Page 1

IMI CORNELIUS INC g One Cornelius Place g Anoka, MN 55303-6234

Telephone (800) 238-3600 Facsimile (763) 422-3246

Installation/Service Manual

OC2R/FLOOR MODEL

POST-MIX DISPENSERS

WITH V3+ FEATURES

(W/REMOTE REFRIGERATION)

IMPORTANT:

TO THE INSTALLER.

It is the responsibility of the

Installer to ensure that the water

supply to the dispensing

equipment is provided with

protection against backflow by an

air gap as defined in ANSI/ASME

A112. 1.2-1979; or an approved

vacuum breaker or other such

method as proved effective by

test.

Water pipe connections and

fixtures directly connected to a

potable water supply shall be

sized, installed, and maintained

according to Federal, State, and

Local laws.

Part No. 569000119

June 12, 1997

Revised: February 16, 2000

Control Code A

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Manual must be read and understood before installing or operating this equipment

IMI CORNELIUS INC; 1997–2000

PRINTED IN U.S.A

Page 2

TABLE OF CONTENTS

SAFETY INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RECOGNIZE SAFETY INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNDERSTAND SIGNAL WORDS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FOLLOW SAFETY INSTRUCTIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CO2 (CARBON DIOXIDE) WARNING 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SHIPPING, STORING, OR RELOCATING UNIT 1. . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT DESCRIPTION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TWO–FLAVOR OVERCOUNTER (OC2R) UNIT 3. . . . . . . . . . . . . . . . . . . . . . . . . .

FOUR–FLAVOR FLOOR MODEL UNIT 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYSTEM THEORY OF OPERATION 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DEFROST SYSTEMS 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MANUAL ELECTRIC DEFROST SYSTEM 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AUTOMATIC ELECTRIC DEFROST SYSTEM 6. . . . . . . . . . . . . . . . . . . . . . . . . . .

‘‘SLEEP’’ (SLEEP TIME) 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

‘‘WAKE UP’’ (WAKE UP TIME) 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

UNPACKING AND INSPECTION 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IDENTIFICATION OF LOOSE-SHIPPED PARTS 9. . . . . . . . . . . . . . . . . . . . . . . . . . .

SELECTING LOCATION 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TWO–FLAVOR OVERCOUNTER (OC2R) DISPENSER 10. . . . . . . . . . . . . . . . . . .

FOUR–FLAVOR FLOOR MODEL DISPENSER 11. . . . . . . . . . . . . . . . . . . . . . . . . . .

REMOTE REFRIGERATION ASS’Y 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLING TWO–FLAVOR OVERCOUNTER (OC2R) DISPENSER 11. . . . . . .

INSTALLING FOUR–FLAVOR FLOOR MODEL DISPENSER 12. . . . . . . . . . . . . .

INSTALLING DRIP TRAY DRAIN KIT 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONNECTING 24 VAC ELECTRICAL CIRCUIT FROM REMOTE

REFRIGERATION ASS’Y TO FCB DISPENSER 12. . . . . . . . . . . . . . . . . . . . . . . . . .

CONNECTING REMOTE REFRIGERATION ASS’Y REFRIGERATION LINES

TO FCB OVERCOUNTER DISPENSER 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREPARING UNIT SYRUP INLET LINES FOR CONNECTION TO SOFT

DRINK TANKS 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONNECTING CITY PLAIN WATER SOURCE LINE TO UNIT 13. . . . . . . . . . . . .

INSTALLING PRIMARY CO2 REGULATOR ASS’Y ON CO2 CYLINDER 14. . . . .

CONNECTING CO2 SOURCE LINE TO UNIT CO2 INLET LINE 14. . . . . . . . . . . .

CONNECTING ELECTRICAL POWER CIRCUIT TO UNIT 14. . . . . . . . . . . . . . . . .

PREPARATION FOR OPERATION 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TURNING ON ELECTRICAL POWER TO REMOTE REFRIGERATION

ASSEMBLY(S) AND FCB DISPENSER 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TURNING ON CO2 SUPPLY TO THE UNIT 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING CO2 REGULATORS 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STARTING FCB AND ADJUSTING WATER-TO-SYRUP “RATIO” (BRIX) OF

DISPENSED PRODUCT 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FILLING FREEZE CYLINDERS WITH PRODUCT 17. . . . . . . . . . . . . . . . . . . . . . . .

i

569000119

Page 3

TABLE OF CONTENTS (cont’d)

CHECKING UNIT FOR SYRUP, CO2, OR PLAIN WATER LEAKS 17. . . . . . . . . .

PLACING UNIT IN OPERATING LOCATION 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING BEATER MOTOR CURRENT (EITHER SIDE) 18. . . . . . . . . . . . . . . .

ADJUSTMENT AND PROGRAMMING MAIN MENU SELECTIONS, COMPONENTS

“DIAGNOSE’’ (DIAGNOSTIC MODE), AND (‘‘TOTALS” DISPLAYED CYCLES AND

HOURS TOTALS) INTO UNIT 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROGRAMMING MAIN MENU SELECTION ONTO MESSAGE DISPLAY 19. . .

SETTING CLOCK (TIME OF DAY) 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROGRAMMING ‘‘DEFROST’’ (AUTOMATIC) SETTINGS INTO UNIT 20. . . . . .

PROGRAMMING ‘‘SLEEP’’ (SLEEP TIME) INTO UNIT 21. . . . . . . . . . . . . . . . . . . .

PROGRAMMING ‘‘WAKE UP’’ (WAKE UP TIME) INTO UNIT 21. . . . . . . . . . . . . . .

PROGRAMMING POINT OF SALE MESSAGE DISPLAY 22. . . . . . . . . . . . . . . . . .

ADJUSTING “VIS SET” (PRODUCT VISCOSITY) OF DISPENSED

PRODUCT 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

‘‘VIS READ’’ (ACTUAL VISCOSITY READOUT) OF PRODUCT IN FREEZE

CYLINDERS 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPLAYED EVAPORATOR REFRIGERATION COILS INLETS AND COMMON

OUTLET SENSORS TEMPERATURES. 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

‘‘VOLTAGE’’ (DISPLAYED VOLTAGE READOUT) 24. . . . . . . . . . . . . . . . . . . . . . . . .

PROGRAMMING COMPONENTS ‘‘DIAGNOSE’’ (DIAGNOSTIC MODE)

INTO UNIT 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPLAYING ‘‘TOTALS’’ (DISPLAYED CYCLES AND HOURS TOTALS)

ONTO MESSAGE DISPLAY 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROGRAMMING FREEZE CYLINDERS BEATER “MOTORS” INTO UNIT

ELECTRONICS 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROGRAMMING PROPER REFRIGERANT TYPE INTO UNIT

ELECTRONICS 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPLAYED ERROR CONDITIONS 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLING CONTROL BOX COVER AND BACK, SIDES, AND TOP PANELS

ON UNIT 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATOR’S INSTRUCTIONS 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

CONTROL PANEL ASS’Y SWITCHES AND DISPLAYED MESSAGES 31. . . . . . .

CONTROL PANEL ASS’Y SWITCHES 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONTROL PANEL ASSEMBLY DISPLAY MESSAGES 32. . . . . . . . . . . . . . . . . . . .

FREEZE CYLINDERS MANUAL OR AUTOMATIC ELECTRIC DEFROST

SYSTEMS 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MANUAL ELECTRIC DEFROST SYSTEM 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AUTOMATIC ELECTRIC DEFROST SYSTEM 33. . . . . . . . . . . . . . . . . . . . . . . . . . .

‘‘SLEEP’’ (SLEEP TIME) OPERATION 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

‘‘WAKE UP’’ (WAKE UP TIME) 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FACEPLATE RELIEF VALVES 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRODUCT SAMPLE VALVES 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRODUCT SHUTOFF VALVES 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRIMARY CO2 REGULATOR 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECONDARY CO2 REGULATORS 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CARBONATED WATER FLOW REGULATORS 34. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYRUP FLOW REGULATORS 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

569000119

ii

Page 4

TABLE OF CONTENTS (cont’d)

DISPENSING VALVES 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPENSED PRODUCT CONDITIONS 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

‘‘OVERRUN’’, AS APPLIED TO FROZEN CARBONATED BEVERAGES 35. . . . .

OPERATING CHARACTERISTICS 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATING UNIT 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REPLENISHING SYRUP SUPPLY 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRODUCT FLAVOR CHANGE 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHECKING CO2 SUPPLY 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING AND SANITIZING 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAILY CLEANING 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SANITIZING 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REMOTE REFRIGERATION ASSEMBLY MAINTENANCE 38. . . . . . . . . . . . . . . . . .

LUBRICATION 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTMENTS 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CARBONATED WATER FLOW RATE 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WATER-TO-SYRUP “RATIO” (BRIX) OF DISPENSED PRODUCT 38. . . . . . . . . .

CO2 REGULATORS 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING BEATERS MOTORS CURRENTS 38. . . . . . . . . . . . . . . . . . . . . . . . . .

PROGRAMMING MAIN MENU SELECTIONS ONTO MESSAGE DISPLAY 38. .

SETTING ‘‘CLOCK’’ (TIME OF DAY) 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROGRAMMING ‘‘DEFROST’’ (AUTOMATIC) SETTINGS INTO UNIT 39. . . . .

PROGRAMMING ‘‘SLEEP’’ (SLEEP TIME) INTO UNIT 39. . . . . . . . . . . . . . . . . . . .

PROGRAMMING ‘‘WAKE UP’’ (WAKE UP) TIME INTO UNIT 39. . . . . . . . . . . . . . .

PROGRAMMING POINT OF SALE MESSAGE DISPLAY 39. . . . . . . . . . . . . . . . . .

ADJUSTING ‘‘VIS SET’’ (PRODUCT VISCOSITY) OF DISPENSED

PRODUCT 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPLAYED EVAPORATOR REFRIGERATION COILS INLETS AND

COMMON OUTLET SENSORS TEMPERATURES 39. . . . . . . . . . . . . . . . . . . . . . .

‘‘VOLTAGE’’ (DISPLAYED VOLTAGE READOUT) 39. . . . . . . . . . . . . . . . . . . . . . . . .

PROGRAMMING COMPONENTS ‘‘DIAGNOSE’’ (DIAGNOSTIC MODE)

INTO UNIT 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPLAYING ‘‘TOTALS’’ (DISPLAYED CYCLES AND HOURS TOTALS)

ONTO MESSAGE DISPLAY 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROGRAMMING PROPER REFRIGERANT TYPE INTO UNIT

ELECTRONICS 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPLAYED ERROR CONDITIONS 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WATER STRAINER SCREEN AND DOUBLE LIQUID CHECK VALVE

MAINTENANCE 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING CO2 GAS CHECK VALVES 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE AND MAINTENANCE 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

PREPARING UNIT FOR SHIPPING, STORING, OR RELOCATING 41. . . . . . . . . .

PERIODIC INSPECTION 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REMOVAL OF PANELS 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DRIP TRAY 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BACK PANEL 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

569000119

Page 5

TABLE OF CONTENTS (cont’d)

SIDE PANELS 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TOP PANEL 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOWER FRONT ACCESS PANEL 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPENING AND CLOSING FRONT ACCESS DOOR 41. . . . . . . . . . . . . . . . . . . . . . .

OPENING FRONT ACCESS DOOR 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLOSING FRONT ACCESS DOOR 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTMENTS 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING PLAIN WATER PRESSURE REGULATOR 45. . . . . . . . . . . . . . . . . . .

ADJUSTING CARBONATED WATER FLOW RATE 45. . . . . . . . . . . . . . . . . . . . . . .

PRODUCT CARBONATION ADJUSTMENT 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICING DISPENSING VALVES CAGED O-RINGS AND FREEZE CYLINDERS

DRIVE SHAFT/ SEAL ASSEMBLIES 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICING DISPENSING VALVES CAGED O-RINGS. 47. . . . . . . . . . . . . . . . . . .

SERVICING FREEZE CYLINDERS DRIVE SHAFT/SEAL ASSEMBLIES. 48. . . .

CLEANING REMOTE REFRIGERATION ASS’Y CONDENSER COIL 51. . . . . . . . .

CLEANING AND SANITIZING 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAILY CLEANING OF UNIT 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SANITIZING SYRUP SYSTEMS 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

YEARLY OR AFTER WATER SYSTEM DISRUPTION 55. . . . . . . . . . . . . . . . . . . . . .

SERVICING CARBONATOR WATER PUMP WATER STRAINER SCREEN 55. .

REPLACING CARBONATOR WATER PUMP DOUBLE LIQUID CHECK

VALVE 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING CARBONATOR TANK LIQUID LEVEL 56. . . . . . . . . . . . . . . . . . . . . . . .

REPLACING FREEZE CYLINDER BEATER DRIVE MOTOR 57. . . . . . . . . . . . . . . .

REPLENISHING SYRUP SUPPLY 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYRUP TANKS SYSTEM 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BAG–IN–BOX SYSTEM 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REPLENISHING CO2 SUPPLY 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING CO2 SYSTEM GAS CHECK VALVES 62. . . . . . . . . . . . . . . . . . . . . . . . .

SYRUP FLAVOR CHANGE 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

TROUBLESHOOTING CONTROL PANEL SWITCHES AND FAULT

MESSAGES 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ONE OR MORE CONTROL PANEL SWITCHES NOT OPERATING. 67. . . . . . . .

ALL CONTROL PANEL SWITCHES NOT OPERATING. 67. . . . . . . . . . . . . . . . . . .

CONTROL PANEL SWITCHES CANNOT BE DEACTIVATED. 68. . . . . . . . . . . . .

PARTIAL MESSAGE OR DULL (POORLY ILLUMINATED) DISPLAY. 68. . . . . . . .

ONE OR MORE FAULT MESSAGES NOT OPERATING. 68. . . . . . . . . . . . . . . . . .

ALL FAULT MESSAGES NOT OPERATING. 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

‘‘CO2 OUT’’ FAULT MESSAGE GOES ON DURING OPERATION. 69. . . . . . . . . .

‘‘H2O OUT’’ FAULT MESSAGE GOES ON DURING OPERATION. 69. . . . . . . . . .

‘‘SYRUP 1’’ OR ‘‘SYRUP 2’’ FAULT MESSAGE GOES ON DURING

OPERATION. 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

‘‘ERROR 1’’ OR ‘‘ERROR 2’’ FAULT MESSAGE GOES ON DURING

OPERATION. 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

569000119

iv

Page 6

TABLE OF CONTENTS (cont’d)

FREEZE CYLINDER AUTOMATIC DEFROST CYCLE DOES NOT OPERATE. 69

UNIT DOES NOT GO OFF AUTOMATIC DEFROST CYCLE. 69. . . . . . . . . . . . . .

MANUAL DEFROST CYCLE DOES NOT OPERATE WHEN ‘‘DEFROST’’

SWITCH IS PRESSED. 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DEFROST CYCLE DOES NOT CANCEL AFTER PRESSING ‘‘CANCEL

DEFROST ’’ SWITCH. 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING PRODUCT BLENDER TANKS AND CARBONATOR 70. . .

CARBONATOR WATER PUMP MOTOR WILL NOT OPERATE. 70. . . . . . . . . . . .

CARBONATOR WATER PUMP WILL NOT SHUT OFF. 70. . . . . . . . . . . . . . . . . . . .

ERRATIC CARBONATOR WATER PUMP CYCLING. 70. . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING DISPENSED PRODUCT 71. . . . . . . . . . . . . . . . . . . . . . . . . . .

BRIX (WATER-TO-SYRUP) ‘‘RATIO’’ TOO LOW. 71. . . . . . . . . . . . . . . . . . . . . . . . .

BRIX (WATER-TO-SYRUP) ‘‘RATIO’’ TOO HIGH. 71. . . . . . . . . . . . . . . . . . . . . . . . .

IMPROPER PRODUCT DISPENSED. 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRODUCT WILL NOT DISPENSE OUT OF DISPENSING VALVE, IN ONLY

SMALL AMOUNTS, OR ONLY LIQUID. 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FREEZE CYLINDER DOES NOT REFILL AT ALL TIMES WHEN

DISPENSING. 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FROZEN PRODUCT CONSISTENCY VARIES EXCESSIVELY. 71. . . . . . . . . . . .

CYLINDER FREEZE-UP. 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING REMOTE REFRIGERATION ASSEMBLY 72. . . . . . . . . . . .

FCB (OC2R) OVERCOUNTER POST-MIX DISPENSER WITH V3+ FEATURES

(ILLUSTRATED PARTS BREAKDOWN) 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

