Page 1

Remote Automation Solutions

Part Number D301232X012

May 2018

FloBoss™ 107 Flow Manager

Instruction Manual

Page 2

FloBoss 107 Flow Manager Instruction Manual

ii Revised May-2018

System Training

A well-trained workforce is critical to the success of your operation. Knowing how to

correctly install, configure, program, calibrate, and trouble-shoot your Emerson equipment

provides your engineers and technicians with the skills and confidence to optimize your

investment. Remote Automation Solutions offers a variety of ways for your personnel to

acquire essential system expertise. Our full-time professional instructors can conduct

classroom training at several of our corporate offices, at your site, or even at your regional

Emerson office. You can also receive the same quality training via our live, interactive

Emerson Virtual Classroom and save on travel costs. For our complete schedule and further

information, contact the Remote Automation Solutions Training Department at 800-338-8158

or email us at education@emerson.com.

Page 3

FloBoss 107 Flow Manager Instruction Manual

Revised May-2018 Contents iii

Contents

Chapter 1 – General Information 1-1

1.1 Scope of Manual ............................................................................................................................1-2

1.2 FloBoss 107 Overview ...................................................................................................................1-2

1.3 Hardware ........................................................................................................................................1-5

1.3.1 Processor and Memory ....................................................................................................1-6

1.3.2 Backplane ........................................................................................................................1-6

1.3.3 Expansion Rack ...............................................................................................................1-6

1.3.4 Central Processing Unit (CPU) ........................................................................................1-6

1.3.5 Battery and Super-capacitor ............................................................................................1-8

1.3.6 Built-in Inputs and Outputs ...............................................................................................1-8

1.3.7 Built-in Communications ..................................................................................................1-8

1.3.8 Built-in Resistance Thermal Device (RTD) ................................................................... 1-10

1.3.9 Built-in Loop Output Power ........................................................................................... 1-10

1.3.10 Optional Inputs and Outputs ......................................................................................... 1-10

1.3.11 Optional Communication Modules – COM3 ................................................................. 1-11

1.3.12 Optional Multi-Variable Sensor (MVS) .......................................................................... 1-12

1.3.13 Optional Integral Sensors ............................................................................................. 1-12

1.3.14 Optional License Key .................................................................................................... 1-12

1.3.15 Optional Enclosures ...................................................................................................... 1-12

1.3.16 Optional LCD Touchpad ............................................................................................... 1-13

1.4 Firmware ..................................................................................................................................... 1-14

1.4.1 History Points ................................................................................................................ 1-15

1.4.2 Alarm Log ...................................................................................................................... 1-16

1.4.3 Event Log ...................................................................................................................... 1-17

1.4.4 Security ......................................................................................................................... 1-17

1.4.5 I/O Database ................................................................................................................. 1-18

1.4.6 Function Sequence Tables (FST) ................................................................................. 1-18

1.4.7 PID Control.................................................................................................................... 1-18

1.4.8 Spontaneous-Report-By-Exception (SRBX) Alarming .................................................. 1-19

1.4.9 Softpoints ...................................................................................................................... 1-19

1.4.10 Opcodes ........................................................................................................................ 1-19

1.4.11 Pass Through Communications .................................................................................... 1-19

1.4.12 ROC and Modbus Protocols ......................................................................................... 1-19

1.4.13 User C Programs .......................................................................................................... 1-20

1.5 ROCLINK™ 800 Configuration Software ..................................................................................... 1-20

1.6 Product Electronics ..................................................................................................................... 1-22

1.6.1 Real-Time Clock ........................................................................................................... 1-22

1.6.2 Diagnostic Monitoring ................................................................................................... 1-22

1.6.3 Automatic Self Tests ..................................................................................................... 1-22

1.6.4 Low Power Mode .......................................................................................................... 1-23

1.7 Flow Measurements .................................................................................................................... 1-23

1.8 Security Gateway ........................................................................................................................ 1-24

1.9 Additional Technical Information ................................................................................................. 1-25

Chapter 2 – Installation and Use 2-1

2.1 Installation Requirements ...............................................................................................................2-1

2.1.1 Environmental Requirements...........................................................................................2-1

2.1.2 Site Requirements ...........................................................................................................2-2

2.1.3 Compliance with Hazardous Area Standards ..................................................................2-4

2.1.4 Power Installation Requirements .....................................................................................2-4

2.1.5 Grounding Installation Requirements ..............................................................................2-5

2.1.6 I/O Wiring Requirements ..................................................................................................2-6

Page 4

FloBoss 107 Flow Manager Instruction Manual

iv Contents Revised May-2018

2.2 Installing the FloBoss 107 and Expansion Rack ............................................................................ 2-7

2.2.1 Required Tools ................................................................................................................. 2-7

2.2.2 Installing the FloBoss 107 without an Expansion Rack ................................................... 2-7

2.2.3 Installing the FloBoss with an Expansion Rack ............................................................... 2-8

2.2.4 Removing an Expansion Rack ....................................................................................... 2-10

2.2.5 Removing and Installing Module Slot Covers ................................................................ 2-11

2.2.6 Removing and Installing Wire Channel Covers ............................................................. 2-11

2.3 Memory Backup Battery ............................................................................................................... 2-12

2.3.1 Removing and Installing the Battery .............................................................................. 2-12

2.4 Central Processor Unit (CPU) ...................................................................................................... 2-13

2.4.1 Removing the CPU Module ........................................................................................... 2-15

2.4.2 Installing the CPU Module ............................................................................................. 2-16

2.4.3 Resetting the CPU ......................................................................................................... 2-16

2.5 License Keys ................................................................................................................................ 2-16

2.6 Startup and Operation .................................................................................................................. 2-17

2.6.1 Startup ........................................................................................................................... 2-17

2.6.2 Operation ....................................................................................................................... 2-17

Chapter 3 – Power Connections 3-1

3.1 Power Input Descriptions ............................................................................................................... 3-1

3.2 Determining Power Consumption .................................................................................................. 3-3

3.2.1 Summary .......................................................................................................................... 3-6

3.3 Wiring Connections ........................................................................................................................ 3-6

3.4 Wiring Power to the CPU Module .................................................................................................. 3-7

Chapter 4 – Inputs and Outputs 4-1

4.1 I/O Description ............................................................................................................................... 4-1

4.2 Installing a Module ......................................................................................................................... 4-5

4.3 Removing a Module ....................................................................................................................... 4-6

4.4 Wiring a Module ............................................................................................................................. 4-7

4.5 Selecting the Type of I/O ................................................................................................................ 4-7

4.6 Analog Inputs (AI) .......................................................................................................................... 4-9

4.6.1 Wiring the Analog Inputs .................................................................................................. 4-9

4.7 8-Point Analog Input/Digital Input (AI/DI) Module ........................................................................ 4-11

4.7.1 Wiring the 8-Point AI/DI ................................................................................................. 4-11

4.8 Analog Outputs (AO) .................................................................................................................... 4-13

4.8.1 Wiring the Analog Outputs ............................................................................................. 4-13

4.9 Discrete Inputs (DI) ...................................................................................................................... 4-14

4.9.1 Wiring the Discrete Inputs .............................................................................................. 4-15

4.10 Discrete Outputs (DO) .................................................................................................................. 4-15

4.10.1 Wiring the Discrete Outputs ........................................................................................... 4-16

4.11 Discrete Outputs Relay (DOR) Module ........................................................................................ 4-17

4.11.1 Wiring the Discrete Output Relays ................................................................................. 4-18

4.12 Pulse Inputs (PI) ........................................................................................................................... 4-19

4.12.1 Wiring the Pulse Inputs .................................................................................................. 4-19

4.13 Application (APP 485) Module ..................................................................................................... 4-20

