Page 1

IMI CORNELIUS INC One Cornelius Place Anoka, MN 55303-6234

Telephone (800) 238-3600 Facsimile (612) 422-3246

Installation Manual

Glacier

Post-Mix Dispenser

IMPORTANT:

TO THE INSTALLER.

It is the responsibility of

the Installer to ensure that

the water supply to the

dispensing equipment is

provided with protection

against backflow by an air

gap as defined in

ANSI/ASME A112.

1.2-1979; or an approved

vacuum breaker or other

such method as proved

effective by test.

Water pipe connections

and fixtures directly

connected to a potable

water supply shall be

sized, installed, and

maintained according to

Federal, State, and Local

codes.

Part No. 560003094

March 10, 1998

Control Code A

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Manual must be read and understood before installing or operating this equipment

IMI CORNELIUS INC; 1998

PRINTED IN U.S.A

Page 2

TABLE OF CONTENTS

GENERAL INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SAFETY INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RECOGNIZE SAFETY INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNDERSTAND SIGNAL WORDS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FOLLOW SAFETY INSTRUCTIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLAIMS INSTRUCTIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY REFERENCE INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT DESCRIPTION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

THEORY OF OPERATION 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNITS WITH INTEGRAL (BUILT-IN) CARBONATORS 4. . . . . . . . . . . . . . . . .

UNITS WITH INTEGRAL (BUILT-IN) CARBONATORS AND SYRUP

PUMPS 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNITS WITH 3–2–1 COIL CONFIGURATIONS (REQUIRING CONNECTION TO

REMOTE CARBONATORS) 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATING CONTROLS 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOOSE-SHIPPED PARTS 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IDENTIFICATION OF LOOSED-SHIPPED PARTS 13. . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SELECTING LOCATION 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SEALING UNIT TO COUNTERTOP 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SELECTING SLEEP MODE OPTIONS (UNITS WITH INTEGRAL

CARBONATORS) 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FILL WATER TANK AND START REFRIGERATION SYSTEM 16. . . . . . . . . . .

CONNECTING SYRUP TUBING TO UNIT 17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONNECTING CO2 AND PLAIN WATER SOURCES 18. . . . . . . . . . . . . . . . . .

CONNECTING CARBONATED AND PLAIN WATER SOURCES TO 3–2–1

COIL CONFIGURATION REMOTE CARBONATOR UNIT 19. . . . . . . . . . . . . . .

CONNECTING DRIP TRAY DRAIN HOSE 19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREPARATION FOR OPERATION 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

OPENING THE CO2 CYLINDER SHUTOFF VALVE AND LEAK CHECKING 21. .

ACTIVATING THE CARBONATOR 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT WITH INTEGRAL (BUILT-IN) CARBONATOR AND WITHOUT

BUILT-IN SYRUP PUMPS. 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT WITH INTEGRAL (BUILT-IN) CARBONATOR AND WITH BUILT-IN

SYRUP PUMPS. 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT REQUIRING CONNECTION TO A REMOTE CARBONATOR. 22. . . . .

ADJUSTING SUGAR SYRUP TANKS CO2 REGULATOR 23. . . . . . . . . . . . . . . . . . .

ADJUSTING DIET SYRUP TANK CO2 REGULATOR 23. . . . . . . . . . . . . . . . . .

ADJUSTING SYRUP PUMPS CO2 REGULATOR (UNITS WITH INTEGRAL

BUILT-IN CARBONATOR AND BUILT-IN SYRUP PUMPS) 23. . . . . . . . . . . . . .

MEASURING AND ADJUSTING DISPENSING VALVE CARBONATED

WATER

FLOW RATE 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING DISPENSING VALVE WATER-TO-SYRUP “RATIO” OF

DISPENSED PRODUCT 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i 560003094

Page 3

TABLE OF CONTENTS (cont’d)

TROUBLESHOOTING 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTMENT OF DISPENSING VALVE SYRUP FLOW REGULATOR DOES

NOT INCREASE TO DESIRED WATER -TO-SYRUP “RATIO”.27. . . . . . . . . . . . . .

ADJUSTMENT OF DISPENSING VALVE SYRUP FLOW REGULATOR DOES

NOT DECREASE TO DESIRED WATER -TO-SYRUP “RATIO. 27. . . . . . . . . . . . . .

DISPENSED PRODUCT CARBONATION TOO LOW. 27. . . . . . . . . . . . . . . . . . . . . .

DISPENSED PRODUCT COMES OUT OF DISPENSING VALVE CLEAR BUT

FOAMS IN CUP OR GLASS. 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPENSED PRODUCT PRODUCES FOAM AS IT LEAVES DISPENSING

VALVE. 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NO PRODUCT DISPENSED. 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ONLY CARBONATED WATER DISPENSED. 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ONLY SYRUP DISPENSED. 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPENSED PRODUCT CARBONATION TOO LOW. 29. . . . . . . . . . . . . . . . . . . . . .

NO PRODUCT DISPENSED FROM ALL DISPENSING VALVES. 29. . . . . . . . . . . .

CARBONATOR NOT OPERATING. 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CARBONATOR NOT OPERATING. 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REFRIGERATION COMPRESSOR DOES NOT OPERATE. 30. . . . . . . . . . . . . . . . .

COMPRESSOR WILL NOT STOP AFTER SUFFICIENT ICE BANK IS

PRODUCED. 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMPRESSOR OPERATES CONTINUOUSLY BUT DOES NOT FORM

SUFFICIENT ICE BANK. 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AGITATOR MOTOR NOT OPERATING. 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

LIST OF FIGURES

FIGURE 1. OPTIONAL CONFIGURATIONS 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 2. PARTS IDENTIFICATION (SIX-FLAVOR UNIT SHOWN) 6. . . . . . . . .

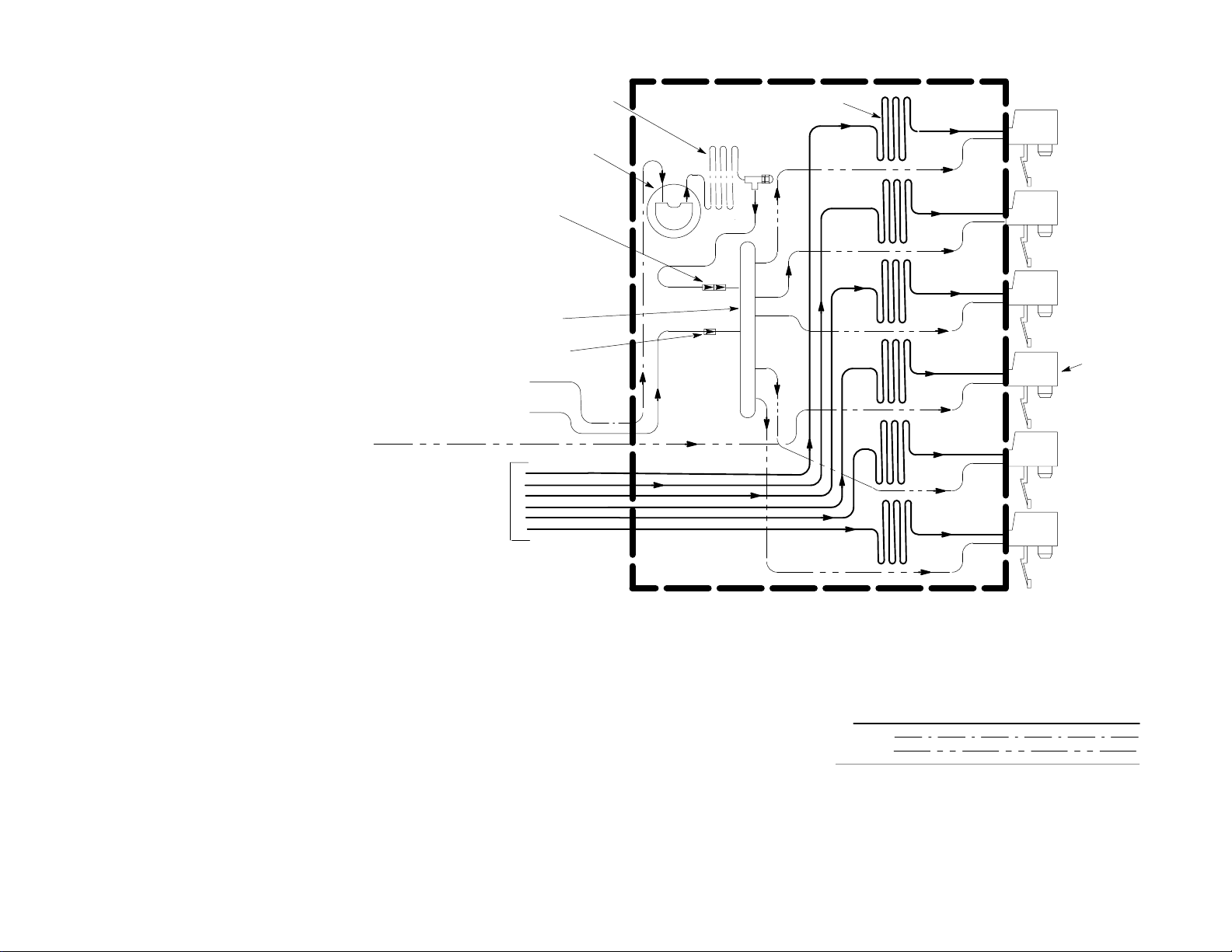

FIGURE 3. FLOW DIAGRAM (SIX-FLAVOR UNIT [P/N 475136102] WITH

INTEGRAL (BUILT-IN) CARBONATOR SHOWN) 7. . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 4. FLOW DIAGRAM (SIX-FLAVOR UNIT WITH INTEGRAL (BUILT-IN)

CARBONATOR SHOWN) 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 5. FLOW DIAGRAM (SIX-FLAVOR UNIT WITH INTEGRAL CARBONATOR

