REHM INVERTIG.PRO digital 450 DC, INVERTIG.PRO digital 240 DC, INVERTIG.PRO digital 350 DC, INVERTIG.PRO digital 280 DC, INVERTIG.PRO digital 240 AC/DC Operating Instructions Manual

...

GB

OPERATING INSTRUCTIONS

TIG inert gas welding units

INVERTIG.PRO digital 240 – 450 DC / AC/DC

Operating instructions

2

Operating instructions

TIG inert gas welding units

INVERTIG.PRO digital 240 DC, 240 AC/DC

INVERTIG.PRO digital 280 DC, 280 AC/DC

INVERTIG.PRO digital 350 DC, 350 AC/DC

INVERTIG.PRO digital 450 DC, 450 AC/DC

Rehm GmbH u. Co. KG

Ottostr. 2

73066 Uhingen, Germany

Telephone: 07161/3007-0

Fax: 07161/3007-20

Email: rehm@rehm-online.de

Internet: http://www.rehm-online.de

Document number: 730 0143

Release date: 25.06.2015

Rehm GmbH u. Co. KG, Uhingen, Germany 2011

The contents of this description are the sole property of Rehm GmbH u. Co. KG

The disclosure or reproduction of this document, the sale and communication of

its content are prohibited unless expressly permitted.

Actions to the contrary will be subject to compensation. All rights are reserved in

the case of patent, utility patent or registered design.

Manufacture using these documents is not permitted.

Subject to change.

