Page 1

Emerson FBxRemote I/O™

Quick Start Guide

Emerson FBxRemote I/O Quick Start Guide

D301902X012

April 2021

Remote Automation Solutions

Page 2

Emerson FBxRemote I/O Quick Start Guide

D301902X012

April 2021

Device Safety Considerations

Reading these Instructions

Before operating the device, read these instructions carefully and understand their safety implications. In some

situations, improperly using this device may result in damage or injury. Keep this manual in a convenient location

for future reference. Note that these instructions may not cover all details or variations in equipment or cover every

possible situation regarding installation, operation, or maintenance. Should problems arise that are not covered

sufficiently in the text, immediately contact Customer Support for further information.

Protecting Operating Processes

A failure of this device – for whatever reason -- may leave an operating process without appropriate protection and

could result in possible damage to property or injury to persons. To protect against this, you should review the

need for additional backup equipment or provide alternate means of protection (such as alarm devices, output

limiting, fail-safe valves, relief valves, emergency shutoffs, emergency switches, etc.). Contact Remote

Automation Solutions for additional information.

Returning Equipment

If you need to return any equipment to Remote Automation Solutions, it is your responsibility to ensure that the

equipment has been cleaned to safe levels, as defined and/or determined by applicable federal, state and/or local

law regulations or codes. You also agree to indemnify Remote Automation Solutions and hold Remote Automation

Solutions harmless from any liability or damage which Remote Automation Solutions may incur or suffer due to

your failure to ensure device cleanliness.

Grounding Equipment

Ground metal enclosures and exposed metal parts of electrical instruments in accordance with relevant safety

standards. For the USA, refer to OSHA rules and regulations as specified in Design Safety Standards for Electrical

Systems, 29 CFR, Part 1910, Subpart S, dated: May 16, 1981 (OSHA rulings are in agreement with the National

Electrical Code). For international locations, refer to

You must also ground mechanical or pneumatic instruments that include electrically operated devices such as

lights, switches, relays, alarms, or chart drives. The FB3000 includes a chassis ground lug. Unless specifically noted,

the chassis ground is isolated from ground terminals on individual modules installed in the device to prevent noise.

The chassis ground lug provides a path to earth ground for electrical safety, static discharge, and stray voltages.

not connect the chassis ground lug directly to a lightning arrestor/lightning rod.

Important: Complying with the codes and regulations of authorities having jurisdiction is essential to ensuring

personnel safety. The guidelines and recommendations in this manual are intended to meet or exceed applicable

codes and regulations. If differences occur between this manual and the codes and regulations of authorities

having jurisdiction, those codes and regulations must take precedence.

Protecting from Electrostatic Discharge (ESD)

This device contains sensitive electronic components which can be damaged by exposure to an ESD voltage.

Depending on the magnitude and duration of the ESD, it can result in erratic operation or complete failure of the

equipment. Ensure that you correctly care for and handle ESD-sensitive components.

System Training

A well-trained workforce is critical to the success of your operation. Knowing how to correctly install, configure,

program, calibrate, and trouble-shoot your Emerson equipment provides your engineers and technicians with the skills

and confidence to optimize your investment. Remote Automation Solutions offers a variety of ways for your personnel

to acquire essential system expertise. Our full-time professional instructors can conduct classroom training at several of

our corporate offices, at your site, or even at your regional Emerson office. You can also receive the same quality

training via our live, interactive Emerson Virtual Classroom and save on travel costs. For our complete schedule and

further information, contact the Remote Automation Solutions Training Department at 800-338-8158 or email us at

education@emerson.com

IEC 60364-4-41: PROTECTION AGAINST ELECTRIC SHOCK.

Do

.

Ethernet Connectivity

This automation device is intended to be used in an Ethernet network which does not have public access. The inclusion

of this device in a publicly accessible Ethernet-based network is

not recommended.

ii

Page 3

Emerson FBxRemote I/O Quick Start Guide

D301902X012

April 2021

Contents

Safety First! ................................................................................................................................................ 1

Required Tools ........................................................................................................................................... 2

Mounting on the DIN Rail ............................................................................................................................ 2

Grounding the FBxRemote I/O™ ................................................................................................................. 3

Removing Battery Saver Tabs ..................................................................................................................... 4

Wiring Communications ............................................................................................................................. 5

Wiring I/O ................................................................................................................................................. 11

Wiring Power ............................................................................................................................................ 16

Installing Field Tools Configuration Software ............................................................................................ 16

Establishing a Connection and Configuring Remote I/O ............................................................................ 18

Connecting to the FBxRemote I/O ............................................................................................................ 18

Configuring the IP Address and DNP3 Address of the Remote I/O ............................................................. 20

Example - Configuring I/O in the FBxRemote I/O ....................................................................................... 22

Example – Transferring Data from the FBxRemote I/O to the Host RTU ..................................................... 25

iii

Page 4

Emerson FBxRemote I/O Quick Start Guide

D301902X012

April 2021

iv

Page 5

DANGER

WARNING

CAUTION

SAFETY FIRST

Safety First!

Notes

If the equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

Wiring to or from this device, which either enters or leaves the user-provided enclosure,

must adhere to wiring methods suitable for Class I, Zone 2 and Division 2 Hazardous

locations, as appropriate for the installation.

This product may display safety label(s) to identify potential hazards. The same types of notices

appear within the documentation. Whenever you see an exclamation point (!) enclosed within a

triangle (shown to the left), consult the documentation for additional safety information about the

hazard and how to avoid it. The labels used are:

Emerson FBxRemote I/O Quick Start Guide

D301902X012

March 2021

MAY CAUSE DEATH

Observe all precautionary signs posted on the equipment.

