Remote Automation Solutions FB1100/FB1200 Flow Computer Battery Field Replacement Guide Manuals & Guides

Page 1

FB1100/FB1200 Flow Computer Battery Field Replacement Guide

FB1100/FB1200 Flow Computer

Battery

Field Replacement Guide

D301815X012

November 2020

For Part Numbers (Kits):

399103-01-5: Battery Pack (lithium)

399186-01-8: Battery Pack (lead acid)

399457-00-0: Battery Pack (lead acid - Enersys)

Remote Automation Solutions

Page 2

FB2100/FB2200 Flow Computer Battery Field Replacement Guide

D301815X012

November 2020

Device Safety Considerations

Reading these Instructions

Before operating the device, read these instructions carefully and understand their safety implications. In some situations,

improperly using this device may result in damage or injury. Keep this manual in a convenient location for future reference.

Note that these instructions may not cover all details or variations in equipment or cover every possible situation regarding

installation, operation, or maintenance. Should problems arise that are not covered sufficiently in the text, immediately

contact Customer Support for further information.

Protecting Operating Processes

A failure of this device – for whatever reason -- may leave an operating process without appropriate protection and could result

in possible damage to property or injury to persons. To protect against this, you should review the need for additional backup

equipment or provide alternate means of protection (such as alarm devices, output limiting, fail-safe valves, relief valves,

emergency shutoffs, emergency switches, etc.). Contact Remote Automation Solutions for additional information.

Returning Equipment

If you need to return any equipment to Remote Automation Solutions, it is your responsibility to ensure that the equipment

has been cleaned to safe levels, as defined and/or determined by applicable federal, state and/or local law regulations or

codes. You also agree to indemnify Remote Automation Solutions and hold Remote Automation Solutions harmless from any

liability or damage which Remote Automation Solutions may incur or suffer due to your failure to ensure device cleanliness.

Grounding Equipment

Ground metal enclosures and exposed metal parts of electrical instruments in accordance with OSHA rules and regulations as

specified in Design Safety Standards for Electrical Systems, 29 CFR, Part 1910, Subpart S, dated: April 16, 1981 (OSHA rulings are

in agreement with the National Electrical Code). You must also ground mechanical or pneumatic instruments that include

electrically operated devices such as lights, switches, relays, alarms, or chart drives.

Important: Complying with the codes and regulations of authorities having jurisdiction is essential to ensuring personnel

safety. The guidelines and recommendations in this manual are intended to meet or exceed applicable codes and regulations.

If differences occur between this manual and the codes and regulations of authorities having jurisdiction, those codes and

regulations must take precedence.

Protecting from Electrostatic Discharge (ESD)

This device contains sensitive electronic components which be damaged by exposure to an ESD voltage. Depending on the

magnitude and duration of the ESD, it can result in erratic operation or complete failure of the equipment. Ensure that you

correctly care for and handle ESD-sensitive components.

System Training

A well-trained workforce is critical to the success of your operation. Knowing how to correctly install, configure, program,

calibrate, and trouble-shoot your Emerson equipment provides your engineers and technicians with the skills and confidence

to optimize your investment. Remote Automation Solutions offers a variety of ways for your personnel to acquire essential

system expertise. Our full-time professional instructors can conduct classroom training at several of our corporate offices, at

your site, or even at your regional Emerson office. You can also receive the same quality training via our live, interactive

Emerson Virtual Classroom and save on travel costs. For our complete schedule and further information, contact the Remote

Automation Solutions Training Department at 800-338-8158 or email us at education@emerson.com.

Ethernet Connectivity

This automation device is intended to be used in an Ethernet network which does not have public access. The inclusion of this

device in a publicly accessible Ethernet-based network is

not recommended.

Page 3

FB1100/FB1200 Flow Computer Battery Field Replacement Guide

Main Battery Type

Used with Orig. Model

Spec Code(s)

Field Replacement Kit

Part Number

UL File Number for these kits: E192567

CPU Type

Lead Acid Battery Type

CPU and Charger Board

399381-01-0

CPU and Charger Board

399381-02-0

(for Enersys battery)

Supported

Removing/Replacing Batteries

Refer to the table below for the correct field replacement kit part number.