Description

Type

Manufacturer

Index

3

Index

Product identification 2

1. Introduction 6

1.1 Preface 6

1.2 General description 7

1.2.1 Principle of the TIG inert gas welding procedure 8

1.2.2 Areas of application of the TIG welding units 8

1.2.3 Functional principle of the TIG welding units 8

1.2.4 Correct use 8

1.3 Symbols used 9

2. Safety notes 10

2.1 Safety symbols used in these operating instructions 10

2.2 Warning symbols on the unit 10

2.3 Notes and requirements 11

3. Functional description 13

3.1 Description of controls 13

3.1.1 Application buttons 14

3.1.2 Multifunction buttons 14

3.1.3 Push and rotate knob (R Pilot) 14

3.1.4 High-resolution TFT display 15

3.2 Switching on 15

3.3 Special features of the control panel 15

3.4 Classic application 15

3.4.1 Multifunction buttons of the Classic application 16

3.4.2 Basic settings of the multifunction buttons 17

3.5 Welding procedure multifunction button 17

3.5.1 TIG welding 17

3.5.2 TIG points 17

3.5.2.1 TIG spot welding, 2-step 18

3.5.2.2 TIG spot welding, 4-step 19

3.5.3 WIG Interval 20

3.5.3.1 TIG interval, 2-step 20

3.5.4 Electrode welding 21

3.6 The welding parameters 21

3.6.1 Basic setting of welding parameters. 21

3.6.2 Gas preflow time 22

3.6.3 Ignition energy 22

3.6.4 Start current 23

3.6.5 Upslope time 23

3.6.6 Welding current I1 23

3.6.7 Welding current I2 24

3.6.8 Downslope time 24

3.6.9 End crater current 25

3.6.10 Gas post-flow time 25

3.7 Polarity multifunction button 26

3.7.1 AC current (AC) 26

3.7.1.1 AC balance (%) 27

3.7.1.2 AC frequency Hz 28

3.7.1.3 AC curve shape selection facility 29

3.7.2 DC current positive terminal 30

3.7.3 DC current negative terminal 30

3.7.4 Dual Wave 30

3.8 Multifunction button 2- / 4-step and high frequency 31

3.8.1 2-step function 32

3.8.2 4-step function 32

Index

4

3.8.3 Welding with high frequency (HF) 33

3.8.4 Welding with Lift-Arc 34

3.9 Pulsing multifunction button 34

3.9.1 I1 pulsing time t1 34

3.9.2 I2 pulse time t2 35

3.10 Electrode welding parameters 35

3.10.1 Welding current I1 during electrode welding 35

3.10.2 Arc Force 36