AND BUILT-IN SYRUP PUMPS) 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

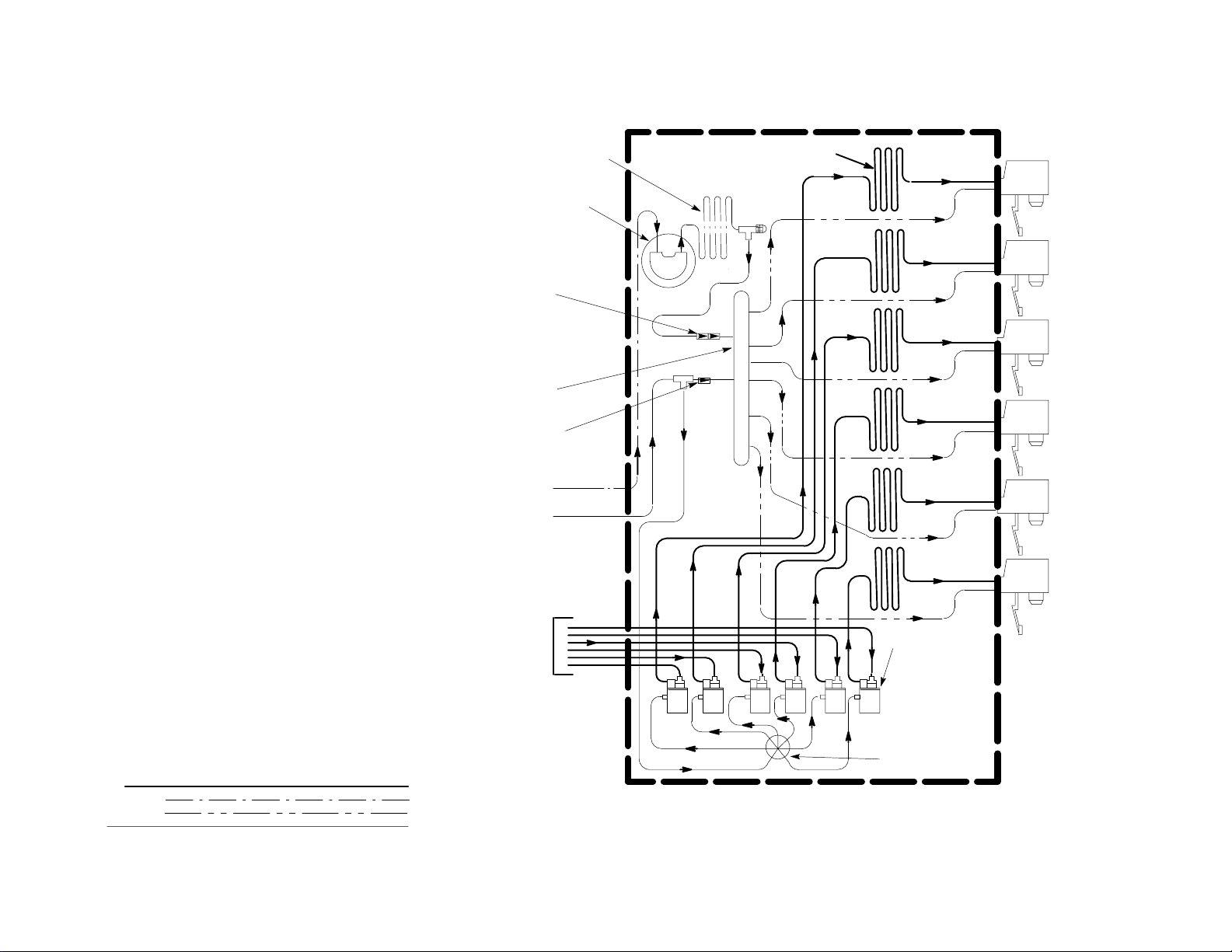

FIGURE 6. FLOW DIAGRAM (SIX-FLAVOR UNIT WITH 3–2–1 COIL

CONFIGURATION REQUIRING CONNECTION TO REMOTE CARBONATOR) 10

FIGURE 7. WIRING DIAGRAM 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 8. CONTROL BOARD DIAGNOSTIC DECAL 12. . . . . . . . . . . . . . . . . . . . .

LIST OF TABLES

TABLE 1. DESIGN DATA 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE 2. LOOSE-SHIPPED PARTS 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

560003094

ii

Page 4

GENERAL INFORMATION

SAFETY INFORMATION

RECOGNIZE SAFETY INFORMATION

This is the safety-alert symbol. When you see this

symbol on our machine or in this manual be alert to

the potentional for personal injury.

Follow recommended precautions and safe operating

practices.

UNDERSTAND SIGNAL WORDS

A signal word - DANGER, WARNING, OR CAUTION

is used with the safety-alert symbol. DANGER identi-

fies the most serious hazards.

Safety signs with signal word DANGER or WARNING

are typically near specific hazards.

DANGER

WARNING

General precautions are listed on CAUTION safety

signs. CAUTION also calls attention to safety messages in this manual.

CAUTION

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual and on your unit. Keep safety signs in good condition. Replace missing or damaged safety signs.

Keep the equipment in proper working condition. Unauthorized modifications to the equipment may impair the

function and/or safety and affect equipment life.

CLAIMS INSTRUCTIONS

Claims: In the event of shortage, notify the car-

rier as well as IMI Cornelius Inc. immediately. In

the event of damage, notify the carrier. IMI Cor-

nelius Inc. is not responsible for damage

occurring in transit, but will gladly render

assistance necessary to pursue your claim.

Merchandise must be inspected for concealed damage within 15 days of receipt.

Warranty Reference Information

(to be filled out by customer)

Unit Part Number:

Serial Number:

Install Date:

Local Authorized

Service Center:

1 560003094

Page 5

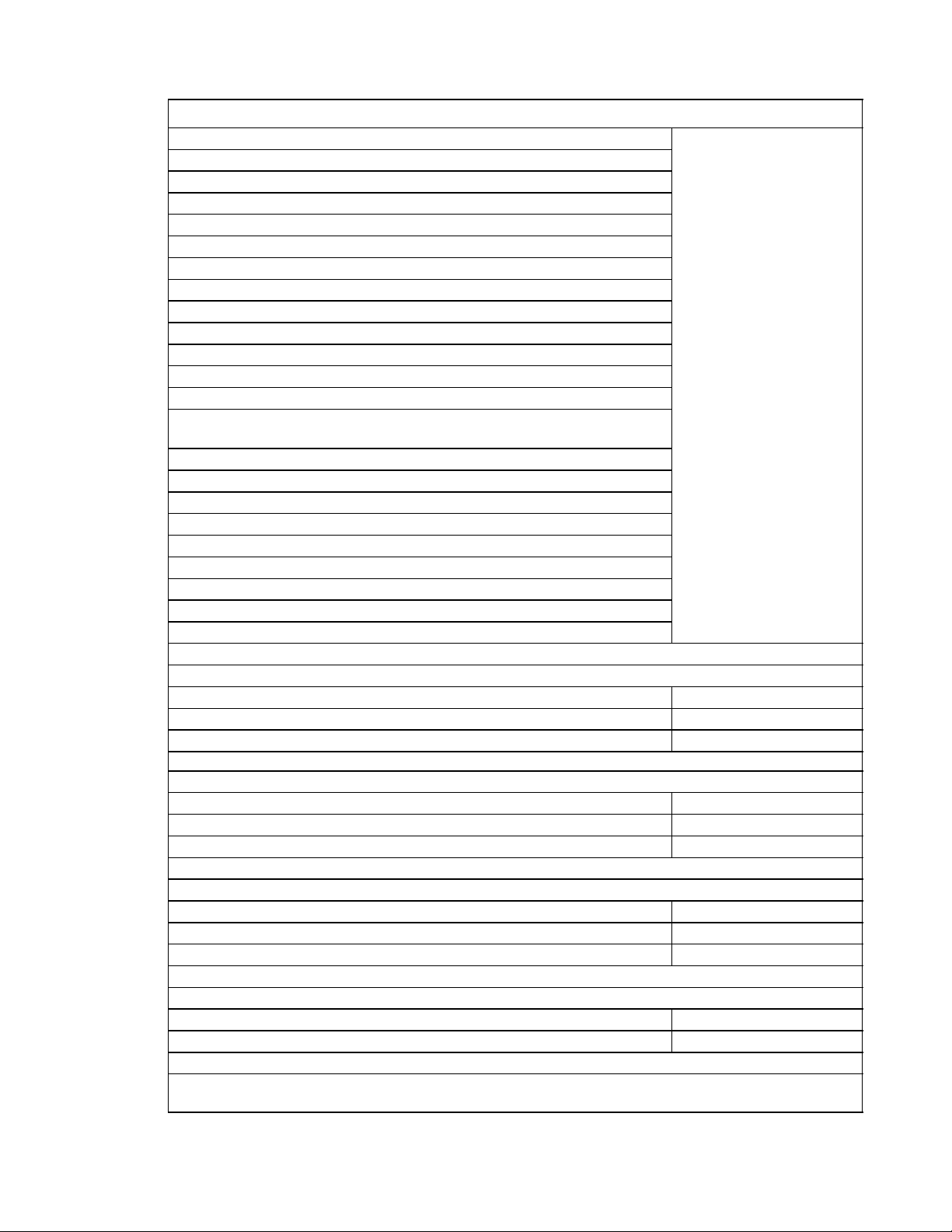

Table 1. Design Data

Unit Description (See *NOTE below)

115V, 60Hz

5-FL Remote Carbonator (3–2–1 Coil Configuration)

6-FL Remote Carbonator (3–2–1 Coil Configuration)

5-Fl Integral Carbonator

6-Fl Integral Carbonator

5-Fl Integral Carbonator W/Syrup Pumps

6-Fl Integral Carbonator W/Syrup Pumps

230V, 50Hz

5-FL Remote Carbonator (3–2–1 Coil Configuration)

6-FL Remote Carbonator (3–2–1 Coil Configuration) Unit Part No.

5- Fl Integral Carbonator (See Nameplate)

6-Fl Integral Carbonator

6-Fl Integral Carbonator, Low-carb No. 4 dispensing valve

(CE approved)

5-Fl Integral Carbonator W/Syrup Pumps

6-Fl Integral Carbonator W/Syrup Pumps

230V, 60Hz (High-Torque Start)

5-FL Remote Carbonator (3–2–1 Coil Configuration)

6-FL Remote Carbonator (3–2–1 Coil Configuration)

5- Fl Integral Carbonator

6-Fl Integral Carbonator

5-Fl Integral Carbonator W/Built-In Syrup Pumps

6-Fl Integral Carbonator W/Built-In Syrup Pumps

Weights (approx):

Integral (Built-In) Carbonator Unit 141 Pounds

Remote Carbonator Unit (3–2–1 Coil Configuration) 121 Pounds

Ice Bank Weight 32 Pounds

Unit Capacity:

Water Tank (No Ice Bank) 10 Gallons

Integral Carbonator Water Pump 100 GPH

Integral Carbonator Water Tank Reserve 52 0z

Overall Dimensions:

Width 18 inches

Height 26 inches

Depth 24.5 inches

Dispensing Rate:

Four 12-oz Drinks/Min @ 40° F or below in 75° F Ambient **225

Four 12-oz Drinks/Min @ 40° F or below in 90° F Ambient **100

**NOTE: Number of 12-oz drinks dispensed 40F or below (Starting With

Stabilized Ice)

*NOTE: The five and six-flavor Remote Carbonator Dispensers require a remote carbonator be connected

to the Dispensers to provide carbonated water. The five and six-flavor Integral Dispensers have an integral

(built-in) carbonator that provides carbonated water for the Dispensers.

560003094 2

Page 6

Table 1. Design Data (cont’d)

Refrigeration System Refrigerant Requirement (R-134A) 6.875 oz

Ambient Operating Temperature 40° F to 110° F

Electrical Requirements:

