Page 1

ELECTRIC CHAIN SAW

OWNER’S MANUAL

®

®

LNT-2 EL-4 EL-7B

EL-3 EL-7

Page 2

®

ELECTRIC CHAIN SAW

1

AB C

1.

5.

3

3

2

D

2.

3.

WARNING ICON G 001

4.

7

!

6.

6

1

7.

2

A1

A

1

E

3

1

4

2

5

A1

A

8

F

15

7

14

1

10

11

4

5

9

12

13

3

4

2

3

5

4

6

10

9

7

6

8

2

GH I

1

2

3

2

4

1

2

103148

Page 3

OWNER’S MANUAL

JL

1

2

M

3

5 cm

4

5 cm

5

2

1

K

4

15

cm

1

3

NO

2

5-10 cm

45°

1

2

1

3

P

S

5

1

F

IL

E

H

O

L

D

E

R

1

3

4

Q

1

2

1

2

1

4

2

5

3

6

7

T

2

1

2

3

4

R

U

2

ECSp005

103148

3

Page 4

®

ELECTRIC CHAIN SAW

SYMBOL

IDENTIFICATION

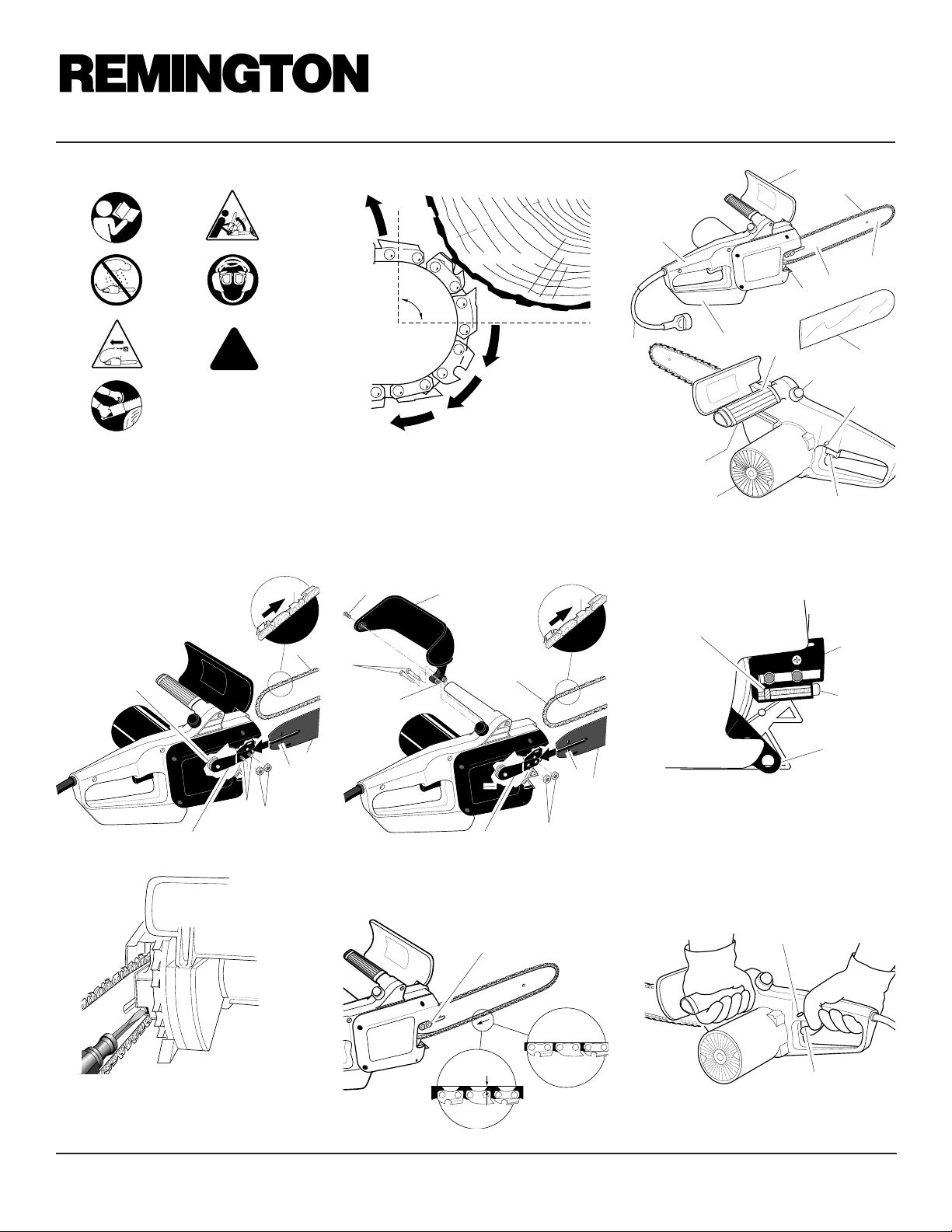

Call Outs For Figure A

1. Read instruction manual

2. Do not expose to rain or use in wet conditions

3. Remove plug immediately if cable is damaged

or cut

4. Hold chain saw with both hands

5. Beware or kickback

6. Hearing and eye protection must be worn

7. Safety information warnings appear throughout

this manual.

Pay close attention to them. Below are definitions

for the safety information listed throughout this

manual.

WARNING indicates a hazard which can cause

severe personal injury, death, or substantial

property damage if you ignore warning.

CAUTION indicates a hazard which will or can

cause minor personal injury or property damage

if you ignore warning.

SAFETY

WARNINGS

IMPORTANT: Read and understand this

manual before assembling or operating this

chain saw. Improper use of saw can cause

severe injury. Keep this manual for future

reference.

BEFORE OPERATING SAW

1. Watch what you are doing. Use common sense. Do

not operate saw when you are tired.

2. Only well-instructed adults should operate chain

saw. Never allow children to operate chain saw.

3. Use proper extension cord.

4. Do not operate chain saw

• in rain or in damp or wet areas

• if saw is damaged, adjusted wrong, or not fully

and securely assembled

• while in tree or on a ladder

5. Wear snug-fitting and protective clothes including

gloves, safety shoes, goggles, safety helmet, and

ear plugs. Use rubber gloves and shoes if working

outdoors.

6. Before cutting, provide a clear work area, secure

footing, and planned retreat path from falling tree.

7. The typical hand-arm vibration at full load while

cutting wood when tested in accordance to ISO/

DIS 7205 is 23.8 M/S2.

8. The typical A-weighted noise levels at full load

while cutting wood when tested in accordance to

ISO 7182 are:

Sound Pressure Level 95 DB(A)

Sound Power Level 100 DB(A)

WHILE OPERATING SAW

1. Keep children, animals, and bystanders away from

chain saw and extension cord. Only chain saw user

should be in work area.

2. Grip chain saw firmly with both hands. Thumbs

and fingers must wrap around saw handles. Never

operate chain saw with one hand. Never use hand

guard as handle.

3. Secure wood you are cutting by using clamps or

chocks.

4. Keep all parts of body away from chain when saw

is running.

5. Cut small brush and saplings with extreme care.

Slender material may catch in chain and be whipped

toward you or pull you off balance.

6. When cutting limb or tree trunk that is under

tension, use extreme caution. Be alert for wood

springing back. When tension is released, limb

could spring back and strike you.

7. Do not activate the chain brake to stop saw. Always

release trigger to stop saw.

8. Carry chain saw from one place to another

• with finger off trigger, saw stopped, and

unplugged

• by holding front handle with guide bar and chain

to rear

KICKBACK

WARNING: Beware of kickback.

Kickback may occur when the nose or tip of the guide bar

touches an object (see Figure B), or when the wood closes

in and pinches the saw chain in the cut. Tip contact may

cause a lightning fast reverse reaction, kicking the guide

bar up and back towards the operator (see Figure B).

Pinching the saw chain along the top of the guide bar may

push the guide bar rapidly back towards the operator.

Either of these reactions may cause you to lose control of

the saw which could result in serious injury to user.

The following steps will reduce the risk of kickback.

• Use both hands to grip saw while saw is running.

Use firm grip. Thumbs and fingers must wrap

around saw handles.

•Keep all safety items in place on saw. Make sure

they work properly.

• Do not overreach or cut above shoulder height.

• Stand slightly to left side of saw. This keeps your

body from being in direct line with chain.

• Do not let guide bar nose touch anything when

chain is moving (see Figure B).

•Watch for shifting of wood or other forces that

may pinch chain.

•Never use dull or loose chain. Keep chain sharp

with proper tension.

Call Out For Figure B

1. 90° Quadrant (Do not let guide bar touch in this

quadrant)

2. Chain Direction

3. Kickback Direction

MAINTENANCE AND STORAGE OF

CHAIN SAW

1. Unplug chain saw from power source

• when not in use

• before moving from one place to another

• before servicing or changing accessories or

attachments

2. Cutting edges on chain are sharp. Use protective

gloves when handling chain.

3. Maintain chain saw with care.

•Keep chain sharp, clean, and lubricated.

• Inspect power cord often. If damaged, have

repaired.

•Never carry chain saw by power cord.

•Never yank power cord to unplug it.

•Keep power cord from heat, oil, and sharp edges.

4. When not in use, store chain saw in a high or locked

place that is dry and out of children’s reach.

5. Inspect chain saw before and after each use. Do

not use chain saw if damaged.

!

