Page 1

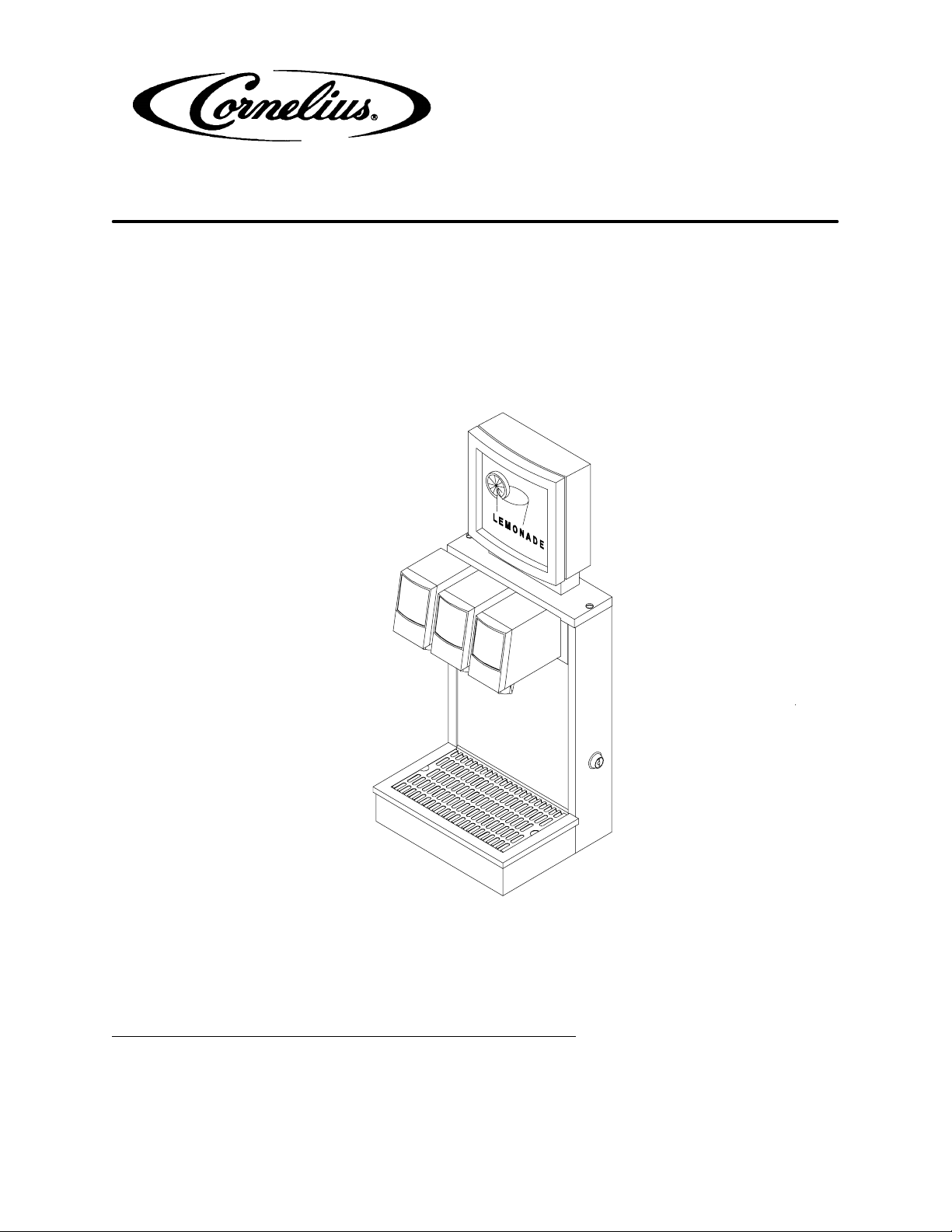

Liquid Base Beverage Dispenser

INSTALLATION & OPERATORS MANUAL

IMI CORNELIUS INC.

One Cornelius Place

Anoka, MN. 55303–6234

Telephone (800) 238–3600

Facsimile (612) 422–3232

Part No. 630460001

June 4 1996

Control Code A

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Installation Manual must be read and understood before starting to install or operate this equipment.

