Page 1

INSTRUCTION MANUAL

GUIDE D’UTILISATION

MANUAL DE INSTRUCCIONES

Tandem Pro

2000CV

STEAM VACUUM CLEANER

ASPIRATEUR À VAPEUR

ASPIRADORA A VAPOR

Page 2

Page 3

ENGLISH 01

FRANÇAIS 21

ESPAÑOL 41

Page 4

01

TANDEM PRO 2000CV

STEAM VACUUM CLEANER

INSTRUCTION MANUAL

ENGLISH

Page 5

02

CONGRATULATIONS

We would like to thank you, and congratulate you for purchasing the

Tandem Pro steam/vacuum cleaner from Reliable Corporation.

Dry vapor steam cleaning can deep clean and sanitize your home

safely and effectively.

The Tandem Pro is a complete multi-use commercial cleaning unit.

It functions as a steam cleaner and steam extractor as well as a

wet/dry vacuum. The 6-bar steam pressure and an accessory kit

that is second to none make the Tandem Pro an ideal chemical-free

alternative for cleaning and sanitizing all surfaces encountered in

commercial cleaning settings.

For your safety and to fully enjoy the advantages of this product,

please take a few minutes to read all the important safeguards and

care instructions. Keep this manual handy for all users and review the

product warranty card for your reference.

Note: your new steam/vacuum cleaner may contain small amounts

of water as all are factory tested prior to shipping.

Carefully read this manual to avoid any improper use. The

Manufacturer accepts no responsibility for damage to people or

things deriving from improper use of the machine, incompetence,

lack of caution or negligence and from the lack of compliance with

the instructions provided in this manual. The pictures shown in this

manual will help explain the running, safety instructions and maintenance operations of the machine. The Manufacturer reserves the

right to make changes to its machines, as a result of performance

optimization.

This manual is an integral part of the machine kit. It must be carefully kept within reach and consulted in case of doubt. If the machine

is given to a third party, even only if it is lent out, please provide the

manual together with the machine, specifying to the new user to carefully read all content before operating the machine.

Page 6

03

IMPORTANT SAFETY REQUIREMENTS

WHEN USING AN ELECTRICAL APPLIANCE, BASIC PRECAUTIONS SHOULD

ALWAYS BE FOLLOWED.

READ ALL INSTRUCTIONS BEFORE USING THIS APPLIANCE

WARNING: TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY:

• Do not leave appliance when plugged in. Unplug from outlet when not in use

and before servicing.

• Do not use outdoors or submerged in water.

• Do not allow to be used as a toy. Close attention is necessary when used

near children. Do not allow children to operate the machine.

• Use only as described in this manual. Use only manufacturer’s recommended attachments.

• Do not use with damaged cord or plug. If appliance is not working as it

should, has been dropped, damaged, left outdoors, or dropped into water,

return it to a service center.

• Do not pull or carry by cord, use cord as a handle, close a door on cord, or

pull cord around sharp edges or corners. Do not run appliance over cord.

Keep cord away from heated surfaces.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

• Do not handle plug or appliance with wet hands.

• Do not put any object into machine openings. Do not use with any opening

blocked; keep free of dust, lint, hair, and anything that may reduce air flow.

• Keep hair, loose clothing, ngers, and all parts of body away from machine

openings and moving parts.

• Turn off all controls on the unit before unplugging.

Page 7

04

• Use extra care when cleaning on stairs.

• Do not use to vacuum or steam ammable or combustible liquids spills or

areas, such as gasoline, or use in areas where they may be present.

• Use only tap water to rell the boiler and water tank. Do not use chemicals,

perfumes or other liquid.

• The hose contains electrical wires. Do not use when damaged, cut, or punc-

tured. Avoid picking up sharp objects.

• Connect to a properly grounded outlet only. See Grounding Instructions.

• This appliance is provided with double insulation. Use only identical replace-

ment parts.

• Do not vacuum anything that is burning or smoking, such as cigarettes,

matches, or hot ashes.

• To Reduce the Risk of Fire, do not use a ammable or combustible liquid to

clean a floor.

• Do not use without dust lters in place.

• Do not allow the use of the machine by inexperienced persons, without

attendance. Should any damage occur on the machine, do not run it, do not

connect the plug to the socket or disconnect it immediately, disconnect the

power supply and contact the authorized Technical Service Centre. Repairs

must be made by authorized personnel and only original spare parts must

be used.

Page 8

05

SAVE THESE INSTRUCTIONS IN A SAFE

PLACE FOR FUTURE REFERENCE

GROUNDING INSTRUCTIONS

This appliance must be grounded. If it should malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of

electric shock. This appliance cord is equipped with an equipment-grounding

conductor and grounding plug. The plug must be inserted into an appropriate

outlet that is properly installed and grounded in accordance with all local codes

and ordinances.

WARNING – Improper connection of the equipment-grounding conductor can

result in a risk of electric shock. Check with a qualied electrician or service

person if you are in doubt as to whether the outlet is properly grounded. Do not

modify the plug provided with the appliance – if it will not t the outlet, have a

proper outlet installed by a qualied electrician.

This appliance is for use on a circuit having a nominal rating more than 120 volts

and is factory-equipped with a specic electric cord and plug to permit connection to a proper electric circuit. Make sure that the appliance is connected to an

outlet with the same conguration as the plug. No adaptor should be used with

this appliance. If the appliance must be reconnected for use on a different type of

electric circuit, the reconnection should be made by qualied service personnel.

TECHNICAL CHARACTERISTICS DESCRIPTION

OF THE MACHINE:

This professional high pressure and high temperature electric steam vacuum

generator is a machine designed for cleaning, and sanitizing multiple surfaces,

and equipment.

Using leading edge technology, the Tandem Pro 2000CV boiler can generate dry

saturated steam at a very high temperature and pressure for a deeper and more

effective cleaning process.

The steam generator combined with a powerful vacuum cleaner allows a deep

and immediate cleaning. The accessories included allow for an easy and practical

use of the machine for numerous surfaces and cleaning tasks.

Page 9

06

SAFETY SYSTEMS OF THE MACHINE:

• Overpressure exhaust valve

• Pressure switch for pressure control

• Safety thermoswitch and thermofuse to control temperature in the boiler

• Low tension handle controls

DESCRIPTION

MODEL

STAINLESS STEEL STRUCTURE

POWER SUPPLY (V/HZ)

POWER (W)

INPUT AMP

WORKING PRESSURE BAR

BOILER TEMPERATURE (C°)

STAINL. STEEL 316 BOILER (TOTAL LITRES)

WATER TANK CAPACITY (LITRES)

ELECTRONIC CONTROL

VACUUM POWER (W)

INITIAL START UP (MIN.)

LENGTH (CM)

WIDTH (CM)

HEIGHT (CM)

NO LOAD WEIGHT (KG.)