WARNING: Some dust created by power

sanding, sawing, grinding, drilling, and other

construction activities contains chemicals

known (to the state of California) to cause

cancer, birth defects, or other reproductive

harm. Some examples of these chemicals are:

• lead from lead-based paints

• crystalline silica from bricks and cement and other masonry products

• arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area, and

work with approved safety equipment, such

as those dust masks that are specially designed

to filter out microscopic particles.

PRODUCT

IDENTIFICATION

Call Outs For Figure C

1. Front Hand Guard

2. Saw Chain

3. Rear Handle

4. Guide Bar Nose

5. Guide Bar

6. Spike

7. Rear Hand Guard

8. Power Cord

9. Scabbard

10. Oil Level Sight Hole (located on saw body,

hidden in illustration by front handle)

11. Oil Cap With Squeeze Bulb

12. Switch Lockout

13. Trigger

14. Motor Housing

15. Front Handle

ASSEMBLY

IMPORTANT: Do not clamp chain saw in vise

during assembly.

FOR MODELS EL-4 AND EL-7B ONLY

1. Lay saw chain out flat.

2. Remove guide bar nuts from guide bar bolts (see

Figure D).

4

103148

Page 5

ASSEMBLY

3. Turn adjusting screw counterclockwise (see Figure

F). Continue to turn adjusting screw until adjusting

block is to rear of adjusting plate.

4. Install guide bar onto saw body. Place rear of guide

bar between adjusting plate and sprocket support.

IMPORTANT:

into oval adjusting hole on guide bar.

5. Attach guide bar nuts to guide bar bolts.

Tighten guide bar nuts finger tight only. Make sure

adjusting block is in oval adjusting hole on guide bar.

6. Place chain around drive sprocket, then along top

groove of guide bar and around guide bar nose.

Note:

Make sure cutting edges of chain are facing

the right direction. Position chain so cutting edges

on top of guide bar face guide bar nose (see Figure D).

!

CAUTION: Do not place chain on saw

backwards. If chain is backwards, saw will

vibrate badly and will not cut.

7. Adjust saw chain tension. Follow steps under Saw

Chain Tension Adjustment.

8. If saw has 2-piece side cover, attach sprocket cover.

Call Outs For Figure D

A. Towards Guide Bar Nose

A1. Cutting Edge

1. Saw Chain

2. Guide Bar

3. Adjusting Hole

4. Guide Bar Nuts

5. Guide Bar Bolts

6. Sprocket Support

7. Drive Sprocket

Call Outs For Figure F

1. Adjusting Block

2. Sprocket Support

3. Adjusting Plate

4. Adjusting Screw

Continued

Make sure to insert adjusting block

IMPORTANT:

FOR MODELS EL-3, EL-7, AND EL-2

ONLY

1. Lay saw chain out flat.

2. Remove guide bar nuts, guide bar bolts, and Phillips

screw from plastic bag.

3. Install hand guard by pressing two bosses (at bottom

of hand guard) into hex-shaped holes in saw body

(see Figure E). Install Phillips screw into hand guard

and saw handle. Tighten screw firmly.

4. Turn adjusting screw counterclockwise (see Figure

F). Continue to turn adjusting screw until adjusting

block is to rear of adjusting plate.

5. Install guide bar onto saw body. Slide guide bar onto

adjusting plate.

adjusting block into oval adjusting hole on guide bar.

6. Rotate sprocket support up over guide bar. Align

holes in sprocket support with guide bar bolt holes

in saw body.

7. Insert front guide bar bolt through saw body and

sprocket support (see Figure E.). Install and tighten

guide bar nut finger-tight only.

8. Place chain around drive sprocket, then along top

groove of guide bar and around guide bar nose.

IMPORTANT:

Make sure to insert

OWNER’S MANUAL

Note:

Make sure cutting edges of chain are facing

the right direction. Position chain so cutting edges

on top of guide bar face guide bar nose (see Figure E).

!

CAUTION: Do not place chain on saw

backwards. If chain is backwards, saw will

vibrate badly and will not cut.

9. Insert rear guide bar bolt through saw body and

sprocket support. Install and tighten guide bar nut

finger-tight only.

block is in oval adjusting hole on guide bar.

10. Adjust saw chain tension. Follow steps under Saw

Chain Tension Adjustment.

Call Outs For Figure E

A. Towards Guide Bar Nose

A1. Cutting Edge

1. Phillips Screw

2. Hand Guard

3. Guide Bar Bolts

4. Bosses

5. Saw Chain

6. Guide Bar

7. Adjusting Hole

8. Guide Bar Nuts

9. Sprocket Support

10. Drive Sprocket

SAW CHAIN TENSION

ADJUSTMENT

!

WARNING: Maintain proper chain tension

always. A loose chain will increase the risk of

kickback. A loose chain may jump out of guide

bar groove. This may injure operator and

damage chain. A loose chain will cause chain,

guide bar, and sprocket to wear rapidly.

Note:

For pre assembled models, the saw chain tension

is properly set at factory. A new chain will stretch.

Check new chain after first few minutes of operation.

Allow chain to cool down. Follow steps below to

readjust saw chain tension.

1. Before adjusting chain, make sure guide bar nuts

are only finger tight (see Figure D and E). Also

make sure adjusting block is in oval adjusting hole

on guide bar (see Figures D, E, and F).

2. Turn adjusting screw clockwise until all slack is

out of chain (see Figure G).

no gap between side links of chain and bottom of

guide bar (see Figure H).

3. Wearing protective gloves, move chain around

guide bar. Chain should move freely. If chain does

not move freely, loosen chain by turning adjusting

screw counterclockwise.

4. After chain tension is correct, tighten guide bar nuts

firmly. If not, guide bar will move and loosen chain

tension. This will increase the risk of kickback. This

can also damage saw.

Check new chain after first few minutes of operation.

Allow chain to cool down. Readjust chain tension.

Call Outs For Figure H

1. Guide Bar Nuts 3. Incorrect Tension

2. Gap 4. Correct Tension

IMPORTANT:

Note:

Note:

A new chain will stretch.

Make sure adjusting

There should be

FILLING OIL TANK

1. Remove oil cap.

2. Fill oil tank with SAE #30 motor oil. Grain-based

biodegradable bar and chain lubricants made from

rapeseed oil, canola oil, or sunflower oil bases also

provide acceptable performance.

temperatures below -1°C, use SAE #10 oil. For

temperatures above 24°C, use SAE #40 oil.

3. Replace oil cap at once. Tighten oil cap firmly for

good seal. This will avoid oil seepage from tank.

4. Wipe off excess oil.

Note:

It is normal for oil to seep when saw is not in use.

Empty oil tank after each use to prevent seepage.

Note:

For

OPERATING CHAIN

SAW

EXTENSION CORDS

Use proper extension cord with this chain saw. Use a

HO7RN extension cord with no less than 1.5 mm2 wire

at distances up to 30 meters. Use a ground fault circuit

interrupter as part of the power supply system.

Use an extension cord heavy enough to carry the

current your saw will draw. An undersized cord will

cause a voltage drop at the saw, loss of power, and

overheating.

Keep cord away from cutting area. Make sure cord

does not catch on branches or logs during cutting.

Inspect cords often. Replace damaged cords.

OILING SAW CHAIN

Always check oil level before using saw. To oil chain,

press squeeze bulb on oil cap. Do not attempt to operate

the oiler while cutting with the saw. Oil will feed onto

guide bar and chain. Press squeeze bulb on oil cap at least

once before each cut. Check oil level often by looking at

oil sight level hole. Oil sight level hole is on left side of

saw, between front handle and front hand guard.

CUTTING WITH THE CHAIN SAW

1. Connect saw to power supply.

2. Make sure area of log to be cut is not touching

ground. This will keep chain from touching ground

as it cuts through log. Touching ground with moving

chain will dull chain.

3. Firmly grip saw as shown in Figure I. Thumbs and

fingers must wrap around saw handles.

4. Make sure your footing is firm. Keep feet apart.

Divide your weight evenly on both feet. Stand

slightly to left side of saw. This keeps your body

from being in direct line with chain.

5. When ready to make a cut, press in switch lockout

with right thumb and squeeze trigger (see Figure

I). This will turn saw on. Releasing trigger will turn

saw off. Make sure saw is running at full speed

before starting a cut.

6. When starting a cut, place moving chain against

wood. Hold saw firmly in place to avoid possible

bouncing or skating (sideways movement) of saw.

7. Guide saw using light pressure. Do not force saw.

Overload can cause motor burn out.

Continued

103148

5

Page 6

®

ELECTRIC CHAIN SAW

OPERATING CHAIN

SAW

Continued

8. Remove saw from a cut with saw running at full

speed. Stop saw by releasing trigger. Make sure

chain has stopped before setting saw down.

9. Practice until you can maintain a steady, even

cutting rate.

Call Outs For Figure I

1. Switch Lockout

2. Trigger

CHAIN BRAKE

(Models EL-4 and EL-7B only)

The chain brake quickly stops the saw chain. Kickback

causes the back of operator’s left hand to contact front

hand guard (see Figure J). When front hand guard

moves forward, the saw chain stops. This reduces the

chance of serious injury during kickback. When the

chain brake activates, release trigger at once.

To reset chain brake, release trigger and move front

hand guard back into position. You must release trigger

first. If not, the saw will start when you reset the front

hand guard.

!

CAUTION: Do not use the chain brake to

stop and start your saw. Quick repeated stops

may cause overheating of the chain brake.

Damage to the chain brake will occur.

