Page 1

Remote Automation Solutions

Part Number D301813X012

QER 17Q001

January 2017

DP – Prognosis™ FC User Manual (for

ROC800-Series)

Page 2

DP – Prognosis FC User Manual (for ROC800-Series)

ii Issued January-2017

Revision Tracking Sheet

January 2017

This manual may be revised periodically to incorporate new or updated information. The revision date

of each page appears at the bottom of the page opposite the page number. A change in revision date

to any page also changes the date of the manual that appears on the front cover. Listed below is the

revision date of each page (if applicable):

Page

Revision

Initial release

January-2017

Page 3

DP – Prognosis FC User Manual (for ROC800-Series)

Issued January-2017 Contents iii

Contents

Chapter 1 – Introduction 1

1.1 Scope and Organization ..................................................................................................................... 1

1.2 Product Overview ............................................................................................................................... 2

1.2.1 Theory of Operation ............................................................................................................. 2

1.2.2 Practical Application ............................................................................................................. 4

1.2.3 Operational Benefits ............................................................................................................ 4

1.3 Program Features .............................................................................................................................. 4

1.3.1 DP – Prognosis FC for up to 12 Meter runs ......................................................................... 4

1.3.2 Three Supported Meter Types ............................................................................................. 4

1.3.3 Customary Seven Diagnostics ............................................................................................. 4

1.3.4 Support for Stacked DPs ..................................................................................................... 5

1.3.5 Supports two or three measured DPs .................................................................................. 5

1.3.6 Adjustable Diagnostic Frequency ........................................................................................ 5

1.3.7 Multi-pass Averaging ........................................................................................................... 5

1.3.8 Pattern Matching .................................................................................................................. 5

1.4 Program Requirements ...................................................................................................................... 5

1.4.1 License Key.......................................................................................................................... 6

Chapter 2 – Installation 7

2.1 Installing the License Key .................................................................................................................. 7

2.1.1 Verifying the License Key Installation .................................................................................. 8

2.2 Downloading the Program .................................................................................................................. 8

2.3 MPU Loading Threshold .................................................................................................................. 12

Chapter 3 – Configuration 15

3.1 Results ............................................................................................................................................. 17

3.2 Configuration .................................................................................................................................... 20

3.3 Advanced ......................................................................................................................................... 24

3.4 Intermediate ..................................................................................................................................... 26

3.5 Detail ................................................................................................................................................ 30

3.6 Saving the Configuration .................................................................................................................. 33

Chapter 4 – Reference 35

4.1 Point Type 220: DP – Prognosis FC Parameters ............................................................................ 36

4.2 Program Status Codes and Messages ............................................................................................ 61

4.3 Pattern Match Codes and Messages ............................................................................................... 63

4.4 Zeroing the meter for Prognosis FC ................................................................................................. 66

Page 4

DP – Prognosis FC User Manual (for ROC800-Series)

iv Contents Issued January-2017

[This page is intentionally left blank.]

Page 5

DP – Prognosis FC User Manual (for ROC800-Series)

Issued January-2017 Introduction 1

Chapter 1 – Introduction

Caution

When implementing control using this product, observe best industry

practices as suggested by applicable and appropriate environmental,

health, and safety organizations. While this product can be used as a

safety component in a system, it is NOT intended or designed to be the

ONLY safety mechanism in that system.

This chapter describes the structure of this manual and an overview of

the DP – Prognosis™ FC program for the ROC800-Series Remote

Operations Controller (ROC800).

1.1 Scope and Organization

This document serves as the user manual for the DP – Prognosis FC

program, which is intended for use in the ROC800-Series Remote

Operations Controllers (ROC800).

This manual describes how to download and configure this program

(referred to as the “DP – Prognosis FC program” or “the program”

throughout the rest of this manual). You access and configure this

program using ROCLINK™ 800 Configuration Software (version 2.41

or greater) loaded on a personal computer (PC) running Windows® 7

(32 or 64-bit).

The sections in this manual provide information in a sequence

appropriate for first-time users. Once you become familiar with the

procedures and the software running in ROC800, the manual becomes a

reference tool.

This manual has the following major sections:

Chapter 1 – Introduction

Chapter 2 – Installation

Chapter 3 – Configuration

Chapter 4 – Reference

This manual assumes that you are familiar with the ROC800 and its

configuration. For more information, refer to the following manuals:

ROC800 Remote Operations Controller Instruction Manual (part

D301217X012)

ROCLINK 800

™

Configuration Software User Manual (for

ROC800-Series) (part D301250X012)

Page 6

DP – Prognosis FC User Manual (for ROC800-Series)

2 Introduction Issued January-2017

1.2 Product Overview

The DP – Prognosis FC program is used to verify the operation of a

differential pressure (DP) meter element and its differential pressure

instrumentation. The program is designed to work with Orifice Meters,

Venturi meters or Cone meters.

1.2.1 Theory of Operation

A DP meter uses a geometric constriction to produce momentum change

in a flow. Figure 1-1 shows an orifice meter and the associated pressure

profile in the pipe.

Figure 1-1. Traditional orifice meter pressure profile

Applying mass and energy conservation equations between pipe cross

sections upstream and in the vicinity of the constriction produces a flow

rate equation dependent on geometry, fluid density and DP.

Traditionally, the differential pressure is measured between a point

upstream of the restriction and the point of lowest pressure (vena

contracta). Flow calculations are performed using this differential

pressure value.

It has been shown that the constriction in a DP meter element actually

produces three predictable and repeatable pressure changes in the flow

stream. The Traditional DP (∆Pt) – mentioned previously - is measured

across the restriction. The Recovery DP (∆P

rec

) can be measured

between the downstream tap and a far downstream tap (~6 diameters

downstream for an orifice meter). The Permanent DP (∆P

ppl

) is

measured between the upstream pressure tap and the far downstream

tap. Figure 1-2 shows how these three values can be observed.

Page 7

DP – Prognosis FC User Manual (for ROC800-Series)

Issued January-2017 Introduction 3

Figure 1-2. Three differential pressures for the DP meter

The DP – Prognosis FC approach involves:

Measuring all three DPs at the meter element (optionally, two of the

DPs can be measured and one can be inferred, but this produces less

reliable results).

Performing flow calculations for all three meters.

Comparing the flow rates of the three meters – producing three

diagnostic values (diagnostics).

Comparing the pressure loss ratios of the three DPs to theoretical

values for pressure loss ratios – producing three diagnostic values

(diagnostics).

Comparing the numerical values of the three DPs for consistency

(∆Pt = ∆P

rec

+ ∆P

ppl

).

As can be seen, this results in seven different uncertainty parameters –

referred to as diagnostics. Customarily, the seven diagnostics are each

compared to allowable uncertainty setpoints – thereby converting the

values to dimensionless form. For instance,

Calculated traditional flow rate = 10.100

Calculated permanent flow rate = 10.800

Percent Difference = 100 * (10.800 – 10.100) / 10.100 = 6.93%

If the allowable percentage for this difference was configured to 2%,

then the dimensionless value of the first diagnostic (x1) would be:

6.93% / 2% = 3.47

In dimensionless form, any value between -1.0 and 1.0 is considered to

be indicative of a properly-performing meter.

Page 8

DP – Prognosis FC User Manual (for ROC800-Series)

4 Introduction Issued January-2017

1.2.2 Practical Application

The DP – Prognosis FC approach can be used to monitor the operation

of a DP meter with the intent of identifying uncertainty in the traditional

calculated measurement. Using the DP diagnostic approach, the

following conditions have been identified in orifice meters:

Orifice plate installed backwards

Damaged orifice plate (worn sharp edge, warped plate, dirty plate)

Obstructed flow in meter tube or through orifice

Physical plate or meter tube size different from values configured in

flow computer

Plugged or leaking transmitter impulse line

Transmitter calibration error

Transmitter calibration drift

Equalizing valve on instrument manifold leaking

Wet gas

1.2.3 Operational Benefits

The DP – Prognosis FC operating at a meter installation, the meter can

be managed by exception. Routine, scheduled inspection/calibration

procedures can be modified such that technicians address known

measurement problems immediately when exceptions are noted – rather

than waiting until the problem is discovered during the next scheduled

inspection. Furthermore, the time of onset of the exception can be

precisely identified – assisting in proper correction to flow data.

Common operating mistakes (installing plate backwards, changing plate

without changing flow computer configuration) are quickly identified

and clarified when DP diagnostics is running in the Flow Computer.

1.3 Program Features

1.3.1 DP – Prognosis FC for up to 12 Meter runs

The single license enables the Prognosis feature for all meters on the

ROC800.

1.3.2 Three Supported Meter Types

The program works with Orifice, Venturi, and Cone meters.

1.3.3 Customary Seven Diagnostics

The program produces the customary seven diagnostic values.

Page 9

DP – Prognosis FC User Manual (for ROC800-Series)

Issued January-2017 Introduction 5

1.3.4 Support for Stacked DPs

The program supports use of stacked DP instruments for Recovery and

for Permanent DP instruments

1.3.5 Supports two or three measured DPs

Although it is not recommended, the program can function using just

one additional DP instrument (plus the traditional DP). When either the

Recovery DP or the Permanent DP instruments are not configured, the

value of the unmeasured DP will be calculated from the other two DPs.

1.3.6 Adjustable Diagnostic Frequency

The diagnostic calculations can be run at a frequency ranging from once

per second to once per 255 days.

When main processor loading is a concern, the frequency of the

calculation can be reduced to alleviate processor loading.

1.3.7 Multi-pass Averaging

The program can be configured to perform multiple calculation cycles

and use the resulting average value of the seven diagnostics. This

feature can be used when there is high latency in DP measured values or

when wet gas is expected – to reduce nuisance alerts.

1.3.8 Pattern Matching

After the seven diagnostic values are calculated, the relationship of

these values to each other is compared with known pattern signatures.

This results in a pattern match code and text message which can provide

insight as to the particular problem – if any – with the meter.

1.4 Program Requirements

The DP – Prognosis FC program is compatible with version 3.61 (or

greater) of the ROC800 firmware or version 1.60 (or greater) of ROC800L

with version 2.41 (or greater) of the ROCLINK 800 software.

Program

specifics

include:File

Name

Target Unit/

Version

User Defined

Points (UDP)

Flash Used

(in bytes)

DRAM Used

(in bytes)

ROCLINK 800

Version

Display

Number

DPMD.tar

ROC800 v3.61

or ROC800L

v1.60

220

68653

131072

2.41

221

For information on viewing the memory allocation of user programs,

refer to the ROCLINK 800 Configuration Software User Manual (for

ROC800) (part D301250X012).

Page 10

DP – Prognosis FC User Manual (for ROC800-Series)

6 Introduction Issued January-2017

1.4.1 License Key

License keys, when matched with valid license codes, grant access to

applications such as the DP – Prognosis FC program.

For ROC800 and ROC800L, the term “license key” refers to the

physical piece of hardware that can contain up to seven different

licenses (refer to Figure 1-1). Each ROC800-series can have none, one,

or two license keys installed. If you remove a license key after enabling

an application, the firmware disables the task from running. This

prevents unauthorized execution of protected applications in a ROC800.

DOC0422A

J1

U1

Figure 1-4. License Key

Note: A single license of the DP – Prognosis FC program for ROC800-

series enables Prognosis FC for all meter runs.

Page 11

DP – Prognosis FC User Manual (for ROC800-Series)

Issued January-2017 Installation 7

Chapter 2 – Installation

This section provides instructions for installing the DP – Prognosis FC

program into the ROC800. Read Section 1.4 of this manual for program

requirements.

Note: The program and license key can be installed in any order. The

manual shows the installation of the license key first.

2.1 Installing the License Key

If you order the DP – Prognosis FC program for a new ROC800, your

ROC800 is delivered with the license key installed.

