Page 1

IMPORTANT: Read and understand this manual before assembling or

operating this appliance. Improper use of this appliance can cause

severe injury or death. Keep this manual for future reference.

®

ENGLISH

TELESCOPING ELECTRIC

CHAINSAW/POLESAW

MODELS RPS2N1: 104317, PS1510A

Page 2

2

www.desatech.com

STOP

PARA

ARRÉT

NE RETOURNEZ PAS LE PRODUIT AU DÉTAILLANT

FAITES LE 1 800 626-2237 POUR OBTENIR

DE L’ASSISTANCE TECHNIQUE

Pour plus de détails, visitez le www.desatech.com.

Conservez votre reçu d’achat pour obtenir le service sous garantie

.

C’est un guide pour l’utilisation sécuritaire et correcte de la tronçonneuse.

CONSERVER CES DIRECTIVES

DO NOT RETURN PRODUCT TO STORE.

CALL 1-800-626-2237 FOR TECHNICAL ASSISTANCE

For more information, visit www.desatech.com

This manual is your guide to safe and proper operation of the saw.

SAVE THESE INSTRUCTIONS.

Keep your purchase receipt for warranty coverage.

PARA AYUDA TÉCNICA LLAME AL 1-800-626-2237

NO DEVUELVA EL PRODUCTO A LA TIENDA

Para más información, www.desatech.com

Guarde su recibo de compra para cobertura de la garantía.

Este manual es su guía para utilizar esta sierra eléctrica de

manera adecuada y segura.

GUARDE ESTAS INSTRUCCIONES.

Page 3

ENGLISH

3

www.desatech.com

Contents

IMPORTANT SAFETY INFORMATION................................................................................4

Before Operating Saw ........................................................................................................................4

While Operating Saw ..........................................................................................................................4

Kickback .............................................................................................................................................5

Maintenance and Storage of Saw ......................................................................................................6

Pole Saw Trimming Precautions .......................................................................................................7

UNPACKING.........................................................................................................................7

PRODUCT IDENTIFICATION ..............................................................................................8

CHAIN SAW TERMS AND DEFINITIONS ...........................................................................9

CHAIN SAW INFORMATION .............................................................................................10

Chain Saw Hardware .......................................................................................................................10

Chain Saw Assembly ........................................................................................................................10

Saw Chain Tension Adjustment ........................................................................................................11

Extension Cords ...............................................................................................................................12

Filling Oil Tank ..................................................................................................................................12

Oiling Chain ......................................................................................................................................12

Cutting withe the Chain Saw ............................................................................................................12

Felling a Tree ....................................................................................................................................13

Limbing a Tree ..................................................................................................................................15

Bucking a Log ...................................................................................................................................15

Trimming a Tree (Pruning) ................................................................................................................16

POLE SAW INFORMATION ..............................................................................................17

Pole Saw Assembly ..........................................................................................................................17

Adjusting Pole Length ......................................................................................................................18

Cutting with the Pole Saw ................................................................................................................18

CLEANING AND MAINTENANCE ....................................................................................19

Cleaning Saw Body ..........................................................................................................................19

Care of Guide Bar ............................................................................................................................19

Sharpening Saw Chain .....................................................................................................................20

Replacement Chain ..........................................................................................................................21

STORAGE ..........................................................................................................................21

TECHNICAL SERVICE ......................................................................................................21

REPLACEMENT PART AND ACCESSORIES ..................................................................21

TROUBLESHOOTING .......................................................................................................22

REPAIR SERVICE .............................................................................................................22

WARRANTY INFORMATION .............................................................................................23

ILLUSTRATED PARTS BREADOWN / PARTS LISTS .....................................................72

RPS2N1: 104317, PS1510A ............................................................................................................72

Chain Saw ........................................................................................................................................73

PARTS CENTRALS ...........................................................................................................75

INTRODUCTION

Your Remington Telescoping Pole Saw is a dual purpose product. The electric chain saw is a separate

operating unit when not assembled to the telescoping pole. Before operating either the chain saw or

the pole saw, make certain you read and understand all Important Safety Information.

Page 4

4

www.desatech.com

IMPORTANT SAFETY INFORMATION

BEFORE OPERATING SAW

1. Read and understand this owner’s manual

before operating saw.

2. Watch what you are doing. Use common sense.

Do not operate saw when you are tired.

3. Use saw for cutting wood only.

• Do not use chain saw for purpose not in-

tended.

• Do not use for cutting non-wood items.

4. Only well-instructed adults should operate saw.

Never allow children to operate saw.

5. Use only electrical voltage noted on model

plate of saw.

6. Use only extension cords marked for outdoor

use. See page 21 for extension cord requirements.

7. Do not operate saw

• while under the influence of alcohol, medica

-

tion, or drugs

• in rain or in damp or wet areas

• where highly flammable liquids or gases are

present

• if pole or saw is damaged, adjusted wrong, or

not fully and securely assembled

• if trigger does not turn saw on and off. Chain

must stop moving when you release trigger.

Have faulty switch replaced by authorized

service center (see Technical Service, page

21).

• while in a hurry

• while in tree or on a ladder

• while on aerial booms, buckets, or platforms

8. Wear snug-fitting clothes when operating chain

saw. Do not wear loose clothing or jewelry.

They can get caught in moving saw chain.

9. Wear the following safety gear when operating

saw:

READ ALL INSTRUCTIONS

Make sure you read and understand all

instructions in Important Safety Infor-

mation on pages 4 through 7. Improper

use of this chain saw can cause severe

injury or death from fire, electrical shock,

body contact with moving chain, or falling wood.

WARNING: When using an electric

chain saw, basic safety precautions

should always be followed to reduce

the risk of fire, electric shock, and injury

to persons, including the following:

• heavy-duty gloves (wear rubber gloves when

working outdoors)

• steel-toed safety footwear with non-skid

soles

• e ye protec tion such as safety glasses,

goggles, or face screen

• safety hard hat

• ear mufflers or ear plugs

• hair covering to contain long hair

• face or dust mask (if working in dusty ar

-

eas)

10. Before cutting, always provide the follow

-

ing:

• clear work area

• secure footing

• planned retreat path from falling limbs

11. Insp ect tree befo re trimmi ng or cutting

down. Make sure there are no dead limbs or

branches that may fall on you. Make allowance for branches to fall freely to the ground.

12. Do not use pole saw to fell saplings. Use

the chain saw withou t pole att achme nt.

13. To reduce the risk of electric shock, this

saw has a polarized plug (one blade is wider

than the other). This plug will fit in a polar

ized outlet only one way. If the plug does

not fit fully in the outlet of your extension

cord, reverse the plug. If it still does not fit,

a polarized extension cord will be necessary. Do not change the plug in any way.

1. Stay alert. Use common sense while operating

saw.

2. Keep work area clean. Cluttered areas invite

injuries.

3. Be aware of extension cord while operating

chain saw. Be careful not to trip over cord.

Keep cord away from chain and operator at

all times.

4. Keep children, animals, and bystanders away

from chain saw and extension cord. Only chain

saw user should be in work area.

5. Do not use the pole saw to cut down trees. Use

the chain saw without pole attachment and

only if you are trained or have expert help.

6. Do not use near power lines. Keep at least 10

feet away from electrical lines.

7. If two or more persons perform bucking and

felling operations at the same time, provide

plenty of distance between operations. Provide

distance of at least twice the height of tree being

felled.

8. Secure wood you are cutting by using clamps

or chocks.

WHILE OPERATING SAW

Page 5

ENGLISH

5

www.desatech.com

IMPORTANT SAFETY INFORMATION

WARNING: Some dust created by

power sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known (to the state

of California) to cause cancer, birth de

fects, or other reproductive harm. Some

examples of these chemicals are:

• lead from lead-based paints

• crystalline silica from bricks and ce

-

ment and other masonry products

• arsenic and chromium from chemi

-

cally-treated lumber

Your risk from these exposures varies,

depending on how often you do this

type of work. To reduce your exposure

to these chemicals: work in a well ventilated area, and work with approved safety

equipment, such as those dust masks

that are specially designed to filter out

microscopic particles.

WARNING: This product contains

chemicals known to the State of Cali

fornia to cause cancer or birth defects,

or other reproductive harm.

9. Grip chain saw firmly with both hands. Never

operate chain saw with one hand. Never use

hand guard as handle.

10. Grip pole saw securely. Place one hand on the

pole and the other on the handle.

11. Keep finger off trigger until ready to make

cut.

12. Before starting chain saw, make sure chain is

not touching anything.

13. To guard against electrical shock, avoid body

contact with grounded objects such as pipes,

fences, and metal posts.

14. Keep all parts of body away from chain when

saw is running.

15. Do not force saw while cutting. Apply light

pressure. It will do the job better and safer at

the rate for which it was intended.

16. Do not cut small brush and saplings with the

pole saw. Use the chain saw only, with extreme

care. Slender matter may catch in the chain and

be whipped toward you. This could also pull

you off balance.

17. When cutting limb or tree trunk that is under

tension, use extreme caution. Be alert for

wood springing back. When wood tension is

released, limb could spring back and strike

operator causing severe injury or death.

18. Carry saw from one place to another

• with saw stopped and unplugged

• Chain saw - by holding front handle (never

use hand guard as handle)

• Pole saw - with telescoping pole returned to

shortest position

• Pole saw - by holding the pole at the balance

point (close to saw end)

• with finger off trigger

• with guide bar and chain to rear

WARNING: Kickback may occur when

the nose or tip of the guide bar touches

an object, or when the wood closes in

and pinches the saw chain in the cut.

Tip contact in some cases may cause a

lightning fast reverse reaction, kicking the

guide bar up and back towards the operator. Pinching the saw chain along the top

of the guide bar may push the guide bar

rapidly back towards the operator. Either

of these reactions may cause you to lose

control of the saw which could result in

serious injury to user.

KICKBACK

This saw has a low-kickback chain and reduced

kickback guide bar. Both items reduce the chance

of kickback. Kickback can still occur with this

saw.

Follow assembly instructions on page 10. Do not

remove front hand guard. Do not replace front

hand guard with substitute.

The following steps will reduce the risk of kickback:

• Use both hands to grip saw while saw is

running

KICKBACK SAFETY DEVICES ON

THIS SAW

Page 6

6

www.desatech.com

IMPORTANT SAFETY INFORMATION

Saw Maintenance and Kickback

Safety

1. Unplug saw from power source:

• when not in use

• before moving from one place to an

other

• before servicing

• before changing accessories or attachments,

such as saw chain and guard

2. Inspect saw before and after each use. Check

saw closely if guard or other part has been damaged. Check for any damage that may affect

operator safety or operation of saw. Check for

alignment or binding of moving parts. Check

for broken or damaged parts. Do not use saw

if damage affects safety or operation. Have

damage repaired by authorized service center.

3. Maintain saw with care:

• Never expose saw to rain.

• Keep chain sharp, clean, and lubricated

for better and safer performance.

• Follow steps outlined in this manual to

sharpen chain.

• Keep handles dry, clean, and free of oil

and grease.

• Keep all screws and nuts tight.

• Inspect power cord often. If damaged,

have repaired by authorized service cen

ter.

• Never carry saw by power cord.

• Never yank power cord to unplug it.

• K

eep power cord from heat, oil, and sharp

edges.

• Inspect extension cords often and re

place if damaged.

4. When servicing, use only identical replace

-

ment parts.

5. When not in use, always store saw:

• in a high or locked place, out of children’s

reach

• in a dry place

• in a carrying case or with scabbard over guide

bar

• drain oil after each use and before storing saw

to prevent oil leakage.

Save these instructions. It is your guide to safe

and proper operation of this saw.

MAINTENANCE AND STORAGE OF

SAW

• For chain saw, use firm grip. Thumbs and

fingers must wrap around saw handles.

• For pole saw, have one hand gripping the

handle and the other gripping the pole. Use

firm grip. Thumbs and fingers must wrap

around pole and handle.

• Use both hands to grip saw while saw is

running. Use firm grip. Thumbs and fingers

must wrap around saw handles.

• Keep all safety items in place on saw. Make

sure they work properly.

• Chain saw - do not overreach or cut above

shoulder height.

• Pole saw - do not overreach or extend arms

above shoulder height.

• K eep solid footin g and balance at all

times.

• Stand slightly to left side of saw. This keeps

your body from being in direct line with

chain.

• Do not let guide bar nose touch anything

when chain is moving (see Figure 1).

• Never try cutting through two branches at

same time. Only cut one log at a time.

• Do not bury guide bar nose or try plunge cut

(boring into wood using guide bar nose).

• Watch for shifting of wood or other forces

that may pinch chain.

• Use extreme caution when reentering a previous

cut.

• Use low-kickback chain and guide bar sup

plied with this chain saw. Only replace these

parts with chains and guide bars listed in this

manual.

• Never use dull or loose chain. Keep chain

sharp with proper tension.

