Remote Automation Solutions Emerson FB3000 Remote Terminal Unit (RTU) Step-by-Step Separator Configuration Guide Manuals & Guides

Page 1

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Emerson FB3000 Remote Terminal Unit (RTU)

Step-by-Step Separator Configuration Guide

Contents i

Page 2

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Device Safety Considerations

Reading these Instructions

Before operating the device, read these instructions carefully and understand their safety implications.

In some situations, improperly using this device may result in damage or injury. Keep this manual in a

convenient location for future reference. Note that these instructions may not cover all details or

variations in equipment or cover every possible situation regarding installation, operation, or

maintenance. Should problems arise that are not covered sufficiently in the text, immediately contact

Customer Support for further information.

Protecting Operating Processes

A failure of this device – for whatever reason -- may leave an operating process without appropriate protection and

could result in possible damage to property or injury to persons. To protect against this, you should review the

need for additional backup equipment or provide alternate means of protection (such as alarm devices, output

limiting, fail-safe valves, relief valves, emergency shutoffs, emergency switches, etc.). Contact Remote

Automation Solutions for additional information.

Returning Equipment

If you need to return any equipment to Remote Automation Solutions, it is your responsibility to ensure that the

equipment has been cleaned to safe levels, as defined and/or determined by applicable federal, state and/or local

law regulations or codes. You also agree to indemnify Remote Automation Solutions and hold Remote Automation

Solutions harmless from any liability or damage which Remote Automation Solutions may incur or suffer due to

your failure to ensure device cleanliness.

Grounding Equipment

Ground metal enclosures and exposed metal parts of electrical instruments in accordance with OSHA rules and

regulations as specified in Design Safety Standards for Electrical Systems, 29 CFR, Part 1910, Subpart S, dated: April

16, 1981 (OSHA rulings are in agreement with the National Electrical Code). You must also ground mechanical or

pneumatic instruments that include electrically operated devices such as lights, switches, relays, alarms, or chart

drives.

Important: Complying with the codes and regulations of authorities having jurisdiction is essential to ensuring

personnel safety. The guidelines and recommendations in this manual are intended to meet or exceed applicable

codes and regulations. If differences occur between this manual and the codes and regulations of authorities

having jurisdiction, those codes and regulations must take precedence.

Protecting from Electrostatic Discharge (ESD)

This device contains sensitive electronic components which be damaged by exposure to an ESD voltage.

Depending on the magnitude and duration of the ESD, it can result in erratic operation or complete failure of the

equipment. Ensure that you correctly care for and handle ESD-sensitive components.

System Training

A well-trained workforce is critical to the success of your operation. Knowing how to correctly install, configure,

program, calibrate, and trouble-shoot your Emerson equipment provides your engineers and technicians with the skills

and confidence to optimize your investment. Remote Automation Solutions offers a variety of ways for your personnel

to acquire essential system expertise. Our full-time professional instructors can conduct classroom training at several of

our corporate offices, at your site, or even at your regional Emerson office. You can also receive the same quality

training via our live, interactive Emerson Virtual Classroom and save on travel costs. For our complete schedule and

further information, contact the Remote Automation Solutions Training Department at 800-338-8158 or email us at

education@emerson.com

.

Contents ii

Page 3

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Contents

Chapter 1. Introduction 1

1.1 FB3000 RTU ............................................................................................................................................ 1

1.1.1 Solutions ...................................................................................................................................... 2

1.1.2 Applications ................................................................................................................................. 2

1.2 Demo Overview ...................................................................................................................................... 2

1.2.1 Demo Folders .............................................................................................................................. 2

1.2.2 I/O Points ..................................................................................................................................... 3

1.3 Field Tools ............................................................................................................................................... 3

1.3.1 FBxConnect.................................................................................................................................. 3

1.3.2 FBxDesigner ................................................................................................................................. 4

Chapter 2. Field Tools & Connecting to RTU 5

2.1 Starting Field Tools .................................................................................................................................. 5

2.2 Field Tools Overview ................................................................................................................................ 7

2.3 Connecting to the RTU ............................................................................................................................ 8

Chapter 3. FBxConnect 11

3.1 FBxConnect Overview............................................................................................................................ 11

3.2 Guided Setup ........................................................................................................................................ 12

3.2.1 IO Setup & Communications ...................................................................................................... 14

3.2.2 History & Summary .................................................................................................................... 29

3.3 Math Blocks ........................................................................................................................................... 30

3.3.1 Simulating Liquid Level .............................................................................................................. 31

3.3.2 Simulating Pressure ................................................................................................................... 35

3.4 Action Blocks & Effects .......................................................................................................................... 38

3.4.1 Simulating the High Level Switch ............................................................................................... 39

3.4.2 Simulating the Low Level Switch ................................................................................................ 40

3.5 PID Loops .............................................................................................................................................. 43

3.5.1 Controlling the Pressure ............................................................................................................. 44

Chapter 4. FBxDesigner 47

4.1 FBxDesigner Overview ........................................................................................................................... 47

4.2 Creating a Project .................................................................................................................................. 49

4.2.1 Creating an FBD Program ........................................................................................................... 51

4.2.2 Creating an FBD Block with ST .................................................................................................... 60

4.2.3 Tasks, Compiling & BootProject ................................................................................................. 65

Chapter 5. FBxVue 69

5.1 FBxVue Overview ................................................................................................................................... 69

5.2 Building a Display with FBxVue .............................................................................................................. 72

Chapter 6. Applications 91

Contents iii

Page 4

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Contents iv

Page 5

Emerson FB3000 Separator Configuration Guide

Release 1 - Core Equipment

Chapter 1. Introduction

This demo guide is an introductory exercise to familiarize you with the capabilities of the

FB3000 Remote Terminal Unit (RTU) and is organized into the following chapters:

Chapter 1: Introduction:

Provides an overview of theFB3000 RTU, this demo, and the required software.

Chapter2: Field Tools & Connecting to the RTU:

Details how to connect to the FB3000 using Field Tools.

Chapter 3: FBxConnect:

Describes how to set up meters and controls using the FBxConnect software.

Chapter 4: FBxDesigner:

Details how to create a control program using the FBxDesigner programming

environment.

Chapter 5: FBxVue

Details how to create user displays using the FBxVue display builder.

Chapter 6: Applications

Describes how to download and distribute the project and display as one packaged

application.

D301884X012

October 2019

1.1 FB3000 RTU

The Emerson FB3000 Remote Terminal Unit (RTU) runs measurement and control

applications suitable for oil and gas, water, wastewater, and other industrial processes. It

combines the ease-of-configuration of the Emerson ROC/FloBoss RTUs and the flexible

programmability of the Emerson ControlWave PLCs.

• 8 slot Chassis (CSA, ATEX, IEC Ex)

• 10.5-30Vdc Dual Power Supply

Cartridges

• 4 Serial + 1 USB Comm ports

• 2 independent Ethernet ports

• 32-bit Processor running at 792 MHz

• 256 MB flash storage for firmware &

reports

• 16 MB SRAM storage for historical data

• 1 GB DRAM execution memory

• Mixed I/O Card (8AI/DI/PI + 2AO + 2DO)

• Isolated Personality Modules (Terminal

Blocks)

• Hot-Swappable I/O

• Connectivity to 10 MVS per Comm port

Introduction 1

Page 6

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

1.1.1 Solutions

The configuration, control and communication data in the RTU are saved in a hierarchy of

folders called a solution (with a file type of .zsl). A solution may also include up to eight

applications. You use FBxConnect to modify, upload, or download solutions.

Note

It is a good practice to always save backups of your solutions.

1.1.2 Applications

Applications add extra functionality to the FB3000. An application consists of a project

created in FBxDesigner and can include multiple displays built with FBxVue. Each

application runs in its own task and can be independently added, removed, started, or

stopped.

1.2 Demo Overview

In this demo you use an FB3000 to simulate and control a two-phase separator, including

the measurement of the outlet gas and liquid streams.

The gas is measured with a DP meter using API 21.1-compliant AGA 3 flow calculations

while the liquid is measured with a linear turbine meter. The liquid level of the separator is

measured by a guided wave radar device and monitored by high- and low-level switches. A

control valve on top of the separator regulates the gas flow to control pressure and a

control valve on the bottom of the separator regulates the liquid to control the liquid level.

During normal operation, a PID controls the gas control valve to maintain the pressure at a

setpoint. The liquid level control valve opens when the high-level switch activates and

closes when the low-level switch activates.

You use FBxConnect to build the FB3000’s standard configuration, which includes IO

configuration, meter set-up, and controls for the simulation of the separator;

to build a program that opens and closes the liquid control valve; and FBxVue to build a

user display that includes a graphic of the separator liquid level, a gauge for the pressure,

and the status of the control valves and meters.

1.2.1 Demo Folders

This demo contains the following folders:

Application:

Contains the Level_Control.zap file which is the packaged application created in this

demo, containing the FBxDesigner project and the FBxVue display.

Display:

Contains the Separator Display.xml file which is the FBxVue display created in this

demo, and an images folder with the Sep_icon_2.png image used in the display.

Documentation:

Contains this document, as well as a slideshow and video version.

FBxDesigner

2 Introduction

Page 7

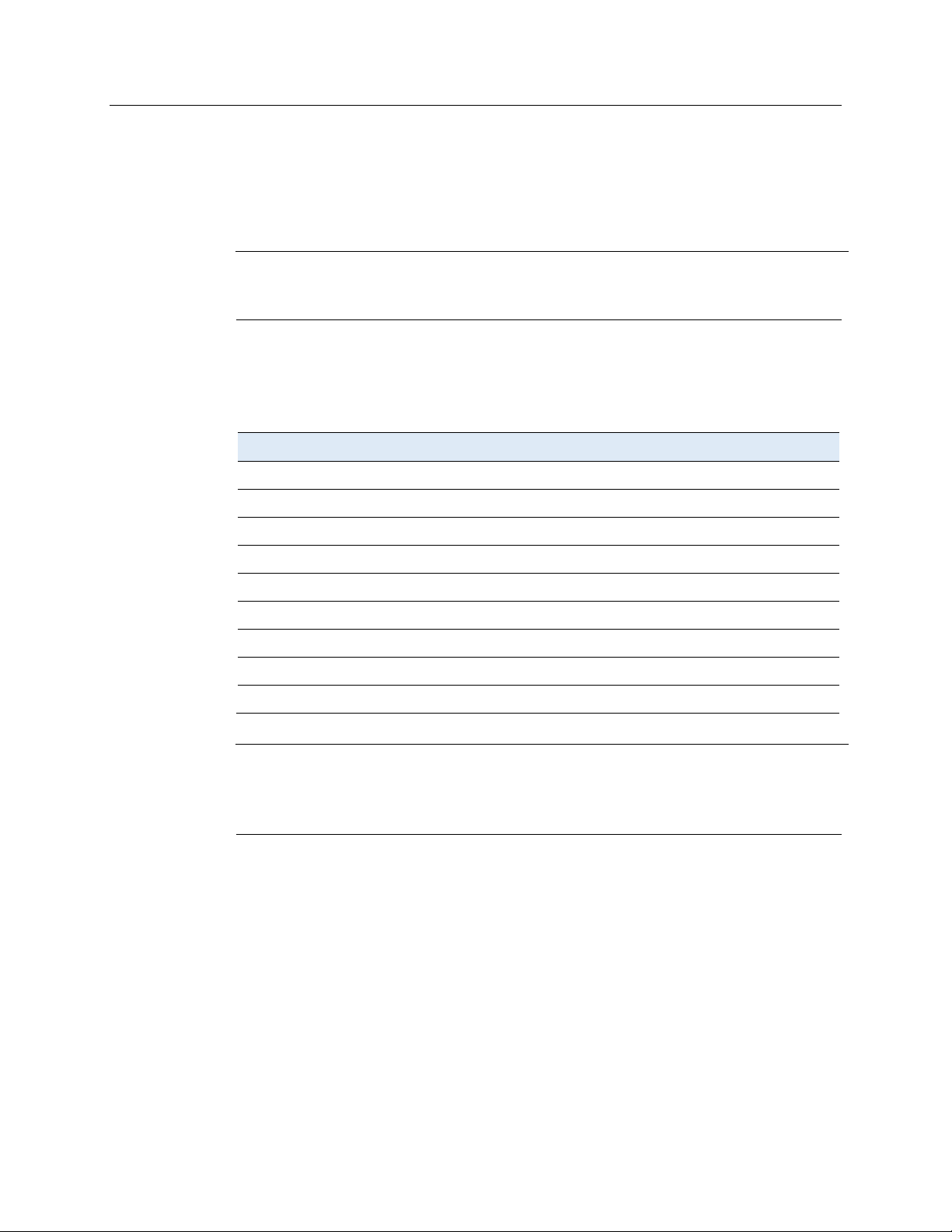

FBxDesigner Project:

I/O Type

Purpose

Signal Type

AI

DI

DI

AI

AI

PI

Digital

DO

AO

Contains the Level_Control.mwt project file along with its accompanying project

folder/source code.

Solution:

Contains the Separator_Demo.zsl solution file and its accompanying folder. This is the

solution created in this demo, which includes a copy of the application.

Note

This document is a complete guide to the demo; any other documents cited are

references.

1.2.2 I/O Points

The following table shows the I/O points to be used. You set up the inputs in override

mode and simulate them using the FB3000 control features.

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Liquid Level 4—20 mA

Hi-level Switch 24 Vdc input

Note

This demo shows the I/O configuration using one 12-channel Mixed IO module (with 8

selectable AI/DI/PI inputs and 2 AO and 2 DO settings). Other types of I/O modules may be

used but are not show in this guide.

1.3 Field Tools

The Field Tools software suite establishes communications with the FB3000, stores

connection information, and contains several applications (primarily FBxConnect and

FBxDesigner).

Lo-level Switch 24 Vdc input

Pressure Setpoint 4—20 mA

Pressure 4—20 mA

Liquid Meter 24 Vdc input

MVS Gas Meter Dat RS-285 Serial

Liquid Level Control Valve 24 Vdc output

Gas Pressure Control Valve 4—20 mA

1.3.1 FBxConnect

FBxConnect automatically opens when you connect to an RTU. Use to create and modify

solutions, download data, and other common tasks for the RTU. FBxConnect includes

configurable control features such as PID Loops, Math Blocks, and Action & Effects. It also

includes an integrated display builder, FBxVue, you use to create customized graphical

displays that can be combined with FBxDesigner projects into applications.

Introduction 3

Page 8

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

1.3.2 FBxDesigner

Note

FBxDesigner is a separate program in Field Tools that must be licensed to a PC.

Use FBxDesigner to program functions beyond what is offered in FBxConnect. FBxDesigner

supports the five IEC61131 programming languages by incorporating the industrystandard MULTIPROG IEC 61131 programming tool and includes a library of predefined

function blocks tailored specifically for referencing data in the FB3000 RTU.

4 Introduction

Page 9

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Chapter 2. Field Tools & Connecting to RTU

Note

For this chapter, you must have already successfuly installed Field Tools and previously

licensed FBxDesigner.

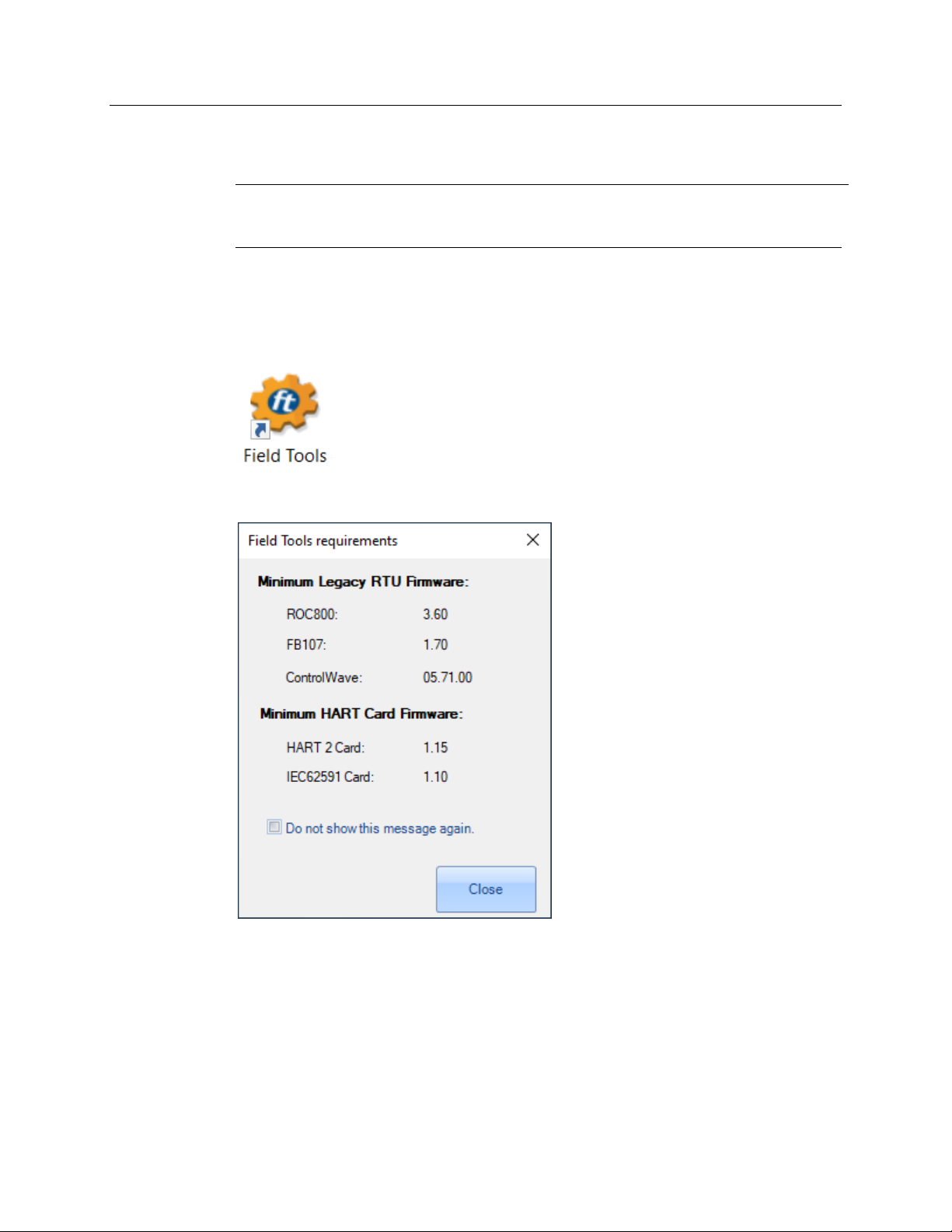

2.1 Starting Field Tools

Click on the Field Tools desktop icon to start Field Tools.

If the Field Tools requirements window pops up, click Close.

If this is the first-time you have opened Field Tools, the default username is admin with no

password.

Field Tools & Connecting to the RTU 5

Page 10

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Click Log in.

Click OK. The system requires that you change the password for the admin account.

To connect to a new FB3000, enter the default password of admin and click OK. Field Tools

starts.

6 Field Tools & Connecting to the RTU

Page 11

Emerson FB3000 Separator Configuration Guide

2.2 Field Tools Overview

Field Tools features a Connections List on the left-hand side of the screen, where you can

save multiple connections, sorted by site. You can open multiple connections at once, and

each selected connection opens a new instance of FBxConnect.

D301884X012

October 2019

Field Tools has the following selections in the top menu:

Connections:

Add Connections, Direct Connect, Import/Export Connections Lists.

Configurations/Solutions:

Create new or open existing solutions with FBxConnect.

Security:

Manage user accounts and passwords.

Settings:

Edit system settings

Help:

Access the online help system and view the version of Field Tools.

Field Tools & Connecting to the RTU 7

Page 12

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

2.3 Connecting to the RTU

To establish a connection with the FB3000 RTU, first ensure that the RTU is powered on

and connected to your computer using one of the comm ports (Ethernet, USB, or serial).

In Field Tools, click Connections > Add connection.

The Local connection to FBx device window displays; use it to create the new connection.

Enter a name for the connection. This will be the name in the Field Tools Connections List.

Select a Connection Type.

If you are connecting through IP with an ethernet cable, enter the default IP address of

the ethernet port you are connecting to (either

192.168.2.10 for port 2):

8 Field Tools & Connecting to the RTU

192.168.1.10 for port 1 or

Page 13

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Note

You may need to change your PC’s ethernet port adapter settings to have a similar IP

address and subnet mask.

If you are connecting through Serial/USB, select the Comm port you are using.

After selecting your connection type, click Connect.

The system then shows the progress of the connection in the lower part of the Connection

parameters pane:

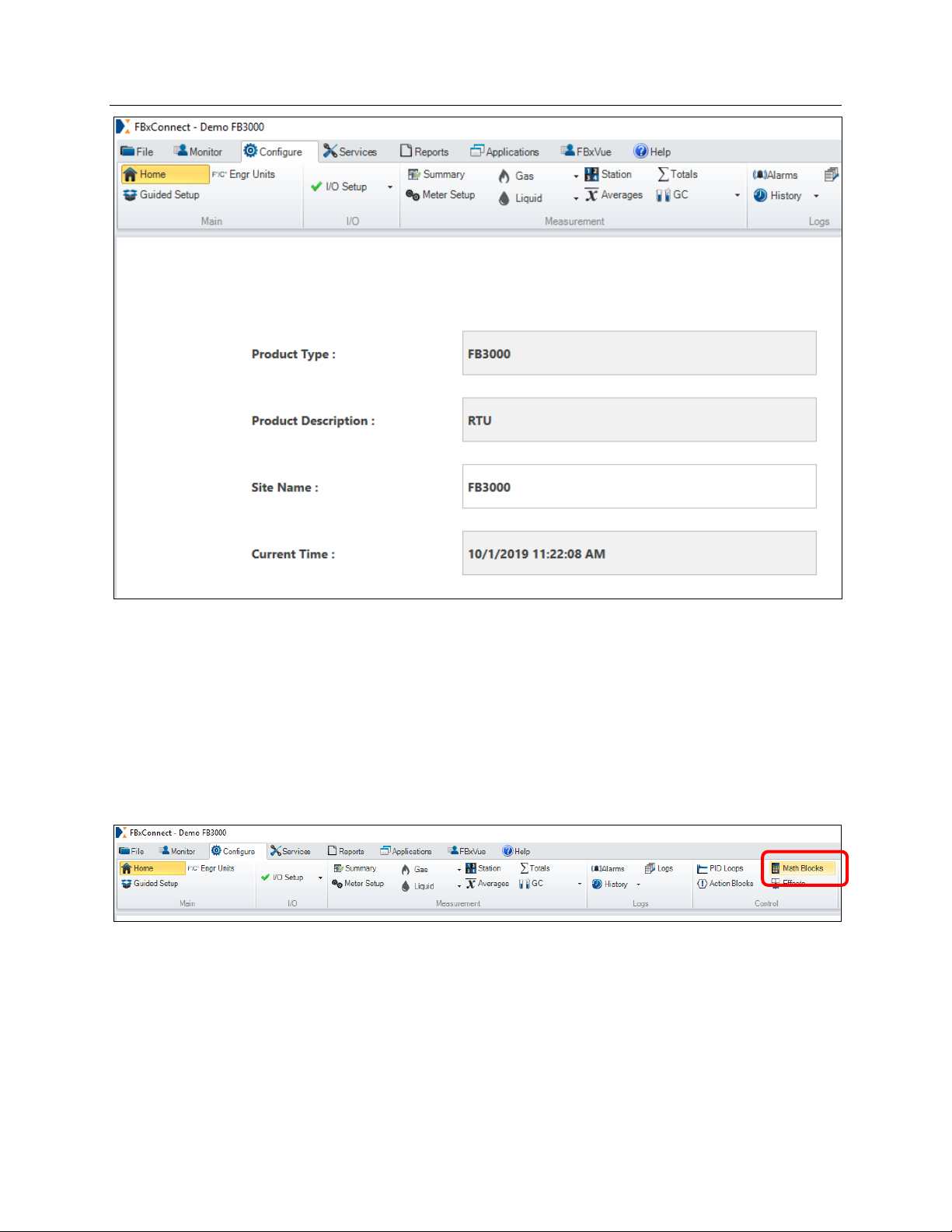

Once a connection establishes, an instance of FBxConnect automatically opens

(FBxConnect may take a few moments to load). When FBxConnect opens, it shows an

image of the FB3000:

Field Tools & Connecting to the RTU 9

Page 14

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

The status bar on the bottom of the screen shows that you are online, logged in as admin,

and indicates the IP address in use.

10 Field Tools & Connecting to the RTU

Page 15

Emerson FB3000 Separator Configuration Guide

Chapter 3. FBxConnect

Use FBxConnect to create or modify a solution, which consists of the standard

configuration along with communication parameters and applications. In this section we

will create the Standard Configuration for the demo.

3.1 FBxConnect Overview

FBxConnect features a ribbon menu on the top of the screen:

The ribbon menu has the following tabs:

D301884X012

October 2019

File:

Upload/Download Solutions, save backup to Flash.

Monitor:

View the status of I/O, system parameters, meters, logs, comm ports, etc.

Configure:

Make changes to the Solution such as setting up Meters, IO, History, and control

functions.

Services:

Upgrade firmware, warm/cold start the RTU, Calibrate I/O, manage User Security

profiles, and add licenses.

Reports:

Download History, Configuration, and Miscellaneous reports.

Applications:

Manage and view Applications.

FBxVue:

Build and view user displays.

Help:

Access the online Help system.

Note

For security purposes, you should change the default admin password (using the Services

tab) on the RTU after your initial login.

FBxConnect 11

Page 16

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

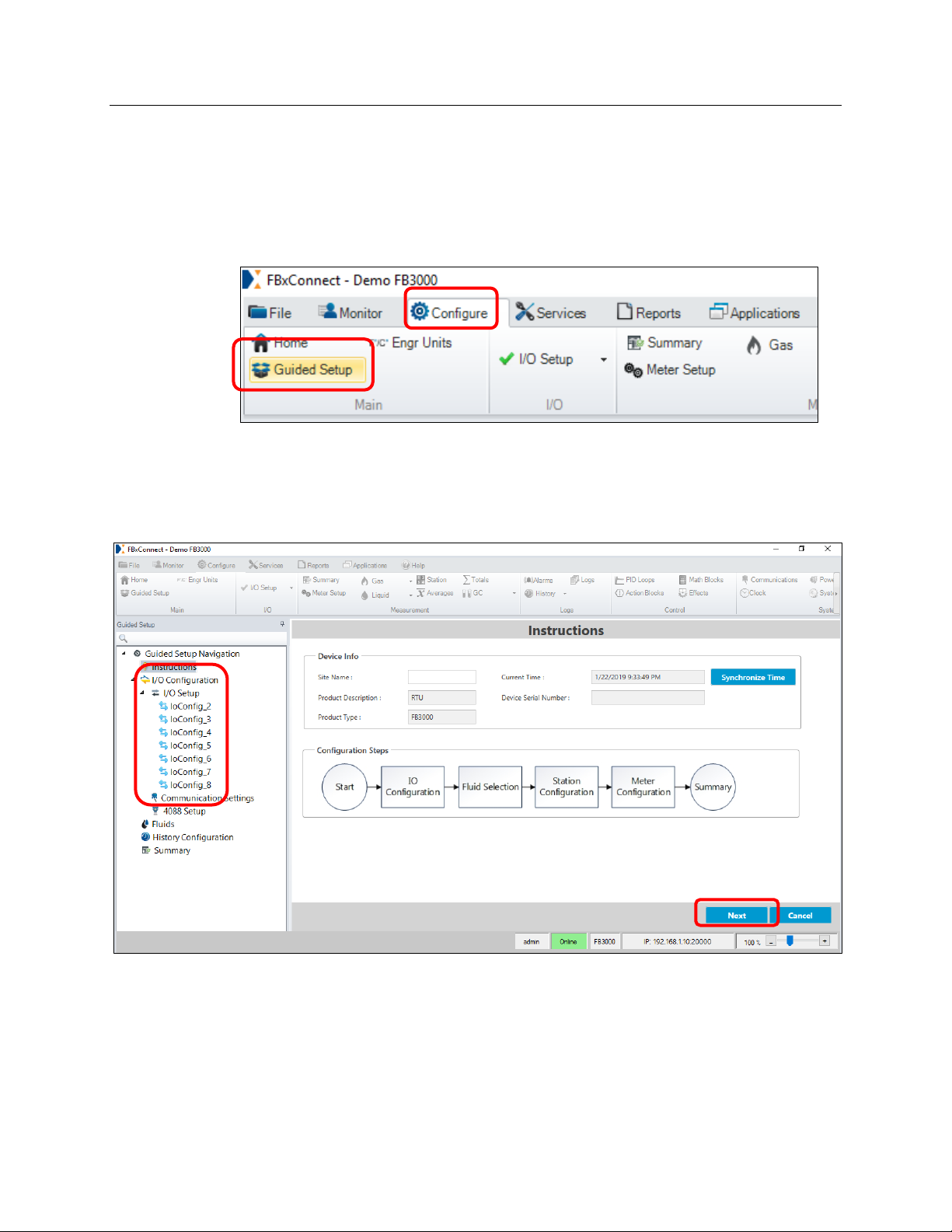

3.2 Guided Setup

The Guided Setup Wizard walks you through the screens needed to set up IO points, set

up meters, and configure history for those meters. Each of these actions can also be found

through other means.

To start the wizard, select the Configure tab and then click Guided Setup.

There are two ways to navigate the Guided Setup:

Click Next or Apply on the bottom right to go to the next page.

Click on a page in the Navigation Pane on the left to directly go to it (this option can

skip important configuration steps, so it is

not recommended).

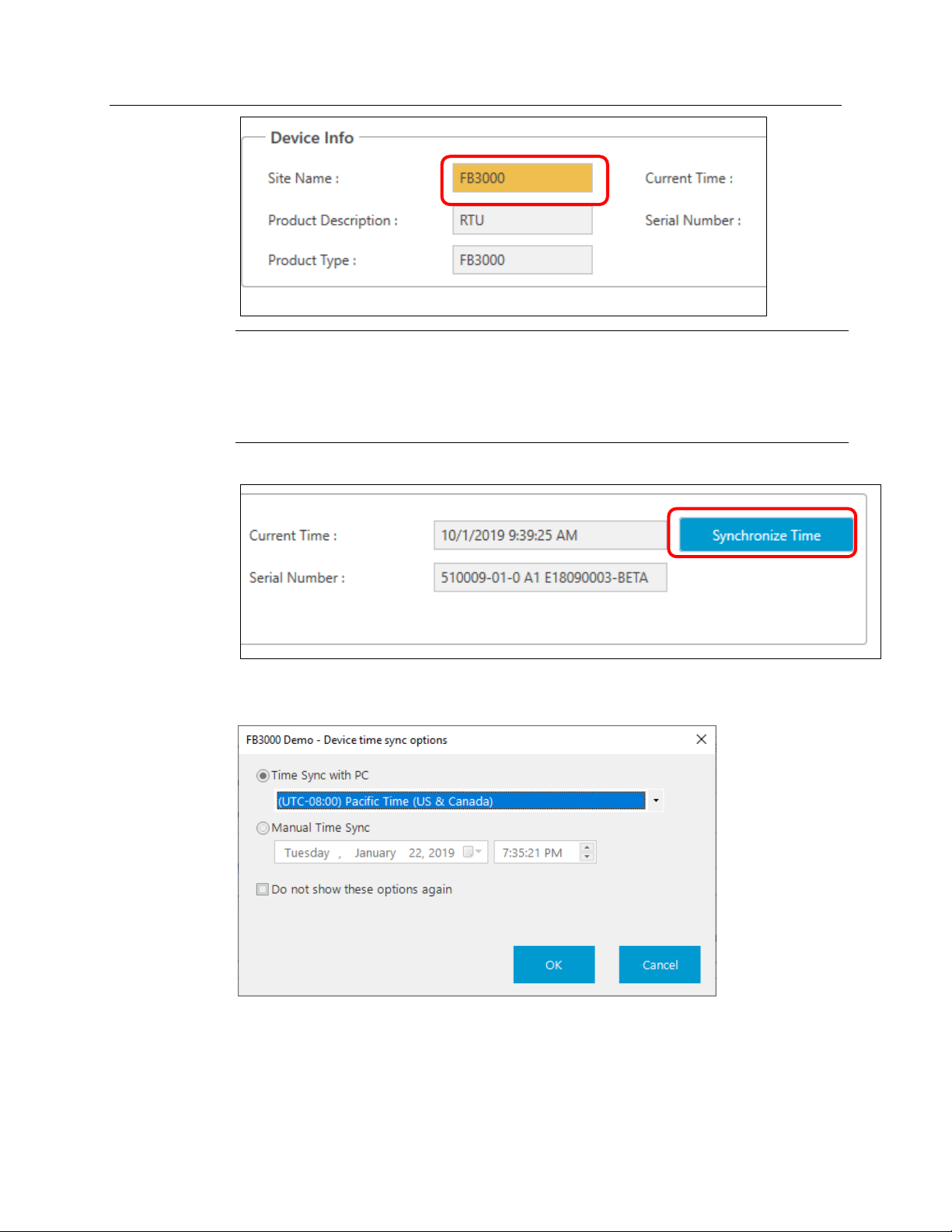

The Instructions page shows the steps in the configuration process and also allows you to

set the Device Info. Enter a Site Name.