If you order the program for an existing ROC800, you must install the

license key yourself.

Caution

Failure to exercise proper electrostatic discharge precautions, such as

wearing a grounded wrist strap may reset the processor or damage

electronic components, resulting in interrupted operations.

When working on units located in a hazardous area (where explosive

gases may be present), make sure the area is in a non-hazardous state

before performing these procedures. Performing these procedures in a

hazardous area could result in personal injury or property damage.

To install a license key:

1. Remove power from the ROC800.

2. If necessary, remove the wire channel cover.

3. Unscrew the screws from the Central Processing Unit (CPU)

faceplate.

4. Remove the CPU faceplate.

5. Place the license key in the appropriate terminal slot (P4 or P6) in

the CPU (refer to Figure 2-1).

Figure 2-1. License Key Installation

Note: When using a single license key, install it in slot P4.

6. Press the license key into the terminal until it is firmly seated (refer

to Figure 2-1).

7. Re-attach the CPU faceplate.

Page 12

DP – Prognosis FC User Manual (for ROC800-Series)

8 Installation Issued January-2017

8. Re-attach the screws on the CPU faceplate.

9. If necessary, re-attach the wire channel cover.

10. Restore power to the ROC800.

2.1.1 Verifying the License Key Installation

After you install the license key, you can verify whether the ROC800

recognizes the key. From the ROCLINK 800 screen, select Utilities >

License Key Administrator. The License Key Administrator screen

displays:

Figure 2-2. License Key Administrator

The DP – Prognosis FC program appears in the Application Name

column. (For further information on the License Key Administrator

screen, refer to the ROCLINK 800 Configuration Software User Manual

(for ROC800-Series), part D301250X012.)

After you verify that the license key is correctly installed and

recognized, proceed to Section 2.2.

2.2 Downloading the Program

This section provides instructions for installing the program into the

Flash memory on the ROC800.

To download the user program using ROCLINK 800 software:

1. Connect the ROC800 to your computer.

2. Start and logon to the ROCLINK 800.

3. Select ROC > Direct Connect to connect to the ROC800.

Page 13

DP – Prognosis FC User Manual (for ROC800-Series)

Issued January-2017 Installation 9

4. Select Utilities > User Program Administrator from the

ROCLINK menu bar. The User Program Administrator screen

displays (see Figure 2-3):

Figure 2-3. User Program Administrator

5. Select any empty program number (in this case, number 1) into

which to download the program.

6. Click Browse in the Download User Program File frame. The Select

User Program File screen displays (see Figure 2-4).

7. Select the path and user program file to download from the CD-

ROM. (Program files are typically located in the Program Files

folder on the CD-ROM.) As Figure 2-4 shows, the screen lists all

valid user program files with the .TAR extension:

Page 14

DP – Prognosis FC User Manual (for ROC800-Series)

10 Installation Issued January-2017

Figure 2-4. Select User Program File

8. Click Open to select the program file. The User Program

Administrator screen displays. As shown in Figure 2-5, note that the

Download User Program File frame identifies the selected program

and that the Download & Start button is active:

Figure 2-5. User Program Administrator

Page 15

DP – Prognosis FC User Manual (for ROC800-Series)

Issued January-2017 Installation 11

9. Click Download & Start to begin loading the selected program.

The following message displays:

Figure 2-6. Confirm Download

10. Click Yes to begin the download. When the download completes the

following message displays:

Figure 2-7. ROCLINK 800 Download Confirmation

11. Click OK. The User Program Administrator screen displays (see

Figure 2-8). Note that:

The Device User Program Environment frame reflects the use of

system memory.

The User Programs Installed in Device frame identifies the

installed program(s).

The Status field indicates that the program is running.

Page 16

DP – Prognosis FC User Manual (for ROC800-Series)

12 Installation Issued January-2017

Figure 2-8. User Program Administrator

12. Click Close. Proceed to Chapter 3 – Configuration to configure the

program.

2.3 MPU Loading Threshold

To maximize the performance of your ROC800 device, always verify

the performance of specific application combinations before using them

in the field to ensure the MPU load typically remains below 85% with

peak MPU loading levels below 95%.

To check the current MPU load at any time, select ROC > Information

> Other Information and review the value in the MPU loading field.

Page 17

DP – Prognosis FC User Manual (for ROC800-Series)

Issued January-2017 Installation 13

Figure 2-9. MPU Loading

Page 18

DP – Prognosis FC User Manual (for ROC800-Series)

14 Installation Issued January-2017

[This page is intentionally left blank.]

Page 19

DP – Prognosis FC User Manual (for ROC800-Series)

Issued January-2017 Configuration 15

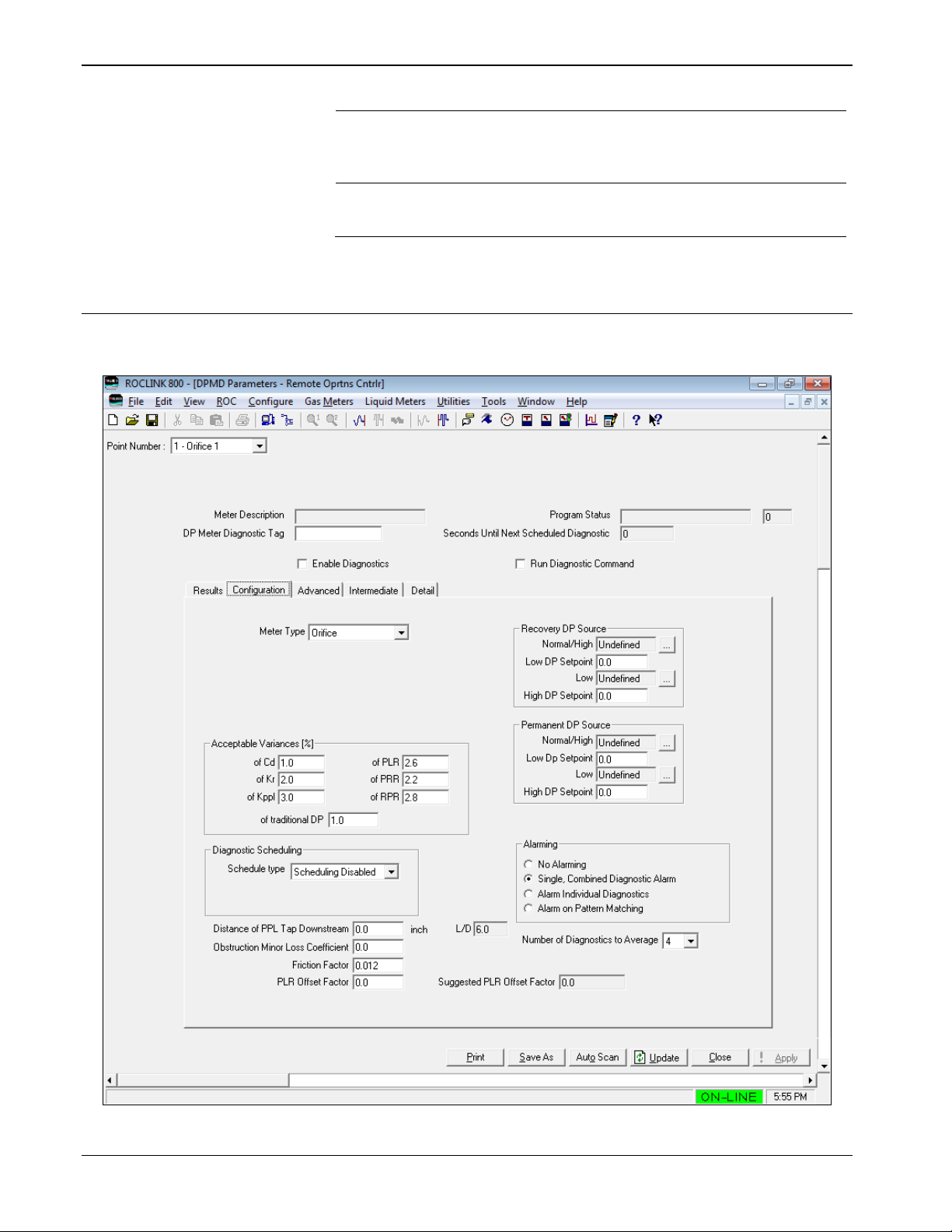

Chapter 3 – Configuration

This section provides information to configure the DP – Prognosis FC

program.

Once you have successfully loaded the DP – Prognosis FC program into

the ROC800, a single user display is available. This display contains

these tabs:

Results

Configuration

Advanced

Intermediate

Detail

Note: The DP – Prognosis FC meter runs corresponds to orifice meter

number 1 in the ROC800. For example, Prognosis FC Point

Number 1 corresponds to meter number 1 in the ROC. The

corresponding meter run in the ROC should be configured and

calculating flow before configuring DP meter diagnostics for the

run. For further information on the configuration of the orifice

meter runs, refer to the ROCLINK 800™ Configuration Software

User Manual (for ROC800-Series) (part D301250X012).

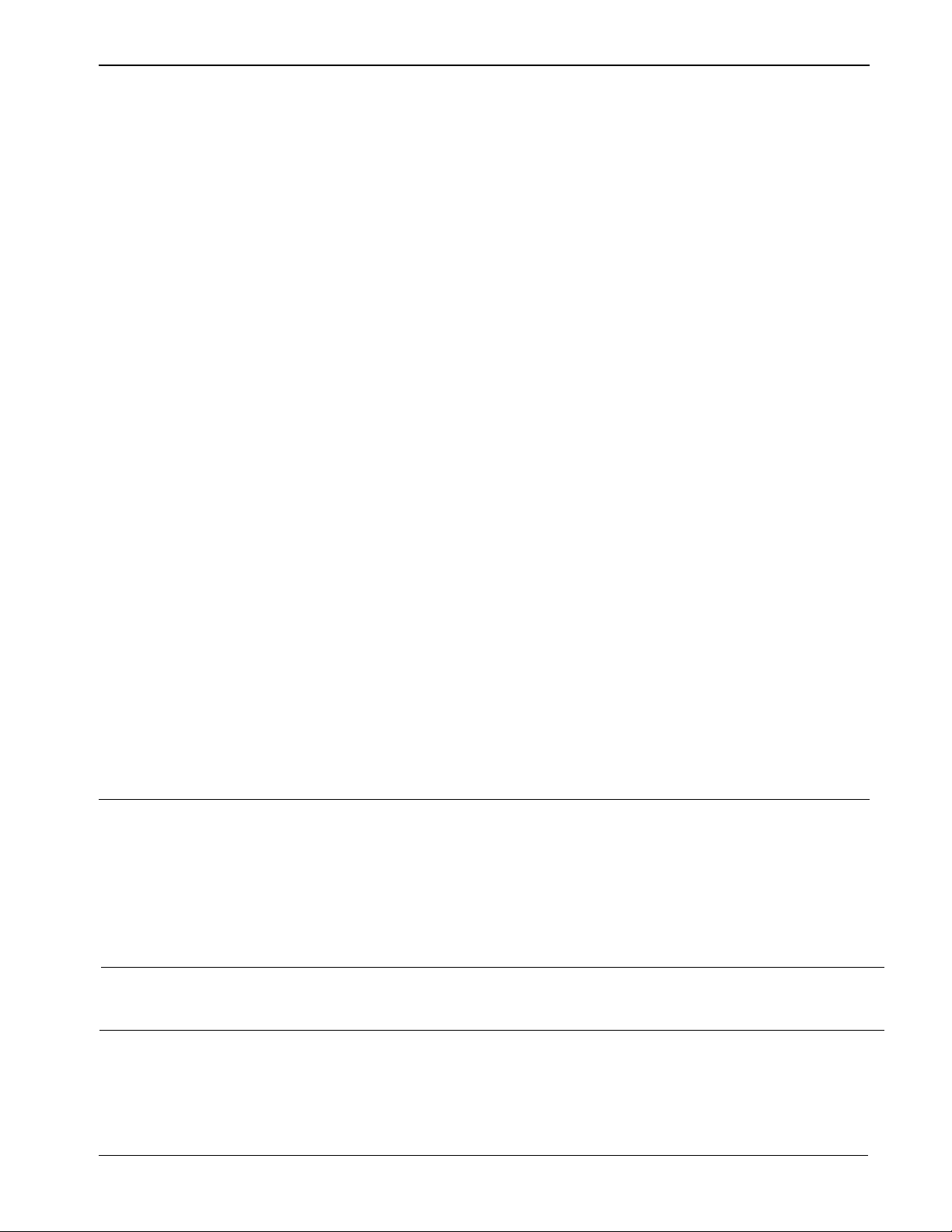

Figure 3-1. Main ROCLINK 800 screen

Page 20

DP – Prognosis FC User Manual (for ROC800-Series)

16 Configuration Issued January-2017

To access the program:

1. From the Directory Tree, select User Program > Program #1,

DPMD.