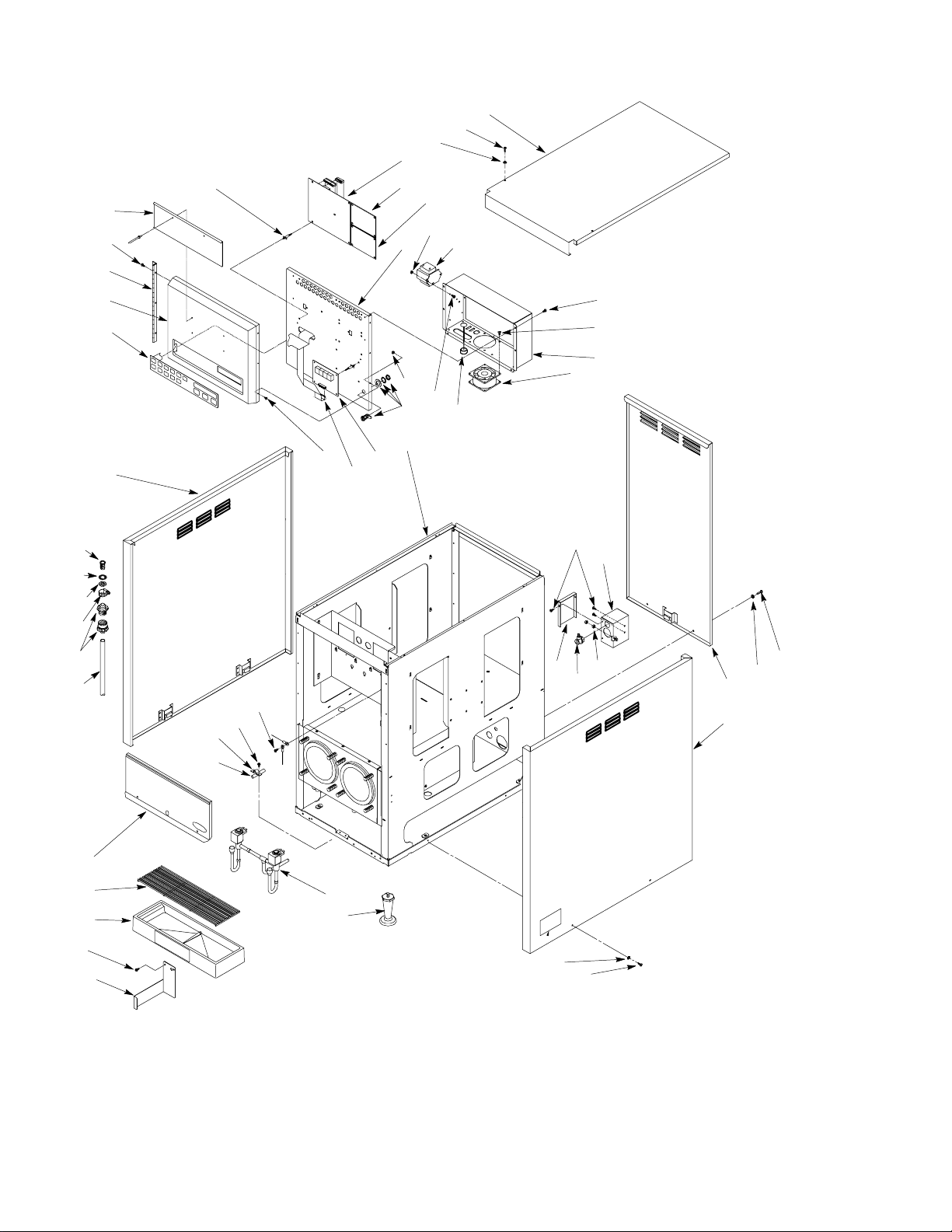

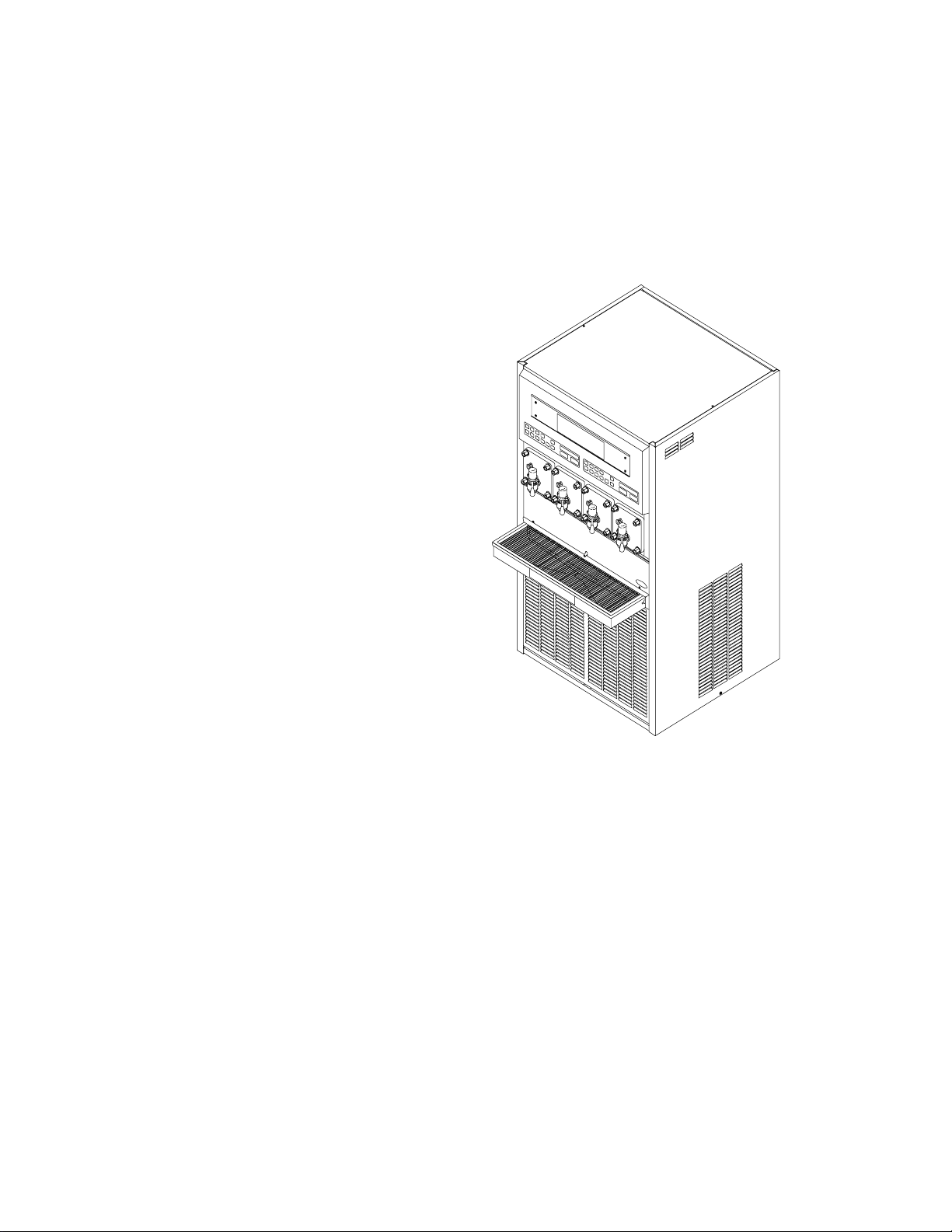

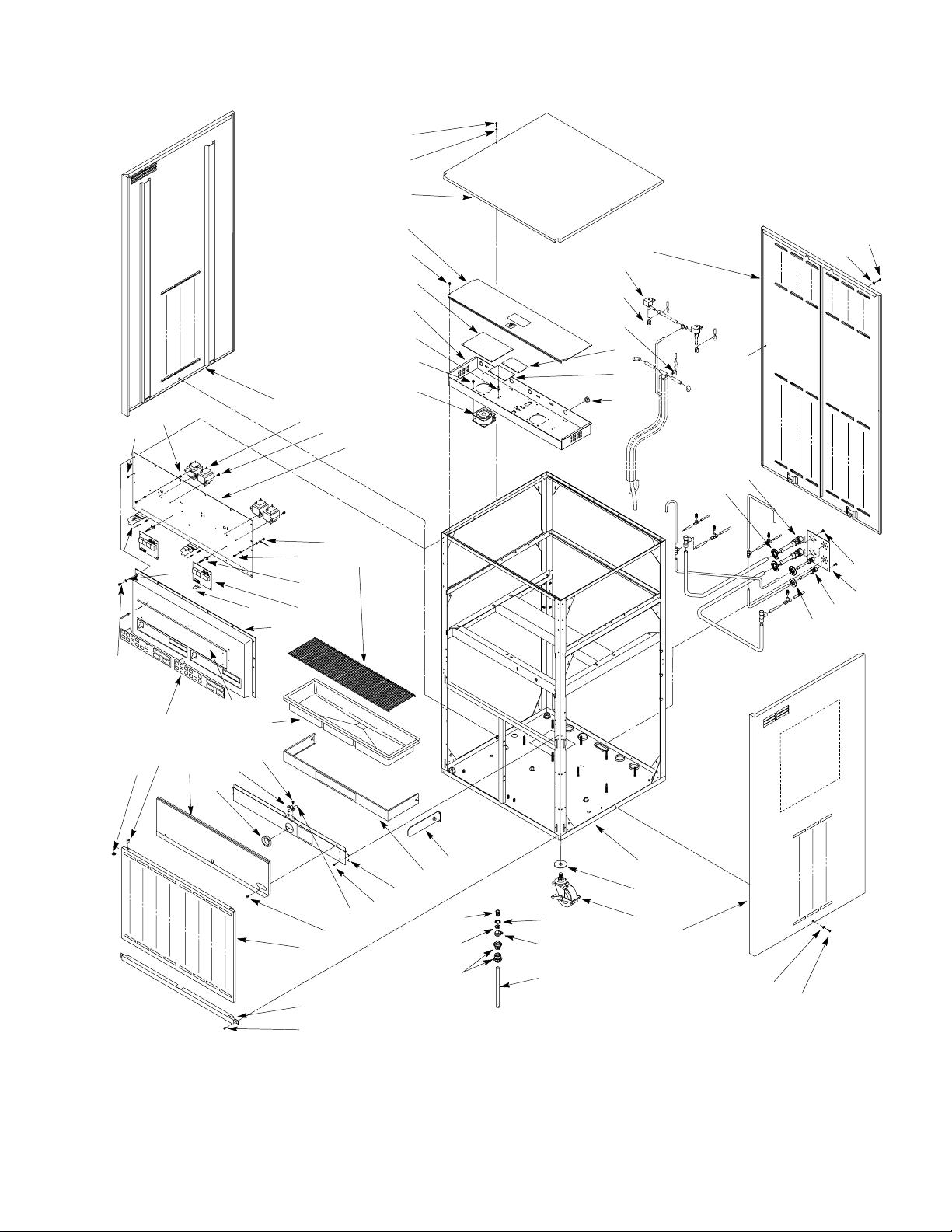

FCB FOUR–FLAVOR FLOOR MODEL POST-MIX DISPENSER WITH V3+ FEATURES

(ILLUSTRATED PARTS BREAKDOWN) 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LIST OF FIGURES

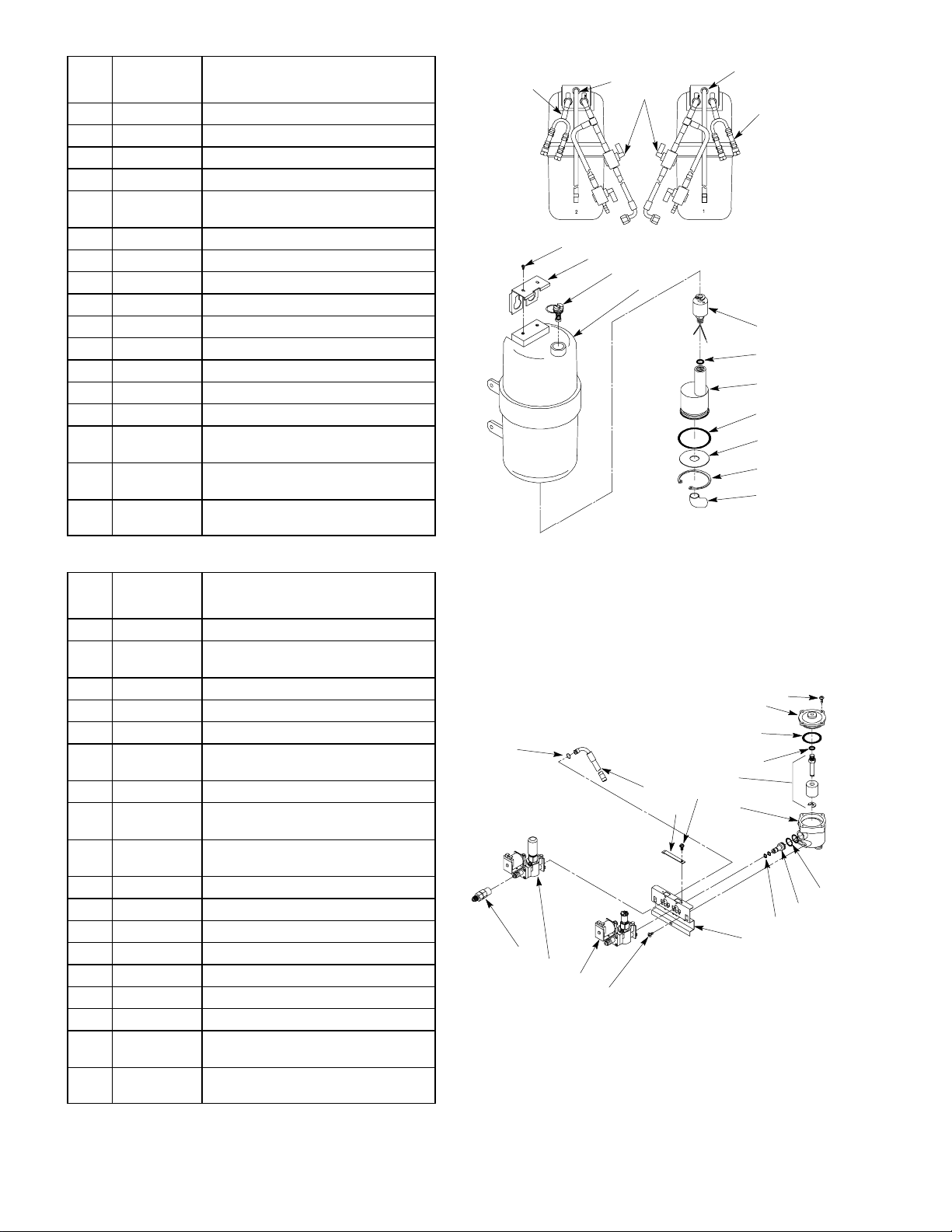

FIGURE 1. TWO–FLAVOR OVERCOUNTER (OC2R) UNIT 3. . . . . . . . . . . . . . . . .

FIGURE 2. FOUR–FLAVOR FLOOR MODEL UNIT 3. . . . . . . . . . . . . . . . . . . . . . . .

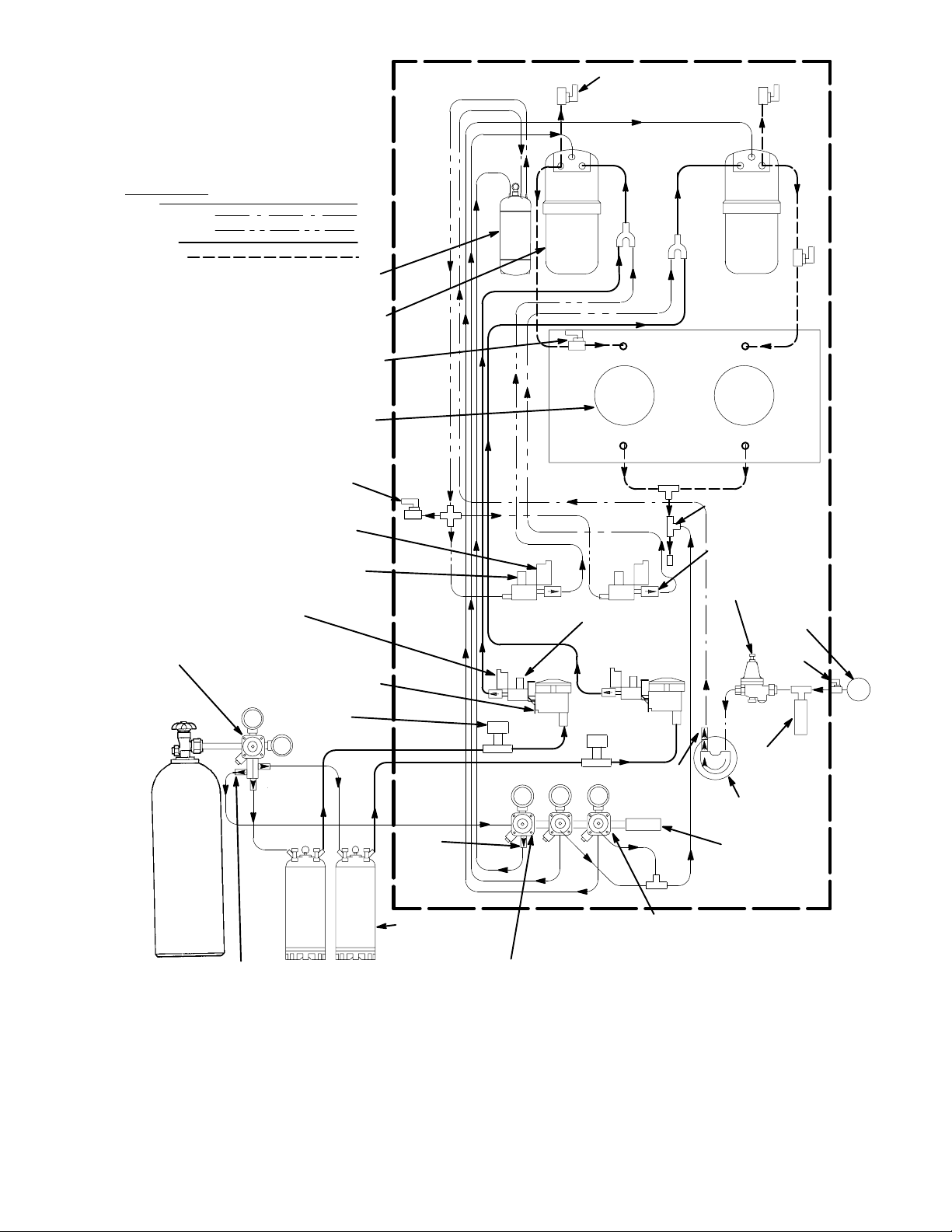

FIGURE 3. FLOW DIAGRAM (TWO–FLAVOR OVERCOUNTER (OC2R) UNIT) 7

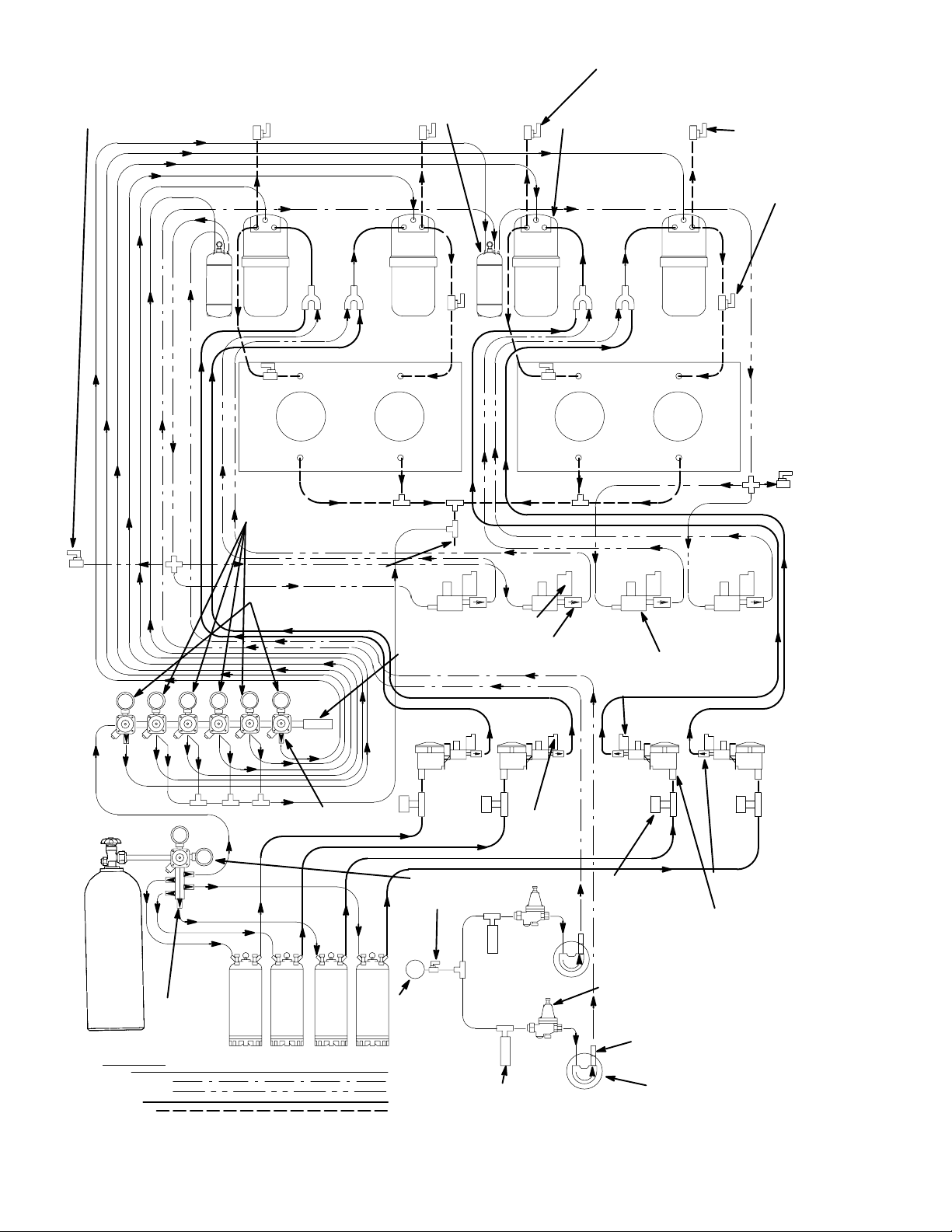

FIGURE 4. FLOW DIAGRAM (FOUR–FLAVOR FLOOR MODEL UNIT) 8. . . . . .

FIGURE 5. CONTROL PANEL 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 6. MASTER AND RELAY CIRCUIT BOARD 25. . . . . . . . . . . . . . . . . . . . . . .

FIGURE 7. OPERATING CONTROLS (FOUR-FLAVOR FLOOR MODEL UNIT) 42

FIGURE 8. PARTS IDENTIFICATION (FOUR-FLAVOR FLOOR MODEL UNIT) 43

FIGURE 9. OPERATING CONTROLS (TWO–FLAVOR OC2R UNIT) 44. . . . . . . . .

FIGURE 10. PARTS IDENTIFICATION (TWO–FLAVOR OC2R0 UNIT) 45. . . . . . .

FIGURE 11. SELF-CLOSING DISPENSING VALVE 47. . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 12. FREEZE CYLINDER CUTAWAY VIEW 50. . . . . . . . . . . . . . . . . . . . . . . .

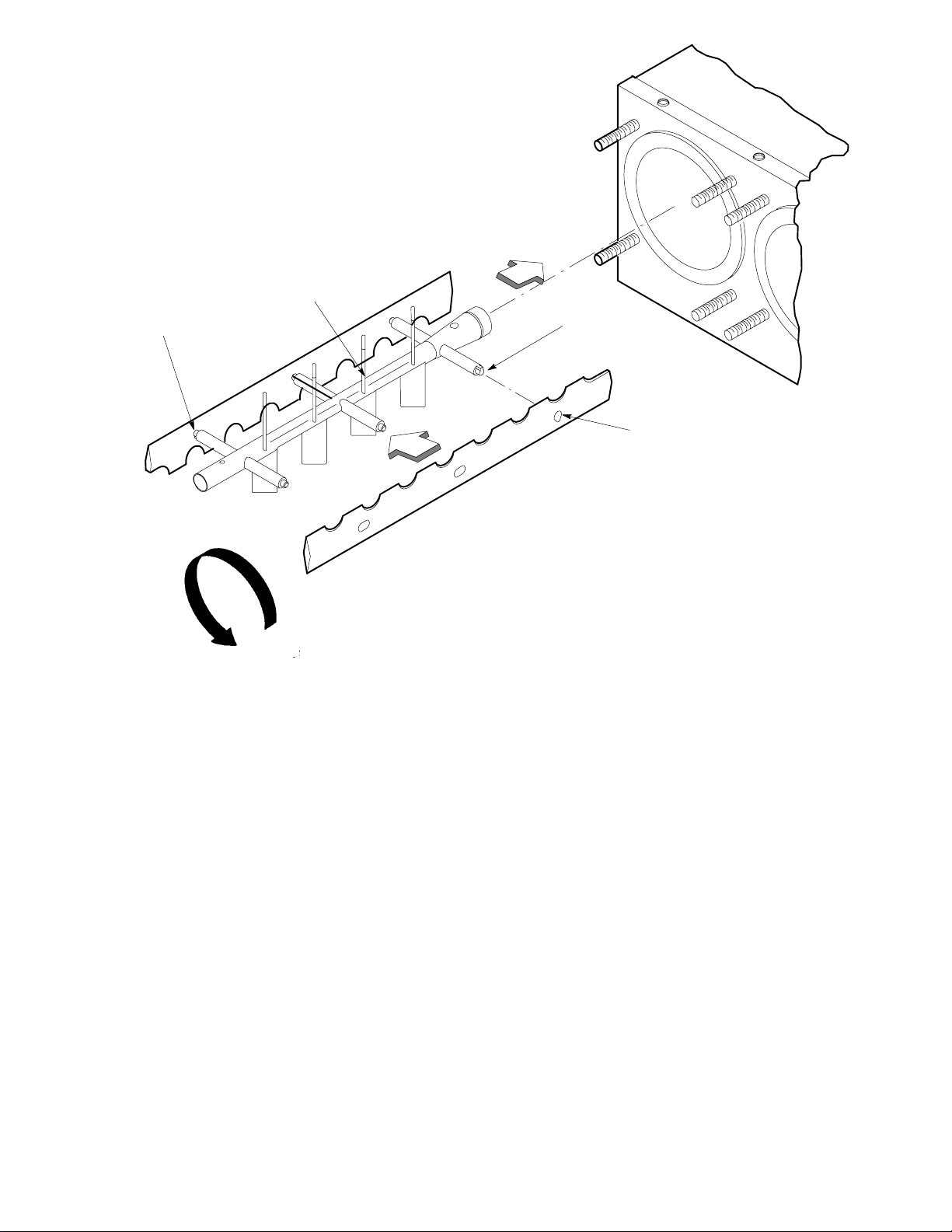

FIGURE 13. BEATERS AND SCRAPER BLADES INSTALLATION 51. . . . . . . . . . .