12 FBxConnect

Page 17

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Note

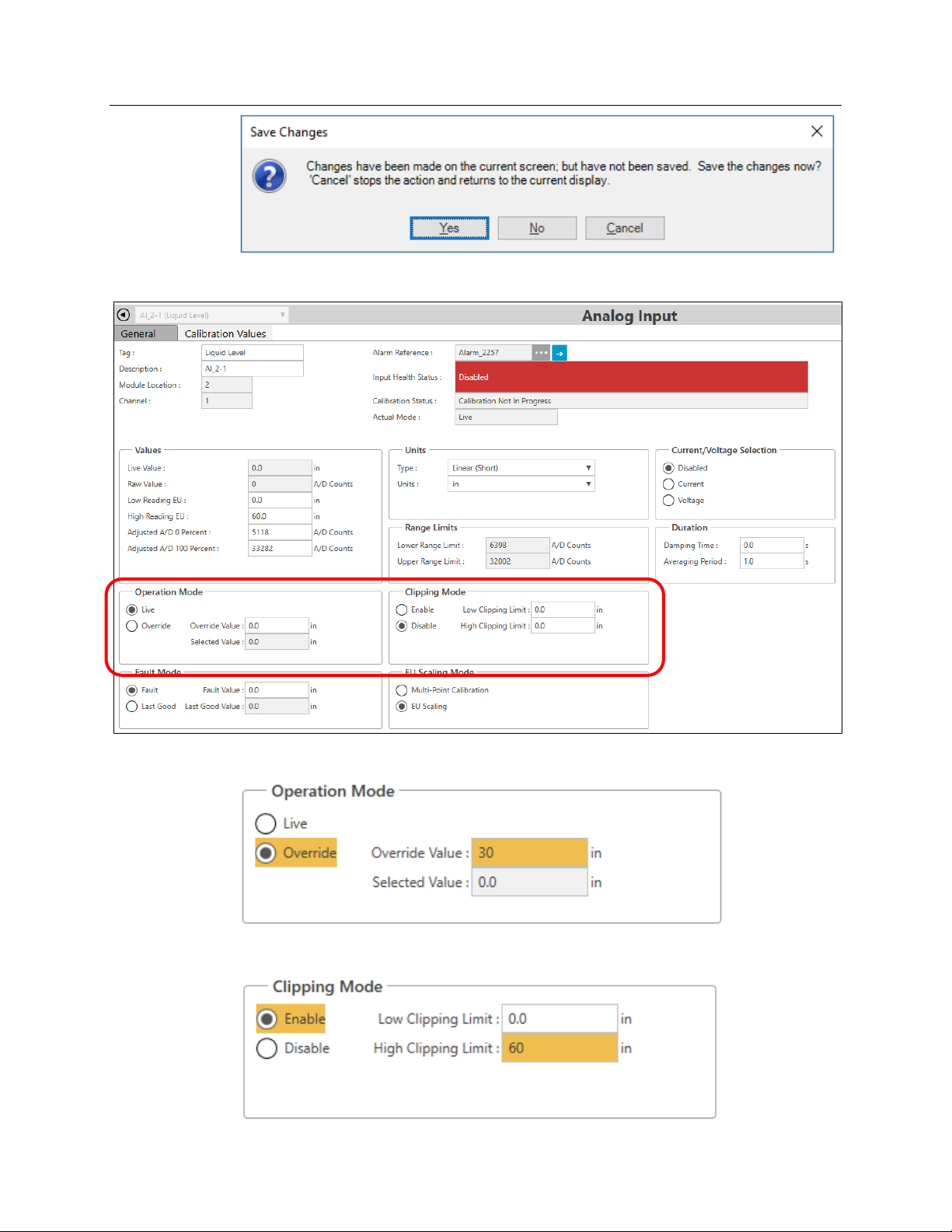

As show above, the system always highlights unsaved changes using yellow or amber.

Clicking

leave a screen without saving, the system displays a verification prompt reminding you to

save or discard the changes.

Click Synchronize Time.

Apply, Save, or Next saves the settings or changes on the current screen. If you

You can either synchronize the date and time with your PC’s clock (you can select a

different time zone) or manually set a date and time.

Click OK, and then click Next.

FBxConnect 13

Page 18

Emerson FB3000 Separator Configuration Guide

Inputs

Tag

Unit Type

Unit

Type

EU Scaling

Mode

Low

High

1

2

D301884X012

October 2019

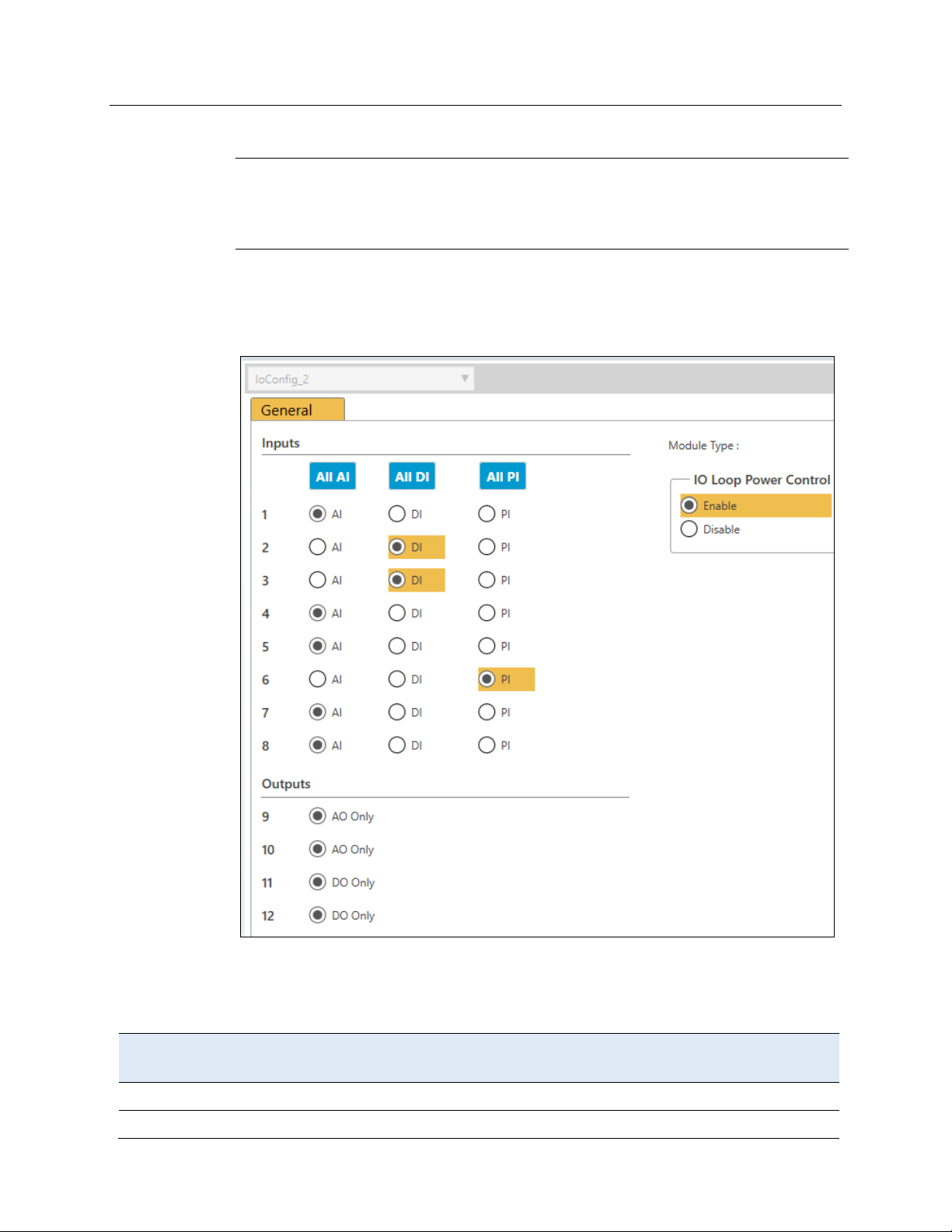

3.2.1 IO Setup & Communications

Note

This section assumes you have installed a 12-channel Mixed IO module in slot 2 for all the

needed I/O. (The 12-channel Mixed IO module has 8 selectable AI/DI/PI inputs and 2 AO and

2 DO settings.)

The next few screens enable you to configure I/O on the RTU.

Select the Input types as shown below.

Enable Loop Power.

Click Apply.

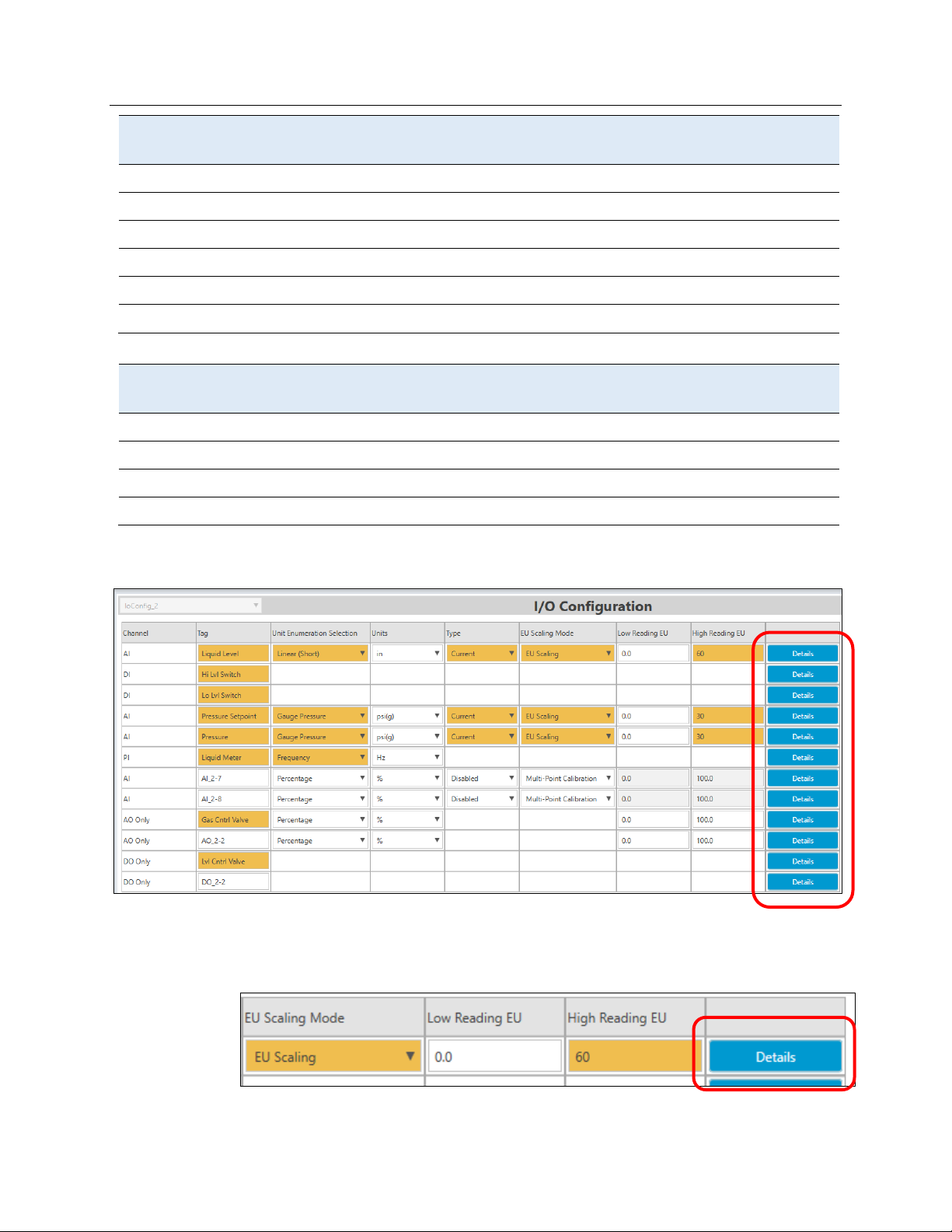

On the next IO Setup screen, you can tag and define each I/O point in the module.

Complete the IO Setup screen according to the following table:

AI Liquid Leve Linear (Short) In Current EU Scaling 0 60

DI Hi Lvl Switch

14 FBxConnect

Page 19

Emerson FB3000 Separator Configuration Guide

Inputs

Tag

Unit Type

Unit

Type

EU Scaling

Mode

Low

High

3

4

5

6

7

8

Outputs

Tag

Unit Type

Unit

Type

EU Scaling

Mode

Low

High

9

10

11

12

D301884X012

October 2019

DI Lo Lvl Switch

AI Pressure Setpoint Gauge Pressure psi(g) Current EU Scaling 0 30

AI Pressure Gauge Pressure psi(g) Current EU Scaling 0 30

PI Liquid Meter Frequency Hz Current

AI

AI

AO Gas Cntrl Valve Percentage % 0 100

AO

DO Lvl Cntrl Valve

DO

When you are done the screen should look like this:

On this screen you can also click Details for each I/O point to individually configure its

behavior. To simulate the separator later, we need to set all the inputs to Override mode.

Click Details for

The system prompts you to save the changes on the current screen. Click Yes to continue.

FBxConnect 15

Liquid Level (AI_2-1)

:

Page 20

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

The system displays a Configuration screen for the selected input:

Select the Override option in the Operation Mode pane and enter an Override Value of 30:

Select the Enable option in the Clipping Mode pane and enter a High Clipping Limit of 60:

16 FBxConnect

Page 21

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

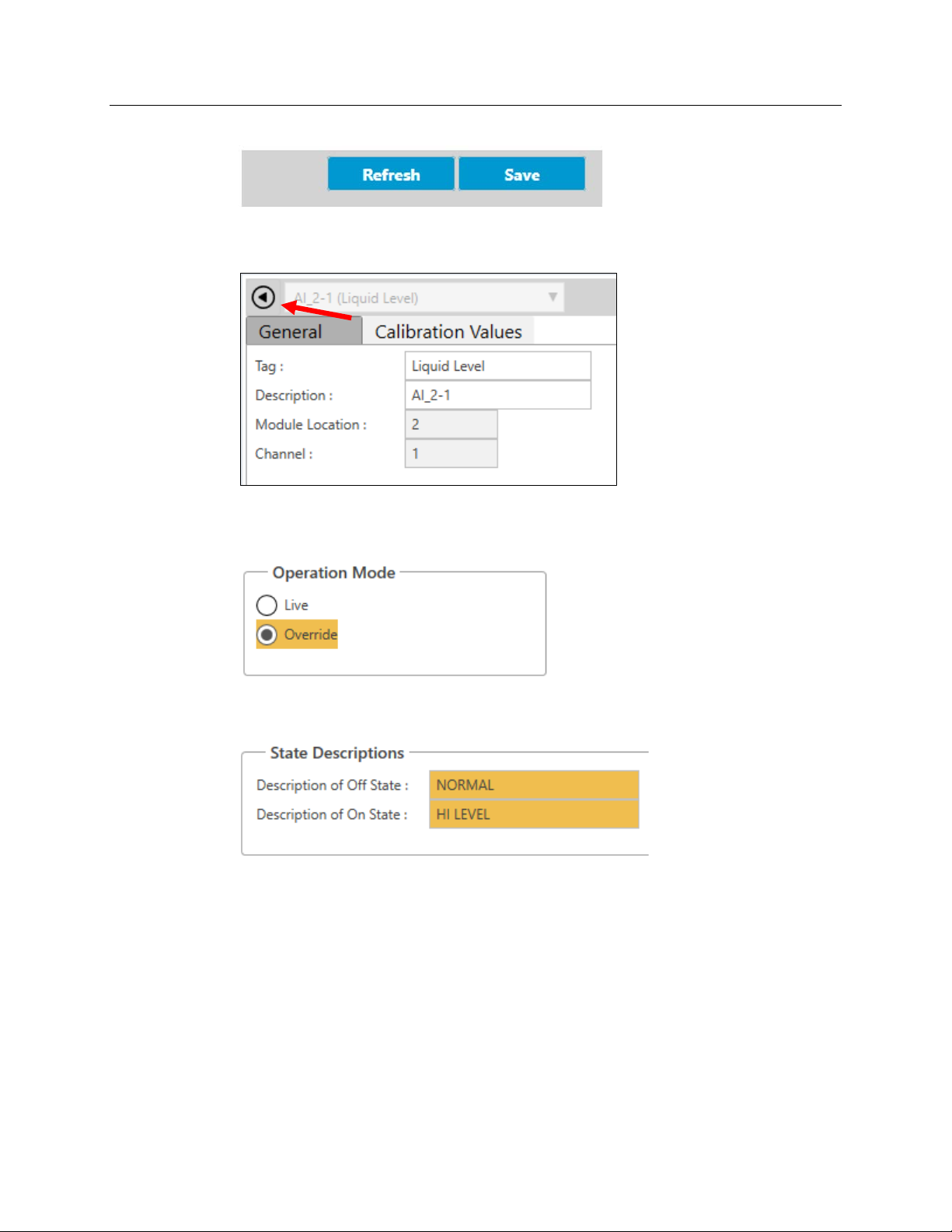

Click Save on the screen’s bottom right corner.

Click the back arrow at the top left corner of the screen to redisplay the IO Configuration

screen.

Click Details for

Select the Override option in the Operation Mode pane.

In the State Descriptions pane, enter NORMAL as the Description of Off State and HI LEVEL

as the Description of On State.

Click Save and click the back arrow to redisplay the IO Configuration screen.

Click Details for

Select the Override option in the Operation Mode pane.

Enter NORMAL as the Description of Off State and LOW LEVEL as the Description of On

State.

Hi Lvl Switch (DI_2-2)

Lo Lvl Switch (DI_2-3)

and make the following edits:

and make the following edits:

Click Save and click the back arrow to redisplay the IO Configuration screen.

Click Details for

Select the Override option in the Operation Mode pane and set an Override Value of

10.

Select the Enable option in the Clipping Mode pane and enter a High Clipping Limit of

30.

FBxConnect 17

Pressure Setpoint (AI_2-4)

and make the following edits:

Page 22

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Click Save and click the back arrow to redisplay the IO Configuration screen.

Click Details for

Select the Override option in the Operation Mode pane and set an Override Value of

10.

Select the Enable option in the Clipping Mode pane and enter a High Clipping Limit of

30.

Click Save and click the back arrow to redisplay the IO Configuration screen.

Click Details for Liquid Meter (PI_2-6) and make the following edits:

Select the Override option in the Operation Mode pane and set an Override Frequency

of

100.

Click Save and click the back arrow to redisplay the IO Configuration screen.

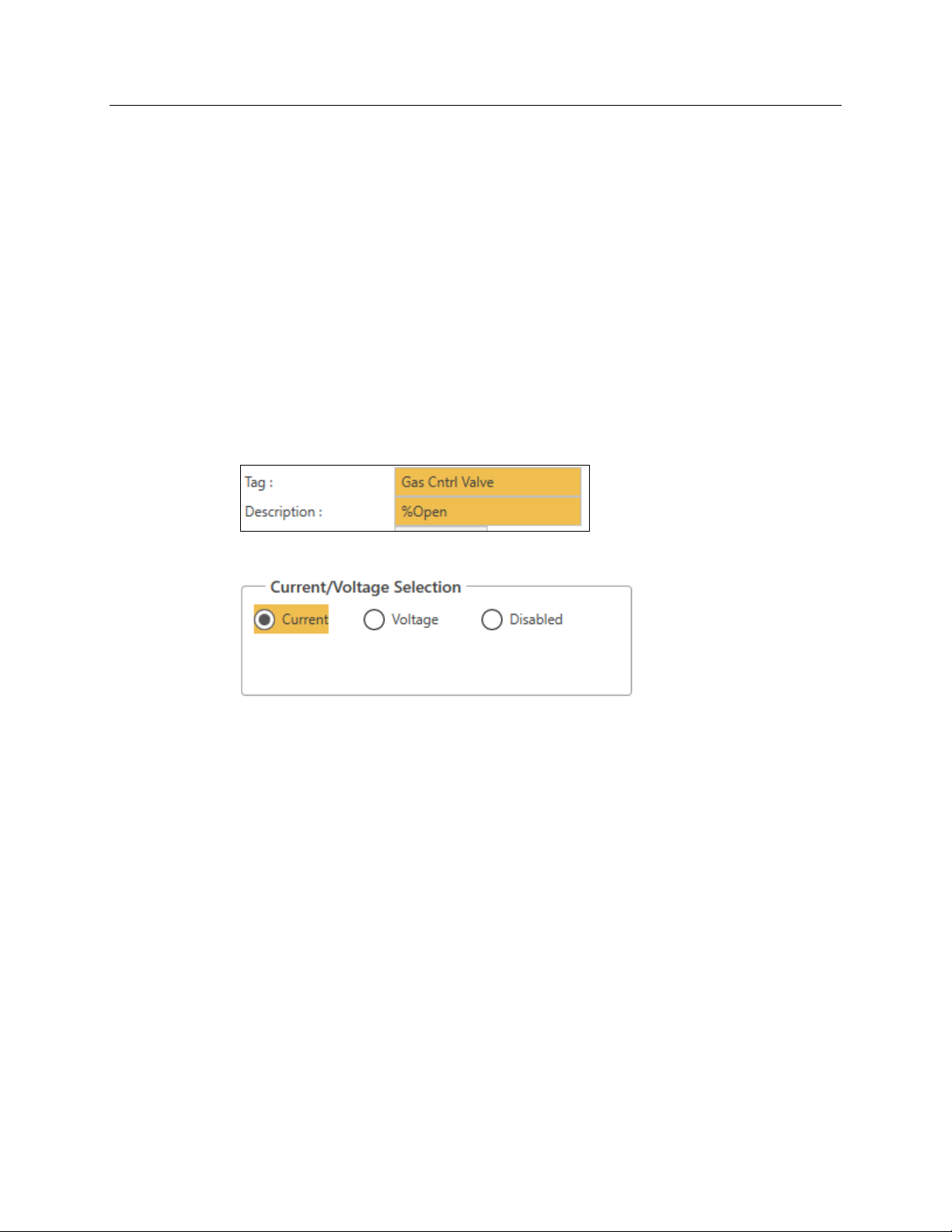

Click Details for

Enter %Open as the description.

In the Current/Voltage Selection pane, select the Current option:

Pressure (AI_2-5)

and make the following edits: :

Gas Cntrl Valve (AO_2-1)

and make the following edits:

Click Save and click the back arrow to redisplay the IO Configuration screen.

Click Details for

Enter OPEN/CLOSE as the Description.

Enter OPEN as the Description of On State and CLOSED as the Description of Off State.

In the Operation Mode pane, select the Auto Value to On.

Click Save and click the back arrow to redisplay the IO Configuration screen.

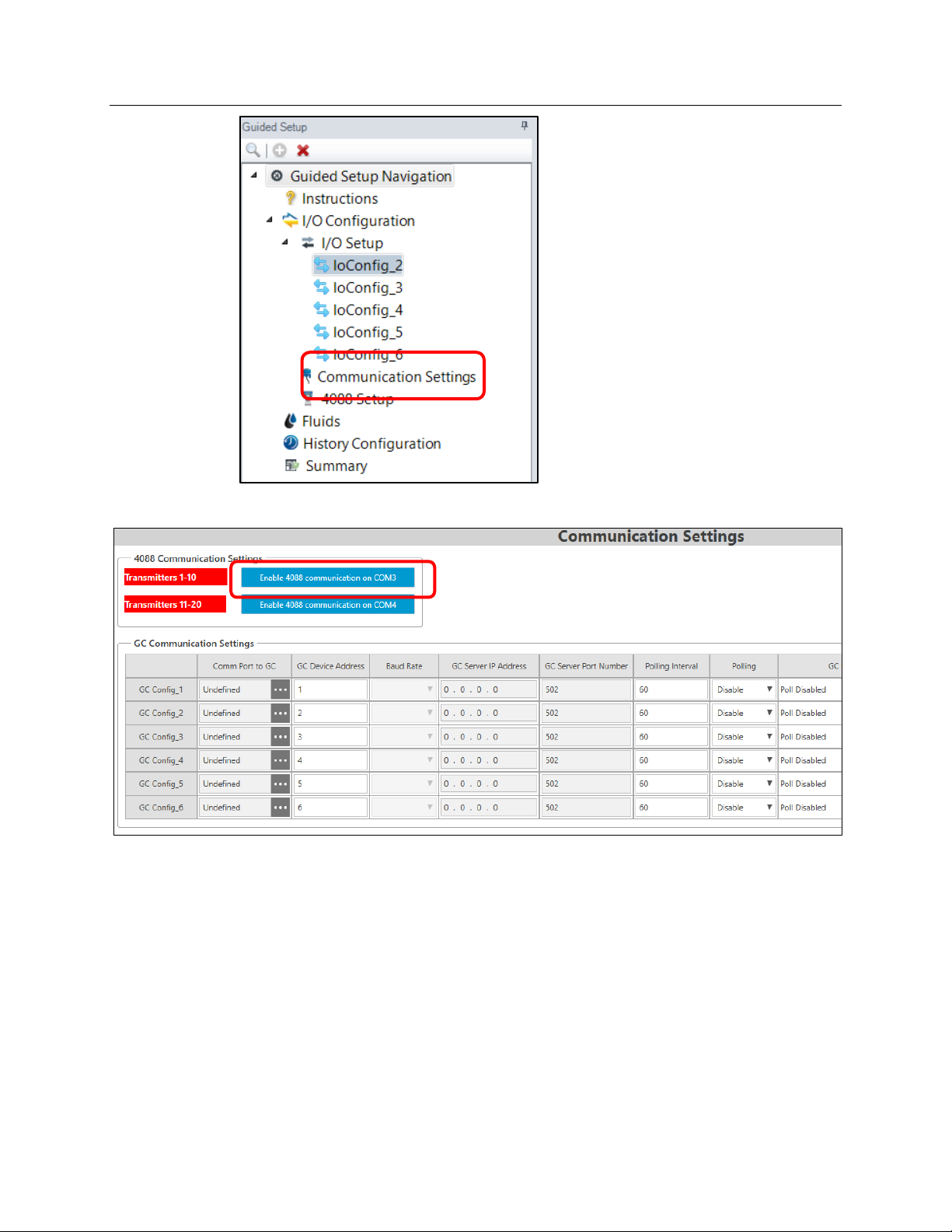

When the IO Configuration screen redisplays, if you were to click Apply, the wizard takes

you to the IO Configuration page for the next module (located in slot 3). Since we are

using the rest of the IO modules for this demo, we want to

Instead, double-click Communication Settings in the Navigation pane on the left-hand side

of the screen to skip to that page.

Lvl Cntrl Valve (DO_2-1)

and make the following edits:

not

skip this step.

18 FBxConnect

Page 23

Emerson FB3000 Separator Configuration Guide

The Communications Settings screen displays.

D301884X012

October 2019

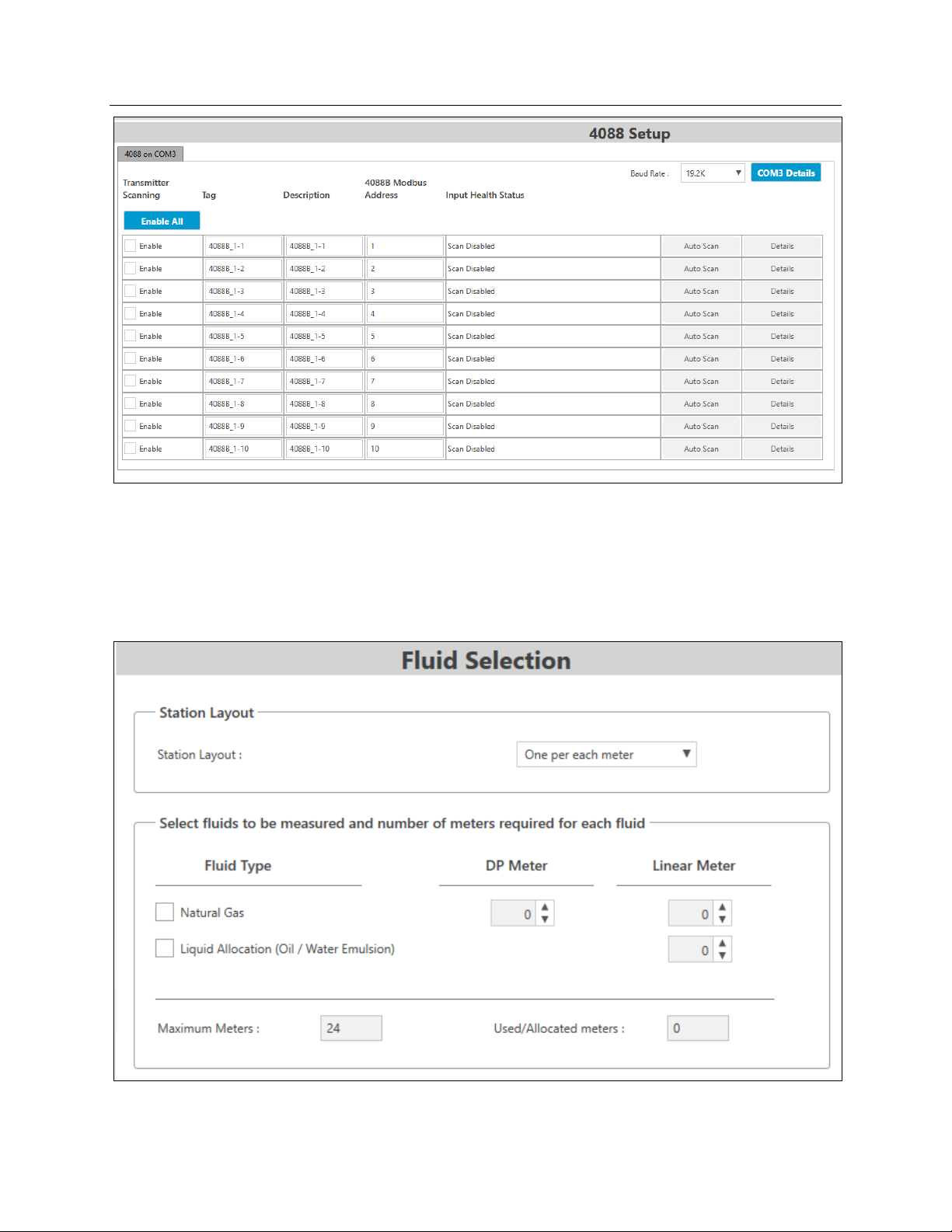

At this point, you set up communications with 4088 MVS transmitters and gas

chromatographs (GCs). Click

This sets the RTU’s COM3 to accept 4088 MVS communications. You can define up to 10

4088s (labeled 1—10; COM4 supports another 10 devices, labeled 11—20).

