Řídicí systém pro

vzduchotechnické jednotky

INSTALLATION AND OPERATING INSTRUCTIONS

Control units

11 /2018

1

Control units VCS

Table of Contents

n e VCS control unit soware is the intellectual property

of REMAK a.s.

n VCS control units are manufactured in accordance with

valid Czech and European regulations and technical standards.

n VCS control units must be installed and used only in accor-

dance with this documentation.

n The manufacturer is not responsible for any damage resul-

ting from use for purposes other than specified in this documentation, and the customer bears the risks of such use.

n The installation and operating documentation must be

available for the operating and servicing staff. It is advisable to store this documentation close to the installed

VCS control unit.

n When handling, installing, wiring, commissioning, repairing

or servicing the air-handling units, it is necessary to observe

valid safety rules, standards and generally recognized

technical rules.

n All equipment connections must comply with the respective

safety standards and regulations.

Introduction

Equipment characteristics .................................................................................................................................................................2

Design .......................................................................................................................................................................................................3

Documentation and Safety Measures ...........................................................................................................................................4

Handling, Transport and Location ................................................................................................................................................... 5

Commissioning ......................................................................................................................................................................................6

Control and Protection Functions ................................................................................................................................................... 8

Basic Operating Modes ...................................................................................................................................................................17

Additional Operating Modes and Functions ............................................................................................................................. 17

Temperature and Time Modes ......................................................................................................................................................19

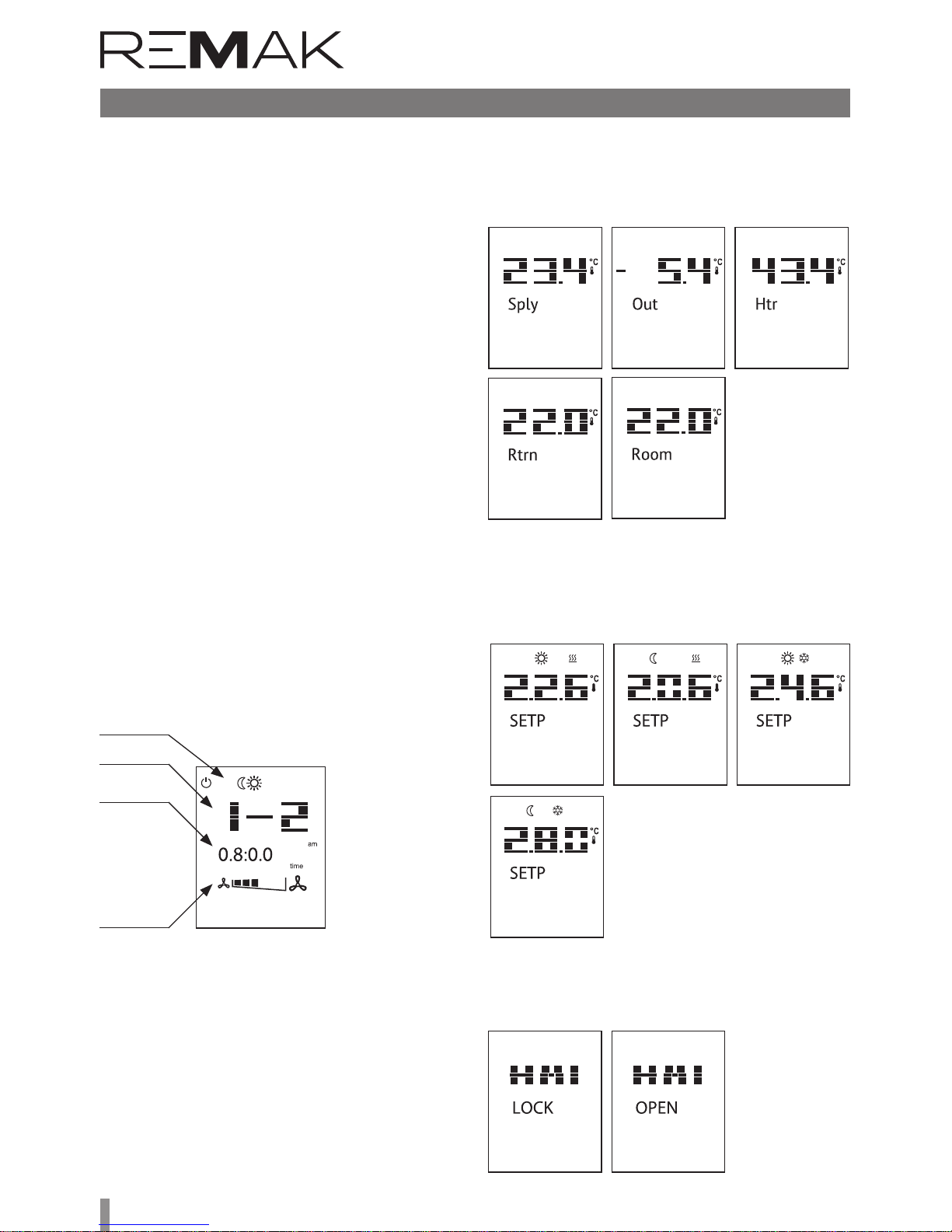

Control (HMI-SG controller) ............................................................................................................................................................20

List of Data Points (HMI-SG controller) ...................................................................................................................................... 27

List of Failures (HMI-SG controller) ..............................................................................................................................................43

REMAK mobile app ...........................................................................................................................................................................47

Control (HMI-DM, HMI-TM and HMI@Web controllers) ........................................................................................................46

Control (HMI@Web – Installation and Connection to PC and LAN/WAN) ....................................................................51

SCADA (Supervisory Control and Data Acquisition) .............................................................................................................. 58

List of Data Points (HMI-DM, HMI-TM and HMI@Web controller) ...................................................................................59

List of Failures (HMI-DM, HMI-TM and HMI@Web controller) ............................................................................................ 68

Other Control ......................................................................................................................................................................................69

Connection to the Master System (LonWorks Standard) ................................................................................................... 70

Connection to the Master System (ModBus Standard) ....................................................................................................... 75

Connection to the Master System (BacNet Standard) ........................................................................................................95

POOL UNITS – descriptioon of control ...................................................................................................................................... 97

PLC Controller for Compressor Output Control ......................................................................................................................99

Electronic Expansion Valve Overheating Controller EC3-X33 ......................................................................................... 104

KHD-S1_ _.R Backup System Wiring Diagram....................................................................................................................110

Unit Activation ................................................................................................................................................................................. 111

Checks and Failures ........................................................................................................................................................................ 113

Troubleshooting .............................................................................................................................................................................. 114

Spare Parts and Service ...............................................................................................................................................................115

Disposal and Recycling ................................................................................................................................................................. 115

n Any changes or modifications to individual components of

the VCS control unit which could affect its safe and proper

functioning are forbidden.

n Before installing and using the air-handling units, it is nece-

ssary to familiarize yourself with and observe the directions

and recommendations included in the following chapters.

n The VCS control units, including their individual parts,

are not intended, due to their concept, for direct sale

to end customers. Each installation must be performed

in accordance with a professional project created by

a qualified designer who is responsible for the proper

selection and dimensioning of components concerning

their suitability for a given application. Installation and

commissioning may only be performed by an authorized

company licensed in accordance with generally valid

regulations.

n REMAK a.s. is not responsible for any damage, direct or

indirect, caused by unauthorized or unqualified used of

the soware or hardware, or for any damage caused by

ignoring the product's Operating Instructions.

Up-to-date version of this document is available at website www.remak.eu

2

Equipment characteristics

Application

VCS control units are compact control and power distributors used for the decentralized regulation and control of airhandling systems. ey provide the equipment with high

stability and safety while allowing easy control, including the

viewing of operating states. (STOP - OPERATION - AUTO).

Main Features

e VCS control unit is intended for the following:

n Complex autonomous control of air-handling systems

n Supply or room air temperature control (cascade control)

n Supply and power actuation of air-handling systems

n Protection and safeguarding of connected components

is control unit provides air-handling systems with control

and safety functions. It can be equipped with the necessary

number of proportional inputs and outputs depending on the

required functions.

Sophisticated control algorithms ensure system stability, user-friendly control and energy savings. Another

advantage is that the control unit's features also contribute to energy savings in air-handling system operation:

n Option to set the unit to 2 temperature modes

• Comfort

• Economy

n Time schedule setting options

(daily or weekly time schedules)

n Additional operating mode setting options:

• Optimized start

• Temperature start-up

• Night chilling

n Precise drive control using data communications

(Modbus RTU protocol)

n Superior antifreeze protection with moderate heating of

the heat exchanger during standby mode

n Precise analogue control of controlled peripheral units

(according to the controlled component)

Unit Design

ese control units are designed in accordance with ČSN

EN 60204-1. e unit's control and power parts are situated in a single box. e components, control and actuating

elements, are fi tted on the DIN bars inside the control unit.

Depending on the version, the VCS control unit can be provided

in plastic (plastic switchboard) or in sheet-steel (sheet-steel

switchboard). Both designs are equipped with transparent

doors. e controls are situated below these doors. Further,

the VCS control unit can be produced as a built-in assembly

and a part of an air-handling unit section, which must be

designed for that purpose and meet specifi c requirements.

Controller HW and SW Concept

e core of the VCS system is created by a powerful Siemens

Climatix series PLC controller. e control unit can be equipped

with one of two POL4xx and POL6xx controller versions

depending on the components used in the air-handling unit.

