Page 1

ELECTRIC CHAIN SAW

OWNER’S MANUAL

®

®

Model EL-3

IMPORTANT

Read and understand this manual before assembling or operating this

chain saw. Improper use of saw can cause severe injury. Keep this

manual for future reference.

Page 2

®

ELECTRIC CHAIN SAW

SAFETY

WARNINGS

Do not assemble or handle guide

bar or saw chain while connected

to a power source.

1. Keep the work area clean. Cluttered

areas invite accidents.

2. Do not let the chain saw get wet. Don’t

use the chain saw in the rain or in damp

or wet locations. Keep the work area

well lit.

3. Keep bystanders and animals out of the

work area.

4. Store the chain saw in a safe place, out

of the reach of children.

5. Don’t force the chain saw. Only make

cuts within the capacity of your chain

saw.

6. Wear proper apparel: safety footwear,

snug fitting clothing, safety glasses,

head and hearing protection. Rubber

gloves and footwear are recommended

when working outdoors.

7. Never carry the chain saw by its cord.

Never yank the cord to disconnect the

plug. Keep the cord away from heat,

oil and sharp edges.

8. Secure your work by use of clamps or

chocks, freeing both hands to hold the

chain saw.

9. Don’t overreach. Keep proper footing

and balance at all times.

10. Always disconnect the cord when the

chain saw is not in use, when moving

from one location to another and before

servicing.

11. Keep the chain saw clean. Never

operate a chain saw that is damaged,

improperly adjusted or not completely

assembled. Keep the saw handles dry,

clean and free of oil.

12. Keep the saw chain properly tensioned

and the saw chain cutters properly

sharpened. Follow the lubricating

instructions.

13. Avoid having loose or missing parts.

Keep all the fasteners tight.

14. Remove all tools before touching the

switch trigger.

15. Never place your finger near the switch

trigger until you are ready to make a

cut.

16. Keep all parts of your body away from

the moving saw chain. Always carry the

chain saw with the motor stopped and

the guide bar and saw chain to the rear .

17. Never operate the chain saw when you

are fatigued.

18. Guard against kickback by following

the explanation in this manual.

19. Use extreme caution when cutting

small branches. Watch for limbs under

tension.

20. Use only extension cords suitable for

outdoor use and appropriately marked.

21. When replacing parts use only identical

replacement parts.

IMPORTANT: Do not use any

other attachments or accessories except those noted in this

manual.

IMPORTANT: Save these instructions for future use.

2

101755

Page 3

OWNER’S MANUAL

CHAIN SAW NAMES

AND TERMS

Boring The process involved in cutting

with the saw chain at the nose (tip) of the

guide bar, in order to make a hole. This is not

recommended because of hazard of kickback.

Bucking The process of cross cutting a

felled tree or log into lengths.

Chain Saw Powerhead A chain saw

without the saw chain and guide bar.

Clutch A mechanism for connecting and

disconnecting a driven member to and from

a rotating source of power.

Drive Sprocket or Sprocket The toothed

part that drives the saw chain.

Felling The process of cutting down a tree.

Felling Back Cut The final cut in a tree

felling operation made on the opposite side

of the tree from the notching undercut.

Front Handle The support handle located

at or toward the front of the chain saw.

Front Handle Guard A structural barrier

between the front handle of a chain saw and

the guide bar, typically located close to the

hand position on the front handle.

Guide Bar A solid railed structure that

supports and guides the saw chain.

Kickback The backward and/or upward

motion of the guide bar occurring when the

saw chain near the nose of the top area of the

guide bar contacts any object such as another log or branch, or when the wood closes

in and pinches the saw chain in the cut.

Kickback, Pinch The rapid pushback of

the saw which can occur when the wood

closes in and pinches the moving saw chain

in the cut along the top of the guide bar.

Kickback, Rotational The rapid upward

and backward motion of the saw which can

occur when the moving saw chain near the

upper portion of the tip of the guide bar

contacts an object, such as a log or branch.