FIGURE 14. SERVICING BEATER MOTOR DRIVE SHAFT/SEAL ASSEMBLY 52

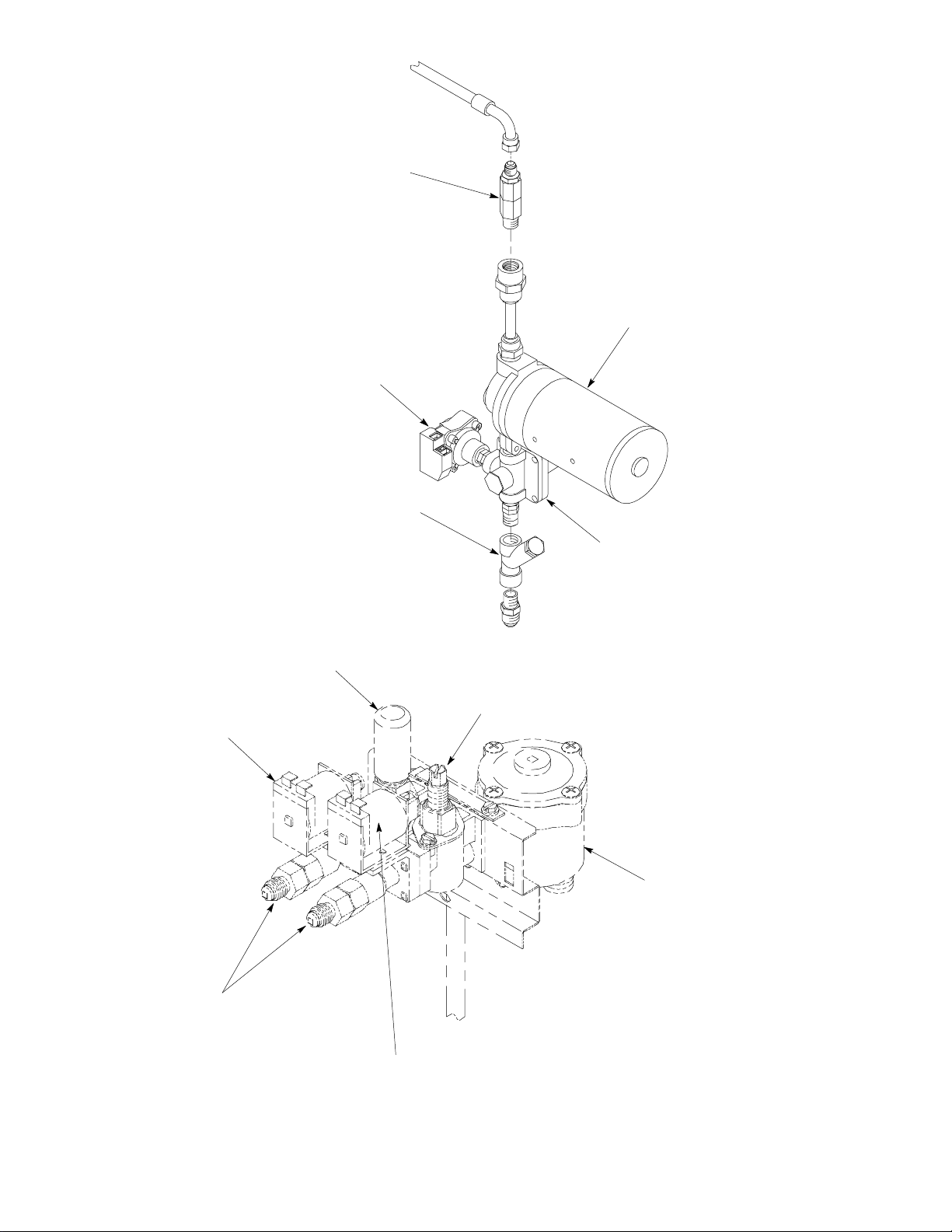

FIGURE 15. WATER STRAINER SCREEN AND DOUBLE LIQUID CHECK VALVE

(OVERCOUNTER (OC2R) UNIT) 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 16. WATER STRAINER SCREEN AND DOUBLE LIQUID CHECK VALVE

(FOUR–FLAVOR FLOOR MODEL UNIT) 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

v

569000119

Page 7

TABLE OF CONTENTS (cont’d)

LIST OF FIGURES (CONT’D)

FIGURE 17. CARBONATOR LIQUID LEVEL CONTROL SWITCH

ADJUSTMENT 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

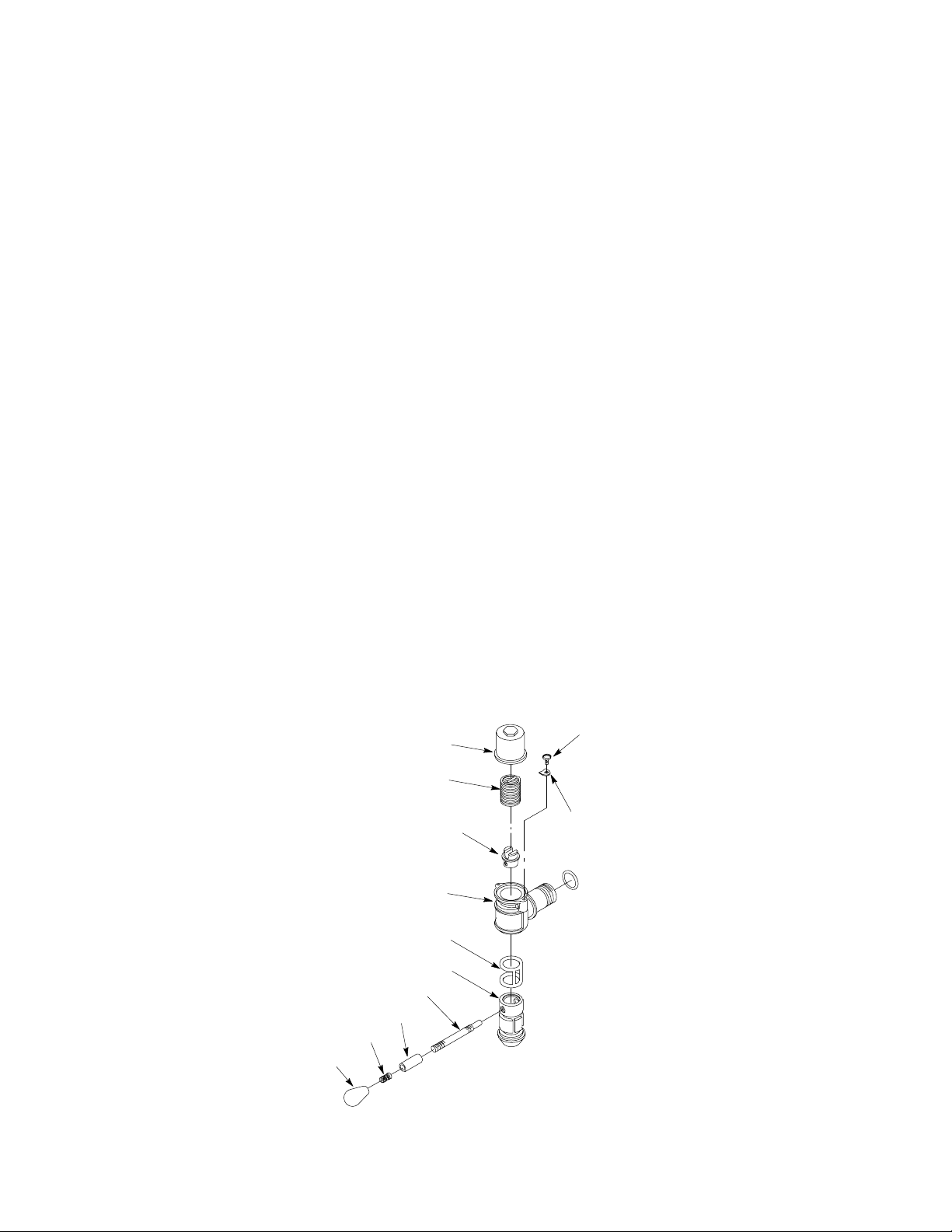

FIGURE 18. CO2 GAS CHECK VALVE 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 19. REFRIGERATION FLOW DIAGRAM 64. . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 20. WIRING DIAGRAM (OVERCOUNTER (OC2) UNIT) 65. . . . . . . . . . . .

FIGURE 21. WIRING DIAGRAM (FOUR–FLAVOR FLOOR MODEL UNIT) 66. . . .

FIGURE 22. OVERCOUNTER FCB POST-MIX DISPENSER ASSEMBLY 74. . . . .

FIGURE 23. OVERCOUNTER FCB POST-MIX DISPENSER ASSEMBLY 76. . . . .

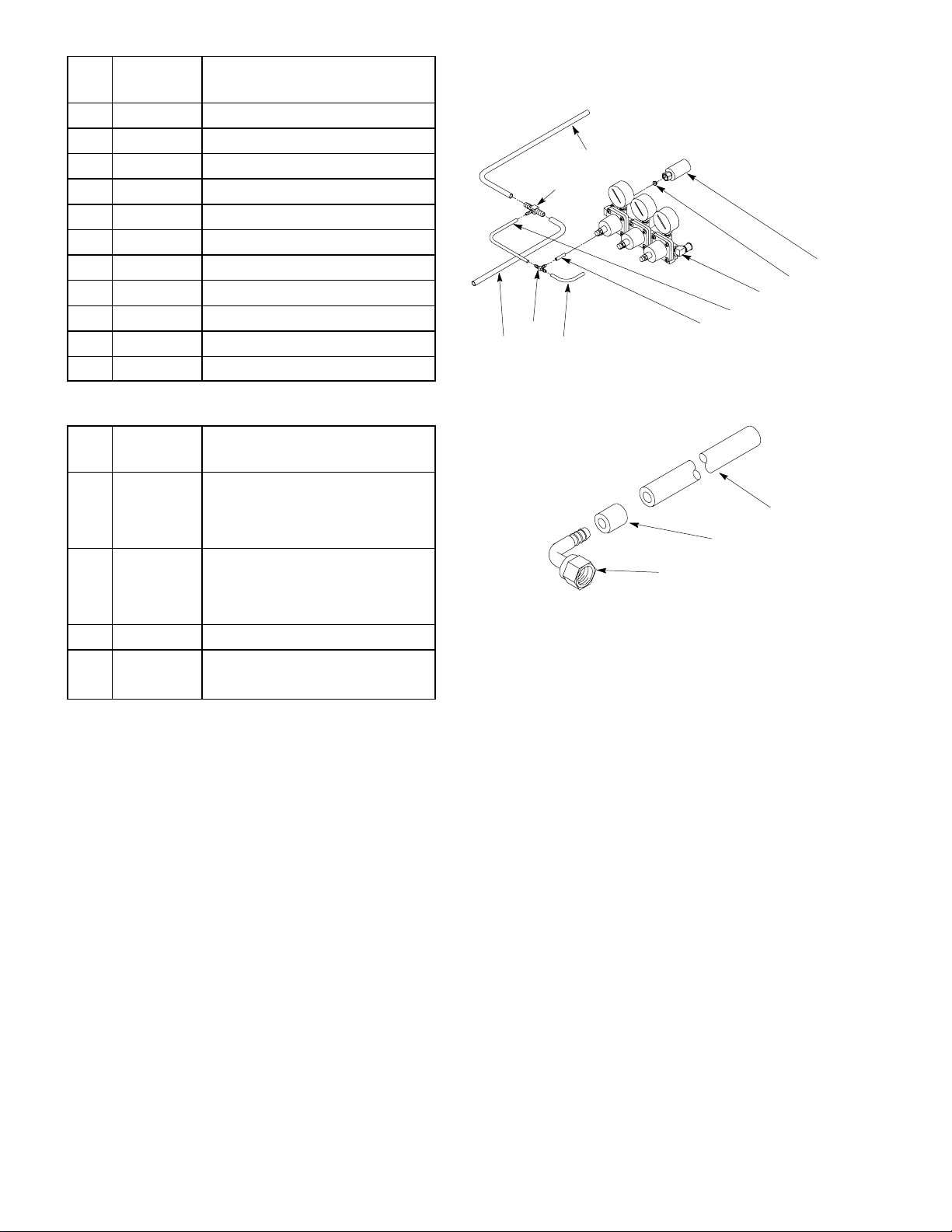

FIGURE 24. BLENDER AND TUBING COMPONENTS 78. . . . . . . . . . . . . . . . . . . . .

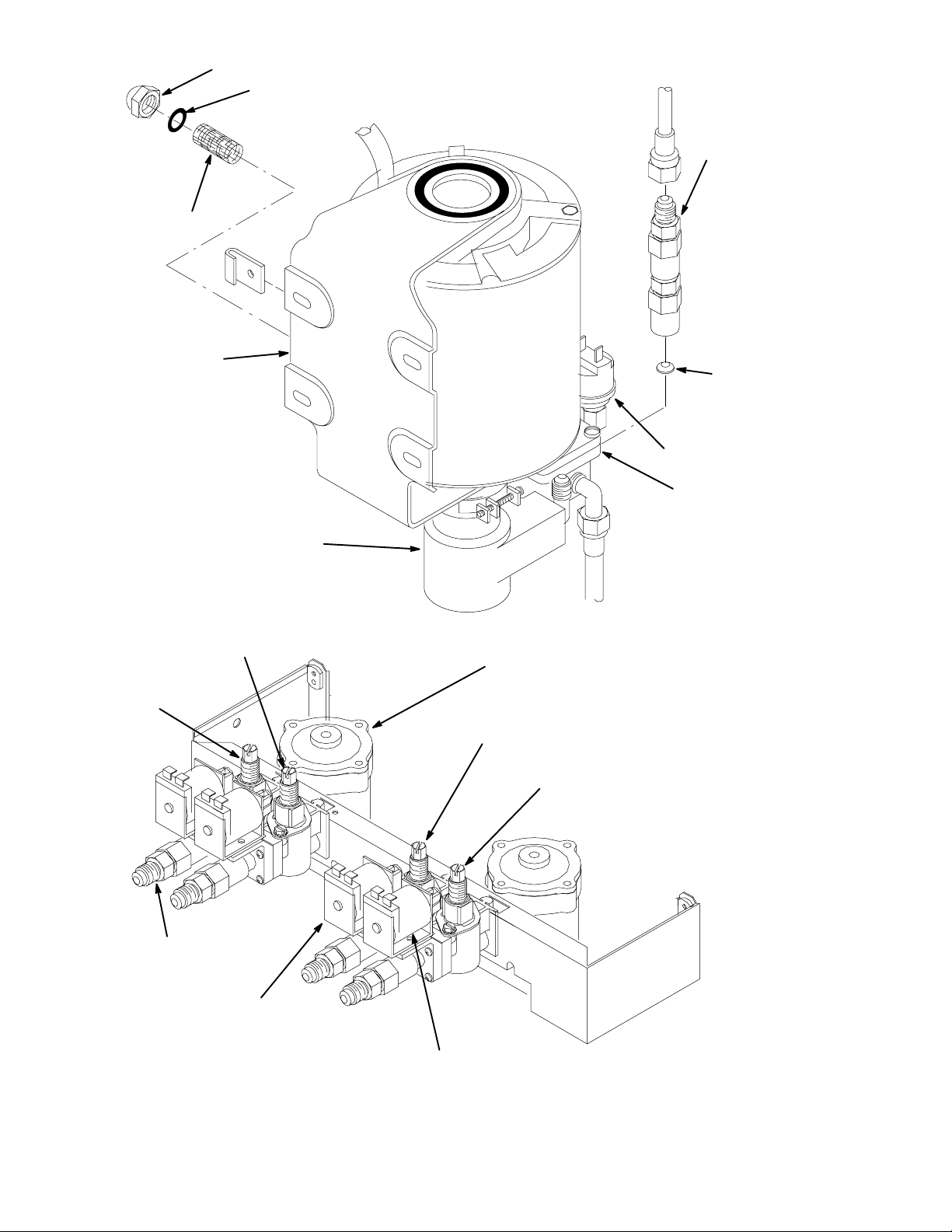

FIGURE 25. SOLENOID AND FLOAT SWITCH COMPONENTS 78. . . . . . . . . . . . .

FIGURE 26. SOLENOID VALVE ASSEMBLY 79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 27. WATER PUMP COMPONENTS 79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 28. REGULATOR ASS’Y COMPONENTS 80. . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 29. TUBE ASSEMBLY (WATER PUMP TO CARBONATOR) 80. . . . . . . . .

FIGURE 30. CO2 REGULATOR ASSEMBLY 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 31. FACEPLATE ASSEMBLY 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 32. DISPENSING VALVE ASSEMBLY 82. . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 33. CARBONATOR TANK AND LINKAGE ASSEMBLY 83. . . . . . . . . . . . .

FIGURE 34. DOUBLE CHECK VALVE ASSEMBLY 83. . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 35. MANIFOLD AND TUBE ASSEMBLY 83. . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 36. TUBING ASSEMBLY 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 37. TUBING ASSEMBLY (SYRUP) 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 38. TUBING ASSEMBLY BLENDER TO FOAM PACK 84. . . . . . . . . . . . . .

FIGURE 39. TUBING ASSEMBLY (SYRUP AND WATER SOLENOID TO

BLENDER) 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 40. TUBING ASSEMBLY (REGULATOR TO BLENDER) 85. . . . . . . . . . . .

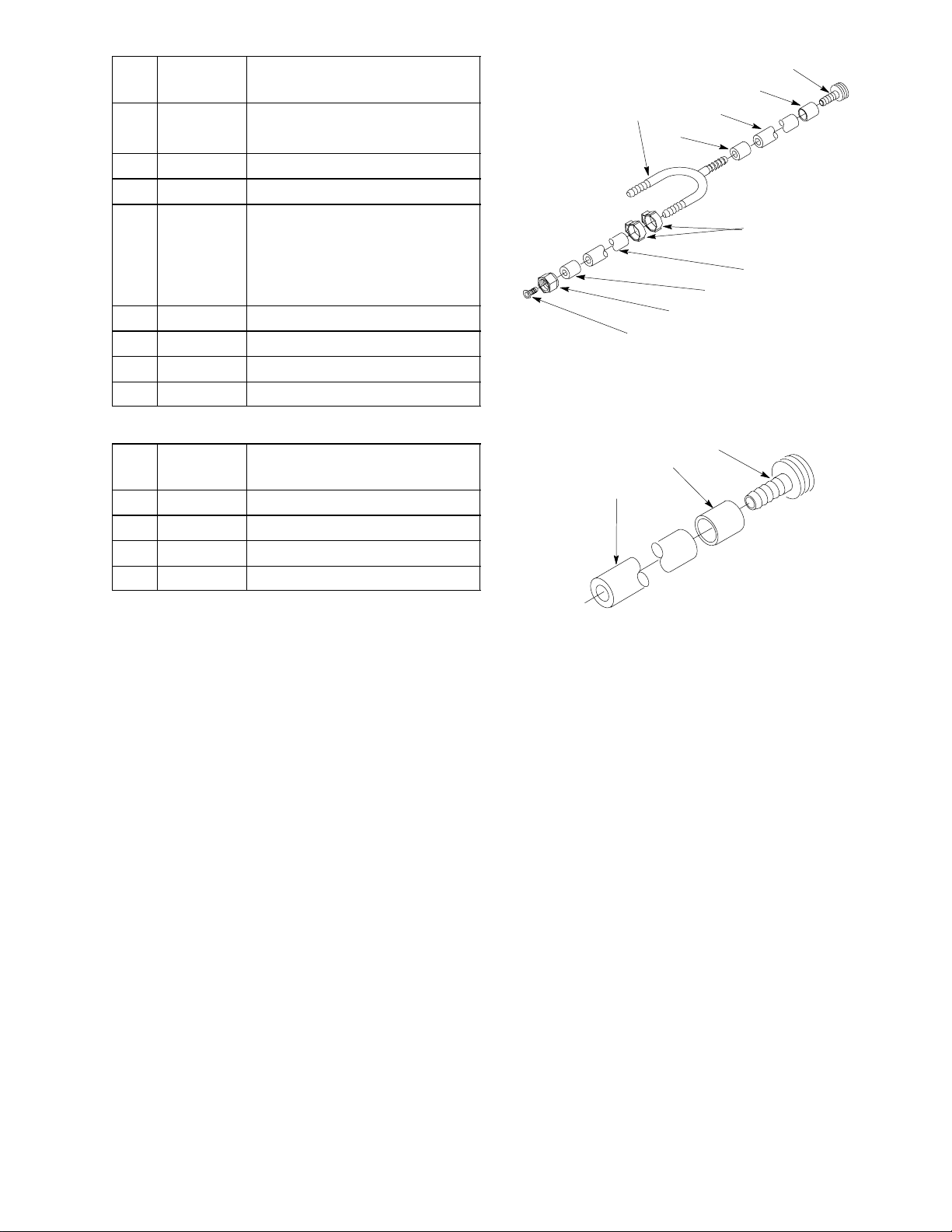

FIGURE 41. 4 FLAVOR FCB POST-MIX DISPENSER ASSEMBLY 87. . . . . . . . . . .