STANDARD ACCESSORY RACK

TANDEM PRO 2000CV

YES

120/60

1700

14

6

150°C

2.3

5

YES

1000 W

7

49

37

100

22

YES

Page 10

07

Page 11

08

Page 12

09

A

A

A

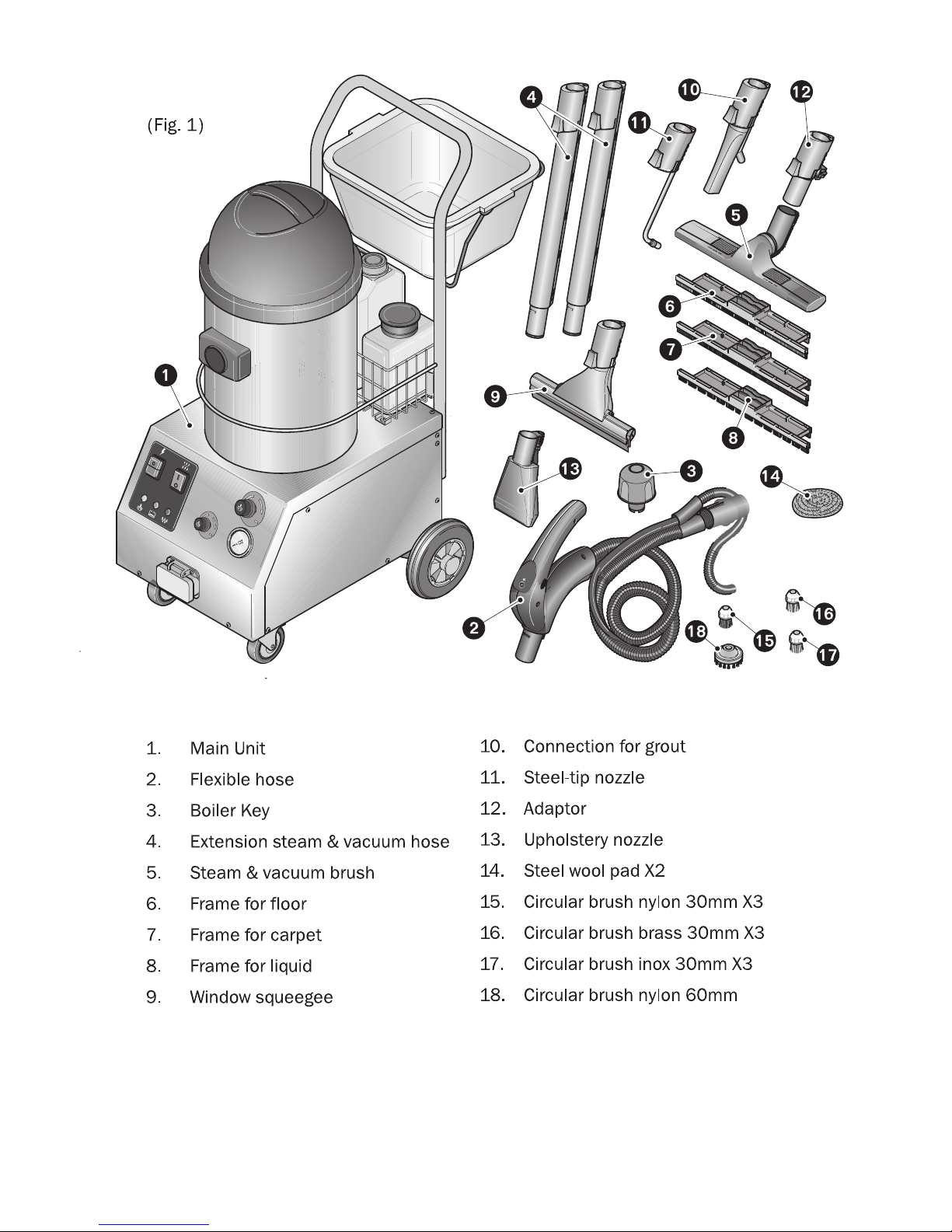

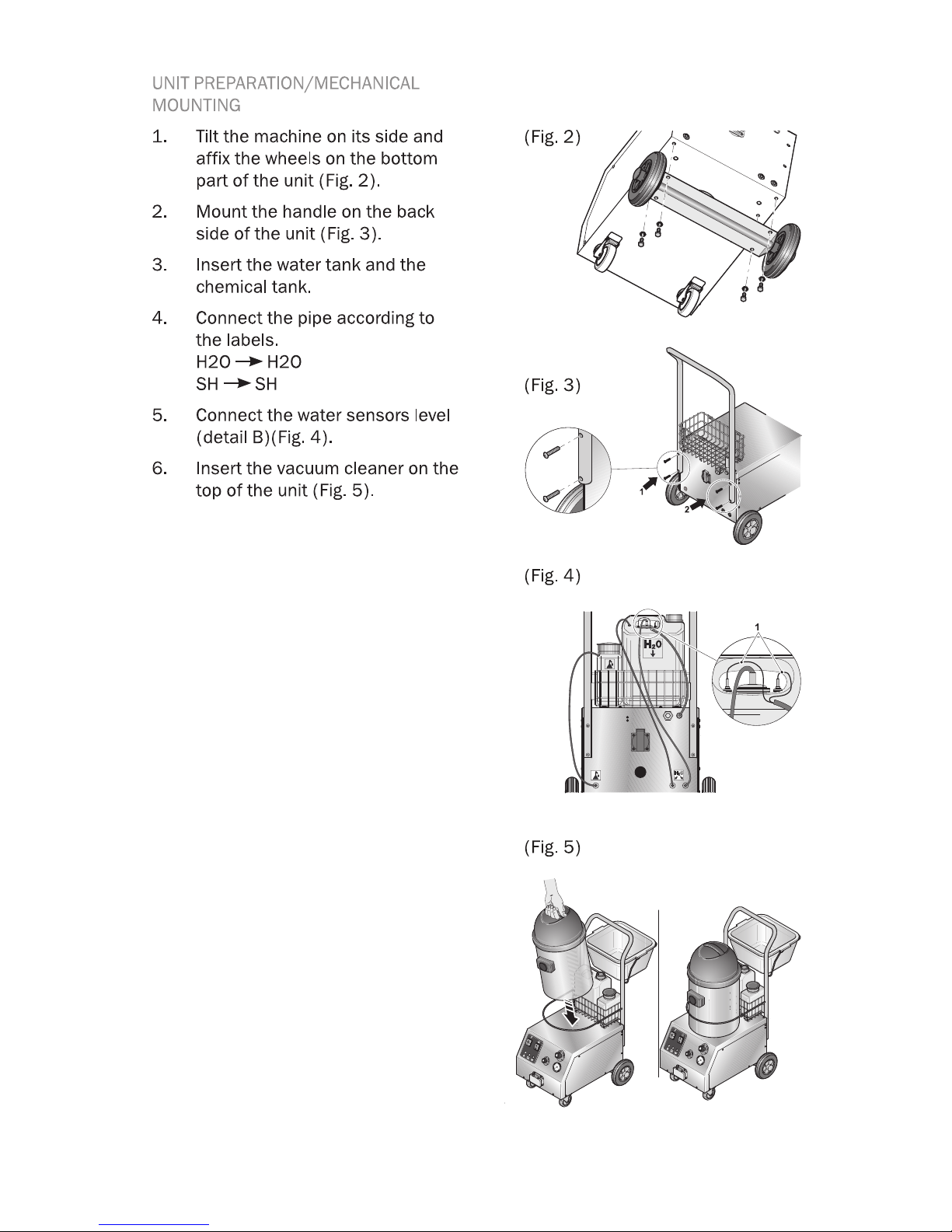

7. Connect the vacuum cleaner plug

into the rear socket of the unit.

CAUTION! Connect only the vacuum cleaner delivered with the unit.

Other vacuum cleaners or tools

can damage the unit (Fig. 6).

8. Rell the water tank with tap water

(1 Fig.7).

CAUTION! Use only tap water,

never use any other substance

(Fig. 7)!

9. If using chemical rell the chemical

tank (2 Fig. 8).

CAUTION! Use only products sug-

gested by manufacturer (Fig. 8).

10. If there is no power to the machine

check the fuse (A).

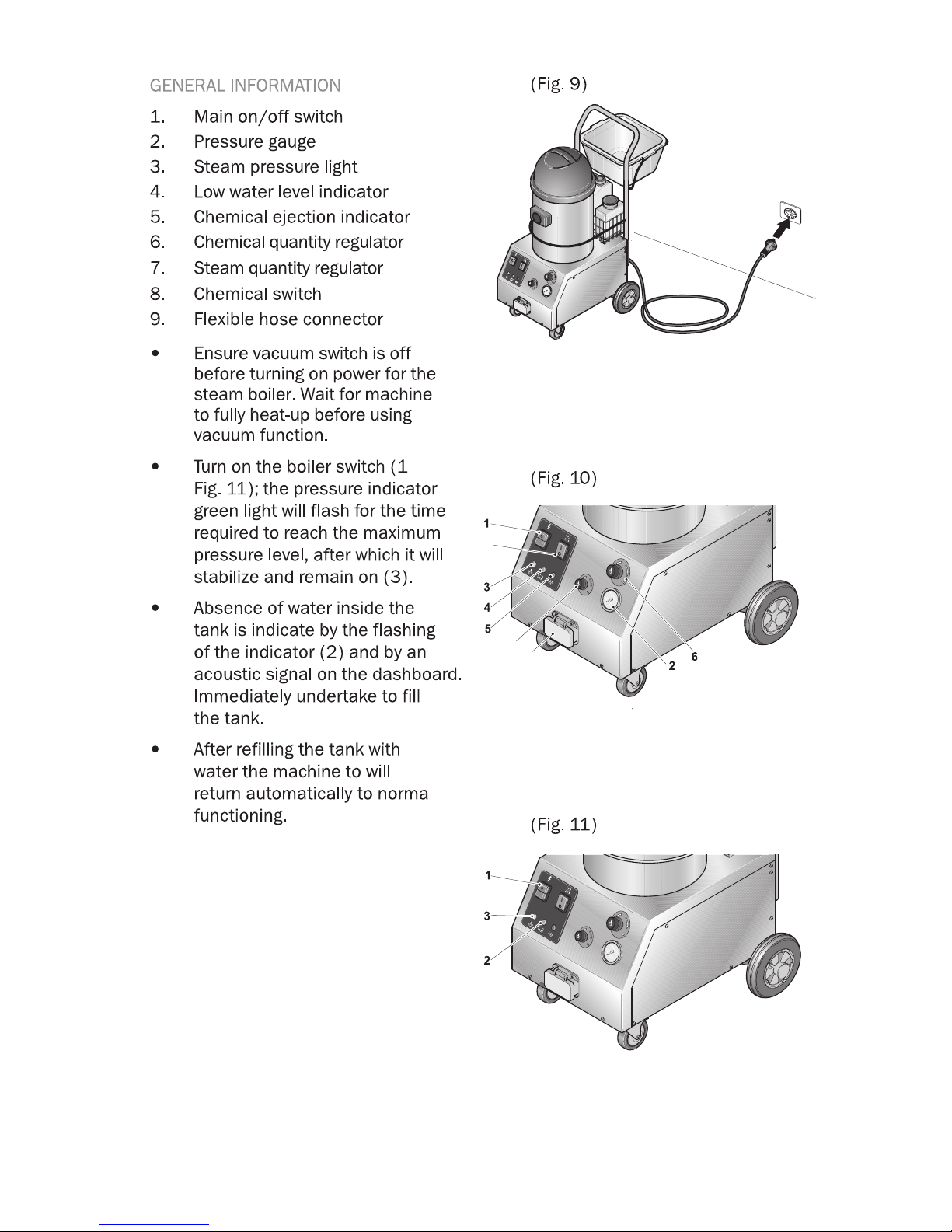

11. Unwind the cable and insert the

plug into the wall socket of a

suitable wiring system. Unless

otherwise stated the machine is

suitable for 120V-60Hz connection

(Fig. 9).

CAUTION! We will not be liable for

any damage caused by operating

conditions with voltages other than

required! Make sure that the plug

is grounded so as to avoid any

problems with the generator function (Fig 9).