2. Double-click Display #221, DPMD Parameters.

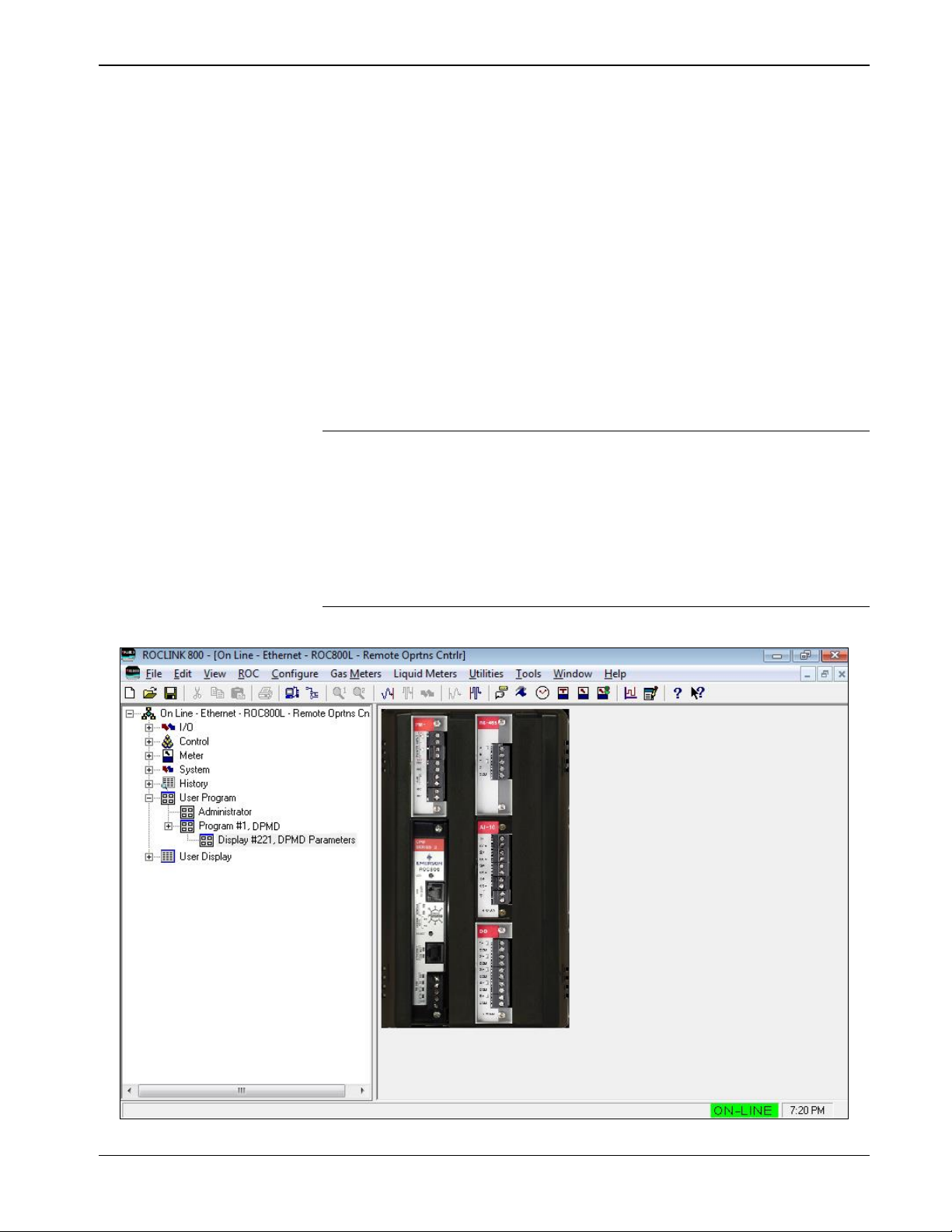

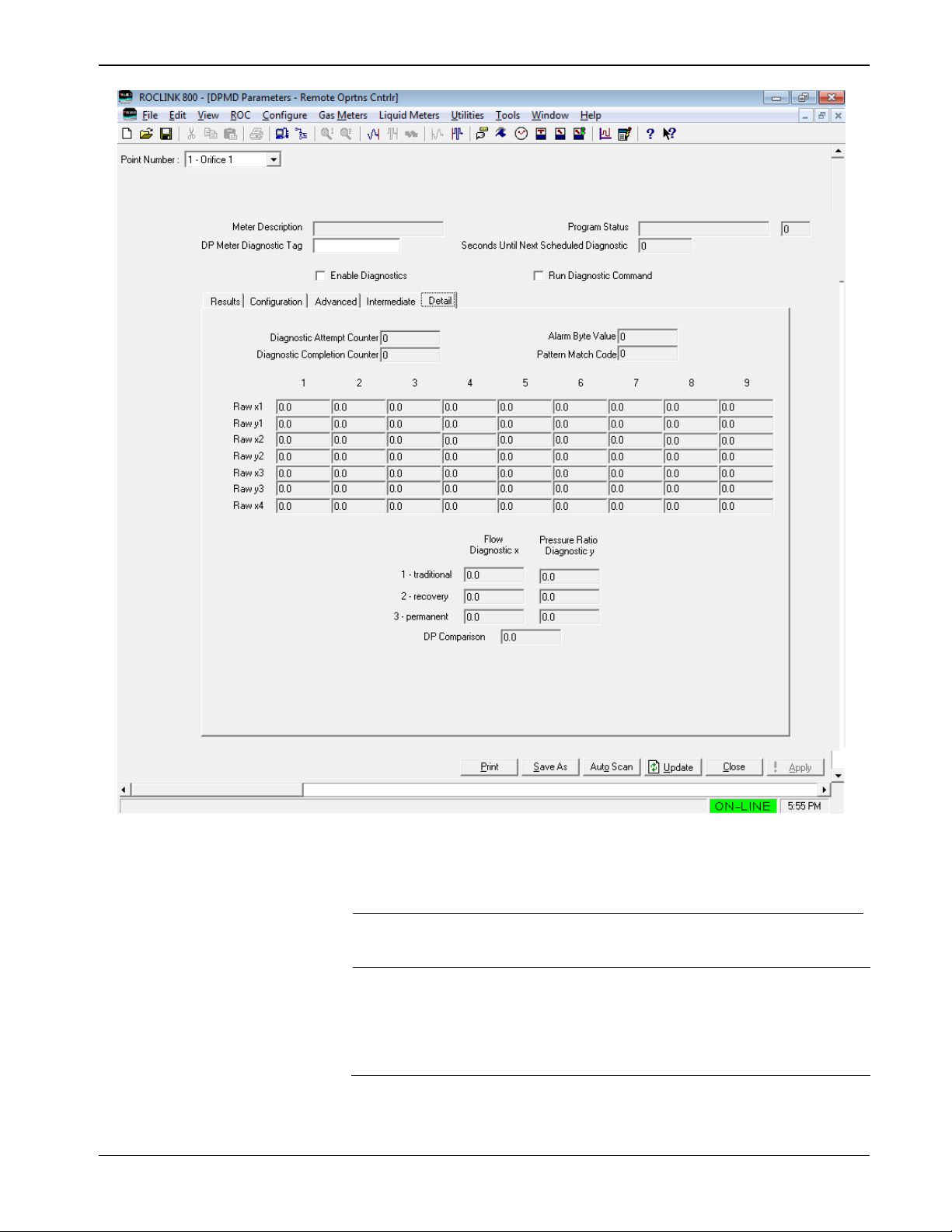

Figure 3-2. DPMD Parameters

1. Review the following fields:

Field

Description

Point Number

Sets the meter for diagnostic.

Meter Description

This read-only field displays the meter

description.

DP Meter

Diagnostic Tag

Sets the description of the meter.

Page 21

DP – Prognosis FC User Manual (for ROC800-Series)

Issued January-2017 Configuration 17

Field

Description

Program Status

This read-only field displays the program

status. For possible status codes and

messages, see Section 4.2 of this manual.

Seconds Until Next

Scheduled

Diagnostic

This read-only field displays the next

scheduled diagnostic in seconds.

Enable Diagnostics

Enables diagnostics for the specified meter.

Run Diagnostic

Command

Select this option to perform an instantaneous

diagnostic of the meter.

2. Proceed to the Section 3.1 – Results tab.

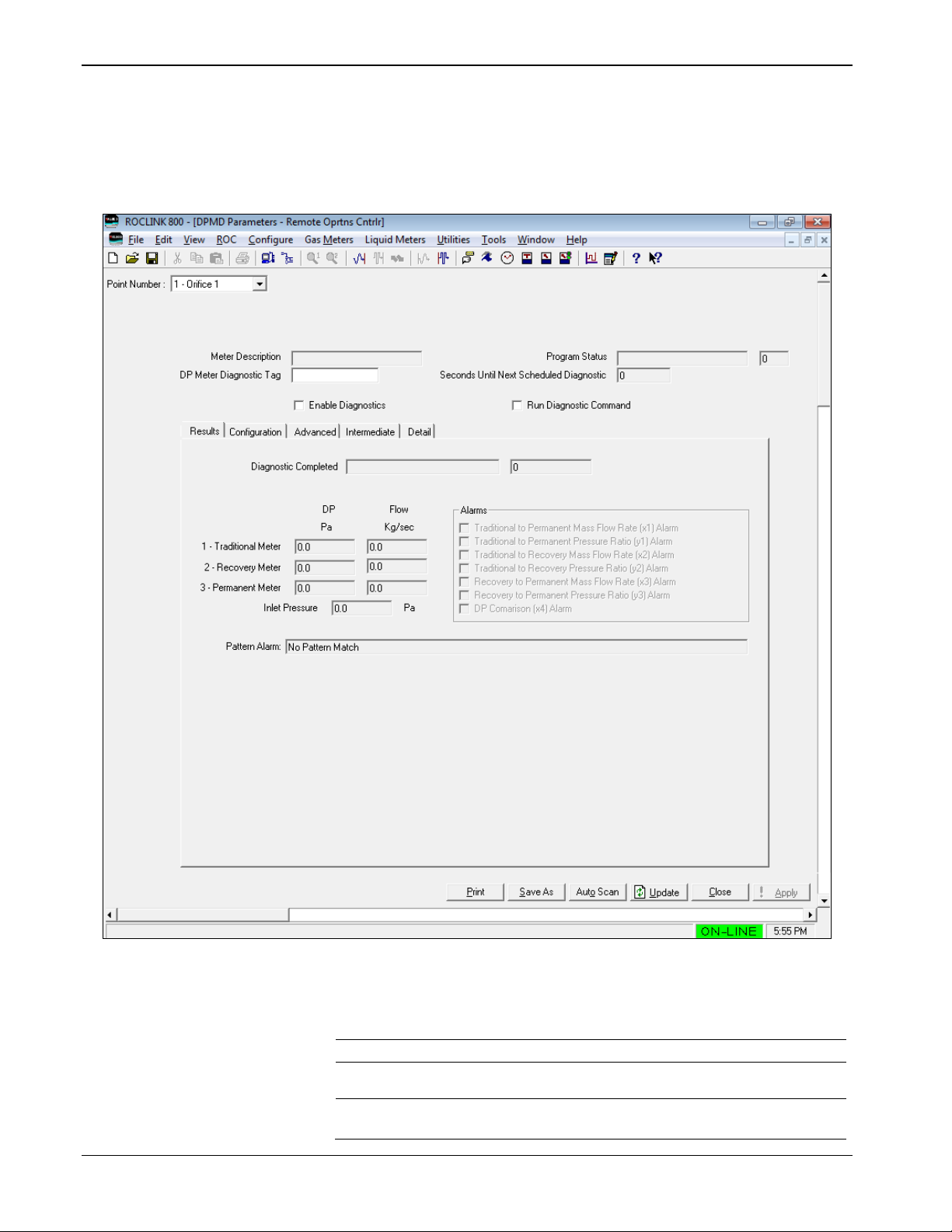

3.1 Results

Each time the Prognosis FC calculations complete, the Results tab of the

Configuration screen provides the summary results of the calculations.