FIGURE 42. 4 FLAVOR FCB POST-MIX DISPENSER ASSEMBLY 89. . . . . . . . . . .

FIGURE 43. BLENDER AND TUBING COMPONENTS 91. . . . . . . . . . . . . . . . . . . . .

FIGURE 44. SOLENOID AND FLOAT SWITCH COMPONENTS 91. . . . . . . . . . . . .

FIGURE 45. ELECTRICAL BOX COMPONENTS 92. . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 46. CARBONATOR WITH PUMP AND MOTOTR COMPONENTS 92. . .

FIGURE 47. TUBE ASSEMBLY (WATER INLET) 92. . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 48. TUBING ASSEMBLY (CO2 REGULATOR TO CARBONATOR) 92. . .

FIGURE 49. TUBE ASSEMBLY (BLENDER TO FOAM PACK) 93. . . . . . . . . . . . . . .

FIGURE 50. TUBING ASSEMBLY (CO2 REGULATOR TO BLENDER) 93. . . . . . .

FIGURE 51. TUBING ASSEMBLY (CARBONATED WATER OUTLET) 93. . . . . . . .

FIGURE 52. PUMP AND MOTOR COMPONENTS 93. . . . . . . . . . . . . . . . . . . . . . . . .

569000119

vi

Page 8

TABLE OF CONTENTS (cont’d)

LIST OF TABLES

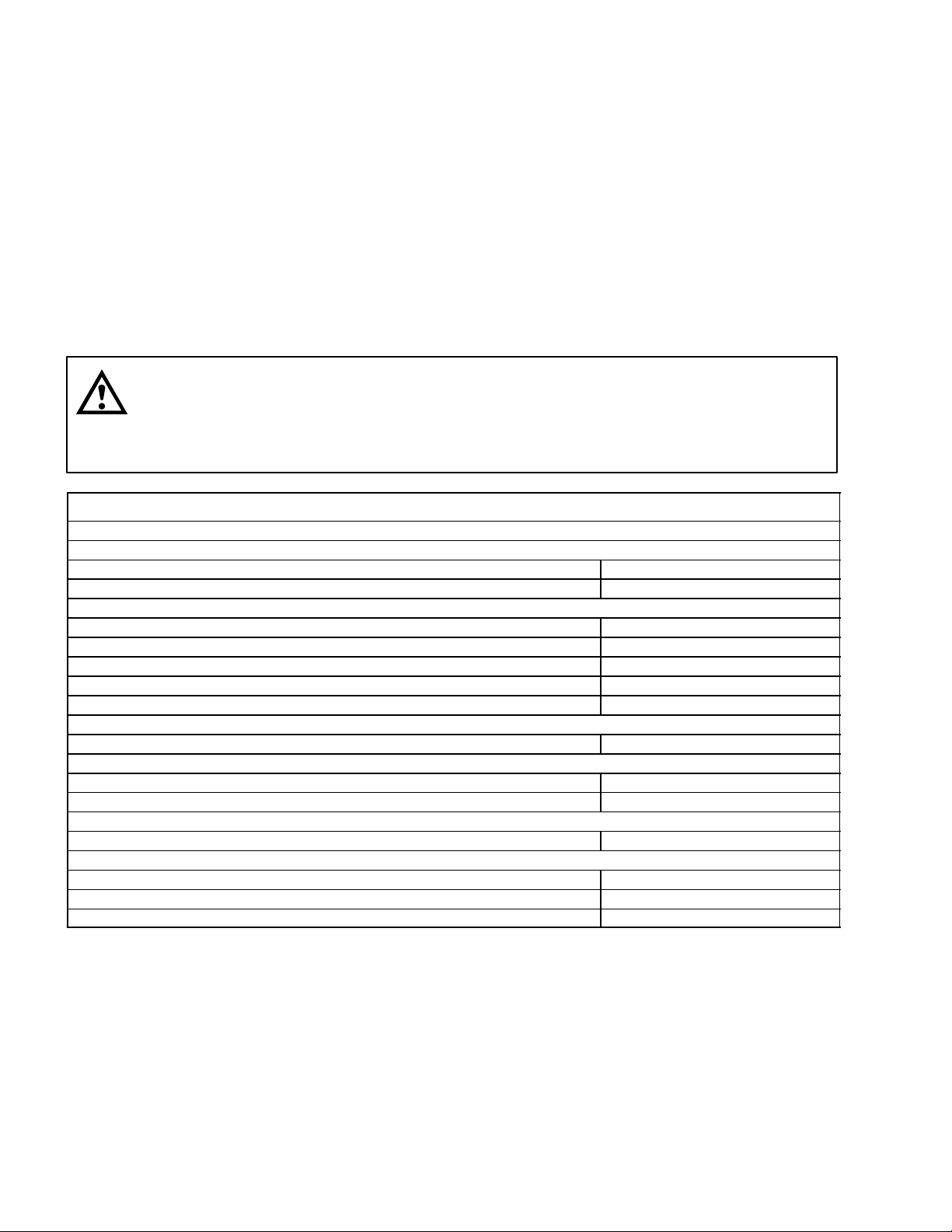

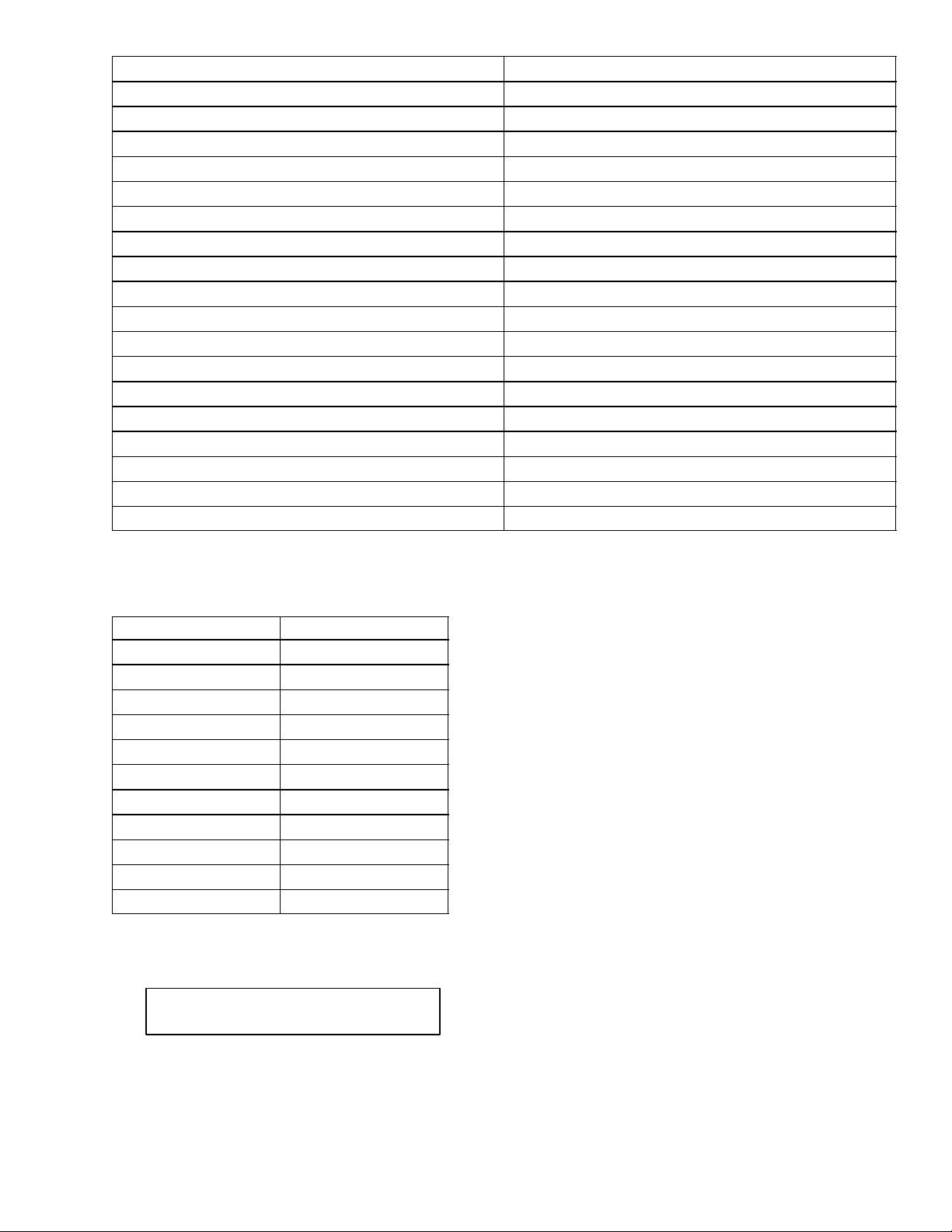

TABLE 1. DESIGN DATA 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE 2. ACCESSORIES AND TOOLS 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE 3. LOOSE-SHIPPED PARTS 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

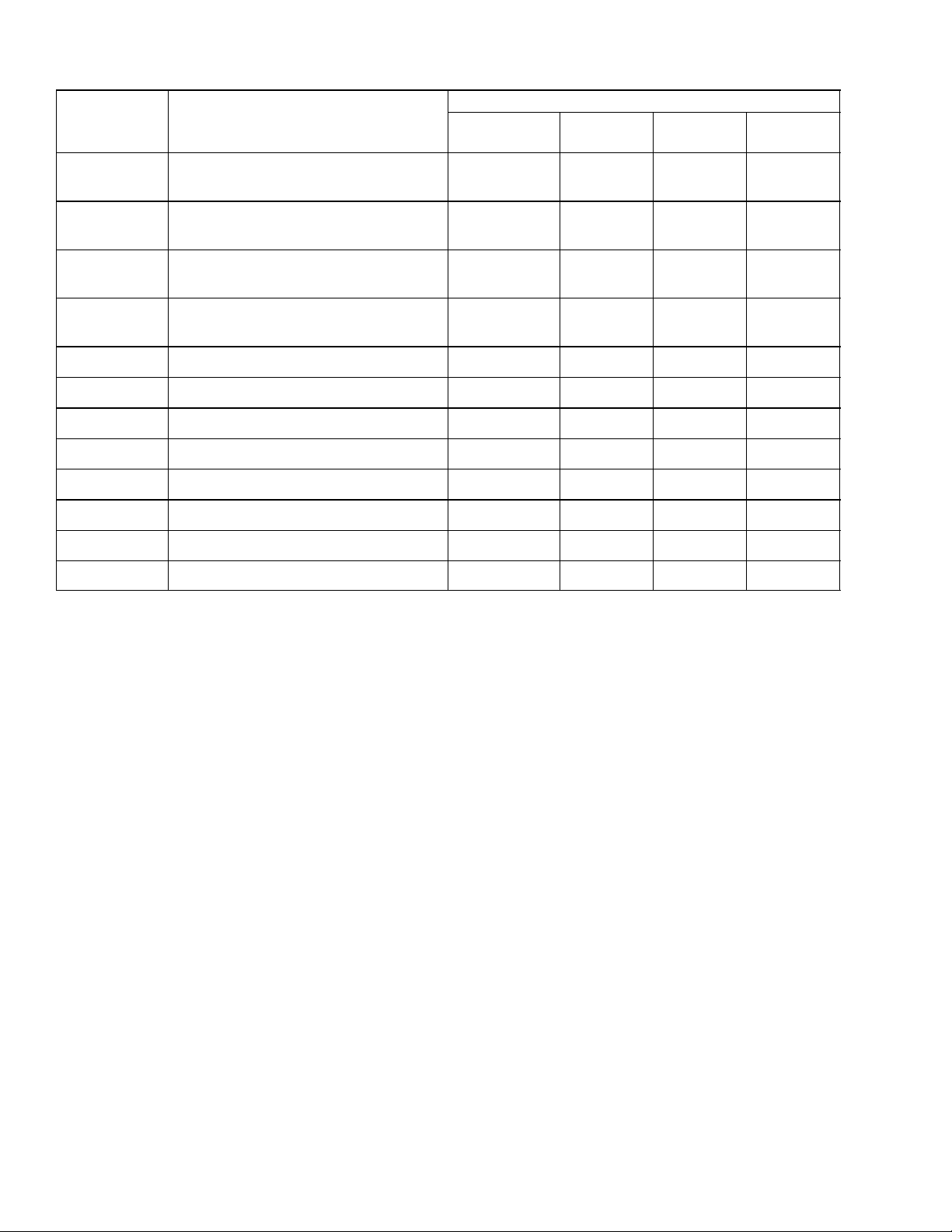

TABLE 4. MAIN MENU SELECTIONS 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

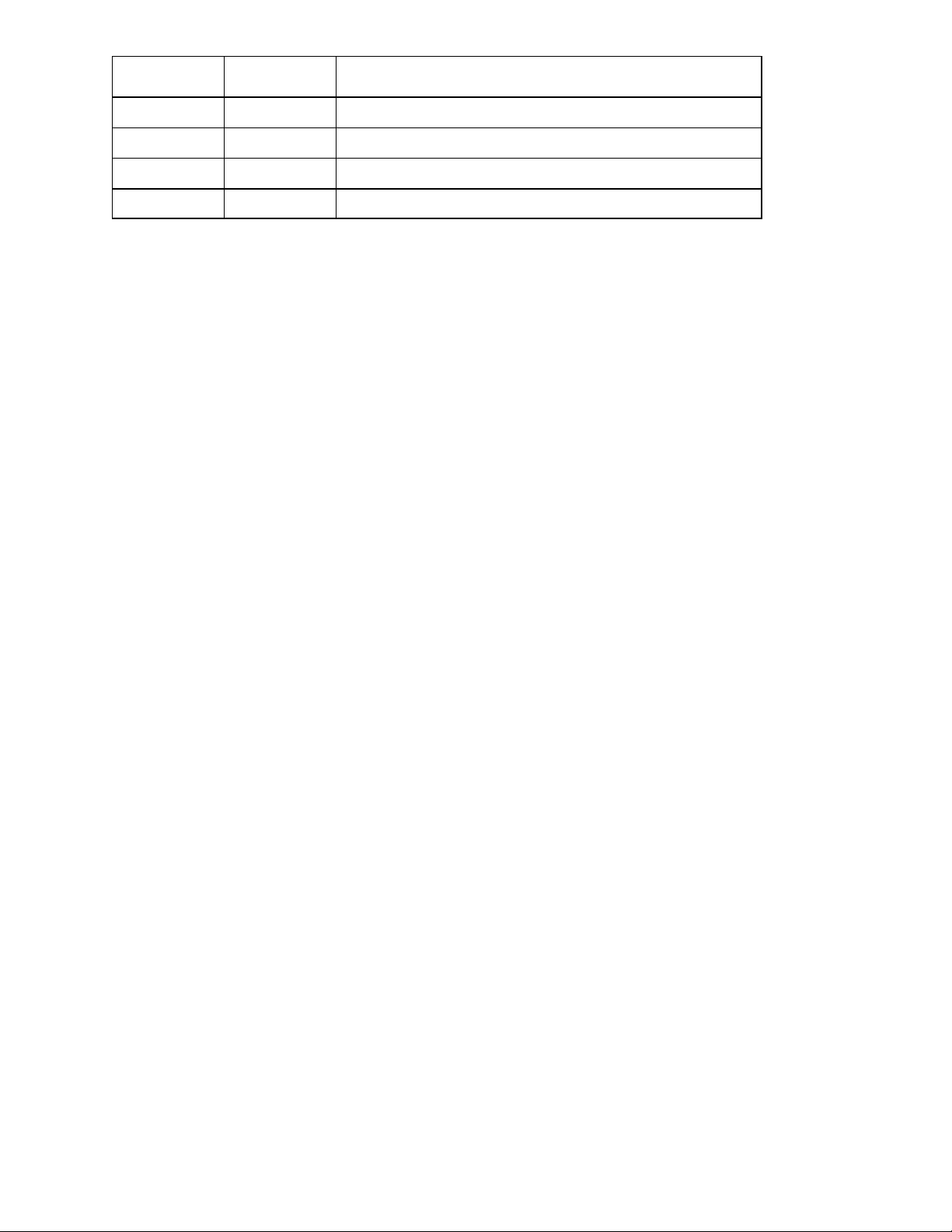

TABLE 5. DIP SWITCH FUNCTIONS 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE 6. MOTOR SELECT 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE 7. POINT OF SALE DISPLAY MESSAGES 23. . . . . . . . . . . . . . . . . . . . . . . .

TABLE 8. “TOTALS” (DISPLAYED CYCLES AND HOURS TOTALS) MENU 27. . .

TABLE 9. DISPLAYED ERROR CONDITIONS 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

569000119

Page 9

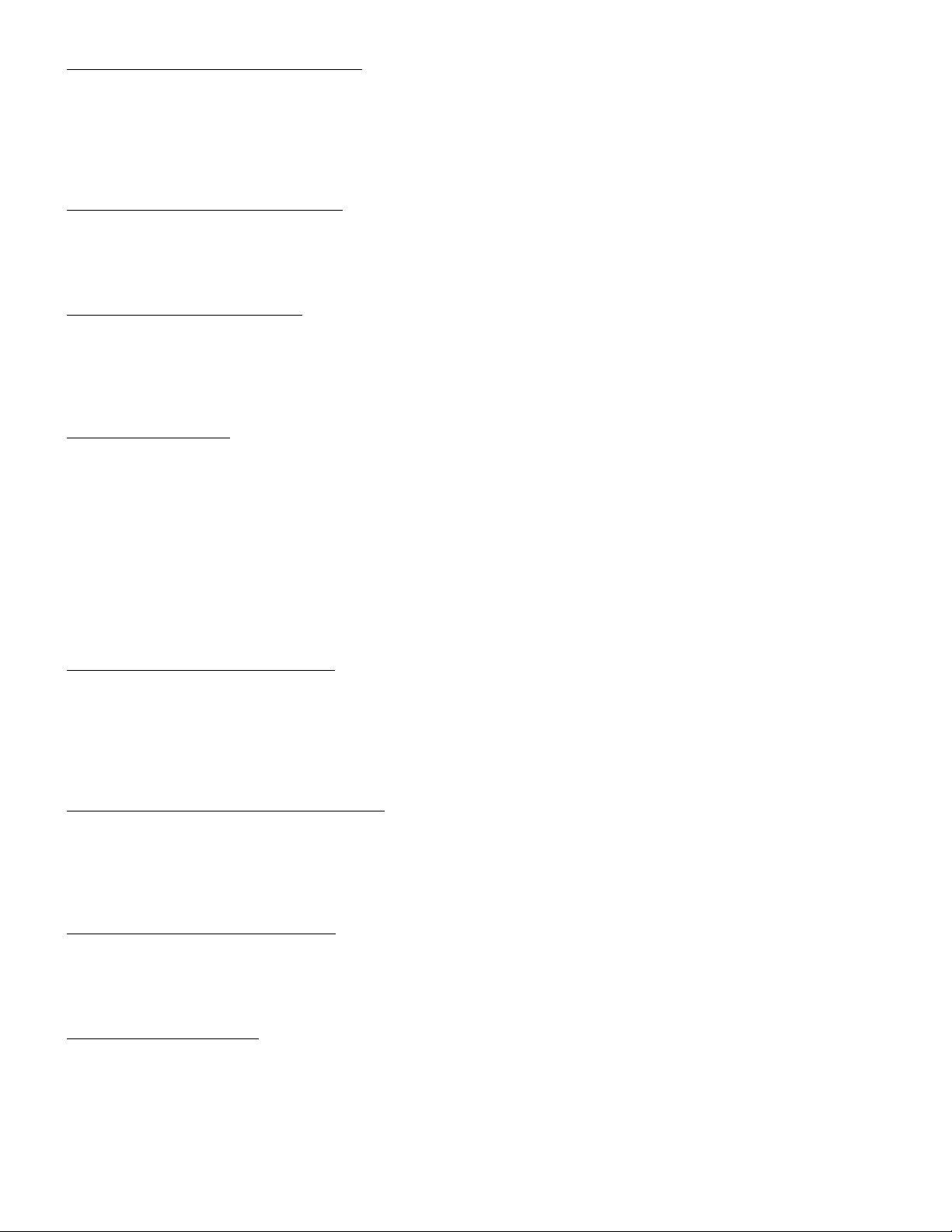

SAFETY INFORMATION

Recognize Safety Information

This is the safety-alert symbol. When you see this

symbol on our machine or in this manual, be alert to

the potentially of personal injury.