Note:

Test chain brake before each use. Firmly grip

saw with both hands. With saw running, move front

hand guard forward with back of left hand. Keep both

hands on the handles. Saw chain should stop. If chain

brake does not work, have saw repaired by authorized

service person.

Call Outs For Figure J

1. Activation of Chain Brake

2. STOP

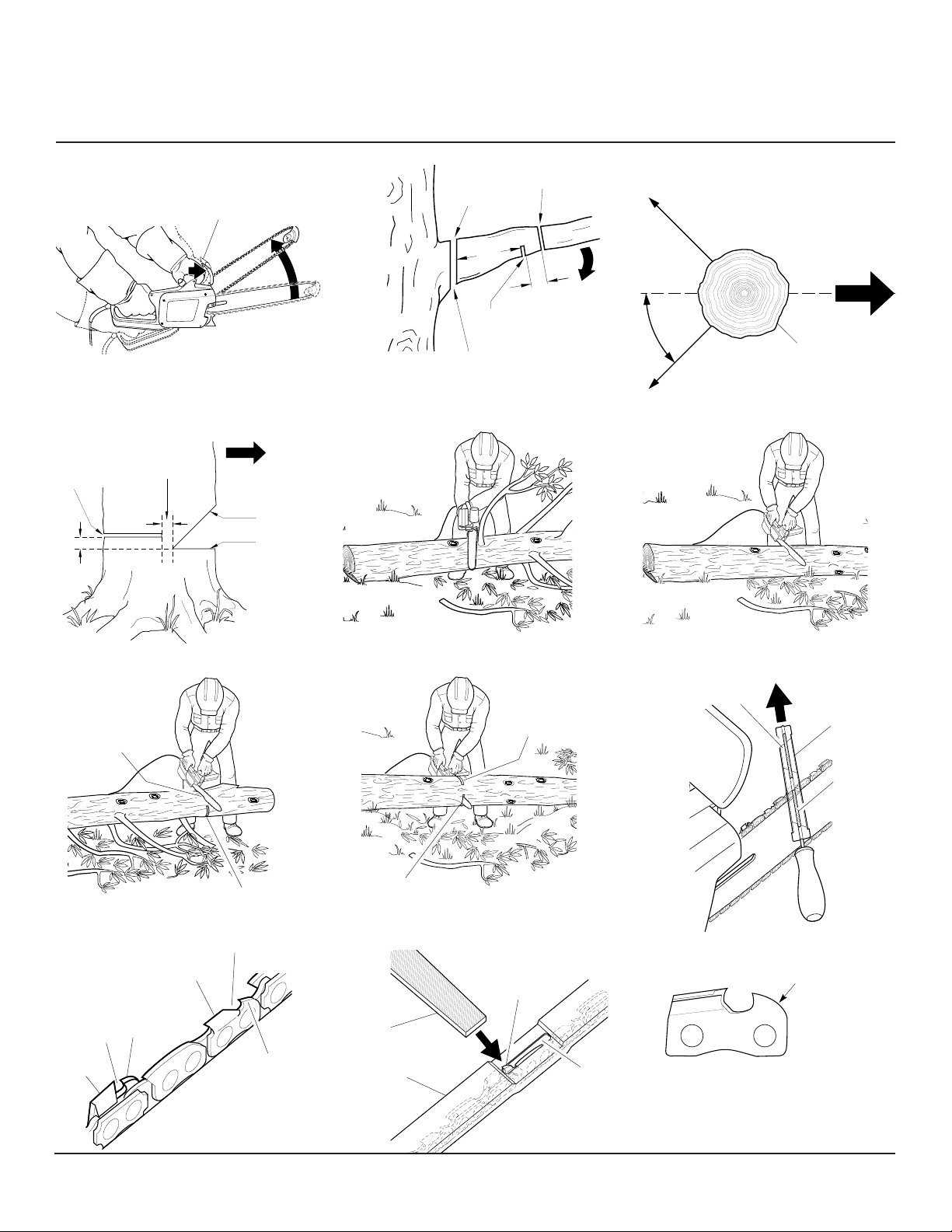

TRIMMING A TREE (Pruning)

Trimming a tree is the process of cutting limbs from a

living tree. Follow directions below to trim a tree.

1. Make first cut 15 cm from tree trunk on underside

of limb. Use top of guide bar to make this cut. Cut

1/3 through diameter of limb (see Figure K).

2. Move 5 to 10 cm farther out on limb. Make second

cut from above limb. Continue cut until you cut

limb off.

3. Make third cut as close to tree trunk as possible on

underside of limb stub. Use top of guide bar to make

this cut. Cut 1/3 through diameter of stub.

4. Make fourth cut directly above third cut. Cut down

to meet third cut. This will remove limb stub.

Call Outs For Figure K

1. 1st Cut - Pruning Undercut (to avoid

splintering)

2. 2nd Cut - Pruning Cut (to avoid pinching)

3. 3rd Cut - Stub Undercut (to avoid splintering)

4. 4th Cut - Final Stub Cut

FELLING A TREE

(Cutting Down a Tree)

!

WARNING: Do not fell a tree without ample

skill or expert help. Be aware of your

surroundings. Do not endanger any person,

strike utility lines, or cause property damage.

If tree strikes utility lines, contact utility

company at once.

Felling is the process of cutting down a tree. Follow

directions below to fell a tree.

Before Felling a Tree

1. Inspect tree. Make sure there are no dead limbs or

branches that may fall on you. Study natural lean

of tree, location of larger branches, and wind

direction. This will help you judge which way tree

will fall.

2. Clear work area around tree.

3. Plan and clear a retreat path before felling. Make

retreat path opposite to planned direction of fall of

tree and at 45° angle (see Figure L).

4. Remove dirt, stones, loose bark, nails, staples, and

wire from tree where you will make felling cuts.

5. Stay on uphill side when felling tree. Tree could

roll or slide downhill after falling.

Call Outs For Figure L

1. Retreat Path

2. Direction of Fall

3. Tree

Felling Procedure

A) Felling Notch

A properly placed felling notch will determine direction tree will fall. Place felling notch on side of tree in

direction you want tree to fall (see Figure M). Follow

directions below to create a felling notch.

1. Make lower notch cut as close to ground as possible.

Hold saw so guide bar is horizontal. Cut 1/3 the

diameter of tree trunk (see Figure M).

make this horizontal lower notch cut first. If you make

this cut second, tree can pinch chain or guide bar.

2. Start upper notch cut the same distance above first

cut as first cut is deep.

cut is 20 cm deep, start upper notch cut 20 cm above

it. Cut downward at 45° angle. The upper notch

should meet end of lower notch cut (see Figure M).

3. Remove tree trunk wedge created by notching cuts.

B) Felling Cut

1. Make felling cut 5 cm higher than lower notch cut

and on opposite side of tree (see Figure M). Keep

felling cut parallel to lower notch cut.

2. Cut towards notch.

!

WARNING: Do not cut all the way through

tree. Leave about 5 cm of tree diameter uncut

directly behind felling notch (see Figure M).

This uncut portion acts as a hinge. The hinge

helps keep tree from twisting and falling in

wrong direction.

Example:

Note:

Always

If lower notch

cut

3. As felling cut nears hinge, tree should begin to fall.

Note:

If needed, drive wedges into felling cut to

control direction of fall. If tree settles back and

pinches chain, drive wedges into felling cut to

remove saw. Only use wedges made of wood, plastic,

or aluminum. Never use wedge made of steel. This

could cause kickback and damage to chain.

4. When tree begins to fall, quickly

•remove saw from felling cut

•release trigger and put saw down

•exit area using retreat path

Call Outs For Figure M

1. 1st Cut - Lower Notch Cut

2. 2nd Cut - Upper Notch Cut

3. 3rd Cut - Felling Cut

4. Hinge

5. Direction of Fall

LIMBING A TREE

Limbing is removing branches from a fallen tree. Do

not remove larger limbs under tree that support log off

ground. Remove each limb with one cut (see Figure N).

Clear cut limbs from work area often. This will help

maintain a safe work area.

Make sure you start your cut where limb will not pinch

saw during cutting. To avoid pinching, start cut on

freely hanging limbs from above limb. Start cut on

limbs under tension from under limb. If pinch occurs,

turn saw off, lift limb, and remove saw.

BUCKING A LOG

!

WARNING:

• If on slope, make sure log will not roll

down hill. Secure log by using wooden

stakes. Stand on uphill side of log while

cutting.

• While cutting log, never hold log with

your hand, leg, or foot or allow another

person to hold log.

Bucking a log is cutting a log into sections. When

possible, raise log or section off ground. Do this by

using limbs, logs, chocks, etc.

When cutting through log, maintain control by reducing cutting pressure near end of cut.

Follow directions below to buck a log.

Entire Length Of Log On Ground

1. Cut log from top (see Figure O).

Log Supported On One End

1. Make first cut on underside of log (see Figure P).

Use top of guide bar to make this cut. Cut 1/3

through diameter of log. This cut will keep section

from splintering when cut.

2. Make second cut directly above first cut. Cut down

to meet first cut. This cut will keep log from

pinching guide bar and chain.

Call Outs For Figure P

1. 1st Cut

2. 2nd Cut

6

103148

Page 7

Log Supported On Both Ends

1. Make first cut from above log (see Figure Q). Cut

1/3 through diameter of log. This cut will keep

section from splintering when cut.