4.13.1 Wiring the Application Module ....................................................................................... 4-20

4.14 Resistance Temperature Detector (RTD) Input ........................................................................... 4-22

4.14.1 Wiring the RTD Input ..................................................................................................... 4-22

4.15 6-Point AO/DO Module ................................................................................................................ 4-23

4.15.1 Wiring the 6-Point AO/DO Module ................................................................................. 4-24

4.16 HART® Module ............................................................................................................................. 4-24

4.16.1 Wiring the HART Module ............................................................................................... 4-25

4.17 Resistance Temperature Detector (RTD) Module ....................................................................... 4-26

4.17.1 Wiring the RTD Module.................................................................................................. 4-26

4.18 IEC 62591 Module ....................................................................................................................... 4-27

Page 5

FloBoss 107 Flow Manager Instruction Manual

Revised May-2018 Contents v

4.18.1 Wiring the IEC 62591 Module ....................................................................................... 4-28

4.19 Additional Technical Information ................................................................................................. 4-28

Chapter 5 – Communications 5-1

5.1 Communications Overview ............................................................................................................5-1

5.2 Installing/Removing a Communication Module ..............................................................................5-5

5.3 Wiring the Local Operator Interface (LOI) Port ..............................................................................5-5

5.3.1 Using the LOI ...................................................................................................................5-6

5.4 Wiring EIA-485 (RS-485) Communications ...................................................................................5-6

5.5 Wiring EIA-232 (RS-232) Communications ...................................................................................5-7

5.6 Liquid Crystal Display (LCD) Touchpad .........................................................................................5-8

5.7 Enhanced Communication Module (ECM) .....................................................................................5-9

5.7.1 Activating the USB Port ................................................................................................ 5-10

5.8 Dial-Up Modem Module .............................................................................................................. 5-15

5.9 Network Radio Module (NRM) .................................................................................................... 5-16

5.9.1 Installing the NRM ......................................................................................................... 5-17

5.10 Additional Technical Information ................................................................................................. 5-17

Chapter 6 – Sensors and Transducers 6-1

6.1 Multi-Variable Sensor (MVS) Module Overview .............................................................................6-1

6.1.1 Installing/Removing an MVS Module ...............................................................................6-4

6.1.2 Configuring a Multi-drop MVS Module Setup ..................................................................6-4

6.1.3 Lightning Protection .........................................................................................................6-6

6.2 Dual Variable Sensor (DVS) Overview ..........................................................................................6-7

6.2.1 Installing/Removing a DVS ..............................................................................................6-8

6.2.2 Physically Connecting a DVS ..........................................................................................6-9

6.2.3 Configuring a DVS ........................................................................................................ 6-10

6.3 Pressure Module (PIM) Overview ............................................................................................... 6-10

6.3.1 Installing/Removing a Pressure Module ....................................................................... 6-11

6.3.2 Configuring a Pressure Module .................................................................................... 6-13

6.4 Additional Technical Information ................................................................................................. 6-14

Chapter 7 – Troubleshooting 7-1

7.1 General Guidelines.........................................................................................................................7-1

7.2 Graphical User Interface (GUI) ......................................................................................................7-2

7.3 Checklists .......................................................................................................................................7-4

7.3.1 LEDs ................................................................................................................................7-4

7.3.2 Serial Communications ....................................................................................................7-4

7.3.3 Inputs/Outputs ..................................................................................................................7-5

7.3.4 Preserving Configuration and Log Data ...........................................................................7-6

7.3.5 ROCLINK 800 Configuration Software ............................................................................7-6

7.3.6 Powering Up.....................................................................................................................7-7

7.3.7 Multi-Variable Sensor (MVS) ...........................................................................................7-7

7.3.8 Resistance Temperature Detector (RTD) ........................................................................7-7

7.3.9 IEC 62591 Module ...........................................................................................................7-8

7.3.10 Network Radio Module (NRM) .........................................................................................7-8

7.4 Procedures .....................................................................................................................................7-8

7.4.1 Resetting the FB107 ........................................................................................................7-9

7.4.2 Restarting and Reconfiguring the FB107 .........................................................................7-9

7.4.3 Troubleshooting Analog Inputs ..................................................................................... 7-10

7.4.4 Troubleshooting Analog Outputs .................................................................................. 7-11

7.4.5 Troubleshooting Discrete Inputs ................................................................................... 7-12

7.4.6 Troubleshooting Discrete Outputs ................................................................................ 7-12

7.4.7 Troubleshooting Pulse Inputs ....................................................................................... 7-13

Page 6

FloBoss 107 Flow Manager Instruction Manual

vi Contents Revised May-2018

7.4.8 Troubleshooting RTD Inputs .......................................................................................... 7-13

7.4.9 Troubleshooting the Multi-Variable Sensor (MVS) ........................................................ 7-15

7.4.10 Troubleshooting the Enhanced Comm Module (ECM) .................................................. 7-16

7.4.11 Troubleshooting the Dual Variable Sensor (DVS) ......................................................... 7-16

7.4.12 Troubleshooting the Pressure Module (PIM) ................................................................. 7-17

7.4.13 Troubleshooting AI/DI .................................................................................................... 7-18

7.4.14 Troubleshooting the Discrete Output Relay (DOR) ....................................................... 7-18

Appendix A – Glossary A-1

Index I-1

Page 7

FloBoss 107 Flow Manager Instruction Manual

Revised May-2018 General Information 1-1

Chapter 1 – General Information

In This Chapter

1.1 Scope of Manual................................................................................. 1-2

1.2 FloBoss 107 Overview ....................................................................... 1-2

1.3 Hardware ............................................................................................ 1-5

1.3.1 Processor and Memory ......................................................... 1-6

1.3.2 Backplane .............................................................................. 1-6

1.3.3 Expansion Rack .................................................................... 1-6

1.3.4 Central Processing Unit (CPU) ............................................. 1-6

1.3.5 Battery and Super-capacitor.................................................. 1-8

1.3.6 Built-in Inputs and Outputs .................................................... 1-8

1.3.7 Built-in Communications ........................................................ 1-8

1.3.8 Built-in Resistance Thermal Device (RTD) ......................... 1-10

1.3.9 Built-in Loop Output Power ................................................. 1-10

1.3.10 Optional Inputs and Outputs................................................ 1-10

1.3.11 Optional Communication Modules – COM3 ........................ 1-11

1.3.12 Optional Multi-Variable Sensor (MVS) ................................ 1-12

1.3.13 Optional Integral Sensors .................................................... 1-12

1.3.14 Optional License Key .......................................................... 1-12

1.3.15 Optional Enclosures ............................................................ 1-12

1.3.16 Optional LCD Touchpad ...................................................... 1-13

1.4 Firmware ........................................................................................... 1-14

1.4.1 History Points ...................................................................... 1-15

1.4.2 Alarm Log ............................................................................ 1-16

1.4.3 Event Log ............................................................................ 1-17

1.4.4 Security ................................................................................ 1-17

1.4.5 I/O Database ....................................................................... 1-18

1.4.6 Function Sequence Tables (FST) ....................................... 1-18

1.4.7 PID Control .......................................................................... 1-18

1.4.8 Spontaneous-Report-By-Exception (SRBX) Alarming ........ 1-19

1.4.9 Softpoints............................................................................. 1-19

1.4.10 Opcodes .............................................................................. 1-19

1.4.11 Pass Through Communications .......................................... 1-19

1.4.12 ROC and Modbus Protocols................................................ 1-19

1.4.13 User C Programs ................................................................. 1-20

1.5 ROCLINK™ 800 Configuration Software .......................................... 1-20

1.6 Product Electronics .......................................................................... 1-22

1.6.1 Real-Time Clock .................................................................. 1-22

1.6.2 Diagnostic Monitoring .......................................................... 1-22

1.6.3 Automatic Self Tests ........................................................... 1-22

1.6.4 Low Power Mode ................................................................. 1-23

1.7 Flow Measurements ......................................................................... 1-23

1.8 Security Gateway ............................................................................. 1-24

1.9 Additional Technical Information ...................................................... 1-25

This manual describes the FloBoss™ 107 Flow Manager (“FB107”), part

of the family of FloBoss flow computers manufactured by Remote

Automation Solutions, a division of Emerson Process Management. For

information about the software you use to configure the FB107, refer to

the ROCLINK™ 800 Configuration Software User Manual (for FloBoss

107) (part D301249X012).

