Page 1

MODEL VERSA MAX™

Autoloading Shotguns

Remington is a Trademark Registered in the United States Patent and Trademark Office

By Remington Arms Company, Inc.

Printed in the U.S.A.

1914 8.10 ORIG

Page 2 ......The Ten Commandments of Firearm Safety

Page 7 ...... Important Parts of the Firearm

Page 11 ...... To Assemble the Firearm

Page 11 ...... To Load the Firearm

Page 14 ...... To Unload the Firearm

Page 17 ...... Lubrication and Maintenance

Page 22 ...... To Function Test the Firearm

Page 27 ...... Parts List

Page 30 ...... How to Obtain Parts and Service

Owner’s

Manual

Instruction Book for:

This manual contains operating, care,

and maintenance instructions. To

ensure safe operation, any user of

this firearm must read and understand this manual

before using the firearm. Failure to follow the

instructions and heed the warnings in this manual

can cause property damage, personal injury,

and/or death.

This manual should always accompany this

firearm, and be transferred with it upon change of

ownership.

WARNING! Keep this firearm out of the reach of

children, unauthorized individuals, and others

unfamiliar with safe handing of firearms.

IMPORTANT!

Remington

®

VERSA MAX

TM

Autoloading Shotguns

Page 2

1st C O M M A N D M E N T

ALWAYS KEEP THE MUZZLE POINTED IN A SAFE DIRECTION.

This is the most important firearm safety rule.

A safe direction is one in which

an accidental discharge will not cause injury to yourself or others. Never allow

your firearm to point at anything you don't intend to shoot. Be especially careful when you're loading or unloading. Treat every firearm as if it were loaded.

And make it a habit to know where the muzzle is pointed at all times, even when

your firearm is un-loaded. No one will be injured by an accidental discharge if

you keep your firearm pointed in a safe direction. It's as simple as that.

2nd C O M M A N D M E N T

Load your firearm only

when you're in the field or on the target range and ready to fire. Never let a

loaded firearm out of your sight or out of your hands. Unload it as soon as you're finished shooting before you bring it into your car, camp or home. Remember, unloading your firearm means unloading it

completely, so there is no ammunition in the chamber or in the magazine. Before handling a firearm

or passing it to someone else, visually check the chamber, receiver and magazine to be certain they

do not contain ammunition. Always keep the firearm's action open when not in use. Never assume a

firearm is unloaded even if you were the last person to use it. Always check for yourself.

Firearms should be Unloaded When Not Actually in Use.

THE TEN COMMANDMENTS OF FIREARM SAFETY

The Ten Commandments of Firearm Safety should be etched in your memory forever. Let them

govern your action wherever and whenever you’re involved with firearms. In the field. On the

range. Or in your home. Please take the time to review and understand these rules.

A Tradition of Performance and Safety.

In 1816 Eliphalet Remington was confident he could make a flintlock that was

as good or better than any he could buy. His confidence was well founded. The

barrel he handcrafted set a new standard for firearm accuracy and spawned

generations of products that have made Remington® America's leading gunmaker. While performance and style are certainly hallmarks of Remington

firearms, one factor ultimately drives their performance. Safety. Eliphalet

Remington never lost sight of the fact that his rifles were potentially lethal and

could kill someone if handled improperly. And after more than 190+ years the

same holds true for any firearm, including your new Remington. Eliphalet

Remington's first flintlock launched a proud tradition of accuracy and responsibility.

Safety is Critical to Performance.

A superbly crafted firearm is only as good as the hands that hold it. You can never be too careful.

Shooting accidents are often caused by careless oversights such as failing to control the direction

of the muzzle, failing to fully engage the safety, leaving ammunition in the chamber or using improper

loads. These oversights can result in the destruction of life, limb or property. There's no calling back

a bullet once it's been fired, so it's critical that you know the principles of safe firearm handling and storage before you ever take your new Remington firearm out of the box.

The proper use and performance of your firearm depends on correct assembly and maintenance,

so it's critical that you familiarize yourself with the information in this instruction book. Even if you're

a veteran shooter with a collection of Remington firearms, take the time to read this literature. Not

all firearms are the same. That means the first step in safe handling is to learn the features and requirements of your new Remington.

Eliphalet Remington’s first

flintstock launched a

proud tradition of accura-

cy & responsibility

2

• Let common sense rule

when you carry a loaded firearm. If you're in a situation that could risk accidental discharge - such as crossing a fence, wading

through a stream or climbing a tree - always unload your firearm. Never pull

or push a loaded firearm toward yourself or another person. Never carry a

loaded firearm in a scabbard, detached holster or gun case.

• Certain firearms

(including some Remington®rifles and shotguns) are

equipped with internal security devices to prevent unauthorized use. In addition, some firearms owners use external devices, such as cable locks and

trigger blocks, for the same purpose. Even if you use such a device, you

should still keep your firearm unloaded when stored or not in use. And using

internal or external devices cannot substitute, however, for securing your

firearms and ammunition in a separate, locked location.

• Safe storage

of firearms is just as critical as safe handling. Never store firearms loaded. Be sure

to keep your firearms in a secure place where unauthorized persons cannot get their hands on them

without your knowledge.

• Take special care

if there are children around. Children are fascinated by firearms. It's a natural

curiosity that can have tragic consequences when not properly supervised. Store your firearms in a

locked gun safe or some other location that physically bars a child from gaining access.

• Ammunition

should be stored and locked in a location separate from your firearm. Never leave an

unsecured firearm or ammunition in a closet, dresser drawer or under the bed. Remember, it is your

responsibility to make sure that children and others unfamiliar with firearms cannot get access to

your firearm and ammunition.

3rd C O M M A N D M E N T

DON'T RELY ON YOUR FIREARM'S SAFETY

Treat every Firearm

as if it can fire at any time, whether or not there's pressure on the trigger. Your

firearm has been carefully designed to maximize performance and safety. However, because a

firearm's safety is a mechanical device, it could fail.

Human error

is a more likely reason for a firearm safety to fail. By mistake, you may think the safety is

on when it really isn't. Or the safety may have been disengaged without your knowledge. Or you

could think your firearm is unloaded when there's actually a cartridge or shell in it. A mechanical safety is not a substitute for common sense. It's merely a supplement to your proper handling of a firearm.

Never touch

the trigger on a firearm until you are ready to shoot. Keep your fingers away from the

trigger when you're loading or unloading. And don't pull the trigger when the safety is engaged or

positioned between safe and fire.

Before using your firearm

, read this instruction book to understand the exact location and operation of

your firearm's safety. Even when the safety is on, maintain control of your loaded firearm and control

the direction of the muzzle. In other words, don't rely on your safety to justify careless handling. If your

firearm's internal mechanisms are broken or have been altered, your firearm may fire even when the

safety is on. Remember, you and your safe firearm handling practices are your firearm's best safety.

4th C O M M A N D M E N T

B

E SURE OF YOUR TARGET AND WHAT’S BEYOND IT.

You can't stop a shot in mid-air, so never fire unless you

know exactly where your shot is going and what it will

strike. Never fire at a sound, a movement or a patch of

color. A hunter in camouflage can easily be mistaken for a

target by an impulsive shooter. Before you pull the trigger be

absolutely sure of your target and what's behind it. Make sure the shot

has a backstop such as a hillside or dense material like sand. Remember,

bullets can travel great distances with tremendous velocity. Know how far your shot will go if

you miss your target or the bullet ricochets.

3

Firearms should be stored in

a secure place where chil-

dren cannot access them. A

gun safe is an ideal way to

secure your firearm

Page 3

5th C O M M A N D M E N T

Use Proper Ammunition

Every firearm is designed

to use a certain caliber or gauge of ammunition. Using the wrong ammunition,

mixing ammunition or using improperly reloaded ammunition can cause serious personal injury or death.

And it only takes one cartridge or shotshell of the incorrect caliber or gauge, or which has been improperly reloaded, to destroy your firearm. It's your responsibility to make sure the ammunition you use exactly matches the caliber or gauge of your firearm. Refer to this instruction book to find out the specific requirements of your firearm. Always read and heed the instructions on ammunition boxes.

Confusing shells

or cartridges can cause serious personal injury or death and destroy your firearm.

Examine your shells or cartridges closely and use only the precise caliber or gauge for your specific

firearm. For example, suppose you accidentally loaded a 20 ga. shell into a 12 ga. shotgun. Because the

20 ga. shell is too small for the chamber, the 20 ga. shell could travel down the barrel and get lodged in

the bore. If you then loaded a standard 12 ga. shell behind it and fired, the 12 ga. shot will slam into the

lodged 20 ga. shell and may cause the barrel to explode right in your hand. This is commonly called a

12/20 burst, and it can kill you.

Check all ammunition

before you load it to make sure it matches your firearm's requirements. Every

Remington®cartridge and shell is head-stamped with its caliber or gauge for easy identification. Likewise,

you'll find the caliber or gauge of your new Remington firearm imprinted on the barrel.

Reloading Requires Extra Diligence.

If you're an ammunition reloader,

you are responsible for personally ensuring that the loads and components of your reloaded ammunition meet your firearm's factory-tested standards. Never use ammunition,

which has been reloaded by someone else!

Many shooters handload

as a hobby or to save money on commercial, factory-made ammunition.

However, it requires a thorough knowledge of reloading procedures and a deep respect for the explosive

potential of gunpowder.

