REHM TIGER 170 DC, TIGER 170 AC/DC, TIGER 170 DC SET, TIGER 210 DC, TIGER 210 DC SET Operating Instructions Manual

...

GB

OPERATING INSTRUCTIONS

TIG welding units

TIGER 170 / 210 DC / AC/DC / SET

Product identification

Product identification

TIG - Gas Shielded Tungsten Arc Welding units

TIGER 170 DC 150 3310

TIGER 170 DC SET 150 3311

TIGER 170 AC/DC 150 3320

TIGER 170 AC/DC SET 150 3321

TIGER 210 DC 150 3350

TIGER 210 DC SET 150 3351

TIGER 210 AC/DC 150 3360

TIGER 210 AC/DC SET 150 3361

Rehm GmbH u. Co. KG

Ottostr. 2

D-73066 Uhingen

Telephone: +49 (0) 7161/3007-0

Telefax: +49 (0) 7161/3007-20

e-mail: rehm@rehm-online.de

Internet: http://www.rehm-online.de

Doc.-No.: 730 1012

Version dated: 06.13

Rehm GmbH u. Co. KG, Uhingen, Germany

The contents of this description are the sole property of Rehm GmbH u. Co. KG

Distribution and reproduction of this document is strictly prohibited. The use and

distribution of its contents to a third party is strictly prohibited, unless otherwise

specifically agreed in writing by the company.

Any infringement will result in a claim for damages. All rights to submit a patent,

utility model, or registered design are reserved.

Third party manufacture based on these documents is not permitted.

Subject to change without prior notice.

Manufacturer:

Product

identification:

Type:

Contents

3

Contents

Product Identification

1. Introduction 5

1.1 Foreword 5

1.2 General description 7

1.2.1 Performance features of the TIGER gas shielded tungsten arc welding unit 8

1.2.2 Principle of TIG welding 10

1.2.3 Areas of application for TIG welding units 10

1.2.4 Operating principle of TIG welding units 10

1.2.5 Correct use 10

1.3 Symbols used in this manual 11

2. Safety information 12

2.1 Safety symbols in this operating manual 12

2.2 Warning symbols on the machine 12

2.3 General 13

3. Description of function 14

3.1 The REHM-Operating concept: Turn and Set 14

3.2 The REHM-Operators panel 14

3.2.1 General description 14

3.2.2 The operators panel at a glance 16

3.2.3 Special characteristics relating to the operating panel 17

3.3 The function of the REHM operators panel 17

3.3.1 The welding current setting I1 17

3.3.2 The Pulse-Function (Pulse time t1) 18

3.3.3 The intermediate welding current setting I2 20

3.3.4 The Pulsed Function (Pulse time t2 – see chapter 3.3.2) 21

3.3.5 Current downslope and manual pulsing 21

3.3.6 Post flow gas time 21

3.3.7 Setting for Direct Current (DC) 22

3.3.8 Setting for Alternating Current (AC) 22

3.3.9 Wave balance 22

3.3.10 AC-Frequency 22

3.3.11 The TIG latched trigger mode (4-step) 23

3.3.12 The non-latched torch trigger mode (2 step) 24

3.3.13 TIG welding with high voltage ignition 25

3.3.15 Stick-electrode welding with the Booster-Function 26

3.3.16 Stick-electrode welding in the Fuse Hold mode 26

3.3.17 TIG - welding 26

3.3.18 The Special mode 27

3.3.19 The control LED’s 31

3.3.20 The Digital display 32

3.3.21 The Turn and Set knob 32

3.4 Anti-Stick Function 32

3.5 INTIG-Energy 33

3.6 EPC: Continuous Mains voltage monitoring 33

3.7 Resetting to Factory settings 34

Contents

4

4. Accessories 35

4.1 WIG PLUS 1 foot operated remote control 35

4.1.1 Switch position; Foot-operated control signal 35

4.1.2 Switch position; Hand-operated control signal 35

4.2 WIG PLUS 2 Hand remote control 35

4.3 REHM TIG-torch R-SR 7-17 und R-SR 7-26 DD with potentiometer and leather 36

4.4 TIGER SET 36

4.5 REHM water cooler RWK 1100 36

4.6 Adapter cable 36

4.7 Tiger-Mechanised welding 37

5. Commissioning 38

5.1 Safety Notes 38

5.2 Working with an increased electrical hazard 38

5.3 Setting up the welding unit 38

5.4 Connecting the welding unit 39

5.5 Ventilation of the welding power source 39

5.6 Guidelines for working with welding power sources 39

5.7 Connecting of the torch or electrode holder cables 39

5.9 Recommended welding lead cross sections 40

6. Operation 41

6.1 Safety instructions 41

6.2 Electrical hazard 41

6.3 Personal safety instructions 42

6.4 Fire prevention 42

6.5 Ventilation 42

6.6 Tests before switching on 42

6.7 Connecting the earth cable 43

6.8 Practical hints for use 43

7. Troubleshooting 46

7.1 Safety instructions 46

7.2 Fault finding table 47

8. Service and maintenance 50

8.1 Safety instructions 50

8.2 Preventative maintenance table 50

8.3 Cleaning the inside of the unit 51

8.4 Proper waste disposal 56

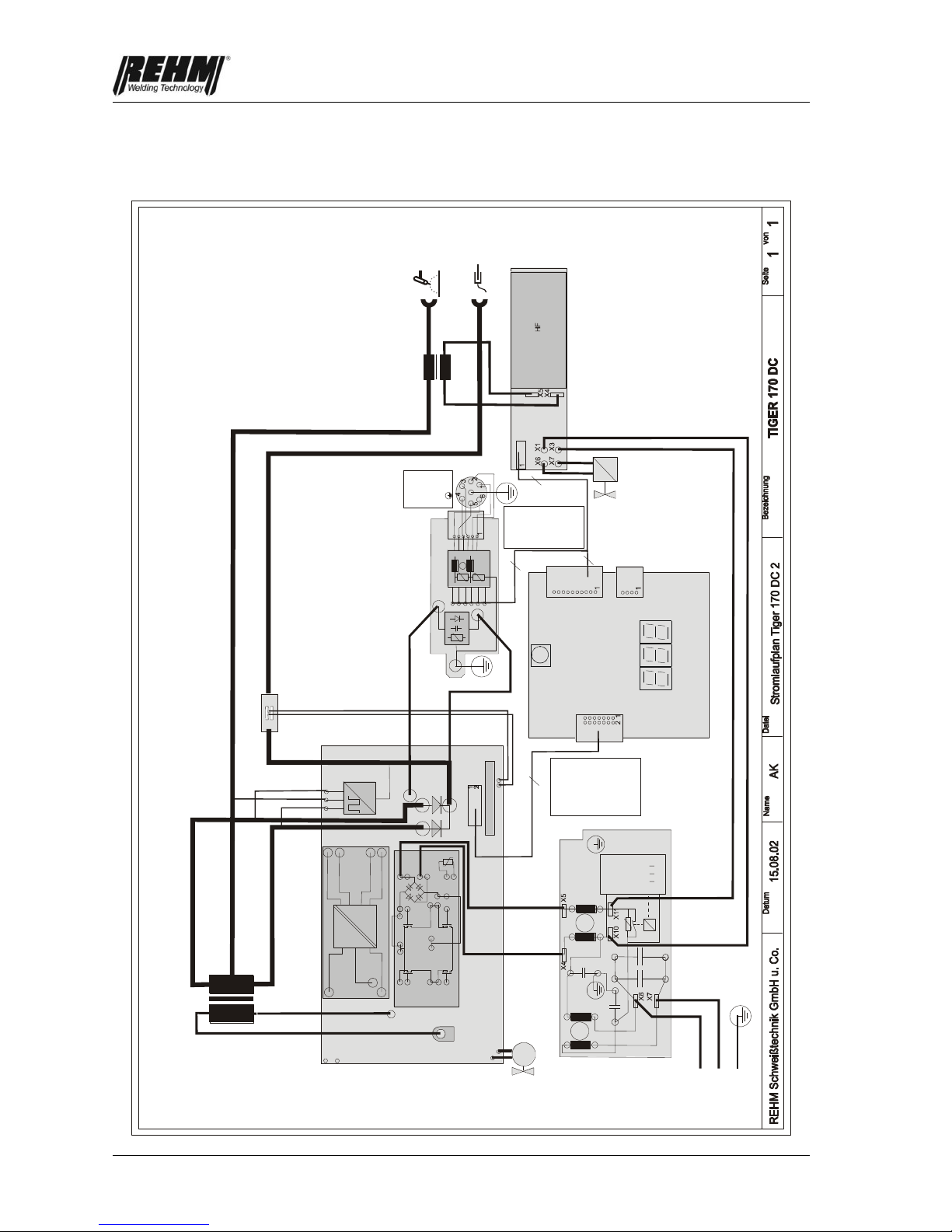

9. Circuit diagrammes 52

10. Spare parts list 56

10.1 Spare parts list with REHM article numbers 56

10.2 Machine components photographs 57

11. Technical Data 59

12. Index 60

Introduction

5

1. Introduction

1.1 Foreword

Dear Customer

Congratulations, you have purchased a REHM TIG / Stick-electrode

welding unit, and therefore a German branded appliance. Thank you for

the confidence you have shown in our quality product.

