef field whenever the effect is

un-activated (that is, none of the causes that list the

effect are true).

If you leave this checkbox blank, the program does not

write any values to the PtDef field when the effect is

un-activated.

Assert Effect

Continuously

Effect Usage

Normal (Not

Hard-Wired

Software

Select this checkbox to have the program continuously

write active or inactive values to the PtDef TLP. This

may be desirable to assure that the output is reasserted to the expected state (for example, when a

DO point is taken out of manual mode).

If you leave this checkbox blank, the program sets the

state one time. This may be useful for a DO point in

momentary mode which resets itself.

Allows effects to be defined as reset points. Reset

points are monitored by causes that require a reset

before clearing from the tripped condition.

Select if the effect is handled like any

used as a

reset)

Reset (DI

Point)

Reset

other normal effect (this is the

default).

Select if the effect is handled as a

reset point requiring a manual action,

such as pressing a reset pushbutton.

Select if the effect is handled as a

reset point that can be reset through

a variable. This variable could then

be assigned to the LCD display or set

by SCADA. The program

automatically reset the field back to

the Inactive Value. The program now

allows the selection of other data

types besides unsigned integer

(UINT8).

26 Revised Aug-16

Page 31

Gas Control Manager Program User Manual (FB107)

Field

Description

Reset Code

Effect Status

Active Link

Tattletale

Current

Active Link

Count

Defines a code that, if matched to a Cause Reset

Code, reset those causes when the program detects a

software or hard-wired reset point.

Shows whether the effect has been tripped (activated).

Shows the first four causes that currently hold this

effect active, and the order in which they occurred.

Shows how many causes currently activate this effect.

2. Click Apply to save your changes.

3. Proceed to Section 3.2.2, Cause Configuration Settings.

A reset point is normally a digital input point, such as a status point. For

example, you may have the “PtDef” configured to be a DI status and the

“Actuated Value” would be the value of the digital input when the reset

button is pushed. All causes that require resets (“Require Reset?” Is

checked) would examine this effect (reset effect) for the activated value.

Causes reset when program detects the activated value.

3.2.2. Cause Configuration Set t ings

To access the Cause Configuration window:

1. Double-click a FB107 or click the Direct Connect icon in the toolbar.

2. The device window opens. Click User Program > Gas Control Mgr

in the ROCLINK configuration tree.

3. Double-click Display #22, Cause Configuration.

4. A display for each cause point appears. Double-click a cause point to

see the Cause Configuration window for that station.

Revised Aug-16 27

Page 32

Gas Control Manager Program User Manual (FB107)

Figure 19. Cause Configuration screen

The Cause Configuration window has seven main sections:

General Cause Configuration. Use this section to assign a name to

your cause, define it as simple or compound, indicate the requirement

for a pre- condition, and enable the cause.

Cause Execution Pre-Condition. This section displays only if you

select Pre-Condition Required in the General Cause Configuration

section. Use this section to define the pre-condition.

Primary Logic Section. Use this section to define the primary logic of

your cause.

Secondary Logic Section. This section displays only if you select

Compound in the General Cause Configuration section. Use this

section to define the secondary logic of your cause.

Effect Assignments. Use this section to link your cause to one or

more effects.

Misc Parameters. Use this section to write logs or alerts, or to have

this cause require a reset.

Cause Status. This informational section shows the status of the

cause. Red indicates tripped, and green indicates not tripped.

Causes can be configured to perform multiple functions, including

true/false logical comparisons, math functions, copying data, state

28 Revised Aug-16

Page 33

Gas Control Manager Program User Manual (FB107)

Field

Description

changes, and watchdog timer. Causes can be linked to eight effects, which

will activate when the cause comparison is true.

1. Review the values in the following fields:

General

Cause

Configuration

Cause

Simple/

Secondary’s

Pre-Condition

Cause Tag

Enabled

Compound

Relationship

with Primary

Required

A 10- character field for the tag from the

cause & effect matrix or a user-selected

tag.

Processes the cause. Leave the checkbox

blank to ignore the cause.

Note: Ensure all portions of the cause

screen are correctly configured

before enabling the cause.

Choose Simple if you want to use one

logic section in this cause. Choose

Compound to use two logic sections,

primary and secondary.

Sets the relationship between the primary

and secondary logic sections.

Note: This section displays only if you

chose Compound for this cause.

The relationship can be "AND" or

"OR".

Select this checkbox to activate this

cause only when the pre-condition has

been met. The Cause Execution PreCondition section displa ys when you

select this option.

Cause

Execution

Pre-Condition

PtDef

Operators

SetPt

Delay Secs.

Primary Logic

Section

Pre-Condition

Met

Preset

“Primary” refers to the fact that this field is in “Part 1” of the

two possible comparisons for each cause.

When the pre-condition goes true, this

box is checked.

Indicates the data point (TLP) value used

as a pre-condition. If the set point is not

reached for this TLP, this cause does not

activate.

Choose how you want the value of this

point to be evaluated – equal (==), greater

than or equal to (>=), not equal (!=), or

less than or equal to (<=).

Identifies the point at which the cause is

activated.

Identifies how long the program waits

after the condition is met before activating

the cause.

Revised Aug-16 29

Page 34

Gas Control Manager Program User Manual (FB107)

Field

Description

PtDef

Tag

Cur Value

Operator

The data point (TLP) value that displays in

the Cur Value field. This item can be any

numerical point including values from other

causes. Click the “…” button to the right of

the field to browse through the list of

available parameter s . You m ust configur e

this field for all cause function types.

The name given to the soft point in the soft

point configuration screen.

Note: The system reads the tag when you

configure the point definition. If you

change the tag after it has been read,

you will not see the updated tag name

until you reconfigure the point

definition. To force an update, set the

PtDef to “Undefined” then reset it to

the desired point. The tag name will

then be read and updated. If a

particular point type selected does not

have a tag as the first parameter, this

field may not display properly.

Displays the current value of the ROC point

(TLP) specified in the “PtDef” field.

Specifies the function (operator) of the

cause. The possible functions are shown in

Table 1.

SetPt Def

SetPt Value

Deadband

or Math

Result

Trip Delay Preset

Secs

The ROC data point (TLP) that becomes a

dynamic source of the set point value (“SetPt

Value” field). When this field is left

“Undefined,” you may enter a static value in

the “SetPt Val” field.