Follow recommended precautions and safe operating

practices.

Understand Signal Words

A signal word - DANGER, WARNING, OR CAUTION

is used with the safety-alert symbol. DANGER identi-

fies the most serious hazards.

DANGER

Safety signs with signal word DANGER or WARNING

are typically near specific hazards.

General precautions are listed on CAUTION safety

signs. CAUTION also calls attention to safety messages in this manual.

WARNING

CAUTION

Follow Safety Instructions

Carefully read all safety messages in this manual and on your machine safety signs. Keep safety signs in

good condition. Replace missing or damaged safety signs. Learn how to operate the machine and how to

use the controls properly. Do not let anyone operate the machine without instructions. Keep your machine in

proper working condition. Unauthorized modifications to the machine may impair function and/or safety and

affect the machine life.

CO2 (Carbon Dioxide) Warning

CO2 Displaces Oxygen. Strict Attention must be observed in the prevention of CO2 (carbon dioxide)

gas leaks in the entire CO2 and soft drink system. If a CO2 gas leak is suspected, particularly in a

small area, immediately ventilate the contaminated area before attempting to repair the leak. Personnel exposed to high concentration of CO2 gas will experience tremors which are followed rapidly by

loss of consciousness and suffocation.

Shipping, Storing, Or Relocating Unit

CAUTION: Before shipping, storing, or relocating this Unit, the syrup systems must be sanitized and

all sanitizing solution must be purged from the syrup systems. All water must also be purged from

the plain and carbonated water systems. A freezing ambient temperature will cause residual water

remaining inside the Unit to freeze resulting in damage to internal components of the Unit.

1 56000119

Page 10

Page 11

THIS PAGE LEFT BLANK INTENTIONALLY

569000119

2

Page 12

GENERAL DESCRIPTION

This section gives the description, theory of operation, and design data for the FCB (OC2R) Overcounter Two–

Flavor and the FCB Floor Model Four–Flavor Post-Mix Dispensers with V3+ Features (hereafter referred to as

a Units).

IMPORTANT: To the user of this manual – This manual is a guide for installing, operating, and maintaining this equipment. Refer to the Table of Contents for page location for detailed information pertaining to questions that arise during installation, operation, service, or maintenance of this

equipment.

This Unit must be installed by a qualified Service Person.This Unit contains no User serviceable parts.

Warranty Registration Date

(to be filled out by customer)

Model Number:

Serial Number:

Install Date:

Local Authorized

Service Center:

UNIT DESCRIPTION

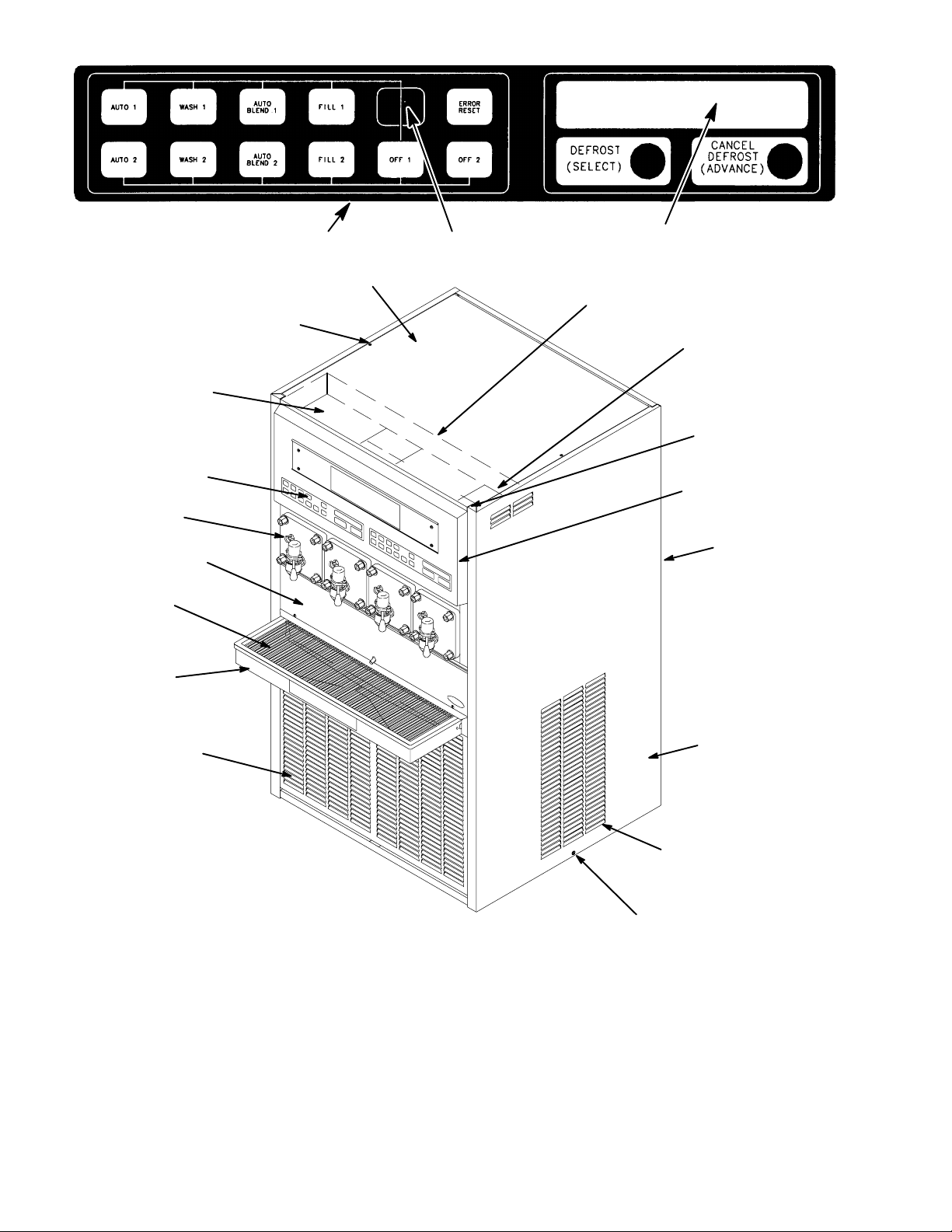

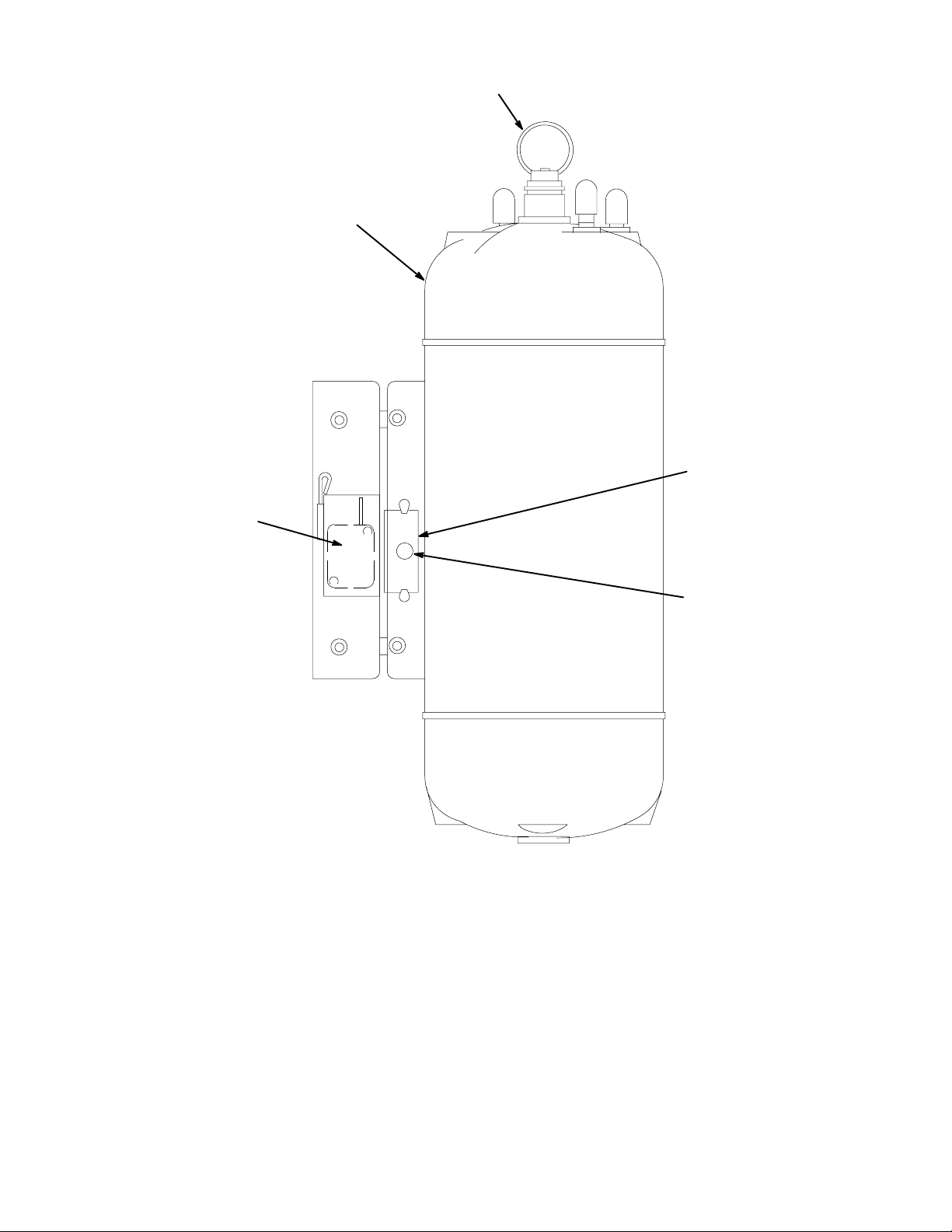

TWO–FLAVOR OVERCOUNTER (OC2R) UNIT

(see Figure 1)

The Two–Flavor Overcounter (OC2R) Unit (see Figure 1) consists basically of two freeze cylinders each con-

taining an internal beater driven by an electric motor, one carbonator which feeds both carbonator-blender

tanks, an electronically controlled automatic electric defrost system to defrost the freeze cylinders, and interconnecting tubing, components and fittings necessary to regulate, transfer and dispense product. The components

are attached to a steel frame and are enclosed in a steel cabinet. The cabinet panels are easily removed to facilitate installation and service and maintenance. A transparent faceplate, with an integral relief valve and a removable self-closing dispensing valve, is mounted on front of each freeze cylinder. A removable drip tray, with a

cup rest, is located directly below the dispensing valves.

IMPORTANT: The OC2R Post-Mix Dispenser (Evaporator Unit) must be used in con-junction with

Remote Refrigeration Assembly P/N 4161170001 (60 HZ). The FCB OC2R Post-Mix Dispenser

(Evaporator Unit) freeze cylinders evaporator coils are connected to and are refrigerated by the Remote

Refrigeration Assembly.

FIGURE 1. TWO–FLAVOR OVER-

COUNTER (OC2R) UNIT

FIGURE 2. FOUR–FLAVOR FLOOR

MODEL UNIT

3

569000119

Page 13

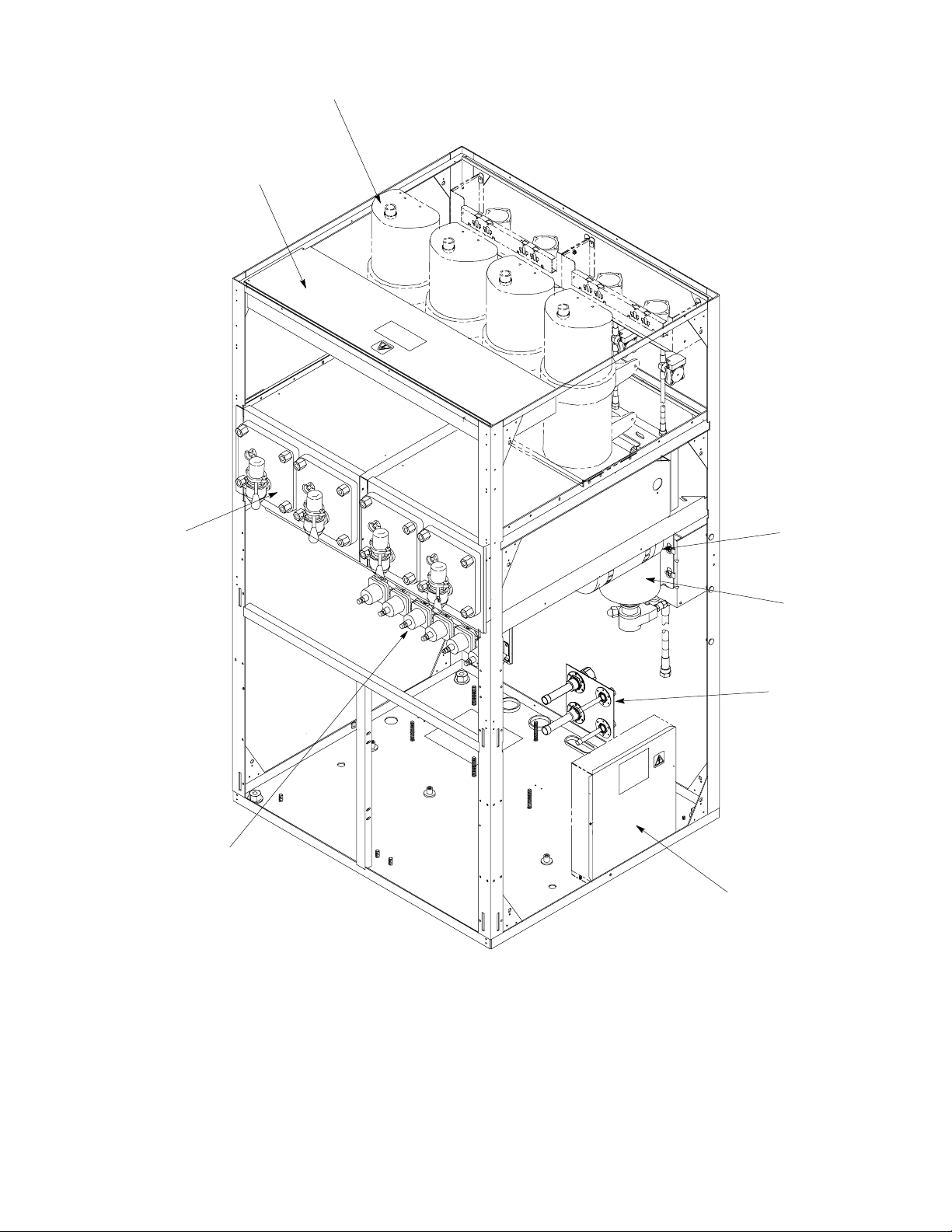

FOUR–FLAVOR FLOOR MODEL UNIT

(see Figure 2)

The Four–Flavor Floor Model Unit (see Figure 2) consists basically of four freeze cylinders each containing an

internal beater driven by an electric motor, two carbonators which feeds all four carbonator-blender tanks, an

electronically controlled automatic electric defrost system to defrost the freeze cylinders, and interconnecting

tubing, components and fittings necessary to regulate, transfer and dispense product. The components are attached to a steel frame and are enclosed in a steel cabinet. The cabinet panels are easily removed to facilitate

installation and service and maintenance. A transparent faceplate, with an integral relief valve and a removable

self-closing dispensing valve, is mounted on front of each freeze cylinder. A removable drip tray, with a cup rest,

is located directly below the dispensing valves.

IMPORTANT: The Four–Flavor Floor Model Dispenser (Evaporator Unit) must be used in con-junction

with two Remote Refrigeration Assemblies P/N 4161170001 (60 HZ). The Four–Flavor Floor Model

Dispenser (Evaporator Unit) freeze cylinders evaporator coils are connected to and are refrigerated by

the Remote Refrigeration Assemblies.

CAUTION: Before shipping, storing, or relocating this Unit, the syrup systems must be

sanitized and all sanitizing solution must be purged from the syrup systems. All water must

also be purged from the plain and carbonated water systems. A freezing ambient

environment will cause residual water in the Unit to freeze resulting in damage to internal

components.

Table 1. Design Data

FCB (OC2R) OVERCOUNTER DISPENSER DATA

Unit Part Number:

230 VAC, 60 Hz 416116XXXX

Overall Dimensions:

Height 33-1/2 inches

Width 19-1/8 inches

Depth Without Drip Tray 35-1/4 inches

Depth With Drip Tray 36 inches

Shipping Weight (approx.) 245 pounds

Refrigeration System:

Refrigerant Type and Charge See Unit Nameplate

Ambient Operating Temperature 40° F to 100° F

Electrical Requirements:

Operating Voltage See Unit Nameplate

Current Draw See Unit Nameplate

569000119

4

Page 14

Table 1. Design Data (cont’d)

FCB FLOOR MODEL FOUR–FLAVOR DISPENSER DATA

Unit Part Number:

230 VAC, 60 Hz 416216XXXX

Overall Dimensions:

Height 60–1/2 inches

Width 32–1/2 inches

Depth Without Drip Tray 32–1/2 inches

Depth With Drip Tray 38 inches

Shipping Weight (approx.) 580 pounds

Refrigeration System:

Refrigerant Type and Charge See Unit Nameplate

Ambient Operating Temperature 40° F to 100° F

Electrical Requirements:

Operating Voltage See Unit Nameplate

Current Draw See Unit Nameplate

Table 2. Accessories and Tools

ACCESSORIES

Installation kits 1155

Cup Holder 511005000

Cup Holder 511006000

CO2 Changeover Kit 511035000

GENERIC FLAVOR TABS

Cola 1085

Cherry 1086

Orange 1087

Lemon-Lime 1089

Strawberry 1090

Banana 1091

SERVICE TOOLS

3-gallon Sanitizing Tank 281884000

Spanner Wrench, Dispensing Valve 322859000

Refractometer, 0-30 Scale 511004000

Wrench, Rear Seal Housing 2899

Tool, Drive/Coupler Adjustment Gauge 3810

SYSTEM THEOR Y OF OPERATION

(see applicable Figure 3 or 4 Flow Diagram)

A CO2 cylinder delivers carbon dioxide (CO2) gas to an adjustable primary CO2 regulator assembly attached to

the cylinder. The primary CO2 regulator assembly in turn delivers CO2 gas to adjustable secondary CO2 regulators inside the Unit and also to the soft drink tanks. CO2 is delivered from the adjustable secondary CO2 regulators to the carbonator tank(s) and also to the product-blender tanks inside the Unit. CO2 gas pressure pushes

5

569000119

Page 15

syrup out of soft drink tanks, through syrup sold-out float switches, through electrically-operated syrup solenoid

valves, through adjustable syrup flow regulators, and on to product blender tanks. At the same time, plain water

passes through water pressure regulator(s) and is pumped into the carbonator tank(s) by the water pump(s) and

is carbonated by CO

from carbonator tank(s), through electrically operated carbonated water solenoid valves through adjustable carbonated water flow regulators, and on to product blender tanks. Carbonated water and syrup enter the tanks

properly proportioned (blended) for the desired BRIX of the dispensed product by adjustment of the syrup flow

regulators. From product blender tanks, the product is pushed by CO

in each freeze cylinder is driven by an electric motor. Scraper blades, attached to the beaters, scrapes product

from the cylinder walls as product enters the freeze cylinders and is frozen. Transparent faceplate, attached to

the front of each freeze cylinder, includes a self-closing dispensing valve and a spring-loaded relief valve that

protects freeze cylinder from accidental over pressure. The relief valve is also used to bleed CO

from the freeze cylinder to atmosphere when filling the cylinder with product. Electronic sensing on each freeze

cylinder motor provides a means of adjusting the viscosity (consistency) of dispensed product to suit customer

preference.

gas pressure also entering tank(s). Carbonated water is pushed by CO2 gas pressure

2

gas into the freeze cylinders. The beater

2

gas pressure

2

DEFROST SYSTEMS

The Unit is equipped with both manual and automatic electric defrost systems. The automatic defrost system

may be programmed into the Unit to occur up to nine different times during a day with a minimum of two hours

between defrost time settings or the system may be completely turned off.