Normal Cutting Position Those posi-

tions assumed in performing the bucking

and felling cuts.

Notching Undercut A notch cut in a tree

that directs the tree’s fall.

Oiler Control A system for oiling the guide

bar and saw chain.

Rear Handle The support handle located at

or toward the rear of the saw.

Reduced Kickback Guide Bar A guide

bar which has been demonstrated to reduce

kickback significantly.

Saw Chain A loop of chain having cutting

teeth, that cut the wood, and that is driven by

the motor and is supported by the guide bar.

Spiked Bumper (Spike) The pointed tooth

or teeth for use when felling or bucking to

pivot the saw and maintain position while

sawing.

Switch A device that when operated will

complete or interrupt an electrical power

circuit to the motor of the chain saw.

Switch Linkage The mechanism that trans-

mits motion from a trigger to the switch.

Switch Lockout A movable stop that

prevents the unintentional operation of the

switch until manually actuated.

101755

3

Page 4

®

ELECTRIC CHAIN SAW

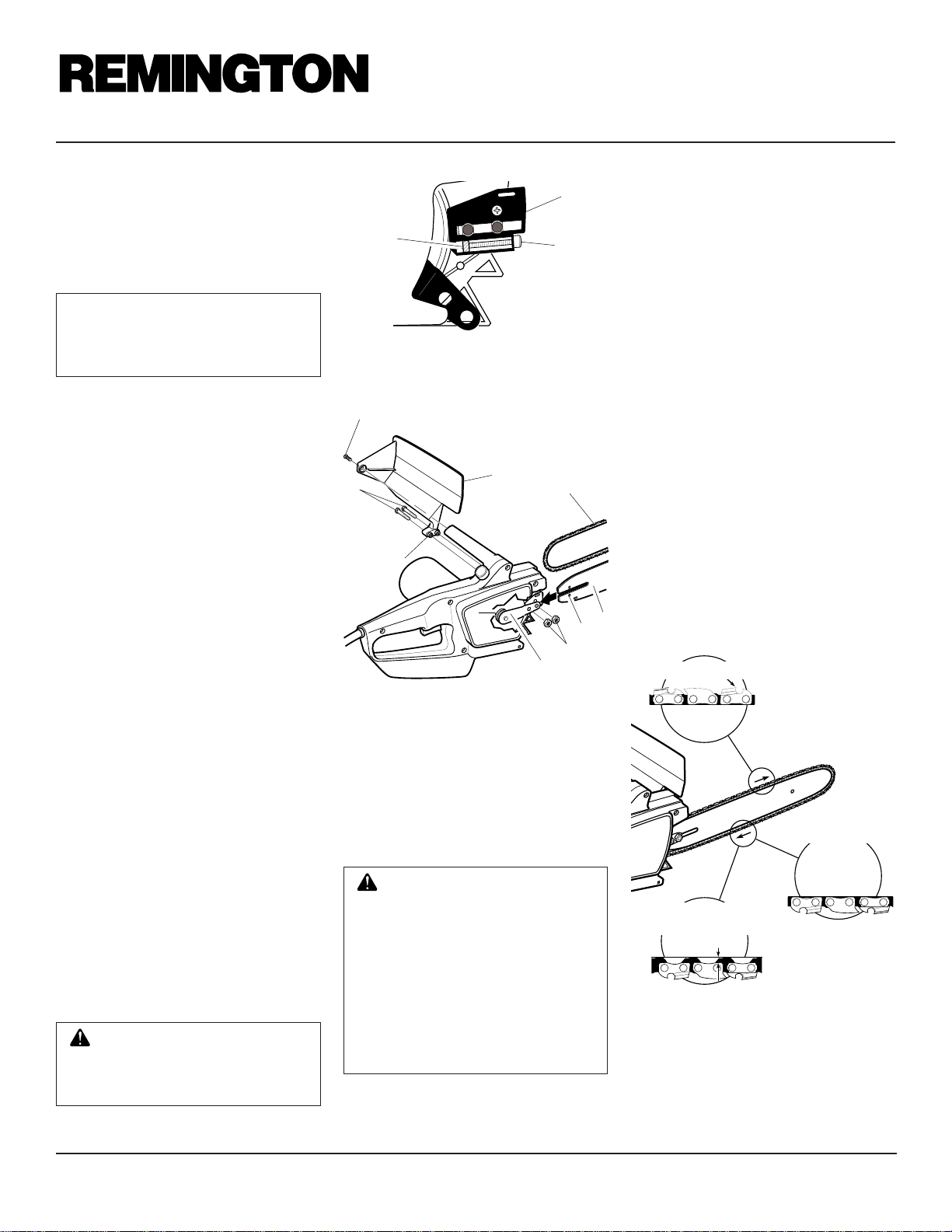

ASSEMBLY

INSTRUCTIONS

ASSEMBLING GUIDE BAR,

SAW CHAIN AND HAND

GUARD

IMPORTANT: Do not clamp in a

vise or abuse during assembly.

Always wear gloves when handling the saw chain.

1. Remove two (2) guide bar nuts (D), two

(2) guide bar bolts (E) and one (1)

Phillips screw (N) from the plastic bag.

2. Lay the saw chain (C) out flat.

3. Install hand guard (K) by press fitting

the two bosses (L) into the hex shaped

holes in the saw body. Install the

Phillips screw (N) into the hand guard

and saw handle and tighten securely.

4. Turn adjusting screw (A)

counterclockwise to move the adjusting

block (B) as far as it will go to the rear

of the mount (See Figure 1).

5. Slide the guide bar (G) on to the

adjusting plate (H) aligning adjusting

block (B) with the square adjusting hole

(I) in the guide bar.

6. Rotate the sprocket support (F) back

over the guide bar so the holes line up.