Failure to do so may result in death or serious injury to personnel.

DANGER TO PERSONNEL AND EQUIPMENT

Observed all precautionary signs posted on the equipment.

Failure to do so may result in injury to personnel or cause damage to the equipment.

MAY CAUSE INJURY TO PERSONNEL OR DAMAGE EQUIPMENT

Observed all precautionary signs posted on the equipment.

Failure to do so may result in injury to personnel or cause damage to the equipment.

General instructions and safety reminders.

1

Page 6

Emerson FBxRemote I/O Quick Start Guide

Tool

Use

For chassis ground lug, panel installation, removal of rear

Magnets

For removing battery

Non-metallic tool

For removing battery

Laptop PC running Field Tools with FBxConnect

1

Upper tab retracts DIN rail clips

2

Lower tab extends DIN rail clips they snap back into place

D301902X012

March 2021

Required Tools

Certain tools and equipment are required for installing and servicing the RTU:

Table 1: Required Tools

#2 Phillips screwdriver

¼ “slotted blade screwdriver For removing personality modules l

configuration software

Mounting on the DIN Rail

The back of RTU chassis includes a removeable mounting plate with a slot for DIN-rail mounting,

using either 7.5 or 15 mm DIN rails.

panel.

For software configuration

Chassis Mounting

2

Page 7

Emerson FBxRemote I/O Quick Start Guide

Grounding the FBxRemote I/O™

The FBxRemote I/O rack includes a chassis ground lug to the left of the power supply modules.

D301902X012

March 2021

Location of Chassis Ground Lug

Once you have installed the unit, run a ground wire (14 AWG protective conductor)

between the ground lug and a known good earth ground.

Use stranded copper wire to earth ground and keep the length as short as possible.

Clamp or braze the ground wire to the ground bed conductor (typically a stranded copper

AWG 0000 cable installed vertically or horizontally).

Run the ground wire so that any routing bend in the cable has a minimum radius of 30.48

cm (12 inches) below ground and 20.32 cm (8 inches) above ground.

If using one or more extension chassis for additional I/O capacity, ground each chassis

individually.

For more information on grounding or if your installation uses cathodic protection, refer to Site

Considerations for Equipment Installation, Grounding, and Wiring (D301452X012).

3

Page 8

Emerson FBxRemote I/O Quick Start Guide

D301902X012

March 2021

Removing Battery Saver Tabs

When you are ready to install the rack and place it into operation, you must remove the battery

saver tabs for the SRAM coin cell batteries. Each power module, as well as the CPU, has a similar

tab.

Grasp the tab on the “REMOVE BEFORE USE” label and pull the tab straight out.

Battery Saver Tab

4

Page 9

1

RS-232 port on device

2

Connect cable shields to suitable Instrument Earth connection point

Wiring Communications

The communication ports allow you to connect to a PC or laptop running FBxConnect software or

to other devices. Regardless of the interface standard [RS-232, RS-485 (4-wire), or RS-485 (2wire)], you must use FBxConnect to configure the port for proper usage.

refer to RS-485 (4-wire) as RS-422.

Serial Ports

Emerson FBxRemote I/O Quick Start Guide

D301902X012

March 2021

Note: Older standards

COM1 Configured as RS-232

5

Page 10

Emerson FBxRemote I/O Quick Start Guide

1

RS-485 (4-wire) port on device

2

Connect cable shields to suitable Instrument Earth connection point

1

RS-485 (2-wire) port on device

2

Connect cable shields to suitable Instrument Earth connection point

D301902X012

March 2021

COM1 Configured as RS-485 (4-wire)

COM1 Configured as RS-485 (2-wire)

6

Page 11

Emerson FBxRemote I/O Quick Start Guide

1

RS-485 port on device

2

Connect cable shields to suitable Instrument Earth connection point

1

RS-485 (4-wire) port on device

2

Connect cable shields to suitable Instrument Earth connection point

D301902X012

March 2021

COM2 Configured as RS-232

COM2 Configured as RS-485 (4-wire)

7

Page 12

Emerson FBxRemote I/O Quick Start Guide

1

RS-485 (2-wire) port on device

2

Connect cable shields to suitable Instrument Earth connection point

1

Enable AC termination using switch

2

RS-485 bus, twisted pair required

3

Connect cable shields to suitable Instrument Earth connection point

D301902X012

March 2021

COM2 Configured as RS-485 (2-wire)

COM3 Configured as RS-485 (2-wire)

8

Page 13

Emerson FBxRemote I/O Quick Start Guide

1

Enable AC termination using switch

2

RS-485 bus, twisted pair required

3

Connect cable shields to suitable Instrument Earth connection point

D301902X012

March 2021

COM4 Configured as RS-485 (2-wire)

9

Page 14

Emerson FBxRemote I/O Quick Start Guide

1

Ethernet Port 1

2

Ethernet Port 2

3

Micro A-B USB Port

D301902X012

March 2021

Ethernet and Micro USB Ports

Located on the top of the CPU module, the two Ethernet ports are standard 8-pin 10/100Base-T RJ 45 8P8C sockets. The Micro A-B USB connector is located on the front of the module. The Micro A-B

USB connector is compatible with either Micro A USB or Micro B USB plugs, but

with Micro C plugs. You can use the Micro A-B USB port for DNP3 slave communications. When

configuring the USB port, ignore baud rate and other settings; simply choose the correct COM port

and communicate as if using one of the serial ports.

is not compatible

Location of Ethernet and USB Ports

10

Page 15

1

External Voltage Source

2

External Current Source

3

Power Supply 30VDC Max

Wiring I/O

You can individually configure AI/DI/PI1 through AI/DI/PI8 as analog inputs (AI), digital inputs (DI),

or pulse inputs (PI).

