Page 1

Instructions for

Installation, Operation

Care and Maintenance

For Single Interlock Preaction Systems

With Dual Solenoid Actuation

Of Pneumatic Pilot Release

Bulletin 739

Single Interlock

Preaction System

4"(100mm),

6"(150mm) & 165mm

Sizes with Trim

LPCB Approved

•

Redundant Solenoid Valve

•

Release

Rated to 175 psi (12.1 bar)

•

Externally Resetable

•

Clapper

One Main Drain

•

Bulletin 739

The Reliable Automatic Sprinkler Co., Inc., 103 Fairview Park Drive, Elmsford, New York 10523

Page 2

General Description

Reliable Single Interlock Preaction Systems are de

signed for water-sensitive areas that require protection

from inadvertent water flow into the sprinkler system pip

ing.

Sprinkler piping in single interlock systems can effec

tively be supervised by means of a Reliable Model A-2

Pressure Maintenance Device and a tank-mounted air

compressor. Loss of supervising pneumatic pressure,

due to a damaged sprinkler or sprinkler pipe will not

cause water to flow through the Model DDX Deluge

Valve and into the system piping. A significant loss of

pneumatic pressure will activate a trouble-annunciating

device when the system pressure falls below a predeter

mined pressure level.

When one electrical detector senses the presence of

fire, the electrical releasing control panel activates fire

alarm devices and energizes the two redundant, nor

mally-closed solenoid valves in the open position (

Arranging detectors in a cross-zoned pattern will require

operation of two detectors before the solenoid valves

can open). These solenoid valves, when closed, retain

sufficient AIR pressure in the Model LP Pilot Line Actua

tor, which in turn preserves sufficient WATER pressure in

the push rod chamber of the Model DDX Deluge Valve in

order to maintain it closed.

Energizing the solenoid valves relieves the air pressure

in the Model LP Dry Valve Actuator (see Fig. 8), thereby

releasing the water pressure that it was retaining. This is

turn relieves the pressure in the push rod chamber of the

Model DDX Deluge Valve. Venting this push rod chamber will open the Model DDX Deluge Valve and allow water to flow into the sprinkler system.

To fully operate a cross-zoned single interlock system,

two electrical detectors must activate and a sprinkler

head must open. During the early stages of a fire, smoke

or heat activates the first detector, which causes the control panel to produce a local alarm and an alarm at the

main fire alarm panel. Electrical relays inside the releas

ing control panel can be used to shut down airmoving

equipment or activate security doors and other electrical

devices. Subsequent activation of a second, nearby or

adjacent detector will cause the panel to energize the

solenoid valves open and release water into the sprinkler

system piping. Water flowing into the sprinkler system

piping will simultaneously produce water pressure that

causes the transfer of contacts in the pressure switch

mounted in the trim. This pressureswitch can electrically

initiate the shutdown or startup of equipment, such as

computers or other second alarm devices. This flow of

water into the sprinkler system piping effectively con

verts the dry system into a wet pipe system. In the event

that the fire subsequently produces sufficient heat to op

erate a sprinkler head, water will flow from that sprinkler,

controlling or suppressing the fire.

The major benefits of a single interlock preaction sys

tem, when compared with a wet pipe (deluge) system

are as follows:

Note:

-

-

-

-

-

-

-

A. A fire alarm sounds prior to the operation of a

sprinkler head, which may enable extinguishing

the fire by handheld means before the actual oper

ation of any sprinklers and subsequent water dam

age.

B. A trouble annunciator signals whenever the in

tegrity of the piping or sprinklers is accidentally or

intentionally disturbed; however, no water flow or

water damage will occur at that time.

C. Speedy detection and an early fire alarm are

provided by fire detectors, without the delay asso

ciated with water delivery time in the event of a fire.

with a wet pipe system, the fire alarm is de

Note:

layed until after water has begun flowing from an

operated sprinkler head.

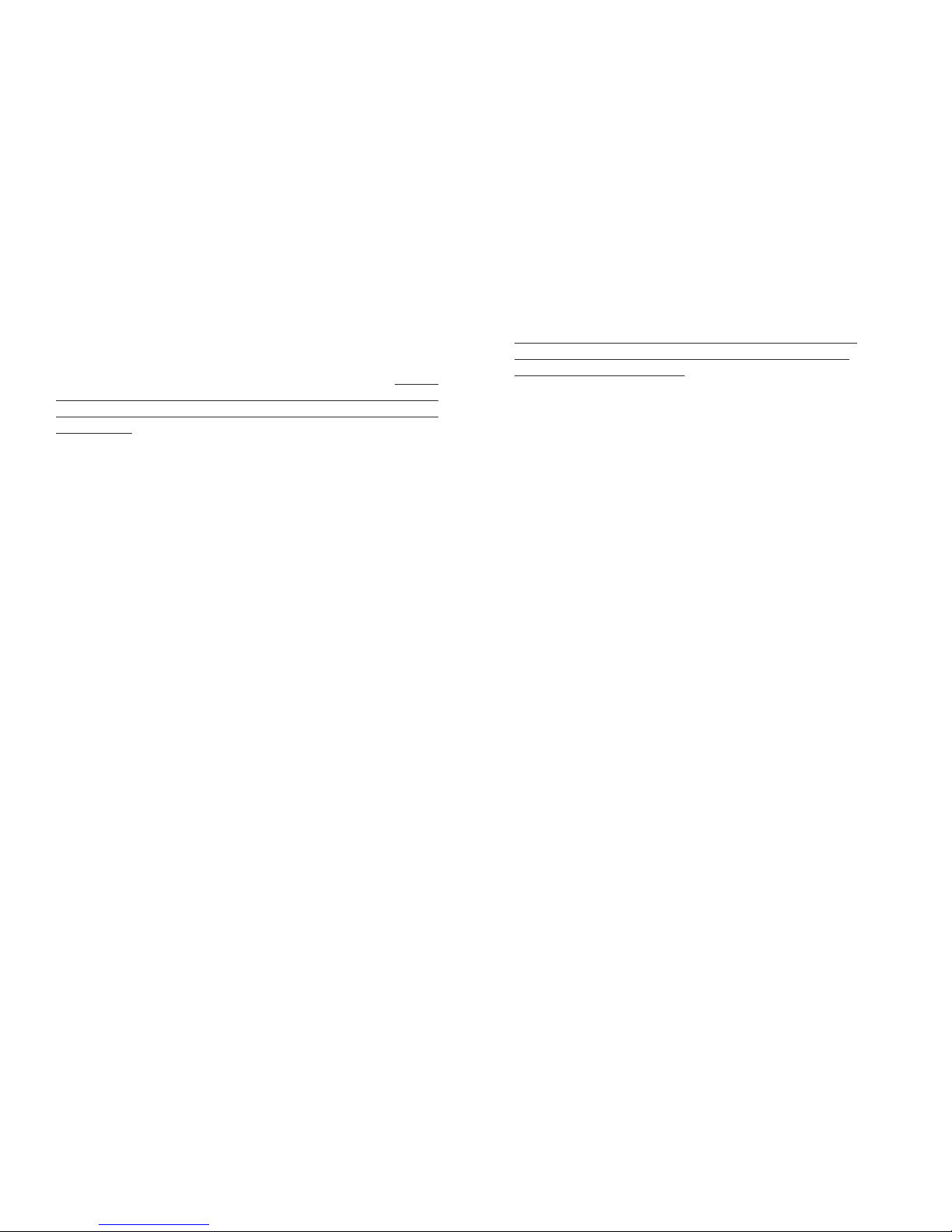

At the heart of Reliable’s Single Interlock Preaction Sys

tem is the Model DDX DelugeValve. This Deluge Valve is

a hydraulically operated, straight-through-design, differ

ential-type valve (see Fig. 1). System maintenance is

simplified since priming water is not required and the

deluge valve can be reset externally without cover re

moval. This is accomplished by pushing in and turning

the external reset knob at the rear of the deluge valve

(see Fig. 1). This feature provides a significant system-restoration time advantage.

