Remote Automation Solutions Gas Chromatograph Interface for ROC809 User Program Manual Manuals & Guides

Page 1

Part Number D301188X012

Form A6145

October 2016

Gas Chromatograph Interface Program User

Manual (for ROC800-Series Remote Operations

Controllers)

Remote Automation Solutions

Page 2

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Page

Revision

All pages

October-2016

All pages

June-2016

All pages

September-2013

All pages

December-2012

All pages

July-2012

All pages

March-2009

All pages

July-2008

All pages

May-2008

All pages

September-2007

All pages

June-2006

All pages

December-2005

All pages

May-2005

Initial release

July-2003

Revision Tracking Sheet

October 2016

This manual may be revised periodically to incorporate new or updated information. The revision date

of each page appears at the bottom of the page opposite the page number. A change in revision date

to any page also changes the date of the manual that appears on the front cover. Listed below is the

revision date of each page (if applicable):

ii Revised October-2016

Page 3

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Contents

Chapter 1 – Introduction 1

1.1 Scope and Organization ..................................................................................................................... 1

1.2 Product Overview ............................................................................................................................... 1

1.2.1 Communications Wiring ....................................................................................................... 2

1.2.2 Autoconfigure ....................................................................................................................... 5

1.2.3 Validating GC Data .............................................................................................................. 7

1.3 Program Features .............................................................................................................................. 9

1.3.1 License Key........................................................................................................................ 10

Chapter 2 – Installation 11

2.1 Installing the License Key ................................................................................................................ 11

2.1.1 Installing the License Key Installation ................................................................................ 12

2.2 Installing the Program ...................................................................................................................... 12

2.3 MPU Loading Threshold .................................................................................................................. 16

Chapter 3 – Configuration 19

3.1 GC Interface Screen ........................................................................................................................ 20

3.2 GC Configuration Screen ................................................................................................................. 23

3.3 GC Stream Data Screen .................................................................................................................. 25

3.4 Station Setup, Gas Quality Tab ........................................................................................................ 29

3.5 Saving the Configuration .................................................................................................................. 30

Chapter 4 – Reference 33

4.1 Point Type 65: GC User Program Configuration and Status ........................................................... 34

4.2 Point Type 66: GC Stream Data ...................................................................................................... 41

Revised October-2016 Contents iii

Page 4

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

[This page is intentionally left blank.]

iv Contents Revised October-2016

Page 5

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Chapter 1 – Introduction

Caution When implementing control using thi s product, observe best industry

practices as suggested by applicabl e and appropriate environmental,

health, and safety organizations. While this product can be used as a

safety component in a system, it is NOT intended or designed to be the

ONLY safety mechanism in that system.

This chapter describes the structure of this manual and presents an

overview of the Gas Chromatograph Interface Program for the

ROC800-Series (ROC800) Remote Operations Controllers.

1.1 Scope and Organization

This document serves as the user manual for the Gas Chromatograph

Interface program, which is intended for use in a ROC800.

This manual describes how to download, install, and configure the Gas

Chromatograph Interface user program (referred to as the “GC Interface

program” or “the program” throughout the rest of this manual). You

access and configure this program using ROCLINK 800

Configuration Software loaded on a personal computer (PC) running

Windows® 2000 (with Service Pack 2), Windows XP (with Service

Pack 3), Windows Vista (32-bit), or Windows 7 (32-bit or 64-bit).

The sections in this manual provide information in a sequence

appropriate for first-time users. Once you become familiar with the

procedures and the software, the manual becomes a reference tool.

This manual has the following major sections:

Chapter 1 – Introduction

Chapter 2 – Installation

Chapter 3 – Configuration

Chapter 4 – Reference

This manual assumes that you are familiar with the ROC800 and its

configuration. For more information, refer to the following manuals:

ROC800-Series Remote Operations Controller Instruction Manual

ROCLINK 800 Configuration Software User Manual (for RO800-

1.2 Product Overview

The GC Interface program enables the ROC800 to communicate

directly with one gas chromatograph (GC) on an EIA-232 (RS-232) or

up to two GCs on an EIA-485 (RS-485) communications port.

Supported gas chromatographs include the Rosemount Analytical

(including Danalyzer) Model 500 series, Model 700 series, Model

(part D301217X012)

Series) (part D301250X012)

Revised October-2016 Introduction 1

Page 6

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

1000/1000A series, 370XA, 700XA series, and 1500XA series. This

includes the associated 2251, 2350, 2350A, and 2360 controllers.

The program communicates directly with the GC using Modbus

protocol (in which the ROC800 has Master status). The ROC800 polls

data from the GC, validates that data, and updates the appropriate

station parameters using that data.

The program can poll up to eight GC streams on one GC or up to a total

of ten streams on two GCs. The total number of streams the program

can process may be limited by the number of stream licenses available

in the ROC800. This value is listed in the App Code field on the License

Key Administrator screen (Utilities > License Key Administrator) in

ROCLINK 800. Refer to Section 2.1.1 for further information on the

ROC800 license keys.

The program assigns a type of gas or liquid for each GC supported. This

allows the program to write GC data to either gas stations (for

measurement of natural gas or related hydrocarbon gases) or liquid

stations when used with a ROC800L (for measurement of light

hydrocarbon liquids).

In order to update station data in the ROC800, you must assign the

streams to gas or liquid station(s) in the database of the ROC800. In the

case of gas, this allows the ROC800 to log the gas component data,

heating value, and specific gravity and use these values in volume,

mass, and energy calculations. In the case of liquid, this allows the

ROC800L to use the fluid component data to calculate the mass, volume

and density of the measured product.

1.2.1 Communications Wiring

The GC must be connected to the communications port on the ROC800

using 12 AWG (or smaller) wire. Figure 1 shows the wiring for an EIA232 (RS-232) to a 2350A GC.

2 Introduction Revised October-2016

Page 7

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Rx

Tx

RTS

DTR

GND

1

2

3

4

5

6

GND

S OUT

S IN

2350/2350A Controller

RS-232

J5 (port 1), J6 (port 2), J10

(port 3), J11 (port 4)

ROC800

RS-232

Serial Port

Rx

Tx

RTS

DTR

GND

1

2

3

4

GND

Tx +

700XA Series

RS-232

TB1 (port 0), TB5 (port 1),

TB8 (port 2)

Rx +

RTS

ROC800

RS-232

Serial Port

Figure 1. Wiring the ROC800 RS-232 to the 2350/2350A Controller

Figure 2. Wiring the ROC800 RS-232 to the 700XA RS-232

Revised October-2016 Introduction 3

Page 8

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

A

B

Y

Z

COM

1

2

3

4

5 GND

Rx

-

Tx

+

700

XA Series

RS

-

485

TB

2

(port

0

)

,

TB

6

(

port

1

)

,

TB9

(

port

2

)

Rx

+

Tx -

ROC800

RS-

485

Serial Port

120

Ω

RX

TX

RTS

DTR

GND

1

2

3

4

CTS

Tx +

370

XA Series

RS-

232/

RS

-485

TB

4

(

Com

1)

, TB

9

(Com

2)

Rx

+

RTS

ROC800

RS

-

232

Serial Port

5

DTR

6

GND

Figure 3. Wiring the ROC800 RS-485 to the 700XA RS-485

Figure 4. Wiring the ROC800 RS-232 to the 370XA RS-232/RS-485

4 Introduction Revised October-2016

Page 9

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

A

B

Y

Z

COM

1

2

3

4

GND

Tx/RX -

370XA Series

RS-485

TB4(Com 1), TB9(Com 2)