Analog Input (AI)

AI Wiring Using 1–5 Vdc or 4–20 mA

Emerson FBxRemote I/O Quick Start Guide

D301902X012

March 2021

11

Page 16

Emerson FBxRemote I/O Quick Start Guide

1

External Current Source

D301902X012

March 2021

AI Wiring Using Loop Power

Analog Output (AO)

AO Wiring

12

Page 17

Emerson FBxRemote I/O Quick Start Guide

1

Power Supply 30VDC Max

2

50 mA load max field device

3

Low side switch - internal

4

Suppression diodes- only one required. Recommended placement is across inductive load.

5

Relay coil or inductive load

D301902X012

March 2021

Digital Input (DI)

DI Wiring (internal pull-up enabled)

Digital Output (DO)

DO Wiring: Low Side Internal Switch

When installing the diode, ensure correct polarity.

13

Page 18

Emerson FBxRemote I/O Quick Start Guide

1

50 mA load max field device

2

High Side Switch - INTERNAL

1

500 mA load max field device

2

30VDC Max Power Supply

3

DOHI_1/DOLO_1 configured as an external low side switch (LSS)

4

DOHI_2/DOLO_2 configured as an external high side switch (HSS)

D301902X012

March 2021

Digital Output (DO) Wiring –High Side Internal Switch with 24V Loop Supply

Digital Output (DO) Wiring –Dry Contact Closure

14

Page 19

Emerson FBxRemote I/O Quick Start Guide

1

500 mA load max field device

1

External Device (Because no power supply, requires internal pull-up to be enabled.)

2

External Device

3

30VDC Max Power Supply

4

Control signal

D301902X012

March 2021

Digital Output (DO) Wiring – Contact Closure using 24V Loop Supply

Pulse Input (PI)

Pulse Input (PI) Wiring

15

Page 20

Emerson FBxRemote I/O Quick Start Guide

1

Input power from external power supply (power for RTU)

2

Loop power from external power supply (power for field devices)

D301902X012

March 2021

Wiring Power

DANGER

EXPLOSION HAZARD: Ensure the area in which you perform this option is non-hazardous.

Performing this operation in a hazardous location could result in an explosion.

The device supports both 12V and 24V power supplies. It accepts DC voltage from 10.5 to 30V; the

amount of power required varies depending upon the options used.

Controller power powers the RTU; field power can power attached field devices.

External Power Connections

Note If using extension chassis, only wire power to the base chassis.

Installing Field Tools Configuration Software

To configure the device, you install Field Tools 3.x software (which includes FBxConnect) on your

PC.

Important

Field Tools (including FBxConnect) is available as a free software download to registered

SupportNet

24 hours to process, so plan accordingly.

If installing TechView, close all other programs down before you begin installation. In

particular Office 365 components must be closed because they can interfere with the Field

Tools installer.

Field Tools cannot reside on a computer running any component of OpenEnterprise 2.x,

OpenEnterprise 3.x, OpenEnterprise Client/Server, or ObjectServer software.

16

users. If you are not a registered SupportNet user, new accounts take up to

Page 21

Emerson FBxRemote I/O Quick Start Guide

D301902X012

March 2021

TechView and other components of BSI_Config software cannot be installed on a

computer running OpenBSI Network Edition versions older than 5.9 Service Pack 2.

You must have administrative privileges to install Field Tools.

You must disable User Account Control (UAC) prior to installing Field Tools (you can re-

enable it after a successful installation).

As part of the installation, software from both Eltima and MACTek® is automatically installed.

Depending upon your permissions, Windows may require you to confirm these installations

before the installation can proceed.

1. Right click on the installer file and choose Run as administrator from the pop-up menu.

2. Follow the on-screen instructions. For details on minimum hardware/software requirements

as well as more details on the installation steps see the Field Tools Quick Start Guide

(D301703X412).

Note

During Field Tools installation, you must select the FBx support including FBxConnect option.

If you purchased FBxDesigner, you should also select the

FBxDesigner -FBx Application

Development option.

3. After software installation re-boot, start Field Tools from either the Windows Start Programs

menu or (if you created it) from the desktop icon.

4. Log onto Field Tools.

Important

The very first time you login with Field Tools, use the default username of admin and leave

password field blank. Then assign a new password when prompted. See the Field Tools

the

Quick Start Guide (D301859X012) for any questions you have on changing default passwords

after installation.

17

Page 22

Emerson FBxRemote I/O Quick Start Guide

CAUTION

D301902X012

March 2021

Establishing a Connection and Configuring Remote I/O

When making multiple FBxConnect connections to the same device (as with a remote and a local

connection), be aware that the changes one connection makes to the device may not be

immediately visible to other connections and may even require the other connections to restart

FBxConnect before changes become visible. For example, simple changes (such as changes to

setpoints) may be immediately visible to all connections, but changing the number of meters,

configuring I/O, adding/deleting menu items, or other major configuration changes may require

re-establishing the connection using FBxConnect.

Important

The FBxRemote I/O rack provides extra I/O for an FB3000 RTU. During configuration you can

connect to it either through an Ethernet cable or a serial cable. When placed in service the FB3000

RTU host only communicates to the I/O rack using Ethernet.