Page 22

DP – Prognosis FC User Manual (for ROC800-Series)

18 Configuration Issued January-2017

Figure 3-3. Results tab

1. Review the following fields:

Field

Description

Diagnostic

Completed

This read-only field displays the timestamp of

the most recent diagnostic run. Provides both

UNIX timestamp and the formatted date/time.

1 – Traditional

Meter

Lists the values for the Traditional Meter.

Note: The Prognosis FC calculations are

performed in metric units – regardless of

the units of measure configured in the

ROC800.

Dp

This read-only field displays the Traditional Dp

used for the calculations.

Flow

This read-only field displays the Mass Flow Rate

as calculated via the Traditional meter.

Page 23

DP – Prognosis FC User Manual (for ROC800-Series)

Issued January-2017 Configuration 19

Field

Description

2 – Recovery Meter

Lists the values for the Recovery Meter.

Note: The Prognosis FC calculations are

performed in metric units – regardless of

the units of measure configured in the

ROC800.

Dp

This read-only field displays the Recovery Dp

used for the calculations.

Flow

This read-only field displays the Mass Flow Rate

as calculated via the recovery meter.

3 – Permanent

Meter

Lists the values for the Permanent Meter.

Note: The Prognosis FC calculations are

performed in metric units – regardless of

the units of measure configured in the

ROC800.

Dp

This read-only field displays the Permanent

Dp used for the calculations.

Flow

This read-only field displays the Mass Flow

Rate as calculated via the Permanent meter.

Inlet Pressure

This read-only field displays the inlet pressure

for the meter(s).

Note: The Prognosis FC calculations are

performed in metric units – regardless of

the units of measure configured in the

ROC800.

Alarms

Checkboxes indicate which – if any – of the

seven diagnostic parameters exceeds

configured acceptable values. When one or

more parameters exceeds acceptable values,

the red box is displayed around this section of

the screen.

Traditional to

Permanent Mass

Flow Rate (x1)

Alarm

When this alarm is selected, there is excessive

difference between the mass flow rates derived

from the traditional and the permanent meters.

Traditional to

Permanent

Pressure Ratio (y1)

Alarm

When this alarm is selected, there is excessive

difference between the observed and

theoretical values for permanent pressure ratio.

Traditional to

Recovery Mass

Flow Rate (x2)

Alarm

When this alarm is selected, there is excessive

difference between the mass flow rates derived

from the traditional and the recovery meters.

Traditional to

Recovery Pressure

Ratio (y2) Alarm

When this alarm is selected, there is excessive

difference between the observed and

theoretical values for recovery to traditional

pressure ratio.

Recovery to

Permanent Mass

Flow Rate (x3)

Alarm

When this alarm is selected, there is excessive

difference between the mass flow rates derived

from the recovery and the permanent meters.

Recovery to

Permanent

Pressure Ratio (y3)

Alarm

When this alarm is selected, there is excessive

difference between the observed and

theoretical values for recovery to permanent

pressure ratio.

Page 24

DP – Prognosis FC User Manual (for ROC800-Series)

20 Configuration Issued January-2017

Field

Description

Dp Comparison (x4)

Alarm

When this alarm is selected, there is excessive

difference between the observed traditional Dp

value and the sum of the recovery and

permanent pressure values

Pattern Alarm

This read-only field displays a text message

describing the results of the pattern matching

algorithm.

2. Proceed to the Section 3.2 – Configuration.

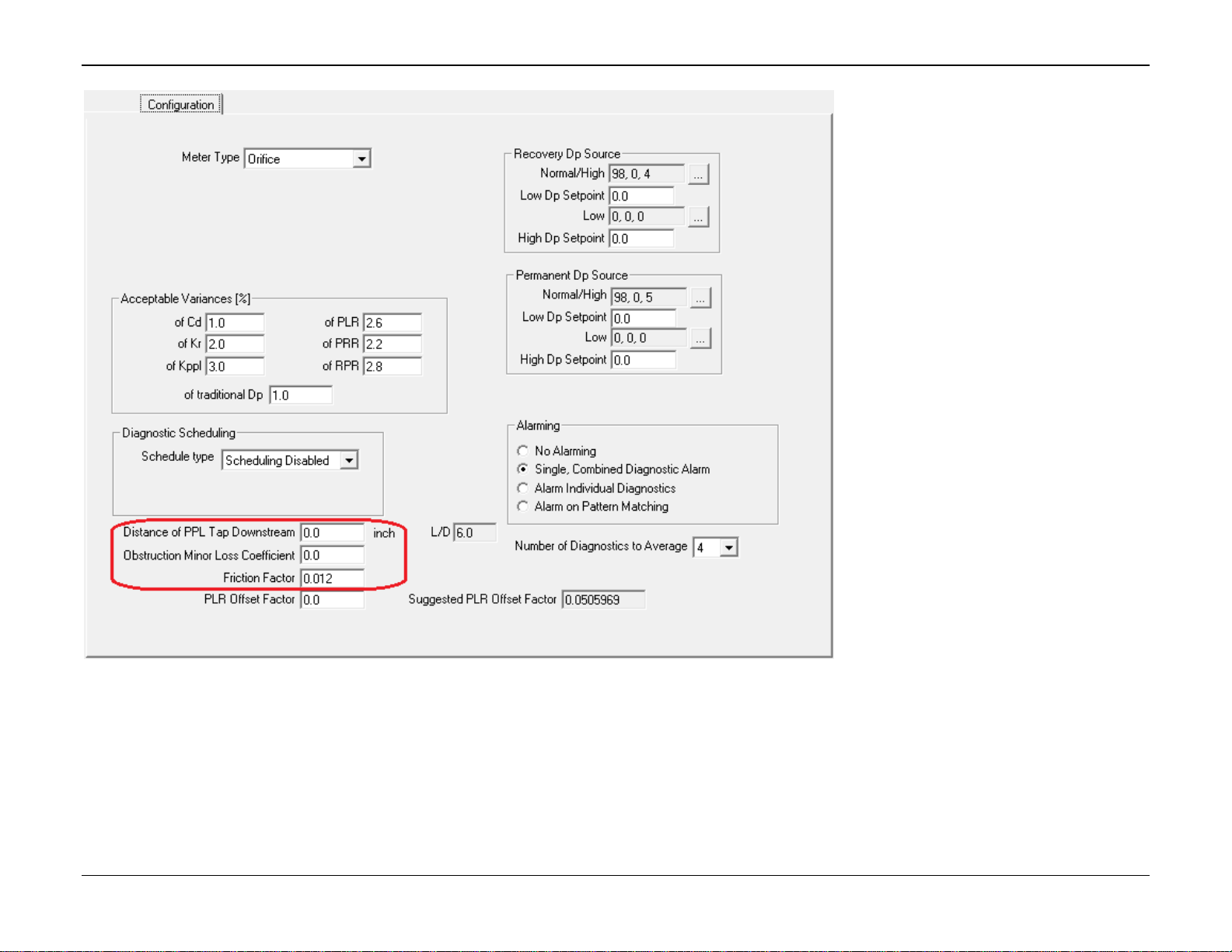

3.2 Configuration

The Configuration tab provides most of the parameters needed to

configure Prognosis FC.

Figure 3-4. Configuration tab

Page 25

DP – Prognosis FC User Manual (for ROC800-Series)

Issued January-2017 Configuration 21

1. Review the values in the following fields:

Field

Description

Meter Type

Selects the appropriate meter type. Click to

select a valid option:

Orifice

Venturi

Cone

Acceptable

Variances [%]

These values serve as the alarm thresholds for

the different diagnostic parameters. You can

increase these values if nuisance alarms are

occurring.

of Cd

Sets the acceptable variance (in percent) of the

discharge coefficient for the traditional meter.

of Kr

Sets the acceptable variance (in percent) of the

flow coefficient for the recovery meter.

of Kppl

Sets the acceptable variance (in percent) of the

flow coefficient for the permanent meter.

of PLR

Sets the acceptable variance (in percent) of the

ratio of permanent to traditional pressure loss.

of PRR

Sets the acceptable variance (in percent) of the

ratio of recovery to traditional pressure loss.

of RPR

Sets the acceptable variance (in percent) of the

ratio of recovery to permanent pressure loss.

of traditional Dp

Sets the acceptable variance (in percent) of the

traditional DP.

Diagnostic

Scheduling

This frame sets the diagnostic calculations for

the meter are to be scheduled. If scheduled,

select the Schedule Type. Click to select a

valid option:

Scheduling Disabled

Scheduling in Days

Scheduling in Hours

Scheduling in Minutes

Scheduling in Seconds

Schedule Type

Sets the time interval between scheduled runs of

Prognosis FC calculations for the meter. The

units of time for the interval are specified with the

Diagnostic Scheduling parameter.

Distance to PPL

Tap Downstream

Sets the distance from the restriction to the far

downstream tap.

If this number is less than the 6 diameters, it will

be ignored. If the value is greater than 6

diameters, a correction value will be applied to

the permanent pressure loss reading to

compensate for excessive distance downstream.

L/D

This read-only field displays the ratio of the far

downstream tap distance to the diameter of the

meter. Ideally, this value should be 6.0.

Page 26

DP – Prognosis FC User Manual (for ROC800-Series)

22 Configuration Issued January-2017

Field

Description

Obstruction Minor

Loss Coefficient

This coefficient is used to compensate for

pressure losses caused by obstructions in the

meter tube located between the downstream tap

and the far downstream tap. One example of

such an obstruction would be a thermowell.

Note: If a thermowell or other obstruction exists

in the flow stream between the

downstream tap and the far downstream

tap.

Friction Factor

Sets the friction factor used to calculate

additional pressure loss if far downstream tap is

located more than 6 diameters downstream.

PLR Offset Factor

Can be used to “zero” the error produced by

anomalies, such as wet gas, non-standard tap

location, and other pressure losses within the

meter

Suggested PLR

Offset Factor

This read-only field displays the PLR offset

factor calculated by the program which can be

used to “zero” the Diagnostics for the meter

Recovery DP

Source

Specifies where the value of the Recovery DP

should be read and the conditions (if applicable)

which will control switching between stacked DP

sensors.

Normal/High

Click to designate input variable from which

the DP should be read for non-stacked DP

installations. For stacked DP installations, this

location designates the parameter for the high

DP instrument value.