TX/Rx +

ROC800

RS-485

Serial Port

5

6

Baud Rate

9600

Data Bits

8

Stop Bits

1

Parity

None

Key-On Delay

200 ms

Key-Off Delay

200 ms

Port Owner

Modbus Master

Figure 5. Wiring the ROC800 RS-485 to the 370XA RS-232/RS-485

1.2.2 Autoconfigure

The GC Program provides an autoconfigure option on the GC Interface

screen (see Figure 17). This option enables the program to

automatically configure the communication ports and Modbus

parameters necessary to poll the GC(s). For this option to work,

however, you must first specify a communication port in the Comm

Port # frame on the GC Interface screen, specify the maximum number

of streams and Modbus address for each GC in use, and modify the

Modbus register table location, if desired. Then, when you select

Autoconfigure, the program sets the selected communication port

parameters to the following values:

Revised October-2016 Introduction 5

The program sets the Modbus configuration parameters for the selected

comm port to the following values:

Page 10

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Transmission Mode

RTU

Byte Order

MSB First

Event Log Enable

Disabled

Master Starting Request Number

1

Master Number of Requests

8

Master Continuous Polling Enable

Disabled

3001–3016

Component IDs, Table 1

3017–3032

Component IDs, Table 2

3034

Current Stream

3035

Mask of Streams associated with Table 1

3045

Cycle Start Time – minutes

3046

GC Alarm 1

3047

GC Alarm 2

3059

Calibration/Analysis Flag

7001–7016

Gas Composition Values Mole % Comp 1–16

7033

BTU (dry)

7034

BTU (saturated)

7035

Specific Gravity

7036

Compressibility

7037

Wobbe Index

7038

Total Unnormalized Mole %

7039

Total GPM CF

7040–7044

User Defined Calc Values

7070–7084

User Defined Average

9034

Active Alarm Status

9035

Unacknowledged Alarm Status

The program automatically configures the Modbus Master Table using

values in the Comm Port # and Modbus Address fields on the GC

Interface screen to poll for the following registers in the GC:

Note: The following values are in accordance with the SIM 2251

Modbus register map.

The Autoconfigure option configures Modbus Master Tables for each

GC with a valid address. The first GC’s master table uses the first

logical point for the communications port and the second GC (if

present) uses the second logical point for its communications port. The

actual poll sequence set for each GC is:

6 Introduction Revised October-2016

Page 11

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

3045–3047

3001–3032

3034–3035

3059

7001–7016

7033–7044

7070–7084

9034–9035

3045

The Modbus Register to TLP Mapping assigns TLPs to registers. The

program maps TLPs to the register table you specify in the Modbus

Register Table Location field on the GC Interface screen. The

parameters necessary for this program automatically map to the

appropriate registers .

The Autoconfigure option will setup Modbus polling according to the

SIM 2251 Modbus register map. Manual adjustments to this Modbus

configuration may be necessary, depending on the gas chromatograph

device make and model.

Finally, when the auto-configure process completes, the program

disables the auto-configure parameter.

Note: After the autoconfigure process completes, you may modify the

Modbus Master Table and/or the Modbus Register Table, but

register 3045 must be the first and last register polled. The first

poll must be stored in a register mapped to GC Stream parameter

Sample Min Start (66,0,17) and the last poll must be stored in a

register mapped to GC Stream parameter Sample Min End

(66,0,16).

1.2.3 Validating GC Data

When the polls are complete, the program validates the data to ensure

the polling was successful and data is correct. This validation occurs

before the program copies the GC stream data to the station. Checks

include:

The Communication Status (Point 121, Parameter 6, 12, 18, etc.)

must return valid responses (value of 8) for all registers polled. The

program does not copy gas analysis data to the station if errors are

present.

If Bypass Alarm 1 (Point 65, Parameter 11) is disabled, the Alarm

Flag 1 (Point 66, Parameter 18, bits 14 & 15) from the GC is

Revised October-2016 Introduction 7

Page 12

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

checked for errors. The program does not copy gas analysis data to

the station if errors are present.

If Bypass Alarm 2 (Point 65, Parameter 12) is disabled, the Alarm

Flag 2 (Point 66, Parameter 19, bits 0, 1, 2 & 3) from the GC is

checked for errors. The program does not copy gas analysis data to

the station if errors are present.

The Calibration Flag (Point 66, Parameter 20) is checked to ensure it

is in the Analysis State. The program does not copy gas analysis

data to the station if the Calibration Flag is not in the Analysis State.

The Starting Sample Minute (Point 66, Parameter 17) must be

different than the previous or the program does not copy gas

analysis data to the station.

The Starting Sample Minute (Point 66, Parameter 17) and Ending

Sample Minute (Point 66, Parameter 16) in the poll must match or

the program does not copy gas analysis data to the station.

The current Stream Number (Point 66, Parameter 2) must be

assigned to a station and have a license key.

The Total Un-Normalized Mole % (Point 66, Parameter 9) must be

within plus or minus Total Mole % Deviation (Point 65, Parameter

14) of 100%. The program does not copy gas analysis data to the

station if the value is outside of this limit.

The Mole Sum (Point 66, Parameter 21) must be within plus or

minus Total Mole % Deviation (Point 65, Parameter 14) of 100%.

The program does not copy gas analysis data to the station if the

value is outside of this limit.

The Heating Value [Point 66, Parameter 4 (dry) or 5 (wet)] must be

between the Heating Value Low Limit (Point 65, Parameter 9) and

Heating Value High Limit (Point 65, Parameter 10) set on the GC

Config screen. The program does not copy gas analysis data to the

station if the value is outside of these limits.

Note: Unless you enable the HV Limits on the GC Stream Data

screen, the program uses the Heating Value limits on the GC

Config screen as the global limits for all streams in the GC.

If you enable HV Limits (Point 66, Parameter 90) on the GC Stream

Data screen, the program checks that the Stream Heating Value is

between the BTU Low Limit (Point 66, Parameter 91) and BTU

High Limit (Point 66 Parameter 92) values. If this value is outside of

these limits, the program does not copy gas analysis data to the

station.

8 Introduction Revised October-2016

Page 13

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

The Specific Gravity (Point 66, Parameter 6) must be between 0.07

1.3 Program Features

Note: The HV Limits on the GC Stream Data screen are set on a

per-stream basis. If you enable HV Limits, the values entered

in the BTU Low Limit and BTU High Limit fields overrides

the Heating Value limits set on the GC Config screen for the

selected stream only.

and 1.52. The program does not copy gas analysis data to the station

if this value is outside of the limits.

Note: The program copies each GC stream component to its

corresponding component in the station, with the exception

of neo-pentane. Neo-pentane is added to the iso-pentane

component and then copied to the station. The heating value

and specific gravity are also copied to the appropriate

station.

File Name

GcInterface-

2-10.tar

Target Unit/

Version

ROC800

Series 1

v2.16

ROC800

Series 2

v3.30

ROC800L

Series 2

v1.20

The GC Interface program version 2.10 is compatible with ROC800

Series 1 (firmware version 2.16 or greater), ROC800 Series 2 (firmware

version 3.30 or greater), ROC800L Series 2 (Firmware 1.20 or greater),

and with ROCLINK 800 configuration (software version 2.00 or

greater).

Note: When the GC Interface program is used on the ROC800L, install

the LiquidCalcs user program version 1.03.00 (or better) to have

access to the liquid stations.

Program specifics include:

User Defined

Point (UDP)

65, 66 53340 2972 94208 2.00 65, 66, 67

Flash Used

(in bytes)

SRAM Used

(in bytes)

DRAM

Used (in

bytes)

ROCLINK

800 Version

Display

Number

Note: You must connect a PC to the ROC800’s LOI port before

starting the download.

Revised October-2016 Introduction 9

Page 14

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

DOC0422A

J1

U1

For information on viewing the memory allocation of user programs,

refer either to the ROCLINK 800 Configuration Software User Manual

(for ROC800-Series) (Part D301250X012).

1.3.1 License Key

License keys, when matched with valid license codes, grant access to

applications such as the GC Interface program.