D301815X012

November 2020

Integral Battery Pack Unplugged” –

Lithium (FB1100 Flow Computer

only)

Integral Battery Pack – Lead Acid for

use with solar panel (Integral Solar

Panel (D5) for Class I Division 2 only)

D3 399103-01-5 (See page 3

of this guide for

replacement instructions)

D1, D4, D5 399186-01-8

399457-00-0 (Enersys

battery)

See page 7 of this guide

for replacement

instructions)

Important

When replacing one of the lead acid batteries, ensure your flow computer has the correct CPU and

charger board for the battery type. See the following compatibility chart:

Charger Board and Lead Acid Battery Compatibility

399186-01-8 Supported Not Supported

399457-00-0 (Enersys) Supported

Ambient Temperature Range

May be used up to a maximum ambient temperature of 80°C and a minimum ambient temperature

of –40°C; refer to the data plate attached to the device for ambient temperature.

Required Tools

#1 Phillips-head screwdriver

#2 Phillips-head screwdriver

Hexagonal torque wrenches with 3mm, #1, and #2 Phillips-head bits. Ranges must include 4

to 6 in-lbs (0.5 to 0.7 N-m), and 10 to 12 in-lbs (.1 to 1.4 N-m)

Important

Use only accessories (batteries)

for this flow computer.

certification.

supplied with the flow computer or sold by Emerson as spare parts

Substituting a part you obtain elsewhere (such as a battery) voids your

1

Page 4

FB1100/FB1200 Flow Computer Battery Field Replacement Guide

WARNING

WARNING

WARNING

DANGER

DANGER

D301815X012

November 2020

EXPLOSION HAZARD – Do not disconnect equipment unless power has been removed or the

area is known to be non-hazardous.

EXPLOSION HAZARD – Batteries must only be changed in an area known to be non-hazardous.

EXPLOSION HAZARD –There are no user-serviceable parts inside the battery pack. Do not open

the battery pack as you may damage the battery pack or injure yourself.

EXPLOSION HAZARD: Ensure the area in which you perform this operation is non-hazardous.

Performing this operation in a hazardous area could result in an explosion.

EXPLOSION HAZARD: Never remove end cap(s) in a hazardous location. Removing cover(s) in a

hazardous location could result in an explosion.

Note

Use these cells only in devices where servicing of the cell circuit and replacement of the lithium cells

will be done by a trained technician.

Important

If this equipment is used in a manner not specified by the manufacturer, the protection provided by

equipment may be impaired.

2

Page 5

FB1100/FB1200 Flow Computer Battery Field Replacement Guide

Removing/Replacing the Main Power Battery (Lithium Battery)

Periodically you must replace the main battery pack. FBxConnect provides a battery life indicator

showing the number of days of usage to help you monitor battery life. In addition, for lithium

batteries only, the Status LED shows yellow when the battery is low and needs to be replaced.

UL Listed Battery Field Installed Accessory Kit for use in Class I, Division 1, Groups C & D and Class I,

Division 2, Groups A, B, C, and D

Flow Computer Integral Lithium Battery Pack Field Installed Accessory Kit Part No. 399103-

01-5 for use with UL Listed Class I, Division 1, Groups C, and D and Class I, Division 2, Groups

A, B, C, and D Model Series FB1100

Battery Pack

D301815X012

November 2020

The device provides two battery connectors, enabling you to hot-swap the battery pack in a nonhazardous location.

Battery Pack (in Flow Computer)

3

Page 6

FB1100/FB1200 Flow Computer Battery Field Replacement Guide

WARNING

1

Screw

2

Retaining Clamp

3

Washer

D301815X012

November 2020

In the following procedure, you slide out the first battery pack (leaving it connected), attach the

new battery to the second (available) connector (so both batteries are connected), and then

disconnect the old battery pack.

Keep the replacement battery pack handy during the procedure.

EXPLOSION HAZARD – Batteries must only be changed in an area known to be non-hazardous.