Click Apply. The 4088 Setup screen displays, which you use to configure communications

with any connected 4088 transmitters.

FBxConnect 19

Enable 4088 communication on COM3.

Page 24

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Since we are not enabling any 4088s for this demo, click Apply to continue. The Fluid

Selection screen displays

3.2.2 Stations & Meters

Using the Fluid Selection screen, you select the fluids to be measured and the type and

quantity of meters. You can also configure stations.

In the Select fluids pane, select the Natural Gas option and add one DP Meter to measure

it.

20 FBxConnect

Page 25

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Under Fluid Type, select the Liquid Allocation option and add one Linear Meter to measure

it.

Click Apply. The wizard displays a verification dialog:

Click OK. Notice that the stations and meter you have added now appear in the navigation

pane:

The wizard displays the Engineering Units screen. Each station has its own set of reporting

units, which you configure on this screen.

FBxConnect 21

Page 26

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Using the buttons at the top of the screen, set all units to your preferred regional type and

click

Apply. The wizard displays the Station screen.

Use this screen to set station parameters such as contract hour, base conditions,

calculation methods, and gas components. Select the options for your organization’s

requirements and click

If you left the Operation Mode on Override (its default value) in the Station screen’s

Component Configuration pane, the wizard displays the Gas Composition screen.

Next.

22 FBxConnect

Page 27

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Enter the appropriate values for the gas component compositions and select a

Normalization Option. Then click

Next. The wizard displays the DP Meter Settings screen.

Use this screen to configuration the options for the gas DP meter and select its inputs.

Select whatever options you prefer in the General section. In the Meter Inputs section,

Click the Point Picker button [

The Point Picker screen opens; use it to select an OPI (a point in the FB3000’s database) to

use for the differential pressure.

FBxConnect 23

...]next to the Differential Pressure option to select a point.

Page 28

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Note the filter on the top of the Point Picker showing Differential Pressure. That filter limits

the listed objects and instances to only three objects rather than displaying the entire

database.

Select DP_ in Objects and instances and then Select 4088B-1 DP (Instance 1-1). This is the

Differential Pressure measurement from the first 4088 MVS instance on COM3.

Note

We enabled COM3 for 4088s earlier so that we could select them here as meter inputs.

Click OK. DP_1-1 is now shown as the DP input.

24 FBxConnect

Page 29

Emerson FB3000 Separator Configuration Guide

Select Override Mode and enter a value of 25.

Define the Static Pressure:

Open the Flowing Pressure Point Picker.

Select Pres_ and then the first 4088 instance again.

Select Override Mode and enter a value of 25.

Define the Temperature:

Open the Flowing Temperature Point Picker.

Select RTD and then the first 4088 instance.

Select Override Mode and enter a value of 75.

D301884X012

October 2019

Click Next. The wizard displays the Engineering Units for station 2 (for the Liquid Allocation

Meter):

FBxConnect 25

Page 30

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

In the Rates pane, select bbl/d as the Volume Units for Rates:

Click Apply to continue. The wizard displays the Stations screen. Note that the station

settings for the Liquid Allocation station do not have the same Calculation and

Composition options.

26 FBxConnect

Page 31

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

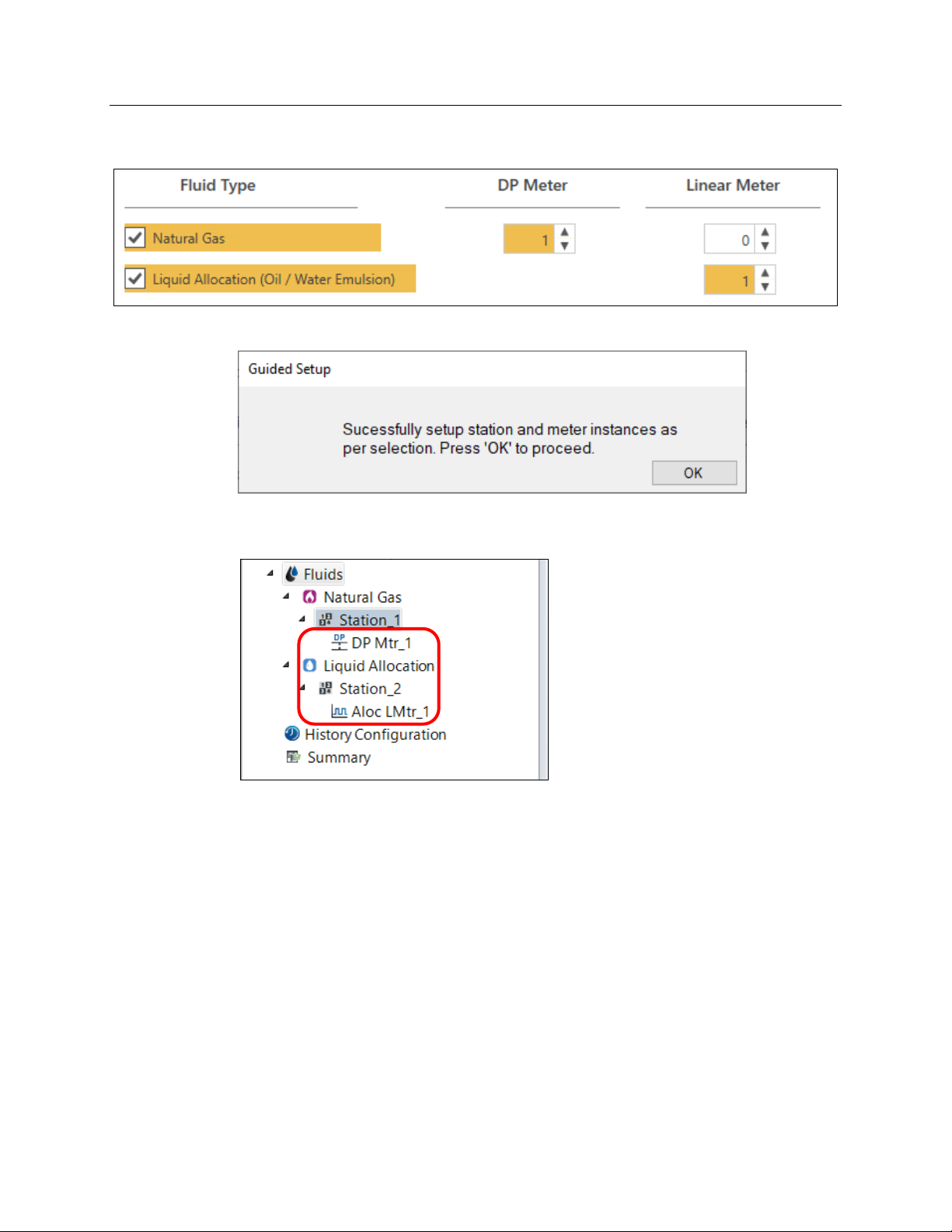

Click Next. The wizard displays the Liquid Allocation Meter screen, which you use to select

inputs for the liquid allocation meter.

First, enter 1000 as the K-factor.

For the Flow Rate Parameter, open the Point Picker and select PI_ > Liquid Meter (Instance

2-6) > Rate.

For the Pressure and Temperature, select the first 4088 instance (as you did with the first

meter):

FBxConnect 27

Page 32

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Notice that it shows the Override Values you already entered. Click Next. The wizard

displays the Liquid Allocation Properties screen.

Click Next. The wizard displays the Default Meter History Setup screen.

28 FBxConnect

Page 33

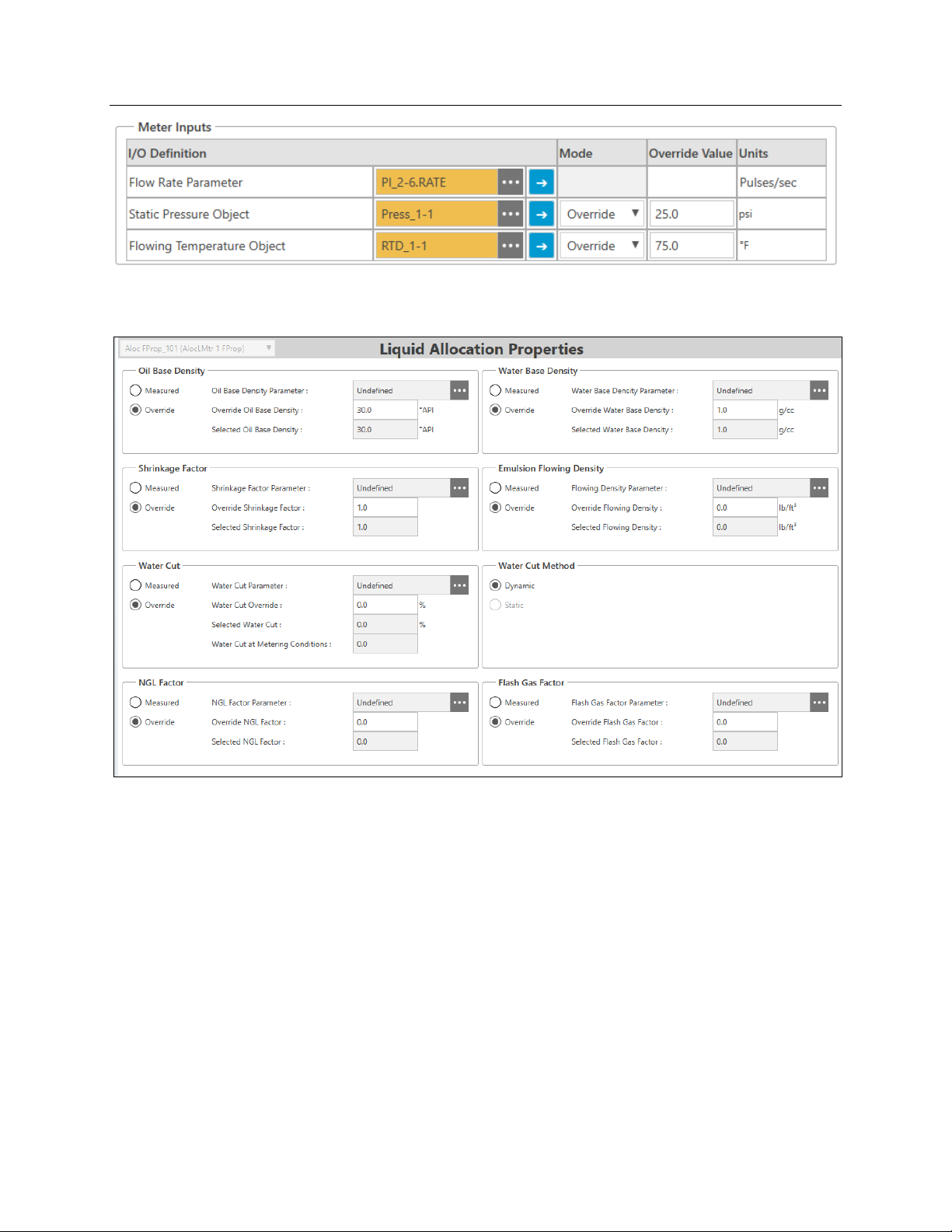

3.2.2 History & Summary

Use this screen to configure history for the meters.

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Keep the default settings and click Next. The wizard displays the Summary screen, which is

the final screen in the guided setup. From this point on, you can randomly select any

station or meter and change its settings or monitor its calculations.

When you are done reviewing your station and meters settings, click Finish. The system

displays the Configuration home page:

FBxConnect 29

Page 34

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

You can directly access all the settings seen in the Guided Wizard from the Configure

menu. Notice that the GUI now includes buttons for the gas and liquid meters.

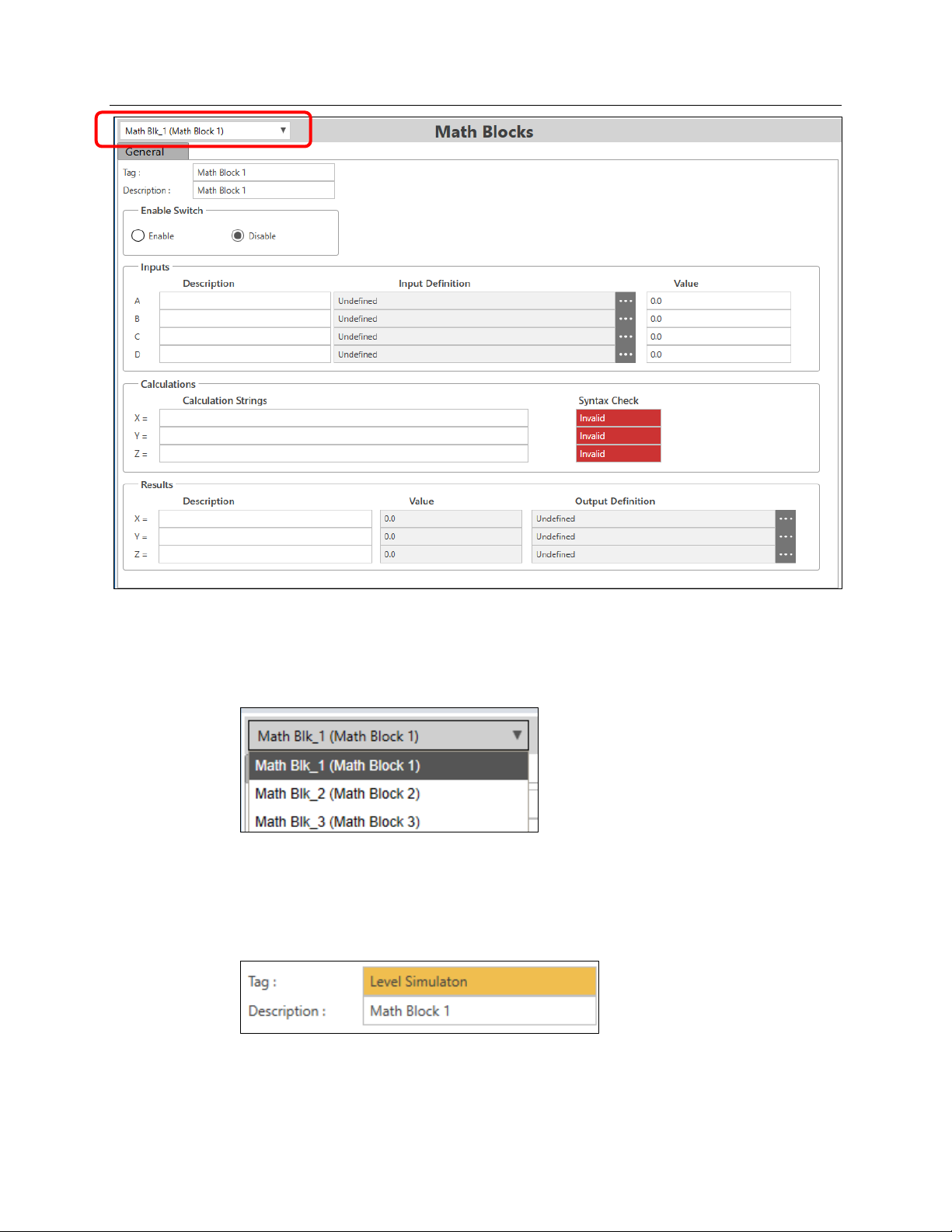

3.3 Math Blocks

You use math blocks to define calculations. Each math block has up to four inputs and

three calculations, which can each be saved to writable OPIs. The system performs math

block calculations once a second.

To configure math blocks, select the Configure tab and click the Math Blocks option:

The Math Blocks screen displays:

30 FBxConnect

Page 35

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Note the drop-down menu option in the upper left-hand corner of the screen. Use it to

select the math block to define.

For this demo, we’ll define two math blocks: one to simulate the liquid level and another

to simulate the pressure:

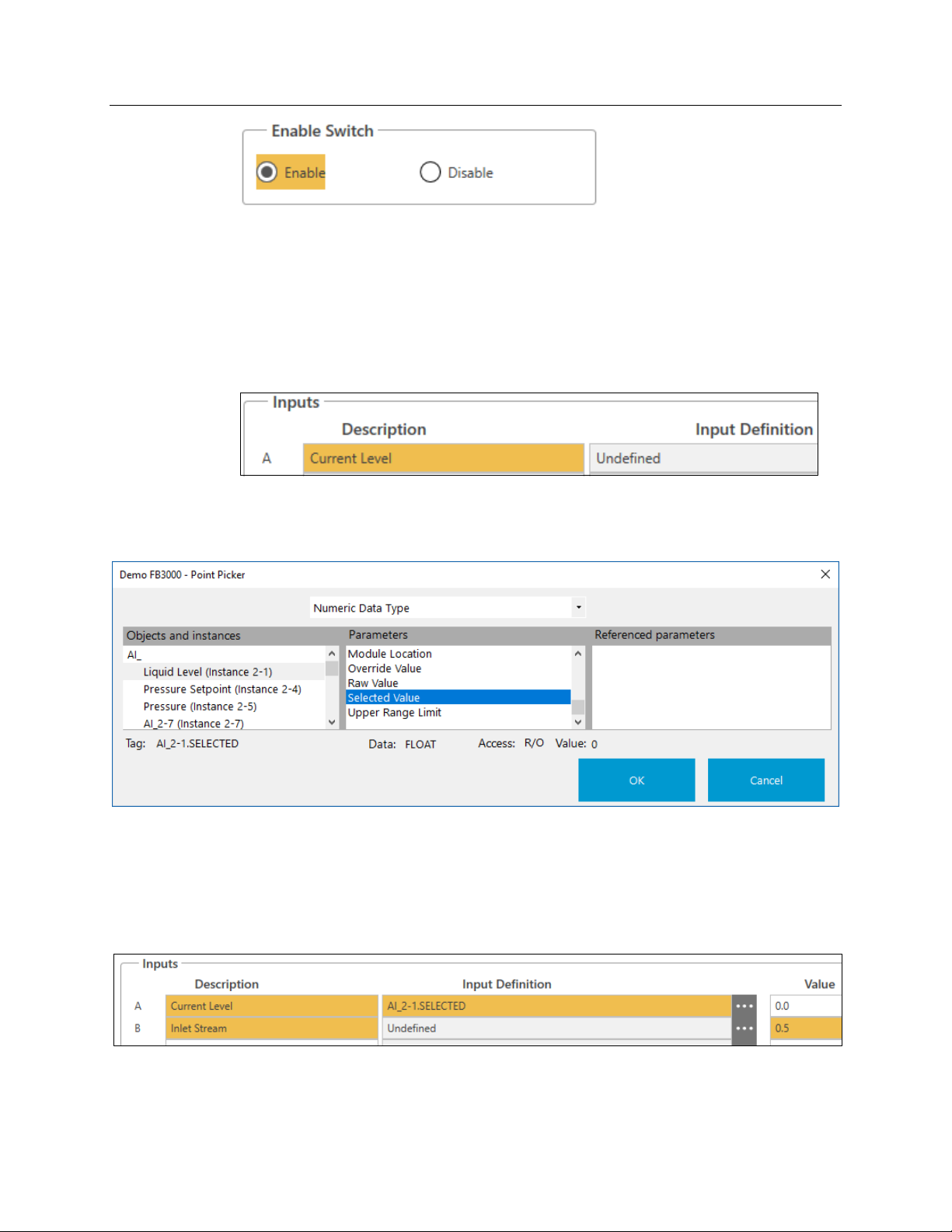

3.3.1 Simulating Liquid Level

You use the first math block to simulate the liquid level in the separator.

Enter Level Simulation as the tag for Math Block 1.

Notice that each control feature has an Enable Switch to turn it on/off. Select the Enable

option for this math block:

FBxConnect 31

Page 36

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

To simulate the liquid level, you need to know the current level, how much the level is

rising due to the inlet stream (we’ll pick an arbitrary number), and how much the level is

falling due to the outlet control valve.

To define the inputs:

For Input A:

Enter Current Level as the Description.

Open the Point Picker.

Select AI_ > Liquid Level (Instance 2-1) > Selected Value.

The Selected Value of a point is equal to the live value when the operation mode is set to

Live and is equal to the override value when the operation mode is set to Override.

For Input B:

Enter Inlet Stream as the Description.

Enter 0.5 as the Value (do not open the Point Picker).

For Input C:

Enter Control Valve as the Description.

Open the Point Picker.

Select No Filter at the top of the Point Picker screen.

32 FBxConnect

Page 37

Emerson FB3000 Separator Configuration Guide

Select DO_ > Lvl Cntrl Valve (Instance 2-1) > Auto Value

D301884X012

October 2019

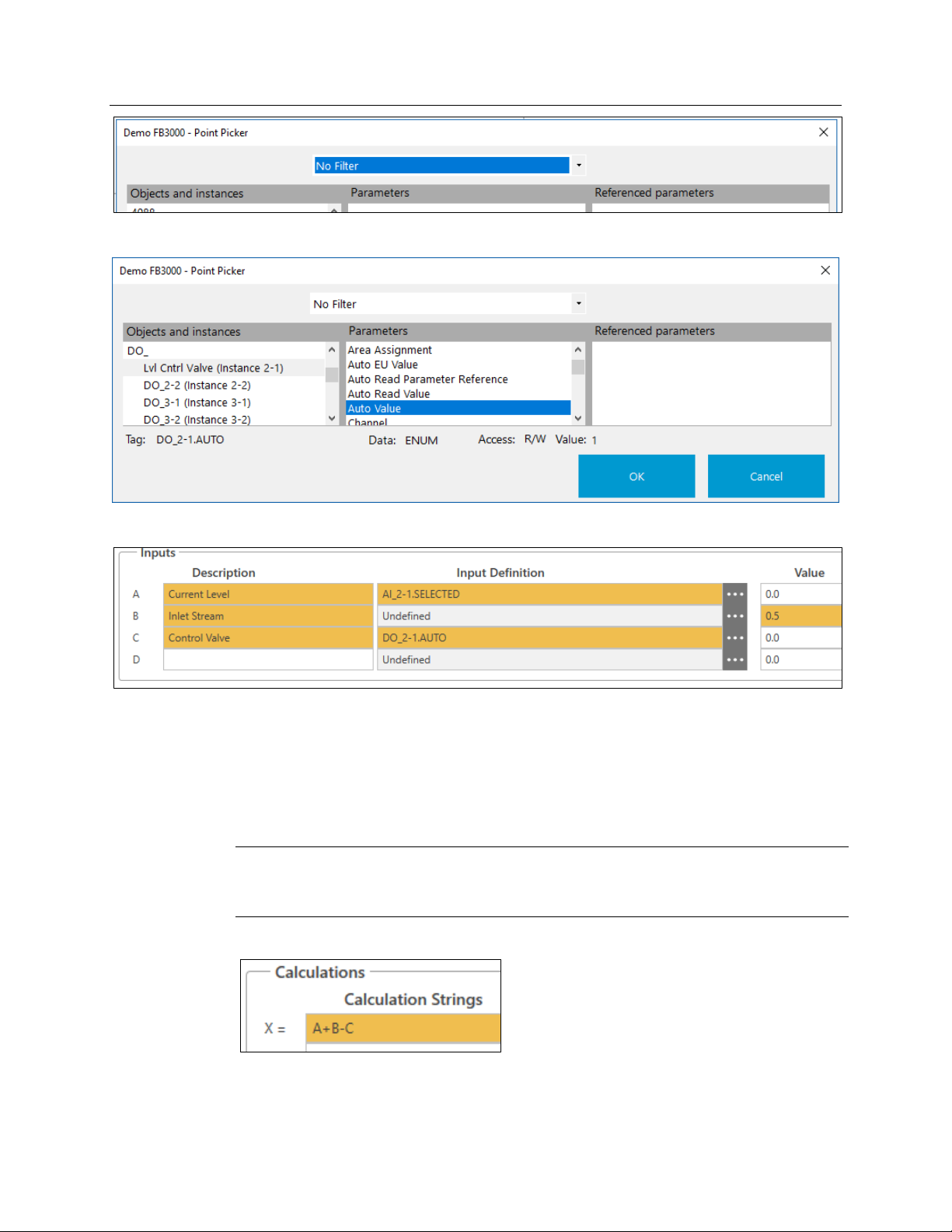

The inputs should now look like this:

With the inputs defined, we can now define the calculations.

The new, calculated level is the current level (Input A) plus the rise due to liquid entering

through the inlet stream (Input B, arbitrarily set to 0.5 inches per second)

due to liquid leaving through the control valve (Input C ). Since the control valve is 0 when

closed and 1 when open, we’ll just use that value so that it causes a fall of 1 inch per

second when open.

Note

This is not an accurate simulation that considers real-world variables like changes in

pressure. It is a simplified calculation intended

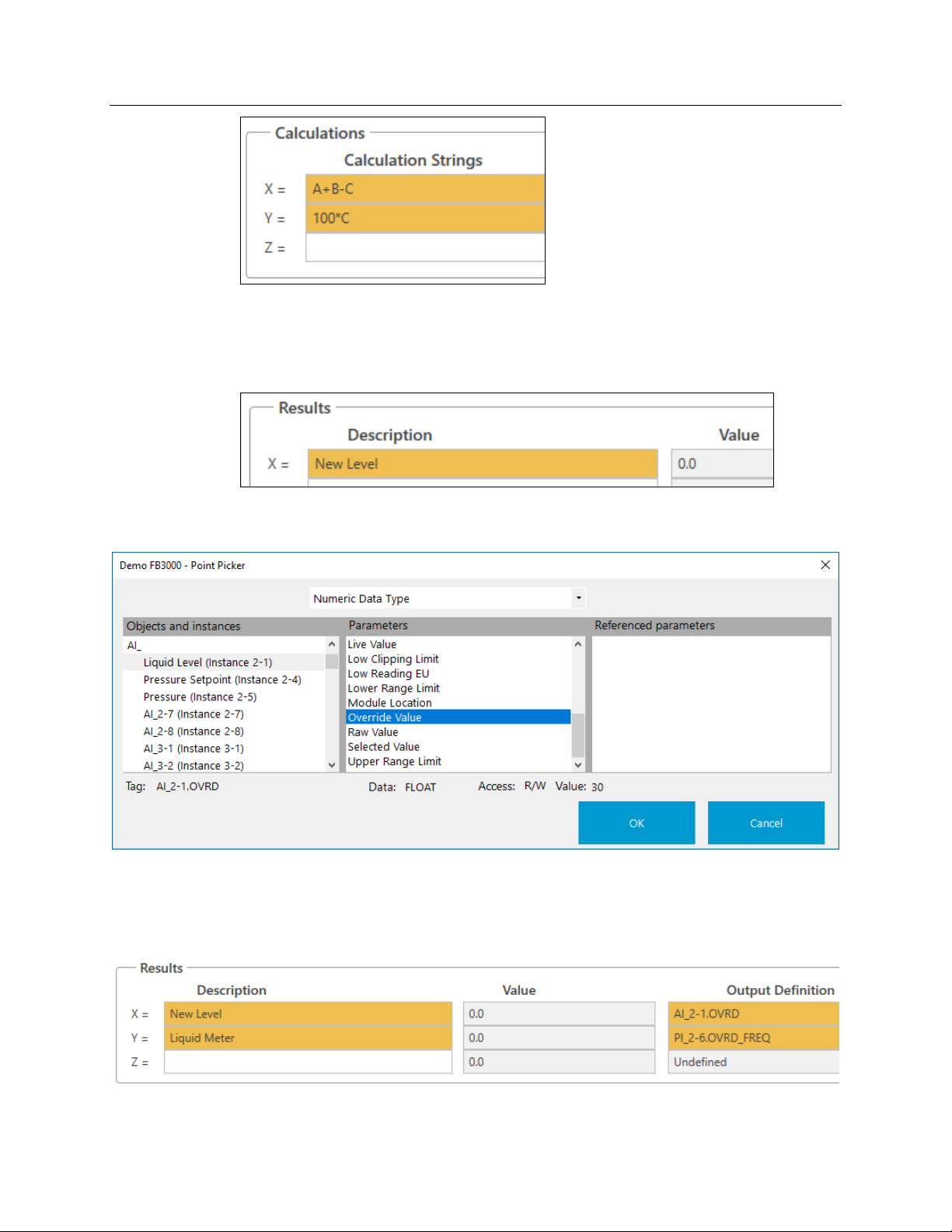

For the X calculation, enter A+B–C:

only for demonstration purposes.

minus the fall

Let’s also calculate a new pulse input for the liquid meter so that it is zero when the valve is

closed and 100 when the valve is open. For the Y calculation, Enter:

FBxConnect 33

100*C

Page 38

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Then we need to store the results:

For Result X:

Enter New Level as the Description.

Open the Point Picker.

Select AI_ > Liquid Level (Instance 2-1) > Override Value.

For Result Y:

Enter Liquid Meter as the Description.

Open the Point Picker.

Select PI_ > Liquid Meter (Instance 2-6) > Override Frequency.

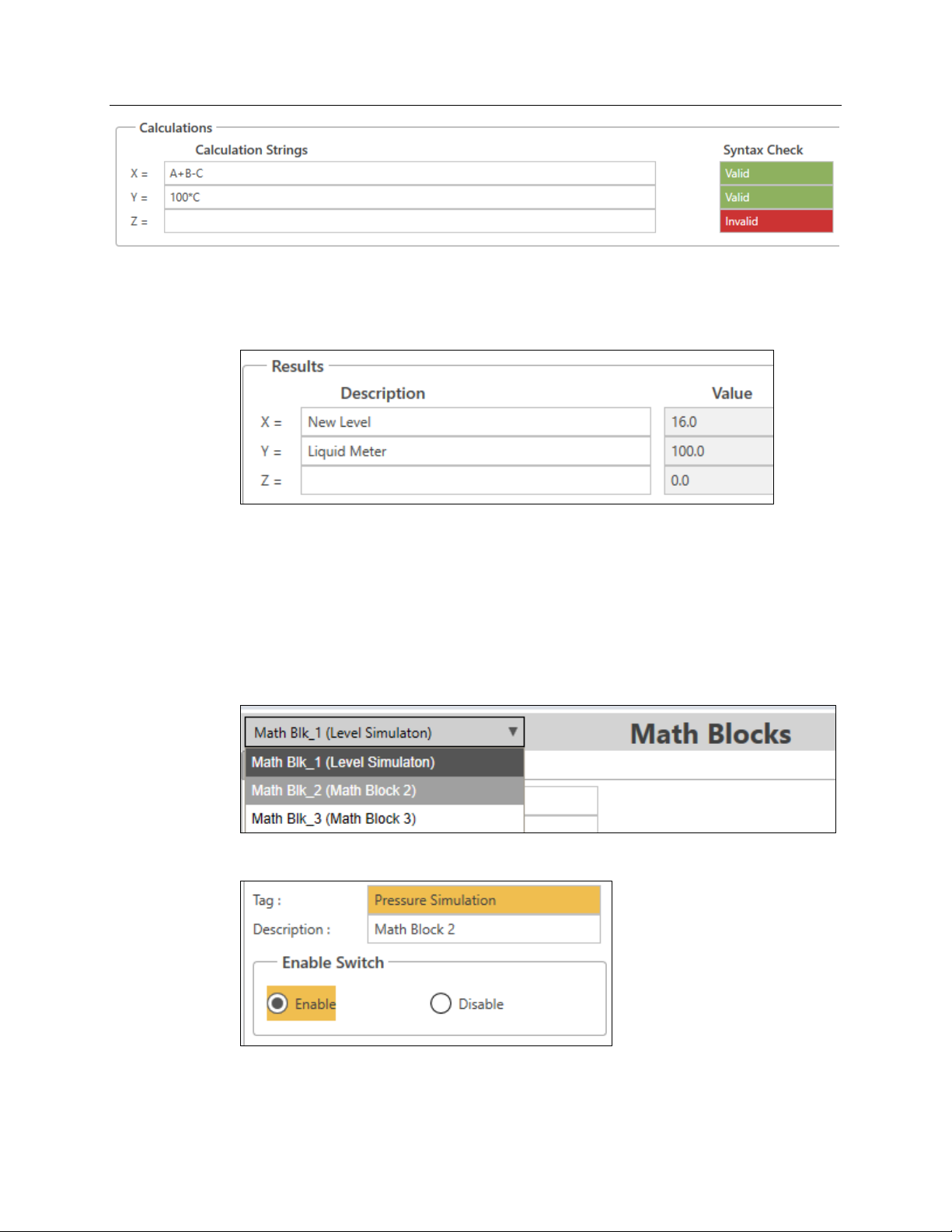

Click Save. At this point, the Syntax Check fields for both calculations should change to

green and display Valid:

34 FBxConnect

Page 39

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

If they do not, there is a syntax error in the calculation that you need to correct.

