Page 1

Product Information Package

s

PIP-EXP I/O TF

February, 2008

ow Power I/O Expansion Board

Low Power I/O Expansion Board

Part No. 392927-XX-X

(For TeleFlow Plus, TeleRTU Plus, TeleRTU Module & TeleRecorder)

CI-3530-20B, CI-3530-25B, CI-3530-35B & CI-3530-55B

For the following Instruction Manuals:

Remote Automa tion Solution

www.EmersonProcess.com/Remote

Page 2

Be sure that these instructions are carefully read and understood before any operation is

attempted. Improper use of this device in some applications may result in damage or injury. The

user is urged to keep this book filed in a convenient location for future reference.

These instructions may not cover all details or variations in equipment or cover every possible

situation to be met in connection with installation, operation or maintenance. Should problems arise

that are not covered sufficiently in the text, the purchaser is advised to contact Emerson Process

Management, Remote Automation Solutions division (RAS) for further information.

IMPORTANT! READ INSTRUCTIONS BEFORE STARTING!

EQUIPMENT APPLICATION WARNING

The customer should note that a failure of this instrument or system, for whatever reason, may

leave an operating process without protection. Depending upon the application, this could result in

possible damage to property or injury to persons. It is suggested that the purchaser review the

need for additional backup equipment or provide alternate means of protection such as alarm

devices, output limiting, fail-safe valves, relief valves, emergency shutoffs, emergency switches,

etc. If additional information is required, the purchaser is advised to contact RAS.

RETURNED EQUIPMENT WARNING

When returning any equipment to RAS for repairs or evaluation, please note the following: The

party sending such materials is responsible to ensure that the materials returned to RAS are clean

to safe levels, as such levels are defined and/or determined by applicable federal, state and/or

local law regulations or codes. Such party agrees to indemnify RAS and save RAS harmless from

any liability or damage which RAS may incur or suffer due to such party's failure to so act.

ELECTRICAL GROUNDING

Metal enclosures and exposed metal parts of electrical instruments must be grounded in

accordance with OSHA rules and regulations pertaining to "Design Safety Standards for Electrical

Systems," 29 CFR, Part 1910, Subpart S, dated: April 16, 1981 (OSHA rulings are in agreement

with the National Electrical Code).

The grounding requirement is also applicable to mechanical or pneumatic instruments that

include electrically operated devices such as lights, switches, relays, alarms, or chart drives.

EQUIPMENT DAMAGE FROM ELECTROSTATIC DISCHARGE VOLTAGE

This product contains sensitive electronic components that can be damaged by exposure to an

electrostatic discharge (ESD) voltage. Depending on the magnitude and duration of the ESD, this

can result in erratic operation or complete failure of the equipment. Read supplemental document

S14006 at the back of this manual for proper care and handling of ESD-sensitive components.

Remote Automation Solutions

A Division of Emerson Process Management

1100 Buckingham Street, Watertown, CT 06795

Telephone (860) 945-2200

Page 3

WARRANTY

A. Remote Automation Solutions (RAS) warrants that goods described herein and manufactured by RAS are

free from defects in material and workmanship for one year from the date of shipment unless otherwise

agreed to by RAS in writing.

B. RAS warrants that goods repaired by it pursuant to the warranty are free from defects in material and

workmanship for a period to the end of the original warranty or ninety (90) days from the date of delivery of

repaired goods, whichever is longer.

C. Warranties on goods sold by, but not manufactured by RAS are expressly limited to the terms of the

warranties given by the manufacturer of such goods.

D. All warranties are terminated in the event that the goods or systems or any part thereof are (i) misused,

abused or otherwise damaged, (ii) repaired, altered or modified without RAS consent, (iii) not installed,

maintained and operated in strict compliance with instructions furnished by RAS or (iv) worn, injured or

damaged from abnormal or abusive use in service time.

E. These warranties are expressly in lieu of all other warranties express or implied (including without limitation

warranties as to merchantability and fitness for a particular purpose), and no warranties, express or

implied, nor any representations, promises, or statements have been made by RAS unless endorsed

herein in writing. Further, there are no warranties which extend beyond the description of the face hereof.

F. No agent of RAS is authorized to assume any liability for it or to make any written or oral warranties beyond

those set forth herein.

REMEDIES

A. Buyer's sole remedy for breach of any warranty is limited exclusively to repair or replacement without cost

to Buyer of any goods or parts found by Seller to be defective if Buyer notifies RAS in writing of the alleged

defect within ten (10) days of discovery of the alleged defect and within the warranty period stated above,

and if the Buyer returns such goods to the RAS Watertown office, unless the RAS Watertown office

designates a different location, transportation prepaid, within thirty (30) days of the sending of such

notification and which upon examination by RAS proves to be defective in material and workmanship. RAS

is not responsible for any costs of removal, dismantling or reinstallation of allegedly defective or defective

goods. If a Buyer does not wish to ship the product back to RAS, the Buyer can arrange to have a RAS

service person come to the site. The Service person's transportation time and expenses will be for the

account of the Buyer. However, labor for warranty work during normal working hours is n ot chargeable.

B. Under no circumstances will RAS be liable for incidental or consequential damages resulting from breach

of any agreement relating to items included in this quotation from use of the information herein or from the

purchase or use by Buyer, its employees or other parties of goods sold under said agreement.

Page 4

How to return material for Repair or Exchange

Before a product can be returned to Remote Automation Solutions (RAS) for repair, upgrade, exchange, or to verify

proper operation, Form (GBU 13.01) must be completed in order to obtain a RA (Return Authorization) number and

thus ensure an optimal lead time. Completing the form is very important since the information permits the RAS

Watertown Repair Dept. to effectively and efficiently process the repair order.

You can easily obtain a RA number by:

A. FAX

Completing the form (GBU 13.01) and faxing it to (860) 945-2220. A RAS Repair Dept. representative will

return the call (or other requested method) with a RA number.

B. E-MAIL

Accessing the form (GBU 13.01) via the RAS Web site (www.emersonprocess.c om/Bristol) and sending it

via E-Mail to Custserve.bristol@emersonprocess.com

. A RAS Repair Dept. representative will return E-

Mail (or other requested method) with a RA number.

C. Mail

Mail the form (GBU 13.01) to

Remote Automation Solutions

A Division of Emerson Process Management

Repair Dept.