See notices at the front of this document.

1. Remove the retaining clamp on the front end cap (if present) using a 3 mm hexagonal

wrench.

Components of Retaining Clamp Assembly

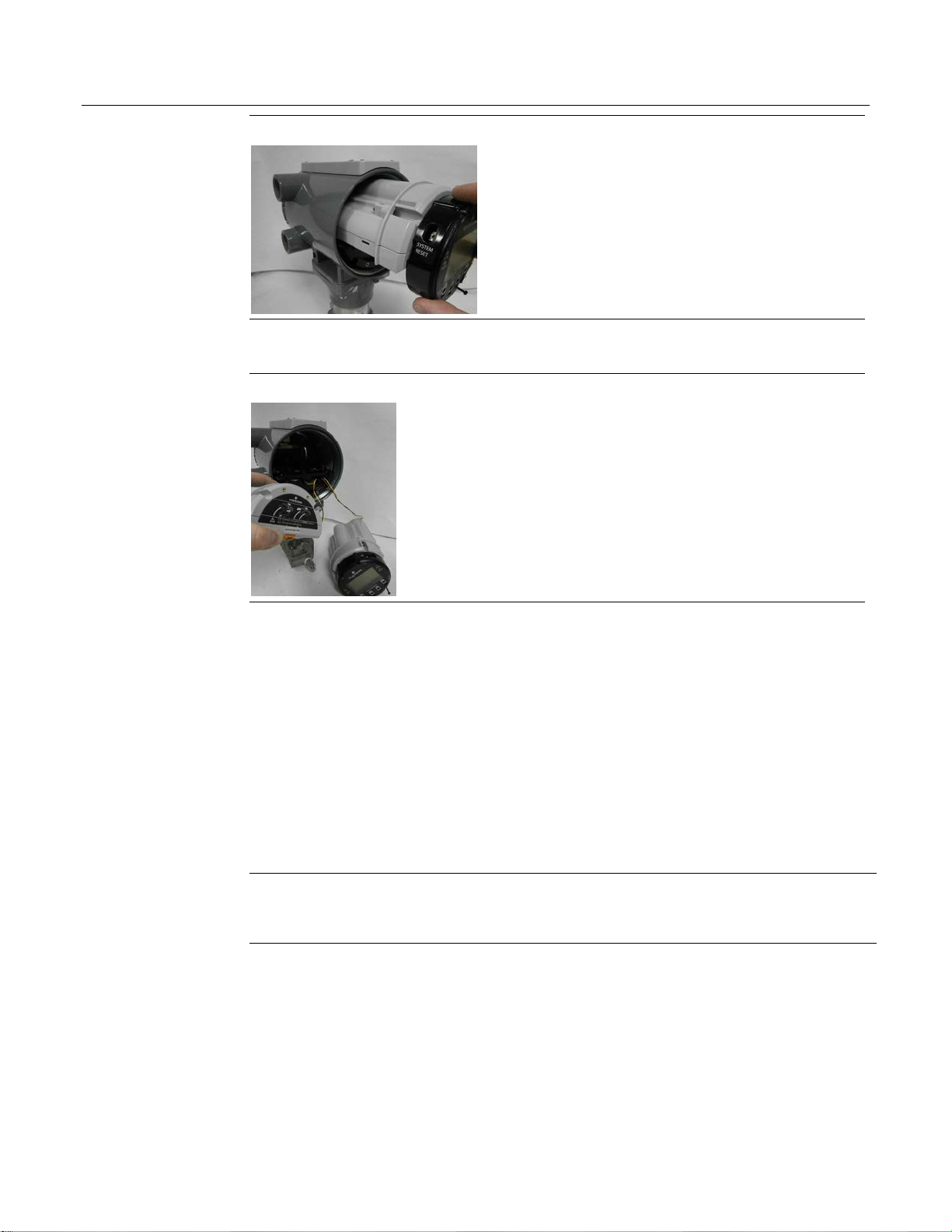

2. Grasp the end cap.

Front End Cap

3. Unscrew the end cap turning it counter-clockwise until the cover comes off. Set it aside in a

safe location.

