Page 1

Part Number D301220X412

February 2022

Config600™ Configuration Software User Manual

Remote Automation Solutions

Page 2

Config600 Configuration Software User Manual

System Training

A well-trained workforce is critical to the success of your operation. Knowing how to

correctly install, configure, program, calibrate, and trouble-shoot your Emerson equipment

provides your engineers and technicians with the skills and confidence to optimize your

investment. Remote Automation Solutions offers a variety of ways for your personnel to

acquire essential system expertise. Our full-time professional instructors can conduct

classroom training at several of our corporate offices, at your site, or even at your regional

Emerson office. You can also receive the same quality training via our live, interactive

Emerson Virtual Classroom and save on travel costs. For our complete schedule and further

information, contact the Remote Automation Solutions Training Department at +1-800-3388158 or email us at education@emerson.com.

ii Revised February 2022

Page 3

Config600 Configuration Software User Manual

Contents

Chapter 1 – Introduction 1-1

1.1 Configuration Updates .................................................................................................... 1-1

1.2 Scope of Manual ............................................................................................................. 1-2

1.3 Software Basics .............................................................................................................. 1-3

1.4 Installing Config600 ......................................................................................................... 1-5

1.5 Accessing Config600 ...................................................................................................... 1-9

1.6 Activating Config600 ....................................................................................................... 1-9

1.7 Additional Technical Information ................................................................................... 1-11

Chapter 2 – PCSetup Editor 2-1

2.1 Create a New Configuration ............................................................................................ 2-1

2.1.1 Name the Configuration (Step 1 of 6) ................................................................ 2-2

2.1.2 Select Measurement Units (Step 2 of 6) ........................................................... 2-3

2.1.3 Specify Modules (Step 3 of 6) ........................................................................... 2-4

2.1.4 Specify Stations (Step 4 of 6) ............................................................................ 2-5

2.1.5 Define Streams (Step 5 of 6) ............................................................................. 2-8

2.1.6 Select Communications (Step 6 of 6) .............................................................. 2-15

2.2 Analyse a Configuration (System Graphic) ................................................................... 2-17

2.3 Open an Existing Configuration (PCSetup Editor) ......................................................... 2-23

2.3.1 Navigating the PCSetup Editor........................................................................ 2-25

2.3.2 The Icon Bar.................................................................................................... 2-26

2.4 The Menu Bar ............................................................................................................... 2-27

2.5 Managing Configurations .............................................................................................. 2-28

2.5.1 Save a Configuration ....................................................................................... 2-28

2.5.2 Regenerate a Configuration ............................................................................ 2-28

2.6 Display Editor ................................................................................................................ 2-29

2.7 Config Transfer Utility .................................................................................................... 2-29

2.8 Config Organiser Utility ................................................................................................. 2-29

Chapter 3 – System Setup 3-1

3.1 Versions .......................................................................................................................... 3-2

3.2 Units ................................................................................................................................ 3-3

3.2.1 Supported Units ................................................................................................ 3-4

3.3 Reports............................................................................................................................ 3-6

3.3.1 General Reports ................................................................................................ 3-7

3.3.2 Base Time Reports ........................................................................................... 3-8

3.3.3 Default Reports ................................................................................................. 3-9

3.3.4 Report History ................................................................................................... 3-9

3.3.5 Adding a General Report to a Configuration ..................................................... 3-9

3.3.6 User Reports ................................................................................................... 3-11

3.3.7 Adding a Base Time Report to a Configuration ............................................... 3-11

3.3.8 Managing Configuration Reports..................................................................... 3-13

3.4 Totalisations .................................................................................................................. 3-14

3.5 Time .............................................................................................................................. 3-16

Chapter 4 – I/O and Comms Configuration 4-1

4.1 Discrete (Digital) Inputs (DI) ............................................................................................ 4-2

4.1.1 Assigning Discrete (Digital) Inputs .................................................................... 4-2

4.1.2 Editing Discrete (Digital) Inputs ......................................................................... 4-3

4.1.3 Adding Discrete (Digital) Inputs ......................................................................... 4-4

4.2 Discrete (Digital) Outputs (DO) ....................................................................................... 4-5

4.2.1 Assigning Discrete (Digital) Outputs .................................................................. 4-5

Revised February 2022 iii

Page 4

Config600 Configuration Software User Manual

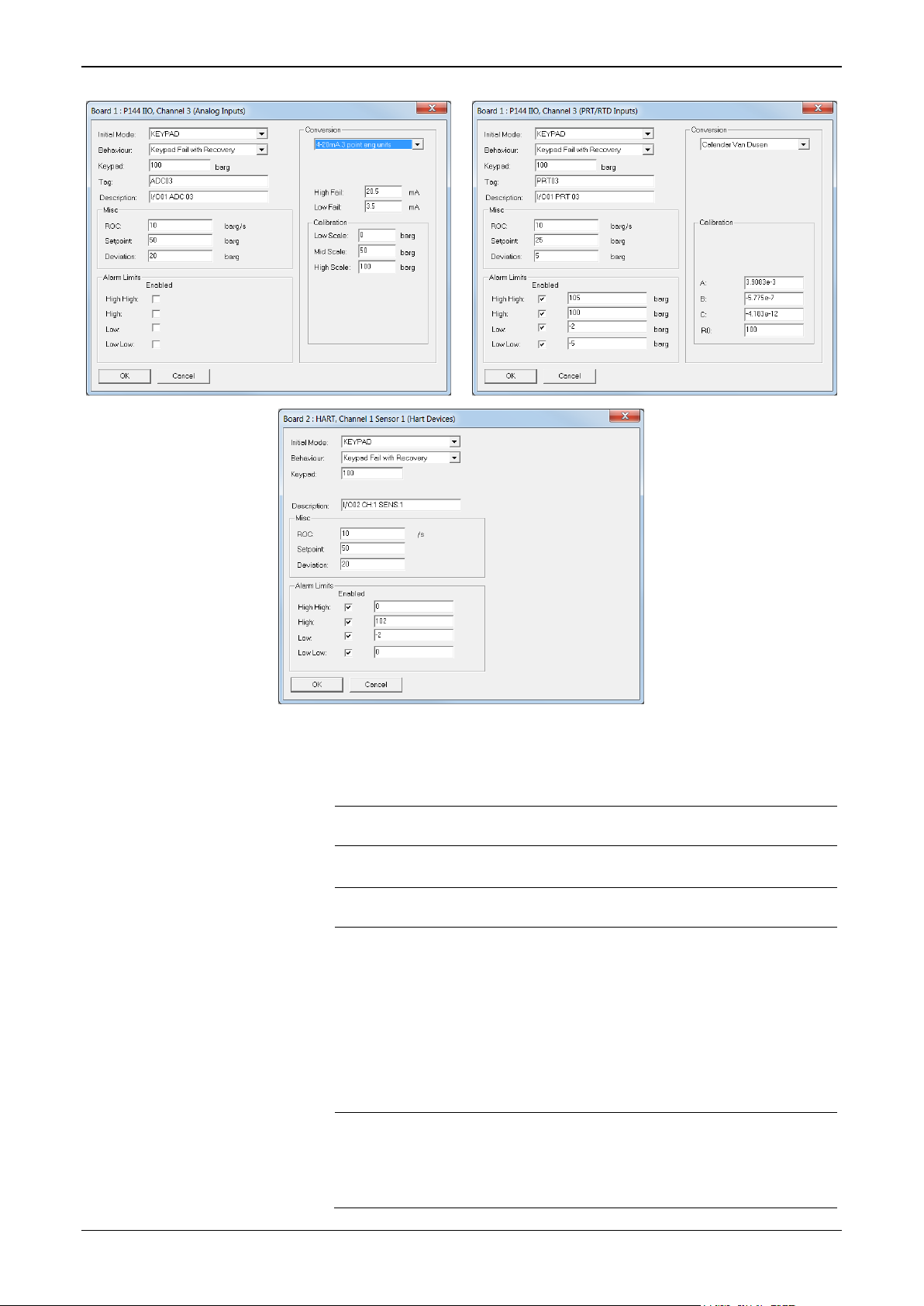

4.3 Analog Inputs (AI) ........................................................................................................... 4-6