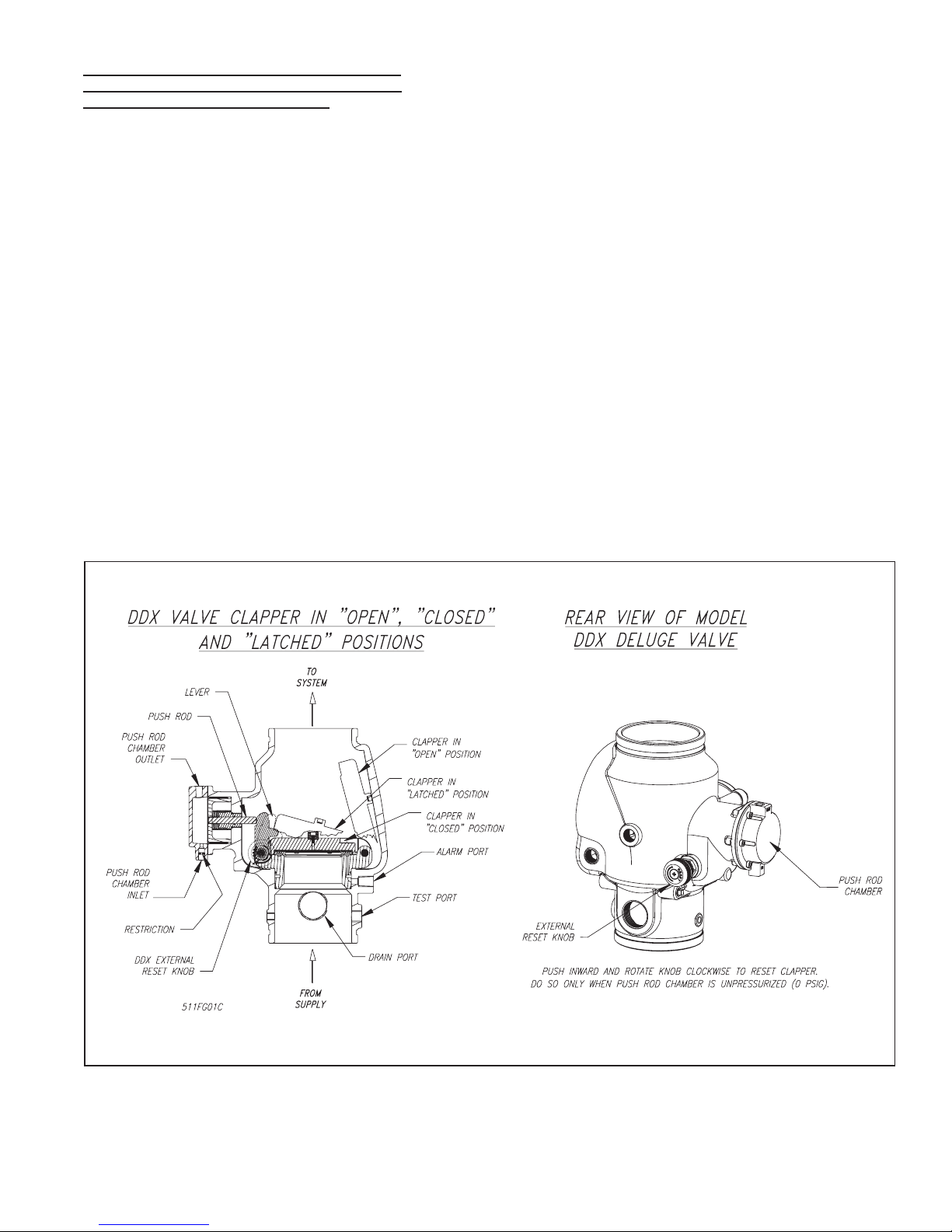

The Reliable Single Interlock Preaction System trim set

(see Fig. 2) provides all of the necessary equipment for

connections to the Model DDX Deluge Valve’s pushrod

chamber inlet and outlet ports, the 2” (50mm) main

drain, alarm devices, air supply, water supply, and required pressure gauges. This trim set is available in individual parts, in time-saving, segmentally assembled kit

forms, or fully assembled to the Model DDX Deluge

Valve.

-

-

-

-

-

-

-

-

Listing & Approvals

The 4” (100mm), 6’ (150mm) and 165mm Single Inter

lock Preaction Systems shown in this bulletin must only

be used in the combination described herein to be Loss

Prevention Certification Board (LPCB) approved. Instal

lation of these systems must be according the require

ments of Technical Bulletin TB21:1994:1.

The majority of the system’s components are individu

ally Listed by Underwriters Laboratories Inc. and Fac

tory Mutual Approved.

-

-

-

-

-

-

-

-

2.

Page 3

Loss Prevention Certification Board

(LPCB) Installation Requirements of

Preaction systems Include:

1. Solenoid valves shall be installed in parallel.

2. Solenoid valves shall function in pneumatic condi

tions only, and be protected by a strainer.

3. LPCB Certified detectors compatible with the control

and indicating equipment shall be used.

4. Suitable electrical detection, control and indicating

equipment and pneumatic systems shall be used.

The control and indicating equipment shall be LPCB

approved / certificated.

5. Connecting cables shall comply with BS 6387:1983,

classification C, W, Z evidenced by LPCB certifica

tion.

6. Pre-action systems shall be electrically monitored to

demonstrate that they are in a ‘ready to operate’

state at all times.

7. Clear dry air shall be used. Compressor tank must

have provision for draining.

8. Pre-action system equipment shall be installed, oper

-

-

ated and maintained as prescribed in the firm’s instal

lation , operating and maintenance manual.

9. Pre-action systems shall be configured in accordance

with the manufacturer’s defined specifications.

10.Pre-action systems shall comply with the details spec

ified in the relatedLPC Technical Bulletin (Ref. TB21).

11.The firm responsible for the complete pre-action sta

tion, including electrics, shall be identified.

12.Normally un-energized solenoids may be used, pro

vided that they are continuously monitored for ‘open’

and ‘short circuit.’

-

-

-

-

-

Fig. 1

3.

Page 4

Fig. 2

3.