Simultaneously, additional external input/output or communication modules can be connected to the POL6xx controller.

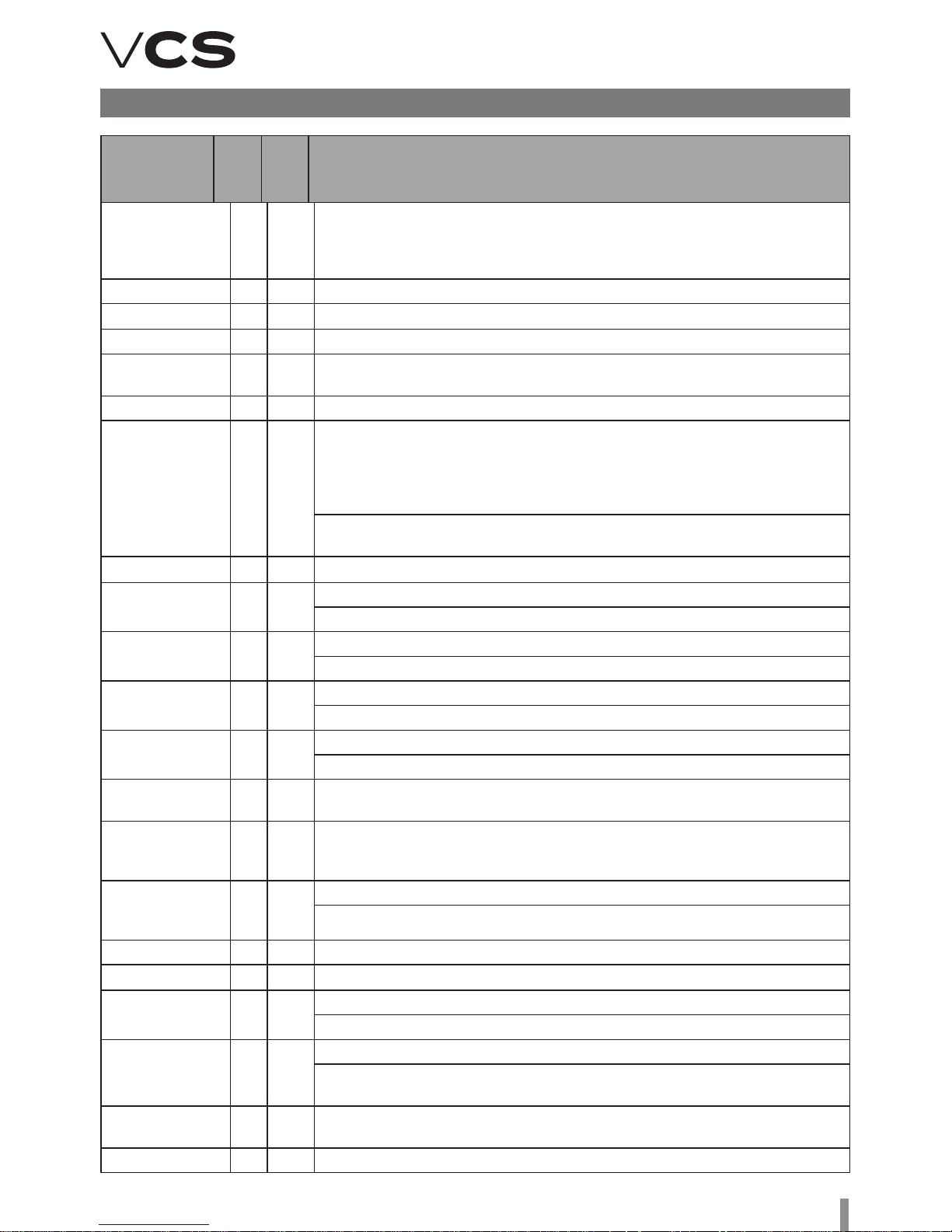

Figure 1 – VCS control unit design

Control unit box

Screws

Circuit breakers

Disconnecter

Master switch

HMI-SG controller

For local control, the HMI-SG POL822/60 hand controller

can be used. e control unit allows up to 8 basic control

sequences to be used depending on the air-handling unit

confi guration. e order of some sequences can be changed

(e.g. heating-mixing damper or cooling-fan cooling).

e heat pump or electric a er-heater can be separated from

basic sequences in the so-called extra sequences.

If this is the case, another sensor must be used in the air inlet,

and a special set-point must be set for this type of control.

is feature can only be used a er prior consultation with the

manufacturer. ese units are delivered adapted to individual

applications so they will provide exactly those features needed

for the operation of a specifi c air-handling device.

Control

Local control

e basic VCS controllers are devices (manual controllers

with bus connection) for so-called local control of the control

unit (see fi g. 2):

a) Room controller - HMI-SG (POL822/60)

b) Comfortable universal alphanumeric driver

- HMI-DM nebo HMI-TM

Note: For details, see controllers instructions part of the

manual.

Distant control

In addition to local VCS controllers, so-called remote control

can be used. For this control, you need to connect VCS to LAN,

WAN or Internet (For production, the control unit must be

confi gured/ordered with the required functionality).

a) HMI@WEB - You can use the HMI @ WEB controller via

the web interface. e controller fully complies with the local

HMI-DM and TM controls.

b) Mobile app (see fig. 3) - You can use simple touch

application for smartphones or tablets with Google Android

(v. 4.0.3 and higher).

c) SCADA web interface

Monitoring and operation using the device’s technological

scheme with operating parameters, respectively using the

tabular interface of an internet browser on a PC. For details,

refer to page 58.

3

Control units VCS

Figure 2 – HMI-SG (-DM, -TM) controllers

Figure 3 – Mobile application

HMI-SG

Figure 4 – VCS control unit internal structure

Other controls (technological)

For basic control (triggering, mode switching)

from a technology or a very simple manual button / switch

control, you can use "Other Controls". External control via one

or two non-voltage contacts.

Control from parent system

When integrating HVAC with the VCS control unit into complex

building management systems (BMS), it is also possible to

connect to these systems. Subsequently, it is possible to

control and monitor the HVAC through them. e ModBus,

LON, and BacNet standards can be used.

The different types of control must be designed when

designing (confi guring) VCS into the project and especially in

production - the usability of remote control and connectivity

to the BMS are dependent on the use of the corresponding

controller.

Detailed descriptions of all controller types, control and their

use - see separate sections / chapters of this manual.

HMI-TM

Control

HMI-DM

Power Part

e power part, like the control part, is always "tailored" for

a specifi c air-handling unit.