The term “license key” refers to the physical piece of hardware that can

contain up to seven different licenses (refer to Figure 6). Each ROC800

can have none, one, or two license keys installed. If you remove a

license key after enabling an application, the firmware disables the task

from running. This prevents unauthorized execution of protected

applications in a ROC800.

Figure 6. License Key

You must install the following license keys to use the GC Interface

Program.

GC Interface Lic en se Ke y.

AGA_3/7/8 License Key (not included in this program).

10 Introduction Revised October-2016

Page 15

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Chapter 2 – Installation

This section provides instructions for installing the GC Interface

program. Read Section 1.3 of this manual for program requirements.

2.1 Installing the License Key

If you order the GC Interface program for a new ROC800, your

ROC800 is delivered with the license key installed. Go to Section 2.2. If

you order the program for an existing ROC800, you must install the

license key yourself.

Caution

Failure to exercise proper electrostatic discharge precautions, such as

wearing a grounded wrist strap may reset the processor or damage

electronic components, resulti n g in interrupted operations.

When working on units located in a hazardous area (where explosive

gases may be present), make sure the area is in a non-hazardous state

before performing these procedures. Performing these procedures in a

hazardous area could result in personal injury or property damage.

To install a license key:

1. Remove power from the ROC800.

2. If necessary, remove the wire channel cover.

3. Unscrew the screws from the Central Processing Unit (CPU)

faceplate.

4. Remove the CPU faceplate.

5. Place the license key in the appropriate terminal slot (P4 or P6) in

the CPU.

Figure 7. License Key Installation

Note: When using a single license key, install it in slot P4.

6. Press the license key into the terminal until it is firmly seated (refer

to Figure 7).

7. Re-attach the CPU faceplate.

8. Re-attach the screws on the CPU faceplate.

9. If necessary, re-attach the wire channel cover.

10. Restore power to the ROC800.

Revised October-2016 Installation 11

Page 16

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

2.1.1 Installing the License Key Installation

After you install the license key, you can verify whether the ROC800

recognizes the key. From the ROCLINK 800 screen, select Utilities >

License Key Administrator. The License Key Administrator screen

displays:

The GC Interface program appears in the Application Name column.

[For further information on the License Key Administrator screen, refer

to the ROCLINK 800 Configuration Software User Manual (for

ROC800-Series) (part D301201X012).

Note: The value in the App Code field on this screen indicates the total

After you verify that the license key is correctly installed and

recognized, proceed to Section 2.2.

2.2 Installing the Program

This section provides instructions for installing the program into the

Flash memory on the ROC800.

To download the user program using ROCLINK 800 software:

1. Connect the ROC800 to your computer.

2. Start and logon to the ROCLINK 800.

Figure 8. License Key Administrator

number of stream licenses available on this ROC800.

3. Select ROC > Direct Connect to connect to the ROC800.

4. Select Utilities > User Program Administrator from the

ROCLINK menu bar. The User Program Administrator screen

displays (see Figure 9):

12 Installation Revised October-2016

Page 17

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Figure 9. User Program Administrator

5. Select any empty program number (in this case, number 1) into

which to download the program.

6. Click Browse in the Download User Program File frame. The Select

User Program File screen displays (see Figure 10).

7. Select the path and user program file to download from the CD-

ROM. (Program files are typically located in the Program Files

folder on the CD-ROM). As Figure 10 shows, the screen lists all

valid user program files with .tar extension:

Revised October-2016 Installation 13

Page 18

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Figure 10. Select User Program File

8. Click Open to select the program file. The User Program

Administrator screen displays. As shown in Figure 11, note that the

Download User Program File frame identifies the selected program

and that the Download & Start button is active:

Figure 11. User Program Administrator

9. Click Download & Start to begin loading the selected program.

The following message displays:

14 Installation Revised October-2016

Page 19

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Figure 12. Confirm Download

10. Click Yes to begin the download. When the download completes the

following message displays:

Figure 13. ROCLINK 800 Download Confirmation

11. Click OK. The User Program Administrator screen displays (see

Figure 14). Note that:

The Device User Program Environment frame reflects the use of

system memory.

The User Programs Installed in Device frame identifies the

installed program(s).

The Status field indicates that the program is running.

Revised October-2016 Installation 15

Page 20

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

12. Click Close and proceed to Chapter 3, Configuration to configure

the program.

2.3 MP U Loa ding Threshold

To maximize the performance of your ROC800 device, always verify

the performance of specific application combinations before using them

in the field to ensure the MPU load typically remains below 85% with

peak MPU loading levels below 95%.

To check the current MPU load at any time, select ROC > Information

> Other Information and review the value in the MPU loading field.

Figure 14. User Program Administrator

16 Installation Revised October-2016

Page 21

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Figure 15. MPU Loading

Revised October-2016 Installation 17

Page 22

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

[This page is intentionally left blank.]

18 Installation Revised October-2016

Page 23

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Chapter 3 – Configuration

After you have loaded the GC Interface program on the ROC800, you

configure the program using three program-specific screens (GC

Interface, GC Configuration, and GC Stream Data) and one ROCLINK

800 screen (Station Setup).

You must configure the software before you can establish

communications with the GC. To configure the program (after logging

onto ROCLINK 800 and successfully installing the program and license

key), proceed through the program screens as shown in this section.

Note: Using MON 2000 software, you set the GC communications

port to the SIM 2251 protocol. For all other parameter

configurations, refer to the MON 2000 documentation.

You can access all the program-specific screens from the main

ROCLINK 800 screen:

Figure 16. ROCLINK 800

Revised October-2016 Configuration 19

Page 24

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

3.1 GC Interf ace Screen

Use this screen to configure one or more GC addresses, select a Comm

port, modify the Modbus Register Table location (if necessary), assign

the GC streams to stations, enable GC polling, and enable automatic

configuration of the Modbus parameters and communications ports. To

access this screen:

1. From the Directory Tree, select Use r Program > Program #1,

GcInterface.

2. Double-click Display #65, GC Interface. The GC Interface screen

displays:

Figure 17. GC Interface

3. Review the values in the following fields:

Field Description

Max Streams

20 Configuration Revised October-2016

Sets the maximum number of streams from

the gas chromatograph. Valid values are 1

through 8, depending on your lice nse. You

cannot define more than 10 streams for both

GCs.

Note: Your license limits the maximum

number of allowable streams for one or

both GCs. See Section 2.1.1 for

instructions on determining the

maximum number of allowable

streams.

Page 25

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Field

Description

Modbus Address

GC Type

Modbus Register

Table Location

Sets the address the ROC800 uses to

communicate with the gas chromatograph.

You must set this value before the program

can poll data and write it to the station. If you

set this field to 0 (the default), GC polling is

disabled.

Note: The Autoconfigure option uses this

value (see Section 1.2.2).

Sets the GC Type. The available types are

Gas or Liquid. If you select Gas, the program

updates the gas components. If you select

Liquid, the program updates the LiquidCalcs

components.

Note: If you select Liquid, only the first 6

stations of the station map are

applicable. The program ignores

assignments of streams to stations

greater than 6.

Identifies the location of the Modbus Register

Table. Valid values are 1–24. The default

value is 24.

Note: The program uses this value for

automatic configuration (see Section

1.2.2).

Comm Port #

IP Configuration Sets the IP address and IP port connected to

Polling Interval

Next Poll Req This display-only field shows the number of

Indicates which ROC800 communications port

the program uses for the EIA-232 (RS-232) or

EIA-485 (RS-485) connection to the GC(s).

The program uses this value for automatic

configuration (see S ec tion 1. 2.2). Cl ic k to

display all valid values. If you select Ethernet,

the program displays an IP configuration

section.

Note: Unlike other programs, the Comm Port

owner is Modbus Master. For that

reason, the Comm Port owner should

not be this program.

the GCs.

Note: This section is available only if you

select Ethernet as the Comm Port #

value.