Low DP Setpoint

Sets the value which provides the threshold for

switching from the high DP instrument to the low

DP instrument. This is for stacked DP

installations.

Low

Click to designate input variable from which

the Low DP should be read for stacked DP

installations.

High DP Setpoint

Sets the value which provides the threshold for

switching from the low DP instrument to the high

DP instrument. This is for stacked DP

installations.

Permanent DP

Source

Specify where the value of the Permanent DP

should be read and the conditions (if applicable)

which will control switching between stacked DP

sensors.

Normal/High

Click to designate input variable from which

the DP should be read for non-stacked DP

installations. For stacked DP installations, this

location designates the parameter for the high

DP instrument value.

Low DP Setpoint

Sets the value which provides the threshold for

switching from the high DP instrument to the low

DP instrument. This is for stacked DP

installations.

Page 27

DP – Prognosis FC User Manual (for ROC800-Series)

Issued January-2017 Configuration 23

Field

Description

Low

Click to designate input variable from which

the Low DP should be read for stacked DP

installations.

High DP Setpoint

Sets the value which provides the threshold for

switching from the low DP instrument to the high

DP instrument. This is for stacked DP

installations.

Alarming

Specifies the type of alarms to be entered into

the ROC800 Alarm log:

No Alarming

No alarms will be

entered into the

ROC800 alarm log.

Single,Combined

Diagnostic Alarm

If any of the seven

diagnostics are outside

of acceptable ranges,

an alarm is set. The

alarm is not cleared

until all of the

diagnostics are within

range.

Alarm Individual

Diagnostics

Alarms are set and

cleared individually for

each of the seven

diagnostics.

Warning: This mode

can create numerous

alarms.

Alarm on Pattern

Match

If the pattern match

feature reveals a nonconforming pattern, an

alarm is set for that

pattern. The alarm is

cleared either when

the pattern returns a

conforming pattern or

when a different nonconforming pattern is

matched.

Number of

Diagnostics to

Average

When Prognosis FC calculations are executed,

the program can perform multiple consecutive

calculations rapidly and average the results.

Click to specify the number of calculation

repetitions to perform and average at each

scheduled interval.

Note: Improper configuration of this parameter

might result in unexpected or unwanted

behavior. For example, setting the

scheduling type to seconds and setting

the schedule to 5 but setting the number

of diagnostics to average to 7 will result

in continuous execution of the Prognosis

FC at 1-second intervals. In some

applications, this may place an undesirable

load on the ROC800’s main processor.

Page 28

DP – Prognosis FC User Manual (for ROC800-Series)

24 Configuration Issued January-2017

2. Enable the Run Diagnostic Command check box and click Apply

to save the changes.

3. Observe the Program Status Description and Code for indications

of either success of operation or configuration problems.

4. Make corrections as necessary.

5. Proceed to Section 3.3 – Advanced.

3.3 Advanced

Once you have successfully configured the DP Meter Diagnostics

program for a meter run, you can make adjustments to the Advanced

configuration parameters if so you desired.

Figure 3-5. Advanced tab

Page 29

DP – Prognosis FC User Manual (for ROC800-Series)

Issued January-2017 Configuration 25

1. Review the following fields:

Field

Description

Cd Calculation

Method

The coefficient of discharge for the traditional

flow rate calculation can be calculated either

from ISO 5167 or from a curve fit. If the meter

has been calibrated to derive a more precise

definition of discharge coefficient vs Reynolds

number, a curve fit of that calibration data can

be entered here.

Kr Calculation

Method

The flow coefficient for the recovery flow rate

calculation can be calculated either from ISO

5167 or from a curve fit. If the meter has been

calibrated to derive a more precise definition of

flow coefficient vs Reynolds number, a

polynomial curve fit of that calibration data can

be entered here.

Kppl Calculation

Method

The flow coefficient for the permanent pressure

loss rate calculation can be calculated either

from ISO 5167 or from a curve fit. If the meter

has been calibrated to derive a more precise

definition of flow coefficient vs Reynolds

number, a curve fit of that calibration data can

be entered here.

Expected/Calibrated

PLR Calculation

The ratio of traditional DP to permanent

pressure loss DP can be calculated either from

a published equation or from a curve fit. If the

meter has been calibrated to derive a more

precise definition of pressure loss ratio vs

Reynolds number, a curve fit of that calibration

data can be entered here.

Expected/Calibrated

PRR Calculation

The ratio of recovery DP to permanent

pressure loss DP can be calculated either from

a published equation or from a curve fit. If the

meter has been calibrated to derive a more

precise definition of pressure loss ratio vs

Reynolds number, a curve fit of that calibration

data can be entered here.

Expected/Calibrated

RPR Calculation

The ratio of traditional DP to recovery pressure

loss DP can be calculated either from a

published equation or from a curve fit. If the

meter has been calibrated to derive a more

precise definition of pressure loss ratio vs

Reynolds number, a curve fit of that calibration

data can be entered here.

Diagnostic

Calculations Cutoff

Thresholds

Specifies the low DP limits for the diagnostic

calculations:

Low Traditional

DP cutoff

Sets the threshold for diagnostic calculations

based on the traditional DP value. When the

traditional DP value falls below this threshold, the

diagnostic calculations will not be executed. This

feature can be used to prevent extraneous

alarms at very low flow rates.

Page 30

DP – Prognosis FC User Manual (for ROC800-Series)

26 Configuration Issued January-2017

Field

Description

Low Recovery DP

cutoff

Sets the threshold for diagnostic calculations

based on the recovery DP value. When the

recovery DP value falls below this threshold, the

diagnostic calculations will not be executed. This

feature can be used to prevent extraneous

alarms at very low flow rates.

Low Permanent

DP cutoff

Sets the threshold for diagnostic calculations

based on the permanent DP value. When the

permanent DP value falls below this threshold,

the diagnostic calculations will not be executed.

This feature can be used to prevent extraneous

alarms at very low flow rates.

2. Click Apply to save the changes.

3. Proceed to Section 3.4 – Intermediate.

3.4 Intermediate

The Intermediate tab provides information about intermediate values

calculated during the Prognosis FC calculations.

Note: The Prognosis FC calculations are performed in metric units –

regardless of the units of measure configured in the ROC800.

Page 31

DP – Prognosis FC User Manual (for ROC800-Series)

Issued January-2017 Configuration 27

Figure 3-6. Intermediate tab

Page 32

DP – Prognosis FC User Manual (for ROC800-Series)

28 Configuration Issued January-2017

1. Review the following fields:

Field

Description

Restriction

Diameter (d)

This read-only field displays the temperaturecorrected meter restriction diameter.

Inlet Diameter (D)

This read-only field displays the temperaturecorrected meter inlet diameter.

Beta

This read-only field displays the calculated

Beta ratio

Meter Inlet Area

This read-only field displays the cross-sectional

area of the meter inlet.

Meter Throat Area

This read-only field displays the cross-sectional

area of the meter restriction.

Velocity of

Approach factor

(E)

This read-only field displays the dimensionless

velocity of approach factor for the meter.

Isentropic

Exponent (kappa)

This read-only field displays the dimensionless

isentropic exponent for the flowing fluid.

Inlet Density (rho)

This read-only field displays the density of the

flowing fluid at the meter inlet.

Viscosity (mu)

This read-only field displays the dynamic

viscosity of the flowing fluid.

Tradinl Expansion

Factor (epsilon)

This read-only field displays the expansion

factor of the traditional meter.

Extra L/D

This read-only field displays the additional

dimensionless pipe diameters between the ideal

and actual location of the far downstream tap.

Kloss

This read-only field displays the total amount of

equivalent dimensionless pipe diameters

(including Extra L/D and any obstructions) for

correcting the far downstream pressure reading.

Head loss (hl)

This read-only field displays the amount by

which the far downstream Dp reading will be

corrected to account for additional losses.

Upstream Static

Pressure

This read-only field displays the upstream static

pressure.

Traditional Dp

Read

This read-only field displays the traditional Dp

value read from the configured input.

Recovery Dp Read

This read-only field displays the recovery Dp

value read from the configured input.

Permanent Dp

Read

This read-only field displays the permanent Dp

value read from the configured input.

Reynolds Number

(Re)

This read-only field displays the calculated

Reynold number.

Discharge

Coefficient (Cd)

This read-only field displays the coefficient of

discharge for the traditional meter.

Inferred Traditional

Dp

This read-only field displays the sum of the

Recovery DP Read and the Permanent Dp

Read.

Traditional DP

Error %

This read-only field displays the difference [%]

between the Traditional Dp Read and the

Inferred Traditional Dp.

Recovery

This read-only field displays the recovery meter

coefficient and corrections made to it.

Meter Coefficient

Kr, Kppl

This read-only field displays the meter

coefficient Kr calculated (vs Reynolds number)

using the method selected on the Advanced

tab.

Page 33

DP – Prognosis FC User Manual (for ROC800-Series)

Issued January-2017 Configuration 29

Field

Description

Meter Coefficient

Kr’, Kppl’

This read-only field displays the meter

coefficient Kr corrected for Head Loss (hl).

Meter Coefficient

Kr’Z, Kppl’Z

This read-only field displays the meter

coefficient Kr corrected for Head Loss (hl) and

PLR Offset Factor defined on the

Configuration tab.

Permanent

This read-only field displays the permanent

meter coefficient and corrections made to it

Meter Coefficient

Kr, Kppl

This read-only field displays the meter

coefficient Kppl calculated (vs Reynolds

number) using the method selected on the

Advanced tab.

Meter Coefficient

Kr’, Kppl’

This read-only field displays the meter

coefficient Kppl corrected for Head Loss (hl).

Meter Coefficient

Kr’Z, Kppl’Z

This read-only field displays the meter

coefficient Kppl corrected for Head Loss (hl)

and PLR Offset Factor defined on the

Configuration tab.

Traditional Mass

Flow Rate

This read-only field displays the mass flow rate

as calculated from the traditional meter.

Recovery Mass

Flow Rate

This read-only field displays the mass flow rate

as calculated from the recovery meter.

Permanent Mass

Flow Rate

This read-only field displays the mass flow rate

[Kg/sec] as calculated from the permanent

meter.

Trad/PPL Rate

Actual Error (psi)

This read-only field displays the actual error

between the traditional and permanent meter

flow rates.

Trad/Rec Rate

Actual Error

(lambda)

This read-only field displays the actual error

between the traditional and recovery meter flow

rates.

Rec/PPL Rate

Actual Error (chi)

This read-only field displays the actual error [%]

between the recovery and permanent meter

flow rates.

Trad/PPL Rate

Aceptable Error

(phi)

This read-only field displays the acceptable

error between the traditional and permanent

meter flow rates.

Trad/Rec Rate

Aceptable Error

(nu)

This read-only field displays the acceptable

error between the traditional and recovery meter

flow rates.

Rec/PPL Rate

Acceptable Error

(xi)

This read-only field displays the acceptable

error [%] between the recovery and permanent

meter flow rates.

PLR

This read-only field displays the uncorrected

and corrected pressure loss ratio information for

the traditional to permanent pressure loss ratio.

Actual

This read-only field displays the actual

pressure ratio.

Calibration

This read-only field displays the theoretical

(uncorrected) pressure ratio.

Calib’

This read-only field displays the theoretical

pressure loss ratio corrected for meter

coefficient Kr corrected for Head Loss (hl).

Calib’Z

This read-only field displays the theoretical

pressure loss ratio corrected for Head Loss (hl)

and PLR Offset Factor.

Page 34

DP – Prognosis FC User Manual (for ROC800-Series)

30 Configuration Issued January-2017

Field

Description

PRR

This read-only field displays the uncorrected

and corrected pressure loss ratio information for

the traditional to recovery pressure loss ratio.

Actual

This read-only field displays the actual

pressure ratio.