You must configure an IP address and a DNP address for the FBxRemote I/O rack. Once this is done,

you can configure the I/O points and FBxNet™ connections either locally, or remotely through the

host RTU.

Connecting to the FBxRemote I/O

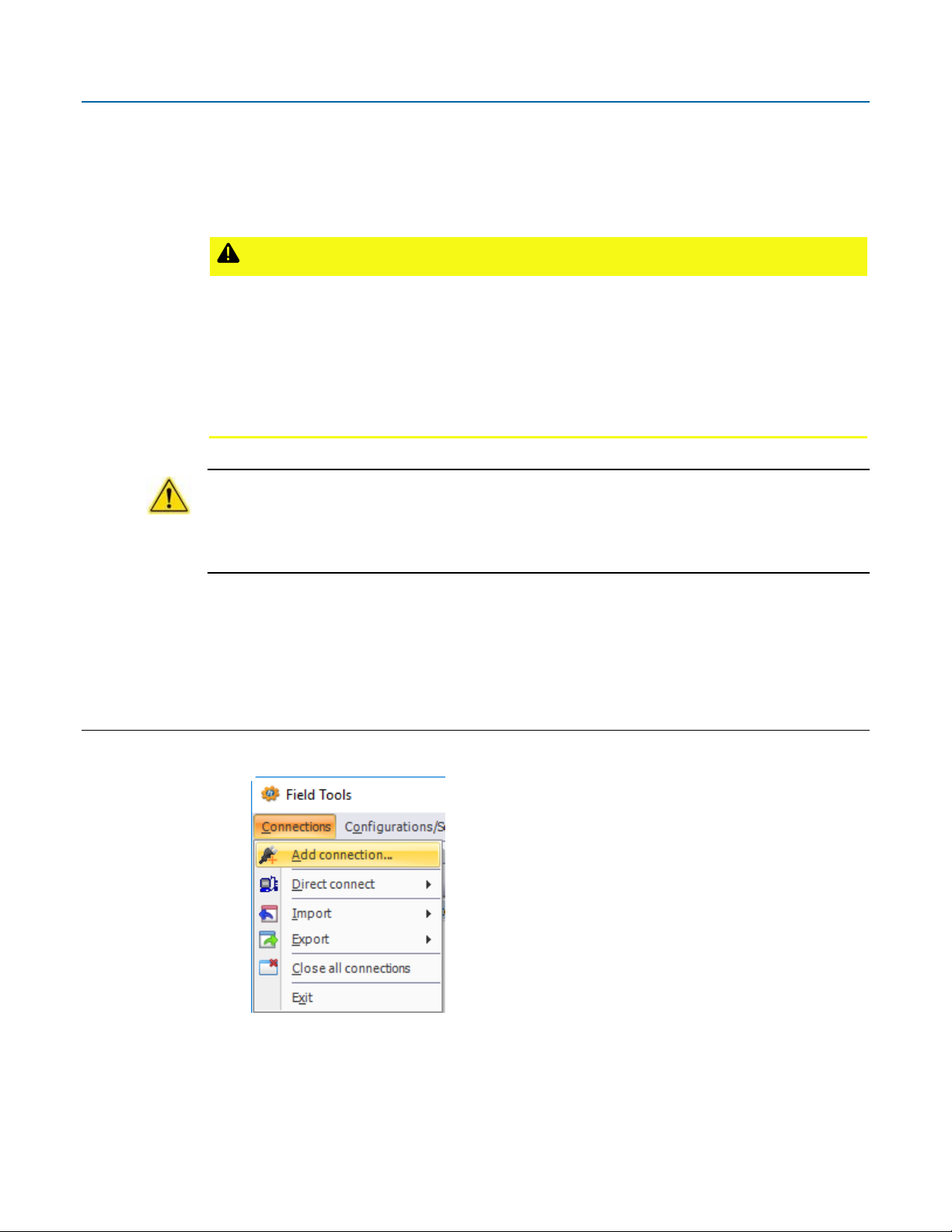

1. Click Connections > Add connection.

18

Page 23

Emerson FBxRemote I/O Quick Start Guide

D301902X012

March 2021

2. Choose FBx as the Device Platform.

3. Choose the Connection Type

For serial: choose the PC Comm port (or the port for the USB/serial adapter). COM 1

defaults to DNP3, 115200 BAUD, 8 data bits no parity 1 stop bit, RS‐232.

For IP: Enter the default IP Address for the Ethernet Port 1 of 192.168.1.10. (Your PC

must be able to access this address.)

WiFI: The FB3000 does not currently support WiFi.

4. Click Connect. Field Tools activates the connection and automatically launches the

FBxConnect tool.

5. If prompted, enter the Username and Password. Initially this is admin for both.

Important

When you finish initial configuration activities, be sure you

user

. Otherwise, anyone reading this document could gain access to your device.

cha nge the password for the admin

19

Page 24

Emerson FBxRemote I/O Quick Start Guide

D301902X012

March 2021

Configuring the IP Address and DNP3 Address of the Remote I/O

1. When FBxConnect opens, click Configure, then click Communications.

2. Click on the ports drop-down and select the Ethernet Port which the FBxRemote I/O rack will

use to communicate with its host RTU.

20

Page 25

Emerson FBxRemote I/O Quick Start Guide

D301902X012

March 2021

3. On the General tab for the Ethernet Port enter the IP address you want to use in the IPv4 IP

Address field, then click Save.

4. Click the DNP tab then specify the DNP address for the rack in the Flow Computer Address

field, then click

Save.