IMI CORNELIUS INC; 1996

Printed in U.S.A.

Page 2

TABLE OF CONTENTS

GENERAL DESCRIPTION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT DESCRIPTION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DESIGN DATA 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RECEIVING 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNPACKING AND INSPECTION 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOCATION SELECTION 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONCENTRATE SOURCE INSTALLATION 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COUNTERTOP HOLE LOCATION (TUBING ACCESS) 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAKING WATER, CONCENTRATE, AND ELECTRICAL CONNECTIONS 3. . . . . . . . . . . . . . . . . . . . . . . . .

COOLANT CONNECTION FOR HEAT EXCHANGER 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONNECT CONCENTRATE TUBING 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SEALING UNIT BASE TO COUNTERTOP (USA) 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREPARATION FOR OPERATION 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING WATER-TO-CONCENTRATE RATIO OF DISPENSED PRODUCT 7. . . . . . . . . . . . . . . . . . .

SETTING THE PORTION CONTROL 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SANITIZING THE SYSTEM (USA) 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SANITIZING THE BAG-IN-BOX CONCENTRATE SYSTEMS 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE 1. DESIGN DATA 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE 2. LOOSE-SHIPPED PARTS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 1. CONNECTION TO EXISTING SODA SYSTEM COOLANT 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IMI CORNELIUS INC. 1996

Page 3

GENERAL DESCRIPTION

UNIT DESCRIPTION

The Three-Flavor Tower is compact and may be island-mounted or installed on a front or rear counter. The

Three-Flavor Tower is designed to dispense three, portion controlled, noncarbonated drinks. One concentrate

flavor is chilled by a heat exchanger. Cooling for the heat exchanger is provided by the existing soft drink system.

