Reliable Controls SS-L-BL-CO2-H20, SS-CO2-UD, SS-CO2-H-UD, SS-CO2-OC-UD, SS-H-O-S User Manual

...

better by design

™

SMART-Sensor

User Guide

™

better by design

™

™

SMART-Sensor

User Guide

© 2002 - 2014 Reliable Controls® Corporation. All rights reserved.

DOCUMENT CONVENTIONS

This document features several conventions to help you learn the material and

procedures. These conventions are outlined below.

Bold-faced type for Window Title Bars.

e.g., The Inputs worksheet is open.

Initial capitals for Field Names and Buttons.

e.g., The value of the Panel Program field is pan. Click the Save button.

Italics in lowercase for field values, file types, directories, and file paths.

e.g., The value of the Panel Program field is pan.

SMART-SENSOR

™

DOCUMENT CONVENTIONS

The pan files are stored in the pan subdirectory of the job directory.

Italics in initial uppercase for Mode Types.

e.g., Toggle the Mode button to switch to Update mode.

Chevrons denote menu items.

e.g., To exit, select Access > Bye from the main menu.

All uppercase for KEYWORDS and Control-BASIC STATEMENTS.

e.g., Click ALARMS to open the Current Alarms worksheet.

Underscore connectors for section references.

e.g., Refer to Reference_Alarms_Alarm Configuration more details.

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

USER GUIDE

i

The following symbols are used to draw your attention to important information.

The exclamation symbol is used to highlight material that requires caution or thought

before implementation.

The light bulb symbol is used to highlight helpful information and practices.

2002 – 2014 Reliable Controls

®

Corporation. All rights reserved.

Printed in Canada

This manual is for information purposes only. The contents and products described are

®

subject to change without notice. Reliable Controls

with respect to this manual. In no event shall Reliable Controls

Corporation makes no representation

®

Corporation be liable for

damages, direct or incidental, arising out of or related to the use of this manual. No part of

this document may be reproduced or transmitted in any form or by any means, without the

®

express written permission of Reliable Controls

Corporation.

Reliable Controls Corporation Tel: 250-475-2036

120 Hallowell Road Fax: 250-475-2096

Victoria, BC, Canada, V9A 7K2 Toll Free: 1-877-475-9301

www.reliablecontrols.com

Reliable Controls, RC-Studio®, and the Reliable Controls logo are registered trademarks of Reliable Controls Corporation.

®

BACnet

is a registered trademark of ASHRAE.

MACH-ProCom, MACH-ProSys, MACH-System, MACH-Global, MACH1, MACH2, MACH-Air, MACH-Zone, MACH-ProAir, MACHProZone, MACH-Pro1, MACH-Pro2, MACH-Stat, SMART-Sensor, SMART-Space, MODBUS-Link, RC-Archive, RC-Toolkit, MACHProWeb, SMART-Space EnOcean Accesspoint, SPACE-Sensor EnOcean, RC-Studio, RC-Reporter, and RC-WebView are trademarks of Reliable Controls.

ii

10/01/14 JW

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

SMART-SENSOR

TABLE OF CONTENTS

OVERVIEW ......................................................................................................................................... 01

GETTING STARTED .......................................................................................................................... 03

ACKAGE CONTENTS ............................................................................................................... 03

P

P

HYSICAL LAYOUT ................................................................................................................... 04

SS-L M

SS M

SS-P M

SS-DUCT M

P

HYSICAL DIMENSIONS ............................................................................................................ 08

SS

SS-P M

SS-DUCT-PB M

SS-DUCT-GD M

M

ODELS .................................................................................................................................. 14

B

O

ODELS ..................................................................................................................04

ODELS .....................................................................................................................05

ODELS .................................................................................................................06

ODELS ..........................................................................................................07

AND SS-L MODELS .....................................................................................................08

ODELS .................................................................................................................11

ODELS ....................................................................................................12

ODELS ...................................................................................................13

ASE MODELS .................................................................................................................14

RDERING OPTIONS .........................................................................................................18

™

TABLE OF CONTENTS

SMART-NET NETWORK TOPOLOGY ............................................................................................... 22

ENSORS PER CONTROLLER ..................................................................................................... 22

S

M

AXIMUM CABLE LENGTHS ...................................................................................................... 23

SMART-S

ENSOR EXPANSION BOARD (SSX) ............................................................................ 24

ORTS .....................................................................................................................25

SSX P

OWER ............................................................................................................................25

P

ND OF LINE (EOL) TERMINATION ....................................................................................26

E

ET TERMINATION ............................................................................................................27

N

NSTALLING ONE SSX EXPANSION BOARD .........................................................................28

I

NSTALLING MULTIPLE SSX EXPANSION BOARDS ................................................................30

I

INSTALLATION .................................................................................................................................. 32

AND SS-L MODELS ............................................................................................................ 32

SS

OOLS .............................................................................................................................32

T

NSTALLATION PROCEDURE ...............................................................................................33

I

SS-DUCT M

SS-P M

W

IRING DETAILS ...................................................................................................................... 41

ODELS .............................................................................................................. 38

ODELS ...................................................................................................................... 39

VERVIEW .......................................................................................................................41

O

IRING FROM CONTROLLER TO SS ...................................................................................42

W

IRING BETWEEN SMART-SENSORS ................................................................................44

W

USER GUIDE

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

iii

CONFIGURING THE SS .................................................................................................................... 46

A

DDRESSING THE SS ............................................................................................................... 46

A

DDRESSING THE SS-L ............................................................................................................ 47

S

ECONDARY POINT DISPLAY .................................................................................................... 48

OPERATOR INTERFACE .................................................................................................................. 49

PERATOR INTERFACE FOR THE SS .......................................................................................... 49

O

ETPOINT ADJUSTMENT OPTIONS ......................................................................................49

S

EST LED ........................................................................................................................49

T

VERRIDE BUTTON ...........................................................................................................50

O

O

PERATOR INTERFACE FOR THE SS-L ...................................................................................... 51

CREEN INTERFACE ..................................................................................................52

LCD S

EGREE C/F SWITCH .......................................................................................................53

D

ISPLAY MODES ...............................................................................................................54

D

ECONDARY POINT ...........................................................................................................54

S

UICK-ADJUST MODE ......................................................................................................55

Q

ISPLAY POINT MODE ......................................................................................................55

D

ACKLIGHT FOR THE SS-L ................................................................................................56

B

SOFTWARE PROGRAMMING .......................................................................................................... 57

CCESSING THE SS WORKSHEET ............................................................................................. 57

A

T

HE SS WORKSHEET ............................................................................................................... 60

ALUES DISPLAYED ..........................................................................................................60

V

ESERVED POINTS ...........................................................................................................61

R

OLUMNS ........................................................................................................................62

C

OMMAND BAR ................................................................................................................64

C

SMART-S

ENSOR SETUP DIALOG BOX ...............................................................................64

INPUT/OUTPUT POINT OPTION (-IO) .............................................................................................. 66

NPUTS .................................................................................................................................... 66

I

O

UTPUTS ................................................................................................................................. 67

CARBON DIOXIDE SENSOR OPTION (-CO2) ................................................................................. 70

VERVIEW ...............................................................................................................................70

O

B

ACKPLATE ............................................................................................................................. 71

W

IRING ................................................................................................................................... 72

C

ALIBRATION ........................................................................................................................... 72

UTOMATIC ......................................................................................................................72

A

ANUAL ..........................................................................................................................73

M

C

ONFIGURATION ..................................................................................................................... 75

OCCUPANCY SENSOR OPTION (-OC) ............................................................................................ 76

DUCT OPTION (-DUCT) .................................................................................................................... 78

NETWORK COMMUNICATION JACK .............................................................................................. 79

ONNECTING AN X-PORT-2 CONVERTER ................................................................................... 80

C

ONBOARD CONFIGURATION TOOLS (SS-L) ................................................................................. 81

iv

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

SMART-SENSOR

SS-L ADDRESS TOOL .............................................................................................................. 82

S

ETUP TOOL ............................................................................................................................ 83

F

LOW TOOL ............................................................................................................................. 87

D

ISABLE SS-L CONFIGURATION TOOLS .................................................................................... 91

PROGRAMMING AND CONFIGURATION EXAMPLES .................................................................... 92

ROGRAMMING EXAMPLE ................................................................................................... 92

SS P

SS-L P

SPECIFICATIONS ............................................................................................................................. 112

P

D

N

C

A

P

O

O

O

O

A

A

ROGRAMMING EXAMPLE ................................................................................................ 100

OWER ................................................................................................................................. 112

ISPLAY (SS-L ONLY) ........................................................................................................... 112

ETWORK .............................................................................................................................112

OMMISSIONING/PROGRAMMING ........................................................................................... 112

MBIENT LIMITS ................................................................................................................... 113

HYSICAL ............................................................................................................................. 113

NBOARD TEMPERATURE SENSOR ........................................................................................ 114

NBOARD HUMIDITY SENSOR (OPTIONAL) ................................................................................ 114

ODELS WITH -H OPTION ...........................................................................................114

SS M

SS-DUCT-EH-RH M

NBOARD MOTION SENSOR (OPTIONAL, -OC MODELS ONLY) ................................................ 115

NBOARD CARBON DIOXIDE SENSOR (OPTIONAL, -CO2 MODELS ONLY) ................................ 115

UXILIARY INPUTS (OPTIONAL, -IO MODELS ONLY) ................................................................ 115

UXILIARY OUTPUTS (OPTIONAL, -IO MODELS ONLY) ................................................................ 116

ODELS WITH -IO OPTION ..........................................................................................116

SS M

SS-DUCT M

ODELS WITH -IO OPTION ...............................................................................116

ODEL ...............................................................................................114

™

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

USER GUIDE

v

NOTES

vi

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

SMART-SENSOR

SS-L-D/W

SS-P

SS-DUCT-PB

SS-DUCT-GD

SS-UD

OVERVIEW

The Reliable Controls® SMART-Sensor™ (SS) is a powerful and dynamic microprocessor-based sensor

that monitors room environmental conditions, and communicates the information back to

MACH-System controllers via SMART-Net™. SMART-Sensor™ LCD (SS-L) models also include the ability

to display and adjust setpoints and other control points located in MACH-System controllers.

