Page 1

P

D

I

An Introduction to:

ACCOL

(Formerly known as "The ACCOL Textbook")

DEVICE

INITIAL

Bristol Babcock

D4056 Issue: January, 2001

Page 2

Notice

Copyright Notice

The information in this document is subject to change without notice. Every effort has been

made to supply complete and accurate information. However, Bristol Babcock assumes no

responsibility for any errors that may appear in this document.

Bristol Babcock does not guarantee the accuracy, sufficiency or suitability of the software

delivered herewith. The Customer shall inspect and test such software and other materials to

his/her satisfaction before using them with important data.

There are no warranties, expressed or implied, including those of merchantability and fitness

for a particular purpose, concerning the software and other materials delivered herewith.

Request for Additional Instructions

Additional copies of instruction manuals may be ordered from the address below per attention

of the Sales Order Processing Department. List the instruction book numbers or give the

complete model, serial or software version number. Furnish a return address that includes

the name of the person who will receive the material. Billing for extra copies will be according

to current pricing schedules.

ACCOL is a trademark and Bristol is a registered trademark of Bristol Babcock. Other

trademarks or copyrighted products mentioned in this document are for information only, and

belong to their respective companies, or trademark holders.

Copyright (c) 2001, Bristol Babcock, 1100 Buckingham St., Watertown, CT 06795. No part of

this manual may be reproduced in any form without the express written permission of Bristol

Babcock.

Page 3

A Few Words About Bristol Babcock

For over 100 years, Bristol® has been providing innovative solutions for the measurement

and control industry. Our product lines range from simple analog chart recorders, to

sophisticated digital remote process controllers and flow computers, all the way to turnkey

SCADA syst em s . Over t he y ea r s , we have bec om e a l ea d i ng supplier to the electronic gas

measurement, water puri f ication, a nd wast ew a ter tr ea tment ind us tries.

On off-shore oil platforms, on natural gas pipelines, and maybe even at your local water

company, there ar e Br i s tol Babcoc k instr um ents, controllers , and sy s tems running y ea r - in

and year-out to provide accurate and timely data to our customers.

Getting Additional Information

In addition to the information contained in this manual, you may receive additional

assistance in using Bristol Babcock products from the following sources:

Contacting Bristol Babcock Directly

Bristol Babcock's world headquarters are located at 1100 Buckingham Street, Watertown,

Connecticut 06795, U.S.A. Our main phone numbers are:

(860) 945-2200

(860) 945-2213 (FAX)

Regular office hours are Monday through Friday, 8:00AM to 4:30PM Eastern Time, excluding

holidays a nd scheduled fact or y s hutdowns. During ot her hours, ca l ler s may leav e m es sages

using Bristol's voice mail system.

Telephone Support - Technical Questions

During regular business hours, Bristol Babcock's Application Support Group can provide

telephone support f or y our technical q uestions.

For technical questions regarding ACCOL, ACCOL Workbench, Open BSI products

(as well as ACCOL DOS-based Tools, or UOI) call (860) 945-2286. Before you call,

please fi nd out the version of software you a r e us i ng .

For technical questions regarding Bristol's OpenEnterprise product, call (860) 945-2501 or

e-mail openenterprise@bristolbabcock.com

For technical questions regarding Bristol's Enterprise Server® / Enterprise

Workstation® products, call (860) 945-2286.

For technical questions regarding Network 3000 hardware products call (860) 945-2502.

For technical questions about ControlWave call (860) 945-2244 or (860) 945-2286.

You can e-mail the Application Support Group at: bsupport@bristolbabcock.com

The Application Support Group also maintains a bulletin board for downloading software

updates to customers. To access the bulletin board, dial (860) 945-2251 (Modem settings:

14.4K baud maximum, No parity, 8 data bits, 1 Stop bit . )

i

Page 4

For assistance in interfacing Bristol Babcock hardware to radios, contact Communication

Technologies in Orlando, FL at (407) 629-9463 or (407) 629-9464.

Telephone Support - Non-Technical Questions, Product Orders, etc.

Questions of a non- technical na ture (pr od uc t orders , liter a ture requests, p r i c e a nd delivery

information, etc.) shoul d b e directed to the nea r es t regional s a l es of f i c e ( l isted bel ow ) or to

your local Bristol sales office or Bristol-authorized sales representative.

U.S. Regi on al Sales Offices Principal International S ales Offices:

Northeast (Watertown) (860) 945-2262 Bristol Babcock Ltd (UK): (441) 562-820-001

Southeast (Birmingham) (205) 980-2010 Bristol Babcock, Canada: (416) 675-3820

Midwest (Chicago) (630) 571-6052 Bristol Meci SA (France): (33) 2-5421-4074

Western (Los Angeles) (909) 923-8488 Bristol Digital Sys. Australasia Pty. Ltd.

Southwest (Houston) (713) 685-6200 BBI, S.A. de C.V. (Mex ic o) (525) 254-2131

61 8-9455-9955

Please call the main Bristol Babcock number (860-945-2200) if you are unsure which office

covers your particular area.

Visit our Site on the World Wide Web

For general information about Bristol Babcock and its products, please visit our site on the

World Wide Web at: www.bristolbabcock.com

Training Courses

Bristol Babcock’s Training Department offers a wide variety of courses in Bristol hardware

and software at our Watertown, Connecticut headquarters, and at selected Bristol regional

offices, throughout the year. Contact our Training Department at (860) 945-2343 for course

information, enrollment, pricing, and schedules.

ii

Page 5

Who Should Read This Manual?

This manual i s intended for use by new ACCOL users. It describes the b asic

concepts in ACCOL, and provides examples of the major structures used by the

ACCOL programmer.

It assumes familiarity with the following subjects:

Use of personal computers, including clicking with a mouse, using di alog

boxes, list boxes, menus, etc.

Windows 98 or Windows NT operating system.

As a minimum, users should have the fol lowing additional manuals available, when

reading this manual:

ACCOL II Reference Manual (document# D4044) which contains detailed

descriptions of all ACCOL modules.

ACCOL Workbench U ser Manual (document# D4051) which contains detailed

instructions on using ACCOL Workbench to create an ACCOL load.

Network 3000 Communications Configuration Guide (document# D5080)

which contains an overview of communications using Bristol Babcock

networks, and a guide to troubleshooting communication problems.

NOTE

This book should not be considered a substitute for ’handson’ experience with ACCOL Workbench and Network 3000

controllers.

New users should strongly consider attending one or more

training courses offered by Bristol Babcock. Contact our

Training Department at the number listed on page ii for

more information.

iii

Page 6

BLANK PAGE

Page 7

Table of Contents

Chapter 1 - What is ACCOL?

Chapter 2 - What Are Signals?

Chapter 3 - What Are Modules?

Chapter 4 - What Are ACCOL Tasks?

Chapter 5 - What Are Data Arrays?

Chapter 6 - What Is Process I/O?

Chapter 7 - How Are Communication Ports Used?

Chapter 8 - What Should I Know About Memory?

Chapter 9 - What Are Signal Lists?

Chapter 10 - What Are Archive Files?

Appendix A - Creating A Sample ACCOL Load

.....................................................................................

..................................................................................

.................................................................................

.......................................................................

..........................................................................

...............................................................................

...........................................................................

.....................................................................

.......................................................

...................................................

...................................................

1-1

2-1

3-1

4-1

5-1

6-1

7-1

8-1

9-1

10-1

A-1

Appendix B - Working with Floating Point Numbers

Glossary

......................................................................................................................

..............................................

B-1

G-1

v

Page 8

BLANK PAGE

Page 9

Chapter 1 - Introduction: What is ACCOL?

What is ACCOL?

ACCOL

dvanced Communications and Control-

A

riented Language. The initial concept for

O

is an acronym which stands for

ACCOL was developed at Bristol in the

early 1970s, and has since become the

standard software programming language

for Bristol Babcock Network 3000-series

devices. Several newer generations of the

language have been developed since then.

The current versions of the ACCOL

language, as well as the

ACCOL Tools

software, which i s used to create programs

in the language, have incorporated

numerous features and improvements

suggested by our customers, and are

markedly different from the initial version.

All are rooted in the initial concept of

ACCOL, however, which was to create a

high-level programming language which

used a ‘modular’ approach for monitoring

and control of process control applications.

What is Network 3000?

Network 3000

process controllers

3335, RTU 3310, and RTU 3305 remote process controllers, as well as GFC 3308-series

flow computers1 and the EGM 3530-xx TeleFlow™ / RTU 3530-xx TeleRTU series2 flow

computers and RTUs. Network 3000-series controllers are utilized in a wide variety of

measurement and control applications throughout the water, waste water, and natural

gas pipeline industries.