21

Page 26

Emerson FBxRemote I/O Quick Start Guide

D301902X012

March 2021

Example - Configuring I/O in the FBxRemote I/O

I/O in the FBxRemote I/O rack is configured the same way as you configure I/O in the FB3000 host

device. You can connect locally to the rack, as described in Connecting to the FBxRemote I/Oand run

FBxConnect to configure the I/O. This example, however, shows how to connect to the remote I/O

through the FB3000 host RTU.

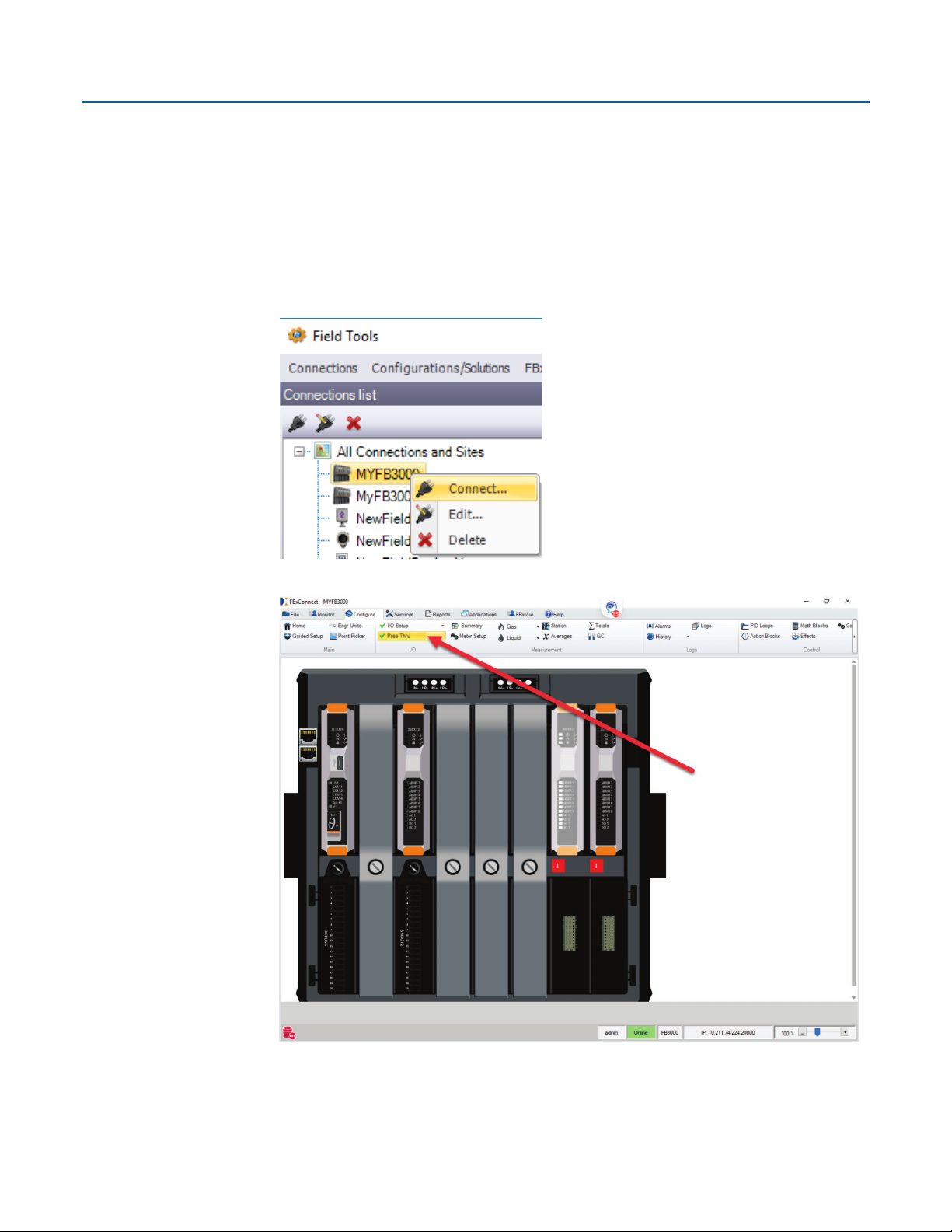

1. In Field Tools, launch an existing IP connection to the host FB3000 RTU.

2. When FBxConnect opens, click the Configure tab, then click Pass Thru.

22

Page 27

Emerson FBxRemote I/O Quick Start Guide

D301902X012

March 2021

3. When Pass Thru screen opens, select the rack you want to connect to (If there’s more

than one), enter the IP address of the rack in the

Rack IP Address field, then specify the

Rack DNP Address, then click Connect via Pass Thru.

4. You will notice that the FBxConnect ribbon changes to reflect only those options

available for the FBxRemote I/O rack.

5. You will notice that the FBxConnect ribbon changes to reflect only those options

available for the FBxRemote I/O rack. For this example, click the

choose

IO Setup > AI.

Configure tab and

23

Page 28

Emerson FBxRemote I/O Quick Start Guide

D301902X012

March 2021

6. You will notice that the FBxConnect ribbon changes to reflect only those options

available for the FBxRemote I/O rack. For this example, click the

choose

See the online help for information on I/O configuration and details of specific fields.

IO Setup > AI. You can now configure the AI as you would any AI in the host RTU.

Configure tab and

24

Page 29

Emerson FBxRemote I/O Quick Start Guide

D301902X012

March 2021

Example – Transferring Data from the FBxRemote

I/O to the Host RTU

You must configure FBxNet™ software for data transfer between the host RTU and the FBxRemote

I/O rack. FBxNet requires an Ethernet connection.