™

OVERVIEW

FIGURE 1: SMART-SENSOR™ SS-UD, SS-L-D/W, SS-P, SS-DUCT-PB, AND SS-DUCT-GD

SS FEATURES INCLUDE:

•

Network up to 16 SMART-Sensors on a single SMART-Net

on the host controller type,

• Fully compatible with all generations of MACH-System controllers,

• Optional LCD display, humidity, CO

, occupancy, 2 Input/2 Output, degree C/F

2

switch, override button, and setpoint slider.

•

(SS-L) Display up to ten points from any Reliable Controls

controller, located anywhere in the system,

•

• (SS-L) Access, view, and adjust data easily with the three-button interface and

(SS-L) Adjust up to ten points from the SMART-Net

®

Reliable Controls

large three-row LCD display,

MACH-System controller,

™

network depending

®

MACH-System

™

host, which can be any

USER GUIDE

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

1

• (SS-P) Measure room temperature in locations where the sensor could be

subject to damage.

• (SS-DUCT) Measure duct temperature and humidity.

2

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

GETTING STARTED

P

ACKAGE CONTENTS

SMART-SENSOR PACKAGE CONTENTS

SMART-SENSOR

Package Contents

™

GETTING STARTED

•

• (SS, SS-L)Two 6–32 1" Phillips screws

• (SS-DUCT) 2 x 1" #8 hex slotted sheet metal screws

• (SS-P) 2 x 1" 6-32 slotted device box screws

One SMART-Sensor

wiring box (SS-DUCT)

™

with backplate (SS, SS-L) or SS coverplate (SS-P) or

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

USER GUIDE

3

PHYSICAL LAYOUT

Backplate

Sensor head

LCD screen (optional)

Optional occupancy sensor

Three-button keypad

X-Po rt-2

™

access port

Two 1 . 6 mm (

1

/16”) Allen screws

(secure sensor head to backplate)

Cooling vents

Sensor head

X-Po rt-2

™

converter access port

Optional Degrees C/F switch

SS-L MODELS

4

FIGURE 2: PHYSICAL LAYOUT (SS-L-OC, SS-L-D PICTURED)

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

SS MODELS

Optional Setpoint Buttons (SS-CO2-UD)

Optional Slider (SS-S)

Thicker backplate for -CO2 models

Two 1.6 mm (

1

/16”) Allen screws

(secure sensor head to backplate)

X-Po rt -2™ converter access port

SMART-SENSOR

Physical Layout

™

GETTING STARTED

FIGURE 3: PHYSICAL LAYOUT (SS-CO2-UD AND SS-S PICTURED)

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

USER GUIDE

5

SS-P MODELS

SS-Plate (SS-P) SS-Plate with Override (SS-P-O)

FIGURE 4: PHYSICAL LAYOUT (SS-P AND SS-P-O PICTURED)

6

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

SS-DUCT MODELS

SS-DUCT-PB SS-DUCT-GD

SMART-SENSOR

Physical Layout

™

GETTING STARTED

FIGURE 5: PHYSICAL LAYOUT (SS-DUCT-PB AND SS-DUCT-GD PICTURED)

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

USER GUIDE

7

PHYSICAL DIMENSIONS

12 cm

(4

3

/4”)

2.4 cm

(

15

/16”)

7 cm

(2

3

/4”)

SS AND SS-L MODELS

FIGURE 6: PHYSICAL DIMENSIONS (SS-L PICTURED)

8

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

SMART-SENSOR

3.5 cm

(1

3

/8”)

1.3 cm

(

1

/2”)

3.0 cm

(1

3

/16”)

3.0 cm

(1

3

/16”)

8.2 cm

(3

1

/4”)

0.15 cm

(

1

/16”)

4.0 cm

(1

9

/16”)

7.0 cm

(2

3

/4”)

12.0 cm

(4

3

/4”)

™

GETTING STARTED

Physical Dimensions

FIGURE 7: STANDARD BACKPLATE PHYSICAL DIMENSIONS (USED FOR ALL SS/SS-L MODELS EXCEPT -CO2)

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

USER GUIDE

9

7.1 cm

(2

13

/16”)

1/2” wire grommet fits

two CAT5 cables.

12.1 cm

(4

3

/4”)

0.9 cm

(

3

/8”)

0.9 cm

(

3

/8”)

1.9 cm

(

3

/4”)

4.9 cm

(1

5

/16”)

8.3 cm

(3

1

/4”)

FIGURE 8: BACKPLATE PHYSICAL DIMENSIONS (USED FOR SS/SS-L MODELS WITH -CO2 OPTION)

10

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

SS-P MODELS

6.99 cm

(2

3

/4”)

9.9 cm

(3

7

/8”)

11.43 cm

(4

1

/2”)

0.45 cm

(

3

/16”)

2.0 cm

(

13

/16”)

6.85 cm

(2

3

/4”)

3.73 cm

(1

1

/2”)

SMART-SENSOR

™

GETTING STARTED

Physical Dimensions

FIGURE 9: PHYSICAL DIMENSIONS (SS-P PICTURED)

The SS-P circuit board will fit into a back box or wall opening sized 3.73 x 6.85 cm (1 1/2" x

3

/4") or greater.

2

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

USER GUIDE

11

SS-DUCT-PB MODELS

10.2 cm

(4”)

12.2 cm

(4

3

/4”)

6.0 cm

(2

3

/8”)

5.7 cm

(2

1

/4”)

9.1 cm

(3

5

/8”)

7.6 cm

(3”)

10.2, 15.2, 20.3, 30.5, 45.7 cm

(4, 6, 8, 12, or 18”)

FIGURE 10: PHYSICAL DIMENSIONS (SS-DUCT-4-PB PICTURED)

12

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

SS-DUCT-GD MODELS

10.7 cm

(4

3

/16”)

5.0 cm

(2”)

5.9 cm

(2

5

/16”)

9.8 cm

(3

7

/8”)

7.8 cm

(3

13

/16”)

10.2, 15.2, 20.3, 30.5, 45.7 cm

(4, 6, 8, 12, or 18”)

10.16 cm

(4”)

9.68 cm

(3

13

/16”)

6.16 cm

(2

5

/8”)

2.7 cm

(1

1

/16”)

10.9 cm

(4

1

/4”)

Cover

To p Vi ew , No Co v er

Side View

19.68 cm

(7

3

/4”)

1.65 cm (

5

/8”)

1.91 cm (

3

/4”)

SMART-SENSOR

™

GETTING STARTED

Physical Dimensions

FIGURE 11: PHYSICAL DIMENSIONS (SS-DUCT-4-GD PICTURED)

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

IGURE 12: PHYSICAL DIMENSIONS (SS-DUCT-EH-RH PICTURED)

F

USER GUIDE

13

MODELS

BASE MODELS

SMART-SENSOR

™

• One onboard space temperature sensor (10k Ω thermistor)

-40 °C to 40 °C (-40 °F to 104 °F)

• One RJ11 connector on bottom to provide network access

(X-Port-2™ converter required)

•

SPACE-Sensor

™

Temperature (SST) style enclosure

IGURE 13: SS BASE MODEL

F

14

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

SMART-SENSOR

Models

™

GETTING STARTED

SMART-SENSOR LCD

™

• One onboard space temperature sensor (10k Ω thermistor) 0 °C (32 °F) to

40 °C (104 °F)

• One RJ11 connector on bottom to provide network access

™

(X-Port-2

converter required)

• LCD and three silicone rubber buttons for operator interface

•

SMART-Space

™

Controller style enclosure

F

IGURE 14: SMART-SENSOR LCD

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

USER GUIDE

15

SMART-SENSOR PLATE (SS-P)

• ACI Stainless Plate temperature sensor (10k Ω thermistor) 0 °C (32 °F) to 50 °C

(122 °F)

• Foam pad insulating sensor from drafts within wall

FIGURE 15: SMART-SENSOR PLATE (SS-P)

16

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

SMART-SENSOR

SS-DUCT-4-PB

SS-DUCT-4-GD

SMART-SENSOR DUCT

• (SS-DUCT-PB) ACI Plastic Box Duct temperature sensor (10k Ω thermistor) -40

°C (-40 °F) to 85 °C (185 °F)

• (SS-DUCT-GD) ACI Galvanized Metal Duct temperature sensor (10k Ω

thermistor) -40 °C (-40 °F) to 85 °C (185°F)

• Foam pad to dampen vibrations

™

GETTING STARTED

Models

FIGURE 16: SMART-SENSOR DUCT (SS-DUCT-4-PB AND SS-DUCT-4-GD)

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

USER GUIDE

17

ORDERING OPTIONS

In addition to the dedicated onboard temperature sensor, Table 1 lists the standard

ordering options that are available.