Calibration

This read-only field displays the theoretical

(uncorrected) pressure ratio.

Calib’

Displays the theoretical pressure loss ratio

corrected for meter coefficient Kr corrected for

Head Loss (hl).

Calib’Z

Displays the theoretical pressure loss ratio

corrected for Head Loss (hl) and PLR Offset

Factor.

RPR

This read-only field displays the uncorrected

and corrected pressure loss ratio information for

the recovery to permanent pressure loss ratio.

Actual

This read-only field displays the actual

pressure ratio.

Calib’Z

This read-only field displays the theoretical

pressure loss ratio corrected for Head Loss (hl)

and PLR Offset Factor. This will be identical to

the Actual value for RPR

PLR Error

Difference

This read-only field displays the calculated

difference between the actual and the corrected

theoretical PLR

PRR Error

Difference

This read-only field displays the calculated

difference between the actual and the corrected

theoretical PRR.

RPR Error

Difference

This read-only field displays the calculated

difference between the actual and the corrected

theoretical RPR.

2. Proceed to Section 3.5 – Detail.

3.5 Detail

The Detail tab provides more detailed information that the summary tab.

It also contains a limited amount of diagnostic information:

Page 35

DP – Prognosis FC User Manual (for ROC800-Series)

Issued January-2017 Configuration 31

Figure 3-7. Detail tab

1. Review the following fields:

Field

Description

Diagnostic Attempt

Counter

This read-only field displays each time a

diagnostic run begins; this counter is

increased.

Diagnostic

Completion

Counter

This read-only field displays each time a

diagnostic run reaches successful completion,

this counter is incremented. If the Diagnostic

Attempt Counter is increasing faster than the

Diagnostic Completion Counter, an error

condition is indicated.

Page 36

DP – Prognosis FC User Manual (for ROC800-Series)

32 Configuration Issued January-2017

Field

Description

Alarm Byte Value

This read-only field displays the numeric

representation of currently-active alarms is

displayed in this field. This is a bit-mapped 8-bit

integer:

Bit 0 – Traditional to Permanent Mass Flow

Rate Alarm

Bit 1 – Traditional to Permanent Pressure

Ratio Alarm

Bit 2 – Traditional to Recovery Mass Flow

Rate Alarm

Bit 3 – Traditional to Recovery Pressure Ratio

Alarm

Bit 4 – Recovery to Permanent Mass Flow

Rate Alarm

Bit 5 – Recovery to Permanent Pressure Ratio

Alarm

Bit 6 – Dp Comparison Alarm

Bit 7 – Not used

Note: This field is a numeric representation of

the Alarms section displayed on the

Results tab

Pattern Match

Code

This read-only field displays the numeric version

of the results of pattern matching. See Chapter 4

– Reference of this document for a listing of the

coded values.

Raw x1, y1, x2, y2,

x3, y3, x4

This read-only field displays the individual

diagnostic values from each repetition. All of the

unused repetition columns are filled with zeros

The Prognosis FC functions can be configured to

run from 1 to 9 repetitions of calculations for

each commanded execution. The results of this

set of runs is averaged.

1 – traditional

This read-only field displays the averaged

values of the individual parameters.

Flow Diagnostic

x

This read-only field displays the flow diagnostic

(x1) for the traditional meter.

Pressure Ratio

Diagnostic y

This read-only field displays the pressure ratio

diagnostic (y1) for the traditional meter.

2 – recovery

This read-only field displays the averaged

values of the individual parameters.

Flow Diagnostic

x

This read-only field displays the flow diagnostic

(x2) for the recovery meter.

Pressure Ratio

Diagnostic y

This read-only field displays the pressure ratio

diagnostic (y2) for the recovery meter.

3 - permanent

This read-only field displays the averaged

values of the individual parameters.

Flow Diagnostic

x

This read-only field displays the flow diagnostic

(x3) for the permanent meter.

Pressure Ratio

Diagnostic y

This read-only field displays the pressure ratio

diagnostic (y3) for the permanent meter.

Dp Comparison

This read-only field displays the averaged value

of the DpL-comparison diagnostic.

2. Proceed to Section 3.6 – Saving the Configuration.

Page 37

DP – Prognosis FC User Manual (for ROC800-Series)

Issued January-2017 Configuration 33

3.6 Saving the Configuration

Whenever you modify or change the configuration, it is a good practice

to save the final configuration to memory. To save the configuration:

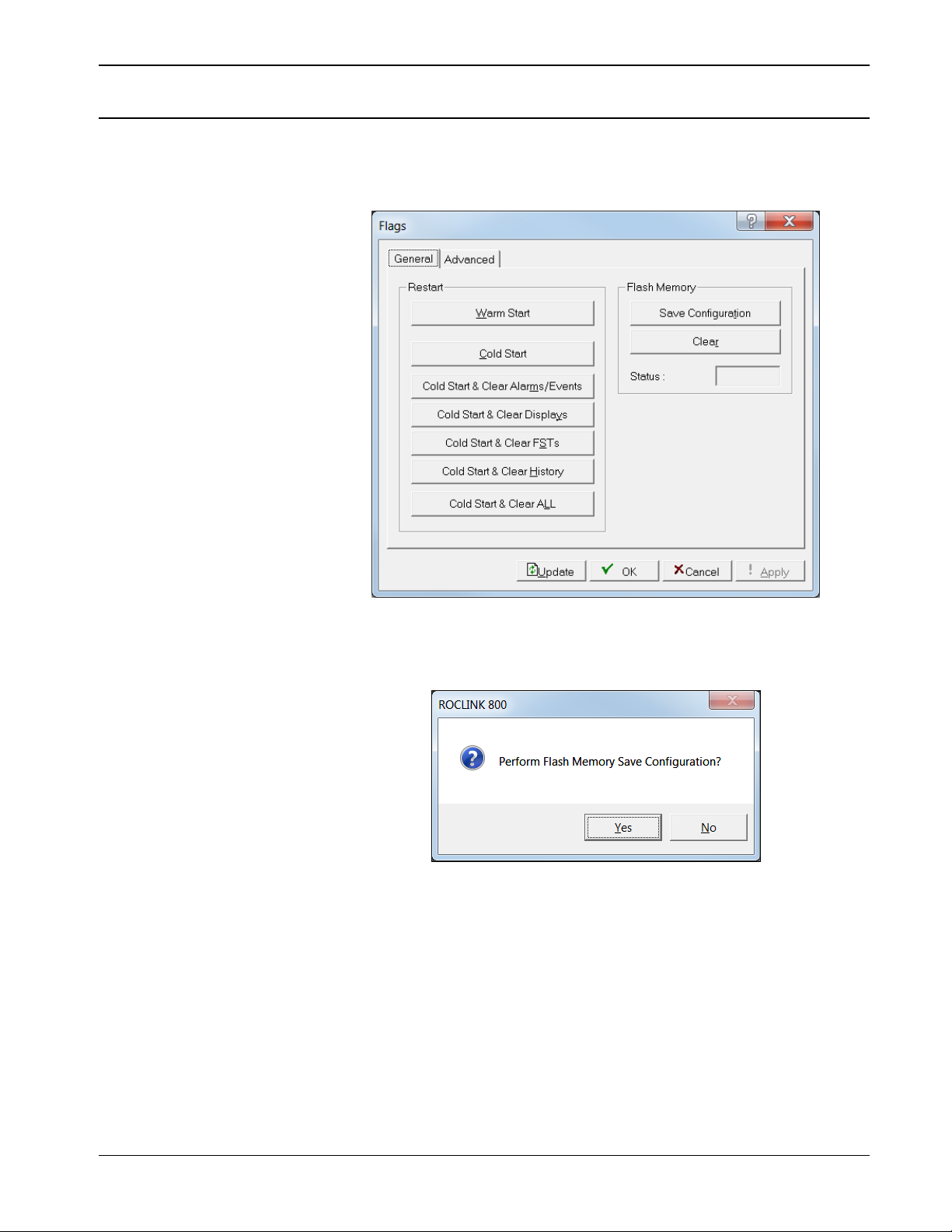

Select ROC > Flags. The Flags screen displays:

Figure 3-8. Flags

1. Click Save Configuration. A verification message displays:

Figure 3-9. Save Verification

Page 38

DP – Prognosis FC User Manual (for ROC800-Series)

34 Configuration Issued January-2017

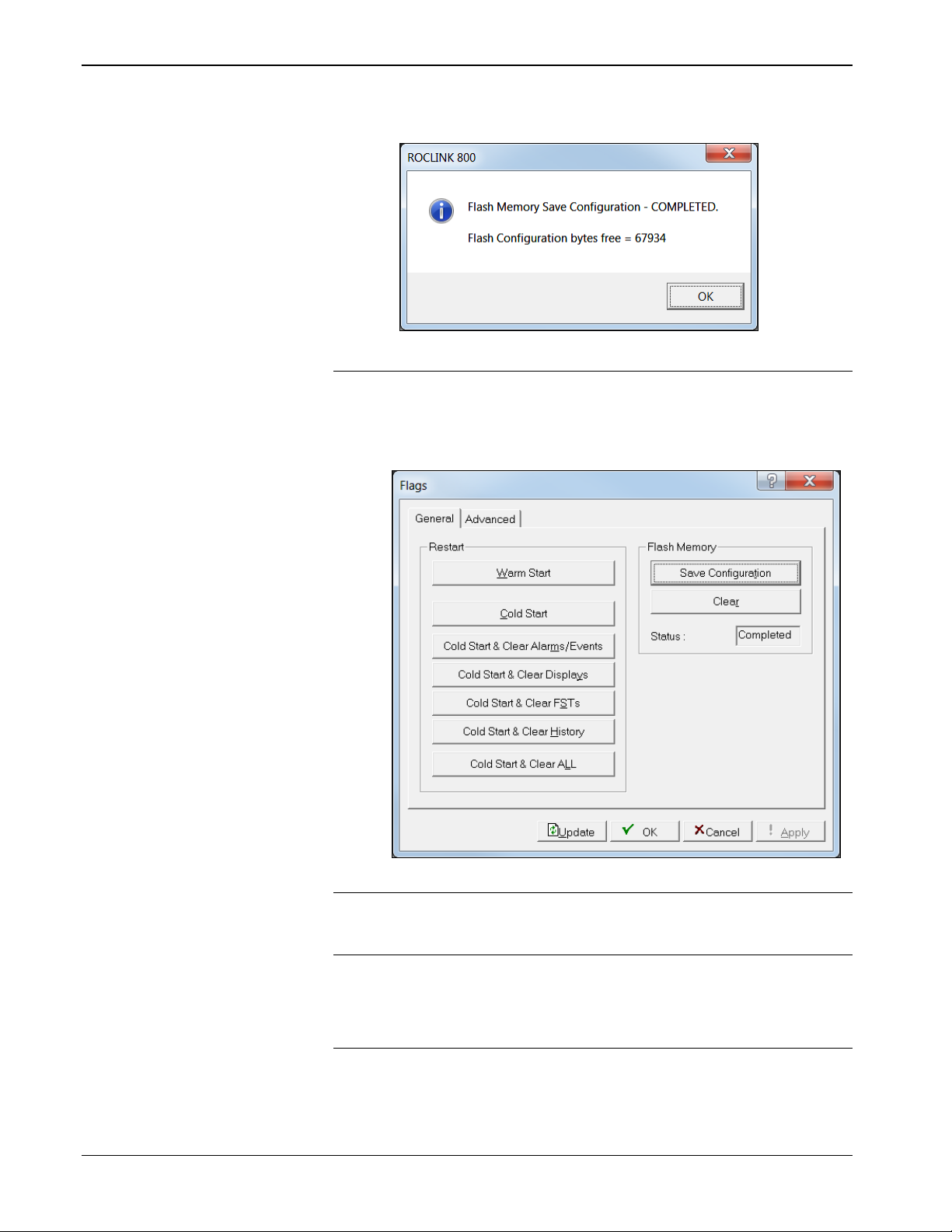

2. Click Yes. When the save process completes, a confirmation

message displays:

Figure 3-10. Confirmation

Note: Depending on the size and complexity of the user program,

this process may take several minutes. When the process

ends, the Status field on the Flags screen displays

Completed.