Only components of the highest quality are used in the development and

production of REHM welding units. In order to ensure a high service life

that can be used under arduous working conditions, only components that

satisfy the REHM stringent quality control requirements are used in our

production. The TIGER range of welding units have been developed and

designed in accordance with the current valid recognised technical safety

regulations. All of the relevant statutory provisions have been observed

and incorporated; confirmation of this is given through the CE mark and

the Declaration of Conformity.

REHM welding units are manufactured in Germany and bear the

corresponding quality indicator "Made in Germany".

REHM endeavours to respond quickly to technological progress in the

interests of the customer. We reserve the right to change the design of

these welding units from time to time, and without notice in order to

ensure compatibility with the current state of the art technical

requirements.

Introduction

6

Unless specifically stated in writing to the contrary by REHM Schweißtechnik und

Co., REHM welding units are only for sale to commercial / industrial users and

are intended only for use by these users.

TIGER gas shielded tungsten arc welding units are only to be used:

a) For the correct purpose.

b) Under perfect safety conditions.

REHM welding units must only be operated and maintained by people who are

trained in the use and maintenance of welding units. Only qualified, authorised

and assigned staff may work on, and with these units.

This operating manual contains important instructions as to how you can operate

this equipment, safely, correctly and economically. A copy of the operating

manual is always to be kept at a suitable location at the site where the unit is

being used. It is imperative that you read the information that is compiled for you

in this operating manual before you use the unit. You will find important

instructions for use of the equipment, which will allow you to fully make use of the

technical superiority of your REHM equipment. In addition, you will find

information on servicing, maintenance, and operating safety, as well as functional

reliability.

TIGER gas shielded tungsten arc welding units are designed according to EN

60974-1 Arc welding equipment - Welding power sources for overvoltage

category III and pollution degree 3 and according to EN 60974-10 Arc welding

equipment, Electromagnetic compatibility (EMC) and may only be used with

mains supply systems, which are three phase four wire systems with earthed

neutral conductors.

This operating manual does not replace the instructions from the REHM service

staff.

Documentation about any additional options that are provided must also be

observed.

Modifications to the unit or the attachment of, or installation of any additional

devices is strictly forbidden. Such alterations automatically invalidate all warranty

and liability claims.

The interference by non-authorised third parties, and the tampering of safety

interlocks, or devices automatically invalidate all warranty and liability claims.

Areas of use

Qualification of

operating

personnel

Purpose of this

document

Alterations to the

unit

Introduction

7

1.2 General description

Fig 1.1: TIGER 170 DC and Tiger 210 AC/DC

Introduction

8

1.2.1 Performance features of the TIGER gas shielded

tungsten arc welding unit

The TIGER is a real powerhouse, compact in size and weighing a mere 5,4 kg

(Tiger 170 DC; 8,4 kg for the Tiger 210 AC/DC). The robust housing makes the

TIGER the ideal companion for coping with the arduous working conditions onsite. However the TIGER is also at home in the workshop as well, having all of

the attributes associated and expected of professional units.

The TIGER is based on the primary inverter design principle. The user has a fully

portable unit and also enjoys the Ingress protection classification of IP23 so it

can be used under difficult operating conditions. The units offer flexibility and are

for the universal use on high and low alloyed steels as well as Aluminium and its

alloys (only for AC/DC units).

REHM-Design housing

The ergonomic design of the machine is a result of the further development of

the REHM-Design concept. The housing has ingress protection classification

IP23. The plastic housing is formed such that is it completely enclosed, the

turn and set knob has a rubber seal, this enables the machine suitable for

welding outside.

REHM Thermal protection

The Tiger is protected against damage caused by over heating by a thermal

sensor. The position of the sensor is directly next to the power transistors and

measures the temperature directly from within the „Hot Spot“.

REHM All round protection

The power transistors are the heart of any inverter; they are completely potted

and sealed together with the primary rectifier and the thermal protection probe

in a single module. This means that dirt and damp will have no affect on this

module. The outer plastic housing is a composite with fibreglass and ensures

the highest protection against mechanical damage. The turn and set knob is

set into the recess in the housing that also serve to prevent accidental

damage. Should the knob receive direct vertical force then this has no

influence on the electrical components. All of the electrical components are

coated with a protective lacquer to protect them against dirt and dampness.

REHM Automation

Connection to an automatic welding system is extremely easy due to the

precise processor control system.

REHM Inverter Technology

The Rehm inverter technology ensures excellent ignition characteristics, and

a steady, stable arc.

By the use of high quality and performance components, the machine can be

produced in an extremely compact design with a low weight.

REHM Ergonom-System ®

The REHM Ergonom-System enables your Tiger to be your sympathetic

partner for all of your welding applications. Apart from the obvious ergonomic

advantages such as the turn and set control knob - which is ideal for right or

left handed persons, the carrying strap and the clearly arranged, easy to

understand operating panel simplify life for the operator. These are many

small details, which help the operator do his job better.

Introduction

9

REHM Operating concept

The TIGER has an entirely new operating concept; this enables setting up the

machine very simply, quickly and safely. The numerous options can all be

accessed from this single control knob The settings are all done via a single

control knob, this can be turned to select or alter the parameter and then

pressed to confirm the setting. Using the combination of LED’s and the 3-digit

digital display the setting can always be accurately set and reproduced for all

welding applications.

REHM Noise Reduction System for AC

The noise is significantly reduced during the welding of Aluminium, by means

of a patented noise reduction process.

REHM Automatic Frequency Control

Low stress and long service life combined with optimum economy by means

of patented Automatic frequency control.

REHM Wave Balance Control

Improved welding speed by the use of a small diameter electrode, combined

with optimum penetration.

REHM ADAPT

®

System

The processor control system makes this generation of welding units ready to

face the future. New process variants and application developments can

simply be retrofitted by means of a software updates.

REHM Dual Wave

The Dual Wave is a newly developed welding process for the welding of

Aluminium or its alloys. This process enables a much more controllable

welding pool and better welding results.

REHM INTIG-Energy (Intelligent Ignition Energy)

INTIG-Energy results in an intelligent control sequence for both TIG and stickelectrode welding. The ignition process takes into consideration the welding

process that has been selected and is controlled via the processor. This

results in a reliable start every time with a stable arc, cleaning the electrode

and the workpiece.

REHM ELSA-System (Electronic Stabilised Arc)

The ELSA-System: The optimum welding performance, even with mains

supply cables up to 100m long is ensured.

REHM EPC (Electronic Power Control)

The EPC continuously monitors the mains supply voltage and protects the

machine under critical situations.

Introduction

10

1.2.2 Principle of TIG welding

With the TIG welding processes, the arc is established between a Tungsten

electrode and the workpiece. The inert gas used is a rare gas, such as Argon,

Helium, or a mixture of these gases. One of the electrical poles of the power

source is connected to the tungsten electrode, the other against the workpiece.

The tungsten electrode is the current conductor and sustains the arc (nonconsumable). The filler material is usually introduced into the weld pool by hand,

in the form of a rod, or by a separate cold wire feed unit, in the form of a wire.

The tungsten electrode and the molten pool, as well as the molten end of the

filler material, are protected from the atmosphere by the inert shielding gas,

which flows from the shielding-gas nozzle, which is positioned concentrically

around the electrode.

1.2.3 Areas of application for TIG welding units

TIGER DC welding units are direct current power sources. They are suitable for

welding all mild, low and high-alloyed steels, stainless steels, and non-ferrous

metals.

TIGER AC/DC welding units are direct current and alternating current power

sources. They can be used to weld all mild, low and high-alloyed steels, stainless

steels, and non-ferrous metals, Aluminium and Aluminium alloys.

1.2.4 Operating principle of TIG welding units

With the TIG welding processes, the arc is established between a Tungsten

electrode and the workpiece. The inert gas used is a rare gas, such as Argon,

Helium, or a mixture of these gases.