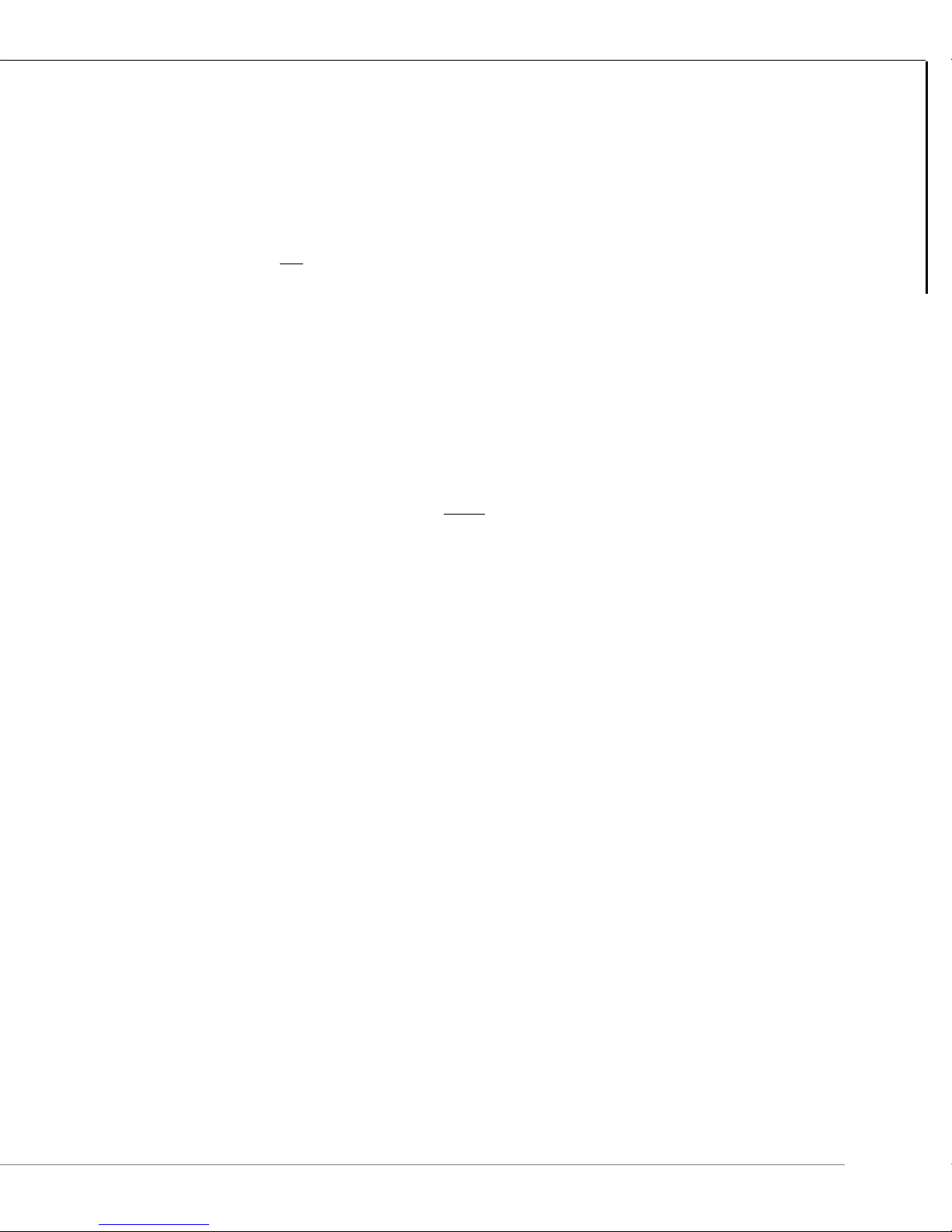

TABLE 1: STANDARD ORDER OPTIONS

Option Description

-BL Adds backlight and transflective LCD to -L models

-CO2

Adds

CO

sensor (not available with -P and -DUCT models)

2

-D Adds °C/°F slide switch to toggle display units to -L models only

-EH-RH Adds Euro Housing and humidity sensor to -DUCT models

-H Adds humidity sensor to SS and SS-L models

-IO Adds 2 inputs and 2 TRIAC outputs (not available on -P models)

-L Adds LCD to base model

-O Adds override button (not available on -DUCT, -S models)

-OC Adds PIR motion sensor (not available on -P, -DUCT models)

-S Adds setpoint slider (not available on -UD, -P, -DUCT models)

-UD Adds setpoint up and down buttons (not available on -P, -DUCT,

-S models)

-P Converts to Plate model

-DUCT Converts to Duct model

-PB Adds black plastic duct mount

-GD Adds galvanized metal duct mount

-## Specifies duct probe length in inches: 4, 6, 8, 12, 18

/W For white enclosure, leave blank for standard warm gray color

18

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

SMART-SENSOR

Table 2 lists the model numbers of all standard SS-L models available to order. If a model

number with a specific combination of options is not listed, check with the ordering desk

for availability. Minimum order quantities and longer lead times may apply.

TABLE 2: STANDARD SS-L MODELS AVAILABLE TO ORDER

Model SMART-Sensor Description

SS-L LCD, warm grey color

SS-L-BL LCD with LED back light

™

GETTING STARTED

Models

SS-L-BL-CO2

SS-L-BL-CO2-H

LCD with LED back light, 0-2000 ppm

LCD with LED back light, 0-2000 ppm

CO

sensor

2

CO

sensor, ± 2% humidity

2

sensor

SS-L-BL-CO2-H-OC

LCD with LED back light, 0-2000 ppm

CO

sensor, ± 2% humidity

2

sensor, PIR Motion Sensor

SS-L-BL-D LCD with LED back light, degrees C/F toggle switch

SS-L-BL-H LCD with LED back light, ± 2% humidity sensor

SS-L-BL-H-IO LCD with LED back light, ± 2% humidity sensor, 2 dry contact

Inputs, and 2 TRIAC Outputs

SS-L-BL-IO LCD with LED back light, 2 dry contact Inputs, and 2 TRIAC

Outputs

SS-L-BL-OC LCD with LED back light, PIR Motion Sensor

SS-L-CO2

SS-L-CO2-H

SS-L-CO2-H-IO

LCD with 0-2000 ppm

LCD with 0-2000 ppm

LCD with 0-2000 ppm

CO

sensor

2

CO

sensor, ± 2% humidity sensor

2

CO

sensor, ± 2% humidity sensor, 2 dry

2

contact Inputs, and 2 TRIAC Outputs

SS-L-CO2-H-OC

LCD with 0-2000 ppm

CO

sensor, ± 2% humidity sensor, PIR

2

Motion Sensor

SS-L-CO2-IO

SS-L-CO2-OC

SS-L-D LCD with degrees C/F toggle switch

SS-L-H LCD with ± 2% humidity sensor

SS-L-H-IO LCD with ± 2% humidity sensor, 2 dry contact Inputs, and 2

SS-L-H-OC LCD with ± 2% humidity sensor, PIR Motion Sensor

SS-L-IO LCD with 2 dry contact Inputs, and 2 TRIAC Outputs

SS-L-OC LCD with PIR Motion Sensor

The SS-L-CO2 model does not have an RJ11 port for SMART-Net™ wiring, but does have an

RJ11 port for connection to an X-Port-2

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

LCD with 0-2000 ppm

TRIAC Outputs

LCD with 0-2000 ppm

TRIAC Outputs

™

.

CO

sensor, 2 dry contact Inputs, and 2

2

CO

sensor, PIR Motion Sensor

2

USER GUIDE

19

Table 3 lists the model numbers of all standard SS models available to order. If a model

number with a specific combination of options is not listed, check with the ordering desk

for availability. Minimum order quantities and longer lead times may apply.

TABLE 3: STANDARD SS MODELS AVAILABLE TO ORDER

Model SMART-Sensor Description

SS-CO2-H-UD

0-2000 ppm

CO

sensor, ± 2% humidity sensor, setpoint up and

2

down buttons

SS-CO2-OC-UD

0-2000 ppm

CO

sensor, PIR Motion Sensor, setpoint up and

2

down buttons

SS-CO2-UD

0-2000 ppm

CO

sensor, setpoint up and down buttons

2

SS-H-O-S ± 2% humidity sensor, override Button, setpoint slider

SS-H-S ± 2% humidity sensor, setpoint slider

SS-H-UD ± 2% humidity sensor, setpoint up and down buttons

SS-IO-UD 2 dry contact Inputs, and 2 TRIAC Outputs, setpoint up and down

buttons

SS-O Override Button

SS-OC-UD PIR Motion Sensor, setpoint up and down buttons

SS-O-S Override Button, setpoint slider

SS-S Setpoint slider

SS-UD Setpoint up and down buttons

SS-P Stainless wall plate temp sensor

SS-P-O Stainless wall plate temp sensor, and override button

SS-DUCT-4-PB Plastic box duct mount temp sensor with 4" probe length

SS-DUCT-4-GD Galvanized metal duct mount temp sensor with 4" probe length

SS-DUCT-IO-4-PB Plastic box duct mount temp sensor with 4" probe length, 2 dry

contact inputs, and 2 solid-state relay (SSR) outputs

SS-DUCT-IO-4-GD Galvanized metal duct mount temp sensor with 4" probe length, 2

dry contact inputs, and 2 SSR outputs

SS-DUCT-8-PB Plastic box duct mount temp sensor with 8" probe length

SS-DUCT-8-GD Galvanized metal duct mount temp sensor with 8" probe length

SS-DUCT-IO-8-PB Plastic box duct mount temp sensor with 8" probe length, 2 dry

contact inputs, and 2 SSR outputs

SS-DUCT-IO-8-GD Galvanized metal duct mount temp sensor with 8" probe length, 2

dry contact inputs, and 2 SSR outputs

SS-DUCT-12-PB Plastic box duct mount temp sensor with 12" probe length

SS-DUCT-12-GD Galvanized metal duct mount temp sensor with 12" probe length

SS-DUCT-IO-12-PB Plastic box duct mount temp sensor with 12" probe length, 2 dry

contact inputs, and 2 SSR outputs

SS-DUCT-IO-12-GD Galvanized metal duct mount temp sensor with 12" probe length,

2 dry contact inputs, and 2 SSR outputs

SS-DUCT-18-PB Plastic box duct mount temp sensor with 18" probe length

20

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

SMART-SENSOR

TABLE 3: STANDARD SS MODELS AVAILABLE TO ORDER

Model SMART-Sensor Description

SS-DUCT-18-GD Galvanized metal duct mount temp sensor with 18" probe length

SS-DUCT-IO-18-PB Plastic box duct mount temp sensor with 18" probe length, 2 dry

contact inputs, and 2 SSR outputs

SS-DUCT-IO-18-GD Galvanized metal duct mount temp sensor with 18" probe length,

2 dry contact inputs, and 2 SSR outputs

SS-DUCT-EH-RH2 Euro housing, combination sensor; 7.25 inch probe for duct

temperature and +/- 2% humidity sensor

SS-DUCT-EH-RH3 Euro housing, combination sensor; 7.25 inch probe for duct

temperature and +/- 3% humidity sensor

SS-P and SS-DUCT are each equipped with a 4-pole screw terminal connection for SMART-

™

Net

, and do not have an RJ11 port for connection to an X-Port-2™.