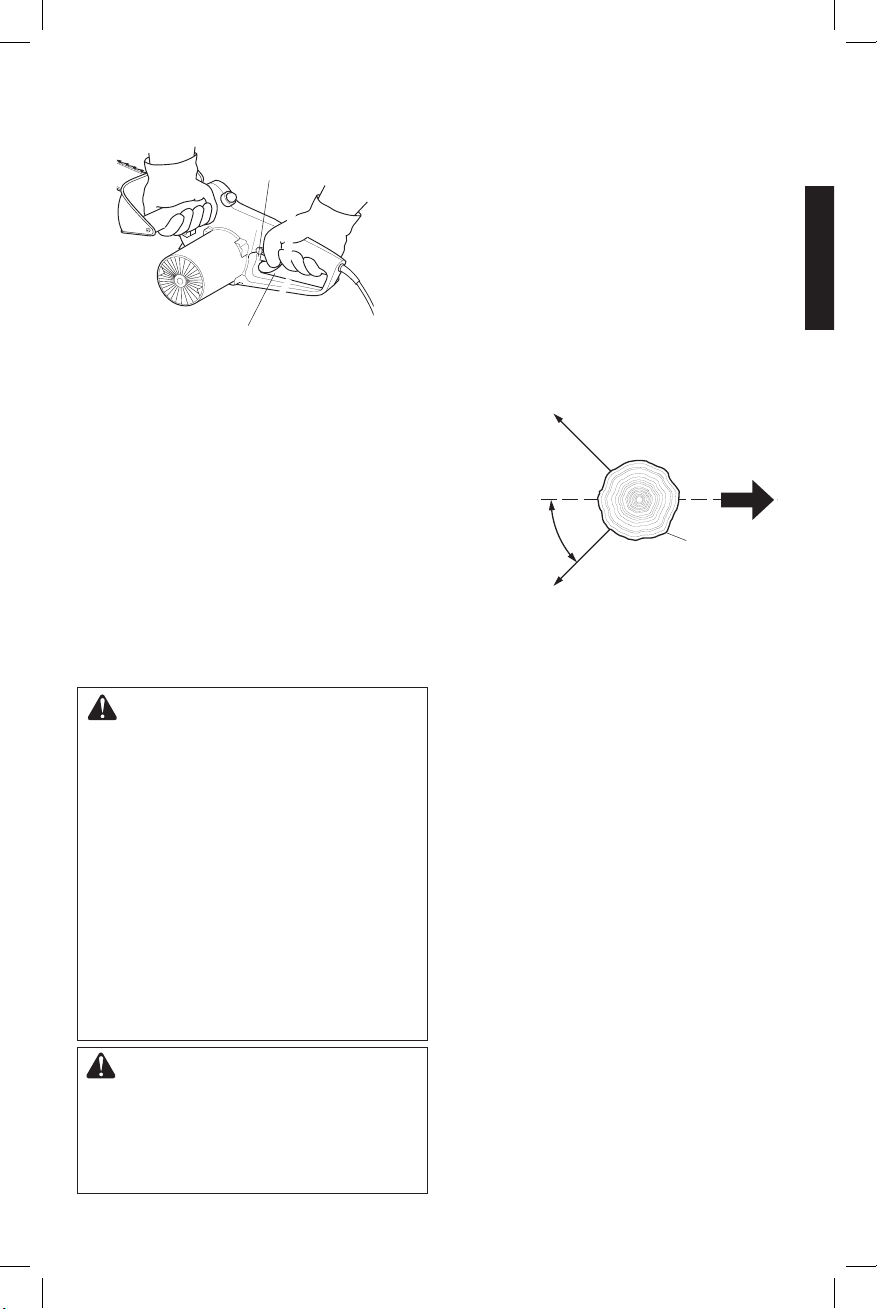

Figure 1 - Kickback Hazard Example: Do Not

Let Nose of Guide Bar Touch Object While

Chain is Moving

90°

Do Not Let

Guide Bar

Touch Here

Follow maintenance instructions in this manual.

Proper cleaning of saw and chain and guide bar

maintenance can reduce chances of kickback.

Inspect and maintain saw after each use. This will

increase the service life of your saw.

Note: Even with proper sharpening, risk of kickback can increase with each sharpening.

Direction

Page 7

ENGLISH

7

www.desatech.com

IMPORTANT SAFETY INFORMATION

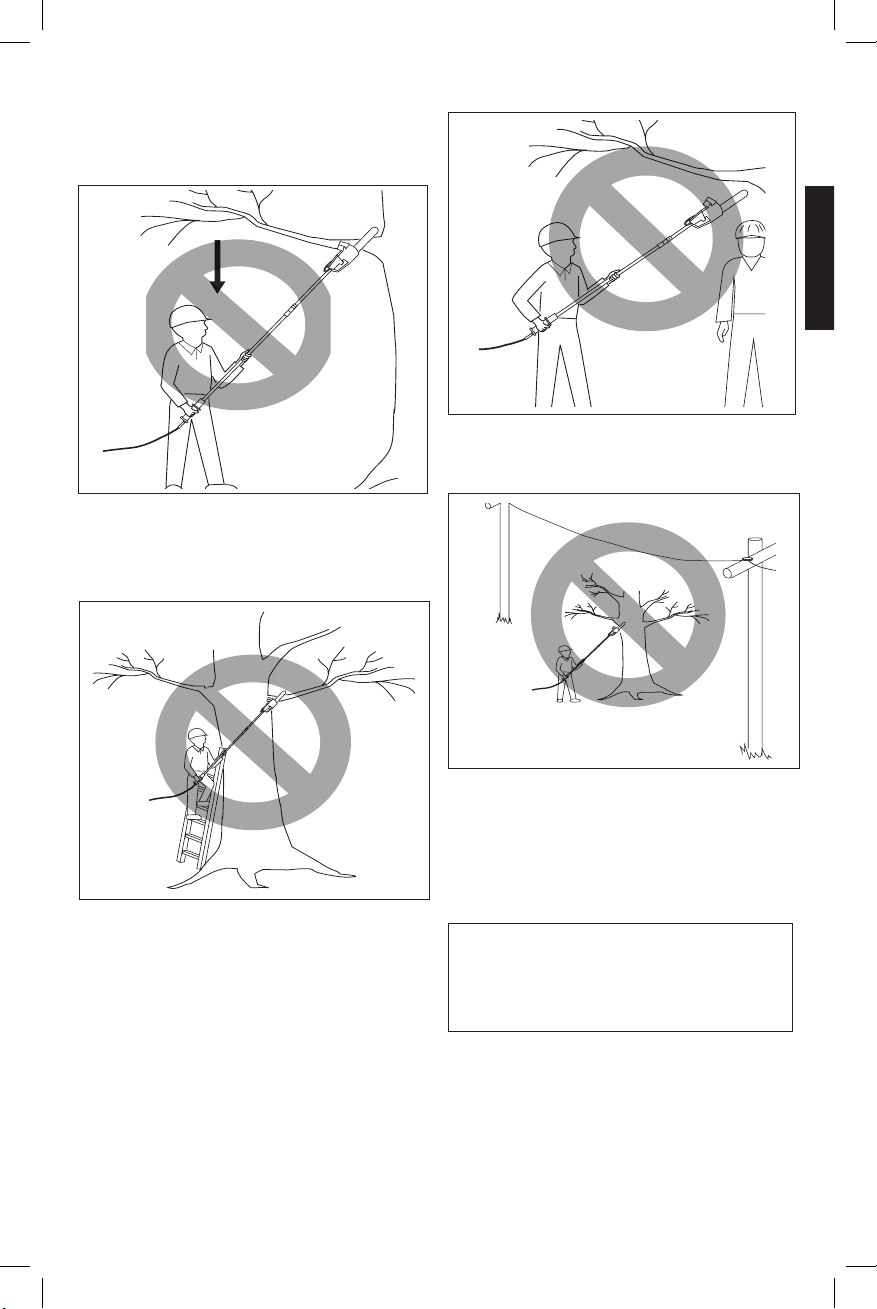

POLE SAW TRIMMING

PRECAUTIONS

Never stand on a ladder or other type of

unstable support while using the pole

saw.

Always use both hands to operate pole

saw. Keep a firm, steady pressure on the

pole saw while cutting but do not try to

force the saw through the wood.

Never stand directly under the limb you

are trimming. Always position yourself out

of the path of falling debris.

Do not use the pole saw to cut limbs

larger in diameter than the length of the

guide bar.

Keep other persons away from cutting end

of pole saw and at a safe distance from

work area.

Do not use pole saw near cable, electric

power or telephone lines. Maintain a minimum clearance of 10 feet from all power

lines.

IMPORTANT: Read and understand this

manual before assembling or operating

this chain saw. Improper use of saw can

cause severe injury. Keep this manual

for future reference.

UNPACKING

1. Remove all items from carton.

2. Check all items for any shipping damage. If

you find any damage or if any parts are missing,

promptly inform dealer where you bought chain

saw.

Page 8

8

www.desatech.com

Rear

Handle

Power

Cord

Front Hand

Guard

Guide Bar

Rear Hand

Guard

Saw

Chain

Guide Bar Nose

Scabbard

Oil Cap With Squeeze

Bulb

Trigger

Trigger

Lockout

Motor Housing

Oil Level Sight Hole (located on

left side of saw body, between

front handle and front hand

guard)

Front

Handle

Spike

Sprocket

Cover

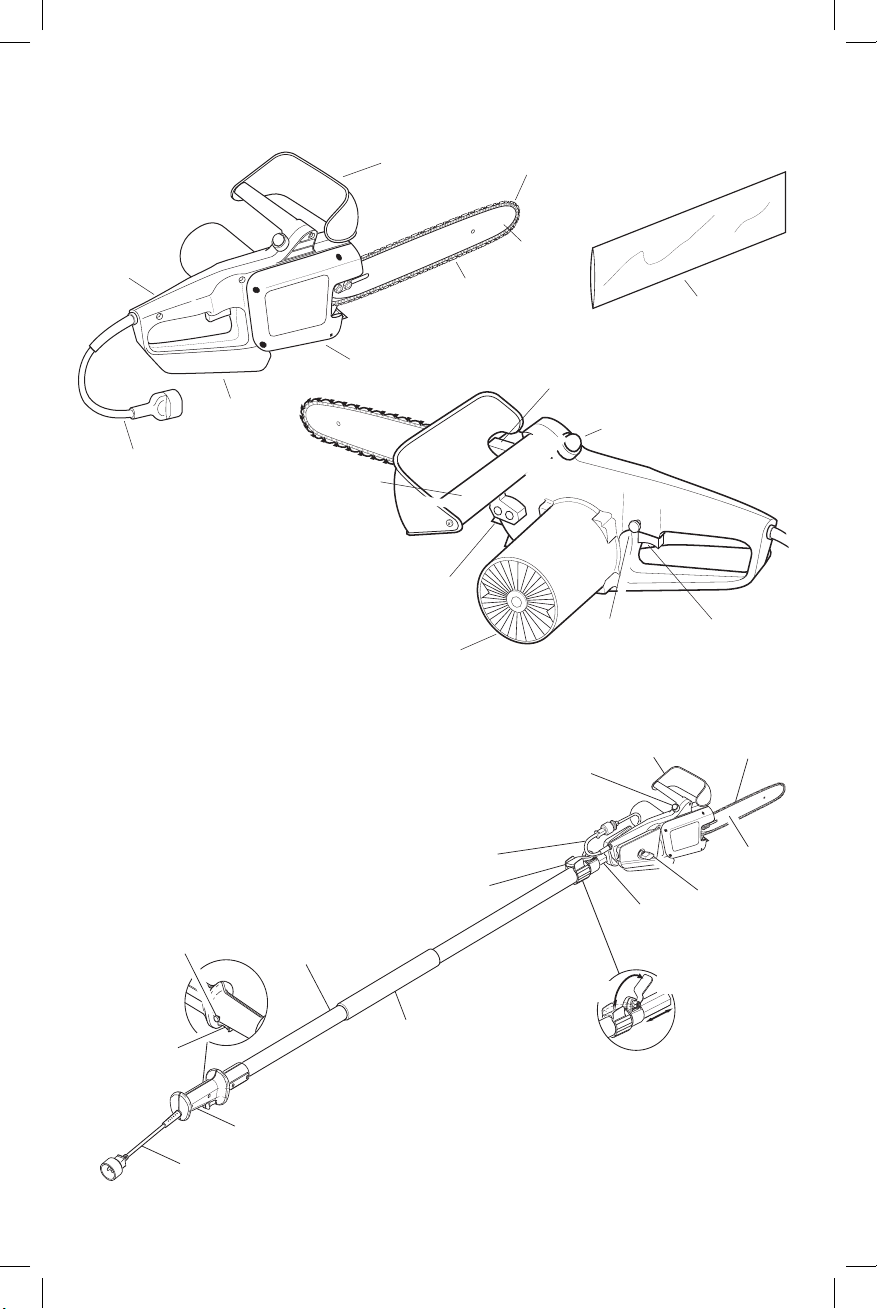

PRODUCT IDENTIFICATION

CHAIN SAW - ALL MODELS

Saw

Chain

Hand Guard

Guide Bar

Oil Cap

Power Cord

Clamping

Lever

Outer Pole

Trigger

Lockout

Power

Cord

Grip

Area

Trigger

Tighten

Loosen

Pole Bracket,

Lock Washer,

Adjustment

Knob

Handle

Inner Pole

POLESAW

MODELS: 104317, PS1510A

Page 9

ENGLISH

9

www.desatech.com

CHAIN SAW TERMS AND DEFINITIONS

Bucking Process of cutting a felled tree or log

into lengths.

Clamping Lever

Lever is loosened to allow

inner pole to be adjustd and tighted to hole pole

in position.

Felling Process of cutting down a tree.

Felling Cut

Final cut when felling a tree. Make

this cut on opposite side of tree from notching

cut.

Front Handle Located at front of saw body.

Front Hand Guard Shield between front

handle and guide bar. Protects left hand while

using saw.

Guide Bar Metal bar that extends from saw

body. The guide bar supports and guides chain.

Guide Bar Nose Tip or end of guide bar.

Inner Pole

The moveable section of tubing to

which the saw is attached.

Kickback Quick backward and upward motion

of guide bar. Kickback may occur when tip of

guide bar touches an object while chain is moving. The guide bar will kick up and back towards

operator.

Limbing Process of cutting limb(s) from a

felled tree.

Low-Kickback Chain

Chain that reduces chance

of kickback as required by ANSI B175.1.

Normal Cutting Position

Stance used while

making bucking and felling cuts.

Notching Cut

Notch cut in tree that directs

fall of tree.

Oiler Control

System for oiling guide bar and

chain.

Outer Pole

Retains the moveable inner pole.

Power Head

Chain saw without chain and guide

bar. Also known as saw body.

Pushback (Kickback, Pinch)

Rapid pushback

of chain saw. Pushback may occur if chain along

top of guide bar is pinched, caught, or contacts a

foreign object.

Rear Handle

Handle located at rear of saw

body.

Reduced Kickback Guide Bar

Guide bar that

reduces chance of kickback.

Replacement Chain

Chain that complies with

ANSI B175.1 when used with a specific saw. It

may not meet ANSI requirements when used with

other saws.

Saw Chain (Chain)

Loop of chain having

cutting teeth for cutting wood. The motor drives

chain. The guide bar supports chain.

Spiked Bumper (Spike) Pointed teeth at front

of saw body beside guide bar. Keep spiked bumper

in contact with wood when felling or bucking. It

helps maintain position of saw while cutting.

Sprocket Toothed wheel that drives chain.

Switch Device that completes or interrupts

electrical circuit to motor of saw.

Switch Linkage This device connects switch

to trigger. It moves switch when you squeeze

trigger.

Trigger Switch Lockout

Device that reduces

accidental starting of saw.

Trigger

Device that turns saw on and off. Squeezing trigger turns saw on. Releasing trigger turns

saw off.

Trimming (Pruning)

Process of cutting limb(s)

from a living tree.

Undercut An upward cut from underside of log

or limb. This is done while in normal cutting position and cutting with top of guide bar.