Notice that that New Level value should start to drop from 30 because the Control Valve is

open.

All the liquid will drain out of the separator until we add controls to close the valve.

3.3.2 Simulating Pressure

You use the second math block to simulate the pressure in the separator, which is used to

module the gas control valve.

Select Math Blk_2 (Math Block 2) from the drop-down menu at the upper right of the

screen:

Enter Pressure Simulation as the Tag and enable the math block.

We simulate the pressure in the same way we simulated the liquid level. We need to know

the current pressure, how much the pressure increases due to an inlet stream, and how

much the pressure decreases due to the control valve.

FBxConnect 35

Page 40

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

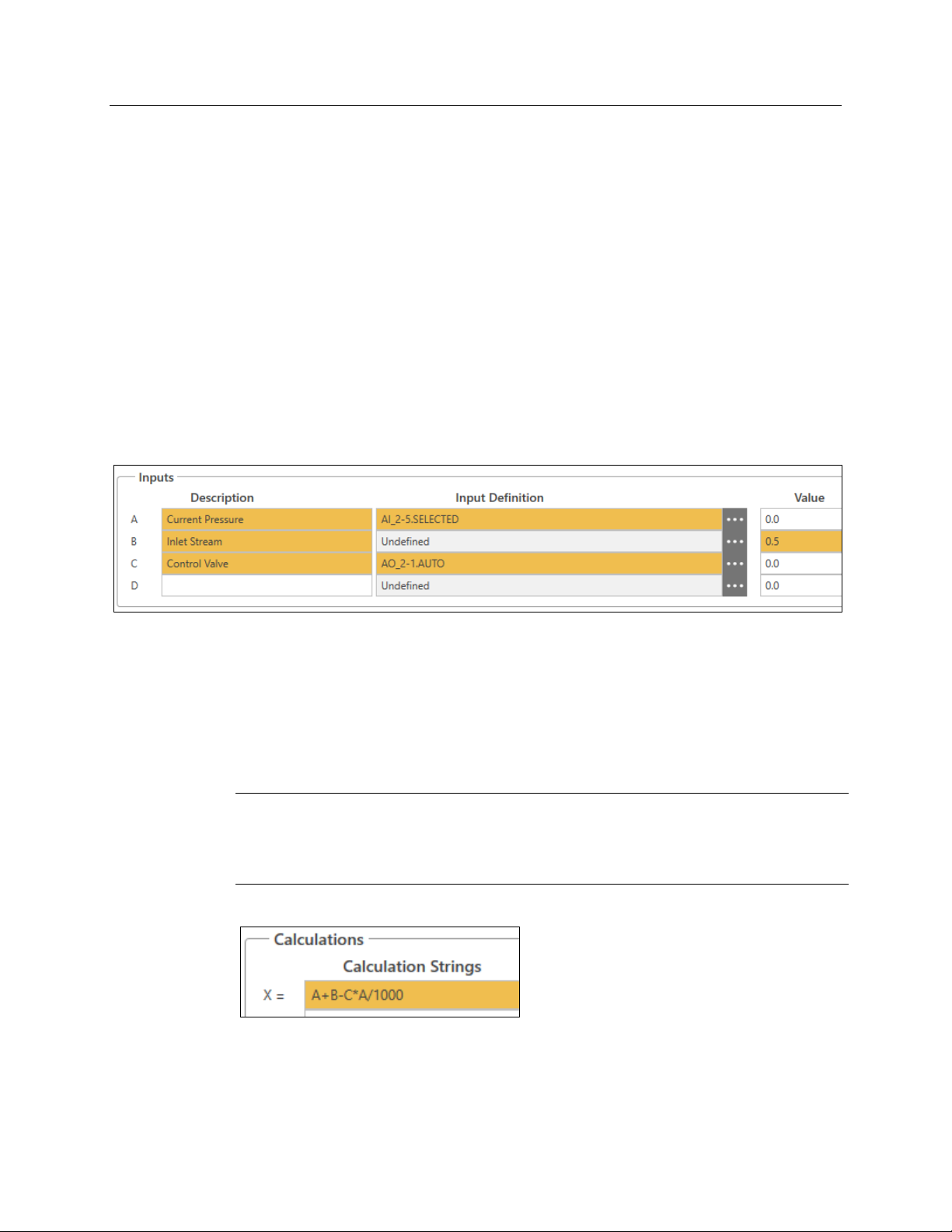

Define the inputs:

For Input A:

Enter Current Pressure as the Description.

Open the Point Picker.

Select AI_ > Pressure (Instance 2-5) > Selected Value.

For Input B:

Enter Inlet Stream as the Description.

Enter 0.5 as the Value.

For Input C:

Enter Control Valve as the Description.

Open the Point Picker.

Select AO_ > Gas Cntrl Valve (Instance 2-1) > Auto Value.

The inputs should look like this:

For this calculation we need to do something different from the control valve outlet, since

this is an analog output calculation that goes from 0 to 100% instead of from 0 to 1.

Additionally, gas compresses and responds to pressure changes much more than liquid, so

we need to account for that.

We approximate the outlet as the Control Valve % Open (Input C) multiplied by the

Current Pressure (Input A) and then divided by 1000 so that it’s about the same magnitude

as the inlet stream.

Note

This an even less-accurate simulation that the liquid simulation, since gas compression and

flow calculations are much more complex. Again, this is a simplified calculation intended

only for demonstration purposes.

So, for the X Calculation, enter A+B–C*A/1000:

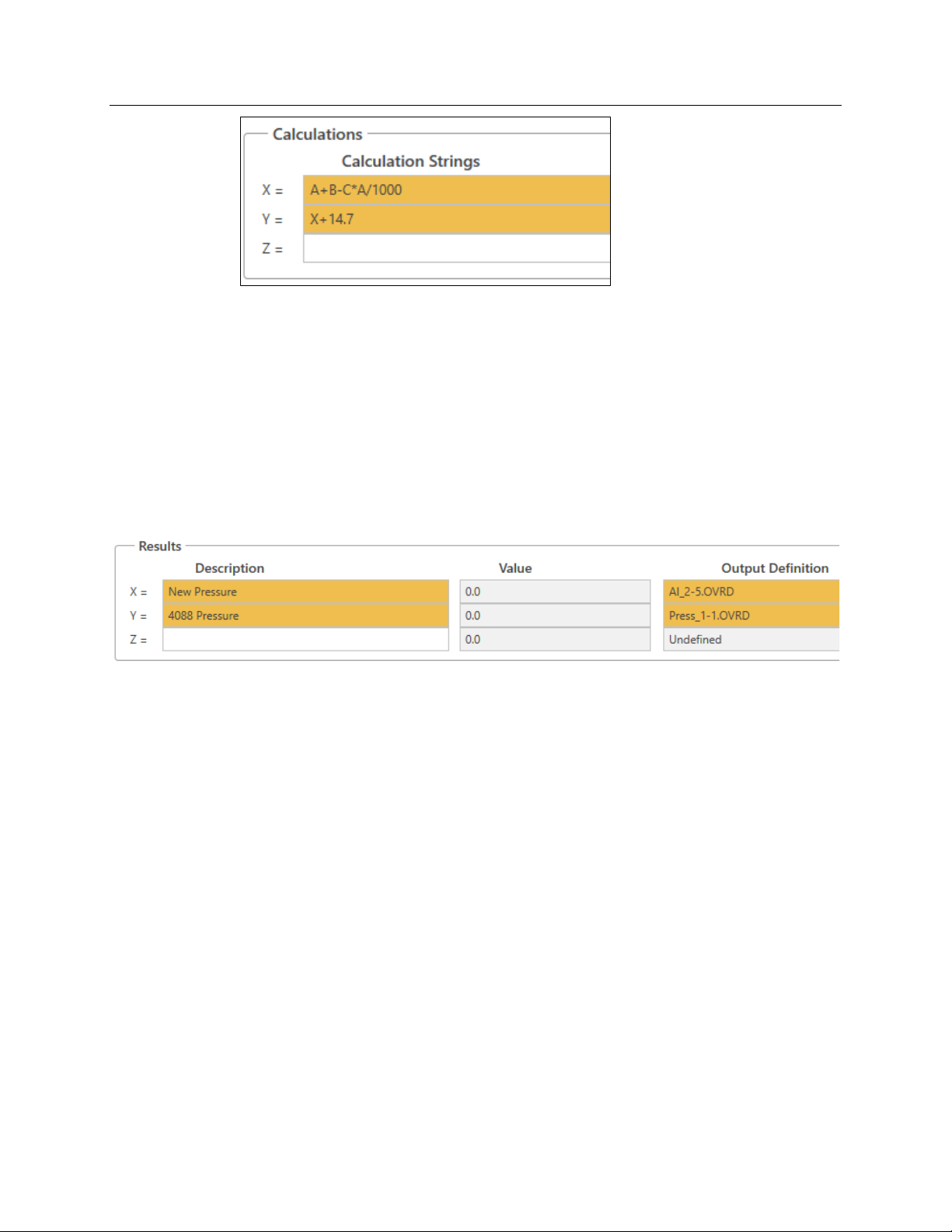

Since we are calculating the pressure of the separator, we also need to update our 4088

static pressure that we’re using for our meters. Since the 4088 Pressure is in Absolute

pressure psi(a) and our input pressure is in Gauge Pressure psi(g), we need to add one

atmosphere of pressure (about 14.7 psi).

For the Y Calculation, enter X + 14.7:

36 FBxConnect

Page 41

Emerson FB3000 Separator Configuration Guide

Now we store the results:

For Result X:

Enter New Pressure as the Description.

Open the Point Picker.

Select AI_ > Pressure (Instance 2-5) > Override Value.

For Result Y:

Enter 4088 Pressure as the Description.

Open the Point Picker.

Select Press_ > 4088B-1 Press (Instance 1-1) > Override Value.

D301884X012

October 2019

Click Save. Check that the values for the Syntax Checks are valid.

The pressure should now start to increase because the control valve is currently closed (0%

open).

FBxConnect 37

Page 42

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

3.4 Action Blocks & Effects

Action blocks enable you to define simple logic operations. Each action bock checks if

some condition is true/valid and if it is, triggers some action or effect(s). An individual

action block can trigger different types of actions or multiple effects. You can also chain

action blocks logically.

Click Action Blocks on the Configure tab.

The Action Blocks screen displays:

Note that the drop-down menu in the upper left-hand side of the screen displays all

defined action blocks:

In this part of the demo we are going to use action blocks (and an effect) to simulate the DI

high-level and low-levels switches.

38 FBxConnect

Page 43

Emerson FB3000 Separator Configuration Guide

3.4.1 Simulating the High Level Switch

Enter High Level Switch as the tag for Action Blk_1 (Action Block 1) and enable the action

block.

Define the logic for the action block:

Enter Liquid Level as the Description of Variable 1.

Open the Point Picker for Variable 1.

Select AI_ > Liquid Level (Instance 2-1) > Selected Value.

D301884X012

October 2019

Select Greater Than as the Operator.

Enter 33 as the value for Variable 2.

Enter 1 as the Deadband EU.

Select Binary Action for Output Type Triggered.

FBxConnect 39

Page 44

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Open the Point Picker for Output Action Point.

Select DI_ > Hi Lvl Switch (Instance 2-2) > Override Value

Keep the default Boolean Behavior value of Force 1 True & O False.

Click Save.

3.4.2 Simulating the Low Level Switch

We use both an action block and an effect to simulate the Low Level Switch.

Select Action Blk_2 (Action Block 2) in the drop-down menu at the top right of the screen.

Enter Low Level Switch as the tag for Action Block 2 and enable the action block.

Define the logic for the action block:

Enter Liquid Level as the description for Variable 1.

Open the Point Picker for Variable 1.

Select AI_ > Liquid Level (Instance 2-1) > Selected Value.

Select Less Than as the Operator.

40 FBxConnect

Page 45

Emerson FB3000 Separator Configuration Guide

Enter 27 as the value of Variable 2.

Enter 1 as the Deadband EU.

Select Effect for Output Type Triggered.

Select Effect 1 as the Trip Effect Link.

D301884X012

October 2019

Click Save. Note that the value of the Basic Logic Block Status for the action block changes

to

ACTIVE because the separator is currently empty.

Next, we configure Effect 1.

Click Effects in the Configure Tab.

An effect writes a certain value to an OPI when active (and can also write a value when

inactive). Each effect can be triggered by any action block.

FBxConnect 41

Page 46

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Enter Low Level Switch as the tag for Effect 1 and enable the switch.

Define the effect:

Open the Point Picker for Output Definition and select No Filter.

Select DI_ > Lo Lvl Switch (Instance 2-3) > Override Value

Enter 1 as Output Active Value to Write

Keep Output Inactive Value to Write at 0 and Inactive Value Set Enable at Checked.

Keep Assert Behavior Continuously to Both States.

42 FBxConnect

Page 47

Click Save. Note that the value for Effect Status is now ACTIVE and it shows that the Low

Level Switch Action Block (2) triggered the effect. Also notice the Output Value (DI 2-3)

changes to 1.0

3.5 PID Loops

A PID loop is a common control loop feedback mechanism. Typically, a process variable is

compared to a setpoint and the error is used to calculate an output. Tuning parameters are

used to create the desired behavior, but there is a trade-off between responding quickly to

error and overshooting or causing oscillation.

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Click PID Loops in the Configure menu.

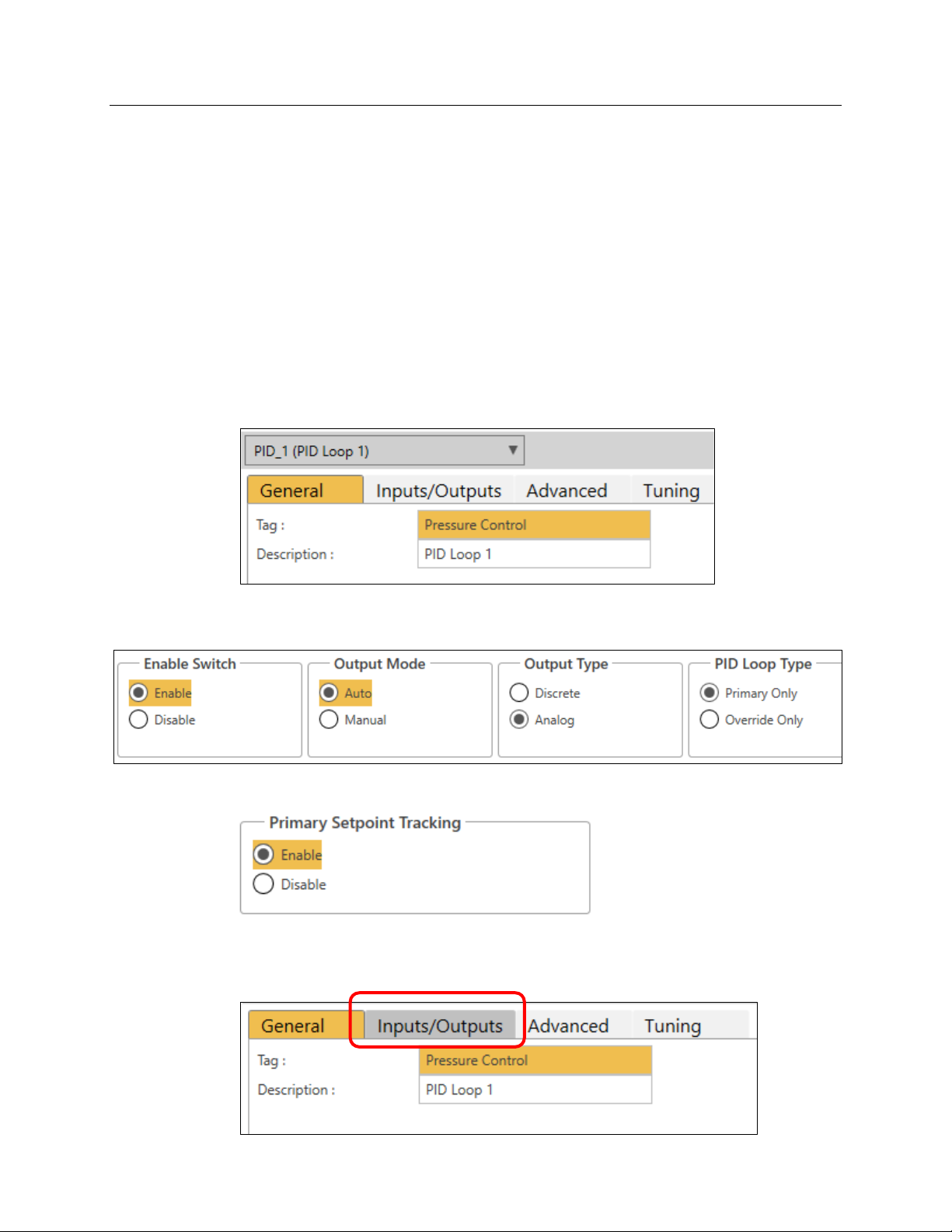

Each PID loop selection has four tabs:

FBxConnect 43

Page 48

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

General:

Configures the main behavior of the PID.

Inputs/Outputs:

Sets the points and ranged of the variables.

Advanced:

Provides advanced behavior and control settings.

Tuning:

Sets basic tuning parameters and shows trending graph of the variables.

3.5.1 Controlling the Pressure

Our demo’s PID loop modulates the gas control valve to control the pressure of the

separator.

Enter Pressure Control as the tag for PID Loop 1:

Enable the PID loop, set the Output Mode to Auto, and keep the defaults of Auto for the

Output Type and

Enable Primary SetPoint Tracking:

Before saving, we need to finish configuring all the settings for the PID Loop.

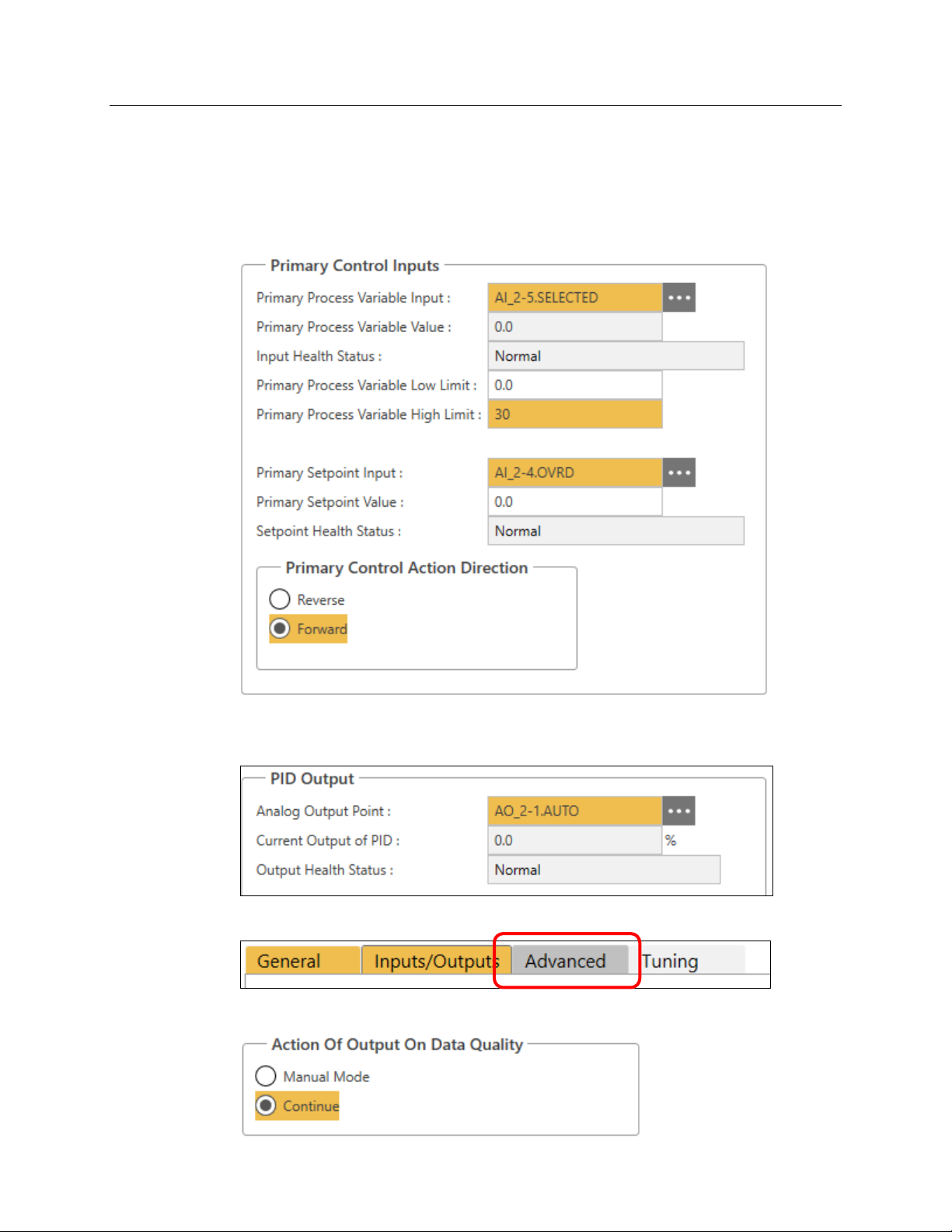

Select the Inputs/Outputs tab.

Primary Only for the PID Loop Type.

44 FBxConnect

Page 49

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Open the Point Picker for Primary Process Variable Input and select AI_ > Pressure

(Instance 2-5) > Selected Value.

Enter 30 as the Primary Process Variable High Limit

Open the Point Picker for Primary Setpoint Input and select AI_ > Pressure Setpoint

(Instance 2-4) > Override Value

Select Forward as the Primary Control Action Direction.

Open the Point Picker for Analog Output Point and select AO_ > Gas Cntrl Valve (Instance

2-1) > Auto Value

Select the Advanced tab:

Select the Continue option for Action of Output on Data Quality:

FBxConnect 45

Page 50

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

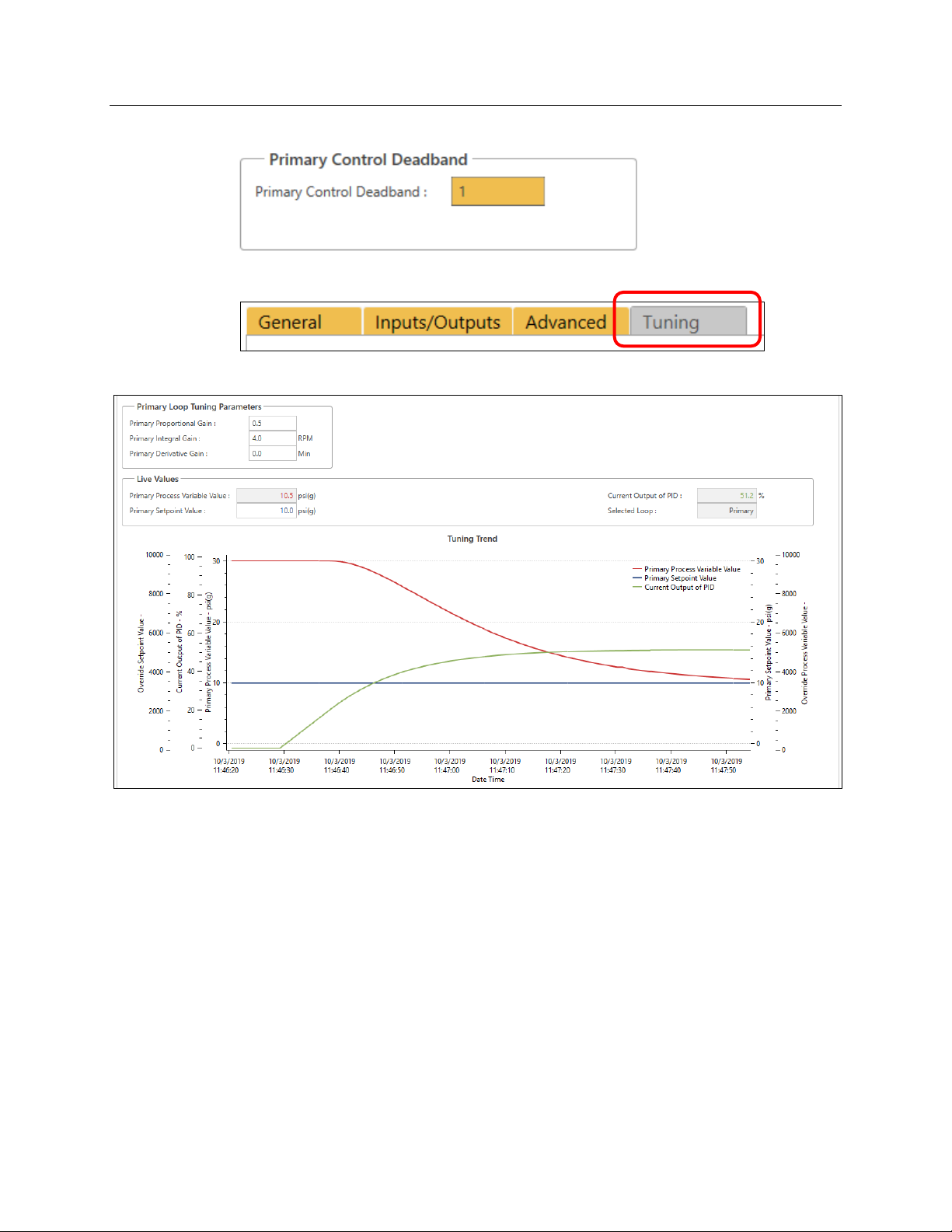

Enter 1 as the Primary Control Deadband:

Select the Tuning tab:

Click Save and observe the trend as the PID loop starts to control the pressure.

You can change the tuning parameters and see the changes in the behavior of the loop.

46 FBxConnect

Page 51

Emerson FB3000 Separator Configuration Guide

1

2

3

4

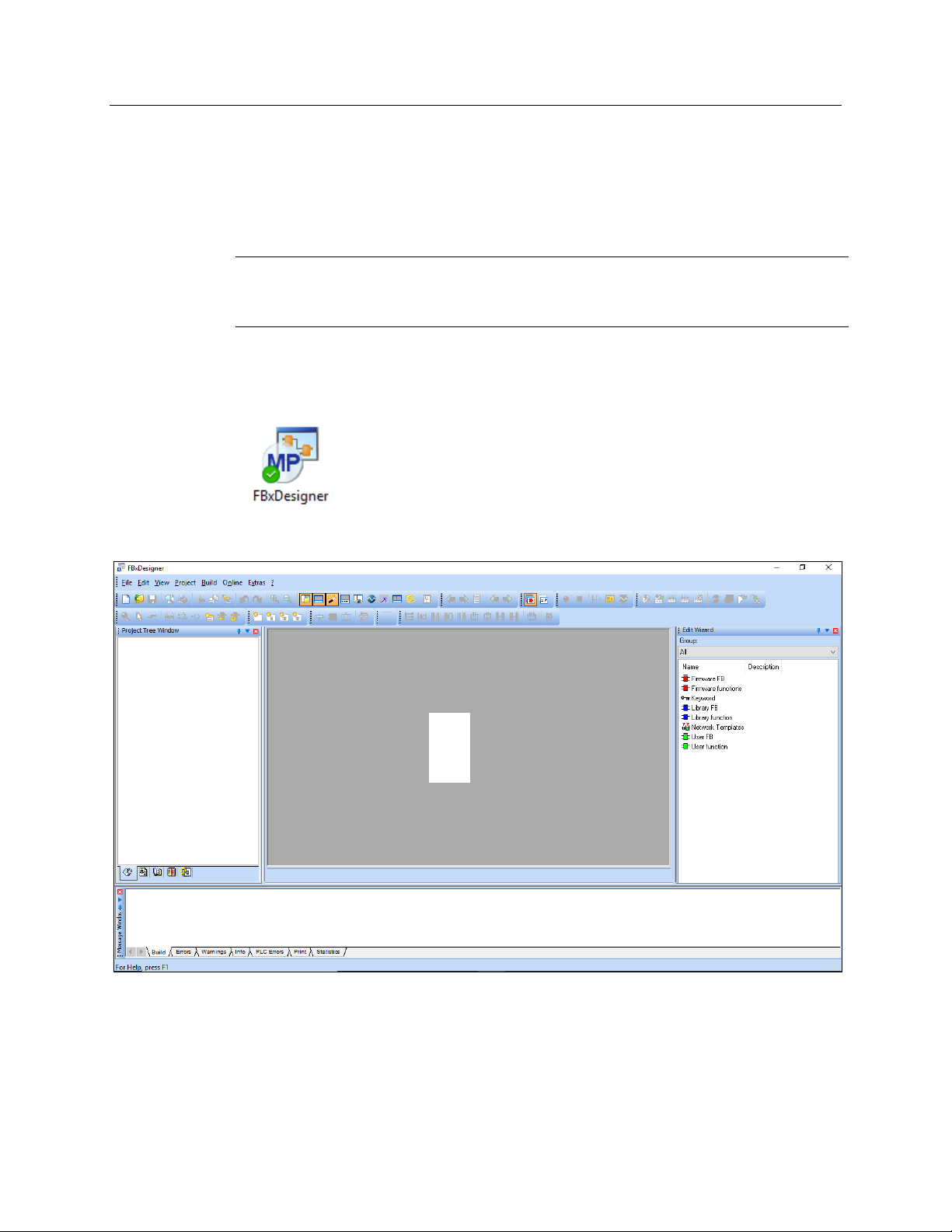

Chapter 4. FBxDesigner

FBxDesigner is an IEC61131 PLC programming environment separate from FBxConnect

than can be used to create more advanced control functions. FBxDesigner projects can be

downloaded to the RTU into application slots, along with graphical displays.

Note

FBxDesigner must be installed and licensed on your PC. For further information on this

product, refer to the FBxDesigner Quick Start Guide, part D301860X012)

4.1 FBxDesigner Overview

Start FBxDesigner by clicking on the FBxDesigner desktop icon.

D301884X012

October 2019

The FBxDesigner workspace screen opens.

FBxDesigner is divided into several panels:

Project Tree Window (1): Shows all the components of the current project and enables

you to navigate to different locations and insert objects.

Edit Wizard (2): Shows a list of the functions/objects that can be added to a program.

Message Window (3): Shows status/results of user actions, such as errors in compiling.

Main Window (4): Provides an editing workspace for the active worksheet.

FBxDesigner 47

Page 52

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

FBxDesigner Basics

An FBxDesigner project consists of one or more Program Organization Units (POUS)

and task(s).

POUs can be programs, functions, or function blocks.

POUs are composed of worksheets that contain comments, variables, and program

code.

Programs can use other functions and function blocks in their program code.

Program code is written in the IEC61131 languages (FDB, ST, LD, SFC, and IL).

A POU does not do anything until it is told to run by a task.

A task defines when to run program instances.

After making a project, you must compile it and create a boot project.

Once created, the boot project can be downloaded to the RTU

In this portion of the demo we are going to use FBxDesigner to create a simple project that

opens and closes the liquid level control valve based on whether the high- and low-level

switches are active.