4.3.1 Assigning Analog Inputs (AI) ............................................................................. 4-6

4.3.2 Editing Analog Inputs (AI) ................................................................................. 4-7

4.3.3 Adding a New I/O Point ................................................................................... 4-15

4.4 Analog Outputs (AO) ..................................................................................................... 4-15

4.4.1 Editing Analog Outputs ................................................................................... 4-15

4.5 Density Inputs ............................................................................................................... 4-17

4.5.1 Assigning Density Input ................................................................................... 4-17

4.5.2 Editing Density Inputs ..................................................................................... 4-18

4.6 Turbine Inputs ............................................................................................................... 4-19

4.6.1 Assigning Turbine Inputs ................................................................................. 4-19

4.6.2 Editing Turbine Inputs ..................................................................................... 4-21

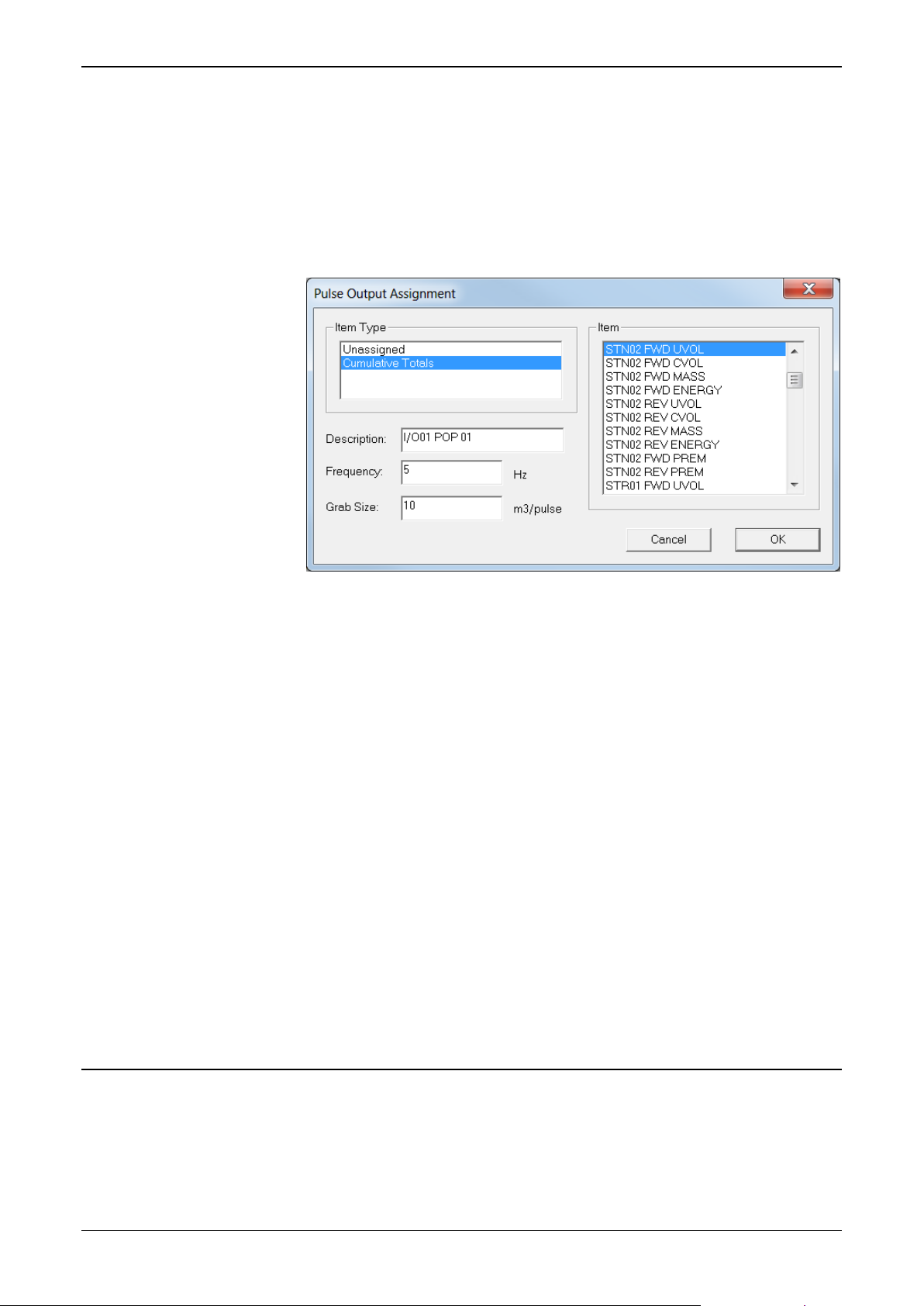

4.7 Pulse Outputs ................................................................................................................ 4-21

4.7.1 Assigning Pulse Outputs ................................................................................. 4-22

4.8 HART Modules .............................................................................................................. 4-22

4.8.1 Editing HART Settings .................................................................................... 4-23

4.9 PID Loop Settings ......................................................................................................... 4-23

4.9.1 Assigning PID Loops ....................................................................................... 4-24

4.9.2 Proportional Plus Integral and Derivative Action ............................................. 4-28

4.10 Communications Port .................................................................................................... 4-30

4.10.1 Editing a Communications Task ...................................................................... 4-30

4.10.2 Setting Up Peer-to-peer Options ..................................................................... 4-34

Chapter 5 – Station Configuration 5-1

5.1 Station Flowrate Limits .................................................................................................... 5-2

5.2 Station Averaging Temperature & Pressure .................................................................... 5-4

5.3 Station Secondary Units Setup ....................................................................................... 5-6

5.4 Station Flow Switching .................................................................................................... 5-8

5.5 Station Gas Composition............................................................................................... 5-10

5.6 Sampling ....................................................................................................................... 5-15

5.7 Prover Configuration Screens ....................................................................................... 5-18

5.7.1 Flow Balance Setup ........................................................................................ 5-18

5.7.2 Prover – Ball (Bi-Directional) (Liquid Only) ...................................................... 5-20

5.7.3 Prover – Compact (Liquid Only) ...................................................................... 5-33

5.7.4 Prover – Master Meter (Gas and Liquid) ......................................................... 5-45

Chapter 6 – Stream Configuration 6-1

6.1 Initial Configurations ........................................................................................................ 6-2