Page 10

10

www.desatech.com

CHAIN SAW INFORMATION

The plastic hardware bags should include the

following:

• (2) Guidebar bolts

• (2) Guidebar nuts

• (1) Phillips self tapping screw

• (1) Saw chain

• (1) Guide bar

• (1) Hand guard

• (1) Scabbard

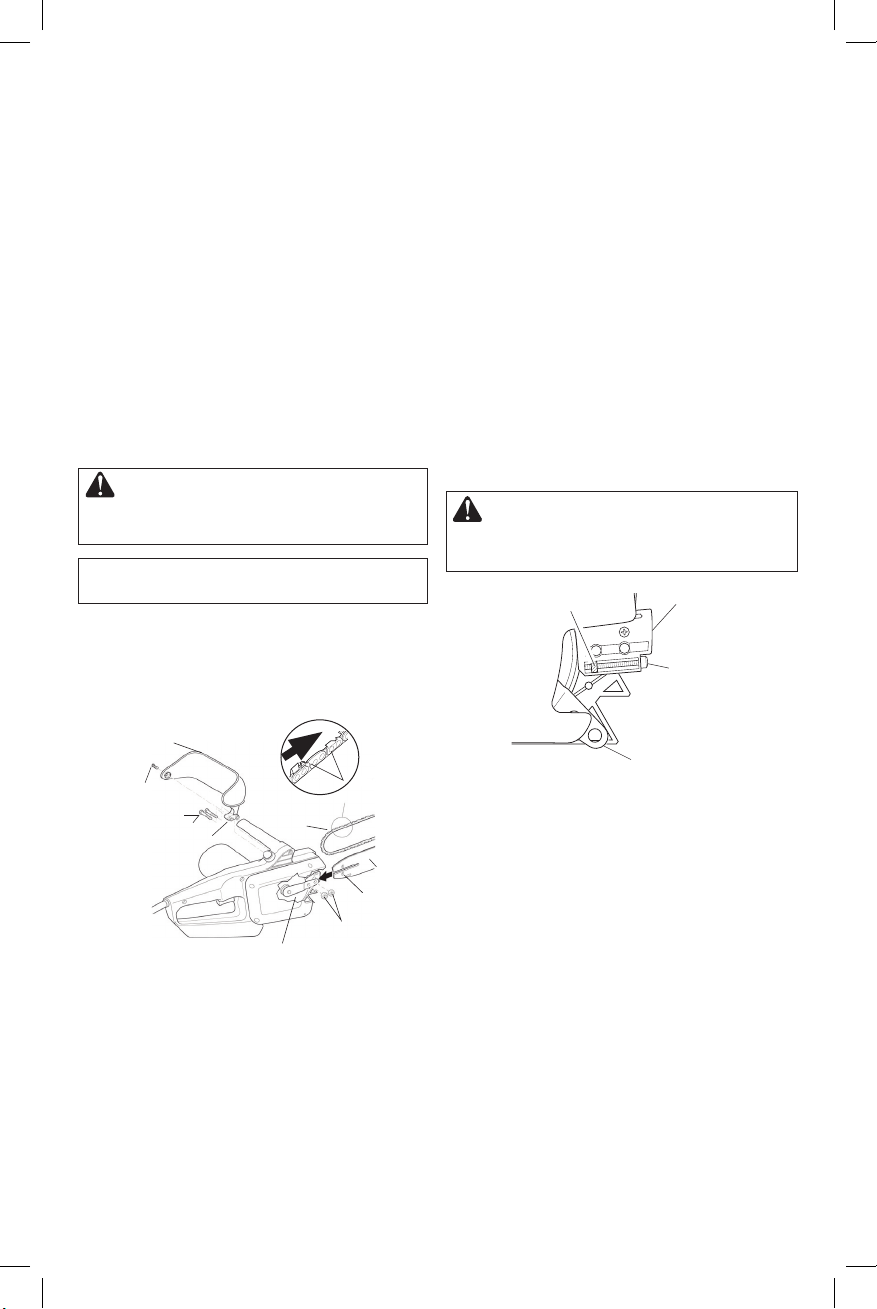

1. Lay chain out flat.

2. Install front hand guard onto saw body. Do this

by pressing two mounting stand-outs on hand

guard into hex-shaped holes in saw body (see

Figure 2).

WARNING: Cutting edges on chain

are sharp. Use protective gloves when

handling chain.

IMPORTANT: Do not clamp chain saw in

vise during assembly.

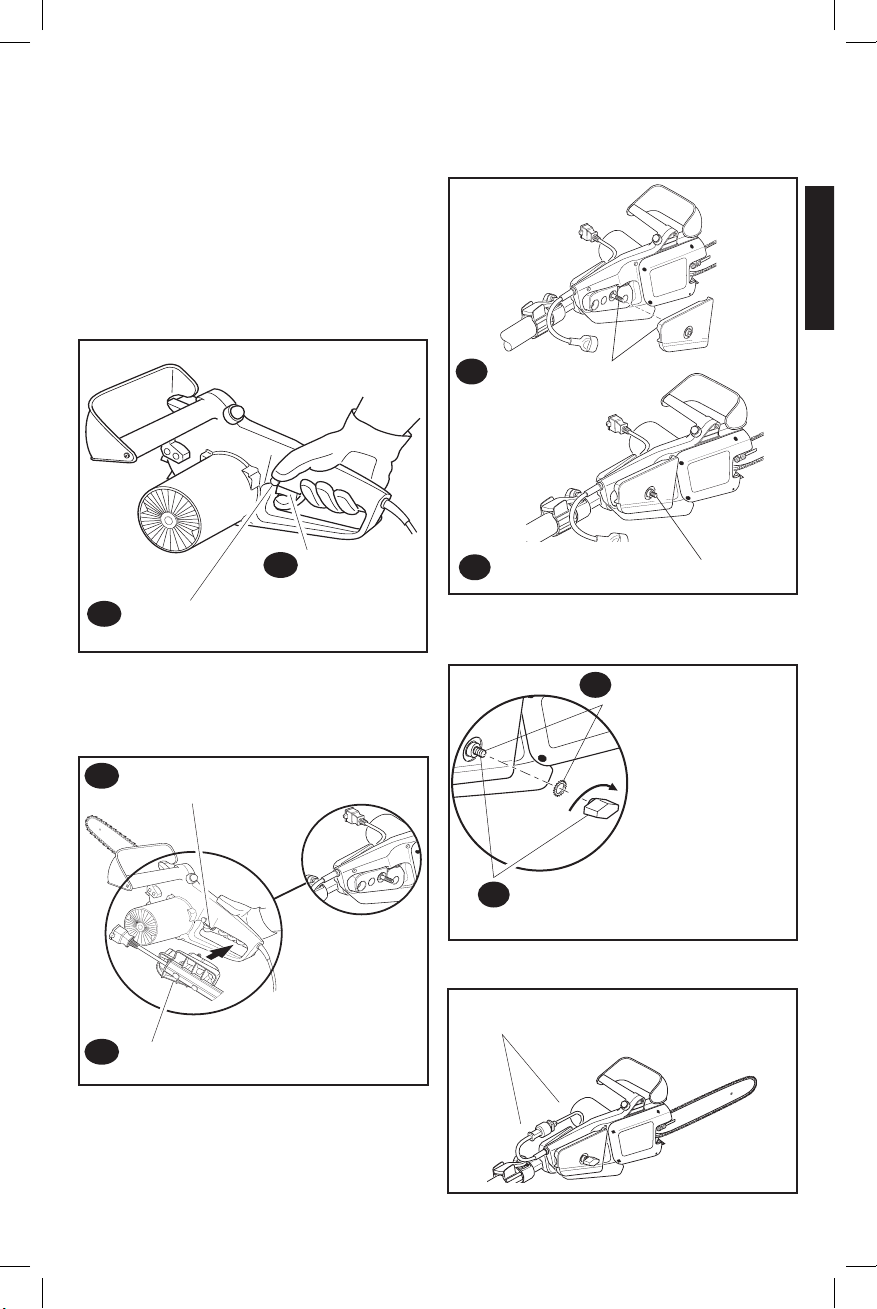

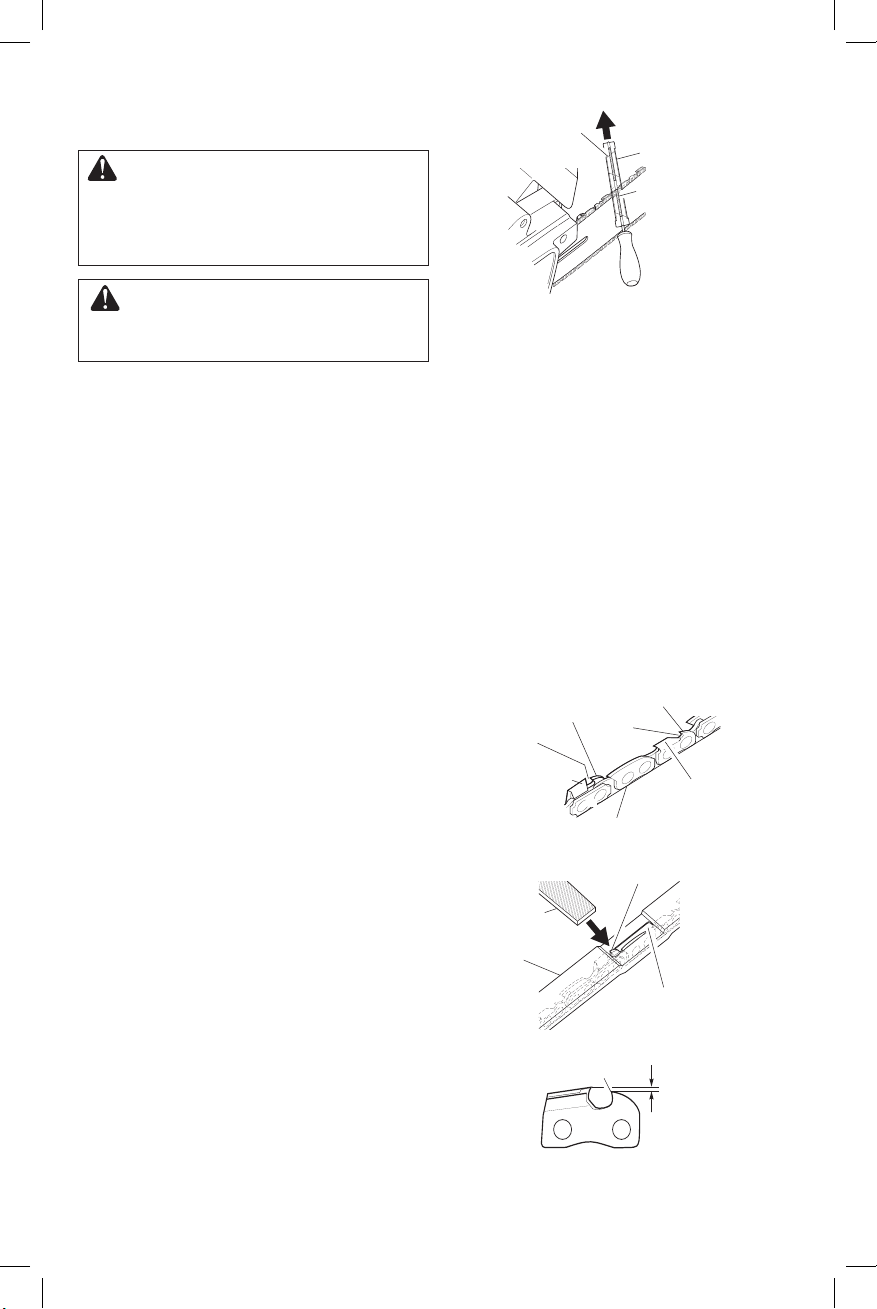

Figure 2 - Assembling Guide Bar, Chain, and

Hand Guard

Figure 3 - Part Locations For Assembling Guide

Bar

Adjusting

Plate

Adjusting Block

Sprocket Support

Adjusting Screw

CAUTION: Do not place chain on saw

backwards. If chain is backwards, saw will

vibrate badly and will not cut.

CHAIN SAW HARDWARE

Assemble the chain saw before assembling the

pole.

Note: Some models are pre-assembled. Assembly

is not needed on these models.

See Saw Chain Tension Adjustment, page 11.

CHAIN SAW ASSEMBLY

3 Insert tapping screw through hand guard and

into saw handle. Tighten screw firmly.

4. Turn adjusting screw counterclockwise (see

Figure 3). Continue to turn adjusting screw

until adjusting block is to rear of adjusting

plate.

5. Install guide bar onto saw body. Place rear of

guide bar between adjusting plate and sprocket

support.

Guide Bar Nuts

Guide Bar

Bolts

Saw

Chain

Guide

Bar

Drive Sprocket

Adjusting

Hole

Mounting

Stand-Outs

Tapping

Screw

Front Hand Guard

Cutting Edge

Towards Guide Bar Nose

IMPORTANT: Make sure to insert adjusting

block into oval adjusting hole on guide bar.

6. Line up holes on sprocket support with center

slot on guide bar and holes in saw body.

7. Insert guide bar bolts through front hand guard,

saw body, center slot of guide bar, and sprocket

support. Attach guide bar nuts to guide bar

bolts.

IMPORTANT: Tighten guide bar nuts finger

tight only. Make sure adjusting block is in oval

adjusting hole on guide bar.

8. Place chain around drive sprocket, then along

top groove of guide bar and around guide bar

nose. Note: Make sure cutting edges of chain

are facing the right direction. Position chain

so cutting edges on top of guide bar face guide

bar nose (see Figure 2).

9. Adjust saw chain tension. Follow steps under

Saw Chain Tension Adjustment, page 11.

Page 11

ENGLISH

11

www.desatech.com

CHAIN SAW INFORMATION

Note: For pre-assembled models, the saw chain

tension is properly set at factory. A new chain will

stretch. Check new chain after first few minutes of

operation. Allow chain to cool down. Follow steps

below to readjust saw chain tension.