Holds the value that is used for comparisons

and math functions. This field is not used for

the One-Scan or Watchdog Timer functions.

If the “SetPt Def” field is configured (other

than “Undefined”), this field gets its value

from the TLP specified in “SetPt Def”.

This field serves three purposes. When

using comparison operators (>=, <=, ==, !=),

it specifies a Deadband value that must be

exceeded before an existing true

comparison can go false. For math

functions (Add, Subtract, Multiply, Divide),

this field holds the result of the math

operation. For the Copy Data function, this

field defines how many fields or parameters

to copy. Deadband is not used with OneScan or Watchdog Timer functions.

The number of user-defined seconds for

which the comparison must be true before

the cause goes true.

30 Revised Aug-16

Page 35

Gas Control Manager Program User Manual (FB107)

Field

Description

Elapsed

Secs

Timer

Timing

Secondary

Logic Section

Effect

Assignments

# Links

The Secondary Logic section has the same fields and logic

as the Primary Logic section.

These are the links to the effects for this cause. The link

labels indicate there are 8 possible links that can be used.

The Link fields will be the 1 to 8 number referenced to one

or more effects where 0 indicates no link. For example, If

you wanted the first effect activated to be effect #4, you

would enter 4 in the “# of Link 1” field. Any number of

effects can be listed here, from zero to eight. If all eight

fields are set to zero (defaults), no effects are connected to

the cause.

Currently

Active

Displays the delay count in seconds up to

the user-defined preset. When the

comparison becomes true, the count

(seconds) increments until it reaches the

“Preset Secs” and the cause becomes true.

If at anytime the comparison turns false, the

count resets to zero and the cause becomes

false.

This field’s value is 1 or 0. It serves as an

indication that the timer has been activated.

This shows the number of effects that are

currently tripped for this cause.

Misc

Parameters

Log Clears

Require

Log Trips

Reset?

Determines if an alarm generated by the

cause will be written to the ROC’s alarm

log. If this field is checked, every time the

cause goes true an alarm will be logged.

The log consists of the cause’s 10character tag and the value of “Cur Value”

along with the date and time.

Determines whether an entry will be

written to the ROC’s alarm log when this

cause is cleared. If this field is checked,

every time the cause is cleared an entry

will be logged. The log consists of the

cause’s 10-character tag and the value of

“Cur Value” along with the date and time.

Note: Log entries that begin with a “Z” as

the first digit are cause entries.

Alarms not generated by Cause &

Effect are not prefixed with a Z.

Check this box if the logic requires that a

reset button needs to be pushed before

the cause is set back to false. A reset can

be a hardware or software reset. For

example: when the cause goes true, it

actuates effects that cause a shutdown,

and it is desired that the shutdown be

maintained until a reset is done.

Revised Aug-16 31

Page 36

Gas Control Manager Program User Manual (FB107)

Field

Description

Reset Code

Minimum Trip

Secs. Preset

Elaps Trip

Secs

Accumulated

Trips

Cause Status Pre-Condition

Met

Primary

Section

Tripped

Secondary

Section

Tripped

Cause

Tripped

A numeric value that must be associated

with the Effect Reset Code that will

provide the reset through a DI point or

software point.

Holds the trip state for a minimum time so

a short duration trip can be detected.

Shows how long the cause has been

tripped. This is also the counter for the

Minimum Trip Secs Preset

Shows how many times the cause has

been tripped.

Shows whether the Pre-Condition section

has been tripped (1 for Yes, 0 for No).

Shows whether the Primar y section has

been tripped (1 for Yes, 0 for No).

Shows whether the Secondary section

has been tripped (1 for Yes, 0 for No).

Shows whether the cause has been

tripped (1 for Yes, 0 for No). If this is a

compound cause and the relationship

between primary and secondar y was set

to AND, the cause will only be tripped if

both the Primary Section and Secondary

Sections are tripped.

2. Click Apply to save your changes.

3. Proceed to Section 3.2.3, Cause and Effect Operate Display.

3.2.3. Cause and Effect Operate Display

The Cause & Effect Operate display is a read-only summary screen

showing all conditions, statistics and linkages for the 16 causes and 8

effects. Red indicates an active or tripped state where green indicates an

inactive or normal state.

32 Revised Aug-16

Page 37

Gas Control Manager Program User Manual (FB107)

Function

Function Description

>=

True If (compare) Greater Than (or equal to)

==

True If (compare) Equal To

!=

True If (compare) Not Equal To

One-Scan Rising

One-Scan Rising (Cur Value, 0 to 1 transition = true)

One-Scan Falling

One-Scan Falling (Cur Value, 1 to 0 transition = true)

Watchdog Timer

Watchdog Timer (resets on changing value of Cur Value)

Copy Data

Copies from Cur Value to SetPt Value (see full explanation

Add

Addition, Cur Value plus SetPt Value

Multiply

Multiplication, Cur Value times SetPt Value

Divide

Division, Cur Value divided by SetPt Value

Figure 20. Cause and Effect Operate Display screen

3.2.4. Configuration Exampl e s

The possible functions are shown in the table below. All comparisons are

between “Cur Value” and “SetPt Value.”

Table 1. List of Functions

<= True If (compare) Less Than (or equal to)

Subtract Subtraction, CurValue minus SetPt Value

Modulus Modulus. Remainder of Integers: Cur Value / SetPt Value

Revised Aug-16 33

Page 38

Gas Control Manager Program User Manual (FB107)