Sets the delay, in seconds, the program waits

before asking the GC for the next set of

results.

Note: The GC typically takes 3 to 6 minutes

to update results.

seconds remaining until the next polling cycle.

After a poll cycle completes, the program

resets this field to the value stored in the

Polling Interval field.

Revised October-2016 Configuration 21

Page 26

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Field

Description

Comm Timeout

Station Map

Poll Mode

Autoconfigure

Sets the period, in seconds, the system waits

for the GC to respond to a Modbus poll.

Associates GC streams with ROC800

stations. Valid values are 1–8. Enter 0 to

disable station updating.

You must configure this parameter before the

program can poll data and write it to the

station. The program stores the gas

composition data for the specified stream in

the gas quality parameters of the specified

station (see Section 3.4).

Note: For a ROC800L, you can select only

the first six stations.

Indicates whether the program attempts to

poll the GC(s).

Note: A valid license key and at least one

valid GC address must be present

before polling can be enabled.

Indicates whether the program automatically

determines the configuration values for

communications ports and Modbus settings

for a Rosemount Analytical Danalyzer gas

chromatograph. See Section 1.2.2 for further

information on autoconfiguration.

The Autoconfigure option will setup Modbus

polling according to the SIM 2251 Modbus

register map. Manual adjustments to this

Modbus configuration may be necessary,

depending on the gas chromatograph device

make and model.

Polling must be disabled and at least one

valid GC address configured before you can

initiate Autoconfigure.

Note: If you do not select this option, you

must configure the comm port, Modbus

comm configuration, Modbus register

mapping, and Modbus master table.

Alternately, you can select

Autoconfigure and then use the

ROCLINK 800 Modbus Configuration

screen (Configure > MODBUS >

Configuration) to change the values

to suit the application.

4. Click Apply to save any changes you have made to this screen.

5. Click Close to return to the ROCLINK 800 screen. Proceed to

Section 3.2 to define GC configuration settings.

22 Configuration Revised October-2016

Page 27

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Field

Description

3.2 GC Configuration Screen

Use this screen to configure GC settings. It also displays communication

status for each polling, configurable AGA update parameters, and some

returned data values. To access this screen:

To access this screen:

1. From the Directory Tree, select Use r Program > Program #1,

GcInterface > Display #66, GC Configuration.

2. Double-click #1, GC Config1. The GC Configuration screen

displays:

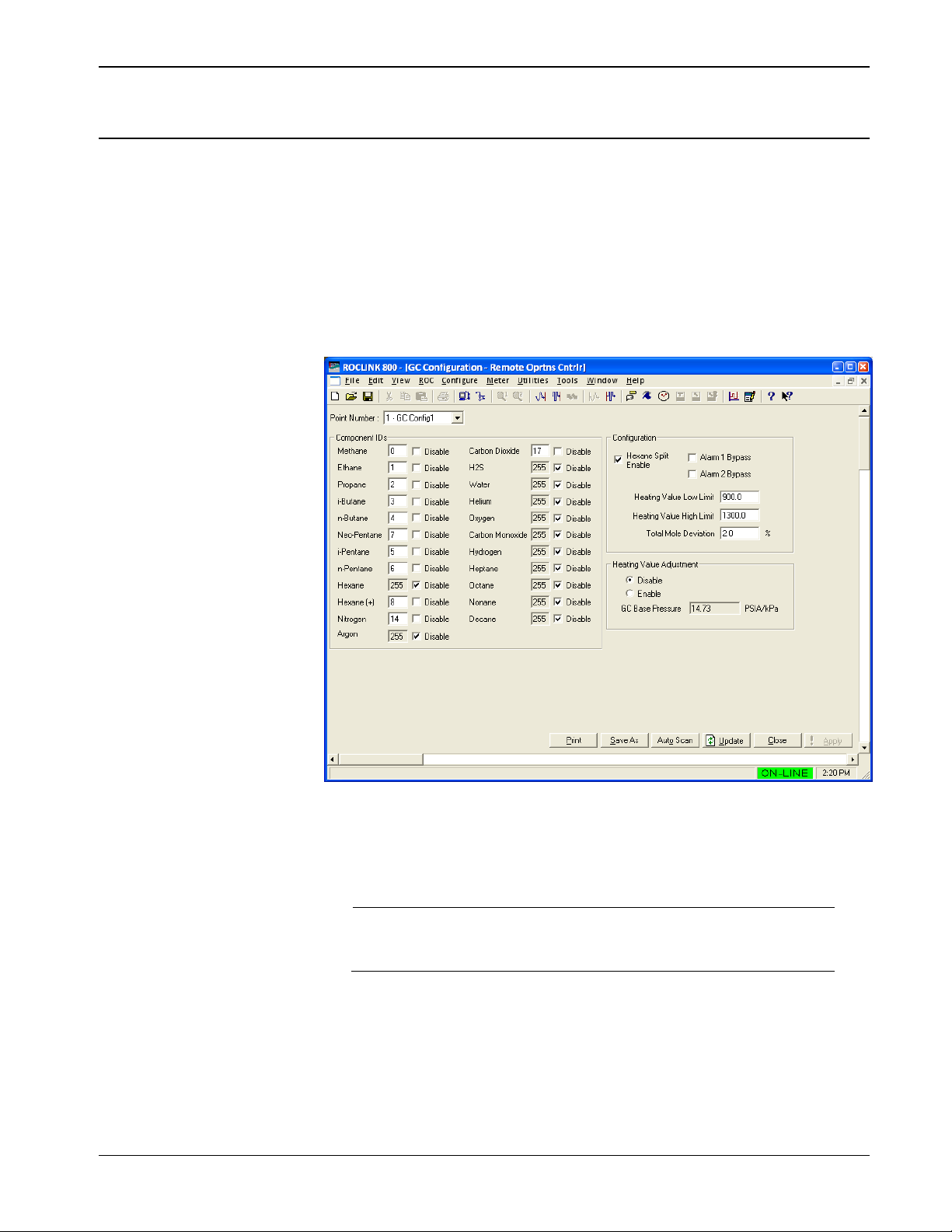

Figure 18. GC Configuration

3. Complete the screen fields based on your organization’s

requirements.

Point Number

Revised October-2016 Configuration 23

Identifies the GC number for this screen. The

program provides one instance for each GC.

Click to display all defined instances.

Page 28

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Field

Description

Component IDs

Assigns each gas component a value in

component data tables 1 and 2. Select

Disable to identify any gases the ROC800

supports but for which the gas chromatograph

does not provide data.

Note: The Hexane and Hexane+ IDs are

mutually exclusive. Select one or the

other but not both. If you have enabled

the Hexane Split option , you must use

Hexane+.

Hexane Split

Enable

Enables the hexane(+) composition to be split

between hexane, heptane, octane, nonane,

and decane. The program uses a pre-defined

split if the component ID for hexane(+) is set

to 8, 9, 10, or 11 (see table below). For any

other valid component ID, the program uses

the split specified on the Station Setup

screen’s Advanced tab (Meter > Setup >

Station).

ID Hexane % Heptane % Octane % Nonane % Decane

8

9

10

11

47.466 35.34 17.194 0 0

50 50 0 0 0

50 25 25 0 0

57.143 28.572 14.285 0 0

Note: The ID selection for a ROC800

mustmatch the ID selection for the

GC.

%

Alarm Bypass 1

and

Alarm Bypass 2

Heating Value

Low Limit

Heating Value

High Limit

Sets whether the program updates station

values in the ROC800 if the Alarm 1 or Alarm

2 field on the GC contains an alarm condition.

Select this check box to allow the program to

update the station values even if the Alarm 1

or Alarm 2 field in the GC displays an alarm.

Sets the minimum heating value the ROC800

accepts for a station update. The ROC800

considers any heating values the GC sends

that are lower than this value to be erroneous

and does not forward them to the station.