7. Insert ONLY the front guide bar bolt

(E) through the body of the saw and

through sprocket support (F). Tighten

the nut (D) only finger tight. This will

allow clearance for the installation of

the saw chain.

8. Slide the saw chain between the side

cover and the sprocket (J), in the top

groove of the guide bar (G) and around

the guide bar nose.

9. Insert remaining guide bar bolt (E) and

install nut (D) finger tight.

10. Adjust the saw chain tension by

following the tension adjustment

instructions.

CAUTION: If saw chain is assembled backwards, the saw will

vibrate excessively and will not

cut.

H

B

Figure 1 - Part Locations For Assembling

Guide Bar

N

K

E

L

J

Figure 2 - Assembling Guide Bar, Chain,

and Hand Guard

A

C

G

I

D

F

SAW CHAIN

TENSION

ADJUSTMENT

CAUTION: The saw chain tension must be properly maintained. Failure to do so will cause

rapid saw chain, guide bar and

sprocket wear. A loose chain will

increase the possibility of kickback and may jump out of the

guide bar groove. This may cause

damage to the chain and injury to

the operator. Tighten guide bar

nuts securely.

1. Before adjusting the saw chain, make

sure the guide bar nuts (D) are only

finger tight (See Figure 1 and 2).

2. Turn adjusting screw (A) clockwise

until all slack is out of the saw chain.

3. Wear protective glov es and pull the saw

chain (C) around the guide bar. It

should move freely.

4. If necessary, readjust chain using

adjusting screw (A). There should be

no gap between the side links of the saw

chain and the bottom of the guide bar

(See Figure 3).

5. Tighten guide bar nuts (D) using a

wrench. Nuts not tightened securely

will allow guide bar movement

resulting in loose chain and increasing

the possibility of kickback and damage

to mating parts.

6. A new chain will stretch and should be

checked after the first few minutes of

operation. Disconnect saw from power

source. Adjust the chain tension after

it has had a few minutes to cool down.