™

GETTING STARTED

Models

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

USER GUIDE

21

SMART-NET NETWORK TOPOLOGY

S

ENSORS PER CONTROLLER

The Reliable Controls® SMART-Sensor™ is a networked sensor. SSs are interconnected

™

using SMART-Net

may be connected to an individual SMART-Net

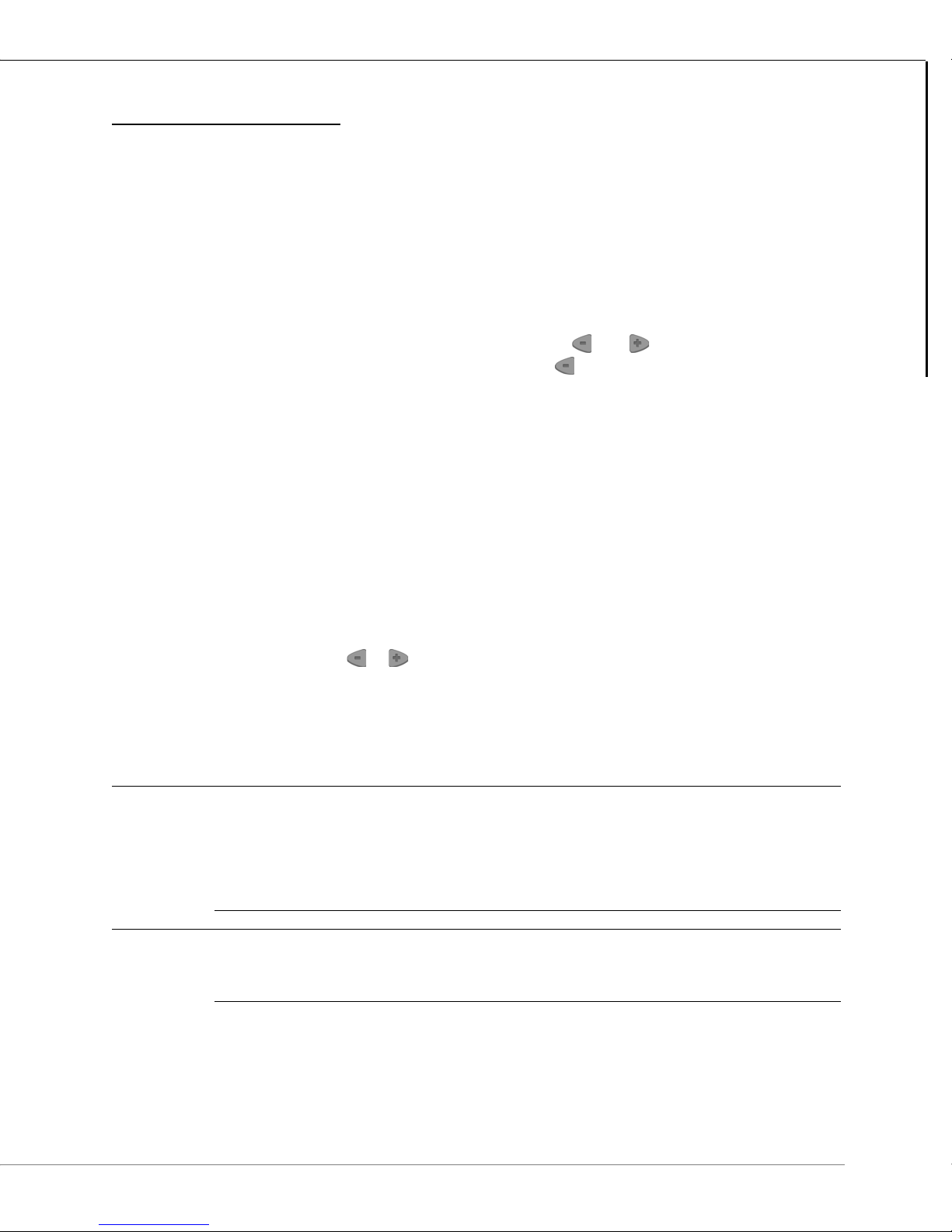

TABLE 4: MAXIMUM SSS PER CONTROLLER

communication and networking. The maximum number of SSs that

™

depends on the host controller.

Controller SSs per Controller

MACH-Air/Zone

MACH-ProAir

MACH-ProZone

MACH-Pro1

MACH-Pro2

MACH-Stat

MACH1

MACH2

™

™

MACH-Global

™

™

™

™

™

™

™

MACH-Pro(Web)Com

™

4

4

8

8

16

4

8

16

16

16

22

MACH-Pro(Web)Sys

™

16

SSs are daisy-chained, using either the RJ11 ports, or the terminal blocks provided. Any

mix of SS models may be installed on a single daisy chain. SMART-Sensor Enocean

™

Access Points

addresses on a SMART-Net

Each SS (or SSEA) on a single SMART-Net

(SSEAs) can also be added to the mix, however each SSEA uses up two

™

.

™

must have a unique address from 1 to a

maximum of 16. All SSs are shipped from the factory with a default address of 1.

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

MAXIMUM CABLE LENGTHS

The total combined cable length of a SMART-Net™ from the controller, including any daisychained SSs, to the final SS should not exceed 80 meters (250 ft). The actual maximum

functional network length can vary based on the type of cable used. For longer networks

and total cable length, use appropriate data cable with a lower resistance and capacitance

per meter (foot). Installing one or more SSX modules will also increase the number of SSs

and total cable distance that can be installed (further details on the SSX are supplied later

in this section).

The following formulas can be used to calculate the maximum length of selected cable.

SMART-SENSOR

™

SMART-NET NETWORK TOPOLOGY

Maximum Cable Lengths

V

max

R

max

Where: D = distance in meters

R

R

V

I

max

=

max

c

max

I

max

D=

= maximum total cable resistance

= resistance per meter of cable

= maximum voltage drop (= 0.5 VDC)

= maximum current

0.03 A per SMART-Sensor

0.005 A per SMART-Sensor

0.015 A per SS with backlight

0.002 A per SS with CO

R

max

R

c

™

LED

™

LCD

2

Poor modular connector installation, high-resistance connections or excessive cable length

may cause the SMART-Net

communication. If this occurs, a Power Lo message may appear on the screen of the

affected SS-L. On an SS model with no LCD screen, the Test LED will remain solid off when

connected if it does not have sufficient voltage.

The recommended wire type is Category 3 or 5, 24AWG solid core. This allows the flexibility

of connecting RJ11 crimp connectors, but still works well for the terminal blocks.

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

™

voltage to drop below the minimum necessary for SS

USER GUIDE

23

The use of the flat satin cable is not advised unless kept to a short distance. This wire is

typically 28 AWG and is not designed for longer distance runs.

SMART-SENSOR EXPANSION BOARD (SSX)

Each SMART-Sensor™ expansion board (SSX) provides five expansion ports that can be

used as a central hub for field installed SSs. A centrally located SSX may reduce the wiring

length to individual SSs, resulting in more robust and error free communication.

Additionally, each SSX can be connected to an external power source for the purpose of

boosting the power to connected SSs, allowing the combined overall cable length of a

SMART-Net

™

to be maximized.

FIGURE 17: SMART-SENSOR™ EXPANSION BOARD

TABLE 5: RECOMMENDED MAXIMUM SMART-NET™ COMBINED CABLE LENGTH END-TO-END

Installation Length

Without SSX 50 meters (150 feet)

With SSX and external power source 80 meters (250 feet)

24

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

SSX PORTS

External power connection

Power jumper

EOL jumpers

Network jumpers

SMART-Net™ Port

SMART-SENSOR

SMART-Sensor Expansion Board (SSX)

SS models with I/O, backlight, or CO2 require more current. An SSX is recommended for

™

applications where more than four SSs are installed on the same SMART-Net

where the total combined cable length of a SMART-Net

™

network exceeds 50 meters (150

network or

feet).

The SSX expansion board has six ports and an external power connector.

PORTS AND EXTERNAL POWER CONNECTOR

• Ports PROG SENS 1–5 connect SSs or an additional SSX to the SSX expansion

board

™

SMART-NET NETWORK TOPOLOGY

•

The SMART-Net

™

port connects the expansion board to the host controller or

daisy-chained SSX expansion boards

FIGURE 18: SMART-SENSOR™ EXPANSION BOARD (SSX) PORTS AND JUMPERS

A rollover Voice Cable (SS-VC) must be used to connect the SSX expansion board to the

host controller or additional SSX expansion boards.

POWER

The SSX expansion board can be powered by an external power supply or it can be

powered by the host controller via the SMART-Net

power supply to the SSX expansion board will aid in maximizing the overall allowable

cable length.

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

™

port. Connecting an external 12 VDC

USER GUIDE

25

The power jumper shunt must be installed correctly to select how the SSX expansion

JP1

board will be powered.

Whenever an SSX is installed consider using an external power supply to reduce voltage

drop and maximize the overall allowable cable length.

TO SET A POWER JUMP-SHUNT FOR AN EXTERNAL POWER SUPPLY

1 Set the power jumper shunt as shown in 22.

FIGURE 19: SSX EXTERNAL POWER JUMPER

2 Connect the external power supply to the 12 VDC and GND terminals.

END OF LINE (EOL) TERMINATION

The SMART-Net™ may be used to extend the EIA-485 network from the host controller to

connected SSs, thereby providing operator workstation access to the network using an X-

™

Port-2

of the network, the End-of-Line (EOL) termination jumpers (JP2 & JP3) of the SSX should

be installed, and the EOL jumpers/switches on the host controller should not be set.

If the SSX expansion board is not located at the physical extremity of the network, the EOL

jumpers (JP2 & JP3) should be removed.

converter. If the EIA-485 network is extended and the SSX is the physical extremity

26

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

FIGURE 20: SSX EOL JUMPERS

JP2 - EOL (A-)

JP3 - EOL (B+

)

EOL

jumper

JP4 - (A-)

JP5 - (B+)

NET

jumpers

NET TERMINATION

SMART-SENSOR

™

SMART-NET NETWORK TOPOLOGY

SMART-Sensor Expansion Board (SSX)

If operator workstation access using an X-Port-2™ converter through an SS is required, the

network jumpers (JP4 & JP5) must be installed.

FIGURE 21: SSX NETWORK JUMPERS

To minimize network distortion, maintain the default factory settings by leaving the jumpers

out. This will improve EIA-485 network performance. It will have no effect on SMART-Net

™

performance. However, the ability to connect an X-Port-2™ converter and operator

workstation to any SS connected to the SSX will be lost.

The jumper sets JP2/JP3 and JP4/JP5 should always be set together. For instance, if JP2 is

installed, JP3 should also be installed. Likewise, if JP4 is installed, JP5 should also be

installed. There is no application where only one jumper of either set should be installed.