Firearms are designed,

manufactured and proof-tested to standards based on factory-loaded ammunition. Handloaded or reloaded ammunition that deviates, either intentionally or accidentally, from load or

component recommendations can be very dangerous.

Reloaders must observe all possible safety precautions and practices related to the proper handling of

explosives. Whether you're a seasoned reloader or just starting out, you should study the subject, watch

reloading demonstrations and talk to experienced reloaders.

The first rule of reloading

is to always follow the manufacturer's instructions for the components you're

using. They'll tell you to follow certain guidelines. Namely:

1. Don't mix or substitute powders or primers.

2. Don't use unknown or substandard components.

3. Use only suitable components that have been factory-tested by reputable ammunition,

powder and bullet manufacturers.

4. Always be sure to use the manufacturer's recommended recipe when reloading.

Not following these guidelines

could result in severe injury to yourself or severe damage to your firearm.

Dangerously high pressure and explosions can result from an overcharge of powder or other deviations from

established reloading guidelines. Be very careful. The process of reloading exposes you to environmentally

hazardous material. Lead, which is known to cause cancer and birth defects, is the most common substance

in bullets and shot. It is important to handle lead bullets and shot with extreme care. Work only in a well-ventilated area and always wash your hands after exposure and before eating. Never smoke while reloading.

Primers and powders

are also highly toxic and flammable. So after reloading be sure to clean up all materials from your work area. Don't leave primer or powder spills anywhere on the floor or bench top. Dispose

of all waste material in accordance with the manufacturer's recommendations.

Finally, when reloading

or handloading concentrate on what you're doing at all times. Do not be distracted by talking to others, listening to the radio or watching TV while reloading. Never reload after consuming alcoholic beverages or drugs of any kind. You are working with extremely hazardous materials and you

can't risk even a few seconds of distraction. Remember, if you reload, you are the ammunition manufacturer and you are responsible for the performance and safety of your reloaded ammunition.

4

6th C O M M A N D M E N T

IF YOUR FIREARM FAILS TO FIRE WHEN THE TRIGGER IS PULLED, HANDLE WITH CARE.

I

f for some reason

the ammunition doesn't fire when you pull the trigger, stop and remember the 1st

Commandment of Firearm Safety - always keep the muzzle pointed in a safe direction. Keep your

face away from the breech, then put the safety on, carefully open the action, unload the firearm and

dispose of the cartridge safely. Remember that anytime there's a shell in the chamber, your firearm

is loaded and ready to use. Even if you tried to shoot and your firearm didn't fire, treat your firearm

as if it could still discharge.

7th C O M M A N D M E N T

Your sight and hearing

risk injury from shooting and should be protected

at all times. Wear protective shooting glasses to guard against falling

shot, clay target chips, powder residue, ruptured cartridge cases and

even twigs and branches in the field. Also be sure to wear eye protection

when you're disassembling or cleaning a firearm so that tensioned parts

(like springs) and cleaning solvents don't come in contact with your

eyes. Continued exposure to shooting noise can permanently damage your hearing. On the

range, where shooting volume is the loudest, be sure to use the maximum protection of a headset. Learn to use ear protection at all times.

8th C O M M A N D M E N T

BE SURE THE BARREL IS CLEAR OF OBSTRUCTIONS BEFORE SHOOTING.

Before loading your firearm

, open the action and make sure there's no ammunition in the chamber

or magazine. Check the barrel for any obstructions or debris. Even a small amount of snow, mud,

excess lubricant or grease in the bore can dangerously increase pressure and cause the barrel to

bulge or burst when firing. Use a cleaning rod and patch to wipe away anti-rust compounds or any

other residues or obstructions in the barrel. Never try to shoot out an obstruction by loading another shell and firing!

When firing

, rely on your instincts. If the noise or recoil of your firearm seems weak, stop everything,

unload your firearm and be sure nothing is lodged in the barrel. Remember the 12/20 burst? That's

what can happen when the barrel is obstructed. Always be sure you're using the correct ammunition in your firearm and that it's free of obstructions.

9th C O M M A N D M E N T

DON'T ALTER OR MODIFY YOUR FIREARM AND HAV E I T SERVICED REGULARLY.

Your firearm has

been designed to operate according to certain factory specifications. You'll jeopardize your safety and that of others around you by attempting to alter its trigger, mechanical safety or other mechanisms. So never alter or modify your firearm in any way.

Like any mechanical device,

a firearm is subject to wear. It must be

maintained and periodically serviced to assure optimum safety and

performance. Only a qualified service facility should service, repair or

modify your Remington firearm. Consult your instruction book for

instructions on how to send your firearm to the factory or for the location of the nearest Remington authorized repair station.

Proper cleaning and lubrication

are also important to firearm maintenance and are necessary to assure accuracy, safety and reliability.

Before cleaning, always make sure that your firearm is completely

unloaded. And always clean the barrel from the chamber end to the muzzle when possible.

Make it a practice to clean your bore every time you're going to shoot. Be sure to clean your entire

firearm before and after long-term storage and no less than once a year. It's also important to clean your

firearm whenever it's been exposed to adverse conditions such as rain, dirt, mud, snow, sleet or saltwater.

ALWAYS WEAR EYE AND EAR PROTECTION WHEN SHOOTING.

5

Page 4

For safe and dependable

operation of your firearm, all parts of your firearm must be properly cleaned

and lubricated. Periodically inspect the internal workings of your firearm to be sure they're clean and

free of rust, unwanted dirt and debris.

Use recommended lubricants

on your firearm and do not over-lubricate. Excessive use of a non-recommended lubricant could adversely affect the function and safe operation of your firearm. Remember, you

are responsible for the proper care and maintenance of your firearm. Failure to properly maintain your

firearm cannot only damage or ruin your firearm, it can expose you and others to unnecessary risks of

personal injury or death.

Remington® has a wide range

of firearm care products and resources for best results when cleaning

your firearm. Everything from solvents and lubricants to rods and patches. They're all available from your

Remington dealer.

10th C O M M A N D M E N T

LEARN THE MECHANICS AND HANDLING CHARACTERISTICS OF YOUR FIREARM.

Not all firearms are alike.

They have different mechanical characteristics that dictate how you should

carry and handle them. Anyone who plans to use a firearm should first become totally familiar with the

type of firearm it is and the safe handling procedures for loading, unloading, carrying, shooting and storing it.

Before you even unpack

your new Remington firearm, read this instruction book from cover to cover and familiarize yourself with the different

component parts of the firearm. Then read, understand and follow the

Ten Commandments of Firearm Safety in this manual.

WARNING! Discharging firearms in poorly ventilated areas, clean-

ing firearms or handling ammunition may result in exposure to

lead, a substance known to cause birth defects, reproductive

harm, cancer and other serious physical injury. Have adequate

ventilation at all times. Wash hands thoroughly after exposure.

SHOOT SOBER!!

There's one other rule that must be followed when handling firearms. In fact, respect for this rule is necessary in order to effectively practice the Ten Commandments of Firearm Safety. The rule is: SHOOT

SOBER! Firearms and alcohol or drugs make a deadly combination. Never consume anything that

would mildly impair your judgment or physical coordination when you're using a firearm. A staggering

percentage of the shooting accidents that occur every year involve alcohol or drugs. Be smart. Always

shoot sober and stay alive.

WARNING! Failure to follow any of these safety rules may cause personal injury or death to the shoot-

er or bystander and damage to property. Do not use a firearm until you fully understand and practice

the Ten Commandments of Firearm Safety. If you have any questions about the safe use of a Remington

firearm, write to us at Remington Arms Company, Inc., Consumer Service, P.O. Box 700, Madison, NC

27025-0700, or call us at 1-800-243-9700.

DON'T KEEP THIS TO YOURSELF.

Now that you're a firearm owner

you have the obligation to help ensure that shooting sports are safe for

everyone - participants and bystanders alike. You can do that by practicing these principles of firearm

safety and passing them on to others - especially new shooters. Set an example for beginners. Be a

guide to their safe entry into the exciting world of shooting sports. Invest your time and patience for the

love of the sport and for its future. After all, it's your love of the sport that led you to buy a new

Remington.

Firearm ownership

is a right and privilege. It's a right guaranteed in this nation's Constitution. It's a privilege, which carries with it a personal responsibility to use your firearm in a way which will ensure your

safety and the safety of others. The preservation of this right and privilege depends on the personal

commitment of you and your fellow shooters to the safe and responsible use of firearms. Let the Ten

Commandments of Firearm Safety outlined in the manual guide you at all times. Teach and promote

these rules whenever you can. Remember, firearm safety depends on you! That's the only way to really

enjoy your new Remington firearm and to preserve sport shooting as we know it today.

6

Remington® VERSA MAX™ Autoloading Shotguns

Congratulations on your choice of a Remington®. With proper care, it should give you

many years of dependable use and enjoyment. For best results, we recommend that you

use Remington Ammunition - the ammunition used in factory testing your firearm against

our rigorous function and performance standards.