6.2 Common Stream Settings ............................................................................................... 6-4

6.2.1 General Settings ............................................................................................... 6-4

6.2.2 Flowrate ............................................................................................................ 6-5

6.2.3 Stream Secondary Units Setup ......................................................................... 6-7

6.2.4 Stream Flow Switching Setup ......................................................................... 6-10

6.2.5 Gas Component Flow Weighted Averaging (GC FWA) ................................... 6-11

6.2.6 Density Measurement ..................................................................................... 6-13

6.2.7 Block Valves.................................................................................................... 6-16

6.2.8 Time & Flow Weighted Averaging Methods .................................................... 6-18

6.3 Gas – Coriolis ................................................................................................................ 6-22

6.3.1 AGA8 (Compressibility) ................................................................................... 6-22

6.3.2 Gas CV (ISO6976 or GPA2172/ASTM D3588) ............................................... 6-25

6.3.3 Gas CV (AGA5)............................................................................................... 6-30

6.3.4 Stream Gas Composition ................................................................................ 6-31

6.3.5 Gas Properties ................................................................................................ 6-36

6.3.6 Ethylene .......................................................................................................... 6-39

6.3.7 Linearisation .................................................................................................... 6-40

6.3.8 Sampling ......................................................................................................... 6-42

6.3.9 Coriolis ............................................................................................................ 6-45

6.4 Gas – DP....................................................................................................................... 6-49

6.4.1 Downstream/Upstream Correction .................................................................. 6-49

6.4.2 Pipe Correction ............................................................................................... 6-52

iv Revised February 2022

Page 5

Config600 Configuration Software User Manual

6.4.3 AGA8 (Compressibility) ................................................................................... 6-55

6.4.4 ISO5167 (Mass Flowrate) ............................................................................... 6-58

6.4.5 ISOTR9464 ..................................................................................................... 6-61

6.4.6 V-Cone (Mass Flowrate) ................................................................................. 6-63

6.4.7 Annubar (Mass Flowrate) ................................................................................ 6-65

6.4.8 Pure Gas Air.................................................................................................... 6-67

6.4.9 Gas CV (ISO6976 or GPA2172/ASTM D3588) ............................................... 6-68

6.4.10 SGERG (Compressibility) ............................................................................... 6-73

6.4.11 NX19 (Compressibility) ................................................................................... 6-76

6.4.12 PTZ (Compressibility) ...................................................................................... 6-77

6.4.13 AGA3 (Volume or Mass Flowrate) ................................................................... 6-79

6.4.14 Stream Gas Composition ................................................................................ 6-81

6.4.15 Z Steam (Compressibility) ............................................................................... 6-85

6.4.16 GOST CV ........................................................................................................ 6-87

6.4.17 GOST Flow ..................................................................................................... 6-88

6.4.18 Gas Properties ................................................................................................ 6-91

6.4.19 DP Cell Input Conditioning .............................................................................. 6-94

6.5 Gas – Turbine ............................................................................................................. 6-111

6.5.1 AGA8 (Compressibility) ................................................................................. 6-111

6.5.2 Gas CV (ISO6976 or GPA2172/ASTM D3588) ............................................. 6-114

6.5.3 AGA7 (Gross Volume Flowrate) .................................................................... 6-118

6.5.4 Stream Gas Composition .............................................................................. 6-121

6.5.5 Gas Properties .............................................................................................. 6-125

6.5.6 Linearisation .................................................................................................. 6-128

6.6 Gas – Ultrasonic .......................................................................................................... 6-130

6.6.1 AGA8 (Compressibility) ................................................................................. 6-130

6.6.2 Gas CV (ISO6976 or GPA2172/ASTM D3588) ............................................. 6-133

6.6.3 AGA7 (Gross Volume Flowrate) .................................................................... 6-138

6.6.4 Stream Gas Composition (Gas Ultrasonic) ................................................... 6-140

6.6.5 Linearisation .................................................................................................. 6-144

6.6.6 Gas Properties (Gas Ultrasonic) ................................................................... 6-146

6.6.7 Ultrasonic Flow Setup ................................................................................... 6-149

6.6.8 Ultrasonic Control .......................................................................................... 6-152

6.6.9 QSonic Interface ........................................................................................... 6-154

6.6.10 SICK Control ................................................................................................. 6-155

6.7 Liquid – Coriolis ........................................................................................................... 6-158

6.7.1 Local Units .................................................................................................... 6-158

6.7.2 Linearisation .................................................................................................. 6-159

6.7.3 Sampling ....................................................................................................... 6-161

6.7.4 Observed Density Correction ........................................................................ 6-164

6.7.5 Standard Density Correction ......................................................................... 6-173

6.7.6 Base Sediment and Water (BSW) ................................................................. 6-179

6.7.7 Coriolis .......................................................................................................... 6-180

6.8 Liquid – Turbine .......................................................................................................... 6-183

6.8.1 Local Units .................................................................................................... 6-183

6.8.2 Linearisation .................................................................................................. 6-184

6.8.3 Observed Density Correction ........................................................................ 6-188

6.8.4 Standard Density Correction ......................................................................... 6-196

6.8.5 Base Sediment and Water (BSW) ................................................................. 6-202

6.9 Liquid - Ultrasonic ....................................................................................................... 6-204

6.9.1 Local Units .................................................................................................... 6-204

6.9.2 Linearisation .................................................................................................. 6-205

6.9.3 Observed Density Correction ........................................................................ 6-208

6.9.4 Standard Density Correction ......................................................................... 6-215

6.9.5 Base Sediment and Water (BSW) ................................................................. 6-221

6.9.6 Daniel Liquid Ultrasonic ................................................................................ 6-223

6.10 Modes of Operation ..................................................................................................... 6-226

6.10.1 Density Failure Modes .................................................................................. 6-227

Revised February 2022 v

Page 6

Config600 Configuration Software User Manual

Chapter 7 – Advanced Setup Configuration 7-1

7.1 Conversions/Constants ................................................................................................... 7-1

7.1.1 Editing Conversions/Constants ......................................................................... 7-1

7.2 Totals Descriptions .......................................................................................................... 7-2

7.2.1 Editing Totals Descriptors ................................................................................. 7-3

7.3 Alarms ............................................................................................................................. 7-3

7.3.1 Editing Alarms ................................................................................................... 7-4

7.3.2 Alarm Descriptions ............................................................................................ 7-6

7.4 Security ......................................................................................................................... 7-14

7.4.1 Editing Security ............................................................................................... 7-14

7.4.2 Editing/Deleting Passwords ............................................................................ 7-16

7.4.3 Data Item Security ........................................................................................... 7-17

7.4.4 PCSetup Editor Login ...................................................................................... 7-19

7.5 Displays/Webserver ...................................................................................................... 7-20

7.5.1 Editing Displays/Webserver ............................................................................ 7-21

7.6 Calc Explorer ................................................................................................................. 7-22

7.6.1 Calc Explorer Options ..................................................................................... 7-23

7.6.2 Adding an Item ................................................................................................ 7-24

7.6.3 Adding All Inputs ............................................................................................. 7-26

7.6.4 Adding All Outputs .......................................................................................... 7-27

7.6.5 Deleting Items ................................................................................................. 7-28