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

USER GUIDE

27

INSTALLING ONE SSX EXPANSION BOARD

TO INSTALL AND CONFIGURE ONE SSX EXPANSION BOARD

1 Configure the SSX expansion board jumpers as required (EOL jumpers,

network jumpers, and the power jumper).

2 Connect a rollover Voice Cable (SS-VC) from the host controller to the SMART-

Net™ port on the SSX.

3 Connect the first SS to any of the PROG SENS ports on the SSX using a rollover

SS-VC.

4 Connect the second and subsequent SSs to the first SS using straight-through

Data Cables (SS-DC) between each SS.

5 Repeat steps 3 and 4 for the remaining SSs to be connected to the SSX.

Each SSX expansion board supports up to a maximum of 16 SSs. The use of an SSX

expansion board does not expand the maximum number of SSs supported by a specific

controller. Refer to Table 4 for the maximum number of SSs supported by each Reliable

Controls

®

MACH-System controller.

28

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

SMART-SENSOR

SS-Ls

SSX

MACH-ProSys

™

rollover SS-VCs

straight through

SS-DCs

™

SMART-NET NETWORK TOPOLOGY

SMART-Sensor Expansion Board (SSX)

The following diagram shows the optimal configuration for one SSX connected to a MACHProSys

™

controller with the maximum of 16 connected SSs.

FIGURE 22: FULLY-LOADED SMART-NET™ WITH 16 SS-LS AND ONE SSX

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

USER GUIDE

29

INSTALLING MULTIPLE SSX EXPANSION BOARDS

TO INSTALL AND CONFIGURE MULTIPLE SSX EXPANSION BOARDS

1 Configure the SSX expansion board jumpers as required - EOL jumpers (A- &

™

power.

™

port on the

2

B+), network jumpers (A- & B+), external power or SMART-Net

Connect a rollover SS-VC from the host controller to the SMART-Net

first SSX.

3 Connect a rollover SS-VC from any of the PROG SENS ports on the first SSX to

™

the SMART-Net

port of the second SSX. Continue to daisy-chain subsequent

SSX expansion boards in this manner as required.

4 Connect the first SS to any free PROG SENS port on any SSX using a rollover

SS-VC.

5 Connect the second and subsequent SSs to the first SS using straight-through

SS-DCs between each SS.

6 Repeat steps 3, 4 and 5 as required.

A rollover Voice Cable (SS-VC) must be used whenever one end of the cable is plugged into

a port on a controller or SSX labelled SMART-Net

™

. Therefore, an SS-VC is required to

connect the first SSX to a controller, daisy-chained SSX expansion boards and the first SS

connected to an SSX or directly to a host controller.

A straight-through Data Cable (SS-DC) must be used only to connect one SS to another

SS.

30

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

SMART-SENSOR

MACH-ProSys

™

SSX

SS-Ls

rollover SS-VCs straight through

SS-DCs

SSX

straight through

SS-DCs

rollover SS-VCs

™

SMART-NET NETWORK TOPOLOGY

SMART-Sensor Expansion Board (SSX)

The following diagram shows the optimal configuration for two SSX expansion boards

™

connected to a MACH-ProSys

controller with the maximum of 16 connect SSs.

FIGURE 23: FULLY-LOADED SMART-NET™ WITH 16 SS-LS AND TWO SSX EXPANSION BOARDS

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

USER GUIDE

31

INSTALLATION

SS

AND SS-L MODELS

TOOLS

In addition to the tools required for mounting the SMART-Sensor™, the following tools are

required:

•

•

A flat-blade instrument screwdriver with 3 mm (

1

/8”) wide blade for wire terminal

screws, and

1

A

/16” Allen key for the Allen screws that secure the SS head to the backplate.

FIGURE 24: 1/16” FLEXIBLE ALLEN KEY (PM-ALLENKEY)

A flexible 1/16” Allen key designed to provide easy access to the Allen screws on the

backplate of the SS is available from Reliable Controls

32

®

using part number PM-ALLENKEY.

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

INSTALLATION PROCEDURE

The installation of the SS requires four sequential procedures: the pre-installation cable

check, product disassembly, mounting, and cable connection and reassembly.

TO PERFORM A PRE-INSTALLATION CABLE CHECK

SMART-SENSOR

™

INSTALLATION

SS and SS-L Models

1

2

For SMART-Net

26–28 AWG (0.14–0.08 mm

If connection to the RJ11 SMART-Net

™

communication wiring, 24–26 AWG (0.25–0.14 mm2) solid or

2

) stranded 6-conductor cable is recommended.

™

port at the host controller is required, a

crimped-on RJ11 modular connector will be required. Installers can choose

between using the RJ11 ports or the screw terminals provided at each SMARTSensor.

FIGURE 25: RJ11 CONNECTORS FOR SOLID CORE (LEFT) AND STRANDED (RIGHT) CONDUCTORS

3 The recommended RJ11 modular connectors are Tyco 5-555042.3 (for Solid

wire only) and Tyco 5-641337.2 (for Stranded wire only).

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

USER GUIDE

33

TO DISASSEMBLE THE SS

1

Use a

1

/16” Allen key to tighten (clockwise) the two Allen screws at the bottom of

the controller. This is counterintuitive but works by moving the Allen screws

inward and out of the way of the sensor head.

FIGURE 26: ALLEN KEY

2 Pull the bottom of the sensor head out and away from the backplate then

straight up toward the top of the SS.

FIGURE 27: CONTROLLER HEAD SEPARATION

34

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

3 Separate the backplate from the SS sensor head.

SMART-SENSOR

™

INSTALLATION

SS and SS-L Models

FIGURE 28: BACKPLATE SEPARATION

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

USER GUIDE

35

TO MOUNT THE SS

1 The SS should be installed in an open area 1.2 m (48”) to 1.5 m (60”) above the

floor in line with other wall mounted devices, or as otherwise required by local

codes or project documentation.

™

The SMART-Sensor

Mounting Method 1

A single device, 2 x 4 electrical box, or 2 x 4 mud ring is installed in the wall prior

to mounting the controller backplate. This method is preferred, as it provides a

firm mounting base for the sensor.

can be mounted using one of three methods.

FIGURE 29: ELECTRICAL BOX MOUNTING

Use the two Phillips screws provided to attach the backplate to the underlying

electrical box or mud ring.

Mounting Method 2

The backplate is screwed directly to the wall, with no electrical box or mud ring.

Use suitable anchors and screws to secure the backplate to the wall. This

method is not recommended by Reliable Controls

loosen over time.

Mounting Method 3

The backplate is screwed to a metal/plastic/wood surface on a larger device or

alternative location. Use two self-tapping (for metal or plastic surface) or wood

screws in this application.

36

®

because the SS is likely to

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

SMART-SENSOR

™

INSTALLATION

SS and SS-L Models

2

Mount the backplate to the wall. Ensure that the SMART-Net

freely through the provided large square opening prior to securing the

backplate.

TO TERMINATE THE CABLING AND REASSEMBLE THE SS

1

Terminate the SMART-Net

Sensor

™

using either the 6-pole terminal strip on the backplate or by crimping an

RJ11 connector and plugging it into either of the onboard RJ11 sockets on the

back of the SS.

™

communication cable conductors to the SMART-

™

cable passes

FIGURE 30: SS TERMINATION METHODS

2 Install the sensor head to the backplate by placing the top of the SS into the

retaining clips on the top of the backplate, and then slowly and firmly bring the

SS down onto the backplate.

FIGURE 31: SS SENSOR INSTALLATION (SS-L PICTURED)

3 Finally, secure the SS by loosening (counter-clockwise) the Allen screws located

at the bottom of the sensor.

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

USER GUIDE

37

SS-DUCT MODELS

Duct

TO MOUNT THE SS-DUCT MODEL

1 Drill a 3/8" hole in the duct and insert the probe through the hole until the foam

pad is tight to the duct.

2 Insert the included one-inch (#8) sheet metal screws (2) through the mounting

holes in the flange and tighten them until the unit is held firmly to the duct.

FIGURE 32: MOUNTING AN SS-DUCT

TO TERMINATE THE CABLING FOR THE SS-DUCT MODEL

1

Terminate the SMART-Net

using the 4-pole terminal strip.

2 Attach the cover plate to the SS-DUCT.

FIGURE 33: TERMINATE THE CABLING FOR THE SS-DUCT

™

communication cable conductors to the SS-DUCT

38

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

SS-P MODELS

TO MOUNT THE SS-P MODEL

1 The Stainless Plate temperature sensor is mounted on the back of a 1 Gang

2 Insert (2) screws through the mounting holes and tighten them until the unit is

SMART-SENSOR

SS-P Models

stainless steel plate. The foam pad will insulate the sensor from any drafts in the

wall. There are two machine screws (6/32" x 1") provided for junction box

mounting.

held firmly in place. Ensure that the sensor is not mounted on an outside wall to

avoid extreme temperature changes from drafts or heat transfer.

™

INSTALLATION

FIGURE 34: MOUNTING AN SS-P

TO TERMINATE THE CABLING FOR THE SS-P MODEL

1

Terminate the SMART-Net

the 4-pole terminal strip.

™

communication cable conductors to the SS-P using

USER GUIDE

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

39

2 Attach the cover plate to the SS-P.

Gnd

Clk

+5

Data

FIGURE 35: TERMINATE THE CABLING FOR THE SS-P

The SMART-Sensor™ is intended to be installed in accordance with the local Electrical Code

for the country and district where it is installed, and in a manner acceptable to the local

authority having jurisdiction.

Ground yourself before touching the device to avoid damaging the electronics. Touch a

grounded metal surface to discharge static electricity.

Do not use conductors larger than 24 AWG (0.25 mm2) to facilitate the proper installation of

an RJ11 modular connector at the host controller.

Do not mount the SS above, or on the surface of heat-producing sources, below cooling

sources, near windows, behind obstructions, or in areas prone to infiltration. When mounted

in or on hollow walls, ensure that the electrical box and penetration is insulated and/or the

backplate is mounted to an insulated subbase to prevent drafts external to the space from

influencing the onboard thermistor.

RJ11 connectors for stranded and solid core conductors are not interchangeable. Using

the wrong connector will cause intermittent communication. The appropriate connector for

stranded conductors will have teeth on the gold plates that pierce the wire (this can be seen

by looking at the side of the connector closely). Connectors for solid core wires have a

single jaw that wraps around the solid conductor.