Page 5

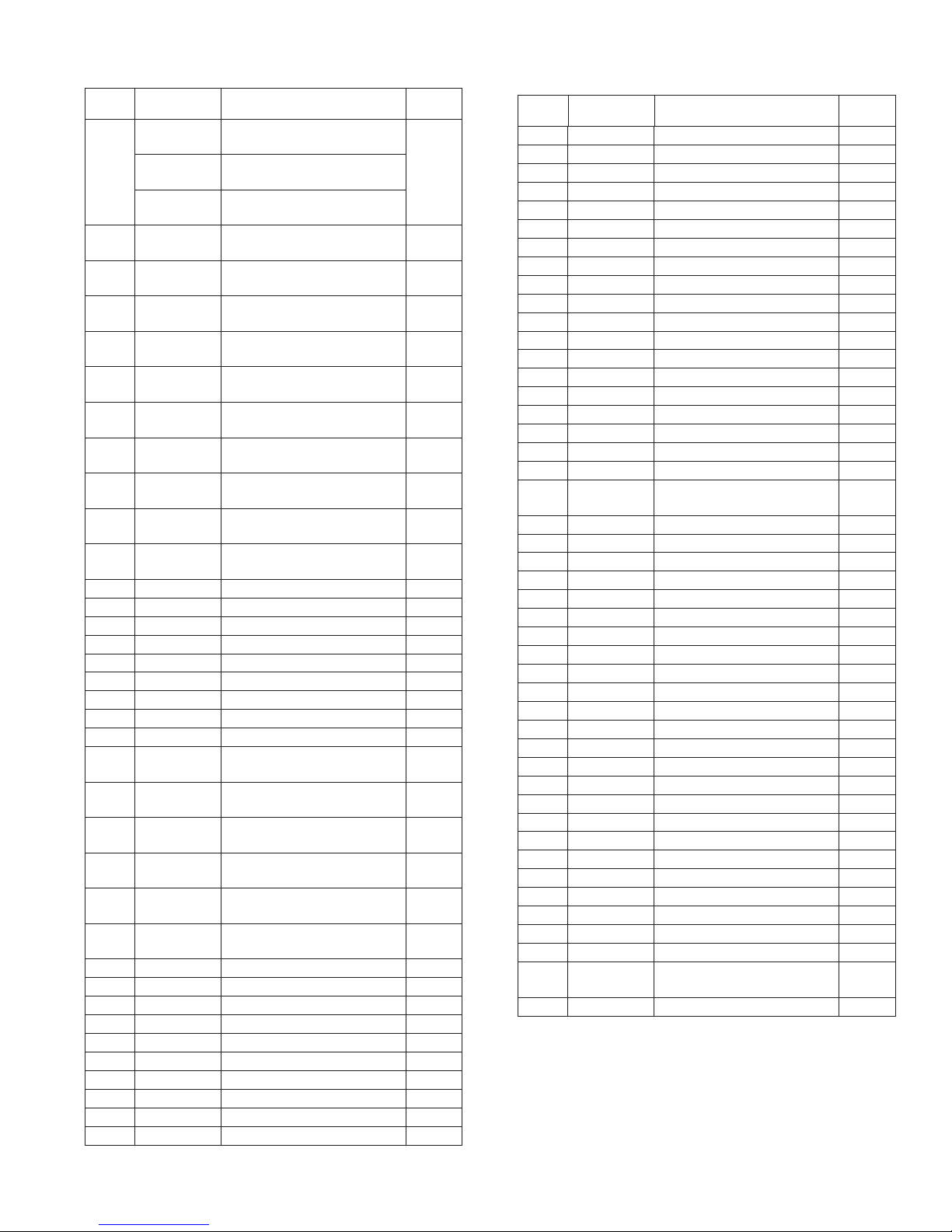

SINGLE INTERLOCK PREACTION SYSTEM PARTS LIST (REFER TO FIG. 2)

ITEM

NO.

1

2 78653004

3 98048000

4 98048015

5 98048022

6 98048025

7 92056809

8 92056810

9 92056811

10 92056702

11 92056704

12 98085666

13 98050004

14 98174400

15 98174403

16 98174401

17 98174404

18 98174405

19 98174402

20 96920912

21 98240006

22 98240101

23 6304000100

24 78653000

25 71030010

26 94616917

27 98543222

28 98543266

29 98543213

30 98543223

31 98543210

32 98543216

33 98543209

34 98543230

35 98543237

36 98543226

PART

NUMBER

6103040026

6103060028

DESCRIPTION

MODEL DDX VALVE,

ASSEMBLY, 4" (100MM)

MODEL DDX VALVE,

ASSEMBLY, 6" (150MM)

MODEL DDX VALVE,

ASSEMBLY, 165 MM

ASSEMBLY, VALVE CAUTION

STATION, 1/2"

BUSHING, REDUCER,

1/2" x 1/4", GALV.

BUSHING, REDUCER,

2" SPIGOT x 1" NPTF, PVC

BUSHING, REDUCER,

3/4" X 1/2", GALV.

BUSHING, REDUCER,

3/4" X 1/4", GALV.

CONNECTOR ASSEMBLY,

NO-LOSS, 3/8 x 1/2 NPT

CONNECTOR,

3/8" ID TUBE x 1/2" NPT

CONNECTOR,

3/8" ID TUBE x 1/4" NPT

CONNECTOR,

3/8" TUBING x 1/4" NPT

CONNECTOR, ELBOW,

3/8" ID TUBE x 1/2" NPT

REDUCER, 1/2" x 1/4"

DRAIN CUP, PVC

ELBOW, STREET, 1/2"

ELL, 1"

ELL, 1/2"

ELL, 1/4"

ELL, 2"

ELL, 3/4"

FLEX LINE, 12"

GAUGE, WATER PRESSURE

(16 BAR) W/ CONNECTOR

GAUGE, WATER PRESSURE

(6 BAR) W/ CONNECTOR

MOD. A-2 AUTO AIR

MAINTENANCE DEVICE, 10PSI

MODEL B MANUAL

EMERGENCY STATION

MODEL LP

DRY VALVE ACTUATOR

NAMEPLATE,

SINGLE INTERLOCK

NIPPLE, STEEL, 1" X 3-1/2"

NIPPLE, STEEL, 1" X 6"

NIPPLE, STEEL, 1" X CLOSE

NIPPLE, STEEL, 1/2" X 1-1/2"

NIPPLE, STEEL, 1/2" X 2-1/2"

NIPPLE, STEEL, 1/2" X 3-1/2"

NIPPLE, STEEL, 1/2" X 2"

NIPPLE, STEEL, 1/2" X 3"

NIPPLE, STEEL, 1/2" X 8"

NIPPLE, STEEL, 1/4" X 1-1/2"

NO

REQ'D

16103060024

1

4

1

1

2

1

1

1

1

1

4

1

1

1

1

1

1

2

1

2

2

1

1

1

1

1

1

1

17

1

1

2

1

1

21

ITEM

NO.

37 98543225

38 98543244

39 98543220

40 98543243

41 98543227

42 98543208

43 98543238

44 98543215

45 98543233

46 98543232

47 98543279

48 99080002

49 98750003

50 98604406

51 98614403

52 98614401

53 98681630

54 78650201

55 98727607

56 96556922

57 96606627

58 96606607

59 98761649

60 98761651

61 96606608

62 96606612

63 96606601

64 89141112

65 98815204

66 98815200

67 98815201

68 98815202

69 98840160

70 98840101

71 98840100

72 78653100

73 98840110

74 98840144

75 98840145

76 98840181

77 98840171

78 6871020010

79 6871020000

80 98840193

81 96686722

82 96686756

PART

NUMBER

DESCRIPTION

NIPPLE, STEEL, 1/4" X 2-1/2"

NIPPLE, STEEL, 1/4" X 2"

NIPPLE, STEEL, 1/4" X 3"

NIPPLE, STEEL, 1/4" X 4"

NIPPLE, STEEL, 1/4" X CLOSE

NIPPLE, STEEL, 2" X 3"

NIPPLE, STEEL, 2" X CLOSE

NIPPLE, STEEL, 3/4" X 1-1/2"

NIPPLE, STEEL, 3/4" X 2-1/2"

NIPPLE, STEEL, 3/4" X 2"

NIPPLE, STEEL, 3/4" X CLOSE

PAD-ADHESIVE

PIPE CROSS, 1/2"

PLUG, SQ. HD., 1/2"

PLUG, SQ. HD., 1/4"

PLUG, SQ. HD., 3/4"

REGULATOR, AIR LINE

STRAINER, 1/2" NPT

STRAINER, 1/4"

SWITCH, PRESSURE,

BAILEY & MACKEY

TEE, GLVN, 2 X 2 X 1

TEE, GLVN., 1/2 X 1/2 X 1/4

TEE, GLVN., 1/2 X 1/4 X 1/2

TEE, GLVN., 1/2"

TEE, GLVN., 1/4 X 1/4 X 1/4

TEE, GLVN., 3/4 X 1/2 X 1/2

TEE, GLVN., 3/4"

TIE, RETAINING

UNION, "O" RING SEAL, 1/2"

UNION, 1/2", IRON, G.J., GALV.

UNION, 1/4", IRON, G.J., GALV.

UNION, 3/4", IRON, G.J., GALV.

VALVE, 3-WAY, 1/4"

VALVE, ANGLE, 1/4"

VALVE, ANGLE, 2"

VALVE, BALL DRIP, 1/2"

VALVE, BALL, 1/4"

VALVE, CHECK GAUGE

VALVE, CHECK, 1"

VALVE, CHECK, 1/2"

VALVE, GLOBE, 1/2"

VALVE, SOLENOID ASCO

VALVE, SOLENOID SKINNER

VALVE, SPRING CHECK, 1/4"

TUBING, COPPER,

3/8" O.D. X 2 FT

TUBING,PVC,3/8"I.D.x6FT

NO

REQ'D

1

1

2

1

1

2

1

1

1

1

3

1

2

1

5

3

1

1

1

1

1

1

2

2

3

1

2

3

1

2

3

1

4

1

1

1

1

2

1

1

1

1

1

2

1

1

3.

Page 6

Fig. 3

System Operation

To fully operate a Reliable Single Interlock Preaction System, two independent events must coexist beforewater flow

will occur. One electrical detector (two detectors in a

cross-zoned system) must activate and a sprinkler head

must open. Operation of either one of these items will only

cause an alarm to annunciate, but will not cause water to

discharge from the sprinkler system piping.