One of the electrical poles of the power source is connected to the tungsten

electrode, the other against the workpiece. The tungsten electrode is the current

conductor and sustains the arc (non-consumable). The filler material is usually

introduced into the weld pool by hand, in the form of a rod, or by a separate cold

wire feed unit, in the from of a wire. The tungsten electrode and the molten pool,

as well as the molten end of the filler material, are protected from the atmosphere

by the inert shielding gas, which flows from the shielding-gas nozzle, which is

positioned concentrically around the electrode.

1.2.5 Correct use

REHM welding units are designed for welding various metals, such as mild, low

and high-alloyed steels, stainless steels, and non-ferrous metals, Aluminium and

Aluminium alloys. The special safety instructions that apply to the area in which

the welding takes place must be observed at all times. If you are unsure about

anything at all, then consult your Health and Safety officer, or contact the REHM

Customer Services department.

Unless specifically stated in writing to the contrary by REHM Schweißtechnik und

Co., REHM welding units are only for sale to commercial / industrial users and

are only intended for use by these users. Persons who are trained in the use and

maintenance of welding units are the only person qualified to operate this

equipment.

Welding power sources must not be placed in areas of high electrical risk.

see Chapter 5, Commissioning.

Introduction

11

This operating manual contains rules and guidelines relating to the correct use of

your unit. If these rules and guidelines are adhered to then the use of the

equipment can be considered to be correct. Risks generated from use of this

equipment are the sole responsibility of the operator. Where special care and

attention is required, provision must be made for this where appropriate.

If you are unsure about anything at all, then consult your Health and Safety

officer, or contact the REHM Customer Services department.

The documentation supplied with the machine explains the limitations of use of

the equipment and must be adhered to.

The use of this equipment must also be carried out in strict accordance with the

local Health and Safety regulations.

Correct use also entails observing the prescribed assembly, dismantling and reassembly, commissioning, operating and maintenance conditions as well as

disposal measures. Please observe in particular the information contained in

chapter 2 Safety.

The unit must only be operated under the above conditions. Any other form of

use is not regarded as correct. The operator bears sole from responsibility for the

consequences of such actions.

1.3 Symbols used in this manual

Lists preceded by a bullet mark: General list

Lists preceded by a square symbol: Working or operating steps which must

be carried out in the order listed.

Chapter 2.2, Warning symbols on the unit

Cross-reference: Refer here to Chapter 2.2, Warning symbols on the unit

Bold type is used for emphasis

Note!

... indicates tips for use and other particularly useful information.

The safety symbols used in this chapter:

Chapter 2.1

Typographical

markings

Safety symbols

Safety information

12

2. Safety information

2.1 Safety symbols in this operating manual

Warning notes and

symbols

You will find this symbol or a symbol giving more precise details of the

hazard with all safety notes in this operating manual that involve any

danger to life or limb.

One of the following instructions (Danger!, Warning!, Caution!) will be used

to show the severity of the hazard:

Danger! … Warns of a hazard which and represents a direct threat. If this is

disregarded, death or very serious injury may be the result.

Warning! ... Warns of a potentially dangerous situation. If this is

disregarded, death or very serious injury may be the result.

Caution! ... Warns of the possibly of harmful situation. If this is

disregarded, the result may be slight or minor injury and material damage

may ensue.

Important!

Indicates a potentially harmful situation. If this is disregarded, the product,

persons, or nearby objects may sustain damage.

Substances that can damage health and/or the environment.

Materials/substances that need to be handled carefully and/or disposed of

according to statutory requirements.

2.2 Warning symbols on the machine

Identify hazards and sources of hazard on the unit.

Danger!

Electrical voltage hazard!

Non-compliance may result in death or injury.

Safety information

13

2.3 General

The unit has been designed, developed and produced on current generally

accepted engineering regulations and standards.

Nevertheless, using it may endanger life and limb for the user, any bystander, or

result in damage to the unit or other items of value.

No safety equipment should ever be dismantled or disabled as this risks creating

hazards and no longer guarantees that the unit is being used correctly and

safely. There are particular guidelines for dismantling safety equipment when

carrying out equipment, repair and servicing work. Safety equipment must always

be reassembled immediately after such work has been completed.

When the use of unusual materials is necessary (e.g. cleaning solvents), the

operator must ensure that the unit is safe to use before switching on and using

the equipment.

All safety and hazard notes as well as the manufacturer’s nameplate on the unit

should, without exception, be maintained in a legible state and must be heeded.

Safety notes are used for work safety and for the prevention of accidents. They

must be heeded.

It is not only the safety notes contained in this chapter that have to be complied

with, but also the special safety notes contained throughout the text.

Besides the notes contained in this operating manual, all safety and accidentprevention regulations with general validity (in Germany, these include UVV BGR

500 - formerly VBG15 -/ BGV-D1: “Schweißen, Schneiden und verwandte

Verfahren [Welding, Cutting and Related Processes]” as well as, in particular,

stipulations for arc welding and cutting mentioned in this publication, or the

relevant National regulations) must be heeded.

In addition, make sure that you read the safety notices posted in the factory

where the machine is being used.

TIGER 210 DC / AC/DC

This device complies with IEC 61000-3-12.

TIGER 170 DC / AC/DC

WARNING: This equipment does not comply with EN/IEC 61000-3-12. If it is

connected to a public low voltage system, it is the responsibility of the installer or

user of the equipment to ensure, by consultation with the distribution network

operator if necessary, that the equipment may be connected.

Dangers of noncompliance

Safety-notes

Requirements

made of the main

power supply

Description of function

14

3. Description of function

3.1 The REHM-Operating concept: Turn and Set

The TIGER has an entirely new operating concept; this enables setting up the

machine very simply, quickly and safely. The numerous options can all be

accessed from this single control knob

The settings are all done via a single control knob, this can be turned to select or

alter the parameter and then pressed to confirm the setting. Using the

combination of LED’s and the 3-digit digital display the setting can always be

accurately set and reproduced using the same principle:

1. Rotate the knob until the required setting is found, the LED’s associated with

the setting will illuminate, and the set value for this setting will show on the

digital display.

2. Depress the knob to select the setting to be changed; the associated LED will

start to blink.

3. Turn the knob to alter the value of the parameter selected.

4. Depress the knob once again to confirm the new value (enter). The

associated LED will then remain continually lit.

For the settings which can only be switched on or off (e.g. non-latch (2-step) with

TIG), the LED will start to blink immediately, once the knob is depressed then the

function is immediately selected.

3.2 The REHM-Operators panel

3.2.1 General description

The operation of the TIG welding units is achieved via panel as shown in Fig 3.1

(for Tiger 170 / 210 DC) or Fig 3.2 (for Tiger 170 / 210 AC/DC).

The only operating element is the turn and set knob (22). This knob is position

centrally and integrated within the operating panel and is therefore well protected

against mechanical damage. This knob is simple and precise and can be turned

easily with the thumb. All of the operating elements including the turn and set

knob (22), the LED’s (1)-(21) and the digital display (23), are fully protected

against both mechanical and moisture. This enables the machine to be used in

the most arduous of operating environments (e.g. site work).

The operating panel is split into several elements, the welding parameter settings

in the welding cycle diagram (1)-(6). The section below this is the AC operating

section (7)-(10). On the right hand side are the TIG functions (11)-(14). In the

middle is the digital display (23). On the left hand side is the welding process

selection (15)-(17). To the left of the control knob is the “special mode” (18). The

sequence in which the LED’s are selected is according to the numbering shown

in Fig 3.1 and 3.2.