Note

If you need more leverage, place a long screwdriver or other appropriate tool across the two

notches in the end cap to act as a pry bar.

4

Page 7

FB1100/FB1200 Flow Computer Battery Field Replacement Guide

D301815X012

November 2020

Front End Cap (unscrewed)

4. With a #2 Phillips-head screwdriver loosen the two captive fastening screws on the battery

pack.

Captive Screws

5. With a #1 Phillips-head screwdriver, loosen the two bottom captive fastening screws on the

HMI module. Leave the two top screws on the HMI module connected to the battery pack.

Captive Screws (loosened)

6. Grasp the HMI module and gently pull it and the battery pack out of the enclosure, leaving

the battery still connected.

5

Page 8

FB1100/FB1200 Flow Computer Battery Field Replacement Guide

D301815X012

November 2020

HMI Module (removed)

7. Connect the new battery to the open connector. Route the wires so they are in the recessed

area. Make sure the wires don’t get caught in the end cap threads.

Flow Computer (two batteries connected)

8. Disconnect the old battery pack’s connector from the unit and set the old battery pack aside.

9. Slide the new battery pack into the unit. Tighten its two captive fastening screws.

10. Loosen the top captive fastening screws on the HMI module to separate it from the old

battery pack.

11. Align the HMI module with the new battery pack and the tab on the CPU carrier bezel. Gently

press the HMI module on, being careful not to pinch the battery wires. Tighten all four

captive screws with a torque value of 4 to 6 in-lbs (0.5 to 0.7 N-m).

12. Carefully align the end cap threads with the threads of the enclosure and replace the front

end cap. Screw the end cap clockwise (eight full turns) until it is tightly sealed to the

enclosure. Endcaps must have at least 8 full threads engaged upon reassembly.

Note

If you need more leverage, place a long screwdriver or other appropriate tool across the two

notches in the end cap to act as pry bar.

13. If applicable, tighten the retaining clamp using the screw and washer onto the end cap using

a 3mm hexagonal wrench. When tightening, torque to 10 to 12 in-lbs (1.1 to 1.4 N-m).

6

Page 9

FB1100/FB1200 Flow Computer Battery Field Replacement Guide

Removing/Replacing the Main Power Battery (Lead Acid Battery)

Periodically you must replace the main battery pack. FBxConnect provides a battery life indicator

showing the number of days of usage to help you monitor battery life.

UL Listed Battery Field Installed Accessory Kit for use in Class I, Division 1, Groups C, and D, Class I,

Division 2, Groups A, B, C, and D

Flow Computer Integral Lead Acid Battery Pack Part No. 399186-01-8 for use with UL Listed

Class I, Division 1, Groups C & D, Class I, Division 2, Groups A, B, C, and D Model Series

FB1100 and FB1200.

Flow Computer Integral Lead Acid Battery Pack Part No. 399457-00-0 for use with UL Listed

Class I, Division 1, Groups C & D, Class I, Division 2, Groups A, B, C, and D Model Series

FB1100 and FB1200.

Battery Pack

D301815X012

November 2020

The device provides two battery connectors, enabling you to hot-swap the battery pack in a nonhazardous location.

7

Page 10

FB1100/FB1200 Flow Computer Battery Field Replacement Guide

WARNING

1

Screw

2

Retaining Clamp

3

Washer

D301815X012

November 2020

Battery Pack (in Flow Computer)

In the following procedure, you slide out the first battery pack (leaving it connected), attach the

new battery to the second (available) connector (so both batteries are connected), and then

disconnect the old battery pack.

Keep the replacement battery pack handy during the procedure.

EXPLOSION HAZARD – Batteries must only be changed in an area known to be non-hazardous.

See notices at the front of this document.

1. Remove the retaining clamp assembly on the front end cap (if present) using a 3 mm

hexagonal wrench.