DESIGN DATA

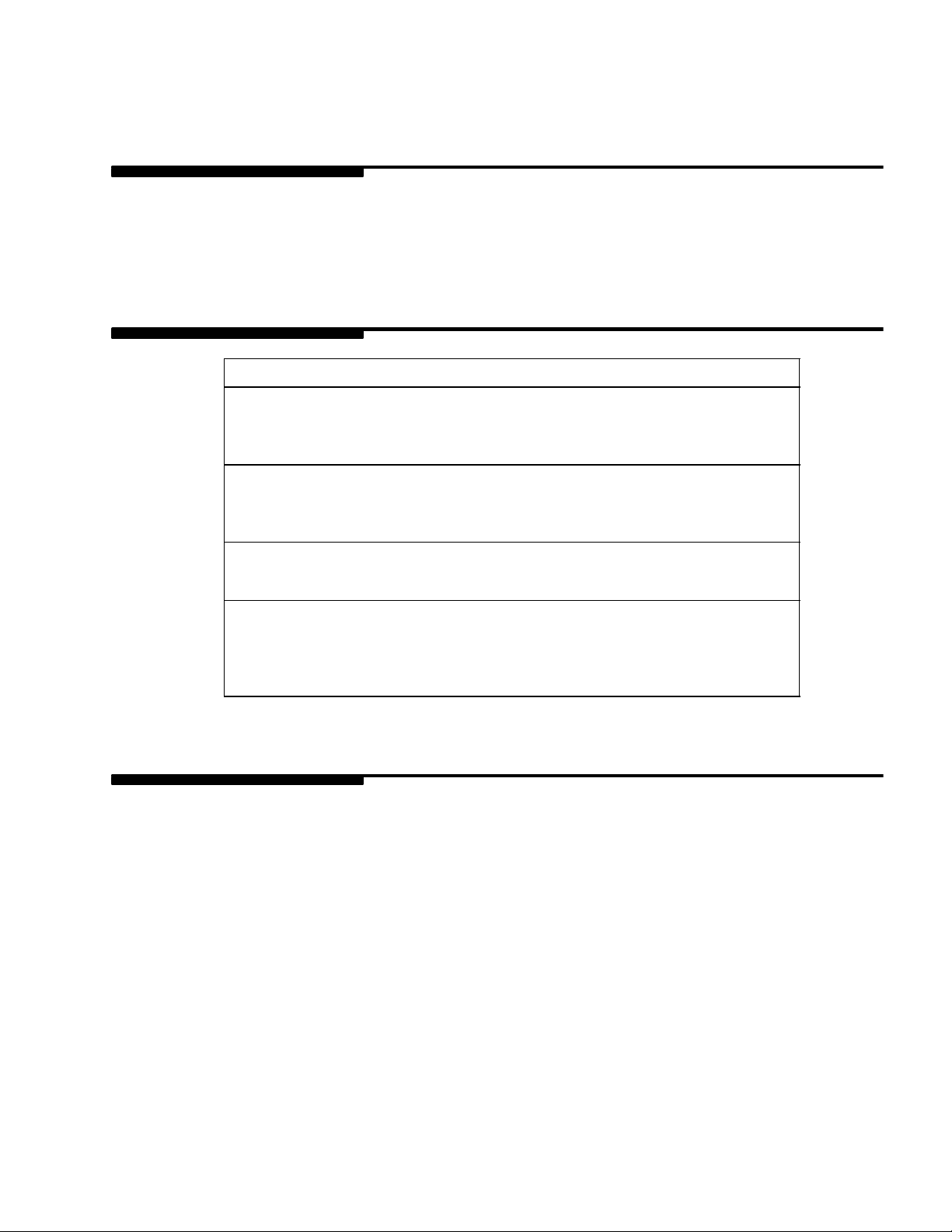

Table 1. Design Data

Overall Dimensions:

Width 10.75 in.

Height 26.25 in.

Depth 9.12 in.

Ambient Operating Temperature:

40 degrees F (4.4 degrees C) to

90 degrees F (32 degrees C)

Electrical Requirements:

115VAC, 60HZ

Inlet Water Requirements:

Minimum Flow Pressure 40 psig

Maximum Static Pressure 55 psig

RECEIVING

Each Unit is completely tested under operating conditions and thoroughly inspected before shipment. At time of

shipment, the carrier accepts the Unit and any claim for damage in transit must be made with the carrier. Upon

receiving Unit from the delivering carrier, carefully inspect the carton for visible indication of damage. Any damage or irregularities should be noted at this time (not later than 15 days from date of delivery) and immediately

reported to the delivering carrier. Request a written inspection from the carrier’s claims inspector to substantiate

claim. File claim with the delivering carrier not with IMI Cornelius Inc.

1

630460001

Page 4

UNPACKING AND INSPECTION

CAUTION: Unit must be lifted by the S/S tower to avoid damage. Do Not lift using valve

housings.

Unpack a Unit as follows:

1. Open carton.

2. Lift Unit from carton.

3. Retain installation manual, and loose shipped parts.

4. Carefully inspect Unit for evidence of damage. If evidence of damage is found, notify delivering carrier and

file a claim against the carrier.

5. Remove loose-shipped parts from carton. Check contents per Table below.

Table 2. Loose-Shipped Parts

90° Drain Elbow

Installation Template

Wire Harness

Power Supply, 115/24 VAC, 75 VA

Valve Decals

Flavor Decals

Installation Manual

LOCATION SELECTION

The Unit may be island-mounted or installed on a front or rear counter provided that the following requirements

are satisfied. A hole must be cut in the countertop to permit access for the water, concentrate, drain tube and

coolant tubing.

WARNING: All electrical wiring must conform to national and local electrical codes.

1. Locate Unit near a grounded electrical outlet having a dedicated circuit fused at jjsr15 amps (slow-blow) for

115VAC units. Alternate protection using an equivalent HACR (US) circuit breaker may be used. The electrical supply for the tower is furnished by a 115/24 transformer which is mounted near the tower.

2. Locate Unit close to a water inlet supply line with pressure and flow as given in the listing of Physical Characteristics and Requirements.

INSTALLATION

CONCENTRATE SOURCE INSTALLATION

IMPORTANT: This instruction does not include instructions for the installation of the concentrate

source system. This should be done to suit the location.