Description of function

15

Fig 3.1: The REHM-Operators panel for TIGER 170 AC/DC and Tiger 210 AC/DC

Fig 3.2: The REHM-Operators panel for TIGER 170 DC and Tiger 210 DC

2sec

8

7

4

3

6

5

9

1

2

2sec

4

3

6

5

1

2

Description of function

16

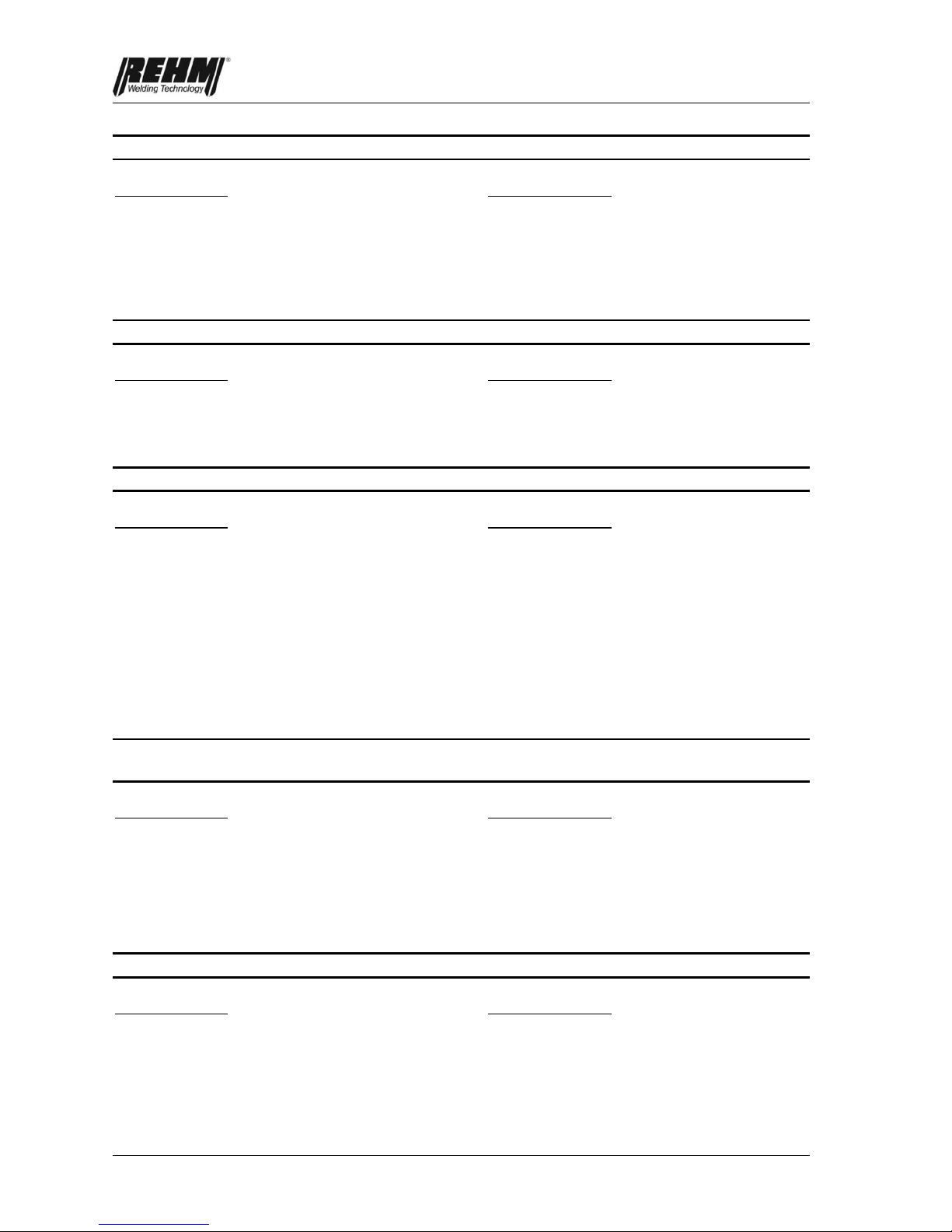

3.2.2 The operators panel at a glance

No.

Symbol

Meaning

1

Setting for welding current I1 for TIG - and Stick-electrode welding (see

Chapter 3.3.1) (Stick-electrode welding means manual metal arc welding)

2

Setting for t1-peak time for pulsed TIG-Welding (see Chapter 3.3.2)

3

Setting for welding current I2 for TIG welding (see Chapter 3.3.3)

4

Setting for t1-background time for pulsed TIG-Welding (see Chapter 3.3.4)

5

Setting for downslope time td for TIG-welding (see Chapter 3.3.5)

6

Setting for Gas post flow time for TIG-welding (see Chapter 3.3.6)

7

Direct current welding (DC) is selected, the electrode is connected to the

minus pole (see Chapter 3.3.7)

8

Alternating current (AC), the electrode is alternately connected to the positive

and negative polarity, according to the Frequency and Balance setting. (only for

AC/DC-machines, see. Chapter 3.3.8).

9

Setting for Balance for AC-TIG-welding (only for AC/DC-machines, see.

Chapter 3.3.9).

10

Setting for Frequency & for activating the Automatic Frequency control for

AC-TIG-welding (only for AC/DC-machines, see. Chapter 3.3.10).

11

Latched torch trigger mode (4-Step) for TIG-welding (see Chapter 3.3.11)

12

Non-Latched torch trigger mode (2-Step) for TIG-welding (see Chapter

3.3.12)

13

The high frequency start (HF) is switched on for igniting the arc during TIGwelding (see Chapter 3.3.13)

14

The high frequency start (HF) is switched off for igniting the arc during TIGwelding (see Chapter 3.3.14)

15

The machine is set to the stick-electrode welding mode with Booster-Function

(see Chapter 3.3.15)

16

The machine is set to the stick-electrode welding mode with Fuse-Hold

function (see Chapter 3.3.16)

17

The machine is set to the TIG-Welding mode (see Chapter 3.3.17)

18

For the activating of the Special-Mode setting of special parameters (see

Chapter 3.3.18)

19

This control lamp indicates that the machine has switched because of over-

temperature (see Chapter 3.3.19)

20

This control lamp indicates: operation, meaning that the machine is in

operation, and there is a voltage on the welding output sockets. (see

Chapter 3.3.19)

21

This control lamp indicates that the Pulse mode is on (see Chapter 3.3.19)

22

23

The turn and set knob, and the digital display (see Chapter 3.3.20 and Chapter

3.3.21)

Description of function

17

3.2.3 Special characteristics relating to the operating panel

The microprocessor controller supports the function of the control panel ensuring

that simplicity and speed are the result.

All of the parameters, which have been set on the machine and last used for

welding, remain stored even after the mains switch has been switched off.

When the machine is switched on again the settings that will be displayed

are those that were last use for welding. NOTE: In order to ensure that the

parameters are saved after switching off, the arc must be ignited with those

settings.

Only those parameters that are relevant to the process can be set. E.g. in the

stick-welding mode the setting for 2/4 step, H.F. on/off etc. cannot be set. In

the same way when in the DC mode the parameters for balance and

frequency cannot be set.

After machine is switched on the display runs through all of the settings one

after the other, showing the values set on the display. This enables the

operator to see how the machine is set up. Either by pressing the turn and

set knob, or the torch trigger then this sequence can be interrupted at any

time.

If the turn and set knob is not depressed for 20 seconds then the display

automatically returns to the I1 welding current setting. Thereby the start

setting on the display is the value of the current I1, which is also important for

the orientation for the operator.

If the turn and set knob is not pressed for 20 seconds, then the display

automatically returns to the I1 welding current setting. As a result, you always

have as the start setting the display of the most important value, current I1,

and the same starting point for the operator. The exception to this is the

selection of the welding current I1 (LED I1 flashing), which remains selected

until the knob is pressed again. This makes it easier – for example – to

quickly find and set the suitable welding current I1 by means of welding tests.

In the interests of safety, and to prevent incorrect operation by mistake, the

turn and set knob must be pressed for more than 2 seconds in order to

activate the special mode or to save or load a program.

3.3 The function of the REHM operators panel

The functions are described in sequence as per Fig. 3.1. and Fig. 3.2.

3.3.1 The welding current setting I1

The setting of the welding current I1 is performed as described in sections 3.1

and 3.2.3. The setting of welding current I1 is done as described in section 3.1,

and is dependant upon the welding process and the power source, either the

Tiger 170 or Tiger 210.

The setting of the welding current I1 can also be done quickly without selecting it

on the operating panel. This is done by depressing the torch button whilst at the

same time alter the current setting to the required value by using the turn and set

knob.

WARNING: Care must be taken when setting the current in this manner, as the

high voltage generator, open circuit voltage, and gas solenoid will be switched on

for 3 seconds; this results in danger for the operator. Furthermore the operator

must also take care that the torch does not come in contact with the workpiece

when using this function as he may strike the arc accidentally.

Description of function

18

The Tiger is a 230V-mains supply primary inverter, due to the high efficiency

virtually all of the mains supply power is converted into power for welding

operation.

During TIG welding the arc voltage is as defined by EN 60974 (UA=0,04*I1+10V)

is less than that as defined for stick-electrode welding (UA=0,04*I1+20V).

Therefore with the same input power TIG welding can supply a higher current.

In addition to this the Tiger 210 DC and Tiger 210 AC/DC have PFC (Power

Factor Correction) to ensure the power from the mains has a pure sine wave

form. This results in a power factor (Cos. phi 0,99) this increases the electrical

efficiency of the unit, enabling a higher welding current to be available for

welding.