Connecting terminals

Connecting terminals

Controller

Siemens Climatix

4

Design

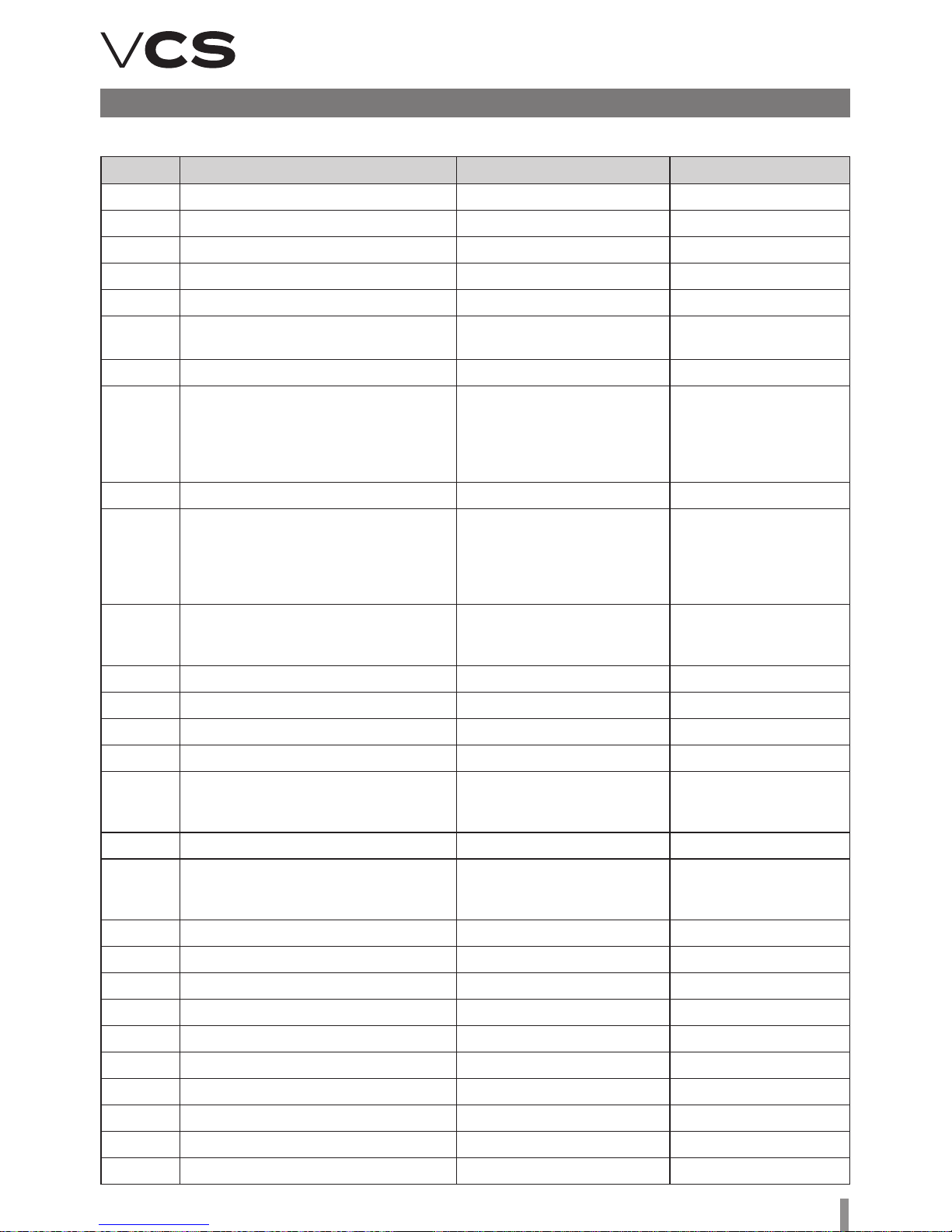

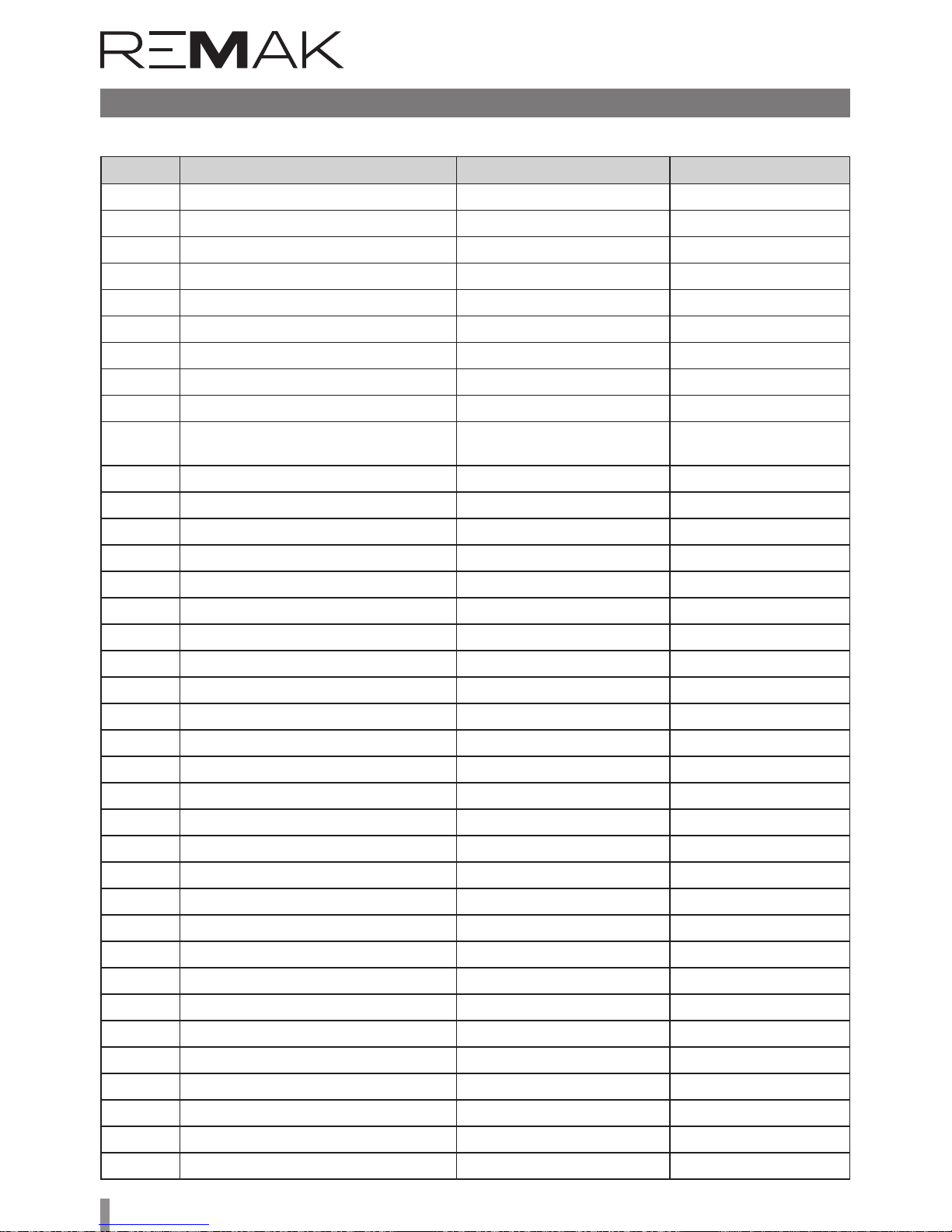

Table 2 – List of connecting cables (example)

Cable No.

Figure 7 – Component wiring (example)

Figure 6 – Summary of connected components (example)

Boxes

Indoor VCS control units are built into plastic or sheet metal

cabinets with front transparent doors under which controls

are located. e permissible ambient temperature is 0 ° C

to + 40 ° C.

VCS in exterior design are built into sheet metal cabinets

with full front doors under which controls are located. In

the confi guration so ware we can design: range of average

temperatures -40 ° C to 35 ° C, cabinet mounting (hanging /

stand), door design (le / right), lighting, service drawer (select

according to customer's destination).

A space of minimum 15 cm must be le on each side of the

box to allow access for cooling air and for changing the fi lter

which is fi tted in front of the fan.

As a standard, we provide a door lock and a box for storing

unit documents. Depending on the particular confi guration of

the control unit, these enclosure dimensions are used (Table

1). e electrical enclosure of the plastic case corresponds to

IP 65 with the door closed and IP 40 when the door is open.

e electrical cabinet cover is IP 55 or IP 66 (depending on

enclosure type) when the door is closed and IP 20 when the

door is open. e metal enclosure with additional ventilation

is IP54 with the door closed and IP 20 with the door open.

The VCS control units can be mounted directly on the

Flammability Levels A and B according to EN 13501-1.

Additionally, the VCS control unit can be manufactured in an

integrated design as part of the ventilation unit section. One

of the options is a built-in section for assembled VZTs, which

includes adjustments for the environment. is section is used

when designing VZT with IP44 protection as well

for outdoor units (with heating or cooling of the control unit).

Table 1 – box dimensions in mm

If needed, the boxes, sized 2000 × 800 × 400 mm and 2000 × 1000 × 400 mm, can be

fi tted with a ventilation set – a fan and a louver in opposite corners.

VCS

ACX36/RMK

Figure 5 – Installation in the XP unit section

Design

e control system design is based on the selection of required features and on its internal confi guration. e design

is performed automatically using the algorithm integrated

into the design so ware also used for the air-handling unit

design. e design output provides an exact specifi cation of

the control unit, including the following individualised lists for

a specifi c device:

n Summary of connected components

n Wiring diagrams of all components

n List of all recommended cables for the connection of all

components (the cables must always be used in accordance with the electrical equipment project documentation).

Version Height Width Depth Usual application

Plastic 610 340 160

Vento, FP, some XP (single-speed)

Plastic 610 448 160

Vento, FP, some XP (single-speed)

Plastic 842 448 160

Vento, FP, some XP (single-speed)

Sheet-steel 800 550 250 XP, sophisticated Vento assemblies

Sheet-steel 1200 750 300 XP

Sheet-steel 1600 750 300 XP

Sheet-steel 2000 800 400 XP

Sheet-steel 2000 1000 400 XP

(Recommended) cable type Power Supply Cable length Note

a) AeroMaster XP b) CAKE

5

Control units VCS

Figure 8 – Example of access to the unit

max. 700 m

HMI-SG

Documentation

Control Unit Designation

e control unit designation is always created by a unique

code (generated by the AeroCAD design program for the

control unit calculation and design), which is only included

in the accompanying technical documentation (not on the

control unit), and by the serial number (for communication

with the manufacturer).

Documentation

VCS control systems can be installed and used only in accordance with the delivered documentation.

Documentation List

n Product Installation and Operating Instructions

n Control system confi guration (summary of connected

components), terminal diagram and list of recommended cables – device printout from the AeroCAD design

program

Additional – General Documentation

e system or device documentation also includes the operating and inspection documentation kept during the device

service life and the Service Regulations, for which the user

is responsible.

Service Regulations

Before putting the air-handling device into permanent operation, the device user in collaboration with the designer, or the

supplier, must issue service regulations in accordance with

local regulations.