Page 8

FloBoss 107 Manager Instruction Manual

1-2 General Information Revised May-2018

This chapter provides an overview of the FB107 and its components.

1.1 Scope of Manual

This manual contains the following chapters:

Chapter 1

General Information

Provides an overview of the hardware and firmware

for the FB107 base unit and the expansion rack.

Chapter 2

Installation and Use

Provides information on installation, tools, wiring,

and other essential elements of the FB107.

Chapter 3

Power Connections

Provides information on determining power

requirements for the FB107.

Chapter 4

Inputs and Outputs

Provides information for the input/output (I/O)

modules, CPU I/O assembly, and the RTD input.

Chapter 5

Communications

Provides information for the built-in communication

ports and the optional communication modules.

Chapter 6

Sensors and

Transducers

Provides information on the optional Multi-Variable

Sensor (MVS), Dual Variable Sensor (DVS), and

Pulse Input modules.

Chapter 7

Troubleshooting

Provides information on diagnosing and correcting

problems.

Glossary

Provides definitions of acronyms and terms.

Index

Provides an alphabetic listing of items and topics

contained in this manual.

1.2 FloBoss 107 Overview

A 32-bit microprocessor-based electronic flow computer, the FB107

electronically measures, monitors, and manages flow. This economical

flow computer reliably and accurately performs flow calculations,

temperature measurements, and data archival.

Note: You configure the functionality of the FB107 and monitor its

operation using a personal computer (PC) running ROCLINK 800

(“ROCLINK 800”) software.

The FB107 can measure up to four meter runs through a variety of

devices, such as an orifice plate, turbine meter, or other pulse-generating

devices. Meter inputs may also use analog transmitters. For multiple

differential pressure-run applications, you can add an optional MultipleVariable Sensor (MVS) module to provide an interface to remote MVS

transmitters.

The FB107 performs minute, hourly, daily, and minimum / maximum

historical data archival for standard history and a configurable time

interval archival for extended history. As the electronic solution to

replace traditional paper charting, the FB107 records the corrected flow

for differential or pulse counts and stores the data.

The FB107 computes flow for both volume and energy. It provides onsite functionality and supports remote monitoring, measurement, data

archival, communications, and control. It stores the results of the flow

Page 9

FloBoss 107 Flow Manager Instruction Manual

Revised May-2018 General Information 1-3

calculations in memory, which can then be and can be communicated to

an external device either on demand or periodically.

The FB107 design allows you to configure specific applications,

including those requiring logic and sequencing control using a Function

Sequence Table (FST).

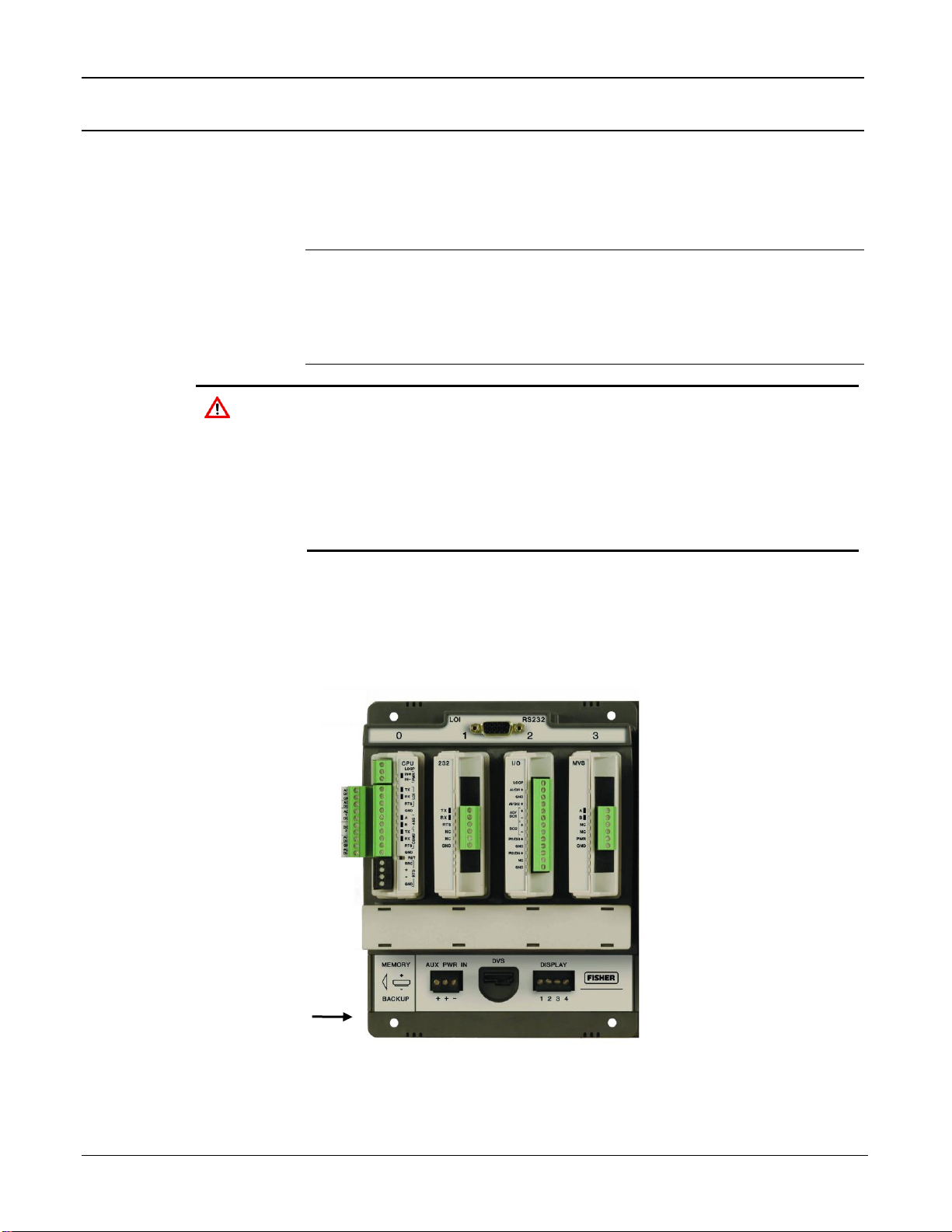

A

Local (LOI) Communication Port

B

Slot 0 = CPU Module

C

CPU I/O Assembly

D

Input Power Connector

E

Memory Backup Battery Connector

F

Slot 3 = I/O or MVS module

G

Slot 2 = I/O, MVS module, or COM module (COM2)

H

Slot 1 = I/O, MVS, or COM module (COM3)

I

Wire Channel Cover

J

Display Connector

K

Integral Sensor Connector

Figure 1-1. FloBoss 107 Base Unit

F

A

G

C

B

D

E

J

I

H

K

Page 10

FloBoss 107 Manager Instruction Manual

1-4 General Information Revised May-2018

A

Slot 4 = I/O or MVS module

B

Slot 5 = I/O or MVS module

C

Connects to FloBoss 107 base unit

D

Slot 7 = I/O or MVS module

E

Slot 6 = I/O or MVS module

F

Wire Channel Cover

Figure 1-2. FloBoss 107 Expansion Rack

D

A

F

E

B

C

Page 11

FloBoss 107 Flow Manager Instruction Manual

Revised May-2018 General Information 1-5

Figure 1-3. FloBoss 107 with Expansion Rack

The FB107 provides the following components and features:

▪ 32-bit processor board, inter-connect board, and backplane board.