2

630460001

Page 5

COUNTERTOP HOLE LOCATION (TUBING ACCESS)

1. Using the template provided, layout the location of the access hole.

2. Cut the access hole in the counter. Be sure there are no sharp edges to damage the tubing.

3. Move the Unit into position over the hole and attach the tower to the counter.

4. Route all tubing (concentrate, water, coolant and drain) through the access in the countertop.

MAKING WATER, CONCENTRATE, AND ELECTRICAL CONNECTIONS

Make Water Connections as follows:

CAUTION: If water source exceeds 65 psig a water pressure regulator kit must be used to

ensure correct Unit operation. Refer to Installation Kits paragraph for part number.

CAUTION: Do not use a saw to cut tubing, use a tubing cutter or knife to avoid

contamination of tubing with particles of material.

CAUTION: Water pipe connections and fixtures directly connected to a potable water

supply shall be sized, installed and maintained according to federal, state, and local laws.

1. Check water pressure. If water pressure is greater than 65 psig, install a water pressure regulator. Regulate the water pressure to 50 psig.

2. Connect tubing marked “Water” to water source, but do not turn-on at this time. Additional tubing may

have to be added to the existing water tubing from the dispenser.

3. If additional tubing is used, flush the tubing thoroughly by running four gallons (15 liters) of water to a drain

or suitable container.

4. Connect to the tower water tubing.

5. Turn on the water supply and check for leaks.

COOLANT CONNECTION FOR HEAT EXCHANGER

Note: The inlet and outlet fittings on the Heat Exchanger are 1/2I. Use 1/2I tubing from the existing

python to the Heat Exchanger. The tubing connections must be leak checked and then insulated to

prevent condensation. Tubing, fittings, clamps and insulation to be supplied by the installer.

1. Select best location to tap into existing recirculating cold carbonated water tubing in the soft drink python.

2. The soft drink system must be shut down and all pressure relieved from the carbonator and associated

carbonated water tubing.

3. Python insulation must be opened to permit access to the tubing.

4. Find the recirculating cold carbonated water line from the cooling unit.

5. Cut the cold carbonated water line and remove approximately 3I of the tubing to permit the installation of

the elbows.

6. Connect tubing as shown in Figure 1.

3

630460001

Page 6

7. Check all connections for leaks before insulating the tubing.

Tubing must be insulated

to prevent condensation

Cold Carbonated Water

From Cooling Unit

Syrup

Tubing

Cold Carbonated Water

Return to Cooling Unit

To Heat

Exchanger Inlet

FIGURE 1. CONNECTION TO EXISTING SODA SYSTEM COOLANT

From Heat

Exchanger Outlet

Oetiker Clamps (8)

Python Insulation

CONNECT CONCENTRATE TUBING

Connect concentrate tubing to the Unit as follows:

1. Sanitize all concentrate systems after connecting concentrate tubing following instructions below. Refer to

sanitizing procedure in this manual.

IMPORTANT: All concentrate systems must be sanitized before unit is put into operation.

2. Route one concentrate tubing for each product up through the hole in the countertop.

3. Apply product decals from the kit to dispense switches to correspond to the product dispensed.

SEALING UNIT BASE TO COUNTERTOP (USA)

To comply with the requirements of the NSF International, (NSF), the base of a Unit must be sealed to the countertop and all access holes to the inside of the Unit must be closed off with a mastic material. To seal a Unit to

the countertop, proceed as follows:

1. The tower must be fastened to the countertop using sheet metal screw or machine screws,whichever is

desired. Before sealing the tower, locate and drill holes for screwing the tower to the countertop.

4

630460001

Page 7

2. Carefully tilt the connected Unit up to expose the base.

3. Apply a silastic sealant e.g. Dow Corning RTV 731 or equivalent on all base edges.

4. Lower Unit into exact operating position on the countertop.

5. Fasten the tower to the countertop.

6. Apply additional sealant around the Unit so that the sealant has a minimum radius of 1/2 inch.

7. Seal the lines and plug the remaining opening with mastic material such as Permagum, or equivalent.

NOTE: When Unit is lowered into place, do not move it, or seal will be broken.

NOTE: All connections should be made before the Unit is sealed to the countertop.