The special features offered by the TIGER include the choice of the Fuse hold

mode or the Booster mode when stick-electrode welding. When using the Fuse

hold mode the actual mains current being drawn is monitored and according to

the output required for welding is automatically reduced so that the fuse does not

trip. The machine uses the trip-switching characteristic of the fuse (Fast acting,

Class L) to ensure that welding can always take place. In the Booster mode the

mains current monitoring function is deactivated, and the machine always welds

with the welding current set (I1).

The following ranges can be set:

Tiger 170 DC and AC/DC

Tiger 210 DC and AC/DC

TIG

3 A … 170 A

3 A … 210 A

Stick- electrode

Fuse hold mode

3 A … 140 A

3 A … 160 A

Electrode

BOOSTER-Mode

3 A … 150 A

3 A … 170 A

3.3.2 The Pulse-Function (Pulse time t1)

The setting of the pulse time t1 is performed as described in section 3.1. The

setting of the pulse time t1 is done as described in section 3.1. The pulsed

welding function is basically divided into two distinct ranges:

1. Conventional pulsing, with pulse times between 0,1 ... 5,0 Seconds

2. High frequency pulsing, with pulsed frequencies between 50 ... 500 Hz

Switching of the pulse function “on” or “off”, as well as the setting of the pulse

times for conventional pulsing as well as high frequency pulsing can be done

either from the setting of t1 or t2. The pulse mode “off” can also be selected by

either of these settings. The setting of Pulse time or the Pulse frequency is

achieved via the turning the “turn and set” setting knob with to the left or the right.

The pulse times t1 and t2 can be set independent from each other between

0,1...5,0 seconds. The high pulse frequency for t1 and t2 can be set between

50...500 Hz in 50-Hz-steps.

During Pulsed TIG welding the current continuously changes between the current

levels I1 and I2. Thereby it is selectable to choose the values of the peak and

background current levels. Fig. 3.3 displays the current/time sequence during

pulsing.

Description of function

19

Fig 3.3: Welding current during pulsed welding

If a twin-button torch is used, pulsing can be switched off and also back on during

welding by pressing torch button 2. If torch button 2 is pressed while the welding

current is pulsing, pulsing is switched off and welding is continued using welding

current I2. This can for example be used to ensure that the lower welding current

I2 is used until a new filler metal is provided and welding is continued with

pulsing welding current by again pressing the torch button 2.

Conventional pulsing: Pulsing with pulse times greater than 0,1 second

The settings of the peak current time (t1) and the background current (t2) times

determine the time in which the peak current (I1) and the background current (I2)

is switched on and off. The digital display instrument always shows the currently

emitted welding current.

The welding current and the time for each pulse should be such that the

workpiece melts during the peak current phase and then is allowed to cool down

during the background current phase. Pulsed TIG welding allows the operator to

have better control of the welding pool under difficult conditions. Particularly

when for example, when welding out of position, bridging gaps, and welding thin

materials.

Note: If a twin button torch is being used, and button 2 is depressed during

pulsing, the pulsing will be switched off and the welding will continue with the

welding current setting I2. Depressing torch button 1 restores the pulsing process

once again.

High frequency pulsing: with a pulse frequency of 50 Hz up to 500 Hz

The welding current values set for the current I1 and I2 determine the pulse

amplitude. The active time for duration of these current settings is equal. With HF

pulsing switching from one current level to another occurs very quickly, hence the

name high frequency pulsing.

In order to calculate the pulse frequency, the following relationship exists

between the pulse timing t1 and t2:

Total pulse time = I1-Pulse time + I2-Pulse time = 1 / Pulse frequency

I1-Pulse time = I2-Pulse time = 0,5 * Total / Pulse time

Example:

Pulse frequency = 50 Hz

Total Pulse time = I1-Pulse time + I2-Pulse time = 1 / 50 Hz = 20 ms = 0,02 s

I1-Pulse time = 0,5 * Total Pulse time = 0,01s

I2-Pulse time = 0,5 * Total Pulse time = 0,01s

This means that the welding current has the value set for I1 for 0,01 s (=10 ms)

and that the welding current has the value set for I2 for 0,01 s (=10 ms), the

switching from once current to the other continues ad. Infinitum.

Current I1

Current I2

Pulse time I1

Pulse time I2

Time

0

Description of function

20

The pulse time can be reduced down to 0,001s (= 1 ms) peak current I1 and

0,001s (= 1 ms) background current I2 this gives a pulsed frequency of = 500 Hz.

When pulsing at this very high frequency the arc is extremely concentrated and

focused, resulting in high stability with deep penetration.

The digital display instrument shows, because of the rapid changes, always the

prevailing mean value, i.e. with a welding current I1 = 100A and I2 = 50A 75A is

displayed.

Pulsing with synchronised pulse start

The program-controlled synchronisation fixes a precisely defined sequence for

each welding operation, thus ensuring that welding results can be reliably

reproduced. This is for extremely important when mechanised welding. Once the

ignition has successfully established the arc, the peak current time (t1) always

commences the welding process. Following this the pulse process is active

pulsing the welding current between the peak and background current settings

for the respective peak and background times (t1 and t2). The settings for the

start current, the welding current upslope downslope and crater fill current can

influence the actual pulsed welding currents.

3.3.3 The intermediate welding current setting I2

The setting of the welding current I2 is performed as described in section 3.1.

The setting of welding current I2 is done as described in section 3.1. The use of

the intermediate welding current I2 only makes sense when TIG welding,

therefore it can only be set in the TIG welding mode. The I2 current level setting

is used for pulsed TIG welding (See chapter 3.3.2) and when it is required to

switch from the main welding current a lower setting during welding, dual current

level control:

Dual level control:

General notes on this function:

Using the dual level current control and a torch equipped with a double pole

switch makes it possible for the user to work between two different current levels

during welding. The welding current can be switched between two different levels

I1 and I2. Pressing the switch 2 on the welding torch changes over the current

level. Some applications are as given below:

Changing from a high current to a low current or visa versa. Useful when

changing position.

Manual pulsing.

Starting with a higher current I1 to heat up the workpiece, then weld with a

reduced current I2.

Starting with a low current I1 on the edge of the workpiece, and then weld with

a higher current I2.

The dual current switching can only be done in the latched torch trigger mode (4step) without pulsing.

The welding current I1 can be set within the following range:

Tiger 170 DC and. AC/DC

Tiger 210 DC and AC/DC

TIG

3 A … 170 A

3 A … 210 A

The setting of the intermediate current I2 can be done by setting the level

required in the parameter I2, or quickly and simply by pressing the torch button 2

Description of function

21

before starting the welding operation. Whilst holding the button 2 down the value

for the current will be shown on the digital display and using the turn and set

knob the value can be adjusted as required.

3.3.4 The Pulsed Function (Pulse time t2 – see chapter 3.3.2)

See chapter 3.3.2

3.3.5 Current downslope and manual pulsing

The setting of the current downslope time is performed as described in section

3.1. The downslope time is the time is which the welding current decays in a

linear progression to the crater fill current. In the non-latched torch trigger mode,

(2-step) the downslope time starts when the trigger is released. In the latched

torch trigger mode (4-step), the downslope time starts when the torch button 1 is

depressed during welding. The controlled decay in the current level reduces the

possibility of end crater cracking.

Manual Pulsing:

If the torch trigger is depressed during the downslope then the welding current

jumps back up to the I1 value. This torch operation enables manual pulsing to be

achieved. (see Chapter 3.2.6) The operator controls the heat input during the

pulsing manually by the length of time that has elapsed between the activating of

the torch trigger during the downslope time.

t

t

t

Fig. 3.4: The current cycle diagram when manual pulsing.

3.3.6 Post flow gas time

The setting of the gas post-flow time is performed as described in section 3.1.

The gas post-flow time is the time that elapses after the arc is extinguished

before the shielding gas solenoid closes again. The shielding gas post-flow

protects the weld pool and the tungsten electrode from oxidisation until they have

cooled down. The pre-selected post-flow time is only activated at the end of the

welding cycle. Accidental activation of the torch button does not result in the

activating the post-flow time. This gas management function lowers the shielding

gas consumption.

Solenoid valve

Welding current

Torch trigger 1

Description of function

22

3.3.7 Setting for Direct Current (DC)

The setting for direct current is performed as described in section 3.1. The Tiger

170 AC/DC and Tiger 210 AC/DC can weld with either direct current (DC) or

alternating current (AC). The Tiger 170 DC und Tiger 210 DC can only be use for

direct current (DC).