3.10.3 Hot Start 36

3.10.4 Anti-Stick Function 36

3.11 Quick setting P1 and P2 (Quick Choice buttons) 36

3.12 Programs application (Progr.) 36

3.12.1 Managing folders 38

3.12.2 Main management settings 39

3.12.2.1 Management: Name / Text Entry 39

3.12.2.2 Management: Rename 40

3.12.2.3 Management: Move 40

3.12.2.4 Management: copy 41

3.12.2.5 Management: Delete 42

3.12.3 Loading programs 42

3.12.4 Saving programs 43

3.13 Assist Application 45

3.13.1 Setting the welding task 46

3.13.2 Welding tip 47

3.13.3 Library 48

3.14 System application button 49

3.14.1 System overview 49

3.14.2 Basic selection of machine settings 50

3.14.3 Explanation of system settings 50

3.14.4 Gas test 54

3.14.5 Access authorisation 54

3.14.6 Diagnosis 56

4. Accessories 57

4.1 Overview 57

4.2 Foot remote control P1 iSystem 59

4.3 REHM TIG torch 59

4.4 REHM water-cooling units TIG - COOL CART and TIG - COOL 59

4.5 Handheld remote control P2 12-pin (analog) 59

4.6 Automation INVERTIG.PRO digital 60

4.6.1 Interface INVERTIG.PRO digital standard 60

5. Putting into operation 61

5.1 Safety notes 61

5.2 Working under increased electrical danger 61

5.3 Setting up the welding unit 61

5.4 Connecting the welding unit 62

5.5 Cooling the welding unit 62

5.6 Guidelines for working with welding power sources 62

5.7 Connecting welding cables or torches 62

5.8 Connecting external components 62

6. Operation 64

6.1 Safety notes 64

6.2 Electrical risks 64

6.3 Personal safety tips 64

6.4 Fire prevention 65

6.5 Ventilation 65

6.6 Checks before starting 65

6.7 Connecting the earth cable 65

Index

5

6.8 Practical notes 66

7. Faults 69

7.1 Safety notes 69

7.2 Table of faults 69

7.3 Error messages 72

8. Maintenance work 73

8.1 Safety notes 73

8.2 Maintenance table 73

8.3 Cleaning the inside of the unit 74

8.4 Correct disposal 74

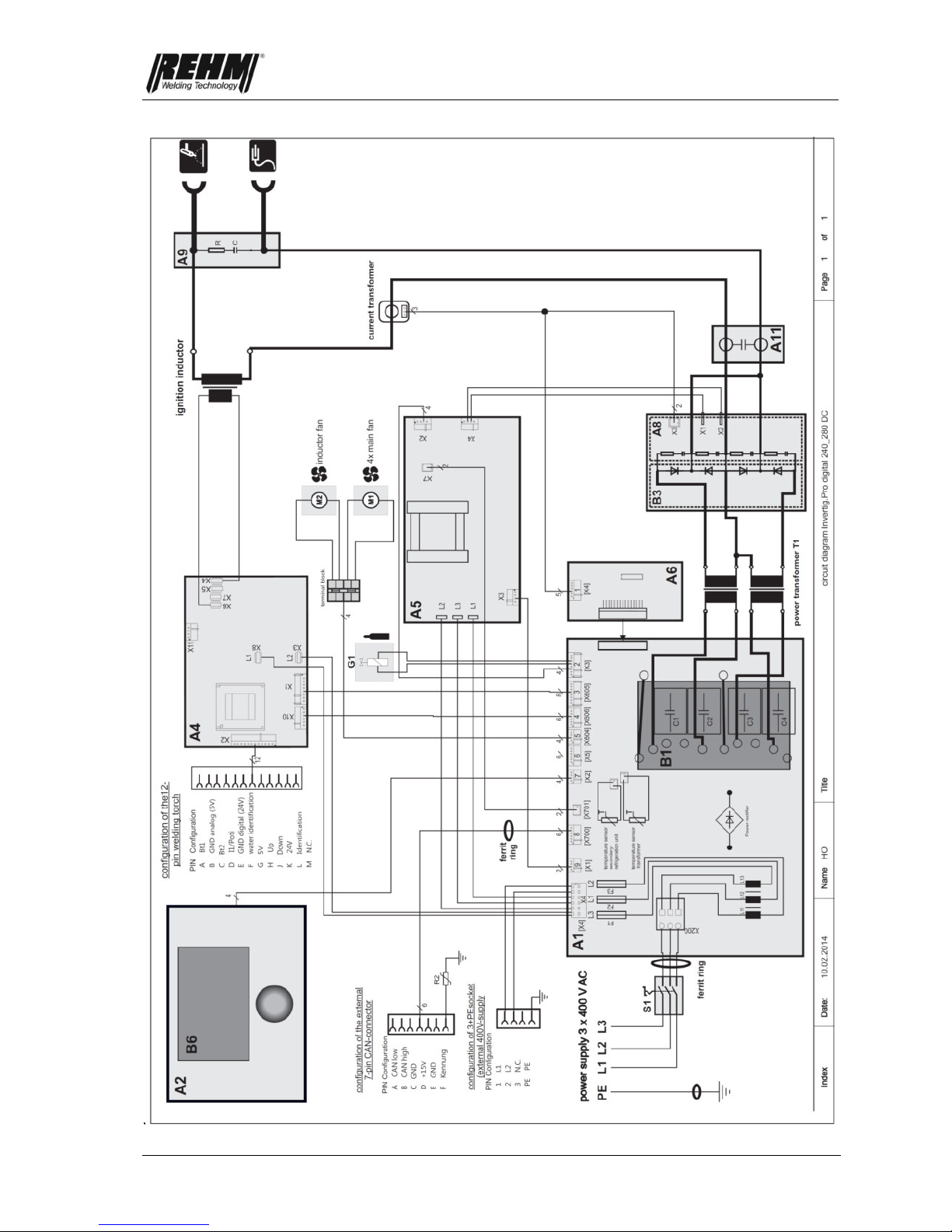

9. Circuit diagrams 75

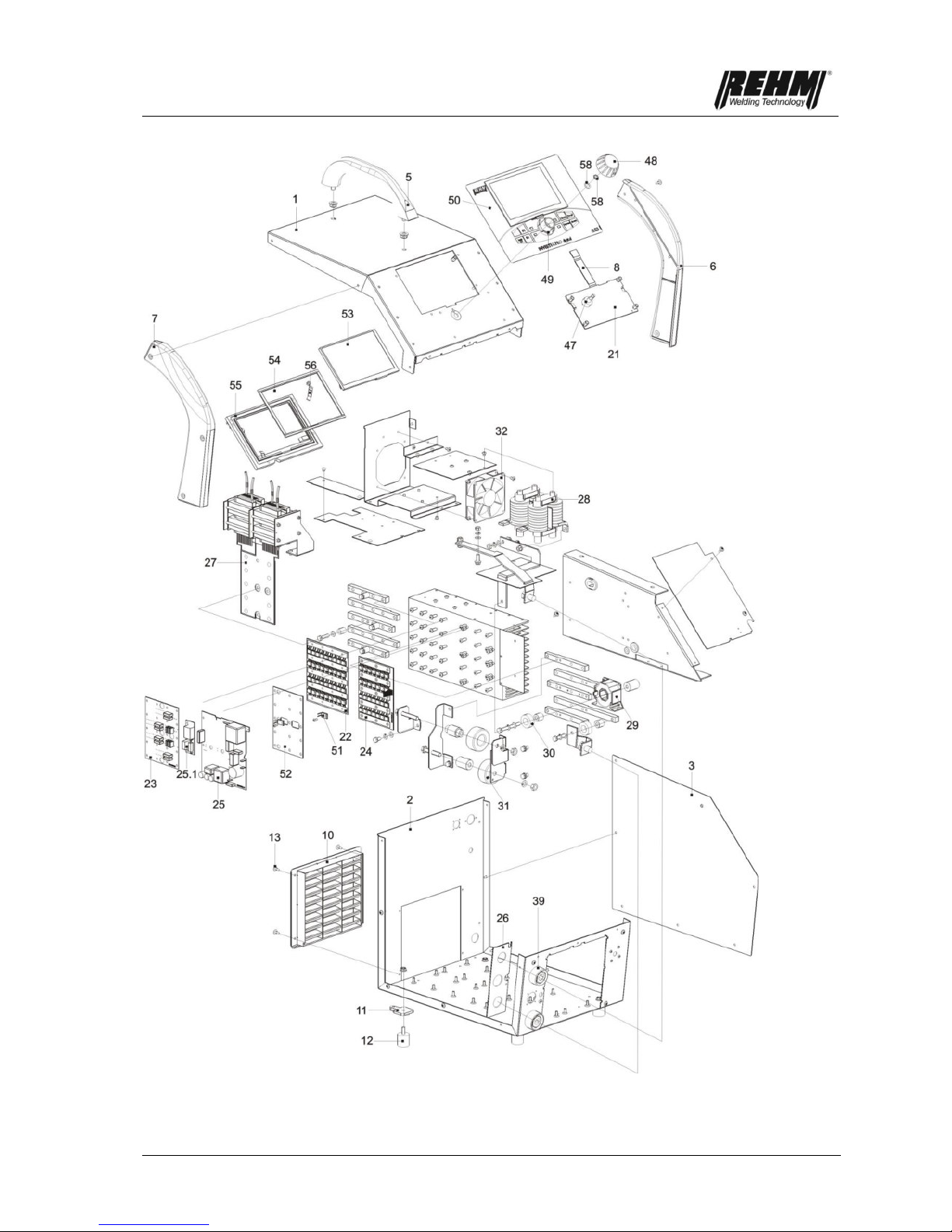

10. Components of the INVERTIG.PRO digital units 79

10.1 List of components with REHM part numbers 79

11. Technical data 83

12. INDEX 84

Introduction

6

1. Introduction