Greater Than

The cause goes true when the value at “Cur Value” is greater than or

Less Than

The cause goes true when the value at “Cur Value” is less than or equal

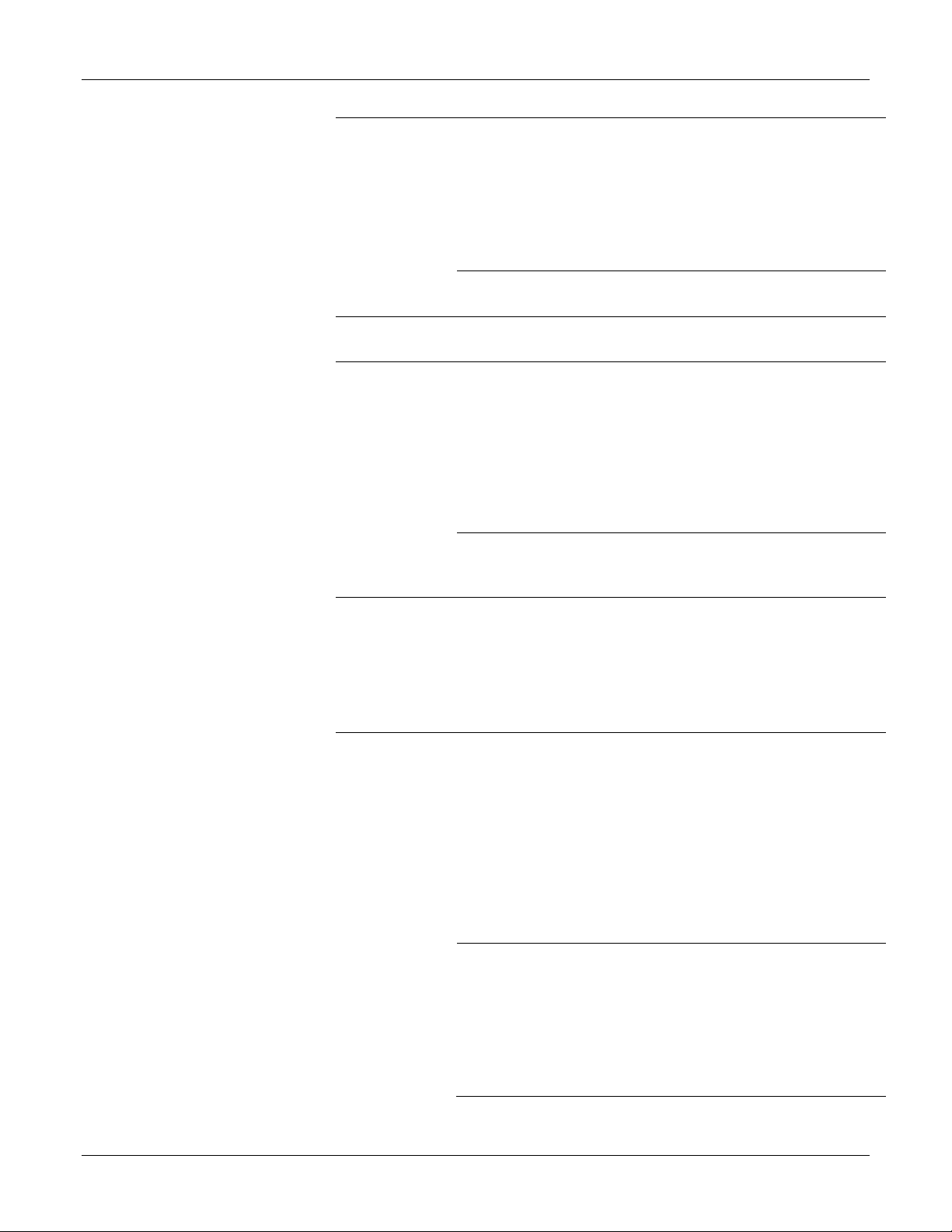

Figure 21. Operator area in the Primary Logic Section

The following examples show how to do configurations with each of the

available functions (operators). These examples do not show compound

logic (AND, OR) or examples utilizing enablers.

( > =)

equal to the value at “SetPt Val”.

Figure 22. Greater Than Operator example

This cause is true because “Cur Value” (831) is greater than “SetPt Val”

(800).

Note: Because of the deadband of 50, the cause will remain true until the

value of analog input A3 falls below 750.

( < =)

34 Revised Aug-16

to the value at “SetPt Value”.

Page 39

Gas Control Manager Program User Manual (FB107)

Equals

The cause goes true when the value at “Cur Value” is equal to the

Not Equal

The cause goes true when the value at “Cur Value” is not equal to the

Figure 23. Less Than Operator example

This cause is true because “Cur Value” (375) is less than or equal to

“SetPt Value” (385).

Note: “SetPt Value” is a dynamic value coming from analog input A3.

( = = )

value at “SetPt Value”.

Figure 24. Equals Operator example

This cause is true because digital input A9 is zero.

Note: Even when the level switch (A9) goes to normal (1) the cause

remains true until someone pushes the reset button if “Reset

Required?” is checked.

( ! = )

Revised Aug-16 35

value at “SetPt Value”.

Page 40

Gas Control Manager Program User Manual (FB107)