7.6.6 Saving as Bitmaps .......................................................................................... 7-29

Chapter 8 – System Editor 8-1

8.1 Accessing the System Editor ........................................................................................... 8-2

8.2 The S600+ Database ...................................................................................................... 8-3

8.2.1 Objects .............................................................................................................. 8-4

8.2.2 Tables ............................................................................................................... 8-5

8.3 Navigating the System Editor .......................................................................................... 8-5

8.3.1 Finding Objects ................................................................................................. 8-6

8.3.2 The System Editor Icon Bar .............................................................................. 8-6

8.3.3 Special Edit ....................................................................................................... 8-7

8.3.4 Edit Dialog ......................................................................................................... 8-8

8.3.5 Asterisks/No Asterisks ...................................................................................... 8-9

8.4 General Guidelines ....................................................................................................... 8-10

Chapter 9 – Config Transfer 9-1

9.1 Connecting to the S600+ ................................................................................................. 9-2

9.1.1 Connecting via Serial Cable .............................................................................. 9-2

9.1.2 Connecting via TCP/IP ...................................................................................... 9-2

9.1.3 Enabling the PC Setup Link .............................................................................. 9-2

9.1.4 Checksum Security ........................................................................................... 9-3

9.2 Accessing Config Transfer .............................................................................................. 9-3

9.3 Communications Settings for Transfer ............................................................................ 9-4

9.3.1 Setting Communication Parameters .................................................................. 9-4

9.4 Send Configuration ......................................................................................................... 9-6

9.4.1 Sending a Configuration .................................................................................... 9-6

9.4.2 Manually Adding a Configuration File to be Transferred ................................... 9-7

9.5 Receive Configuration ..................................................................................................... 9-8

9.5.1 Receiving a Configuration ................................................................................. 9-8

9.6 Log Transfers .................................................................................................................. 9-9

9.6.1 Logging a Transfer ............................................................................................ 9-9

9.7 CFX Licensing ............................................................................................................... 9-10

9.7.1 Transferring a License .................................................................................... 9-10

9.7.2 Removing a License ........................................................................................ 9-12

vi Revised February 2022

Page 7

Config600 Configuration Software User Manual

Chapter 10 – Remote Front Panel 10-1

10.1 Configuring Your PC without a Native Serial Comm Port .............................................. 10-1

10.1.1 Changing the Port on Your USB Communications Port .................................. 10-2

10.2 Configuring Your PC with a Native Serial Comm Port ................................................... 10-3

10.3 Configuring the S600+ to Use the Remote Front Panel ................................................ 10-4

10.4 Accessing the Remote Front Panel ............................................................................... 10-7

10.4.1 Remote Front Panel Startup Menu .................................................................. 10-7

10.4.2 Disabling the Remote Front Panel .................................................................. 10-8

10.4.3 Restoring the Remote Front Panel .................................................................. 10-9

Chapter 11 – Remote Archive Uploader 11-1

11.1 Accessing the Remote Archive Uploader ...................................................................... 11-2

11.2 Automatic Archive Polling.............................................................................................. 11-2

11.2.1 Configure Automatic Polling ............................................................................ 11-2

11.2.2 Add or Edit an Automatic Poll.......................................................................... 11-4

11.2.3 Enable Automatic Polling ................................................................................ 11-6

11.3 Manual Archive Polling .................................................................................................. 11-6

11.3.1 Configuring Config600 Communications ......................................................... 11-7

11.3.2 Reload Tree .................................................................................................... 11-8

11.3.3 Upload All Reports / Upload New Reports .................................................... 11-10

11.4 Viewing Reports .......................................................................................................... 11-11

11.4.1 Report Archive .............................................................................................. 11-11

11.5 Saving ......................................................................................................................... 11-12

11.5.1 Directory Settings (File Locations) ................................................................ 11-12

11.5.2 File Settings .................................................................................................. 11-13

11.5.3 Save As ......................................................................................................... 11-14

11.5.4 Folder Formats .............................................................................................. 11-15

11.5.5 Data Integrity ................................................................................................. 11-17

11.6 Printing the Report ...................................................................................................... 11-18

11.6.1 Print ............................................................................................................... 11-18

11.6.2 Print Preview ................................................................................................. 11-18

11.6.3 Print Setup .................................................................................................... 11-19

11.7 Abort Transfer ............................................................................................................. 11-20

Chapter 12 – Report Editor 12-1

12.1 Accessing the Report Editor .......................................................................................... 12-2

12.1.1 Via PCSetup.................................................................................................... 12-2

12.1.2 Via Report Editor ............................................................................................. 12-3

12.1.3 Report Names ................................................................................................. 12-5

12.2 Using the Report Editor ................................................................................................. 12-6

12.2.1 Adding a Data Point ........................................................................................ 12-7

12.2.2 Editing a Data Point ........................................................................................ 12-9

12.2.3 Adding Report Lines ........................................................................................ 12-9

12.2.4 Deleting Report Lines .................................................................................... 12-10

Chapter 13 – Display Editor 13-1

13.1 Accessing the Display Editor ......................................................................................... 13-1

13.2 Navigating the Display Editor ........................................................................................ 13-2

13.3 Editing the Display Editor .............................................................................................. 13-3

13.3.1 Insert Menu ..................................................................................................... 13-5

13.3.2 Insert/Append Page ........................................................................................ 13-5

13.3.3 Edit Line .......................................................................................................... 13-5

13.3.4 Translate ......................................................................................................... 13-7

13.3.5 Save ................................................................................................................ 13-8

13.3.6 Menu/Page Clipboard ..................................................................................... 13-8

Revised February 2022 vii

Page 8

Config600 Configuration Software User Manual

13.4 Regenerating Displays .................................................................................................. 13-8

Chapter 14 – Modbus Editor 14-1

14.1 Supported Function Codes............................................................................................ 14-1

14.2 Accessing the Modbus Editor ........................................................................................ 14-2

14.3 Using the Modbus Editor ............................................................................................... 14-2

14.4 Map Properties .............................................................................................................. 14-3

14.4.1 Insert a Data Point .......................................................................................... 14-5

14.4.2 Quick Insert ..................................................................................................... 14-6

14.4.3 Insert Special .................................................................................................. 14-6

14.4.4 Insert Special .................................................................................................. 14-7

14.4.5 Delete a Data Point ......................................................................................... 14-8

14.4.6 Edit Modbus Format ........................................................................................ 14-8

14.4.7 Insert a Message........................................................................................... 14-10

14.4.8 Insert a Slave ................................................................................................ 14-12

14.5 Regenerating Maps ..................................................................................................... 14-12

Chapter 15 – LogiCalc Editor 15-1

15.1 Accessing the LogiCalc Editor ....................................................................................... 15-2

15.1.1 LogiCalc Tips .................................................................................................. 15-4

15.1.2 Starting a LogiCalc .......................................................................................... 15-5

15.2 Creating a LogiCalc ....................................................................................................... 15-5

15.2.1 Variables ......................................................................................................... 15-6

15.2.2 LogiCalc Loops ............................................................................................... 15-7

15.2.3 LogiCalc Constants ......................................................................................... 15-8

15.2.4 Connecting to Data Items ................................................................................ 15-9

15.2.5 If/Then/Endif .................................................................................................. 15-11