1.1 Preface

Dear Customer,

You have purchased a REHM inert gas welding unit, a branded German

product. We would like to take this opportunity to thank you for putting

your trust in our quality products.

Only the highest quality components are used in the development and

manufacturing of INVERTIG.PRO digital welding units. In order to

guarantee high durability, even under the toughest of conditions, all

REHM welding units contain components that live up to strict REHM

quality requirements. The INVERTIG.PRO digital welding unit has been

designed and built in accordance with established safety requirements.

All of the relevant legal requirements have been taken into account and

are supported by the conformity declaration and the CE mark.

REHM welding units are produced in Germany and carry the "Made in

Germany" quality mark.

As REHM is constantly developing its products in line with technical

progress, we reserve the right to adapt and modify this welding unit at any

time, in order to meet the latest technical requirements.

Introduction

7

1.2 General description

Figure 1: INVERTIG.PRO digital

Introduction

8

1.2.1 Principle of the TIG inert gas welding procedure

When TIG welding, the arc burns freely between a tungsten electrode and the

work piece. The shielding gas used is an inert gas like Argon, Helium or a mix of

these.

One pole of the energy source is at the tungsten electrode, the other on the work

piece. The electrode is the conductor and the arc carrier (permanent electrode).

The additional material is introduced in stick format by hand, or in wire format

using a separate cold wire feed unit. The tungsten electrode and the pool crater

as well as the liquid melting end of the additional materials are all protected from

the oxygen in the air by the inert gas employed which is released from the

nozzles arranged concentrically around the electrode.

1.2.2 Areas of application of the TIG welding units

INVERTIG.PRO digital DC welding units are direct current power sources. They

are suitable for welding all alloyed and non-alloyed steels, stainless steels and

non-ferrous metals.