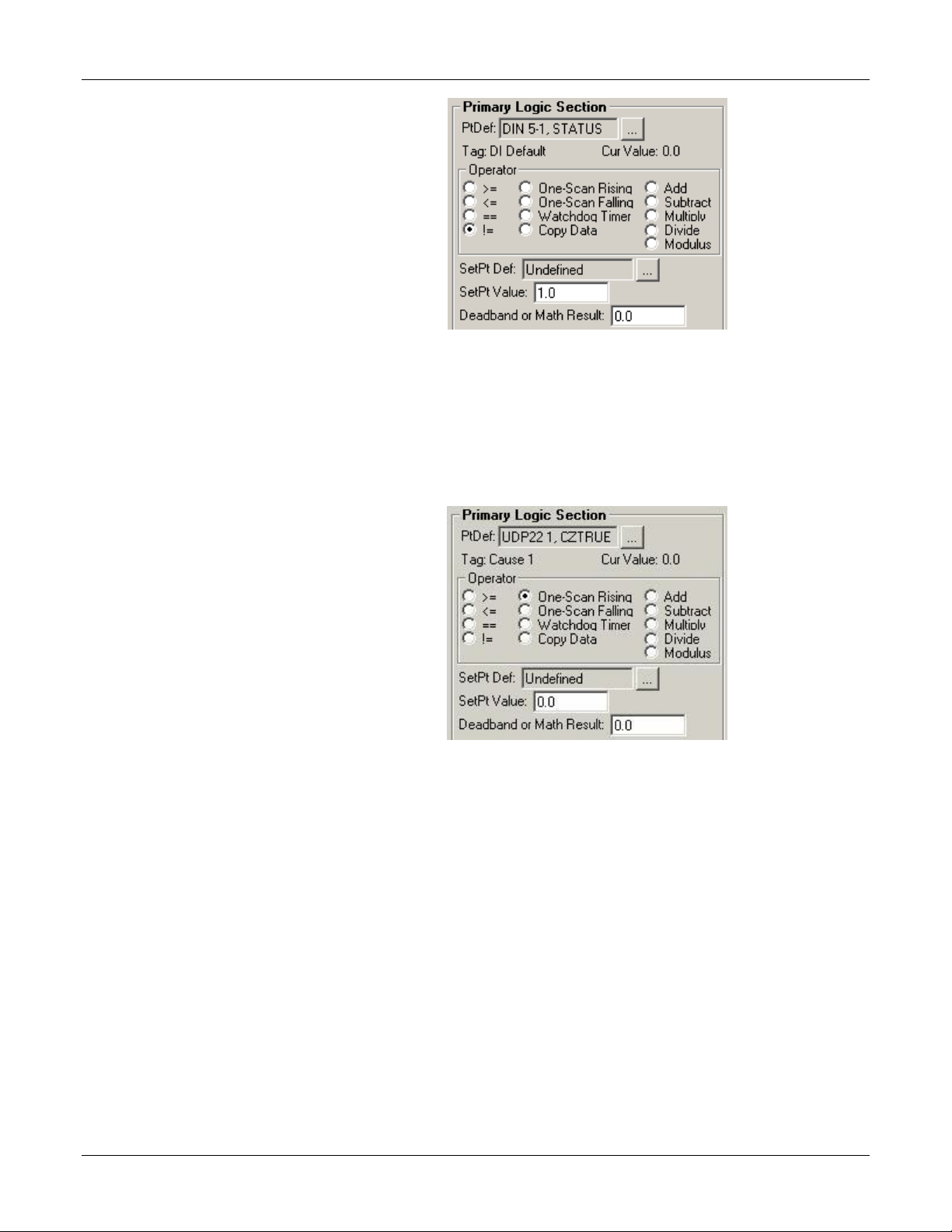

One-Scan Rising

The cause goes true when the value at “Cur Value” changes from zero

One-Scan Falling

The cause goes true when the value at “Cur Value” changes from one

Figure 25. Not Equal Operator example

This cause is true because the statue of digital input A9 (0) does not equal

the set point value (1).

to one. The cause will be true for one scan (1 second) only.

Figure 26. One-Scan Rising Operator example

The input to this cause is the status of cause #1 (true/false). When cause

#1 goes true, this cause will go true for one second. The effect for this

cause might be the mode of a digital output (versa valve or momentary

solenoid).

Inputs for this function should be limited to Boolean types because only a

zero to one transition will cause a trip.

to zero. The cause will be true for one scan (1 sec) only.

36 Revised Aug-16

Page 41

Gas Control Manager Program User Manual (FB107)

Watchdog Timer

The cause goes true when the value at “Cur Value” does not change

Figure 27. One-Scan Falling Operator example

The input to this cause is the status of cause #1 (true/false). When cause

#1 goes false, this cause will go true for one second. Effect #2 might be

the mode of a digital output (versa valve or momentary solenoid).

Inputs for this function should be limited to Boolean types because only a

one to zero transition will cause a trip.

within the time span defined at “True Delay sec”. This is an example

using the comm. port Valid Receive Counter to detect when

communication stops:

Figure 28. Watchdog Timer Operator example

The value (1053) is from the valid receipt-counter of a remote ROC. It is

stored in Soft Point #1 – Data #1.

The intent here is to alarm if there is no valid Modbus communication for

a 2-minute period. The effect this cause triggers might be a remote alarm

dialer channel.

Revised Aug-16 37

Page 42

Gas Control Manager Program User Manual (FB107)

Copy Data

The cause copies from Cur Value to SetPt Value. The numeric value in

the “Deadband” field tells the system what type of copy to make and

how much data to copy.

This is an example how to copy Orifice meter run parameters to

Softpoint data points.

Figure 29. Copy Data Operator example

The 1XX value in the Deadband/Result field commands that the copy is

from incremental parameters to incremental parameters, and is configured

38 Revised Aug-16

to copy 16 parameters (by parameter to parameter) starting from Orifice

Page 43

Gas Control Manager Program User Manual (FB107)