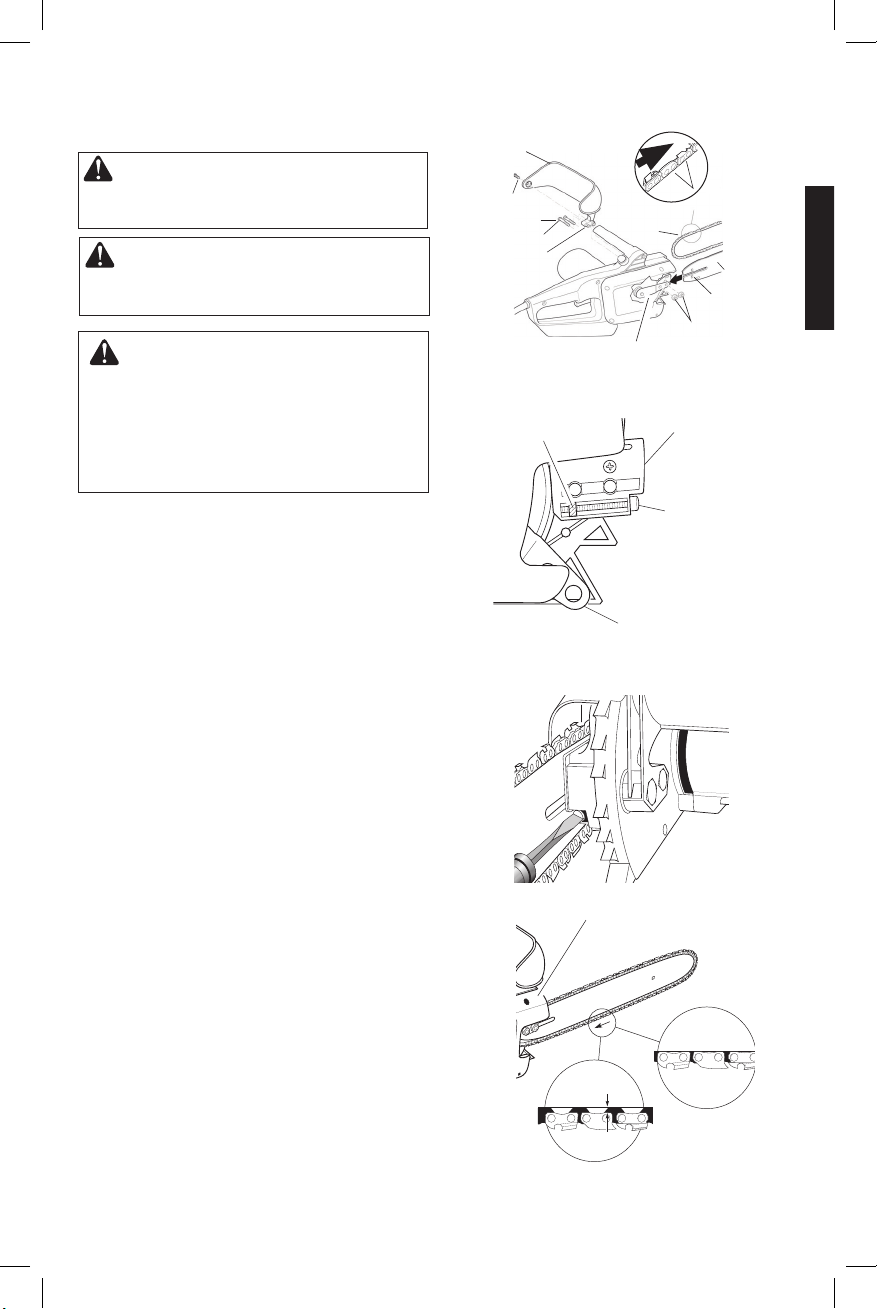

1. Before adjusting chain, make sure guide bar

nuts are only finger tight (see Figure 4). Also

make sure adjusting block is in oval adjusting

hole on guide bar (see Figures 4 and 5).

2. Turn adjusting screw clockwise. (see Figure

6). Note: There should be no gap between side

links of chain and bottom of guide bar (see

Figure 7).

3. Wearing protective gloves, move chain around

guide bar. Chain should move freely. If chain

does not move freely, loosen chain by turning

adjusting screw counterclockwise.

4. After chain tension is correct, tighten guide

bar nuts firmly. If not, guide bar will move and

loosen chain tension. This will increase the risk

of kickback. This can also damage saw. Note: A

new chain will stretch. Check new chain after

first few minutes of operation. Allow chain to

cool down. Read just chain tension.

SAW CHAIN TENSION ADJUSTMENT

WARNING: Unplug chain saw from

power source before adjusting saw chain

tension.

WARNING: Cutting edges on chain

are sharp. Use protective gloves when

handling chain.

WARNING: Maintain proper chain

tension always. A loose chain will in

crease the risk of kickback. A loose chain

may jump out of guide bar groove. This

may injure operator and damage chain. A

loose chain will cause chain, guide bar,

and sprocket to wear rapidly.

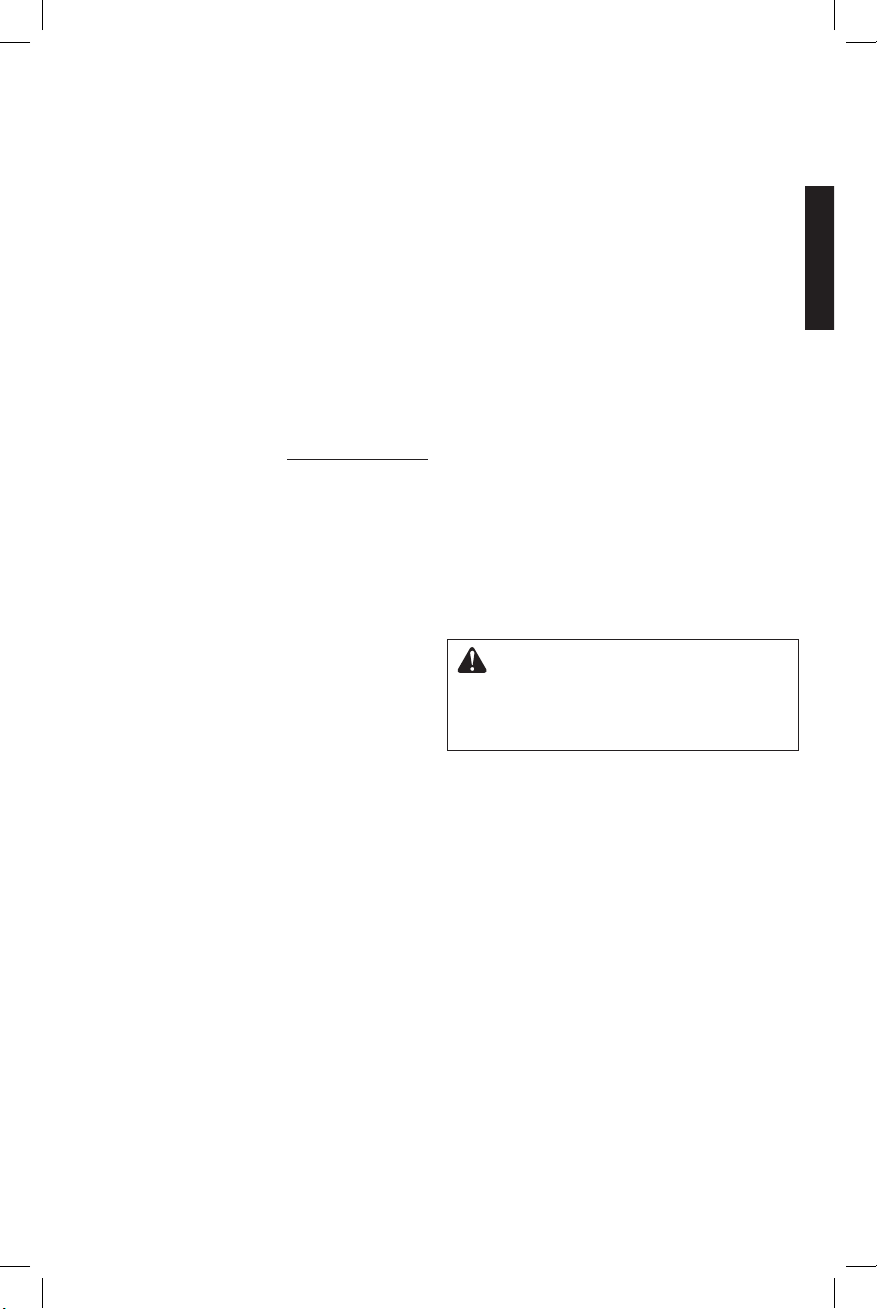

Figure 6 - Turning Adjusting Screw

Figure 5 - Part Locations For Assembling

Guide Bar

Adjusting Plate

Adjusting Block

Sprocket Support

Adjusting

Screw

Figure 7 - Saw Chain Adjustment

Guide Bar

Correct

Tension

Guide Bar

Incorrect

Tension

Guide Bar Nuts

Gap

Figure 4 - Assembling Guide Bar, Chain, and

Hand Guard

Guide Bar Nuts

Guide Bar

Bolts

Saw Chain

Guide Bar

Drive Sprocket

Adjusting

Hole

Mounting

Stand-Outs

Tapping

Screw

Cutting Edge

Towards Guide Bar Nose

Front Hand Guard

Page 12

12

www.desatech.com

CHAIN SAW INFORMATION

1. Remove oil cap.

2. Fill oil tank with SAE #30 motor oil.

Note:

For temperatures below 30°F, use SAE #10 oil.

For temperatures above 75°F, use SAE #40 oil.

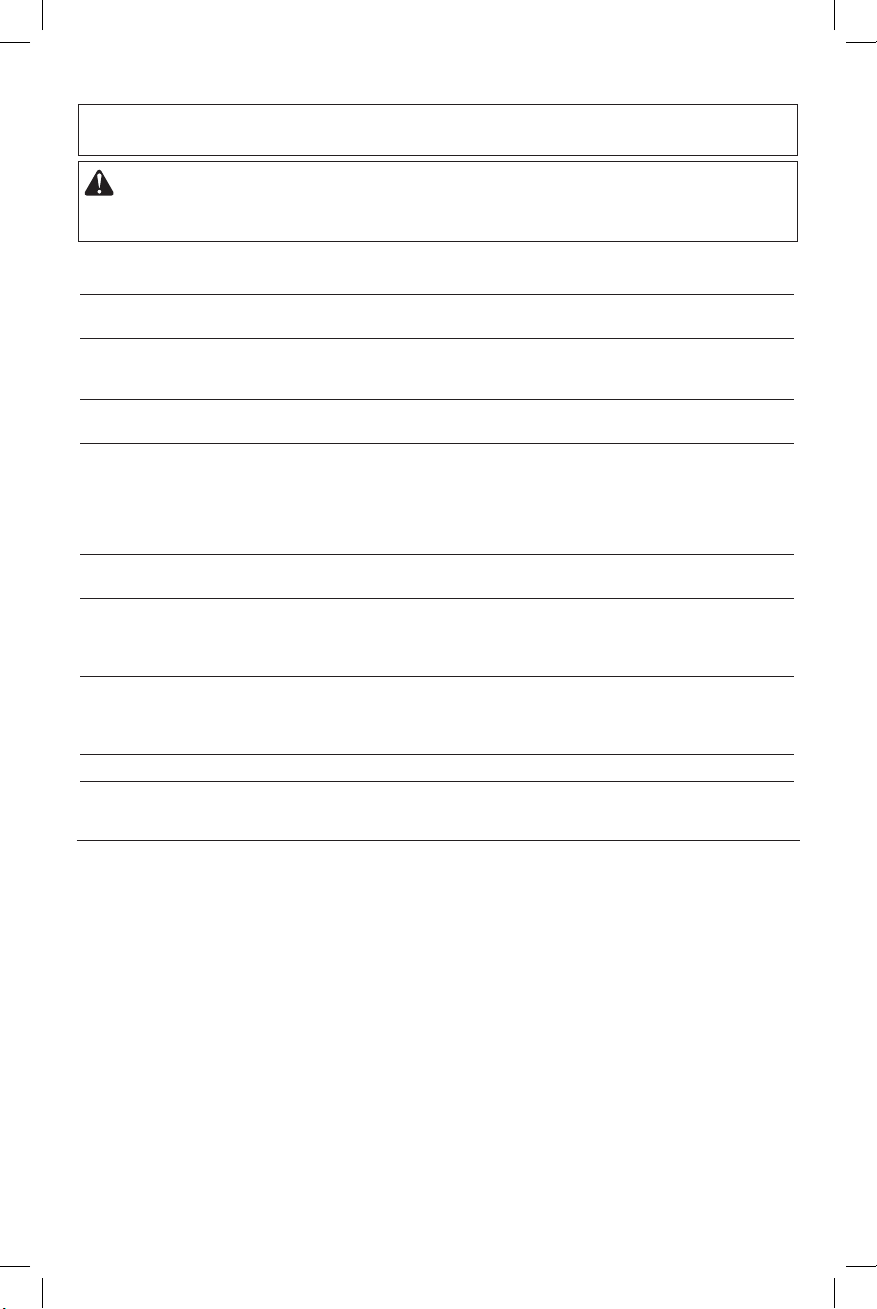

Figure 8 - Tying Extension Cord and Power

Cord in Knot

Figure 9 - Pressing Squeeze Bulb on Oil Cap

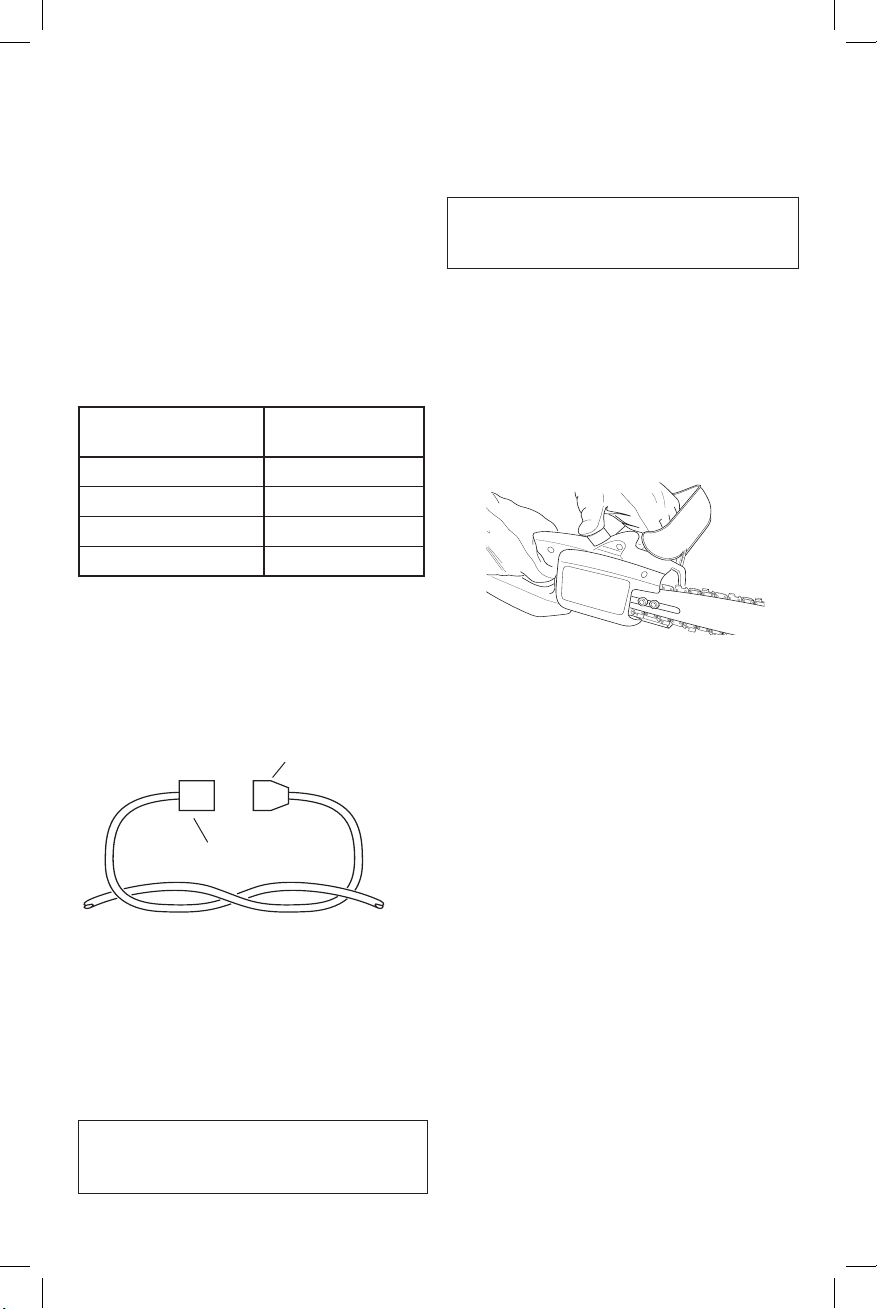

to Oil Chain

Always check oil level before using saw. Do not

attempt to operate the oil system while saw is

in operation. To oil chain, press squeeze bulb.