2. Make second cut on underside of log, directly under

first cut. Use top of guide bar to make this cut. Cut

up to meet first cut. This will keep log from pinching

guide bar and chain.

Call Outs For Figure Q

1. 1st Cut

2. 2nd Cut

CLEANING AND

MAINTENANCE

NOTICE: Below are instructions for servicing

your chain saw. Any servicing not mentioned

below should be done by an authorized service

center.

CLEANING SAW BODY

Keep saw body clean. Use a soft cloth dampened with

a mild soap and water mixture. Wipe saw body to clean.

When cleaning saw body,

• do not submerge saw in any liquids

• do not use products that contain ammonia,

chlorine, or abrasives

• do not use chlorinated cleaning solvents, carbon

tetrachloride, kerosene, or gasoline

CARE OF GUIDE BAR

Uneven bar wear causes most guide bar problems.

Incorrect sharpening of chain cutter and depth gauge

settings often cause this. When bar wears unevenly, it

widens guide bar groove. This causes chain clatter and

rivet popping. Saw will not cut straight. Replace guide

bar if this occurs.

Inspect guide bar before sharpening chain. A worn or

damaged guide bar is unsafe. A worn or damaged guide

bar will damage chain. It will also make cutting harder.

Normal Guide Bar Maintenance

1. Remove guide bar from chain saw.

2. Remove sawdust from guide bar groove

periodically. Use putty knife or wire.

3. Clean oil slots after each day of use.

4. Remove burrs from sides of guide bar. Use flat file

to make side edges square.

Replace guide bar when

• bar is bent or cracked

• inside groove of bar is badly worn

SHARPENING YOUR SAW CHAIN

!

WARNING: Unplug chain saw from power

source before servicing. Severe injury or death

could occur from electrical shock or body

contact with moving chain.

OWNER’S MANUAL

!

WARNING: Cutting edges on chain are

sharp. Use protective gloves when handling

chain.

Keep chain sharp. Your saw will cut faster and more

safely. A dull chain will cause undue sprocket, guide

bar, chain, and motor wear. If you must force chain into

wood and cutting creates only sawdust with few large

chips, chain is dull.

Items Needed to Sharpen Chain

Purchase these items from your local dealer, hardware

store, or chain saw supplies outlet.

•4 mm round file • Depth gauge tool

• File guide • Vise

• Medium sized flat file

Sharpening Cutters

Use file guide for 30° filing.

1. Adjust chain for proper tension (see Saw Chain

Tension Adjustment).

2. Clamp guide bar in vise to hold saw steady.

Do not clamp chain.

3. Press four millimeter round file (attached to file

guide) into groove between top plate and depth

gauge on chain. File guide should rest on both top

plate and depth gauge (see Figures R and S).

File at midpoint of guide bar.

4. Hold file guide level. Make sure 30° mark on file

guide is parallel to center of guide bar (see Figure

R). This will insure that you file cutters at 30° angle.

5. File from inside towards outside of cutter until

sharp. Only file in this one direction (see Figure

R).

Note:

sharpen cutter.

6. After each cutter if sharpened, move chain forward

to sharpen next cutter. File all cutters on one side

of chain.

7. Move to other side of chain and repeat process.

Call Outs For Figure R

1. Filing Direction

2. 30° Guide Mark

3. File Guide

4. 4 mm Round File

5.

Note:

and filing direction for sharpening cutters on left

side of chain.

Call Outs For Figure S

1. Left Side of Chain

2. Groove

3. Top Plate (right side of chain)

4. Depth Gauge (left side of chain)

5. Top Plate (left side of chain)

6. Depth Gauge (right side of chain)

7. Right Side of Chain

Filing Cutter Depth Gauges

The cutter depth gauge clearance is reduced as cutters

are sharpened. After every second or third sharpening,

reset cutter depth gauges.

1. Place depth gauge tool firmly across top of two

cutters. Make sure depth gauge enters slot in depth

gauge tool (see Figure T).

Two or three strokes with file should

This illustration shows file guide placement

Note:

Note:

2. Use medium flat file. File depth gauge level with

depth gauge tool.

3. Remove depth gauge tool. With flat file, round off

front corner of cutter depth gauge (see Figure U).

Call Outs For Figure T

1. Depth Gauge

2. Flat File

3. Depth Gauge Tool

4. Depth Gauge Slot

Call Outs For Figure U

1. Front Corner

After several hand filings, have authorized service

center or sharpening service machine sharpen chain.

This will insure even filing.

REPLACING SAW CHAIN

Replace chain when cutters are too worn to sharpen or

when chain breaks. Only use replacement chain noted

in this manual. Always include new drive sprocket

when replacing chain. This will maintain proper driving of chain.

RECYCLING

In the event it is not practical to repair your chain saw, be

sure to follow local and country codes for recycling

plastic and metallic materials when disposing of the unit.

STORAGE

If storing saw for more than 30 days, follow steps

below.

1. Drain oil tank.

2. Remove and clean guide bar and chain. Clean guide

bar and chain by soaking in petroleum based

solvent or mild soap and water mixture.

3. Dry guide bar and chain.

4. Place chain in container filled with oil. This will

prevent rust.

5. Wipe a thin coating of oil over surface of guide

bar.

6. Wipe off outside of saw body. Do this with soft

cloth dampened with a mild soap and water

mixture.

7. Store chain saw in a high or locked place that is

dry and out of children’s reach.

REPLACEMENT

PARTS

!

WARNING: Use only replacement parts

described in this manual. Use of other parts

could damage saw or injure operator.

Purchase these parts from your local dealer.

Part Number Description

097572-03S Guide bar, 400 mm

097570-01S Guide bar, 350 mm

091375-02S Chain, 400 mm

091374-02S Chain, 350 mm

107713-01 Drive sprocket

103148

7

Page 8

TROUBLESHOOTING

WARNING: Unplug chain saw from power source before servicing. Severe injury or death

!

could occur from electrical shock or body contact with moving chain.

OBSERVED FAULT

Saw runs, but does not cut.

Saw does not cut unless heavily forced. Cutting produces only sawdust with few large chips.

Saw runs slow. Saw stalls easily.

Motor of saw does not run when you squeeze trigger.

Motor of saw runs, but chain does not move.

Chain does not get oil.

Chain comes off guide bar.

Saw smokes.

Saw leaks oil.

POSSIBLE CAUSE

Chain assembled backwards on guide bar.

Chain is dull.

Low power supply voltage.

Switch lockout not pressed in to release trigger.

Chain brake activated.

Extension cord connections loose.

Open line fuse or circuit breaker.

Bad motor brushes.

Open wiring circuit on saw.

Gear train failure.

Clogged oil slot in guide bar.

Oil is too thick.

Chain is loose.

Guide bar and chain not assembled right.

Saw damaged. Do not use saw.

Oil cap is not secure.

REMEDY

See Assembly.

See Sharpening Your Saw Chain.

Extension cord wire size too small. See Extension

Cords.

Press in switch lockout before squeezing trigger.

Release trigger and move front hand guard back to-

wards rear of saw.

Check cord connections.

Check line fuse or circuit breaker.

Contact authorized service person.

Contact authorized service person.

Contact authorized service person.

Remove guide bar and clean oil slot.

Use correct weight of oil. See Filling Oil Tank.

Tighten chain. See Saw Chain Tension Adjustment.

See Assembly.

Contact authorized service person.

Tighten oil cap.

Note:

Empty oil tank when not in use.

Chain brake does not stop saw chain

(EL-4 and EL-7B only).

Brake failure.

Contact authorized service person.

LIMITED WARRANTY

ELECTRIC CHAIN SAW

This product is warranted to be free from defects in materials and workmanship for six (6) months from the date of first purchase when operated and

maintained in accordance with instructions. This warranty is extended only to the original retail purchaser.

This warranty covers only the cost of parts required to restore this to proper operating condition. Transportation and incidental costs associated with

warranty repairs are not reimbursable under this warranty.

Warranty service is available only through authorized dealers or service centres.

This warranty does not cover commercial, industrial, or rental usage, nor does it apply to parts that are not in original condition because of normal wear

and tear, or parts that fail or become damaged as a result of misuse, accident, lack of proper maintenance, tampering, or alteration.

The warrantor assumes no responsibility for indirect, incidental or consequential damages.

THIS EXPRESS WARRANTY IS GIVEN IN LIEU OF ANY OTHER WARRANTY EITHER EXPRESSED OR IMPLIED, INCLUDING

WARRANTIES OR MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Manufacturer:

DESA International

2701 Industrial Drive

Bowling Green, KY 42101

U.S.A.

Page 9

ELECTROSIERRA

MANUAL DEL PROPIETARIO

®

®

LNT-2 EL-4 EL-7B

EL-3 EL-7

Page 10

®

ELECTROSIERRA

1

AB C

1.

5.

3

3

2

D

2.

3.

WARNING ICON G 001

4.

7

!

6.

6

1

7.

2

A1

A

1

E

3

1

4

2

5

A1

A

8

F

15

7

14

1

10

11

4

5

9

12

13

3

4

2

3

5

4

6

10

9

7

6

8

2

GH I

1

2

3

2

4

1

2

103148

Page 11

MANUAL DEL PROPIETARIO

JL

1

2

M

3

5 cm

4

5 cm

5

2

1

K

4

15

cm

1

3

NO

2

5-10 cm

45°

1

2

1

3

P

S

5

1

F

IL

E

H

O

L

D

E

R

1

3

4

Q

1

2

1

2

1

4

2

5

3

6

7

T

2

1

2

3

4

R

U

2

ECSp005

103148

3

Page 12

ELECTROSIERRA

®

IDENTIFICACION DE

LOS SIMBOLOS

Leyenda para la Figura A

1. Leer el manual de instrucciones

2. No dejar expuesta a la lluvia ni usar en

condiciones húmedas

3. Quitar el enchufe inmediatamente si el cable

está dañado o cortado

4. Sujetar la electrosierra con las dos manos

5. Estar atento a los culatazos

6. Protegerse los oídos y los ojos

7. Las advertencias de seguridad aparecen en

todo este manual.