When set correctly for service, the Model DDX Deluge

Valve is hydraulically established to withhold the supply wa

ter from the sprinkler system piping. The Reliable Model

DDX Deluge Valve is shown in both closed and open posi

tions in Fig.1. In the closed position, the supply pressure

acts on the underside of the clapper and also on the push

rod through the push rod chamber’s inlet restriction. The re

sultant force due to the supply pressure acting on the push

rod is multiplied by the mechanical advantage of the lever

and is more than sufficient to hold the clapper closed

against normal supply pressure surges.

When a fire is detected, the energized solenoid valves vent

the air from the Model LP Dry Valve Actuator (see Fig. 8),

which in turn vents the push rod chamber to atmosphere

through the chamber’s outlet. Since the pressure cannot be

replenished through the inlet restriction as rapidly as it is

vented, the pushrod chamber pressure falls instanta

neously. When the pushrod chamber pressure approaches

approximately one-third of the supply pressure, the upward

force of the supply pressure acting beneath the clapper

overcomes the lever-applied force thereby opening the

clapper.

Once the clapper has opened, the lever acts as a

latch, preventing the clapper from returning to the

closed position. Water from the supply flows through

the deluge valve into the system piping. Water also

flows through the deluge valve alarm outlet to the

alarm devices.

After system shutdown, resetting the Model DDX De

luge Valve is quite simple. Doing so only requires

pushing in and turning the reset knob at the rear of the

valve (see Fig.1). The external reset feature of the

Model DDX Deluge Valve provides a means for sim

ple, economical system testing, which is one essential

facet of a good maintenance program.

The external reset feature does not, however, elimi

nate another important facet of good maintenance,

namely, periodic cleaning and inspection of the inter

nal valve parts. In the event that water builds up inside

the valve due to condensate from the air supply sys

tem or water left inside from valve system testing, a

drain is available for venting. After closing the main

supply valve, a small valve over the drain cup can be

opened slightly until the water inside the valve body

and the main pipe column has drained. See the sec

tion titled “Draining Excess/Condensate Water From

System” in this bulletin for the detailed procedure.