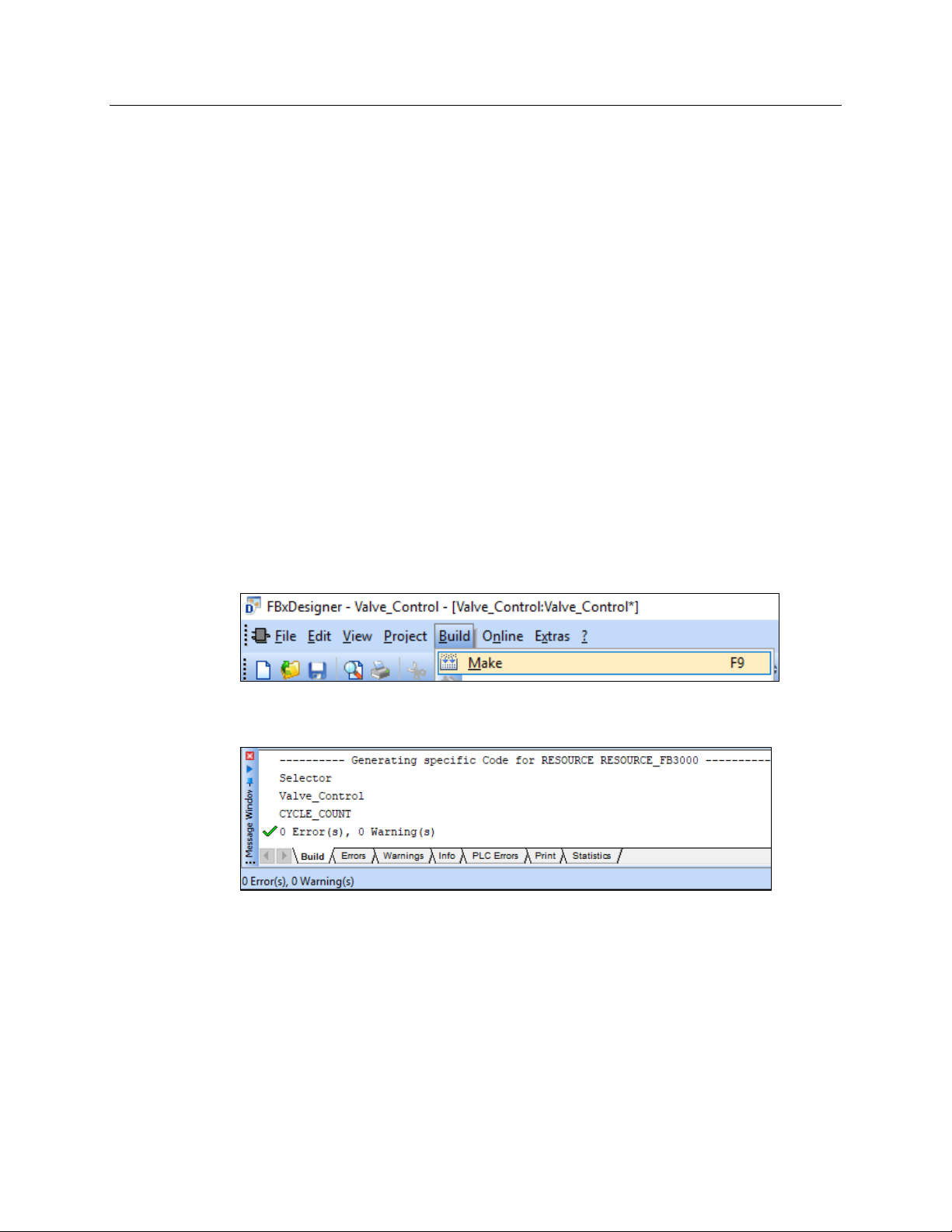

Periodically Check the Project for Errors

When you are creating a project (and as you proceed through this guide), it is a good

practice to frequently check the project for errors as you add new sections of code and

make changes. Click

for errors.

Build > Make on the top menu to compile the entire project and check

The Message Window on the bottom of the FBxDesigner screen displays any errors and

warnings that you must correct.

Errors are typically syntax mistakes, improper Data Type usage, or missing variables.

Warnings usually indicate that you have created something that is not being used.

48 FBxDesigner

Page 53

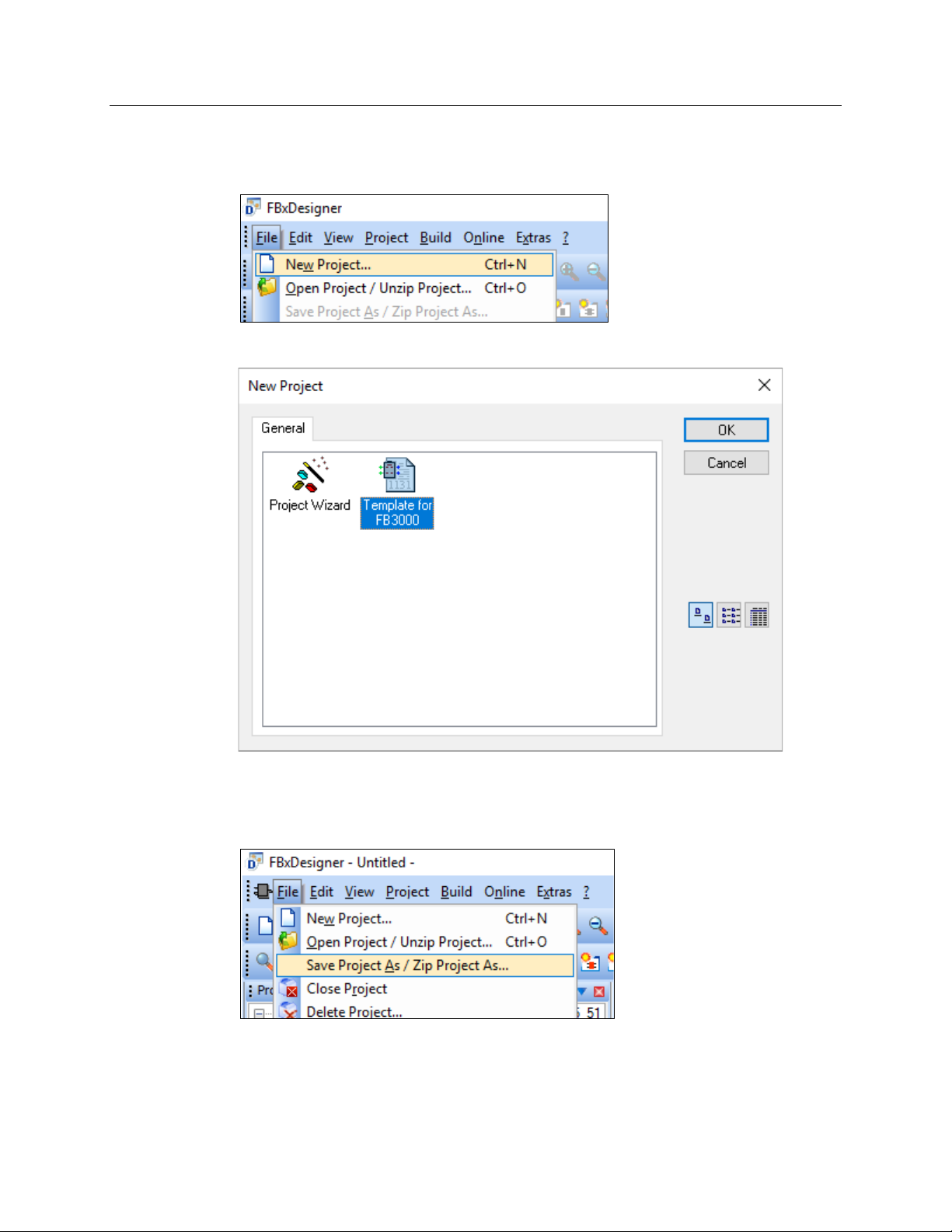

4.2 Creating a Project

To start a project, click File > New Project on the menu in the upper left of the screen.

The New Project screen displays. Select Template for FB3000 and click OK.

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

This creates a project with the configuration to run on an FB3000 RTU.

Before continuing any further, save the Project to give it a name and place in which to

store its associated files. On the FBxDesigner menu, click

Save this project as Level_Control in a location you can easily find later.

FBxDesigner 49

File > Save Project As.

Page 54

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

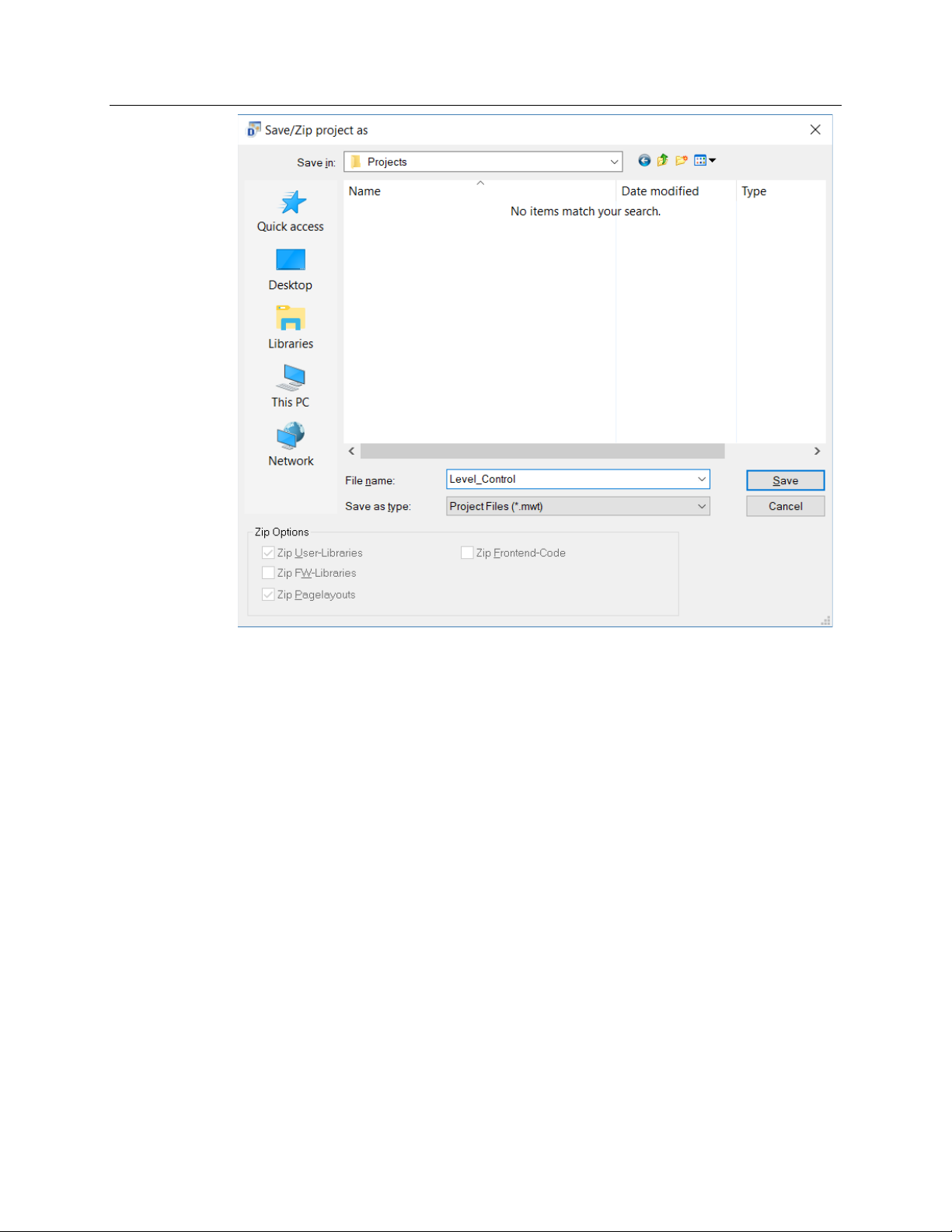

Note that the Project Tree window (on the left of the screen) has been populated with

objects:

50 FBxDesigner

Page 55

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Note

The system maintains an audit program called Cycle Count that tracks the number of

execution cycles the default task has run.

Now let’s start making our program.

4.2.1 Creating an FBD Program

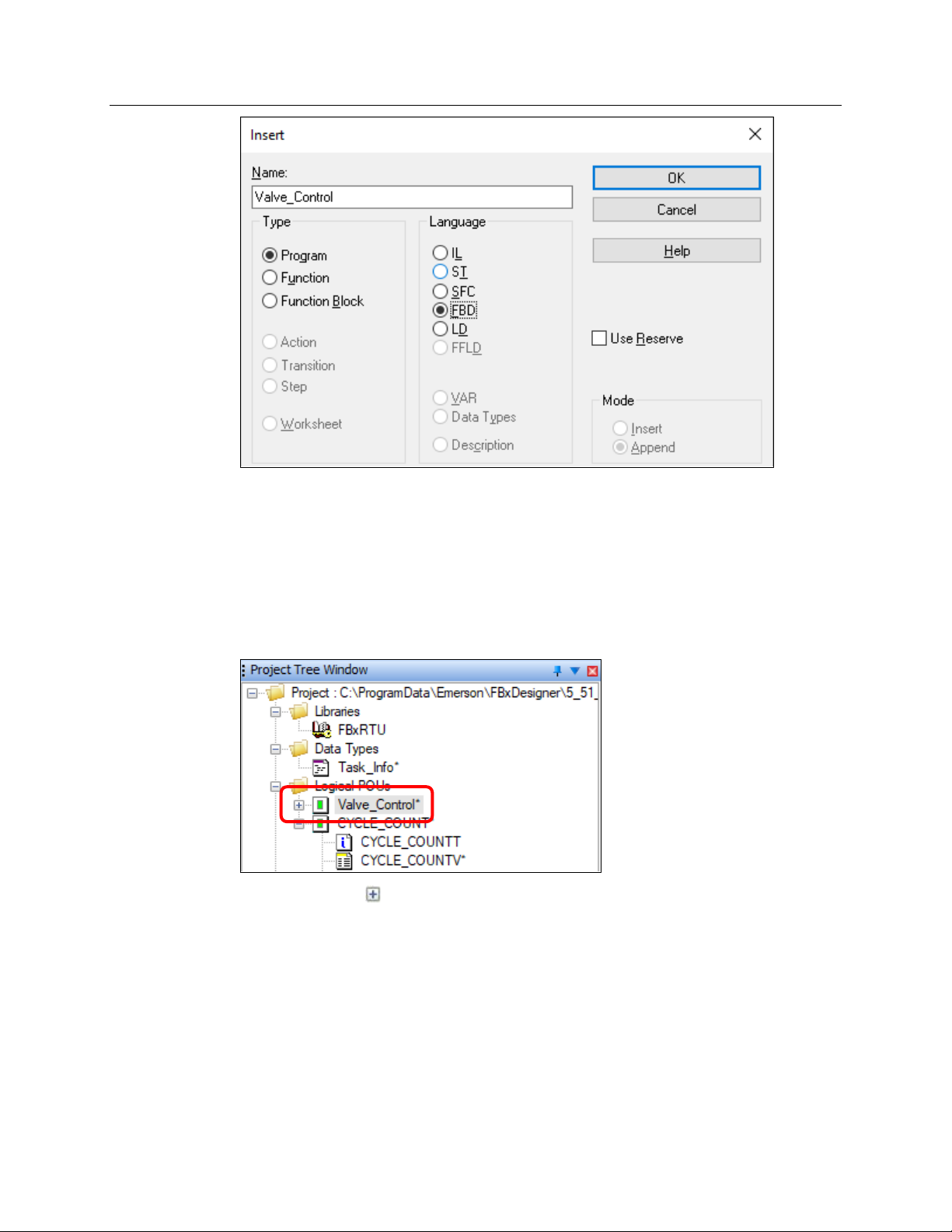

To make a new program, right-click Logical POUs > Insert > Program:

The Insert screen displays.

FBxDesigner 51

Page 56

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Enter Valve_Control (use the underscore; no spaces are allowed in project names) as the

Name.

Select FBD (Function Block Diagram) as the Language. FBD is a graphical “language” that

enables you to arrange function blocks on the screen and link them together like a flow

chart.

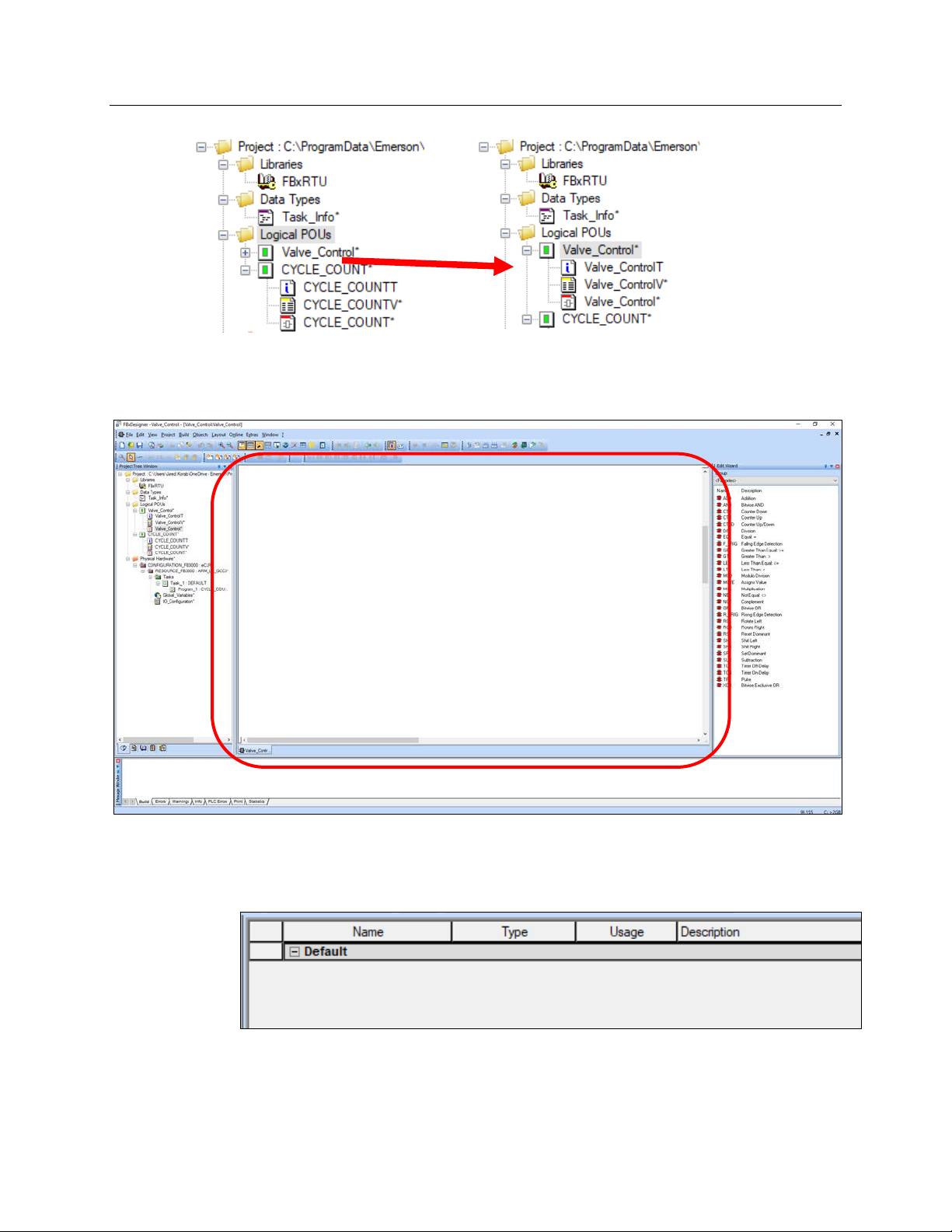

Click OK. The FBxDesigner screen displays; note that our Valve_Control project is now

listed as a Logical POU in the Project Tree Window.

Click the plus sign ( ) next to the POU in the Project Tree to expand the POU and display

its component worksheets.

52 FBxDesigner

Page 57

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Double-click the first worksheet (Valve_ControlT). A blank worksheet opens in the central

pane on the FBxDesigner screen:

This first worksheet is just a text document that is used for comments. Use it to describe

the purpose and functionality of a program for future reference by other developers.

Double-click the second worksheet (Valve_ControlV) to open the Variables list.

Note that it is currently empty. FBxDesigner automatically populates this worksheet with

the variables and functions created as you build the program code in the third worksheet.

FBxDesigner 53

Page 58

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Note

If you created a variable or function that you ended up not using in the program, you should

delete it from this worksheet. You can also edit variable and functions if they are the wrong

type.

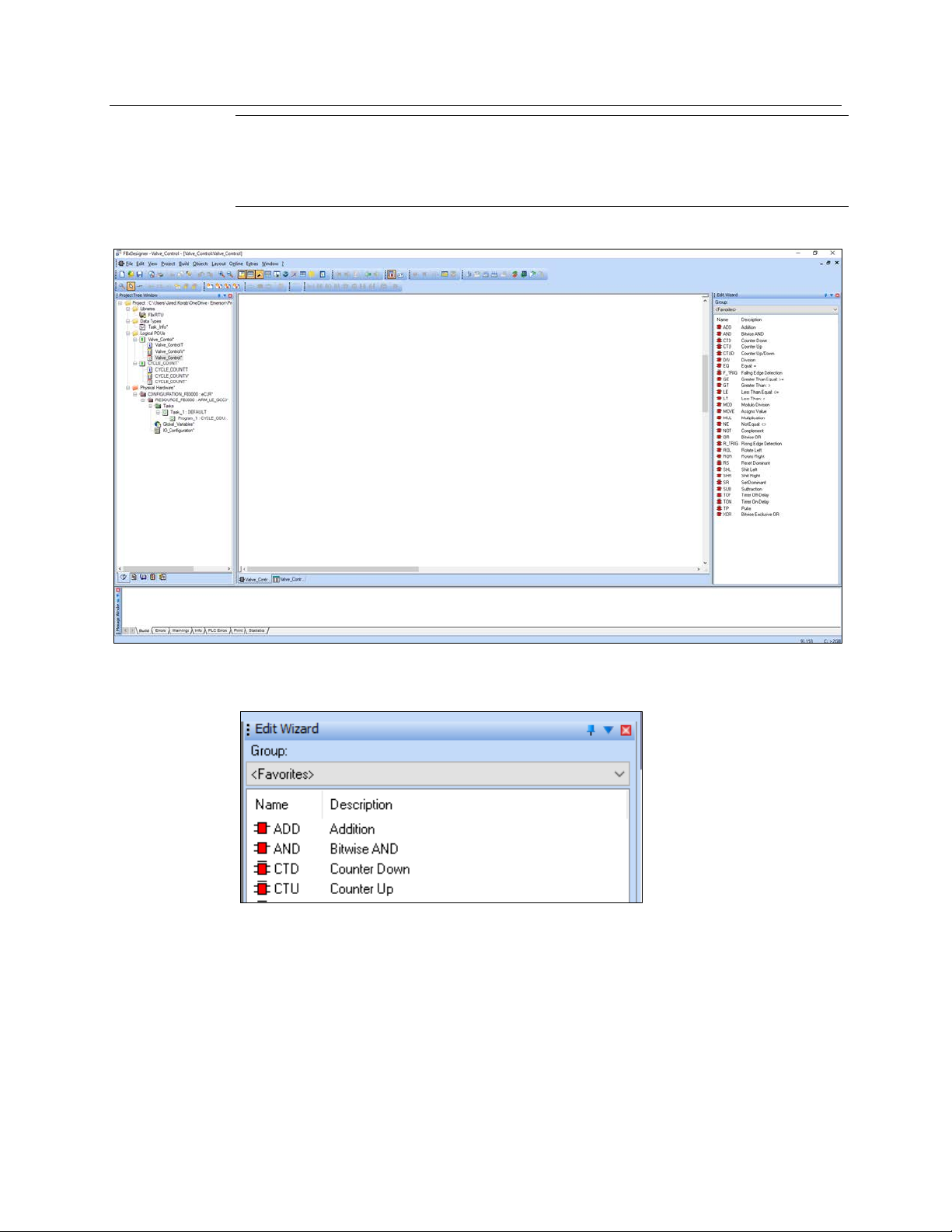

Double-click the third worksheet (Valve_Control) to open the Program Code.

This is where you write the actual program. Note that the Edit Wizard (at the right side of

the screen) has now populated with function blocks:

You use the Edit Wizard to find function blocks and add them to your program.

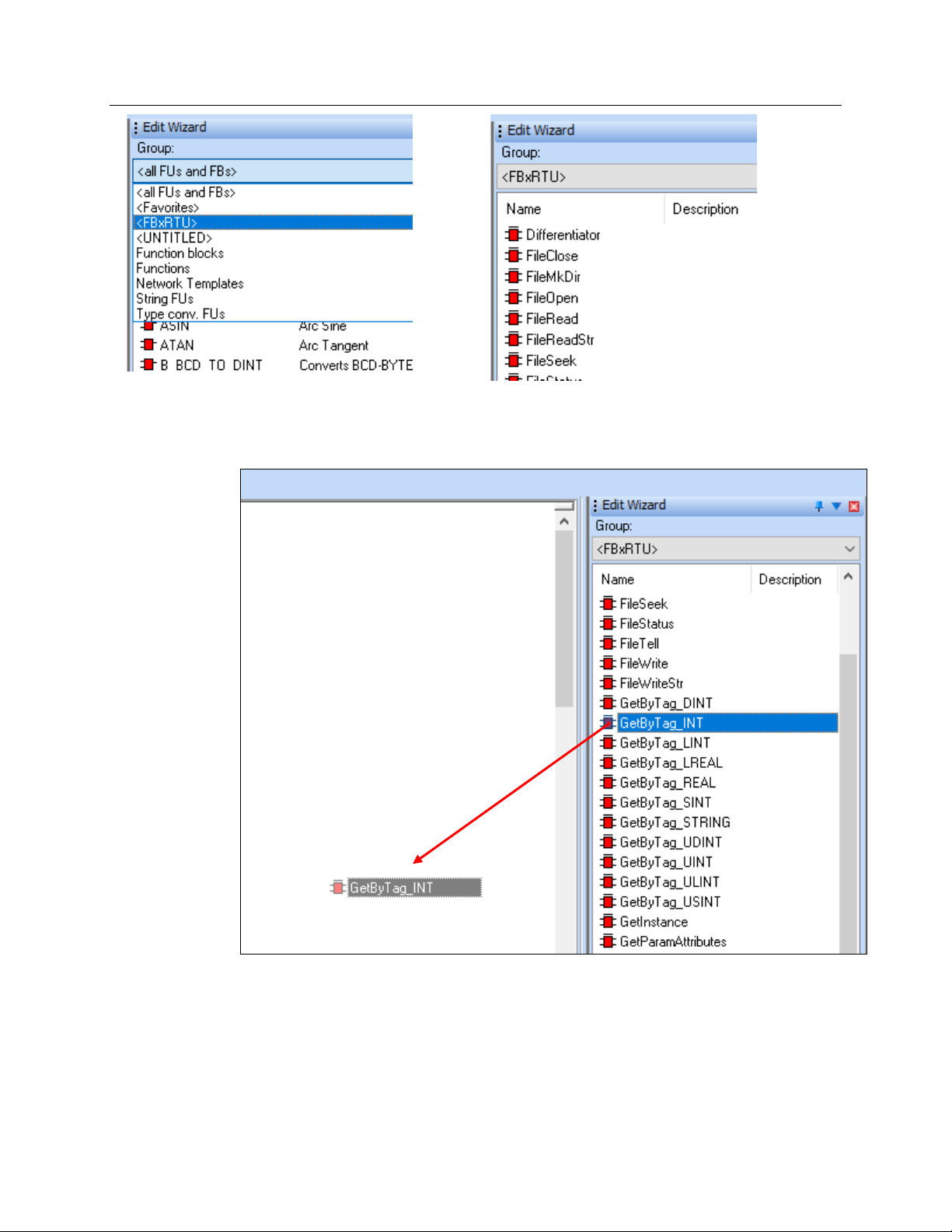

Select <FBxRTU> from the Group drop-down menu to see the function blocks that interact

directly with the FB3000.

54 FBxDesigner

Page 59

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

In the <FBxRTU> group, find the GetByTag_INT function block and drag-and-drop it into

the main window.

The Variable Properties window opens (which occurs whenever you add a new variable or

function block to the program code):

FBxDesigner 55

Page 60

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Enter HighLevelSwitch as the name and click OK. This creates a function block in the main

window.

Notice that the GetByTag_INT Function Block has two inputs (on its left side) and three

outputs (on its right side). The input

output

Value is the tag’s value. The other inputs and outputs are not needed in this demo.

Tag tells the block what OPI point to find and the

56 FBxDesigner

Page 61

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Note

To learn more about a specific function block, right-click it and select Help on FB/FU:

Create a second GetByTag_Int function block and name it LowLevelSwitch.

Click-and-drag the second function block underneath the first:

Find the SetByTag_INT function block and add one, naming it SetValve. Arrange it to the

right of the first two, with space between them:

FBxDesigner 57

Page 62

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

The SetByTag_INT function block is used to change the value of the DO controlling the

Liquid Level Control Valve.

Now let’s connect these function blocks to the tags. Double-click on the blue dot

connected to Tag on the first block.

The Variable Properties window opens again.

Instead of creating a variable name and then giving it the value of the tag, we can just

enter the value of the tag

and find the tag:

58 FBxDesigner

directly into the Name field as data. First, go back to FBxConnect

Page 63

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Open the Point Picker, select DI_ > Hi Lvl Switch (Instance 2-2) > Selected Value. Copy the

text that displays in the Tag field on the bottom left of the Point Picker.

Return to FBxDesigner, paste the copied text into the Name field of the Variable Properties

screen and bracket it with apostrophes (

The paired apostrophes ensure that FBxDesigner interprets the value as a string, which is

the data type required for the tag.

‘DI_2-2.SELECTED’):

Click OK.

Repeat this process for the other two tags. Select the Low Level Switch Selected Value tag

(as

‘DI-2-23.SELECTED’) for the second block and the Liquid Level Control Valve Auto Value

tag (as

‘DO-2-1.AUTO’) for the third block:

FBxDesigner 59

Page 64

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Now we need to define a function block in the middle to take the output values from the

first two blocks and determine what to send to the third block’s input value.

Let’s create a function block to do just that.

4.2.2 Creating an FBD Block with ST

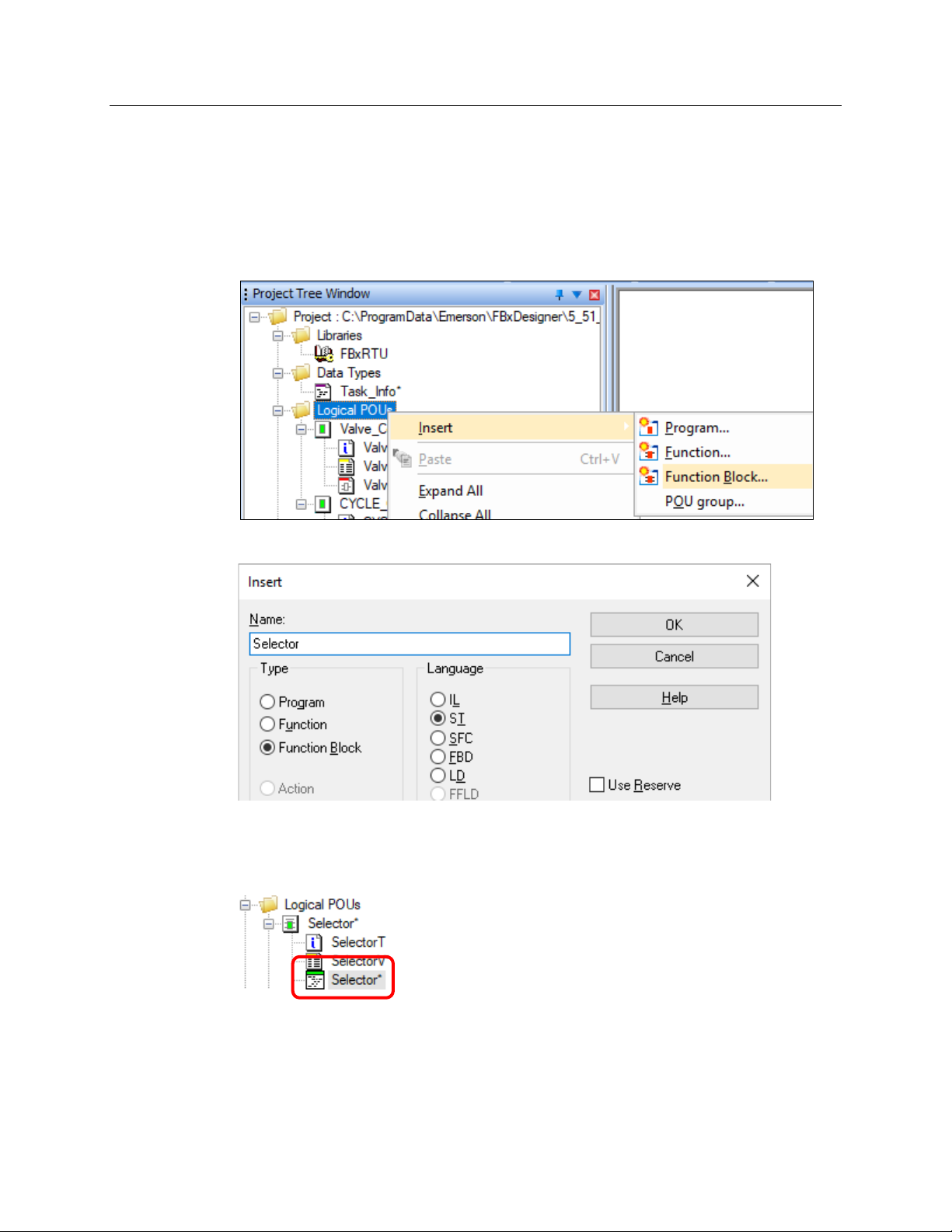

In the Project Tree Window, right-click Logical POU > Insert > Function Block.