Prestar atención al mensaje que les sigue. A

continuación damos la definición de los avisos

de seguridad que aparecen en diferentes

partes de este manual.

ADVERTENCIA indica un riesgo, que de no

respetarse la advertencia, podría causar

graves lesiones personales, la muerte o daños

considerables a la propiedad.

PRECAUCION indica un riesgo, que de no

respetarse la advertencia, podría causar

lesiones personales menores o daños a la

propiedad.

ADVERTENCIAS

DE SEGURIDAD

IMPORTANTE: Leer y entender este manual

antes de armar o manejar esta electrosierra. El

uso indebido de la sierra puede causar lesiones

graves. Guardar este manual para referencia

futura.

ANTES DE MANEJAR LA

ELECTROSIERRA

1. Estar atento a lo que se está haciendo. Emplear

sentido común. No usar esta sierra cuando se está

cansado.

2. Solamente personas adultas y capacitadas deben

manejar la electrosierra. No permitir que los niños

manejen la electrosierra.

3. Usar un cordón de extensión adecuado.

4. No manejar la electrosierra

• en la lluvia o lugares húmedos o mojados

• si está dañada, mal ajustada o no está total y

firmemente armada

• estando trepado en un árbol o en una escalera

5. Usar ropa protectora y bien ajustada incluidos

guantes, zapatos protectores, gafas, casco y tapones

para los oídos. Usar guantes de goma y zapatos

para trabajar al aire libre.

6. Antes de cortar, despejar la zona de trabajo, tener

una buena base de apoyo y preparar una vía para

escapar del árbol cuando empieza a caer.

7. La magnitud típica de la vibración transmitida a la

mano y brazo mientras se corta madera es de 23,8

m/s2 según ISO/DIS 7205.

8. Los niveles típicos de intensidad de ruido con

ponderación "A" mientras se corta madera cuando

se prueban de acuerdo a la norma ISO 7182 son:

Nivel de presión sonora 95 dB(A)

Nivel de potencia sonora 100 dB(A)

MIENTRAS SE MANEJA LA

ELECTROSIERRA

1. Mantener la electrosierra y el cordón de extensión

lejos del alcance de los niños, animales y

espectadores. Solamente el operador de la

electrosierra deberá estar en la zona de trabajo.

2. Sujetar la electrosierra firmemente con las dos

manos. Los pulgares y dedos deben empuñar

completamente las asas de la sierra. Nunca manejar

la electrosierra con una sola mano. Nunca usar el

protector de la mano como asa.

3. Afianzar la madera que se está cortando, con

fijaciones o cuñas.

4. Mantener todas las partes del cuerpo lejos de la

cadena mientras la sierra está funcionando.

5. Cortar los arbustos pequeños y arbolitos con mucho

cuidado. El material delgado puede quedar atrapado

en la cadena y ser lanzado hacia el operador,

causando la pérdida del equilibrio.

6. Tener sumo cuidado al cortar ramas o troncos de

árboles que estén bajo tensión. Estar alerta al hecho

que la madera puede saltar de golpe. Al quitar

tensión, la rama puede saltar y golpear al operador.

7. No activar el freno de la cadena para parar la sierra.

Para hacerlo, soltar el gatillo.

8. Para trasladar la sierra de un lugar a otro

• quitar el dedo del gatillo, pararla y desenchufarla

• sujetar el asa delantera con la barra guía y la

cadena hacia atrás

CULATAZOS

!

ADVERTENCIA: Estar atento a los

culatazos.

El culatazo ocurre cuando la nariz o punta de la barra

guía toca un objeto (ver la Figura B), o cuando la

madera se junta y aprisiona la cadena de aserrar durante

el corte. Como resultado, se produce un movimiento

repentino hacia atrás que mueve la barra guía de la

electrosierra hacia arriba y atrás hacia el operador (ver

la Figura B). El aprisionar la cadena a lo largo de la

parte superior de la barra guía puede empujar la barra

rápidamente hacia el operador. Cualquiera de estas dos

reacciones puede causar la pérdida del control de la

sierra y resultar en graves lesiones para el usuario.

Los pasos siguientes reducirán el riesgo de que ocurran

culatazos.

•

Sujetar la electrosierra con las dos manos.

Empuñarla firmemente. Los pulgares y dedos deben

empuñar completamente las asas de la sierra

• Mantener todos los dispositivos de seguridad

instalados en la sierra. Asegurarse de que

funcionan bien.

• No extenderse demasiado para cortar, ni cortar

por encima de la altura de los hombros.

• Situarse un poco hacia la izquierda de la

electrosierra. Esto impide que el cuerpo quede

directamente en línea con la cadena.

• No dejar que la punta de la barra guía toque

ningún objeto mientras la cadena está

funcionando (ver la Figura B).

• Estar atento al desplazamiento de la madera u

otras fuerzas que puedan aprisionar la cadena.

• Nunca usar una cadena que esté desafilada o floja.

Mantener la cadena bien afilada y correctamente

tensada.

.

Leyenda para la Figura B

1. Cuadrante de 90° (no dejar que la punta de la

barra guía toque en este cuadrante)

2. Sentido de movimiento

3. Sentido del culatazo

MANTENIMIENTO Y

ALMACENAMIENTO DE LA

ELECTROSIERRA

1. Desenchufar la electrosierra del tomacorriente

• cuando no esté en uso

• antes de trasladarla de un lugar a otro

• antes de reparar o cambiar accesorios o

aditamentos

2. Los bordes cortantes de la cadena son afilados. Usar

guantes de trabajo para manipular la cadena.

3. Tener cuidado al hacer trabajos de mantenimiento

a la sierra.

• Mantener la cadena bien afilada, limpia y

lubricada.

• Inspeccionar el cordón eléctrico frecuentemente.

Si está dañado, repararlo.

• Nunca acarrear la electrosierra del cordón

eléctrico.

• Nunca tirar del cordón para desenchufarlo.

•Proteger el cordón eléctrico del calor, aceite y

objetos cortantes.

4. Cuando no esté en uso, guardar la electrosierra en

un lugar seco elevado o bajo llave y lejos del

alcance de los niños.

5. Inspeccionar la electrosierra antes y después de

cada uso. No usar la electrosierra si está dañada.

!

ADVERTENCIA: Algo del polvo creado

por el lijado, aserrado, desgastado, taladrado

mecánicos, y otras actividades de

construcción contiene substancias químicas

conocidas (al Estado de California) como

causantes de cáncer, defectos de nacimiento,

u otras lesiones al sistema reproductor.

Algunos ejemplos de estas substancias

químicas son:

• plomo provenientes de pinturas con

base de plomo

• sílice cristalino proveniente de ladrillos

y cementos y otros productos de

mampostería

• arsénico y cromo proveniente de madera

tratada químicamente

Su riesgo de esas exposiciones varía

dependiendo cuan a menudo usted efectúa

este tipo de trabajo. Para reducir su exposición

a estas substancias químicas: trabaje en un

área bien ventilada, y trabaje con equipo

aprobado de seguridad, tal como máscaras

contra polvo que están especialmente

diseñadas para filtrar partículas

microscópicas.

4

103148

Page 13

MANUAL DEL PROPIETARIO

IDENTIFICACION DEL

PRODUCTO

Leyenda para la Figura C

1. Protector de la mano delantero

2. Cadena

3. Asa trasera

4. Punta de la barra guía

5. Barra guía

6. Estaca

7. Protector de la mano trasero

8. Cordón eléctrico

9. Funda

10. Mirilla de nivel de aceite (ubicada en el cuerpo

de la sierra, oculta en la ilustración por el asa

delantera)

11. Tapa de aceite con bulbo exprimible

12. Botón de seguro

13. Gatillo

14. Cuerpo del motor

15. Asa delantera

ARMADO

IMPORTANTE: No fijar la sierra en una prensa

durante el armado.

PARA MODELOS EL-4 Y EL-7B

SOLAMENTE

1. Tender plana la cadena.

2. Quitar las tuercas de los pernos de la barra guía

(ver la Figura D).

3.

Girar el tornillo de ajuste en sentido contrahorario

(ver la Figura F). Seguir girando el tornillo hasta que

el bloque de ajuste esté detrás de la placa de ajuste

4. Instalar la barra guía en el cuerpo de la sierra.

Colocar la parte trasera de la guía entre la placa de

ajuste y el soporte de la rueda dentada.

IMPORTANTE:

de ajuste en el agujero ovalado en la barra guía.

5. Instalar las tuercas en los pernos de la barra guía.

IMPORTANTE:

de la barra guía. Asegurarse que el bloque de ajuste

esté en el agujero ovalado en la barra.

6. Colocar la cadena alrededor de la rueda dentada

impulsora, en la ranura superior y alrededor la punta

de la barra guía.

Nota:

Asegurarse que los bordes cortantes de la

cadena estén orientados en el sentido correcto.