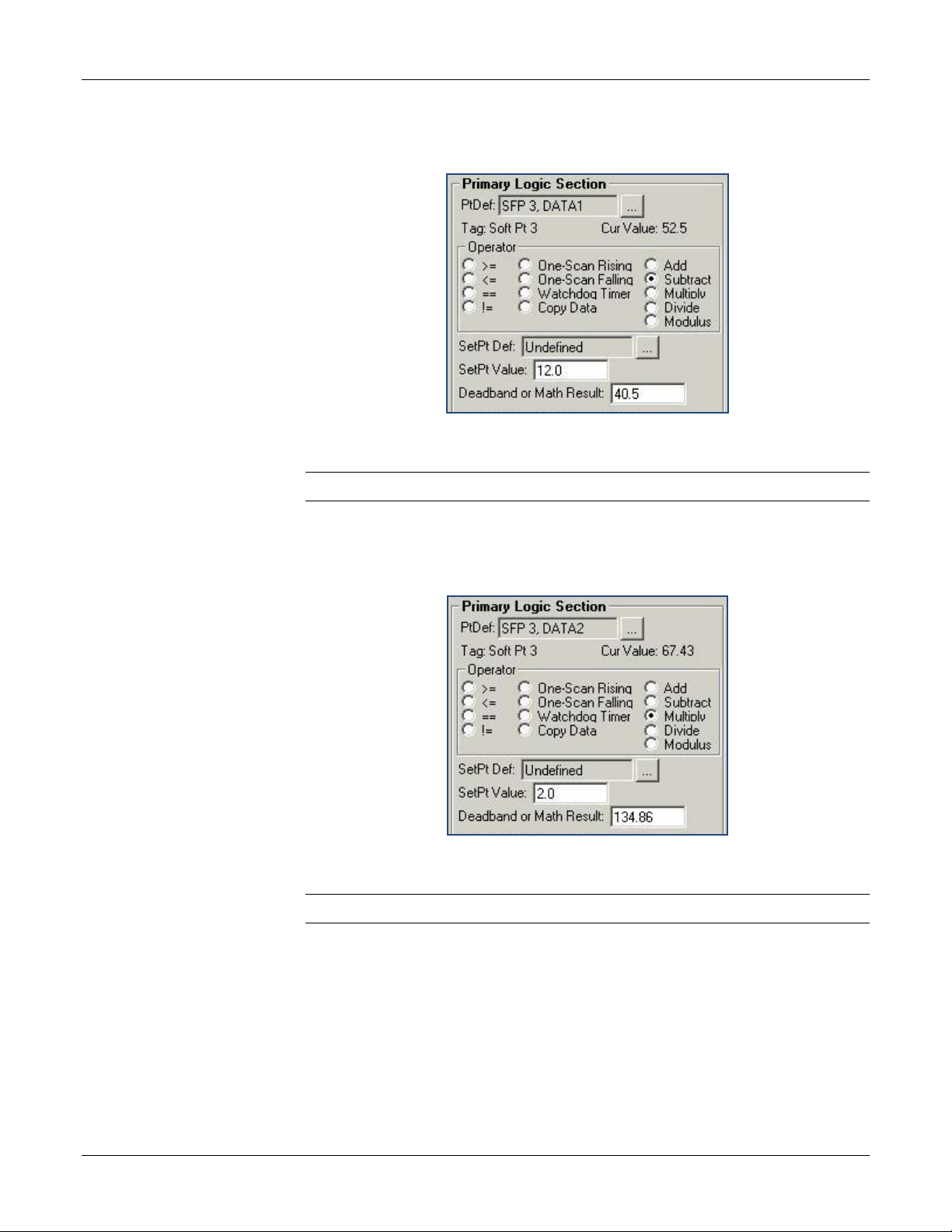

Add

The sum of “Cur Value” and “SetPt Value” is placed in the

Meter Run values #1, parameter 0 (flow rate per day). The 16 copied

items land in soft point #1, starting at DATA1 and ending at DATA16.

The Copy Data function copies data from “PtDef” to “SetPt Def.” There

are four different types of copies – by logicals, by parameters, logicals to

parameters, parameters to logicals. The numeric value in the “Deadband”

field tells the system what type of copy to make and how much data to

copy:

Table 2. Types of Copies

Number Copy Type Description

XX Logicals Source data located in a Logical order wil l be

copied to the Target data location in a Logical

order.

1XX Parameters Source data located in a Parameter order will

be copied to the Target data location in a

Parameter order.

2XX Logicals to

Parameters

3XX Parameters

to Logicals

Source data located in a Logical order will be

copied to the Target data location in a

Parameter order.

Source data located in a Param eter order will

be copied to the Target data location in a

Logical order.

Example: 105 in the Deadband field means copy parameters 0 through 4 to

parameters 1 through 5 on another TLP.

“Deadband/Result” register. If the SetPt Def is undefined, the value

entered in SetPt Value will be added as a constant. The cause status is

always zero.

Note: No effects are used with math operations.

Revised Aug-16 39

Figure 30. Add Operator example

Page 44

Gas Control Manager Program User Manual (FB107)

Subtract

The difference of “Cur Value” and “SetPt Value” is placed in the

Mutiply

The product of “Cur Value” and “SetPt Value” is placed in the

Divide

The quotient of “Cur Value” divided by “SetPt Value” is placed in the

“Deadband/Result” register. The cause status is always zero.

Figure 31. Subtract Operator example

Note: No effects are used with math operations.

“Deadband/Result” register. The cause status is always zero.

Figure 32. Multiply Operator example

Note: No effects are used with math operations.