We recommend including the following in these service

regulations:

n Air-handling device assembly confi guration, its intend-

ed use and a description of its operation in all operating

modes

n Description of all safety and protective elements and

their functions

n Summary of the health protection principles, safety and

operating rules to be observed when operating the airhandling equipment

n List of requirements for operating staff qualifi cations and

training, nomenclature list of personnel authorized to operate the air-handling device

n Detailed emergency and accident instructions to be fol-

lowed by the operating staff

n Operating particularities in diff erent climatic conditions

(e.g. summer or winter operation)

n Inspection, checking and maintenance schedule, includ-

ing a list of checking steps, and their recording

Documentation Availability

e documentation delivered with the control system (original)

and operating documentation must be permanently available

for the operating and service staff and stored near the airhandling equipment. e Installation and Operating Instructions

are also available at the website: https://www.remak.eu

Warning

e manufacturer reserves the right to make changes and

amend the documentation due to technical innovations and

changes to legislation without prior notice. Information on

changes and updates are always available at the website

https://www.remak.eu

Safety Measures

n VCS control units are manufactured in accordance with

valid regulations and technical standards.

n VCS control units must be installed and used only in ac-

cordance with this documentation.

n Any damage caused by improper use contrary to this

documentation is the responsibility of the subject who

failed to observe the instructions included in this documentation.

n When handling, installing, wiring, commissioning, repair-

ing or servicing the air-handling units, it is necessary to

observe valid safety rules, standards and generally recognized technical rules.

n In particular, it is necessary to use suitable tools and per-

sonal protective work aids (e.g. gloves) because of sharp

edges and corners, respectively voltage, when performing any handling, installing, dismounting, repairing or

checking.

n Any changes or modifi cations to individual components

of the VCS control unit which could aff ect its safe and

proper functioning are forbidden.

n e air-handling equipment confi guration and documen-

tation must not be changed without the prior consent of

the manufacturer.

n e VCS control units, including their individual

parts, are not intended, due to their concept, for direct sale to end customers. Each installation must be

performed in accordance with a professional project created by a qualifi ed designer who is responsible for the

proper selection of equipment concerning its suitability

for the given application.

n All connections of the equipment, including the VCS con-

trol unit, to the power mains must be performed in accordance with applicable local wiring standards and regulations.

n Wiring installation, commissioning, maintenance and re-

pairs may only be performed by a specialized assembly

company, respectively an authorized person duly qualifi ed in accordance with generally valid regulations.

n Before installing and using the air-handling units, it

is necessary to familiarize yourself with and observe

the directions and recommendations included in the

following chapters.

HMI-SG

6

Conditions for Handling

e device can only be commissioned, operated and serviced

by qualified personnel.

n e VCS control unit can only be operated by person-

nel provably trained and warned about possible dangers

(by the manufacturer or authorized representative of the

manufacturer) in accordance with the applicable Service

Regulations for the air-handling unit.

n It is forbidden to remove, bypass or disconnect the safe-

ty equipment, safety functions and guards.

n Only air-handling components in perfect condition can be

used. Failures affecting the equipment safety must be removed immediately.

n All safety measures against electrical accidents must be

strictly observed. Any action resulting in restriction, even

temporary, of the safety and protection functions must

be avoided.

n It is strictly forbidden to remove safety guards, casings

or other safeguards, operate the equipment or its components if the safeguards are disabled or restricted.

n Any action resulting in restriction of the prescribed insu-

lation of the safety voltage must be avoided.

n When changing fuses, it is necessary to ensure the non-

voltage state of the control unit and use only the specified fuses and protection elements.

n It is necessary to eliminate electromagnetic interference

and the harmful effects of over-voltage on the signal,

control and power cables, which could unintentionally initiate dangerous actions and functions or cause destruction of the electronic parts in individual components.

n Never work on the connected equipment under voltage!

Before starting work on the air-handling unit, switch off

and lock the master switch to disconnect the supply voltage. Use protective and work aids in accordance with

the Service Regulations and standards applicable in the

country where the unit is installed.

n If individual technical assemblies of the air-handling unit

are equipped with service switches, and if allowed by the

Service Regulations, installation conditions and characteristics, then such assembly (e.g. heater, fan, etc.) can

be disconnected by switching off and locking the corresponding service switch.

n Never use abrasive cleaners, cleaners unsuitable for plas-

tics or acid or alkaline solutions to clean to unit.

n Avoid splashing water, impacts and vibrations.

Each air-handling equipment component must always

be installed in accordance with the appropriate installation instructions.

e manufacturer recommends fully ensuring the flawless condition and functioning of all protective elements

and equipment. Aer failures, such as short circuits, have

been removed, check the functionality of the automatic

circuit breakers and protective elements, and verify the

condition of the protective wiring interconnection and

grounding.

To ensure safe operation, it is necessary to verify the conditions of the water heating/cooling pumps – perform

manual pump turning and set the output curve (over-design impairs the control quality).

Warning: If the remote control is used (including automatic

schedule program), safety access must be ensured for each

physical interference or entry into the air-handling unit (inspection, maintenance or repair) – i.e. disconnect the power supply

by turning off the switch – avoid remote initiation of the unit

by other users when work is being performed on the unit.

Transport and Storage

Before Installation

VCS control units are packed in cardboard boxes or installed

in the corresponding air-handling unit section, if they are

integrated into the air-handling unit. Measures for handling

fragile goods must be taken when handling the unit.

e units must be stored in rooms complying with the following conditions:

n Maximum relative air humidity must not exceed 85%,

without water condensation

n Ambient temperature between –25°C and +60°C

Dust, water, caustics, corrosive agents or other materials

negatively affecting the structure or the unit’s components

(causing degradation of plastic parts and insulation) must

not enter the unit.

Installation and Location

e VCS control unit location must provide good access for

the operating personnel and easy connection of the cables.

e installation site must be flat without rough spots.

When planning the air-handling unit location, it is necessary to

keep sufficient space for maintenance, service and operating.

Check the completeness and intactness of the delivery in accordance with the bill of delivery before installation.

ese control units are designed for normal (indoor, dustless,

dry, non-explosive) environments. ey can be mounted on

A and B combustibility grade materials in accordance with

EN 13501-1.

Permissible ambient temperature: +0 °C to +40 °C (24h average must not exceed +35 °C)

e VCS control units in the switchboard boxes are mounted

in the vertical position directly on the wall. e KAEDRA plastic

switchboard box can also be partially embedded under plaster.

e VCS unit installed in steel switchboard boxes can also be

placed directly on the floor. e cables can be run along cable

trenches, cable trays or under plaster.

e power cables are connected from below.

We recommend the wall-mounted units be fixed to the wall

using dowels and screws suitable for the wall structure.

Manipulace, transport, umístění

n e air-handling equipment can only be operated in ac-

cordance with the applicable Service Regulations. e

operating staff must comply with the requirements included in the Service Regulations, respectively with the

manufacturer's requirements (authorisation for some

service activities).

n To avoid unintentional unit start-up, the master switch

must be switched off and locked when repairing the

VCS unit.

7

Control units VCS

Note: As appropriate, the above-mentioned instructions apply also for control units integrated into the air-handling unit

while observing the control unit installation and operating

instructions delivered with the air-handling unit.

Check the completeness and intactness of the delivery in accordance with the bill of delivery before installation.

Commissioning

Fitting and Wiring Check

A careful check and verification of the wiring of all control

system components in accordance with the attached unit

wiring diagram must be performed before the first start-up.

e system cannot be connected to the power supply until

these checks have been performed.

First of all, it is necessary to check the presence, locations and

connections of the temperature sensors, fan thermo-contacts

and heaters in accordance with the M&C project. Further, the

connections of all error inputs must be checked.

It is also essential to check the fans, electric heaters, heat exchangers, filters and other parts of the connected air-handling

unit for correct fitting in accordance with the air-handling

accompanying documentation.

e above-mentioned checks must include a functionality

check of each component.

Special attention must be paid to the check of the conductive interconnection of all parts of the air-handling unit and

associated devices.

Conditions for Connection

e connections must be performed in accordance with the

applicable local wiring standards and regulations. Before putting the unit into operation, an initial wiring inspection must

be performed in accordance with the national regulations.

Settings

e VCS control unit has been manufactured according to the

customer’s requirements (the project), and the basic parameters have been pre-set so that the unit is ready for operation.

With these settings, the control unit will start and begin the

control for the pre-set parameters providing the connection

of the unit has been performed correctly.

However, the professionals performing the unit commissioning

must always check or adapt the air-handling unit’s operating

parameters to the specific design and behaviour of the control

system and operating or local conditions.

It is especially necessary to pay attention to the control

constants and parameter, various correction values,

temperature modes and time schedules, optional modes

and functions.

e data points are accessible through the HMI control panel.

Setting the user access levels is an important part of the

settings procedure.

e default factory settings must be re-set according to the

user and service company needs.

e Access passwords are the basic pre-set parameters which

need to be reset when commissioning the unit, see the chapter

Control (HMI-SG).

Additional Settings:

n To optimize the interaction between the control unit and

peripheral devices, it is necessary to set, using the HMISG controller (see the List of Data Points in the section

Settings – Control Signal Characteristic), corresponding values of the analogue signals for heating, cooling,

heat recovery and gas heating, optional from 0–10 V and

2–10 V (pre-set).

e values 2–10V are suitable for REMAK or Belimo actuators.

Room temperature Measuring Point Selection

n Up to two room temperature sensors can be installed in

the air-conditioned room (HMI-SG controller with an integrated temperature sensor plus one additional temperature sensor, or two HMI-SG controllers with integrated

temperature sensors). e final room temperature value for the control can be set as the minimum, maximum

or average of both sensors (see the List of Data Points -

Temperature Measuring Point Selection).

Selection of the specific point for adjusting or measuring the

temperature value entering the control process results in more

accurate setting of the room temperature.

Warning

e device parameters are structured and made available

to users in accordance with their user roles (access levels).

ese roles must be assigned to the users according to their

expertise and responsibility for device operation.

Basic Application Parameterization

n Default and common operation parameterization is de-

scribed in the chapter Control (see particular controller).