15.2.6 Special Functions .......................................................................................... 15-12

15.2.7 Saving and Compiling a LogiCalc ................................................................. 15-13

15.2.8 Running a LogiCalc in Simulation Mode ....................................................... 15-14

15.3 Installing a LogiCalc on the S600+ .............................................................................. 15-15

15.3.1 Remotely Debugging a LogiCalc ................................................................... 15-16

15.4 LogiCalc Examples ..................................................................................................... 15-16

15.4.1 Perform PTZ Calculations ............................................................................. 15-17

15.4.2 Convert Temperature Units ........................................................................... 15-18

15.4.3 Convert Density Units to Kgm3 ..................................................................... 15-18

15.4.4 Convert Density Units from Kgm3 ................................................................. 15-19

15.4.5 Perform PTZ Calculations and Convert Units................................................ 15-20

15.4.6 Perform PTZ Calculations on All Streams ..................................................... 15-22

15.5 LogiCalc Lanuage Specifications ................................................................................ 15-23

15.5.1 LogiCalc Statements ..................................................................................... 15-23

15.5.2 Built-In Functions .......................................................................................... 15-26

15.5.3 Alarms ........................................................................................................... 15-28

Appendix A – Glossary A-1

Appendix B – Proving B-1

B.1 Bi-Directional (Ball) Prover – Liquid Only ....................................................................... B-2

B.1.1 Inputs/Outputs .................................................................................................. B-3

B.1.2 Communications .............................................................................................. B-3

B.1.3 Pulse Measurement ......................................................................................... B-4

B.1.4 Sphere Switch Interface ................................................................................... B-5

B.1.5 Valve Interface ................................................................................................. B-8

B.1.6 Prove Sequence and Control ........................................................................... B-9

B.1.7 Prover Run Control Stages ............................................................................ B-20

B.1.8 Prove/Stream Data ......................................................................................... B-28

B.1.9 Prove Reports ................................................................................................ B-30

viii Revised February 2022

Page 9

Config600 Configuration Software User Manual

B.1.10 Proving Calculations ...................................................................................... B-31

B.2 Compact Prover – Liquid Only ..................................................................................... B-39

B.2.1 Inputs/Outputs ................................................................................................ B-40

B.2.2 Communications ............................................................................................ B-41

B.2.3 Pulse Measurement ....................................................................................... B-42

B.2.4 Proving Control Signal Timing ........................................................................ B-42

B.2.5 Prove Sequence and Control ......................................................................... B-44

B.2.6 Prover Run Control Stages ............................................................................ B-54

B.2.7 Run Stage Abort Index ................................................................................... B-60

B.2.8 Run Stage Calculation Index .......................................................................... B-61

B.2.9 Prove/Stream Data ......................................................................................... B-61

B.2.10 Prove Reports ................................................................................................ B-63

B.2.11 Proving Calculations ...................................................................................... B-64

B.3 Master Meter Prover – Gas and Liquid ........................................................................ B-73

B.3.1 Master Meter/Stream combinations ............................................................... B-75

B.3.2 Inputs/Outputs ................................................................................................ B-76

B.3.3 Communications ............................................................................................ B-76

B.3.4 Pulse Measurement ....................................................................................... B-76

B.3.5 Prove Sequence and Control ......................................................................... B-77

B.3.6 Prover Run Control Stages ............................................................................ B-86

B.3.7 Prove/Stream Data ......................................................................................... B-92

B.3.8 Prove Reports ................................................................................................ B-93

B.3.9 Proving Calculations ...................................................................................... B-95

Appendix C – Batching C-1

C.1 Batching Overview ......................................................................................................... C-2

C.1.1 Product Table ................................................................................................... C-2

C.1.2 Station Batch Setup ......................................................................................... C-8

C.1.3 Product Interface Detection ............................................................................ C-14

C.1.4 Slops Handling Examples .............................................................................. C-17

C.2 Batch Sequence and Control ....................................................................................... C-18

C.2.1 Batch Sequence Stages ................................................................................. C-19

C.2.2 Retrospective Batch Totals ............................................................................ C-28

C.2.3 Batch Alarms .................................................................................................. C-29

C.2.4 Batch Ticket ................................................................................................... C-29

C.3 Batch Recalculation ..................................................................................................... C-31

C.3.1 Displays ......................................................................................................... C-31

C.3.2 Batch Ticket ................................................................................................... C-35

C.3.3 Recalculating Batches .................................................................................... C-37

C.4 Flow Switching ............................................................................................................. C-46

C.4.1 Station Flow Switching Setup ......................................................................... C-46

C.4.2 Stream Flow Switching Setup ........................................................................ C-48

C.4.3 Flow Switching Algorithms ............................................................................. C-49

C.4.4 Alarms ............................................................................................................ C-52

C.5 Batch Stack .................................................................................................................. C-52

C.5.1 Configuring the Batch Stack Through the PCSetup Editor ............................. C-53

C.5.2 Configuring the Batch Stack with the System Editor ...................................... C-55

C.5.3 Configuring the Batch Stack through the Front Panel Display ....................... C-57

C.5.4 Slot Edit Commands (Front Panel Display) .................................................... C-58

C.5.5 Configuring the Batch Stack from the Webserver .......................................... C-63

C.5.6 Slot Edit Commands (Webserver) .................................................................. C-64

C.6 Basic Batching Setup ................................................................................................... C-68

Appendix D – Field Calibration D-1

D.1 Analogue Input Calibration ............................................................................................. D-1

D.1.1 Calibration Control Requirements .................................................................... D-2

D.1.2 Linear Two-point ADC Device Calibration ........................................................ D-3

D.1.3 Non-linear Three-point Curve-fit ADC Device Calibration ................................ D-6

D.1.4 Non-linear Three-point Curve Calibration Control Mechanism ......................... D-7

D.1.5 Offset PRT Device Calibration ......................................................................... D-8

Revised February 2022 ix

Page 10

Config600 Configuration Software User Manual

D.1.6 Linear Two-point Device PRT Calibration ........................................................ D-8

D.1.7 Non-linear Three-point Curve-Fit PRT Device Calibration ............................... D-9

D.2 Analogue Output Calibration ........................................................................................ D-10

D.2.1 Calibration Control Requirements .................................................................. D-10

D.2.2 DAC Device Calibration ................................................................................. D-11

Appendix E – S600+ Database Objects and Fields E-1

E.1 Database Objects ........................................................................................................... E-2

E.1.1 ADC ................................................................................................................. E-2

E.1.2 ALARM ............................................................................................................. E-3

E.1.3 ALARMHIST..................................................................................................... E-3

E.1.4 ARRTXT ........................................................................................................... E-3

E.1.5 CALCALMITEM................................................................................................ E-4

E.1.6 CALCTAB ........................................................................................................ E-5

E.1.7 CONFTAB ........................................................................................................ E-6

E.1.8 CUMTOT .......................................................................................................... E-6

E.1.9 DACOUT .......................................................................................................... E-6

E.1.10 DIGIO ............................................................................................................... E-6

E.1.11 DOSETUP ........................................................................................................ E-7

E.1.12 DPCELL ........................................................................................................... E-7

E.1.13 EVENTHIST ..................................................................................................... E-8