These controllers coll ect data from field instrumentation such as pressure transmitters,

flow meters, electrical contacts and switches. The incoming data is received through

connection points on

1

Network 3000 controllers are often referred to as simply ’33xx controllers’ because of the ’33’ in the model number.

2

3530 TeleFl o w and Te l eRTU uni ts only support a subset o f ACCOL modules an d features. Task slip

counts and rate information, communication statistics, and crash blocks are not available. See the ACCOL

II Reference Manual (D4044) and contac t Bristo l Ba bcock Appl ication Support for mor e infor mation.

3

The term ‘I/O’ is an abbrevi ati on f or input/ out put and ref e rs to data coming i n, and goi ng out, of a partic ul ar

device. The ‘Process I/O board’ is an electronic de v ic e (board/card) in the controlle r through which data comes in and

out from field instrumentation (the process).

is the name for a product family of Bristol Babcock digital

, and auxiliary equipment, which includes the DPC 3330, DPC

process I/O boards

in the controll er.3 Based on th e i n comin g da ta,

remote

An Introduction to ACCOL Page 1-1

Page 10

Chapter 1 - Introduction: What is ACCOL?

the controllers can execute pre-programmed instructions to control a process.

For example, in response to data collected from field instruments, the controller can

issue commands to open valves when a certain pressure is reached, or to start

compressors or pumps if a flow rate decreases below setpoint. All of these preprogrammed instructions are written u sing ACCOL.

In addition to directly controlling a process, a Network 3000 controller can serve as a

node

other controllers.

in a communi cations network . Each controll er (node) can thus share i ts data with

Data is sent to the network through one or more of the controller’s

ports

with cables. Controllers which are far away can communicate through dial-up modems

using either dedicated phone lines or the pu blic teleph one system. For some app lications,

radio or satellite links may be appropriate.

Typically, one or more PC workstations is also connected to the network. These

workstations generally include

programming, as well as

Open BSI Utilities are a collection of programs which facilitate communication with the

controller network by the ACCOL Tools, and by third-party applications. Open BSI

Utilities also allow an operator to collect and view data from the network, and to monitor

the status of network communications. Separate utilities may be purchased which allow

scheduled data collection, and file export capability to third-party applications such as

Microsoft Excel spreadsheets or data bases such as Microsoft Access.

Often, the PC workstations are also equipped with

Acquisition (SCADA)

allow the presentation of data to an operator in the form of graphical displays, trends,

and printed logs or reports. The PC workstation can use one of several different packages

for this purpose including Iconics Genesis software, Intellution® FIX® software, or

Bristol Babcock’s own OpenEnterprise software.

. If controllers are located near each oth er, n etwork con n ection s can be ‘hard-wired’

ACCOL Tools

Open Bristol System Interface (BSI) Utilities

or

Human-Machine Interface (HMI)

software to allow for ACCOL

Supervisory Control and Data

software packages which

communication

software. The

Page 1-2 An Introduction to ACCOL

Page 11

Chapter 1 - Introduction: What is ACCOL?

How Are the Controllers Programmed?

ACCOL programming is done using a set of software programs referred to as the

ACCOL Tools

ACCOL Workbench

necessary functions for ACCOL program generation, with the cut, paste, search, and

replace capabilities of a text editor.

. The most important program in the ACCOL Tools software set is

. ACCOL Workbench, is a Windows-based tool wh ich combines the

The ACCOL programmer uses ACCOL Workben ch to construct an

The ACCOL source file con sists of

ASCII

text, and has a file extension of (.ACC).

ACCOL source file

When editing the source file, the programmer selects from a large set of pre-programmed

ACCOL software

module

the source file. These modules and statements perform common mathematical,

communication, and process control functions.

template s and

control statements

5

which can be inserted in

Each module receiv es a series of in put

values, upon which it performs

certain calculations. It then generates

a series of output values which may

be used by other modules. For

example, the PID3TERM module

generates outputs which allow

proportional, integral, and derivative

control over an input value.

Each module includes a set of

module termi nals

and outputs of the module. The name of an ACCOL

numerical value, is entered on the required module terminals.

which are used to specify the inputs

signal

or, in some cases, just a

Signal

s are software

structures which allow d ata to be passed between modules.6 Each signal has a specific

name which should reflect the type of data it holds. For example, if a signal is used to

store the level of water in water tank number 3, the signal should have a name such as

TANK3.WATER.LEVL. Each signal name, as well as certain characteristics associated

with the signal such as its initial value, engineering units, etc. must be defined in the

ACCOL source file. A typical ACCOL source file includes several hundred signals;

however, depending upon the complexity of the system, thousands of signals may be

used.

4

The ACCOL source file can also be edited directly with any ASCII text editor. AccolCAD software, available separately

from Bristol Babcock, can also be used to generate the ACCOL source file. Notes For Older Network 3000 Products:

Different methods for program generation exist for older model controllers; these units use an older DOS-based set of

ACCOL Tools which include the ACCOL II Batch Compiler (ABC) and ACCOL II Interactive Compiler (AIC). These

older tools are not discussed in this manual.

5

There are numerous modules and control statements to choose from. For information on particular modules and

control statements see the ACCOL II Ref e renc e Manual (document# D4044).

6

For users familiar with other high-level programming languages such as BASIC or ‘C’, signals can be thought of as

‘variables’. In some industries, they are ref e rred to as ‘tags’.

4

.

An Introduction to ACCOL Page 1-3

Page 12

Chapter 1 - Introduction: What is ACCOL?

By entering the same signal name on terminals of different modules, a connection

between the modules is estab lished , and the mod ules are said to be ‘wired’ tog ether.

7

In

this wa y, the outp ut of one mo dul e serve s as the inp ut to a noth er mod ul e; a llo wing d ata

values to be shared between modules.

The programmer combines the appropriate modules and control statements together into

functional blocks called

ACCOL Task

s. ACCOL tasks provide a way to divide up the

source file, and make it more manageable. Although an ACCOL source file can

theoretically include more than 100 tasks, most ACCOL programmers find that using a

few tasks, say less than ten, is most efficient. Each ACCOL task executes at a userdefin ed rate, and wi th a user-def ined priori ty. In this way ta sks which perf orm critical

process control operations can take precedence over tasks which perform less important

calculations.

The ACCOL source file may include other structures which allow for data storage and

management, such as

signal lists

and

data arrays

. These subjects will be discussed

later in this manual.

7

The modules, terminals, signals, and the connections between them all exist in the software program which executes in

the controller. There are no physical modules to be wired together. Unless otherwise noted, whenever these terms are

used in this book, they ref er to soft ware structures in the ACCOL, not physical hardware devices.

Page 1-4 An Introduction to ACCOL

Page 13

Chapter 1 - Introduction: What is ACCOL?

Once the ACCOL source file has been completed,

it must be translated into a format which is

compatible with the Network 3000 series

controller. To perform this translation, the

ACCOL programmer initiates an ACCOL

Workbench ‘build’ command. If there are no

errors in the ACCOL source file, the ‘build’

command generates an intermediate ACCOL

Object File8 (.ACO), and a final ACCOL Load

File (.ACL).

All of the modules and statements originally

entered in the ACCOL source file, are stored as

machine-readable instructions in the ACCOL

Load file. The ACCOL Load file, generally

referred to as simply the

then be

downloaded

into the

ACCOL load

Network 3000-series controller.

memory

9

, may

of the

Once in memory, the controller will begin executing each of the machine-readable

instructions in the ACCOL load, in order to perform whatever measurement and control

duties are required for its particular application.

8

The ACO file is useful only for certain ACCOL Tools, it may NOT be edited by the user.

9

Downloading is performed using the Open BSI Downloader.

An Introduction to ACCOL Page 1-5

Page 14

BLANK PAGE

Page 15

Chapter 2 - What Are Signals?

What Are Signals?

Signals are the primary vehicle by which data is passed from module to module in the

ACCOL load. They are similar to ‘variables’ in other programming languages. The

ACCOL programmer uses signals to specify the inputs to, and outputs from, ACCOL

modules. By placing an ACCOL signal name on a module terminal, that terminal is said

to be ‘wired’ to that signal. Placing that

establishes a connection between the modules; the value of a signal on an output

terminal of one module serves as an input to another module, and so on.