Colocar la cadena de modo que los bordes cortantes

encima de la barra queden hacia la punta de la barra

guía (ver la Figura D).

!

PRECAUCION: No colocar la cadena en la

electrosierra al revés. Si la cadena está al

revés o invertida, la electrosierra vibrará

excesivamente y no cortará.

7. Ajustar la tensión de la cadena. Seguir los pasos

indicados bajo Ajuste de la tensión de la cadena.

8. Si la sierra tiene una cubierta lateral de 2 piezas,

fijar la cubierta de la rueda dentada.

Asegurarse de insertar el bloque

Apretar sólo a mano las tuercas

Leyenda para la Figura D

A. Hacia la punta de la barra guía

A1. Borde cortante

1. Cadena

2. Barra guía

3. Agujero de ajuste

4. Tuercas de la barra guía

5. Pernos de la barra guía

6. Soporte de rueda dentada

7. Rueda dentada impulsora

Leyenda para la Figura F

1. Bloque de ajuste

2. Soporte de rueda dentada

3. Placa de ajuste

4. Tornillo de ajuste

PARA MODELOS EL-3, EL-7 Y EL-2

SOLAMENTE

1. Tender plana la cadena.

2. Sacar de la bolsa de plástico las tuercas y los pernos

de la barra guía, y el tornillo Phillips (cabeza de

cruz).

3. Instalar el protector de la mano encajando a presión

las dos salientes (en la parte inferior del protector)

en los agujeros hexagonales en el cuerpo de la sierra

(ver la Figura E). Instalar el tornillo Phillips en el

protector de la mano y el asa de la sierra. Apretar

el tornillo firmemente.

4. Girar el tornillo de ajuste en sentido contrahorario

(ver la Figura F). Seguir girando el tornillo hasta

que el bloque de ajuste esté detrás de la placa de

ajuste.

5. Instalar la barra guía en el cuerpo de la sierra.

.

Deslizar la barra guía sobre la placa de ajuste.

IMPORTANTE:

de ajuste en el agujero ovalado en la barra guía.

6. Girar el soporte de la rueda dentada por encima de

la barra guía. Alinear los agujeros del soporte de la

rueda dentada con los agujeros de los pernos de la

barra guía en el cuerpo de la sierra.

7. Insertar el perno delantero de la barra guía a través

del cuerpo de la sierra y soporte de la rueda dentada

(ver la Figura E). Instalar y apretar sólo a mano la

tuerca de la barra guía.

8. Colocar la cadena alrededor de la rueda dentada

impulsora, en la ranura superior y alrededor la punta

de la barra guía.

Nota:

Asegurarse que los bordes cortantes de la

cadena estén orientados en el sentido correcto.

Colocar la cadena de modo que los bordes cortantes

encima de la barra queden hacia la punta de la barra

guía (ver la Figura E).

!

PRECAUCION: No colocar la cadena en la

electrosierra al revés. Si la cadena está al

revés o invertida, la electrosierra vibrará

excesivamente y no cortará.

9. Insertar el perno trasero de la barra guía a través

del cuerpo de la sierra y soporte de la rueda dentada.

Instalar y apretar sólo a mano la tuerca de la barra

guía.

IMPORTANTE:

ajuste esté en el agujero ovalado en la barra.

10. Ajustar la tensión de la cadena. Seguir los pasos

indicados bajo Ajuste de la tensión de la cadena.

Asegurarse de insertar el bloque

Asegurarse que el bloque de

Leyenda para la Figura E

A. Hacia la punta de la barra guía

A1. Borde cortante

1. Tornillo Phillips

2. Protector de la mano

3. Pernos de la barra guía

4. Salientes

5. Cadena

6. Barra guía

7. Agujero de ajuste

8. Tuercas de la barra guía

9. Soporte de rueda dentada

10. Rueda dentada impulsora

AJUSTE DE LA

TENSION DE LA

CADENA

!

ADVERTENCIA: Siempre mantener la

cadena bien tensada. Una cadena floja

aumentará el riesgo de que ocurran culatazos.

Una cadena floja puede salirse de la ranura de

la barra guía, lo cual puede lesionar al operador

y dañar la cadena. Una cadena floja causará el

desgaste rápido de la cadena, la barra guía y la

rueda dentada.

Nota:

Para los modelos prearmados, la tensión de la

cadena fue debidamente ajustada en la fábrica. Una

cadena nueva se estira. Revisar la cadena nueva después de unos pocos minutos del funcionamiento inicial. Dejar que la cadena se enfríe. Seguir los pasos a

continuación para reajustar la tensión de la cadena.

1. Antes de ajustar la cadena, asegurarse que las

tuercas de la barra guía estén apretadas sólo a mano

(ver las Figuras D y E). También, asegurarse que el

bloque de ajuste esté en el agujero ovalado en la

barra (ver las Figuras D, E y F).

2. Girar el tornillo de ajuste en sentido horario hasta

eliminar todo el huelgo de la cadena (ver la Figura

G).

Nota:

los eslabones laterales de la cadena y la parte

inferior de la barra guía (ver la Figura H).

3. Ponerse guantes protectores y mover la cadena

alrededor de la barra guía. La cadena deberá

moverse libremente. De lo contrario, soltar la

cadena girando el tornillo de ajuste en sentido

contrahorario.

4. Una vez que la tensión de la cadena está correcta,

apretar firmemente las tuercas de la barra guía. De

no hacerlo, la barra se desplazará y aflojará la

tensión de la cadena. Esto aumentaría el riesgo de

que ocurran culatazos. También puede dañar la

sierra.

la cadena nueva después de unos pocos minutos

del funcionamiento inicial. Dejar que la cadena se

enfríe. Volver a ajustar la tensión de la cadena.

Leyenda para la Figura H

1. Tuercas de la barra guía

2. Espacio

3. Tensión incorrecta

4. Tensión correcta

No debe quedar ningún espacio entre

Nota:

Una cadena nueva se estirará. Revisar

103148

5

Page 14

ELECTROSIERRA

®

LLENADO DEL TANQUE

1. Quitar la tapa del aceite.

2. Llenar el tanque con aceite para motor SAE N° 30.

Los lubricantes biodegradables para barras y

cadenas elaborados de bases de aceite de colza,

canola o girasol también proporcionan un

rendimiento aceptable.

bajo -1°C, usar aceite SAE N° 10. Para

temperaturas sobre 24°C, usar aceite SAE N° 40.

3. Volver a colocar la tapa del aceite inmediatamente

y apretarla firmemente para lograr un buen cierre.

Esto evitará el derrame de aceite del tanque.

4. Limpiar el exceso de aceite.

Nota:

Es normal que escape aceite cuando la sierra no

está en uso. Vaciar el tanque después de cada uso para

impedir escape o goteo de aceite.

Nota:

Para temperaturas

MANEJO DE LA

ELECTROSIERRA

CORDONES DE EXTENSION

Usar un cordón de extensión apropiado con esta

electrosierra. Usar un cordón de extensión HO7RN con

alambre no inferior a 1,5 mm2 para distancias de hasta

30 metros. Se recomienda usar un interruptor de pérdidas a tierra como parte del sistema de suministro

eléctrico.

Usar un cordón de extensión con capacidad suficiente

para transportar la corriente que consumirá la sierra.

Un cordón de capacidad insuficiente causará una caída

de voltaje en la sierra, la pérdida de potencia y el

sobrecalentamiento.

Mantener el cordón lejos de la zona de corte. Asegurarse que el cordón no se atasque en las ramas o troncos

durante el corte. Inspeccionar los cordones eléctricos

frecuentemente. Reemplazar los que estén dañados.

LUBRICACION DE LA CADENA

Antes de usar la sierra, inspeccione siempre el nivel de

aceite. Para aceitar la cadena, presione el bulbo

exprimible en la tapa de aceite. No intente operar la

aceitera mientras está cortando con la sierra. El aceite

fluye sobre la guía de la barra y la cadena. Presione para

exprimir el bulbo en la tapa de aceite una vez por lo

menos antes de cada corte. Inspeccione a menudo el

nivel de aceite observando el orificio de nivel de aceite

de la mirilla. El orificio de nivel de aceite de la mirilla

está en el lado izquierdo de la sierra, entre el mango

delantero y la guarda manual delantera.

CORTES CON LA ELECTROSIERRA

1. Conectar la sierra al suministro eléctrico.

2. Asegurarse que la parte del tronco que se va a cortar

no esté tocando el suelo. Eso evitará que la cadena

toque el suelo mientras corta el tronco. La cadena se

desafilará si toca el suelo mientras está en movimiento.

3. Sujetar firmemente la sierra como se muestra en la

Figura I. Empuñar completamente las asas con los

pulgares y dedos.

4. Asegurarse de tener los pies bien apoyados. Mantener

los pies separados. Distribuir el peso uniformemente

en ambos pies. Situarse un poco hacia la izquierda de

la electrosierra. Esto impide que el cuerpo quede

directamente en línea con la cadena.

5. Una vez que se está listo para iniciar el corte,

oprimir el botón del seguro con el pulgar derecho

y apretar el gatillo (ver la Figura I). Esto hará

funcionar la sierra. Al soltar el gatillo la sierra se

apaga. Asegurarse que la sierra esté funcionando a

máxima velocidad antes de iniciar el corte.

6. Al iniciar el corte, colocar la cadena en movimiento

contra la madera. Sujetar firmemente la sierra en

su lugar para evitar que rebote o patine (movimiento

lateral).