▪ Central processing unit (CPU).

▪ Field-upgradeable 2 MB flash ROM (read only memory).

▪ 2 MB battery backed-up RAM (random access memory) storage.

▪ Two-, three-, or four-wire 100-ohm resistance thermal device (RTD)

input.

▪ Battery and super-capacitor backed memory retention to provide short

and longer-term data, configuration, and operational integrity when

the FB107 is not in service or is in storage.

▪ Three built-in communication ports.

▪ Input power and output loop power.

▪ Extensive applications firmware.

1.3 Hardware

The FB107 is available with four basic configurations:

▪ Non-isolated CPU without I/O.

▪ Non-isolated CPU with six points of I/O.

▪ Isolated CPU without I/O.

▪ Isolated CPU with six points of I/O.

Note: Isolation occurs between the CPU and the field logic.

W

6

Page 12

FloBoss 107 Manager Instruction Manual

1-6 General Information Revised May-2018

The FB107 base unit has four slots. Slot 0 is reserved for the CPU

module, which provides three communication ports, an RTD, power

input, loop power output, system variables, and optional 6 points of I/O.

Slots 1 and 2 can each contain one communication module. Slots 1, 2,

and 3 can contain input/outputs (I/O), MVS, and application modules.

1.3.1 Processor and Memory

The FB107 derives processing power from a 32-bit CMOS

microprocessor. The microprocessor features a single 32-bit internal data

bus and a single 16-bit external data bus. The microprocessor has lowpower operating modes, including inactivity and low battery condition.

The FB107 has high-speed direct memory access.

The FB107 has 2 MB of static random access memory (SRAM) for

storing database, historical, configuration, alarms, and events data.

1.3.2 Backplane

The backplane board routes signals to and from the CPU to the I/O

modules, application modules, expansion rack, the Multi-Variable Sensor,

and communication modules.

1.3.3 Expansion Rack

The four-slot optional expansion rack (see Figure 1-3) enables the FB107

to expand its I/O capabilities to meet your needs. The expansion rack

supports optional I/O, MVS, and application modules.

1.3.4 Central Processing Unit (CPU)

The base unit on the FB107 has four slots. Slot 0 is for the CPU module.

The CPU provides connections to the field wiring including surge and

static discharge protection for the field wiring. Electronics include the

RTD circuits and the final I/O drivers/receivers.

The CPU components include:

▪ RTD input.

▪ Input power.

▪ Loop power output.

▪ Reset (RST) switch.

▪ System variables.

▪ Diagnostic monitoring.

▪ Real-time clock.

▪ Automatic self-tests.

▪ Power saving modes.

▪ Local operator interface (LOI) EIA-232 (RS-232).

▪ EIA-485 (RS-485) communications (COM1).

Page 13

FloBoss 107 Flow Manager Instruction Manual

Revised May-2018 General Information 1-7

▪ EIA-232 (RS-232) communications (COM2).

▪ Boot Flash – System initialization and diagnostics.

▪ SRAM (static random access memory) with battery backup – Data

logs and configuration.

▪ Flash ROM (Read-only memory) – Firmware image.

▪ 32-bit microprocessor and the real-time operating system (RTOS)

provide both hardware and software memory protection.

▪ Optional CPU I/O assembly and terminations (see Figure 1-4).

Figure 1-4. CPU

Page 14

FloBoss 107 Manager Instruction Manual

1-8 General Information Revised May-2018

1.3.5 Battery and Super-capacitor

A super capacitor (“super-cap”) and a coin type battery work together to

provide backup power for the static RAM and the real-time clock. This

helps to ensure retention of short and longer-term data, configuration, and

operational integrity when the FB107 is not in service or is in storage.

For information on replacing the battery, refer to Section 2.3.1, Removing

and Installing the Battery.

Note: The super-cap is not field-replaceable.

1.3.6 Built-in Inputs and Outputs

The built-in inputs and outputs (I/O) on the CPU consist of a 3- or 4-wire

100-ohm resistance thermal detector (RTD) input interface and five

diagnostic analog inputs (AI) that monitor the:

▪ Logical voltage.

▪ Battery voltage from the backplane voltage input connector.

▪ Charge in voltage originating from the CPU power input.

▪ System milliamps originating from the power input from the CPU.

▪ Board temperature originating at the CPU.

1.3.7 Built-in Communications

The FB107 supports up to four communication ports. The base CPU has

three built-in communication ports:

▪ Local Operator Interface (RS-232C) – LOI for asynchronous serial

communication (Local Port).

▪ EIA-485 (RS-485) – COM1 for asynchronous serial communication.

▪ EIA-232 (RS-232) – COM2 for serial communication.

Local Operator

Interface Port

The Local Operator Interface (LOI) port provides for a direct, local

link between the FB107 and a personal computer (PC) through an

optional Local Operator Interface Cable using EIA-232 (RS-232C)

communications.

The LOI local port allows you to access the FB107 for configuration and

transfer of stored data. The LOI port is capable of initiating a message in

support of Spontaneous-Report-by-Exception (SRBX) alarming.

The LOI is software-configurable with baud rates from 300 to 115.2 K

and it uses a DB9 connection.

Note: You can purchase an LOI cable from your sales representative.

The LOI supports ROC or Modbus slave protocol communications. The

LOI also supports the log-on security feature of the FB107, if you enable

the security on LOI using ROCLINK 800.

Page 15

FloBoss 107 Flow Manager Instruction Manual

Revised May-2018 General Information 1-9

Default values for the LOI port are: 19,200 baud rate, 8 data bits, 1 stop

bit, no parity, group 1, and address 2.

EIA-485 (RS-485) Serial

Communications

COM1

COM1 provides EIA-485 (RS-485) serial communication protocols

with baud rates from 300 to 115.2 K. COM1 provides standard

differential data transmissions over distances of up to 1220 meters

(4000 feet), if wired in daisy chain pattern and properly terminated.

Note: Using a star installation pattern reduces data transmission to 602

m (2000 ft).

The EIA-485 (RS-485) drivers are designed for true multi-point

applications with multiple devices on a single bus.

Note: COM1 is labeled 485 on the CPU.

Use COM1 to monitor or modify the FB107 from a remote site, using a

host or ROCLINK 800. COM1 also supports the log-on security feature

of the FB107 if you enable the security on COM1 using ROCLINK 800.

COM1 sends and receives messages using the ROC or Modbus slave and

host protocol. COM1 is capable of initiating a message in support of

Spontaneous-Report-by-Exception (SRBX) alarming.

Default values for the EIA-485 (RS-485) communications are: 19,200

baud rate, 8 data bits, 1 stop bit, no parity, 10 millisecond key-on delay,

and 10 millisecond key-off delay. The maximum baud rate is 115.2 Kbps.

EIA-232 (RS-232) Serial

Communications

COM2

COM2 allows for EIA-232 (RS-232) asynchronous serial

communication protocols with baud rates from 300 to 115.2 K, host

serial interface. COM2 provides standard single-ended data

transmission over distances of up to 15 meter (50 feet).

Use COM2 to monitor or alter the FB107 from a remote site, using

ROCLINK 800. COM2 also supports the log-on security feature of the

FB107 if you enable the security on COM2 using ROCLINK 800.

COM2 sends and receives messages using the ROC or Modbus slave or

host protocol. COM2 is capable of initiating a message in support of

Spontaneous-Report-by-Exception (SRBX) alarming.