5

630460001

Page 8

STRAINER

POTABLE WATER

SOURCE

PRIMARY REGULATOR

70-80 PSI

MULTI-FLAVOR TOWER

B-I-B INSTALLATION

WATER PRESSURE

REGULATOR

COOLANT FROM

EXISTING SOFT

DRINK SYSTEM

CO2 CYLINDER

CHECK VALVE

BAG-IN-BOX (3)

CONCENTRATE

PUMP (3)

CO2 MANIFOLD

LINE LEGEND

CO

2

PLAIN WATER

CONCENTRATE

6

630460001

Page 9

Connect concentrate tubing to concentrate Sources

Connect concentrate tubing to concentrate sources for bag-in-box (or tank).

Make Electrical Connections

Mount the transformer beneath the tower and route the 24V lead up into the tower and connect to the plugs in

the tower for the valves and merchandiser.

PREPARATION FOR OPERATION

All Units as shipped will dispense only non-carbonated drinks.

Purging the Concentrate Systems

1. Place a cup or other container under the nozzle.

2. Operate each valve in turn by pressing the Cancel/Pour button and observe concentrate flow. Purging is

completed when all air is removed from the system. If concentrate continues to show air bubbles, check

tightness of tubing connections.

Purging the Water System

1. Place a cup or other container under the nozzle.

2. Operate each valve in turn by pressing the Cancel/Pour button and observe water flow. Purging is completed when all air is removed from the system.

ADJUSTING WATER-TO-CONCENTRATE RATIO OF DISPENSED PRODUCT

Note: The water flow rate must be set before any attempt is made to set the water-to-concentrate ratio.

Concentrate must be disconnected while setting the water flow rate. Water should be dispensed by pressing the

Cancel/Pour switch on the control panel.

1. Using a graduated cup and a stop watch or second hand on your watch, set the flow rate to 2.5 ounces per

second. This is equal to 10 ounces in 4 seconds

Note: After the water flow rate is set, DO NOT adjust the water flow rate unless the flow rate is wrong.

DO NOT adjust the water flow rate to set the water-to-concentrate ratio. Anytime the water flow rate is

changed the water-to-concentrate ratio must be checked and adjusted as necessary.

The water-to-concentrate ratio is measured by use of a ratio cup having two chambers into which the water and

concentrate are dispensed. The ratio, if incorrect, is adjusted by turning the related concentrate flow regulator

adjusting screw located on each concentrate valve.

1. Dole Dispensing Valve

A. Remove dispensing valve cover (pull from bottom edge).

B. Remove nozzle from the dispensing valve by turning and pulling down.

C. Place the syrup/water separator on the dispensing valve by pushing up and turning to tighten.

D. Press valve cover CANCEL/POUR switch (see Figure 1) momentarily to fill separator with syrup.

E. Place the brix cup under the separator, the large section of the cup under the large round body of the

separator and the small section of the cup under the extended arm, which is the syrup tube.

F. Press valve cover CANCEL/POUR switch and fill the brix cup to approximately 3/4 of the cup capacity.

7

630460001

Page 10

LED Indicator

Light

Cancel/Pour

Switch

Figure 1

Note: Check local specifications for dispensed product water to syrup ratio specifications.

G. If the ratios are correct, proceed to Step I. If the ratios are not correct, proceed to step H.

H. Turn valve syrup flow control labeled “S4” (right-side control) adjusting screw to the left (COUNTER-

CLOCKWISE) for less syrup or to the right (CLOCKWISE) for more syrup.

I. Remove the syrup/water separator by turning and pulling down.

J. Reinstall the nozzle by pushing up and turning until it is locked.

K. Repeat Steps E through J until the ratios are correct on all dispensing valves. Syrup calibration check

is complete.

L. Install dispensing valve front cover.

2. Adjust the ratios for the remaining valves following the same procedure.

3. Replace the valve covers.

SETTING THE PORTION CONTROL

Note: In case of electrical power failure, the portion control has full memory function.

1. Press and hold “S” (small) and “XL” (extra-large) dispense switches at the same time on the front cover

until for 3 seconds, after that time the portion control ”set mode” has been activated. The “set mode” will be

confirmed by a flashing red LED.