Page 13

10

8

7

9

Page 14

11

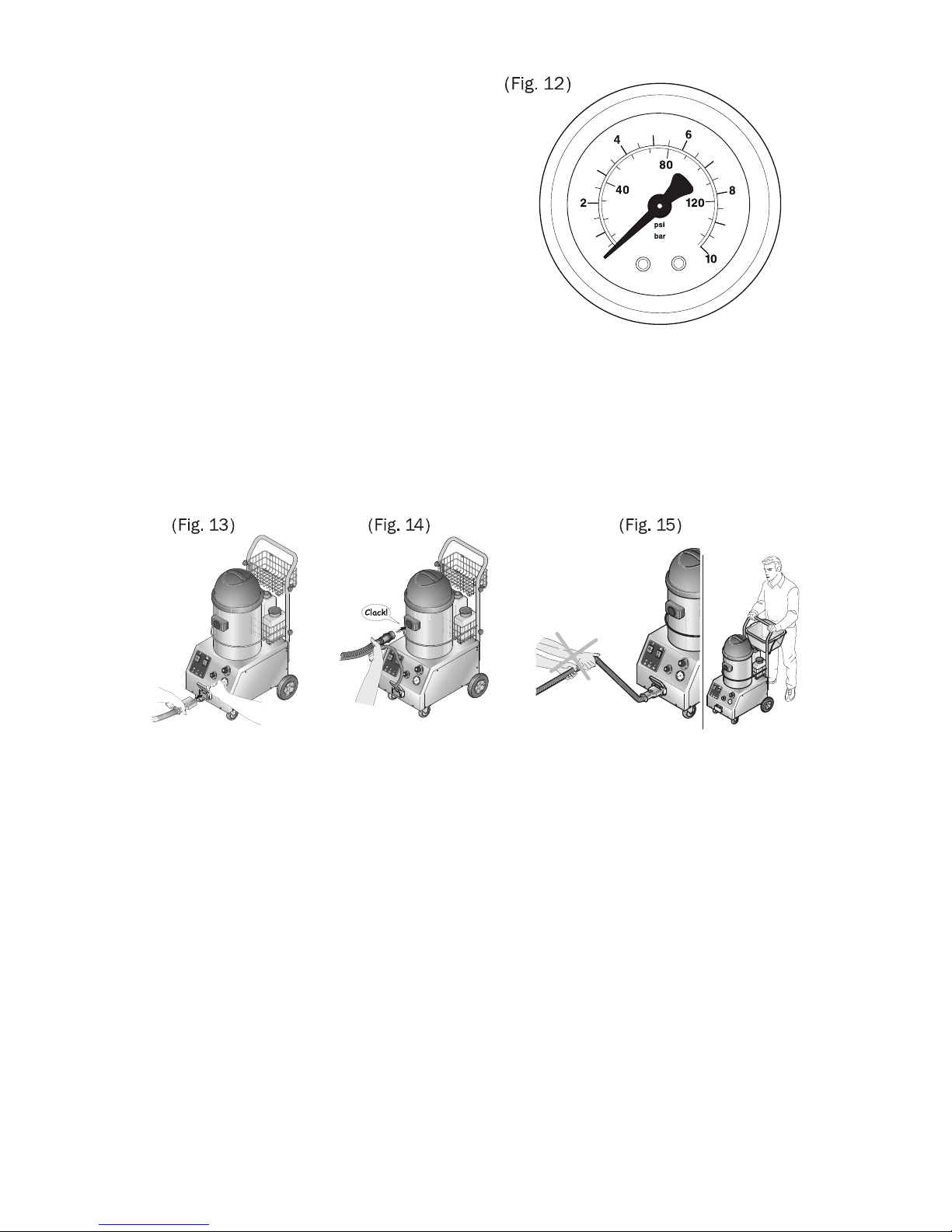

Pressure Gauge

• A pressure reading gauge is present

on the control panel.

• 0–4: minimum/medium pressure.

• 4–6: medium/maximum pressure.

• 6–8: maximum pressure.

• 8–10: Over-pressure

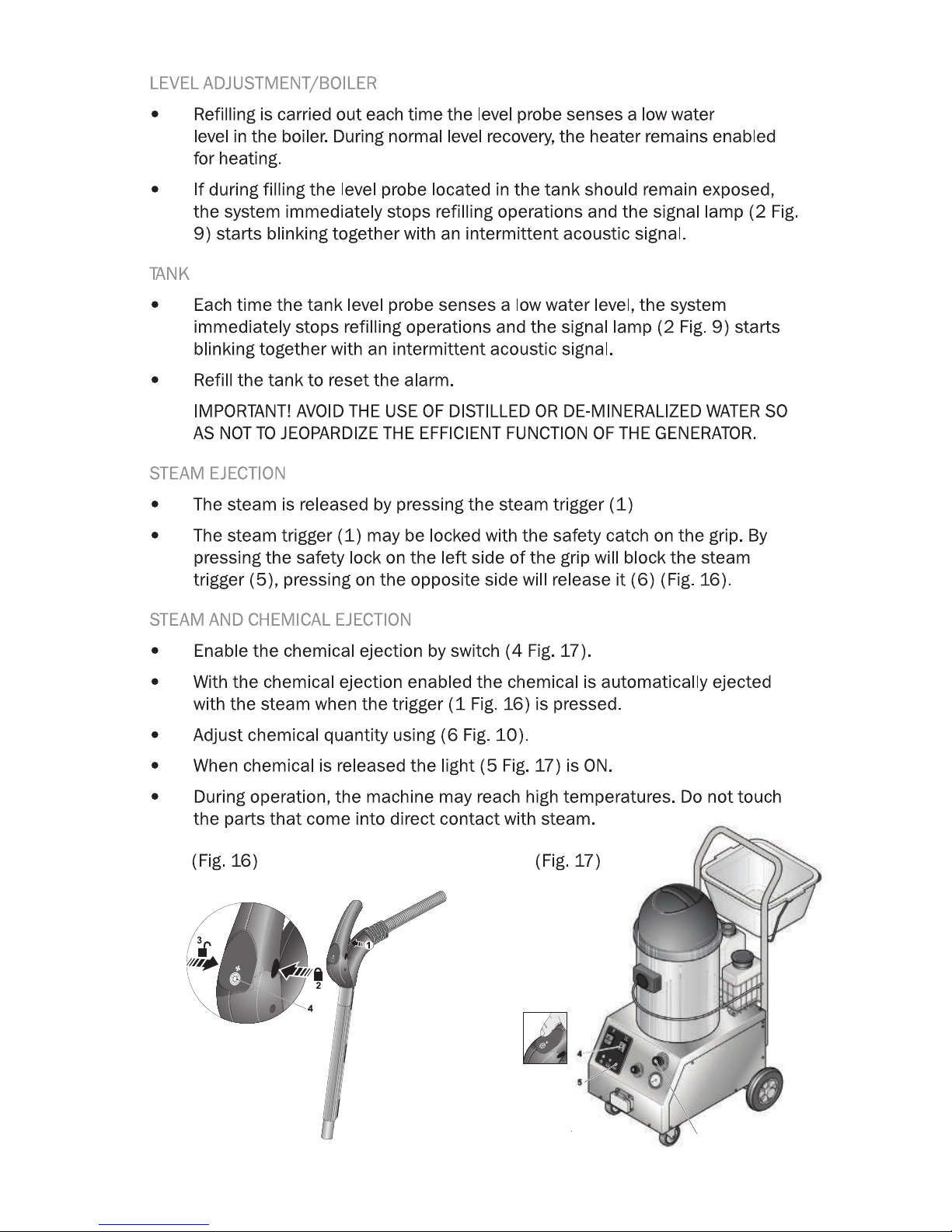

• Open the latch of the hose inlet, on

the machine front, and connect the

hose making sure that it is properly

connected (Fig. 13).

• Insert and connect the other end of

the hose in the vacuum inlet (Fig. 14).

• To move the machine push from backward as shown in (Fig. 15).

FIRST FILL-UP

• If the boiler and water tank are completely empty, all system functions are

disabled.

• Ensure there is water in the tank, and manually ll if empty.

• With the tank full and the boiler empty, after feeding the generator through

the switches (see the “PREPARATION” paragraph), the system controls the

water lling pump until the correct level is reached in the boiler. In this phase

the heater is deactivated. Once lling is completed, the pump is turned off,

and heating is simultaneously enabled through the boiler heater.

• Discharge any residual air from the boiler during the heating stage, by pressing switch 2 (Fig. 20) and pressing the steam delivery button 1 (Fig. 20). This

operation is important, given the power of the generator to prevent excessive

rise in pressure.

Page 15

6

12

Page 16

13

Page 17

14

Page 18

15

Page 19

16

Page 20

17

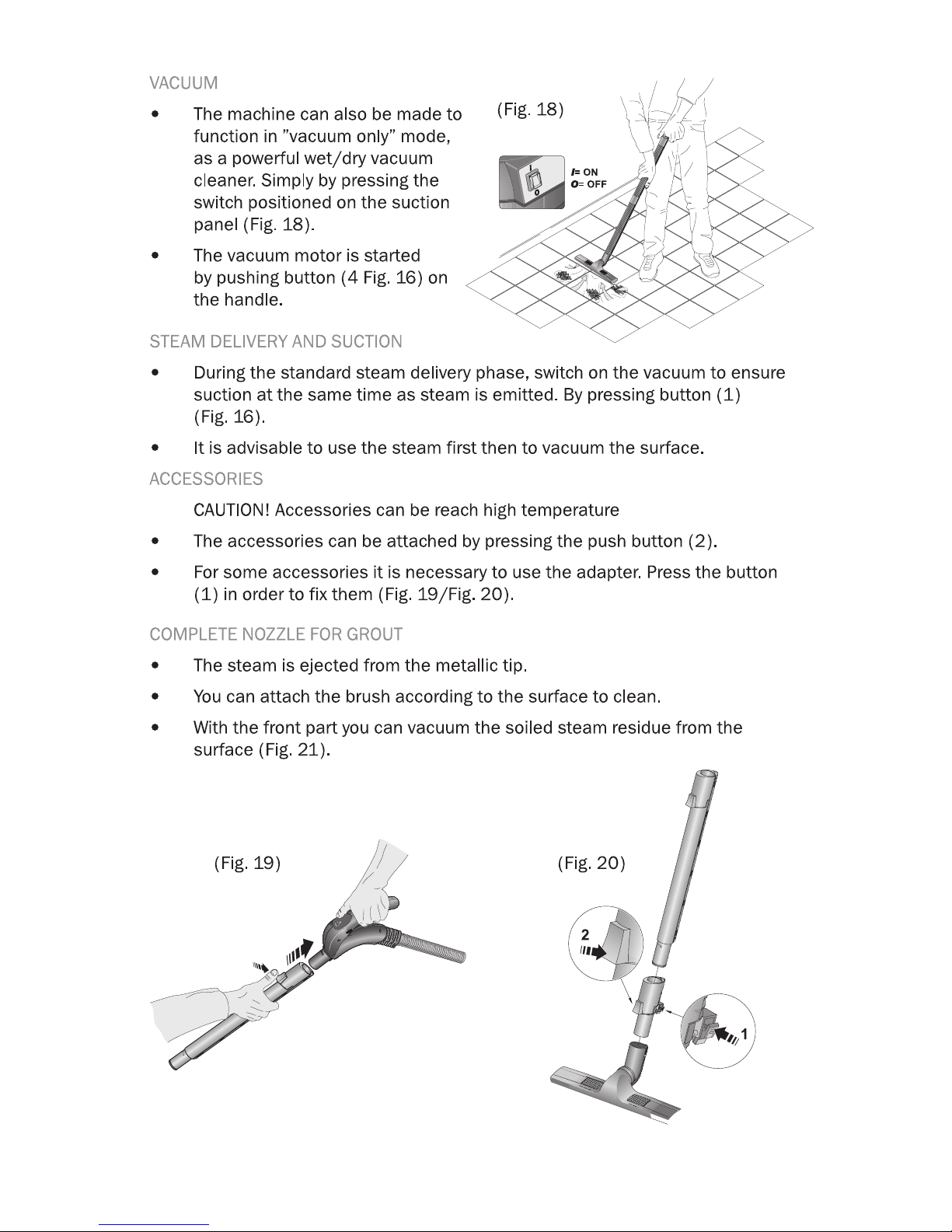

OPTIONAL STEAM KIT

The machine can works also with optional Steam Kit. The optional steam kit

provides different accessories where it is possible to use only the steam or

steam+chemical function.