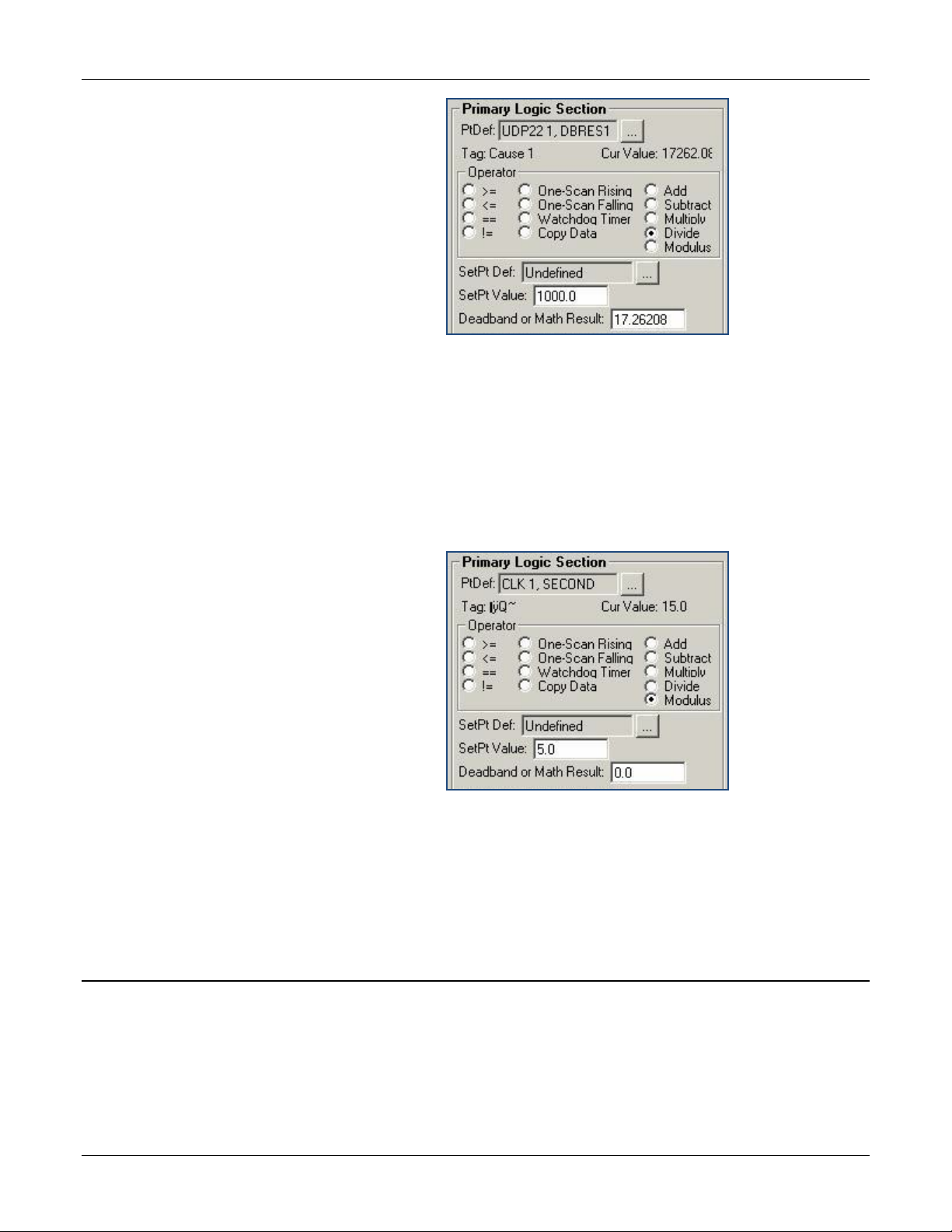

“Deadband/Result” register. The cause status is always zero.

40 Revised Aug-16

Page 45

Gas Control Manager Program User Manual (FB107)

Modulus

The remainder of the integer division of “Cur Value” divided by “SetPt

Figure 33. Divide Operator example

The quotient of “Cur Value” divided by “SetPt Value” is placed in the

“Deadband/Result” register. The cause status is always zero.

Value” is placed in the “Deadband/Result” register. The cause status is

always zero. This is an example how to create 5-second execution from

ROC clock seconds:

Figure 34. Modulus Operator example

The seconds from the ROC clock are divided by five. Every five seconds

the modulus (remainder) is zero. Another cause can look at this cause’s

result field for a zero as part of condition for taking action. In this way a 5second execution clock is created.

3.3. Flow Summation

To start the Flow Summation Program:

1. Double-click a ROC device or click the Direct Connect icon in the

toolbar.

2. The device window will open. Click User Program > Gas Control

Mgr in the ROCLINK configuration tree.

Revised Aug-16 41

Page 46

Gas Control Manager Program User Manual (FB107)

Field

Description

Station

3. Double-click Display #36, Flow Sum.

4. You will see a display for each station. Double-click a station to see

the Flow Sum window for that station.

3.3.1. Flow Sum

The Flow Sum fields are described below:

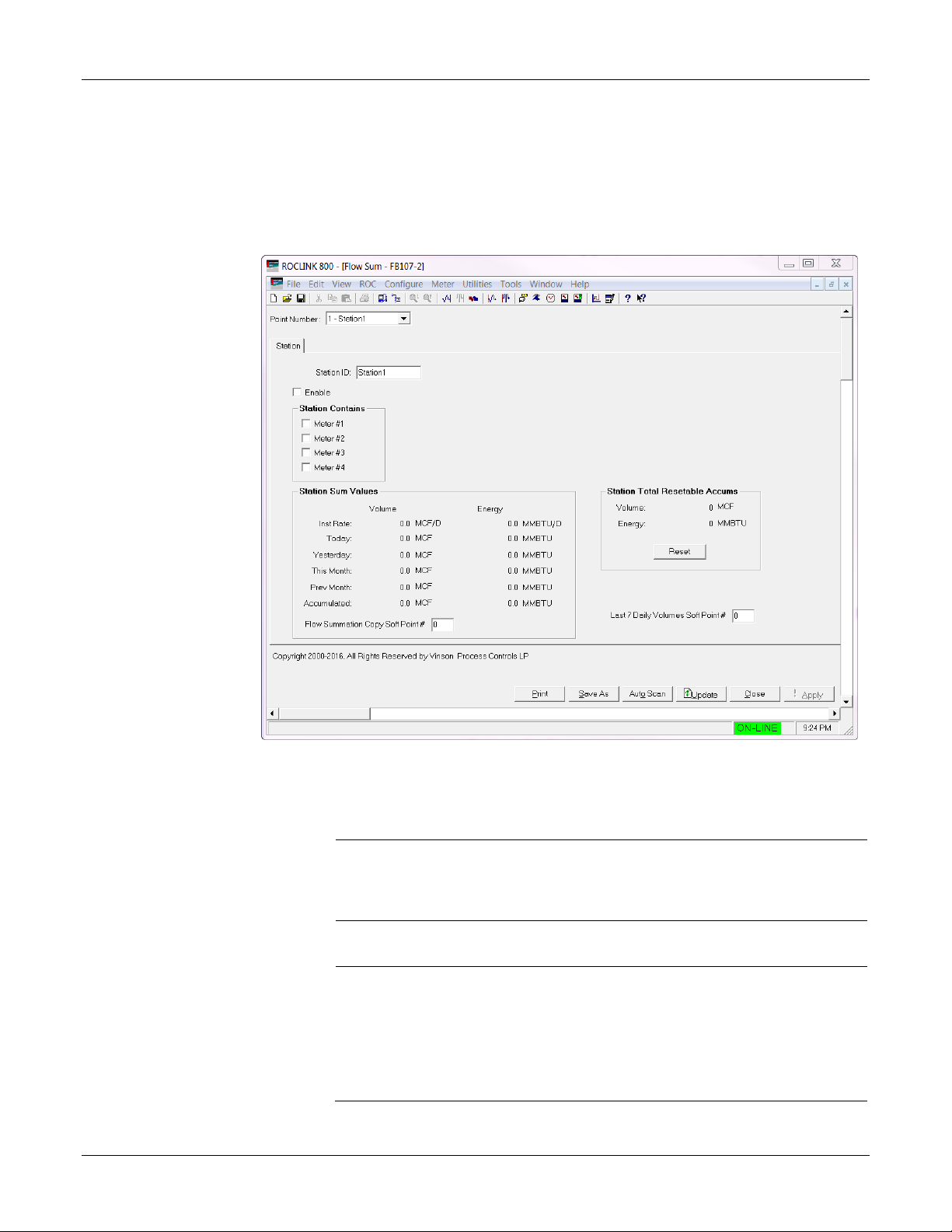

Figure 35. Flow Sum screen

1. Review the values in the following fields:

Enable

Summation

Contains

Station Sum

values

42 Revised Aug-16

If you check Enable Summation, the program looks at

the following four fields and uses the ones that are

checked as a factor in the flow sum. If this field is not

checked, the remainder of this section is ignored.