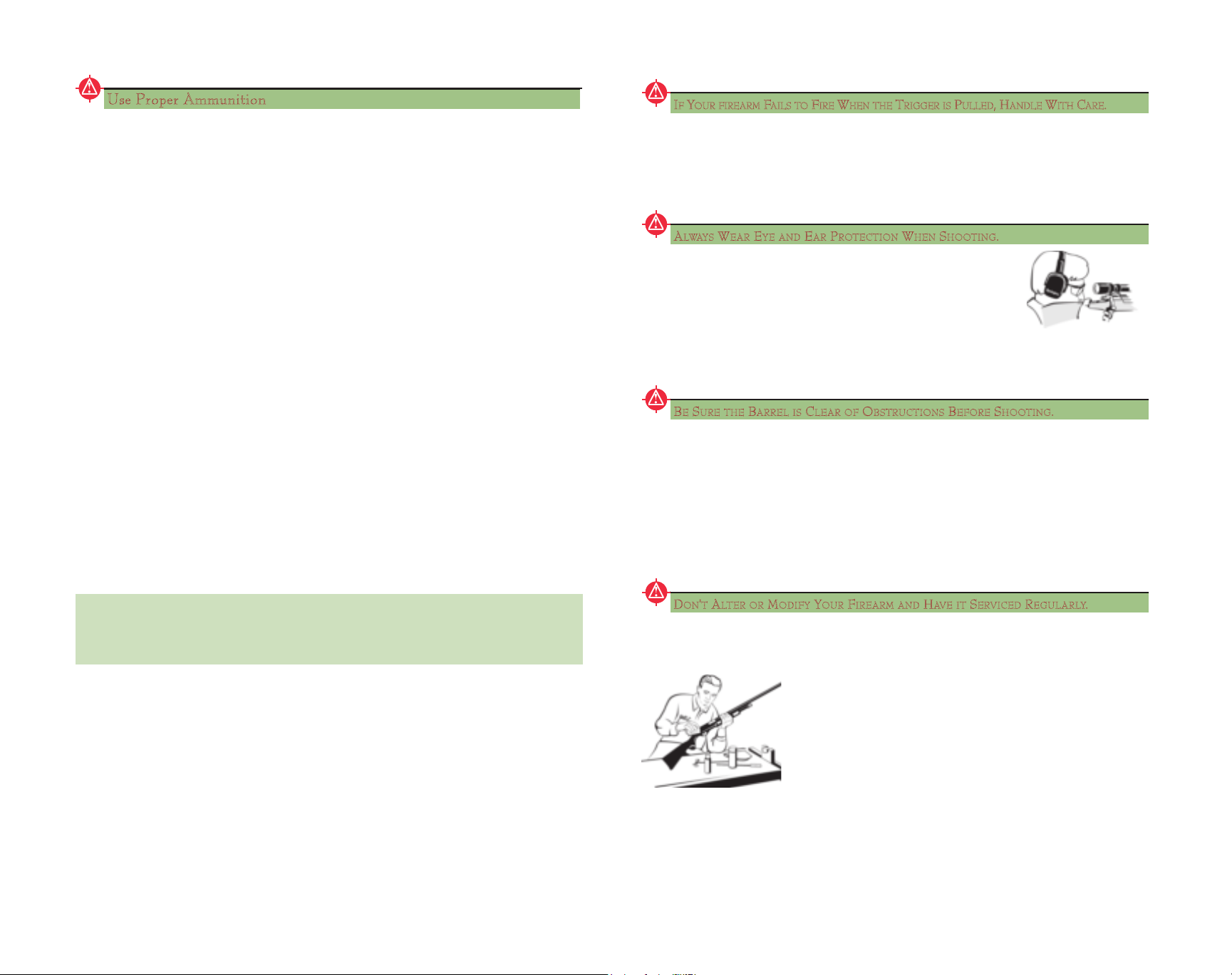

PICTURE 1

This picture shows the main parts of the REMINGTON® Versa Max Autoloading

Shotgun. The picture will aid in understanding the instructions.

General Operation

The Remington® VERSA MAX™ is a gas

operated, autoloading shotgun. The

firearm is capable of firing successive

shots with 2 3/4, 3, and 3 1/2 inch shotshell cartridges interchangeably. At the

start of the firing cycle when the trigger is

pulled, the disconnector is activated and

the hammer is released, striking the firing

pin. In turn, the firing pin strikes the

chambered shotshell’s primer, igniting the

shot charge. High pressure gas from

behind the shot charge passes through

ports in the barrel to the gas cylinders.

The residual gas pressure forces the bolt

assembly rearward, operating the action.

The spent shell is extracted from the

chamber. The hammer is re-cocked. The

disconnector is deactivated when the

trigger is released. The trigger and cartridge release are reset. As the action

continues rearward the spent shell

engages the ejector, expelling it from the

receiver through the ejection port. When

the bolt is fully rearward, a new shotshell

is released from the magazine onto the

carrier. As the bolt moves forward the

carrier rises to place the new shell in

front of the bolt. Completing the cycle,

the bolt continues forward pushing the

shell into the chamber. The bolt head

rotates, locking the cartridge into battery

(firing position). When the last shell has

been discharged, the bolt assembly

locks in the open position.

Caution: The Versa Max manual bolt

hold open, loading, and unloading procedures are not the same as a Remington

1100 or 11-87 autoloading shotgun. See

“To Load the Firearm” and “ To Unload

the Firearm”, sections of this manual.

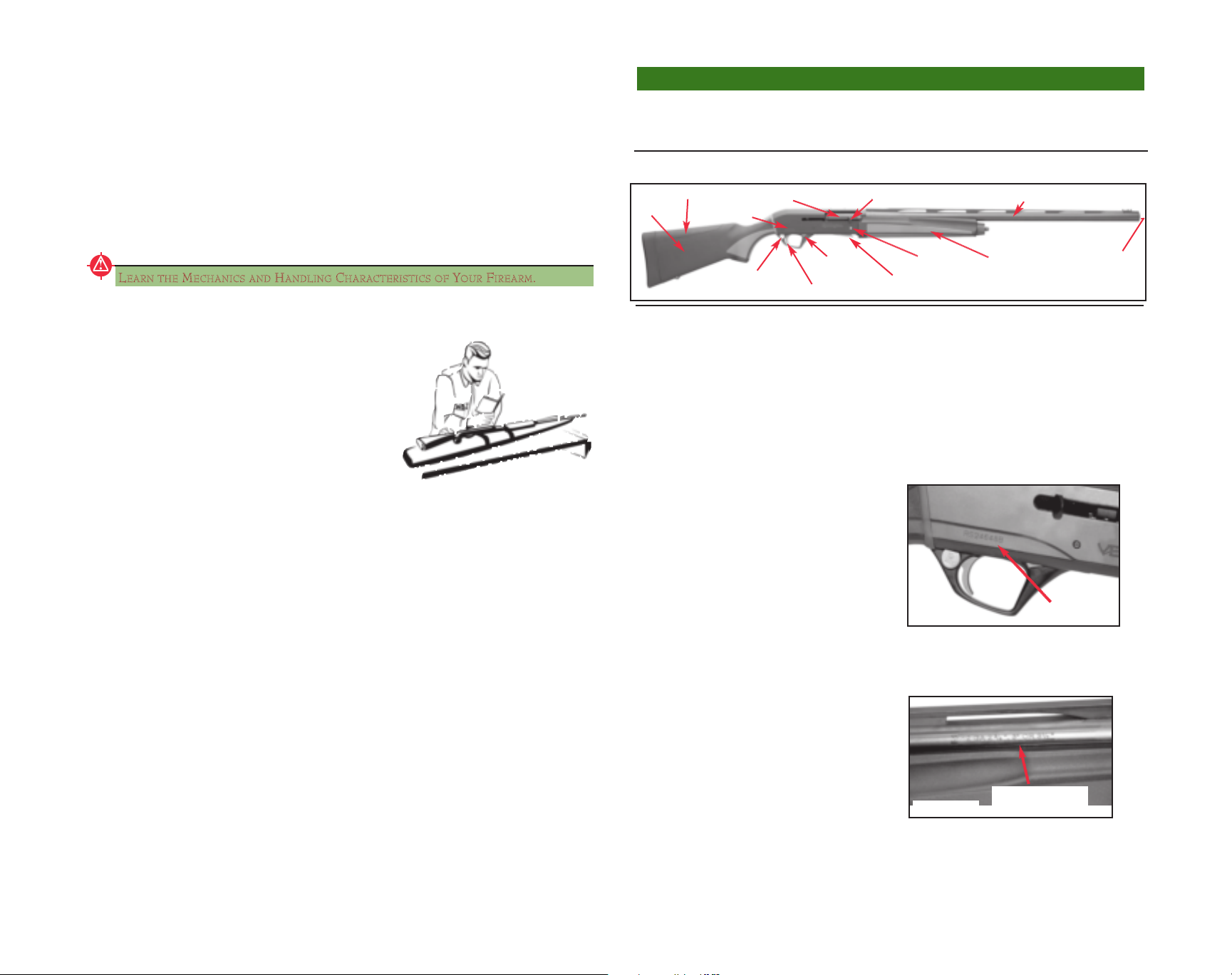

Serial Number and Cartridge

Designation

:

The serial number is located on the

shooter’s right side of the receiver. See

Picture 2.

Specifications for the correct gauge and

length of the shotshell intended for use in

your firearm is located on the shooter’s

left side of the barrel. See Picture 3.

WARNING! Only use the specified

gauge and length of shotshell ammunition specified for your firearm as designated on the barrel. See “To Load the

Firearm,” page 11.