MANUAL ELECTRIC DEFROST SYSTEM

The Manual electric defrost system may be activated at any time by pressing ‘‘DEFROST’’ switch on front of the

Unit. Refrigeration compressor will operate for a short time, then both freeze cylinders will go into defrost and

defrost for approximately 15-minutes. At end of manual defrost cycle, Unit will return to normal operation. Manual defrost may be cancelled at any time by pressing ‘‘CANCEL DEFROST’’ switch.

AUTOMATIC ELECTRIC DEFROST SYSTEM

The automatic electric defrost system may be programmed into the Unit to occur up to nine different times a day

with a minimum of two hours between defrost settings. At start of each automatic defrost cycle, refrigeration

compressor will operate for a short time. No. 1 freeze cylinder only will go into defrost cycle and defrost for

approximately 15-minutes, then will return to normal operation This ends automatic defrost cycle of No. 1 freeze

cylinder. No. 2 freeze cylinder will defrost 30-minutes after the start of No. 1 freeze cylinder. The next automatic

defrost cycle will occur according to time programmed into the Unit.

‘‘SLEEP’’ (SLEEP TIME)

‘‘SLEEP’’ ((SLEEP TIME) may be programmed into Unit to allow Unit to go into sleep time (Unit shut down,

freeze cylinders beaters and refrigeration systems not operating). At start of sleep time, refrigeration compressor will operate for 30 seconds to pump freon out of freeze cylinders evaporator coils, then No. 1 freeze cylinder

will go into defrost and defrost for 60 seconds. After No. 1 freeze cylinder has defrosted, No. 2 freeze cylinderwill go into defrost and defrost for 60-seconds. At end of No. 2 freeze cylinder defrost, Unit will shut down and

go into sleep time.

‘‘WAKE UP’’ (WAKE UP TIME)

‘‘WAKE UP’’ (WAKE UP TIME) may be programmed into the Unit to allow Unit to resume normal operation at a

desired time. When programmed wake up time is reached, an alarm will sound for a short duration, then Unit

will resume normal operation.

NOTE: Automatic defrost, sleep time, and wake up time may be used in any combination together or

separately.

569000119

6

Page 16

*WATER PRESSURE REGULATOR IS

FACT ORY ADJUSTED TO 45-PSI AND

SHOULD NOT BE READJUSTED.

**SYRUP SOLD-OUT SWITCHES ARE

FACTORY ADJUSTED AND SHOULD

NOT BE READJUSTED.

LINE LEGEND

CO

2

PLAIN WATER

CARB WATER

SYRUP

PRODUCT

CARBONATOR

PRODUCT BLENDER

TANK(2)

PRODUCT SHUTOFF

VALVE(2)

CYLINDER(2)

CARBONATED WATER

VOLUME SAMPLE VALVE

CARBONATED WATER

SOLENOID VALVE(2)

CARBONATED WATER

FLOW REGULATOR(2)

SYRUP SOLENOID

VALVE(2)

PRIMARY CO

REGULATOR ASS’Y

2

SYRUP SOLD-OUT

FLOAT SWITCH(2)

**SYRUP SOLD-OUT

SWITCH

TANK

FREEZE

PRODUCT SAMPLE

VALVE(2)

SYRUP FLOW

REGULATOR(2)

FREEZE CYLINDER

OVERFLOW TUBE

LIQUID CHECK

VALVE(2)

*WATER PRESSURE

REGULATOR

PLAIN WATER

SOURCE

SHUTOFF

VALVE

CO

2

CYLINDER

WATER

PRESSURE

SWITCH

CARBONATOR

WATER PUMP

CO

2

PRESSURE

SWITCH

CO

CHECK

2

VALVE(3)

CO

2

CHECK

VALVE

SOFT DRINK

TANK(2)

DOUBLE

LIQUID

CHECK

VALVE

SECONDARY CO2 REGULATORS

TO PRODUCT BLENDER

TANKS (60–PSI GAGE) (2)

SECONDARY CO2 REGULATOR

TO CARBONATOR TANK

(100-PSI GAGE)

FIGURE 3. FLOW DIAGRAM (TWO–FLAVOR OVERCOUNTER (OC2R) UNIT)

7

569000119

Page 17

*WATER PRESSURE REGULATORS

ARE FACTORY ADJUSTED TO 45-PSI

AND SHOULD NOT BE READJUSTED.

CARBONATED WATER

VOLUME SAMPLE VALVE

**SYRUP SOLD-OUT SWITCHES

ARE FACTORY ADJUSTED AND

SHOULD NOT BE READJUSTED.

CARBONATOR

TANK (2)

PRODUCT SAMPLE

VALVE (4))

PRODUCT BLENDER

TANK (4)

PRODUCT

SHUTOFF

VALVE (4)

CARBONATED

WATER

SAMPLE VALVE (2)

1

FREEZE

CYLINDER (4)

SECONDARY CO2 REGULATORS

TO PRODUCT BLENDER

TANKS (60-PSI GAGES)

FREEZE CYLINDERS

OVERFLOW TUBE

SECONDARY CO2 REGULATORS

TO CARBONATOR TANKS

(100-PSI GAGES)

2

CARBONATED WATER

SOLENOID (4)

CO2 PRESSURE

SWITCH

11

LIQUID CHECK

VALVE (4)

22

CARBONATED WATER

FLOW REGULATOR (4)

SYRUP FLOW

REGULATOR (4)

CO

2

CYLINDER

LINE LEGEND

CO

2

PLAIN WATER

CARB WATER

SYRUP

PRODUCT

569000119

CO2 GAS

CHECK VALVE (5)

FIGURE 4. FLOW DIAGRAM (FOUR–FLAVOR FLOOR MODEL UNIT)

CO2 GAS

CHECK VALVE (2)

CO2 REGULATOR

121122

SYRUP TANK (4)

PLAIN WATER

PRIMARY

SHUTOFF VALVE

SOURCE

WATER PRESSURE

SWITCH

(2)

8

SYRUP

SOLENOID (4)

**SYRUP SOLD-OUT

SWITCH (4)

*WATER PRESSURE

REGULATOR (2)

DOUBLE LIQUID

CHECK VALVE (2)

CARBONATOR

WATER PUMP (2)

LIQUID CHECK

VALVE (4)

SYRUP FLOAT

SWITCH (4)

Page 18

INSTALLATION

This section covers unpacking and inspection, selecting location, installing the FCB Post–Mix Dispenser, preparing for operation, and operation.

UNPACKING AND INSPECTION

NOTE: The FCB Post-Mix Dispenser was thoroughly inspected before leaving the factory and the carrier

has accepted and signed for it. Any damage or irregularities should be noted at time of delivery (or not

later than 15 days from date of delivery) and immediately reported to the delivering carrier. Request a

written inspection report from Claims Inspector to substantiate any necessary claim. File claim with the

delivering carrier, not with IMI Cornelius Inc.

1. Unpack FCB Dispenser and remove all shipping tape and packing materials.

2. Unpack LOOSE-SHIPPED parts. Make sure all items are present and in good condition.

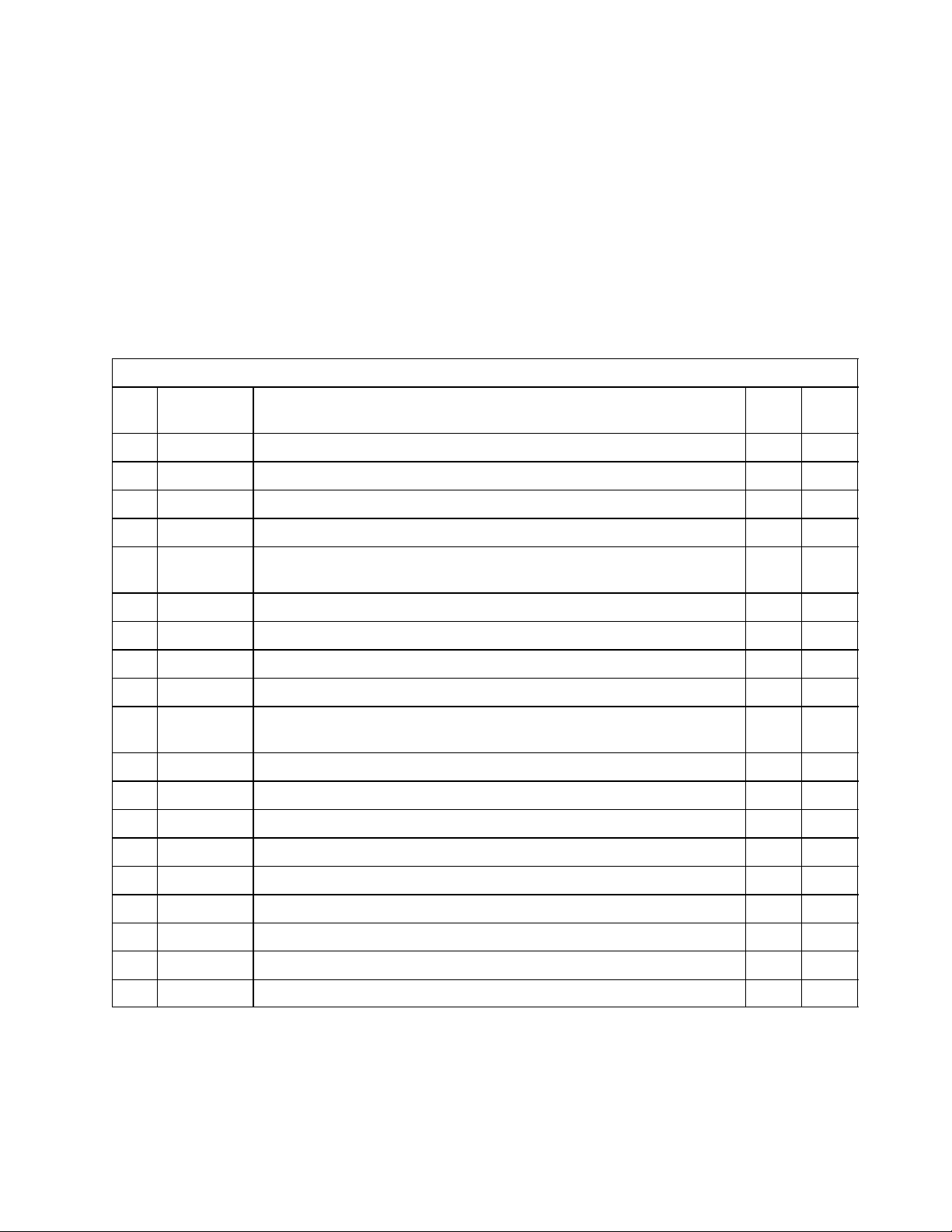

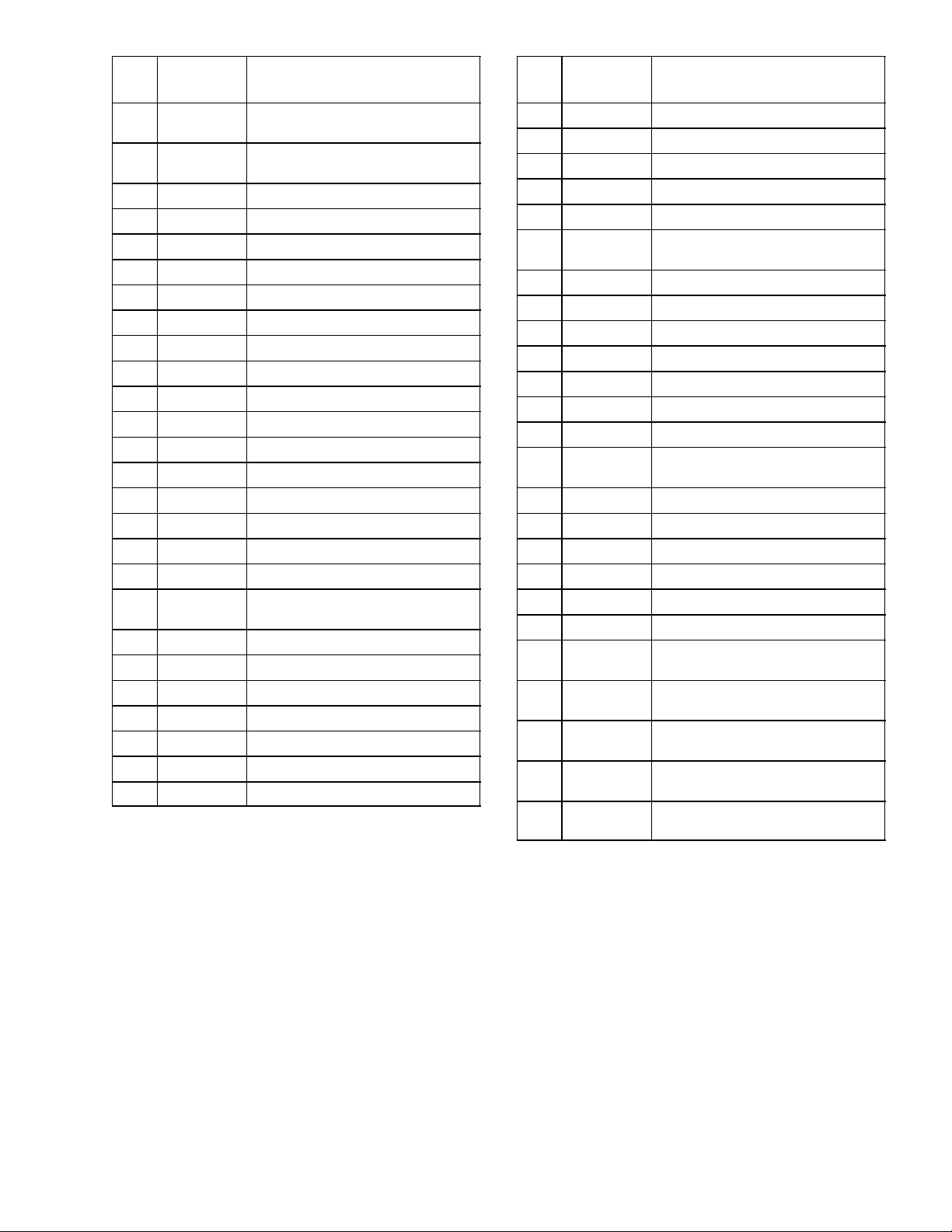

Table 3. Loose-Shipped Parts

Item

No. Part No. Name

1 178025100 Tapered Gasket, White 4 5

2 322859000 Spanner Wrench, Dispensing Valve 1 1

3 325216000 Cleaning Brush 1 1

4 311304000 Tapered Gasket, Black 1 5

5 317660000

325992000

6 325282 Thread Cutting Screw, Hex Hd.; No. 8 by 18 by 1/2-in. long 2 4

7 2738 Drip Tray Support, Left 1 X

8 2739 Drip Tray Support, Right 1 X

9 325986000 Drip Tray Support, (Both Left and Right Sides) X 2

10 317659029

325990039

11 326002000 Kit, Drip Tray Drain Hose 1 1

12 2899 Wrench, Rear Seal Housing 1 1

13 3810 Tool, Drive/Coupler Adjustment Gauge 1 1

14 324252000 Leveling Leg 4 X

Cup Rest

Cup Rest

Drip Tray

Drip Tray

2–Fl

Qty.

1

X

1

X

4–Fl

Qty.

X

1

X

1

15 3247 Spacer, White 2 X

16 3221 Front Access Panel 1 X

17 3108 Thread Cutting Screw, Phil Pan Hd; No. 10 by 32 by 1-in. long 2 X

18 3680 Seal Kit, Freeze Cylinder Drive Shaft 1 1

19 325018000 Caster Kit, 4–inch Dia. Casters X 1

IDENTIFICATION OF LOOSE-SHIPPED PARTS

1. TAPERED GASKETS, WHITE (item 1) are used to seal connections when connecting Unit product inlet lines

to product tanks and connecting Unit CO2 inlet line to CO2 source.

2. SPANNER WRENCH, DISPENSING VALVE (item 2) is used to remove shank nuts securing dispensing

valves to faceplates.

9

569000119

Page 19

3. CLEANING BRUSH (item 3) is used to clean faceplate relief valves passages.

4. TAPERED GASKET, BLACK (item 4) is used to seal connection when connecting plain water source line to

Unit water inlet line.

5. DRIP TRAY SUPPORTS (item 7) and (item 8) to be installed on front of the Two–Flavor Overcounter Unit

(See Figure 9) and secured with Thread Cutting SCREWS (item 6). and THREAD CUTTING SCREWS

(Item 17).

6. CUP REST (item 5) to be installed in DRIP TRAY (item 10), then drip tray to be installed on drip tray supports.

7. DRIP TRAY DRAIN HOSE KIT (item 11) to be installed on drip tray as instructed in Instructions provided in

the Kit.

8. WRENCH, REAR SEAL HOUSING (item 12) used to remove the drive shaft/seal assembly from inside the

freeze cylinder.

9. TOOL, DRIVE/COUPLER ADJUSTMENT GAUGE (item 13) is used for servicing the beater motor drive

shaft/ seal assembly (See Figure 10).

10. LEVELING LEGS (item 14) are to be installed on bottom of the Unit.

11. FRONT ACCESS PANEL (item 16) to be installed on front of the Unit (See Figure 9) and secured with

WHITE SPACERS (item 15) and THREAD CUTTING SCREWS (item 17). SPACERS TO BE INSTALLED

BETWEEN THE FRONT PANEL AND THE UNIT FRAME.

12. SEAL KIT, FREEZE CYLINDER DRIVE SHAFT (item 18) is intended to replace seals on the freeze cylinder

beater drive shaft assembly. Refer to SERVICE AND MAINTENANCE section of this manual for installation

instructions.

SELECTING LOCATION

CAUTION: This Unit is intended for indoor installation only. Do not install this Unit in an

outdoor environment which would expose it to the outside elements.

TWO–FLAVOR OVERCOUNTER (OC2R) DISPENSER

Locate the Dispenser so the following requirements are satisfied:

1. Close to a filtered plain water inlet supply line with a minimum pressure of 12-psig.

2. A properly grounded 208–230 VAC, 60Hz single-phase electrical circuit connected through a 15-amp

minimum-rated disconnect switch (not provided) fused at 15-amps (slow-blow) or circuit connected through

an equivalent HACR circuit breaker must be available to be connected to the electrical box located inside

the Unit. ALL WIRING MUST CONFORM TO NATIONAL AND LOCAL CODES. MAKE SURE UNIT IS

PROPERLY GROUNDED.

3. The Unit must be placed in a location which will allow shortest possible refrigeration lines route (not to exceed 50–feet in length) from the Two–Flavor Overcounter Dispenser to the Remote Refrigeration Assembly.

IMPORTANT: Unit operating ambient temperature MUST NOT EXCEED 100° F. Several means are

available to achieve proper ambient temperature and air circulation through the Unit which are wall air

intake grilles and ceiling exhaust fans, air conditioning, etc. Consult local codes.

569000119

CAUTION: Do not place or store anything on top of the Unit.

10

Page 20

Circulating air, required to cool the beater drive motors, enters through louvers on back and sides of the Unit.

Restricting air from entering the Unit will decrease cooling of the beater motors.

4. When placing Unit in operating location, do not allow wall or obstruction to block louvers on back and sides

of the Unit. A minimum of 6-inches clearance must be allowed between back of Unit and wall or obstruction,

6-inches clearance on both sides of the Unit, and a minimum of 12-inches must be provided above the Unit

for service and maintenance.

FOUR–FLAVOR FLOOR MODEL DISPENSER

CAUTION: This Unit is intended for indoor installation only. Do not install this Unit in an

outdoor environment which would expose it to the outside elements.

Locate the Dispenser so the following requirements are satisfied:

1. Close to a filtered plain water inlet supply line with a minimum pressure of 12-psig.

2. The Unit requires a properly grounded 208–230 VAC , 60 Hz single-phase electrical power circuit. The elec-

trical power circuit may be connected through a (not provided) 50-amp minimum-rated disconnect switch

fused at 50-amps or the power circuit may be connected through an equivalent HACR circuit breaker. ALL

WIRING MUST CONFORM TO NATIONAL AND LOCAL CODES. MAKE SURE THE UNIT IS PROPERLY

GROUNDED.

3. The Unit must be placed in a location which will allow the shortest possible refrigeration lines route (not to

exceed 50–feet in length) from the Four–Flavor FCB Dispenser to the two Remote Refrigeration Assemblies.

IMPORTANT: Unit operating ambient temperature MUST NOT EXCEED 100° F. Several means are

available to achieve proper ambient temperature and air circulation through the Unit which are wall air

intake grilles and ceiling exhaust fans, air conditioning, etc. Consult local codes.

CAUTION: Do not place or store anything on top of the Unit.

4. When installing Unit, do not allow obstruction to block grille on front which will block off air intake to inside of

Unit. If installation dictates only one side or back being unobstructed, allow 18-inches clearance between

Unit and obstruction. If both sides or one side and back are unobstructed, allow 12-inches clearance. If both

sides and back are unobstructed, allow 6-inches clearance.