This section will describe the five different types of signals: logical, logical alarm, analog,

analog alarm, and string. A special set of signals created by the system, called

signals

discuss signal naming conventions, and signal characteristics.

will also be discussed. Before covering these topics, however, it’s important to

Signal Naming Conventions

same

signal name on another terminal

system

Every signal has a unique name. Signal names are divided up into three parts as shown

below:

base_name.extension.attribute

The signal

letter.1 The remaining characters can be any mixture of numbers and letters.

The signal

The signal

Note the presence of periods ‘.’ between the base name and extension, and between the

extension and attribute. These serve as separator characters between each part of the

signal name, and are always required. If the signal contains no attribute, the signal

name should include an end ing period, i.e. ‘

nor an attribute is used, the signal name should have two ending periods, i.e. ‘

Here are some examples of valid ACCOL signa l names:

base_name

extension

attribute

can be any mixture of 0 to 4 letters or numbers.

STATION1.TEMP.DEGC

PUMP4.STATUS.

TANK3..LEVL

POWRFAIL..

PUMP3425.STATUS.FAIL

can be from 1 to 8 characters in length, and must begin with a

can be any mixture of 0 to 6 letters or numbers.

base.extension.’

and if neither an extension,

base..’

1

The only exception to this rule is for

‘#’. System signals are created by the ACCOL Tools, and are used for specific ‘housekeeping’ duties. The ACCOL

programmer can use system signals, but cannot create them.

An Introduction to ACCOL Page 2-1

system signals

. All system signals have a base name begi nning with the characte r

Page 16

Chapter 2 - What Are Signals?

The reason signals are divided up into three

parts is that it allows a greater level of

organization for signals.

In the figure, at right, the Open BSI

DataView utility is being used to search for

all signals which share the common

extension ‘LEVEL’. The same type o f search

could be conducted based on base names or

attributes.

Characteristics Common to All Signals

Every ACCOL signal has a set of characteristics associated wi th it. Depending up on the

type of signal (logical, logical alarm, analog, analog alarm, or string) the characteristics

may vary, however, every signal, no matter which type, shares the characteristics

described below:

Initial S tate or Value

Manual Inhibit/Enable Flag

This is the starting value, a s specified i n the ACCOL

source file, which this signal will have when the

ACCOL load is initial ly downloaded i nto the Network

3000 controller. The signal will maintain its initial

state or value, until such time as it is changed, either

manually, through the intervention of an operator, or

via control instructions in the ACCOL load.

The manual inhibit/enable flag is a status value,

associated with the signal, which determines whether

or not an operator can change the value of the signal.

The value of a manually enabled signal can be altered

by an operator. When a signal is manually inhibited,

however, an operator cannot change the signal’s

value, without firs t manua lly enabling the s ignal.

Control Inhibit/Enable Flag

Page 2-2 An Introduction to ACCOL

The control inhibit/enable flag is a status value,

associated with the signal, which determines whether

or not the execution of ACCOL control logic (modules,

tasks, etc.) can change the value of the signal. The

value of a control enabled signal can be altered by

Page 17

Chapter 2 - What Are Signals?

ACCOL control logic. When a signal is control

inhibited, however, control logic cannot change the

signal’s value. This flag is sometimes referred to as

‘AUTO/MANUAL’.

Base name Text

Every signal has a base name. If desired, a descriptive

text message may be associated with the base name.

The full text of this message is only visible in those

SCADA/HMI packages which are specifically

equipped to display it. The base name text for a

particular base name is

same base name

For example, if the base name COMPRSR2 has

descriptive text of ‘COMPRESSOR NUMBER 2’, and

the ACCOL source file contains two signals with a

base name of COMPRSR2:

COMPRSR2.POWER.STAT

COMPRSR2.RUN.TIME

then both those signals will share the common base

name descriptive text of ‘COMPRESSOR NUMBER 2’.

Base name text can be def ined in the *BASENAMES

section of the ACCOL source file, -OR- it can be

defined via a separate string signal. (String signals

will be discussed later in this section.)

.

shared by a ll sig nals with t he

and

,

ACCOL supports six levels of securi ty access (1 to 6), with 6 being the highest level. Each

level has, associated with it, a security code. Any operator using Open BSI Utilities, or

certain ACCOL Tools must sign-on wi th one of these security codes. On ce sign ed on, the

operator is then allowed access to system functions which accept a security level

than or equal to

has access to functions requiring level 1 to 4, but is prohibited from accessing functions

requiring security level 5 or 6.

Read Priority

Write Priority

An Introduction to ACCOL Page 2-3

his or her security level. For example, an operator with security level 4

The

Read Priority

security level an operator must sign on with, in order

to view (i.e. read the value of) this signal.

The

Write Priority

security level an operator must sign on with, in order

to change the value of (i.e. write to) this signal.

value specifies the minimum

value specifies the minimum

less

Page 18

Chapter 2 - What Are Signals?

Additional signal characteristics vary depending upon the signal type, and will be

described, below:

Logical Signals

Logical signals can only have two possible values: ON or OFF.

2

Logical signals are therefore used for data which can only h ave two possible states. For

example, if a valve is either OPENED or CLOSED, its value can be stored in a logical

signal. Similarly, if a pump is either ON or OFF, a logical signal could be used to store

its value. Logical signals are also useful in the creation of Boolean logic expressions.

Logical sig nals have the following ch aracteristics: ( in addition to those described under

Characteri stics Common to All Signal Types

ON/OFF Text

In certain on-line tools (in Open BS I, for example) the state of a

).

logical signal is shown as ‘ON’ if the signal is ON, and ‘OFF’ if

the signal is OFF. A signal’s ON/OFF text may be changed,

howeve r, to b etter re pre sen t th e si gn al ’s fun ction. For example, it

may be desirab l e to edit th is text i n the sou rce fi le so th a t the ON

text is ‘ACTIVE’, a nd th e O FF text i s ‘FAILED’. Both th e O N te xt

and OFF text may be up to six characte rs in length.

LOC/GLB Flag

Certain HMI/SCADA packages will only collect data from signals

which are alarms, or are specified as global signals ‘GLB’. These

packages will ignore signals specified as local ‘LOC’. This flag,

therefore, allows the user to designate whether or not such

packages should collect data from this signal.

RBE Flag

Report by Exception (RBE) is a method of data collection , used b y

certain HMI/SCADA packages, which will cause data from

signals to be collected only if the signal value changes. This

minimizes the amount of message traffic in the system. By

default, signals are NOT RBE signals.

Logical Alarm Signals

Logical Alarm Signals are similar to logical signals, except that when they change state,

they gen erate an

2

The controller stores an OFF as the number ‘0’ and an ON as the number ‘1’.

3

Alarm messages are immediately transmitted out of the controller’s slave port, to the next hi ghest node i n the

network, until they reach whatever device is used to notify the operator of the alarm (PC Workstation, printer, etc.)

Page 2-4 An Introduction to ACCOL

alarm message

.3 These signals are used to store data which is more

Page 19

Chapter 2 - What Are Signals?

critical to the operation of a process, for example, a logical alarm signal might be u sed to

indicate that a p ump or compressor has failed.

Logical alarm signals have the following characteristics: (in addition to those described

under

Characteri stics Common to All Signal Types

).

ON/OFF Text

RBE Flag

Alarm Priority

See description under

See description under

signals should NOT be designated as RBE signals.

Logical Signals

Logical Signals

.

. NOTE: In general, alarm

4

Alarm signals can also be further classified based on the severity of

the alarm condition. This severity level is called the

alarm priority

There are four possible priority levels, which will be discussed in

ascending level of importance. The choice of which signals should

have a given alarm priority is entirely at the discretion of the

programmer.

Event -

Signals specified as event alarms are used to indicate

normal, everyday occurrences.

Operator Guide -

Signals specified as operator guide alarms

are used to indicate everyday occurrences as well, however,

they are slightly more important than events.

Non-Critical -

Signals specified as non-critical are used to

indicate problems which, while not serious enough to cause

damage to a plant or process, require corrective action by an

operator.

.

Critical -

Signals specified as critical are used to indicate

dangerous problems which require immediate operator

attention, and corrective action.

Alarm Type

The type of an alarm specifies under what conditions the signal

enters an alarm state. There are three possible choices:

Alarm ON -

with this choice, an alarm message is generated

when the signal turns ON, and a ‘return to normal’ alarm

message i s generated when the signal turns OFF.

4

Alarms are always reported before RBE change reports, therefore, if a signal is collected both as an alarm, and as an

RBE change, there is a possibility that an older RBE message could arrive after an alarm message, thereby overwriting

newer data with older data. Be c ause of thi s inte ract ion of t he t wo data collect ion me thods, i t is recommende d that al arm

signals NOT be designated as RBE signals. For more information on Report by Exception, see the ACCOL II Reference

Manual (document# D4044).