7. Guiar la sierra aplicando una leve presión. No forzar

la sierra. Si el motor se sobrecarga se puede quemar.

8. Retirar la sierra de un corte con la misma funcionando

a máxima velocidad. Para apagar la sierra, soltar el

gatillo. Asegurarse que la sierra esté completamente

detenida antes de apoyarla en el suelo.

9. Practicar el uso de la sierra hasta que se pueda

mantener un ritmo constante y uniforme de corte.

Leyenda para la Figura I

1. Botón de seguro

2. Gatillo

FRENO DE LA CADENA

(Modelos EL-4 y EL-7B solamente)

Este freno detiene rápidamente la cadena. El culatazo hace

que el dorso de la mano izquierda del operador toque el

protector delantero (ver la Figura J). Cuando el protector se

mueve hacia adelante, la cadena se para. Esto reduce la

posibilidad de lesionarse gravemente durante el culatazo.

Cuando el freno se activa, soltar el gatillo inmediatamente.

Para reposicionar el freno de la cadena, soltar el gatillo y

mover el protector delantero de vuelta a su lugar. Primero

es necesario soltar el gatillo. De lo contrario, la electrosierra

empezará a funcionar al reposicionar el protector delantero.

!

PRECAUCION: No usar el freno de la

cadena para parar y arrancar la sierra. Las

paradas rápidas repetidas pueden causar el

sobrecalentamiento del freno y su

consiguiente daño.

Nota:

Probar el freno de la cadena antes de cada uso.

Sujetar firmemente la electrosierra con las dos manos.

Con la sierra funcionando, mover el protector delantero hacia adelante con el dorso de la mano izquierda.

Mantener las dos manos en las asas. La cadena debe

detenerse. Si el freno no funciona, hacer reparar la

electrosierra por un mecánico autorizado.

Leyenda para la Figura J

1. El freno se activa

2. La cadena se detiene

PODA DE UN ARBOL

La poda es el proceso de cortar las ramas de un árbol

vivo. Para podar un árbol seguir las indicaciones dadas

a continuación.

1. Hacer el primer corte a 15 cm del tronco por el lado

inferior de la rama. Para hacer este corte, usar la parte

superior de la barra guía. Cortar a una profundidad de

1/3 del diámetro de la rama (ver la Figura K).

2. Situarse de 5 a 10 cm más afuera en la rama. Hacer

el segundo corte desde el lado superior de la rama.

Seguir cortando hasta que la rama caiga.

3. Hacer el tercer corte lo más cerca posible del tronco

por la parte inferior del tocón restante de la rama.

Para hacer este corte, usar la parte superior de la

barra guía. Cortar 1/3 del diámetro del tocón.

4. Hacer el cuarto corte directamente encima del

tercero. Cortar hasta llegar al lugar donde se hizo

el tercer corte. Con ello se quitará el tocón.

Leyenda para la Figura K

1. 1er corte - Muesca guía para podar (para

evitar el astillado)

2. 2º corte - Corte para podar (para evitar el

aprisionamiento)

3. 3er corte - Muesca guía en el tocón (para

evitar el astillado)

4. 4º corte - Corte final del tocón

TUMBA DE UN ARBOL

(Corte de un árbol)

!

ADVERTENCIA: No cortar o tumbar un

árbol sin tener la experiencia o ayuda

competente para hacerlo. Estar alerta a lo que

sucede en los alrededores. No arriesgar la

vida de ninguna persona, no chocar con cables

de alto voltaje o causar daños a la propiedad

ajena. Si el árbol cae sobre algún cable de

servicio público, notificar a la empresa

correspondiente de inmediato.

La tumba es el proceso de cortar un árbol en pie. Para

tumbar un árbol seguir las indicaciones dadas a continuación.

Antes de tumbar un árbol

1. Inspeccionar el árbol. Asegurarse que no tenga ramas

muertas que puedan caer encima del operador.

Estudiar la inclinación natural del árbol, la ubicación

de las ramas más grandes y la dirección del viento.

Esto ayudará a calcular la forma en que caerá el árbol.

2. Despejar el lugar alrededor del árbol.

3. Planificar y despejar una ruta de escape antes de iniciar

el corte. La ruta de escape tiene que ser en sentido

contrario a la dirección en que se espera que caiga el

árbol y en un ángulo de 45 °(ver la Figura L).

4. Quitar la tierra, piedras, corteza suelta, clavos,

grapas y alambres del árbol de las partes donde se

harán los cortes para tumbarlo.

5. Situarse en el lado cuesta arriba cuando se tumbe

el árbol. El árbol puede rodar o deslizarse cerro

abajo después de caer.

Leyenda para la Figura L

1. Ruta de escape

2. Dirección de la caída

3. Arbol

Procedimiento para tumbar

A) Entalladura para tumbar

Una entalladura debidamente colocada determinará la

dirección en que caerá el árbol. Hacer la entalladura en

el lado del árbol en la dirección que se desea que caiga

(ver la Figura M). Para hacer la entalladura seguir las

indicaciones dadas a continuación.

1. Hacer la entalladura inferior lo más cerca posible

del suelo. Sujetar la sierra de modo que la barra

guía esté horizontal. Cortar 1/3 del diámetro del

tronco del árbol (ver la Figura M).

hacer primero este corte horizontal inferior de la

entalladura. Si se hace en segundo lugar, el árbol

puede aprisionar la cadena o barra guía.

Nota:

Siempre

6

103148

Page 15

MANUAL DEL PROPIETARIO

MANEJO DE LA

ELECTROSIERRA

Continuación

2. Iniciar la entalladura superior a la misma distancia

sobre la primera entalladura que la profundidad de

ésta.

Ejemplo:

cm de profundidad, iniciar la entalladura superior

a 20 cm sobre ella. Cortar hacia abajo en un ángulo

de 45°. La entalladura superior debe unirse al

extremo de la inferior (ver la Figura M).

3. Quitar la cuña del tronco creada por las

entalladuras.

B) Corte final o de tumba

1. Hacer el corte final 5 cm más arriba que la

entalladura inferior y en el lado contrario del árbol

(ver la Figura M). Mantener el corte final paralelo

a la entalladura inferior.

2. Cortar hacia la entalladura.

!

ADVERTENCIA: No atravesar

completamente el árbol. Dejar sin cortar unos

5 cm del diámetro del árbol directamente detrás

de la entalladura (ver la Figura M). Esta porción

sin cortar actúa como una bisagra o

articulación. La bisagra impide que el árbol se

tuerza y caiga en la dirección equivocada.

3. Cuando el corte final se aproxima a la bisagra, el

árbol comienza a caer.

Nota:

final para controlar la dirección de la caída. Si el árbol

se asienta y aprisiona la cadena, meter cuñas en el corte

final para retirar la sierra. Usar solamente cuñas de

madera, plástico o aluminio. Nunca usar una cuña de

acero. Eso podría causar un culatazo y dañar la cadena.

4. Cuando el árbol comienza a caer, rápidamente

•retirar la sierra del corte final

• soltar el gatillo y dejar la sierra en el suelo

• salir del lugar por la ruta de escape

Leyenda para la Figura M

1. 1er corte - Entalladura inferior

2. 2º corte - Entalladura superior

3. 3er corte - Corte final

4. Bisagra o articulación

5. Dirección de la caída

DESRAMADO DE UN ARBOL

El desramado consiste en quitar las ramas de un árbol caído.

No quitar las ramas más grandes debajo del árbol porque

sostienen el tronco elevado del suelo. Quitar cada rama

pequeña con un solo corte (ver la Figura N). Despejar

frecuentemente las ramas cortadas de la zona de trabajo.

Eso ayudará a mantener una zona de trabajo segura.

Asegurarse de iniciar el corte en un punto donde la

rama no vaya a aprisionar la sierra durante el corte. Para

evitar que eso suceda, iniciar el corte en las ramas que

están colgando libremente desde arriba. Iniciar el corte

en las ramas que están bajo tensión desde abajo. En

caso de ocurrir aprisionamiento, apagar la sierra, levantar la rama y retirar la sierra.

Si la entalladura inferior tiene 20

De ser necesario, meter unas cuñas en el corte

TROZADO DE UN TRONCO

ADVERTENCIA:

!

• Si el tronco se encuentra en una pendiente,

asegurarse que no vaya a rodar cerro abajo.

Sujetar el tronco con estacas de madera.

Situarse en el lado cuesta arriba del tronco

durante el corte.

• Mientras se corta el tronco, nunca sujetarlo

con la mano, pierna o pie, ni permitir que

otra persona sujete el tronco.

El trozado consiste en cortar un tronco en secciones.

Siempre que sea posible, sostener el tronco o sección

elevado del suelo. Para ello, apoyarlo sobre ramas,

troncos, cuñas, etc.

Durante el corte del tronco, mantener el control reduciendo la fuerza antes de terminar el corte.

Para trozar un tronco seguir las indicaciones dadas a

continuación.

Con toda la extensión del tronco apoyada en

el suelo

1. Cortar el tronco desde arriba (ver la Figura O).

Tronco apoyado en un extremo

1. Hacer el primer corte en el lado inferior del tronco (ver

la Figura P). Para hacer este corte, usar la parte superior

de la barra guía. Cortar 1/3 del diámetro del tronco.

Este corte evitará que la sección se astille al cortarla.