Components of Retaining Clamp Assembly

8

2. Grasp the end cap.

Page 11

FB1100/FB1200 Flow Computer Battery Field Replacement Guide

D301815X012

November 2020

Front End Cap

3. Unscrew the end cap by turning it counter-clockwise until it comes off. Set the end cap aside

in a safe location.

Note

If you need more leverage, place a long screwdriver or other appropriate tool across the two

notches in the end cap to act as pry bar.

Front End Cap (unscrewed)

4. With a #2 Phillips-head screwdriver loosen the two captive fastening screws on the battery

pack.

Captive Screws

5. With a #1 Phillips-head screwdriver, loosen the two bottom captive fastening screws on the

HMI module. Leave the two top screws on the HMI module connected to the battery pack.

9

Page 12

FB1100/FB1200 Flow Computer Battery Field Replacement Guide

D301815X012

November 2020

Captive Screws (loosened)

6. Grasp the HMI module and gently pull it and the battery pack out of the enclosure, leaving

the battery still connected.

HMI Module (removed)

7. Connect the new battery to the open connector. Route the wires so they are in the recessed

area. Make sure the wires don’t get caught in the end cap threads.

Flow Computer (two batteries connected)

8. Disconnect the old battery pack’s connector from the unit and set the old battery pack aside.

9. Slide the new battery pack into the unit. Tighten its two captive fastening screws.

10

10. Loosen the top captive fastening screws on the HMI module to separate it from the old

battery pack.

11. Align the HMI module with the new battery pack and the tab on the CPU carrier bezel. Gently

press the HMI module on, being careful not to pinch the battery wires. Tighten all four

captive screws with a torque value of 4 to 6 in-lbs (0.5 to 0.7 N-m).

Page 13

FB1100/FB1200 Flow Computer Battery Field Replacement Guide

D301815X012

November 2020

12. When replacing the end cap, carefully align the end cap threads with the threads of the

enclosure and replace the front end cap. Screw the end cap clockwise (eight full turns) until it

is tightly sealed to the enclosure. End caps must have at least 8 full threads engaged upon

reassembly.

Note

If you need more leverage, place a long screwdriver or other appropriate tool across the two

notches in the end cap to act as a pry bar.

13. If applicable, tighten the retaining clamp using the screw and washer onto the end cap using

a 3mm hexagonal wrench. When tightening, torque to 10 to 12 in-lbs (1.1 to 1.4 N-m).

11

Page 14

FB1100/FB200 Flow Computer Battery Field Replacement Guide

For customer service and technical support,

Global Headquarters,

North America, and Latin America:

end-user.

Europe:

Middle East/Africa:

Asia-Pacific:

T +65 6777 8211| F +65 6777 0947

D301815X012

November 2020

visit www.Emerson.com/SupportNet

Emerson Automation Solutions

Remote Automation Solutions

6005 Rogerdale Road

Houston, TX 77072 U.S.A.

T +1 281 879 2699 | F +1 281 988 4445

www.Emerson.com/RemoteAutomation

Emerson Automation Solutions

Remote Automation Solutions

Unit 1, Waterfront Business Park

Dudley Road, Brierley Hill

Dudley DY5 1LX UK

T +44 1384 487200 | F +44 1384 487258

Emerson Automation Solutions

Remote Automation Solutions

Emerson FZE

P.O. Box 17033

Jebel Ali Free Zone – South 2

Dubai U.A.E.

T +971 4 8118100 | F +971 4 8865465

Emerson Automation Solutions

Remote Automation Solutions

1 Pandan Crescent

Singapore 128461

© 2018-2020 Remote Automation Solutions, a business unit of Emerson Automation

Solutions. All rights reserved.

This publication is for informational purposes only. While every effort has been made to ensure

accuracy, this publication shall not be read to include any warranty or guarantee, express or

implied, including as regards the products or services described or their use or applicability.

Remote Automation Solutions (RAS) reserves the right to modify or improve the designs or

specifications of its products at any time without notice. All sales are governed by RAS terms

and conditions which are available upon request. RAS accepts no responsibility for proper

selection, use or maintenance of any product, which remains solely with the purchaser and/or

Remote Automation Solutions

Loading...

Loading...