Operating Voltage See Unit

Nameplate

Current Draw See Unit

Nameplate

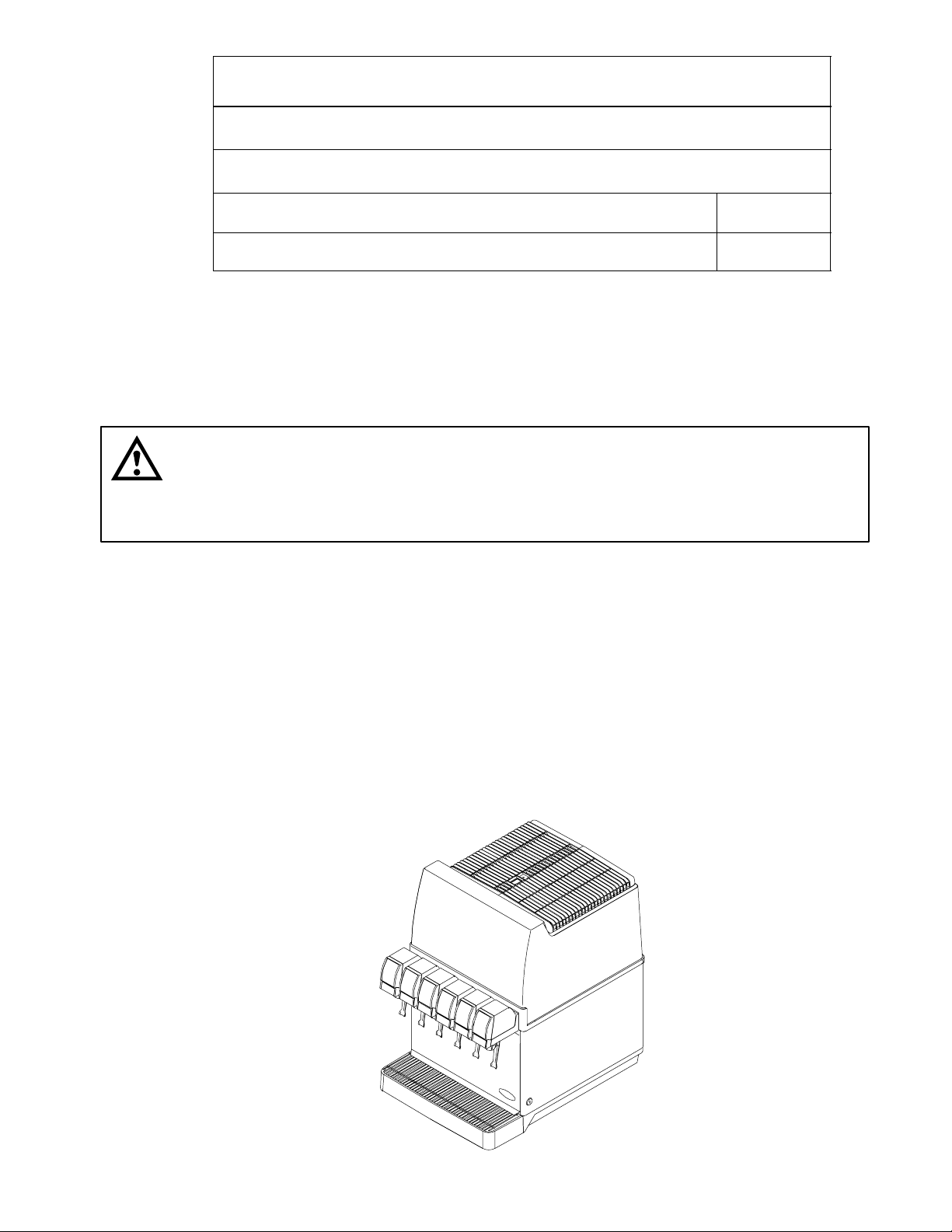

IMPORTANT: To the user of this manual - This manual is a guide for installing this equipment. Refer to

table of contents for page location of detailed information pertaining to questions that arise during

installation of this equipment.

These Dispensers (hereafter referred to as Units) must be installed and serviced by a qualified Service Person.

These Units contain no User serviceable parts.

CAUTION: Before shipping, storing, or relocating Unit, syrup systems must be sanitized

and all sanitizing solution must be purged from syrup coils. All water must be purged from

carbonated and plain water systems and ice bank melted and all water drained from water

tank. A freezing ambient environment will cause residual water remaining inside Unit to freeze

resulting in damage to internal components.

Unit Description

The Units are compact, lightweight and are in three configurations. The first model, either a five or a six-flavor, is

equipped with an integral (built-in) carbonator. The second model, either a five or six-flavor, is equipped with an

integral (built-in) carbonator and built-in syrup pumps to provide syrup to the Unit. The third model, also either a five

or a six-flavor, requires connection to a remote carbonator. The Units may be island-mounted or installed on a front

or rear counter. Their refrigeration assemblies are the 1/3 H.P. drop-in type and are easily removed for service and

maintenance. Adjustable water flow regulators and syrup flow regulators, located on the dispensing valves, are

easily accessible to control water flow rate of the dispensing valve and Water-to-Syrup “Ratio” of the dispensed

product. The only requirements for operation are installation of the Unit on a countertop, installation of LooseShipped Parts, connection to a remote carbonator for the model requiring connection to a remote carbonator, connections to plain water and syrup supplies, adjustment of CO

cal outlet with proper electrical requirements, and adjusting dispensing valves water and syrup flow regulators for

proper water flow rate and Water-to Syrup “Ratio” of the dispensed product.

regulators, plugging Unit power cord into an electri-

2

GLACIER SIX-FLAVOR UNIT SHOWN

3 560003094

Page 7

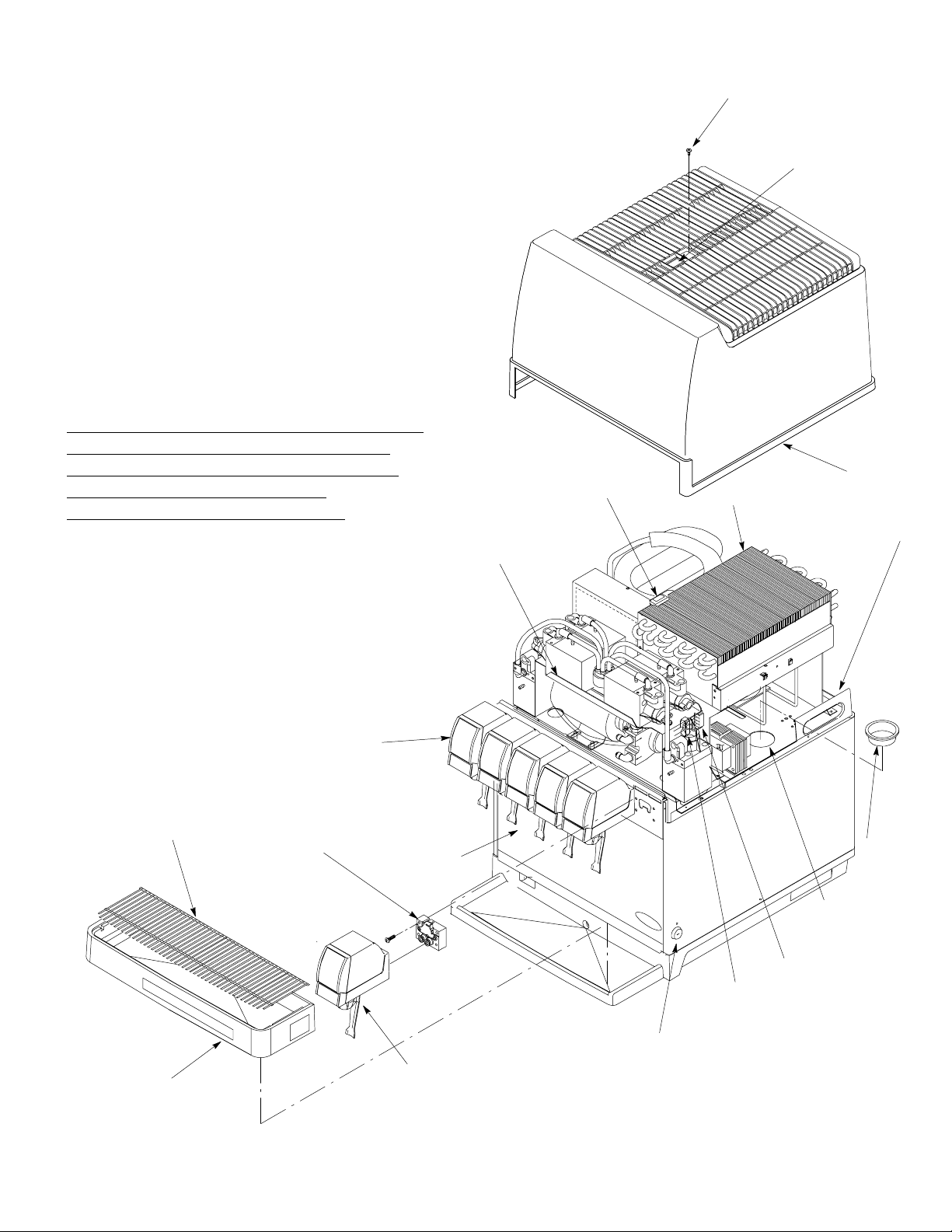

THEORY OF OPERATION

NOTE: Refer to Figure 1 for optional dispensing valves dispensing configurations. For Units with integral

(built–in) carbonators (see Figure 3 and 4) and Units with integral (built–in) carbonators and syrup pumps

(see Figure 5). The five-flavor Units may be configured to dispense all carbonated and no still (noncarbonated) drinks or four carbonated and one noncarbonated drink. The six-flavor Units may be configured to

dispense five carbonated and one noncarbonated drinks, four carbonated and two noncarbonated drinks,

or six carbonated and no non-carbonated drinks.

UNITS WITH INTEGRAL (BUILT-IN) CARBONATORS

Standard Units with Integral (Built-In Carbonators. (see Figure 4)

A syrup tanks system or a bag–in–box syrup system may be connected to these Units to provide syrup supply to

the Units. Plain water enters the integral (built-in) carbonator carbonated water tank and is carbonated by regulated

CO2 gas pressure also entering the tank. When dispensing valve is opened, syrup is pushed through the Unit cooling coils, and on to the dispensing valve. Carbonated water tank CO

from the tank to the dispensing valve. Syrup and carbonated water meet simultaneously at the dispensing valve

resulting in a carbonated drink being dispensed. A still (noncarbonated) drink is dispensed in the same manner as

the carbonated drink except plain water is substituted for carbonated water.

gas head pressure pushes carbonated water

2

Dispenser P/N 475136102 (Six-Flavor Unit with Integral (Built-In) Carbonator with Low-Carb No. 4 Dispensing

Valve).) See Figure 3

This Unit operates in much the same way as the standard Units with integral (built-in) carbonators

(See Figure 4). No. 4 dispensing valve is set up to dispense a low-carb drink by connecting a low-carb remote carbonator to the No. 4 dispensing valve water inlet line or plain water may be connected to the water line to dispense

a still (non-carbonated) drink.

UNITS WITH INTEGRAL (BUILT-IN) CARBONATORS AND SYRUP PUMPS

(See Figure 5)

A CO2 cylinder delivers carbon dioxide (CO2) gas through an adjustable CO2 regulator to the syrup pumps and

also the integral (built-in) carbonator located inside the Unit. Plain water enters the carbonator carbonated water

tank and is carbonated by regulated CO2 gas pressure also entering the tank. Opening one of the dispensing

valves causes the CO2 operated syrup pump associated with that valve to operate which pumps syrup from the

syrup bag-in-box, through the Unit cooling coil, and on to the dispensing valve. Carbonated water tank CO

gas

2

head pressure pushes carbonated water from the tank to the dispensing valve. Syrup and carbonated water meet

simultaneously at the dispensing valve resulting in a carbonated drink being dispensed. A still (non-carbonated)

drink is dispensed in the same manner as the carbonated drink except plain water is substituted for carbonated

water.

UNITS WITH 3–2–1 COIL CONFIGURATIONS (REQUIRING CONNECTION TO REMOTE

CARBONATORS)

(See Figure 6)

The three Unit water inlet lines may be connected to either plain water or carbonated water (remote car

bonito) source lines. Plain or carbonated water connected to No. 1 water inlet line will allow No. 5 valve to dispense

either a still (noncarbonated) or a carbonated drink. Plain or carbonated water connected to No. 2 water inlet line

will allow No. 3 and No. 4 valves to dispense either still (noncarbonated) or carbonated drinks. Plain or carbonated

water connected to No. 3 water inlet line will allow No. 1, 2, and No. 6 valves to either dispense still (noncarbonated) or carbonated drinks. A syrup tank system or a syrup bag–in–box/syrup pump system may be connected to

the Unit to provide syrup supply to the Unit.