40

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

WIRING DETAILS

MACH-ProCom

™

SMART-Net™ RJ11 jack

MACH-ProZone

™

SMART-Net™

RJ11 jack and green connector

MACH-ProAir

™

SMART-Net™

RJ11 jack

MACH-ProAir

™

SMART-Net™

screw terminals

OVERVIEW

SS and SS-L models all feature a 6-pole wiring terminal block on the backplate and a

duplex RJ11 connection port on the rear of the sensor head, except -CO2 models do not

have a duplex RJ11 connection port. Either SMART-Net

for easy installation and daisy-chain wiring topology of multiple SSs. Standard

telecommunications data cable such as CAT3 or CAT5 is commonly available and is

recommended for this application. For long distances solid core conductors are

recommended. SS-P, SS-DUCT, and SSEAs do not have RJ11 ports, and must be

terminated using the four-wire connectors provided.

Four conductors are required to support SMART-Net

connection to the MACH-System using the RJ11 port at the bottom of some

SMART-Sensors

™

™

, an additional 2 conductors must be run.

SMART-SENSOR

Wiring Details

termination method may be used

™

. If the application requires

™

INSTALLATION

On all MACH-System controllers that support SMART-Net

™

MACH-ProZone

MACH-ProAir

, a single RJ11 port is provided for connection to SMART-Net™. The

™

and MACH-ProZone™ controllers also have a second port for connection

without crimping.

™

except the MACH-ProAir™ and

FIGURE 36: SMART-NET PORTS ON THE MPC, MPZ, AND MPA

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

USER GUIDE

41

WIRING FROM CONTROLLER TO SS

6

5

4

3

2

1

6

5

4

3

2

1

Controller’s RJ11 SS’s RJ11

If the connection between the controller and the first SMART-Sensor™ is completed using

an RJ11 crimp at each end, a rollover Voice Cable (SS-VC) is used to connect the host

controller to the first SS’s RJ11 jack on the SMART-Net

FIGURE 37: VOICE CABLE FROM HOST CONTROLLER TO FIRST SS

™

.

F

IGURE 38: RJ11 PIN-OUT BETWEEN CONTROLLER AND FIRST SS USING A ROLLOVER CABLE

TABLE 6: VOICE CABLE (SS-VC) ROLLOVER CABLE PIN-OUT

Controller

1 Clock 6 Clock

2 +5 VDC 5 +5 VDC

3 A 4 A

4 B 3 B

5 GND 2 GND

6 Data 1 Data

If a controller’s SMART-Net™ terminal block is used, the wiring connections should match

point to point. For example, the Clock connector on the controller should be connected to

42

the Clock connector on the SS’s terminal block, the Data to Data, and so forth.

SMART-Sensor™ LCD

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

FIGURE 39: MACH-PROAIR™ CABLING TO AN SS

MPA SMART-Net Connector

SS SMART-Net Connector

MPA SMART-Net Connector

SS-DUCT SMART-Net Connector

SMART-SENSOR

Wiring Details

™

INSTALLATION

F

IGURE 40: MACH-PROAIR

For MACH-ProAir™ and MACH-ProZone™ controllers, a 4-pole terminal block is provided in

addition to the standard RJ11 connector. Either of these methods can be used for SMART-

™

wiring. Note that the terminal block does not include terminals for the A and B EIA-

Net

485 conductors. If the EIA-485 network must be run to SMART-Sensors

connection at SMART-Sensors

at the controller's EIA-485 terminal block.

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

™

CABLING TO AN SS-DUCT

™

, then the additional two conductors must be terminated

™

to facilitate PC

USER GUIDE

43

WIRING BETWEEN SMART-SENSORS

Straight-through data cable

SS-DC

6

5

4

3

2

1

6

5

4

3

2

1

After the first SS, straight-through Data Cables (SS-DC) cables are used for connecting

™

additional SSs to the SMART-Net

or RJ11 socket may be used to terminate the SMART-Net

using a daisy-chain topology. Either the terminal block

™

at each SS.

FIGURE 41: CABLING FROM SS TO ADDITIONAL SSS

FIGURE 42: RJ11 PIN-OUT BETWEEN TWO SSS

TABLE 7: DATA CABLE (SS-DC) STRAIGHT THROUGH CABLE PIN-OUT

SMART-Sensor™ SMART-Sensor™

1 Data 1 Data

2 GND 2 GND

3 B 3 B

4 A 4 A

5 +5 VDC 5 +5 VDC

6 Clock 6 Clock

44

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

SMART-SENSOR

MACH-ProSys

™

Voice Cable (SS-VC)

rollover cable

Data Cable (SS-DC)

straight through cabl

e

Wiring Details

™

INSTALLATION

FIGURE 43: CONNECTING TO MULTIPLE SS-LS

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

USER GUIDE

45

CONFIGURING THE SS

4 - least significant bit

3

2

1

1 2 3 4

SS-P

1 2 3 4

SS-DUCT

SS

Each controller can host multiple SSs on its SMART-Net™. After all the SSs have been

installed, if there is more than one SS connected to a controller, each SS must be

configured with a unique address.

ADDRESSING THE SS

To address an SS that does not have an LCD screen, a DIP switch rack with four switches

is provided. Locate the DIP switch rack and configure the address by closing or opening

the appropriate switches as shown in Figure 44.

FIGURE 44: PROTECTOR DIRECTOR FOR THE SS, SS-P, AND THE SS-DUCT SHOWING THE ADDRESS CONFIGURATION

The 16 possible addresses are represented in binary and switch #4 (the switch located a

the top) is the least significant bit. For example, to configure the SSEA as address #1 open

switches #1, 2, and 3 while closing switch #4.

Do not skip SS addresses. When the host controller encounters the first unpopulated

SMART-Sensor worksheet, the previous SS address will be interpreted as the last device and

communication with higher addresses will not occur.

When addressing SSs be mindful of the maximum number of SSs supported by the host

controller.

46

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

ADDRESSING THE SS-L

To address an SS-L, it is necessary to invoke the onboard configuration tool embedded in

the SS-L firmware. The three-button operator interface of the SS-L and specific key-code

combinations are required to address the SS-L.

TO ADDRESS AN SS-L

1 Complete the installation and power up the SS-L.

SMART-SENSOR

™

CONFIGURING THE SS

Addressing the SS-L

2

After the initialization sequence, hold the and buttons for five seconds,

release for two seconds, then press the button.

3 The LCD screen displays SSADDR and the current address of the SS-L. The

default SS-L address is 1.

FIGURE 45: SS-L ADDRESS SCREEN

4

Press the or to configure the desired SS-L address between 1 and 16.

5 After the desired configuration is complete, allow the onboard configuration tool

to time-out. The LCD screen will revert to the standard operator display.

Do not skip SS-L addresses. When the host controller encounters the first blank

(unprogrammed) SS-L it will be interpreted as the last SS-L and communication with higher

addresses will not occur.

When addressing SS-Ls be mindful of the maximum number of SS-Ls supported by the

host controller.

To benefit from the full-functionality of the SMART-Sensor™ LCD, firmware version 6.35, or

higher, must be installed in the host controller. System data and SMART-Sensor

configuration must be input using RC-Studio

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

®

2.0, or higher.

USER GUIDE

™

LCD

47

SECONDARY POINT DISPLAY

The secondary point can be configured to display an additional value and descriptive

abbreviation on the idle screen of the display in the top row. This can be useful for

displaying the value of important space or system conditions such as setpoint, humidity

or CO

secondary display.

TO CHANGE THE SECONDARY DISPLAY POINT

1 The secondary point display may also be configured using the SS-L Addressing

from the host controller. Any of the ten SS-L display points can be selected as the

2

feature.

2

After the initialization sequence, hold the and buttons for five seconds,

release for two seconds, then press the button.

3 The LCD screen displays SSADDR and the current address of the SS-L. Press

the button to select the 2 DISP screen.

FIGURE 46: SS-L SECONDARY DISPLAY CONFIGURATION SCREEN

4

Press the or to configure the desired SS-L point to be displayed as the

secondary point.

5 After the desired configuration is complete, allow the onboard configuration tool

to time-out. The LCD screen will revert to the standard operator display.

48

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

OPERATOR INTERFACE

SS-UD SS-S

O

PERATOR INTERFACE FOR THE SS

SETPOINT ADJUSTMENT OPTIONS

SS models can be ordered with optional Up/Down arrows (-UD) or the Slider (-S). These

options are typically used to control the temperature setpoint.

SMART-SENSOR

™

OPERATOR INTERFACE

Operator Interface for the SS

FIGURE 47: OPTIONAL UP/DOWN BUTTONS OR SLIDER ON AN SS

For SS models with the -UD or -S option, the buttons or slider affect point #2 on the

SMART-Sensor worksheet, called the Quick-adjust point. Moving the slider or pressing

the buttons will adjust the value of the Quick-adjust point, typically a setpoint.

TEST LED

SS models without the LCD screen have a Test LED located at the bottom of the circuit

board next to the onboard temperature sensor. The Test LED is used to prove wiring

integrity. After powering up the controller, the light is used to display test results. If

sufficient DC voltage is available (3.4 VDC), the light is enabled. If sufficient voltage is not

available, the light will remain off. If sufficient voltage is available and SMART-Net

communication is detected, the light will flash 8 times per second, for at least 2 minutes. If

sufficient voltage is available, but the SS cannot detect SMART-Net

light will stay on solid until power is cycled. To re-initiate the test, disconnect and

reconnect SMART-Net

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

™

™

communications, the

™

.

USER GUIDE

49

FIGURE 48: TEST LED (SS AND SS-P SHOWN)

Test LED fully lit

Override button

OVERRIDE BUTTON

An SS model with an override button (-0), allows an operator to manually change the value

of a point mapped to point number 3 in the SMART-Sensor worksheet. The digital range

of ON/OFF must be used.

When the middle button on a model with an override button is pressed and point 3 is set

to digital ON/OFF, the digital value is set TRUE or ON and a 10 minute timer is initialized.

After 10 minutes has passed, the value of point 3 reverts to FALSE or OFF. The user is able

to force the value to FALSE either manually or with a Control-BASIC

™

program.

FIGURE 49: SS AND SS-P WITH OVERRIDE BUTTON (-O) OPTION

The -O option is often used to provide manual override of Unoccupied mode.