2. Hacer el segundo corte directamente encima del

primero. Cortar hacia abajo hasta llegar al lugar

donde se hizo el primer corte. Este corte evitará

que el tronco aprisione la barra guía y la cadena.

Leyenda para la Figura P

1. 1er corte

22º corte

Tronco apoyado en los dos extremos

1. Hacer el primer corte desde el lado superior del tronco

(ver la Figura Q). Cortar 1/3 del diámetro del tronco.

Este corte evitará que la sección se astille al cortarla.

2. Hacer el segundo corte en el lado inferior del tronco

directamente debajo del primer corte. Para hacer

este corte, usar la parte superior de la barra guía.

Cortar hacia arriba hasta llegar al lugar donde se

hizo el primer corte. Este corte evitará que el tronco

aprisione la barra guía y la cadena.

Leyenda para la Figura Q

1. 1er corte

2. 2º corte

LIMPIEZA Y

MANTENIMIENTO

AVISO: A continuación explicamos cómo cuidar

y mantener la electrosierra. Cualquier trabajo

de mantenimiento no mencionado deberá

hacerlo un centro de servicio autorizado.

LIMPIEZA DEL CUERPO DE LA SIERRA

Mantener limpio el cuerpo de la sierra. Usar un paño

suave humedecido con una mezcla de agua y jabón

suave. Frotar el cuerpo de la sierra con un paño.

Para limpiar el cuerpo de la sierra,

• no sumergirla en ningún tipo de líquido

• no usar productos que contengan amoníaco, cloro

o abrasivos

• no usar solventes de limpieza clorados, tetracloruro

de carbono, keroseno o gasolina

CUIDADO DE LA BARRA GUIA

El desgaste desigual de la barra es el causante de la

mayoría de los problemas de la barra guía. Frecuentemente, la causa de esto es el afilado incorrecto de los dientes

cortadores y los ajustes incorrectos del calibrador de

profundidad. Cuando se desgasta desigualmente, se ensancha la ranura de la barra guía. Esto causa la vibración

de la cadena y la expulsión de los remaches. La sierra no

cortará derecho. Si esto ocurre, cambiar la barra guía.

Inspeccionar la barra antes de afilar la cadena. Una barra

desgastada o dañada es peligrosa. Una barra desgastada

o dañada dañará la cadena. También dificultará el corte.

Mantenimiento normal de la barra guía

1. Sacar la barra guía de la electrosierra.

2. Quitar periódicamente el aserrín de la ranura de la

barra. Usar una espátula para masilla o un alambre.

3. Limpiar las ranuras de aceite después de cada día

de uso.

4. Quitar las rebabas de los costados de la barra guía.

Usar una lima plana para cuadrar los bordes

laterales.

Cambiar la barra guía cuando

• está torcida o trizada

• la ranura interior de la barra está muy desgastada

AFILADO DE LA CADENA

!

ADVERTENCIA: Desenchufar la

electrosierra del tomacorriente antes de

reparar. Podrían ocurrir graves lesiones o la

muerte debido a electrochoque o contacto del

cuerpo con la cadena en movimiento.

!

ADVERTENCIA: Los bordes cortantes de

la cadena son afilados. Usar guantes de trabajo

para manipular la cadena.

Mantener la cadena bien afilada. La sierra cortará más

rápido y seguro. Una cadena desafilada causará el desgaste indebido de la rueda dentada, barra guía, cadena y

motor. Si es necesario meter a la fuerza la cadena en la

madera y el corte produce solamente aserrín con pocas

virutas grandes, la cadena está desafilada.

Artículos necesarios para afilar la cadena

Obtener estos artículos a través del concesionario, ferretería

o tienda de artículos para electrosierras en la localidad.

• lima redonda de 4 mm

• Calibrador de profundidad

• Lima plana de tamaño mediano

• Prensa

• Guía de lima

103148

Continuación

7

Page 16

ELECTROSIERRA

®

LIMPIEZA Y

MANTENIMIENTO

Continuación

Afilado de los dientes cortadores

Usar una guía de lima para limado de 30°.

1. Ajustar la tensión de la cadena al valor adecuado

(ver Ajuste de la tensión de la cadena).

2. Fijar la barra guía en una prensa para sujetar bien

firme la sierra.

3. Meter a presión una lima redonda de 4 mm (sujeta

a la guía) en la ranura entre la placa superior y el

calibrador de profundidad en la cadena. La guía de

lima debe quedar apoyada sobre la placa superior

y el calibrador de profundidad (ver las Figuras R y

S).

Nota:

4. Sujetar la guía de lima bien nivelada. Asegurarse

que la marca de 30° en la guía de lima está paralela

a la parte central de la barra guía (ver la Figura R).

Esto asegurará que se limen los dientes cortadores

en un ángulo de 30°.

5. Limar de adentro hacia afuera del diente cortador

hasta que quede afilado. Sólo limar en este sentido

(ver la Figura R).

de la lima para afilar el diente cortador.

6. Después de afilar cada diente, mover la cadena

hacia adelante para afilar el próximo diente. Afilar

todos los dientes cortadores en un lado de la cadena.

7. Trasladarse al otro lado de la cadena y repetir el proceso.

Leyenda para la Figura R

1. Sentido de limado

2. Marca de referencia de 30°

3. Guía de lima

4. Lima redonda de 4 mm

5.

Nota:

guía de lima y el sentido de limado para afilar

los dientes cortadores del lado izquierdo de la

cadena.

Leyenda para la Figura S

1. Lado izquierdo de la cadena

2. Ranura

3. Placa superior (lado derecho de la cadena)

4. Calibrador de profundidad (lado izquierdo de la

cadena)

5. Placa superior (lado izquierdo de la cadena)

6. Calibrador de profundidad (lado derecho de la

cadena)

7. Lado derecho de la cadena

Nota:

No fijar la cadena.

Limar en la mitad de la barra guía.

Nota:

Basta dos o tres pasadas

Este dibujo muestra la colocación de la

Limado de los calibradores de profundidad

de los dientes cortadores

El espacio libre del calibrador de profundidad del

diente cortador se reduce cuando se afilan los dientes.

Después del segundo o tercer afilado, reposicionar los

calibradores de profundidad.

1. Colocar la herramienta para calibradores de

profundidad firmemente encima de la parte superior

de dos dientes cortadores. Asegurarse que el

calibrador se introduzca en la ranura en la

herramienta (ver la Figura T).

2. Usar una lima plana mediana. Afilar el calibrador

de profundidad a nivel con la herramienta para

calibradores.

3. Quitar la herramienta. Con la lima plana, redondear

la esquina delantera del calibrador de profundidad

del diente cortador (ver la Figura U).

Leyenda para la Figura T

1. Calibrador de profundidad

2. Lima plana

3. Herramienta para calibrador de profundidad

4. Ranura para calibrador de profundidad

Leyenda para la Figura U

1. Esquina delantera

Después de varios limados a mano, llevar la cadena

para que la afilen a máquina en un centro de servicio

autorizado. Eso asegurará un afilado uniforme.

SUSTITUCION DE LA CADENA

Cambiar la cadena cuando los dientes cortadores están

demasiado desgastados para afilarlos o si la cadena se

corta o rompe. Usar únicamente la cadena de repuesto

indicada en este manual. Siempre incluir una rueda

dentada impulsora nueva cuando se sustituye la cadena.

Esto mantendrá el accionamiento correcto de la cadena.

RECICLAJE

En caso de no ser práctico reparar la electrosierra, antes de

desecharla averiguar y respetar las disposiciones reglamentarias locales para el reciclaje de plástico y metales.

ALMACENAMIENTO

Si se va a tener guardada la electrosierra durante más de

30 días, proceder de la manera siguiente.

1. Vaciar el tanque de aceite.

2. Quitar y limpiar la barra guía y la cadena.

Limpiarlas remojándolas en un solvente a base de

petróleo o una mezcla de agua y jabón suave.

3. Secar la barra guía y la cadena.

4. Colocar la cadena en un recipiente lleno de aceite.

Esto impedirá la oxidación.

5. Aplicar con un trapo una capa delgada de aceite

sobre la superficie de la barra guía.

6. Limpiar con un trapo el exterior del cuerpo de la

sierra. Usar un paño suave humedecido con una

mezcla de agua y jabón suave.

7. Guardar la electrosierra en un lugar seco elevado o

bajo llave y lejos del alcance de los niños.

REPUESTOS

!

ADVERTENCIA: Usar solamente los

repuestos que se describen en este manual. El

uso de otro tipo de piezas podría dañar la

sierra o causar lesiones al operador.

Comprar estos repuestos a través del concesionario local.

N° de pieza Descripción

097572-03S Barra guía, 400 mm

097570-01S Barra guía, 350 mm

091375-02S Cadena, 400 mm

091374-02S Cadena, 350 mm

107713-01 Rueda dentada impulsora

8

103148

Page 17

MANUAL DEL PROPIETARIO

NOTA

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

103148

9

Page 18

LOCALIZACION

DE AVERIAS

ADVERTENCIA: Desenchufar la electrosierra del tomacorriente antes de reparar. Podrían ocurrir

!

graves lesiones o la muerte debido a electrochoque o contacto del cuerpo con la cadena en

movimiento.

AVERIA OBSERVADA

La sierra funciona, pero no corta.

La sierra no corta a menos que se le empuje con fuerza.

El corte produce solamente aserrín con muy pocas

virutas grandes.

La sierra funciona lentamente. Se para fácilmente.

El motor de la sierra no funciona cuando se aprieta el

gatillo.