Use protective gloves to protect hands

from chain teeth.

Cutting Edges Forward

Guide Bar

Incorrect Saw

Chain Tension

Gap

Guide Bar

Figure 3 - Saw Chain Adjustment

Standard Chain

Correct Saw Chain

Tension

Guide Bar

4

101755

Page 5

OWNER’S MANUAL

OPERATING

INSTRUCTIONS

FILLING OIL RESERVOIR

1. Remove the oil fill knob.

2. Fill the oil reservoir with SAE #30

motor oil.

3. Replace and tighten fill knob

IMMEDIATELY. This will avoid

continuous oil feed.

4. Wipe off excess oil.

Note:

When cutting in temperatures below

30°F, use SAE #10 oil. In temperatures

above 75°F, use SAE #40 oil.

EXTENSION CORDS

The proper extension cord must be used

with the chain saw. Use a HO7RN extension

cord no less than 1.5 square millimeters at

distances up to 30 meters. It is recommended

that a ground fault circuit interrupter be part

of the power supply system.

Use an extension cord heavy enough to

carry the current your saw will draw. An

undersized cord will cause a voltage drop at

the saw, loss of power and overheating.

WARNING: Read and understand all instructions before operating the saw.

SAW CONTROLS

Front Handle The support located toward

the front of the chain saw which extends

from the left side of the chain saw. The

proper grip of this handle in the normal

cutting position gives you the greatest ability to control the chain saw in the cut (See

Figure 4).

Rear Handle The support located toward

the rear of the saw, houses the control trigger. A firm grip of this handle while cutting

is necessary to control the chain saw in the

cut.

Trigger Switch The control which starts

and stops the motor. The motor only operates at full speed.

Switch Lockout The moveable button that

prevents unintentional operation of the trigger. The trigger cannot be depressed to start

the saw again until the lockout is pushed in.

When the trigger is released the lockout will

automatically lock the trigger in the power

off position.

Guard The restraint in front of the handle

which prevents accidental contact of the

hand with the chain.

Oil Fill Knob By pushing the oil fill knob,

using only moderate pressure, oil will feed

on the guide bar and saw chain. To keep the

saw chain oiled, push the oil fill knob at least

once before each cut. Frequently check the

oil sight level hole located on the front left

side of the chain saw.

Guard

LEFT SIDE

Front Handle

RIGHT SIDE

Power

Cord

Figure 4 - Left and Right Sides

Sprocket

Sprocket

Guard

Manual Oil

Control

Switch

Lockout

Switch

Trigger

Guide Bar

Sprocket

Support

Rear

Handle

Saw

Chain

KICKBACK

WARNING: Guard against

kickback. Study this section before operating saw.

Kickback is the sudden upward and/or backward movement of the chain saw while

cutting. If the chain saw moves toward the

operator in an uncontrolled manner, serious

or fatal injuries may result. Understanding

why kickback occurs can help you reduce

the chance of kickback and maintain control.

Kickback Safety Devices On

Your Saw

Your saw is equipped with a low-kickback

saw chain and a reduced kickback guide bar.

Both devices reduce the possibility of rotational kickback which can occur when the

tip of the bar contacts a solid object.

assume that kickback will not happen

NOT

DO

because of these devices. Contact of the

guide bar tip with any object should be

avoided.

A properly installed Front Hand Guard can

help reduce injuries from kickback. Install

by following the assembly instructions in

this manual. DO NOT remove or replace it

with a substitute.

Causes of Kickback

Kickback occurs when a chain cutter going

around the upper quadrant of the guide bar

nose is suddenly stopped (See Figure 5).

This can happen when the cutter contacts a

solid object or is pinched. The result is a

sudden reverse action which kicks the saw

tip up and/or back toward the operator.

Kickback may also occur when a chain

cutter is pinched along the length of the bar.