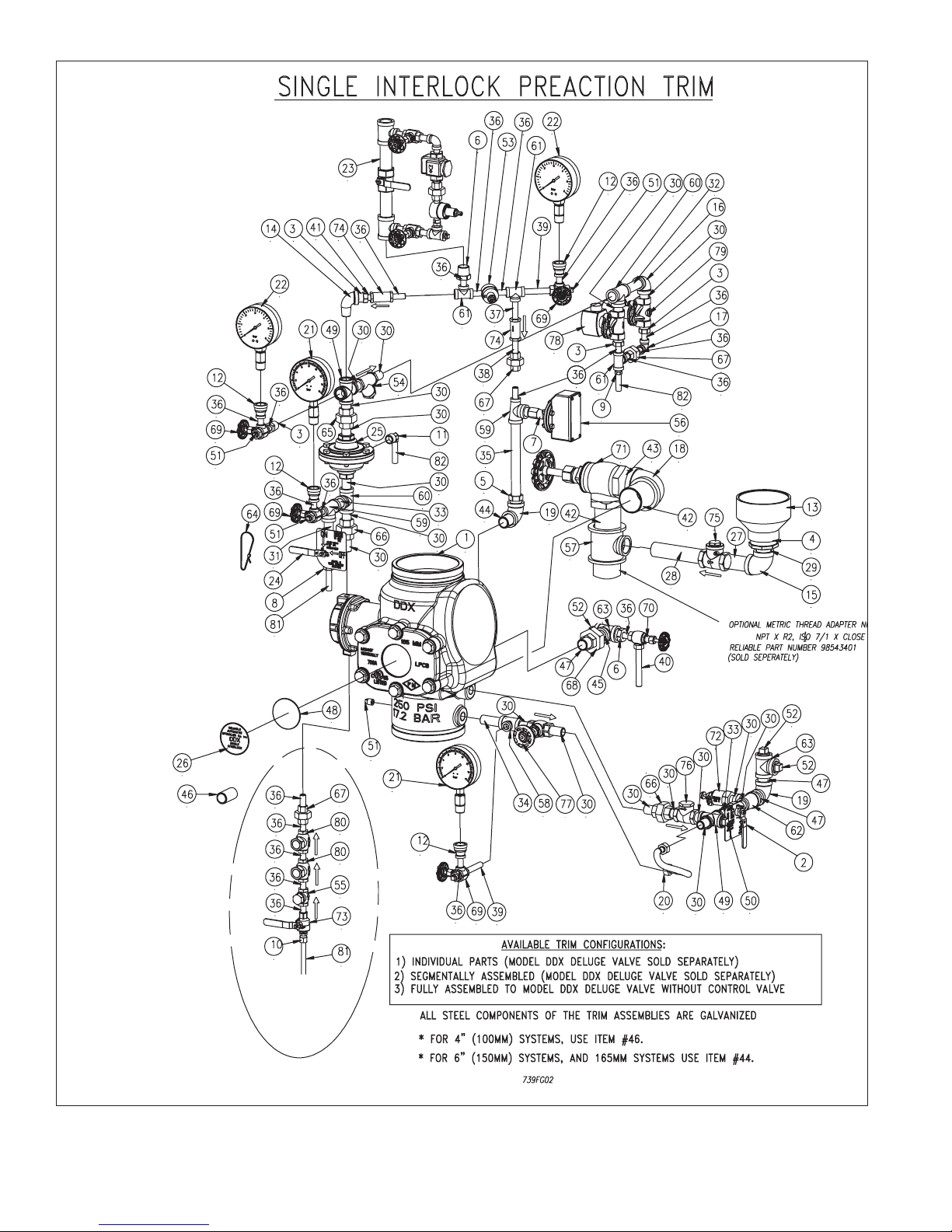

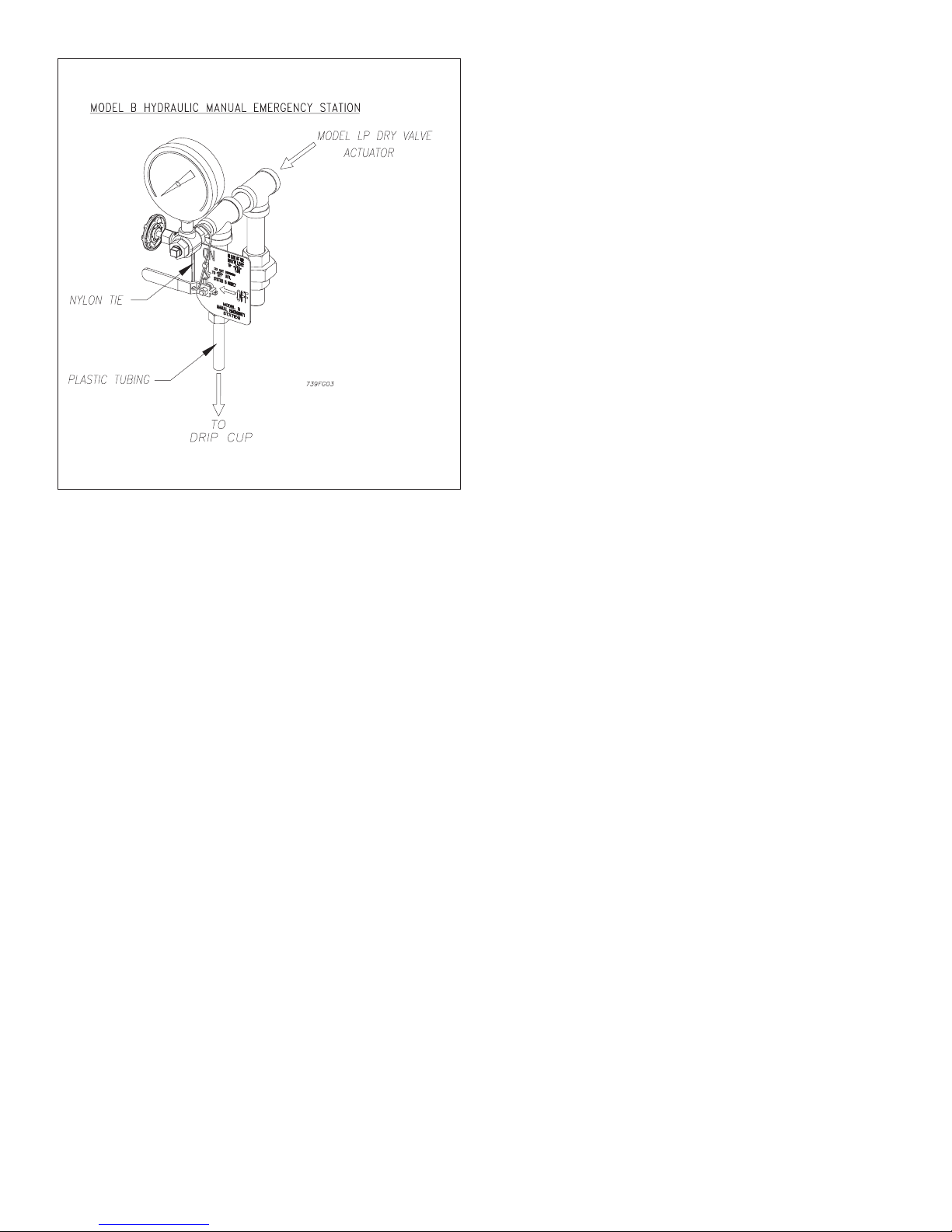

The Model B Manual Emergency Station (see Fig. 3)

is also included in the trim set. It consists of an aluminum nameplate mechanically attached to a ball valve.

The valve handle in its OFF position is guarded

against accidental turning to the ON position (and

system discharge) by a nylon cable tie provided with

each trim kit. The cable tie is inserted, as shown in Fig.

3, after the system has been restored for operation.

The nylon cable tie is designed to allow, in case of an

emergency, forceful turning of the valve handle to the

ON position. As an alternative to the Model B Hydraulic Manual Emergency Station, the Model A Hydraulic

Manual Emergency Pull Box (see Reliable Bulletin

-

506) is also available and can be provided as an option.

-

Whenever ambient temperature conditions are high,

the water temperature in the Model DDX Deluge

Valve’s pushrod chamber could possibly increase,

-

thereby increasing the pressure in the chamber to val

ues exceeding the rated pressure of the system. In an

indoor installation where standard room temperatures

are exceeded, a pressure relief kit may be needed.

Pressure relief kit, P/N 6503050001, can be installed

into the pushrod chamber’s releasing line to limit the

pressure to 175 psi (12,1 bar).

-

-

-

-

-

-

-

-

6.

Page 7

Pressurizing Line Connection

The water supply for the push-rod chamber must be

provided by connection of its inlet pressurizing line to the

water supply piping. Pressurizing lines for multiple

Model DDX Deluge Valve push-rod chambers must

never be manifolded together, having only a single tap

on the water supply piping. Each Model DDX Deluge

Valve must have its own push-rod chamber pressurizing

line connection. This connection must be made on the

supply side of the main water supply control valve. This

can be accomplished by:

a. Using a tapped connection directly below or next to

the main water supply control valve using a welded

outlet or the appropriate mechanical fittings. A

grooved-end outlet coupling is one way to achieve

this.

b. Using a water supply control valve that has an avail

able threaded (NPT) supply-side tap design to allow

for a direct water supply connection to the Model DDX

Deluge Valve’s push-rod chamber.

Caution:

signed with an inlet restriction built into the pushrod

chamber. It is important not to introduce additional re

strictions into the direct water supply connection or the

discharge from the pushrod chamber by installing addi

tional valves or improperly installing the copper lines

used in the trim of the valve.

Reliable’s Model DDX Deluge Valve is de

The sections of the preaction trim that contains the two

redundant normally-closed solenoid valves, and the up

per portion of the Model LP Dry Valve Actuator, require

pneumatic pressure settings per Table A. When estab

lishing the preaction system for service, refer to Table A of

this bulletin for the correct pneumatic pressuresettings for

a corresponding water supply pressure. Note:

the initial system set-up, a higher pneumatic pressure

may be required in order to properly seat the internal dia

phragm of Model LP Dry Valve Actuator.

Refer to Reliable Bulletin 251 and/or Fig. 3 of this bulletin

for instructions on how to modify these pressure settings.

-

Water Pressure

psi (bar)

Table A

Pneumatic Pressure to be Pumped

into Sprinkler System, psi (bar)

Maximum Not Less Than Not More Than

-

-

-

20 (1,4) 10 (0,7) 14 (0,9)

50 (3,4) 12 (0,8) 16 (1,1)

75 (5,2) 13 (0,9) 17 (1,2)

100 (6,9) 15 (1,0) 19 (1,3)

125 (8,6) 16 (1,1) 20 (1,4)

150 (10,3) 17 (1,2) 21 (1,4)

175 (12,1) 18 (1,2) 22 (1,5)

-

-

During

-

System Design Considerations

The automatic sprinklers, air compressor, releasing devices, electric releasing control equipment, fire detection devices, manual pull stations, and signaling devices

which are utilized with this Reliable Single Interlock

Preaction System must be Loss Prevention Certification

Board (LPCB) approved, as applicable.

The deluge valve and all interconnecting piping must

be located in a readily visible and accessible location

and in an areathat can bemaintained at a minimum tem

perature of 40°F (4°C). Note:

Heat tracing is not permit

ted.

The redundant solenoid valves are operated and su

pervised by an electrical releasing/control panel. Details

on the electrical connections and the Prescient Pre-Ac

tion Sprinkler Extinguishing Fire Alarm Panel can be

found on Figure 5 of this bulletin.

System Air Pressure Requirements

When a Reliable Single Interlock Preaction System is

utilized, the sprinkler system piping requires a minimum

of 7 psi (0,5 bar) supervisory pneumatic pressure. The

Model A-2 Pressure Maintenance Device, along with an

additional air pressure regulator, are used to maintain

the system’s pneumatic pressure between 7 and 10 psi

(0,5 and 0,7 bar) where a dry nitrogen gas supply or a

clean, dependable, and continuous (24 hours per day, 7

days per week) compressed air source is available.

System Electrical Requirements

All releasing, alarm and detectiondevices in this Reliable

Single Interlock Preaction System are supervised by the

Prescient Pre-Action Sprinkler Extinguishing Fire Alarm

Panel. Connect these devices as shown in Fig. 5. The

power supply, the standby emergency power supply, battery charger, and the rectifier circuitry are all contained

within this panel. For additional and detailed wiring information, refer to the manufacturer’s literature included with

the Prescient Releasing Control Panel. Caution:

or disassembly of the solenoid valves should only be

done by a trained technician. An improperly repaired or

partially assembledsolenoid valve could result in failureof

the valve to operate.

-

Repairs

7.

Page 8

Fig. 4

8.

Page 9

Fig. 5

9.

Page 10

Technical Data

Reliable Single Interlock Preaction Systems, with asso

ciated trim, sizes 4” (100mm), 6” (150mm) and 165mm

are rated for use at minimum water supply pressure of 20

psi (1,4 bar) and maximum supply pressure of 250 psi

(17,2 bar). Water supplied to the inlet of the valve and to

the pushrod chamber must be maintained between 40°F

(4°C) and 140°F (60°C).

The following list of technical bulletins pertains to valves

and devices that may be used in this preaction system:

formula with C=120 and a flow velocity of 15ft/sec

-

(4.6 m/sec)):

7. Installation position: Vertical

Valve Size Equivalent Length

4" (100mm)

6" (150mm) & 165mm

14' (4.27 m)

29.4' (9 m)

Deluge Valve Reliable 510/511

Hydraulic Emergency Station (Model A) Reliable 506

Solenoid Valve Reliable 707

Mechanical Sprinkler Alarm Reliable 612/613

Pressure Maintenance Device Reliable 252

Air Compressor Reliable 707/708

Electric Emergency Station Reliable 707

Thermal/Smoke Detectors Reliable 707

Fire Alarm Devices Reliable 707

Wa te rf lo w Pr es su re A la rm S wi tc h Bailey & Mackey Ltd.