The Insert screen displays.

Name the function block as Selector and select ST (Structured Text) as the Language

(Structured Text is a high-level textual language good for loops and calculations).

Double-click Selector to open the program code worksheet.

Note the it is a text worksheet rather than a graphical one like FBD.

60 FBxDesigner

Page 65

Emerson FB3000 Separator Configuration Guide

IF High = 1

…

D301884X012

October 2019

Let’s start programming. We want this function block to take in the statuses of the Highlevel and Low-level Switches and

close the valve (send 0) if the Low Level switch is active. If neither switch is active, the

function block should send no value so that the Valve status does not change.

Let’s start with an IF statement to check if the High_Level switch is active.

Enter:

open the valve (Send 1) if the High Level switch is active or

THEN

Valve := 1;

This checks if the High-Level Switch Input is equal to 1, and if it is, sends 1 to the Valve

output. If it is

Enter:

not equal to 1, we then need to check if the Low-Level Switch is active.

ELSIF Low = 1

FBxDesigner 61

THEN

Valve := 0;

END_IF;

Note that the IF statement must end with an END_IF statement.

Although we are done typing the code, we have not yet defined our variables. Essentially,

the program does not yet know what the words High, Low, and Valve mean.

Page 66

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

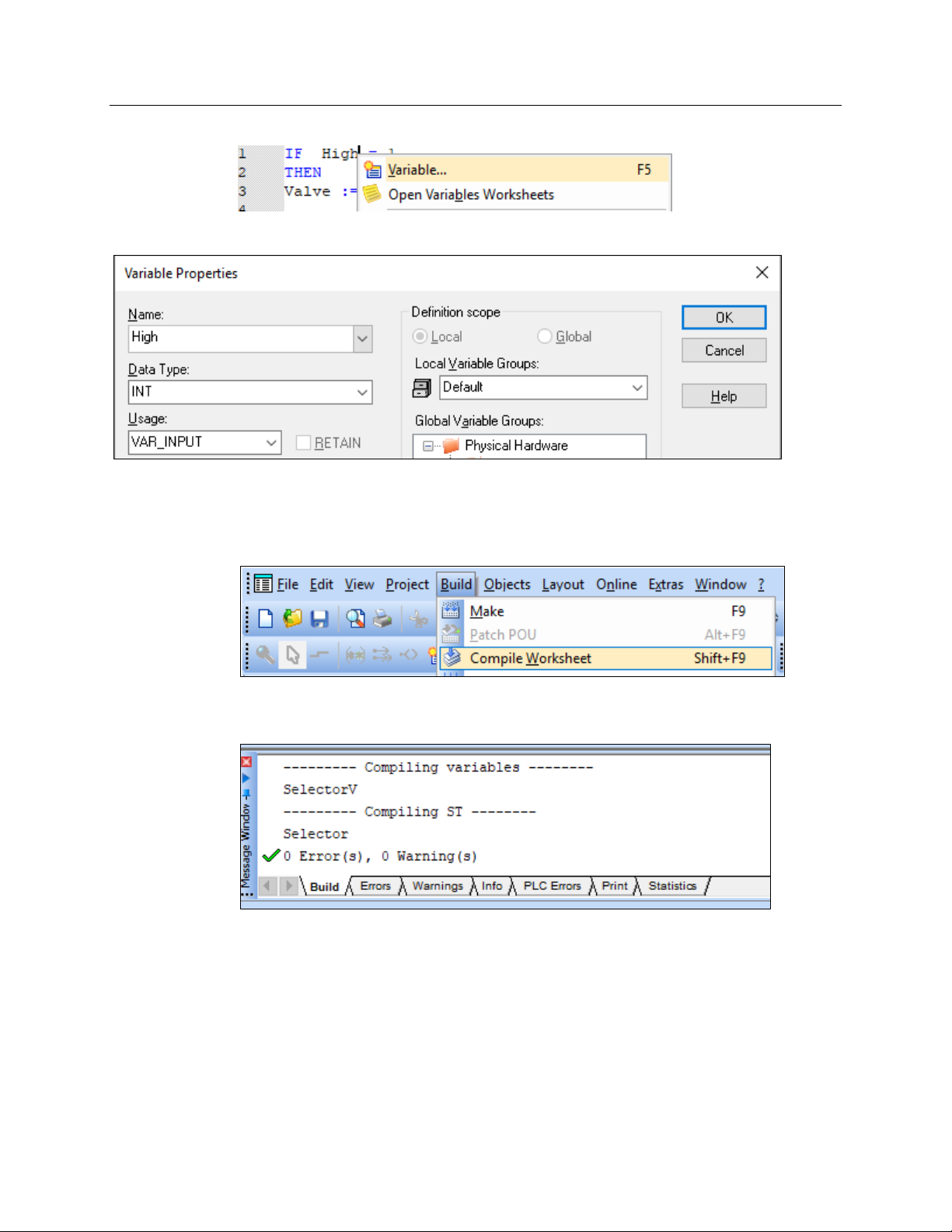

Right-click the word High and click Variable to open the Variable Properties window.

Select INT as the Data Type and select VAR_INPUT as the Usage. Click OK.

Repeat the process for the variables Low and Valve but indicate Valve as VAR_OUTPUT.

Finally, before leaving this worksheet, click Build > Compile Worksheet from the top menu.

This performs a check for any syntax errors or undefined variables in the code. Any errors

or warnings then appear in the Message Window at the bottom of the FBxDesigner screen:

Resolve any listed errors or warnings. Ensure that you have spelled all words correctly,

used punctuation as shown, and have defined all three variables.

62 FBxDesigner

Page 67

Emerson FB3000 Separator Configuration Guide

IF High = 1

END_IF;

D301884X012

October 2019

THEN

Valve := 1;

ELSIF Low = 1

THEN

Valve := 0;

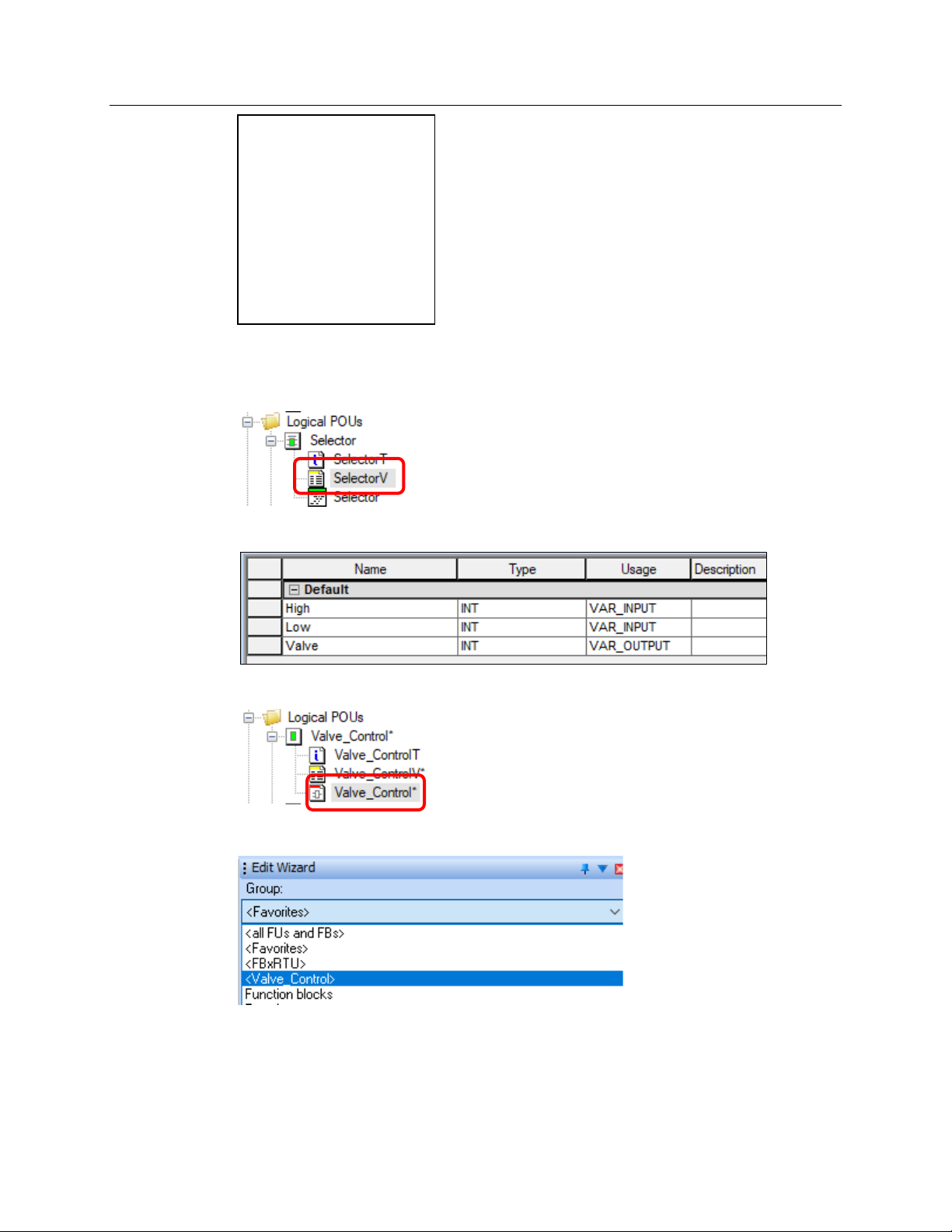

When you are done with the code, double-click the Variables worksheet of Selector

(

SelectorV):

You should now have three variables defined:

Double-click Valve_Control to redisplay the Code worksheet:

In the Edit Wizard, select the Group <Valve_Control>.

FBxDesigner 63

The <Valve_Control> group should now contain our newly defined function block:

Page 68

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

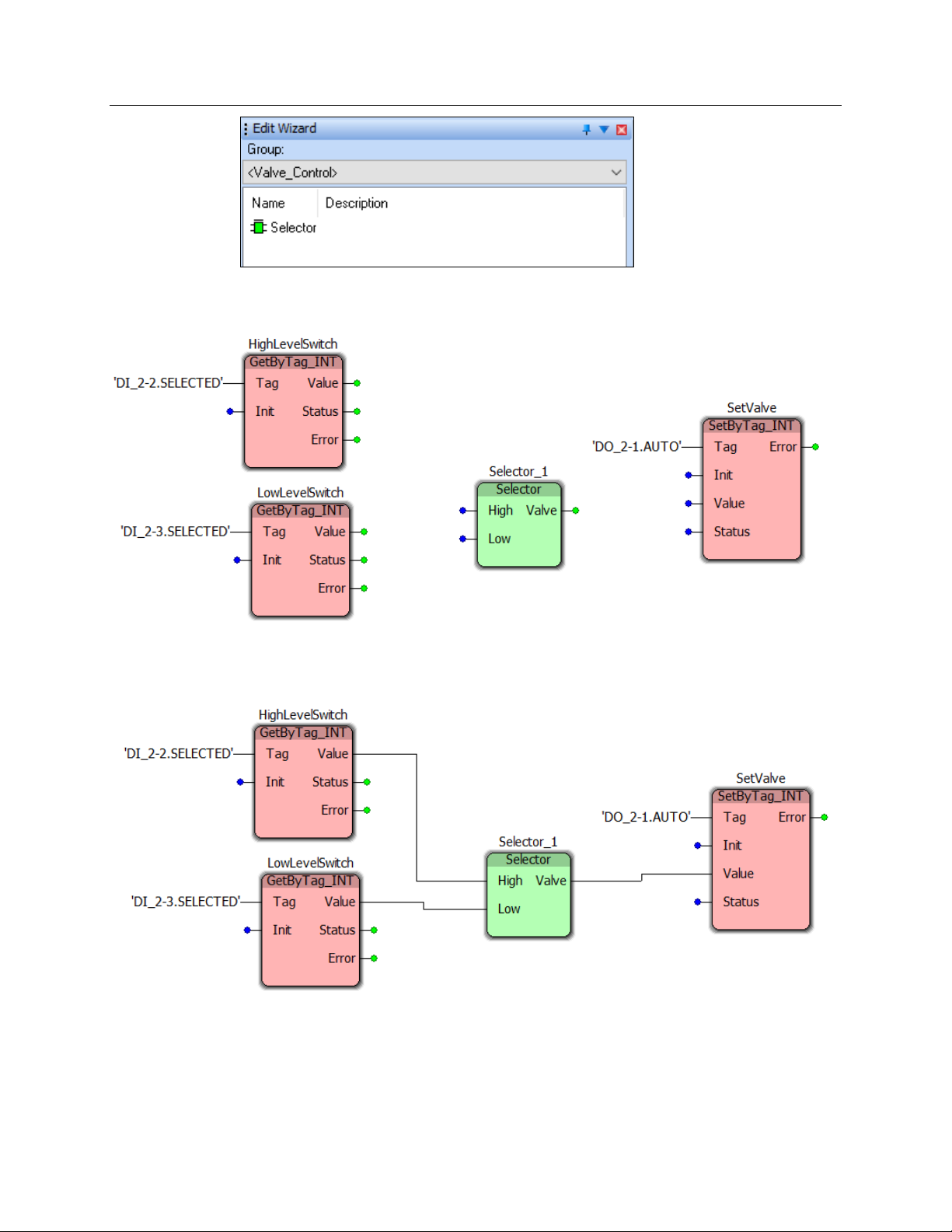

Click-and-drag to add a Selector function block in the middle of the program workspace.

Click

OK on the Variable Properties window. The workspace should now look like this:

Connect the function blocks as shown below, by clicking-and-dragging from the green

output dots to the blue inputs dots.

Click Build > Compile Worksheet to check for any errors or warnings.

Now we need to create a task to run an instance of this program.

64 FBxDesigner

Page 69

Emerson FB3000 Separator Configuration Guide

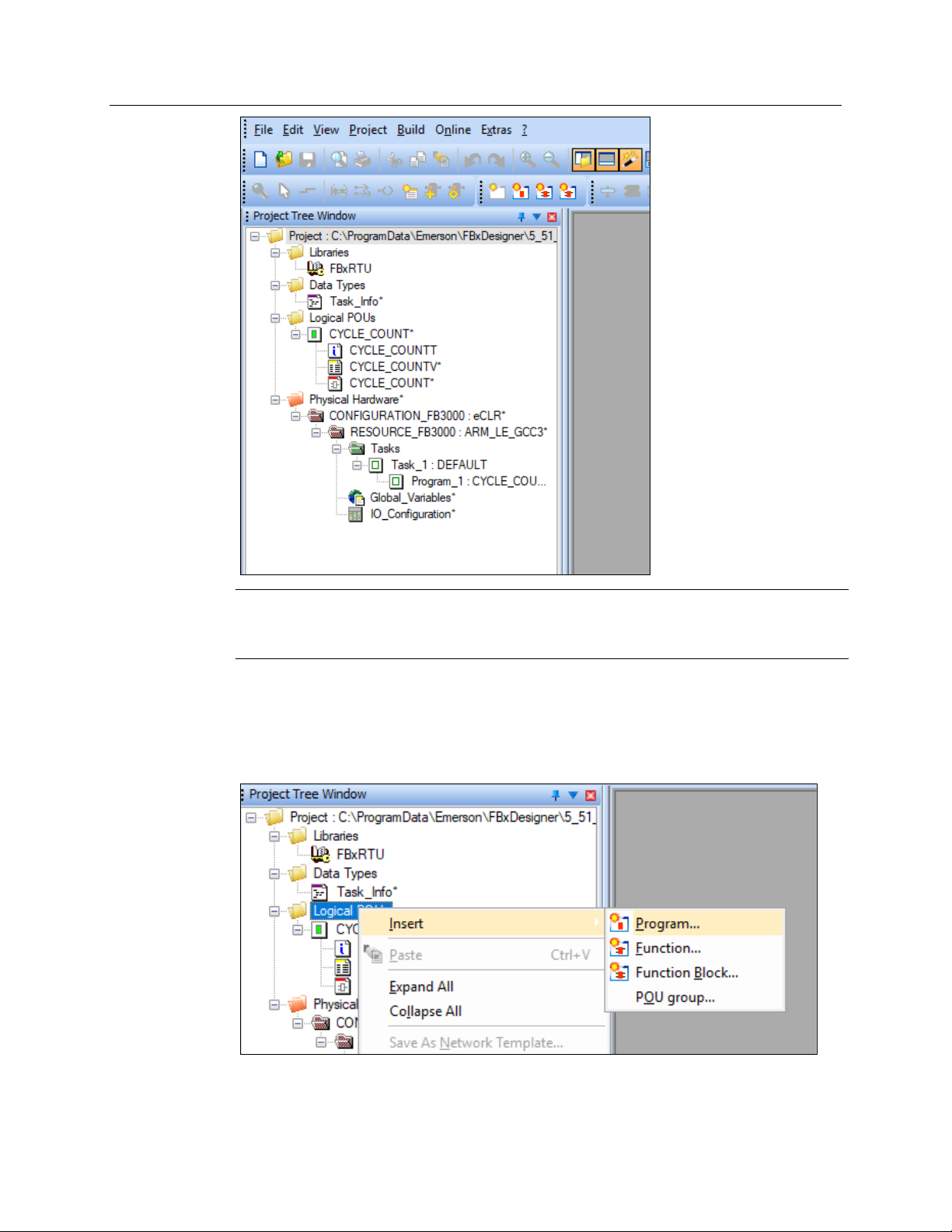

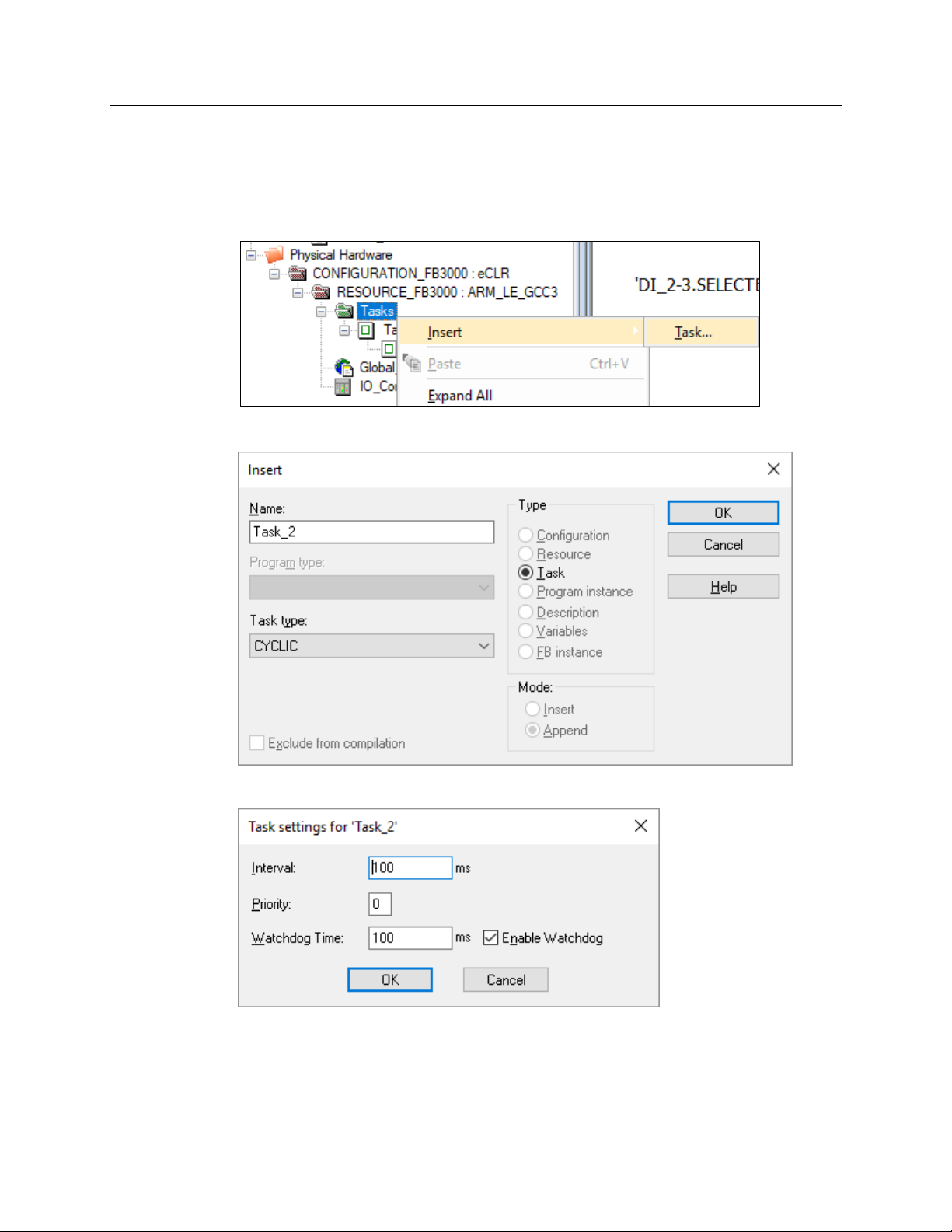

4.2.3 Tasks, Compiling, & BootProject

A task runs and executes programs. If you want to run any program, you must call that

program using a task.

In the Project Tree window, right-click Tasks > Insert > Task.

The Insert screen displays.

D301884X012

October 2019

Enter Task_2 in the Name field and click OK. The Task settings screen displays.

If you define multiple tasks, you can change the execution time for the tasks and set

relative priorities. Click

FBxDesigner 65

OK. The FBxDesigner screen displays.

Page 70

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

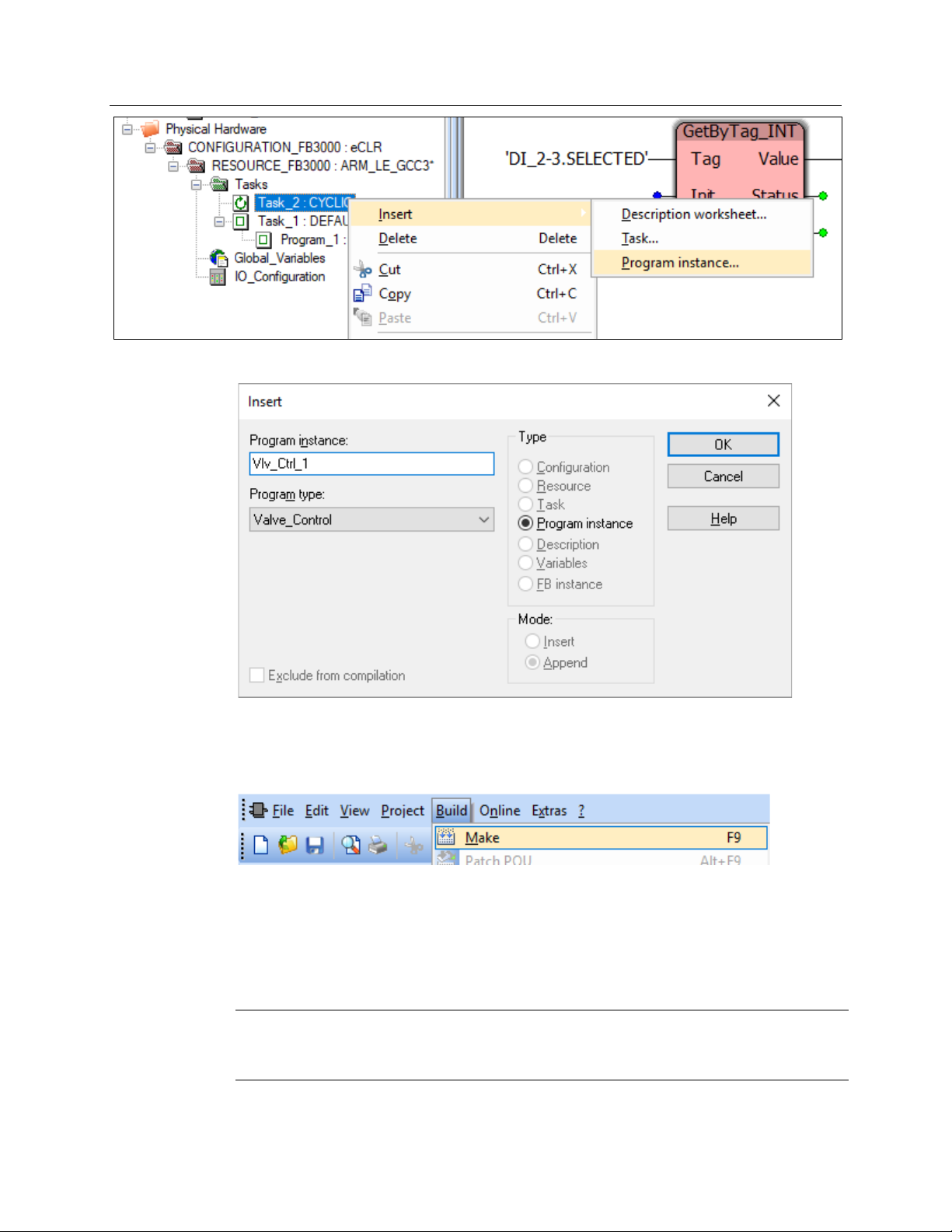

Right-click Task_2 and select Insert > Program instance. The Insert screen displays.

Name the Program Instance Vlv_Ctrl_1, select Valve_Control as the Program Type, and

click

OK. The FBxDesigner screen displays.

Select Build and click Make to compile the entire project.

If there are no errors, you have successfully made a project. Select Save the Project in the

top menu.

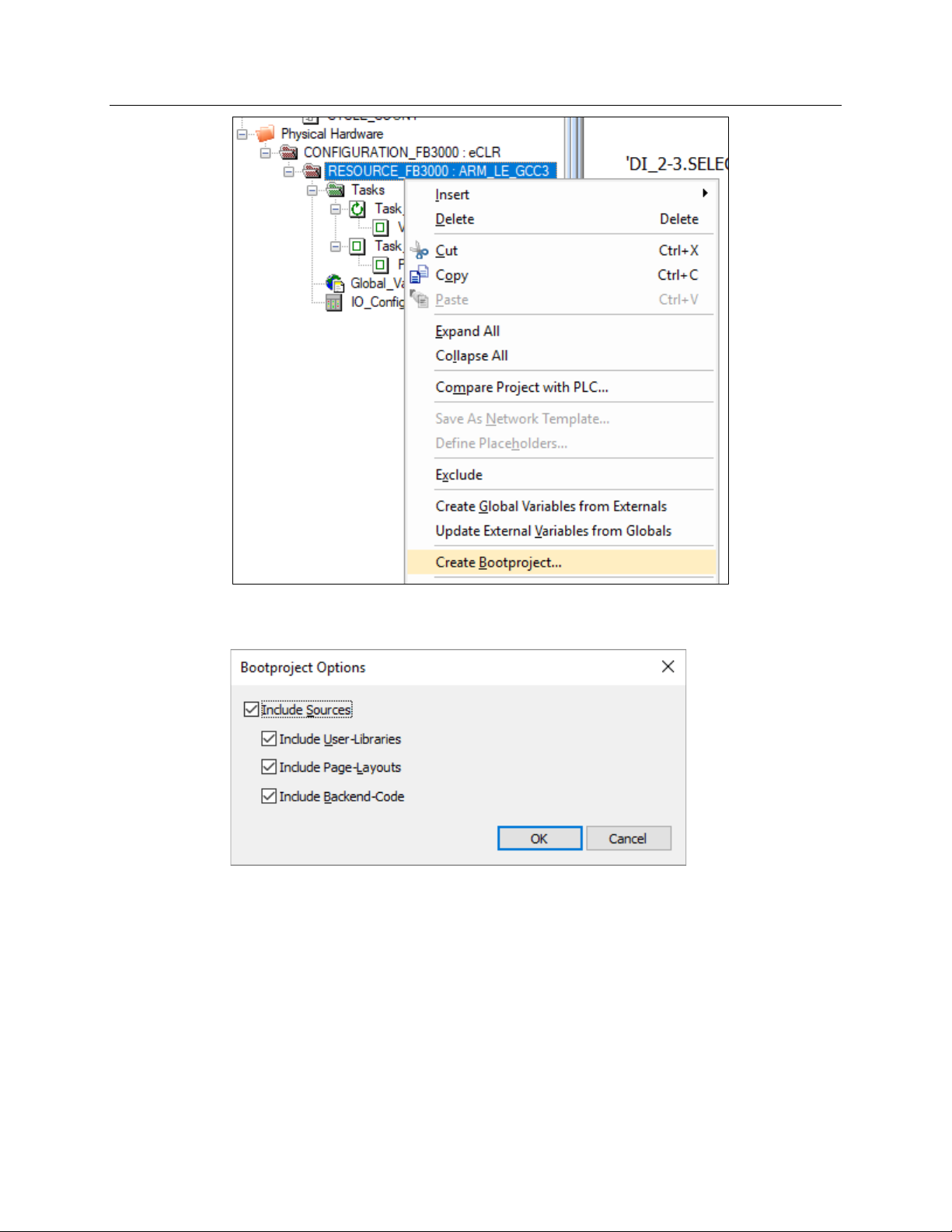

Now you need to make the boot project so it can be downloaded to the RTU.

In the Project Tree window, right-click RESOURCE_FB3000 : ARM_LE-GCC3… and select

Create Bootproject.

Note

This menu option is unavailable if you have made uncompiled changes. You must compile

your project before continuing.

66 FBxDesigner

Page 71

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

The Bootproject Options screen displays. You can include the source code with the

downloaded application.

If you choose to include the source code, someone with access to the RTU and

FBxDesigner can download this FBxDesigner project from the installed application and edit

it. If you do not include the source code, then the application cannot be looked into or

edited from the RTU.

Click OK. Once FBxDesigner completes the bootproject, the project is ready for download

to the RTU. Refer to Section 6, Applications in this guide for further information on

downloading a project.