Figure 3-11. Flags, Status - Completed

3. Click Update on the Flags screen. This completes the process of

saving your new configuration.

Note: For archive purposes, you should also save this configuration

to your PC’s hard drive or a removable media (such as a

flash drive) using the File > Save Configuration option on

the ROCLINK 800 menu bar.

Page 39

DP – Prognosis FC User Manual (for ROC800-Series)

Issued January-2017 Reference 35

Chapter 4 – Reference

This section provides information on the user-defined point types the

DP Meter Diagnostics program uses:

Point Type 220: DP Meter Diagnostics Parameters

The following topics are discussed in this section:

Program Status Codes and Messages

Pattern Match Codes and Messages

Zeroing the meter for Prognosis FC

Page 40

DP – Prognosis FC User Manual (for ROC800-Series)

36 Reference Issued January-2017

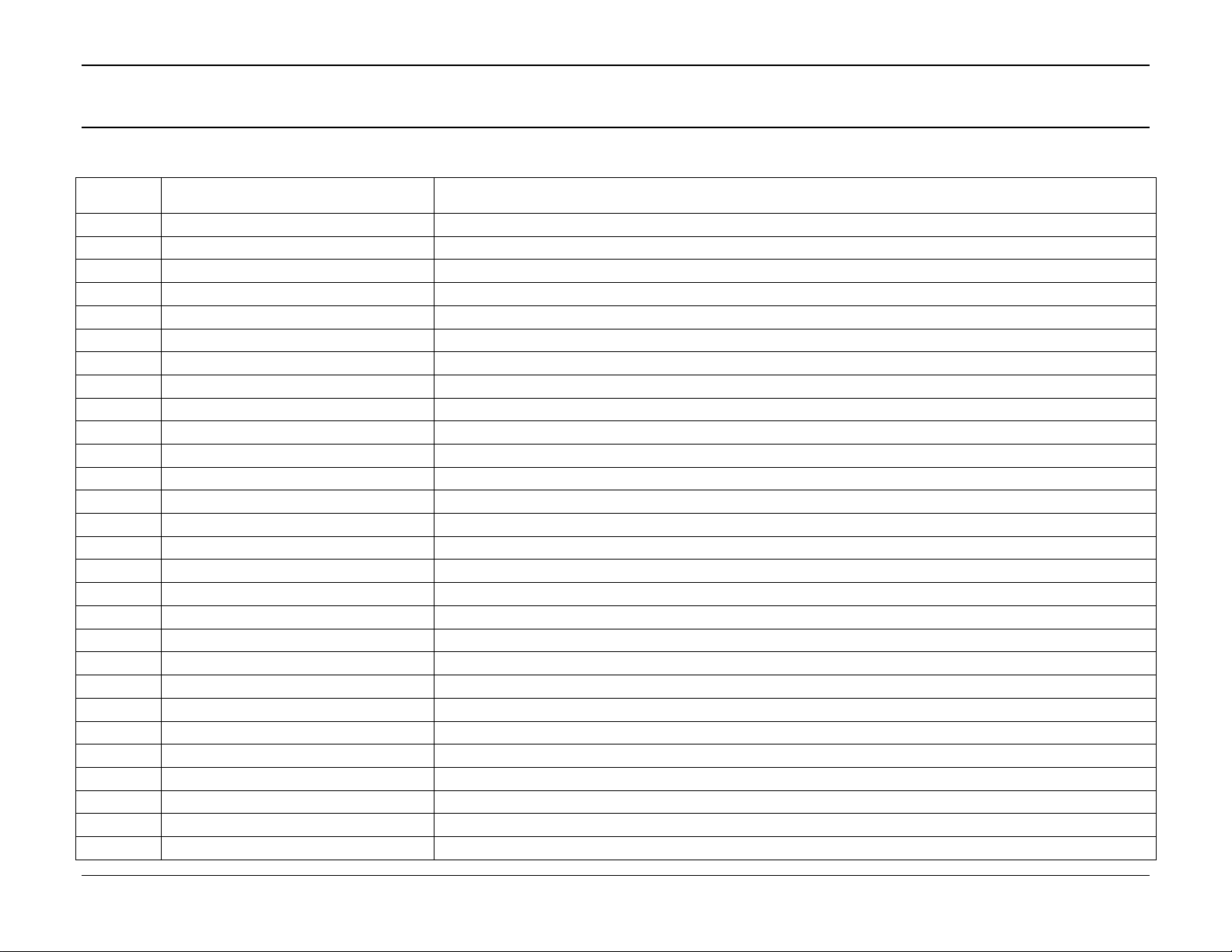

4.1 Point Type 220: DP – Prognosis FC Parameters

Point type 220 contains the parameters for the configuration and the output parameters of the DP – Prognosis FC user program. The program

supports up to 12 logicals of point type 220.

Point Type 220: DPMD Configuration Parameters

Parm

#

Name

Access

System

or User

Update

Data

Type

Length

Range

Default

Version

Description of functionality

and meaning of values

0

Tag

R/W

User

AC

10

0x20 0x7E for

each ASCII

character

“”

1.00

An alternate text descriptor

1

Cd Polynomial A

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

Coefficient used for calculating

Cd of Cd Method is anything

other than “ISO 5167 equation”

2

Cd Polynomial B

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

Coefficient used for calculating

Cd of Cd Method is anything

other than “ISO 5167 equation”

3

Cd Polynomial C

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

Coefficient used for calculating

Cd of Cd Method is anything

other than “ISO 5167 equation”

4

Cd Polynomial D

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

Coefficient used for calculating

Cd of Cd Method is anything

other than “ISO 5167 equation”

5

Kr Polynomial A

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

If Kr Method = “derive Kr from

curve-fit polynomial” then Kr is

calculated using a Cd computed

= KrA+(KrB*Re)+(KrC*( Re

^2))+(KrD*( Re ^3))

6

Kr Polynomial B

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

If Kr Method = “derive Kr from

curve-fit polynomial” then Kr is

calculated using a Cd computed

= KrA+(KrB*Re)+(KrC*( Re

^2))+(KrD*( Re ^3))

7

Kr Polynomial C

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

If Kr Method = “derive Kr from

curve-fit polynomial” then Kr is

calculated using a Cd computed

= KrA+(KrB*Re)+(KrC*( Re

^2))+(KrD*( Re ^3))

8

Kr Polynomial D

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

If Kr Method = “derive Kr from

curve-fit polynomial” then Kr is

calculated using a Cd computed

= KrA+(KrB*Re)+(KrC*( Re

^2))+(KrD*( Re ^3))

Page 41

DP – Prognosis FC User Manual (for ROC800-Series)

Issued January-2017 Reference 37

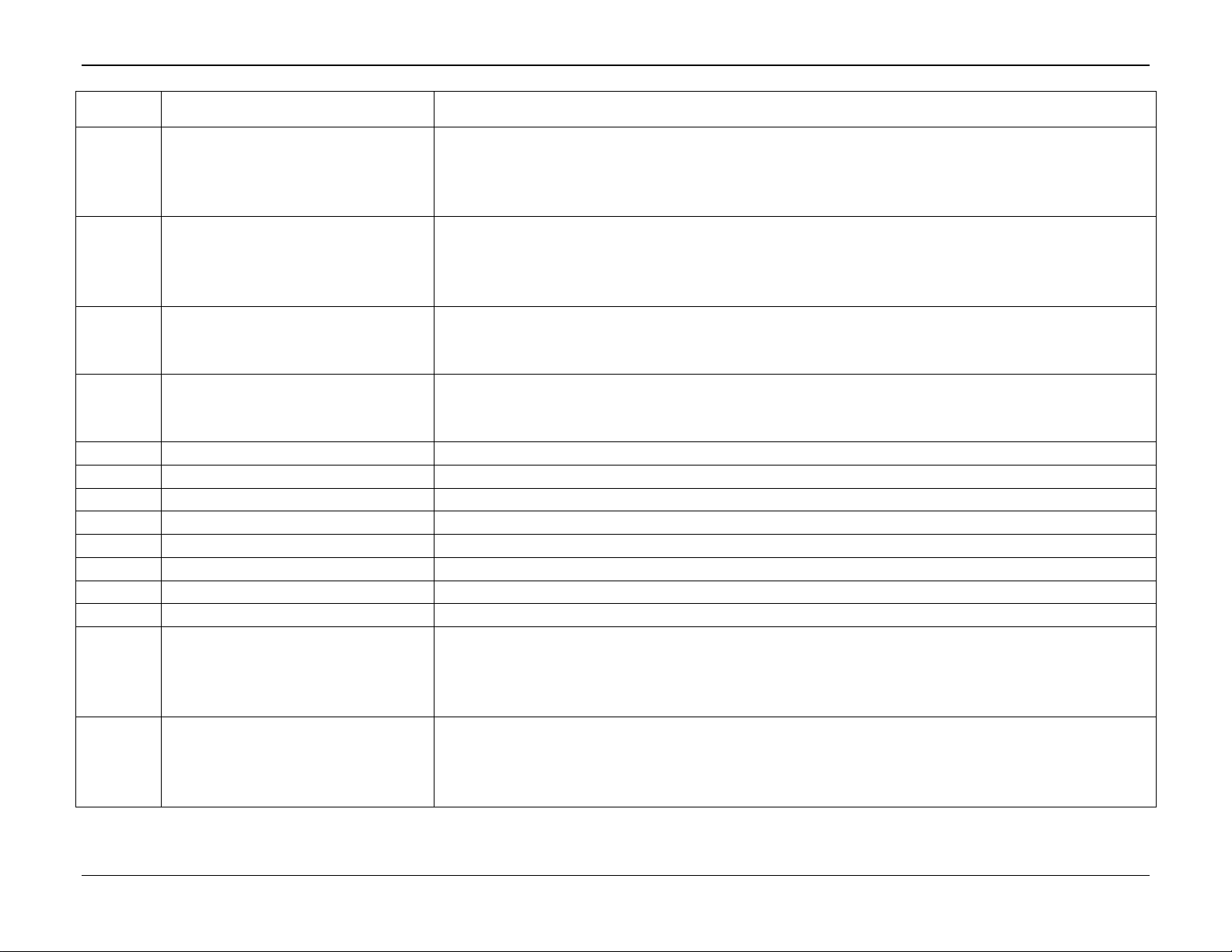

Point Type 220: DPMD Configuration Parameters

Parm

#

Name

Access

System

or User

Update

Data

Type

Length

Range

Default

Version

Description of functionality

and meaning of values

9

Kppl Polynomial A

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

If Kppl Method = “derive Kppl

from curve-fit polynomial” then

Kppl is calculated using a Cd

computed =

KpplA+(KpplB*Re)+(KpplC*( Re

^2))+(KpplD*( Re ^3))

10

Kppl Polynomial B

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

If Kppl Method = “derive Kppl

from curve-fit polynomial” then

Kppl is calculated using a Cd

computed =

KpplA+(KpplB*Re)+(KpplC*( Re

^2))+(KpplD*( Re ^3))

11

Kppl Polynomial C

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

If Kppl Method = “derive Kppl

from curve-fit polynomial” then

Kppl is calculated using a Cd

computed =

KpplA+(KpplB*Re)+(KpplC*( Re

^2))+(KpplD*( Re ^3))