Important Parts of the Firearm

7

Serial Number

PICTURE 2

PICTURE 3

Stock

Bolt

Release

Barrel

Muzzle

Operating Handle

Safety Mechanism

Ejection Port

Cartridge

Release

Receiver

Trigger

Gauge & Length

Designation

Carrier

Fore-end

Comb Insert

Page 5

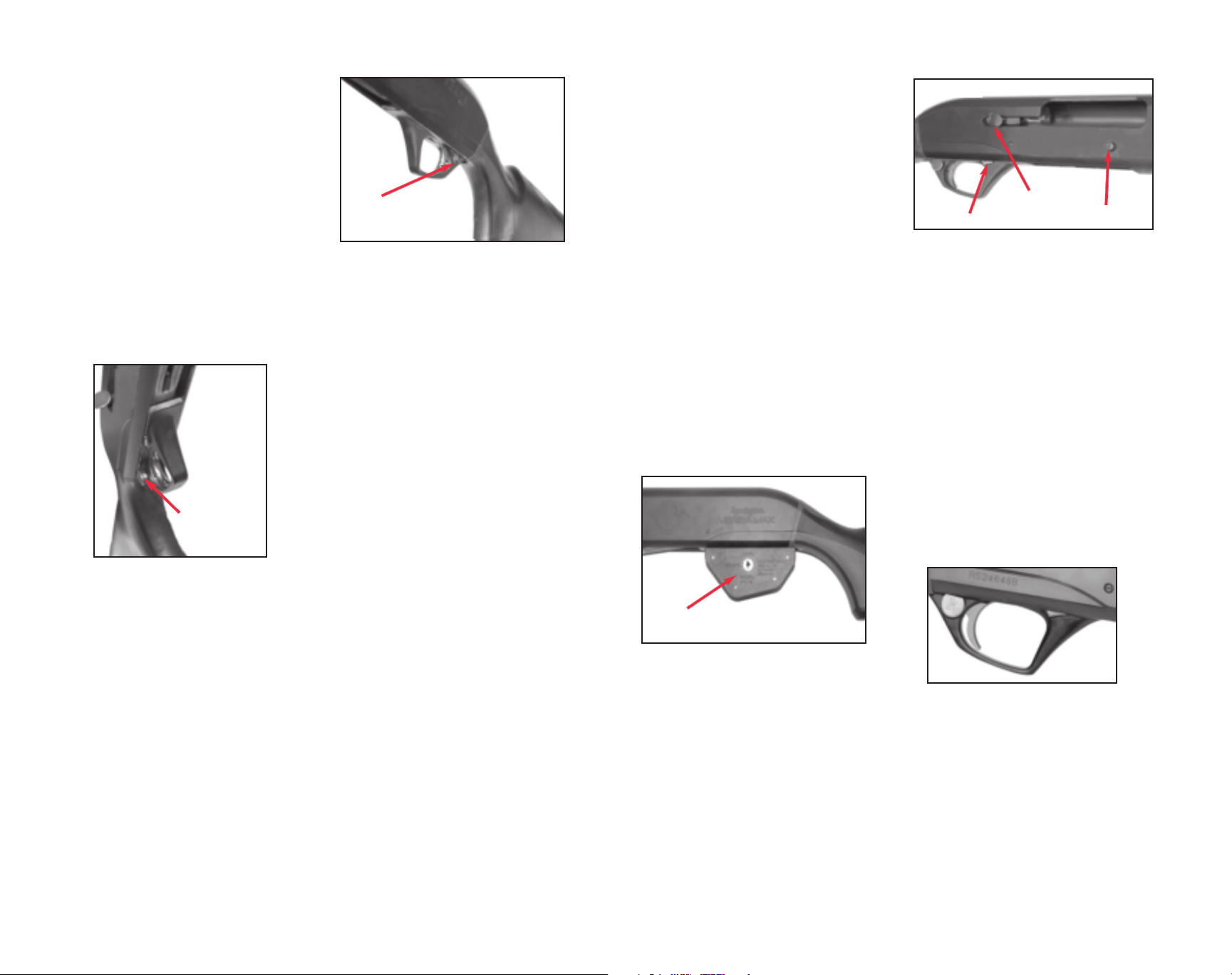

The Safety Mechanism

The manual safety mechanism on the

Versa Max shotgun provides protection

against accidental or unintentional discharge under normal usage when properly engaged and in good working order.

This safety mechanism is not a substitute

for following the rules of safe firearm

handling. The cross bolt type safety prevents the trigger from being pulled when

fully engaged in the “ON” or "SAFE" position.

To engage the safety mechanism, push

the “Safety Button,” located at the rear of

the trigger guard, to the shooter’s right

until the button stops and THE RED

BAND MARKING CANNOT BE SEEN.

See Picture 4.

Always engage the safety mechanism by

moving the safety button to the shooter’s

right before handling, loading or unloading the firearm.

When you are ready to FIRE

the firearm,

disengage the Safety Mechanism by

pushing the Safety Button to the shooter’s left until the button stops and the

RED BAND MARKING IS VISIBLE. See

Picture 5. You have now disengaged the

Safety Mechanism and the firearm is

ready to FIRE.

Do not touch the trigger

while moving the

safety mechanism. Your fingers and all

other objects should be kept outside of the

trigger guard and away from the trigger

until you are actually ready to FIRE.

Never pull the trigger

when the Safety

Mechanism is in the "ON” or “SAFE"

position.

WARNING! The firearm will discharge

when the trigger is pulled and the

safety

mechanism

is OFF or in the “FIRE" posi-

tion.

Even when the safety

is engaged in the

"ON” or “SAFE" position, careless handling

can cause the firearm to discharge.

See

The Third Commandment of Firearm

Safety.

NOTE: If desired, a left-handed shooter

may have the operation of the safety

mechanism reversed by the factory or a

Remington® Authorized Repair Center.

Once reversed to accommodate a lefthanded shooter, the safety mechanism’s

“ON” and “OFF” positions will be exactly

opposite as described in this manual.

Additional Features:

Besides the manual safety mechanism,

the Versa Max autoloading shotguns

incorporate passive features providing

additional protection against accidental or

unintentional discharge under normal

usage and in good working order. These

passive features such as the inertia firing

pin system, steel alloys and/or their metallurgical treatments, the hammer, sear,

and trigger engagements, the trigger disconnect, the breech lock-up system,

head space, and the trigger guard all

work without direct input from the user

as long as your firearm is kept clean and

in good working order.

WARNING! Do not alter, modify, bypass,

or render these safety features inoperative.

8

PICTURE 5

Safety Mechanism

“FIRE” Position

PICTURE 4

Safety

Mechanism

“Safe”Position

The Locking Device

This firearm was originally sold with a keyoperated locking device to assist the

owner in protecting against unauthorized

use. These are storage locking devices,

which should be used when the firearm is

stored or not in use. Always store a firearm

completely unloaded.

These locking devices DO NOT eliminate

the need for safe firearm handling and storage, including keeping this and every

firearm unloaded and locked in a secure

place when not in use. Read and follow

these and other safety rules in this instruction manual. Failure to read, understand,

and obey these rules can result in serious

personal injury or death. See the “Ten

Commandments of Firearm Safety,” on

page 2.

Keep your locking device

engaged when

your firearm is not in use. Keep the keys

in a secure place, inaccessible to others.

DO NOT leave your keys or any ammunition with your firearm, which should be

kept locked in a safe place.

To secure your firearm with an external

locking device, See instructions provided

in the packaging.

The Operating Handle, Bolt

Release, and Cartridge Release

The operating handle is used to move the

bolt rearward, opening the action. The bolt

release is used to release the bolt from the

locked open position. See Picture 6.

The cartridge release is used to manually

release cartridges from the magazine and

to manually reset the bolt lock open feature.

WARNING! When the operating handle

(bolt) is forward in the closed position and

the safety mechanism is in the “OFF” or in

the “FIRE” position, the firearm can be

discharged by pulling the trigger.

The Trigger Assembly

Pulling the trigger FIRES the firearm.

The trigger assembly of your Versa Max

shotgun is a single-action (SA) system.

When the trigger is pulled fully rearward, it

starts the firing sequence by releasing the

hammer. The trigger assembly is not

adjustable. All repairs to the trigger

assembly must be made by the factory or

a Remington Authorized Repair Center.

WARNING! Never place your finger on

the trigger unless you are ready to discharge or fire the firearm.

WARNING! Never manipulate, adjust or

change any of the internal components of

your firearm. Improper manipulation of any

internal component may effect the safety

and reliability of your firearm and may

cause serious injury or death.

9

PICTURE 6

Bolt

Release

Operating

Handle

Cartridge

Release

Trigger Lock

Page 6

The Choke Tube

The inside bore constriction at the muzzle

end of a shotgun’s barrel is known as the

“Choke”. When a shot shell is discharged, shot travels down the bore, exiting the muzzle and begins to “spreadout”. The spread of the shot is controlled

by changing the muzzle constriction. The

Versa Max has a changeable, screw-in,

choke tube system. To change or replace

the barrel’s choke tube, see: “To Change

the Choke Tube,” on page 14. For more

information about choke tubes, see: The

Remington Guide to Shotguns and Shot

Shell Ammunition, publication or visit our

web site at www.remington.com.

WARNING! Unload your shotgun before

removing or installing a choke tube and

the safety mechanism is engaged by

placing the safety in the “ON” or “SAFE”

position

WARNING! Never discharge your shotgun without a choke tube properly

installed, as damage or injury may occur.

WARNING! Never discharge steel shot

through a lead only choke tube. Choke

tubes NOT designated for steel will be

marked “Lead Only”.