Model 1381V

Valve Description

1. Rated working pressure:

Valve & System - 175 psi (12,1 bar)

2. Factory tested to a hydrostatic pressure of 500 psi

(34,5 bar). (Valve only)

3. End and trim connections:

•

ANSI/AWWA C606 grooved inlet and outlet

Valve

Size

4"

(100mm)

165mm

6"

(150mm)

•

Threaded openings Per ANSI B 2.1

4. Face to face dimensions:

Valve Size Color

4" (100mm)

6" (150mm)

165mm Red

•

4" (100 mm) — 14” (355 mm)

•

6" (150 mm) & 165 mm — 16” (406 mm)

5. Shipping weight:

6. Friction loss (Expressed in equivalent length of

Valve Size Weight

4" (100 mm)

6" (150 mm) & 165mm

Schedule 40 pipe, based on Hazen & Williams

Groove Dimensions

Outlet

Diameter

4.500"

(114mm)

6.500"

(165mm)

6.625

(168mm)

Groove

Diameter

4.334"

(110)

6.330"

(161mm)

6.455"

(164mm)

Groove

Width

3

"

8

(10mm)

Black

64 lb. (29 kg)

95 lb. (43 kg)

Outlet Face

to Groove

5

"

8

(16mm)

Maintenance

Reliable Single Interlock Preaction Systems and asso

ciated equipment shall periodically be given a thorough

inspection and test. NFPA 25, Inspection, Testing and

Maintenance of Water Based Fire Protection Systems,

provides minimum maintenance requirements. System

components shall be tested, operated, cleaned, and in

spected at least annually, and parts replaced as re

quired.

Resetting the Single Interlock Preaction

System

Refer to Figs. 2, 6, and 7.

1. Close the main valve controlling water supply (Fig.

7) to the Deluge Valve and close off the air supply to

the sprinkler system at the air supply’s source.

2. Close the pushrod chamber supply valve, valve A

(Fig. 7).

3. Open the main drain valve, valve B (Fig. 7), and

drain system.

4. Open all drain valves and vents at low points

throughout the system, closing them when flow of

water has stopped. Open valve D (Fig. 7). Note:

The above steps accomplish the relieving of pres-

sure in the pushrod chamber of the Deluge Valve.

5. With Valve F (Fig. 7) open, push in the plunger of ball

drip valve, valve G (Fig. 7), to force the ball from its

seat, and drain any water in the alarm line.

6. With the Model B Manual Emergency Station, valve

D(Fig.7), open, push in and rotate the deluge

valve’s external reset knob (#38, Fig. 6) clockwise

until you hear a distinct clicking noise, indicating that

the clapper has closed. Note:

be rotated only after pressure in the pushrod cham

ber has been reduced to atmospheric conditions (0

psig).

7. Inspect and replace any portion of the sprinkler sys

tem subjected to fire conditions.

8. Close valve F (Fig. 7). Activate a solenoid-release

pull station (Or other means of electric detection.) to

energize the solenoid valve(s). Silence any alarms

or audible tones on the releasing/control panel.

Open valve A (Fig. 7) to begin pressurizing the

push-rod chamber and its associated piping, while

simultaneously venting any entrapped air. Note:

This venting of the air from the actuation piping is

very important to ensure proper system operation

and avoidance of falsely trippingthe Deluge Valve.

The reset knob can

-

-

-

-

-

10.

Page 11

9. Upon seeing a solid flow of water from the drain tub

ing, and the cessation of the “gurgling” sound at the

drip cup, H (Fig. 7), close valve D (Fig. 7) then rapidly

apply compressed air or nitrogen into the to chamber

of the Model LP Dry Valve Actuator until the pressure

conforms to Table A levels as indicated on the air

pressure gauge. The Model LP Dry Valve Actuator

will close during this pressurizing process and the

water will stop flowing into the drip cup. At this point,

the pressure gauge which indicates push-rod cham

ber pressure (Fig. 7) will equalize to the available wa

ter supply pressure. Note:

isolate the various pressure gauges in the trim during

system set-up by closing the ¼” 3-way valves (#68

Fig. 2) that they are connected to. During set-up,

pressure fluctuations may occur that can be poten

tially damaging to the gauges.

10. De-energize the solenoid valve(s). This is accom

plished by resetting the solenoid-release pull station

and/or the detectors that were activated in Step #8

above. Note:

fore the releasing/control panel can be reset.

11. Open valve F (Fig. 7). Open slightly the main valve

controlling water supply (Fig. 7) to the deluge valve,

closing drain valve B (Fig. 7) when water flows. Ob

serve if water leaks through the ball drip valve, valve

G (Fig. 7), into the drip cup, H (Fig. 7). If no leak oc

curs, the seluge valve’s clapper is sealed. Open

slowly, and verify that the main valve controlling water

supply is fully opened and properly monitored.

12. Verify that valve A (Fig. 7) and valve F (Fig. 7) are

open.

13. Secure the handle of the Model B Manual Emergency

Station, valve D (Fig. 7), in the OFF position with a nylon tie (#64, Fig. 2).

All detection devices must be reset be

It may be necessary to

-

-

-

-

-

7. Testing alarms — make sure that valve F (Fig. 7) is

open. Open valveC (Fig. 7) permitting water from the

supply to flow to alarm portion of the trim. Typical de

vices that are connected to this section of the trim are

pressure switches and/or a mechanical sprinkler

alarms (water motor). After testing has been com

pleted, close this valve securely. Push in on the

plunger of ball drip valve G (Fig. 7) until all of the water

has drained from the alarm line.

8. Operational test — Open the Model B Manual Emer

gency Station, valve D (Fig. 7). Note:

test will cause the deluge valve to openand flow water

into the sprinkler system.

9. Secure the Model B Manual Emergency Station,

valveD(Fig.7),intheOFFpositionwithanylontie

(#64, Fig. 2) after the deluge valve is reset.

An operational

-

-

-

Testing the Model DDX Deluge Valve

without Flowing Water

-

-

-

Refer to Fig. 7

1. Close the valve controlling water supply to deluge

valve and open the main drain valve B.

2. Verify that valve A is open, allowing water to enter the

push rod chamber.

3. Operate detection system – energize the solenoid

valve(s) by operating a detector or manual pull sta

tion.

4. Operation of the detection system will result in a sud-

den drop ofwater pressure in thepush rodchamber.

5. Reset the detection system — reverse the operations

performed in step three above and then proceed according to the directions listed in the “Resetting the

Single Interlock Preaction System” section of this bul-

letin for resetting the Deluge Valve.

-

Inspection and Testing

Refer to Figs. 2, 6, and 7.

1. Water supply — be sure the valve(s) controlling water

supply to the Deluge Valve are opened fully and

properly monitored.

2. Alarm line—be sure that valve F (Fig. 7) is opened

and remains in this position.

3. Other trimming valves — check that valve A (Fig. 7) is

open as well as all of the pressure gauge’s ¼” 3-way

valves. Valves C, D,and E (Fig. 7) should be closed.

4. Ball drip valve, valve G (Fig. 7)—make sure that valve

F (Fig. 7) is open. Push in on the plunger to be sure

the ball check is off its seat. If no water appears, the

deluge valve’s water seat is tight. Inspect the bleed

hole (see Fig. 7) on the underside of the deluge

valve’s push rod chamber for leakage.

5. System pneumatic pressure — check the Model LP

Dry Valve Actuator’s air pressure gauge (Fig. 7) and

water supply pressure gauge (Fig. 7) for confor

mance to Table A.

6. Releasing device - Model LP Dry Valve Actuator (Fig.

7). Verify that the outlet is not leaking water. Check the

Model LP Dry Valve Actuator’s air pressure gauge

(Fig. 7) for proper pressure settings. Verify that the

tubing line from the actuator is not pinched or

crushed, which could prevent proper operation of the

deluge valve.

Draining Excess/Condensate Water from

the System

Refer to Fig. 7

1. Close the main valve controlling water supply to de

luge valve. Also, close valve A and open the main

drain valve B.