Oil will feed onto the guide bar and chain. Press

squeeze bulb at least once before each cut (see

Figure 9). Check oil level often by looking at

oil sight level hole. Oil sight level hole is on left

side of saw, between front handle and front hand

guard.

3. Replace oil cap at once. Tighten oil cap firmly

for good seal. This will minimize oil seepage

from tank.

4. Wipe off excess oil.

IMPORTANT: Do not use "bar and

chain" oil. It is too thick and may not

oil properly.

Note: It is normal for oil to seep when saw

is not in use. Empty oil tank after each

use to prevent seepage.

Keep cord away from cutting area. Make sure cord

does not catch on branches or logs during cutting.

Inspect cords often. Replace damaged cords.

The extension cord may come undone from the

power cord during use. To avoid this, make a knot

with the two cords as shown in Figure 8.

FILLING OIL TANK

OILING CHAIN

1. Connect saw to extension cord. Connect extension cord to power supply.

2. Make sure section of log to be cut is not laying

on ground. This will keep chain from touching

ground as it cuts through log. Touching ground

with moving chain will dull chain.

3.

Use both hands to grip saw. Always use left

hand to grip front handle and right hand to grip

rear handle. Use firm grip. Thumbs and fingers

must wrap around saw handles (see Figure 10,

page 13).

4. Make sure your footing is firm. Keep feet

apart. Divide your weight evenly on both

feet.

5. When ready to make a cut, press in trigger

lockout with right thumb and squeeze trigger

(see Figure 10, page 13). This will turn saw

on. Releasing trigger will turn saw off. Make

sure saw is running at full speed before starting

a cut.

6. When starting a cut, place moving chain

against wood. Hold saw firmly in place to

avoid possible bouncing or skating (sideways

movement) of saw.

CUTTING WITH THE CHAIN SAW

Chain Saw Power Cord

Extension Cord

Use proper extension cords with this saw. Use

only extension cords marked for outdoor use.

The cord must be marked with suffix W or W-A

following the cord type designation. Example:

SJTW-A or SJTW.

Use proper sized cord with this saw. Cord must

be heavy enough to carry current needed. An

undersized cord will cause voltage drop at saw.

Saw will lose power and overheat. Follow cord

size requirements listed below.

EXTENSION CORDS

Cord

Length

AWG Cord

Size

25 feet 16 AWG

50 feet 16 AWG

100 feet 16 AWG

150 feet 14 AWG

Page 13

ENGLISH

13

www.desatech.com

Fig ure 10 - Trigger Lockout and Trigger

Location

Trigger

Trigger

Lockout

7. Guide saw using light pressure. Do not force

saw. The motor will overload and can burn out.

It will do the job better and safer at the rate for

which it was intended.

8. Remove saw from a cut with saw running

at full speed. Stop saw by releasing trigger.

Make sure chain has stopped before setting

saw down.

9. Practice until you can maintain a steady, even

cutting rate.

WARNING:

• Avoid kickback. Kickback can re

sult in severe injury or death. See

Kickback, page 5, to avoid risk of

kickback.

•

Do not fell a tree without ample skill

or expert help.

• Keep children, animals, and bystanders away from area when felling a

tree.

•

If two or more persons perform bucking and felling operations at the same

time, provide ample distance between

operations. Provide distance of at

least twice the height of tree being

felled.

FELLING A TREE

(Cutting Down a Tree)

WARNING: When felling a tree, be

aware of your surroundings. Do not

endanger any person, strike utility lines,

or cause property damage. If tree strikes

utility lines, contact utility company at

once.

Felling is the process of cutting down a tree. Make

sure your footing is firm. Keep feet apart. Divide

your weight evenly on both feet. Follow directions

below to fell a tree.

BEFORE FELLING A TREE

1. Before felling, inspect tree. Make sure there

are no dead limbs or branches that may fall

on you. Study natural lean of tree, location of

larger branches, and wind direction. This will

help you judge which way tree will fall.

2. Clear work area around tree.

3. Plan and clear a retreat path before felling.

Make retreat path opposite to planned direction

of fall of tree and at 45° angle

(see Figure 11 ).

Direction of

Fall

Retreat

Path

45°

Tree

Retreat

Path

Figure 11 - Retreat Path From Tree

4.

Remove dirt, stones, loose bark, nails, staples,

and wire from tree where you will make felling

cuts.

5. Stay on uphill side when felling tree. Tree

could roll or slide downhill after falling.

Page 14

14

www.desatech.com

CHAIN SAW INFORMATION

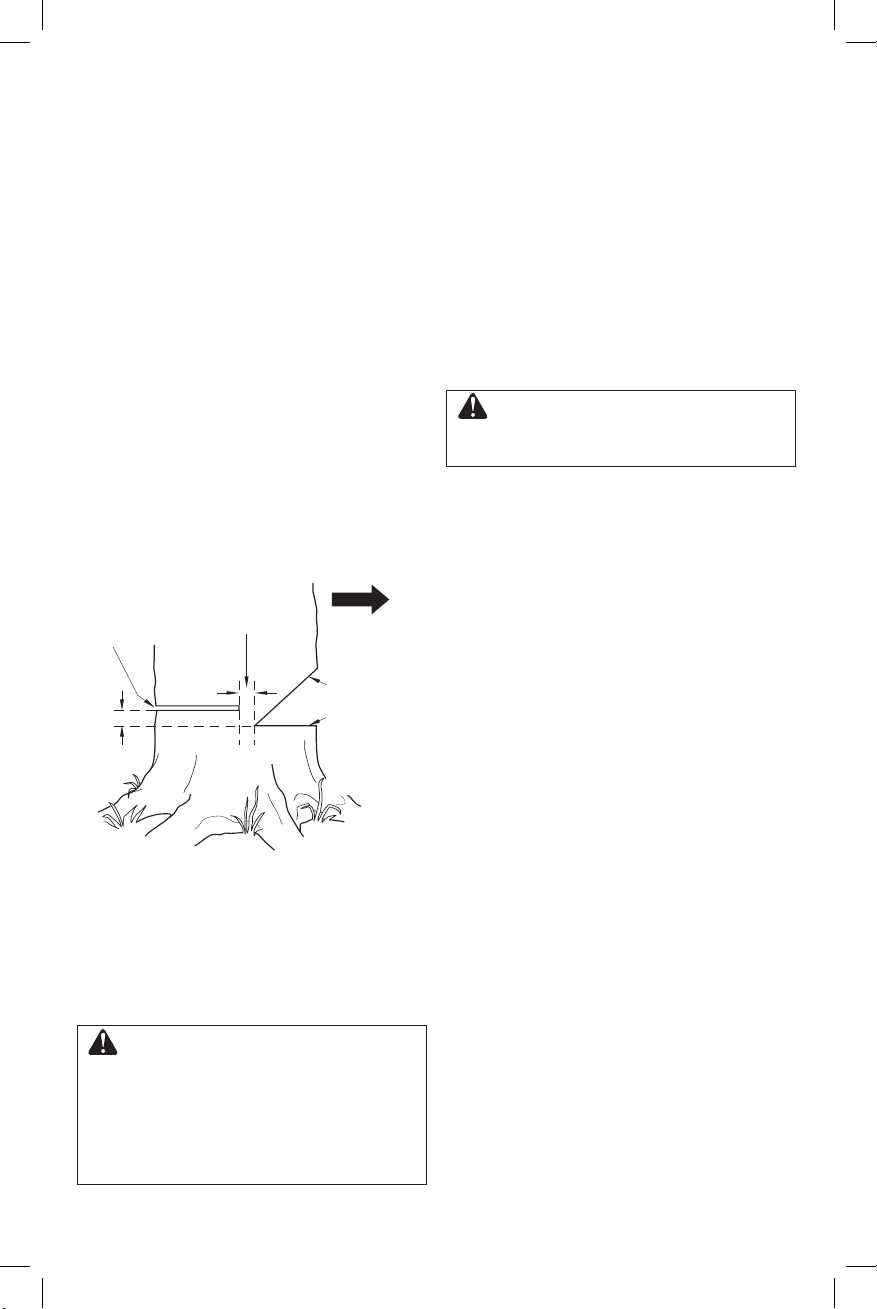

Felling Procedure

A) Felling Notch

A properly placed felling notch will determine

direction tree will fall. Place felling notch on

side of tree in direction you want tree to fall (see

Figure 12). Follow directions below to create a

felling notch.

1. Make lower notch cut as close to ground as

possible. Hold saw so guide bar is horizontal.

Cut 1/3 the diameter of tree trunk (see Figure

12). Note: Always make this horizontal lower

notch cut first. If you make this cut second, tree

can pinch chain or guide bar.

2. Start upper notch cut the same distance above

first cut as first cut is deep.

Example: If lower notch cut is eight inches

deep, start upper notch cut eight inches above

it. Cut downward at 45° angle. The upper

notch cut should meet end of lower notch cut

(see Figure 12).

3. Remove tree trunk wedge created by notching

cuts.

Direction of Fall

Hinge

2"

2nd Cut Upper Notch

Cut

3rd Cut Felling Cut

2"

1st Cut Lower Notch

Cut

Figure 12 - Felling A Tree

B) Felling Cut

1. Make felling cut two inches higher than lower

notch cut and on opposite side of tree (see

Figure 12). Keep felling cut parallel to lower

notch cut.

2. Cut towards notch.

WARNING: Do not cut all the way

through tree. Leave about two inches

of tree diameter uncut directly behind

felling notch (see Figure 12). This uncut

portion acts as a hinge. The hinge helps

keep tree from twisting and falling in

wrong direction.

WARNING: Be alert for falling over-

head limbs. Watch your footing while

exiting area.

3. As felling cut nears hinge, tree should begin to

fall. Note: If needed, drive wedges into felling

cut to control direction of fall. If tree settles back

and pinches chain, drive wedges into felling cut

to remove saw. Only use wedges made of wood,

plastic, or aluminum. Never use wedge made of

steel. This could cause kickback and damage to

chain.

4. When tree begins to fall, quickly

• remove saw from felling cut

• release trigger to turn saw off

• put saw down

• exit area using retreat path

Page 15

ENGLISH

15

www.desatech.com

CHAIN SAW INFORMATION

BUCKING A LOG

Bucking a log is cutting a log into sections. Make

sure your footing is firm. Keep feet apart. Divide your

weight evenly on both feet. When possible, raise log

or section off ground. Do this by using limbs, logs,

chocks, etc.

When cutting through log, maintain control by

reducing cutting pressure near end of cut. Do not

relax your grip on chain saw handles. Do not let

moving chain touch ground. Ground will dull moving chain. After cutting through log, release trigger

to turn saw off before moving saw.

Follow directions below to buck a log.

Entire Length Of Log On Ground

Cut log from top (see Figure 14).

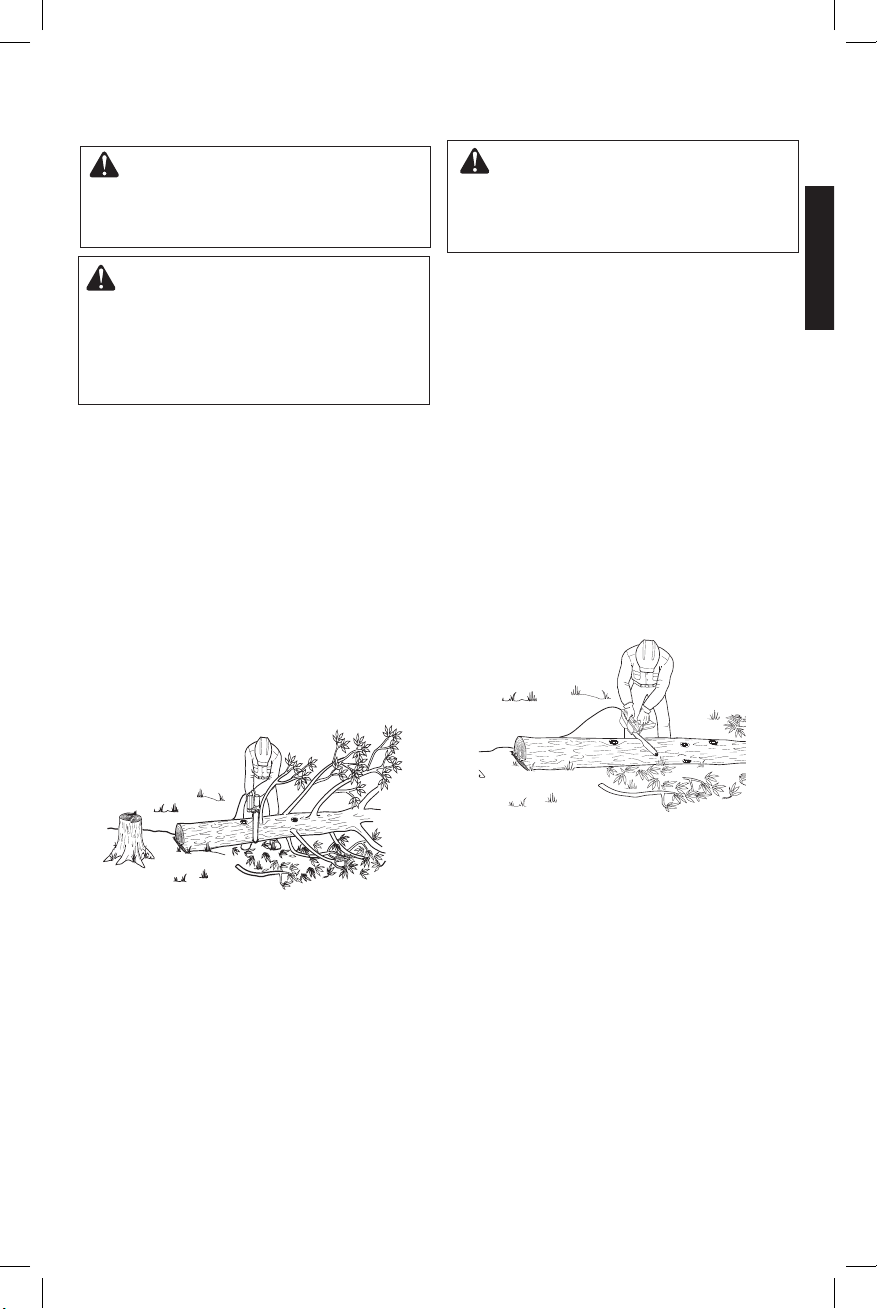

LIMBING A TREE

WARNING: When cutting limb that

is under tension, use extreme caution.