Lock the selected accessory onto the flexible hose handle. Slip both ends on so

they t completely (Fig. 14), taking care to double-check that assembly is correct.

Press button (1) on the handgrip to enable the steam ejection.

Press the trigger (5) on the bottom of the handle to eject steam (Fig. 15).

STEAM SUPPLY CONTROLS/CHEMICAL SUPPLY CONTROLS

• Keep button pressed (3 Fig. 16) on the handgrip to enable chemical

supply, the yellow pilot light (4) on the dashboard will turn on.

• All accessories included in the supply can be assembled by simply tting

the two edges completely as shown in (Fig. 19).

• The square brush is usually employed to clean oors and for large at

surfaces. The brush is equipped with a lever allowing the handle to rotate

as shown in (Fig. 20).

• Moreover 4 handy hooks allow to hang a cloth.

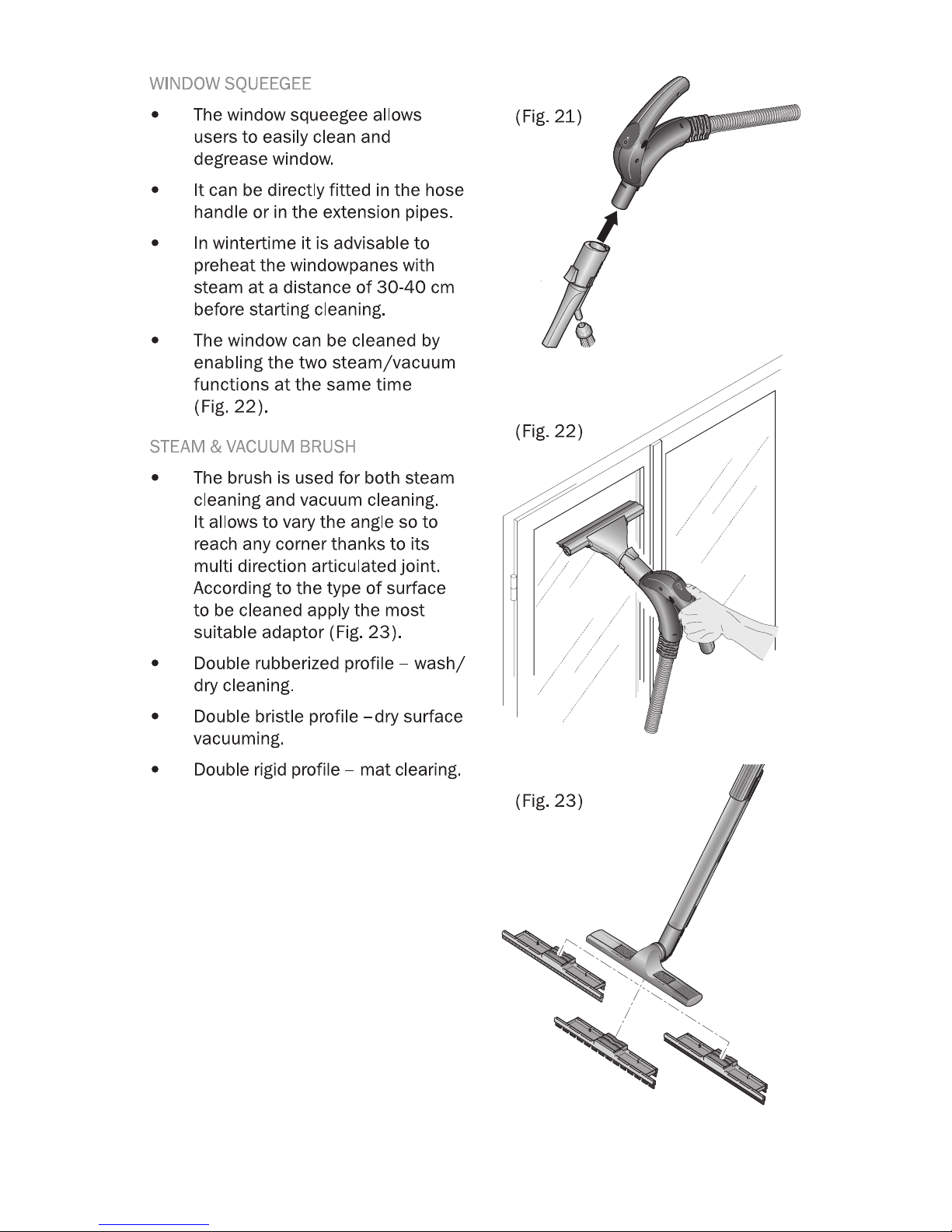

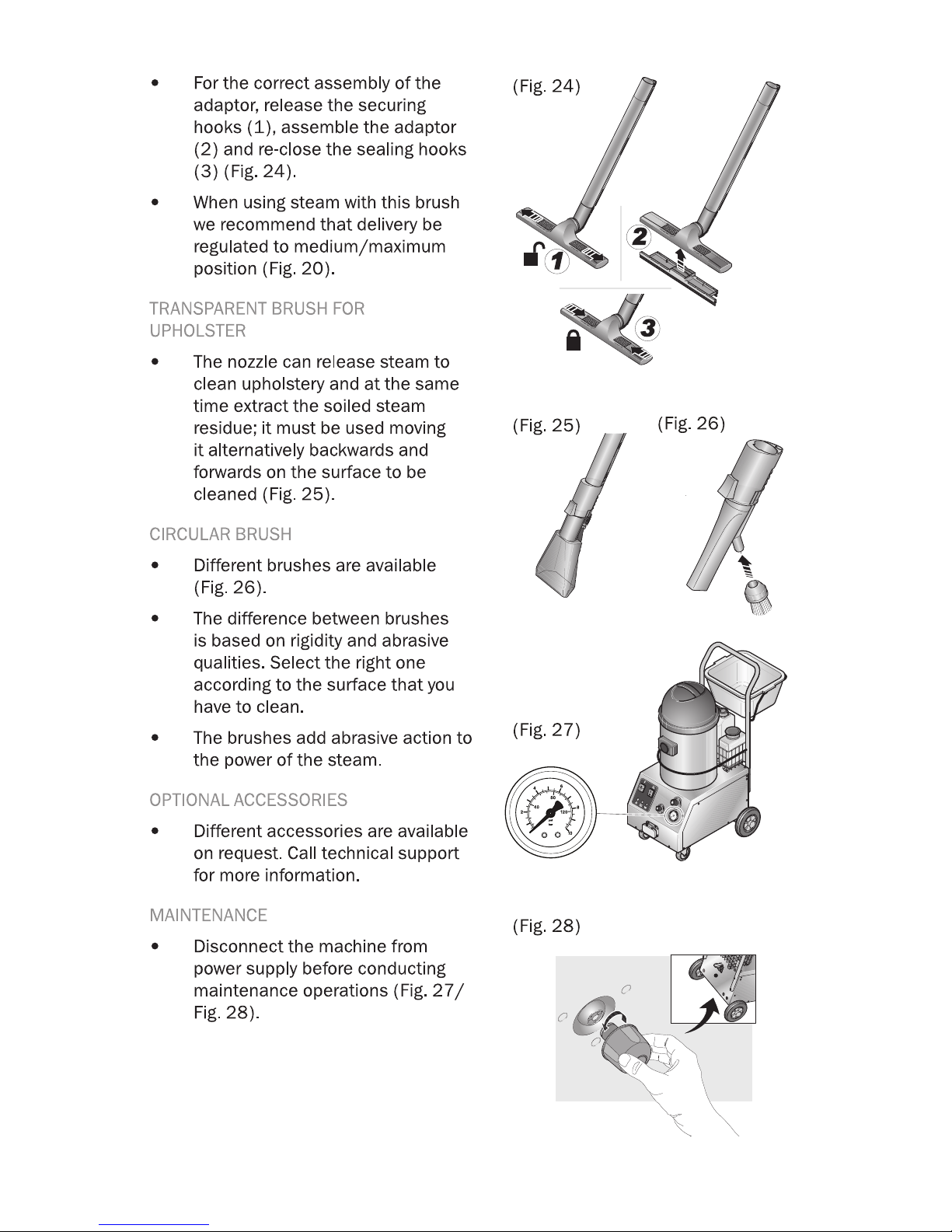

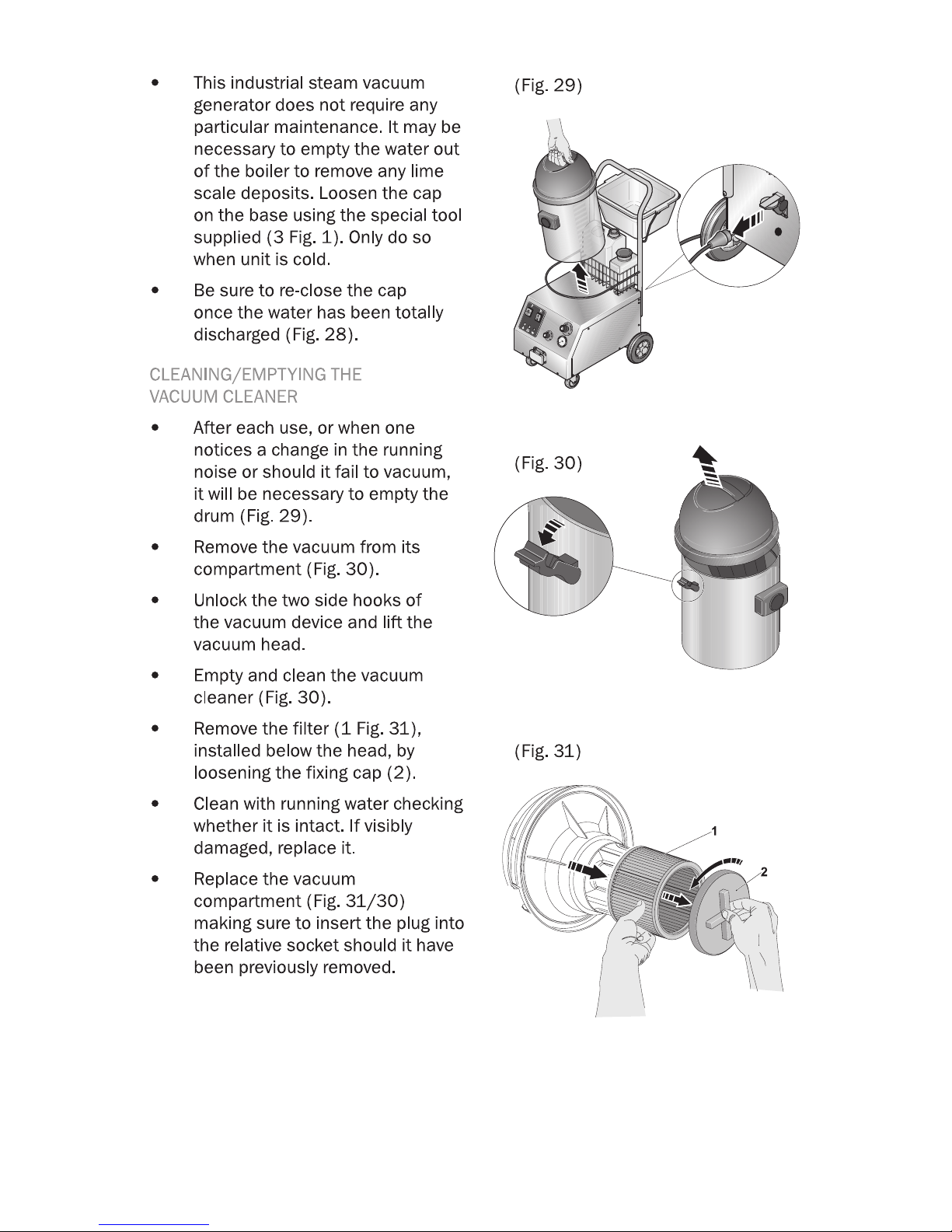

• Rotating triangular brush (Fig. 21).

• The rotating triangular brush is usually employed to clean small,delicate

surfaces and for uneven and irregular surfaces (armchair fabric pleats).

It has softer bristles. The steam is distributed directly on bristles

(patented system).

WANDS

• Wands are recommended for regular cleaning. Wands must be tted

directly on the hose handgrip or on the wand extensions.

• Both can be used coupled with the set of circular brushes (Fig. 22).

WASHING/WIPING DEVICE

• The washing/wiping device is used to clean and wipe a surface.

• It consists of a natural bristle brush and a metal/silicone rod. It can be

directly tted in the hose handgrip or in the extensions (Fig. 24).

Page 21

Reliable Corporation (“Reliable”) warrants to the original purchaser of the boiler noted

above from Reliable (the “Reliable Boiler Tank”) that it will be free from defects in

materials and workmanship when utilized for normal use by the original purchaser only.

Should the Reliable Boiler Tank need replacement, Reliable will do so at no parts and

labor cost to the original purchaser, exclusive of shipping.

Subject to the conditions and limitations set forth below, Reliable will either repair or

replace any part of a Reliable Boiler Tank that proves defective by reason of improper

workmanship or materials. If the defective Reliable Boiler Tank is no longer available and

cannot be repaired effectively or replaced with an identical model, Reliable shall replace

the defective Reliable Boiler Tank with a current Reliable Boiler Tank of equal or greater

value. Repaired parts or replacement products will be provided by Reliable on an exchange

basis, and will be either new or refurbished to be functionally equivalent to new. If Reliable

is unable to repair or replace a Reliable Boiler Tank, it will refund the current value of that

Reliable Boiler Tank at the time the warranty claim is made.

This limited warranty does not cover any damage to a Reliable Boiler Tank that results

from improper installation, accident, abuse, misuse, unreasonable use, natural disaster,

insufcient or excessive electrical supply, abnormal mechanical or environmental

conditions or any unauthorized disassembly, repair or modication. This limited warranty

does not extend to any indirect, consequential or incidental damages that may be suffered

by a user from the use of a Reliable Boiler Tank, including without limitation, any liability for

third party claims for damage, and is limited to the amount paid by the original purchaser

for the Reliable Boiler Tank with respect to which this limited warranty protection applies.

This limited warranty does not apply with respect to products that have been altered or

which are missing serial numbers or for products not purchased directly from Reliable or a

dealer authorized by Reliable to sell the Reliable Boiler Tank.

This limited warranty is the only warranty that applies to the Reliable Boiler Tank,

supersedes any and all terms that may be contained in any other document or purchase

order and may not be altered or amended except expressly in writing by Reliable.

To obtain a repair or replacement under the terms of this warranty, please contact our

customer service group at 1 800 268 1649 or at support@reliablecorporation.com. You

will be required to submit an original receipt via fax or e-mail. The receipt must reect that

you are the original purchaser, the product was bought directly from Reliable or from an

authorized Reliable dealer and that the warranty claim is being made in compliance with

the terms set out in this document or any subsequent document issued by Reliable in

connection with this policy. You will be issued a return authorization number (RA#) and

asked to ship the defective product together with proof of purchase and RA#, prepaid

insured to the following address: Reliable Corporation, 5–100 Wingold Ave, Toronto, ON

M6B 4K7.

Freight collect shipments will be refused. The risk of loss or damage in transit will be borne

by the customer. Once Reliable receives the defective product, it will initiate the repair or

replacement process.

RELIABLE CORPORATION LIFETIME

PRODUCT WARRANTY POLICY FOR

PRESSURIZED STEAM BOILER TANKS

18

Page 22

Reliable Corporation (“Reliable”) warrants to original purchaser of its products that

every product sold by Reliable (a “Reliable Product”) is free from defects in material and

workmanship for a period of one year from the date of purchase if properly used and