When welding with DC the polarity of the output sockets always remains the

same. The marking on the outlet sockets indicate which outlet is positive polarity

and which is the negative polarity. When TIG welding the torch is always

connected to the negative pole. The reason for this is that the positive pole has

an extremely high thermal loading during welding. The negative pole also has the

torch symbol assigned to it.

When stick-electrode welding the polarity is dependant upon the type of

electrode being used, and therefore which socket should be connected to the

electrode holder. For this information the manufacturers data sheet should be

referred to ensure correct usage.

3.3.8 Setting for Alternating Current (AC)

The setting for alternating current is performed as described in section 3.1. The

Tiger 170 AC/DC and Tiger 210 AC/DC has the possibility of operating in the

Direct Current (DC) or the Alternating Current (AC) welding output modes

With AC welding mode the electrode polarity continually changes from positive to

negative. The electrical loading on the electrode alters from negative to positive

according to the balance and frequency setting on the machine for each positive

or negative cycle. During TIG welding the torch is connected to the negative pole

of the power source. The use of AC enables the welding of Aluminium and

Aluminium alloys.

When stick-electrode welding the machine parameters for frequency and balance

are automatically set to 50Hz and 50% respectively. This mean that it is then

irrelevant which socket is connected to the stick-electrode holder and which is

connected to the workpiece cable. AC stick-electrode welding offers the

advantage that arc blow because of strong magnetic fields can be minimised.

3.3.9 Wave balance

The setting of the wave balance is performed as described in section 3.1. The

wave balance setting option is possible with alternating current (AC) welding. It

can be varied from -80 % to +80 % and makes it possible to influence the arc

from, the penetration, and cleaning effect when welding Aluminium within a very

wide range. In the middle position (50 %), the negative and positive welding

current is distributed equally for each current cycle. In the event of increasing

negative balance, the proportion of negative welding current is increased (up to

- 80 %) and the positive proportion is reduced. This makes the arc slimmer and

produces a deeper penetration combined with a reduced electrode load. In the

event of increasing positive balance, the proportion of positive welding current is

increased (up to + 80 %) and the negative proportion is reduced. The positive

proportion improves cleaning of the weld pool. The arc becomes wider and the

penetration is reduced.

3.3.10 AC-Frequency

The setting of the frequency is performed as described in section 3.1. The setting

for the frequency can only be done in conjunction with the AC TIG welding. The

value for the frequency determines how fast the polarity changes from negative

to positive on the welding outlet sockets of the power source. The setting range

for this parameter is between 50Hz to 200Hz for example with a frequency

setting of 200Hz the polarity changes from plus to minus every 5ms (=0.005

Description of function

23

seconds). As the welding current changes from one polarity to the other it passes

through zero, and the arc has to be re-stuck as the current changes direction and

rises to the desired current value. The processor controls this whole process.

This processor regulates the manner in which the current rises, such that the arc

is extremely responsive. A further advantage is that it has a noise level reduction

effect. This not only provides significant advantages for the operator, but also

substantially improves the welding result.

Another special feature of the Tiger AC/DC machines is that in the AC welding

mode the patented Rehm Automatic Frequency Control can also be selected. To

active this function the selection “Aut” is made, this is the one before the 50Hz

setting in the frequency function parameter.

The automatic frequency control, which is a Rehm development, enables that the

machine has an extremely stable arc in the lower operating current range and

that the electrode can carry high current loads in the upper current ranges. The

AC operating frequency is automatically synchronised to the actual welding

current.

This function means simplifies the job for the operator, as he no longer has to

select the frequency for welding task. However in some special cases the

operator can also override this control and set the value for the application as

required, giving him a free choice for flexibility.

3.3.11 The TIG latched trigger mode (4-step)

The setting for the 4-step function is performed as described in section 3.1. In

the latched trigger mode (4-Step) the torch trigger must not be permanently

depressed which minimises operator fatigue.

Step 1: Torch button is depressed.

The gas solenoid opens and gas flows.

The arc will be struck once the pre-flow gas time has elapsed.

The welding current level will be that as set by the start current parameter.

Step 2: Torch button is released.

The welding current will rise automatically for the time set by the upslope time

parameter to the welding current level I1.

Step 3: Torch button is depressed.

The welding current will decay automatically for the time set by the downslope

time parameter to the crater fill current level.

The current stays at the crater fill current level.

Step 4: Torch button is released.

The arc extinguishes itself.

The shielding continues to flow for the time set by the post-flow gas time

parameter.

Description of function

24

Fig. 3.5 The current cycle diagram for latched trigger operation (4 step)

Special Note:

to Step 2 If the torch button is pressed during the downslope phase, the arc

will extinguish and the shielding gas flows for the time set by the

post flow gas parameter.

to Step 3 The arc can be extinguished at any time during the downslope

phase. Releasing the torch button before the crater fill current

extinguishes the arc and the shielding gas flows for the time set by

the post flow gas parameter.

3.3.12 The non-latched torch trigger mode (2 step)

The setting for the 2-step function is performed as described in section 3.1. The

non-latched torch trigger mode is recommended for fast controlled tacking, and

for manual spot welding operations.

Step 1: Torch button is depressed.

The gas solenoid opens and gas flows.

The arc will be struck once the pre-flow gas time has elapsed.

The welding current level will automatically rise in the time set by the upslope

time parameter for the start current up to the welding current (I1).

Step 2: Torch button is released.

The welding current will decay automatically for the time set by the downslope

time parameter to the crater fill current level and the arc extinguishes itself.

The shielding continues to flow for the time set by the post-flow gas time

parameter.

Torch trigger 1

Solenoid valve

Welding current

t

t

t

Description of function

25

Fig. 3.6 The current cycle diagram for non-latched trigger operation (2 step).

Special note:

to step 2 If the torch trigger is depressed during the downslope then the

welding current jumps back up to the I1 value. This torch operation

enables manual pulsing to be achieved. (see Chapter 3.2.6)

3.3.13 TIG welding with high voltage ignition

The setting for HF ignition is performed as described in section 3.1. The Tiger is

equipped with a high voltage ignition unit as standard. When the stick-electrode

welding mode is selected, the high frequency ignition unit is automatically

disconnected.

The high voltage ignition unit pre-ionises the gas surrounding the tip of the

electrode. This enables contact free ignition to take place between the electrode

and the workpiece in both the AC and the DC welding modes. Contact free

ignition eliminates tungsten inclusions that result in faulty welds. In both modes of

operation the high voltage generator is automatically switched off after the arc

has struck. Chapter 3.3.10 describes the re-ignition process when AC welding,

this is achieved without a high voltage generator.

This results in a significant reduction in the electrical radiation emitted by the high

voltage generator. Furthermore the AC welding process can then be completely

HF free, as has been the case for DC welding for some time now. (See chapter

3.3.14)

3.3.14 TIG welding without high voltage ignition, (Lift Arc)

The setting for Lift Arc is performed as described in section 3.1. When welding

with DC contact arc ignition (Lift Arc) ignition can be carried out. “HF-Off” is

selected, microprocessor controlled contact ignition takes place to strike the arc.

In order to ignite the welding arc, the tip of the electrode must be placed on the

workpiece and the torch button depressed. The processor control system

reduces the ignition current so that the tip of the electrode does not heat up. The

electrode is then gradually lifted away from the workpiece, this action ignites the

arc under the system processor control, this results in arc ignition without HF and

also minimum wear on the tungsten electrode. This process is essential when

welding in areas where sensitive electronic equipment is in operation (e.g. repair

welds on CNC-controlled machines in hospitals etc.) and where there may be a

risk of damage caused by high-voltage.

Solenoid valve

Welding current

Torch trigger 1

t

t

t

Description of function

26

3.3.15 Stick-electrode welding with the Booster-Function

The setting for Booster function is performed as described in section 3.1. In the

Booster mode the mains current monitoring function is deactivated, and the

machine always welds with the welding current set (I1), which is on the TIGER

170 150 A and the TIGER 210 170 A. If a higher value is set, then the machine

automatically reduces this to 150 A or 170 A respectively.

When stick welding, improved ignition and a more stable arc can be achieved by

fine tuning of the settings for Hot-start and Arc-force (see chapters 3.3.18.7 and

3.3.18.8)

3.3.16 Stick-electrode welding in the Fuse Hold mode

The setting for Fuse Hold function is performed as described in section 3.1. In

this mode of operation, the actual current drawn from the mains is continuously

monitored. If necessary, the welding current is reduced to the level required to

prevent the mains fuse form tripping out. A fast acting circuit breaker Type L,

similar to the type normally installed in households should be installed in the

mains supply cabinet as the Fuse Hold function is designed for use in

conjunction with this type of circuit breaker.