E.1.14 FREQT ............................................................................................................. E-8

E.1.15 HART ............................................................................................................... E-8

E.1.16 HARTTAB ...................................................................................................... E-10

E.1.17 IOASSIGN ...................................................................................................... E-10

E.1.18 KPINT ............................................................................................................ E-10

E.1.19 KPINTARR ..................................................................................................... E-10

E.1.20 KPREAL ......................................................................................................... E-12

E.1.21 KPREALARR ................................................................................................. E-12

E.1.22 KPSTRING ..................................................................................................... E-13

E.1.23 LOG ............................................................................................................... E-13

E.1.24 MULTI ............................................................................................................ E-14

E.1.25 PID ................................................................................................................. E-14

E.1.26 PIP ................................................................................................................. E-14

E.1.27 POP ............................................................................................................... E-14

E.1.28 PRDTOT ........................................................................................................ E-14

E.1.29 PRT ................................................................................................................ E-15

E.1.30 PRV_CTL ....................................................................................................... E-16

E.1.31 REP00 – REP39 ............................................................................................ E-17

E.1.32 SECURITY ..................................................................................................... E-17

E.1.33 SYSOBJ ......................................................................................................... E-17

E.1.34 TASK .............................................................................................................. E-17

E.1.35 TOTTAB ......................................................................................................... E-17

E.2 Database Fields ........................................................................................................... E-18

E.2.1 Alarm Text Tables .......................................................................................... E-19

E.2.2 Batching/Totalisation ...................................................................................... E-19

E.2.3 DIGIO Setup Table ......................................................................................... E-19

E.2.4 DP Stack Type ............................................................................................... E-19

E.2.5 DP Live/Check Mode Selection ...................................................................... E-19

E.2.6 DP Cut Off Mode ............................................................................................ E-19

E.2.7 Event History Type ......................................................................................... E-19

E.2.8 HART Poll Format .......................................................................................... E-20

E.2.9 HART Master Mode ....................................................................................... E-20

E.2.10 I/O (P144) PID Type ....................................................................................... E-20

E.2.11 Prover (P154) Dual Chronometry Switch Pair ................................................ E-20

E.2.12 Prover (P154) Type ........................................................................................ E-21

E.2.13 Password Tables ............................................................................................ E-21

E.2.14 Truth Tables ................................................................................................... E-21

E.2.15 Turbine Meter Setup Tables ........................................................................... E-21

E.3 Mode Tables ................................................................................................................ E-21

E.3.1 ADC/PRT/HART Modes (MODE TAB PLANTI/O) .......................................... E-21

x Revised February 2022

Page 11

Config600 Configuration Software User Manual

E.3.2 CALC/ALM Auto Switch Modes...................................................................... E-22

E.3.3 CALC/ALM modes (MODE TAB CALC) ......................................................... E-22

E.3.4 Density Transducer Modes (MODE TAB DENS IP) ....................................... E-22

E.3.5 DP Modes (MODE TAB DP STACK) ............................................................. E-22

E.3.6 HART Modes (MODE TAB PLANTI/O) .......................................................... E-23

Appendix F – Peer-to-Peer Link Communications F-1

F.1 Peer-to-Peer Link Input Functionality ............................................................................. F-1

F.2 Enabling the Peer-to-Peer Link ...................................................................................... F-3

F.2.1 Configuring the Peer-to-Peer Link .................................................................... F-4

F.3 Critical Data .................................................................................................................... F-9

F.3.1 Passing an Object from the Duty to the Standby S600+ ................................ F-13

F.3.2 Period Object Transfer ................................................................................... F-16

F.4 Automatic Failover ....................................................................................................... F-16

F.4.1 Configuring the S600+ for Automatic Failover ................................................ F-18

F.5 External / Custom Failover Modes ............................................................................... F-24

F.6 Displays........................................................................................................................ F-26

F.6.1 Control Displays ............................................................................................. F-26

F.6.2 Feed-back Displays ........................................................................................ F-27

F.6.3 Option Displays .............................................................................................. F-28

F.7 Downloading and Verifying the Peer to Peer Link ........................................................ F-28

Appendix G – Firewall G-1

G.1 Rules File ....................................................................................................................... G-1

G.1.1 *Filter Keyword ................................................................................................. G-2

G.1.2 Default Policies ................................................................................................ G-2

G.1.3 User Defined Chains ........................................................................................ G-2

G.2 Adding Rules to the Chain.............................................................................................. G-3

G.2.1 Applying a Rule to a Range of IPs ................................................................... G-3

G.2.2 Inverting a Rule ................................................................................................ G-3

G.2.3 After Checking the Rules ................................................................................. G-3

G.2.4 Committing the Rules ....................................................................................... G-3

G.3 Operational Behaviour ................................................................................................... G-3

Appendix H – CFX Reporting H-1

H.1 Adding CFX Report Functionality to a Configuration File ............................................... H-1

H.2 Enabling CFX at the Stream Level ................................................................................. H-3

H.3 Changing CFX Settings from Config600 ........................................................................ H-4

H.4 Regenerating the CFX Report Template ........................................................................ H-5

H.5 Generating a CFX Report from the Web Browser .......................................................... H-5

H.6 Understanding the CFX File Structure ........................................................................... H-8

Appendix I – Network Printing I-1

I.1 Overview .......................................................................................................................... I-1

I.1.1 Supported Printers ............................................................................................. I-2

I.1.2 Supported Paper Sizes ...................................................................................... I-2

I.2 Configuring Printers from PCSetup .................................................................................. I-2

I.3 Configuring Printers from the S600+ ................................................................................ I-4

I.3.1 Configuring at Runtime ...................................................................................... I-4

I.3.2 Printer Options ................................................................................................... I-4

Revised February 2022 xi

Page 12

Config600 Configuration Software User Manual

I.4 Printing Retries ................................................................................................................. I-5

I.5 Editing Report Line Lengths ............................................................................................. I-5

I.6 Network Printing Alarms ................................................................................................... I-8

Appendix J – Sampling J-1

J.1 Overview ......................................................................................................................... J-1

J.2 Input / Outputs ................................................................................................................. J-1

J.2.1 Sampler Output ................................................................................................. J-2

J.2.2 Sampler Can Select Output .............................................................................. J-2

J.3 Sampling Options ............................................................................................................ J-2

J.3.1 Sampler Method ................................................................................................ J-2

J.3.2 Sampler Mode ................................................................................................... J-3

J.3.3 Can Fill Indicator ............................................................................................... J-4

J.3.4 Auto Disable ...................................................................................................... J-4

J.3.5 Auto Restart ...................................................................................................... J-4

J.4 Sampling Sequence ........................................................................................................ J-5

J.5 Sampling Alarms ........................................................................................................... J-10

J.6 Sampling Displays ......................................................................................................... J-11

J.7 Sampling – System Editor ............................................................................................. J-13

Appendix K – Chromatographs K-1

K.1 Station/Stream Assignment ............................................................................................ K-2

K.1.1 Single Metering Stream with No Station ........................................................... K-2

K.1.2 Multiple Metering Streams Assigned to a Common Station ............................. K-2

K.1.3 Individual Metering Streams Assigned to a Chromatograph ............................ K-2

K.1.4 Multiple Metering Streams Separately Assigned to a Stream .......................... K-3