Note

Full details on FBxNet™ configuration are included in Chapter 4 of the Field Tools Quick Start Guide or

in Field Tools online help. This example shows how to transfer a single value from the rack to the

host RTU. if you are transferring large amounts of data, it may be easier to manually edit CSV files in

Excel or a text editor than use the steps shown here.

Before You Begin

Before you begin, you must have active Field Tools connections with both the FB3000 RTU and the

FBxRemote I/O rack.

Also, you must create an FBxNet user in each device that uses FBxNet. In this case, that means you

must create an FBxNet user in the FB3000 host RTU, and then create an identical FBxNet user in the

FBxRemote I/O rack. You create an FBxNet user within FbxConnect as follows:

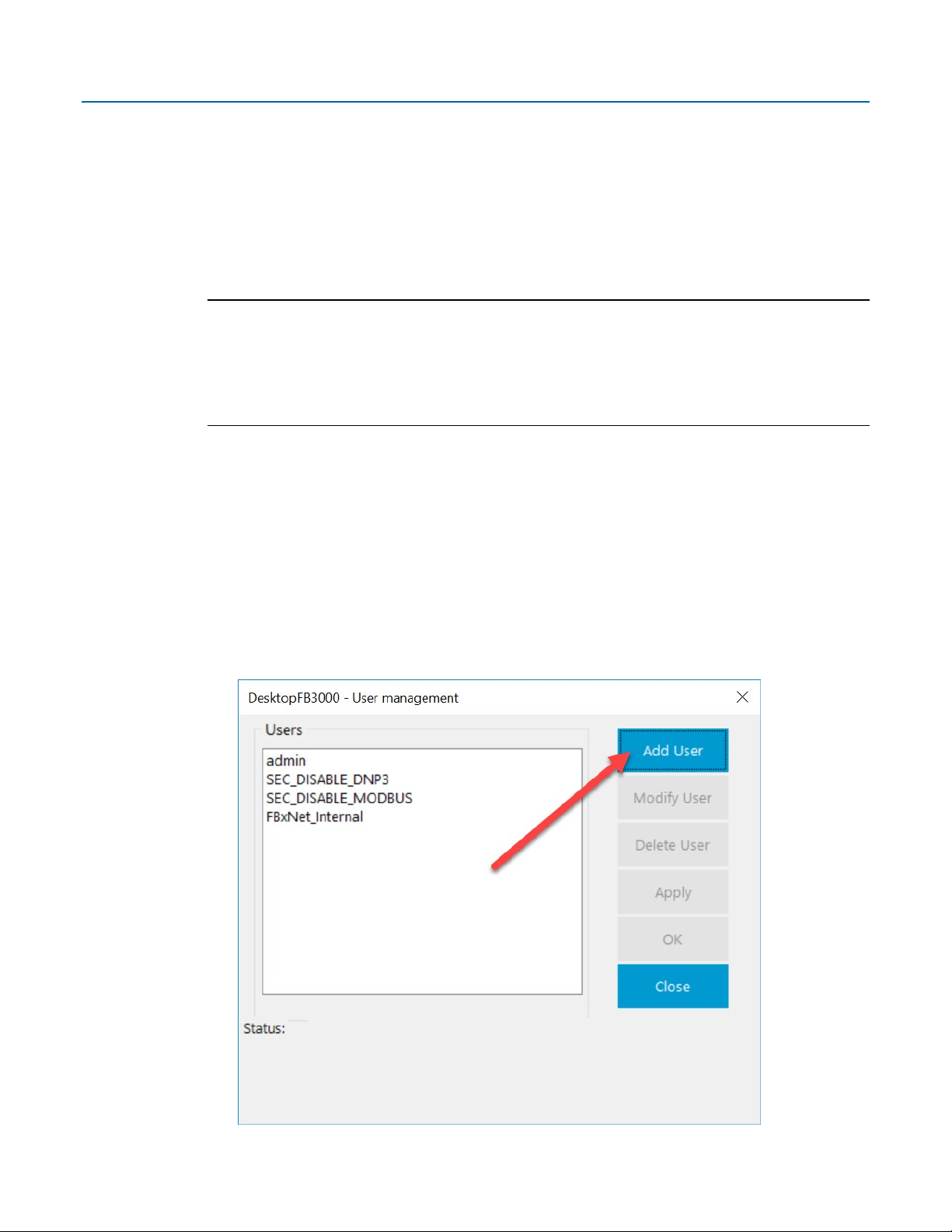

1. Click Services > User Management

2. In the User Management screen, click Add User

25

Page 30

Emerson FBxRemote I/O Quick Start Guide

D301902X012

March 2021

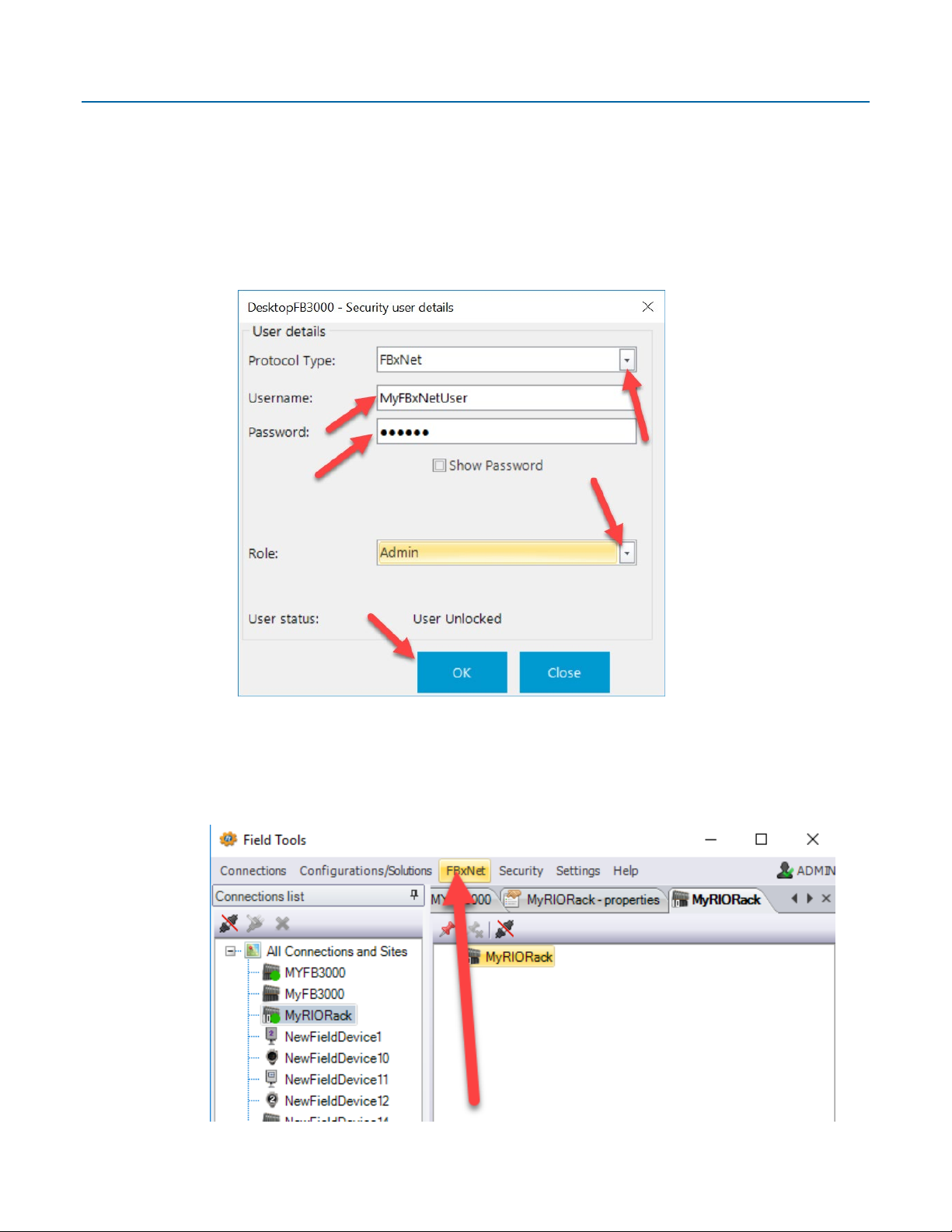

3. For the user details:

Select FBxNet as the Protocol Type.

Specify a Username and Password combination. All FBxNet users you define on your

network must share this same username/password combination.

Specify the Role for the user; Admin provides the most access; Auditor provides the

least access.

4. Click OK to save your changes, and OK to exit the User Management screen.

Configuring FBxNet to Transfer Data

1. In Field Tools, click FBxNet

26

Page 31

Emerson FBxRemote I/O Quick Start Guide

D301902X012

March 2021

2. In FBxNet, click the Add Site

I con.

3. This creates an icon for the site in the Subscriber List pane. Specify a Site Name (here we used

“CENTRAL” then check the box for specifying a designated device, and enter the

Designated

Device IP Address. For this example, this address is the IP port on the host FB3000 RTU that

communicates with the FBxRemote I/O rack. Click

Save when finished.

4. Now you’ll notice the site name gets added, and the name of the RTU you specified as the

designated device shows below it. (This name might not necessarily be the same name you use

in Field Tools, it’s the RTU name stored in the RTU.)

For the Subscriber Name and IP Address, enter the name and IP address of your FB3000 host

RTU. Then click

Add Publisher.

27

Page 32

Emerson FBxRemote I/O Quick Start Guide

D301902X012

March 2021

5. The publisher is your FBRIO rack so edit the Name field to make it the name of the FBxRemote

I/O rack and enter the

IP Address for the FBxRemote I/O rack.