Be alert for wood springing back. When

wood tension is released, limb could

spring back and strike operator causing

severe injury or death.

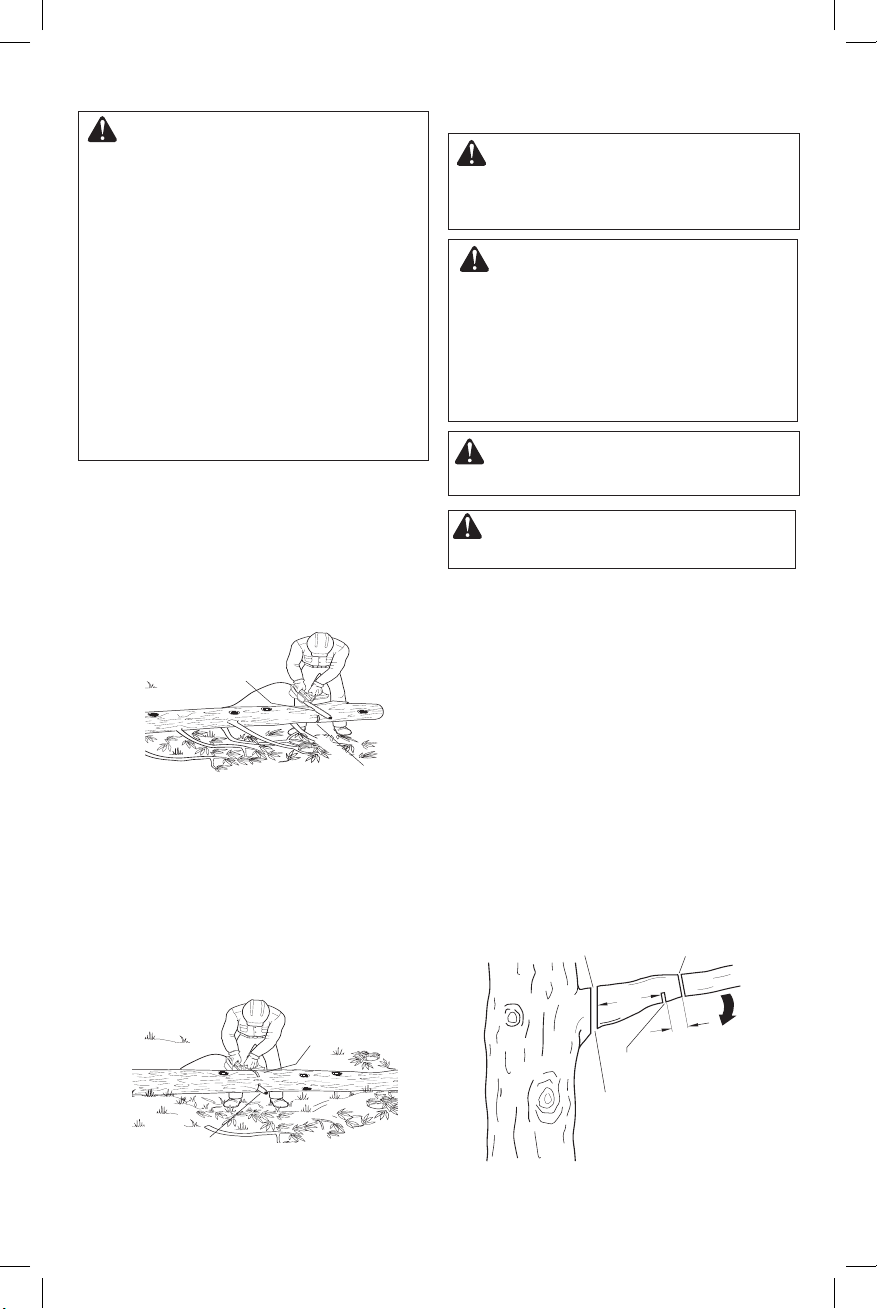

Figure 13 - Limbing A Tree

Figure 14 - Bucking Log With Entire Length

On Ground

WARNING: Avoid kickback. Kick-

back can result in severe injury or death.

See Kickback, page 5, to avoid risk of

kickback.

WARNING: Avoid kickback.

Kickback can result in severe injury

or death. See Kickback, page 5, to

avoid risk of kickback.

Limbing is removing branches from a fallen tree.

Make sure your footing is firm. Keep feet apart.

Divide your weight evenly on both feet. Do not

remove larger limbs under tree that support log

off ground. Remove each limb with one cut (see

Figure 13). Clear cut limbs from work area often.

This will help maintain a safe work area.

Make sure you start your cut where limb will

not pinch saw during cutting. To avoid pinching,

start cut on freely hanging limbs from above

limb. Start cut on limbs under tension from under

limb. If pinch occurs, turn saw off, lift limb, and

remove saw.

Page 16

16

www.desatech.com

CHAIN SAW INFORMATION

WARNING:

•

If on slope, make sure log will not

roll down hill. Secure log by using

wooden stakes. Drive wooden stakes

into ground on downhill side of log.

Stand on uphill side of log while cutting. Log may roll after cutting.

• Never try cutting through two logs

at same time. This could increase

the risk of kickback.

• While cutting log, never hold log with

your hand, leg, or foot.

• While cutting log, never allow an

-

other person to hold log.

• Turn off and unplug saw before mov

-

ing from one place to another.

Figure 15 - Bucking Log When Log Is Supported

On One End

1st Cut

2nd

Cut

Log Supported On One End

1. Make first cut on underside of log (see Figure

15). Use top of guide bar to make this cut. Cut

1/3 through diameter of log. This cut will keep

section from splintering when cut.

2. Make second cut directly above first cut. Cut

down to meet first cut. This cut will keep log

from pinching guide bar and chain.

Log Supported On Both Ends

1. Make first cut from above log (see Figure 16).

Cut 1/3 through diameter of log. This cut will

keep section from splintering when cut.

2. Make second cut on underside of log, directly

under first cut. Use top of guide bar to make

this cut. Cut up to meet first cut. This will keep

log from pinching guide bar and chain.

1st Cut

2nd Cut

Figure 16 - Bucking Log When Log Is Supported

On Both Ends

TRIMMING A TREE (PRUNING)

WARNING: Do not extend arms above

shoulders when using pole saw.

CAUTION: Seek professional help if

facing conditions beyond your ability.

WARNING: Avoid kickback. Kickback

can result in severe injury or death.

See Kickback, page 5, to avoid risk of

kickback.

WARNING: Do not operate pole

saw while:

• in a tree

• on a ladder or any other unstable

surface

• in any awkward position

You may lose control of pole saw causing severe injury.

Trimming a tree is the process of cutting limbs

from a living tree. Make sure your footing is firm.

Keep feet apart. Divide your weight evenly on

both feet. Follow directions below to trim a tree.

1. Make first cut six inches from tree trunk on

underside of limb. Use top of guide bar to make

this cut. Cut 1/3 through diameter of limb (see

Figure 17).

2. Move two to four inches farther out on limb.

Make second cut from above limb. Continue

cut until you cut limb off.

3. Make third cut as close to tree trunk as possible

on underside of limb stub. Use top of guide bar

to make this cut. Cut 1/3 through diameter of

stub.

4. Make fourth cut directly above third cut. Cut

down to meet third cut. This will remove limb

stub.

Figure 17 - Cutting A Limb

2" to 4"

2nd Cut - Pruning Cut

(to avoid pinching)

1st Cut - Pruning

Undercut (to avoid

splintering)

3rd Cut - Stub Undercut

(to avoid splintering)

6"

4th Cut

- Final Stub

Cut

Page 17

ENGLISH

17

www.desatech.com

The hardware bag contains the following items:

• (1) Handle Bracket

• (1) Knob

• (1) .250" Lock Washer

Step ❶ – Squeeze Trigger

Push in and hold trigger lockout

button.

Squeeze and hold

trigger.

1A

1B

Step ❷ – Insert Pole Bracket into

Saw

Insert pole bracket into saw. Note: Pole

Bracket holds trigger in “ON” position.

Continue to hold trigger while

completing step 2B.

2A

2B

Step ❸ – Attach Handle Bracket

to Pole Bracket

Slide handle bracket onto

clamping bolt.

Clamping bolt should extend through

handle bracket.

3A

3B

Step ❹ – Secure Handle Bracket

to Pole Bracket

Place lockwasher onto

clamping bolt.

Thread knob onto clamping bolt. Note:

After knob makes contact with handle

bracket, tighten 1 1/2 to 2 more turns.

T

I

G

H

T

E

N

4A

4B

POLE SAW INFORMATION

POLE SAW ASSEMBLY

RPS2N1

Step ❺ – Connect to Power Cord

Plug saw power cord into receptacle cord at end

of inner pole.

Page 18

18

www.desatech.com

POLE SAW INFORMATION

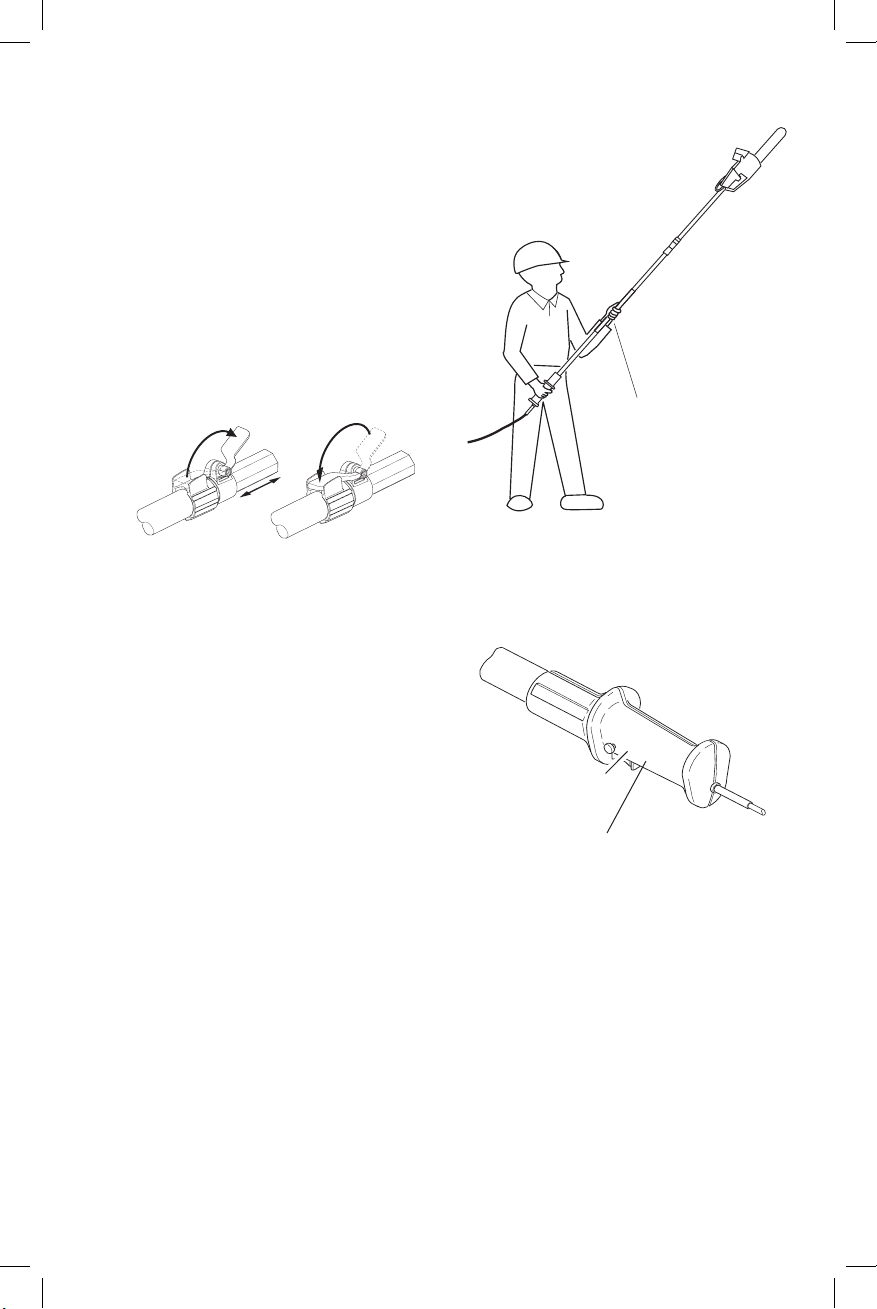

Figure 18 - Extending Telescopic Pole

UNLOCK LOCK

ADJUSTING POLE LENGTH

RPS2N1

The Remington RPS2N1 Pole Saw has a telescoping pole assembly that will extend from 57 inches

(fully retracted) to 96 inches (fully extended). A

cam levered collet is used to hold the pole in position at any extended length.

1. To extend the pole, loosen the clamping lever

(see Figure 18). Pole will slide freely.

2. Pull inner pole section out to desired length of

extension. Note: Only extend pole to minimum

length required to reach limb that is being

cut.

3. To lock pole in position, tighten clamping lever

(see Figure 18).

CUTTING WITH THE POLE SAW

1. Connect saw to extension cord. Connect extension cord to power supply.

2. Use both hands to grip pole saw. Use only

designated grip areas when operating pole

saw (see Figure 19). Use firm grip. Thumbs

and fingers must wrap around pole saw handle

and pole.

3. Make sure your footing is firm. Keep feet

apart. Divide your weight evenly on both feet.

4. When ready to make a cut, press in trigger

lockout and squeeze trigger (see Figure 20).