K.1.5 Multiple S600+s Connected to a Single Chromatograph.................................. K-3

K.2 Inputs and Outputs ......................................................................................................... K-3

K.2.1 Main Setup Parameters ................................................................................... K-4

K.2.2 Component Set Selection Inputs ...................................................................... K-4

K.2.3 Component Set Selection Outputs ................................................................... K-4

K.2.4 Telemetry Configuration Parameters ............................................................... K-4

K.2.5 Telemetry Outputs ............................................................................................ K-5

K.3 Configuration Type: Keypad Mole Percentage Set Only ................................................ K-6

K.4 Configuration Type: 2551/2350 Euro ............................................................................. K-7

K.4.1 Telemetry Stages ............................................................................................. K-7

K.4.2 Determining the Mole Percentage Set ........................................................... K-11

K.4.3 Handling Operator Commands....................................................................... K-11

K.5 Configuration Type: 2251/2350 USA ............................................................................ K-11

K.5.1 Telemetry Stages ........................................................................................... K-12

K.5.2 Determining the Mole Percentage Set ........................................................... K-13

K.5.3 Handling Operator Commands....................................................................... K-14

K.6 Configuration Type: Siemens ....................................................................................... K-14

K.6.1 Telemetry Stages ........................................................................................... K-14

K.6.2 Determining the Mole Percentage Set ........................................................... K-16

K.6.3 Handling Operator Commands....................................................................... K-17

K.7 Configuration Type: Generic ........................................................................................ K-17

K.7.1 Telemetry Stages ........................................................................................... K-17

K.7.2 Determining the Mole Percentage Set ........................................................... K-19

K.7.3 Handling Operator Commands....................................................................... K-20

K.8 Configuration Type: Download from Supervisory System ............................................ K-20

K.9 Normalisation, Additionals, and C+6 Handling ............................................................. K-20

K.9.1 Normalisation ................................................................................................. K-20

K.9.2 Application of Additionals ............................................................................... K-21

K.9.3 C6+ Handling ................................................................................................. K-21

K.9.4 C6+ Handling (SIM 2251 Method) .................................................................. K-21

K.9.5 C7+ Handling ................................................................................................. K-22

K.9.6 No C6+ or C7+ Handling ................................................................................ K-23

K.10 Alarms, Displays, Reports, and Maps .......................................................................... K-23

K.10.1 Alarms ............................................................................................................ K-23

xii Revised February 2022

Page 13

Config600 Configuration Software User Manual

K.10.2 Displays ......................................................................................................... K-23

K.10.3 Reports .......................................................................................................... K-24

K.10.4 Modbus Maps................................................................................................. K-27

Index Index-1

Revised February 2022 xiii

Page 14

Config600 Configuration Software User Manual

[This page is intentionally left blank.]

xiv Revised February 2022

Page 15

Chapter 1 – Introduction

Caution

In This Chapter

1.1 Configuration Updates ....................................................................... 1-1

1.2 Scope of Manual ............................................................................... 1-2

1.3 Software Basics ................................................................................. 1-3

1.4 Installing Config600 ........................................................................... 1-5

1.5 Accessing Config600 ......................................................................... 1-9

1.6 Activating Config600 ......................................................................... 1-9

1.7 Additional Technical Information ..................................................... 1-11

This manual describes how to use the Config600™ configuration

software suite of editors (referred to as “Config600”) to configure the

FloBoss™ S600+ Flow Computer (referred to as “S600+”). The

software runs on a personal computer (PC) running Microsoft®

Windows

or 64-bit), Windows 10 (32-bit or 64-bit), or Server 2003. Refer to the

technical specification Config™ 600 Configuration Software

(Config600).

This manual discusses configuring S600+ options, including

calculations; input/output (I/O); communications; Proportional,

Integral, and Derivative (PID) loops; stations; streams; displays;

Modbus maps; LogiCalc programming; and reports.

®

2000 with Service Pack 2, XP, Vista®, Windows 7 (32-bit

Config600 Configuration Software User Manual

Use this manual in conjunction with the FloBoss S600+ Flow Manager

Instruction Manual (part D301150X412).

When implementing control using this product, observe best industry

practices as suggested by applicable and appropriate environmental,

health, and safety organizations.

This chapter details the structure of this manual and provides an

overview of the Config600 software.

1.1 Configuration Updates

The S600+ CPU module has also been enhanced and now contains an

upgraded version of firmware. You can download existing

configurations from earlier versions of Config600 without change.

However, if you use the latest version of Config600 to modify an old

configuration, the configuration file upgrades and will work only with

version 8 and above. That means you can no longer use old versions of

Config600 to edit that configuration.

When you open an older configuration in the current version of

Config600, the following dialog box displays:

Revised February 2022 Introduction 1-1

Page 16

Config600 Configuration Software User Manual

Chapter

Description

Chapter 1

Defines the scope of the document, provides an

install the software.

Chapter 2

Describes the PCSetup Editor interface, the

and the System Graphic utility.

Chapter 3

Configuration

Describes the System Setup screens (Versions, Units,

the configuration wizard.

Chapter 4

Configuration

Describes the Input/Output (I/O) assignment screens,

task settings screen in the PCSetup Editor.

Chapter 5

Station Configuration

Describes the Station Settings screens in the PCSetup

Editor.

Chapter 6

Stream Configuration

Describes the Stream Settings screens in the PCSetup

Editor.

Chapter 7

Describes the Advanced Setup screens (Conversions,

Calc Explorer utility.

Chapter 8

Describes the advanced configuration editor, the

Note: This utility is available only with Config600 Pro.

Chapter 9

Describes the configuration transfer utility. Use this

configuration files from the host PC to the S600+.

PRO

If you click OK to upgrade, you cannot then use this configuration on

an S600+ which has firmware less that version 0.6.05. If you need to

use this configuration on older S600+ flow computers, click Close (

to end this process. We suggest you then re-create this configuration

using the most current version of Config600 or create a copy of the old

configuration.

1.2 Scope of Manual

Figure 1-1. Config Upgrade dialog

)

This manual contains the following chapters:

Introduction

PCSetup Editor

System Setup

I/O and Comms

Advanced Setup

Configuration

overview of the Config600 software, and details how to

configuration generator, how to save configurations,

Reports, and Totalisation) in the PCSetup Editor, and

the PID loop settings screens, and the communication

Totals Descriptors, Alarms, Security, and

Displays/Webserver) in the PCSetup Editor and the

System Editor

Config Transfer

1-2 Introduction Revised February 2022

System Editor (which includes Station Mapping).

utility to send new or modified files to the S600+ over

either a dedicated serial port or a TCP/IP connection.

Config Transfer also enables you to retrieve

Page 17

Config600 Configuration Software User Manual

Chapter

Description

Chapter 10

Describes how to set up the Remote Front Panel to

Panel)

Chapter 11

Uploader

Describes how to automatically upload all reports and

computer.

Chapter 12

Report Editor

Chapter 13

Display Editor

Describes the editor you use to customize the front

panel and webserver displays of the S600+.

Chapter 14

Modbus Editor

Chapter 15

Describes the editing tool for the LogiCalc programming

Note: This tool is available only with Config600 Pro.

Appendix A: Glossary

Provides definitions of acronyms and terms.