Sets the maximum heating value the ROC800

accepts for a station update. The ROC800

considers any heating values the GC sends

that are greater than this value to be

erroneous and does not forward them to the

station.

24 Configuration Revised October-2016

Page 29

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Field

Description

Total Mole

Deviation

Heating Value

Adjustment

GC Base

Pressure

Sets, as a percentage, either the difference

plus or minus from 100% that the program

allows for Total Unnormalized Mole % or the

sum of the component mole percentages. The

program subtracts or adds this value to 100%

to determine the range. The ROC800

considers any stream gas compositions that

exceed this value to be erroneous and does

not forward them to the station. Valid values

are 0-100%.

Sets whether the program (in case of differing

base pressures between the GC and the

station point) adjusts the GC’s heating value

before storing the value in the station

parameter. If you click Enable, the heating

value stored in the station equals the GC

heating value multiplied by the ratio of the

station base pressure to the GC’s base

pressure.

Sets the base pressure, in PSIA or kPa, the

GC uses to determine the heating value that

is returned on a Modbus request.

Note: This field is active only if you enable

the Heating Value Adjustment.

4. Click Apply to save your changes.

5. Click Close to return to the ROCLINK 800 screen. Proceed to

Section 3.3 to review stream data.

3.3 GC Stream Data Screen

Use this screen to review stream data the ROC800 has received from the

GC(s). The program provides one iteration of this screen for each active

stream in each GC. You can move between stream data displays using

either the Point Number drop-down box on this screen or from the list

on the Directory Tree. With the exception of the Alarm Logging Mode

and HV Limits, the fields on this screen are display-only. To access this

screen:

To access this screen:

1. From the Directory Tree, select User Program > Program #1,

GcInterface > Display #67, GC Stream Data.

2. Double-click #1, Cur Stream. The GC Stream Data screen displays:

Revised October-2016 Configuration 25

Page 30

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Figure 19. GC Stream Data

3. Review and change as necessary the values in the following fields:

Field Description

Point Number

Calibration/

Analysis Flag

HV Limits Select the Enable checkbox to allow user-defined

BTU Low

Identifies the stream number for this screen. Click

to display all defined streams.

This read-only field indicates the chromatograph’s

status (self-calibration or analysis).

Heating Value (HV) limits to be set for the selected

run. If the HV Limits are enabled, the BTU

Low/High values for the selected run will override

the Heating Value High/Low Limits set on the GC

Configuration screen.

Sets the minimum heating value for

Limit

the selected run that the ROC800

accepts for a station update. The

ROC800 considers any heating

values the GC sends that are

greater than this value to be

erroneous and does not forward

them to the station.

Note: Values entered in this field

override the Heating Value

Low Limits set on the GC

Configuration screen for the

selected run only.

26 Configuration Revised October-2016

Page 31

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Field

Description

BTU High

Limit

Stream This read-only field identifies the defined stream

for the GC.

Stream Data This read-only field shows values for the selected

stream.

Component Data This read-only field shows component values for

the selected stream.

User Defined

Averages

User Calcs This read-only field identifies any user-defined

This read-only field shows historical averages for

the selected stream.

calculations for the selected stream.

Sets the maximum heating value for

the selected run that the ROC800

accepts for a station update. The

ROC800 considers any heating

values the GC sends that are

greater than this value to be

erroneous and does not forward

them to the station.

Note: Values entered in this field

override the Heating Value

High Limits set on the GC

Configuration screen for the

selected run only.

Diagnostics This read-only field shows any diagnostic codes

for the selected stream.

Component Mask This read-only field shows which of the two

Component ID tables each stream uses. Bit 0 of

the Component Mask represents stream 1, bit 1

represents stream 2, and so on. If the bit is set, the

program uses Component ID table 1. If the bit is

not set, the program uses Component ID table 2.

Note: This value reflects settings from the GC.

Error Code This read-only field provides a color-c oded er ror

display. Red indicates an alarm condition.

Note: Error code changes are logged in the Event

Log as UDP66. Error code entries in the

Event Log are the numerical values shown

in parenthesis.

OK (0)

Poll Seq

Fail (1)

Alarm

Fail (2)

Cal Flag

Fail (3)

All checks passed.

Poll Sequence Failure – One or

more master table requests were

unsuccessful (not an 8).

Alarm Check Failure – There are

non-bypassed alarms in effect.

Calibration Check Failure – The

unit is in calibration mode.

Sample Min

Change (4)

Revised October-2016 Configuration 27

Sample Minute Changed – The

sample minute changed while

collecting data.

Page 32

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Field

Description

Unnorm

Mole %

Fail (5)

Mole Sum

Fail (6)

Heat Val

Range

Fail (7)

Spec Grav

Range

Fail (8)

Alarm Logging

Mode

Indicates how the program logs alarms with

Spontaneous Report by Exception (SRBX)

notification. Click to select a mode (described

below).

Note: The system generates one alarm,

regardless of the number of different errors

that may occur in the time before the alarm

clears. SRBX notification occurs based on

the Alarm Logging Mode. For the system to

generate an alarm (such as for a Poll

Sequence Failure error), you must first

enable the Alarm Logging Mode param eter

on the current logical stream.

Total Un-Normalized % Failure –

The total un-normalized mole

percentage is not within range.

Mole Sum Check Failure – The

mole sum is not within the range.

BTU Range Failure – BTU is not

within specified ranges.

Specific Gravity Range Failure –

Specific gravity is not within

specified ranges.

Disable

Logging

Enable

Logging,

No SRBX

Enable

Logging,

SBRX in Set

Enable

Logging,

SRBX on

Clear

Enable

Logging,

SRBX on

Both

Minimum

Specific Gravity

Maximum

Specific Gravity

The user entered minimum specific gravity for the

selected stream.

Note: This field applies only to the currently

selected stream.

The user entered maximum specific gravity for the

selected stream.

Note: This field applies only to the currently

selected stream.

No logging occurs.

Logging occurs, but without

generating SRBX notifications.

Logging occurs, and SRBX

notifications occur on alarm set.

Logging occurs, and SRBX

notifications occur on alarm clear.

Logging occurs, and SRBX

notifications occur on both alarm

set and alarm clear.

28 Configuration Revised October-2016

4. Click Apply to save your changes.

Page 33

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Field

Description

5. Click Close to return to the ROCLINK 800 screen. Proceed to

Section 3.4 to set up station parameters.

3.4 Sta t ion Setup, Gas Quality Tab

Use this screen to set gas quality and heating values. To access this

screen:

To access this screen:

1. Select Meter > Setup > Station from the ROCLINK 800 menu bar.

The Station Setup screen displays.

Figure 20. Station Setup, Gas Quality tab

2. Select the Gas Quality tab.

3. Review and change as necessary the values in the following fields:

Station

Gas Quality

Revised October-2016 Configuration 29

Select the station number to which the GC stream

has been assigned.

Indicates source of the gas quality. The GC

Interface program sets this field to Live when it

copies data to the station.

Page 34

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Field

Description

Heating Value

Basis

Heavy Gas

Option

4. Click Apply to save your changes. Proceed to Section 3.5 to save

the configuration.

3.5 Savi ng t he Conf iguration

Whenever you modify or change the configuration, it is a good practice

to save the final configuration to memory. To save the configuration:

1. Select ROC > Flags. The Flags screen displays:

Determines the heating value (dry or saturated) the

program copies to the station. Valid values for this

program are Dry or Wet. If you select Wet, the

program copies the saturated heating value to the

station. If you select As Deliv or Dry, the program

resets the value to Dry and copies the dry heating

value to the station.

Permits calculations for hexane and other heavy

gases.

Note: The program automatically selects this

option if you checked the Hexane Split

Enable option on the GC Configuration

screen.