The Magazine Plug

A magazine plug is provided with your

shotgun to limit the magazine capacity to

two (2) shot shells. A limited magazine

capacity limit is required by the Federal

Migratory Bird regulations and certain

state laws. Check with your local Fish &

Game Commission or other appropriate

authorities to determine whether a magazine plug is required to limit the magazine capacity within your jurisdiction.

To install or remove a magazine plug,

See: “To Install the Magazine Plug,” on

page 14.

WARNING! Before installing or removing

a magazine plug, make sure the firearm is

completely unloaded and the safety

mechanism is engaged by placing the

safety in the “ON” or “SAFE” position.

The Barrel

WARNING! The inside of the barrel and

chamber must be clean and free of

obstructions.

See the “Ten Command-

ments of Firearm Safety,” on page 2.

I. To Check the Barrel for Obstructions:

1. Always keep the firearm pointed in a

safe direction.

2. Engage the safety mechanism in the

"ON” or “SAFE" position. The red

band will NOT be visible.

3. Engage the bolt hold open by pressing the cartridge release fully

upward. See Picture 6.

4. Open the bolt by pulling the operating handle fully rearward, locking the

bolt in the open position.

5. Visually check the chamber, loading

port and magazine to make sure the

firearm is completely unloaded.

6. Insert a cleaning rod into the muzzle.

7. Push the rod completely through the

barrel until the rod can be seen at the

ejection and loading port.

II. To Remove a Barrel Obstruction:

WARNING! NEVER try to remove an

object from the barrel by loading a shotshell

(cartridge) and firing. This may cause the

barrel to burst or a shotshell to rupture and

cause serious personal injury or death.

1. Always keep the firearm pointed in a

safe direction.

2. Engage the safety mechanism in the

“ON” or “SAFE" position. The red

band will NOT be visible.

3. Engage the bolt hold open by pressing the cartridge release fully

upward. See Picture 6.

4. Open the bolt by pulling the operating handle fully rearward, locking the

bolt in the open position.

5. Visually check the chamber, loading

port, and magazine to make sure the

shotgun is completely unloaded.

6. Remove the barrel. See “To Dis-

assemble the Firearm for Cleaning,”

on Page 18.

7. Insert the cleaning rod of the correct

bore size into the muzzle and lightly

tap the rod to free object from the

barrel.

10

8. Push the rod all the way through the

barrel until the rod can be seen at the

ejection and loading port.

9. If an object cannot be easily pushed

out of the barrel with a cleaning rod,

return the barrel to the factory or a

Remington Authorized Repair Center.

To Assemble the Firearm:

The firearm was shipped with the barrel

assembly removed. See Picture 7 for

location of parts.

Note: The bore and chamber must be

cleaned before assembly. See “To Clean

the Barrel,” on Page 19.

1. Always keep the firearm pointed in a

safe direction.

2. Engage the safety mechanism in the

“ON” or “Safe” position by moving the

safety button fully to the shooter’s

right. The red band will NOT be visible.

3. Visually check the barrel making sure

there are no obstructions.

4. Unscrew and remove the magazine

cap by turning it counterclockwise.

5. Remove the fore-end from the magazine tube by sliding it forward.

6. Reset the bolt hold open by pressing

the cartridge release. See Picture 6.

7

.

Open the bolt by pulling the operating handle rearward until the bolt

locks in the open position.

8

.I

nsert the barrel into the receiver and

the barrel ring over the magazine

tube. See Picture 8.

9. Place the fore-end over the magazine

tube until it seats against the receiver.

10

.

Replace the magazine cap on top of

the magazine tube. Tighten by turning clockwise until hand-tight.

To Load and Unload the Firearm

To Load the Firearm:

WARNING! The specific gauge and

length of shotshell ammunition suitable

for use in your shotgun is marked on the

barrel. Different gauges and shell

lengths are not interchangeable. DO

NOT use any ammunition other than the

designated gauge and length specified

for your shotgun. Using incorrect ammunition in your firearm can result in a

severe malfunction of your firearm or

ammunition, leading to personal injury

and/or death.

See “The Ten

Commandments of Firearm Safety,” on

page 2.

Ammunition:

The VERSA MAX™ shotgun is designed

to function with 2 3/4, 3, or 3 1/2 inch,

ammunition. If you experience any initial

cycling problems with certain loads, we

recommend firing a number of cartridges

of standard game loads to speed the

break-in of your new shotgun.

Always check the cartridge for the correct

gauge and length before loading the

firearm. To find additional ammunition

information, see the Remington catalog or

visit the Remington website at www.remington.com.

WARNING! Do not apply oil, grease, or

any lubricants to cartridges.

11

PICTURE 8

PICTURE 9

Shotgun Shell / Cartridge

Gauge Marking

Head

Body &

Load Marking

Rim

Primer

PICTURE 7

Barrel Ring

Magazine Tube

Receiver

Barrel Assembly

Trigger Lock

Choke Tubes

Accessory Package

Barrel

Page 7

7. Close the bolt assembly by pressing

the Bolt Release.

8. Push up to three (3) 2 3/4” or 3” cartridges or two (2) 3 1/2” cartridges of

the correct gauge, one at a time, fully

forward into the magazine tube, ensuring the rim of each shell engages

the feed latch and is held inside the

magazine tube. See Picture 12.

9. Release a shotshell from the magazine onto the carrier by pressing the

Cartridge Release lever. See Picture

6.

10. Pull the operating handle fully rearward then release, chambering the

staged round.

WARNING! The shotgun is now cocked

and fully loaded. Make sure the safety

mechanism is still engaged in the “ON” or

“SAFE” position. Always keep the firearm

pointed in a safe direction.

How to Change a Chambered

Cartridge without Feeding a

Cartridge from the Magazine

(cut-off)

1. Always keep the firearm pointed in a

safe direction.

2. Engage the safety mechanism in the

“ON” or “SAFE" position. The red

band will NOT be visible.

3. Pull the operating handle rearward,

extracting and ejecting the chambered cartridge.

4. While holding the operating handle

rearward, drop a cartridge onto the

carrier through the ejection port. See

Picture 13.

5. Chamber (load) the staged cartridge

by releasing the operating handle.

To Discharge the Firearm:

WARNING! Always wear eye and hear-

ing protection when discharging your

firearm. See “The Ten Com-

mandments of Firearm Safety,” on page 2.

1. Point the muzzle at your

intended target.

2. Disengage the safety mechanism by

moving the safety button to the “OFF”

or “FIRE” position. The red band will

be visible.

3. With target acquired and the butt of

the shotgun firmly mounted against

your shoulder, pull the trigger. The

firearm will discharge each time the

trigger is pulled until the magazine

and chamber are empty. The bolt will

remain Open when the last shell has

been discharged.

WARNING! If a cartridge does not discharge when the trigger is pulled (misfire), keep the firearm pointed in a safe

direction and wait one minute before

opening the bolt. See: “To Unload the

Firearm,” on page 14.

WARNING! If the “report” of the shot is

noticeably softer or louder or any way

irregular, keep the firearm pointed in a

safe direction; unload the firearm and

check for bore obstructions. See: “To

Remove a Barrel Obstruction,” on page

10.

4. Engage the safety mechanism in the

“ON” or “Safe” position by moving the

safety button fully to the shooter’s

right. The red band will NOT be visible.

5. With the bolt locked open, visually

check the chamber, loading port, and

magazine to make sure the firearm is

completely unloaded.

To Fully Load the Firearm:

WARNING! Always check the cartridge

for the correct designation before loading

the firearm.

Caution: The bore should be cleaned

before loading the firearm the first time.

Follow the cleaning instructions shown on

Page 19, “To Clean the Barrel.”

1. Always keep the firearm pointed in a

safe direction.

2. Engage the safety mechanism in the

“ON” or “Safe” position by moving

the safety button fully to the shooter’s

right. The red band will NOT be visible.

3. Engage the bolt hold open by pressing the cartridge release upward.

See Picture 6.

4. Pull the operating handle fully rearward to lock the bolt in the open

position.

5. With the bolt locked open, visually

check the chamber, loading port,

and magazine making sure the

firearm is completely unloaded. If the

chamber is not unloaded, see page

14, “To Unload the Firearm.”

6. Make sure the barrel and chamber

are free of obstructions, see page

10, “To Check the Barrel for

Obstructions.”

I. To Load the Chamber:

7. Place one shell onto the carrier

through the ejection port. See Picture

10.

8. Close the bolt assembly by pressing

the Bolt Release, chambering the

cartridge.

WARNING! When releasing the bolt,

keep hands, clothing and other objects

away from the bolt and bolt handle.

II. To Load the Magazine:

9. Push up to three (3) 2 3/4” or 3” cartridges or two (2) 3 1/2” cartridges of

the correct gauge, one at a time,

fully forward into the magazine tube

(see Picture 11), ensuring the rim of

each shell engages the feed latch

and is held inside the magazine

tube. See Picture 12.

WARNING! The firearm is now cocked

and fully loaded. Make sure the safety

mechanism is still engaged in the “ON” or

“SAFE” position. Always keep the firearm

pointed in a safe direction.

To Load the Chamber From the

Magazine:

Note: The bolt must be fully forward and

the hammer must be cocked before the

magazine can be loaded.

1. Always keep the firearm pointed in a

safe direction.

2. Engage the safety mechanism in the

“ON” or “Safe” position by moving

the safety button fully to the shooter’s

right. The red band will NOT be visible.