50

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

OPERATOR INTERFACE FOR THE SS-L

Three-button keypad

SMART-SENSOR

™

OPERATOR INTERFACE

Operator Interface for the SS-L

The SMART-Sensor™ LCD (SS-L) allows for the display and adjustment of ten point values

®

from its SMART-Net host, which can be any Reliable Controls

MACH-System controller

except a SMART-Space Controller (SSC). The SMART-Space controller does not support

SMART-Net.

An SS-L can display points from networked controllers other than its SMART-Net host,

however those points cannot be adjusted by an operator using the SS-L buttons. If the

SMART-Net host is a BACnet only device (e.g., MACH-ProZone, MACH-ProAir), then any

network points to be displayed must be entered using BACnet references. If the SMARTNet host supports Reliable Controls Protocol (RCP), then any network points to be

displayed must be entered using RCP references.

Navigation through the configured LCD display screens and operator interaction with the

point values are both performed using the custom silicone rubber three button keypad.

The standard functionality of the buttons is outlined in Table 8.

FIGURE 50: SSL THREE-BUTTON KEYPAD

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

USER GUIDE

51

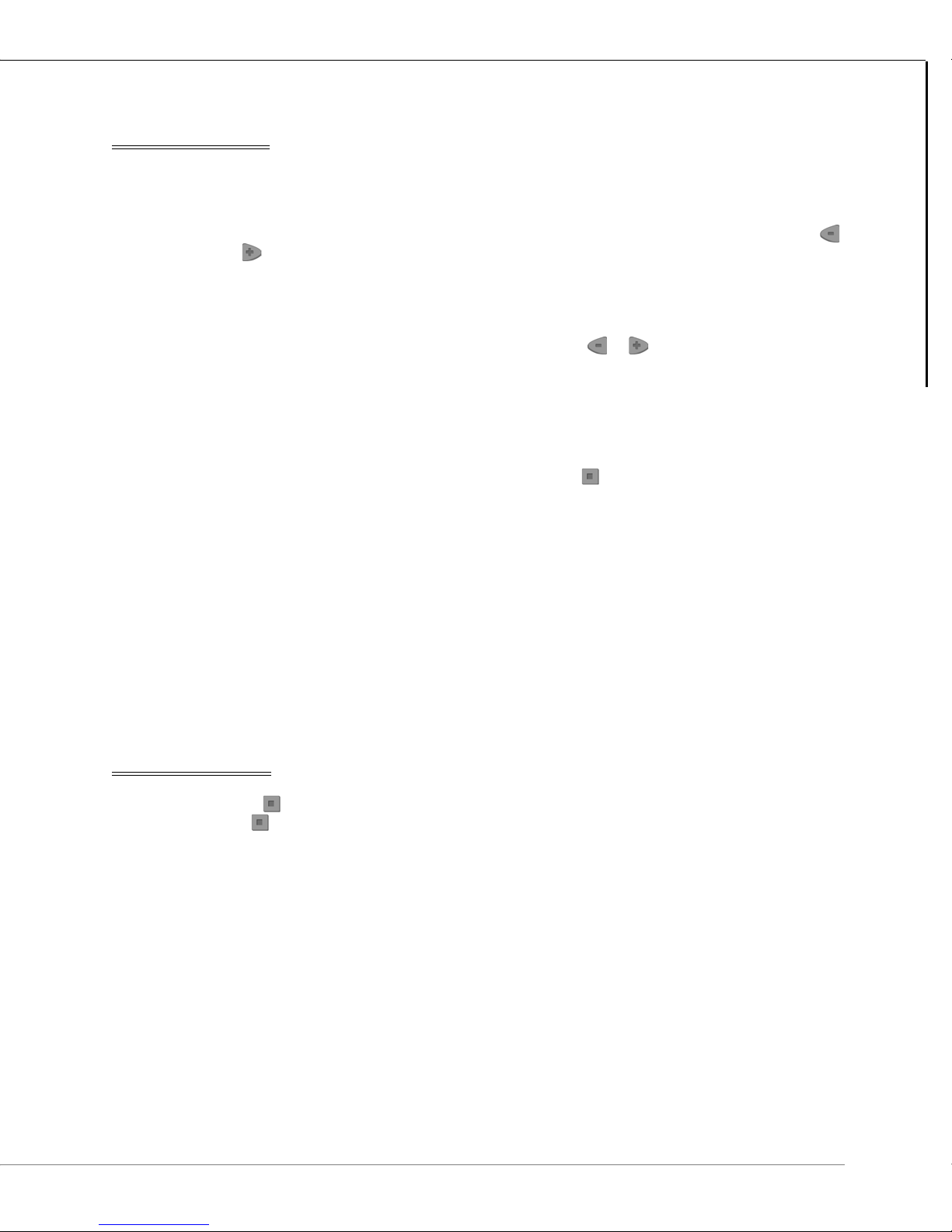

TABLE 8: SSL INTERFACE BUTTON CONTROL

Top Row

Middle Row

Bottom Row

Button Functionality

LCD SCREEN INTERFACE

The SS-L features a 36 mm x 36 mm (1 3/8” x 1 3/8”) LCD display screen. This screen is

capable of displaying text and icons arranged in three rows as outlined in Table 9.

TABLE 9: SSL LCD SCREEN DISPLAY ROWS

Row Display

Pressing the center navigation button cycles the LCD display through each

of the configured point values.

Pressing the increment button will increase the value of analog points or

toggle the status of binary points configured to permit operator

modification.

Pressing the decrement button will decrease the value of analog points or

toggle the status of binary points configured to permit operator

modification.

To p

Six 7.62 mm (

5

/16”) alphanumeric characters may be used to display:

1) a short point name or, 2) the configured secondary point.

Middle

Four 15.24 mm (

5

/8”) alphanumeric characters used to display the

present value of the configured point. The units of the point may also

be displayed.

Bottom Up to six simultaneous unique icons may be displayed to indicate

system status (icon details in Table 10).

FIGURE 51: SS-L LCD SCREEN DISPLAY

52

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

SMART-SENSOR

Degree C/F switch

Operator Interface for the SS-L

Up to seven icons may be configured along the bottom row of the SS-L LCD screen to

display system status. A description of the seven available icons is detailed in Table 10.

TABLE 10: SS-L SCREEN DISPLAY ICONS

Icon Description

Auto

Manual

Cool

Heat

Fan status/low speed

™

OPERATOR INTERFACE

While an SS-L may be freely configured to display ten user-defined data points and

BACnet

numbers are reserved for onboard input and output options if present. Refer to the SS-L

Programming section of this manual for a list of the reserved point numbers.

DEGREE C/F SWITCH

SS-L models with the -D option have a degree C/F switch used for selecting degrees

Celsius or Fahrenheit on display units. Sliding the switch to the left selects degrees C while

sliding to the right selects degrees F. The Degree C/F switch only invokes a local

conversion on the SS-L-D. It does not affect RC-Studio

BASIC

Fan medium speed

Fan high speed

®

object values from any Reliable Controls® MACH-System controller, specific point

®

™

functionality in any way.

System Groups or Control-

FIGURE 52: SS-L-D SHOWING THE DEGREE C/F SWITCH

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

USER GUIDE

53

DISPLAY MODES

IDLE/DEFAULT MODE

The SS-L LCD has three main display modes: Idle (the default), Quick-adjust, and Display

point.

Idle mode is the SS-L's default screen display. If there has not been any button activity on

the SS-L for 20 seconds, the display will automatically revert to the default screen.

The default screen displays the present value of the point or object configured in row

number one of the SS-L worksheet in the center (or middle row) of the LCD.

Any points or objects configured to appear as an icon will be displayed in the bottom row

of the default LCD screen.

FIGURE 53: SS-L IDLE MODE DISPLAYING POINT DESCRIPTOR

SECONDARY POINT

If the secondary point is enabled in the SMART-Sensor Setup dialog box, the present

value of the point or object configured as the secondary point will be displayed in the top

row of the default LCD together with the programmed two-character abbreviation.

FIGURE 54: SS-L IDLE MODE DISPLAYING SECONDARY POINT

54

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

QUICK-ADJUST MODE

The SSL's Quick-adjust mode allows for easy operator adjustment of a setpoint.

When the SSL LCD is in Idle mode (displaying the default screen), pressing either the

or button will cause the SSL to go into Quick-adjust mode.

In Quick-adjust mode, the SS-L displays the present value for the point or object

configured in row number two of the SMART-Sensor worksheet. The display blinks to

indicate that the value can be modified. Pressing the or button further will decrease

or increase the point value, typically a setpoint. After the desired adjustment is complete,

the display will continue to flash briefly until the value is communicated to the controller.

After 20 seconds have elapsed without further button interaction, the display will revert to

the Idle mode. Alternatively, after the setpoint has been adjusted, the operator can

advance to the next point or object by pressing the button.

SMART-SENSOR

™

OPERATOR INTERFACE

Operator Interface for the SS-L

FIGURE 55: SS-L QUICK-ADJUST MODE

DISPLAY POINT MODE

If the button is pressed, the SS-L goes into Display Point mode. Continued pressing of

the button will scroll through the configured points or objects according to the order in

which they were entered in the SMART-Sensor worksheet.

FIGURE 56: SS DISPLAY POINT MODE

USER GUIDE

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

55

The present value or state of any point or object that is configured for Can Change in the

SMART-Sensor worksheet can be modified using the buttons of an SS-L. When editing the

quick adjust point (pressing left or right from the idle screen), the value will steadily blink on

the SS-L display.

BACKLIGHT FOR THE SS-L

Models with the optional backlight (-BL) allow for easier reading of the LCD display screen

in dim or dark environments. The backlight turns on whenever any of the buttons are

pressed and remains on for 10 seconds after last button press.

56

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

SMART-SENSOR

Accessing the SS Worksheet

SOFTWARE PROGRAMMING

The SMART-Sensor™ LCD (SS-L) is custom configurable to display/adjust up to ten point values from

the host MACH-System controller. An SS-L can display points from networked controllers other than its

SMART-Net™ host, however those points cannot be adjusted by an operator using the SS-L buttons. If

the SMART-Net™ host is a BACnet only device (e.g., MACH-ProZone™, MACH-ProAir™), then any

network points to be displayed must be entered using BACnet references. If the SMART-Net™ host

supports Reliable Controls Protocol (RCP), then any network points to be displayed must be entered

using RCP references.