General Overview of Parameters

For a general overview of parameters available in the menu

and access authorization of users, refer to the chapter VCS

– Parameter Overview and Default Factory Settings. For the

menu with HMI controller parameters and default values, refer

to the chapter Control (HMI-SG).

Important Notes

Correct assembly, installation, commissioning and proper

control are the essential conditions for flawless and safe

operation of the control unit. e components connected to

the control unit must correspond with the specification in the

control unit documentation.

e procedures specified by the manufacturer in the unit

documentation and the Service Regulations measures must

be observed throughout the unit service life.

Commissioning

8

Location of Control System Sensors

Inlet Air Temperature Sensor (NS 120)

Control and anti–freeze sensors must always be situated

behind the heater, respectively cooler – to measure the supply air temperature. ey must not be situated in the room.

VO antifreeze protection sensor (NS 130R)

e return water temperature sensor must be situated in

the return water line from the water heater so that it will be

sufficiently bathed in water. e heating water circuit must

ensure all the required functions for the water heater control

and safety when the unit is shut down (filling the system

with antifreeze mixture) as specified in the air-handling

device project documentation. A capillary tube can be used

as additional antifreeze protection. If it is not installed on the

air-handling unit by the manufacturer, the capillary tube must

be run (meandering way) through the entire cross-section of

the water heater’s rear side.

Outdoor air temperature sensor (NS120)

Ideally, it should be situated in the outside environment – only

then are the control system’s functions ensured even in the

STOP mode or immediately aer unit start-up (e.g. moderate

pre-heating of the exchanger based on the actual outside

temperature, etc.).

If the sensor is situated in the fresh air inlet duct inside the

building, the measured temperature is only correct when the

fans are switched on (air flows) and the starting conditions

are negatively affected – which can endanger the air-handling

device’s safety and even result in the water heat exchanger

breaking down.

Outdoor Temperature Sensor

– installed outside (NS110A)

e sensor (as with any thermometer) must be installed

so that objective outdoor temperature measurement will

be achieved. It must be protected against negative effects

like sunshine, rainfall, frost deposits, e.g. situating it under a

building’s roof, using outdoor VZT roofs, situating it in the inlet

louvers, inlet ducts or separate covering roof.

Room Temperature Sensors

Optionally, a room (NS100), duct (NS120) or HMI-SG controller integrated sensor can be used by the designer.

Commissioning

EO Pre-Heating Control Temperature Sensor (NS 120)

To ensure correct control, the sensor must be situated behind

the electric pre–heater (EO) – before other temperature

adjusting components.

Flue Gas Temperature Sensor

e Pt 100 sensor is used to measure the flue gas temperature. e sensor must be situated in a representative place

within the flue gas installation.

Inlet Air Humidity Sensor

is is a duct sensor which must always be situated in an inlet

branch aer the air-handling unit. e selected position must

be representative enough for the measured value. It must not

be situated in the room.

Room Humidity Sensor

Optionally, a room or duct sensor can be used by the designer.

n e room sensor must be situated in the room in a "rep-

resentative" place so that it will not be influenced by local

effects (windows, doors, etc.)

n e duct sensor must be situated in the outlet duct from

the room – the advantage here is that the mean humidity of

the room outlet air is measured.

TH 167 Gas Heating Safety ermostat

e sensor must be situated before the gas heater section

behind the fan section. e thermostat must be situated so

that it will start the fans to protect the air-handling components situated in front of the gas heater chamber if back air

flow occurs.

Air Quality Sensor – CO2 (VOC, CO)

e air quality sensors are placed in the outlet air duct or in

the "representative" spots, thus ensuring objective air quality

value measuring.

Connection of the fan frequency inverters,

heat exchanger to the Modbus bus

Safety Conditions

n Properly carried out transport, storage, installation, com-

missioning and careful handling is the main condition for

correct and trouble-free operation.

n Protection, switching, wire routing and grounding must

fully comply with the local regulations applicable for wiring.

n e 230/400 V AC power wiring must be strictly separated

from the signal wiring (e.g. 24 V AC SELV)!

Figure 9 – Room sensor installation

• e room sensor or HMI-SG controller with integrated room

sensor must be situated in a spot "representing" the room temperature, and they must not be affected by local effects (heaters,

windows, vertical temperature distribution in the room, etc.)

• e duct sensor must be situated in the room outlet duct

– the advantage in this is that the average temperature of the

air flowing from the room is measured without being affected

by local effects (and it is hidden).

Heat Exchanger's Antifreeze Protection Sensor

(NS 130R)

e sensor must be situated in the outlet air duct behind the

heat exchanger.

9

Control units VCS

Control and Protection Functions

Wiring

n A shielded conductor must be used for the Modbus bus

connection. e maximum conductor length depends on

the communication speed. A maximum length of approx.

1000 m is recommended for the baud rate of 9600 Bd. e

recommended conductors are included in the documentation

created by the AeroCAD design program.

n e controller is connected to two terminals marked A+

and B- and to the REF signal detection reference voltage

terminal, which must always be interconnected with other

participants on the bus.

n To ensure correct functioning of the bus, the fi rst and last

device on the bus must be fi tted with a terminal resistor. e

fi rst device, i.e. the master controller, terminal resistor setting

is performed using the so ware (ensured by REMAK in the

factory). e last device terminal resistor setting is performed

on the last frequency inverter in the line connection. Refer to

the Modbus bus wiring diagram. e setting procedure of

the last terminal resistor is described in the documentation

for a corresponding frequency inverter. A 120 Ohm resistor

connected between the communication can also be used to

terminate the wiring.

Fan Failure Detection

n To detect any fan failure, the motor thermo-contact and

diff erential pressure sensor are connected to the frequency

inverter inputs. e information provided by these elements

is transmitted through the Modbus communication line to the

control system, where it is processed.

Modbus RTU Communication Settings

n Each frequency inverter connected to the bus must be

assigned a unique address as defi ned in the control system

data points.

Pre-set Frequency Inverter Addresses – ModBus:

Inlet Fan

Inlet fan address =1

Backup or twin fan address =2

Backup twin fan 1 address =3

Backup twin fan 2 address =4

Outlet fan

Outlet fan address =5

Backup or twin fan address =6

Backup twin fan 1 address =7

Backup twin fan 2 address =8

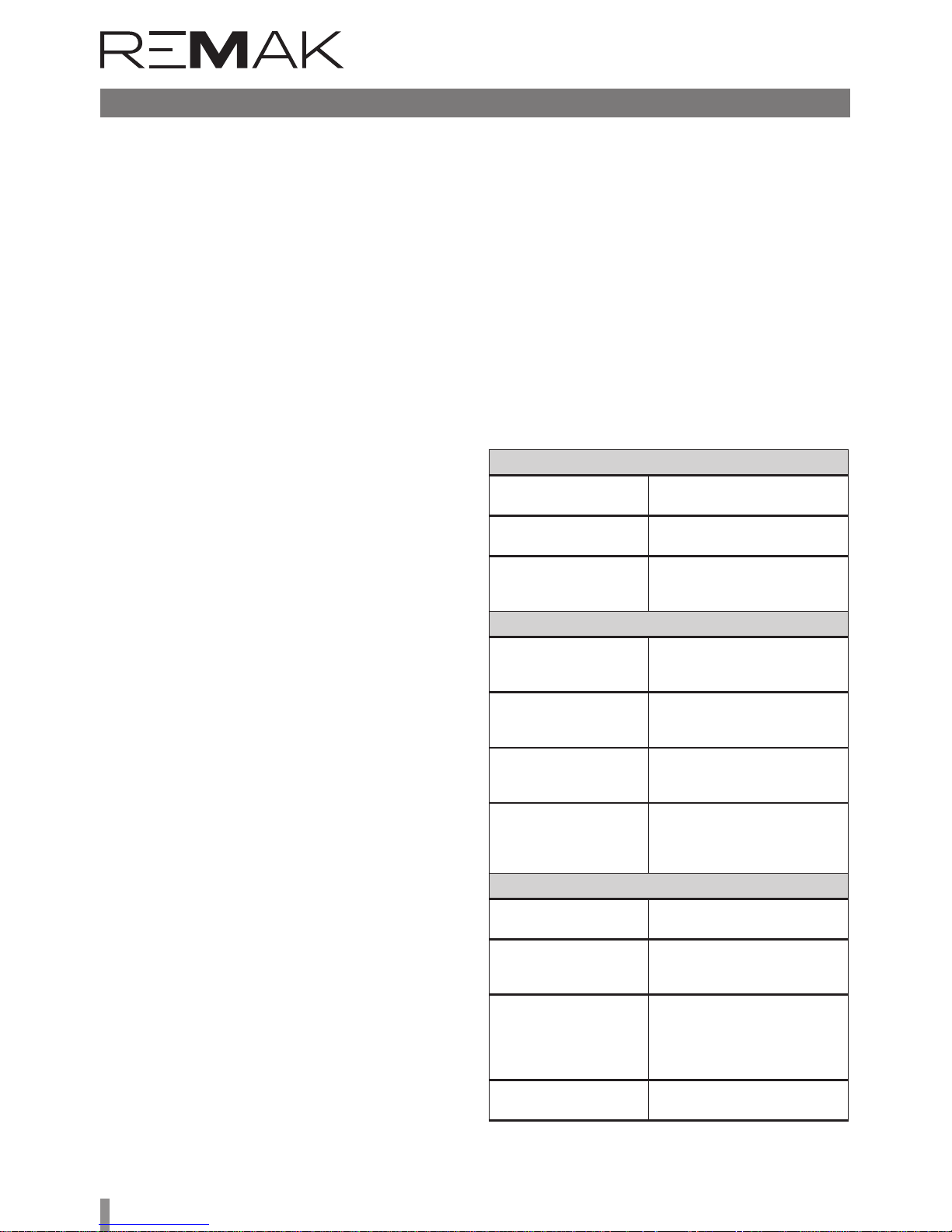

Figure 10 – Inverter connection to the Modbus RTU

Figure 11 – Inverter association with a corresponding

section

terminal

resistor

RS485

FM1

Master

controller

FM2 FM3

Warning

e frequency inverter association cannot be exchanged

between diff erent sections! For information about frequency

inverter association with a corresponding section, refer to

the fi gure.