maintained. Subject to the conditions and limitations set forth below, Reliable will either

repair or replace any part of a Reliable Product that proves defective by reason of improper

workmanship or materials. If the defective Reliable Product is no longer available and

cannot be repaired effectively or replaced with an identical model, Reliable shall replace

the defective Reliable Product with a current Reliable Product of equal or greater value.

Repaired parts or replacement products will be provided by Reliable on an exchange basis,

and will be either new or refurbished to be functionally equivalent to new. If Reliable is

unable to repair or replace a Reliable Product, it will refund the current value of that Reliable

Product at the time the warranty claim is made.

This limited warranty does not cover any damage to a Reliable Product that results from

improper installation, accident, abuse, misuse, natural disaster, insufcient or excessive

electrical supply, abnormal mechanical or envsteamermental conditions, wear and tear

resulting from normal use of the product, or any unauthorized disassembly, repair, or

modication. This limited warranty does not extend to any indirect, consequential or

incidental damages that may be suffered by a user or from the use of a Reliable Product,

including without limitation, any liability for third party claims for damage, and is limited to

the amount paid by the original purchaser Reliable Product with respect to which this limited

warranty protection applies. This limited warranty does not apply with respect to products

that have been altered or which are missing serial numbers or for products not purchased

directly from Reliable or a dealer authorized by us to sell Reliable Products.

This limited warranty is the only warranty that applies to any Reliable Product, supersedes

any and all terms that may be contained in any other document or purchase order and may

not be altered or amended except expressly in writing by Reliable.

To obtain a repair or replacement under the terms of this warranty, please contact our

customer service group at 1-800-268-1649 or at support@reliablecorporation.com.

You will be required to submit an original receipt via fax or e-mail. The receipt must reect

that you are the original purchaser, the product was bought directly from

us or from an authorized Reliable dealer and that the warranty claim is being made within

the warranty period. You will be issued a return authorization number (RA#) and asked to

ship the defective product together with proof of purchase and RA#, prepaid insured to the

following address:

Reliable Corporation, 5-100 Wingold Avenue, Toronto, ON M6B 4K7. Freight collect

shipments will be refused. The risk of loss or damage in transit will be borne by

the customer. Once Reliable receives the defective product, it will initiate the repair or

replacement process.

If you have any questions regarding this warranty, you may write to:

Reliable Corporation

100 Wingold Avenue, Unit 5

Toronto, Ontario

Canada M6B 4K7

www.reliablecorporation.com

RELIABLE PRODUCTS WARRANTY

19

Page 23

20

Page 24

21

TANDEM PRO 2000CV

ASPIRATEUR À VAPEUR

GUIDE D’UTILISATION

FRANÇAIS

Page 25

FÉLICITATIONS

Nous aimerions vous remercier et vous féliciter pour l’achat de

l’aspirateur à vapeur Tandem Pro de Reliable Corporation.

Le nettoyage à sec au jet de vapeur peut nettoyer en profondeur et

désinfecter votre domicile de façon sûre et efcace.

Tandem Pro est un nettoyeur commercial complet à usages multiples.

Il fonctionne comme un nettoyeur à vapeur et un extracteur à vapeur

et aussi comme un aspirateur à sec/humide. Sa pression de vapeur

de 6 bars et son kit d’accessoires sans égal font du Tandem Pro

une alternative idéale aux produits chimiques en matière de nettoy-

age et de désinfection de toutes les surfaces rencontrées au sein

d’installations commerciales.

Pour votre sécurité et an de proter pleinement des avantages de

ce produit, veuillez prendre quelques minutes pour lire toutes les

mises en garde et les instructions d’entretien importantes. Veuillez

conserver ce manuel à portée de main de tous les utilisateurs et

consulter la carte de garantie du produit en cas de besoin.

Remarque : dans la mesure où tous les appareils sont testés en

usine avant l’expédition, votre nouvel aspirateur à vapeur peut contenir de petites quantités d’eau.

Veuillez lire attentivement ce manuel an d’éviter toute utilisation

incorrecte. Le fabricant rejette toute responsabilité concernant les

blessures ou les dommages résultant d’une utilisation incorrecte de

l’appareil, d’une incompétence, d’un manque de prudence ou d’une

négligence liée au non-respect des instructions fournies dans le

présent manuel. Les images présentées dans ce manuel permettent

d’expliquer le fonctionnement, les instructions de sécurité et les

opérations d’entretien de l’appareil. Le fabricant se réserve le droit

d’effectuer des modications de ses appareils, en raison d’une opti-

misation des performances.

Ce manuel fait partie intégrante de l’ensemble de l’appareil. Il doit

être soigneusement conservé à portée de main et consulté en

cas de doute. Si l’appareil est donné à un tiers, même lorsqu’il est

uniquement prêté, veuillez aussi fournir le manuel avec ce dernier, en

indiquant au nouvel utilisateur de lire attentivement l’ensemble de

son contenu avant toute utilisation de l’appareil.