Software programming and configuration of an SS-L is performed using RC-Studio® 2.0, or higher.

ACCESSING THE SS WORKSHEET

TO ACCESS THE SMART-SENSOR WORKSHEET

™

SOFTWARE PROGRAMMING

1

In RC-Studio

the System Tree. If the System Tree is not visible, select Network > System

Tree or press Ctrl + P.

FIGURE 57: SYSTEM TREE COMMAND

®

2.0, locate the host controller of the SS-L to be programmed in

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

USER GUIDE

57

2

Expand the SMART-Net

™

network for any controller in the System Tree by

clicking the + next to the SMART-Sensors node. A list of available SMART-

Sensor worksheets is displayed. There is a separate worksheet for each

™

possible SS SMART-Net

address based on the host controller type.

FIGURE 58: SSL WORKSHEETS IN A MACH-PROSYS™ & MACH-STAT

™

58

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

SMART-SENSOR

™

SOFTWARE PROGRAMMING

Accessing the SS Worksheet

3

To configure the display of a specific SMART-Sensor

™

LCD, use the SMART-

Sensor worksheet.

To open the worksheet, click the desired sensor from the SMART-Sensors node

in the System Tree.

In Figure 59, Sensor #1 is selected to configure the SS-L at address number 1.

FIGURE 59: SELECT AN SMART-SENSOR WORKSHEET

FIGURE 60: SMART-SENSOR 1 WORKSHEET

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

USER GUIDE

59

THE SS WORKSHEET

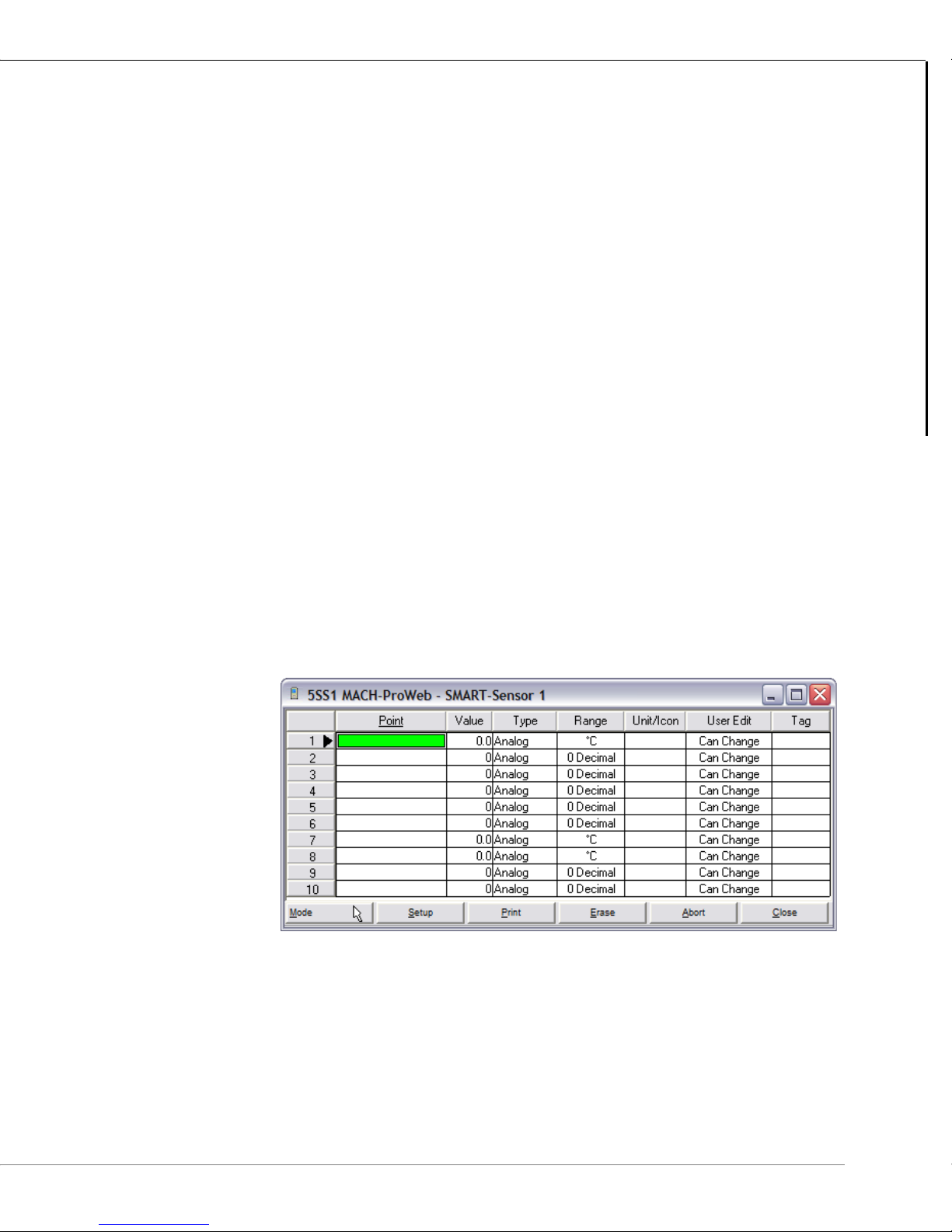

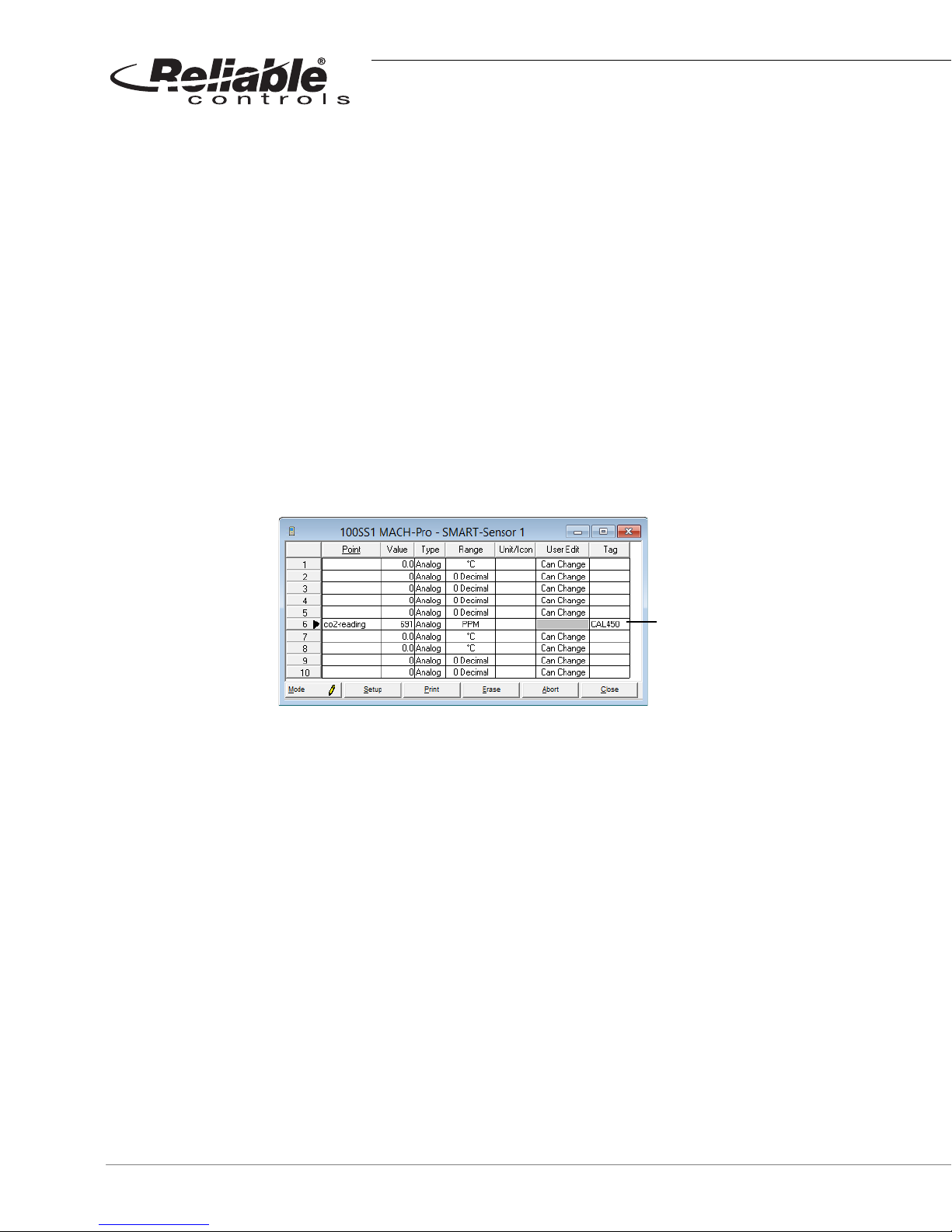

FIGURE 61: SMART-SENSOR 1 WORKSHEET

VALUES DISPLAYED

The SMART-Sensor worksheet has ten rows. Each row (1–10) corresponds to the values

that will be displayed on the LCD of the SS-L and the order in which they will appear.

The point or object that is defined to be displayed in row number one will be displayed

when the SS-L is in Idle mode.

The point or object that is defined to be displayed in row number two is the quick-adjust

point. If a user presses either the or button while the SS-L is in Idle mode, the

present value of the point defined in row two will be displayed.

If the point or object in row two is set to Can Change in the User Edit column, when the

value is accessed as the quick-adjust point, the value will be displayed flashing steadily and

may be modified. If, however, the point or object is configured to Display Only in the User

Edit column then the value will still be displayed and will still flash steadily, but the value will

not be modified in the controller.

The SS-L only supports one decimal place. When the SS-L is configured for two decimals,

the value will display properly in RC-Studio

®

, but the SS-L will show only one decimal place.

On the SS-L display, a value of 5 or less on the second decimal place will round down, while

®

a value of 6 or more will round up. For example, a value of 71.15 shown in RC-Studio

, will

be displayed as 71.1 on the SS-L. And 71.16 will be displayed as 71.2 on the SS-L.

60

2004 – 2014 Reliable Controls® Corporation. All rights reserved.

RESERVED POINTS