2. Fill the cup to be used for small drinks with desired amount of ice, then place the cup under the dispensing

valve nozzle.

3. Press and hold switch labeled “S” (small) on dispensing valve cover until cup is filled to the desired level,

then release the switch.

4. Repeat Steps 2 and 3 to program the “M” (medium), “L” (large), and “XL” (extra-large) dispense switches.

5. After adjusting all dispensed drink volumes, press and release CANCEL/POUR switch to cancel portion

control “set mode” and return to normal operation.

Dispensing of a portion control drink may be stopped by pressing the CANCEL/POUR switch. Drinks may be

manually dispensed (non-portion control) by pressing the CANCEL/POUR switch.

8

630460001

Page 11

SANITIZING THE SYSTEM (USA)

IMPORTANT: Only trained personnel should perform sanitizing procedures.

WARNING: Wear protective eyewear to avoid eye injury.

The syrup systems must be sanitized once every six months; whenever there is a flavor change, or an off flavor

is noted in the product. This is the ‘‘ambient’’ sanitizing procedure whereby syrup is first flushed from the system

with water, then a detergent is introduced, followed by a second water flush. A sanitizer is next placed in the

system and it is finally purged with concentrate.

SANITIZING THE BAG-IN-BOX CONCENTRATE SYSTEMS

This is a procedure for sanitizing concentrate systems of the Liquid Base Beverage Dispenser.

SANITIZE THE BAG-IN-BOX SYSTEM AS FOLLOWS:

1. Disconnect the concentrate tube-end connectors from the bag-in-box containers.

2. Wash each tube-end fitting in warm water to remove any concentrate accumulation.

3. Install a bag valve (this can be cut from an empty bag-in-box container) on each concentrate tube-end connector. This opens the tube-end fitting so detergent, sanitizing solution and flush water can be pumped into

the system.

4. Fill a clean plastic 5-gallon container with potable (drinking) water.

5. Place the tube-end connectors (with installed bag valves) into the water.

6. Place a waste container under the valve dispensing nozzle.

7. Operate each concentrate valve by pressing the Canel/Pour button to cause concentrate to flow from the

nozzle.

8. Operate each valve until only water is dispensed.

9. Remove the concentrate tube-end connectors from the water.

10. Fill the 5-gallon container with potable (drinking) water at room temperature (70 degrees to 100 degrees F)

and add 3/4 ounce per gallon of water (6 ml per liter) of Diversey DIVOFLOW 185, or equivalent detergent.

Detergent must contain sodium hydroxide, be non-perfumed, and have low-sudsing characteristics. The

detergent should be able to be rinsed off easily. The sodium hydroxide should be between 2 percent and

10 percent in the concentrated detergent.

11. Mix the contents of the container thoroughly.

12. Place the concentrate tube-end connectors (with bag valves installed) into the detergent.

13. Operate each valve until the water is displaced by the detergent.

CAUTION: To avoid damage to metallic parts of the system, do not allow the detergent

solution to remain in a concentrate system longer than 15 minutes.

14. Allow the detergent to remain in the concentrate tubing for at least 10 minutes, but no longer

than 15 minutes.

9

630460001

Page 12

15. Remove the tube-end connectors from the detergent.

16. Dispose of unused detergent in a sanitary sewer, not in a storm drain. Wash the container thoroughly.

17. Fill the 5-gallon container with potable (drinking) water. Place the tube-end connectors in the water.

18. Hold each dispensing valve open until the detergent is displaced by the water.

WARNING: Phenolphthalein must be kept away from children. It is a powerful laxative and

may cause serious illness if taken internally.

19. Dispense a one-ounce sample of water from the nozzle. Test the sample using a drop of phenolphthalein

indicator. (This indicator becomes pink-colored in the presence of even small amounts of detergent) When

the indicator remains clear, all detergent has been removed.

20. Remove the tube-end connectors from the water.

21. Fill the 5-gallon container with 4 gallons (15.1 liters) of water at a temperature between 70 degrees F. to a

maximum of 100 degrees F.