Page 26

23

Page 27

24

Page 28

25

CONSERVEZ CES INSTRUCTIONS

DANS UN LIEU SÛR POUR TOUTE

CONSULTATION ULTÉRIEURE

INSTRUCTIONS DE MISE À LA TERRE

Cet appareil doit être mis à la terre. S’il venait à fonctionner incorrectement ou

à tomber en panne, la mise à la terre offre une voie de moindre résistance au

courant électrique an de réduire le risque de choc électrique. Le cordon de

l’appareil est équipé d’un conducteur de mise à la terre et d’une broche de mise à

la terre. La che doit être insérée dans une prise murale adéquate correctement

installée et mise à la terre conformément à tous les codes et ordonnances locales.

AVERTISSEMENT – Un branchement incorrect du conducteur de mise à la terre

de l’appareil peut entraîner un risque de choc électrique. Consultez un électricien

qualié ou du personnel de maintenance, si vous avez des doutes quant à la

mise à la terre correcte de la prise murale. Ne modiez pas la che fournie avec

l’appareil – si elle ne correspond pas à la prise murale, faites installer une prise

appropriée par un électricien qualié.

Cet appareil doit être utilisé sur un circuit dont la tension nominale est supérieure

à 120 volts et équipé en usine d’un cordon et d’une che électrique spéciques

an de permettre un branchement sur un circuit électrique approprié. Assurez-vous

que l’appareil soit branché à une prise murale ayant la même conguration que la

che. Aucun adaptateur ne devrait être utilisé avec cet appareil. Si l’appareil doit

être reconnecté pour une utilisation avec un type de circuit électrique différent, le

rebranchement devra être effectué par un personnel de maintenance qualié.

DESCRIPTION DES CARACTÉRISTIQUES

TECHNIQUES DE L’APPAREIL :

Ce générateur de vapeur électrique professionnel à haute température et haute

pression est un appareil destiné au nettoyage et à la désinfection de surfaces et

d’équipements multiples.

Utilisant une technologie de pointe, le chauffe-eau Tandem Pro 2000CV peut

générer de la vapeur saturée sèche à de très hautes températures et pressions

pour un processus de nettoyage efcace en profondeur.

Le générateur de vapeur combiné à un aspirateur puissant permet un nettoyage

immédiat en profondeur. Les accessoires inclus permettent une utilisation simple

et pratique de l’appareil pour un grand nombre de surfaces et de tâches de

nettoyage.

Page 29

26

SYSTÈMES DE SÉCURITÉ DE

L’APPAREIL :

• Soupape d’évacuation de surpression.

• Pressostat pour le contrôle de la pression.

• Thermorupteur et thermofusible de sécurité pour contrôler la température

dans le chauffe-eau.

• Commandes de la poignée basse tension.

DESCRIPTION

MODÈLE

STRUCTURE EN ACIER INOXYDABLE

ALIMENTATION ÉLECTRIQUE (V/HZ)

PUISSANCE (W)

AMPÉRAGE D’ENTRÉE

PRESSION DE FONCTIONNEMENT (BAR)

TEMPÉRATURE DU CHAUFFE-EAU (C°)

CHAUFFE-EAU EN ACIER INOXYDABLE 316

(CAPACITÉ TOTALE EN LITRES)

CAPACITÉ DU RÉSERVOIR D’EAU (LITRES)

COMMANDE ÉLECTRONIQUE

PUISSANCE D’ASPIRATION (W)

DÉMARRAGE INITIAL (MIN.)

LONGUEUR (CM)

LARGEUR (CM)

HAUTEUR (CM)

POIDS À VIDE (KG)

RAIL PORTE-ACCESSOIRES STANDARD

TANDEM PRO 2000CV

OUI

120/60

1700

14

6

150°C

2,3

5

OUI

1000 W

7

49

37

100

22

OUI

Page 30

27

Page 31

(Fig. 2)

(Fig. 3)

(Fig. 4)

(Fig. 5)

28

Page 32

29

A

A

A

7. Raccordez la che du nettoyeur

à vapeur dans la prise située à

l’arrière de l’unité.

ATTENTION ! Connectez unique-

ment le nettoyeur à vapeur fourni

avec l’appareil. Tout autre nettoyeur à vapeur ou outil peut

endommager l’appareil (Fig. 6).

8. Remplissez le réservoir d’eau avec

de l’eau du robinet (1 Fig. 7).

ATTENTION ! Utilisez uniquement

de l’eau du robinet, n’utilisez jamais

d’autres substances (Fig. 7) !

9. En cas d’utilisation de produits

chimiques, remplissez le réservoir

de produits de chimique (2 Fig. 8).

ATTENTION ! Utilisez uniquement

les produits recommandés par le

fabricant (Fig. 8).

10. S’il n’ya pas de puissance à la

machine – vérier le fusible (A).

11. Déroulez le câble et insérez la

che dans la prise murale d’un

système électrique adapté. Sauf

indications contraires, l’appareil

convient pour une connexion de

120V-60Hz (Fig. 9).

ATTENTION ! Nous rejetons toute

responsabilité pour tout dommage causé par des conditions

d’utilisation avec des tensions

différentes de celles requises !

Assurez-vous que la che soit mise

à la terre an d’éviter tout problème de la fonction du générateur

(Fig. 9).

Page 33

30

8

7

9

Page 34

MANOMÈTRE

• Une jauge de lecture de la pression est

présente sur le tableau de contrôle.

• 0–4 : pression minimum/ moyenne.

• 4–6 : pression moyenne/ maximum.

• 6–8 : pression maximum.

• 8–10 : Surpression

• Ouvrez le verrouillage de l’arrivée du

tuyau, à l’avant de l’appareil, et raccordez le tuyau en vous assurant qu’il soit

correctement raccordé (Fig. 13).

• Insérez et raccordez l’autre extrémité du

tuyau dans l’entrée d’aspiration (Fig. 14).

• Pour déplacer l’appareil, poussez-le par

l’arrière tel qu’illustré sur la gure (Fig. 15).

31

PREMIER REMPLISSAGE

• Si le chauffe-eau et le réservoir d’eau sont complètement vides, toutes les

fonctions du système sont désactivées.

• Assurez-vous qu’il y ait de l’eau dans le réservoir et remplissez-le manuellement s’il est vide.

• Avec le réservoir rempli et le chauffe-eau vide, après avoir alimenté le

générateur à l’aide des interrupteurs (voir le paragraphe « PRÉPARATION

»), le système contrôle la pompe de remplissage de l’eau jusqu’à ce qu’un

niveau correct soit atteint dans le chauffe-eau. Au cours de cette phase, le

chauffage est désactivé. Dès que le remplissage est terminé, la pompe est

désactivée et le chauffage est activé au même moment dans le chauffe-eau.

• Déchargez tout l’air résiduel contenu dans le chauffe-eau au cours de l’étape

de chauffage en appuyant sur l’interrupteur 2 (Fig. 20) et en appuyant sur

le bouton d’approvisionnement de la vapeur 1 (Fig. 20). Cette opération est

importante, étant donné la puissance du générateur pour éviter toute élévation excessive de la pression.

Page 35

6

35

32

Page 36

33

Page 37

34

Page 38

35

Page 39

36

Page 40

37

Page 41

Reliable Corporation (« Reliable ») garantit à l'acheteur original du chauffe-eau susmentionné

de Reliable (le « réservoir de chauffe-eau Reliable ») qu'il sera exempt de tout défaut de

fabrication et de main d'œuvre dans le cadre d'une utilisation normale par l'acheteur original

uniquement. Si un remplacement du réservoir de chauffe-eau Reliable s'avérait nécessaire,

Reliable y procédera sans aucun frais de pièces ni de main d'œuvre pour l'acheteur original, à

l'exclusion des frais d'expédition.

Soumis aux conditions et limitations établies ci-après, Reliable réparera ou remplacera toute

pièce d'un réservoir de chauffe-eau Reliable qui s'avère défectueux en raison d'un défaut de

fabrication ou de matériaux défectueux. Si le réservoir de chauffe-eau Reliable défectueux n'est

plus disponible et ne peut pas être réparé efcacement ou remplacé par un modèle identique,

Reliable remplacera le réservoir de chauffe-eau Reliable défectueux par un réservoir de chauffe-

eau Reliable actuel de valeur équivalente ou supérieure. Les pièces réparées ou les produits

remplacés seront fournis par Reliable sur la base d'un échange, et seront soit neufs ou remis

à neuf pour être fonctionnellement équivalents aux neufs. Si Reliable n'est pas en mesure

de réparer ou de remplacer un réservoir de chauffe-eau Reliable, elle remboursera la valeur

actuelle dudit réservoir de chauffe-eau Reliable au moment où la réclamation de garantie est

réalisée.

Cette garantie limitée ne couvre aucun dommage subi par un réservoir de chauffe-eau Reliable

résultant d'une installation incorrecte, d'un accident, d'un abus, d'une mauvaise utilisation,

d'une utilisation déraisonnable, d'une catastrophe naturelle, d'une alimentation électrique

insufsante ou excessive, de conditions mécaniques ou environnementales anormales, ou de

tout démontage, réparation ou modication non autorisé. Cette garantie limitée ne s'étend à

aucun dommage indirect ou direct dont peut être victime un utilisateur suite à l'utilisation d'un

réservoir de chauffe-eau Reliable, y compris mais sans s'y limiter, toute responsabilité pour des

réclamations de tiers pour des dégâts, et se limite au montant payé par l'acheteur original du

réservoir de chauffe-eau auquel cette protection de garantie limitée s'applique. Cette garantie

limitée ne s'applique pas aux produits qui ont été modiés ou dont les numéros de séries sont

manquants, ou aux produits non achetés directement auprès de Reliable ou d'un revendeur

agréé par Reliable pour vendre des réservoirs de chauffe-eau Reliable.

Cette garantie limitée est l'unique garantie qui s'applique au réservoir de chauffe-eau Reliable,

elle remplace toutes conditions qui peuvent être contenues dans un autre document ou bon de

commande et ne peut être transformée ou modiée, sauf dérogation expressément écrite de

Reliable.

Pour obtenir une réparation ou un remplacement en vertu des conditions de cette garantie,

veuillez contacter notre service à la clientèle au 1 800 268 1649 ou par courriel à support@

reliablecorporation.com. Il vous sera demandé d'envoyer le reçu original par fax ou courriel.