The machine is designed for use with all the common types of stick-electrodes.

The maximum current on the Tiger 170 is 140 A, and on the Tiger 210 is 160 A. If

a higher current is set, the current is automatically limited to 140 A or 160A

respectively.

This current enables the welding of standard electrodes up to 3.25mm to be used

The polarity of the electrode can be obtained from the manufacturers data sheet.

If there is a permanent short circuit between the electrode and the workpiece

during welding, the Anti-Stick Function is automatically activated after approx.

1.3s. This function automatically limits the welding current to approx. 35 A. This

prevents the electrode from overheating and burning out. The operator

terminates the short circuit simply by removing the contact between the electrode

and the workpiece.

When stick welding, improved ignition and a more stable arc can be achieved by

fine tuning of the settings for Hot-start and Arc-force (see chapters 3.3.18.7 and

3.3.18.8)

3.3.17 TIG - welding

The setting for TIG welding is performed as described in section 3.1. It is

possible to weld with up to 170 A on the TIGER 170, and up to 210 A on the

TIGER 210. The mains current monitoring is deactivated in the TIG welding

mode. Even though the welding current is higher, the load on the mains supply is

lower than by stick-electrode welding, therefore the chances of the mains fuse

tripping are greatly reduced.

When TIG welding the arc is established between the end of the nonconsumable Tungsten electrode and the workpiece. An inert shielding gas

protects the electrode and the weld pool and prevents them from oxidising during

the welding process. The usual selection of gas is pure Argon, however Helium

and other mixtures can also be used depending upon the application.

The negative pole of the power source is connected to the torch, and the positive

pole to the workpiece. The tungsten electrode is the current conductor and

sustains the arc (non-consumable). The filler material is usually introduced into

the weld pool by hand, in the form of a rod, or by a separate cold wire feed unit,

in the from of a wire. The tungsten electrode and the molten pool, as well as the

molten end of the filler material, are protected from the atmosphere by the inert

Description of function

27

shielding gas, which flows from the shielding-gas nozzle, which is positioned

concentrically around the electrode.

3.3.18 The Special mode

3.3.18.1 General Description

The operating panel enables the complete overview of the important settings for

the both TIG and stick-electrode welding on the TIGER machine. In addition to

this the numerous special parameters and functions in the special mode can also

be set and altered according to the individual requirements.

These are:

A – The gas pre-flow time

B – The ignition energy

C – The start current

D – The up-slope time

E – The crater fill current

F – Dual Wave

H – Hot Start

I – Arc Force

S – Save programme

L – Load programme

The special mode is activated by turning the turn and set knob until the special

mode LED (Fig 3.1 and Fig 3.2, LED18) is illuminated, and then depressing the

turn and set knob for longer than 2 seconds. Once the mode is activated the

digital display show the letter assigned to the special parameter and the value

set. (e.g. “A2.4” means that the gas pre flow time (A) is set to 2.4 seconds). The

alteration of the parameters and their values is done by using the turn and set

knob as described on the following page:

The alteration of the parameters,

Turn the knob until the required parameter is displayed

Depress the knob to select the parameter, the letter on the digital display

starts to blink

Turn the knob until the required value is reached

Press the knob to save the value (enter)

Particular characteristics of the Special mode

The processor also controls the special mode, in that only those functions that

relate to the operating mode selected can be accessed and altered.

For TIG-welding A – The gas pre-flow time

B – The ignition energy

C – The start current

D – The up-slope time

E – The crater fill current

F – Dual Wave

Description of function

28

For Stick-electrode welding: H – Hot Start

I – Arc Force

For TIG- and Stick-electrode welding: S – Save programme

L – Load programme

For loading and saving programs, the turn and set knob must be pressed for

longer than 2 seconds. This prevents already selected settings or saved

programs from being overwritten inadvertently or due to incorrect operation.

In order to recognise whether or not a programme is already stored in a certain

programme number, then the digital displays shows a point next to the letter „S“.

Fig. 3.7. Saving a program. Program 16 is not yet reserved (the point on the

„S“ is not illuminated). Program 17 is reserved (the point on the „S“

is illuminated)

When the newly developed welding process is activated („F-1“), both LED’s for

DC and AC illuminate (see Fig 3.1 LED7 und LED8)

The orientation of the letters to the machine parameter settings

The orientation of the letters to the machine parameter settings is simplified by

following the letters placed along the current cycle diagram printed next to the

special mode on the panel. As shown in Fig. 3.8: The gas pre flow time (A), the

ignition energy (B), the start current (C), the upslope time (D), and the crater fill

current (E) easily recognisable by their position.

2sec

Fig. 3.8: Position of the special mode on the operator’s panel

The alteration and setting of the parameters can be made by the selection of the

letter for the parameter as shown:

H – Hot Start: Hot Start begins with H

I – Arc Force: for changing the current characteristic, Current = I

S – Save programme: Save begins with S

L – Load programme: Load begins with L

F – Dual Wave: V from Dual Wave cannot be displayed, but F is used instead

Description of function

29

3.3.18.2 Pre-flow gas time ( A )

The pre-flow gas time is the time for which the gas solenoid opens after

depressing the torch button 1 until the arc ignition cycle starts. This ensures that

the tip of the tungsten electrode and the workpiece is protected from the

atmosphere before the ignition takes place

If during the gas post flow time the welding process is re-started, the processor

automatically set the gas pre-flow time to „zero“. This reduces the waiting time

and improves efficiency of the machine. This is very important when tack welding

for example.

3.3.18.3 Ignition Energy ( B )

The ignition energy is infinitely variable between 10% and 99% for both the Lift

Arc and HF ignition arc starting modes.

In direct relationship to the welding current setting I1, the processor then

automatically applies the pre-selected value depending upon the setting of the

welding current I1 during the ignition cycle. The pre-selected value of the ignition

energy will be dependant upon the type of tungsten electrode, and the diameter,

as well as the welding application.

When welding on thin materials and when using small diameter tungsten

electrodes the value for the ignition energy will be lower.

3.3.18.4 Start current ( C )

The start current is the current at which the machine produces directly after the

arc is struck. The value is infinitely variable between 10% and 99% of the welding

current I1. E.g. if the start current is set at 40% (C40) and the welding current is

set at 100A then the start current will be 40A. The advantages of adjusting the

start current are:

Lower loading on the electrode due to lower thermal shock.

Search arc can be set in the latched (4 step) trigger mode, to start at the

beginning of a weld.

The welding with a reduced current is possible at the beginning of a weld, or

where heat build up occurs.

3.3.18.5 Current upslope time ( D )

The current upslope time is the time in which the welding current rises in a linear

transition from the start current to the welding current (I1). In the non-latched

torch trigger mode (2step), the time commences directly after the arc has ignited.

In the latched torch trigger mode (4step), the time starts as soon as the trigger is

released after step 1 and current is flowing.

3.3.18.6 Crater fill current ( E )

The crater fill current is the current at which the welding process will be

terminated. The setting is infinitely variable between 10% and 99% of the welding

current I1. E.g. if the crater fill current is set at 40% (E40) and the welding current

is set at 100A then the crater fill current will be 40A. The advantages of adjusting

the crater fill current are:

The elimination of crater cracking and cracking at the end of the weld seam

due to rapid cooling of the weld pool.

Manual pulsing (see chapter 3.2.6).

The welding with a reduced current is possible at the end of the weld on

edges, or where heat build up occurs.

Description of function

30

3.3.18.7 Hot start ( H )

In order to improve the ignition when stick-electrode welding, the ignition current

is given a short boost when starting. This hot start current is higher than the

welding current that has been set (I1). The setting value for the hot start is a

direct relationship to the welding current. The setting can be adjusted between

0% and 70%; this means that with a setting of 30% (H30) and the welding current

of 100A the hot start current is 130A.

3.3.18.8 Arc Force ( I )

In order to ensure a stable arc during stick-electrode welding it is very important

for the smooth droplet transfer that in addition to the welding current (I1) that a

very short current pulse is also given by the welding unit this is called the Arc

force. The size of the pulse is defined by the Arc force setting which can be

infinitely variable from 0% to 70% of the welding current (I1) which is set, this

means that with a setting of 50% (I50) and the welding current at 100A the arc

force current will be 150A.

3.3.18.9 Program save and load ( S ) ( L )

There can be up to 99 different programmes with machine settings stored under

a freely selectable programme number and recalled for use. All for the machine

parameters settings that can be set are stored and then reloaded for

implementation.