1100 Buckingham Street

Watertown, CT 06795

A RAS Repair Dept. representative will return call (or other requested method) with a RA number.

D. Phone

Calling the RAS Repair Department at (860) 945-2442. A RAS Repair Department representative will

record a RA number on the form and complete Part I, send the form to the Customer via fax (or other

requested method) for Customer completion of Parts II & III.

A copy of the completed Repair Authorization Form with issued RA number should be included with the product

being returned. This will allow us to quickly track, repair, and return your product to you.

Page 5

Remote Automation Solutions (RAS)

Repair Authorization Form (on-line completion)

(

Providing this information will permit Bristol, also doing business as Remote Automation Solutions (RAS) to

effectively and efficiently process your return. Completion is required to receive optimal lead time. Lack of information

may result in increased lead times.)

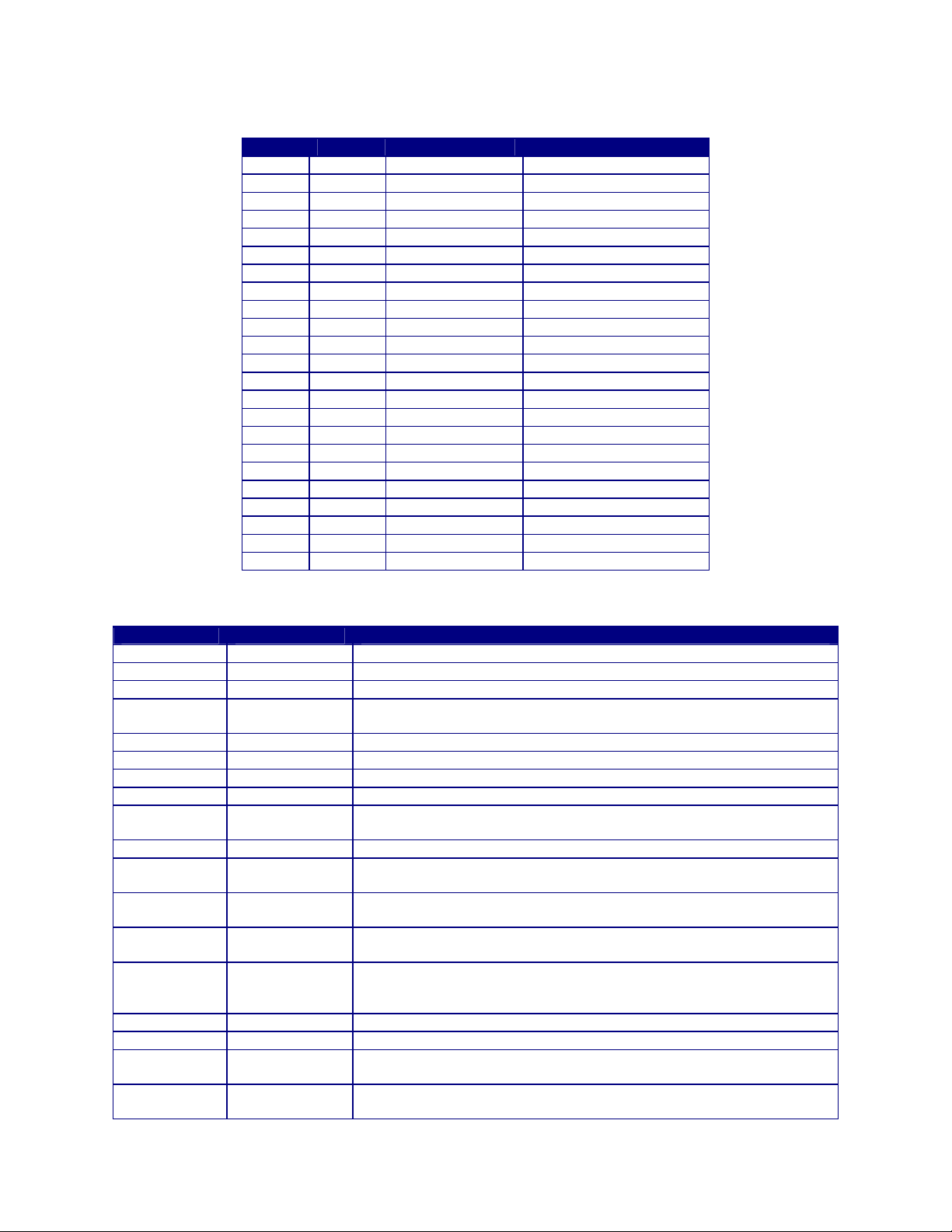

Date RA # SH Line No.

Standard Repair Practice is as follows: Variations to

this is practice may be requested in the “Special

Requests” section.

• Evaluate / Test / Verify Discrepancy

• Repair / Replace / etc. in accordance with this form

• Return to Customer

Part I Please complete the following information for single unit or multiple unit returns

Address No. (office use only)

Bill to : Ship to:

Purchase Order: Contact Name:

Phone: Fax: E-Mail:

Please be aware of the Non warranty standard

charge:

• There is a $100 minimum evaluation charge,

which is applied to the repair if applicable (√ in

“returned” B,C, or D of part III below)

Part II Please complete Parts II & III for each unit returned

Model No./Part No. Description:

Range/Calibration: S/N:

Reason for return

: Failure Upgrade Verify Operation Other

1. Describe the conditions of the failure (Frequency/Intermittent, Physical Damage, Environmental Conditions,

Communication, CPU watchdog, etc.) (Attach a separate sheet if necessary)

2. Comm. interface used: Standalone RS-485 Ethernet Modem (PLM (2W or 4W) or SNW) Other:

3. What is the Firmware revision? What is the Software & version?

Part III If checking “replaced” for any question below, check an alternate option if replacement is not

available

A. If product is within the warranty time period but is excluded due

to the terms of warranty,, would you like the product:

repaired returned replaced scrapped?

B. If product were found to exceed the warranty period, would you like the product:

C. If product is deemed not repairable would you like your product:

D. If RAS is unable to verify the discrepancy, would you like the product:

repaired returned replaced scrapped?

returned replaced scrapped?

returned replaced *see

below?