Le reçu doit prouver que vous êtes l'acheteur original, que le produit a été acheté directement

chez Reliable ou chez un revendeur agréé par Reliable et que la réclamation de garantie est

effectuée conformément aux conditions dénies dans le présent document ou tout document

subséquent publié par Reliable en rapport avec la présente garantie. Un numéro d'autorisation

de retour (Nº AR) vous sera donné et il vous sera demandé d'expédier le produit défectueux

accompagné de la preuve d'achat et du Nº AR, les frais d'assurances étant prépayés à l'adresse

suivante : Reliable Corporation, 5–100 Wingold Ave, Toronto, ON M6B 4K7.

Les expéditions avec fret à destination seront refusées. Le risque de perte ou

d'endommagement lors du transport sera assumé par le client. Une fois que Reliable aura reçu

le produit défectueux, elle initiera la réparation ou le remplacement.

POLITIQUE DE GARANTIE À VIE DES

RÉSERVOIRS DE CHAUFFE-EAU SOUS

PRESSION DE RELIABLE CORPORATION

38

Page 42

Reliable Corporation (« Reliable ») garantit à l'acheteur original de ce produit que chaque

produit vendu par Reliable (un « Produit Reliable ») est exempt de tout défaut de pièce et

de main d'œuvre pour une période d'un an à compter de la date d'achat, s'il est utilisé et

entretenu correctement. Soumis aux conditions et limitations établies ci-après, Reliable

réparera ou remplacera toute pièce d'un produit Reliable qui s'avère défectueuse en raison

d'un défaut de fabrication ou de main d'œuvre. Si le Produit Reliable défectueux n'est plus

disponible et ne peut pas être réparé efcacement ou remplacé par un modèle identique,

Reliable remplacera le Produit Reliable défectueux par un Produit Reliable actuel de

valeur équivalente ou supérieure. Les pièces réparées ou les produits remplacés seront

fournis par Reliable sur la base d'un échange, et seront ou neufs ou remis à neuf pour être

fonctionnellement équivalents aux neufs. Si Reliable n'est pas en mesure de réparer ou

de remplacer le Produit Reliable, elle remboursera la valeur actuelle du Produit Reliable au

moment où la réclamation de garantie est réalisée.

Cette garantie limitée ne couvre aucun dommage subi par un Produit Reliable résultant

d'une installation incorrecte, d'un accident, d'un abus, d'une mauvaise utilisation,

d'une catastrophe naturelle, d'une alimentation électrique insufsante ou excessive, de

conditions mécaniques ou environnementales anormales, de l'usure et de la détérioration

résultant de l'usure normale du produit, ou de tout démontage, réparation ou modication

non autorisé(e). Cette garantie limitée ne s'étend à aucun dommage indirect ou direct

dont peut être victime un utilisateur ou suite à l'utilisation d'un Produit Reliable, y compris

mais sans s'y limiter, toute responsabilité pour des réclamations de tiers pour des

dégâts, et se limite au montant payé par l'acheteur original du Produit Reliable auquel

cette protection de garantie limitée s'applique. Cette garantie limitée ne s'applique pas

aux produits qui ont été modiés ou dont les numéros de séries sont manquants, ou aux

produits non achetés directement auprès de Reliable ou d'un revendeur agréé pour la

vente de Produits Reliable.

Cette garantie limitée est l'unique garantie qui s'applique à tout Produit Reliable, elle

remplace toutes conditions qui peuvent être contenues dans un autre document ou bon

de commande et ne peut être transformée ou modiée, sauf dérogation expressément

écrite de Reliable.

Pour obtenir une réparation ou un remplacement en vertu des conditions de cette

garantie, veuillez contacter notre service à la clientèle au 1-800-268-1649 ou par courriel

à support@reliablecorporation.com.

Il vous sera demandé d'envoyer le reçu original par télécopie ou courriel. Le reçu doit

prouver que vous êtes l'acheteur original, que le produit a été acheté directement chez

nous ou chez un revendeur agréé par Reliable et que la réclamation de garantie est

effectuée pendant la période de garantie. Un numéro d'autorisation de retour (Nº AR) vous

sera fourni et il vous sera demandé d'expédier le produit défectueux accompagné de la

preuve d'achat et du Nº AR, les frais d'assurances étant prépayés à l'adresse suivante :

Reliable Corporation, 5-100 Wingold Avenue, Toronto, ON M6B 4K7. Les expéditions avec

fret payable à destination seront refusées. Le risque de perte ou d'endommagement

lors du transport sera assumé par le client. Une fois que Reliable aura reçu le produit

défectueux, elle initiera la réparation ou le remplacement.

Si vous avez des questions concernant la présente garantie, vous pouvez écrire à :

Reliable Corporation

100 Wingold Avenue, Unit 5

Toronto, Ontario

Canada M6B 4K7

www.reliablecorporation.com

GARANTIE DES PRODUITS RELIABLE

39

Page 43

40

Page 44

41

TANDEM PRO 2000CV

ASPIRADORA A VAPOR

MANUAL DE INSTRUCCIONES

ESPAÑOL

Page 45

42

FELICITACIONES

Felicitaciones Nos gustaría agradecerle y felicitarlo por haber comprado la aspiradora a vapor Tandem Pro de Reliable Corporation.

La limpieza con vapor de agua en seco puede profundizar la limpieza

e higienizar su hogar en forma segura y efectiva.

La Tandem Pro es un unidad de limpieza comercial completa y

multiuso. Funciona como limpiadora aspiradora y extractor de vapor

y como aspiradora en húmedo y en seco. La presión de vapor de 6

bares y un equipo de accesorios insuperable hacen que la aspiradora

Tandem Pro sea una alternativa ideal y sin químicos para la limpieza

e higienización de todas las supercies que se encuentran en entor-

nos de limpieza comerciales.

Para su seguridad y con el propósito de disfrutar de las ventajas de

este producto, dedique algunos minutos a leer todas las medidas de

protección e instrucciones para el cuidado del equipo. Tenga a mano

este manual para todos los usuarios y revise la tarjeta del certicado

de garantía del producto.

Nota: su nueva aspiradora puede tener pequeñas cantidades de

agua ya que todas las unidades son probadas en la fábrica antes de

su envío.

Lea cuidadosamente este manual para evitar cualquier uso inadecuado. El fabricante no asume ninguna responsabilidad por los daños

que la aspiradora pueda ocasionar a personas o bienes como consecuencia del uso inadecuado de la máquina, incompetencia, falta de

precauciones o negligencia y por el incumplimiento de las instruccio-

nes suministradas en este manual. Las imágenes que aparecen en

este manual ayudarán a explicar el funcionamiento, las instrucciones

de seguridad y las operaciones de mantenimiento de la máquina. El

fabricante se reserva el derecho de realizar cambios en sus máqui-

nas, como resultado de una optimización del rendimiento.

Este manual es una parte integral del equipo de la máquina. Debe

mantenerse cuidadosamente dentro del alcance y ser consultado

en caso de duda. Si la máquina es suministrada a un tercero, incluso

a modo de préstamo, entregue el manual junto con la máquina e

indíquele al nuevo usuario que lea cuidadosamente todo el contenido antes de utilizar la máquina.

Page 46

43

Page 47

44

Page 48

45

GUARDE ESTAS INSTRUCCIONES PARA

FUTURAS CONSULTAS

INSTRUCCIONES DE CONEXIÓN A TIERRA

Este artefacto requiere de una conexión a tierra. En caso de mal funcionamiento

o avería, la conexión a tierra ofrece menor resistencia a la corriente eléctrica para

reducir el riesgo de una descarga eléctrica. El cableado de este artefacto está

equipado con un equipo-conductor de conexión a tierra y un enchufe de conexión

a tierra. El enchufe debe insertarse en un tomacorriente apropiado, instalarse

adecuadamente y tener conexión a tierra, de conformidad con todos los códigos

y ordenanzas locales.

ADVERTENCIA – La conexión inadecuada del equipo-conductor de conexión

a tierra puede generar riesgo de una descarga eléctrica. Consulte con un

electricista calicado o personal de servicio técnico si tiene dudas respecto de la

conexión a tierra de un tomacorriente. No modique el enchufe suministrado con

el aparato – si no entra en el tomacorriente, contrate a un electricista calicado

para que instale un tomacorriente apropiado.

Este aparato es para utilizar en un circuito con una capacidad nominal de más

de 120 voltios y está equipado de fábrica con un cable eléctrico y un enchufe

especícos para permitir la conexión a un circuito eléctrico apropiado. Asegúrese

de que el aparato esté conectado a un tomacorriente con la misma conguración

que el enchufe. No se debe utilizar ningún adaptador con este aparato. Si el

aparato debe ser conectado nuevamente para su uso en otro tipo de circuito

eléctrico, la nueva conexión debe ser realizada por personal de servicio técnico

calicado.

DESCRIPCIÓN DE LAS CARACTERÍSTICAS

TÉCNICAS DE LA MÁQUINA:

Este generador de vapor eléctrico a alta presión y alta temperatura es una

máquina diseñada para la limpieza e higienización de múltiples supercies y

equipos.

Con tecnología de avanzada, la caldera Tandem Pro 2000CV puede generar vapor

saturado seco a muy alta temperatura y presión para un proceso de limpieza más

profundo y efectivo.

El generador de vapor combinado con una poderosa aspiradora permite una

limpieza profunda e inmediata. Los accesorios incluidos permiten un uso fácil y

práctico de la máquina para distintas supercies y tareas de limpieza.

Page 49

46

SISTEMAS DE SEGURIDAD DE LA

MÁQUINA:

• Válvula de escape de sobrepresión.

• Interruptor de presión para control de presión.

• Interruptor térmico de seguridad y termofusible para controlar la temperatura

en la caldera.

• Controles de baja tensión en asas.

DESCRIPCIÓN

MODELO

ESTRUCTURA DE ACERO INOXIDABLE

ENERGÍA ELÉCTRICA (V/HZ)

ENERGÍA (W)

AMP DE ENTRADA

BARES DE PRESIÓN DE TRABAJO

TEMPERATURA DE CALDERA (C°)

CALDERA 316 DE ACERO INOXIDABLE

(TOTAL DE LITROS)

CAPACIDAD DEL TANQUE DE AGUA (LITROS)

CONTROL ELECTRÓNICO

PODER DE ASPIRACIÓN (W)

ARRANQUE INICIAL (MIN.)

LARGO (CM)

ANCHO (CM)

ALTURA (CM)

PESO SIN CARGA (KG.)

ESTANTE ACCESORIO ESTÁNDAR

TANDEM PRO 2000CV

SÍ

120/60

1700

14

6

150°C

2.3

5

SÍ

1000 W

7

49

37

100

22

SÍ

Page 50

47

Page 51

48

Page 52

49

A

A

A

7. Conecte la aspiradora en el

enchufe trasero de la unidad.