30 Configuration Revised October-2016

Figure 21. Flags

Page 35

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

2. Click Save Configuration. A verification message displays:

Figure 22. Save Verification

3. Click Yes to begin the save process. The Flash Write Status field on

the Flags screen displays In Progress. When the Save Configuration

completes, the Flash Write Status field on the Flags screen displays

Completed.

4. Click Update on the Flags screen. This completes the process of

saving your new configuration.

Note: For archive purposes, you should also save this configuration

to your PC’s hard drive or a removable media (such as a

flash drive) using the File > Save Configuration option on

the ROCLINK 800 menu bar.

Revised October-2016 Configuration 31

Page 36

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

[This page is intentionally left blank.]

32 Configuration Revised October-2016

Page 37

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Chapter 4 – Reference

This section provides tables of information on the user-defined point

types the GC Interface program uses.

Point Type 65 – GC User Program Configuration and Status

Point Type 66 – GC Stream Data

Revised October-2016 Reference 33

Page 38

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

0

Point Tag ID

R/W

User

AC

10

character

“GC

1.00

Identification name for the GC

printable ASCII characters.

1

Point Version Number

R/O

User

U32

4

00xFFFFFFFF

1

1.00

Version number of this user

for calculation to run.

2

User Program Status

R/O

Program

UINT8 1 03

0

1.00

Indicates running status. Valid

3 = Bad Point Type Version

3

Autoconfiguration

R/W

Both

UINT8 1 01

1

1.00

Sets autoconfiguration option.

1 = Autoconfiguration enabled

4

Comm Port Number

R/W

User

UINT8 1 15

2

1.00

Comm Port to be used.

5

GC Address

R/W

User

UINT8 1 0255

0

1.00

The Modbus address for the

autoconfiguration is enabled.

6

MODBUS Location

R/W

User

UINT8 1 124

24

1.00

This is the location to which

configured (Logical + 1).

results.

4.1 Point Type 65: GC User Program Configurat ion and Status

Point type 65 contains the parameters for configuring the GC Interface program and houses the status information from the gas

chromatograph. The program maintains two logical points of this point type.

Point Type 65: GC User Program Configuration and Status

Param

#

Name Access

Program or

User Update

Data

Type

Length Range Default Version

0x20 → 0x7E for

each ASCII

Config“

Description of Functionality

and Meaning of Values

Program. Values must be

defined point. Version number

of user defined point must

match version of user program

values are:

0 = No Error

1 = License Unavailable

2 = Comm Configuration Failed

7 Polling Interval R/W User FL 4 Any Positive

34 Reference Revised October-2016

Floating Point

Number

Valid values are:

0 = Autoconfiguration disabled

GC. A zero disables polling.

The GC Address parameter

only configures the Modbus

Master Table when

the Modbus registers are

60 1.00 Amount of delay in seconds

before asking for next set of

results. The GC typically takes

3 to 6 minutes to update the

Page 39

Point Type 65: GC User Program Configuration and Status

8

Next Poll Request

R/W

Program

FL 4 Any Positive

0

1.00

Displays the number of

the Poll Interval Parameter.

9

Heating Value Low

R/W

User

FL 4 Any Positive

900.0

1.00

This is the minimum heating

the ROC.

10

Heating Value High

R/W

User

FL 4 Any Positive

1300.0

1.00

This is the maximum heating

the ROC.

11

Bypass Alarm 1

R/W

User

UINT8 1 01

0

1.00

Indicates how to interpret

condition present.

Param

#

Name Access

Program or

User Update

Data

Type

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Length Range Default Version

Description of Functionality

and Meaning of Values

Limit

Limit

Floating Point

Number

Floating Point

Number

Floating Point

Number

seconds remaining until the

next polling cycle. After a poll

cycle is complete, t hi s fie ld is

preset to the number stored in

value accepted by the ROC for

a n AGA update. Heating

values sent by the GC which

are less than this number are

considered to be erroneous

and will not be forwarded to

value accepted by the ROC for

an AGA update. Heating

values sent by the GC which

are less than this number are

considered to be erroneous

and will not be forwarded to

alarm 1 value. Valid values

are:

0 = Disable bypass – Don’t

populate the AGA gas

composition information if

an “Alarm 1” is present.

1 = Enable bypass – Allow the

ROC AGAs to be updated

even if the “Alarm 1” field in

the GC shows an alarm

Revised October-2016 Reference 35

Page 40

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

12

Bypass Alarm 2

R/W

User

UINT8 1 01

0

1.00

Indicates how to interpret

condition present.

13

Max Streams

R/W

User

UINT8 1 0255

6

1.00

Maximum number of GC

for this program.

14

Total Mole % Deviation

R/W

User

FL 4 0100.0

2.0

1.00

The difference plus or minus

Default is 98%-102%.

15

Hexane Split Enable

R/W

User

UINT8 1 01

1

1.00

Enables the GC’s automatic

heavy gasses.

16

Communication

R/W

User

FL 4 060.0

45.0

1.00

Time to wait in seconds for the

Polls.

17

Station 1 Stream

R/W

User

UINT8 1 08

0

1.00

Stream data to be used to

composition.

18

Station 2 Stream

R/W

User

UINT8 1 08

0

1.00

Stream data to be used to

composition.

Point Type 65: GC User Program Configuration and Status

Param

#

Name Access

Program or

User Update

Data

Type

Length Range Default Version

Description of Functionality

and Meaning of Values

alarm 2 value. Valid values

are:

0 = Disable bypass – Don’t

populate the AGA gas

composition information if

an “Alarm 2” is present.

1 = Enable bypass – Allow the

ROC AGAs to be updated

even if the “Alarm 2” field in

the GC shows an alarm

stream licenses to check out

from 100% that is allowable for

both Total Unnormalized Mole

% and mole sum values.

Timeout

36 Reference Revised October-2016

C6 (+) split percentage for

GC to respond to all Modbus

update station #1. Valid values

are:

0 = Disable updating station.

1-8 = Stream number to use to

update station’s gas

update station #2. Valid values

are:

0 = Disable updating station.

1-8 = Stream number to use to

update station’s gas

Page 41

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

19

Station 3 Stream

R/W

User

UINT8 1 08

0

1.00

Stream data to be used to

composition.

composition.

21

Station 5 Stream

R/W

User

UINT8 1 08

0

1.00

Stream data to be used to

composition.

22

Station 6 Stream

R/W

User

UINT8 1 08

0

1.00

Stream data to be used to

composition.

composition.

Point Type 65: GC User Program Configuration and Status

Param

#

20 Station 4 Stream R/W User UINT8 1 08 0 1.00 Stream data to be used to

Name Access

Program or

User Update

Data

Type

Length Range Default Version

Description of Functionality

and Meaning of Values

update station #3. Valid values

are:

0 = Disable updating station.

1-8 = Stream number to use to

update station’s gas

update station #4. Valid values

are:

0 = Disable updating station.

1-8 = Stream number to use to

update station’s gas

update station #5. Valid values

are:

0 = Disable updating station.

1-8 = Stream number to use to

update station’s gas

23 Station 7 Stream R/W User UINT8 1 08 0 1.00 Stream data to be used to

Revised October-2016 Reference 37

update station #6. Valid values

are:

0 = Disable updating station.

1-8 = Stream number to use to

update station’s gas

update station #7. Valid values

are:

0 = Disable updating station.

1-8 = Stream number to use to

update station’s gas

Page 42

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

24

Station 8 Stream

R/W

User

UINT8 1 08

0

1.00

Stream data to be used to

composition.

composition.

26

Station 10 Stream

R/W

User

UINT8 1 08

0

1.00

Stream data to be used to

composition.

27

Station 11 Stream

R/W

User

UINT8 1 08

0

1.00

Stream data to be used to

composition.

composition.

29

Methane Component

ID

R/W

User

UINT8 1 0255

0

1.00

GC’s Component ID for

methane.

30

Ethane Component ID

R/W

User

UINT8 1 0255

1

1.00

GC’s Component ID for ethane.