3. Engage the bolt hold open by pressing the cartridge release. See Picture

6.

4. Pull the operating handle fully rearward to lock the bolt in the open

position.

5. With the bolt locked open, visually

check the chamber, loading port,

and magazine making sure the shotgun is completely unloaded.

6. Make sure the barrel and chamber

are free of obstructions, see page

10, “To Check the Barrel for

Obstructions.”

WARNING! When loading, keep hands,

clothing and other objects away from the

bolt and bolt handle.

12

13

PICTURE 13

PICTURE 12

Feed Latch

Shotshell latched in

Magazine

Drop

Cartridge into

Ejection Port.

PICTURE 11

Magazine

Bolt Assembly

Closed

PICTURE 10

Cartridge

Bolt Release

Page 8

To Unload the Firearm

WARNING! NEVER assume your firearm

is unloaded to justify careless handling.

Always control the direction of the muzzle

of your firearm, even if you think it is completely unloaded.

1. Always keep the firearm pointed in a

safe direction throughout the unloading process.

2. Engage the safety mechanism in the

“ON” or “Safe” position by moving the

safety button fully to the shooter’s

right. The red band will NOT be visible.

3. Release a shotshell from the magazine

onto the carrier by pressing the

Cartridge Release lever. See Picture 6.

4. Pull the operating handle fully rearward, extracting the chambered cartridge.

5. Chamber (load) the staged cartridge

by releasing the bolt.

6. Repeat steps 3 thru 5 until all cartridges are removed from the firearm.

When all cartridges are removed from

the firearm, the bolt will remain open in

the locked position.

7. With the bolt locked open, visually

check the chamber, loading port, and

magazine to make sure the firearm is

completely unloaded and free of

obstructions.

To Change the Choke Tube:

WARNING! Completely unload the firearm

before changing the choke tube. See “To

Unload the Firearm,” page 14.

1. Always keep the firearm pointed in a

safe direction.

2. Engage the safety mechanism in the

“ON” or “Safe” position by moving the

safety button fully to the shooter’s

right. The red band will NOT be visible.

3. Engage the bolt hold open by pressing

the cartridge release. See Picture 6.

4. Pull the operating handle fully rearward to lock the bolt in the open position.

5. With the bolt locked open, visually

check the chamber, loading port, and

magazine to make sure the firearm is

completely unloaded. If the firearm is

not unloaded, See “To Unload the

Firearm,” page 14.

6. Place the choke tube wrench supplied

with your shotgun into the choke tube.

See Picture 14.

7. Turn the choke tube wrench counterclockwise until the choke tube can be

removed from the barrel.

8. Select the desired choke tube and

insert it into the barrel muzzle.

9. Place the choke tube wrench onto

choke tube and tighten by turning

clockwise. Do Not Over Tighten!

10. Remove choke tube wrench.

11. With the Safety in the “ON” or “SAFE”

position, bolt open, and the chamber

and magazine completely unloaded,

check the choke tube periodically to

make sure it is tight and secure.

CAUTION: Never discharge the shotgun

without a choke tube properly installed.

After installing a choke tube, ensure the

choke tube wrench has been removed.

To Install the Magazine Plug:

WARNING! Check with you local Fish &

Game Commission or other appropriate

authorities to determine whether a magazine plug is required in your jurisdiction.

1. Always keep the firearm pointed in a

safe direction.

2. Engage the safety mechanism in the

“ON” or “Safe” position by moving the

safety button fully to the shooter’s right.

The red band will NOT be visible.

3. Completely unload the chamber and

magazine. See “To Unload the

Firearm,” on page 14.

4. With bolt locked open, visually recheck the chamber, loading port, and

magazine, making sure the shotgun is

completely unloaded.

5. Ensure the barrel and chamber are

free of obstructions, see page 10, “To

Check the Barrel for Obstructions.”

6. Remove the magazine cap by turning

it counterclockwise.

7. If required, place the choke tube

wrench onto the magazine spring

retainer.

14

8.

Push down on the choke tube

wrench and retainer (approximately)

one half (1/2) inch or until you can

turn the Magazine Spring Retainer

clockwise.

WARNING! Use extreme care when

removing the magazine spring retainer,

as the magazine spring is under compression. Wear eye protection to avoid

serious personal injury.

9. Turn the Magazine Retainer approximately 1/4 turn. Slowly release the

magazine spring and retainer as it is

under pressure. Remove the magazine spring retainer. Do not remove

the magazine spring.

10. With the magazine spring in the magazine tube, place the magazine plug

into the center of the magazine

spring.

11. Place the open end (end without

teeth) of the magazine spring retainer

on top of magazine spring.

12. Push the magazine spring, plug, and

retainer into the magazine tube while

aligning the magazine retainer detent

slots with the detents in the magazine tube. See Picture 16.

13. Once the detents are aligned, push

the magazine spring, plug, and retainer down into the magazine tube

(approximately 1 1/2 inch) until the

magazine retainer can be turned 1/4

of a turn, locking the retainer in position.

14. If used, carefully remove the choke

tube wrench from the magazine

retainer.

15. Replace the magazine cap by turning clockwise until tight. Do not over

tighten.

Sights:

WARNING! Before adjusting the sights or

mounting any telescopic sights, make sure

the firearm is completely unloaded and the

safety mechanism is engaged by placing

the safety in the “ON” or “SAFE” position.

See instructions provided in packaging to

change the front sight’s fiber optic (litepipe).

Receiver Mounted Optics:

The top of the Versa Max receiver is drilled

and tapped for an optic sight mount (not

provided). For optic mounting and adjustment see the instructions provided with

your optic sight system.

The Stock Adjustments:

I. To Change the Length of Pull:

The Versa Max is provided with spacers to

change the Length-Of-Pull (LOP). The LOP

may be adjusted from 14 1/4 to 15 1/4 inches.

To install and adjust the LOP, see the LOP

instructions provided with packaging.

II. The Drop at Comb Insert:

The Versa Max stock is designed to allow

easy height adjustment of the drop at the

comb from 1 7/16” (standard), 1 7/8” and

2 1/8” by changing the comb insert.

Order additional comb inserts through

your Remington Dealer. See mounting

instructions provided with your comb

insert packaging.

15

PICTURE 16

Magazine

Spring Retainer

Slots

PICTURE 15

Fore-end

Magazine

Spring Retainer

PICTURE 14

Muzzle

Choke Tube

Length-Of-Pull Spacers

Butt Stock

Page 9

Note: Drop at comb measurements are shown

with the standard (1 7/16”) Comb Insert.

16

17

To adjust the 3 Hole Stock Cast

Plate (marked “B”)

12. With the recoil pad and the stock retaining bolt removed, remove the stock

from the receiver by pulling rearward.

13. Remove the stock cast plate from the

stock by inserting a long screwdriver or

punch into the front of the stock. Then

push the cast plate out of the rear of

the stock. See Picture 18.

14. Choose the stock cast plate “B” mounting hole (Reference Picture 17) which

corresponds to the drop at heel and

cast desired. See Chart 1.

15. Place the stock mounting lock washer

and washer onto the stock retaining

bolt.

16. Ensure the pivot block is attached to

the receiver. If not, orient the pivot

block so the alignment bosses mate

with the receiver.

17. Install the pivot block onto the receiver

by sliding it over the action spring tube.

18. Mount the stock onto the receiver.

19. Insert the stock cast plate “B”.

20. Insert the stock retaining bolt thru the

desired stock cast plate mounting hole

(See Picture 17a) and into the action

spring tube.

21. Secure stock retaining bolt with a 3/16

Allen Wrench by turning clockwise.

Torque to 75 in-lbs; do not over tighten.

22. Replace and secure the recoil pad by

turning the mounting screws clockwise

until tight. Do not over tighten.

Cleaning, Lubrication and

Maintenance

WARNING! Before cleaning, make sure

your firearm is completely unloaded (both

the chamber and the magazine) and

engage the safety by placing the safety

mechanism in the “ON” or "SAFE" position.

WARNING! After each use, follow the

lubrication and maintenance directions in

this Owner’s Manual. If the firearm is

immersed in water, it must be thoroughly

cleaned and lubricated as soon as possible. In case of saltwater immersion, first

flush all parts with fresh water, then dry,

clean and lubricate the firearm. If the

firearm does not function properly, have

it checked and repaired by a Remington

Authorized Repair Center before further

PICTURE 18

Tap-out Cast Plate

from front of Stock

III. Heel Drop & Cast:

The Versa Max stock is designed for easy

heel drop and cast adjustments for

improved stock fit to enhance handling performance. By using the Stock Cast Plates

provided, the heel drop can be adjusted

from 2 to 2 1/2 inches and the cast can be

adjusted to the right or left 1/4 inch. If the

drop and/or cast is adjusted, the point-ofimpact will vary slightly depending on the

shooter’s style.

The heel drop and cast can be adjusted

by moving the stock mounting bolt to different mounting holes in the Stock Cast

Plate. See Picture 17. The Versa Max is

supplied with two Stock Cast Plates, providing nine (9) different drop and cast

possibilities. See Chart 1.

To Adjust Heel Drop & Cast

1. Always keep the firearm pointed in a

safe direction.

2. Engage the safety mechanism in the

“ON” or “SAFE" position. The red band

will NOT be visible.

3. Completely unload the chamber and

magazine. (See “To Unload the

Firearm,” page 14.)

4. With the bolt locked open, visually recheck the chamber, loading port, and

magazine, making sure the shotgun is

completely unloaded.