An Introduction to ACCOL Page 2-5

Page 20

Chapter 2 - What Are Signals?

Alarm OFF

- with this ch oice, an alarm messa ge is gen erated

when the signal turns OFF, and a ‘return to normal ’ alarm

message i s generated when the signal turns ON.

Change of State

- with this choice, an alarm message is

generated anytime the signal changes state from ON to

OFF, or from OFF to ON.

Alarm Inhibit/

Enable Flag

The alarm inhibit/enable flag is a status value, associated with the

signal, which determines whether or not alarm messages will be

transmitted. Setting th is fla g to ‘Enable’ allows transmission of alarm

messages to occur. Setting this flag to ‘Inhibit’ prevents the

transmission of alarm messages from this signal.

Analog Signals

Analog signals are used to store numerical data. Examples of such data might inclu de,

temperature readings, pressure readings, or flow totals. The numerical data is stored as

4-byte floating point numbers in IEEE format.5 The non-zero numerical value of an

analog signal can range from:

+1.175494 x 10

-38

to +3.402823 x 10

38

Analog signals have the following characteristics: (in ad dition to those described under

Characteri stics Common to All Signal Types

LOC/GLB Flag

Certain HMI/SCADA packages will only collect data from signals

).

which are alarms, or are specified as global signals ‘GLB’. These

packages will ignore signals specified as local ‘LOC’. This flag,

therefore, allows the user to designate whether or not such

packages should collect data from this signal.

RBE Flag

Report by Exception (RBE) is a method of data collection , used b y

certain HMI/SCADA packages, which will cause data from

signals to be collected only if the signal value changes. This

minimizes the amount of message traffic in the system. By

default, signals are NOT RBE signals.

RBE Deadband

5

See Appendix B for more information on working with floating point numbers.

Analog signals whi ch have been designated a s RBE signals may

Page 2-6 An Introduction to ACCOL

Page 21

Chapter 2 - What Are Signals?

have an associated

deadband

.6 The deadband represents a

range, above and below the last reported value of the signal, in

which changes to the signal will not be reported. If the signal

goes out of this range, for a period of time long enough to be

detected by an RBE scan, then an exception has occurred, and

the change will be reported.

Units Text

Units text specifies the engineering units for this particular

signal . Up to si x characte rs of un its text may b e def ined. Typica l

examples of units text include: ‘HOURS’, ‘FEET ’, ‘INCHES’, and

‘PSIG’.

Analog Alarm Signals

Analog Alarm Signals are similar to analog signals, except that when the signal value

exceeds certain pre-defined alarm limits, an alarm message is generated. These signals

are used to store data which is more critical to the operation of a process, for example, an

analog alarm signal might be used for temperature or pressure readings of critical

system components.

Analog alarm signals have the following characteristics: (in addition to those described

under

Units Text

RBE Flag

RBE Deadband

Characteri stics Common to All Signal Types

See description under

See description under

Analog Signals

Analog Signals

signals should NOT be designated as RBE signals.

See description under

Analog Signals

).

.

. NOTE: In general, alarm

7

.

Alarm Enable/

Inhibit Flag

See description under

Logical Al arm Signals

.

Alarm Limits

and

Deadbands

6

The concept of deadbands is explai ne d in more de tai l i n t he di scussion of al arm limits for analog al arm signals, lat e r

in this section.

7

Alarms are always reported before RBE change reports, therefore, if a signal is collected both as an alarm, and as an

RBE change, there is a possibility that an older RBE message could arrive after an alarm message, thereby overwriting

newer data with older data. Be c ause of thi s inte ract ion of t he t wo data collect ion me thods, i t is recommende d that al arm

signals NOT be designated as RBE signals. For more information on Report by Exception, see the ACCOL II Reference

Manual (document# D4044).

An analog alarm signal generates an alarm message when the value

An Introduction to ACCOL Page 2-7

Page 22

Chapter 2 - What Are Signals?

of the signal exceeds a pre-defined

alarm limit

. Up to four alarm

limits may be defined; every analog alarm signal must have at least

one limit defined, or else the signal will never generate an alarm

message.

The four alarm limits are the high alarm limit, the high-high alarm

limit, the low alarm limit, and the low-low alarm limit. Each of these

alarm limits can be specified in the ACCOL source file as either a

constant, or as an ACCOL signal. In general, specifying an ACCOL

signal provides more flexibility, because it allows the limit to be

changed dynamically, either by the operator, or through logic in the

ACCOL load.

In addition to the alarm limits, there are two

deadband

s: the low

deadband and the high deadband. A deadband represents a range

just above or below the alarm limit (depending upon whether it’s a

high or low alarm) in which the signal remains in an alarm state,

despite the fact that its value no longer exceeds the alarm limit.

Withou t the deadb and, if th e signal’s value rapidly fluctuates above

and below the alarm limit, the signal would constantly be going in

and out of an alarm state, thereby flooding the system with alarm

and return to normal messages. A properly defined deadband helps

prevent this situati on.

Deadbands can be defined in the ACCOL source file as either

constants, or as signals.

When the value of an analog alarm signal passes one of its alarm

limits, an alarm message is generated.

8

In the case of a high, or high-high alarm, the alarm condition does

not clear (i .e. generate a ‘return to normal’ ala rm message) u ntil the

value of the signal goes below the alarm limit,

minus

the value of the

high deadband.

In the case of a low, or low-low alarm, the alarm cond ition does not

clear until the value of the signal rises above the alarm limit,

plus

the value of the low deadband.

An example of alarm limits and deadbands is illustrated in the figure on the opposite

page. In this example, we are showing a plot of the valu e of a signal measuring Celsius

8

In order for alarm limits to function properly, t he hi gh-hi gh li mit must be a highe r number than the high l i mit, t he high

limit must be a higher number than the low limit, and the l ow-low limit must be a lower number than the low limit. In

addition, deadbands should always be entered as positive numbers.

Page 2-8 An Introduction to ACCOL

Page 23

Chapter 2 - What Are Signals?

temperature, as it fluctuates over time. The four alarm limits and two deadbands are

shown in the figure. The normal range for this signal is temperatures between 40

0

70

C. Temperatures outside of this range are considered to be alarm conditions.

0

C and

Starting from the left of the graph, the value of the sign al increases un til it reaches 70

C, the high alarm limit (see Item 1). At this point a high ala rm message is generated,

and the signal is considered to be in a ‘high alarm’ state.

The value of the signal continues to increase. When it passes the high-high alarm limit

of 900 C a ‘high-high’ alarm mess ag e i s ge n era ted (se e Ite m 2) . At th i s p oi nt, the si gn al i s

considered to be in a high-high alarm state.

The value of the signal then starts to decrease. Although the value passes below 900C, it

is still considered to be in a ‘high-high’ alarm state because there is a 100 high deadband

in effect (deadbands are shown as shaded areas on the graph.) When the signal value

falls lower than 80

0

C point (900 C high alarm limit minus the high deadband of 100 C)

the signal is no longer in a ‘high-high’ alarm state (See Item 3). It is still however in a

‘high’ alarm state.

0

As the value of the signal decreases below 70

C, it remains in a ‘high’ alarm state until

its value falls below 600 C (700 C alarm limit, minus a 100 C high deadband). (See Item 4).

At this point, the signal is in its normal range, and a ‘return-to-normal’ alarm message is

sent.

0

Then, however, the value of the signal continues to drop. When it reaches 400 C, a ‘Low

Alarm’ message is generated (See Item 5).

The signal remains in a ‘Low Alarm’ state until the signal value drops to 200 C. (See Item

6). This causes a ‘Low Low Alarm’ messa ge to be generated.

The signal remains in a ‘Low-Low Alarm’

state until the signal rises above 300 C, (20

0

C low-low alarm limit plus low deadband of

100 C). (See Item 7). The signal is still in a

‘Low Alarm’ state, however.

Once the signal rises above 500 C (400 C low

alarm limit + low deadband of 100 C), it has

left the low-alarm state, and a ‘return to

normal’ alarm message is sent (See Item 8).

As long as the signal remains in the

normal range (between 40 and 700 C), no

more alarm messages will be generated.

An Introduction to ACCOL Page 2-9

Page 24

Chapter 2 - What Are Signals?

String Signals

The last type of signal is the string signal. The value of a string signal is a message

consisting of up to 64 characters of ASCII text. These messages are called

strings

signal called STATION.TAG.NAME may have a value of ‘ELM STREET COMPRESSOR

STATION’.