REMOTE REFRIGERATION ASS’Y

(see Figure 19)

The Remote Refrigeration Assembly(s) (one required for the Overcounter (OC2R) Dispenser and two required for

the Four–Flavor Floor Model Dispenser) must be located in a location which will allow shortest possible refrigeration lines route (not to exceed 50–feet in length) from the Refrigeration Assembly(s) to the FCB Post-Mix Dispenser. Refer to Installation Instructions provided with the Remote Refrigeration Assembly(s).

INSTALLATION

INSTALLING TWO–FLAVOR OVERCOUNTER (OC2R) DISPENSER

INSTALLING LEVELING LEGS

Very carefully, tilt Unit up and install LEVELING LEGS (item 14) in four corners of the Unit base.

11

569000119

Page 21

PLACING UNIT IN OPERATING LOCATION

1. Place Unit in operating location meeting requirements of SELECTING LOCATION.

2. After Unit has been placed in operating location, make sure the Unit is sitting level by using a carpenters

level and adjusting the four leveling legs installed on the Unit.

INSTALLING DRIP TRAY SUPPORTS AND DRIP TRAY

(see Figure 9)

1. Install DRIP TRAY SUPPORTS (items 7 and 8) on front of Unit and secure with THREAD CUTTING

SCREWS (item 6).

2. Install DRIP TRAY (item 10) on drip tray supports.

INSTALLING FOUR–FLA VOR FLOOR MODEL DISPENSER

1. Place Unit in operating location meeting requirements of SELECTING LOCATION.

NOTE: An alternate to sealing the Unit base to the floor would be to install the CASTER KIT (item 19)

provided with the Unit LOOSE–SHIPPED PARTS.

2. After Unit has been placed operating location, make sure it is sitting in a level position on a surface that provides adequate support and stability.

3. To comply with National Sanitation Foundation (NSF) requirements, Unit installed with base contacting the

floor must have base sealed to the floor with Dow Corning RTV 731 or equivalent.

INSTALLING DRIP TRAY SUPPORTS, DRIP TRAY, AND CUP REST

1. Install DRIP TRAY SUPPORTS (item 9) on panel above lower front access panel on front of the Unit. Secure

supports to panel with THREAD CUTTING SCREWS (item 6).

2. Place DRIP TRAY (item 10) in place on front of the Unit.

INSTALLING DRIP TRAY DRAIN KIT

1. Install DRIP TRAY DRAIN HOSE KIT (item 11) on Unit as instructed in Installation Instructions provided with

the Kit.

NOTE: Drip tray drain hose may be routed to a waste container, but is not recommended due to sanitation and cleaning problems. Connection of drain hose to a permanent drain is most highly recommended.

2. Route drip tray drain hose to and connect to permanent drain.

3. Place CUP REST (item 5) in drip tray.

CONNECTING 24 VAC ELECTRICAL CIRCUIT FROM REMOTE REFRIGERATION ASS’Y

TO FCB DISPENSER

OVERCOUNTER (OC2R) DISPENSER

1. Remove back, sides, and top panel from Unit as instructed in SERVICE AND MAINTENANCE section of this

manual.

2. Route 24 VAC electrical circuit from Remote Refrigeration Assembly up through hole in Dispenser base to

inside of the Dispenser.

569000119

12

Page 22

3. Connect 24 VAC power circuit grey and red electrical wires to labeled 24 Volt grey and red wires hanging

down close to the electrical control box inside the Dispenser. Use wire nuts to secure connections.

FOUR–FLAVOR FLOOR MODEL DISPENSER

1. Remove back, sides, and top panel from Unit as instructed in SERVICE AND MAINTENANCE section of this

manual.

2. Route 24 VAC electrical circuits (grey and red electrical wires) from both Remote Refrigeration Assemblies

up through hole in Dispenser base to inside of the Dispenser.

3. Remove cover from the electrical control box.

4. Route Remote Refrigeration Assemblies 24 VAC electrical circuits through hole to inside of the electrical

control box.

5. Refering to wiring diagram inside the electrical control box, connect the Refrigeration Assemblies 24 VAC

electrical circuits grey and red electrical wires to labeled grey and red electrical wires located inside the electrical control box. Use wire nuts to secure connections.

CONNECTING REMOTE REFRIGERATION ASS’Y REFRIGERATION LINES TO FCB

OVERCOUNTER DISPENSER

(see Figure 19)

OVERCOUNTER (OC2R) DISPENSER

Connect refrigeration lines, routed from the Remote Refrigeration Assembly, to refrigeration connectors on bottom

of the Overcounter (OC2R) Dispenser.

FOUR–FLAVOR FLOOR MODEL DISPENSER

Connect refrigeration lines, routed from the two Remote Refrigeration Assemblies, to refrigeration connectors on

back side of the Four–Flavor Floor Model Dispenser. Refer to refrigeration diagram on back side of Dispenser

before making refrigeration lines connections.

PREPARING UNIT SYRUP INLET LINES FOR CONNECTION TO SOFT DRINK TANKS

(see applicable Figure 3 or 4)

1. Route labeled Unit syrup inlet lines out through hole in Unit base to soft drink tanks location.

2. Install liquid disconnects on ends of Unit syrup inlet lines. DO NOT CONNECT SYRUP LINES TO SOFT

DRINK TANKS AT THIS TIME.

CONNECTING CITY PLAIN WATER SOURCE LINE TO UNIT

(see applicable Figure 3 or 4)

NOTE: The Unit requires connection to a city plain water source line with a minimum water pressure of

12-psig. IMI Cornelius Inc. recommends that a water shutoff valve and water filter be installed in the City

plain water source line (see Figure 3). A Cornelius Water Filter (P/N 313860000) and Quick Disconnect

Set (P/N 313867000) are recommended.

1. Connect and route city plain water source line up to the Unit.

2. Before connecting the city plain water source line to the Unit, open shutoff valve in city plain water source

line for a period of time to flush out any metal shavings, then close valve.

3. Connect the city plain water source line to the Unit plain water inlet line. Seal connection with TAPERED

GASKET, BLACK (item 4). DO NOT OPEN THE CITY PLAIN WATER SOURCE LINE SHUTOFF VALVE AT

THIS TIME.

13

569000119

Page 23

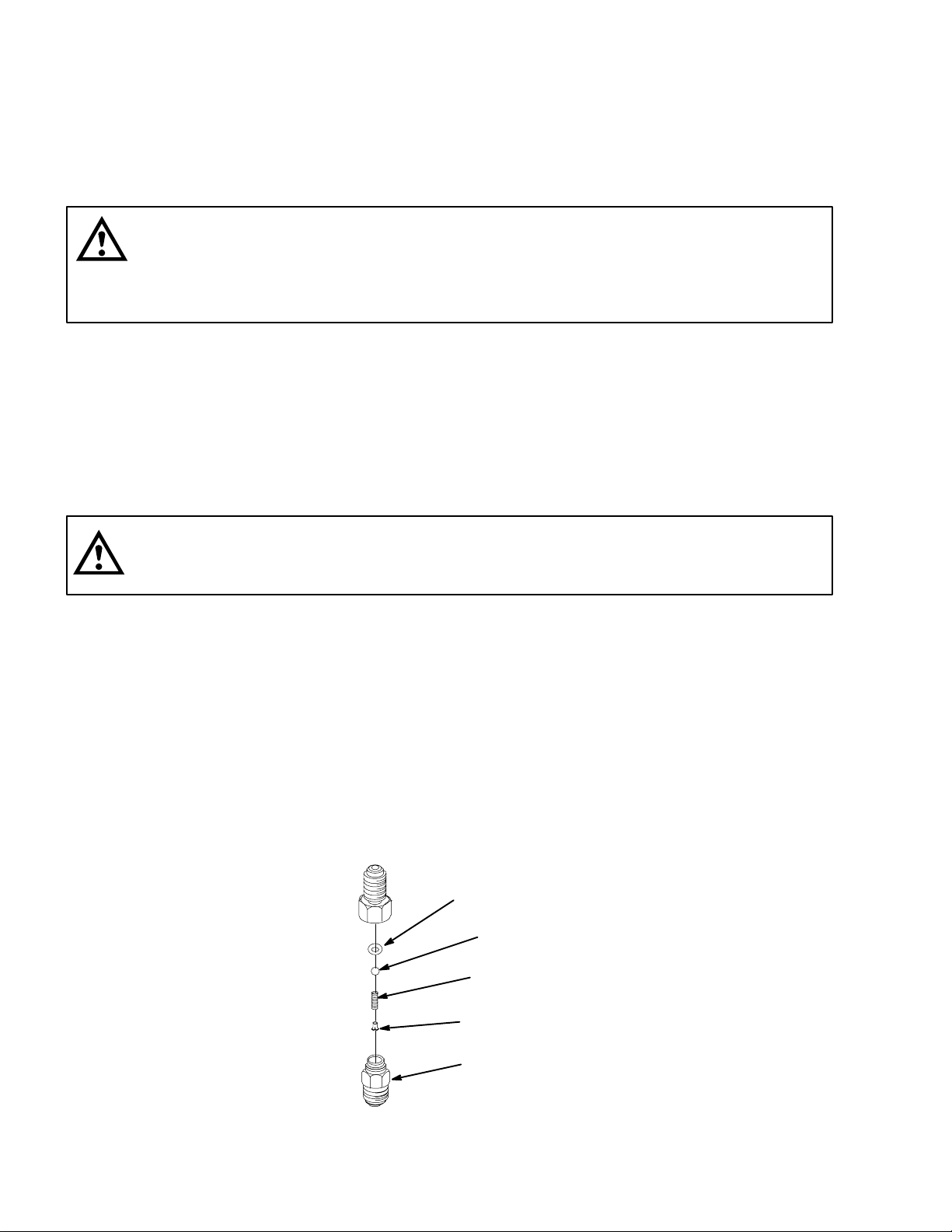

INSTALLING PRIMARY CO2 REGULATOR ASS’Y ON CO2 CYLINDER

(see applicable Figure 3 or 4)

WARNING: To avoid personal injury and/or property damage, always secure CO2 cylinder in

upright position with a safety chain to prevent it from falling over. Should the valve become

accidentally damaged or broken off, CO

WARNING: CO2 displaces oxygen. Strict attention must be observed in the prevention of

CO2 (carbon dioxide) gas leaks in the entire CO2 and soft drink system. If a CO2 gas leak is

suspected, particularly in a small area, immediately ventilate the contaminated area before

attempting to repair the leak. Personnel exposed to high concentration of CO2 gas will experience

tremors which are followed rapidly by loss of consciousness and suffocation.

1. Unscrew protector cap (with chain attached) from CO2 cylinder valve. Before installing primary CO2 regulator

on CO2 cylinder, open CO2 cylinder valve slightly counterclockwise to blow away any dirt or dust from regulator outlet fitting, then close valve.

2. Remove shipping plug from primary CO2 regulator assembly coupling nut and make sure gasket is in place

inside nut. Install regulator assembly on CO2 cylinder so gages can be easily read, then tighten coupling nut.

DO NOT OPEN CO2 CYLINDER VALVE AT THIS TIME.

cylinder can cause serious personal injury.

2

CONNECTING CO2 SOURCE LINE TO UNIT CO2 INLET LINE

(see applicable Figure 3 or 4)

1. Connect and route a CO2 source line from the primary CO2 regulator up to the Unit.

2. Connect the CO2 source line to the Unit CO2 inlet line and seal connection with TAPERED GASKET, WHITE

(item 1). DO NOT TURN ON THE CO2 SOURCE AT THIS TIME.

CONNECTING ELECTRICAL POWER CIRCUIT TO UNIT

(see applicable Figure 20 or 21)

WARNING: Make sure Unit 15-amp minimum-rated disconnect switch (not provided) or

equivalent HACR circuit breaker is in the ‘‘OFF’’ position.

1. Route 208–230 VAC, 60 Hz single-phase electrical power circuit (meeting requirements of SELECTING

LOCATION) through Unit base to electrical control box inside the Unit.

WARNING: The Unit must be electrically grounded to avoid possible fatal electrical shock

or serious injury to the operator. A screw, with lock washer, is provided inside the electrical

control box to connect the power circuit ground wire which will electrically ground

the Unit.

2. Overcounter (OC2R) Dispenser–Connect electrical power circuit to to electrical wires inside the electrical

control box as shown in wiring diagram (Figure 20), then install cover on the electrical control box. DO NOT

TURN ON ELECTRICAL POWER TO UNIT AT THIS TIME.

Four–Flavor Floor Model Dispenser–Connect electrical power circuit to electrical terminal block inside the

electrical box as shown in wiring diagram (Figure 21), then install cover on the electrical control box. DO

NOT TURN ON ELECTRICAL POWER TO UNIT AT THIS TIME.

569000119

14

Page 24

PREPARATION FOR OPERATION

TURNING ON ELECTRICAL POWER TO REMOTE REFRIGERATION ASSEMBLY(S) AND

FCB DISPENSER

1. Turn on electrical power to the Remote Refrigeration Assembly(s) at disconnect switch(s).

2. Turn on electrical power to the Unit. Operational status of the Unit is now being displayed as fault messages

on the control panel message display. The following fault messages will be continuously displayed at

2-second intervals until necessary operation requirements are satisfied.

‘‘OFF 1’’ (Beater Motor No. 1 not operating)

‘‘OFF 2’’ (Beater Motor No. 2 not operating)

‘‘H2O OUT’’ (No water supply to Unit)

‘‘CO2 OUT’’ (No CO2 gas supply to Unit)

‘‘SYRUP 1’’ (No syrup supply to Unit No. 1 syrup system)

‘‘SYRUP 2’’ (No syrup supply to Unit No. 2 syrup system)

TURNING ON CO2 SUPPLY TO THE UNIT

Unit Connected to a CO2 Cylinder..

Open CO2 cylinder valve slightly to allow the lines to slowly fill with gas, then open the valve fully to back seat the

valve. Back-seating the valve prevents leakage around the valve shaft. The “CO

OUT” fault message on the Unit

2

control panel message display should have gone out.

Unit Connected to a Bulk CO2 Supply.

Open the bulk CO2 supply shutoff valve slightly to allow the lines to slowly fill with gas, then open the valve fully.

to back seat the valve. Back-seating valve prevents leakage around valve shaft.The “CO

OUT” fault message on

2

the Unit control panel message display should have gone out.

ADJUSTING CO2 REGULATORS

(see applicable Figure 3 or 4)

Adjusting CO2 Source Primary CO2 Regulator.

Unit Connected to a Bag-In-Box Syrup Source System.

Adjust CO2 source (CO

cylinder or bulk CO

2

) primary CO

2

Unit Connected to a Syrup Tanks Syrup Source System.

Adjust CO2 source (CO

cylinder or bulk CO

2

) primary CO

2

regulator to read not less then 80 psi.

2

regulator to read 80 to 100 psi.

2

15

569000119

Page 25

Adjusting Unit Secondary CO2 Regulators.

Product Blender Tanks Secondary CO

Check and if necessary, adjust the Unit product blender tanks secondary CO

Regulators.

2

regulators with 60-psi gages at 25

2

to 30-psi for the best textured dispensed product.

IMPORTANT: The Carbonator secondary CO

regulator must be adjusted 25-psi higher or more above the

2

product blender tanks secondary CO2 regulators pressure settings. The carbonated water and syrup

pressures must be able to overcome and vent the product blender tanks head pressures while the tanks

are filling with carbonated water and syrup. The carbonator tank secondary CO2 regulator not adjusted

high enough will cause decreased flow of carbonated water into the blender tanks which will increase

BRIX of the dispensed product.

Carbonator Secondary CO2 Regulator.

Adjust the carbonated water tank secondary CO2 regulator with 100-psi gage to read 50 to 80-psi. Pull up on carbonator tank relief valve to purge air from the tank.

STARTING FCB AND ADJUSTING WATER-TO-SYRUP “RATIO” (BRIX) OF DISPENSED

PRODUCT

1. Open shutoff valve in city plain water line connected to the Unit. Check for water leaks and tighten or repair

leaks if evident. ‘‘H2O OUT’’ fault message should have gone out but ‘‘SYRUP 1’’, and ‘‘SYRUP 2’’ fault messages will continue to be displayed.

IMPORTANT: Product shutoff valves, located in lines leading from product blender tanks to freeze

cylinders (see applicable Figure 3 or 4), must be closed at this time. Closing valves prevents product

from filling freeze cylinders while checking BRIX of product in product blender tanks.

2. Close product shutoff valves, located in lines leading from the product blender tanks to the freeze cylinders,

to prevent product from entering the cylinders.

IMPORTANT: The following CO2 and liquid disconnects disconnecting and connecting procedure for the

soft drink tank replacement or filling the soft drink tank in place must be performed in the order as

follows:

To disconnect soft drink tank from Unit syrup system.

A. Disconnect liquid disconnect from the soft drink tank. NOTE - Disconnecting liquid quick

disconnect from the soft drink tank first prevents syrup from backflowing through the Unit syrup flow regulator which may alter the regulator adjustment.

B. Second, disconnect CO2 quick disconnect from the soft drink tank.

To connect soft drink tank into the Unit syrup system.

C. First, connect CO2 quick disconnect to the soft drink tank to pressurize the tank.

D. Second, connect liquid quick disconnect to the soft drink tank.

3. Pressurize the soft drink tanks containing syrup, then connect the tanks into the Unit syrup systems.“OFF 1”,

“OFF 2”, “SYRUP 1”, and “SYRUP 2” fault messages will continue to be displayed.

4. The following steps A through J are instructions for adjusting the Water-to-Syrup “Ratio” (Brix) of the dispensed product on on of the systems.

NOTE: The Unit control panel assembly is equipped with a hidden “SECURITY SWITCH” located

between the “FILL 1” and the “ERROR RESET” control switches (see Figure 5). Pressing in and holding

the “SECURITY SWITCH” for 3 seconds deactivates the control switches preventing tampering with the

Unit normal operation. To reactivate the control switches, press in and hold the “SECURITY SWITCH” for

3 seconds.

569000119

16

Page 26

NOTE: The adjustable carbonated water flow regulators (see applicable Figure 3 or 4 and 15 or 16), located in their respective systems, control carbonated water flow rate to the product blender tanks. The

water flow regulators are factory adjusted at 1.3 0.05 oz/sec and should not normally require adjustment. If adjustment is necessary, adjust as instructed in SERVICE AND MAINTENANCE section of this

manual.

A. Press ‘‘FILL 1’’ switch to fill No. 1 syrup system sold-out float. ‘‘SYRUP 1’’ fault message will go out and

‘‘FILL 1’’ fault message will come on. ‘‘OFF 1’’, ‘‘OFF 2’’, and ‘‘SYRUP 2’’ fault messages will continue to

be displayed.

B. Press ‘‘AUTO BLEND 1’’ switch to fill No. 1 system product blender tank with product. ‘‘FILL 1’’ fault

message will go out when ‘‘AUTO BLEND 1’’ switch is pressed. When product blender tank is full, press

‘‘FILL 1’’ switch to prevent more product from entering tank. ‘‘OFF 1’’, ‘‘OFF 2’’, and ‘‘SYRUP 2’’ fault

messages will continue to be displayed.

C. Open No. 1 product blender tank product sample valve (see applicable Figure 3 or 4) and take a sample

(approximately 6 ounces) of product in a cup or glass.

NOTE: Temperature compensated hand-type refractometers (P/N 511004000) are available from The

Cornelius Company.

D. Check product BRIX with a temperature compensated hand-type refractometer. BRIX should read

13 ± 1. If BRIX is not within tolerance, adjust white syrup flow regulator for No. 1 syrup system as follows:

E. Turn regulator adjusting screw to the left (counterclockwise) no more than 1/8-turn at a time to reduce

syrup flow rate or turn screw to the right (clockwise) no more than 1/8-turn to increase flow rate.

F. Place container under No. 1 product sample valve. Open valve to purge product out of product blender

tank, line, and valve, then close valve. ‘‘OFF 1’’, ‘‘OFF 2’’, and ‘‘SYRUP 2’’ will continue to be displayed.

G. Press ‘‘AUTO BLEND 1’’ switch to run new batch of product into product blender tank. When product

blender tank is full, press ‘‘FILL 1’’ switch to prevent more product from entering product blender tank.

‘‘OFF 1’’, ‘‘OFF 2’’, and ‘‘SYRUP 2’’ fault messages will continue to be displayed.

H. Repeat steps C and D preceding to check product sample for BRIX.

I. Repeat steps F through H preceding until proper BRIX adjustment is achieved.

J. Repeat steps A through I preceding to adjust BRIX of dispensed product on No. 2 system. After com-

pleting BRIX adjustment on No. 2 system, only the ‘‘OFF 1’’ and ‘‘OFF 2’’ fault messages should contin-

ue to be displayed.

NOTE: Syrup systems may be sanitized at this time as instructed.

FILLING FREEZE CYLINDERS WITH PRODUCT

1. Open product shutoff valves, located in lines leading from product blender tanks to freeze cylinders.

2. Press ‘‘AUTO BLEND 1’’ and ‘‘AUTO BLEND 2’’ switches to begin filling freeze cylinders. Open freeze cylinders faceplates relief valves to bleed air from cylinders while filling with product, then close valves. Do not

relieve freeze cylinder pressure too fast or product will foam excessively in cylinder and lose carbonation.