Checks each meter to be added to the flow

summation.

Inst Rate

The sum of volume and energy

flow rates for all the meters

selected above. The units of the

volume flow rates are in MSCF or

M3 per day. The units of the energy

flow rates are in MMBTU or GJ per

day.

Page 47

Gas Control Manager Program User Manual (FB107)

Field

Description

Today

Yesterday

This Month

Prev Month

The sum of volume and energy

accumulated today for all of the

meters selected above. The units

of the volume are in MCF or M3.

The units of the energ y are in

MMBTU or GJ.

The sum of volume and energy

accumulated yesterday (the 24

hours before the last contract hour)

for all the meters s elec ted abo ve.

The units of the volume are in MCF

or M3. The units of the energy are

in MMBTU or GJ.

The sum of volume and energy

accumulated this month (month to

date) for all of the meters selected

above. The units of the volume are

in MCF or M3. The units of the

energy are in MMBTU or GJ. The

values are taken from the “Extra

Run Parameters” field of each

meter.

The sum of volume and energy

accumulated during the previous

month for all of the meters selected

above. The units of the volume are

in MCF or M3. The units of the

energy are in MMBTU or GJ. The

values are taken from the “Extra

Run Parameters” field of each

meter.

Accumulated

Flow

Summation

Copy Soft Point

#

Revised Aug-16 43

Specifies the softpoint where all of the meter values

are copied. The values are written to an alternate

place to make the data accessible because some

SCADA hosts might not be able to access userdefined point types (type 36). The program ignores

this field if the value is less than one (default=0) or

greater than thirty-two. The six flow values are placed

at Data1 through Data6. The equivalent “Energy”

values (rate through previous month accumulation) are

placed at Data7 through Data12. The energy fields are

in MMBTU.

The on-going accumulation of

volume and energy calculated by

the program, which do not reset

upon the change of the day or

month. These values increase

every second during flowing

conditions as an accumulation is

calculated from the flowrate. When

this accumulated value reaches

“interval” value, the program resets

the accumulation to zero.

Page 48

Gas Control Manager Program User Manual (FB107)

Field

Description

Last 7 Daily

Volumes Soft

Point #

2. Click Apply to save your changes.

3.3.2. Examples

Softpoints assignments are given below:

Softpoint Assignments – (Example: Starting at Softpoint 11)

Softpoint 11

Softpoint 12

Softpoint 13

Softpoint 14

Softpoint 15

This function is active when the field is set to a

number greater than zero. There is only one field for

this function. It uses two softpoints for every enabled

calculation for a maximum of eight softpoints. The

previous seven-day’s daily flow and energy totals for

each meter are written to the softpoints at each

contract hour. The data is organized as per

Table 4.

Table 3. Softpoint Assignments

Meter 1 Daily Accumulated Flow

Meter 1 Daily Accumulated Energ y

Meter 2 Daily Accumulated Flow

Meter 2 Daily Accumulated Energ y

Meter 3 Daily Accumulated Flow

Table 3 and

Softpoint 16

Softpoint 17

Softpoint 18

Meter 3 Daily Accumulated Energ y

Meter 4 Daily Accumulated Flow

Meter 4 Daily Accumulated Energ y

Each softpoint contains seven days of flow information along with

timestamps.

Table 4. Data point assignments

Data Point Assignments

Data1 Sunday’s Value Data11 Sunday’s Timestamp

Data2 Monday’s Value Data12 Monday’s Timestamp

Data3 Tuesday’s Value Data13 Tuesday’s Timestamp

Data4 Wednesday’s Value Data14 Wednesday’s Timestamp

Data5 Thursday’s Value Data15 Thursday’s Timestamp

Data6 Friday’s Value Data16 Friday’s Timestamp

Data7 Saturday’s Value Data17 Saturday’s Timestamp

The day-of-the-week is the day on which the daily flow period started. For

instance, if the contract hour is at 9am, the value stamped down at 9am on

Wednesday morning is listed at Data3 (Tuesday’s value).

44 Revised Aug-16

Page 49

Gas Control Manager Program User Manual (FB107)

Sample

The first three meters are selected. The flow totals from these three

meters are added together and displayed on the screen.

These totals are written to soft point #10.

Figure 36. Sample values

Flow data for the group is written to the designated soft point. The

numbers are placed into data points as described in the following table.

Table 5. Data Point Definitions

SOFTPOINT - DATA POINT DEFINITIONS

Data 1 Inst flow Data 7 Inst energy

Data 2 Today’s flow accum Data 8 Today’s energy accum

Data 3 Yesterday's flow accum Data 9 Yesterday's energy accum

Data 4 This month’s flow accum Data 10 This month’s energy accum

Data 5 Previous month’s low accum Data 11 Previous month’s energy accum

Data 6 Flow accumulated Data 12 Energy accumulated

Revised Aug-16 45

Page 50

Gas Control Manager Program User Manual (FB107)

Chapter 4 – Reference

This section provides information on the user-defined point type the Gas

Control Manager program uses:

Point Type 22: Cause Configuration

Point Type 23: Effect Configuration

Point Type 35: Run Switching

Point Type 36: Flow Sum

46 Revised Aug-16

Page 51

Gas Control Manager Program User Manual (FB107)

ag

4.1. Point Type 22: Cause Configurat ion

Point type 22 applies to Cause Configuration. There are 16 logicals of this point type.