* Continue investigating by contacting the customer to learn more about the problem experienced? The person

to contact that has the most knowledge of the problem is: phone

If we are unable to contact this person the backup person is:

phone

Special Requests:

Ship prepaid to: Remote Automation Solutions, Repair Dept., 1100 Buckingham Street, Watertown, CT 06795

Phone: 860-945-2442 Fax: 860-945-2220

Form GBU 13.01 Rev. D 12/04/07

Page 6

Emerson Process Management

Training

GET THE MOST FROM YOUR EMERSON

INSTRUMENT OR SYSTEM

• Avoid Delays and problems in getting your system on-line

• Minimize installation, start-up and maintenance costs.

• Make the most effective use of our hardware and software.

• Know your system.

As you know, a well-trained staff is essential to your operation. Emerson offers a full

schedule of classes conducted by full-time, professional instructors. Classes are offered

throughout the year at various locations. By participating in our training, your personnel

can learn how to install, calibrate, configure, program and maintain your Emerson products

and realize the full potential of your system.

For information or to enroll in any class, go to http://www.EmersonProcess.com/Remote

click on “Training” or contact our training department in Watertown at (860) 945-2343.

and

Page 7

PIP-EXPI/OTF

LOW POWER I/O EXPANSION BOARD

PT. Number 392927-XX-X

Product Information Package

TABLE OF CONTENTS

SECTION TITLE PAGE #

Section 1 - INTRODUCTION

1.1 GENERAL INTRODUCTION .......................................................................................... 1

1.1.1 Configuration Hardware ................................................................................................... 2

Section 2 - INSTALLATION & SERVICE

2.1 REMOVAL/REPLACEMENT & INSTALLATION OF THE LPI/OEB .......................... 5

2.1.1 Removal/Replacement of the Low Power I/O Expansion Board ..................................... 5

2.1.2 Installation of the Low Power I/O Expansion Board....................................................... 7

2.2 I/O CONFIGURATION & WIRING ................................................................................. 9

2.2.1 LPI/OEB Discrete Input Wiring (TB4)............................................................................. 9

2.2.2 LPI/OEB Discrete Output Wiring (TB4) .......................................................................... 9

2.2.3 LPI/OEB Analog Input Wiring (TB2) ............................................................................. 10

2.2.4 LPI/OEB Analog Output Wiring (TB3) .......................................................................... 12

2.2.5 LPI/OEB High Speed Counter Wiring (TB3) ................................................................. 13

2.3 RS-232/RS-485 COMMUNICATIONS ........................................................................... 13

Section 3 - TROUBLESHOOTING

3.1 FIELD WIRING SIGNAL CHECKS .............................................................................. 15

Section 4 - SPECIFICATIONS

4.1 INPUT/OUTPUT SPECIFICATIONS ............................................................................ 16

4.1.1 Discrete Inputs ................................................................................................................ 16

4.1.2 Discrete Outputs.............................................................................................................. 16

4.1.3 Analog Inputs................................................................................................................... 16

4.1.4 Analog Outputs................................................................................................................ 17

4.1.5 Communication Port........................................................................................................ 18

4.1.6 High Speed Counter ........................................................................................................ 18

4.2 ENVIRONMENTAL SPECIFICATIONS....................................................................... 18

Supplements

Special Instructions for Class I, Division 2 Hazardous Locations...........................................Appendix A

PIP-EXPI/OTF Page 0-1 Table Of Contents

Page 8

Section 1

INTRODUCTION

1.1 GENERAL INTRODUCTION

The Low Power I/O Expansion Board (LPI/OEB) measures approximately 4” by 7.25” and

mounts piggy-back on either the TeleFlow or TeleRTU CPU Board. Removable card-edge

connectors are provided to accommodate field wiring. A 1.25” by 1.2” cutout area is incorporated into the board’s design to accommodate mounting of the Multivariable Transducer’s Wet End Connector and Balance Board onto the TeleFlow CPU Board. The

LPI/OEB operates in conjunction with Revision 3 and higher TeleFlow CPU Boards and

with TeleRTU CPU Boards. Three versions of the LPI/OEB are available; fully populated

version P/N 392927-01-2 (see Figure 1), depopulated version that supports DI/DO and the

Comm. Port P/N 392927-02-0 and a depopulated version that supports DI/DO only P/N

392927-03-9.

Figure 1 - Low Power I/O Expansion Board

PIP-EXPI/OTF Page 1 Low Power I/O Expansion Board

Page 9

The Low Power I/O Expansion Board provides the following additional I/O capabilities to

the TeleFlow Plus EGMCs, TeleRTU Plus and TeleRTU Module RTUs and TeleRecorders:

• 8 Discrete I/O

All eight DI/O function in both input and output capacities. Field terminals for each

DI/O are I/O and GND. Each Discrete Input will accept signals from 0 to 16 VDC. The

Discrete Outputs utilize open drain FETs with a maximum working voltage of 16 VDC

and a minimum load of 100 mA. DI/Os are not isolated.

• 4 Analog Inputs (available on 392927-01-2 only)

Two single-ended Analog Inputs are available for 4 to 20 mA or 1 to 5 VDC signal

operation (Jumper Configurable) and two additional single-ended Analog Inputs are

available for 1 to 5 VDC signal operation only. The two 4-20 mA Inputs will support

externally powered transmitters; however, internally powered 4-20 mA transmitters

will require an external power supply. All four channels support low power voltage

output transmitters such as Rosemount and Honeywell. Resolution is 12 bits (1.42

mV) and combined error (including linearity, hysteresis and temperature effects) is ≤

±0.2%. Each Analog Input channel includes field wiring terminals for signal,

transmitter power (+9.5V), and ground. Note: Analog Inputs are designated AI5

through AI8; AI1 through AI4 are assigned to the TeleRTU CPU.

• 1 Analog Output (available on 392927-01-2 only)

The Analog Output can be configured for 4 to 20 mA or 1 to 5 VDC operation (Jumper

Configurable). Resolution is 12 bits and combined error including linearity, hysteresis

and temperature effects is ≤ ±0.2% after calibration.

• 1 High Speed Counter Input (available on 392927-01-2 only)

The High Speed Counter input will accept pulses (with an input range from 0 to 16

VDC and up to 10KHz) from CMOS or TTL sources, including transistors, FETs,

mechanical relays, or other signaling devices.