Auxiliary Fan

Auxiliary fan address =9

Twin fan address =10

Rotary Heat Regenerator

RHR motor address =11

n e data points of all frequency inverters for communica-

tion with the Modbus bus must be set in accordance with the

VCS control unit:

• Baud rate (9600 Bd – pre-set)

• Parity (none – pre-set)

• Number of stop bits (2 stop bits – pre-set)

• Response time limit

• Number of data bits (as standard, 8 bits – pre-set)

All data points for the used frequency inverters are available

on our website: www.remak.eu

Corresponding

section number

Order

number

5

0064 / 5

00

64 / 5

64 / 5

0064 / 5

10

Main Control Feature and

Protection Description

Using the appropriate sensors, the VCS control unit can

provide comprehensive protection of the air-handling unit,

such as active antifreeze protection, fan state monitoring,

filter fouling or over-temperature detection of the required

temperature. Any deviations from the defined states or

parameters are monitored and signalled and simultaneously,

safety features are activated.

Depending on the failure consequence, the following happens:

n e failure is only signalled and safety features are automati-

cally activated. Once the failure has ceased, the unit will return

to the standard mode without interference from the operator.

n If a serious failure occurs, the unit will be switched to

the STOP mode, and it can only be restarted after the

failure has been removed and the operator's interference.

e VCS control unit system enables the air-handling unit

behaviour (fan action) to be set when fire is detected

(external failure, inlet or outlet air high temperature).

The settings can be as follows: the inlet or outlet fan is

activated, both fans are activated or both fans are stopped

(air-handling unit shutdown). e control unit is switched to

the fire mode. e settings can be performed using the HMI

controller in the List of Data Points, section Checks, System

and Network Settings – Fire Alarm.

Heating Control

Control is based on the required temperature, i.e. the selected

temperature mode and data from the supply air temperature

sensors, outdoor temperature and the water heat exchanger

return water temperature. Control can be affected by correction values, maximum and minimum limits or antifreeze

protection.

Water heating

It is controlled by the SUMX mixing set actuator using a 0–10V

continuous control signal (working range of 2–10V).

Heating Mixing Set Pump Control

e mixing set pump is controlled depending on the outdoor

temperature value and valve position (required heater output).

n If the air-handling unit is in the STOP and Run mode, the

pump is switched on when the outdoor temperature drops

below 5°C and switched off when the outdoor temperature

rises above 6°C. In this case, the pump is stopped without

any run-down.

n If the air-handling unit is in the Run mode, the pump is

controlled by the valve actuator control algorithm. e pump

is switched on when the request for the valve opening is

higher than 5%.

n If the pump has not been used for 168 hours, it will be

switched on and turned for 60 seconds.

n Failures (electrical) of the pump are sensed by the pump

circuit breaker’s auxiliary contact even in the STOP mode.

Water Heater Antifreeze Protection Operation

e VCS control unit uses so-called active antifreeze protection. It uses a three-stage concept.

Antifreeze Protection Features:

Control and Protection Functions

Note: is chapter describes only the basic control functions

– the detailed design, respectively compatibility, of the entire

device is ensured by the configuration performed using the

AeroCAD design soware. For more detailed information,

contact the manufacture, REMAK a.s.

Main Control Features

e VCS control unit enables automatic control of the following basic functions for air temperature adjustment:

n Heating

n Cooling

n Mixing

n Recuperation (Heat Recovery)

n Dehumidification

n PID controllers with pre-set control constants are as-

signed for all the above-mentioned functions. Basic settings

of parameters are performed in the factory. e parameters

can be changed using the HMI controller in the List of Data

Points menu, item Control Constants.

n A check, respectively optimization, of the unit settings must

always be performed when commissioning the unit.

n Control ensures energy-saving operation. Cascade tem-

perature control – room temperature control or supply air

temperature control.

n e required temperature for the air-conditioned room

can be set by selecting one of two temperature modes. Each

mode has two pre-set temperature values to maintain the

required temperature (an upper limit for heating and a lower

limit for cooling). ese values can be changed using the HMI

controller in the List of Data Points, section Settings – Temperature Modes.

n First, the control algorithm will start to control the functions

which don't require energy, i.e. heat-recovery and mixing (depending on the user option). If this is not enough to maintain

the required parameters or these features are not included in

the air-handling unit, heating and cooling functions will be applied. If the heating or cooling control is not effective enough,

an air output control will be added (heating/cooling-dependent

fan speed compensation – user option). is control does not

allow heating and cooling to be used at the same time, only

one control sequence can be used at a time. is does not

apply for special control application with controlled humidification where a cooler can be used for dehumidification and a

heater for aer-heating to the required temperature.

Heat pump, water and electric heater or gas heater functions

can be connected to the heating control sequence. Heat pump,

water cooler and condenser unit functions can be connected

to the cooling control sequence.

Temperature Correction and Limitation

The control unit enables adjustment and settings of the

restricting limits for maximum and minimum supply air

temperatures. In addition, it is possible to set the supply air

and room temperature limits, respectively other correction or

comfort options (e.g. set-point value compensation or heating/cooling-dependent fan speed compensation).

Control and Protection Functions

11

Control units VCS

n Switching of the unit to the STOP mode

n Switching off of the fans

n Closing of the dampers

n Freezing danger signalling

n Mixing set control

n Pump starting

n If the air-handling unit is in the Run mode, then antifreeze

protection is activated when the outdoor temperature drops

below 10 °C (factory settings) and the water heat exchanger

return water temperature drops below 15 °C (factory settings). e extent of the mixing valve opening depends on

the water heat exchanger’s return water temperature value.

Antifreeze protection will be deactivated when temperatures

rise above the limit parameters.

n If the air-handling unit is in the STOP - STAND-BY mode,

then antifreeze protection is activated when the outdoor

temperature drops below 10 °C (factory settings) and the

water heat exchanger’s return water temperature drops

below 30 °C (factory settings). e extent of the mixing valve

opening depends on the water heat exchanger’s return water

temperature value. Antifreeze protection will be deactivated

when temperatures rise above the limit parameters.

n e control unit continuously monitors the water heat

exchanger’s return water temperature. If the temperature is

still falling and drops below 8°C (factory settings), the following

protection actions will be immediately taken regardless of the

outdoor temperature:

n e air-handling unit will be shut down, the dampers will

be closed, the fans will be switched off and the failure alarm

will be activated.

n e mixing valve will be opened depending on the water

temperature, and the circulation pump will be switched on.

n e above-mentioned state will last until the operator

checks the air-handling system or removes the failure cause

and confirms the air-handling system is free of failure and

resets the failure.

n e control unit simultaneously monitors the supply air

temperature in the Run mode. If the supply air temperature

drops below 6 °C (factory settings), the following protection

actions will be immediately taken regardless of the outdoor

temperature:

n e air-handling unit will be shut down, the dampers will

be closed, the fans will be switched off and the failure alarm

will be activated.

n e mixing valve will be opened depending on the water

temperature, and the circulation pump will be switched on.

Pre-Start Unit Pre-Heating Functions

n To avoid false freezing danger assessment in winter or

during transition seasons, especially when the air-handling

unit is being started, the control unit features a heating

circuit pre-heating.

n Pre-heating is dependent on the outdoor temperature

value. If the outdoor temperature is higher than 10 °C, the

value of the valve opening will be 0 %, and pre-heating will

not be activated.

Pre-heating will be activated when the outdoor temperature

drops below 10 °C. e mixing set valve will be forced to open

to the value which is derived from the outdoor temperature

(factory settings: +10 °C = +10 %, -10 °C = 100 %) for 120

Control and Protection Functions

seconds. Once this time has elapsed, the valve will be closed,

"ramped down", until the mixing set control signal for heating is reached.

n If the air-handling unit is restarted within 5 minutes of the

moment the air-handling unit was shut down, pre-heating

will not be activated.

n Antifreeze protection setting parameters can be accessed

through the HMI controller in the List of Data Points menu,

sections Parameters and Control Constants.

Electric Heating

Electric heating can be controlled using the following options:

n Switching of the full EO, EOS heater output

n Sequential switching of the EOSX electric heater’s indi-

vidual sections

n Sequential switching of the EO heaters

n Control of the EOS electric heaters using a PV valve (up

to 45 kW)

Electric heater protection

n If electric heater overheating (failure) is signalled (the

temperature inside the heater exceeds +80 °C) by opening

the emergency thermostat contacts in the heater, this signal

is interpreted by the control unit.

n Electric heater control in the REMAK unit is doubled – the

heater thermostat failure signal is simultaneously sent to the

controller and auxiliary module.

n e controller will interpret the failure signal and perform

appropriate safety functions; first, the control signal for

electric heating is blocked and then the heater contactor is

disconnected.

n e auxiliary safety module will mechanically disconnect

the EO/S/X circuit breaker (i.e. it will trip the under-voltage

trigger of the circuit breaker).