INVERTIG.PRO digital AC/DC welding units are both direct and alternating

current sources. They can be used to process all alloyed and non-alloyed steels,

stainless steels, non-ferrous metals, aluminium and aluminium alloys.

1.2.3 Functional principle of the TIG welding units

Our TIG INVERTIG.PRO digital welding units are primary-clocked power sources

in which the welding current is switched by one of the most modern highperformance transistor switches. The On/Off switch relationship of the highperformance transistor switch regulates the set welding current. In conjunction

with the high switching frequency of 100 kHz this generates an extreme stable

and quiet arc. A precise processor controller guarantees constant welding current

even when the distance between the torch and the work piece changes or the

power supply fluctuates. The INVERTIG.PRO digital units have the frequency

automation developed by REHM which ensures for optimum adaptation of the

welding current frequency of the welding current when using alternating current.

With the new REHM AC-Matic, the AC curve shape is automatically adapted to

the current strength. A sine wave curve shape is automatically selected for low

currents, and the square wave curve shape is automatically used for higher

currents

The use of the most modern transistor switching technology means that these

power sources are extremely effective.

1.2.4 Correct use

REHM welding units are designed to weld various metals such as non-alloyed

and alloyed steel, stainless steel and aluminium. You should also pay attention to

the special regulations pertaining to your area of application.

REHM welding units are designed for use with hand-controlled and machinecontrolled operations.

REHM welding units are, unless explicitly permitted in writing by REHM; only for

sale to commercial and industrial users and only for use by such. They may only

be operated by persons trained in the use and maintenance of welding units.

Welding current sources may not be set up in areas with increased electrical risk.

These operating instructions contain rules and guidelines for the correct use of

your unit. Only when these are adhered to can it be described as correct use.

Introduction

9

Risks and damaged caused as a result of a different type of use is the

responsibility of the operator. In the event of special requirements, it may be

necessary for additional special conditions to also be taken into account.

If anything is unclear, consult your safety officer or contact REHM's customer

service department.

You should also pay attention to the special notes regarding correct use set out

in the suppliers documentations.

National regulations regarding the operation of the unit are valid with no

restrictions .

Welding current sources may not be used to defrost tubes.

Correct use also covers the observation of the correct measures with regard to

mounting, removal and remounting, taking into service, operation and

maintenance as well as disposal. Please pay special attention to the

specifications in Chapter 2 Safety notes and Chapter 8.4 Correct disposal.

The unit may only be operated under the conditions set out above. Any other use

is not correct. The consequences are the responsibility of the operator.

1.3 Symbols used

Lists with bullets: General lists

Lists with a square: Work or operational steps that must be carried out in the

sequence listed.

Chapter 2.2, Warning symbols on the unit

Cross-references: In this case, to Chapter 2.2 Warning symbols on the unit

Bold is used for emphasis

Note!

... Refers to tips and other useful information.

The safety symbols used in this manual: Chapter 2.1

Typographic

symbols

Safety symbols

Safety notes

10

2. Safety notes

2.1 Safety symbols used in these operating

instructions

Warning notes and

symbols

This or a symbol more specific to the danger can be found with all safety

notes in these operating instructions which carry a risk to life and limb.

One of the following signalling words (Danger! Warning! Caution!) indicate

the degree of danger:

Danger! ... indicates immediate threat of danger.

If this is not avoided it may lead to death or serious injury.

Warning! ... indicates a potentially dangerous situation.

If this is not avoided it may lead to death or serious injury.

Caution! ... indicates a situation in which damage may occur.

If this is not avoided it may lead to slight or minor injuries and damage to

property.

Important!

Indicates a potentially damaging situation. If this is not avoided it may lead

to damage to the product or to something in the vicinity.

Materials that may be hazardous to health or environment. Materials that

must be treated/disposed of in accordance with the law.

2.2 Warning symbols on the unit

indicate dangers and sources of danger on the unit.

Danger!

Dangerous electrical voltage!