This will turn pole saw on. Releasing trigger

will turn pole saw off. Make sure saw is running

at full speed before starting a cut.

5. When starting a cut, place moving chain

against wood. Hold pole saw firmly in place to

avoid possible bouncing or skating (sideways

movement) of saw.

6. Guide pole saw using light pressure. Do not

force pole saw. The motor will overload and

can burn out. It will do the job better and safer

at the rate for which it was intended.

7. Remove pole saw from a cut with saw run

ning at full speed. Stop pole saw by releasing

trigger. Make sure chain has stopped before

setting pole saw down.

Grip Area

Figure 19 - Designated Grip Areas

Figure 20 - Pole Saw Handle with Trigger

Lockout

Trigger

Lockout

Trigger

Page 19

ENGLISH

19

www.desatech.com

CLEANING AND MAINTENANCE

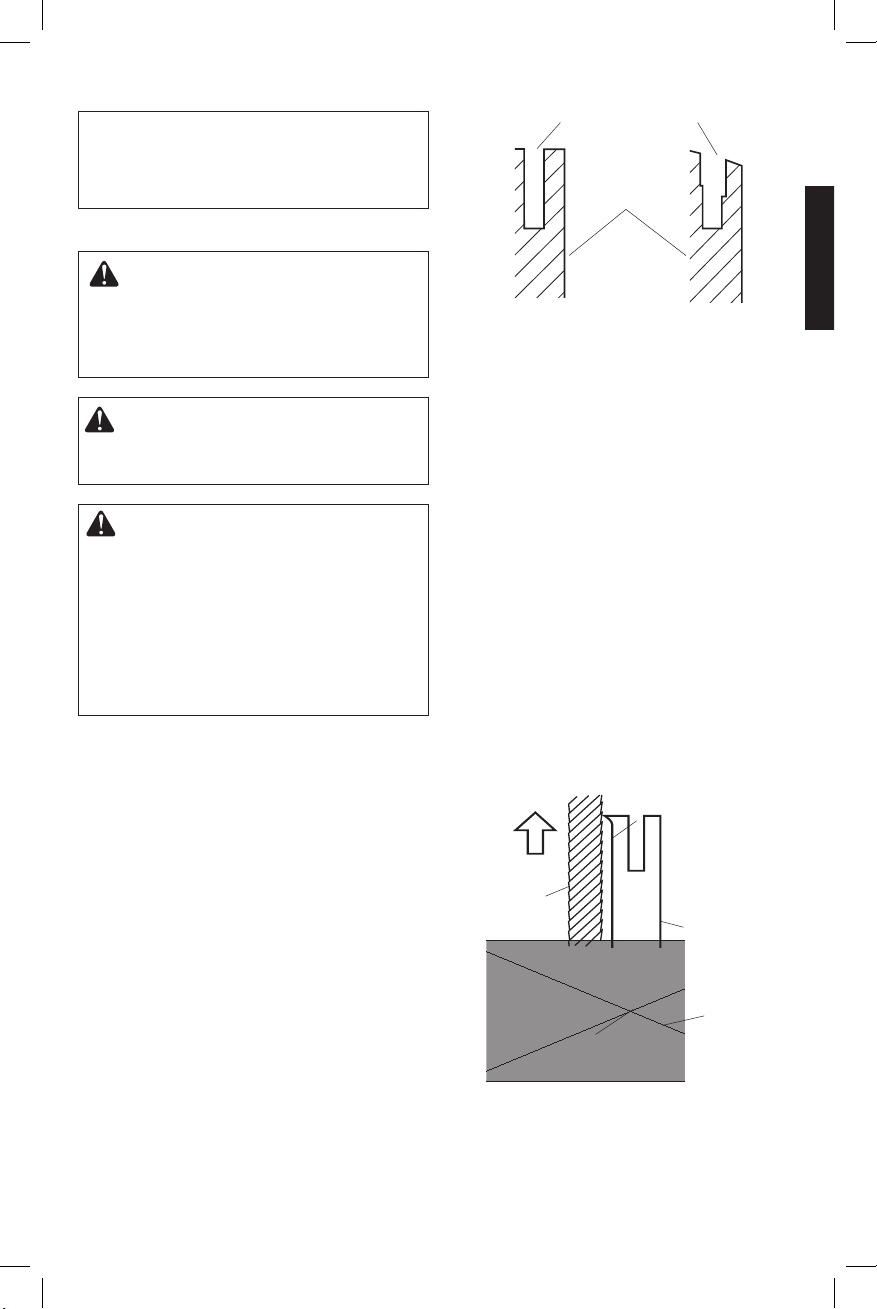

1. Remove guide bar from chain saw.

2. Remove sawdust from guide bar groove peri

-

odically. Use putty knife or wire (see Figure

22).

3. Clean oil slots after each day of use.

4. Remove burrs from sides of guide bar. Use flat

file to make side edges square.

Replace guide bar when

• bar is bent or cracked

• inside groove of bar is badly worn

Note: When replacing guide bar, see Replacement

Parts and Accessories, page 21, for replacement

information. See Parts List, page 76, for correct

bar.

CLEANING SAW BODY

NOTICE: These are instructions for servicing your chain saw. Any servicing

not mentioned should be done by an

authorized service center.

WARNING: Unplug chain saw from

power source before servicing. Severe

injury or death could occur from electrical shock or body contact with moving

chain.

WARNING: Cutting edges on chain

are sharp. Use protective gloves when

handling chain.

WARNING: When cleaning saw

body,

• do not submerge saw in any liq

-

uids

• do not use products that contain

ammonia, chlorine, or abrasives

• do not use chlorinated cleaning

solvents, carbon tetrachloride, kerosene, or gasoline

Keep saw body clean. Use a soft cloth dampened

with a mild soap and water mixture. Wipe saw

body to clean.

Figure 22 - Guide Bar Maintenance

Flat

File

Burr

Oil Slot

Cleaning Groove

With Putty Knife

Guide Bar

Figure 21 - Guide Bar Cross Section Showing

Uneven Bar Wear

Guide Bar With

Uneven Wear

Guide Bar

Normal Guide

Bar

Guide Bar Groove

CARE OF GUIDE BAR

Uneven bar wear causes most guide bar problems.

Incorrect sharpening of chain cutter and depth

gauge settings often cause this. When bar wears

unevenly, it widens guide bar groove (see Figure

21). This causes chain clatter and rivet popping.

Saw will not cut straight. Replace guide bar if

this occurs.

Inspect guide bar before sharpening chain. A

worn or damaged guide bar is unsafe. A worn or

damaged guide bar will damage chain. It will also

make cutting harder.

Normal Guide Bar Maintenance

Page 20

20

www.desatech.com

CLEANING AND MAINTENANCE

WARNING: Unplug chain saw from

power source before servicing. Severe

injury or death could occur from electrical shock or body contact with moving

chain.

WARNING: Cutting edges on chain

are sharp. Use protective gloves when

handling chain.

SHARPENING SAW CHAIN

Keep chain sharp. Your saw will cut faster and

more safely. A dull chain will cause undue sprocket, guide bar, chain, and motor wear. If you must

force chain into wood and cutting creates only saw

dust with few large chips, chain is dull.

Items Needed to Sharpen Chain

Purchase these items from your local dealer, hardware store, or chain saw supplies outlet.

• 5/32" round file

• Depth gauge tool

• File guide

• Vise

• Medium sized flat file

Sharpening Cutters

Use file guide for 30° filing.

1. Adjust chain for proper tension (see

Saw Chain

Tension Adjustment, page 11).

2. Clamp guide bar in vise to hold saw steady.

Note: Do not clamp chain.

3.

Press 5/32" round file (attached to file guide)

into groove between top plate and depth gauge

on chain. File guide should rest on both top plate

and depth gauge (see Figure 23). Note: File at

midpoint of guide bar.

4. Hold file guide level. Make sure 30° mark on

file guide is parallel to center of guide bar (see

Figure 23). This will insure that you file cutters

at 30° angle.

5. File from inside towards outside of cutter

until sharp. Only file in this one direction (see

Figure 23). Note: Two or three strokes with

file should sharpen cutter.

6. After each cutter is sharpened, move chain

forward to sharpen next cutter. File all cutters

on one side of chain.

7. Move to other side of chain and repeat pro

-

cess.

Figure 23 - File and File Guide Placement On

Chain

Note: This illustration shows file guide placement and

filing direction for sharpening cutters on left side of

chain.

FILE HOLDER

File

Guide

Filing Direction

5/32" Round

File

30° Guide

Mark

Filing Cutter Depth Gauges

The cutter depth gauge clearance is reduced as

cutters are sharpened. After every second or third

sharpening, reset cutter depth gauges.

1. Place depth gauge tool (.025") firmly across

top of two cutters. Make sure depth gauge enters slot in depth gauge tool (see Figure 25).

2. Use medium flat file. File depth gauge level with

depth gauge tool.

3.

Remove depth gauge tool. With flat file, round

off front corner of cutter depth gauge (see Figure

26).

After several hand filings, have authorized service

center or sharpening service machine sharpen

chain. This will insure even filing.

Figure 24 - Chain Part Locations

Groove

Depth Gauge (left side

of chain)

Top Plate (left

side of chain)

Right Side of Chain

Groove

Depth Gauge (right side

of chain)

Top Plate (right

side of chain)

Figure 25 - Depth Gauge Tool On Chain

Flat File

Depth Gauge Slot

Depth Gauge

Tool

Depth

Gauge

Front Corner

.025"

Figure 26 - Round Off Front Corner Of Depth

Gauge

Page 21

ENGLISH

21

www.desatech.com

CLEANING AND MAINTENANCE

REPLACING SAW CHAIN

Replace chain when cutters are too worn to

sharpen or when chain breaks. Only use replacement chain noted in this manual. Always include

new drive sprocket when replacing chain. This

will maintain proper driving of chain. Note: For

proper chain and drive sprocket, see Parts List,

page 74.

Replacement saw chains may be available at your

local hardware or home improvement store.

The following list gives the specifications for

replacement chains.

All chains will be .050 gauge, 3/8 pitch.

8" chainsaws have 34 drive links

10" chains have 39 drive links

You may also order the replacement saw chains

from the "Online Outlet" at www.desatech.com

using the part number listed in the illustrated parts

list on pages 72-74 of this manual.

STORAGE

If storing saw for more than 30 days, follow steps

below:

1. Drain oil tank after each use.

2. Remove and clean guide bar and chain. Clean

guide bar and chain by soaking in petroleum

based solvent or mild soap and water mixture.

3. Dry guide bar and chain.

4. Place chain in container filled with oil. This

will prevent rust.

5. Wipe a thin coating of oil over surface of guide

bar.

6. Wipe off outside of saw body. Do this with soft

cloth dampened with a mild soap and water mixture.

7. Store chain saw

•

in a high or locked place, out of children’s

reach

• in a dry place

TECHNICAL SERVICE

You may have further questions about assembling, operating, or maintaining this product. If so, you can visit

our Technical Service web site at www.desatech.com or

contact our Technical Service Department at 1-800-6262237 (English Only). You may also write to:

DESA Power Tools

ATTN: Technical Service

P.O. Box 90004

Bowling Green, KY 42102-9004

When contacting DESA Power Tools, have ready

• Your Name

• Your Address

• Your Phone Number

• Model Number of Product

• D ate of Purc hase (Include copy of

receipt for written requests).

REPLACEMENT PARTS

AND ACCESSORIES

For original replacement parts and accessories,

contact your nearest Authorized Dealer or Authorized Service Center for this product. If they

can not supply the part or accessory, contact your

nearest Parts Central listed on page 75. Each Authorized Dealer, Authorized Service Center, and

Parts Central is independently owned and operated. You may also order parts from the "Online

Outlet" at www.desatech.com.

See pages 72 through 74 for an Illustrated Parts

List.

If you need additional referral information, contact

our Technical Service Department (see Technical

Service).

In Canada call 1-800-561-3372 for parts and service

information.

WARNING: Use only replacement

parts and accessories described in this

manual. Use of other parts or accessories

could damage saw or injure operator.

We reserve the right to amend these specifications

at any time without notice. The only warranty

applicable is our standard written warranty. We

make no other warranty, expressed or implied.

Page 22

22

www.desatech.com

REPAIR SERVICE

Note: Only use original replacement parts. This

will protect your warranty coverage for parts

replaced under warranty.

Each Authorized Service Center is independently

owned and operated.

WARRANTY SERVICE

If product requires warranty service, return it to

nearest Authorized Service Center. You must show

proof of purchase. If faulty materials or workmanship

caused damage, we will repair or replace product

without charge.

Note: Normal wear, misuse, abuse, neglect, or accidental damage is not covered under warranty.

TROUBLESHOOTING

WARNING: Unplug chain saw from power source before servicing. Severe injury or death could occur from electrical shock or body contact with

moving chain.

Note: For additional help, visit DESA Power Tools technical service web site

at www.desatech.com.

OBSERVED FAULT POSSIBLE CAUSE REMEDY

Saw runs, but does not cut Chain assembled backwards

on guide bar

See Chain Saw Assembly, page 10

Saw does not cut unless heavily

forced. Cutting produces only

sawdust with few large chips

Chain is dull

See Sharpening Saw Chain, page 20

Sa w r uns sl ow. Sa w s tal ls

easily

Low power supply voltage Extension cord wire size too small. See

Extension Cords, page 12

Motor of saw does not run

when you squeeze trigger

1. Trigger lockout not pressed

in to release trigger

2. Extension cord connections loose

3. Open line fuse or circuit breaker

4. Worn out motor brushes

5. Open wiring circuit on saw

1. Pr ess in trigger lockout before

squeezing trigger

2. Check cord connections

3. Check line fuse or circuit breaker

4. See authorized service center

5. See authorized service center

Motor of saw runs, but chain

does not move

Drive Sprocket Failure Remove and Inspect Drive Sprocket

for damage

Chain does not get oil 1. Clogged oil slot in guide bar

2. Oil is too thick

1. Remove guide bar and clean oil

slot

2. Use correct weight of oil. See

Filling Oil Tank, page 12

Chain comes off guide bar 1. Chain is loose

2. Guide bar and chain not

assembled correctly

1. Tighten chain. See

Saw Chain Ten-

sion Adjustment, page 11

2. See

Chain Saw Assembly, page 10

Saw smokes Saw damaged. Do not use saw See authorized service center

Saw leaks oil It is normal for oil to seep

when the saw is not in use.

Note: Empty oil tank when not in use

NON-WARRANTY SERVICE

If product requires service, return it to nearest

Authorized Service Center. Repairs will be billed

to you at regular repair list prices.

For additional Service Center or warranty information, call 1-800-626-2237 or visit our Technical

Service web site at www.desatech.com.