String signals are typically used to provide readable status messages. Some SCADA/HMI

packages are also equipped to display these messages.

, because they are a bunch of characters tied together. For example, a string

character

A less common use of string sign als i s to hol d the b ase n ame des criptiv e text fo r

signal. Normally a signal’s base name descriptive text is defined in the source file as a

constant; if a string si gnal na me is entered instead, the base name d escriptive text can

be changed on-line.

The Calculator Module (which will be discussed in the section

certain functions for string manipulation including checking the length of a string,

comparing the value of two strings, and concatenating (putting together) two strings.

String signals have the following characteristics: (in addition to those described under

Characteri stics Common to All Signal Types

String Length

The length (number of characters) of the message (including spaces).

No string may be longer than 64 characters.

).

Modules

) also supports

another

Page 2-10 An Introduction to ACCOL

Page 25

System Signals

Chapter 2 - What Are Signals?

Every ACCOL load contains a series of

automatically by the system, and are distinguished from other ACCOL signals by the

presence of a pound sign ‘#’ at the beginning of the base name.

For example, the system signal #TIME.000. indicates the current Julian date and time.

The system signal #NODEADR.. indicates the local address of the controller (as set via

hardware or software sw itches).

There are numerous other system signals which are used for ‘housekeeping’ such as

holding task characteristics, and error informati on.

The ACCOL programmer cannot create or delete system signals, but can make use of

them on module terminals, or in equations.

For more information on system signals, see the

(document# D4044).

system signals

System signals are created

ACCOL II Reference Manual

How Are Signals Created?

All signals must be defined in the

‘*SIGNALS’ section of the ACCOL

source file (.ACC). Base name

descriptive text for the signals is

defined in the ‘*BASENAMES’

section of the file.

Instruction s for defining si gnals and

base name text are included in the

ACCOL Workbench User Manual

(document# D4051).

An Introduction to ACCOL Page 2-11

Page 26

Chapter 2 - What Are Signals?

How Does the Operator View Signal Values?

There are several different ways to view signal data in a running Network 3000 series

controller.

"

While running the Open BSI DataView utility, users can call up signals by a signal

search, by the full signal name, or through lists. Signal values may also be changed

via dialog boxes. See the

Open BSI Utilities Manual

(document# D5081) for details.

"

Signal data can be exported to DDE compliant applications such as spreadsheets and

word processors using the Open BSI DDE Server program. See the

Collection/Export Utilities Manual

"

Users with Bristol Babcock’s Universal Operator Interface (UOI) software can

(document# D5083) for details.

Open BSI

configure text-based menus and logs to include signal data. See the

Configuration Manual

"

If you are using an HMI/SCADA software package such as OpenEnterprise,

(document# D5074) for details.

Enterprise Serv er, Intellution® FIX®, Iconics Genesis, etc., signal values may be used

to drive the color and appearance of graphic symbols on screen disp lays, trend lines,

etc. See the documentation accomp anying the HMI/SCADA sof tware for details.

UOI

Page 2-12 An Introduction to ACCOL

Page 27

Chapter 3 - What Are Modules?

What Are Modules?

Module

communication, and process control functions.

programmer chooses from a library of modules, and in serts the selected modules into one

or more ACCOL

Each module has a series of

s are pre-programmed structures which are used to perform mathematical,

s in the source file.

task

terminal

2,3

s which represent its inputs and outputs. The

1

Within ACCOL Workbench, the

programmer ‘wires’ these terminals in software, by typi ng an ACCOL signal name next

to the terminal . By placi ng the s ame sign al name on termin als of diffe rent modu les, th e

programmer establishes a connection for data flow between the modules. In this way,

data flows from an output terminal of one module, to an input terminal of another

module, and so on.

4

How Do Modules Execute?

When a module executes, it reads its input terminals, performs any necessary

calculations, and then updates i ts outpu t terminals.

Except for certain special modules in Task 0 (discussed later in this manual) modules do

NOT execute unless the line of the

the outpu t terminal s of a modul e do N OT cha nge at any time ex cept wh en th e modu le i s

executing.

on which they are defined executes, therefore

task

What Kinds of Modules Are Available?

There are over 80 different ACCOL modules. We will discuss a few broad categories of

available modules here. A full description of each module is included in the

Reference Manual

(document# D4044).

1

If you are familiar with other programming languages, you can think of a module as a sub-routine, or procedure.

2

The pre-programming instructions for each module reside in

in the remote process controller. When you instal l ne w versions of ACCOL Tools software, which include ne w modules,

you may also need to install an upgrade to t he cont roll er fi rmware, in order to use the new modules or features. For some

controller models, the firmware is referred to as the

Memory (EPROM) chips. In other controllers, the firmware is installed into a FLASH memory area. See the hardware

manual of your controller for more information.

3

The method for inserting modules into a task will be discussed in greater detail later.

4

The terminals of a module are only updated with data when the module executes.

An Introduction to ACCOL Page 3-1

PROM set

firmware

, because it resides in Erasable Programmable Read only

, a special kind of e ncode d soft ware that resides

ACCOL II

Page 28

Chapter 3 - What Are Modules?

Natural Gas Modules

There are several modules available

which implement natural gas

industry calculations, including

those described in

Association

reports. Among these

American Gas

modules are AGA3ITER, AGA5,

AGA7, AGA8GROSS, AGA8DETAIL,

FPV and ISO5167.

Input/Output (I/O) Modules

10 * AGA8DETAIL

ENABLE ;LOGICAL_SIGNAL

PRIORITY ;ANALOG_SIGNAL_OR_VALUE

FLOW_TEMP ;ANALOG_SIGNAL_OR_VALUE

STAT_PRESS ;ANALOG_SIGNAL_OR_VALUE

BASE_TEMP ;ANALOG_SIGNAL_OR_VALUE

BASE_PRESS ;ANALOG_SIGNAL_OR_VALUE

LIST ;ANALOG_SIGNAL_OR_VALUE

ARRAY ;ANALOG_SIGNAL_OR_VALUE

COLUMN ;ANALOG_SIGNAL_OR_VALUE

ERROR ;ANALOG_SIGNAL

STATUS ;ANALOG_SIGNAL

Z_FLOWING ;ANALOG_SIGNAL

Z_BASE ;ANALOG_SIGNAL

FPV ;ANALOG_SIGNAL

Most every ACCOL source file

includes some I/O modules, since

these modules are necessary to send

and receive data through the

controller’s process I/O boards. The

most commonly used include the

analog input (ANIN), analog output

(ANOUT), digital input (DIGIN) and

digital output (DIGOUT).

Mathematical Modules

These modules implement a variety of

different arithmetic and logical

functions. Among those available are

the AVERAGER, COMPARATOR,

INTEGRATOR, DIFFERENTIATOR,

TOT/TRND, MUX, and DEMUX

modules.

20 * ANOUT

DEVICE DEVICE_ID

INITIAL CHANNEL

OUTPUT 1 ;ANALOG_SIGNAL_OR_VALUE

ZERO 1 ;ANALOG_SIGNAL_OR_VALUE

SPAN 1 ;ANALOG_SIGNAL_OR_VALUE

TRACK 1 ;LOGICAL_SIGNAL

RESET 1 ;ANALOG_SIGNAL

30 * INTEGRATOR

INPUT ;ANALOG_SIGNAL_OR_VALUE

RESET ;LOGICAL_SIGNAL

ZERO ;ANALOG_SIGNAL_OR_VALUE

SPAN ;ANALOG_SIGNAL_OR_VALUE

OUTPUT ;ANALOG_SIGNAL

Page 3-2 An Introduction to ACCOL

Page 29

Chapter 3 - What Are Modules?

Communication Modules

These modules sup port da ta transmission

through the controller’s

ports

. Among the most commonly used

communication

modules are MASTER, SLAVE,

EMASTER, LOGGER, CUSTOM,

IP_CLIENT, and IP_SERVER.

Process Control Modules

These modules implement algorithms

which are useful for process control

applications including PID loop control

(PID3TERM), LEAD/LAG, SCHEDULER,

SEQUENCER, and STEPPER.