2. Open the condensate drain valve E until all of the wa

ter has drained. Close valve E. Note:

keep valve E open for an extended period of time be

cause that will cause enough system air to bleed off,

thereby causing an undesirable activation of a trou

ble/alarm-annunciating device.

3. Close the main drainvalve B. If system contains pres

surized air, allow the air pressure to come back up to

specification. Open valve A first, and then open the

main valve controlling the water supply to the deluge

valve.

-

Be sure not to

-

-

-

-

-

11.

Page 12

Fig. 6

Models DDX 4" (100mm), 6" (150mm) & 165mm Deluge Valve Parts List

Part Number

Item

4"(100mm)

No

Valve

1 91006005 91006007 91006027 Valve Body 1

2 96016004 96016006 96016006 Seat 1

3 91916004 91916006 91916006 Clapper 1

4 92116064 92116066 92116065 Cover 1

5 93416004 93416006 93416006

6 93706004 93706006 93706006

7 94506004 94506006 94506006 Lever 1

8 92126066 Cover, Pushrod 1

9 95406407 O-ring (014) 1

10 95406007 O-ring (114) 1

11 95406016 O-ring (161) 2

12 95406024 O-ring (912) 2

93706001 N/A N/A Gasket, Clapper, 4"

13

N/A 93706002 93706002 Gasket, Clapper, 6"

14 96216086 Hinge Pin, Clapper 1

15 96216046 Pin, Lever 1

16 95606131

17 96216066

18 95106006 Piston 1

19 95200038

20 95506006 Pushrod 1

21 93916006 Pushrod Guide 1

6"(150mm)

Valve

165mm

Valve

Description

Seal Faceplate

Subassembly

Gasket, Cover

(Not Shown)

Threaded Stud,

#10-32 x ¾"

Pin, Locking, Seat

(Not Shown)

Plug, Socket,

Æ 3/8" - 18 NPT

(Not Shown)

No.

Req'd

1

1

1

1

2

2

Part Number

Item

4"(100mm)

No.

Valve

22 95306267

23 95606128

24 95606129

95606107 N/A N/A

25

N/A 91106006 91106006

26 96906111

27 95606127

28 95606130

29 95606114

30 93916006 Shaft, Reset 1

31 96406004 Spring, Lever 1

32 96406906 Spring 2

33 96906904

34 95276006 Diaphragm 1

35 92306006 Disc, Bumper 1

36 94106066 Housing, Reset 1

37 94206406 Inlet, Orifice 1

38 94356006 Knob, Reset 1

39 85000050

6"(150mm)

Valve

165mm

Valve

Description

Ring, Retaining

(2 Assembled to

Item No. 14)

Screw, Button Head,

#10-32 x 3/8"

Screw, Hex Washer

Head, #10-32 x 3/8"

Screw, Hex Cap,

Æ ½"-13 x 1-1/2"

Screw, Hex Cap,

Æ 5/8"-11 x 1-3/4"

Spring Lock

Washer, #10

Screw, C'sunk Cap

Head, Æ 3/8"-16 x ¾"

Screw, Socket Head,

#10-32 x 1"

Screw, Socket Head,

Æ ¼"-20 x 5/8"

Teflon Washer, Æ ½"

(2 Assembled to

Item No.14)

Grease, GPL-201

(Not Shown)

No.

Req'd

3

1

4

6

1

1

1

6

3

1

12.

Page 13

Fig. 7

13.

Page 14

Maintenance Procedures - Model DDX

Deluge Valve

RefertoFigs.2,6&7.

1. Mechanical sprinkler alarm (water motor–not

shown) not operating:

This is most likely caused by a clogged screen in the

strainer of the water motor. Proceed as follows: Re

move plug from the strainer. Remove and clean the

screen. Replace the screen and the plug, and then

tighten securely (Ref. Bulletin 613).

2

Leakage out of the ball drip valve G (Fig. 7).

a. Water leakage due to a watercolumn above

the deluge valve’s clapper:

This condition can be caused by leakage past

the system side of the Model DDX Deluge

Valve’s seal faceplate subassembly (#5, Fig.

6). Be sure that this surface is free of any type

of debris. To eliminate leakage due to a water

column, refer to the section in this bulletin

marked “Draining Excess/Condensate Water

From System”. If the problem continues pro

ceed to the following section.

b. Leakage, air or water from the ball drip

valve, G (Fig. 7):

If system air is leaking out the ball drip valve,

the problem is either damage to the airside of

the Model DDX Deluge Valve’s seal faceplate

subassembly (#5, Fig. 6), seat (#2, Fig. 6), or

the upper seat O-ring (#11, Fig. 6).

If supply water is leaking out theball drip valve,

the problem could be caused by damage to

the Model DDX Deluge Valve’s seal faceplate

subassembly (#5, Fig. 6), seat (#2, Fig. 6), or

lower seat O-ring (#11, Fig. 6). The following

section provides instructions to correct both

conditions:

A) Shut down the valve controlling the water

supply to the Deluge Valve and open the main

drain valve B (Fig. 7). Open the water column

drain valve E (Fig. 7). Close the push rod

chamber supply valve A (Fig. 7) and open the

Model B Manual Emergency Station D (Fig.

7).

B) Remove the deluge valve’s front (handhold)

cover (#4, Fig. 6) and inspect the seat (#2,

Fig. 6), clapper (#3, Fig. 6), and seal face

plate subassembly (#5, Fig. 6) for damage.

If inspection indicates damage to the clapper

(#3, Fig. 6) or seal faceplate subassembly

(#5, Fig. 6) only, then the clapper subassem

bly can be removed as follows:

At the rear of the deluge valve, disconnect the

water column drain trim section at the ¾” un

ion (#68, Fig. 2). Remove the retaining ring

(handhold cover side) from the clapper hinge

pin (#14, Fig. 6) and push this pin through the

water column drain line and remove the clap

per subassembly. Remove the four retaining

screws (#24, Fig. 6) holding the seal face

plate subassembly (#5, Fig. 6). Inspect the

clapper (#3, Fig. 6) visually before re-install

ing. Apply a small amount of silicone-based

lubricant to the four retaining screws. Install a

new seal faceplate subassembly. Torque the

retaining screws to approximately 40

inch-pounds and reassemble.

If the seat (#2, Fig. 6) is damaged or it is sus

pected that the leakage is through the lower

O-ring (#11, Fig. 6), the seat-clapper subas

sembly is easily removedas aunit as follows:

Using a 5/16” Allen wrench, remove the two

3/8” NPT pipe plugs (#19 (not shown) Fig. 6)

-

-

-

-

-

-

-

-

located on the side of the Model DDX Deluge

Valve. The seat-clapper subassembly is re

tained by two locking pins (#17 (not shown)

Fig. 6). The centers of these pins have a

¼”-20 threaded hole. Remove the two lock

ing pins by engaging them with a ¼”-20

screw or threaded rod and pulling them out.

Note:

so turning them with the attached ¼”-20

screw or threaded rod is not recommended.

A proven method is to use ¼”-20 threaded

rod with a locknut on the un-inserted end.

Grab hold of the locknut with pliers or

vice-grips and tap the pliers or vice-grips in

the direction moving away from the deluge

valve. Doing so should pull the locking pins

out of the deluge valve. With the clapper (#2,

Fig. 6) in the closed position (not latched),

dislodge the seat-clapper subassembly from

the deluge valve’s body by inserting two

large flathead screw drivers under the lever

and clapper mounting ears of the seat and

pry up until the seat-clapper subassembly is

free of its bore. Reach into the deluge valve

and grasp the seat-clapper subassembly

from the sides. Lift up and rotate the

seat-clapper subassembly through 90 degrees about the main access of deluge valve

so that the lever-side of the seat-clapper subassembly faces the outlet of the deluge

valve. Rotate the seat-clapper subassembly

around the centerline of the deluge valve until

the top of the clapper faces the handhold

opening and then pull it out clapper

hinge-pin side first. Visually examine all of

the components of the seat-clapper subas

sembly, replacing any component that ap

pears damaged. New O-rings (#11, Fig. 6)

should always be used for reassembly.

Re-assembly:

It is likely that the lower seat O-ring (#11, Fig.