5. Remove the recoil pad from the stock

by removing the two mounting screws

with a #2 phillips screwdriver.

6. Remove the stock retaining bolt and

washers with a 3/16 Allen Wrench by

turning counterclockwise.

To adjust the 5 Hole Stock Cast

Plate (marked “A”)

7. Choose the stock cast plate “A” mounting hole (Reference Picture 17) which

corresponds to the heel drop and cast

desired. See Chart 1.

8. Place the stock mounting lock washer and

the washer onto the stock retaining bolt.

9. Insert the stock retaining bolt thru the

desired stock cast plate “A” mounting

hole (See Picture 17a) into the action

spring tube.

10. Secure the stock retaining bolt with a

3/16 Allen Wrench. Torque to 75 in-lbs;

do not over tighten.

11. Replace and secure the recoil pad. Do

not over tighten.

Lubrication:.

Over-lubrication should be avoided

at all times. A light application of

Rem

TM

Oil helps to prevent rusting.

WARNING! Excessive use of a lubricant could adversely affect the

function and safe operation of your

firearm. Failure to properly maintain your firearm can not only damage your firearm, it can expose you

and others to unnecessary risks of

personal injury or death.

When the firearm is to

be stored, it should be

carefully cleaned and

thoroughly oiled.

Outside metal surfaces

should be wiped with Rem

TM

Oil

occasionally. When the firearm is to

be reused, all excess lubrication must

be removed. The chamber and bore

must be thoroughly wiped dry.

For safe and dependable operation

of your firearm, the barrel and

action must be cleaned periodically.

Remington recommends using

Remington cleaning products and

lubricants or their equivalents.

WARNING! The use of a non recom-

mended lubricant or cleaner could

adversely affect the function and safe

operation of your firearm. Do not use

congealing lubricants. The use of

non-congealing lubricants such as

Rem™ Oil is strongly recommended.

NOTE: Remington’s Rem™ Oil is

available from your local dealer. If

your dealer is out of stock, ask the

dealer to order Rem™ Oil from the

Remington Distributor.

Cast Plate

Mounting

Hole

Drop

at

Heel

Drop

at

Comb

Cast

Left

Cast

Right

TL

(Top Left)

2 1/2 1 9/16 -- 1/4

TR

(Top Right)

2 1/2 1 9/16 1/4 --

CC

(Center Center)

2 1/4 1 1/2 -- --

BL

(Bottom Left)

2 1 7/16 -- 1/4

BR

(Bottom Right)

2 1 7/16 1/4 --

TC

(Top Center)

2 1/2 1 9/16 -- --

CR

(Center Right)

2 1/4 1 1/2 1/4 --

CL

(Center Left)

2 1/4 1 1/2 -- 1/4

BC

(Bottom Center)

2 1 7/16 -- --

5 Hole Cast Plate “A”

3 Hole Cast Plate “B”

PICTURE 17

Stock Cast Plates

A

B

B

Chart 1

Cast position “CL” is obtained by

installing the Cast Plate B backwards

Stock

Cast Plate

Comb Insert

Pivot Block

Heel

Comb

Stock Retaining Bolt

PICTURE 17a

Butt Stock

Flat Washer

Lock Washer

Page 10

use. Failure to follow these instructions

may lead to firearm malfunctions which

could result in serious personal injuries

or death.

CAUTION: The chamber and bore should

be cleaned before loading and firing the

firearm the first time.

To Disassemble the Firearm for

Cleaning:

CAUTION: The Versa Max firearm should NOT

be disassembled beyond what is described in this

manual, except by the factory or a Remington

Authorized Repair Center.

WARNING! Unload the firearm before

cleaning. Look into the ejection port

and visually check the chamber and

magazine to make sure there are no

cartridges in the firearm. Always

wear eye protection when handling,

disassembling and

reassembling the firearm.

To Remove the Barrel:

1. Always keep the firearm

pointed in a safe direction.

2. Engage the safety

mechanism in the “ON”

or “SAFE" position. The

red band will NOT be

visible.

3. Completely unload the chamber and

magazine. (See “To Unload the

Firearm,” page 14.)

4. With the bolt locked open, visually

check the chamber, loading port,

and magazine making sure the shotgun is completely unloaded.

5. Remove the magazine cap by turn-

ing it counterclockwise.

6. Remove the fore-end from the magazine by sliding it forward.

7. While holding the barrel above the

barrel ring, pull the barrel from the

receiver.

To Remove the Gas Pistons:

8. With the barrel removed from the

receiver, remove both gas cylinder

plugs by turning counterclockwise

using the 3/16 Cylinder Plug Wrench

provided in packaging. See Picture

19.

9. Remove the gas pistons from the muz-

zle end of the gas block. See Picture

20.

To Remove the Trigger Assembly:

10. While holding the operating handle,

push the bolt release then slowly let

the bolt move forward.

11. Tap out the trigger plate pin with a

drive punch. See Picture 21.

12. Remove the trigger plate from the

receiver by pushing the bolt release

while pulling the trigger plate downward from the receiver. See Picture 22.

To Remove the Bolt Assembly:

13. With the bolt fully forward, the barrel

and trigger plate removed, pull the

operating handle outward from the

bolt.

14. Remove the bolt assembly from the

receiver by sliding it forward.

To Disassemble the Bolt Assembly:

WARNING! Use extreme care when

removing the firing pin and firing pin

retainer, as the firing pin is under compression. Wear eye protection to avoid

serious personal injury.

15. While holding the firing pin in place

with one hand, remove the firing pin

retaining pin by pulling it outward from

the bolt. See Picture 23.

16. Remove the firing pin and firing pin

spring from the rear of the bolt assembly.

17. Turn the bolt assembly upside down to

remove the bolt cam pin.

18. Pull the bolt head from the bolt body.

To Clean the Barrel:

1. Use the instructions and equipment

provided in a quality cleaning kit

such as a Remington Cleaning Kit.

For recommendations, see your

dealer or a Remington Authorized

Service Center.

2. Saturate cleaning patch with Brite

Bore™ or equivalent.

3. Attach the patch to a cleaning rod

tip.

4. Pass the patch through the bore

from the chamber end to the muzzle

several times, removing loose

residue and fouling.

5. Select the correct gauge cleaning

brush and attach a brush to the

cleaning rod.

6. Spray the bore brush with Brite Bore.

7. Push the cleaning rod through the

barrel several times.

8. Remove the brush from the rod and

attach a tip with a cleaning patch.

9. Push the cleaning patch through the

bore.

10. Repeat several times using a new

cleaning patch each time until the

patch is removed from the barrel

without fouling residue.

11. Remove all shooting residue from the

barrel’s locking notch and ejector.

See Picture 25.

18 19

PICTURE 25

Ejector

Locking Notch

Chamber

PICTURE 23

Firing Pin Retaining Pin

Bolt Body

Bolt Head

Bolt Cam Pin

PICTURE 24

Gas Block

Gas Pistons

Gas Plugs

Barrel

PICTURE 19

Gas

Cylinder

Plugs

Plug Wrench

PICTURE 22

Push Bolt Release

PICTURE 21

Trigger Plate Pin

PICTURE 20

Gas Cylinders

Remove

Barrel

Gas Pistons

Page 11

12. Spray the gas block, gas plugs, and

gas pistons with Brite Bore™ or

equivalent cleaner and brush to

remove shooting residue.

13. To dry, use compressed air or allow

to air dry.

14. Inspect the gas plug’s O-rings for

signs of wear. Replace if worn.

15. Push a clean patch saturated with

Rem™ Oil or equivalent through the

barrel including the gas block.

16. Push a clean dry patch through the

barrel to remove excess lubricant.

17. Apply a light application of Rem™ Oil

to the outside of the barrel, gas pistons, and O-ring with a soft clean

cloth.

18. Remove all excess lubricant with a

clean dry patch.

WARNING! After cleaning, Make sure

the barrel and chamber are free of

obstructions, see page 9, “To Check the

Barrel for Obstructions.”

To Clean the Choke Tube:

1. Remove the choke tube from the barrel. See “To Change the Choke Tube,”

page 14.

2. Brush the choke tube, including the

threads with Brite Bore™ or equivalent until clean.

3. Brush the mating barrel choke tube

threads with Brite Bore™ or equivalent until clean.

4. Push a clean patch through the

choke tube.

5. Repeat several times using a new

cleaning patch each time until all

residue is removed.

6. Wipe clean and let dry.

7. When dry, apply a light application of

Rem™ Oil. Include the mounting

threads and mating threads in the

barrel.

8. To insert the choke tube into the barrel see, “To Change the Choke Tube,”

page 14.

To Clean the Bolt Assembly:

1. Spray the bolt assembly components

using Rem™ Action Cleaner or equivalent. Brush if necessary to remove

all residue.

2. To dry, use compressed air or allow

to air dry.

3. Applying a light application of Rem™

Oil.

4. Remove all excess lubricant with a

clean dry patch.

To Clean the Trigger Assembly:

CAUTION: Clean the Trigger Assembly

as a unit. Do not disassemble.

1. Thoroughly spray Rem™ Action

Cleaner inside the trigger assembly

where specified in Picture 26.

2. Thoroughly dry the trigger assembly

either by compressed air or let air dry.

3. Disengage the safety mechanism by

moving the safety button to the left.

4. With your thumb on hammer and the

safety disengaged, pull the trigger

rearward and release, see Picture 27.