The result is a sudden linear reverse action

which kicks the saw straight back at the

operator.

DIRECTION

CONTACT HERE

90 DEGREE

QUADRANT

Figure 5 - Causes of Kickback

101755

5

Page 6

®

ELECTRIC CHAIN SAW

OPERATING

INSTRUCTIONS

Continued

Examples of Kickback

With the saw in operation, kickback occurs

when:

• The chain at the guide bar nose

touches any solid object.

• Incorrectly starting a boring cut.

•A cutter on guide bar nose strikes the

bottom of the saw cut while the guide

bar is being reinserted in the cut (See

Figure 6).

• The chain is pinched in the cut.

Figure 6 - Examples of Kickback

To Help Reduce the Chance of

Kickback

1. Hold the chain saw firmly with both

hands with thumbs and fingers

encircling the handles.

2. Always be attentive to what you are

doing, be alert for shifting of the log or

other conditions which will cause a pinch.

3. Always know where the nose of the

guide bar is. DO NOT let the guide bar

nose contact any object (See Figure 6).

4. Never use a dull or loose chain. Always

use a correctly sharpened, properly

tensioned chain.

5. Use your saw within its capacity. DO

bury the nose (See Figure 6).

NOT

6. MAINTAIN SAFETY SYSTEM.

Normal Wear On Saw and its

Effects On Kickback Safety

Follow the maintenance instructions in this

manual on cleaning the saw, proper storage,

chain and guide bar maintenance. Regular

inspection and a good maintenance program will increase the service life of your

saw. Even with proper sharpening, kickback potential can increase with each filing.

CUTTING WITH THE CHAIN

SAW

Cutting with your electric chain saw can be

made easier and safer if you will follow

these simplified instructions. Before trying

to cut with the chain saw be sure to:

1. Read all the safety precautions on the

front cover.

2. Support the log to be cut off the ground

so the saw chain does not touch the

ground as it cuts through the wood.

3. Keep the nose of the guide bar from

contacting a log, branch, the ground or

any other obstruction.

4. DO NOT overreach.

5. Stand with your weight evenly

distributed on both feet and slightly to

the left side of the saw . This keeps your

body from being in a direct line with

the cutting chain (see figure 7).

Figure 7 - The Correct Stance

Figure 8 - Do Not Operate With One Hand

6. DO NOT OPERATE WITH ONE

(See Figure 8). Use a firm grip

HAND

with thumbs and fingers encircling both

handles as shown in Figure 9.

Figure 9 - Operate With Both Hands

7. When ready to make a cut, push in the

lockout button and squeeze the trigger

switch. Start the chain saw above the

log. Always bring the saw up to speed

before letting the chain touch the wood.

8. When starting a cut, be alert to possible

bouncing or skating (sideward

movement) of the saw.

9. Place the saw against the wood and

guide it using a light pressure.

10. DO NOT FORCE THE SAW SO

THAT THE CHAIN SPEED IS

GREATLY REDUCED. THIS WILL

OVERLOAD THE MOTOR AND

CAN CAUSE MOTOR BURN OUT.

11. Stop the saw by releasing the trigger

switch. Make sure the chain has come

to a complete stop before setting the

saw down.

12. If you have never used a chain saw

before, in addition to reading and

understanding the operating instructions,

you should seek informed practical

instruction from your chain saw dealer

or other knowledgeable individuals. As

a minimum, you should practice cutting

logs on a sawhorse or cradle until you

are able to maintain a steady even cutting

rate before attempting to cut limbs from

a tree.

TRIMMING A TREE

WARNING: DO NOT OPERATE

your chain saw while IN A TREE,

ON A LADDER, ON ANY OTHER

UNSTABLE SURFACE or IN ANY

AWKWARD POSITION which

might cause you to loose control

of the chain saw. DO NOT cut

limbs higher than your shoulder.