Ignoring may lead to death or injury,

Safety notes

11

2.3 Notes and requirements

The unit has been developed and constructed in accordance with recognised

technical knowledge.

However, using the unit may hold dangers for the life and limb of the user or third

parties or influence the unit or cause damage to other property.

None of the safety measures may be removed or put out of action, as this causes

risks and correct use of the unit cannot be guaranteed. Removing the safety

features during set up, repairs and maintenance is described specially. As soon

as this work is completed, the safety features must be replaced.

When using additional products (for example, solution for cleaning) the operator

of the unit is to ensure that the unit is safe for the product to be used.

All safety and danger notes as well as the type panel on the unit are to be

maintained, kept in a readable state and observed.

Safety notes serve to protect when working and to prevent accidents . They

must be observed.

The safety notes listed in this chapter must be observed along with the special

notes made in running text.

In addition to the instructions in these operating instructions, general safety and

accident prevention regulations (in Germany including UVV BGV A3, TRBS 2131

and BGR 500 Chapter 2.26 (formerly VGB15): "Welding, cutting and associated

processes" and in particular the references to arc welding and cutting and the

appropriate national regulations) must be observed.

Please also note the safety notices in the workplace of the operator.

REHM welding units are, unless explicitly permitted in writing by REHM; only for

sale to commercial and industrial users and only for use by such.

The INVERTIG.PRO digital inert gas welding units are designed in accordance

with EN 60974-1 Arc welding equipment - Welding power sources for

overvoltage category III and pollution level 3 and with EN 60974-10 Arc welding

equipment - Electromagnetic compatibility for Group 2 Class A, and are suitable

for use in all areas, except residential, which are directly connected to a public

low voltage power supply. Due to the cable-related and radiated interferences it

may be difficult to guarantee the electromagnetic compatibility in these areas. For

this purpose, the observation of suitable measures to fulfil the requirements (filter

for network connection, shielding using, for example, screened lines, shortest

possible welding lines, grounding the work piece, equipotential bonding) as well

as the evaluation of the environment (for example, computers, control units, radio

and television masts, neighbouring persons, for example, those using a

pacemaker) should all be carried out. The responsibility for interferences lies with

the operator. See DIN EN60974-10:2008-09, Appendix A for more notes and

recommendations.

High performance units may affect the main power supply thanks to their high

power consumption. For certain units types, there may be connection restrictions,

requirements regarding the maximum permitted net impedance or requirements

regarding the minimum required available power at the point of connection to the

main power supply (see technical data) In these cases, the user of such a unit

must ensure, if necessary by consulting the power suppliers, whether the unit

may be connected.

INVERTIG.PRO digital TIG gas-shielded welding units should only be used

for the specified uses

in a safety-related correct condition

Dangers of nonobservation

Safety instructions

Areas of use

Requirements

made of the main

power supply

Safety notes

12

REHM welding units may only be operated and maintained by persons who have

been educated and trained to operate and maintain welding units. Only qualified,

authorised and trained personnel may work on and with the units.

These operating instructions contain important notes regarding how to operate

this unit safely, correctly and economically. A copy of the operating instructions

should always be kept on site in a suitable location. Please make sure that you

read the information summarised in this operating manual before using the

equipment. It contains important notes regarding use of the device which enables

you to fully use the technical advantages of this REHM devices. In addition, you

will also find information regarding maintenance and upkeep of the units as well

as the operational and functional safety.

These operating instructions do not replace the instructions by REHM's service

personnel.

The documentation for any additional options must also be taken into

consideration.

Changes to the unit or the addition or installation of additional elements is not

permitted. This would expire all guarantee and liability claims.

All third-party changes or deactivation of safety features renders all guarantee

claims invalid.

Qualifications of

the operating

personnel

Purpose of the

document

Changes to the unit

Functional description

13

3. Functional description

3.1 Description of controls

7301671d

INVERTIG.PRO digital

Classic Progr.