• 1 RS-232 or RS-485 Asynchronous Serial Communications Port (not on 392927-03-9)

Note: Only supported by units with TeleFlow/ACCOL Firmware

The Asynchronous Serial Communications Port can be jumper configured for either

RS-232 or RS-485 operation at programmable speeds of up to 19.2 Kbps.

1.1.1 Configuration Hardware

Fully populated Low Power I/O Expansion Boards contain 8 potentiometers, 15 Jumper

Blocks and 5 removable card-edge (Terminal Blocks) connectors. Tabulated information

about Terminal Block, Jumper and Potentiometer assignments are contained in Tables 1, 2

and 3 respectively.

Table 1 - Low Power I/O Exp. Board Terminal Block Assignments

TB # PIN # MNEMONIC DESCRIPTION

TB1 1 +VEXT +21V EXTERNAL

TB1 2 -VEXT -21V EXTERNAL

TB2 1 EXC5 EXCITATION 5

TB2 2 AIN5 ANALOG IN 5

TB2 3 GND GROUND

TB2 4 EXC6 EXCITATION 6

TB2 5 AIN6 ANALOG IN 6

TB2 6 GND GROUND

TB2 7 AIN7 ANALOG IN 7

TB2 8 AIN8 ANLOG IN 8

Low Power I/O Expansion Board Page 2 PIP-EXPI/OTF

Page 10

Table 1 - Low Power I/O Exp. Bd. Terminal Block Assignments (Continued)

TB # PIN # MNEMONIC DESCRIPTION

TB2 9 GND GROUND

TB3 1 AO ANALOG OUT

TB3 2 GND GROUND

TB3 3 HSC HIGH SPEED CNTR

TB3 4 GND GROUND

TB4 1 DIO1 DISCRETE IN/OUT 1

TB4 2 DIO2 DISCRETE IN/OUT 2

TB4 3 GND GROUND

TB4 4 DIO3 DISCRETE IN/OUT 3

TB4 5 DIO4 DISCRETE IN/OUT 4

TB4 6 GND GROUND

TB4 7 DIO5 DISCRETE IN/OUT 5

TB4 8 DIO6 DISCRETE IN/OUT 6

TB4 9 GND GROUND

TB4 10 DIO7 DISCRETE IN/OUT 7

TB4 11 DIO8 DISCRETE IN/OUT 8

TB5 1 GND GROUND

TB5 2 CD RS232 DCD

TB5 3 DTR RS232 DTR

TB5 4 CTS/RX- RS232/485 CTS/REC

TB5 5 RTS/TX- RS232/485 RTS/XMIT

TB5 6 RXD/RX+ RS232/485 REC

TB5 7 TXD/TX+ RS232/485 XMIT

Table 2 - Low Power I/O Exp. Bd. User Configurable Jumper Block Assignments

JUMPER # POSITION PURPOSE

JP6 2-7 (only) Configuration for 1-5V Analog Input (AIN5)

JP6 2-7 & 4-5 Configuration for Non-Isolated Current Input (AIN5)

JP6 1-2, 3-6 & 4-5 Configuration for Internally Sourced Current Input (AIN5)

JP7 1-4

JP7 All Open Configuration for Internally Sourced Current Input (AIN5)

JP8 2-7 (only) Configuration for 1-5V Analog Input (AIN6)

JP8 2-7 & 4-5 Configuration for Non-Isolated Current Input (AIN6)

JP8 1-2, 3-6 & 4-5 Configuration for Internally Sourced Current Input (AIN6)

JP9 1-4

JP9 All Open Configuration for Internally Sourced Current Input (AIN6)

JP10 1-2

JP10 2-3

JP11 1-2

JP11 2-3

JP13, 14, 16 JP13 to JP16 RS-232 Signals present at TB5 - RS-485 Converter asleep.

JP13, 14, 16 JP14 to JP16 RS-485 Signals present at TB5 - RS-232 Converter asleep.

JP15 1-2

JP17 1-2

Configuration for 1-5V Analog Input (AIN5)

Configuration for Non-Isolated Current Input (AIN5)

Configuration for 1-5V Analog Input (AIN6)

Configuration for Non-Isolated Current Input (AIN6)

Used in conjunction with 1-5V Analog Input - leaves 9.5V

regulated power supply ON continuously.

Used in conjunction with 1-5V Analog Input - shuts down the

9.5V power supply during TeleFlow CPU SLEEP Mode.

Used in conjunction with an internally sourced 4-20 mA Current

Loop Analog Input - leaves current loop powered continuously.

Used in conjunction with an internally sourced 4-20 mA Current

Loop Analog Input - shuts down the internal current loop when

the TeleFlow CPU is in SLEEP Mode.

Used in conjunction with RS-485 Communications

Installed = Transmit End Node (120-Ohm) Termination

Used in conjunction with RS-485 Communications

Installed = Receive End Node (120-Ohm) Termination

PIP-EXPI/OTF Page 3 Low Power I/O Expansion Board

Page 11

Table 2 - Low Power I/O Exp. Bd. User Configurable Jumper Block Assignments

(Continued)

JUMPER # POSITION PURPOSE

JP19 1-2

JP19 2-3

JP20 1-2

JP21 1-2

JP22 1-2

JP22 2-3

Used in conjunction with Analog Output - Current Loop output

configuration.

Used in conjunction with Analog Output - Voltage output

configuration.

Used with RS-485 Communications for RX Pull-up.

Install at End Node with (120-Ohm) RX Termination Installed.

Used with RS-485 Communications for RX Pull-down.

Install at End Node with (120-Ohm) RX Termination Installed.

RS-232 - RTS to CTS Loopback

RS-232 - Use External CTS

Table 3 - Low Power I/O Board Potentiometer Assignments

POT. # POTENTIOMETER USAGE

R29 Analog Input #7 circuitry offset calibration

R30 Analog Input #8 circuitry offset calibration

R33 1-5V Analog Output Adjustment - 1V point

R36 Analog Input #5 circuitry offset calibration

R37 Analog Input #6 circuitry offset calibration

R45 1-5V Analog Output Adjustment - 5V point

R48 4-20mA Analog Output Adjustment - 4mA point

R49 4-20mA Analog Output Adjustment - 20mA point

Note All potentiometer adjustments require the use of TeleFlow Diagnostics

Low Power I/O Expansion Board Page 4 PIP-EXPI/OTF

Page 12

Section 2

INSTALLATION & SERVICE

2.1 REMOVAL/REPLACEMENT & INSTALLATION OF THE LPI/OEB

2.1.1 Removal/Replacement of the Low Power I/O Expansion Board

Low Power I/O Expansion Board Field Upgrade Kits contain the following major parts:

1. Low Power I/O Expansion Board

2. Five #4-40 - .188” x .469” Standoffs & Five #4-40 - .408” x .469” Standoffs*

* Use these Standoffs (BBI P/N SK100210M) if the others are insufficient!