Note:

When conditions are encountered

which are beyond your experience or capacity seek professional help.

6

101755

Page 7

OWNER’S MANUAL

Cutting a Limb

1. Make the first cut from the underside about

1/2 foot from the trunk and 1/3 through

the diameter of the limb (See Figure 10).

2. Make the second cut two to four inches

farther out on the limb from above until

the limb falls.

3. Make the third cut 1/3 the diameter of

the limb stub from underneath as close

to the trunk as possible.

4. Make the fourth cut from above as close

to the trunk as possible to meet the third

cut.

4th Final

Stub Cut

3rd Stub Undercut

(to avoid splintering)

2nd Limbing Cut

(to avoid pinching)

6 "

(15cm)

2" to 4"

1st

Limbing Undercut

(to avoid splintering)

(5-10 cm)

1. The chain saw operator should keep on

the uphill side of the terrain as the tree

is likely to roll or slide downhill after

it is felled.

2. CONSIDER the natural lean of the tree,

the location of larger branches and the

wind direction to judge which way the

tree will fall.

3. A RETREA T P A TH should be planned

and cleared as necessary before cuts are

started. The retreat path should extend

back and diagonally to the rear of the

expected line of fall as illustrated in

Figure 11.

CLEAR the work area around the tree

4.

to be cut and on your retreat path.

5.

REMOVE dirt, stones, loose bark, nails,

staples, and wire from the tree where

felling cuts are to be made.

Retreat Path

Direction of Fall

4. As the felling cut gets close to the hinge,

the tree should begin to fall. If there is

any chance that the tree may not fall in

the desired direction or it may rock back

and bind the saw chain, stop cutting

before the felling back cut is complete

and use wedges of wood, plastic or

aluminum to open the cut and drop the

tree along the desired line of fall.

5. When the tree begins to fall remove the

chain saw from the cut, stop the motor,

put the chain saw down, then use the

retreat path planned. Be alert for overhead

limbs falling and watch our footing.

Direction of

Fall

3rd Felling

Cut

Approx. 2"

(5 cm)

Hinge

2nd - Upper

Notching Cut

1st - Lower

Notching Cut

Figure 10 - Cutting A Limb

FELLING A TREE

WARNING: Felling a tree

should not be undertaken unless

the person has extensive experience or obtains professional assistance.

CAUTION: When bucking and

felling operations are being performed by two or more persons

at the same time, the felling operation should be separated from

the bucking operation by a distance of at least twice the height

of the tree being felled. Trees

should not be felled in a manner

that would endanger any person,

strike any utility line or cause any

property damage. If the tree does

make contact with any utility line,

the utility company should be notified immediately.

45°

Figure 11 - Retreat Path From Tree

FELLING TECHNIQUES

1. Make the first lower notching cut 1/3

the diameter of the tree and

perpendicular to the line of fall. This

will help to avoid pinching of either the

saw chain or the guide bar when the

second notching cut is made (See

Figure 12).

2. Make the second upper notching cut at

an angle to meet the first notching cut

at 1/3 the diameter of the tree.

3. Make the felling back cut at least 2

inches higher than the horizontal

notching cut as illustrated in Figure 12.

Keep the felling back cut parallel to the

horizontal notching cut. Make the

felling back cut so enough wood is left

to act as a hinge. The hinge wood keeps

the tree from twisting and falling in the

wrong direction. DO NOT cut through

the hinge.

Figure 12 - Felling A Tree

LIMBING

Limbing is removing the branches from a

fallen tree. When limbing, leave larger lower

limbs to support the log off the ground.

Remove the small limbs in one cut as illustrated in Figure 13. Branches under tension

should be cut from the bottom up to avoid

binding the chain saw.

Keep work off ground. Leave support limbs until log is cut.