560003094 4

Page 8

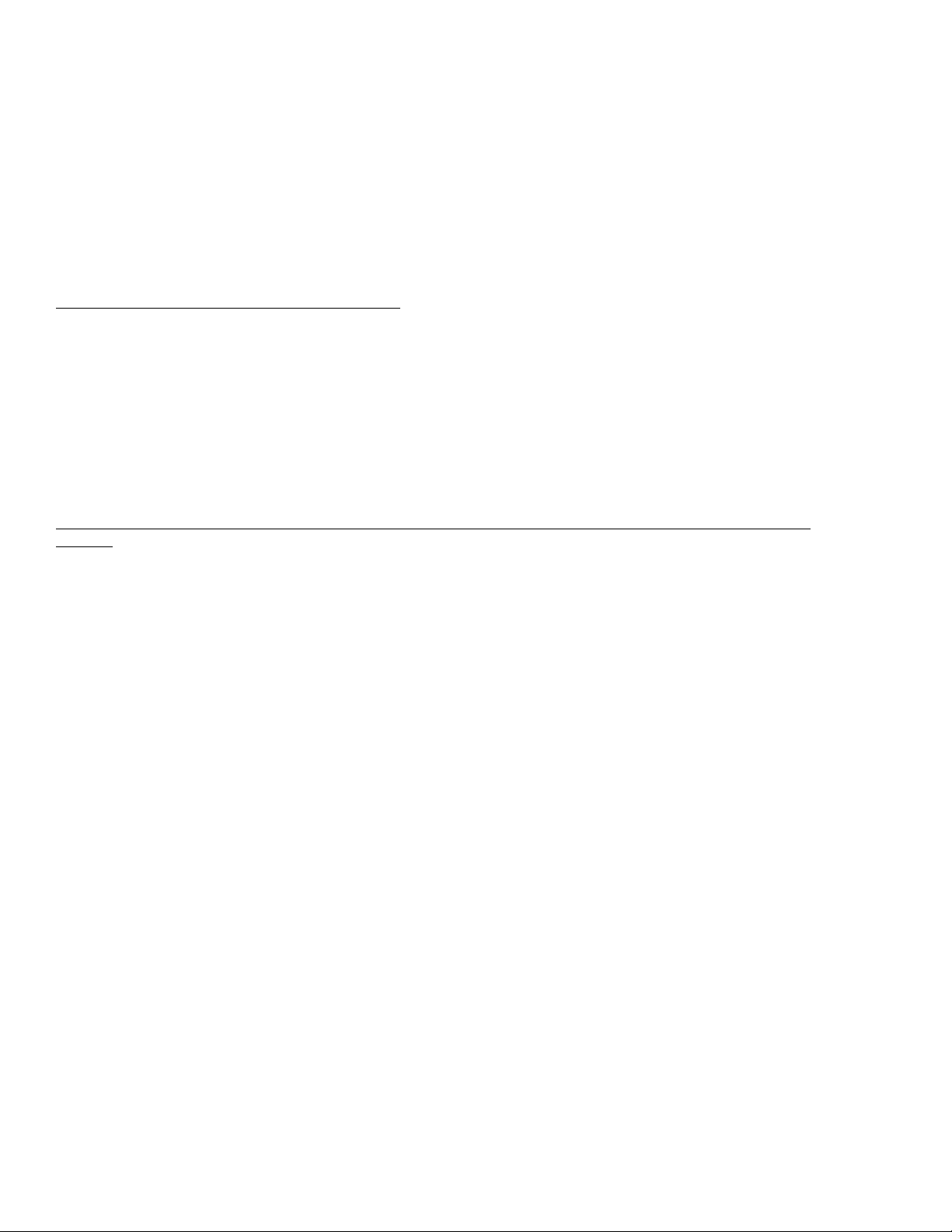

5

FIVE VALVES CARB

NO VALVES NON-CARB

61

1

6

5

FOUR VALVES CARB

NO. 3 VALVE NON-CARB

5-FLAVOR WITH INTEGRAL (BUILT-IN) CARBONATOR

PART NO:

426015

426025

475015

475025

476015

476025

2

6

4

FIVE VALVES CARB

NO. 4 VALVE NON-CARB

6-FLAVOR WITH INTEGRAL (BUILT-IN) CARBONATOR

46

32

5

FOUR VALVES CARB

NO. 3 & 4 VALVES NON-CARB

62

5

FIVE VALVES CARB

NO. 4 VALVE CUSTOM

INDIVIDUAL SUPPLY COIL

52 6

3

4

SIX VALVES CARB

NO VALVES NON-CARB

PART NO:

426016

426026

475016

475026

476016

476026

6-FLAVOR UNIT (P/N 475136102) WITH INTEGRAL (BUILT-IN) CARBONATOR

Parts Identification for Optional Configurations

Item P/N Description Item P/N Description

1 2535 Connector, Straight, Plain wa-

ter

2 2483 Connector, Elbow, Plain water 5 2649 Plug Assembly

3 2350 Tube, Straight, S/S 6 311765-001 Dual Check Valve Assembly

FIGURE 1. OPTIONAL CONFIGURATIONS

NOTE: 1. Illustrations show view of tubing connections on top front of the water tank.

2. Connections require lubrication prior to assembly.

4 2484 Connector, Tee

5

560003094

Page 9

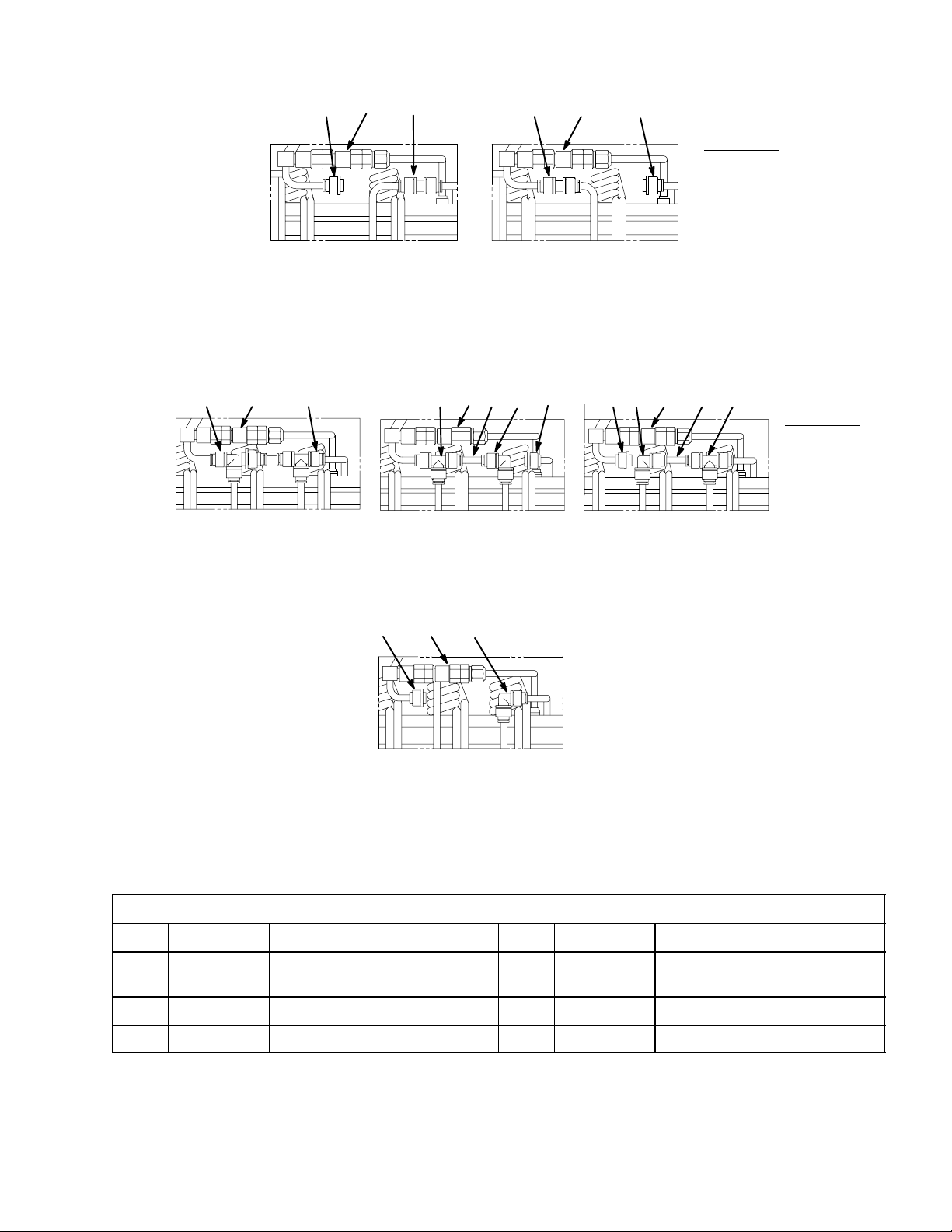

OPERATING CONTROLS

DISPENSING VALVE LEVER: The dispensing valve lever, located on the bot-

tom of the dispensing valve, needs only to be pressed with a cup or glass to

dispense product.

KEY-LOCK SWITCH: The key-lock switch, located on the

bottom right side of the dispenser, prevents operation of the

dispensing valves when switch is in the “OFF” position.

This key-lock switch does not affect operation of the

refrigeration system.

CONTROL BOARD POWER SWITCH: The control board

power switch is located on the top of the refrigeration

assembly and is accessible through a hole in top of the

hood. THIS SWITCH IS AN ON-OFF SWITCH AND

CONTROLS ONLY THE 24 VAC LOW VOLTAGE

POWER SOURCE TO THE CONTROL BOARD.

HIGH VOLTAGE IS STILL PRESENT INSIDE THE

DISPENSER. USE CAUTION, UNPLUG UNIT

POWER CORD FROM ELECTRICAL OUTLET

BEFORE PERFORMING INTERNAL

MAINTENANCE ON THE DISPENSER.

INTEGRAL CARBONATOR

PUMP & MOTOR ASSEMBLY

CONTROL BOARD

POWER SWITCH

HOOD SCREW

REFRIGERATION

POWER SWITCH

ACCESS HOLE

HOOD

CONDENSER

REFRIGERATION

DECK LIFTING HANDLES

CUP REST

DRIP TRAY

DISPENSING

VALVES (6)

VALVE MOUNTING

BLOCK

FRONT PANEL

KEY-LOCK SWITCH

DISPENSING VALVE

LEVER

FIGURE 2. PARTS IDENTIFICATION (SIX-FLAVOR UNIT SHOWN)

FILL HOLE

PLUG

WATER T ANK

FILL HOLE

CONNECTOR

CARBONATOR MOTOR

POWER CORD

560003094 6

Page 10

PLAIN WATER

COOLING COIL

SYRUP COIL (6)

7

be a bag–in–box system or a syrup

tanks system

VALVE WATER INLET

NO.4 DISPENSING

(SEE NOTE 2)

DOUBLE LIQUID

CHECK VALVE

CARBONATED

WATER TANK

CO2 CHECK VALVE

PLAIN WATER INLET

CO2 INLET

SYRUP INLETS

(SEE NOTE 1)NOTE 1: The syrup sources may either

WATER PUMP

AND MOTOR

1

2

3

STILL (NON-CARB

OR

LOW-CARB DRINK

4

5

6

NOTE 2: The No. 4 dispensing valve water inlet may be connected

to a low-carb carbonator for a low-carb drink to be dispensed

from No. 4 dispensing valve or the water inlet line may be connected to filtered plain water to dispense a still (non-carbonated)

drink from No. 4 dispensing valve.