Repeat multiple times, ensure the trigger returns completely to the forward

position each time. Repeat step 1 thru

4 if the trigger does not fully return.

WARNING! If the trigger does not fully

return to the forward position each time it

is released, then your firearm is NOT in a

safe operating condition and it must NOT

be used until you have had it repaired by

a Remington Authorized Repair Center.

The use of a firearm that is not in a safe

operating condition may result in serious

personal injury or death.

20

5. With the hammer fully rearward in the

cocked position; engage the safety

mechanism, multiple times, in the

“ON” or “Safe” position by moving the

safety button fully to the shooter’s

right. The red band will NOT be visible.

6. The safety button must be positioned

fully in the "ON" or “SAFE" position.

The safety should NOT remain in a

position between the "SAFE" and

"FIRE" position. If the safety mechanism does not freely return to the full

"SAFE" or "FIRE" position, repeat steps

1 and 2. If the safety mechanism

does not freely return to the

"SAFE" or "FIRE" position after

repeating operations 1 and 2, return

the firearm to a Remington Authorized Repair Center for an inspection of the safety and trigger

assembly.

WARNING! If the safety mechanism does

not freely return to the full “SAFE” or

“FIRE” position; the firearm is NOT safe to

use. The use of a firearm that is not in a

safe operating condition may result in

serious personal injury or death. Return

the firearm to the factory or to a Remington

Authorized Repair Center.

7. Apply a light application of Rem™ Oil

to the areas specified in Picture 26.

To Clean the Receiver Assembly:

1. Thoroughly spray and brush all com-

ponents inside the receiver using

Rem

TM

Action Cleaner or equivalent.

2. Air dry or use compressed air to thor-

oughly dry the receiver assembly.

3. Spray the outside of the magazine

tube with Rem

TM

Action Cleaner and

wipe clean. Scrub, if necessary, with

steel wool.

4. Wipe with a clean cloth and air dry or

use compressed air to thoroughly dry

the magazine tube.

5. Apply a light application of Rem™ Oil to

the inside and outside of the receiver.

6. Remove all excess lubricant with a

clean dry cloth.

NOTE: While your firearm has been

designed and manufactured to provide improved corrosion protection,

21

only proper care will keep your

firearm in a good operating condition

and maintain its appearance. After

extensive use, the protective coating

on plated parts may be worn sufficiently, reducing the corrosion protection. Such worn parts should be

replaced to assure the integrity of

the corrosion protection. Remington

recommends you have your firearm

serviced periodically by a

Remington Authorized Repair Center

ensuring the proper function and

replacement of any worn parts. For

firearm service see: “Repair

Service,” on page 30.

To Reassemble the Bolt Assembly:

1. Place the bolt head in the bolt body.

Align the bolt head cam pin hole

with bolt body cam pin slot.

2. Insert cam pin into bolt. Align cam

pin indicator with the center line of

the bolt. See Picture 28.

3. Place firing pin spring over the firing

pin.

4. Insert the firing pin and the firing pin

spring into the rear of the bolt body,

through the cam pin and bolt head,

until flush with rear of bolt body.

5. While holding the firing pin assembly

flush with the bolt body, insert the firing pin retaining pin fully.

WARNING! When the bolt cam pin is

not in the bolt assembly, the firearm is

NOT safe to use. Leaving the bolt cam

pin out of the assembly can cause serious personnel injury or death to you and

others.

6. Clean and reassemble the bolt

assembly, if the bolt head does not

move freely. If the bolt head still

does not move freely after cleaning,

see page 30, to obtain service. Do

Not use the firearm until it has been

properly serviced.

PICTURE 28

Cam Pin

Alignment Indicator

PICTURE 26

Rem Action Cleaner

1

2

3

4

PICTURE 27

Extractor

Page 12

To Reassemble the Gas Block:

1. Insert the gas pistons; small end first,

into the the top of the gas cylinders.

See Picture 20.

2. Secure each piston in the gas cylinder by inserting the gas cylinder

plugs into the top of the gas cylinders. Secure the gas plugs into gas

cylinder by turning clockwise. Do not

over tighten. See Picture 19.

To Reassemble the Firearm:

WARNING! Always wear eye protection when handling, disassembling

and reassembling the firearm.

1. Insert the bolt assembly; link first, into

the front of the receiver.

2. Ensure the link assembly inserts into

the action spring follower at the rear

of the receiver. See Picture 29.

3. Insert the operating handle into the

bolt body until the operating handle

detent is engaged. See Picture 6.

4. To install the trigger plate, ensure the

hammer is in the cocked position. If

the hammer is not in the cocked position, rotate the hammer fully rearward

until it engages the trigger.

5. While pushing the bolt release, insert

the trigger plate assembly into the

receiver. See Picture 30.

6. Attach the trigger plate to the receiver by replacing the trigger plate pin.

7. To attach the barrel to the receiver,

engage the bolt hold open by pressing the cartridge release. See Picture

6.

8.Open the bolt by pulling the operating

handle fully rearward until the bolt

locks in the open position.

9

.I

nsert the barrel into the receiver and

the barrel ring over the magazine

tube. See Picture 8.

10. Place the fore-end over the magazine

tube.

11

.

Replace the magazine cap on top of

the magazine tube. Tighten by turning

clockwise until hand-tight.

--------------------------------------------------

To Function Test the Firearm:

When the firearm is fully reassembled, a short

function test should be conducted to ensure

proper operation before loading or discharging

the firearm. If the firearm does not function as

described in any part of the Function Test, then

the firearm should be reassembled and function tested again. Do NOT discharge the shotgun, if the firearm fails the Function Test again,

send the firearm to a

Remington Authorized

Repair Center or call: 1-800-243-9700, Mon

- Fri., 9:00AM-5:00PM Eastern Time.

WARNING! Completely unload the

firearm before Function Testing. Look into

the ejection port and visually check the

chamber and magazine to make sure

there are no cartridges in the firearm.

Always wear eye protection when handling the firearm.

1. Always keep the firearm pointed in a safe

direction throughout the Function Testing

process.

2. Engage the safety mechanism in the “ON”

or “Safe” position by moving the safety

button fully to the shooter’s right. The red

band will NOT be visible.

3. Engage the bolt hold open by pressing

the cartridge release. See Picture 6.

4. Pull the operating handle fully rearward to

lock the bolt in the open position.

22

23

5. With the bolt locked open, visually

check the chamber, loading port, and

magazine making sure the firearm is

completely unloaded. If the chamber is

not unloaded, see page 14, “To

Unload the Firearm.”

6. Make sure the barrel and chamber are

free of obstructions, see page 10, “To

Check the Barrel for Obstructions.”

7. With the bolt locked open, check if the

bolt cam pin is installed by removing

the operating handle. The bolt head

should NOT move, as in Picture 31, if

the cam pin is installed.

8. Tilt the muzzle downward. If the bolt

head does not move forward, the bolt

cam pin is installed.

9. If the bolt head moves forward, pro-

truding into the ejection port after the

operating handle is removed or when

the muzzle is tilted downward, as

shown in Picture 32, the bolt cam pin is

Not present. Disassemble the firearm

and replace the cam pin. See: “To Disassemble the Firearm for Cleaning,” on

page 18.

WARNING! If bolt cam pin is missing;

do NOT use the firearm, the firearm is

NOT safe. Using the firearm without a

bolt cam pin may lead to firearm malfunctions which could result in serious

personal injury or death.

10. If the bolt cam pin is present,

replace the operating handle. Close

the action by pressing the bolt

release. The bolt should slide forward and lock into the firing position.

The hammer should NOT release.

WARNING! If the hammer does NOT

remain cocked when the action is

smartly closed, the firearm is NOT safe

to use. Using the firearm in this condition may lead to firearm malfunctions

which could result in serious personal

injury or death. Return the firearm to the

factory or to a Remington Authorized Repair

Center.

11. With the Safety mechanism

engaged, pull the trigger fully rearward. The trigger should not move

and the hammer should NOT

release.

12. To check if the hammer released in

step 10 or 11, disengage the safety

mechanism by moving the safety

button to the “OFF” or “FIRE” position. The red band will be visible.

Pull the trigger fully rearward. The

hammer should release. The cartridge release lever will move into

the receiver.

13. After the trigger is pulled and

released, verify the trigger returns to

the fully forward position..

WARNING! If the trigger does not fully

return to the forward position each time it is

released, your firearm is NOT in a safe

operating condition and it must NOT be

used until you have it inspected and the

problem corrected by a Remington

Authorized Repair Center. Using the

firearm in this condition may lead to

firearm malfunctions which could result in

serious personal injury or death.

14. Open the action by first pushing the

cartridge release. Then pull the

operating handle fully rearward,

locking the bolt in the open position.

15. Close the action by pressing the bolt

release.

PICTURE 30

Push Bolt Release

PICTURE 32

Ejection Port

Operating Handle

Mounting Hole

Bolt Head

Cam Pin NOT Installed

PICTURE 29

Bolt Link

Assembly

Action

Spring

Follower

Bottom of

Receiver

Stock

PICTURE 31

Ejection Port

Operating Handle

Mounting Hole

Bolt Head

Cam Pin Installed

Page 13

24

Firearm Maintenance Record

DATE Service Performed By

All rights to this instruction manual are reserved. The information in this document is

subject to change without notice. Remington reserve the right to change the content

herein without the obligation to notify any person or organization of such changes.

Remington

®