Figure 13 - Limbing A Tree

101755

7

Page 8

®

ELECTRIC CHAIN SAW

OPERATING

INSTRUCTIONS

Continued

BUCKING A LOG

Bucking a log is cutting a log into lengths. It

is important to make sure your footing is

firm and your weight is evenly distributed

on both feet. When possible, the log should

be raised and supported by the use of limbs,

logs or chocks. Follow the simple directions

for easy cutting.

When the log is supported along its entire

length as illustrated in Figure 14, it is cut

from the top (overbuck).

Figure 14 - Log Supported Along Entire

Length

When the log is supported on one end as

illustrated in Figure 15, cut 1/3 of the diameter from the underside (underbuck). Then

make the finishing cut by overbucking the

top 2/3 to meet the first cut.

2nd Cut

1st Cut

Figure 15 - Log Supported One End

When the log is supported on both ends, as

illustrated in Figure 16, cut 1/3 of that diameter from the top, overbuck. Then make the

finishing cut by underbucking the lower 2/

3 to meet the first cut.

1st Cut

2nd Cut

Figure 16 - Log Supported On Both End

When bucking on a slope always stand on

the uphill side of the log, because the log

may roll after cut. When “cutting through,”

to maintain complete control, reduce the

cutting pressure near the end of the cut

without relaxing your grip on the chain saw

handles. Don’t let the chain contact the

ground. After completing the cut, wait for

the chain saw to stop before you move the

chain saw. Always stop the motor before

moving from tree to tree.

8

101755

Page 9

OWNER’S MANUAL

MAINTENANCE

AND STORAGE

CLEANING THE CHAIN SAW

To clean housing of dirt and oil, wipe with a

damp cloth using a solution of warm water

and a mild detergent. DO NOT use products

that contain ammonia, chlorine or abrasives,

DO NOT use chlorinated cleaning solvents,

carbon tetrachloride, kerosene or gasoline.

DO NOT submerge saw in any liquids.

CARE OF THE GUIDE BAR

Most guide bar problems are caused by

uneven bar wear. Incorrect filing of cutter

and depth gauge settings are the primary

cause of uneven bar wear. When the bar

wears unevenly it widens the bar slot and

causes chain clatter, rivet popping and difficulty in making a straight cut.

1. Remove saw dust from the guide bar

groove periodically with a putty knife

or a wire (See Figure 17).

2. Clean oil holes after each day of use.

3. Remove burrs and restore square edges

to an uneven rail top by filing with a

flat file.

4. Replace the guide bar if it is bent or

cracked.

Note:

See the section on Accessories for the

proper replacement guide bar and chain.

HAND SHARPENING

PROCEDURE

1. Disconnect the saw from the power

source. W ear glov es when handling the

chain.

2. Properly tension the saw chain.

3. Position the cutter that is to be filed in

the center of the guide bar. Move the

chain after each cutter is finished.

4. Place the round file and guide on the

cutter so it rests on the top plate and

the depth gauge. Hold the file level and

with the guide marks parallel to the

guide bar.

Filing

Direction

30° Guide

Mark

5. File from inside toward the outside of

the cutter in one direction only. Use a

light stroke, only one or two strokes are

needed. File all cutters the same.

6. Move to the other side of the guide bar

and file all cutters on the second side.

Care should be taken to never file into

the bottom of the top plate or it will

become dull faster.

Filing

Direction

Filing

Direction

File Guide

FILE HOLDER

Round File

Figure 17 - Guide Bar Maintenance

101755

Figure 18 - File and File Guide Placement On Chain

9

Page 10

®

ELECTRIC CHAIN SAW

MAINTENANCE

AND STORAGE

Continued

FILING THE CUTTER DEPTH

GAUGES

The cutter depth gauge clearance is reduced

as the cutting edges are sharpened. The

cutter depth gauge clearance will need to be

set after every second or third sharpening.

1. Place the depth gauge set firmly across

the top of two cutters so the depth gauge

enters the slot in the gauge set.

2. With a flat file, use a firm forward

pressure to file gauge level with depth

gauge set.