3. Five #4-40 x 3/16” Pan Head Screws - (May be required in lieu of original screws).

To remove an installed Low Power I/O Expansion Board, follow steps 1 through 7 below. To

replace the Low Power I/O Expansion Board, follow steps 2 through 6 below in reverse

order, installing rather than removing the item in question and then perform step 7.

1. Open the Instrument Front Cover.

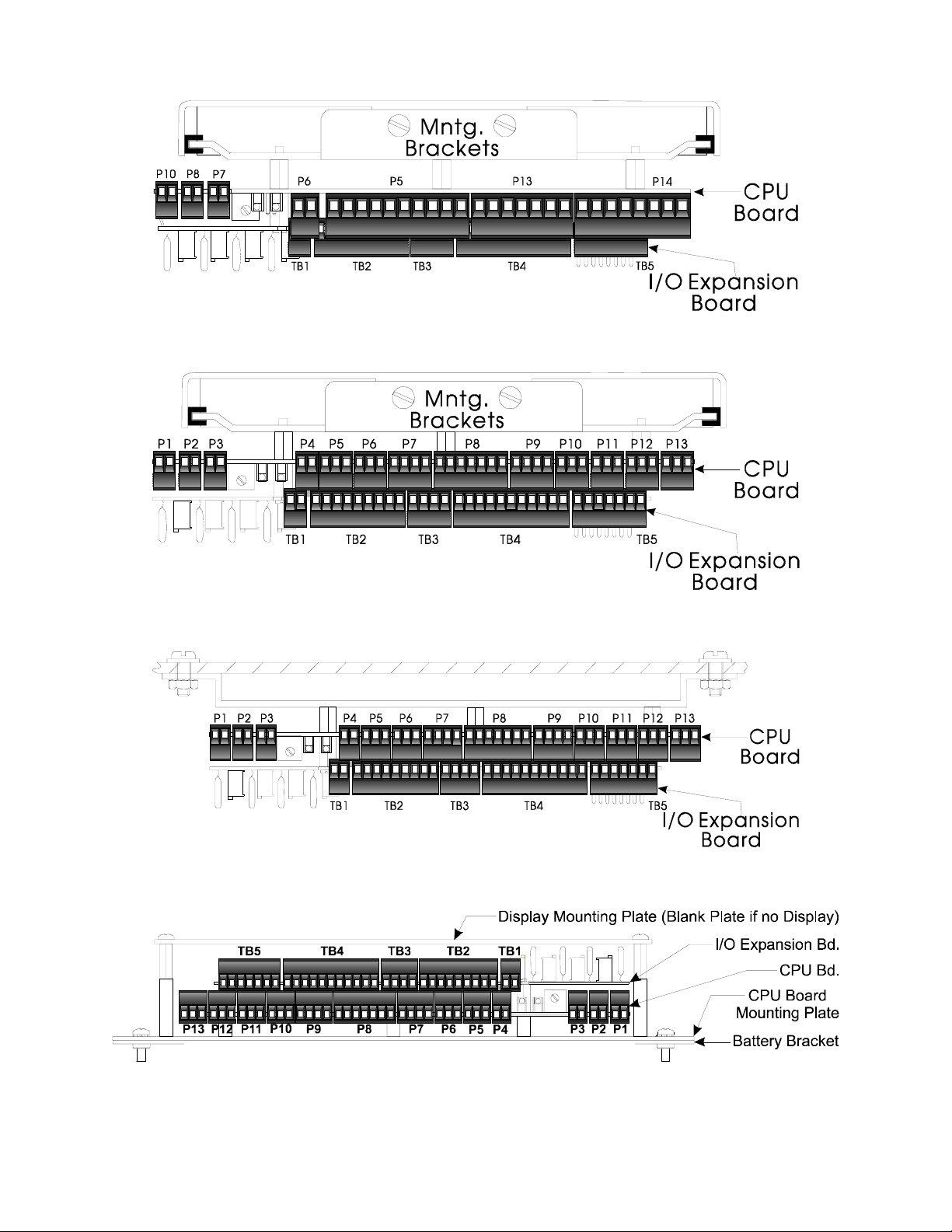

2. Disconnect the wiring harness connectors associated with power, i.e., P10, P8, P7 and

P6 from the TeleFlow CPU Board or P1, P2, P3 and P4 from the TeleRTU CPU Board.

3. Disconnect I/O connectors P5, P13 and P14 from the TeleFlow CPU Board or P5, P6, P7,

P8, P9, P10, P11, P12 and P13 from the TeleRTU CPU Board.

4. Disconnect I/O connectors TB1, TB2, TB3, TB4 and TB5 from the Low Power I/O

Expansion Board.

5. Remove the two screws that secure the sliding bracket to the fixed bracket and carefully

slide the CPU Board (with non-removed cabling) and I/O Expansion Board toward the

front of the unit until the sliding bracket is free of the fixed bracket. In the case of

Model 3530-35B, skip this step. In the case of the TeleRecorder (3530-55B) remove the

four screws that secure the Blank Plate or Display Mounting Plate to the four long

standoffs.

6. Remove the five screws that secure the Low Power I/O Expansion Board to its mounting

stand-offs and unplug I/O Expansion Board (Connector P1) from CPU Board (Connector

J2).

Note: If a replacement LPI/OEB is available follow steps 2 through 6 in reverse

order (after configuring the LPI/OEB), installing rather than removing

the item in question If a replacement I/O Expansion Board is not

immediately available and the unit must be placed back into operation

(without expanded I/O) follow steps 2 through 5 in reverse order,

installing rather than removing the item in question. Then go to step 7.