Default values for the EIA-232 (RS-232) communications module are:

19,200 baud rate, 8 data bits, 1 stop bit, no parity, 10 millisecond key-on

delay, and 10 millisecond key-off delay. The maximum baud rate is 115.2

Kbps.

Note: When you install a communication module in slot 2, the

firmware redirects communications port (COM2) on the CPU to

the type of module installed in slot 2. Configure COM2 based on

the type of communication module installed in slot 2.

Page 16

FloBoss 107 Manager Instruction Manual

1-10 General Information Revised May-2018

1.3.8 Built-in Resistance Thermal Device (RTD)

The FB107 supports a direct input from a resistance thermal device (RTD)

sensor to measure flowing temperature. An RTD temperature probe

typically mounts in a thermowell on the meter run. The RTD has a

measurement range of 40 to 400°C (40 to 752°F). The RTD is located

on the CPU.

1.3.9 Built-in Loop Output Power

Using ROCLINK 800, you can configure the I/O on the CPU module to

set the loop output power to 10 volts dc or 24 volts dc:

▪ The 24-volt setting of the loop output power is used to power

devices that require 24 volts dc to ground, allowing the external

device to send the FB107 a 4 to 20 mA signal based on pressure,

temperature, level, and such.

▪ The 10-volt setting of the loop output power is intended for low

power transmitters. The loop current is designed to deliver 80 mA

to power two field devices that connect back to the two analog

inputs.

Note: The CPU I/O assembly uses the CPU’s loop power output and

ground connections.

The I/O module only supports 24 volts dc loop output power. When 10

volts is selected, the loop output power will be 10V+ depending on input

power supply

1.3.10 Optional Inputs and Outputs

The input/output (I/O) options for the FB107 provide terminals for

expanded monitoring and control applications. Use I/O to drive a sampler

or odorizer, open a valve, or monitor an additional analog input.

You can order the expanded 6-point I/O as an:

▪ I/O assembly that mounts directly on the CPU module (optional I/O

assembly).

▪ I/O modules that mount in the I/O slots.

Both configurations provide terminations for six points of I/O and both

provide the same selections for I/O. You can configure five of the six

points of I/O using ROCLINK 800 software.

The six points of I/O consists of:

▪ Two analog inputs (AI) or discrete inputs (DI).

▪ One analog output (AO) or discrete output (DO).

▪ One discrete output (DO).

▪ Two pulse inputs (PI) or discrete inputs (DI).

Page 17

FloBoss 107 Flow Manager Instruction Manual

Revised May-2018 General Information 1-11

Adding an expansion rack to the FB107 base unit increases I/O by four

slots for a total of six slots of I/O. The FB107 supports up to six I/O

modules and one CPU I/O assembly.

Other available I/O modules include the 8-point AI/DI, the 6-point

AO/DO, the Discrete Output Relay (DOR) module, the HART module,

the Pulse Input (PI) module, the MVS I/O module, and the Resistance

Temperature Detector (RTD) module (see Chapter 4, Inputs and

Outputs). The Multi-Variable Sensor (MVS), Dual Variable Sensor

(DVS), and Pressure module (PM) are factory-installed options (see

Chapter 5, Sensors and Transducers).

You can install I/O modules in slots 1 through 3 on the FB107 base unit

and in slots 4 through 6 on the expansion rack. If you install a

communications module in slot 1, you can install an I/O module in slot 7.

You can use current analog inputs of 4 to 20 mA when you select the

250-ohm resistor in the AI configuration using ROCLINK 800.

Note: See Chapter 4, Inputs and Outputs, for more information on

FB107 I/O modules.

1.3.11 Optional Communication Modules – COM3

Optional communication modules provide the ability to send and receive

data through COM3. The COM3 port is capable of initiating a message in

support of Spontaneous-Report-by-Exception (SRBX) alarming.

You can install communication modules in slots 1 or 2 on the base unit.

Installing a communications module in slot 1 on the base unit activates

the COM3 communications port. Installing a communications module in

slot 2 redirects the CPU’s communications port (COM2) to the type of

module installed in slot 2.

The FB107 accommodates following types of communication modules:

▪ EIA-485 (RS-485) serial communication protocols with baud rates

from 300 to 115.2 Kbps to provide standard differential data

transmissions over distances of up to 1220 meter (4000 feet).

▪ EIA-232 (RS-232) serial communication protocols with baud rates

from 300 to 115.2 Kbps, host serial interface to provide standard

single-ended data transmission over distances of up to 15 meter (50

feet).

▪ Enhanced Communication module (ECM) provides an Ethernet and a

USB 2.0 port.

▪ Dial-Up Modem module provides communication over a Public-

Switched Telephone Network (PSTN) up to 2400 bps bits per second

(bps).

Page 18

FloBoss 107 Manager Instruction Manual

1-12 General Information Revised May-2018

COM3 can communicate with other devices using ROC or Modbus host

and slave protocols. The firmware can automatically detect ROC or

Modbus slave protocols.

Note: See Chapter 5, Communications, for more information on FB107

communication modules.

1.3.12 Optional Multi-Variable Sensor (MVS)

The optional Multi-Variable Sensor (MVS) module provides differential

pressure, static pressure, and temperature inputs to the FB107 for

differential pressure flow calculation.

You can install only one MVS module in the FB107. You can install the

MVS module in slots 1 through 3 on the base unit or in slots 4 through 7

on the expansion rack, regardless of the position of any other type of

module.

The MVS module provides current-limited power and EIA-485 (RS-485)

communications to external remote MVS transmitters. The FB107

supports six remote transmitters with up to four meter runs. See Chapter

6, Sensors and Transducers, for more information.

1.3.13 Optional Integral Sensors

The FB107 supports a Dual Variable Sensor (DVS) or a Pressure module

(PM), either of which attaches to the bottom of an FB107 enclosure and

connect to the DVS port on the FB107’s base unit. See Chapter 6,

Sensors and Transducers, for more information.

1.3.14 Optional License Key

The optional application license key provides extended functionality,

such as the use of various user programs. The FB107 supports up to six

different user programs. For example, you need to install a license key

with the proper license in the FB107 to run User C programs.

1.3.15 Optional Enclosures

You can place your FB107 in weather-tight enclosures. Enclosures

protect the FB107 electronics from physical damage and harsh

environments. You can choose between a polycarbonate (see Figure 1-5),

or a steel (see Figure 1-6) enclosure.

Note: If you have a PIM attached to a polycarbonate enclosure or a

DVS attached to a steel enclosure, adjust the height dimensions

accordingly.

For further information, refer to product data sheet FloBoss 107E

Enclosure Options (FB107:ENC).

Page 19

FloBoss 107 Flow Manager Instruction Manual

Revised May-2018 General Information 1-13

Figure 1-5. Polycarbonate enclosure with a DVS module

Figure 1-6. Steel enclosure with a PIM module

1.3.16 Optional LCD Touchpad

The optional LCD Touchpad provides an external user interface to the

process and operational information contained in the FB107. Use the

Page 20

FloBoss 107 Manager Instruction Manual

1-14 General Information Revised May-2018

transreflective touch-sensitive screen to view and change parameters and

review historical and real-time data in the FB107. For further

information, refer to product data sheet FloBoss 107 LCD Touchpad

(FB107:LCD).

1.4 Firmware

The firmware makes extensive use of configuration parameters, which

you manage using ROCLINK 800 software. The firmware contained in

flash ROM on the processor board determines the FB107’s functionality.

The firmware provides a complete operating system for the FB107, and is

field-upgradeable using a serial connection such as the LOI port.

Firmware includes:

▪ Input and output database.

▪ Historical database.

▪ Event and alarm log database, holding up to 240 alarms and 240

events.