Point Type 65: GC User Program Configuration and Status

Param

#

25 Station 9 Stream R/W User UINT8 1 08 0 1.00 Stream data to be used to

Name Access

Program or

User Update

Data

Type

Length Range Default Version

Description of Functionality

and Meaning of Values

update station #8. Valid values

are:

0 = Disable updating station.

1-8 = Stream number to use to

update station’s gas

update station #9. Valid values

are:

0 = Disable updating station.

1-8 = Stream number to use to

update station’s gas

update station #10. Valid

values are:

0 = Disable updating station.

1-8 = Stream number to use to

update station’s gas

28 Station 12 Stream R/W User UINT8 1 08 0 1.00 Stream data to be used to

38 Reference Revised October-2016

update station #11. Valid

values are:

0 = Disable updating station.

1-8 = Stream number to use to

update station’s gas

update station #12. Valid

values are:

0 = Disable updating station.

1-8 = Stream number to use to

update station’s gas

Page 43

Point Type 65: GC User Program Configuration and Status

31

Propane Component

ID

R/W

User

UINT8 1 0255

2

1.00

GC’s Component ID for

propane.

32

i-Butane Component ID

R/W

User

UINT8 1 0255

3

1.00

GC’s Component ID for iButane.

ID

Butane.

Component ID

pentane.

ID

pentane.

ID

pentane.

hexane.

39

Hexane (+) Component

ID

R/W

User

UINT8 1 0255

8

1.00

GC’s Component ID for hexane

(+).

39

Nitrogen Component

ID

R/W

User

UINT8 1 0255

14

1.00

GC’s Component ID for

nitrogen.

40

Carbon Dioxide

Component ID

R/W

User

UINT8 1 0255

17

1.00

GC’s Component ID for carbon

dioxide.

41

H2S Component ID

R/W

User

UINT8 1 0255

255

1.00

GC’s Component ID for H2S.

42

Water Component ID

R/W

User

UINT8 1 0255

255

1.00

GC’s Component ID for water.

43

Helium Component ID

R/W

User

UINT8 1 0255

255

1.00

GC’s Component ID for helium.

44

Oxygen Component ID

R/W

User

UINT8 1 0255

255

1.00

GC’s Component ID for

oxygen.

45

Carbon Monoxide

Component ID

R/W

User

UINT8 1 0255

255

1.00

GC’s Component ID for carbon

monoxide.

46

Hydrogen Component

ID

R/W

User

UINT8 1 0255

255

1.00

GC’s Component ID for

hydrogen.

47

Heptane Component

ID

R/W

User

UINT8 1 0255

255

1.00

GC’s Component ID for

heptane.

48

Octane Component ID

R/W

User

UINT8 1 0255

255

1.00

GC’s Component ID for octane.

49

Nonane Component ID

R/W

User

UINT8 1 0255

255

1.00

GC’s Component ID for

nonane.

50

Decane Component ID

R/W

User

UINT8 1 0255

255

1.00

GC’s Component ID for

decane.

51

Argon Component ID

R/W

User

UINT8 1 0255

255

1.00

GC’s Component ID for argon.

Param

#

Name Access

Program or

User Update

Data

Type

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Length Range Default Version

Description of Functionality

and Meaning of Values

33 n-Butane Component

34 Neo-Pentane

35 i-Pentane Component

36 n-Pentane Component

37 Hexane Component ID R/W User UINT8 1 0255 255 1.00 GC’s Component ID for

R/W User UINT8 1 0255 4 1.00 GC’s Component ID for n-

R/W User UINT8 1 0255 7 1.00 GC’s Component ID for neo-

R/W User UINT8 1 0255 5 1.00 GC’s Component ID for i-

R/W User UINT8 1 0255 6 1.00 GC’s Component ID for n-

Revised October-2016 Reference 39

Page 44

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

52

Heating Value Adjust

R/W

User

UINT8 1 01

0

2.0

Enables adjustment of GC

1 = Enabled

53

GC Base Pressure

R/W

User

FL

4

0Valid Positive

Number

14.73

2.0

Base Pressure configured in

54

Poll Mode

R/W

User

UINT8 1 01

0

2.0

Enables polling of the GC(s). A

1 = Enabled

55

GC IP Address

R/W

User

AC

20

Any Valid IP

Address

0.0.0.0

2.10

Identifies the IP address for the

GC.

56

Identifies the IP

address for the GC.

R/W

User

UINT16 2 065535

502

2.10

Identifies the IP port address

for the GC.

1 = Liquid Chromatograph

Point Type 65: GC User Program Configuration and Status

Param

#

Name Access

Program or

User Update

Data

Type

Length Range Default Version

Description of Functionality

and Meaning of Values

Option

Floating Point

57 GC Type R/W User UINT8 1 01 0 2.10 Indicates the type of GC.

Heating Value (due to different

base pressures in the GC and

station) before storing the

value in the Station point.

Valid values are:

0 = Disabled

the GC.

valid license key and at least

one valid GC address must be

present before polling can be

enabled. Valid values are:

0 = Disabled

When you select gas, the

program writes composition

data to the associated gas

station(s). When you select

liquid, the program writes

composition data to the

associated liquid station(s).

Valid values are:

0 = Gas Chromatograph

40 Reference Revised October-2016

Page 45

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

0

Point Tag Id

R/W

User

AC

10

“Cur

1.00

Logical zero has “Cur Stream”,

characters.

1

Point Version Number

R/O

User

U32

4

1

1.00

Version number of this user

for calculation to run.

2

Stream Number

R/O

User

UINT16 2 08

1-8

1.00

Stream number the data in this

for GCs 1 and 2.

3

Component Table

R/O

Program

UINT16 2 00xFFFF

0

1.00

Mask of streams associated

included.

4

Dry Heating Value

R/O

Program

FL

4

Any non-negative

0

1.00

Contains the last Dry Heating

returned from the GC.

5

Saturated Heating

R/O

Program

FL

4

Any non-negative

0

1.00

Contains the last Saturated

returned from the GC.

number

from the GC.

4.2 Point Type 66: GC Stream Data

Point type 66 contains the parameters for configuring the GC Interface program and houses the status information from the gas

chromatograph. The program maintains 11 logical points of this point type. Logical 0 is the current steam, and logicals 1 through 10 are

mapped to streams on the gas chromatographs, as assigned by the maximum streams per GC (point type 65, parameter 13).

Point Type 66: GC Stream Data

Param

#

Name Access

Program or

User Update

Data

Type

Length Range Default Version

0x20 → 0x7E for

each ASCII

character

Stream”

or

“Stream

#”

Description of Functionality

and Meaning of Values

others have identification name

for the specific stream. # is

replaced with logical + 1.

Values must be printable ASCII

0→0xFFFFFFFF

Mask

IEEE floating point

number

Value

6 Specific Gravity R/O Program FL 4 Any non-negative

IEEE floating point

number

IEEE floating point

defined point. Version number

of user defined point must

match version of user program

depending

on logical

0 1.00 Contains the last specific

logical refers to. Logical zero

has a value 1-8 depending on

the last stream read. Logicals

1-10 are set to 1-MaxStreams

with Component Table #1. Bit

n

= 1 implies stream n is

2

Value in BTU/cf or

MegaJoule/m

Heating Value in BTU/cf or

MegaJoule/m3 calculated and

gravity calculated and returned

3

calculated and

Revised October-2016 Reference 41

Page 46

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

7

Compressibility

R/O

Program

FL

4

Any IEEE floating

0

1.00

Contains the last

the GC.

8

Wobbe In dex

R/O

Program

FL

4

Any IEEE floating

0

1.00

Contains the last Wobbe Index

from the GC.

9

Total Un-Normalized

R/O

Program

FL

4

Any non-negative

0

1.00

Contains the total un-nomalized

10

Total GPM

R/O

Program

FL

4

Any IEEE floating

point number

0

1.00

Contains the total GPM

returned from the GC.