7. Close and secure the Door.

PIP-EXPI/OTF Page 5 Low Power I/O Expansion Board

Page 13

Figure 2A - I/O Expansion Board Mounted to TeleFlow Plus CPU Board

Figure 2B - I/O Expansion Board Mounted to TeleRTU Plus CPU Board

Figure 2C - I/O Expansion Board Mounted to TeleRTU Module CPU Board

Figure 2D - I/O Expansion Board Mounted to TeleRecorder CPU Board

Low Power I/O Expansion Board Page 6 PIP-EXPI/OTF

Page 14

2.1.2 Installation of the Low Power I/O Expansion Board

1. Open the Instrument Front Cover.

2. Disconnect the wiring harness connectors associated with power, i.e., P10, P8, P7 and

P6 from the TeleFlow CPU Board or P1, P2, P3 and P4 from the TeleRTU CPU Board.

3. Disconnect I/O connectors P5, P13 and P14 from the TeleFlow CPU Board or P5 through

P13 from the TeleRTU CPU Board.

4. For Models 3530-20B & 3530-25B remove the two screws that secure the sliding bracket

to the fixed bracket and carefully slide the CPU Board (with non-removed cabling

toward the front of the unit until the sliding bracket is free of the fixed bracket. In the

case of Model 3530-35B, skip this step. In the case of the TeleRecorder (3530-55B)

remove the four screws that secure the Blank Plate or Display Mounting Plate to the

four long standoffs.

5. Remove the five screws that secure the CPU Board to its standoffs.

6. Install the appropriate five standoffs supplied with the I/O Expansion Option in place of

the five screws removed in step 5. In the case of the TeleRecorder, replace the

BlankPlate or Display Mounting Plate that was removed in step 4.

7. Route field wiring cable(s) associated with the I/O Expansion Board into the TeleFlow

Plus, TeleRTU Plus or TeleRecorder through a ¾” conduit fitting (user installed) (see

Figure 3A, 3B or 3C) on the bottom of the enclosure. Configure the LPI/OEB Jumpers

(see Table 2 and Section 2.2).

Figure 3A - Bottom View of TeleFlow Plus

PIP-EXPI/OTF Page 7 Low Power I/O Expansion Board

Page 15

Figure 3B - Bottom View of TeleRTU Plus

Figure 3C - Bottom View of TeleRecorder

8 Install the I/O Expansion Board by aligning its connector P1 with CPU Board Con-

nector J2 and then securing the boards with either the five screws removed in step 5, or

the five screws supplied with the kit. Connect I/O Wiring to the appropriate removable

I/O Expansion Board Connectors (TB1, TB2, TB3, TB4 and TB5) (see Section 2.2).

Connect the wiring harness connectors associated with power, i.e., P10, P8, P7 and P6

on the TeleFlow CPU Board or P1, P2, P3 and P4 on the TeleRTU CPU Board. Connect

I/O connectors P5, P13 and P14 to the TeleFlow CPU Board or P5, P6, P7, P8, P9, P10,

P11, P12 and P13 to the TeleRTU CPU Board.

9. Close and secure the Instrument front Cover.

Low Power I/O Expansion Board Page 8 PIP-EXPI/OTF

Page 16

2.2 I/O CONFIGURATION & WIRING

Figure 4 - LPI/OEB Discrete Input Configuration

2.2.1 LPI/OEB Discrete Input Wiring (TB4) (see Figure 4 and Table 4)

Discrete Inputs have a range of 0-16 Vdc ±10% and have surge suppression but are not

isolated. A Discrete Input is activated by closing the connection between DI/On and Ground

(GND) with a Dry Contact (such as a transistor, mechanical relay, TTL, CMOS and other

devices which provide from 0-16 Vdc). The Discrete Input (DI) is lightly pulled up to 5V.

2.2.2 LPI/OEB Discrete Output Wiring (TB4) (see Figure 5 and Table 4)

Each Discrete Output is wired to an open drain capable of switching up to +16 Vdc at

100mA. Surge suppression is provided via 16V bi-directional Transorbs across each out-put;

however, since these outputs are not isolated, caution must be exercised to ensure that the

load current does not adversely affect operation of the TeleFlow Plus or related devices.

Table 4 - Low Power I/O Expansion Board Discrete I/O Terminal Designations

TB4 Pin # Pneumonic Description

1 DIO1 Discrete In/Out 1

2 DIO2 Discrete In/Out 2

3 GND Ground

4 DIO3 Discrete In/Out 3

5 DIO4 Discrete In/Out 4

6 GND Ground

7 DIO5 Discrete In/Out 5

8 DIO6 Discrete In/Out 6

9 GND Ground

10 DIO7 Discrete In/Out 7

11 DIO8 Discrete In/Out 8

PIP-EXPI/OTF Page 9 Low Power I/O Expansion Board

Page 17

Figure 5 - LPI/OEB Discrete Output Configuration

2.2.3 LPI/OEB Analog Input Wiring (TB2) (see Figures 6 through 8 and Table 5)

Up to 4 single ended analog inputs can be wired to the I/O Expansion Board. Analog Inputs

5 and 6 can be configured as 1-5 V non-isolated inputs, 4-20 mA non-isolated inputs, or 4-20

mA loops powered internally and referenced to the board’s analog ground (AGND). When

configured for internally powered current loop operation (which can be turned off when the

CPU Board is in SLEEP mode), an external 21V power supply is required. Analog Inputs 7

and 8 can only be configured for 1-5 V non-isolated input operation

Figure 6 - LPI/OEB Non-Isolated 4-20mA Current Source AI Configuration

Low Power I/O Expansion Board Page 10 PIP-EXPI/OTF

Page 18

Figure 7 - LPI/OEB 1-5V Non-Isolated Voltage Analog Input Configuration

Figure 8 - LPI/OEB 4-20 mA Internally Sourced Analog Input Configuration

PIP-EXPI/OTF Page 11 Low Power I/O Expansion Board

Page 19

Table 5 - LPI/OEB Analog Input Terminal Designations

TB# Pin # Pneumonic Description

TB1-1 +21VEXT External +21VDC

TB1-2 21VGND External 21V Gnd.