Point Type 22: Cause Configuration

Parm Name Abbr Access System

or User

Update

0 Cause Tag PTTAG R/W User AC10 10 0x20 -> 0x7E

1 Enable Cause ENABLE R/W User UINT8 1 0 -> 1 0 1.00 Cause Enabled:

2 Input1 Definition INDEF1 R/W User TLP 3

3 Input1 Tag INTAG1 R/O System AC10 10 0x20 -> 0x7E

4 Cur Value1 CUVAL1 R/O System FL 4 Any

DataType Length Range Default Ver Description

for each

ASCII

character

for each

ASCII

character

FloatingPoint

Number

Cause 1 to

Cause16

17,0,2 1.00 Primary Logic Point Selection

<none> 1.00

0 1.00 Primary Logic Current Value:

1.00 Cause Tag Name

0 = Disable

1 = Enable

Selected Primary Logic PointT

ID

Revised Aug-16 47

Page 52

Gas Control Manager Program User Manual (FB107)

n

Point Type 22: Cause Configuration

Parm Name Abbr Access System

or User

Update

5 Function1 Type RELAT1 R/W User UINT8 1 1, 2, 3, 4, 5, 7,

6 SetPt1 Definition SETDEF R/W User TLP 3

7 SetPt1 Value SETPT1 R/W User FL 4

DataType Length Range Default Ver Description

8,10, 11, 12,

13,14, 18

Any

FloatingPoint

Number

1 1.00 Primary Logic Operator:

1) >=

2) <=

3) ==

4) !=

5) Watch Dog Timer

7) One Scan Rising

8) One Scan Falling

10) Add

11) Subtract

12) Multiply

13) Divide

14) Modulus

18) Copy Data

0,0,0 1.00 Primary Logic Set PointSelectio

0 1.00 Primary Logic Setpoint Value

8 Deadband orResult1 DBRES1 R/W Both FL 4 Any

FloatingPoint

Number

9 Part2 Enable USEPT2 R/W User UINT8 1 0 -> 1 0 1.00 Secondary Enable:

10 Input2 Definition INDEF2 R/W User TLP 3

11 Input2 Tag INTAG2 R/O System AC10 10 0x20 -> 0x7E

for each

ASCII

character

12 Cur Value2 CUVAL2 R/O System FL 4 Any 0 1.00 Secondary Logic Current Value

0 1.00 Primary Logic Deadband orMath

Result

0 = Simple

1 = Compound

0,0,0 1.00 Secondary Logic PointSelection

<none> 1.00 Selected Secondary LogicPoint

Tag ID

48 Revised Aug-16

Page 53

Point Type 22: Cause Configuration

FloatingPoint

Gas Control Manager Program User Manual (FB107)

Parm Name Abbr Access System

or User

Update

13 Function2 Type RELAT2 R/W User UINT8 1 1, 2, 3, 4, 5, 7,

14 SetPt2 Definition SETDF2 R/W User TLP 3

15 SetPt2 Value SETPT2 R/W User FL 4 Any

DataType Length Range Default Ver Description

Number

8,10, 11, 12,

13,14, 18

FloatingPoint

Number

1 1.00 Secondary Logic Operator:

1) >=

2) <=

3) ==

4) !=

5) Watch Dog Timer

7) One Scan Rising

8) One Scan Falling

10) Add

11) Subtract

12) Multiply

13) Divide

14) Modulus

18) Copy Data

0,0,0 1.00 Secondary Logic Set

PointSelection

0.0 1.00 Secondary Logic SetpointValue

16

17 And/Or Mode ANDOR R/W User UINT8 1 15 -> 16 15 1.00 Secondary Relationship

18 Cause Trip/Clear CZTRUE R/O System UINT8 1 0 -> 1 0 1.00 Cause Tripped Status:

Deadband orResult2

DBRES2 R/W Both FL 4

Any

FloatingPoint

Number

0.0 1.00

Secondary Logic Deadband

orMath Result

withPrimary:

15 = And with Primary

16 = Or with Primary

0 = No

Revised Aug-16 49

Page 54

Gas Control Manager Program User Manual (FB107)

1 = Yes

ag

Point Type 22: Cause Configuration

Parm Name Abbr Access System

or User

Update

19 Part1 Trip/Clear P1TRUE R/O System UINT8 1 0 -> 1 0 1.00 Primary Section TrippedStatus:

20 Part2 Trip/Clear P2TRUE R/O System UINT8 1 0 -> 1 0 1.00 Secondary Section

21 Use Digital Enabler ENABRQ R/W User UINT8 1 0 -> 1 0 1.00 Pre-Condition Required:

22 Digi Enab Definition ENADEF R/W User TLP 3

23 Digi Enab Tag ENATAG R/O System AC10 10 0x20 -> 0x7E

24 Digi Enab

ProcessValue

ENAPV R/O System FL 4 Any

DataType Length Range Default Ver Description

0 = No

1 = Yes

TrippedStatus:

0 = No

1 = Yes

0 = Disable

1 = Enable

0,0,0 1.00 Pre-Condition Point Selection

<none> 1.00

for each

ASCII

character

0.0 1.00 Pre-Condition Selected

FloatingPoint

Number

Selected Pre-Condition PointT

ID

PointValue

25 Digi Enabler Type ENAREL R/W User UINT8 1 0 -> 3 0 1.00 Pre-Condition Operator:

0) ==

1) !=

2) >=

3) <=

26 Digi Enab StPtValue ENSTPT R/W User FL 4 Any

FloatingPoint

Number

27 Digi Enab

ResultStatus

50 Revised Aug-16

ENARLT R/O System UINT8 1 0 -> 1 0 1.00 Pre-Condition Met:

0.0 1.00 Pre-Condition Setpoint

0 = No

1 = Yes

Page 55

Point Type 22: Cause Configuration

Gas Control Manager Program User Manual (FB107)

Parm Name Abbr Access System

or User

Update

28 Enab Delay

SecsPreset

29 Enab Delay

SecsElapsed

30 Pri Trip Delay

SecsPreset

31 Pri Trip Delay

SecsElapsed

32 Scan Interval SCANIV R/W User UINT8 1 0 -> 5 3 1.00 Scan Interval: (Not Used)

33 Log Alarms LOGALM R/W User UINT8 1 0 -> 1 0 1.00 Log Trips to Alarm Log:

ENAPRE R/W User UINT16 2 0 -> 65535 30 1.00 Pre-Condition Timer

ENACNT R/O System UINT16 2 0 -> 65535 0 1.00 Pre-Condition Timer (Secs)

TRPPR1 R/W User UINT16 2 0 -> 65535 0 1.00 Primary Logic Trip Preset(Secs)

TRPCT1 R/O System UINT16 2 0 -> 65535 0 1.00 Primary Logic Trip

DataType Length Range Default Ver Description

Preset(Secs)

Elapsed(Secs)

0 = 100 mSec

1 = 200 mSec

2 = 500 mSec

3 = 1 Sec

4 = 2 Sec