Page 23

ENGLISH

23

www.desatech.com

Bowling Green, KY 421029004

800-626-2237 (English Only)

www.desatech.com

Industries of Canada, Inc.

82 Akron Road

Toronto, Ontario

M8W1T2

416-255-5333

Fax: 416-255-5677

www.desatech.com

WARRANTY INFORMATION

REMINGTON BRAND ELECTRIC CHAIN SAW

LIMITED WARRANTIES

NEW PRODUCTS

Standard Warranty

DESA Power Tools warrants this new product and any parts thereof to be free from defects in material and workmanship for a period of one (1) year from the date of first purchase from an authorized dealer provided the product has

been maintained and operated in accordance with DESA Power Tools’ warnings and instructions.

FACTORY RECONDITIONED PRODUCTS

Limited Warranty

DESA Power Tools warrants factory reconditioned products and any parts thereof to be free from defects in material

and workmanship for 90 days from the date of first purchase from an authorized dealer provided the product has been

installed, maintained and operated in accordance with DESA Power Tools’ warnings and instructions.

TERMS COMMON TO ALL WARRANTIES

The following terms apply to all of the above warranties:

• Always specify model number when contacting the manufacturer. To make a claim under this warranty the bill of

sale or other proof of purchase must be presented.

• This warranty is extended only to the original retail purchaser when purchased from an authorized dealer.

• This warranty covers the cost of part(s) required to restore this product to proper operating condition and an allow

ance for labor when provided by a DESA Power Tools Authorized Service Center. Warranty parts must be obtained

through authorized dealers of this product and/or DESA Power Tools who will provide original factory replacement

parts. Failure to use original factory replacement parts voids this warranty.

• Travel, handling, transportation, diagnostic, material, labor and incidental costs associated with warranty repairs,

unless expressly covered by this warranty, are not reimbursable under this warranty and are the responsibility of

the owner.

• Excluded from this warranty are products or parts that fail or become damaged due to misuse, accidents, lack of

proper maintenance, tampering, or alterations.

• Excluded from this warranty are products purchased for commercial, industrial or rental usage.

• This is DESA Power Tools’ exclusive warranty, and to the full extent allowed by law; this express warranty excludes

any and all other warranties, express or implied, written or verbal and limits the duration of any and all implied warranties, including warranties of merchantability and fitness for a particular purpose to one (1) year on new products

and 90 days on factory reconditioned products from the date of first purchase. DESA Power Tools makes no other

warranties regarding this product.

• DESA Power Tools’ liability is limited to the purchase price of the product, and DESA Power Tools shall not be

liable for any other damages whatsoever under any circumstances including indirect, incidental, or consequential

damages.

• Some states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of incidental

or consequential damages, so the above limitation or exclusion may not apply to you.

• This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

For information about this warranty contact:

Model _______________________

Date Purchased ______________

Page 24

SIERRA ELÉCTRICA

SIERRA ELÉCTRICA

DE PÉRTIGA TELESCÓPICA

MANUAL PARA EL USUARIO

®

Modelo

IMPORTANTE: Lea cuidadosamente este manual antes de armar u operar

esta sierra eléctrica. El uso indebido de la misma puede provocar graves

lesiones. Guarde este manual para consultarlo cuando lo necesite.

RPS2N1: 104317, PS1510A

24

Page 25

INTRODUCCIÓN

Su sierra Remington de Pértiga Telescópica es un producto de doble propósito. La sierra eléctrica de

cadena es una unidad que funciona separadamente cuando no está ensamblada a la Pértiga Telescópica.

Antes de operar ya sea la sierra de cadena o la Sierra de Pértiga, asegúrese de haber leído y entendido

toda la Importante Información de Seguridad.

Contents

INFORMACIÓN IMPORTANTE DE SEGURIAD................................................................26

Antes de utilizar la sierra ..................................................................................................................26

Al utilizar la sierra .............................................................................................................................26

Contragolpes ....................................................................................................................................28

Mantenimiento y almacenamiento de su sierra eléctrica..................................................................29

Precauciones para Podar con la Sierra de Pértiga .........................................................................30

DESEMBALAJE.................................................................................................................30

IDENTIFICACIÓN DEL PRODUCTO .................................................................................31

TÉRMINOS Y DEFINICIONES DE LA SIERRA DE CADENA ..........................................32

INFORMACIÓN SOBRE LA SIERRA DE CADENA ..........................................................33

Accesorios de la sierra de cadena ...................................................................................................33

Ensamblado de la sierra de cadena .................................................................................................33

Ajuste de tensión de la dadena serrada ...........................................................................................34

Cables de prolongación ....................................................................................................................35

Lubricación .......................................................................................................................................35

Lubricación de la cadena .................................................................................................................35

Realización de cortes .......................................................................................................................36

Tala de un Árbol ................................................................................................................................36

Desmembramiento de un Árbol ........................................................................................................38

Trozado de un tronco .......................................................................................................................38

Poda de un árbol ..............................................................................................................................39

INFORMACIÓN SOBRE LA SIERRA DE PÉRTIGA .........................................................40

Ensamblado de la sierra de pértiga ..................................................................................................40

Ajuste de la longitud de la sierra de pértiga .....................................................................................41

Corts con la sierra de pértiga ...........................................................................................................41

LIMPIEZA Y MANTENIMIENTO ........................................................................................42

Limpieza del cabezal ........................................................................................................................42

Cuidado de la barra de guía .............................................................................................................42

Afi lado de la cadena .........................................................................................................................43

Recambio de la cadena serrada ......................................................................................................44

ALMACENAMIENTO .........................................................................................................44

SERVICIO TÉCNICO .........................................................................................................45

ACCESORIOS Y PIEZAS DE REPUESTO .......................................................................45

SERVICIO DE REPARACIÓN ...........................................................................................45

DIAGNÓSTICO Y RESOLUCIÓN DE PROBLEMAS ........................................................46

INFORMACIÓN DE GARANTÍA ........................................................................................47

DESGLOSE ILUSTRADO DE PARTES ............................................................................72

RPS2N1: 104317, 106821, 106821A, PS1510A ..............................................................................72

Sierra elécctrica ................................................................................................................................73

CENTRAL DE PIEZAS ......................................................................................................75

ESPAÑOL

25

Page 26

INFORMACIÓN IMPORTANTE DE SEGURIDAD

• cuando tenga prisa;

ADVERTENCIA: Al utilizar una sierra eléctrica, deben seguirse siempre

las precauciones de seguridad básicas para reducir el riesgo de incendios,

choque eléctrico y lesiones a personas, incluyendo las siguientes:

LEA TODAS LAS INSTRUCCIONES

Asegúrese de leer y comprender completamente todas las instrucciones en

Información importante de seguridad

en las páginas 26 y 30. El uso indebido

de esta sierra eléctrica puede provocar

lesiones graves (y aun la muerte) a causa

de incendio, shock eléctrico, el contacto

del cuerpo con la cadena en movimiento

o la caída de un trozo de árbol.

ANTES DE UTILIZAR LA SIERRA

1. Lea detenidamente este manual para el usuario

antes de utilizar la sierra eléctrica.

2. Proceda con cautela. Utilice el sentido común.

No utilice la sierra cuando se sienta cansado.

3. Utilice la sierra sólo para cortar madera. No la

utilice con fi nes para los que no ha sido diseñada.

No la use para cortar elementos que no sean de

madera.

4. La Sierra de Pértiga o la sierra de cadena deberían

ser operadas solamente por personas adultas bien

instruidas. Nunca permita que sea utilizada por

niños.

5. Utilice sólo el voltaje eléctrico indicado en la

placa del modelo de la sierra.

6. Utilice sólo cables de prolongación diseñados

para el aire libre. Consulte la página 45para

conocer las requisitos del cable de prolongación.

7. No opere la Sierra de Pértiga o la sierra de cadena

• cuando se encuentre bajo la infl uencia de

alcohol, medicamentos o drogas;

• bajo la lluvia o en áreas húmedas o moja-

das;

• en presencia de líquidos o gases altamente

infl amables;

• Si la pértiga o la sierra está dañada, mal regu-

lada, o no está completamente ensamblada

y con fi rmeza;

• si no es posible encenderla y apagarla me-

diante el gatillo. La cadena debe dejar de

moverse al soltar el gatillo. Si el interruptor

se encuentra defectuoso, hágalo reemplazar

en un centro de servicios autorizado (consulte Servicio Técnico en la página 45).

www.desatech.com

• Mientras esté en un árbol o una escalera;

• Mientras esté sobre el brazo aéreo

de grúa, en cucharas o en plataformas.

8. Al utilizar la sierra, lleve ropa ajustada. No

utilice ropa ni lleve accesorios sueltos, ya que

éstos pueden quedar atrapados en la cadena en

movimiento.

9. Cuando opere las sierras use el siguiente

equipo de seguridad:

• guantes resistentes (utilice guantes de goma

para trabajar al aire libre);

• calzado resistente con suelas no resbaladi-

zas;

• protección ocular, tal como gafas de seguri-

dad o una pantalla facial;

• casco de seguridad;

• orejeras o tapones para los oídos;

• cubrecabellos, especialmente si tiene cabello

largo;

• máscara contra el polvo (el trabajar en zonas

polvorientas).

10. Antes de comenzar a cortar, asegúrese de contar

con:

• zona de trabajo limpia;

• calzado fi rme;

• Una vía de retiro planifi cada para que caigan

las ramas.

11. Inspeccione el árbol antes de talarlo. Asegúrese de que no tenga ramas o vástagos secos que

puedan caerele encima. Deje que las ramas

caigan al suelo libremente

12. No use su Sierra de Pértiga para cortar árboles

tiernos. Use la sierra de cadena sin la pértiga.

13. Para reducir el riesgo de shock eléctrico, esta

sierra tiene un enchufe polarizado (un conector

es más ancho que el otro) y sólo entrará de una

manera en un tomacorriente polarizado. Si el

enchufe no entra completamente en el tomacorriente de su cable de prolongación, inviértalo.

Si, aun así, tampoco entra, necesitará un cable

de prolongación polarizado. No altere el enchufe

de manera alguna.

AL UTILIZAR LA SIERRA

1. Permanezca alerta. Use el sentido común

mientras opere la unidad.

2. Mantenga limpia el área de trabajo. Las áreas

de trabajo sucias pueden provocar lesiones.

3. Tenga en cuenta la posición del cable de prolongación. Asegúrese de no tropezar sobre él.

Manténgalo alejado de la sierra y del operario

en todo momento.

26

Page 27

INFORMACIÓN IMPORTANTE DE SEGURIDAD

4. Mantenga a los niños, animales y observadores

alejados de la sierra y del cable de prolongación. Sólo el operario de la sierra debe

permanecer en el área de trabajo.

5. No use la Sierra de Pértiga para talar árboles.

Use la sierra de cadena sin la pértiga y solamente si Ud. está entrenado o tiene asistencia

de experiencia.

6. No la use cerca de las líneas de energía. Mantenga

al menos una distancia de 10 pies de las líneas

eléctricas.

7. Si dos o más personas realizan tareas de tala

y trozado al mismo tiempo, cerciórese de que

haya una buena cantidad de espacio entre ellos.

El espacio que separa a ambas personas debe

ser por lo menos igual al doble de la altura del

árbol que se está talando.

8. Asegure la madera que se ha de cortar mediante mordazas o cuñas.

9. Sujete la sierra fi rmemente con ambas manos.

Nunca utilice la sierra con una sola mano.

Nunca utilice el protector de mano a manera

de mango.

10. Agarre la sierra de pértiga en forma segura.

Ponga una mano en la pértiga y la otra en al

asa.

11. No coloque el dedo en el gatillo hasta que esté

listo para realizar el corte.

12. Antes de activar la sierra, asegúrese de que no

se encuentre en contacto con nada.

13. Para protegerse de un shock eléctrico, evite

el contacto corporal con objetos conectados a

tierra tales como caños, vallas, cercas y postes

de metal.

14. Mantenga todas las partes del cuerpo alejadas

de la sierra mientras la cadena esté en movimiento.

15. Al cortar, no aplique gran fuerza a la sierra.

Para realizar el trabajo de manera más segura,

mejor y en la cantidad de tiempo para la cual

fue diseñada la sierra, basta aplicar una ligera

presión sobre ella.

16. No corte maleza ni ramas tiernas con la

Sierra de Pértiga. Use solamente la sierra de

cadena con extremo cuidado. Los materiales

fi nos pueden atascarse en la cadena y azotar

contra su cuerpo o provocar que pierda el

equilibrio.

17. Proceda con sumo cuidado al cortar ramas

o vástagos de árboles que se encuentran en

tensión. Esté preparado para actuar en caso

de contragolpe de la madera. Al liberarse la

tensión de la madera, la rama puede moverse

hacia el operario, golpearlo y provocarle le-

siones graves y aun la muerte.

18. Lleve la sierra eléctrica de un lugar a otro

• con la cadena detenida y la sierra desenchufada;

• Sierra de cadena - sosteniendo el asa frontal

(nunca use la protección de las manos como

asa)

• Sierra de pértiga- Con la pértiga telescópica

retraída a su posición más corta

• Sierra de pértiga

su punto de equilibrio (cerca del extremo de

la sierra);

• con el dedo fuera del gatillo;

• con la barra de guía y la cadena mirando hacia

atrás.

- Sosteniendo la pértiga en

ADVERTENCIA: Este producto con-

tiene substancias químicas conocidas en

el estado de California como causas de

cáncer o de defectos al recién nacido o

de otros daños de reproducción.

ADVERTENCIA: El polvo causado

cuando se usan herramientas motorizadas

para lijar, cortar, esmerilar y taladra, a igual

que otras actividades de construcción,

contienen substancias químicas conocidas

(en el estado de California) como causantes

de cáncer, defectos al recién nacido u otros

daños a los órganos de reproducción.

Algunos ejemplos de estas substancias

químicas son:

• plomo de las pinturas hechas a base

de plomo

• sílice cristalina proveniente de ladrillos y cemento y de otros productos

de albañilería

• arsénico y cromo provenientes de

madera tratada con substancias químicas

Su riesgo debido a la exposición a estos

elementos varía de acuerdo a cuán a

menudo realiza este tipo de trabajo. Para

reducir su exposición a estas substancias químicas: trabaje en una área bien

ventilada y use el equipo de seguridad

aprobado tales como aquellas mascarillas contra el polvo diseñadas en forma

especial para fi ltrar las partículas mi-

croscópicas.

ESPAÑOL

27

www.desatech.com

Page 28

INFORMACIÓN IMPORTANTE DE SEGURIDAD

ADVERTENCIA: Los contragolpes pu-

eden ocurrir cuando el extremo o la punta