TB2-1 EXC5 Excitation 5

TB2-2 AIN5 Analog Input #5

TB2-3 GND Ground

TB2-4 EXC6 Excitation 6

TB2-5 AIN6 Analog Input #6

TB2-6 GND Ground

TB2-7 AIN7 Analog Input #7

TB2-8 AIN8 Analog Input #8

TB2-9 GND Ground

2.2.4 LPI/OEB Analog Output Wiring (TB3) (see Figure 9 and Table 1)

Figure 9 - LPI/OEB Analog Output Configuration

Low Power I/O Expansion Board Page 12 PIP-EXPI/OTF

Page 20

The single analog output can be configured for 4 to 20 mA or 1 to 5 V operation. The analog

output section of the LPI/OEB consists of a bus interface, a one channel Digital to Analog

Converter (DAC) and signal conditioning circuitry designed to generate a 4-20 mA output or

a 1-5 V output. Jumper JP19 controls selection. When set in position 1-2, JP19 configures

the analog output for current loop operation. When set in position 2-3, Jumper JP19

configures the analog output for 1 to 5 V operation.

2.2.5 LPI/OEB High Speed Counter Wiring (TB3) (see Figure 10 & Table 1)

The High Speed Counter input circuitry is powered from the 5V power source on the

LPI/OEB. The HSC Input is configured as a dry contact input with filtering and surge

protection. Field connections are HSC and GND. The frequency range of the HSC is DC to

10KHz. Field devices can be open collector transistors, open drain FETs or dry contacts.

Figure 10 - LPI/OEB High Speed Counter Configuration

2.3 RS-232/RS-485 COMMUNICATIONS

Terminal Block TB5 can be configured to support RS-232 or RS-485 communications (see

Figure 11).

For RS-232 operation the following configuration jumpers must be set:

JP13 Jumper to JP16

JP22 Pin-1 to Pin-2 for RTS to CTS Loopback or Pin-2 to Pin-3 for use with an external

CTS

For RS-485 operation the following configuration jumpers must be set:

JP14 Jumper to JP16

JP15 - 120 Ohm TX Termination (at end nodes ONLY)

JP17 - 120 Ohm RX Termination (at end nodes ONLY)

JP20 - RX Pull-up (Install at end node with RX Term. Installed)

JP21 - TX Pull-up (Install at end node with TX Term. Installed)

PIP-EXPI/OTF Page 13 Low Power I/O Expansion Board

Page 21

Figure 11 - RS-232/485 Communication Configuration Diagram

Low Power I/O Expansion Board Page 14 PIP-EXPI/OTF

Page 22

Section 3

TROUBLESHOOTING

3.1 FIELD WIRING SIGNAL CHECKS

Check Input or Output Field Wires at the Card Edge Connector and at the field device.

Check wiring for continuity, shorts & opens. Check the I/O signals at the card-edge connectors (see Figures 4 through 10 as follows):

Figure 4 - LPI/OEB Discrete Input Configuration

Figure 5 - LPI/OEB Discrete Output Configuration

Figure 6 - LPI/OEB Non-Isolated 4-20 mA Current Source Analog Input Configuration

Figure 7 - LPI/OEB 1-5V Non-Isolated Voltage Analog Input Configuration

Figure 8 - LPI/OEB 4-20 mA Internally Sourced Analog Input Configuration

Figure 9 - LPI/PEB Analog Output Configuration

Figure 10 - LPI/OEB High Speed Counter Configuration

If RS-232 or RS-485 communications problems are encountered, check Low Power I/O

Expansion Board Configuration Jumpers for proper configuration (see Table 2). Check

communication signals at card-edge Connector TB5 (see Table 1 and Figure 11 - RS-232/485

Communication Configuration Diagram).

PIP-EXPI/OTF Page 15 Low Power I/O Expansion Board

Page 23

Section 4

SPECIFICATIONS

4.1 INPUT/OUTPUT SPECIFICATIONS

4.1.1 Discrete Inputs

Number of DIs: 8 selectable non-isolated DI Max. (Note: Any DI/O

configured for DO operation diminishes the number

of DIs, i.e., if 6 DI/O are configured for DO operation,

only 2 DI/O can be configured for DI operation)

Input Type: 0 - 16 Vdc

Input Current: 5mA ±10% (Contact Closure)

Surge Suppression/protection: 16V Bi-directional Transient Absorption Zeners

Across input

4.1.2 Discrete Outputs

Number of DOs: 8 selectable non-isolated DO Max. (Note: Any DI/O

configured for DI operation diminishes the number

of DOs, e.g., if 6 DI/O are configured as DI operation,

only 2 DI/O can be configured for DO operation)

Output Type: Open Drain 16Vdc @ 100mA

Surge Suppression/Protection: 16V Bi-directional Transient Absorption

Zeners across output

4.1.3 Analog Inputs

Number of Inputs: 2 Analog Single Ended Inputs (Selectable Current

Input or Voltage Input operation)

2 Analog Single Ended Inputs (Voltage Input only)

Input Type: 1-5 Volt dc

or

4-20 mA Current Loop (Externally Sourced)

or

4-20 mA Current Loop (Internally Sourced)

(Requires external 21V Power Supply)

Accuracy: At room temperature +25°C (77°F)

V/I Input ±0.1% of Span

Low Power I/O Expansion Board Page 16 PIP-EXPI/OTF

Page 24

At -20°C to +70°C (-4°F to +158°F)

V/I Input ±0.2% of Span

At -40°C to +70°C (-40°F to +158°F)

V/I Input ±0.3% of Span

Input Filtering: Single Pole (50 msec time constant) 300 msec to

±0.1% of input value

Settling time of any selected AI is 18 μsec to .01%

Common Mode Rejection Ratio 47 to 63 Hz is 90dB

Normal Mode Rejection at 60 Hz is 26dB

Input Impedance: 1-5 V Input - 195 kohms

4-20 mA Input - 250 ohms

Common Mode Range: 0V to +5V

Surge Suppression/Protection: 22V Bi-directional Transient Absorption Zeners

across input

4.1.4 Analog Outputs

Number of Outputs: 1

Output Range: 4-20 mA into a 250 ohm load

or

1-5 VDC @ 5mA Max.