11

User Defined Calc 1

R/O

Program

FL

4

Any IEEE floating

0

1.00

Contains the value in the User

from the GC.

from the GC.

13

User Defined Calc 3

R/O

Program

FL

4

Any IEEE floating

0

1.00

Contains the value in the User

from the GC.

14

User Defined Calc 4

R/O

Program

FL

4

Any IEEE floating

0

1.00

Contains the value in the User

from the GC.

15

User Defined Calc 5

R/O

Program

FL

4

Any IEEE floating

0

1.00

Contains the value in the User

from the GC.

16

Sample Minute End

R/O

Program

UINT16 2 00xFFFF

0xFFFF

1.00

Contains the sample minute at

requests.

17

Sample Minute Start

R/O

Program

UINT16 2 060

0

1.00

Contains the sample minute at

requests.

Point Type 66: GC Stream Data

Param

#

Name Access

Program or

User Update

Data

Type

Length Range Default Version

Description of Functionality

and Meaning of Values

point number

point number

Mole %

12 User Defined Calc 2 R/O Program FL 4 Any IEEE floating

IEEE floating point

number

point number

point number

point number

point number

point number

Compressibility value

calculated and returned from

value calculated and returned

mole percent returned.

Defined 1 Calculation returned

0 1.00 Contains the value in the User

Defined 2 Calculatio n returned

Defined 3 Calculatio n returned

Defined 4 Calculatio n returned

Defined 5 Calculatio n returned

42 Reference Revised October-2016

the end of the Modbus

the start of the Modbus

Page 47

Point Type 66: GC Stream Data

18

Alarm 1

R/O

Program

UINT16 2 0255

0

1.00

Contains the value of the

are clear.

19

Alarm 2

R/O

Program

UINT16 2 0255

0

1.00

Contains the value of the

are clear.

20

Calibration Flag

R/O

Program

UINT16 2 0255

1

1.00

Contains the value of the

1

21

Mole Sum

R/O

Program

FL

4

Any non-negative

number

0

1.00

Contains the sum value of the

#5.

22

Error Code

R/O

Program

UINT8 1 08

0

1.00

Contains the error checking

Failure

Param

#

Name Access

Program or

User Update

Data

Type

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

Length Range Default Version

Description of Functionality

and Meaning of Values

“Alarm 1” field of the GC. A

zero represents that all alarms

“Alarm 2” field of the GC. A

zero represents that all alarms

“Calibration Flag” field of the

GC. Valid values are:

0 = Calculation data

= Analysis data

IEEE floating point

mole percent read in poll block

result code. For more

information, refer to Section

3.3. Valid values are:

0 = All checks passed.

1 = Poll Sequence Failure.

2 = Alarm Check Failure.

3 = Calibration Check Failure.

4 = Sample Minute Charged

5 = Total Un-Normalized %

Failure.

6 = Mole Sum Check Failure.

7 = BTU Range Failure

8 = Specific Gravity Range

Revised October-2016 Reference 43

Page 48

Gas Chromatograph Interface Program User Manual (for ROC800-Series)

23

Alarm Logging Mode

R/W

Program

UINT8 1

0

1.00

Enable Alarm Log Entry

both

#1 Table 1

Table 1 on the GC.

#2 Table 1

Table 1 on the GC.

#3 Table 1

Table 1 on the GC.

27

Component Index

#4 Table 1

R/O

Program

UINT8 1 0255

0

1.00

Component index #4 read from

Table 1 on the GC.

28

Component Index

#5 Table 1

R/O

Program

UINT8 1 0255

0

1.00

Component index #5 read from

Table 1 on the GC.

29

Component Index

#6 Table 1

R/O

Program

UINT8 1 0255

0

1.00

Component index #6 read from

Table 1 on the GC.

30

Component Index

#7 Table 1

R/O

Program

UINT8 1 0255

0

1.00

Component index #7 read from

Table 1 on the GC.

31

Component Index

#8 Table 1

R/O

Program

UINT8 1 0255

0

1.00

Component index #8 read from

Table 1 on the GC.

32

Component Index

#9 Table 1

R/O

Program

UINT8 1 0255

0

1.00

Component index #9 read from

Table 1 on the GC.

33

Component Index

#10 Table 1

R/O

Program

UINT8 1 0255

0

1.00

Component index #10 read

from Table 1 on the GC.

34

Component Index

#11 Table 1

R/O

Program

UINT8 1 0255

0

1.00

Component index #11 read

from Table 1 on the GC.

35

Component Index

#12 Table 1

R/O

Program

UINT8 1 0255

0

1.00

Component index #12 read

from Table 1 on the GC.

36

Component Index

#13 Table 1

R/O

Program

UINT8 1 0255

0

1.00

Component index #13 read

from Table 1 on the GC.

Point Type 66: GC Stream Data

Param

#

Name Access

Program or

User Update

Data

Type

Length Range Default Version

Description of Functionality

and Meaning of Values

generation. If Error Code

indicates Stream is in failure,

alarm log entry is generated.

Valid values are:

0 = Disable Logging

1 = Enable Logging, No SRBX

2 = Enable Logging, SRBX on

Set only

3 = Enable Logging, SRBX on

Clear only

4 = Enable Logging, SRBX on

24 Component Index

25 Component Index

26 Component Index

R/O Program UINT8 1 0255 0 1.00 Component index #1 read from

R/O Program UINT8 1 0255 0 1.00 Component index #2 read from

R/O Program UINT8 1 0255 0 1.00 Component index #3 read from

44 Reference Revised October-2016

Page 49

Point Type 66: GC Stream Data

37

Component Index

#14 Table 1

R/O

Program

UINT8 1 0255

0

1.00

Component index #14 read

from Table 1 on the GC.

38

Component Index

#15 Table 1

R/O

Program

UINT8 1 0255

0

1.00

Component index #15 read

from Table 1 on the GC.

#16 Table 1

from Table 1 on the GC.

#1 Table 2

Table 2 on the GC.

#2 Table 2

Table 2 on the GC.

#3 Table 2

Table 2 on the GC.

#4 Table 2

Table 2 on the GC.

44

Component Index

#5 Table 2

R/O

Program

UINT8 1 0255

0

1.00

Component index #5 read from

Table 2 on the GC.

45

Component Index

#6 Table 2

R/O

Program

UINT8 1 0255

0

1.00

Component index #6 read from

Table 2 on the GC.

46

Component Index

#7 Table 2

R/O

Program

UINT8 1 0255

0

1.00

Component index #7 read from

Table 2 on the GC.

47

Component Index

#8 Table 2

R/O

Program

UINT8 1 0255

0

1.00

Component index #8 read from

Table 2 on the GC.

48

Component Index

#9 Table 2

R/O

Program

UINT8 1 0255

0

1.00

Component index #9 read from

Table 2 on the GC.

49

Component Index

#10 Table 2

R/O

Program

UINT8 1 0255

0

1.00

Component index #10 read

from Table 2 on the GC.

50

Component Index

#11 Table 2

R/O

Program

UINT8 1 0255

0

1.00

Component index #11 read

from Table 2 on the GC.

51

Component Index

R/O

Program

UINT8 1 0255

0

1.00

Component index #12 read

52

Component Index

#13 Table 2

R/O

Program

UINT8 1 0255

0

1.00

Component index #13 read

from Table 2 on the GC.

53

Component Index

#14 Table 2

R/O

Program

UINT8 1 0255

0

1.00

Component index #14 read

from Table 2 on the GC.

54

Component Index

#15 Table 2

R/O

Program

UINT8 1 0255

0

1.00

Component index #15 read

from Table 2 on the GC.

55

Component Index

#16 Table 2

R/O

Program

UINT8 1 0255

0

1.00

Component index #16 read

from Table 2 on the GC.

Param

#

Name Access

Program or