28

Page 33

Emerson FBxRemote I/O Quick Start Guide

D301902X012

March 2021

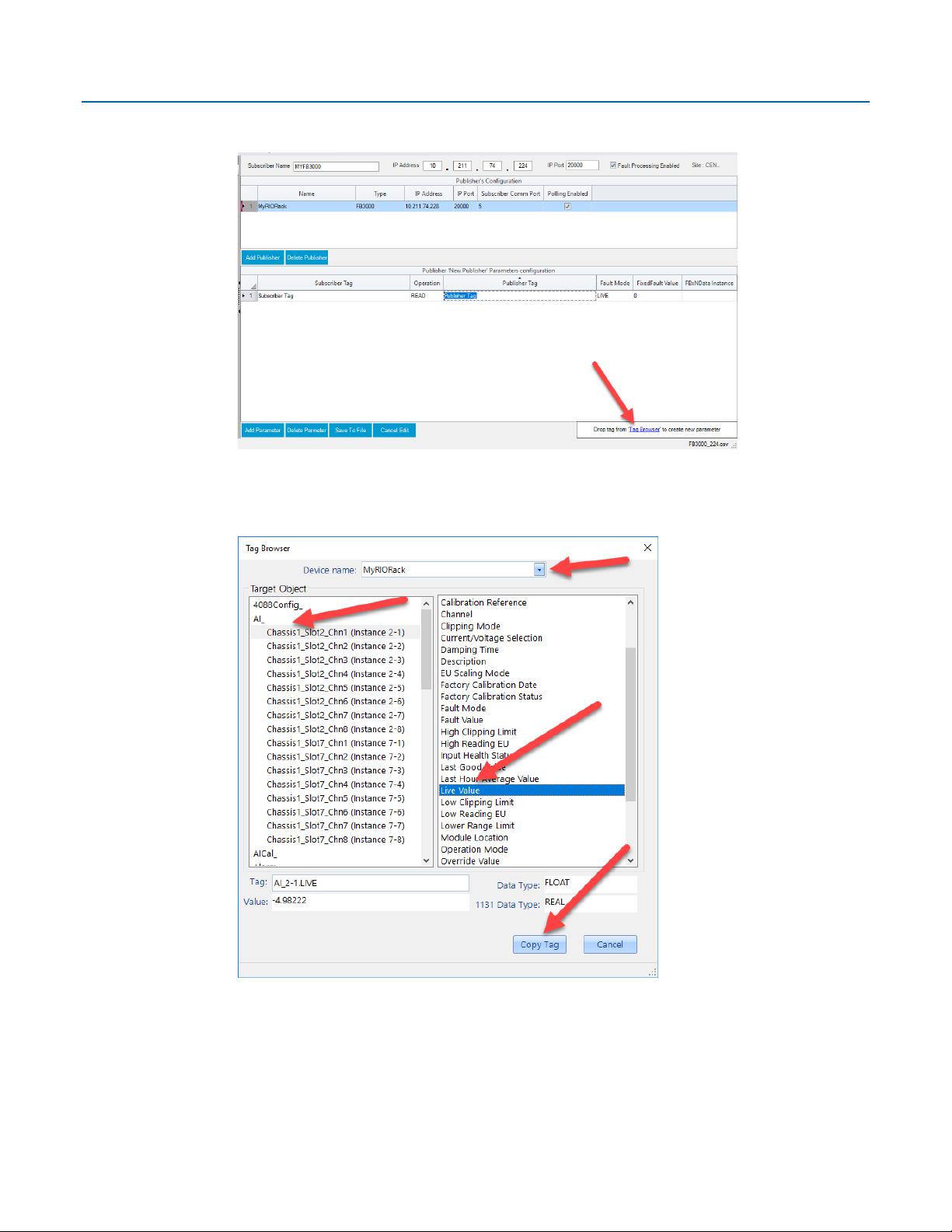

6. Click Add Parameter and a new line is added in the Publisher Parameters Configuration pane.

7. Click Tag Browser (or Open Tag Browser in the menu bar). Select the Device name (in this case

it’s your FBxRemote I/O rack), then choose the AI you want and its associated parameter (in

this case

Live Value) finally click Copy Tag.

29

Page 34

Emerson FBxRemote I/O Quick Start Guide

D301902X012

March 2021

8. In the Publisher Parameters Configuration pane, click in the Publisher Tag field, and right click

to paste in the tag you copied from the Tag Browser.

9. Now go back to the Tag Browser and select the Device name (in this case it’s your FB3000 host

RTU), then choose the destination parameter (in this case

PID Loop 1) then finally click

Copy Tag.

Primary Process Variable Input to

30

Page 35

Emerson FBxRemote I/O Quick Start Guide

D301902X012

March 2021

10. Now paste the copied tag into the Subscriber Tag field.

11. This completes the definition of the parameter. You can repeat this entire process for other

parameters you want to transfer. When finished, click

12. Now click File > Download files to update the CSV files in the subscriber(s). You’re done!

Save To File to save the CSV file.

31

Page 36

Emerson FBxRemote I/O Quick Start Guide

For customer service and technical support,

Global Headquarters,

North America, and Latin America:

end-user.

Europe:

Middle East/Africa:

Asia-Pacific:

T +65 6777 8211| F +65 6777 0947

D301902X012

April 2021

visit www.Emerson.com/SupportNet

Emerson Automation Solutions

Remote Automation Solutions

6005 Rogerdale Road

Houston, TX 77072 U.S.A.

T +1 281 879 2699 | F +1 281 988 4445

www.Emerson.com/RemoteAutomation

Emerson Automation Solutions

Remote Automation Solutions

Unit 1, Waterfront Business Park

Dudley Road, Brierley Hill

Dudley DY5 1LX UK

T +44 1384 487200

Emerson Automation Solutions

Remote Automation Solutions

Emerson FZE

P.O. Box 17033

Jebel Ali Free Zone – South 2

Dubai U.A.E.

T +971 4 8118100 | F +971 4 8865465

Emerson Automation Solutions

Remote Automation Solutions

1 Pandan Crescent

Singapore 128461

© 2021 Remote Automation Solutions, a business unit of Emerson Automation Solutions. All

rights reserved.

This publication is for informational purposes only. While every effort has been made to ensure

accuracy, this publication shall not be read to include any warranty or guarantee, express or

implied, including as regards the products or services described or their use or applicability.

Remote Automation Solutions (RAS) reserves the right to modify or improve the designs or

specifications of its products at any time without notice. All sales are governed by RAS terms

and conditions which are available upon request. RAS accepts no responsibility for proper

selection, use or maintenance of any product, which remains solely with the purchaser and/or

Remote Automation Solutions

Loading...

Loading...