Calculator Module

40 * MASTER

50 * PID3TERM

INPUT ;ANALOG_SIGNAL_OR_VALUE

SETPOINT ;ANALOG_SIGNAL_OR_VALUE

DEADBAND ;ANALOG_SIGNAL_OR_VALUE

PROPORTION ;ANALOG_SIGNAL_OR_VALUE

INTEGRAL ;ANALOG_SIGNAL_OR_VALUE

DERIVATIVE ;ANALOG_SIGNAL_OR_VALUE

RESET ;ANALOG_SIGNAL_OR_VALUE

TRACK ;LOGICAL_SIGNAL

OUTPUT ;ANALOG_SIGNAL

ERROR ;ANALOG_SIGNAL

REMOTE ;ANALOG_SIGNAL_OR_VALUE

POINT ;ANALOG_SIGNAL_OR_VALUE

MODE ;ANALOG_SIGNAL_OR_VALUE

INTYPE ;ANALOG_SIGNAL_OR_VALUE

OUTTYPE ;ANALOG_SIGNAL_OR_VALUE

INDEX ;ANALOG_SIGNAL_OR_VALUE

INLIST ;ANALOG_SIGNAL_OR_VALUE

OUTLIST ;ANALOG_SIGNAL_OR_VALUE

STATUS_1 ;ANALOG/LOGICAL_SIGNAL

STATUS_2 ;ANALOG_SIGNAL

One module which deserves special mention is the CALCULATOR module. If you are

unable to find a module which suits your needs, you may often be able to create the

needed module yourself by entering statements in a Calculator Module. This module

supports a wide range of arithmetic operators (add, subtract, multiply, divide, square

root, SIN, COSINE), logical operators (IF, ELSE, AND, INCL OR, EXCL OR), and other

operators related specifically to signals, and strings.

60 * CALCULATOR

10 :IF((TANK7.WATER.LEVL>12)&(DRAIN.ENABLE.ON))

20 OPEN.DRAIN.VALV=#ON

30 :ENDIF

How Are Modules Placed in the ACCOL Source File?

Modules are inserted inside

ACCOL Tasks

discussed in the next section. For information about inserting modules in them, see the

ACCOL Workbench U ser Manual

(document# D4051).

in the ACCOL source fil e. ACCOL Task s are

An Introduction to ACCOL Page 3-3

Page 30

BLANK PAGE

Page 31

Chapter 4 - What Are ACCOL Tasks?

What Are ACCOL Tasks?

An ACCOL

sequentially as a functional block. Task execution occurs at a user-specified rate and

priority.

ACCOL tasks provide a way to organize the ACCOL source file into smaller, more

manageable pieces. For example, at a compressor station for a natural gas pipeline, there

are critical flow, temperature and pressure calculations, as well as I/O operations; these

might fit well in one high priority task. Less critical calculations, such as daily flow

totals, a nd averag es, might be separated o ut into a lowe r priority task. Communicati on

through master modules may be handled through yet another task.

Each ACCOL task is assigned a unique number. ACCOL supports over 100 tasks,

however, most users find that using a few tasks is most efficient.

task

is a series of modules and control statements which execute

Communication Between Tasks

Data is transferred from one task to another in the same way that data moves from

modul e to modu le, vi a signals.

To send a value of an output terminal in one task to the value of an input terminal in

another task, simply ‘wire’ the same signal name on both terminals.

Other ACCOL structures, such as data arrays, si gnal lists, etc., are also sh ared among

all tasks.

Task Rate

The task rate specifies how often the controller will initiate execution of this task.1

The task rate is specifi ed in units of seconds, an d is defined in the ACCOL source file ,

and may b e mod if i ed on - li n e th rou gh th e # RATE .

the task number). The task rate can be as fast as 0.02 seconds (20 milliseconds), or as

slow as 5400 seconds (90 minutes). Setting the task rate to 0 stops execution of the task.

In the timing diagra m, on the next page, an ACCOL load with a si ngle task has a task

rate set at 1 second. Each second, the task is scheduled to start executing, and it

1

If the time it takes to execute the task is longer than the rate specified, the next execution of the task will NOT be

started on schedule. It must wait until the previous execution of the task has completed. This delay is called

is recorded as a slip count error in the system signal #RCNT.nnn where nnn is the task number.

nnn

system signal (where

nnn

slippage

specifies

, and

An Introduction to ACCOL Page 4-1

Page 32

Chapter 4 - What Are ACCOL Tasks?

completes execution (in this case) in 0.25 seconds.2 For the remai ni n g ti me, th e co ntro ll er

is not executing any tasks, and is said to be idle.

In this s ituatio n, with only o ne task i n the l oad, th e task rate co uld safel y be set fa ster,

to say, 0.3 seconds, th ereby minimizing the idle time.

Idle Idle Idle

Time Time Time

0 0.25 1 1.25 2 2.25 3

(all time in seconds)

Task Rate = 1 second = task execution

Since an ACCOL load can have many tasks, be aware that each task must share

execution time. Some tasks may have critical calculations which require frequent

updates. To efficiently use the system, tasks should b e schedul ed to run as freq uently as

needed, but not so fast as to cause slippage of the execution time.

For exampl e, in the timin g diagram, abo ve, with a 1 second task rate, the controller is

idle for 0.75 seconds out of every 1.00 second. Therefore, if other tasks are added to the

load, an d the sum of thei r execution time s is always les s than 0.75 se conds, they cou ld

also all have 1 second task rates.

Continuous Tasks

If desired, a task may be set to run continuously. by specifying ‘C’ as its task rate, when

creating the ACCOL source file off-line, or setting the appropriate #RATE.

nnn

signal to a

value of ‘-1’ when operating on-line. Care must be taken, however, to ensure that

continuous tasks are given a priority lower than any other task, or to use WAIT

statements to stop execution of the continuous task. If these precautions are NOT taken ,

any tasks w ith a lower priority than the continuous task WILL NEVER execute.

Task Priority

Each task is assig ned a priority.

Task priority

the highest priority, and 1 being the lowest. If a task performs operations which are

critical to the safe operation of a process, it should be assigned a high priority. Tasks

which perform less important calculations may be assigned a lower priority.

can range from 1 to 64, with 64 being

Task priority can be changed on-line via the #PRI.

nnn

system signal (where

nnn

corresponds to the task number).

2

The time it takes to execute a task may be measured using the system signals #RTTIME.000 and #RTTIME.001.

Page 4-2 An Introduction to ACCOL

Page 33

Chapter 4 - What Are ACCOL Tasks?

ACCOL uses a technique cal led

tasks execute concurrently, however, higher priority tasks are given priority over lower

priority ones.

If two or more tasks are scheduled to execute at the same moment, the one with the

higher priority will be executed first. As time becomes available, the task with the next

highest priority will be executed, and so on. If two tasks share the same priority, they

will be executed on a rotating basis.

If a high priority task is required to run, and a lower priority task has not finished

execution, execution of the lower priority task will be suspended to allow the higher

priority task to run. The lower priority task can only resume execution when higher

priority tasks have finished.

If you have a continuous task (described earlier), it must have the lowest priority relative

to all other tasks, or it must be stopped by WAIT sta tements ( WAIT FO R, WAIT D ELAY,

etc.) or else NO O THER TASKS WILL EXECUTE.

System Tasks

pre-emptive multi-tasking

. This means that multiple

Another co nsideration when setting task priority is to avoid conflicts with

A system task is a task in the system firmware, which performs some function during the

execution of the ACCOL load. A tabl e of system task priori ties is includ ed in the ‘Task’

section of the

task a priority that is higher than one of the system tasks which will be used in your

ACCOL load, or the system task may be unable to run when it is needed.

ACCOL II Reference Manu al

(document# D4044). Never assign an ACCOL

system tasks

Redundancy Frequency

If you are using a

frequency of 1 should be specified.3 If you are NOT using redundant controllers, a

redundancy frequency of 0 sh ould be specified.

redundant

pair of Network 3000 controllers, then a redundancy

Task 0 - The Special Task

Every ACCOL load has a task numbered 0. Task 0 is a special task which does not

execute at a specified rate. Instead, it is used to hold certain modules which do NOT

3

In general, a redundancy frequency of 1 should be specified for redundant units. For additional information on

redundancy frequency, see t he ‘R e dundancy Conc ept s’ secti on of the A CCOL II Refe renc e Manual (document#

D4044).

.

An Introduction to ACCOL Page 4-3

Page 34

Chapter 4 - What Are ACCOL Tasks?

execute on their own, except when activated by other ACCOL modules. The followi ng are

non-executing modules, which are appropriate for u se in Task 0:

AUDIT

EASTATUS

EAUDIT

RBE

REDUNDANCY

RIOSTATS

SLAVE

All other modules should be placed in tasks which execute at a specified rate.

Task Control Statements

Normally, the modules in a task execute in sequential order.

Task Control Statements

can be inserted in the task to modify the flow of execution.