FBxDesigner 67

Page 72

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

68 FBxDesigner

Page 73

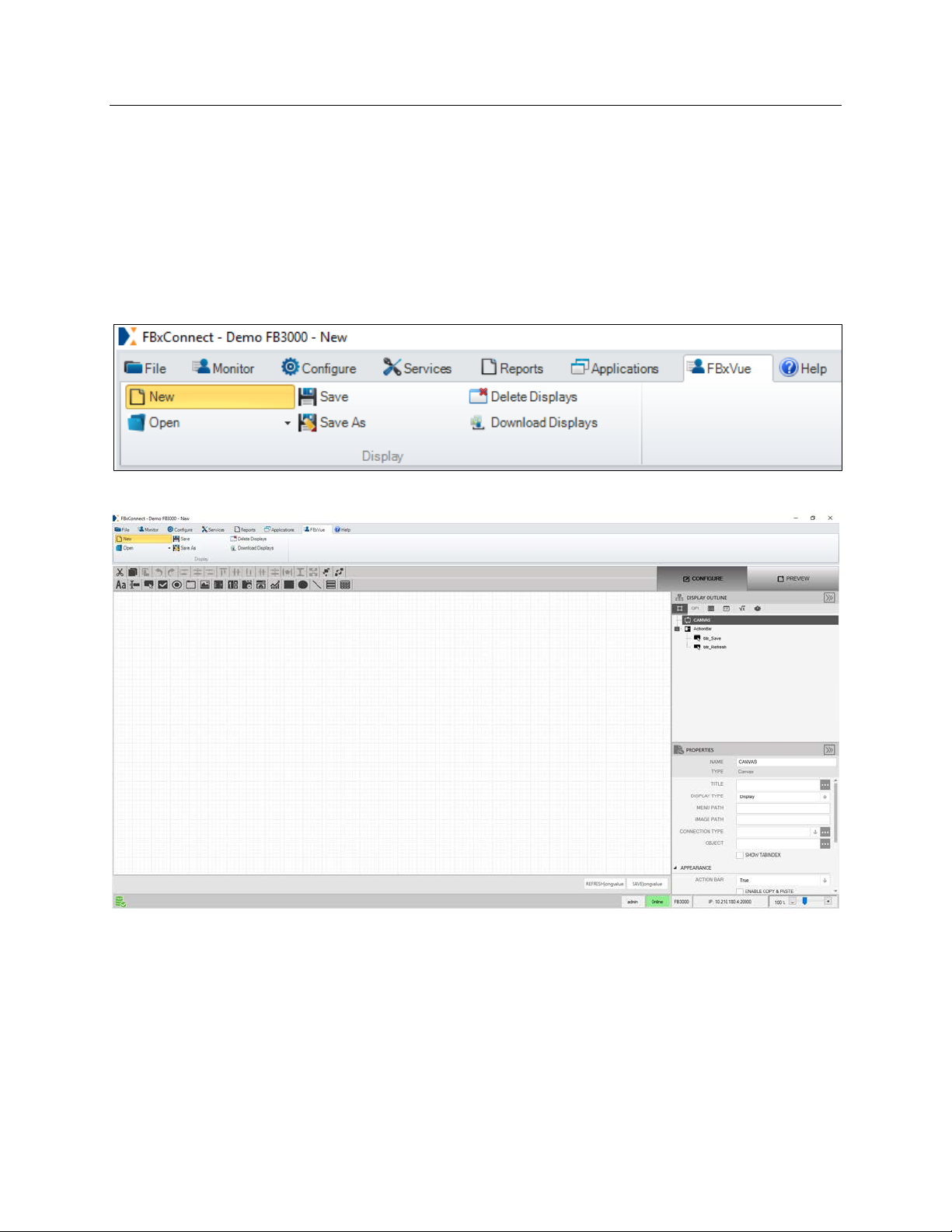

Chapter 5. FBxVue

FBxVue is a graphical display builder included as part of FBxConnect. All the screens in

FBxConnect can be created with FBxVue.

5.1 FBxVue Overview

Select the FBxVue tab in FBxConnect and then click New to create a new display.

The FBxConnect workspace screen displays.

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

FBxVue consist of these sections:

Developer Toolbar: On top, contains Layout buttons to manage the position and

appearance of controls, and Control buttons to add controls to the display.

Canvas: Main work space where you add controls to.

Action Bar: Has buttons on the bottom of the Display such as Save and Refresh.

Configure/Preview: Buttons located on the top right to toggle editing/viewing.

Display Outline: Menu on the middle right, used for organizing & selecting controls.

Properties Pane: Menu on the bottom right, used for editing the selected control.

FBxVue 69

Page 74

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

The layout buttons in the Developer Toolbar enable you to manage the position and

appearance of controls:

Cut / Copy / Paste

Undo / Redo

Align Selected Objects by Left / Centers / Right / Top / Bottom

Make Spacing Equal Horizontally / Vertically

Make selected Objects the same Width / Height / Both

Bring selected Object to Front / Back layer

Use the control buttons in the Developer Toolbar to create new controls:

Label: Shows text, used to label objects.

TextBox: Shows the name, value, and units of an OPI. Allows the user to enter a new

value if the OPI is writable.

Button: A button that evaluates an expression when clicked.

Checkbox: Allows multiple entries to be selected at once.

GroupBox: A frame that can hold multiple controls inside it.

Properties Pane: Menu on the right, used for editing the objects in the display.

NumericUpDown: Allows you to select an object from a numbered list.

TabControl: A frame that has tabs on top to allow multiple pages in the same space.

Gauge: Shows a value visually.

Chart: Can plot multiple values over time.

Rectangle / Ellipse / Line: simple shapes.

Accordion: A collapsible menu that can show multiple objects.

Grid: A grid for displaying objects.

Use the Preview mode while building the display to see how the controls will look on the

finished display.

The Display Outline screen contains all the controls, OPIs, data sources, variable,

expressions, and timers associated with the current display.

70 FBxVue

Page 75

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

The Properties window allows you to edit the available properties of a selected control, or

of the canvas itself. The properties available depend on the type of control selected.

FBxVue 71

Page 76

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

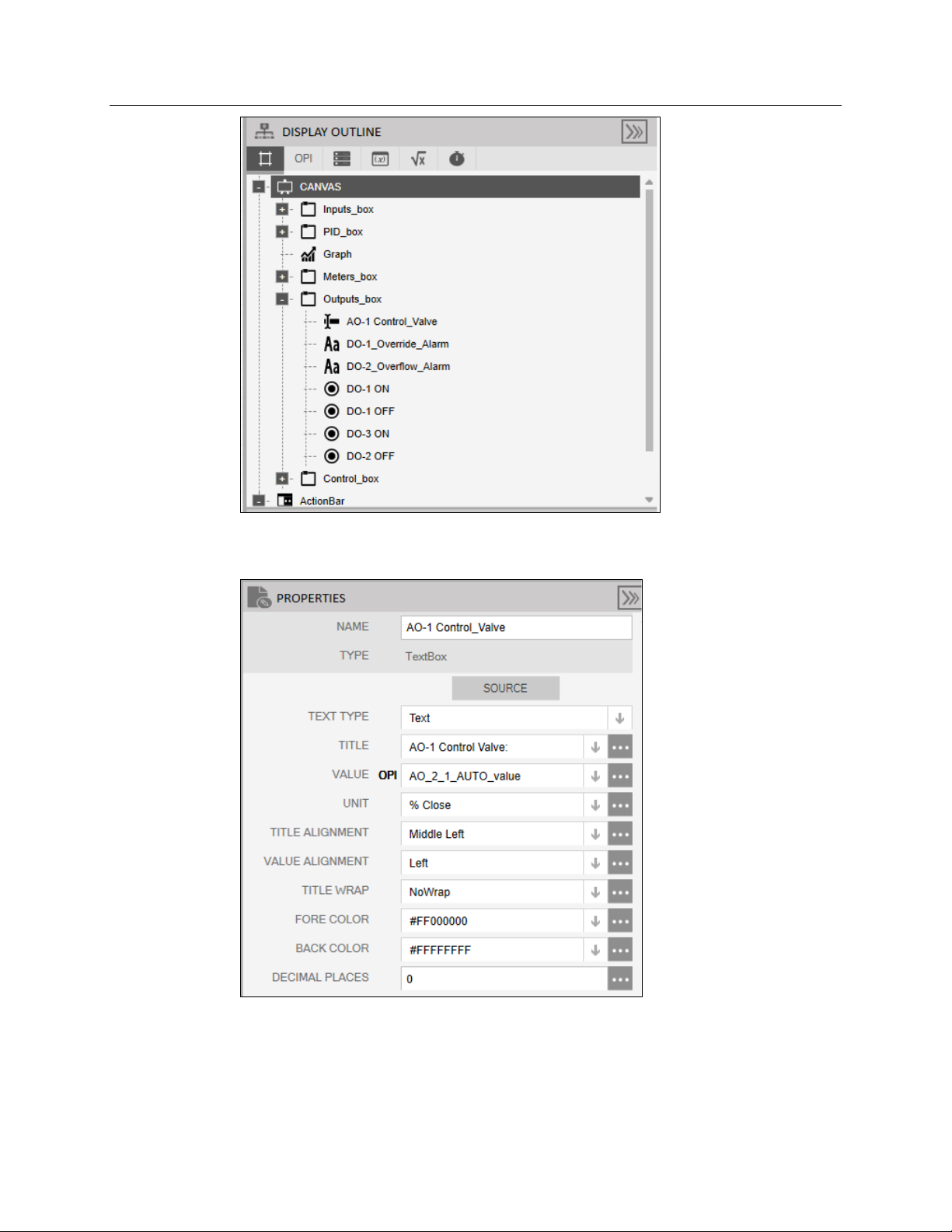

5.2 Building a Display with FBxVue

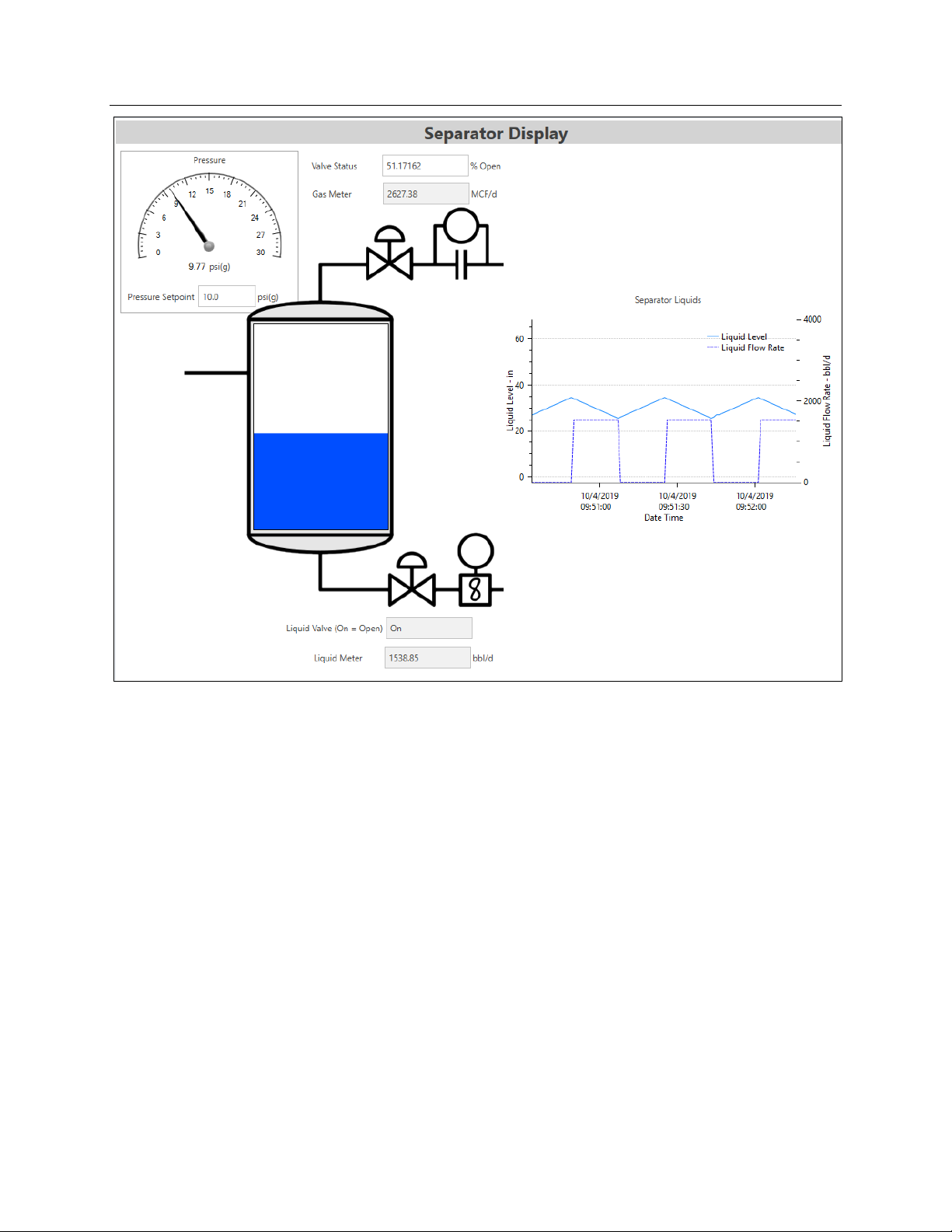

In this section, we build a display to show:

A graphic of the liquid level in the separator tank

Pressure Gauge & Pressure Setpoint

Chart showing Trend line of Liquid Level and Liquid Meter Flow rate

Valve Statuses and Meter Flow Rates

This is what the final display should look like:

First, give the display a title. With Canvas selected in the Display Outline, enter Separator

Display as the Title in the Properties window.

72 FBxVue

Page 77

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Open the Point Picker for Title Style in the Appearance section of the Properties window.

Select Display Title so that the title will be big and bold. Click OK.

FBxVue 73

Page 78

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Click Preview on the top right to see what the title will look like.

The Separator Display title should appear at the top:

74 FBxVue

Page 79

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Click Configure (next to Preview) to return to editing.

Note

Preview the display frequently as you add controls to test their appearance and

functionality.

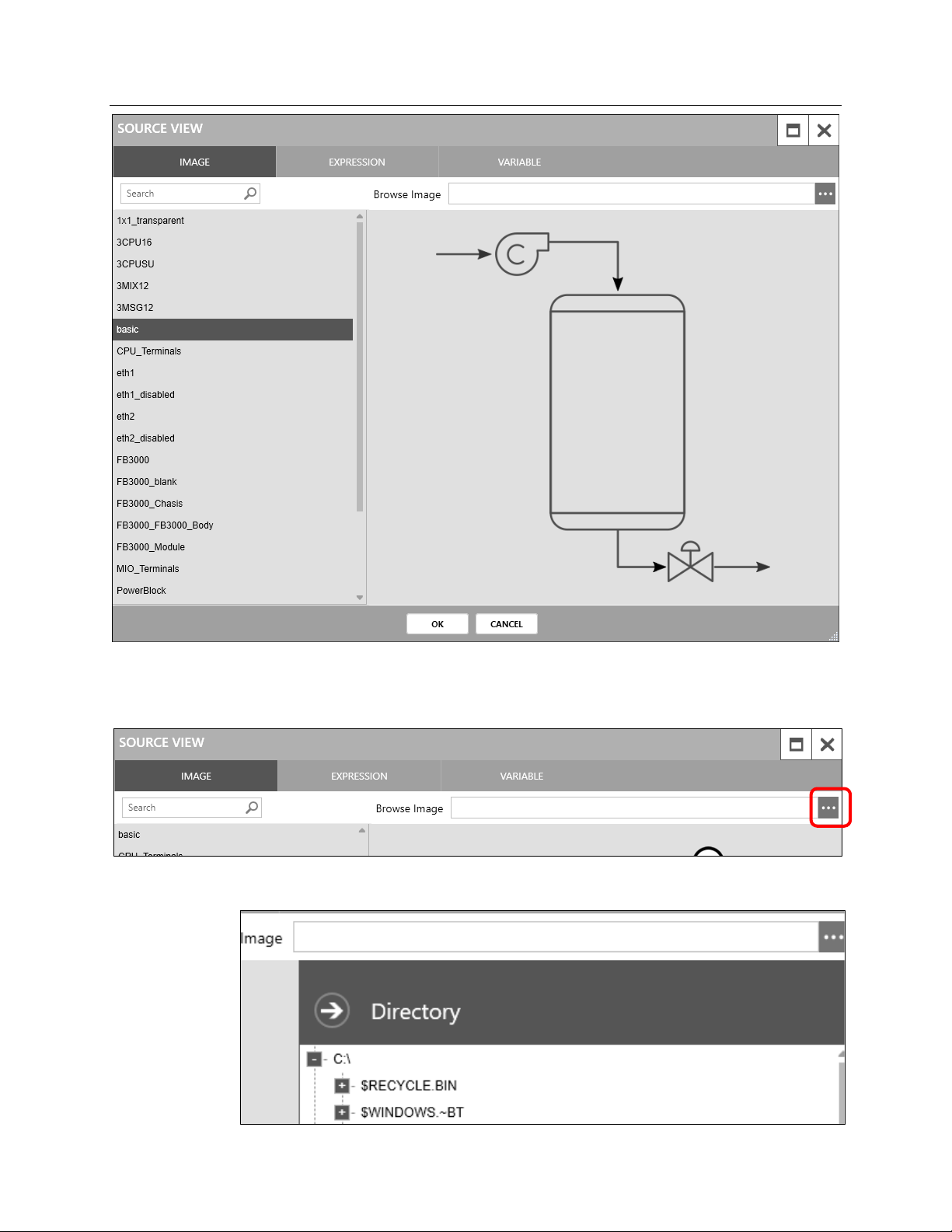

Let’s add the graphic of the separator. Click the Image button on the Developer

toolbar.

Click-and0drag over the left area of the canvas, as shown below.

With the Image selected (it will appear yellow and be highlighted in the Display outline),

click on the Point Picker for Source in the Properties Window

A Source View window opens with a list of images on the left-hand side:

FBxVue 75

Page 80

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

You can select from one of the Separator images included in the list, or you can include any

picture you have on your PC. To select a picture from your PC, click on the Point Picker in

the Browse Image field:

This opens a directory to your PC that you can use to browse to an image you have ready.

76 FBxVue

Page 81

Emerson FB3000 Separator Configuration Guide

Sep_icon

Sep_icon_2.png

D301884X012

October 2019

This document should be packaged inside a demo folder than includes the image

Sep_icon_2.png, located inside the Display/Images folder.

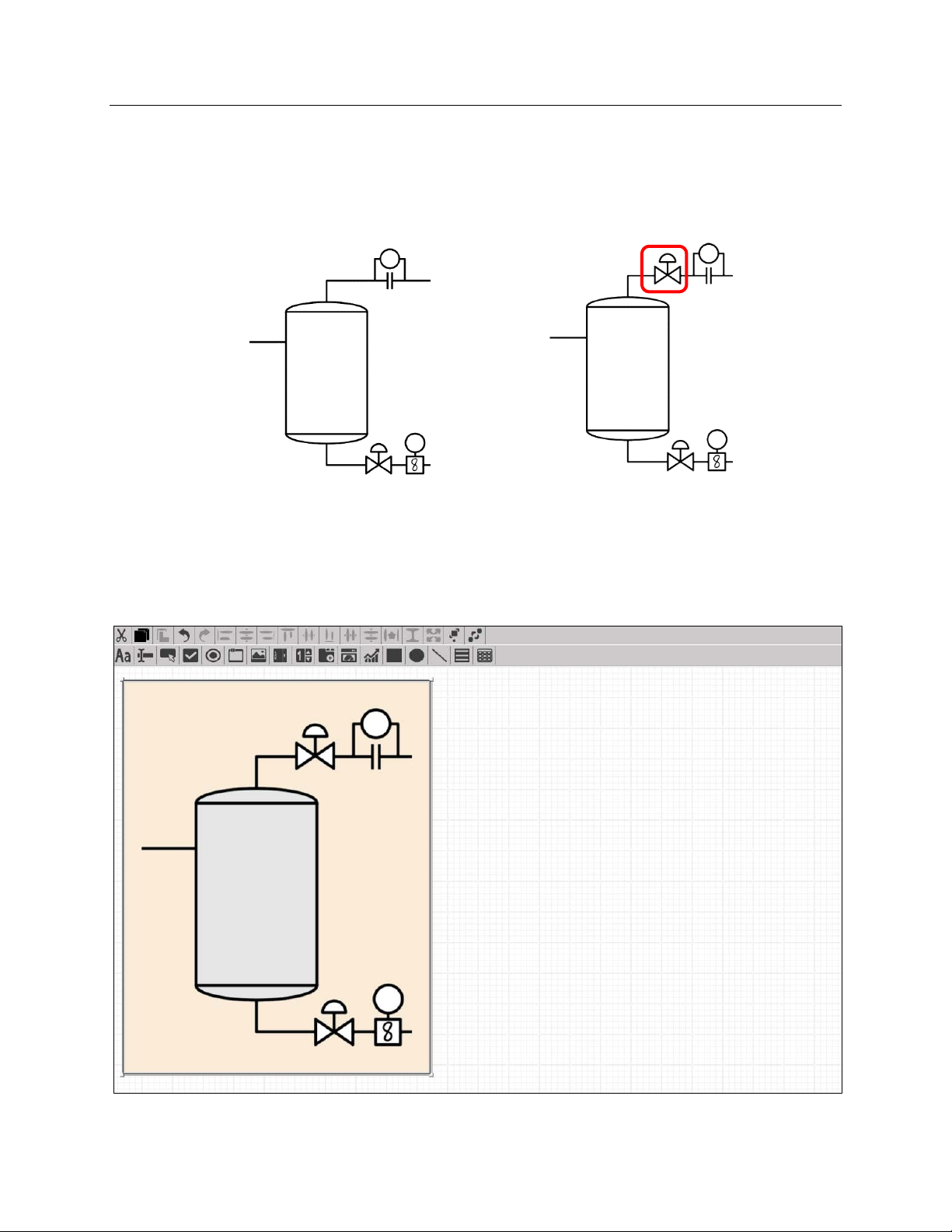

You can either choose the Sep_icon image that is included in FBxVue or browse for the

Sep_icon_2.png image in the Directory. The only difference is the presence of a valve for

the gas stream.

(included in FBxVue)

The display should look like this. To move or resize the image, click and drag on it or its

corners.

(included with this guide)

Now we can add a rectangle object over the separator tank that shows the liquid level

height.

FBxVue 77

Page 82

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

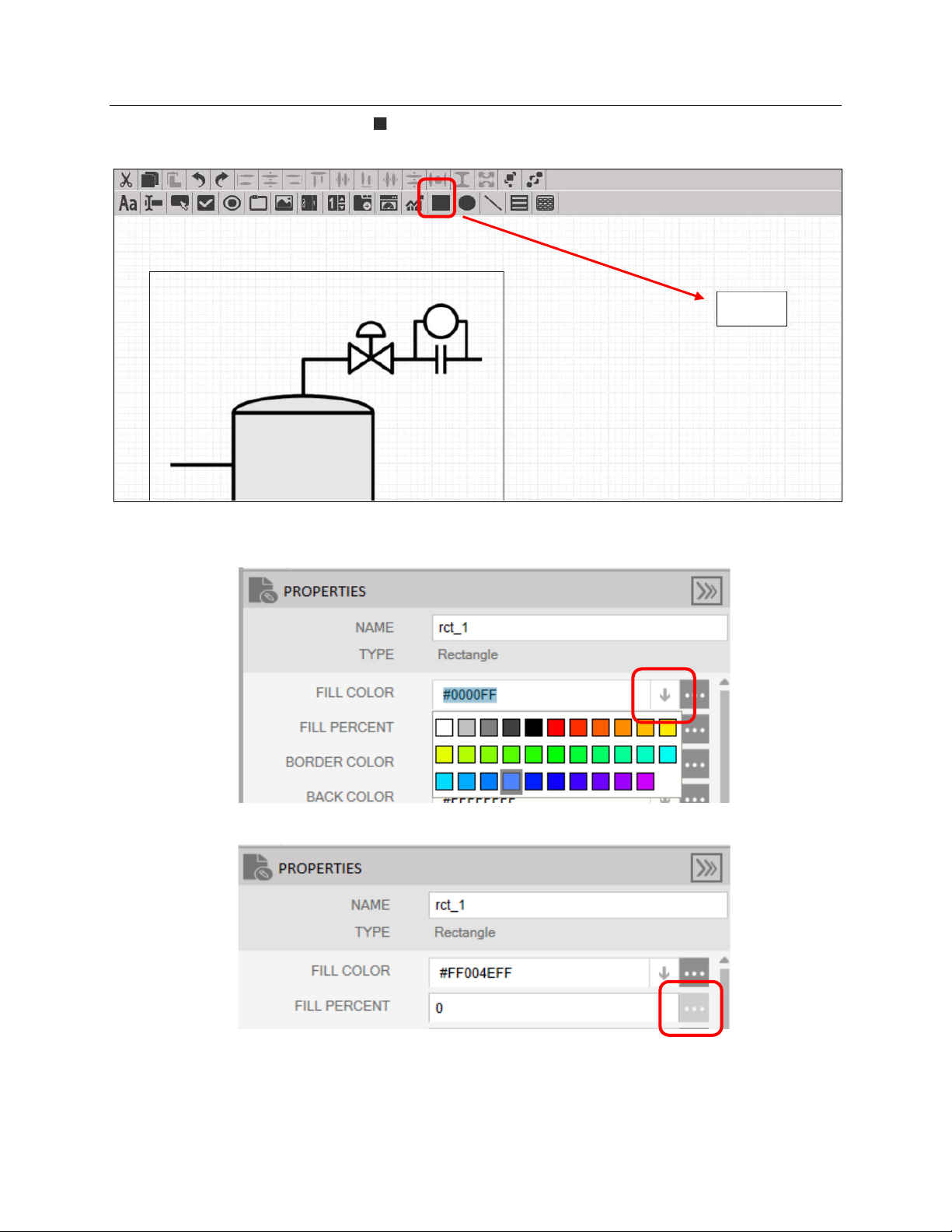

Click the Rectangle ( ) icon and click somewhere on the blank portion of the canvas to

create a rectangle:

With the Rectangle selected, on the Properties window, click the down arrow for Fill Color

and select a color to represent the liquid:

Click the Point Picker button for Fill Percent.

78 FBxVue

Page 83

Emerson FB3000 Separator Configuration Guide

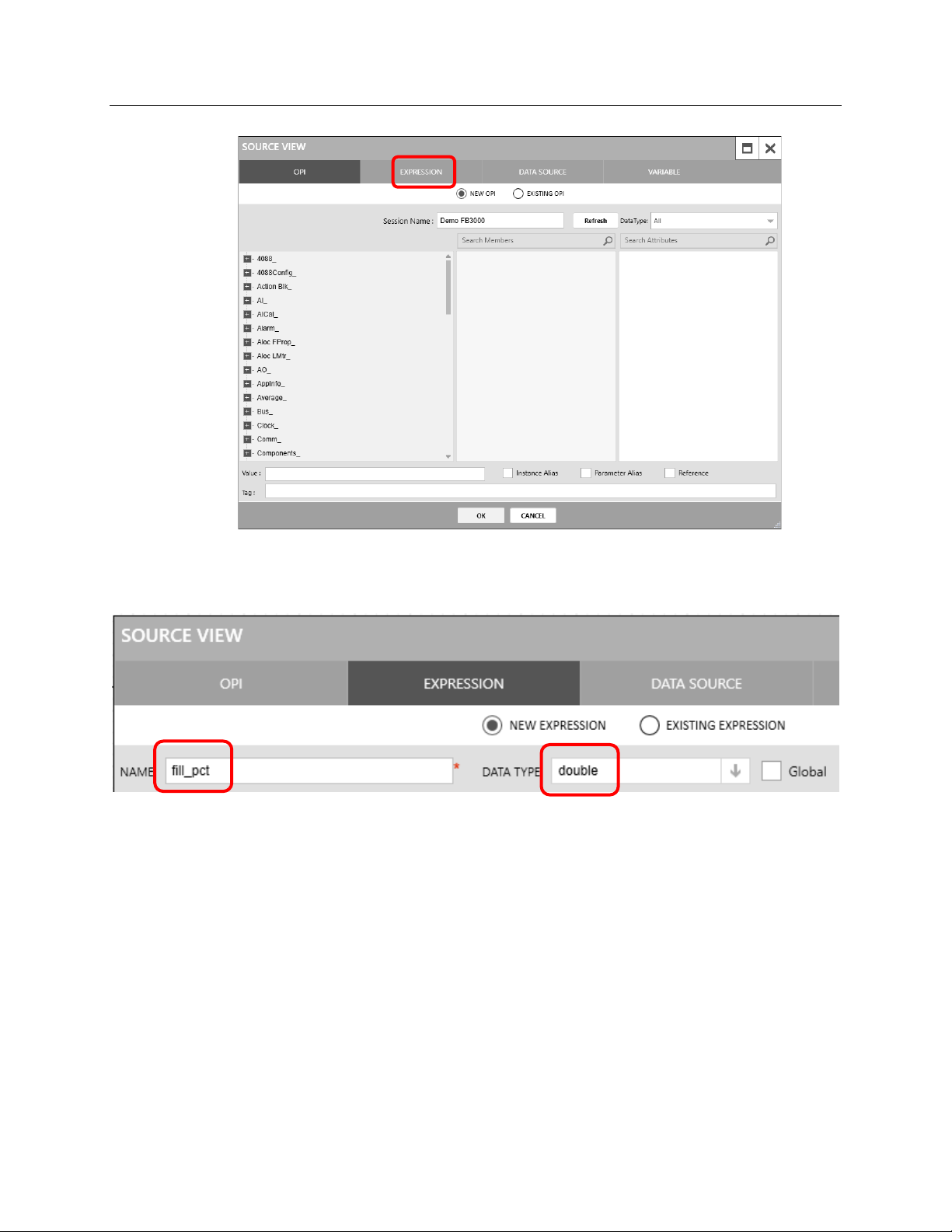

The Source View window opens. Select the Expression tab.

D301884X012

October 2019

An expression is a program written in C# to return (output) some value, like a function

block. This expression will return the fill percentage of the separator, so name it

and select

We need to use the value of the liquid level, so select the OPI tab. The OPI screen displays.

double as the Data Type.

fill_pct

FBxVue 79

Page 84

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

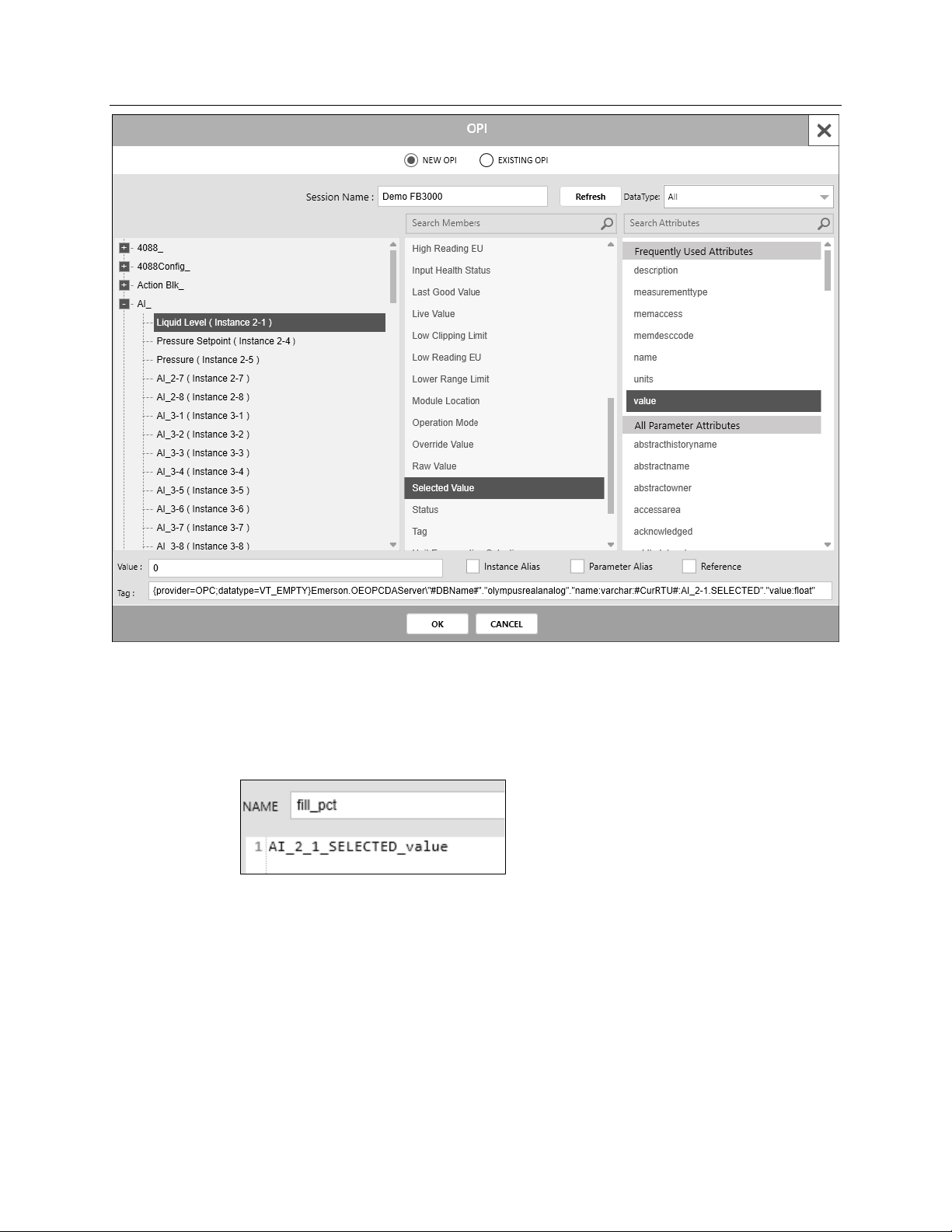

In the OPI window (Point Picker) that opens, select AI_ > Liquid Level (Instance 2-1) >

Selected Value > value. Note that you must select the Value attribute for the Selected

Value point. Click

FBXVue inserts the OPI into the expression, using a different syntax than the tag you would

copy off an FBxConnect point picker would have:

Using the OPI, enter the following expression:

OK.

return AI_2_1_SELECTED_value * 1.666;

(the 1.666 comes from multiplying by 100% and then dividing by 60 inches). Click

Evaluate.