Accuracy: At room temperature +25°C (77°F)

±0.1% of Span

At -20°C to +70°C (-4°F to +158°F)

±0.2% of Span

At -40°C to +70°C (-40°F to +158°F)

±0.3% of Span

Setting Time: 100 msec to .1%

Surge Suppression: 16V Unidirectional Transient Absorption Zeners

across output

Isolation: Outputs are not isolated and are referenced to

Analog Ground

4.1.5 Communication Port

Configuration: RS-232 or RS-485 (Jumper Selectable)

PIP-EXPI/OTF Page 17 Low Power I/O Expansion Board

Page 25

ESD: RS-232 - 16V Bi-directional Transient Absorption

Zeners across output

RS-485 - 5V Bi-directional Transient Absorption

Zeners across output

4.1.6 High Speed Counter

Number of Inputs: 1

Input Type: Voltage

Input Current: 5mA ±10% (open collector/contact closure)

Input Frequency: DC to 10kHz

Input Impedance: 4.7 kohms ±10% for 16V input range

Surge Suppression: 16V Bi-directional Transient Absorption Zeners

across input

4.2 ENVIRONMENTAL SPECIFICATIONS

Temperature: Operating: -40°C to +70°C (-40°F to +158°F)

Storage: -40°C to +85°C (-40°F to +185°F)

Relative Humidity: 15-95% RH Non-condensing

Vibration: 10 to 500 Hz at 1g on axis per SAMA PMC-31-1

without damage or impairment

ESD Susceptibility: Field connected circuits are designed to meet the

requirements of IEC 801-2 for ESD withstand

capability up to 10KV

EMI Capability: Designed to coexist inside a shielded enclosure with

the TeleFlow or TeleRTU electronics. EMI radiation

is insignificant and susceptibility is comparable or

superior to associated electronics

Transient Susceptibility: Field connected circuits are designed to meet the

requirements of ANSI/IEEEC37.90.1-1989 (Formerly IEEE 472) for surge withstand capability.

Part Numbers: 392927-01-2 - Fully Populated LPI/OEB

392927-02-0 - Depopulated has DI/DO and Comm.

392927-03-9 - Depopulated has DI/DO only

Low Power I/O Expansion Board Page 18 PIP-EXPI/OTF

Page 26

Low Power I/O Expansion Board

Special Instructions for Class I, Division 2 Hazardous Locations

1. The BBI Low Power I/O Expansion Board (LPI/OEB) is listed by Underwriters

Laboratories (UL) as nonincendive and is suitable for use in Class I, Divis ion 2, Groups

A, B, C and D hazardous locations or non-hazardous locations only. Read this document

carefully before installing a nonincendive BBI LPI/OEB Board. In the event of a conflict

between the LPI/OEB Board User Manual (PIP-EXPI/OTF) and this document, always

follow the instructions in this document.

2. Wiring must be performed in accordance with Class I, Division 2 wiring methods as

defined in Article 501-4 (b) of the National Electrical Code, NFPA 70 for installations

within the United States, or as specified in Section 18-152 of the Canadian Electrical

Code for installation in Canada.

3. WARNING: EXPLOSION HAZARD - Substitution of components may impair

suitability for use in Class I, Division 2 environments.

4. WARNING: EXPLOSION HAZARD - When situated in a hazardous location,

turn off power before servicing/replacing the unit and before installing or

removing I/O wiring.

5. WARNING: EXPLOSION HAZARD - Do Not disconnect equipment unless the

power has been switched off or the area is known to be nonhazardous.

07/21/2000 Appendix A of PIP-EXPI/OTF - LPI/OEB Board Page 1 of 1

Page 27

BLANK PAGE

Page 28

Product Information Package

PIP-EXPI/OTF

Low Power I/O Expansion Board

February, 2008

Emerson Process Management

Remote Automation Solutions

1100 Buckingham Street

Watertown, CT 06795

Phone: +1 (860) 945-2262

Fax: +1 (860) 945-2525

www.EmersonProcess.com/Remote

Emerson Process Management

Remote Automation Solutions

6338 Viscount Rd.

Mississauga, Ont. L4V 1H3

Canada

Phone: 905-362-0880

Fax: 905-362-0882

www.EmersonProcess.com/Remote

Emerson Process Management Mexico

Viveros de la Colina No 238

Col. Viveros de la Loma

Tlalnepantla, Mexico 54080

www.EmersonProcess.com/Remote

Emerson Process Management

Bristol Babcock, Ltd.

Blackpole Road

Worcester, WR3 8YB

United Kingdom

Phone: +44 1905 856950

Fax: +44 1905 856969

www.EmersonProcess.com/Remote

Emerson Process Management

Bristol Digital Systems Australasia

22 Portofino Crescent,

Grand Canals Bunbury, Western Australia 6230

Mail to: PO Box 1987 (zip 6231)

Phone: +61 (8) 9725-2355

Fax: +61 (8) 8 9725-2955

www.EmersonProcess.com/Remote

NOTICE

“Remote Automation Solutions (“RAS”), division of Emerson Process

Management shall not be liable for technical or editorial errors in this manual

or omissions from this manual. RAS MAKES NO WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WITH

RESPECT TO THIS MANUAL AND, IN NO EVENT SHALL RAS BE LIABLE

FOR ANY INCIDENTAL, PUNITIVE, SPECIAL OR CONSEQUENTIAL

DAMAGES INCLUDING, BUT NOT LIMITED TO, LOSS OF PRODUCTION,

LOSS OF PROFITS, LOSS OF REVENUE OR USE AND COSTS

INCURRED INCLUDING WITHOUT LIMITATION FOR CAPITAL, FUEL AND

POWER, AND CLAIMS OF THIRD PARTIES.

Bristol, Inc., Bristol Babcock Ltd, Bristol Canada, BBI SA de CV and the Flow

Computer Division are wholly owned subsidiaries of Emerson Electric Co.

doing business as Remote Automation Solutions (“RAS”), a division of

Emerson Process Management. FloBoss, ROCLINK, Bristol, Bristol

Babcock, ControlWave, TeleFlow and Helicoid are trademarks of RAS. AMS,

PlantWeb and the PlantWeb logo are marks of Emerson Electric Co. The

Emerson logo is a trademark and service mark of the Emerson Electric Co.

All other trademarks are property of their respective owners.

The contents of this publication are presented for informational purposes

only. While every effort has been made to ensure informational accuracy,

they are not to be construed as warranties or guarantees, express or implied,

regarding the products or services described herein or their use or

applicability. RAS reserves the right to modify or improve the designs or

specifications of such products at any time without notice. All sales are

governed by RAS’ terms and conditions which are available upon request.

© 2008 Remote Automation Solutions, division of Emerson Process

Management. All rights reserved.

Loading...

Loading...