▪ Applications, such as PID, AGA, and FST.

▪ Real-time clock.

▪ Determining task execution.

▪ 1992 AGA-3 flow calculations (with user-selectable AGA8

compressibility Detail, Gross 1, or Gross 2).

▪ 1996 AGA-7 flow calculations (with user-selectable AGA8

compressibility).

▪ ISO5167-2003 flow calculations.

▪ ROC or Modbus host or slave (ASCII or RTU).

▪ Establishing and managing communications.

▪ Communications based on the ROC protocol or Modbus slave and

host (ASCII or RTU) protocol for use with EFM applications.

▪ Alarm call-in to host for Spontaneous-Report-By-Exception (SRBX).

▪ Standard and Extended History.

▪ Self-test capability.

▪ User level security.

The FB107 provides the functions required for a variety of field

automation applications. Designed for expandability, the FB107

monitors, measures, and controls equipment in a remote environment.

You can use the FB107 for:

▪ Applications requiring flow computation.

▪ Logic and sequencing control using a user-defined Function Sequence

Table (FST).

▪ Closed-loop (PID) control capabilities (requires optional I/O module

or CPU I/O assembly).

▪ Custom User C application support.

Page 21

FloBoss 107 Flow Manager Instruction Manual

Revised May-2018 General Information 1-15

Real-Time Operating

System (RTOS)

The FB107 firmware uses a pre-emptive, multi-tasking, message-based

real-time operating system (RTOS). Tasks are assigned priorities and,

at any given time, the operating system determines which task will run.

For instance, if a lower priority task is executing and a higher priority

task needs to run, the operating system suspends the lower priority task,

allows the higher priority task to run to completion, then resumes the

lower priority task’s execution.

TLP

The FB107 reads data from and writes data to data structures called

“points.” A “point” is a ROC protocol term for a grouping of

individual parameters (such as information about an I/O channel) or

some other function (such as a flow calculation). Points are defined by

a collection of parameters and have a numerical designation that

defines the type of point.

The logical number indicates the physical location for the I/O or the

logical instance for non-I/O points within the FB107. Parameters are

individual pieces of data that relate to the point type. The point type

attributes define the database point to be one of the possible types of

points available to the system.

A sample TLP might be analog input (T), rack location B1 (L), and

Engineering Units (P).

Together, these three components—the type (T), the logical (L), and the

parameters (P)—identify specific pieces of data that reside in an FB107

database. Collectively, this three-component address is often called a

TLP.

1.4.1 History Points

The FB107 saves history to either of two databases: Standard or Extended

History. You can configure the number of entries/logs available to

Standard (maximum of 100) and Extended History (maximum of 25).

History for meter runs includes the Averaging Techniques as well as

accumulation per second and accumulation per minute.

You can select the number of history points to archive, the sample

interval in minutes (for Extended or Standard History) or seconds (for

Extended History only), the number of days to archive, and whether to

log history data at the beginning or the end of the period.

History is one block of memory divided into two areas, one for Standard

History and one for Extended History. Standard History uses all of the

memory that it requires for the configured number of points. Extended

History only receives the surplus memory Standard History does not use.

Standard History archival properties include:

▪ Up to 100 points of minute data from the last 60 minutes.

▪ Up to 100 points of hourly data for 35 days.

▪ Up to 100 points of daily data for 35 or 60 days.

▪ Min / max historical data for today and yesterday.

Page 22

FloBoss 107 Manager Instruction Manual

1-16 General Information Revised May-2018

Extended History archiving provides a monitoring resolution for the

FB107 that is similar to a chart recorder. You can configure Extended

History to archive up to 25 history points with archiving intervals at 1, 2,

3, 4, 5, 10, 12, 15, 20, 30, or 60 second or minute intervals.

Minute Historical

Log

The FB107 has a 60-minute historical log for every history point. The

Minute Historical Log stores the last 60 minutes of data from the

current minute. Each history point has Minute Historical Log entries,

unless the history point is configured for FST-controlled logging.

Hourly Historical

Log

The FB107 has a total of 35 days of hourly historical logs available for

every history point. The Hourly Historical Log is also called the

Periodic database. Normally, the Hourly Log is recorded at the

beginning of every hour, although you can configure it for either the

beginning or end of every hour. The exceptions are FST Minute and

FST Second logging.

The time stamp for periodic logging consists of the month, day, hour, and

minute. The exception is for FST Second logging, in which the time

stamp consists of the day, hour, minute, and second.

Daily Historical

Log

The FB107 has a total of 35 or 60 daily historical logs for every history

point. The Daily Log is recorded at the configured contract hour every

day with a time stamp that is the same as the Hourly Log. Each history

point has daily historical log entries, unless the history point is

configured for FST-controlled logging.

Min / Max Historical

Log

The Min / Max database displays the minimum and the maximum

values for the database points over a 24-hour period for today and

yesterday. You can view the Min / Max historical, but not save it to

disk.

Extended History Log

The FB107 has configurable archive times that, in turn, determine the

number of entries. You can configure Extended History to archive up

to 25 history points with archiving intervals at 1, 2, 3, 4, 5, 10, 12, 15,

20, 30, or 60 second or minute intervals.

1.4.2 Alarm Log

The alarm log contains the change in the state of any alarm signal that has

been enabled for alarms. The system alarm log has the capacity to

maintain and store up to 240 alarms in a “circular” log. The alarm log has

information fields that include time and date stamp, alarm clear or set

indicator, and either the tag name of the point or a 14-byte detail string in

ASCII format.

In addition to providing functionality for appending new alarms to the

log, the alarm log allows host packages to request the index of the most

recently logged alarm entry. Alarm logging is available internally to the

system, to external host packages, and to FSTs.

Page 23

FloBoss 107 Flow Manager Instruction Manual

Revised May-2018 General Information 1-17

Note: ROCLINK 800 does not store alarm logs to the flash ROM when

you select the Save Configuration function.

The alarm log operates in a circular fashion with new entries overwriting

the oldest entry when the buffer is full. The alarm log provides an audit

history trail of past alarms. The system stores the alarm log separately

from the event log to prevent recurring alarms from overwriting

configuration audit data.

1.4.3 Event Log

The event log contains changes to any parameter within the FB107 made

through the protocol. This event log also contains other FB107 events,

such as power cycles, cold starts, and disk configuration downloads. The

event log provides an audit history trail of past operation and changes.

The event log has information fields that include point type, parameter

number, time and date stamp, point number (if applicable), the operator

identification, the previous or current parameter values, and either the tag

name of the point or a 14-byte detail string in ASCII format.

The system event log has the capacity to maintain and store up to 240

events in a circular log. The event log operates in a circular fashion with

new entries overwriting the oldest entry when the buffer is full. The event

log provides an audit trail history of past operation and changes. The

system stores the event log separately from the alarm log to prevent

recurring alarms from overwriting configuration audit data.

In addition to providing functionality for appending new events to the

log, the event log allows host packages to request the index of the most

recently logged event entry. Event logging is available internally to the

system, to external host packages, and to the FST.

Note: ROCLINK 800 does not store event logs to the flash ROM when

you select the Save Configuration function.

The FB107 has the ability to limit the AGA calculation-related events to

only critical events. Selecting Enabled in the Limit Meter Events field on

the Meter Setup’s Advanced tab (Meter > Setup) keeps the system from

filling the event log with unnecessary events. The events not logged

include temperature, pressure, Reynolds number, and warnings for orifice

diameter, pipe diameter, and beta ratio.