Thereby the entire machine settings can be simply reloaded for those repeat jobs

within seconds saving a great deal of time and ensuring consistent quality

Additionally the basic parameter setting of the machine such as the start current,

crater fill current, ignition energy, etc. can be individually set for each person who

uses the machine. Recalling these is done at the touch of a button.

Loading a programme:

Selecting the load setting in the special mode does the loading of a

programme. The first digit of the digital display shows the letter „L“ which

stands for Load

By depressing the turn and set knob the function load is activated and the „L“

begins to blink.

The turn and set knob is then turned and the required programme number can

be selected.

The turn and set knob is depressed once again for more than 2 seconds and

the selected programme number will be loaded into the machine. The loading

of the programme can be recognised as the display will go blank for a short

time, additionally the LED’s will change their position according to those

determined by the programme settings.

Saving a Programme:

Selecting the load setting in the special mode does the loading of a

programme. The first digit of the digital display shows the letter „S“ which

stands for Save.

Depressing the turn and set knob activates the load function, and the „S“

begins to blink.

The turn and set knob is then turned and the required programme number can

be selected.

The turn and set knob is depressed once again for more than 2 seconds

then all of the parameters which are set at that time will be saved. The saving

of the programme can be recognised, as the display will go blank for a short

time. The knob must be pressed for more than 2 seconds in order to prevent

the accidental saving or overwriting of an existing programme, (similar to a car

radio).

Description of function

31

In order to recognise whether or not a programme is already stored in a certain

programme number, then the digital displays shows a point next to the letter „S“.

It is also recommended that a list is made of the programmes stored in the

machine together with their application, this will reduce the risk of mistakes when

loading a programme.

3.3.18.10 Dual-Wave ( F )

The Dual Wave process from REHM is a combination of AC and DC welding.

The processor controls the welding process and automatically alternates the

current from AC for 0.2 seconds to DC for 0.3 seconds. The selected values for

the welding current I1 or I2, the frequency and the wave balance are applied as

for DC-only or AC-only welding.

The Dual Wave process is activated by setting the value "1" at the "F" setting

option in the Special mode. In the display, the LEDs for DC and AC light up at the

same time. To deactivate the Dual Wave process, either the value can be altered

to "0" or DC or AC can be set directly (see sections 3.3.7 and 3.3.8).

NOTE: The Dual Wave function is activated by the special mode, when it is

active both the AC and DC LED’s (7 and 8) illuminate. Deactivating the Dual

Wave can be done either via the special mode, or by selecting either the AC or

the DC mode on the control panel.

The Dual-Wave process enables the operator to have more control over the

welding pool. This is particularly important, when for example welding out of

position or when joining two differing thickness together on Aluminium or

Aluminium alloys.

Fig. 3.9: The welding current cycle for the Dual-Wave- process

__

+

Description of function

32

3.3.19 The control LED’s

The following control LED’s give an overview of the important status conditions of

the machine:

Whether conventional or high frequency pulsing this LED will

illuminate to indicate that pulsing is activated. (See chapter 3.3.2.

und 3.3.4.)

There is open circuit voltage on the torch or the electrode holder.

In the case that this LED flashes on and off then an internal fault

condition has been recognised. This can be reset by power off and

then on again. If fault cannot be cleared then please contact Rehm

customer service (RKS).

Temperature control. This (yellow) LED will illuminate if the

maximum allowable temperature of the machine has been exceeded.

As long as this LED is illuminated then the power module is disabled,

therefore there is no output from the power source possible. In the

TIG welding mode when this fault condition occurs the post flow gas

time will still elapse. Once the machine cools down again the LED

will extinguish and the welding operation can continue as before. If

this Led starts to flash off and on, and the digital display shows and

„Err“ then an internal fault has been recognised. This can be reset

by power off and then on again. If fault cannot be cleared then

please contact Rehm customer service (RKS).

3.3.20 The Digital display

The digital display enables the selection of the parameters and their values to be

displayed. The display is a three-digit display. Its large display area with selfilluminating digits enables the display to be easily read, even from a distance and

also in poorly lit conditions. As the display is control via the processor it always

show the values and status in real time. This means for example that when a

programme is to be stored the point beside the letter “S” can also be displayed to

indicate that the programme is already number selected is already occupied.

3.3.21 The Turn and Set knob

The settings are all done via a single control knob, this can be turned to select or

alter the parameter and then pressed to confirm the setting. Using the

combination of LED’s and the 3-digit digital display the setting can always be

accurately set and reproduced using the same principle. This turn and set knob is

positioned centrally on the operating panel and is suitable for both right handed

and left handed personnel, as it can easily be operated with the thumb. The form

of the knob enables both simple and precise setting of the parameters and

functions. It is fully integrated within the housing of the Tiger and is therefore

protected by mechanical damage. Even if it is knocked from above the electrical

components within the housing remain undamaged. The turn and set knob is a

combined encoder and switch. As such it does not have an end stop therefore it

cannot be damage by truing it past the end point.

3.4 Anti-Stick Function

If there is a permanent short circuit between the electrode and the workpiece

during welding, the Anti-Stick Function is automatically activated after approx.

1.3s. This function automatically limits the welding current to approx. 35 A. This

Description of function

33

prevents the electrode from overheating and burning out. The operator

terminates the short circuit simply by removing the contact between the electrode

and the workpiece.

3.5 INTIG-Energy

The highly intelligent processor ensures that the ideal ignition energy is

automatically chosen depending upon the actual weld current setting; this applies

not only for HF, but also for the Lift-Arc ignition sequence.

When "HF-On", is selected the high-frequency ignition unit is ready for operation.

To ignite the arc, the electrode must be held about 3 to 5 mm above the

workpiece. When the torch button is pressed, the shielding gas is pre-ionised by

a high-voltage, the current flows between the end of the electrode and the

workpiece so that the main arc is established. The ignition of the arc without

contact between the tungsten electrode prevents tungsten inclusions in the weld.

Once the arc has successfully been ignited the high-frequency ignition unit is

switched off automatically during welding

When “HF-Off” is selected, microprocessor controlled contact ignition takes place

(Lift Arc) to strike the arc. In order to ignite the welding arc, the tip of the

electrode must be placed on the workpiece and the torch button depressed. The

processor control system reduces the ignition current so that the tip of the

electrode does not heat up.

The electrode is then gradually lifted away from the workpiece, this action ignites

the arc under the system processor control, this results in arc ignition without HF

and also minimum wear on the tungsten electrode. This process is essential

when welding in areas where sensitive electronic equipment is in operation (e.g.

repair welds on CNC-controlled machines in hospitals etc.) and where there may

be a risk of damage caused by high-voltage.

The electrode diameter depends on the welding current. A diameter of 1.6 mm is

recommended for welding currents up to 70 A and 2.4 mm for higher currents.

When stick-electrode welding in either the Booster or Fuse-hold mode is

selected, then the HF-ignition is automatically switched off.

During stick-electrode welding the INTIG-Energy is always determines the

correct setting of the Hot-start current. The ignition process is carefully controlled

by the processor and ensures that the output for a soft and safe start is realised.

Even the re-starting of difficult electrodes (e.g. Basic coated) can be achieved as

the power is controlled when the electrode makes contact with the workpiece

(similar to the Lift-Arc process during TIG welding).

3.6 EPC: Continuous Mains voltage monitoring

The EPC (Electronic Power Control) system continually monitors the mains

supply voltage. As soon as an over voltage is detected, the EPC unit disconnects

the machine electronics from the mains supply. The separation is via electrical

components that due to the fault condition become overheated, and thereby alter

their electrical resistance. Thereby it is essential that when the over voltage fault

has been corrected, that sufficient time is allowed to enable these components to

reach their required operating temperature again, which can depending upon the

ambient and machine temperature be more than a few minutes.

If the Tiger is switched on and off several times in succession then the EPC unit

operates as described above. This is a safety function that prevents the inverter

from becoming damaged from voltage or current surges.

Description of function

34

Resetting to Factory settings

If the turn and set knob is depressed and at the same time the machine is

switched on by the mains switch then the function of the Tiger will be reset to that

which was delivered from the factory. The welding current I1 will remain saved.

The factory setting resets your Tiger to the default values in all parameters for

TIG welding in 2-step mode with high-voltage ignition.

Please note that ignition with high-voltage pulses is selected for TIG

welding in the factory setting.

Extra care must be taken when the HF is activate by the factory setting, The

HF ignition may cause a safety hazard if incorrectly used.

Care must also be taken when using the factory reset. All of the set-up

parameters are set to the default values. This includes the parameters in the