22. Add 1.0 oz. (29.57 ml) of H.B. Fuller Monarch C–S or equivalent sanitizer [to provide a 200 ppm

(200 mg/liter) active quaternary sanitizing solution] to the container. Mix thoroughly.

23. Place the concentrate tube-end connectors in the sanitizing solution.

24. Operate each valve until only the sanitizing solution is dispensed.

CAUTION: To avoid damage to metallic parts of the system, do not allow the sanitizing

solution to remain in the concentrate systems longer than 15 minutes.

25. Allow the sanitizing solution to remain in the concentrate systems from 8 to 10 minutes.

26. Remove concentrate tube-end connectors from the sanitizing solution and remove the bag valves from the

tube-end connectors. (Save the bag valves).

27. Connect each concentrate tube-end connector to the preselected concentrate source.

28. Operate each valve until the concentrate purges the sanitizer from the tubes, and only concentrate is dispensed.

29. Dispense and taste each product for off-taste.

30. Dispose of the waste sanitizing solution in the sanitary sewer, (not in storm drain). Rinse both containers.

10

630460001

Page 13

WARRANTY

IMI Cornelius Inc. warrants that all equipment and parts are free from defects in material and workmanship under normal use and service. For a copy of the warranty applicable to your Cornelius, Remcor or Wilshire product, in your country, please write, fax or telephone the IMI Cornelius office nearest you. Please provide the

equipment model number, serial number and the date of purchase.

IMI Cornelius Offices

AUSTRALIA D P.O. 210, D RIVERWOOD, D NSW 2210, AUSTRALIA D (61) 2 533 3122 D FAX (61) 2 534 2166

D AM LANGEN FELDE 32 D A-1222 D VIENNA, AUSTRIA D (43) 1 233 520 D FAX (43) 1-2335-2930

AUSTRIA

D BOSKAPELLEI 122 D B-2930 BRAASCHAAT, BELGIUM D (32) 3 664 0552 D FAX (32) 3 665 2307

BELGIUM

D RUA ITAOCARA 97 D TOMAS COELHO D RIO DE JANEIRO, BRAZIL D (55) 21 591 7150 D FAX (55) 21 593 1829

BRAZIL

ENGLAND

D TYTHING ROAD ALCESTER D WARWICKSHIRE, B49 6 EU, ENGLAND D (44) 789 763 101 D FAX (44) 789 763 644

D 71 ROUTE DE ST. DENIS D F-95170 DEUIL LA BARRE D PARIS, FRANCE D (33) 1 34 28 6200 D FAX (33) 1 34 28 6201

FRANCE

GERMANY

GREECE

HONG

ITALY

NEW

SINGAPORE

SPAIN

USA

D CARL LEVERKUS STRASSE 15 D D-4018 LANGENFELD, GERMANY D (49) 2173 7930 D FAX (49) 2173 77 438

D 488 MESSOGION AVENUE D AGIA PARASKEVI D 153 42 D ATHE NS, GREECE D (30) 1 600 1073 D FAX (30) 1 601 2491

KONG D 1104 TAIKOTSUI CENTRE D 11-15 KOK CHEUNG ST D TAIKOKTSUE, HONG KONG D (852) 789 9882 D FAX (852) 391 6222

D VIA PELLIZZARI 11 D 1-20059 D VIMARCATE, ITALY D (39) 39 608 0817 D FAX (39) 39 608 0814

ZEALAND D 20 LANSFORD CRES. D P.O. BOX 19-044 AVONDALE D AUCKLAND 7, NEW ZEALAND D (64) 9 8200 357 D FAX (64) 9 8200 361

D 16 TUAS STREET D SINGAPORE 2263 D (65) 862 5542 D FAX (65) 862 5604

D POLIGONO INDUSTRAIL D RIERA DEL FONOLLAR D E-08830 SANT BOI DE LLOBREGAT D BARCELONA, SPAIN D (34) 3 640 2839 D FAX (34) 3 654 3379

D ONE CORNELIUS PLACE D ANOKA, MINNESOTA D (612) 421-6120 D FAX (612) 422-3255

LD004

4/21/98

11

630460001

Page 14

Loading...

Loading...