¡PRECAUCIÓN! Conecte solamente

la aspiradora entregada con la

unidad. Si conecta otra aspiradora

u otras herramientas puede dañar

la unidad (Fig. 6).

8. Rellene el tanque de agua con

agua del grifo (1 Fig.7).

¡PRECAUCIÓN! ¡Use solamente

agua del grifo, nunca use otra

sustancia (Fig. 7)!

9. Si usa químicos rellene el tanque

químico (2 Fig. 8).

¡PRECAUCIÓN! Use solamente los

productos sugeridos por el fabricante (Fig. 8).

10. Si no hay energía a la máquina –

compruebe el fusible (A).

11. Desenrosque el cable e inserte

el enchufe en el tomacorriente

doméstico de un sistema de

cableado adecuado. A menos que

se indique lo contrario, la máquina

es adecuada para conexión a

120V-60Hz (Fig. 9).

¡PRECAUCIÓN! ¡No será respon-

sable por los daños provocados

por condiciones operativas con

voltajes distintos de los requeridos! Asegúrese de que el enchufe

esté conectado a tierra para evitar

problemas con el funcionamiento

del generador (Fig 9).

Page 53

50

8

7

9

Page 54

51

MANÓMETRO

• El panel de control cuenta con un

manómetro.

• 0–4: presión mínima/media.

• 4–6: presión media/máxima.

• 6–8: presión máxima.

• 8–10: presión excesiva

• Abra la manija de la entrada de la

manguera, en el frente de la máquina, y

conecte la manguera; asegúrese de que

esté correctamente conectada (Fig. 13).

• Inserte y conecte el otro extremo de la manguera

en la entrada de la aspiradora (Fig. 14).

• Para mover la máquina, empuje desde la parte

trasera como se indica en (Fig. 15).

PRIMER LLENADO

• Si la caldera y el tanque de agua están completamente vacíos, todas las

funciones del sistema se deshabilitan.

• Asegúrese de que haya agua en el tanque y llénelo manualmente si está vacío.

• Con el tanque lleno y la caldera vacía, luego de alimentar el generador a

través de los interruptores (ver el párrafo de “PREPARACIÓN”), el sistema

controla la bomba de llenado de agua hasta que la caldera alcance el nivel

correcto. En esta fase, la caldera está desactivada. Una vez que naliza el

proceso de llenado, la bomba se apaga y el calentamiento se habilita simul-

táneamente a través del calentador de la caldera.

• Libere el aire residual de la caldera durante la etapa de calentamiento pre-

sionando el interruptor 2 (Fig. 20) y el botón de liberación de vapor 1 (Fig.

20). Esta operación es importante debido al poder del generador para evitar

un aumento excesivo en la presión.

Page 55

6

52

Page 56

53

Page 57

54

Page 58

55

Page 59

56

Page 60

Reliable Corporation (“Reliable”) garantiza al comprador original de la caldera descrita arriba

vendida por Reliable (la “Caldera Reliable”) que se encuentra libre de defectos de material

y mano de obra si es utilizada correctamente solo por el comprador original. Si la Caldera

Reliable necesitara algún cambio, Reliable no le cobrará al comprador original el costo de las

piezas y la mano de obra, excepto el envío.

Conforme a las condiciones y limitaciones establecidas a continuación, Reliable reparará o

cambiará la pieza de la Caldera Reliable que demuestre estar defectuosa a causa de material

o fabricación inadecuadas. Si la Caldera Reliable defectuosa deja de estar disponible y no

puede ser reparada con ecacia o reemplazada por un modelo idéntico, Reliable cambiará la

Caldera Reliable defectuosa por otra Caldera Reliable vigente de igual o mayor valor. Las piezas

de recambio o repuestos serán suministrados por Reliable a cambio de las piezas originales,

y serán piezas nuevas o piezas que estarán reacondicionadas para convertirse en productos

funcionalmente equivalentes a piezas nuevas. Si Reliable no puede reparar o reemplazar una

Caldera Reliable, la compañía reembolsará el valor de la Caldera Reliable que esté vigente al

momento de reclamar la garantía.

Esta garantía limitada no cubre los daños que sufra una Caldera Reliable como resultado de

una instalación inadecuada, accidente, abuso, uso incorrecto o irrazonable, desastre natural,

suministro de energía eléctrica insuciente o excesivo, condiciones mecánicas o ambientales

anormales, o cualquier desarme, reparación o modicación no autorizada. Esta garantía

limitada no se extiende a ningún daño indirecto, resultante o accidental que el usuario pueda

sufrir por el uso de una Caldera Reliable, incluyendo, entre otros, la responsabilidad ante los

reclamos presentados por terceros; y se limita al monto pagado por el comprador original de la

Caldera Reliable respecto del cual tiene aplicación esta protección de garantía limitada. Esta

garantía limitada no es válida para los productos que hayan sido modicados o que no tengan

número de serie, o para los productos que no hayan sido comprados directamente a Reliable o

a través de un vendedor autorizado por Reliable para comerciar la Caldera Reliable.

Esta garantía limitada es la única garantía que se aplica a la Caldera Reliable, reemplaza todos

los términos que puedan estar contenidos en cualquier otro documento u orden de compra, y

no puede ser alterada o modicada, excepto que Reliable así lo haya autorizado expresamente

por escrito.

Para obtener la reparación o cambio según los términos de esta garantía, comuníquese

con nuestro grupo de servicio al cliente al 1 800 268 1649 o escriba a support@

reliablecorporation.com. Usted deberá presentar, por fax o correo electrónico, el comprobante

original. Este comprobante debe demostrar que usted es el comprador original, que el producto

fue adquirido directamente de nuestras ocinas o de un vendedor de Reliable autorizado y que

el reclamo de la garantía se realiza dentro del período establecido en este documento o en un

documento posterior emitido por Reliable en relación con esta póliza. Usted recibirá un número

de autorización (RA#) y deberá enviar el producto defectuoso, junto con el comprobante

de compra, el RA# y los seguros pagados por adelantado, a la siguiente dirección: Reliable

Corporation, 5-100 Wingold Ave, Toronto, ON M6B 4K7.

Los costos de envío por cobrar serán rechazados. El riesgo de sufrir una pérdida o daño en

tránsito será asumido por el cliente. Una vez que Reliable reciba el producto defectuoso, la

compañía iniciará el proceso de reparación o cambio.

RELIABLE CORPORATION – GARANTÍA DEL

PRODUCTO DE POR VIDA – PÓLIZA PARA

CALDERAS PRESURIZADAS A VAPOR

57

Page 61

Reliable Corporation (“Reliable”) garantiza al comprador original de sus productos que todas

las unidades vendidas por Reliable (un “Producto Reliable”) se encuentran libres de defectos

de material y de mano de obra durante el período de un año a partir de la fecha de compra,

si son utilizadas correctamente y han recibido el mantenimiento adecuado. En virtud de las

condiciones y limitaciones establecidas a continuación, Reliable reparará o reemplazará

la pieza de un Producto Reliable que demuestre estar defectuosa a causa de material o

fabricación inadecuadas. Si el Producto Reliable defectuoso deja de estar disponible y no se

lo puede reparar en forma ecaz ni reemplazar por un modelo idéntico, Reliable cambiará el

Producto Reliable defectuoso por un Producto Reliable vigente de igual o mayor valor. Reliable

proporcionará piezas reparadas o de repuesto a cambio de las piezas originales, y serán piezas

nuevas o reacondicionadas para convertirse en productos funcionalmente equivalentes a

piezas nuevas. Si Reliable no puede reparar ni reemplazar un Producto Reliable, reembolsará el

valor del Producto Reliable que esté vigente al momento de reclamar la garantía.

Esta garantía limitada no cubre los daños que sufra un Producto Reliable como resultado de

una instalación inadecuada, accidente, abuso, uso incorrecto, desastre natural, suministro de

energía eléctrica insuciente o excesivo, condiciones mecánicas o ambientales anormales,

desgaste provocado por el uso normal del producto, o cualquier desarme, reparación o

modicación no autorizada. Esta garantía limitada no se extiende a ningún daño indirecto,

resultante o accidental que el usuario pueda sufrir o que pueda causar el uso de un Producto

Reliable, incluyendo, entre otros, la responsabilidad ante los reclamos presentados por

terceros; y se limita al monto pagado por el comprador original del Producto Reliable respecto

del cual tiene aplicación esta protección de garantía limitada. Esta garantía limitada no es

válida para productos que hayan sido modicados o que no tengan número de serie, o para

productos que no hayan sido comprados directamente a Reliable o mediante un vendedor

certicado que cuente con nuestra autorización para vender Productos Reliable.

Esta garantía limitada es la única que se aplica a todos los Productos Reliable, reemplaza todos

los términos que puedan estar contenidos en cualquier otro documento u orden de compra, y

no puede ser alterada ni modicada excepto que Reliable así lo haya autorizado expresamente

por escrito.

Para obtener una reparación o cambio según los términos de esta garantía, comuníquese

con nuestro grupo de atención al cliente al 1-800-268-1649 o escriba a support@

reliablecorporation.com.

Usted deberá presentar, por fax o correo electrónico, el comprobante original. Este

comprobante debe demostrar que usted es el comprador original, que el producto fue adquirido

directamente en nuestras ocinas o a un vendedor de Reliable autorizado y que el reclamo

de la garantía se realiza dentro del período correspondiente. Usted recibirá un número de

autorización (RA#) y deberá enviar el producto defectuoso, junto con el comprobante de

compra, el RA# y seguros pagados por adelantado, a la siguiente dirección:

Reliable Corporation, 5-100 Wingold Avenue, Toronto, ON M6B 4K7. Los costos de envío por

cobrar serán rechazados. El riesgo de sufrir una pérdida o daño en tránsito será asumido por el

cliente. Una vez que Reliable reciba el producto defectuoso, la compañía iniciará el proceso de

reparación o reemplazo.

Si tiene preguntas sobre esta garantía, puede escribir a la siguiente dirección:

Reliable Corporation

100 Wingold Avenue, Unit 5

Toronto, Ontario

Canada M6B 4K7

www.reliablecorporation.com

GARANTÍA DE LOS PRODUCTOS RELIABLE

58

Page 62

Page 63

Page 64

1 800 268 1649

www.reliablecorporation.com

Loading...

Loading...