560003094

FIGURE 3. FLOW DIAGRAM (SIX-FLAVOR UNIT [P/N 475136102] WITH INTEGRAL (BUILT-IN) CARBONATOR SHOWN)

LINE LEGEND

SYRUP

PLAIN WATER

CARB WATER

CO

2

DISPENSER

Page 11

560003094

PLAIN WATER

COOLING COIL

SYRUP COIL (6)

8

NOTE 1: The syrup sources may either

be a bag–in–box system or a syrup

tanks system

NO.4 DISPENSING VALVE

PLAIN WATER INLET

DOUBLE LIQUID

CHECK VALVE

CARBONATED

WATER TANK

CO

CHECK VALVE

2

PLAIN WATER INLET

CO2 INLET

SYRUP INLETS

(SEE NOTE 1)

WATER PUMP

AND MOTOR

1

2

3

STILL (NON-

4

CARB) DRINK

5

6

DISPENSER

LINE LEGEND

SYRUP

PLAIN WATER

CARB WATER

CO

2

FIGURE 4. FLOW DIAGRAM (STANDARD SIX-FLAVOR UNIT WITH INTEGRAL (BUILT-IN) CARBONATOR SHOWN)

Page 12

PLAIN WATER

COOLING COIL

WATER PUMP

AND MOTOR

DOUBLE LIQUID

CHECK VALVE

CARBONATED

WATER TANK

SYRUP COIL (6)

1

2

3

9

560003094

NOTE: Syrup sources may either be a

bag–in–box system or a syrup tanks

system

LINE LEGEND

SYRUP

PLAIN WATER

CARB WATER

CO

2

CO2 CHECK VALVE

PLAIN WATER INLET

CO2 INLET

SYRUP INLETS

(SEE NOTE)

4

5

6

SYRUP PUMP (6)

32

1

4

65

CO2 MANIFOLD

DISPENSER

FIGURE 5. FLOW DIAGRAM (SIX-FLAVOR UNIT WITH INTEGRAL CARBONATOR AND BUILT-IN SYRUP PUMPS)

Page 13

560003094

10

NOTE: Syrup sources may either be a

syrup bag–in–box system or a syrup

tanks system

LINE LEGEND

SYRUP

PLAIN OR CARB WATER

WATER

COOLING COIL

(4)

DISPENSER

SYRUP COIL (6)

1

2

3

4

5

6

PLAIN WATER OR

CARBONATED

WATER INLET

LINES

1

2

NO.3 WATER INLET LINE FOR

VALVES NO. 1, 2, AND 6

NO.2 WATER INLET LINE FOR

VALVES NO. 3 AND 4

3

NO.1 WATER INLET LINE

FOR VALVE NO. 5

1

2

4

3

SYRUP INLET LINES

5

(SEE NOTE)

6

FIGURE 6. FLOW DIAGRAM (SIX-FLAVOR UNIT WITH 3–2–1 COIL CONFIGURATION REQUIRING CONNECTION TO REMOTE CARBONATOR)

Page 14

FIGURE 7. WIRING DIAGRAM

56000309411

Page 15

.

.

.

FIGURE 8. CONTROL BOARD DIAGNOSTIC DECAL

.

.

560003094

12

Page 16

INSTALLATION

LOOSE-SHIPPED PARTS

1. After Unit has been unpacked, remove screw securing hood to Unit, then remove hood.

2. Remove Unit front access panel by lifting panel up, then pull out on bottom.

3. Unpack Loose-Shipped Parts. Make sure all items are present and in good condition.

Table 2. Loose-Shipped Parts

Item

No. Part No. Name

1 2488

3094

2 2134

3093

3 2190 Lock, Key 1 1

4 315865000 Drain Hose, 75-in. Long 1 1

5 140133000 Hose Clamp 1 1

6 3915 Cover, Base Opening 1 1

7 3534 Fitting 5 6

8 3297 *Lever, Water (UF-1 Valve) 1 1

*LEVER, WATER (item 8) is optional and is intended to be installed on the UF-1 Dispensing Valve only.

Cup Rest, Black

Cup Rest, Gray

Drip Tray, Black

Drip Tray, Gray

Qty.

5FL

1

1

1

1

Qty.

6FL

1

1

1

1

IDENTIFICATION OF LOOSED-SHIPPED PARTS

1. DRIP TRAY (item 2) to be installed on Unit, then CUP REST (item 1) to be installed in the drip tray.

2. LOCK KEY (item 3) locks and unlocks the keyed lock switch on side of the Unit.

3. DRAIN HOSE (item 4) to be installed on Unit.

4. HOSE CLAMP (item 5) used to secure DRAIN HOSE (item 4) when hose is connected to Unit.

5. Install COVER, BASE OPENING (item 6) in opening located in back of the Unit base if syrup, CO2 and water

source lines and drip tray drain hose will not be routed out through the opening.

INSTALLATION

SELECTING LOCATION

CAUTION: This Unit is intended for indoor installation only. Do not install this Unit in an

outdoor environment which would expose it to the outside elements.

This unit may be island-mounted or installed on a front or rear counter. The counter must be capable of supporting

230 pounds and allow access for syrup, water and CO2 tubing.

Allow sufficient clearance (15 inches vertical) above top of the hood to the nearest obstruction for ventilation and

removal of the hood and the drop-in refrigeration assembly. A total of 42.5 is required above the counter.

The Unit must have 5 inches clearance on both sides and 5 inches clearance on back side.

13

560003094

Page 17

FOR INDOOR USE

ONLY

18 in.

DO NOT PLACE

ANY OBJECT

ON UNIT.

Allow sufficient clearance

(15 vertical) above top of the hood to

the nearest obstruction for ventilation

and removal of the hood and the drop-in

refrigeration assembly. A total of 42.5

is required above the counter.

The Unit must have 5

clearance o n both sides and 5

clearance on back side.

27.5 in.

NAMEPLATE

24.5 in.

POWER CORD

(MAINS CORD)

GFCI (ELCB) OUTLET

Connect to a properly grounded, accessible, dedicated electrical outlet, with GFCI (ELCB) fused at 15 amps (“slow-blow”) or an equivalent

HACR circuit breaker. Electrical supply (Voltage, Hertz) must agree with the equipment nameplate.

ALL ELECTRICAL WIRING MUST CONFORM TO NA TIONAL AND LOCAL ELECTRICAL CODES

SEALING UNIT TO COUNTERTOP

To comply with NSF International (NSF) requirements within the United States, the Unit base must be sealed to the

countertop and all access holes inside of the Unit base must be sealed with permagum or other sealant. Proceed as

follows to seal the Unit base to the countertop.

NOTE: An alternate arrangement to avoid the sealing process would be to install the available 4 Legs,

P/N 314744000. Four of these legs are required.

APPLY SEALANT

TO BASE BOTTOM EDGES.

560003094 14

Page 18

1. Place Unit in operating position on countertop.

2. Tilt Unit up in preparation to install the drip tray DRAIN HOSE (item 4).

3. Connect drip tray drain hose to fitting on drip tray holder. Secure connection with HOSE CLAMP (item 5).

NOTE: Install COVER, BASE OPENING (item 6) in opening located in back of the Unit base if syrup, CO2 and

water source lines and drip tray drain hose will not be routed out through the opening.

4. Route drip tray drain hose under and to the back of the Unit.

5. Tilt the Unit to expose the bottom of the base.

6. Liberally apply a silastic sealant such as Dow Corning RTV 731 or equivalent on the base bottom edges.

NOTE: Do not move the Unit after positioning or the seal will be broken.

7. Lower the Unit into operating position to complete the seal to the countertop.

8. Seal all access holes to the inside of the Unit base with permagum or other sealant after completing installation

of the Unit.

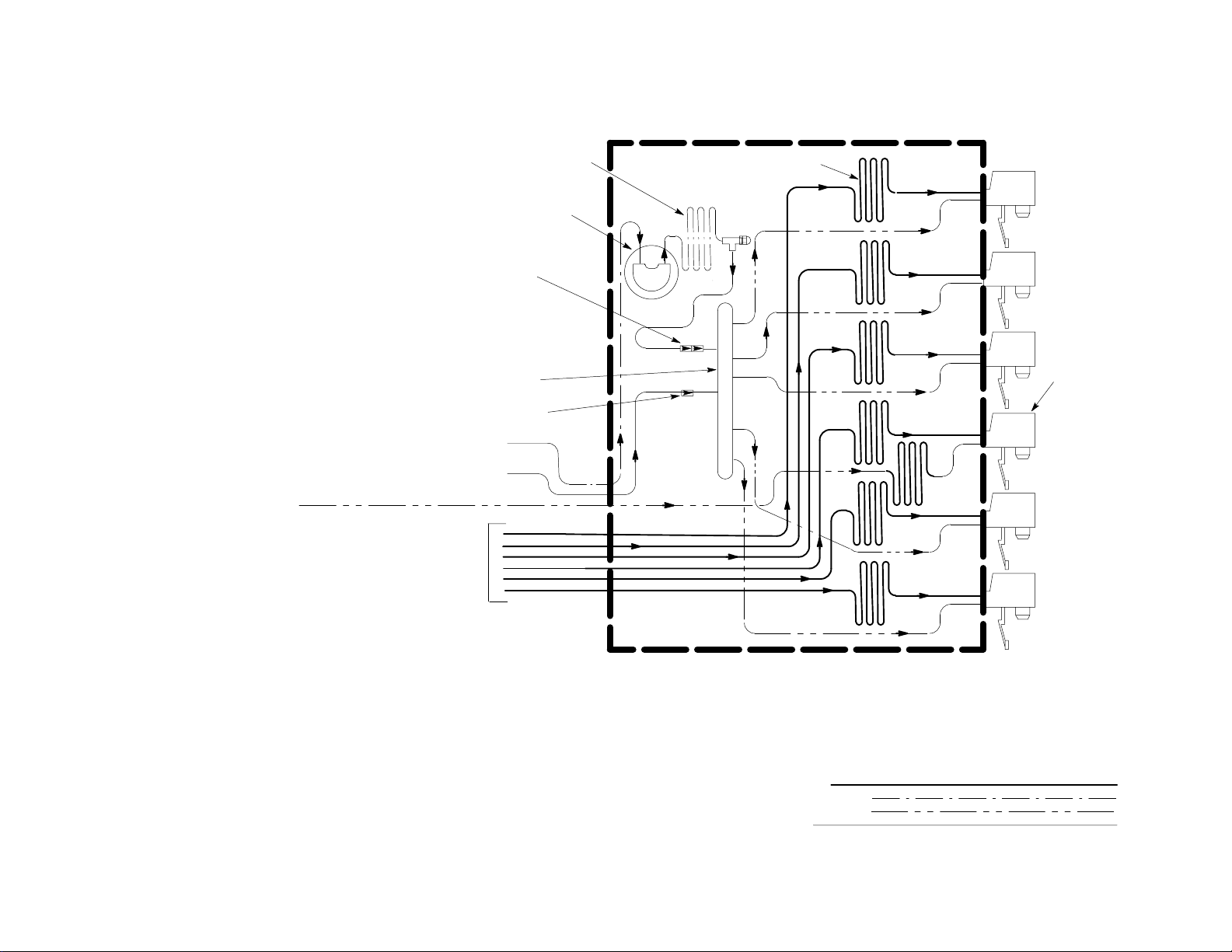

SELECTING SLEEP MODE OPTIONS (UNITS WITH INTEGRAL CARBONATORS)

NOTE: The Unit control board (see Figure 7) is equipped with a sleep mode 3-socket connector and a 2-pin

jumper block which when plugged into the 3-socket connector in different configurations, allows the User to

select the desired “SLEEP MODE” option.

The five and six-flavor Units, with integral carbonators, are factory set to operate in either “MODE 2” or

“MODE 3” option with “SLEEP MODE” active. Please review this setting on the control board and select the

required setting for your installation.