1.4.4 Security

The FB107 permits device-based security. You can define and store a

maximum of 16 log-on identifiers (IDs). In order for the unit to

communicate, the log-on ID supplied to ROCLINK 800 software must

match one of the IDs stored in the FB107. This security feature is enabled

by default on the Local Operator Interface port (Security on LOI). You

Page 24

FloBoss 107 Manager Instruction Manual

1-18 General Information Revised May-2018

can configure security protection on COM1, COM2, and COM3, but this

security is disabled by default.

1.4.5 I/O Database

The I/O database contains the I/O points the operating system firmware

supports, including the system analog inputs and variables, MultiVariable Sensor (MVS) values, communications, and smart application

modules. The firmware automatically determines the point type and point

number location of each installed module. It then assigns each input and

output to a point in the database and includes user-defined configuration

parameters for assigning values, statuses, or identifiers. The firmware

scans each input, placing the values into the respective database point.

These values are available for display and historical archiving.

1.4.6 Function Sequence Tables (FST)

The FB107 supports FST user programmability. You can develop four

FST programs with a maximum length of 3000 bytes each. You configure

the number of FST lines per execution cycle in ROCLINK 800.

The FST code resides in static RAM and is backed up to flash memory

when you issue the Save Configuration function through ROCLINK 800.

Note: You must first enable FSTs (Configure > Control > FST

Registers) in order to make them available.

1.4.7 PID Control

The PID Control applications firmware provides Proportional, Integral,

and Derivative (PID) closed-loop control for a FB107, which enables the

stable operation of a feedback control loop that employs a regulating

device, such as a control valve. The FB107 supports eight PID control

loops and requires an optional CPU I/O assembly or I/O module.

The firmware sets up an independent PID algorithm (loop) in the FB107.

The PID loop has its own user-defined input, output, and override

capability.

A PID control loop maintains a process variable at setpoint. If PID

override control is configured, the primary loop is normally in control of

the regulating device. When the change in output (user-selectable) for the

primary loop becomes lesser or greater than the change in output

calculated for the secondary (override) loop, the override loop takes

control of the regulating device. A typical example is for flow control

with a pressure override loop.

Note: You must first enable PID control loops (ROC > Information) in

order to make them available for use.

Page 25

FloBoss 107 Flow Manager Instruction Manual

Revised May-2018 General Information 1-19

1.4.8 Spontaneous-Report-By-Exception (SRBX) Alarming

The SRBX functionality allows you to set up a communications port that

enables the FB107 to contact the host computer when specified alarm

conditions exist. To configure SRBX alarming, each communications

port must have the SRBX parameter enabled, each point must have the

alarming parameter enabled, and points must have an SRBX parameter

(SRBX on Set, SRBX on Clear, or SRBX on Set & Clear) selected.

SRBX occurs over a serial line if the host is set up for receiving fieldinitiated calls.

1.4.9 Softpoints

Softpoints are global data storage areas that any FB107 application can

use. For example, a softpoint may store the results of a specified FST

calculation or store an intermediate result of a specified value an FST or

user program acquires. Softpoints consist of a tag identifier, one integer

value, and twenty floating values. Thirty-two softpoints provide storage

for over 704 variables.

1.4.10 Opcodes

Use the Opcode Table to group data being polled for more efficient

communications. You can assign parameters from different point types

can be assigned to the opcode table data points, which can substantially

reduce the number of polls from a host computer. The FB107 supports

eight opcode tables, each with 44 values.

1.4.11 Pass Through Communications

By using the FB107 communications ports, Pass Through

Communications mode allows one unit to receive data and then pass it

through to other devices connected on any other communications port.

For example, the host communicates via a radio on the FB107 COM2

port. Other FB107 units can then be connected via EIA-485 (RS-485) on

the COM1 port of the first FB107, and then all the FB107 units can use

the one radio to communicate to the host.

Note: The Device Group of the FB107 receiving the data must match the

Device Group of the FB107s to which the data is passed. The

Device Group is located on the Information screen (ROC >

Information).

1.4.12 ROC and Modbus Protocols

The FB107 has the capability to communicate with other devices using

ROC or Modbus protocols. The firmware can automatically detect the

two protocols (ROC or Modbus) at baud rates of up to 115.2 Kbps bps.

Page 26

FloBoss 107 Manager Instruction Manual

1-20 General Information Revised May-2018

ROC protocol supports serial communications to local or remote devices,

such as a host computer.

An FB107 can act as a Modbus host or slave device using either Remote

Terminal Unit (RTU) or American Standard Code for Information

Interchange (ASCII) modes. This allows you to easily integrate the

FB107 into other systems. Extensions to the Modbus protocol allow the

retrieval of history, event, and alarm data in Electronic Flow Metering

(EFM) Measurement applications.

Notes:

▪ The LOI port only supports ROC or Modbus slave protocols.

▪ The FB107 auto-detects either ROC or Modbus slave protocol

messages on all comm ports. To enable Modbus host on a particular

comm port, you must select Modbus host as the port owner. As a

Modbus host, the comm port then does not support ROC protocol

messages.

1.4.13 User C Programs

Optionally, you can order custom application programs developed in User

C to provide functionality not included in the firmware, such as

calculations for steam and custom communication drivers. Examples of

custom User C programs include:

▪ Flow calculation.

▪ Properties calculations.

▪ Communications programs.

▪ Special applications.

You can transfer licenses for User C programs to the FB107 using

ROCLINK 800’s License Key Administrator function (Utilities >

License Key Administrator).

1.5 ROCLINK™ 800 Configuration Software

ROCLINK 800 Configuration software is a Microsoft® Windows-based

program that runs on a PC and enables you to monitor, configure, and

calibrate the FB107.

Many of the configuration screens, such as meters, I/O, and PIDs, are

available while ROCLINK 800 is off-line. This enables you to configure

the system while either on-line or off-line with the FB107.

The Local Operator Interface (LOI local port) provides a direct link

between the FB107 and a PC. The LOI port uses a DB9 connector with

standard EIA-232 (RS-232C) pinout. With a personal computer running

ROCLINK 800, you can locally configure the FB107, extract data, and

monitor its operation.

Page 27

FloBoss 107 Flow Manager Instruction Manual

Revised May-2018 General Information 1-21

Remote configuration is possible from a host computer using a serial

communications line. You can duplicate configurations and save them to

a disk. In addition to creating a backup, this feature is useful when you

are similarly configuring multiple FB107s for the first time, or when you

need to make configuration changes off-line. Once you create a backup

configuration file, you can load it into an FB107 with the Download

function (File > Download).

Access to the FB107 is restricted to authorized users with correct user ID

and password.

You can build custom displays for the FB107 in ROCLINK 800 that

combine both graphic and dynamic data elements. The displays can

monitor the operation of the FB107 either locally or remotely.

You can archive historical values for any numeric parameter in the

FB107. For each parameter configured for historical archiving, the system

keeps time-stamped minute, periodic, and daily data values as well as

yesterday’s and today’s daily minimum and maximum values.

You can collect history values from the FB107 using ROCLINK 800 or

another third-party host system. You can view history directly from the

FB107 or from a previously saved disk file. For each history segment,

you can configure the number of periodic history values archived, the

frequency of archiving the periodic values, the number of daily values

archived, and the contract hour.

ROCLINK 800 can create an EFM (Electronic Flow Measurement) report

file that contains all configuration, alarms, events, periodic and daily

history logs, and other history logs associated with the meter runs in the

FB107. This file then becomes the custody transfer audit trail.

Use ROCLINK 800 to:

▪ Configure and view input/output (I/O) points, flow calculations, meter

runs, PID control loops, system parameters, and power management

features.

▪ Retrieve, save, and report historical data.

▪ Retrieve, save, and report events and alarms.

▪ Perform two-, three-, four-, or five-point calibration on analog inputs

and Multi-Variable Sensor (MVS) inputs.

▪ Perform two-, three-, four-, or five-point calibration on RTD inputs.

▪ Implement user security.