CHECKING UNIT FOR SYRUP, CO2, OR PLAIN WATER LEAKS

1. Inspect the entire Unit and the entire system for syrup, CO2,or plain water leaks and repair if evident.

2. Install the Unit back and side panels.

3. Install Unit front access panel (see Figure 9) and secure with THREAD CUTTING SCREWS (item 17) and

WHITE SPACERS (ITEM 15).

4. Close front access door, then use a flat blade screwdriver to turn lock clockwise to lock the door.

17

569000119

Page 27

PLACING UNIT IN OPERATING LOCATION

1. Disconnect electrical power from Unit at the electrical power source disconnect switch.

IMPORTANT: When installing Unit in it’s operating position, do not allow obstructions to block sides,

top, and front of the Unit which will block off cooling air intake to the inside of the Unit. Air flow through

the Unit must be present to provide adequate cooling. Refer to SELECTING LOCATION

and front clearances to be observed when placing Unit in operating position.

2. Referring to the preceding NOTE, very carefully, place the Unit in operating location.

3. Make sure the Unit is sitting level. The Unit may be leveled by using a carpenter’s level and adjusting the

four leveling legs installed on the Unit during installation.

4. Restore Unit to operation by connecting electrical power at the electrical power source disconnect switch.

for sides, top,

ADJUSTING BEATER MOTOR CURRENT (EITHER SIDE)

Adjusting beater motor current (either side) procedure is very important and must be performed as instructed. Be

sure you fully understand the instructions before performing the current adjustments or doing any preventative

maintenance current readings check.

IMPORTANT: Any current adjustments or preventative maintenance current readings check on the beater

motor current (either side) must be performed with both freeze cylinders fully defrosted. A partially

defrosted freeze cylinder will cause false current readings to be displayed on the message display.

Adjust beater motor current (either side) as follows:

1. Using a flat blade screwdriver, turn lock counterclockwise to unlock the front access door, then open the

door.

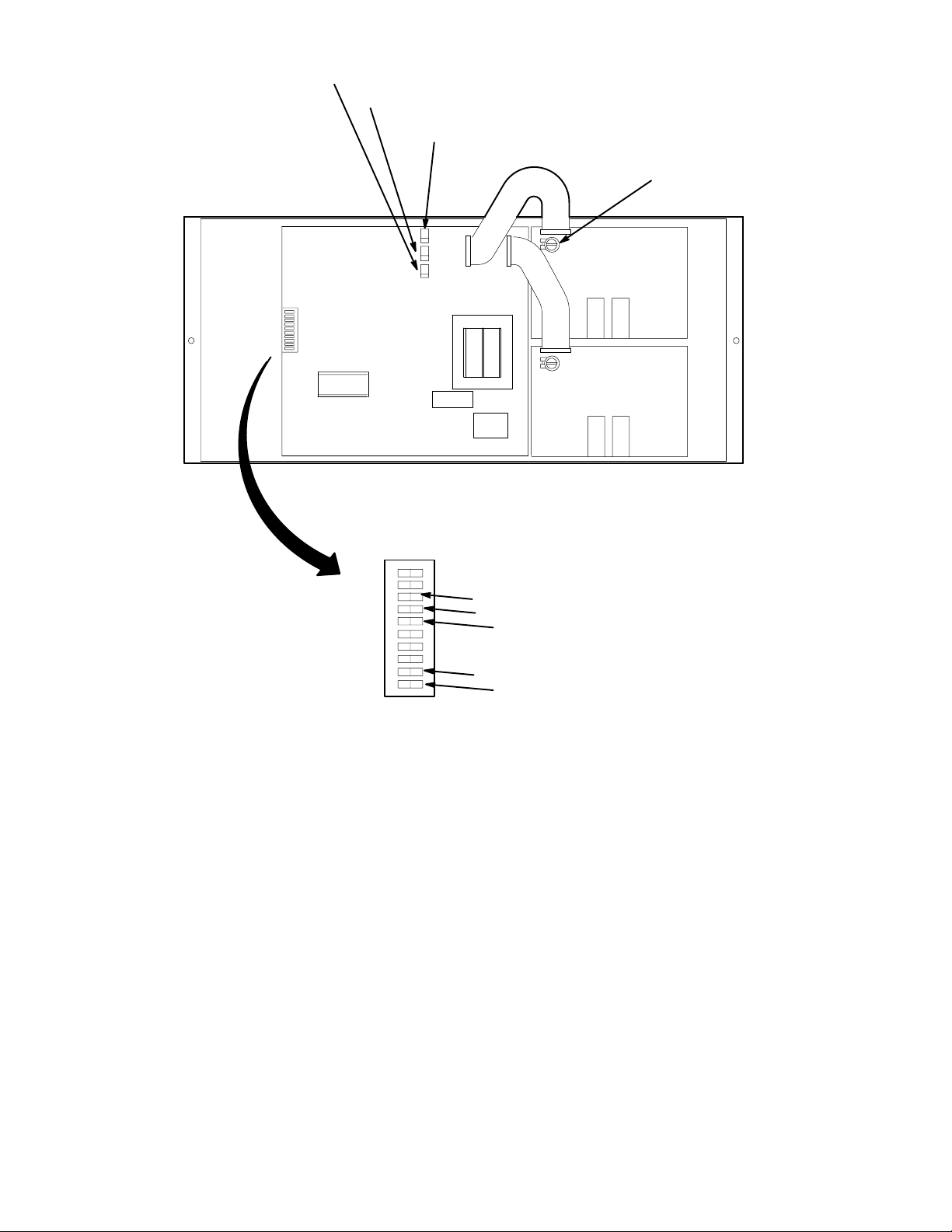

2. Remove four screws securing the upper electrical control box cover (control box located on back of the front

access door). Remove cover for access to the master circuit board (see Figure 6 ).

3. Place No. 4 ‘‘BEATER MOTOR CURRENT READOUT’’ switch on DIP SWITCH assembly on master circuit

board (see Figure 6) in ‘‘ON’’ position. Both freeze cylinders beater motors will start and operate and beaters

motors current ratings will be displayed on message display.

4. Display should be adjusted to read A150 B150 ± 2 by adjusting MOTOR CURRENT ADJUSTMENTS located on No. 1 and No. 2 relay circuit boards (see Figure 6). These figures will fluctuate slightly with variations in line voltage and motor loads.

5. After completion of adjusting beater motor current to A150 B150 ± 2, make sure No. 5 ‘‘MOTOR CURRENT

SELF-CALIBRATION’’ switch on DIP SWITCH assembly on master circuit board (see Figure 6) is in ‘‘OFF’’

position. No. 5 switch in ‘‘OFF’’ position allows the ‘‘MOTOR CURRENT’’ SELF-CALIBRATION’’ electronics

to automatically self-calibrate the beaters motors currents at completion of each defrost cycle.

CAUTION: IF NO. 4 ‘‘BEATER MOTOR CURRENT READOUT’’ SWITCH ON DIP SWITCH

assembly is placed in ‘‘ON’’ position and beater motor current readings were A155 B145

and switch was then placed back in ‘‘OFF’’ position without readjusting to A150 B150 ± 2,

beater motor current has just been reset at A155 B145. Operating the FCB Dispenser at these

current readings may have serious effects on its operation.

ANY TIME THE NO. 4 ‘‘BEATER MOTOR CURRENT READOUT’’ SWITCH ON DIP SWITCH ASSEMBLY IS

PLACED IN ‘‘ON’’ POSITION, THE BEATER MOTOR CURRENT READINGS MUST BE READJUSTED TO

A150 B150 ± 2 AS INSTRUCTED, THEN SWITCH MUST BE PLACED BACK IN THE ‘‘OFF’’ POSITION.

6. Close front access door, then use a flat blade screwdriver to turn lock clockwise to lock the door.

7. Install FRONT ACCESS PANEL (item 16) and SPACERS (item 15) and secure with THREAD CUTTING

SCREWS (item 17). MAKE SURE SPACERS ARE INSTALLED BETWEEN THE FRONT ACCESS PANEL

AND THE UNIT FRAME (see Figure 5).

569000119

18

Page 28

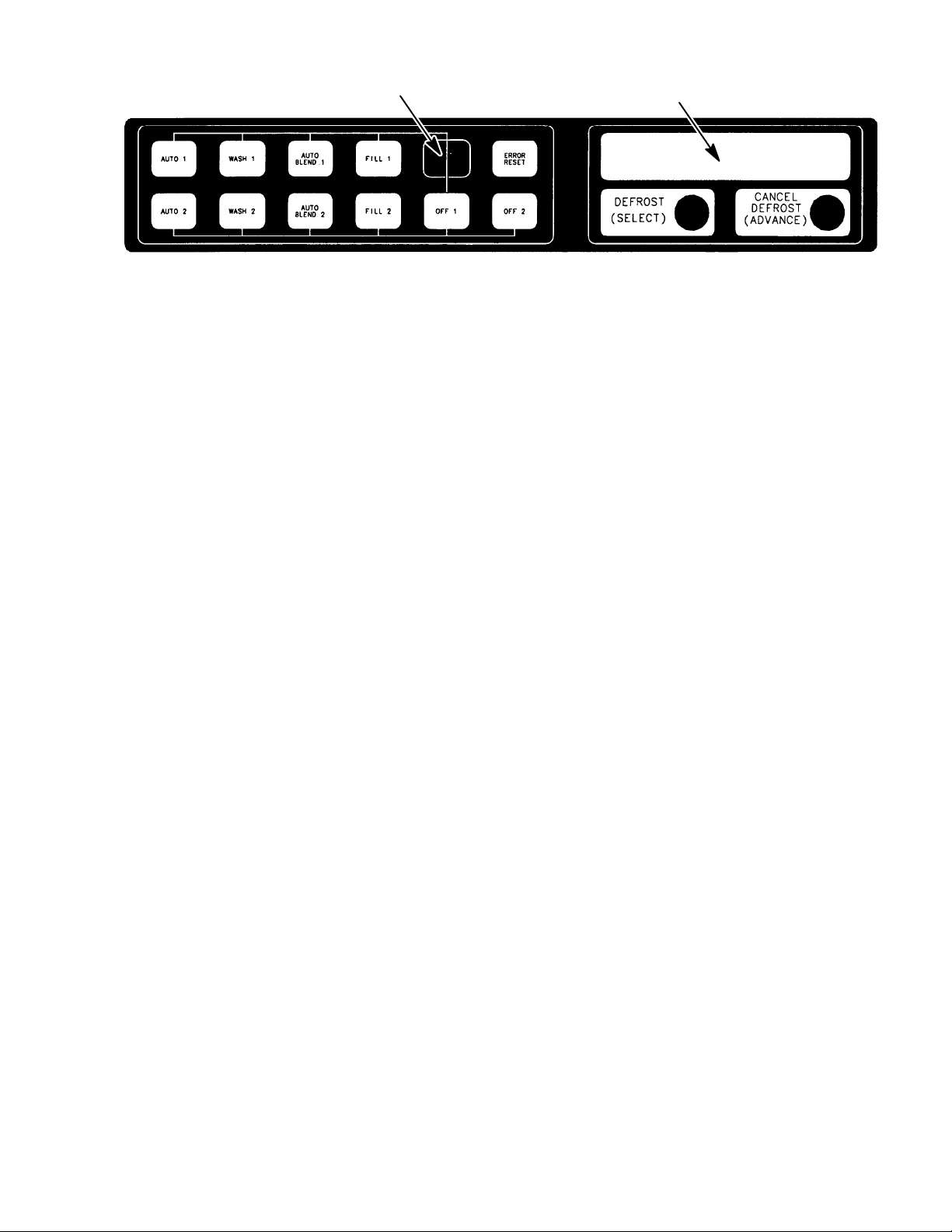

HIDDEN SECURITY

SWITCH

FIGURE 5. CONTROL PANEL

MESSAGE DISPLAY

ADJUSTMENT AND PROGRAMMING MAIN MENU SELECTIONS,

COMPONENTS “DIAGNOSE’’ (DIAGNOSTIC MODE), AND (‘‘TOTALS”

DISPLAYED CYCLES AND HOURS TOTALS) INTO UNIT

NOTE: The Unit control panel switches are as shown in Figure 5.

The following instructions outline adjustments and programming main menu selections, components ‘‘DIAGNOSE’’ (DIAGNOSTIC MODE), and ‘‘TOTALS” (DISPLAYED CYCLES AND HOURS TOTALS) into the Unit.

NOTE: Plain water, CO2 and syrup supplies to Unit must be satisfied to turn off ‘‘H2O OUT’’, ‘‘CO2 OUT’’,

‘‘SYRUP 1’’, and ‘‘SYRUP 2’’ fault messages on message display before adjustments and programming

procedures can be performed on the Unit.

PROGRAMMING MAIN MENU SELECTION ONTO MESSAGE DISPLAY

The MAIN MENU SELECTIONS (see Table 4) may be brought up on the message display as follows:

1. Press ‘‘AUTO 1’’, ‘‘WASH 1’’, and ‘‘BLEND 1’’ control switches (see Figure 5) at the same time and hold

them pressed for a minimum of 1/2 second to bring up MAIN MENU SELECTIONS on message display. The

word ‘‘CLOCK’’ will appear on display. You are now in the MAIN MENU SELECTIONS as shown in Table 4

To advance through the MENU SELECTIONS, repeatedly press the ‘‘CANCEL DEFROST’’ (ADVANCE)

switch. Once you reach the desired selection, press the ‘‘DEFROST’’ (SELECT) switch to lock in on the

selection.

NOTE: To exit MENU SELECTION and return to MAIN MENU SELECTIONS, press ‘‘ERROR RESET’’ (RESET) switch. Press ‘‘ERROR RESET (RESET) switch again to exit from MAIN MENU SELECTIONS.

SETTING CLOCK (TIME OF DAY)

NOTE: The CLOCK (TIME OF DAY) must be programmed into Unit before ‘‘DEFROST’’ (AUTOMATIC),

‘‘SLEEP’’ (SLEEP TIME), and ‘‘WAKE UP’’ (WAKE UP TIME) can be programmed into the Unit.

Program ‘‘CLOCK’’ (TIME OF DAY) into Unit as follows:

1. Refer to PROGRAMMING MAIN MENU SELECTIONS ONTO MESSAGE DISPLAY and bring up ‘‘CLOCK’’

on display. Press ‘‘DEFROST’’ (SELECT) switch to lock in on selection.

2. Press ‘‘CANCEL DEFROST’’ (ADVANCE) switch to bring up flashing hour number on display.

3. Press ‘‘CANCEL DEFROST’’ (ADVANCE) switch to advance hours on display to desired hour. Press

‘‘DEFROST’’ (SELECT) switch to lock in hour on display.

19

569000119

Page 29

4. After hour (time of day) has been locked in on message display, minute numbers will be flashing on display.

Press ‘‘CANCEL DEFROST’’ (ADVANCE) switch to advance minute numbers to desired minutes (time of

day). Press ‘‘DEFROST’’ (SELECT) switch to lock in minute (time of day) on display.

5. Press ‘‘ERROR RESET’’ switch two times to exit from MENU SELECTION.

PROGRAMMING ‘‘DEFROST’’ (AUTOMATIC) SETTINGS INTO UNIT

The automatic defrost system may be programmed into the Unit to occur up to nine different times during a day

with a minimum of two hours between defrost time settings. Program automatic defrost time settings into the Unit

as follows:

1. Refer to PROGRAMMING MAIN MENU SELECTIONS ON TO MESSAGE DISPLAY and bring up

‘‘DEFROST’’ on message display. Press ‘‘DEFROST’’ (SELECT) switch to lock in on selection.

2. Press ‘‘CANCEL DEFROST’’(ADVANCE) switch to bring up flashing hour number on display.

3. Press ‘‘CANCEL DEFROST’’(ADVANCE) switch to advance hours on display to desired hour. Press

‘‘DEFROST’’(SELECT) switch to lock in hour on display.

4. After hour (time of day) has been locked in on message display, minute numbers will be flashing on display.

Press ‘‘CANCEL DEFROST’’ (ADVANCE) switch to advance minute numbers to desired minutes (time of

day). Press ‘‘DEFROST’’ (SELECT) switch to lock in minute (time of day) on display.

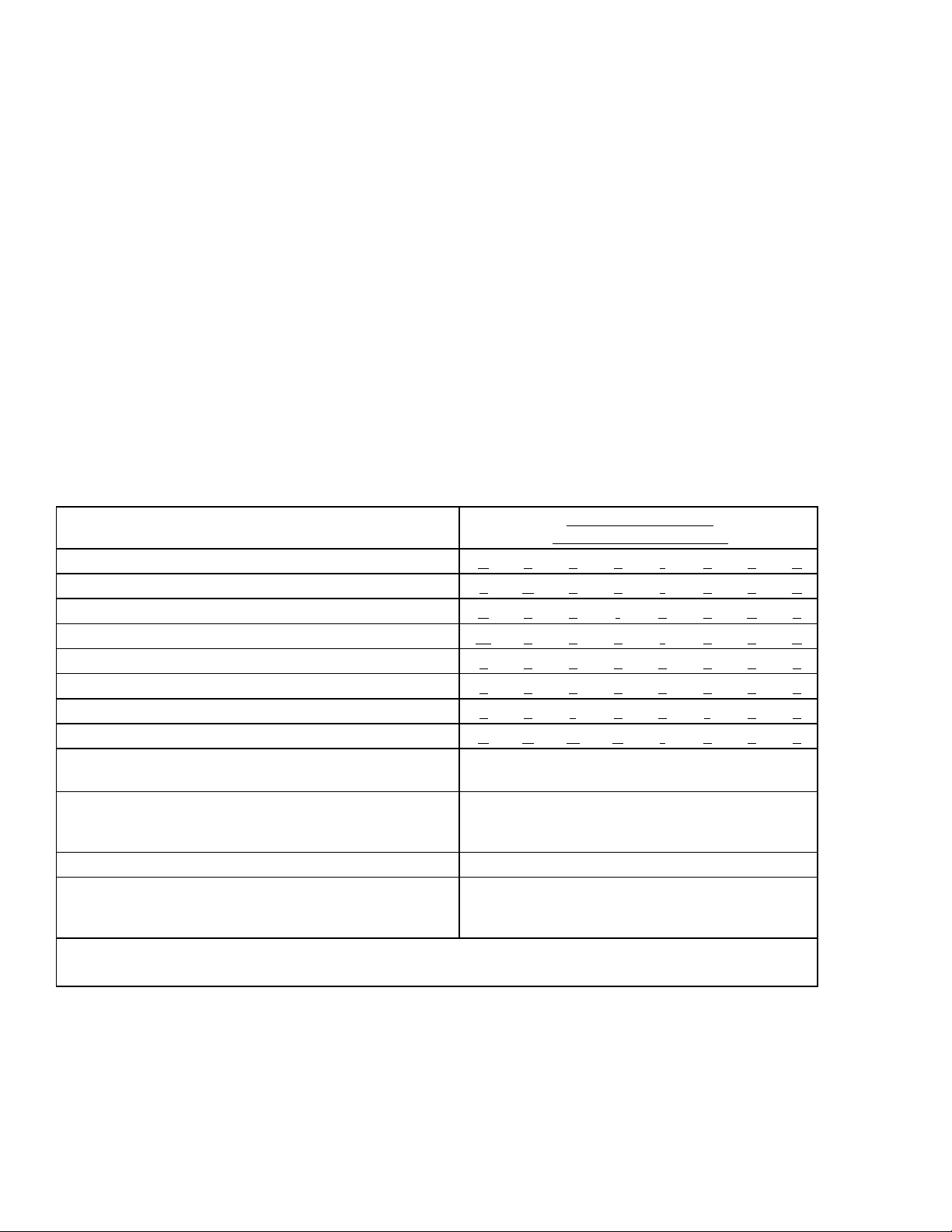

MENU SELECTIONS

“CLOCK” (TIME OF DAY) see note below C _ 1 2 - 0 0 A

“DEFROST” (AUTOMATIC) 3 D 1 0 - 0 0 A

“SLEEP” (SLEEP TIME) S 1 2 - 3 0 A _

“WAKE UP” (WAKE UP TIME) W _ 0 7 - 1 5 A

“VIS SET” (PRODUCT VISCOSITY SETTING) 1 2 _ _ _ _ 1 0

“VIS READ” (ACTUAL VISCOSITY READOUT) 1 6 _ _ _ _ 1 1

“SENSORS (TEMPERATURES READOUT) 7 5 * 7 5 * 7 5

“VOLTAGE” (DISPLAYED VOLTAGE READOUT) V R M S * 2 3 0

“DIAGNOSE” (DIAGNOSTIC MODE)

“TOTALS”

“MOTORS” (BEATER MOTOR MANUFACTURER) See Table 6

“REF TYPE” (REFRIGERANT TYPE)

NOTE: The “CLOCK” (TIME OF DAY) must be programmed into the Unit before “DEFROST” (AUTOMATIC) “SLEEP” (SLEEP TIME), and “WAKE UP” (WAKE UP TIME) will function.

See Programming Components Diagnose into

Unit.