3-SOCKET

CONNECTOR 2-PIN JUMPER BLOCK

MODE 1

(A)

Selecting “Sleep Mode” Option

MODE OPTION

MODE 2

(B)

INPUT

MODE 3

(C)

DESCRIPTION

CONFIGURATION

MODE 1 No Jumper No Sleep Mode W/Plain Water Booster

MODE 2 Input 1 Jumpered Sleep Mode W/Plain Water Booster

MODE 3 Input 2 Jumpered Sleep Mode W/Plain Water Wakeup

Sleep Mode Jumper Option

Mode 1 Option (see illustration A).

If Mode 1 is selected and no jumper block is connected to the 3-socket connector as shown in illustration A, the integral carbonator Unit will switch the agitator motor on to operate continuously. “SLEEP MODE” will not be active but

“PLAIN WATER BOOSTER” will be activated (carbonator water pump starts and increases water pressure to the

plain water valve when valve is activated) only when optional jumper wires are connected between the plain water

valve and the control board. (See ACTIVATING PLAIN WATER PRESSURE BOOSTER OR PLAIN WATER

WAKEUP OPTIONS for instructions to install optional jumper wires.)

15

560003094

Page 19

Mode 2 Option (see illustration B).

If Mode 2 is selected and jumper block is plugged into the 3-socket connector as shown in illustration B, “SLEEP

MODE” and “PLAIN WATER BOOSTER” will be activated. “SLEEP MODE” is entered during periods of refrigeration

compressor and carbonator water pump inactivity. If compressor and carbonator water pump motor have not been

operating (inactive) for ten (10) minutes, the Unit will go into “SLEEP MODE”. While the Unit is in “SLEEP MODE”,

the agitator motor will be cycled on every ten (10) minutes and operate for thirty (30) seconds, then stop. “SLEEP

MODE” will continue until either the refrigeration compressor, carbonator water pump motor, or the plain water valve

become active. Once active, the agitator motor will operate continuously until the refrigeration compressor and the

carbonator water pump have turned off and been inactive for ten (10) minutes. “SLEEP MODE” will again occur.

“PLAIN WATER BOOSTER” (wakes up agitator motor and starts water pump which increases plain water pressure to

the plain water valve) will be active only when optional jumper wires are connected between the plain water valve and

connector on the refrigeration deck. (See ACTIVATING PLAIN WATER PRESSURE BOOSTER OR PLAIN WATER

WAKEUP OPTIONS for instructions to install optional jumper wires.)

Mode 3 Option (see illustration C).

If Mode 2 is selected and jumper block is plugged into the 3-socket connector as shown in illustration B, “SLEEP

MODE” and “PLAIN WATER WAKEUP” will be activated. “SLEEP MODE” is entered during periods of refrigeration

compressor and carbonator water pump inactivity. If compressor and carbonator water pump motor have not been

operating (inactive) for ten (10) minutes, the Unit will go into “SLEEP MODE”. While the Unit is in “SLEEP MODE”,

the agitator motor will be cycled on every ten (10) minutes and operate for thirty (30) seconds, then stop. “SLEEP

MODE” will continue until either the refrigeration compressor, carbonator water pump motor, or the plain water valve

become active. Once active, the agitator motor will operate continuously until the refrigeration compressor and the

carbonator water pump have turned off and been inactive for ten (10) minutes. “SLEEP MODE” will again occur.

“PLAIN WATER WAKEUP” (wakes up agitator motor only and does not start water pump to increase water pressure

to the plain water valve) will be activated only when the optional jumper wires are connected between the plain water

valve and connector on the refrigeration deck. (See ACTIVATING PLAIN WATER PRESSURE BOOSTER OR PLAIN

WATER WAKEUP OPTIONS for instructions to install optional jumper wires.)

FILL WATER TANK AND START REFRIGERATION SYSTEM

1. Loosen screw securing hood to Unit, then lift hood up to remove.

CONTROL BOARD

POWER SWITCH

INTEGRAL CARBONATOR

PUMP AND MOTOR

ASSEMBLY

CARBONATED WATER

TANK SENSOR

CONNECTOR

FILL HOLE

PLUG

WATER TANK

FILL HOLE

DISPENSING

VALVE (6)

560003094 16

CARBONATOR MOTOR

POWER CORD

AND CONNECTOR

Page 20

2. Make sure plug is secure in water tank drain hose.

NOTE: Use low-mineral-content water if a local water problem exists. Do not use distilled or deionized water.

3. Remove fill-hole plug from drop-in refrigeration deck fill hole.

4. Fill water tank with clean water until water runs out of water tank overflow hose into the drip tray.

5. Install fill-hole plug back in the fill hole.

6. Disconnect carbonator tank sensor wiring harness connector from Unit wiring harness mating connector.

7. Make sure control board power switch on top of the refrigeration assembly is in the “OFF” position.

8. Plug Unit power cord into electrical outlet.

9. Place control board power switch in “ON” position. Refrigeration compressor will start after a 2 minute built-in

time delay and start building an ice bank. If water in water bath is above temperature of 60° F, the agitator motor

will not operate until refrigeration system has cooled the water temperature down to below 60° F. Agitator motor

will then start and operate.

CONNECTING SYRUP TUBING TO UNIT

Units Without Built-In Syrup Pumps.

1. Route the required pieces of 3/8 I.D. syrup tubing (labeled for flavor identification) from syrup source (tank or

Bag-in-Box) up to the back of the Unit. See flow diagram Figure 3 or 6 for the proper connection detail.

2. Connect the labeled syrup source tubing to the matching labeled barbed syrup inlet fittings located behind the

front panel of the Unit. Make sure the flavors are correctly connected. Secure the connections with tubing

clamps. DO NOT CONNECT SYRUP SUPPLIES TO SYRUP SYSTEMS AT THIS TIME.

SYRUP INLET

LINES (4, 5, 6)

SYRUP PUMP ASS’Y

SYRUP TUBING, 5 OR 6

17

SYRUP INLET

LINES (1, 2, 3)

560003094

Page 21

Units With Built-In Syrup Pumps.

(see Figure 4)

1. Route the required pieces of 3/8 I.D. syrup tubing (labeled for flavor identification) from bag-in-boxes syrup

sources up to the back of the Unit. See flow diagram Figure 4 for the proper connection detail.

2. Route labeled syrup tubes under the Unit up behind the front panel to inside of the Unit.

3. Connect the labeled syrup source tubing to matching labeled syrup pumps syrup inlet fittings. Make sure the flavors are correctly connected. Secure the connections with tubing clamps. DO NOT CONNECT SYRUP SUPPLIES TO SYRUP SYSTEMS AT THIS TIME.

CONNECTING CO2 AND PLAIN WATER SOURCES

NOTE: IMI Cornelius Inc. recommends that a water shutoff valve be installed in the plain water supply connected to this system and that the water supply be filtered.

Integral (Built-In) Carbonator Unit Without Syrup Pumps.

1. Route CO2 tube from the CO2 source to the back of the Unit. See flow diagram Figure 3 for the proper connection detail.

2. Route plain water tube from a plain water source shut-off valve to the back of the Unit. Water supply must be

capable of supplying 100 GPH at a pressure not to exceed 50 PSI. A water pressure regulator must be installed

if the pressure exceeds 50 PSI.

3. Connect the plain water tube to the Unit carbonator pump inlet fitting. Seal the connection with a tapered gasket.

4. Connect CO2 tube to Unit CO2 inlet check valve located behind the front panel.

WATER

TUBING

SHUT-OFF

VALVE

CO2 TUBING

Integral (Built-In) Carbonator Unit With Syrup Pumps.

1. Route CO2 tube from the CO2 source to the back of the Unit. See flow diagram Figure 4 for the proper connection detail.

560003094 18

Page 22

2. Route plain water tube from a plain water source shut-off valve to the back of the Unit. Water supply must be

capable of supplying 100 GPH at a pressure not to exceed 50 PSI. A water pressure regulator must be installed

if the pressure exceeds 50 PSI.

3. Connect the plain water tube to the Unit carbonator pump inlet fitting. Seal the connection with a tapered gasket.

4. Connect CO2 tube to Unit CO2 inlet check valve located behind the front panel.

CONNECTING CARBONATED AND PLAIN WATER SOURCES TO 3–2–1 COIL

CONFIGURATION REMOTE CARBONATOR UNIT

1. Route carbonated water tube from the remote carbonator to the back of the Unit. See flow diagram Figure 6 for

the proper connection detail.

2. Route plain water tube (if required) from plain water source to the back of the Unit. This plain water is for any

noncarbonated flavors. See flow diagram Figure 6 for the proper connection detail.

3. Connect carbonated water and plain water tubes to appropriate connections behind the front panel.

CARBONATED

WATER TUBING

PLAIN WATER

TUBING

CONNECTING DRIP TRAY DRAIN HOSE

NOTE: The Unit is equipped with a drip tray drain hose. If desired to utilize the drip tray drain hose, the drip

tray outlet must be drilled out as the outlet is covered with a thin layer of plastic. AFTER DRILLING, MAKE

SURE ALL BURRS ARE REMOVED FROM THE DRILLED HOLE.

The drip tray drain hose should not be routed to a waste container due to sanitation and cleaning problems.

Install drip tray drain hose on Unit as follows: (Refer to table 2, Loose Shipped Parts.)

1. Install drip tray DRAIN HOSE (item 4) on Unit and secure with HOSE CLAMP (item 5).

2. Route the drain hose to a permanent drain such as a floor drain.

3. The drain hose must be attached to the drain to allow a 3 air gap between the drain and the end of the hose. All

connections must comply with local plumbing and health codes.

4. Install the DRIP TRAY (item 2) in the Unit and then install the CUP REST (item 1) on the drip tray.

19

560003094

Page 23

3 AIR GAP

DRIP TRAY

DRAIN HOSE

560003094 20

Page 24

PREPARATION FOR OPERATION

OPENING THE CO

NOTE: Make sure primary and secondary CO2 regulators adjusting screws are turned to the left (counterclockwise) until all tension is relieved from the adjusting screws springs before opening the CO

cylinder shutoff valve.

1. The valve on the CO2 cylinder must be opened slowly. Open the valve until it is open to it’s fullest and

“back-seated”. This prevents any CO2 from leaking around the valve shaft.

2. Check for leaks at all connections. Repair any leaks that are found.

CYLINDER SHUTOFF VALVE AND LEAK CHECKING

2

TURN CCW TO OPEN

VALVE

2

ACTIVATING THE CARBONATOR

UNIT WITH INTEGRAL (BUILT-IN) CARBONATOR AND WITHOUT BUILT-IN SYRUP

PUMPS.

1. Open plain water shut-off to the carbonator. Check for leaks and repair as needed.

2. Pull up on carbonated water tank relief valve (accessible through hole in refrigeration assembly platform)

until water spurts from valve.

SUGAR SYRUP

REGULATOR

PRIMARY CO

REGULATOR

2

DIET SYRUP

REGULATOR

TO CARBONATOR

56000309421

Page 25

3. Adjust CO

regulator for the carbonator at a nominal 70 PSIG. PRESSURE TO THE CARBONATOR

2

MUST NOT EXCEED 80 PSIG.

4. Place control board power switch in “OFF” position.

5. Unplug Unit power cord from electrical outlet.

6. Connect carbonator tank sensor wiring harness connector into Unit wiring harness connector.

7. Plug Unit power cord into electrical

outlet.

8. Place control board power switch in “ON” position. After a 2 minute built-in time delay, refrigeration compressor will start and carbonator pump motor will start when carbonator calls for more

water.

9. Make sure the key-lock switch on the side of the Unit is ON. Dispense from all the dispensing valves until

all air is purged from the system and carbonated water is being dispensing from the valves.