3. Round off cutter gauge depth to

maintain original shape.

Note:

After several hand filings of the saw

chain it is a good practice to have your

authorized service center or sharpening service shop precision sharpen the saw chain

on a sharpening machine to insure uniform

dimensions.

Correct Gauge

Clearance .025"

(0.64 mm)

Check Gauge

Clearance

Drive Link

Figure 19 - Chain Depth And Clearances

Side Link

As The Cutters

Are Filed Back

Depth Gauge Set

Cutter

The Gauge

Must Be

Lowered

And

Rounded

Off

STORING YOUR CHAIN SAW

Follow these instructions when storing your

chain saw for more than 30 days.

1. Drain the oil reservoir.

2. Remove, clean and dry the guide bar

and chain.

3. Place the saw chain in a container filled

with oil to prevent rust.

4. Wipe on a coating of oil to the entire

surface of the guide bar and wrap in

heavy paper, cloth or plastic.

5. Wipe off the outside surfaces of the

saw.

6. Store the saw in a dry place out of the

reach of children.

Note:

It is normal for oil seepage to occur

when the saw is not in use. Empty the oiler

reservoir after each use to prevent lubricant

from seeping.

ACCESSORIES AVAILABLE

FOR YOUR CHAIN SAW

FROM YOUR DEALER

Part No. Description

097570-01S BAR, Guide 14" (350mm)

091374S CHAIN, Saw, 14" (350mm)

075752 SPROCKET, Drive

097572-03S BAR, Guide 16" (400mm)

091375S CHAIN, Saw, 16" (400mm)

10

101755

Page 11

TROUBLE

SHOOTING

OWNER’S MANUAL

PROBLEM

Saw operates but does not cut.

Saw does not cut unless heavily forced. Chips are fine,

dust like.

Saw seems to run slow and easily stalled.

Saw does not operate when trigger switch is squeezed.

Saw runs but chain does not move.

Chain does not get oil.

Saw chain comes off guide bar.

Saw smokes.

Saw leaks oil.

SOLUTION

Saw chain is assembled backwards. See manual for correct assembly.

Dull saw chain. See manual.

Low supply voltage. Check extension cord size noted in the manual. Low

voltage can cause poor performance and motor burnout.

Lock out button has not been depressed to release trigger. OR, extension cord

connections are loose. OR, line fuse or circuit breaker is open. OR, motor

brushes need replacement. See your service center. OR, wiring circuit open,

See your service center.

Gear train failure. See your service center.

Oil slot in bar or mount is clogged with saw dust. Remove and clean. OR, oil

is not thin enough. See manual.

Chain is too loose and requires adjustment. See manual. Or, bar and chain are

not assembled properly. See manual, recheck assembly.

DO NOT operate. See your service center

Oil cap is not secure.

Note:

when storing, empty oil tank to avoid seepage.

101755

11

Page 12

LIMITED WARRANTY

This product is warranted to be free from defects in materials and workmanship for six (6) months from the

date of first purchase when operated and maintained in accordance with instructions. This warranty is

extended only to the original retail purchaser.

This warranty covers only the cost of parts required to restore this to proper operating condition.

Transportation and incidental costs associated with warranty repairs are not reimbursable under this

warranty.

Warranty service is available only through authorized dealers or service centres.

This warranty does not cover commercial or rental usage nor defects resulting from misuse, accidents, lack

of proper maintenance, bar, chain.

The warrantor assumes no responsibility for indirect, incidental or consequential damages.

THIS EXPRESS WARRANTY IS GIVEN IN LIEU OF ANY OTHER WARRANTY EITHER EXPRESSED

OR IMPLIED, INCLUDING WARRANTIES OR MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

PRINTED IN USA

2701 Industrial Drive

P.O. Box 90004

Bowling Green, KY 42102-9004

101755-01

REV. D

3/97

Loading...

Loading...