Modules can be conditionally skipped using IF/ENDIF/ELSE/ELSEIF statements.

Modules can be repeatedly executed using FOR/ENDFOR statements.

The enti re task can wait f or a particular e vent to occur, or time to elapse, using WAIT

statements.

The task can even suspend its execution with a S USPEND statement. The task can then

only be re-started by a RESUME statement in a

different

task.

In the simple example task, shown, below, only one of the two single-line calculator

modules will execute; which one is chosen depends upon the hour of the day determined

in the IF statement:

**TASK 2 RATE: 0.500000 PRI: 1 REDUN: 0

10 * C SIMPLE TASK TO TURN ON LIGHTS IN A ROOM

20 * C BETWEEN 4:00 PM AND 6:00 AM

30 * IF ((#TIME.005.>16)|(#TIME.005.<6))

40 * CALCULATOR ROOM.LIGHT.=#ON..

50 * ELSE

60 * CALCULATOR ROOM.LIGHT.=#OFF..

70 * ENDIF

The following is a list of sections in the

ACCOL II Reference Manu al

(document# D4044)

which contain details on control statements.

ABORT

BREAK

CONTROL STATEMENTS

Page 4-4 An Introduction to ACCOL

Page 35

Chapter 4 - What Are ACCOL Tasks?

IF/ENDIF/ELSE/ELSEIF

FOR/ENDFOR

GOTO

RESUME

SUSPEND

WAIT DELAY

WAIT DI/RWAIT DI

WAIT FOR

WAIT TIME

How Are ACCOL Tasks Created?

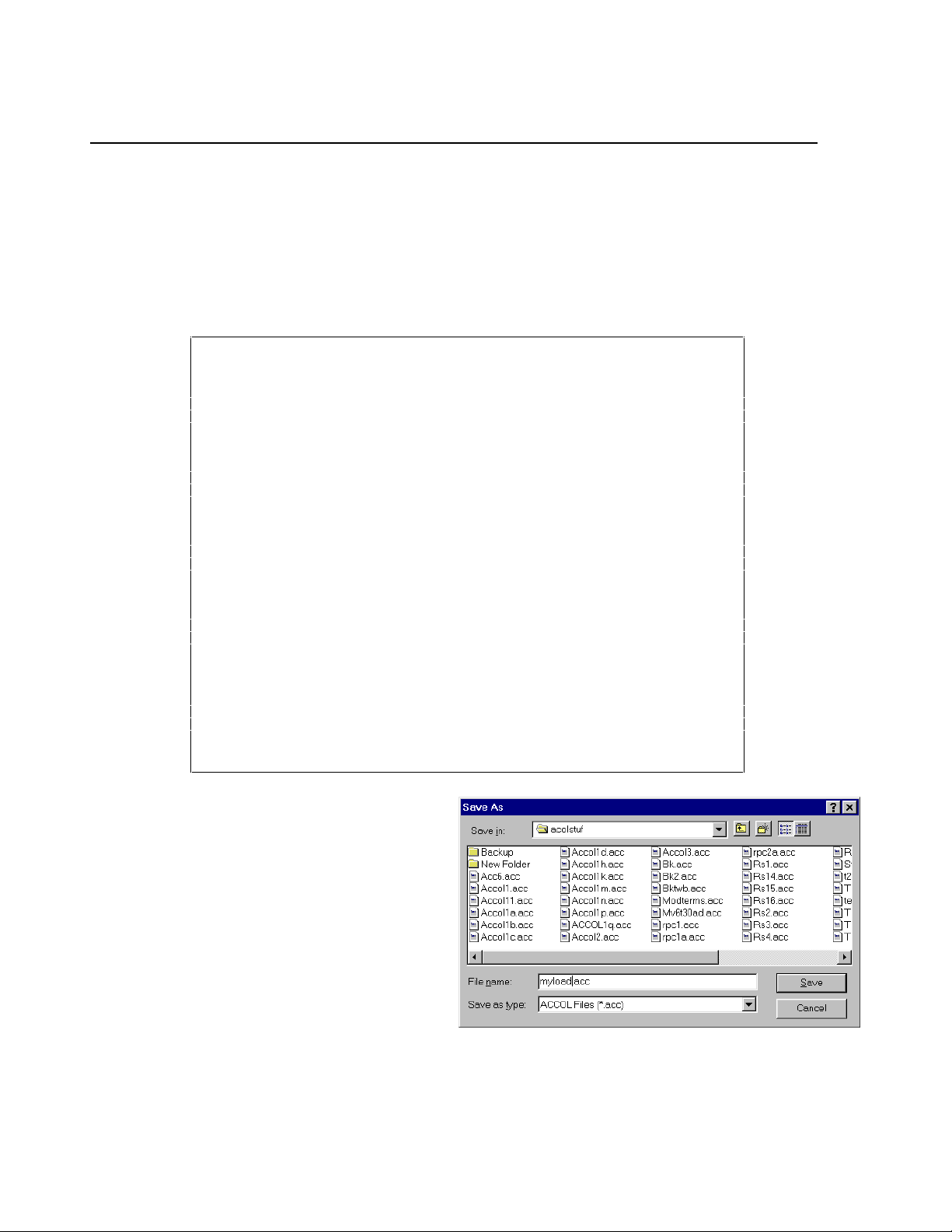

Each task has a separate *TASK

section in the ACCOL source file.

Tasks are inserted in the file

within ACCOL Workbench. For

information on doing this, see the

ACCOL Workbench User Manual

(document# D4051).

An Introduction to ACCOL Page 4-5

Page 36

BLANK PAGE

Page 37

Chapter 5 - What Are Data Arrays?

What Are Data Arrays?

Data arrays are essentially tables. They are organized in rows and columns, and each

array element (cell) can hold a single piece of data.

Arrays can be on e dimensional (1 column by n number of rows):

-OR- two dimensional (m columns by n number of rows).

A particular array includes either all analog data, or all logical data; data types cannot

be mixed within the sa me array.

1

Arrays are identified by a number from 1 to 255. There can be up to 255 logical arrays,

and 255 analog arrays. Both types of arrays can share the same numbers; for example,

there can be a logical array #1, as well as an analog array #1. All arrays are accessible by

any ACCOL task in the ACCOL loa d.

Each array is cl assified as ei ther

"

Data entries for a Read Only array a re made directly in th e ACCOL source file. Th ey

Read-Only

(RO) or

Read/Write

(RW).

may be changed using ACCOL Workbench in either off-line or on-line mode; but

cannot be changed via DataView or other access methods. The data entries may,

however, be viewed by operators, and referenced by ACCOL modules.

1

In some applications, Julian Date/ Time i nformation c an be stored in an array, vi a syste m signals. This data i s treate d

as analog information.

An Introduction to ACCOL Page 5-1

Page 38

Chapter 5 - What Are Data Arrays?

"

Read/Write Array entries, conversely, can only be specified on-line, either by an

operator entering values, or by the execution of ACCOL logic.

Modules Which Are Commonly Used With Arrays

Although many ACCOL modules use arrays, some are specifically designed for array

access or array data manipulation.

"

Storage Module

This module allows data to be read from a data array and stored in a

signal list

read from a signal list and stored in a data array.

"

Function Module

This module can use an array as a look- u p tab le. The f irst row a nd fi rst colu mn of the

array must each include values in ascending order. These values will be used as

indices, to look up values from among the remaining array elements. Interpolation

can be p erformed b y the module if row and column indices a r e not exac t.

"

Stepper Module

This module is used in applications which can be divided up into a specific set of

steps, and where each step requires a certain set of signal outpu ts. Each row of the

array represents required signal outputs for a step in the sequence.

"

Encode Module

Function 8 of the Encod e Module al lows array rows (o r columns) to be sh ifted with in

the array, in a specified direction. This simplifies array manipulation in a variety of

applications.

or

"

Calculator Module

Individual array elements (cells) can be read using Calculator equations. In addition,

array elements in read/write arrays can be changed using Calculator equations. See

the ‘Calculator’ section of the

ACCOL II Reference Manual

(document# D4044) for

details.

All of these modules are discussed in detail in the

ACCOL II Reference Manual

(document# D4044).

Page 5-2 An Introduction to ACCOL

Page 39

Chapter 5 - What Are Data Arrays?

Typical Applications For Read Only Arrays

Because read only arrays cannot be changed, they are typically used to store reference

information, which the ACCOL logic will refer to later.

Steam Table

One possible application for a read only analog array is to store a steam table. In the

figure, shown below, a portion of a steam table is shown in an array format. The first

column represents absolute pressure, and the top-most row represents a range of

temperatures. The remaining array elements represent enthalpy in units of BTUs per

pound of steam.