UNIT WITH INTEGRAL (BUILT-IN) CARBONATOR AND WITH BUILT-IN SYRUP PUMPS.

1. Open plain water shut-off to the carbonator. Check for leaks and repair as needed.

2. Pull up on carbonated water tank relief valve (accessible through hole in refrigeration assembly platform)

until water spurts from valve.

3. Adjust CO

regulator for the carbonator at a nominal 70 PSIG. PRESSURE TO THE CARBONATOR

2

MUST NOT EXCEED 80 PSIG.

4. Place control board power switch in “OFF” position.

5. Unplug Unit power cord from electrical outlet.

6. Connect carbonator tank sensor wiring harness connector into Unit wiring harness connector.

PRIMARY CO

REGULATOR

2

TO CARBONATOR

AND SYRUP PUMPS

7. Plug Unit power cord into electrical outlet.

8. Place control board power switch in “ON” position. After a 2 minute built-in time delay, refrigeration compressor will start and carbonator pump motor will start when carbonator calls for more water.

9. Make sure the key-lock switch on the side of the Unit is in the “ON” position. Dispense from all the dispensing valves until all air is purged from the system and carbonated water is being dispensed from the valves.

UNIT REQUIRING CONNECTION TO A REMOTE CARBONATOR.

1. Refer to carbonator manual for proper CO

ingly.

560003094 22

operating pressure. Adjust the primary CO2 regulator accord-

2

Page 26

2. Open the plain water source shut-off to the carbonator. Check for leaks and repair as needed.

3. Plug the remote carbonator power cord into an electrical outlet. The carbonator pump motor will start

when carbonator calls for more water.

4. Make sure the key-lock switch on the side of the Unit is in “ON” position. Dispense from dispensing valves

until all air is purged from the carbonated water system and carbonated water is being dispensed from the

valves.

SUGAR SYRUP

REGULATOR

PRIMARY CO

REGULATOR

2

DIET SYRUP

REGULATOR

TO CARBONATOR

ADJUSTING SUGAR SYRUP TANKS CO2 REGULATOR

Adjust the sugar syrup tank CO2 regulators to 40 PSI for syrup tubing that does not exceed 40 feet.

For syrup tubing that exceeds 40 feet, use the following table to calculate the correct pressure:

Starting Pressure Add for Horizontal Length Add for Vertical Lift

40 PSI 1 PSI/10 feet 1 PSI/2 feet

Based on this formula, a system with 80 feet of horizontal tubing and 10 feet of vertical tubing would require an

operating pressure of 40 PSIG [40 PSI (First 40 feet, horizontal) + 4 PSI (40 additional feet @ 1 PSI per 10 feet,

horizontal) + 5 PSI (10 feet vertical @ 1 PSI for each 2 feet of vertical lift)] = 49 PSI.

To adjust the CO

regulator, loosen the lock nut, then turn the adjusting screw clockwise until the gauge regis-

2

ters the desired pressure. Tighten the lock nut when the desired pressure is set.

ADJUSTING DIET SYRUP TANK CO2 REGULATOR

Adjust the diet syrup tank CO2 regulators to 10 PSI for syrup tubing that does not exceed 30 feet. Diet syrup

tubing that is longer than 30 feet may require a slightly higher pressure, but in any case, do not exceed

12 PSI maximum. Excessive CO2 pressure will cause the diet syrup to carbonate and result in foaming of the

product.

To adjust the CO

regulator, loosen the lock nut, then turn the adjusting screw clockwise until the gauge

2

registers the desired pressure. Tighten the lock nut after the desired pressure is set.

ADJUSTING SYRUP PUMPS CO2 REGULATOR (UNITS WITH INTEGRAL BUILT-IN

CARBONATOR AND BUILT-IN SYRUP PUMPS)

CO2 pressure to operate Units equipped with an integral (built-in) carbonator and built-in syrup pumps is

provided by a CO2 regulator in the system. The CO2 regulator provides regulated CO2 pressure to both the

integral carbonator and also the built-in syrup pumps. Adjust the CO2 regulator to 70 PSI. DO NOT EXCEED

MAXIMUM PRESSURE SPECIFIED ON THE SYRUP PUMPS.

56000309423

Page 27

To adjust the CO

regulator, loosen the lock nut, then turn the adjusting screw clockwise until the gauge

2

registers the desired pressure. Tighten the lock nut after the desired pressure is set.

MEASURING AND ADJUSTING DISPENSING VALVE CARBONATED WATER

FLOW RATE

1. Remove cover from the dispensing valve by lifting the front cover up 1/4 inch and pulling forward.

2. Install syrup diversion tube assembly on the dispensing valve by pushing rubber end of the syrup diversion

tube onto the syrup outlet of the inner nozzle.

3. Measure the water flow rate by dispensing water into a graduated cup for a set period of time.

NOTE: Adjusting screw stops are built into the valve to prevent leakage when the screws are adjusted

too far clockwise. Stop adjusting clockwise when turning resistance increases. Turn the screw counterclockwise 1–1/2 turns after the stop are contacted.

4. Turn the water flow regulator adjusting screw to the left (counterclockwise) to decrease the water flow rate

or turn the adjusting screw to the right (clockwise) to increase the water flow rate, then recheck the flow

rate. Adjustments should be no more than 1/4 turn at a time.

5. Remove syrup diversion tube from the dispensing valve, then install cover on the dispensing valve.

Counterclockwise

to Decrease

Clockwise

to Increase

WATER FLOW

REGULATOR

SYRUP FLOW

REGULATOR

INNER NOZZLE

NOZZLE

SYRUP DIVERSION

TUBE

RATIO CUP

ADJUSTING DISPENSING VALVE WATER-TO-SYRUP “RATIO” OF DISPENSED

PRODUCT

NOTE: Make sure the dispensing valve water flow rate is as desired before adjusting the valve for Water-to-Syrup ‘‘Ratio’’ (Brix) of the dispensed product.

560003094 24

Page 28

Adjust Water–to–Syrup “Ratio” (Brix) of the dispensed product by using ratio cup (P/N 311100000) and syrup

diversion tube assembly (P/N 319540000) as follows:

1. Remove cover from the dispensing valve by lifting front cover up 1/4 inch and pulling forward.

2. Install syrup diversion tube assembly on the dispensing valve by pushing the rubber end of the syrup diversion tube onto the syrup outlet of the inner nozzle.

Notice: Refer to syrup manufacturer’s recommendations on syrup package for water-to-syrup ratio.

3. Dispense enough to fill syrup diversion tube with syrup.

4. Hold large chamber of the ratio cup under the dispensing valve nozzle. Place free end of the syrup diversion tube into the syrup chamber marked for the proper ratio. Dispense approximately 6 ounces of water

into the ratio cup. Water and syrup levels should be even in cup.

Note: Adjusting screw stops are built into the valve to prevent leakage when the screws are adjusted

clockwise too much. Stop adjusting clockwise when turning resistance increases. Turn the screw

counterclockwise 1–1/2 turns after the stop are contacted.

5. Adjusting Syrup Flow Regulator – If water and syrup levels are uneven in the ratio cup, adjust by

turning the dispensing valve syrup flow regulator adjusting screw labeled SYRUP as follows.

A. For less syrup, turn the adjusting screw counterclockwise no more than 1/4 turn at a time.

B. For more syrup, turn the adjusting screw clockwise no more than 1/4 turn at a time.

6. Repeat water-to-syrup ratio test and adjust syrup flow regulator as many times as necessary until proper

ratio of dispensed drink is achieved.

7. Remove syrup diversion tube assembly from dispensing valve.

8. Install dispensing valve front cover.

56000309425

Page 29

THIS PAGE LEFT BLANK INTENTIONALLY

560003094 26

Page 30

TROUBLESHOOTING

IMPORTANT: Only a service person should service internal components or electrical wiring.

WARNING: Disconnect electrical power to the Unit to prevent personal injury before

attempting any electrical repairs to the internal components. If repairs are to be made to

one of the syrup systems, disconnect applicable syrup tank, then bleed system pressure

before proceeding. If repairs will be made to the CO

electrical power to the carbonator, shut-off CO

before proceeding.

TROUBLESHOOTING POST-MIX SYSTEM

Trouble Probable Cause Remedy

or carbonated water systems, disconnect

2

and water supplies, then bleed systems pressure

2

ADJUSTMENT OF

DISPENSING VALVE SYRUP

FLOW REGULATOR DOES

NOT INCREASE TO DESIRED

WATER -TO-SYRUP “RATIO”.

ADJUSTMENT OF

DISPENSING VALVE SYRUP

FLOW REGULATOR DOES

NOT DECREASE TO

DESIRED WATER -TO-SYRUP

“RATIO.

A. No syrup supply. A. Replenish syrup supply.

B. Syrup supply container not

securely connected into

B. Securely connect syrup supply

container into syrup system.

system.

C. Syrup Tanks System.

Syrup tanks CO2 regulator out

C. Adjust syrup tanks CO

as instructed.

of adjustment.

Syrup Bag-in-Box System.

Syrup pumps CO2 regulator

Adjust pumps CO2 regulator as

instructed.

out of adjustment.

D. Improper Baume of syrup. D. Replace syrup supply.

E. Inoperative dispensing valve

syrup flow control.

F. Tapered washer inside tube

swivel nut connection distorted

E. Repair dispensing valve syrup

flow control.

F. Replace tapered gasket. Make

sure it seats properly.

from being overtightened

restricting syrup flow.

A. Dirty or inoperative dispensing

valve syrup flow control.

A. Disassemble and clean

dispensing valve syrup flow

control.

regulator

2

DISPENSED PRODUCT

CARBONATION TOO LOW.

A. Carbonator CO

of adjustment for existing

regulator out

2

A. Adjust carbonator CO

As instructed.

regulator.

2

water conditions or

temperature.

B. Air in carbonator water tank. B. Vent air out of carbonator water

tank through relief valve. Open

No. 1 dispensing valve to make

carbonator water pump cycle on.

C. Water, oil, or dirt, in CO

supply.

2

C. Remove contaminated CO

Clean CO

system (lines,

2

2.

regulator, etc.) using a mild

detergent. Install a clean CO

2

supply.

56000309427

Page 31

Trouble RemedyProbable Cause

DISPENSED PRODUCT

COMES OUT OF

A. Oil film or soap scum in cups

or glasses.

A. Use clean cups or glasses.

DISPENSING VALVE CLEAR

BUT FOAMS IN CUP OR

GLASS.

B. Ice used for finished drink is

sub-cooled.

B. Do not use ice directly from

freezer. Allow ice to become “wet”

before using. (Refer to following

NOTE.)

NOTE: Crushed ice also causes dispensing problems. When finished drink hits sharp edges of ice,

carbonation is released from dispensed drink.

DISPENSED PRODUCT

PRODUCES FOAM AS IT

LEAVES DISPENSING VALVE.

A. Recovery rate of refrigeration

system exceeded, ice bank

depleted.

B. Carbonator CO2 regulator

pressure too high for existing

A. Allow ice bank to recover.

B. Reduce carbonator CO2 regulator

pressure settings.

water conditions or

temperature.

C. Syrup Tanks System.

Syrup over-carbonated with

CO2 as indicated by bubbles in

inlet syrup lines leading to unit.

C. Remove syrup tanks quick

disconnects. Relieve tank CO

pressure, shake tank vigorously,

then relieve tank CO2 pressure as

many times as necessary to

remove over-carbonation.

2

D. Dispensing valve restricted or

dirty.

E. Tapered gasket inside

carbonated water line swivel

nut connector distorted

restricting carbonated water

flow.

F. Dirty water supply. F. Check water filter. Replace

NO PRODUCT DISPENSED. A. Dispensing valves keyed

lock-out switch in “OFF”

position.