▪ Create, save, and edit graphical displays.

▪ Create, save, edit, and debug Function Sequence Tables (FSTs) of up

to 3000 bytes.

▪ Set up communication parameters.

▪ Configure Modbus parameters.

▪ Update the firmware.

Page 28

FloBoss 107 Manager Instruction Manual

1-22 General Information Revised May-2018

1.6 Product Electronics

This section describes the FB107 electronic components.

1.6.1 Real-Time Clock

The real-time clock provides the FB107 with the time of day, month,

year, and day of the week, as well as real-time stamping of the database

values. The real-time clock automatically switches to backup power when

the FB107 loses primary input power. Backup power for the real-time

clock is adequate for a period in excess of one-year with no power

applied to the FB107.

The internal super-cap provides backup for the data and the real-time

clock when the main power is not connected. The super-cap has a oneyear minimum backup life with the battery installed and no power applied

to the FB107.

Note: The real-time clock uses the super-cap to keep the current time

when you replace the lithium battery.

1.6.2 Diagnostic Monitoring

The electronics board has five diagnostic inputs incorporated into the

circuitry for monitoring system integrity. Access these analog inputs

using the I/O function of ROCLINK 800 software (Configure > I/O).

Refer to Table 1-1.

Table 1-1. System Analog Inputs

System AI

Point Number

Function

Point of

Origination

Normal Range

E1

Logic voltage

CPU

3.0 to 3.6

E2

Battery voltage

Backplane voltage

input connector P1

11.25 to 16 Volts dc

8 to 30 Volts dc

E3

Charge in voltage

CPU power input

0 to 18 Volts dc

8 to 30 Volts dc

E4

System milliAmps

CPU power input

E5

Board temperature

CPU

–40 to 85C (–40 to 185F)

For information on configuring alarms and System AI points, refer to

Chapter 7 in the ROCLINK 800 Configuration Software User Manual

(for FloBoss 107) (Form A6217).

1.6.3 Automatic Self Tests

The FB107 becomes active when input power with the proper polarity

and startup voltage (typically set greater than 8.0 volts) is applied to the

PWR+ / PWR connector (provided the power input fusing/protection is

Page 29

FloBoss 107 Flow Manager Instruction Manual

Revised May-2018 General Information 1-23

operational). The battery and logical voltage tests ensure that the FB107

is operating in the optimum mode.

The software arms the watchdog timer every scan period. If the timer is

not armed in 6 seconds, the software automatically resets.

1.6.4 Low Power Mode

Under pre-defined conditions, the FB107 uses a sleep mode to conserve

power.

During sleep mode, the CPU powers down, although I/O continues to

accumulate. The FB107 enters sleep mode after one minute of inactivity

on the communication ports. You can disable sleep mode, which ensures

that the FB107 stays awake all the time. You configure this option (which

is Disabled by default) on the Sleep Mode field on the CPU module’s

Advanced tab.

The FB107 wakes from sleep mode occurs when it receives either a:

▪ Timed interrupt from the real-time clock.

▪ Signal from one of the communication ports.

1.7 Flow Measurements

Gas and liquid calculation methods include:

▪ AGA and API Chapter 21 compliant for AGA linear and differential

meter types.

▪ AGA3 – Differential for gas.

▪ AGA7 – Pulse (ISO 9951) for gas.

▪ AGA8 – Compressibility for Detailed (ISO 12213-2), Gross I (ISO

12213-3), and Gross II for gas.

▪ ISO 5167 – Differential.

FB107 firmware completes full calculations every second on the

configured meter run (up to four) for AGA3, AGA7, AGA8, and ISO

5167.

Note: You must enable meter runs and adjust the number of available

meters (ROC > Information > Device Information screen >

Points tab, AGAs field) so that additional meter runs become

available. You can also optimize a system by disabling unused

meters or PIDs.

The primary function of the FB107 is to measure flow in accordance with

the 1992 American Petroleum Institute (API), International Standards

Organization (ISO), and American Gas Association (AGA) standards.

The primary inputs used for AGA3 flow measurement function are

differential pressure, static pressure, and temperature. The differential and

static pressure inputs are sampled once per second. The temperature

Page 30

FloBoss 107 Manager Instruction Manual

1-24 General Information Revised May-2018

input, which is sampled and linearized once per second, comes from an

RTD probe.

AGA3 calculations conform to the methods described in American Gas

Association Report No. 3, Orifice Metering of Natural Gas and Other

Related Hydrocarbon Fluids. Based on the second and third editions, the

calculation method is 1992 AGA3.

The primary inputs used for AGA7 flow measurement are pulse input (PI)

counts, static pressure, and temperature. The pulse input counts are

acquired from a rotary meter, turbine meter, or other pulse-generating

devices. The static pressure inputs come from the pressure transducers,

and the temperature input is read from an RTD probe. The AGA7

calculations conform to methods described in American Gas Association

Report No. 7, Measurement of Natural Gas by Turbine Meters (2006),

and use the AGA8 method for determining the compressibility factor.

The ISO5167-2003 firmware calculates gas flow. Measurement of fluid

flow occurs through pressure differential devices inserted in circular

cross-section pipes running full.

The AGA8 method calculates the compressibility factor based on the

physical chemistry of the component gasses at specified temperatures and

pressures.

1.8 Security Gateway

For enhanced data security when using an IP/Ethernet connection,

Remote Automation Solutions recommends adding an industrial router

with VPN and firewall security. Recommended solutions include the

MOXA EDR-810, the Hirschman Eagle One, or the Phoenix mGuard

rs4000 (or equivalents). An example of how to install one of these

devices to the RTU/flow computer can be found in the Remote

Automation Solutions MOXA® Industrial Secure Router Installation

Guide (part D301766X012). For further information, contact your Local

Business Partner or the individual vendor’s website.

Page 31

FloBoss 107 Flow Manager Instruction Manual

Revised May-2018 General Information 1-25

1.9 Additional Technical Information

Refer to the following documents (available at

www.EmersonProcess.com/Remote) for additional and most-current

information on each of the modules discussed in this chapter.

Table 1-2. Additional Technical Information

Name

Form Number

Part Number

ROCLINK 800 Configuration Software User Manual (for FloBoss 107)

A6217

D301249X012

FloBoss 107 Flow Manager

FB107

D301233X012

FloBoss 107 Firmware

FB107:FW1

D301235X012

FloBoss 107 Inputs and Outputs (I/O)

FB107:IO1

D301236X012

FloBoss 107 6-Point Analog Output / Discrete Output Module

FB107:AODO

D301637X012

FloBoss 107 HART Module

FB107:HART

D301639X012

FloBoss 107 Resistance Temperature Device (RTD) Module

FB107:RTD

D301465X012

FloBoss 107 Communication Modules

FB107:COM

D301237X012

FloBoss 107 Enhanced Communication Module

FB107:ECM

D301642X012

FloBoss 107 Dial-up Modem Module

FB107:DIAL

D301643X012

FloBoss 107 Multi-Variable Sensor (MVS)

FB107:MVS

D301239X012

FloBoss 107 Discrete Output Relay Module

FB107:DOR

D301466X012

FloBoss 107 8-Point AI/DI Module

FB107:AIDI

D301464X012

FloBoss 107E Enclosure Options

FB107:ENC

D301276X012

FloBoss 107 LCD Touchpad

FB107:LCD

D301241X012

FloBoss 107 Flow Manager LCD User Manual

A6241

D301258X012

Page 32

FloBoss 107 Manager Instruction Manual

1-26 General Information Revised May-2018

[This page is intentionally left blank.]

Page 33

FloBoss 107 Flow Manager Instruction Manual

Revised May-2018 Installation and Use 2-1

Chapter 2 – Installation and Use

In This Chapter