80 FBxVue

Page 85

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

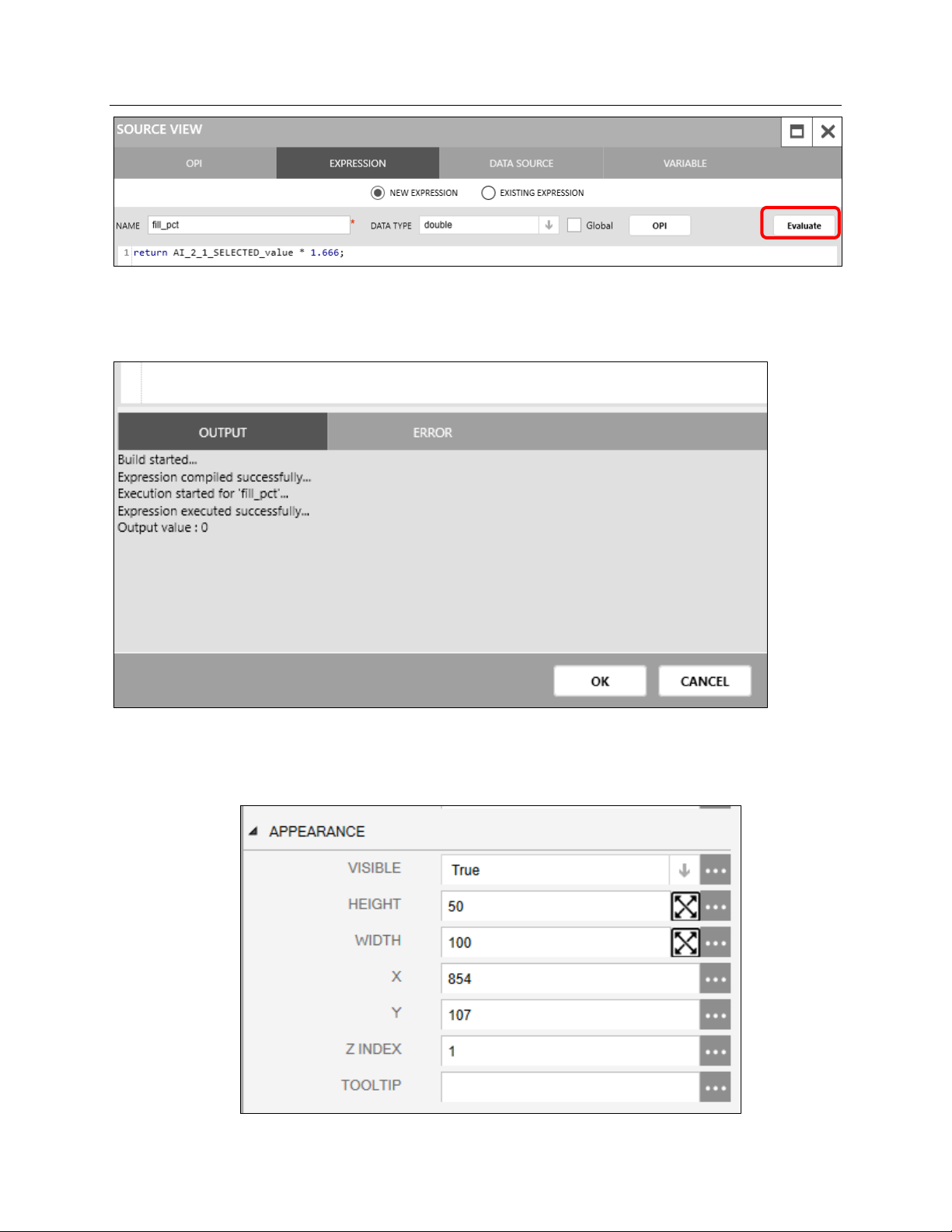

A message window at the bottom of the Source View screen (much like the message

window on the bottom of the FBxDesigner screen) alerts you to any errors or warnings If

there are no errors, the message evaluates the code and tells you what was returned.

Click OK.

In the Properties window, enter 1 as the Z Index for the rectangle. This allows the rectangle

to be visible on top of the separator image.

FBxVue 81

Page 86

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

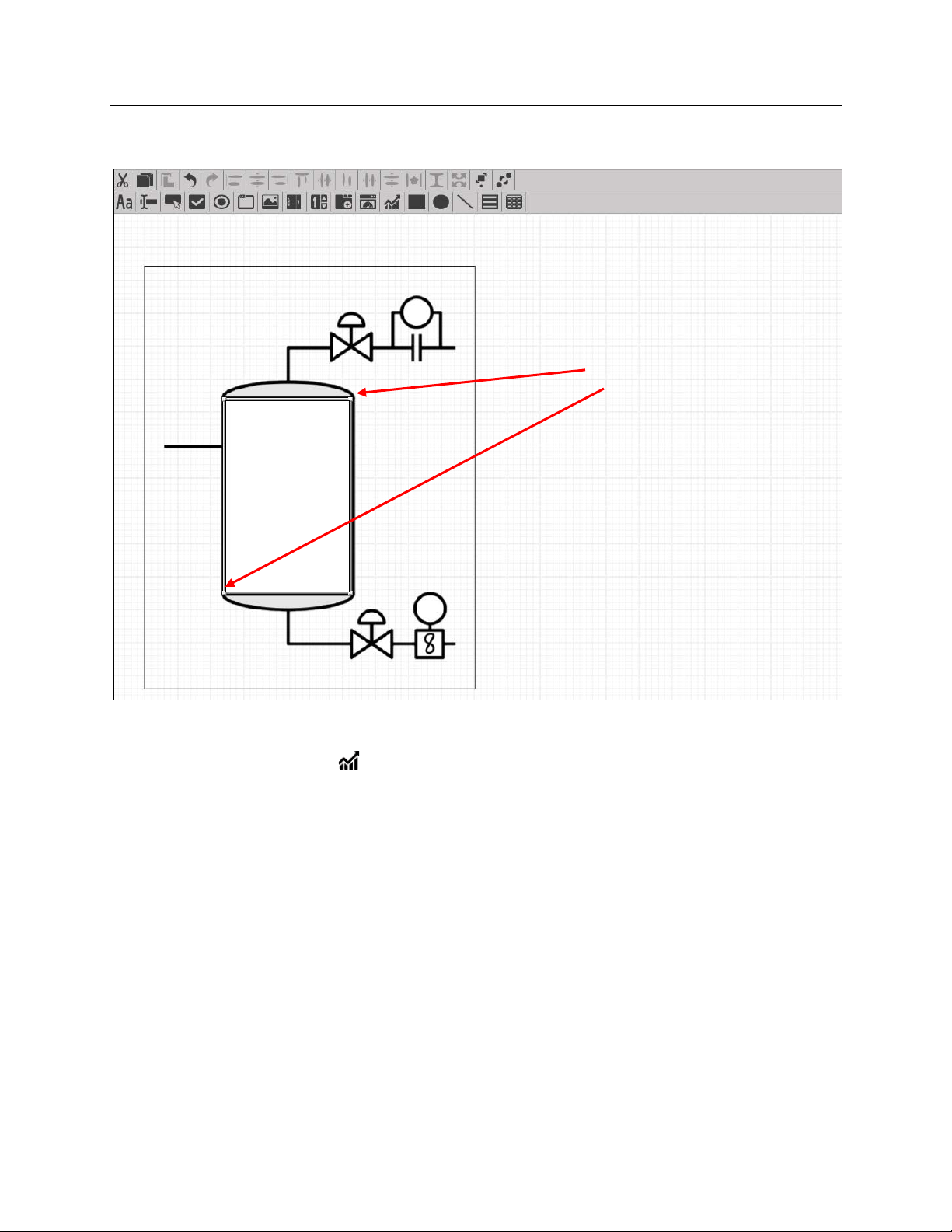

Now, click-and-drag the corners of the rectangle so that it covers the rectangle of the

separator tank.

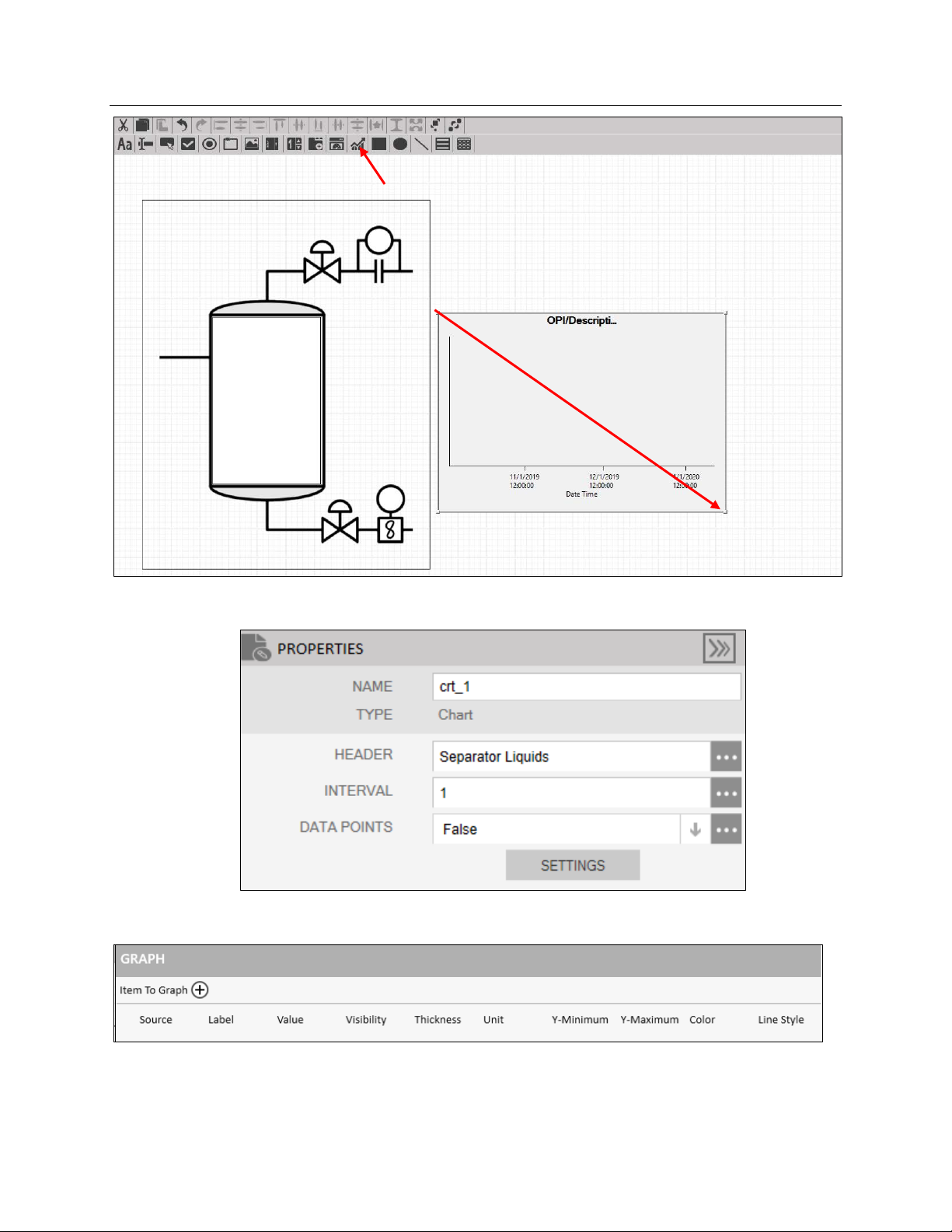

Now let’s add a chart to show the trend of the liquid level and the liquid turbine flow rate.

Click the Chart ) button and click-and-drag an area in the center of the display, to the

right of the separator tank, as shown below:

82 FBxVue

Page 87

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

With the Chart selected, enter Separator Liquids as the header and enter 1 as the interval:

Click Settings to set-up the chart. The Graph screen displays.

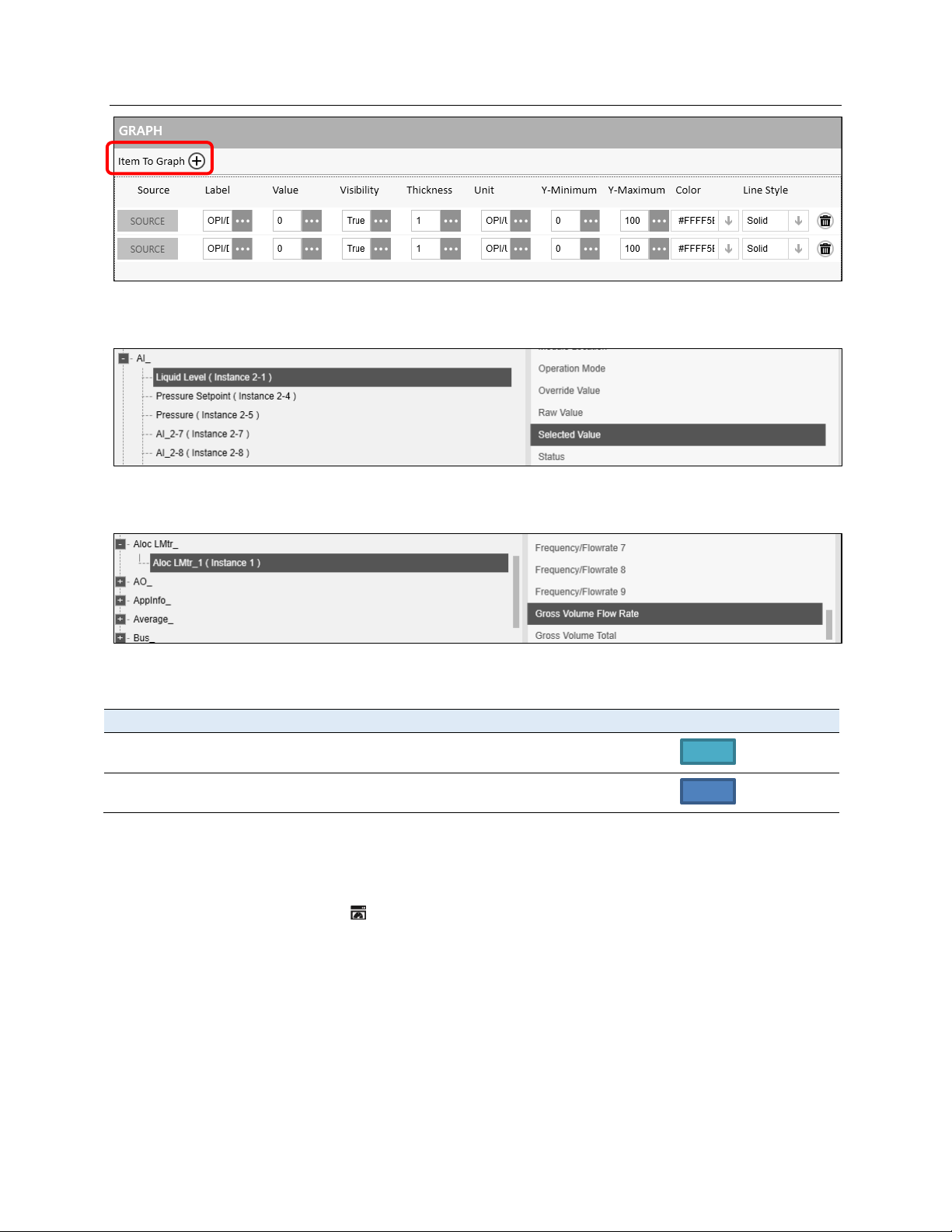

In the Graph screen, click the Item to Graph (+) button twice to add two variables.

FBxVue 83

Page 88

Emerson FB3000 Separator Configuration Guide

Source

Label

Value

Visibility

Thickness

Unit

Y-Min

Y-Max

Color

Line Style

D301884X012

October 2019

Click Source for the first variable and then select AI_ >Liquid Level (Instance 2-1) and

Selected Value.

Click Source for the second variable and select Aloc LMtr_ > Aloc LMtr_1 (Instance 1) >

Gross Volume Flow Rate

- Liquid

- Liquid

Level

Flow Rate

Enter the following values for the rest of the properties:

-

-

True 1 In 0 60

True 1 bbl/d 0 4000

Click OK on the bottom of the Graph window.

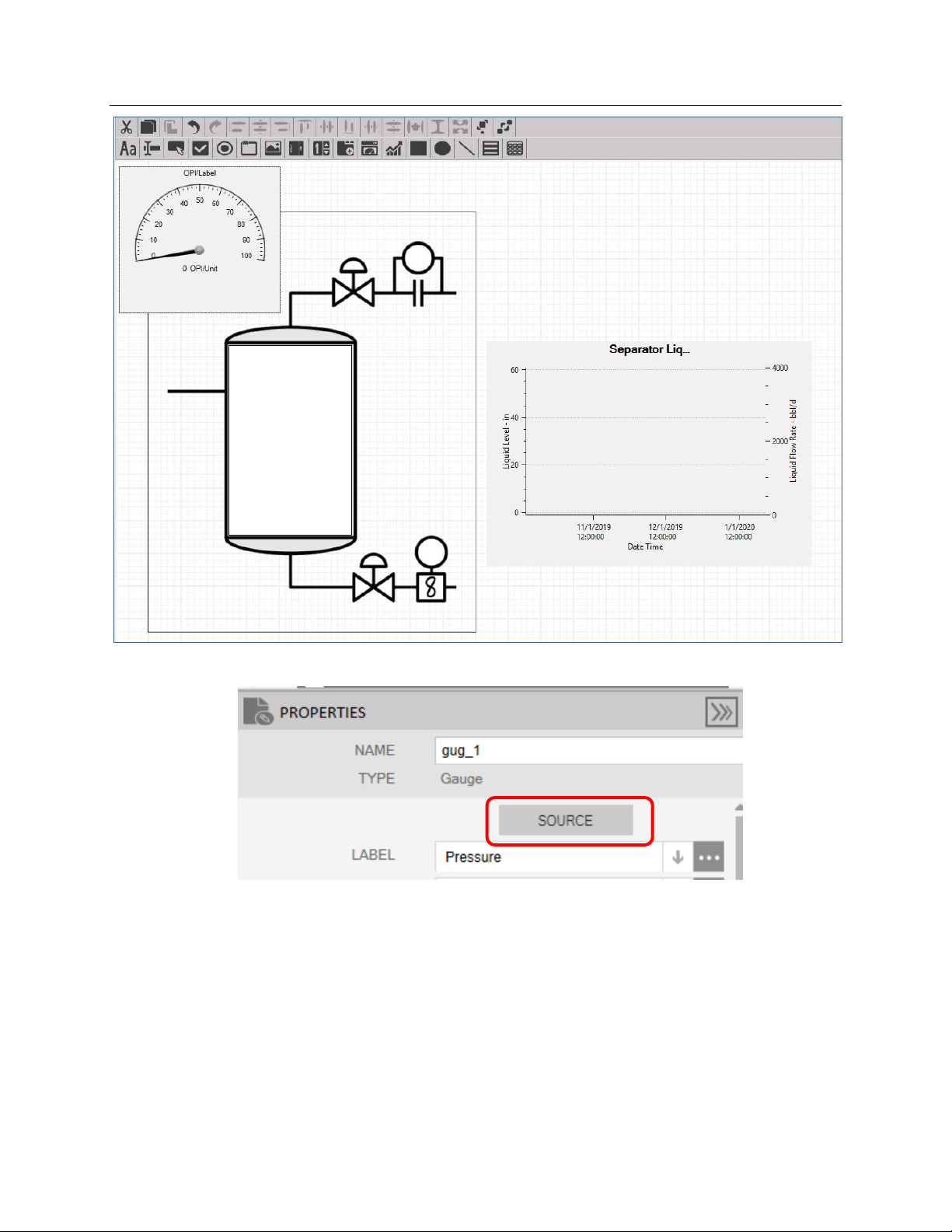

Now let’s add a pressure gauge to monitor the pressure.

Click the Gauge ( ) button and click-and-drag the top left corner as shown below.

Solid

Dash

84 FBxVue

Page 89

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

With the Gauge selected, click on Source in the Properties window.

In the Point Picker, select AI_ > Pressure > Selected Value.

Notice that this selection completes many fields immediately:

FBxVue 85

Page 90

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

However, these system-provided values are not always the most useful properties. Enter

Pressure as the label (otherwise the label would be “Selected Value”). Enter psi(g) as the

unit, and enter

0 as the minimum and 30 as the maximum. The result should be:

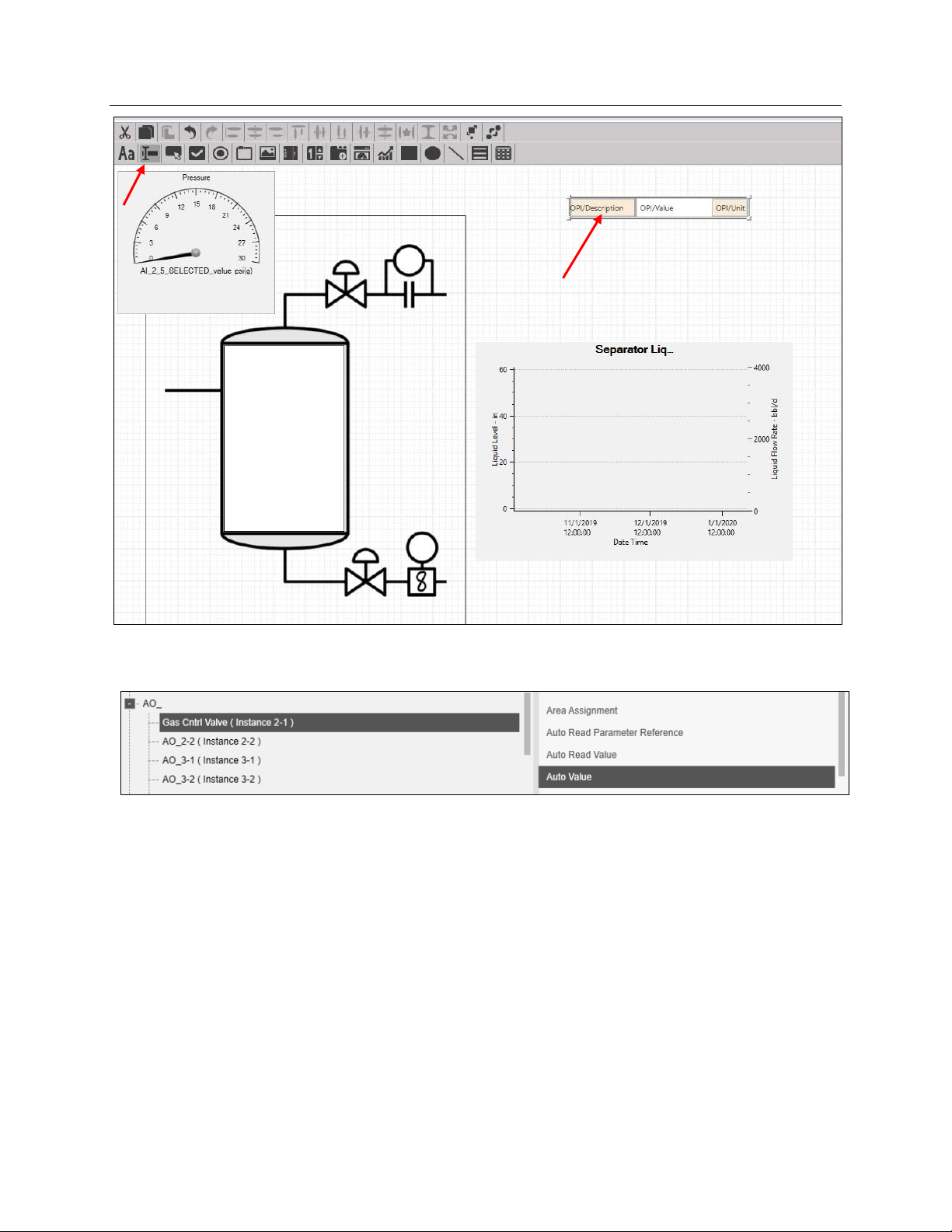

Now let’s add the Valve and Meter info to the screen.

Click the TextBox ( ) button and then click an empty space in the canvas:

86 FBxVue

Page 91

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

In the Properties window, click on Source and select the Auto Value of the Gas Control

Valve.

Enter Valve Status as the Title and %Open as the unit.

Click-and-drag the TextBox to be near the Gas Control Valve on top of the separator.

FBxVue 87

Page 92

Emerson FB3000 Separator Configuration Guide

Source

Title

Location

D301884X012

October 2019

Create four more TextBoxes, with the following properties:

DP_Mtr > DP Mtr_1 > Cor. Vol. Flow Rate

DO > Lvl_Cntrl_Valve > Auto Value Valve Status (On =

Aloc LMtr_ > Aloc LMtr_1 > Gross Vol Flow Rate Liquid Meter Near Meter on Bottom

AI_ > Pressure Setpoint > Override Value Pressure Setpoint Under Pressure Gauge on

Make sure to preview your display as you move and adjust the location of objects. You can

also click-and-drag parts of the text boxes to make the title or value sections bigger or

smaller. When done, the display should look similar to this when previewing it:

Gas Meter Near Meter on Top

Near Valve on Bottom

Open)

Top left

88 FBxVue

Page 93

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Note that the Liquid Level does not change until after we download the FBxDesigner

project.

When you are done, click Save As in the FBxVue top menu.

You can either save the display on your PC as an .xml file or save it directly to the device as

a standalone display. For this demo, we will download it to the PC so that we can install it

with FBxDesigner.

Click Browse.

FBxVue 89

Page 94

Emerson FB3000 Separator Configuration Guide

D301884X012

October 2019

Enter Separator Display as the file name and click Save; place the file in a folder you can

find later.

90 FBxVue

Page 95

Emerson FB3000 Separator Configuration Guide

Chapter 6. Applications

Now that you have a project and display ready, you can download them to the RTU. First,

you need package them together as an application.

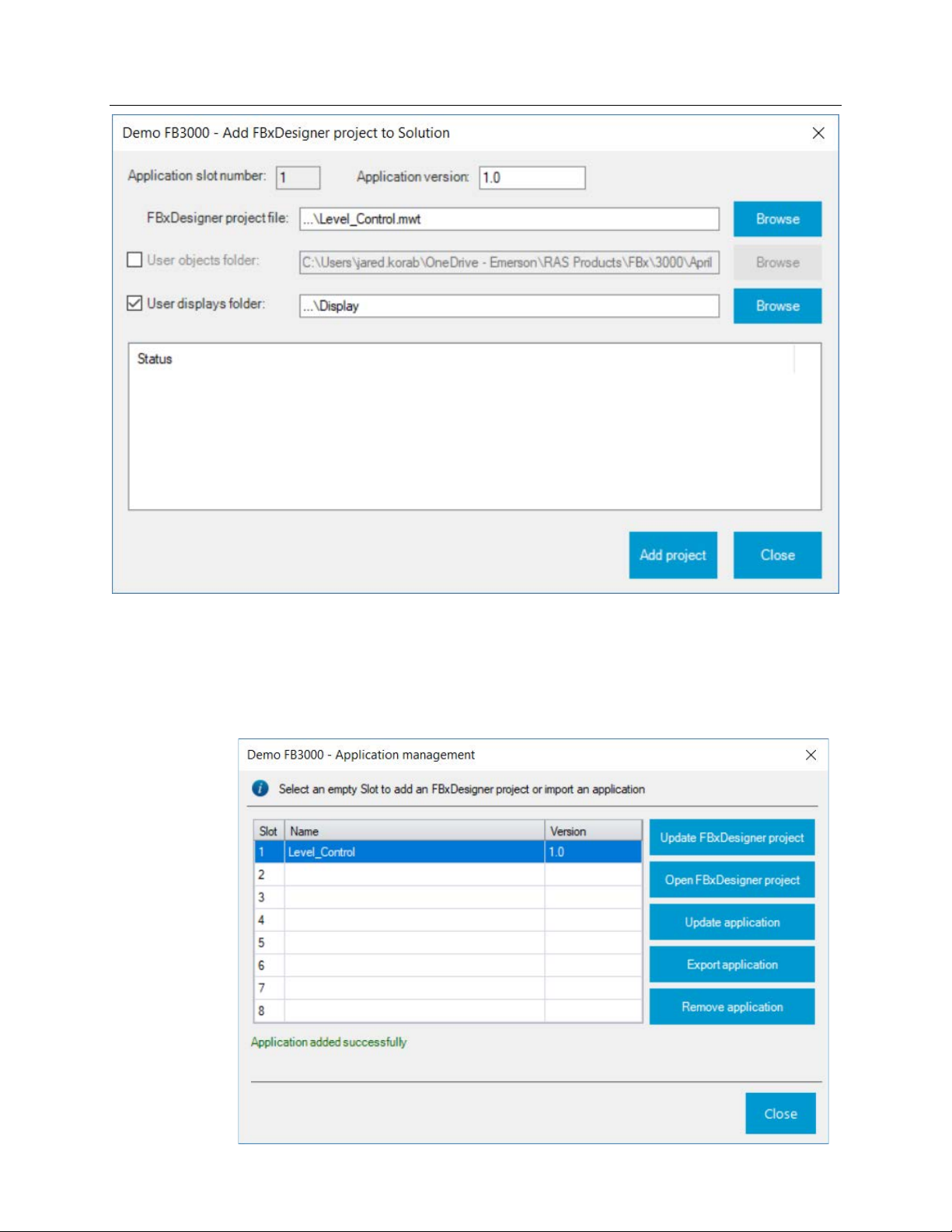

In FBxConnect, select the Applications tab and click Management:

The Application Management screen displays:

D301884X012

October 2019

Notice that the screen displays 8 available slots for applications.

Select slot 1 and click Add FBxDesigner project. The Add FBxDesigner project to Solution

screen displays.

Applications 91

Page 96

Emerson FB3000 Separator Configuration Guide