B. No electrical power to Unit. B. Plug in Unit power cord or check

C. Disconnected dispensing

valves power cord.

D. Disconnected or broken wiring

to dispensing valve.

E. Inoperative transformer or

dispensing valve solenoids.

D. Sanitize syrup system as

instructed in Service and

Maintenance Manual.

E. Replace tapered gasket. Make

sure it is properly seated.

cartridge.

A. Place keyed lock-out switch in

“ON” position.

for blown power fuse or tripped

circuit breaker.

C. Connect dispensing valves power

cord.

D. Connect or replace wiring.

E. Replace inoperative part.

ONLY CARBONATED WATER

DISPENSED.

A. Syrup supply container not

securely connected into syrup

system.

B. No syrup supply. B. Replenish syrup supply.

560003094 28

A. Securely connect syrup supply

container into syrup system.

Page 32

Trouble RemedyProbable Cause

ONLY CARBONATED WATER

DISPENSED. (cont’d)

C. Syrup Bag-in-Box System.

Inoperable syrup pump.

Syrup Tanks System.

Syrup tanks CO

regulator not

2

properly adjusted.

D. Inoperable dispensing valve. D. Repair dispensing valve.

E. Dispensing valve syrup flow

control not properly adjusted.

ONLY SYRUP DISPENSED. A. Water inlet supply line shutoff

valve closed.

B. Carbonator not operating. B. Restore carbonator operation.

C. CO

regulator not properly

2

adjusted.

DISPENSED PRODUCT

CARBONATION TOO LOW.

A. Carbonator CO

of adjustment for existing

regulator out

2

water conditions or

temperature.

B. Air in carbonated water tank. B. Vent air from carbonated water

C. Replace inoperable syrup pump.

Adjust syrup tanks CO

regulator

2

as instructed.

E. Adjust dispensing valve syrup

flow control (Water-to-Syrup

“Ratio”) as instructed.

A. Open water inlet supply line

shutoff valve.

C. Adjust CO

regulator as

2

instructed.

A. Adjust carbonator CO

regulator

2

as instructed.

tank by dispensing from No. 1

dispensing valve to make

carbonator water pump motor

cycle on.

NO PRODUCT DISPENSED

FROM ALL DISPENSING

VALVES.

C. Water, oil or dirt in CO

supply. C. Have service person remove

2

contaminated CO

clean CO

system (lines,

2

supply, then

2

regulator, etc.) using a mild

detergent. Install a clean CO

2

supply.

A. Dispensing valves keyed

lock-out switch in “OFF”

A. Place keyed lock-out switch in

“ON” position.

position.

B. No electrical power to Unit. B. Plug in Unit power cord or check

for blown power fuse or tripped

circuit breaker.

C. Dispensing valves power cord

disconnected.

D. Disconnected or broken wiring

C. Connect dispensing valves power

cord.

D. Connect or replace wiring.

to dispensing valve.

E. Inoperative transformer or

E. Replace inoperative part.

valve solenoids.

56000309429

Page 33

TROUBLESHOOTING CARBONATOR

Trouble Probable Cause Remedy

UNIT INTEGRAL CARBONATOR

CARBONATOR NOT

A. CO2 supply depleted. A. Replenish CO2 supply.

OPERATING.

B. Water supply to carbonator

B. Correct water supply problem.

disrupted. Control board has

shut down (5-minute max

operating time).

C. Carbonated water tank water

level probe electrical wiring

C. Connect electrical wiring to water

level probe (see NOTE).

disconnected.

D. Carbonator electrical fuse on

control board blown. (PLACE

D. Replace fuse (5-amp slo-blow

max).

CONTROL BOARD POWER

SWITCH IN “OFF” POSITION

BEFORE REPLACING

FUSE).

E. Inoperative carbonated water

E. Replace probe (see NOTE.)

tank water level probe.

F. Inoperative carbonator pump

F. Replace pump or motor.

or motor.

G. Inoperative control board. G. Replace control board.

NOTE: After completing repairs, place control board power switch (on top of Unit) in “OFF” position,

then place switch back into “ON” position to restart the Unit.

UNIT CONNECTED TO REMOTE CARBONATOR

Trouble Probable Cause Remedy

CARBONATOR NOT

A. Carbonator not operating. A. Refer to manual provided with

OPERATING.

TROUBLESHOOTING REFRIGERATION SYSTEM

Trouble Probable Cause Remedy

REFRIGERATION

A. Ice bank sufficient. A. No refrigeration called for.

COMPRESSOR DOES NOT

OPERATE.

B. No water in water tank. B. Fill water tank with water as

C. Control board power switch on

top of Unit in “OFF” position.

D. Unit power cord unplugged, or

drop-in refrigeration assembly

power cord unplugged.

E. Ice temperature sensor

electrically disconnected.

your carbonator.

instructed.

C. Place control board power switch

in “ON” position (will be a built-in

2-minute time delay before

refrigeration compressor starts).

D. Plug in power cord.

E. Electrically connect or replace

inoperable sensor.

F. No power source (blown fuse

or tripped circuit breaker).

560003094 30

F. Replace fuse or reset circuit

breaker. (NOTE: Fuse or circuit

breaker are not part of unit).

Page 34

Trouble RemedyProbable Cause

REFRIGERATION

COMPRESSOR DOES NOT

OPERATE. (cont’d)

G. Low voltage. G. Voltage must be at least 103 volts

(115 VAC unit) or 208 (230 VAC

unit) at compressor terminal when

compressor is trying to start.

H. Loose, disconnected, or

broken wiring.

I. Overload protector cut out;

overheated compressor.

Condenser fan motor not

operating as required.

H. Tighten connections or replace

broken wiring.

I. Compressor will cool enough to

restart. Do not overdraw cooling

capacity of Unit. Refer to

“CONDENSER FAN MOTOR

NOT OPERATING” in this

section.

J. Inoperative overload protector

J. Replace inoperative part.

or start relay.

K. Inoperative ice bank probe. K. Replace ice bank probe.

L. Inoperative control board. L. Replace control board.

NOTE: During normal operation, if carbonator or refrigeration compressor have not operated for

10-minutes, Unit will go into “SLEEP TIME”. While Unit is in “SLEEP TIME”, agitator motor will operate

every 10 minutes for 30 seconds, then stop. “SLEEP TIME” will continue until either the refrigeration

compressor or the carbonator motor start, then agitator motor will operate continuously until both

compressor and carbonator motor have been off for 10 minutes. “SLEEP TIME” cycle will again occur.

COMPRESSOR WILL NOT

STOP AFTER SUFFICIENT

A. Ice bank probe location

incorrect.

A. Place probe in proper location.

ICE BANK IS PRODUCED.

COMPRESSOR OPERATES

CONTINUOUSLY BUT DOES

NOT FORM SUFFICIENT ICE

BANK.

AGITATOR MOTOR NOT

OPERATING.

B. Ice temperature sensor

B. Replace ice temperature sensor.

inoperative.

C. Control board inoperative. C. Replace control board.

A. Cooling capacity is exceeded

by overdrawing.

B. Unit located in excessively hot

area or air circulation through

condenser coil is restricted.

A. Water bath temperature above

60° F.

A. Reduce amount of drinks drawn

per given time.

B. Relocate Unit or check and if

necessary, clean condenser coil

as instructed.

A. Water bath temperature must be

below 60° F in order for the

agitator motor to operate.

B. Agitator motor in “SLEEP

B. See NOTE.

TIME” mode.

C. No power source (blown fuse

or tripped circuit breaker).

C. Replace fuse or reset circuit

breaker. (NOTE: Fuse or circuit

breaker are not part of the

Unit).

D. Agitator motor propeller

D. Remove obstruction.

obstructed.

E. Low voltage. E. Voltage must be at least 103 volts

(115 VAC Unit) or 208 (230 VAC

Unit) at compressor terminals

when compressor is trying to

start.

56000309431

Page 35

Trouble RemedyProbable Cause

AGITATOR MOTOR NOT

OPERATING. (cont’d)

F. Loose, disconnected, or

broken wiring.

F. Tighten connections or replace

broken wiring.

G. Inoperative agitator motor. G. Replace agitator motor.

NOTE: During normal operation, if carbonator or refrigeration compressor have not operated for

10-minutes, Unit will go into “SLEEP TIME”. While Unit is in “SLEEP TIME”, agitator motor will operate

every 10 minutes for 30 seconds, then stop. “SLEEP TIME” will continue until either the refrigeration

compressor or the carbonator motor start, then agitator motor will operate continuously until both

compressor and carbonator motor have been off for 10 minutes. “SLEEP TIME” cycle will again occur.

560003094 32

Page 36

WARRANTY

IMI Cornelius Inc. warrants that all equipment and parts are free from defects in material and workmanship under normal use and service. For a copy of the warranty applicable to your Cornelius, Remcor or Wilshire product, in your country, please write, fax or telephone the IMI Cornelius office nearest you. Please provide the

equipment model number, serial number and the date of purchase.

IMI Cornelius Offices

AUSTRALIA P.O. 210, RIVERWOOD, NSW 2210, AUSTRALIA (61) 2 533 3122 FAX (61) 2 534 2166

AM LANGEN FELDE 32 A-1222 VIENNA, AUSTRIA (43) 1 233 520 FAX (43) 1-2335-2930

AUSTRIA

BOSKAPELLEI 122 B-2930 BRAASCHAAT, BELGIUM (32) 3 664 0552 FAX (32) 3 665 2307

BELGIUM

RUA ITAOCARA 97 TOMAS COELHO RIO DE JANEIRO, BRAZIL (55) 21 591 7150 FAX (55) 21 593 1829

BRAZIL

ENGLAND

TYTHING ROAD ALCESTER WARWICKSHIRE, B49 6 EU, ENGLAND (44) 789 763 101 FAX (44) 789 763 644

71 ROUTE DE ST. DENIS F-95170 DEUIL LA BARRE PARIS, FRANCE (33) 1 34 28 6200 FAX (33) 1 34 28 6201

FRANCE

GERMANY

GREECE

HONG

ITALY

NEW

SINGAPORE

SPAIN

USA

CARL LEVERKUS STRASSE 15 D-4018 LANGENFELD, GERMANY (49) 2173 7930 FAX (49) 2173 77 438

488 MESSOGION AVENUE AGIA PARASKEVI 153 42 ATHENS, GREECE (30) 1 600 1073 FAX (30) 1 601 2491

KONG 1104 TAIKOTSUI CENTRE 11-15 KOK CHEUNG ST TAIKOKTSUE, HONG KONG (852) 789 9882 FAX (852) 391 6222

VIA PELLIZZARI 11 1-20059 VIMARCATE, ITALY (39) 39 608 0817 FAX (39) 39 608 0814

ZEALAND 20 LANSFORD CRES. P.O. BOX 19-044 AVONDALE AUCKLAND 7, NEW ZEALAND (64) 9 8200 357 FAX (64) 9 8200 361

16 TUAS STREET SINGAPORE 2263 (65) 862 5542 FAX (65) 862 5604

POLIGONO INDUSTRAIL RIERA DEL FONOLLAR E-08830 SANT BOI DE LLOBREGAT BARCELONA, SPAIN (34) 3 640 2839 FAX (34) 3 654 3379

ONE CORNELIUS PLACE ANOKA, MI NNESOTA (612) 421-6120 FAX (612) 422-3255

LD004

4/21/98

56000309433

Page 37

IMI CORNELIUS INC.

CORPORATE HEADQUARTERS:

One Cornelius Place

Anoka, Minnesota 55303-6234

(612) 421-6120

(800) 238-3600

38315221001

Loading...

Loading...