Appendix B: Proving

Provides a description of the three proving methods

compact, and master meter.

Appendix C: Batching

Describes the type of batch method you can use for

non-permanent flows or “start-stop” batching.

Appendix D: Field

Describes hardware calibration you perform after

analogue converter counts and current.

Appendix E: S600+

Provides an alphabetic listing of the database objects

Editor, Display Editor, and System Editor).

Appendix F: Peer-to-

Describes the bi-directional communications link

through the supervisory system.

Appendix G: Firewall

Provides information detailing the S600+ firewall to

keep out unwanted incoming network connections.

Appendix H: CFX

Provides information on creating Common File

eXchange (CFX) reports.

Appendix I: Network

Printing

Provides information on network printing options for the

S600+.

Index

Provides an alphabetic listing of items and topics

contained in this manual.

PRO

Remote Front Panel

Remote Archive

LogiCalc Editor

configure your S600+ and perform certain functions

from your PC.

Note: The Remote Front Panel requires part

S600+EXT (the licence key for Remote Front

alarms in the historical archive in the S600+ flow

Describes the report format editor.

Describes the Modbus map editor.

language.

Confi600 supports: bi-directional (and uni-directional),

1.3 Software Basics

Config600 software is a Microsoft Windows-based suite of tools that

enables you to configure and communicate with the S600+ using a host

PC. The software has three versions:

Calibration

Database Objects and

Fields

Peer Communications

production to determine the relationship between

you can access through the Connect Wizard (which is

part of the Report Editor, Modbus Editor, LogiCalc

between the A and B computers allowing the duty

S600+ to update the standby S600+ with any operator

changes made locally at the duty S600+ keypad or

Config600 Lite, which provides a basic set of tools designed to

help you modify existing configurations.

Config600 Lite Plus, which adds a tool to create configurations to

Config600 Lite.

Revised February 2022 Introduction 1-3

Page 18

Config600 Configuration Software User Manual

Tool

Config600 Lite

Config600 Lite Plus

Config600 Pro

PCSetup X X

X

Config Transfer

X X X

Report Editor X X

X

Modbus Editor X X

X

Display Editor X X

X

LogiCalc Editor

X

System Editor

X

Config Generator

X X

Remote Archive Uploader1

X X X

Remote Front Panel1

X X X

Version History

X X X

Config600 Pro, which provides a more powerful set of tools to

help you create and manage configurations.

Note: If you are new to the S600+, review Chapter 2, PCSetup

Editor. This section describes the basic steps involved in

configuring your S600+ for your application. You can then use

the PCSetup Editor (available in Config600 Pro) to edit

existing configurations.

Table 1-1 compares the tools available in each version.

Table 1-1. Config600 Tools

1

Remote Archive Uploader and Remote Front Panel are extended functions of Config600 which you must

license separately to use. Contact your sales representative for further information.

Using the PCSetup Editor in Config600, you define the initial S600+

configuration settings for gas, liquid, or prover applications. These

initial configurations include system setup, Input/Output (I/O) setup,

stations, and streams. You save these configurations to a configuration

directory on the host PC. Using the Config Transfer utility, you send

(“download”) the configuration to the S600+ through a serial or

Ethernet communications port. The download also stores the sent

configuration permanently in the S600+’s memory.

With Config600 Pro software, you can:

Use the Config Generator Wizard to create new configurations.

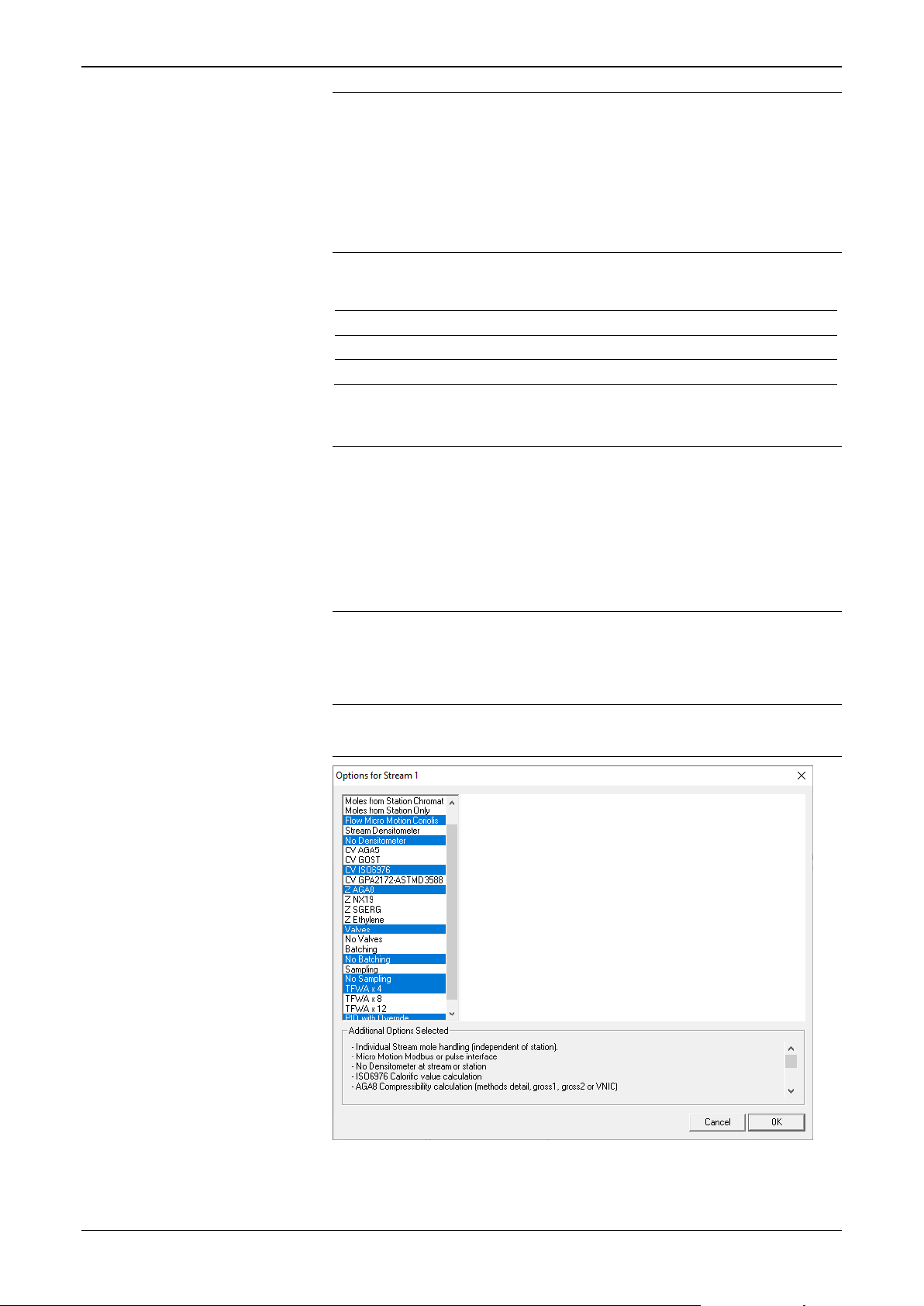

Use the Config Transfer utility to send or receive the