6) has remained at the bottom of the deluge

valve body’s bore. Discard this O-ring and

clean the bore. Lubricate the borewith O-ring

grease and place the lower seat O-ring on

the step at the bottom of the bore, verifying

that it is in full contact with the bore. Lubri

cate the bottom step and upper seat O-ring

(#11, Fig. 6) of the refurbished seat-clapper

subassembly. Insert theseat-clapper subas

sembly into the handhold opening of the de

luge valve lever-first, rotating it until the lever

side faces the outlet of the deluge valve. Ro

tate the seat-clapper subassembly until the

lever (#7, Fig. 6) faces the push rod (#20, Fig.

6), then drop the seat-clapper subassembly

into the deluge valve’s bore. Verify that the

seat-clapper subassembly is fully depressed

in to the deluge valve’s body. Check to see

that the lever lines up with the push rod. Ad

The two locking pins are not threaded,

-

-

-

-

-

-

-

-

-

-

-

14.

Page 15

just if necessary. Clean and lubricate the two

locking pins (#17 (not shown) Fig. 6) with

O-ring lubricant and drive them into the de

luge valve body. Reinstall the 3/8” NPT pipe

plugs (#19 (not shown) Fig. 6). Reassemble

the handhold cover and set up the Model

DDX Deluge Valve as per the section of this

bulletin entitled “Resetting the Single Inter

lock Preaction System”.

3. Leakage out of thepush rod chamber vent hole:

A small bleed hole is located on the underside of the

push rod chamber (see Fig. 6). If there is air or water

leakage coming out of this hole, do the following:

A) Shut down the valve controlling water supply

to the deluge valve. Relieve the inlet pressure

by opening the main drain valve B (Fig. V).

Close valve A (Fig. 7), the valve that supplies

water to the push rod chamber, and open the

Model B Manual Emergency Station, valve D

(Fig. 7).

B) Remove the trim at the unions nearest to the

push rod chamber cover (#8, Fig. 6).

C) Take the push rod chamber cover (#8, Fig. 6)

off by removing the six retaining screws (#29,

Fig. 6).

Condition #1: Water coming out of the bleed

hole:

Water coming out of the bleed hole is caused by a

leaking diaphragm (#34, Fig. 6). Visually inspect the

push rod chamber cover (#8, Fig. 6) and piston (#18,

Fig. 6) to determine what could have damaged the

diaphragm and correct. Install a new diaphragm.

NOTE:

The diaphragm has two different surfaces, it

is not bi-directional. It will fail if installed backwards!

Roll the diaphragm so that the smooth surface (the

-

pressure side) conforms to the inside of the push rod

chamber cover and re-assemble the six retaining

screws (#29, Fig. 6) with an installation torque of 15

foot-pounds. Set up the Model DDX Deluge Valve as

per the section of this bulletin entitled “Resetting the

-

Single Interlock Preaction System”.

Condition #2: System Air coming out of the bleed

hole:

System air coming out of the bleed hole is caused by

a defective O-ring assembled to the push rod guide

(#21, Fig. 6). Remove the piston-push rod subas

sembly, push rod spring (#32, Fig. 6), and push rod

guide (#21, Fig. 6). Verify by hand turning, that the

push rod cannot be unscrewed from the piston. Re

place all of the O-rings and the push rod guide. The

correct installation torque for the push rod guide is 35

inch-pounds. CAUTION:

Do not over-tighten the

push rod guide. Re assemble the components that

were initially removed. Re-install the diaphragm (#34,

Fig. 6) if it appears to be in good shape, otherwise,

replace it also. NOTE:

ent surfaces, it is not bi-directional. It will fail if in

The diaphragm has two differ

-

stalled backwards! Roll the diaphragm so that the

smooth surface (the pressure side) conforms to the

inside of the push rod chamber cover and re-assem

ble the six retainingscrews (#29, Fig. 6) with an installation torque of 15 foot-pounds. Set up the Model

DDX Deluge Valve as per the section of this bulletin

entitled “Resetting the Single Interlock Preaction System”.

Fig. 8

15.

Page 16

Model LP Dry Valve Actuator Parts List

P/N 71030010

Refer to Fig. 8

Item

No.

1 94106936

2 94106935

3 96006905

4 92206311

5 95106911

6 96906311

7 94906406

8 95406901

9

10 96406902

Part No. Description Qty.

Required

Lower Housing

Upper Housing

Seat

Diaphragm

Facing Plate Assembly

Diaphragm Washer

Facing Plate Nut

Seat O-Ring

95606305

Bolt

Compression Spring

1

1

1

1

1

1

1

1

6

1

Maintenance – Model LP Dry Valve Actuator

RefertoFigs.7and8

1. If water constantly flows through the Model LP Dry

Valve Actuator and into the drain, there is a leak in the

seal of the Actuator’s seat.

2. Close the main valve controlling water supply (Fig. 7) to

the Deluge Valve and close off the air/nitrogen supply

to the sprinkler system. Close valve A (Fig. 7).

3. Drop pressure in the system by opening the ¼” angle

valve, valve E (Fig. 7), and remove the Actuator from

the system.

4. Remove all six bolts (#9, Fig. 8) holding the Actuator to

gether. Clean or replacethe facing plate assembly (#5,

Fig. 8) and seat (#3, Fig. 8).

5. Reassemble the Actuator, using a torque of 8 ft-lbs on

the facing plate nut (#7, Fig. 8) and 12 ft-lbs on the six

bolts (#9, Fig. 8). Use a cross-tightening pattern. Rein

stall the Actuator. Set up the Model DDX Deluge Valve

as per the section of this bulletin entitle “Resetting the

Single Interlock Preaction System.”

Ordering Information

Specify

Valve Model & Size — 4”(100mm) Model DDX Deluge Valve (P/N 6103040026), 6”(150mm) Model DDX Deluge Valve

(P/N 6103060024), 165mm Model DDX Deluge Valve (P/N 6103060028).

Trim — The trim set is available in individual parts, in time-saving segmentally assembled kit forms, or fully assembled

to the Model DDX Deluge Valve.

-

-

Trim Configurations

Fully Assembled to Model DDX Valve 6505040400 6505060400 6505065400

Segmentally Assembled

(Model DDX Valve Sold Separately)

(Model DDX Valve Sold Separately)

Individual Parts

4" (100mm) Valve 6" (150mm) Valve 165mm Valve

Trim Part Numbers

6502071710

6502071700

Note: For metric installations, a 2" NPT x R2, ISO 7/1x Close Nipple(Reliable P/N 98543401) is sold separately as an

adapter for the single drain outlet of the trims.

16.

Page 17

Fig. 9

17.

Page 18

Installation Dimensions in Inches (mm)

VALVE A B C D E F G H J K L M N P Q

1

3

1

4"

(100mm)

6"

(150mm)

& 165mm

5

(133)

1

6

(159)

13

6

4

4

(171)

(337)

3

7

(197)

13

4

(337)

4

7

7

4

(200)

1

7

7

4

(200)

3

1

1

1

25

8

(654)

26

8

(654)

5

8

4

2

(140)

3

1

5

4

2

(140)

(216)

1

8

(216)

13

2

(343)

14

2

(368)

1

6

2

4

(159)2½(64)14(335)12(305)

1

3

1

8

(222)

3

4

(83)16(406)

4

2

12

(318)

49

(1251)23(584)

1

51

2

(1302)25(635)

1

4

1

4

RS

3

33

4

(857)36(914)

3

35

4

(908)38(965)

10

(273)

10

(273)

3

4

3

4

The equipment presented in this bulletin is to be installed in accordance with the latest pertinent Standards of the Na

tional Fire Protection Association, Factory Mutual Research Corporation, or other similar organizations and also with the

provisions of governmental codes or ordinances whenever applicable.

Manufactured by

The Reliable Automatic Sprinkler Co., Inc.

(800)431–1588 Sales Offices

(800)848–6051 Sales Fax

(914)829–2042 Corporate Offices

Www.reliablesprinkler.com Internet Address

P/N 9999970344

09/07

Reliable Fire Sprinkler Ltd.

Unit A2, Epsom Business Park

Kiln Lane, Epsom

Surrey, KT171JF

England

Phone: 0372 728899

Fax: 1372 724461

-

Loading...

Loading...