12

Kppl Polynomial D

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

If Kppl Method = “derive Kppl

from curve-fit polynomial” then

Kppl is calculated using a Cd

computed =

KpplA+(KpplB*Re)+(KpplC*( Re

^2))+(KpplD*( Re ^3))

13

PLR Polynomial A

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

Coefficient used for calculating

PLR if PLR Method is anything

other than “ISO 5167 equation”

14

PLR Polynomial B

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

Coefficient used for calculating

PLR if PLR Method is anything

other than “ISO 5167 equation”

15

PLR Polynomial C

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

Coefficient used for calculating

PLR if PLR Method is anything

other than “ISO 5167 equation”

16

PLR Polynomial D

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

Coefficient used for calculating

PLR if PLR Method is anything

other than “ISO 5167 equation”

17

PRR Polynomial A

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

Coefficient used for calculating

PRR if PRR Method is anything

other than “calculate from PLR

and theoretical relationships”

Page 42

DP – Prognosis FC User Manual (for ROC800-Series)

38 Reference Issued January-2017

Point Type 220: DPMD Configuration Parameters

Parm

#

Name

Access

System

or User

Update

Data

Type

Length

Range

Default

Version

Description of functionality

and meaning of values

18

PRR Polynomial B

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

Coefficient used for calculating

PRR if PRR Method is anything

other than “calculate from PLR

and theoretical relationships”

19

PRR Polynomial C

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

Coefficient used for calculating

PRR if PRR Method is anything

other than “calculate from PLR

and theoretical relationships”

20

PRR Polynomial D

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

Coefficient used for calculating

PRR if PRR Method is anything

other than “calculate from PLR

and theoretical relationships”

21

RPR Polynomial A

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

Coefficient used for calculating

RPR if RPR Method is anything

other than “calculate from PLR

and theoretical relationships”

22

RPR Polynomial B

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

Coefficient used for calculating

RPR if RPR Method is anything

other than “calculate from PLR

and theoretical relationships”

23

RPR Polynomial C

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

Coefficient used for calculating

RPR if RPR Method is anything

other than “calculate from PLR

and theoretical relationships”

24

RPR Polynomial D

R/W

User

FL

4

Any IEEE floating

point value

0.0

1.00

Coefficient used for calculating

RPR if RPR Method is anything

other than “calculate from PLR

and theoretical relationships”

25

PPL Tap Distance

R/W

User

FL

4

Any positive, non-

zero IEEE floating

point value

0.0

1.00

Distance between the restriction

(orifice plate) and the PPL

pressure tap. Units of measure

are same as used for orifice and

pipe diameter.

26

Obstruction Minor Loss Coefficient

R/W

User

FL

4

Any positive, non-

zero IEEE floating

point value

0.0

1.00

Sum of minor loss coefficients

for any obstructions between

the flow restriction (orifice plate)

and the PPL pressure tap

27

Friction Factor

R/W

User

FL

4

Any positive, non-

zero IEEE floating

point value

0.012

1.00

Friction factor for calculating

pressure loss in the meter body

Page 43

DP – Prognosis FC User Manual (for ROC800-Series)

Issued January-2017 Reference 39

Point Type 220: DPMD Configuration Parameters

Parm

#

Name

Access

System

or User

Update

Data

Type

Length

Range

Default

Version

Description of functionality

and meaning of values

28

PLR Offset Factor

R/W

User

FL

4

Any positive, non-

zero IEEE floating

point value

0.0

1.00

Factor for offsetting the PLR of

the meter

29

Acceptable Variance of Cd

R/W

User

FL

4

Any positive, non-

zero IEEE floating

point value

1.0

1.00

Maximum acceptable variance

percentage of discharge

coefficient

30

Acceptable Variance of Kr

R/W

User

FL

4

Any positive, non-

zero IEEE floating

point value

2.0

1.00

Maximum acceptable variance

percentage of recovery meter

coefficient

31

Acceptable Variance of Kppl

R/W

User

FL

4

Any positive, non-

zero IEEE floating

point value

3.0

1.00

Maximum acceptable variance

percentage of permanent

pressure loss meter coefficient

32

Acceptable Variance of PLR

R/W

User

FL

4

Any positive, non-

zero IEEE floating

point value

2.6

1.00

Maximum acceptable variance

permanent pressure loss ratio

33

Acceptable Variance of PRR

R/W

User

FL

4

Any positive, non-

zero IEEE floating

point value

2.2

1.00

Maximum acceptable variance

recovery pressure loss ratio

34

Acceptable Variance of RPR

R/W

User

FL

4

Any positive, non-

zero IEEE floating

point value

2.8

1.00

Maximum acceptable variance

of ratio of pressure recovery

pressure to permanent pressure

loss

35

Acceptable Variance of Traditional

Dp

R/W

User

FL

4

Any positive, non-

zero IEEE floating

point value

1.0

1.00

Maximum acceptable variance

of the measured traditional Dp

from the inferred traditional Dp

36

Cd Text Polynomial A

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the Cd

polynomial coefficient A

37

Cd Text Polynomial B

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the Cd

polynomial coefficient B

38

Cd Text Polynomial C

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the Cd

polynomial coefficient C

39

Cd Text Polynomial D

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the Cd

polynomial coefficient D

40

Kr Text Polynomial A

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the Kr

polynomial coefficient A

Page 44

DP – Prognosis FC User Manual (for ROC800-Series)

40 Reference Issued January-2017

Point Type 220: DPMD Configuration Parameters

Parm

#

Name

Access

System

or User

Update

Data

Type

Length

Range

Default

Version

Description of functionality

and meaning of values

41

Kr Text Polynomial B

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the Kr

polynomial coefficient B

42

Kr Text Polynomial C

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the Kr

polynomial coefficient C

43

Kr Text Polynomial D

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the Kr

polynomial coefficient D

44

Kppl Text Polynomial A

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the Kppl

polynomial coefficient A

45

Kppl Text Polynomial B

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the Kppl

polynomial coefficient B

46

Kppl Text Polynomial C

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the Kppl

polynomial coefficient C

47

Kppl Text Polynomial D

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the Kppl

polynomial coefficient D

48

PLR Text Polynomial A

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the PLR

polynomial coefficient A

49

PLR Text Polynomial B

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the PLR

polynomial coefficient B

50

PLR Text Polynomial C

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the PLR

polynomial coefficient C

51

PLR Text Polynomial D

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the PLR

polynomial coefficient D

52

PRR Text Polynomial A

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the PRR

polynomial coefficient A

53

PRR Text Polynomial B

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the PRR

polynomial coefficient B

Page 45

DP – Prognosis FC User Manual (for ROC800-Series)

Issued January-2017 Reference 41

Point Type 220: DPMD Configuration Parameters

Parm

#

Name

Access

System

or User

Update

Data

Type

Length

Range

Default

Version

Description of functionality

and meaning of values

54

PRR Text Polynomial C

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the PRR

polynomial coefficient C

55

PRR Text Polynomial D

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the PRR

polynomial coefficient D

56

RPR Text Polynomial A

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the RPR

polynomial coefficient A

57

RPR Text Polynomial B

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the RPR

polynomial coefficient B

58

RPR Text Polynomial C

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the RPR

polynomial coefficient C

59

RPR Text Polynomial D

RW

User

AC

20

Any valid

numerical ASCII

characters

“0.0”

1.00

Text version of the RPR

polynomial coefficient D

60

Recovery Low DP Setpoint

R/W

User

FL

4

Any positive, non-

zero IEEE floating

point value

0.0

1.00

If Regular Dp source is being

used and Dp falls below this

setpoint value, the system will

switch to using the Low DP

source.

61

Recovery High Dp Setpoint

R/W

User

FL

4

Any positive, non-

zero IEEE floating

point value

0.0

1.00

If low DP source is being used

and Dp rises above this value,

the system will switch to use the

Regular Dp source

62

Permanent Low DP Setpoint

R/W

User

FL

4

Any positive, non-

zero IEEE floating

point value

0.0

1.00

If Regular Dp source is being

used and Dp falls below this

setpoint value, the system will

switch to using the Low DP

source.

63

Permanent High Dp Setpoint

R/W

User

FL

4

Any positive, non-

zero IEEE floating

point value

0.0

1.00

If low DP source is being used

and Dp rises above this value,

the system will switch to use the

Regular Dp source

64

Recovery Dp Source

R/W

User

TLP 3 Any valid TLP

(assumed to be a

floating point TLP)

0,0,0

1.00

Source of differential pressure

signal measured from

downstream tap to PPL tap.

Page 46

DP – Prognosis FC User Manual (for ROC800-Series)

42 Reference Issued January-2017

Point Type 220: DPMD Configuration Parameters

Parm

#

Name

Access

System

or User

Update

Data

Type

Length

Range

Default

Version

Description of functionality

and meaning of values

65

Recovery Low Dp Source

R/W

User

TLP 3 Any valid TLP

(assumed to be a

floating point TLP)

0,0,0

1.00

Source of differential pressure

signal measured from

downstream tap to PPL tap to

be used for “low” side of a

stacked DP arrangement.

66

Permanent Dp Source

R/W

User

TLP 3 Any valid TLP

(assumed to be a

floating point TLP)

0,0,0

1.00

Source of differential pressure

signal measured from upstream

tap to PPL tap.

67

Permanent Low Dp Source

R/W

User

TLP 3 Any valid TLP

(assumed to be a

floating point TLP)

0,0,0

1.00

Source of differential pressure

signal measured from upstream

tap to PPL tap to be used for

“low” side of a stacked DP

arrangement.

68

Enable DPMD

R/W

User

UINT8 1 0-1

0

1.00

Valid values are:

0 = Disable DPMD for this

meter

1 = Enable DPMD for this meter

69

Meter Type

R/W

User

UINT8 1 0-2

0

1.00

Valid values are:

0 = Orifice

1 = Venturi

2 = Cone

Page 47

DP – Prognosis FC User Manual (for ROC800-Series)

Issued January-2017 Reference 43

Point Type 220: DPMD Configuration Parameters

Parm

#

Name

Access

System

or User

Update

Data

Type

Length

Range

Default

Version

Description of functionality

and meaning of values

70

PLR Method

R/W

User

UINT8 1 0-8

1

1.00

Valid values are:

0 – Use ISO 5167-2 equation 7

for all Beta ratios

1 – Use f(Beta) equation

disclosed by Stevens in

2012 for Beta ratios above

0.55

2 – Direct polynomial curve-fit

PLR = A + B*Re + C*Re^2 +

D*Re^3

3 – Direct curve fit PLR = A +

B*(e^(C*Re))

4 – Direct curve fit PLR = A +

B*(10^(C*Re))

5 – Direct curve fit PLR = A +

B*ln((C*Re))

6 – Direct curve fit PLR = A +

B*log((C*Re))

7 – Direct curve fit PLR = A +

B*(C^(D*Re))

8 – Direct curve fit PLR = A + B

*((C*Re)^D)

Note: Methods 0 and 1 are only

valid for an Orifice Meter.

71

Generate Events

R/W

User

UINT8 1 0-1

1

1.00

Valid values are:

0 – Generate events in the

event log when meter

diagnostic configuration

parameters are modified

1 – Do not generate events

72

Generate Alarms

R/W

User

UINT8 1 0-3

3

1.00

Valid values are:

0 – Do not generate alarms

1 – Generate only a single,

combined alarm for all

diagnostics

2 – Generate alarms based on

the seven individual

diagnostics

3 – Generate alarm based upon

pattern matching

Page 48

DP – Prognosis FC User Manual (for ROC800-Series)

44 Reference Issued January-2017

Point Type 220: DPMD Configuration Parameters

Parm

#

Name

Access

System

or User

Update

Data

Type

Length

Range

Default

Version

Description of functionality

and meaning of values

73

Kr Method

R/W

User

UINT8 1 0-8