0 360 380 400 420 450

80 1211.0 1221.5 1231.5 1240.3 1255.7

85 1210.0 1220.5 1230.7 1239.7 1255.1

90 1209.0 1219.8 1230.0 1239.1 1254.5

A user could configure a Function Module to access the array. The Function Module uses

the values in row 1 and column 1 to lo cate appropriate array cel ls. For example, if the

Function module ROW terminal is 85, an d the Function module COLUMN terminal is

400, the Function module OUTPUT terminal will have a value of 1230.7. If the ROW and

COLUMN values fall between the values in the rows and columns, an interpolation will

be performed. For example, if the ROW terminal is 85, and the column terminal is 390, a

value halfway between the 380 COLUMN value of 1220.5 and the 400 COLUMN value

of 1230.7 will be calculated, resulting in an OUTPUT value of 1225.6.

For details on how to configure the Function Module, see the

Manual

Output Statuses For A Water Filter Backwash Sequence

One possible use of a logical read only array would be to hold the status values to be

used for each step of a water filter backwash sequence in a water treatment plant.

For example, let’s say that a simple water treatment plant has three valves and three

pumps which are used as part of a backwash sequence. The details of the sequence are

presented in the table on the next page. (Note: This sequence has been greatly simplified

for purposes of explaining the Stepper Module; the details of an actual backwash

sequence are longer and more complex.)

(document# D4044).

ACCOL II Reference

An Introduction to ACCOL Page 5-3

Page 40

Chapter 5 - What Are Data Arrays?

Device: Influent

Valve

Step 1 CLOSED OFF OFF CLOSED OPENED ON

Step 2 CLOSED OFF OFF CLOSED CLOSED OFF

Step 3 CLOSED OFF OFF OPENED CLOSED OFF

Step 4 CLOSED OFF ON OPENED CLOSED OFF

Step 5 CLOSED OFF OFF CLOSED CLOSED OFF

Step 6 OPENED ON OFF CLOSED OPENED ON

The details of this sequence can be stored in a logical array of ON/OFF status values.

The ACCOL programmer creates an array, as shown below, where each column

corresponds to a specific device (pump, valve, etc.,) and each row represents a specific

step of the backwash sequence. The programmer enters in each element of the array a 1

for ON (open, start, etc.) or a 0 for OFF (close, stop, etc.).

Influent

Pump

0 000 11

0 000 00

0 001 00

0 011 00

0 000 00

1 100 11

Wash

Pump

Drain

Valve

Effluent

Valve

Effluent

Pump

The Stepper Module executes the rows in an order specified by the ACCOL programmer,

for a specified duration. When a particular step (row) is activated, the proper status

commands for that step are retrieved from the array, and output to logical signals in

order to drive the action of the valves, pumps, etc.

For details on how to configure the Stepper Module, see the

(document# D4044).

ACCOL II Reference Manua l

Page 5-4 An Introduction to ACCOL

Page 41

Chapter 5 - What Are Data Arrays?

Typical Applications for Read/Write Arrays

Read/Write arrays are used for data which changes durin g execution, either via ACCOL

logic, or via operator intervention.

Storing Hourly Totals or Averages

One common usage would be for storing hourly flow, temperature, and pressure totals for

a natural gas pipeline compressor station.

For this example application, the programmer has

created three analog signals named

COMPRSR5.PRESUR., COMPRSR5.TEMP., and

COMPRSR5.FLOW. which contain the current

pressure , temperatu re, and flow to tals, re spective ly,

for this compressor station.

Each of these signals is ‘wired’ to one of the INPUT

terminals of the Storage Module. Every hour, the

value of these signals will be copied, using the

Storage Module, into the next available row of a 3

column by 24 row read/write analog array. For

information on using the Storage Module, see the

ACCOL II Reference Manual

Detecting Task Execution Errors

Sometimes an ACCOL programmer

configures structures which result in illegal

operations. For example, entering a

calcul ator equati on wh ich attemp ts to divi de

a value by zero. Su ch errors, are detected by

the firmware. In order for the user to view

the error code, however, an analog read/

write error array must be defined.

The number of the array must be specified

using the #ERARRAY.. system signal. The

array itself must have four columns, and as

many rows as the high est numbere d task in

the system. Each row represents an ACCOL

Task, the columns associated with that row

(document# D4044).

An Introduction to ACCOL Page 5-5

Page 42

Chapter 5 - What Are Data Arrays?

Address 2

Address 3

Address 2

Address 3

contain data about which type of module or equation in the task cau sed the error, and

the error code. Note that if there are multiple errors, only the most recently detected

error will be displayed for each task.

For a full descripti on of how to conf igu re the error a rray, a s well as a d escrip tion of wh at

each error code means, see the #ERARRAY.. portion of the ‘System Signals’ section in the

ACCOL II Reference Manual

on-line mode, can also display the meaning of the error code.

Node Array For Tuning On/Off Polling to Selected Network 3000 Nodes in a BSAP

Network

One importan t use for a Read/Write Log ical Array is to set up a node array f or turnin g

ON/OFF communication requests to slave nodes of this controlle r.

(document# D4044). ACCOL Workbench, when operating in

The number of the logical array to

be used is specified by the system

#NDARRAY

1

1

signal #NDARRAY..

1

The ACCOL programmer creates a

1

number of rows equal to the highest

slave address. For example, if the

ACCOL program we are creating is

for a controller whi ch is master to 4

slave controllers, a four row by one

column logical read/write array

Address 1

Address 1

Address 4

Address 4

should be created.

Normally, the operator or ACCOL logic should leave each element set to ON, so that

communication with slave nodes can occur. If, for whatever reason, one or more slave

nodes are taken out of service (failure, main tenance, repairs, communication problems)

then polling for them should be turned off using the #NDARRAY. This prevents

unnecessary communication attempts by the master to a non-existent node.

In the figure, shown above, the third slave node has been struck by

lightning and so has failed. The master controller (which contains the

node array) will continue attempts to communicate with it, until, the third

element in the #NDARRAY (corresponding to address 3) is changed from

ON to OFF by the operator, as shown at right.

For a full descrip tion of how to configu re the node array, see the #NDARRAY portion of

the ‘System Signals’ section in the

Page 5-6 An Introduction to ACCOL

ACCOL II Reference Manual

(document# D4044).

Page 43

Chapter 5 - What Are Data Arrays?

Detecting Process I/O Board Diagnostic Failures

If a failure is detected in one of a controller’s process I/O boards, the resu lting error cod e

can be stored in a Read/Write Logi cal Array.

The array must be specified using the #DIAG.002 system signal, and must have as many

rows as the number of process I/O board slots in the controller. The first eight columns

display th e error code, in bina ry with O FF and ON represented as 0 an d 1 , respecti vely.

Additional columns display more information.

In the figure, below, the analog input board in slot 3 is experiencing an amplifier gain

failure.

A full description of how to configure and interpret entries in this array is included in

the #DIAG.002 portion of the ‘System Signals’ section of the

(document# D4044).

ACCOL II Reference Manu a l

An Introduction to ACCOL Page 5-7

Page 44

Chapter 5 - What Are Data Arrays?

How Are Data Arrays Created?

Data arrays are inserted into the

ACCOL source file using ACCOL

Workbench. For information on

creating arrays, see the

Workbench User Manual

D4051).

How Does the Operator View Data Array Values?

There are several different ways to view data array values in a running Network 3000

series controller.

ACCOL

(document#

"

While running the Open BSI DataView utility, users can call up the array for viewing

on the screen. Individual entries can also be edited if this is a read/write array. See

Open BSI Utilities Manual

the

"

Users with Bristol Babcock’s Universal Operator Interface (UOI) software can

configure text-based menus and logs to include data array values. See the

Configuration Manual

"

While running the Open BSI Data Collector or Open BSI Scheduler, users can

retrieve array data, and store it in files for export to third-party HMI applications.

See the

Open BSI Scheduler Manual

Open BSI Collection/Export Utilities Manual

(document# D5074) for details.

(document# D5081) for details.

(document# D5083) and the

(document# D5082), respectively, for details.

UOI

Page 5-8 An Introduction to ACCOL

Page 45

Chapter 6 - What is Process I/O?

What is Process I/O?

Field in strumentation de vices such as fl owmeters, pressure tra nsmitters, and electrical

contacts collect data from a process (such as a pump control station, a compressor

station, a factory assembly line, etc.).

transmitted to the Network 3000 controller. Among the most commonly used process I/O