At the same time, control logic will ensure safe cooling of the

heater when the air-handling unit is being shut down – transition to the STOP mode. e controller will ensure run-down of

the fans (optional) so that the heating core is cooled.

Gas heating

e gas heater is controlled using a burner output controller

and a bypass damper (if the section is equipped with a BP

damper). The required heating temperature is controlled

depending on the required temperature (selected mode) and

the readings from the inlet temperature, outdoor temperature

and flue gas temperature sensors.

Gas Burner Output Control

n Single-stage ON/OFF control

n Two-stage control (two output stages)

n Modular (three-point), step-less control of the entire burner

output range

Burner lighting is contingent on the fan operation.

At a 5 % request for heating, the 1st burner output stage is

switched on. e minimum pre-set running time of this stage

is 150 seconds. If the required temperature is not reached,

the 2nd stage will be switched on at 70 % of the request for

heating (two-stage output control). e second output stage

is not restricted to the minimum running time, and will be

switched off at 40 % of the request for heating.

12

Control and Protection Functions

Further re-lighting of the burner is possible once the protection time of 150 seconds has elapsed. Modular control of

the burner is step-less based on the actual requirement (set

point) within the Min to Max output range of the gas burner.

e bypass damper (if included in the section) is controlled by

a 0-10V signal (the operating range is 2–10 V depending on

the required flue gas temperature (160 °C pre-set). e regulating damper position controls the air flow coming through the

gas section and bypass section so that a constant flue gas

temperature is maintained. Accordingly:

n when T

flue gas

> T

flue gas required

the bypass damper closes

(closed = 0 V)

n when T

flue gas

< T

flue gas required

the bypass damper opens

(open = 10 V)

Protection and Safety Functions:

e control unit ensures fan run-down to cool down the gas sections (the pre-set run-out time is 180 s). e gas section temperature is monitored by the ESD3J triple safety thermostat,

which ensures the following protection and safety functions:

n If the temperature exceeds 50 °C, the fans will be switched

on, even if in the STOP mode.

n If the temperature exceeds 80 °C in the Run mode, the

burner will be stopped, the fans switched to the run-down

mode and then the unit STOPPED; if the temperature exceeds

110°C, the burner will be disconnected from the supply voltage. If back air draw (chimney effect) occurs during the STOP

mode and the air temperature in front of the gas section rises

above 50 °C, the TH 167 thermostat will close and switch on

the fans, open the inlet and outlet dampers, and thus the gas

section will be cooled down.

n Fan malfunction – the unit is immediately switched to the

STOP mode without fan run-out (evaluated also during the

STOP mode)

Heating and Cooling using Heat Pump

Two general control options are available for heat pumps.

Control is not fixed to a specific heat pump type. e control

option selection depends on the designer’s consideration

and heat pump type. Two control contacts and an analogue

output are used for control.

Option A

e first digital contact is used to define the air temperature

adjustment type – cooling/heating. e second digital contact

is used to define the process activation – off/on. e analogue

output 0..10 V represents the proportion of the request for

heating or cooling.

Option B

e first digital contact is used to define the heating process

– heating off/heating on. e second digital contact is used to

define the cooling process – cooling off/cooling on.

Analogue output 0..10 V represents the proportion of the

request for heating or cooling.

e heat pump control is equipped with an outdoor temperature-dependent blocking. e blocking alert is only informative

and is not a failure state. e heat pump will be shut down if

the outdoor temperature is equal to or lower than the refer-

Cooling Control

All cooling sources can be disabled depending on the outdoor

temperature. Cooling is not disabled if the outdoor temperature is higher than the pre-set cooling enable temperature

(pre-set 12 °C).

Water Cooling

It is controlled the same way as water heating. e mixing

set pump is switched depending on the control signal for the

cooling valve. If the air-handling unit is in the Run mode, the

pump will be switched on when the control signal for the cooling valve is higher than 5% and switched off when the control

signal for the cooling valve is lower than 1%.

n Pump turning for 60 seconds is performed aer every 168

hours of pump inactivity..

Direct Cooling

Direct cooling is controlled by switching the condensing unit

output or by step-less control of the inverter condensing unit.

If a single-circuit condensing unit is used, it will be switched on

when 20 % of the control signal is required and switched off at

10 % (10 % hysteresis) of the control signal. If a double-circuit

condensing unit, respectively two single-circuit condensing

units are used, two stages will be switched. e first stage will

be switched on when 20% of the control signal is required and

switched off at 10% (10% hysteresis) of the control signal. e

second stage will be switched on when 70 % of the control

signal is required and switched off at 60 % (10 % hysteresis)

of the control signal. Frequent switching of the single-stage

condensing unit is eliminated by repeated cooling blocking

for a certain time depending on the setting.

To eliminate the simultaneous switching of both stages at

a sudden control signal increase, the timing (duration of the

first stage) is set.

Inverter Cooling Unit

It is controlled using the start enable signal and step-less

compressor output control signal. e minimum operating

time can also be set. e condensing unit will be switched on

when 20 % of the control signal is required and switched off at

10 % (10 % hysteresis) of the control signal. e unit compressor speed is controlled using a 0–10 V control signal.

ence temperature (see the Data Points). e heat pump will be

started if the outdoor temperature is higher than the reference

temperature (with hysteresis of 3 °C). Frequent switching of

the heat pump is eliminated by blocking of the cooling/heating

restart for 120 seconds. e minimum operating time of the

heat pump can also be set. When cooling/heating is required,

the heat pump will be switched on at 20% of the control signal

and switched off at 10% of the control signal (hysteresis of

10%). e low reference signal on the analogue output (0-10V)

can be set in a range from 0% to 50 % of the control signal

(pre-set 30 %, i.e. a 3-10 V control). e unit can be equipped

with a function blocking the air-handling unit operation when

defrosting the heat pump. e shut-off state of the air-handling

unit is indicated on controllers. Aer the heat pump defrosting

process has been completed, the air-handling unit operation

will automatically be resumed.

Furthermore, it is possible changing behaviour of different

control signals, e.g. AO signal inversion (see Data Points).

13

Control units VCS

Control and Protection Functions

Inverter Unit and Single-Stage Condensing Unit

Combination

When cooling is required, the inverter will be switched on

first and then the output will be raised to the maximum.

Consequently, the single-stage condensing unit is switched

on while the inverter output is lowered to 30 % of the control

signal. If the request for cooling is still rising, the inverter

output will be increased from 30 % up to the maximum level

of the control signal.

If the request for cooling is decreasing, the inverter output will

start to decrease and will be switched off at 0% of the control

signal. e single-stage condensing unit is still in operation.

In this phase of control, time blocking of the inverter is applied and simultaneously the single-stage condensing unit is

prevented from being switched off. If the request for cooling

is still decreasing once this time has elapsed, the inverter

will be switched on with a maximum control signal and the

single-stage condensing unit will be switched off. When the

single-stage condensing unit is switched off, the inverter

output will be at the maximum. en the inverter output is

reduced in accordance with the request. us step-less control

is ensured in the entire cooling capacity range.

Direct Evaporator Protection

is protection is ensured using the CAP 2M capillary thermostat, which disconnects the control signal in the event of ice

build-up on the evaporator. If two evaporators are used, each

of them will have its own thermostat.

Heat Recovery Control

Heat Recovery control of the rotary heat regenerator is ensured by step-less control using the heat exchanger frequency

inverter through the Modbus communication bus. e plate

heat exchanger, respectively plate heat exchanger bypass, is

controlled using a 0–10 V (2–10 V) continuous signal. 100%

of the step-less control signal equals 100 % heat recovery,

i.e. maximum speed of the rotary heat regenerator or closed

bypass of the plate heat exchanger. A digital output for twopoint control (ON/OFF) is another option – thus, for example,

the glycol circuit pump can be switched.

Heat Exchanger Antifreeze Protection

n Rotary heat regenerator protection is ensured using the

NS 120 temperature sensor situated in the outlet air duct

behind the heat exchanger. If the temperature drops below

the pre-set ice build-up threshold, the speed of the rotary

heat regenerator will be reduced. If the speed reduction is not

enough to de-freeze the heat exchanger, the heat exchanger

will be stopped. e heat exchanger speed reduction depends

on the PID controller’s constant setting.

n Similarly as the rotary heat regenerator, control of the plate

heat exchanger is ensured using the NS 120 temperature

sensor and bypass actuator control. If the temperature behind

the plate heat exchanger drops below the pre-set ice build-up

threshold, the bypass damper actuator will be activated and

the damper will stay open until the ice build-up melts from the

heat exchanger. A pressure loss sensor or a CAP 3M capillary

probe can also be used in some cases.

Protection of the plate heat exchangers without bypass can

be ensured by a fan speed reduction.

Plate heat exchanger

– air-handling unit run-out

In some cases, the run-out will be performed when the

air-handling unit is stopped. is will ensure drying of the

heat-exchanger and prevent the creation of conditions for

the growth of microorganism. Temperature and humidity

sequences are active during this run-out. This feature is

conditioned by previous operation of the heat recovery and the

outside air temperature. As default, this feature is switched off.

For the change in all values, refer to List of Data Points – Fans.

Mixing Damper Control

It is ensured by step-less control of the mixing damper actuators using a 0–10V (2–10V) continuous signal. e signal is

directly proportional to the air circulation, i.e. 100 % of the

signal corresponds to 100 % of the required air circulation

(0 % of fresh air).

e maximum level of air recirculation (when the fans are

running) is limited by the minimum (hygienic) request for

fresh air. If the device is in the STOP mode, the inlet and outlet

duct dampers are closed and the circulation damper is open.

Heat Recovery and Mixing Economy Control

If the temperature in the room (in the outlet duct) is lower

than the outdoor temperature and a request for cooling

simultaneously exists, the heat recovery and air recirculation

functions will be automatically switched on at the maximum

level to minimize the energy demand for cooling. is happens if the temperature difference reaches 3 °C (the room

temperature is lower than the outdoor temperature) while the

temperature in the room (in the outlet duct) is higher than the

required temperature and the difference between these two

temperatures is at least 2 °C.

Heat recovery and mixing functions will be switched off when

the outdoor temperature is lower or equal to the room (outlet

air) temperature, or the room (outlet air) temperature is higher

or equal to the required room temperature. Heat Exchanger

control function activation settings are described in the chapter Additional Operating Mode and Function Setting Options.

Heat Recovery and Mixing Control

at Air-Handling Unit Start-Up

e starting outdoor temperature and time are set for heat

recovery and mixing (see Data Points). If the outdoor temperature is lower than the pre-set value at the air-handling

unit start-up, the heat recovery and mixing functions will be

switched on at the maximum level.

Mixing Sequence Selection

e mixing sequence for heating control is optional – the preset sequence for heating is as follows: first, the mixing function

is applied and if the request for heating still increases, then the

heating function will be applied (pre-set). is sequence can be

changed according to user needs, see the chapter Additional

Operating Mode and Function Setting Options.

Humidity Control

e control unit evaluates the control signal for humidification

or dehumidification depending on the room and inlet humidity

sensors and the required humidity selected by the user.

14

Control and Protection Functions

Humidification

Humidification control can be ensured by two methods.

Depending on the technology used, control for the required

humidity can be performed by the VCS control unit or by an

autonomous control (e.g., integrated into the humidifier).

In the first case, humidity control is ensured by the VCS control

unit. Settings of humidity set-points and control parameters

are included in the VCS control unit. e same applies for

dehumidification. us, full accord of dehumidification and

humidification control is ensured and unsuitable settings of

set-points cannot be made. Furthermore, all the necessary

parameters and information can be found in the control

unit controllers. e control unit sends the start command,

the request for humidification output to the humidifier, and

monitors humidifier failures.

If autonomous control is used, the control unit sends information on the air-handling unit operation to the humidifier.

In this case, control for the desired humidity is fully ensured

autonomously by a specific humidifier. e control unit has

no information about the state or output of the humidifier.

Dehumidification

Air dehumidification is ensured by water or direct cooling.

In case of dehumidification, aer-heating is ensured by the

heater, which is situated aer the cooler. e control unit evaluates the control signal for the air cooler and heater depending

on the room sensors and the required humidity selected by

the user. e humidity in the room can be set from 20% to

95%. If the air-handling unit is equipped with a water cooler or

a condensing unit with an inverter, the humidification process

can be controlled using 0–10 V (2–10 V) step-less control. If

the air-handling unit is equipped with a one-stage or a twosage condensing unit, the humidification process is controlled

using step control. When cooling is active due to a request for

dehumidification, air aer-heating is allowed (exceptionally)

using the heater situated aer the cooler.

If the request for heating is increased above 90 %, the request

for dehumidification cooling is gradually reduced until the

required inlet air temperature, respectively zero value of the

request for cooling (at 100 % request for heating), is achieved

– temperature control is prioritised to humidification.

Auxiliary Control Functions

Pre-heating function

Pre-heating is switched ON/OFF depending on the pre-set

outdoor temperature value (pre-set 5 °C).

e electric pre-heater (EO) is switched using a contactor. It

is controlled according to the pre-set (required) temperature

and compared with the temperature behind the preheater

(measured by the NS 120 sensor). If the air-handling unit is

switched off when the EO pre-heater is active, run-down of

the fans will be performed. Failures are evaluated similarly as

with EO heaters but the system is not shut down.

Water pre-heating is controlled by switching the pump (not

included in the REMAK delivery) depending on the request for

pre-heating. Antifreeze protection is ensured by a temperature

sensor (NS130R) situated in the water heat exchanger return

line. If the water temperature in the water heat exchanger’s

return line drops below the pre-set value, the freezing alarm

Figure 12 – Actual set-points with compensation (shi)

Control signal for controller

heating

H shi

cooling

C shi

Room set-point

TH1 ......Basic set-point of the required temperature for heating – upper heating limit

TH2 ......Actual/current set-point of the required temperature for heating – upper heating limit = (TH1 - shi H)

TC1 ......Basic set–point of the required temperature for heating – upper cooling limit

TC2 ......Actual/current set-point of the required temperature for heating – upper cooling limit = (TH1 -shi C)

H shi for heating set-points

(A negative shi causes a reduction in the required temperature for heating.)

C shi for cooling set-points

(A negative shi causes a reduction in the required temperature for cooling.)

will be activated, including safety functions, and the airhandling unit will be stopped.

Auxiliary Aer-Heating Function with EOS

is function is applied when the main heater output is not

sufficient (e.g. when water heating is shut down during transition seasons, etc.) It is possible to restrict the maximum

electric after-heater output for each output stage. Thus

correct cooling of the heating rods is ensured (see the Data

Points). e electric aer-heating function can also work as

an independent sequence with its own settings of required

temperatures. e electric aer-heating function is disabled

in the following cases:

n When night chilling is active

n During temperature start-up

Heating Water Source Switching

If this auxiliary function is active and the controller detects the

need for heating water (request for air heating), the output

for the heating water source (boiler) will be switched on – if

the device is started in advance before the fans have been

switched on. is function will only be applied if the outdoor

temperature is higher than the pre-set value (factory settings:

15 °C) otherwise the output is switched on permanently. Correct operation of the assembly must be ensured by suitable

settings of the device start-up sequence parameters. To enable

the heating water source switching function’s correct operation, the outdoor temperature sensor must be installed so it

will be able to read the actual outdoor temperature.

Figure 13 – Set-Point Compensation (Shi)

Description and Settings

T3 .....Starting point for heating compensation

T4 .....End point for heating compensation

c ........Max. compensation value (delta T)

x.........Actual outdoor temperature

y.........Required heating set-point shi

T1 .....Starting point for cooling compensation

T2 .....End point for cooling compensation

C ........Max. compensation value (delta T)

X ........Actual outdoor temperature

Y ........Required cooling set-point shi

delta T (K)

Outdoor temperature (°C)

Heating compensation settings Cooling compensation settings

15

Control units VCS

Control and Protection Functions

Temperature Required Value Compensation

Temperature compensation is actually a correction (shi) of

the required value (set point) of the controlled (room) temperature according to the outdoor temperature sensor reading,

which adjusts (in addition to other correction values) the

temperature specified in the temperature mode settings. It is

mainly used to reduce differences between outdoor and indoor

temperatures (to eliminate thermal shocks) and the energy

demand of device operation. On the other hand, it can increase

differences ("aggressiveness") in control, if adjusted reversely.

Note: e data point values on the controller are described in

full text (not using abbreviations like TH1, TC1, etc.). Generally,

minus control is also possible.

Fan Speed Compensation

e VCS control unit system enables the pre-set fan speed

to be adjusted depending on the air temperature, air quality

or mixing damper position using fan speed compensations.

T3 .....Starting point for heating compensation

T4 .....End point for heating compensation

c ........Max. compensation value (delta T)

x.........Actual outdoor temperature

y.........Actual fan speed shi for heating

the supply air temperature and comparing it with the required

supply air temperature and then followed by fan output

compensation. e compensation will be activated if the

difference between the required supply air temperature and

the actual supply air temperature is greater than the pre-set

temperature hysteresis. e actual correction extent is related

to the settings of the PID controller constants.

n Heating Compensation: It reduces the fan output and

thus sufficient supply air heating is achieved based on the

smaller air volume (used to eliminate insufficient output of

the heat exchanger).

n Cooling Compensation: It increases the fan output (higher

air-flow rate) and thus makes the room environment more

comfortable, if cooling is insufficient.

is type of compensation also enables a change to the priority

cooling – fan. So the change in the fan speed is applied first

and then active cooling is applied as the request for cooling is

rising. e settings can be performed using the HMI controller,

refer to the chapter Additional Operating Mode and Function

Setting Options.

Air Quality-Dependent Fan Speed Compensation

e fan output can be adjusted depending on the measured

CO2 (VOC, CO) content and the pre-set required value. If the

CO2 (VOC, CO) content is higher than the pre-set (permissible)

value, the fan speed will be increased. e compensation extent is affected by the settings of the PID controller constants.

e measured value range must be set depending on the sensor used. Further, the sensor characteristic (Normal ascending

for CO2 and VOC or Inverse descending for CO) must be set.

For the settings, refer to the Data Points.