System Assist

P2

P1

12

1

2

3

4

56789

10

11

Figure 2: INVERTIG.PRO digital control panel

1

Classic application button

Page 16

2

Program application button (Progr.)

Page 37

3

Assist application button

Page 46

4

System application button

Page 50

5

Multifunction button for top right TFT display

Page 15 et seq.

6

Multifunction button for bottom right TFT display

Page 15 et seq.

7

Push and rotate knob (R Pilot)

Page 15

8

Multifunction button for top left TFT display

Page 15 et seq.

9

Multifunction button for bottom left TFT display

Page 15 et seq.

10

Quick Choice button P1

Page 37

11

Quick Choice button P2

Page 37

12

High resolution TFT display

Page 16

Functional description

14

3.1.1 Application buttons

The application buttons are used to go directly to the required applications

(Classic [1], Program [2], Assist [3] and System [4]). All application buttons are

assigned to a particular colour, which can be found again on the screen. The

user therefore knows which application he is in immediately.

3.1.2 Multifunction buttons

Certain activities can be called up with the multifunction buttons (e.g. Load,

Save) or settings can be made (e.g. welding procedure, polarity). These activities

are dependent on the selected parameters of the respective application.

In the corners of the display there are pull-down menus with control functions

Call-up takes place using the multifunction buttons [5 + 6]

[8 + 9] which are located around the push and rotate knob (R Pilot) [7].

Fig. 3: INVERTIG.PRO digital / Classic application control panel

View of Polarity pull-down menu

Multifunction button for calling up the Polarity pull-down menu

3.1.3 Push and rotate knob (R Pilot)

The push and rotate knob [7] is centrally located and can be operated by both

right and left handed persons. Due to the special holder, it is extremely well

protected from mechanical effects. The push and rotate knob does not have a

stop, meaning that over-rotating is not possible.

The push and rotate knob [7] is used for navigating in the screen display area.

Rotating the push and rotate knob always selects or modifies a setting.

Pressing the push and rotate knob makes the selection that has been made or

confirms the change.

Functional description

15

3.1.4 High-resolution TFT display

The high-resolution TFT display shows a quick and clear display of the welding

parameters, all relevant information and also error messages (see Chap. 7) in

high-quality graphics. The TFT display is protected by an impact-resistant plastic

screen.

The graphical display has a resolution of 800 * 400 pixels.

3.2 Switching on

The INVERTIG.PRO digital welding system is started up using the main switch.

The machine model appears on the TFT display [12] for approx. 10 seconds

(e.g.INVERTIG.PRO digital 450 AC/DC). Subsequently you are automatically in

the Classic application [1], and all settings from the previous welding procedure

or the factory settings are displayed.

3.3 Special features of the control panel

Provided that the arc has been ignited, all selected parameters are saved in the

device when the power is switched off at the main switch. After the device has

been switched on, all settings are displayed clearly and comprehensively.

Only the parameters that are currently required are displayed, e.g. TIG

parameters such as 2/4 step with HF or Lift-Arc etc. are suppressed during

electrode welding. Similarly, the parameters for frequency and balance are

suppressed during DC welding.

3.4 Classic application

The Classic application [1] contains all of the parameters that are needed for the

welding process, the welding procedure selection, the polarity, the high

frequency and the pulses. All parameters can be individually adjusted for the

respective welding task. The currently selected parameter value is always

displayed in the middle at the top.

The orange border colour indicates that you are in the Classic application.

Functional description

16

Fig. 4: INVERTIG.PRO digital / Classic application control panel

Set value of selected parameter

Min./max. value range display / Graphical display of selected

value of currently selected parameter

Overview of all welding parameters, including all currently set values

Designation of selected parameter

3.4.1 Multifunction buttons of the Classic application

The multifunction buttons [5 + 6] and [8 + 9] can be used to select the 2 / 4 step

function, high frequency [5], pulsing [6], the welding procedure [8] and the

polarity [9].

Fig. 5: INVERTIG.PRO digital / Classic application control panel

View of pull-down menus of multifunction buttons

Functional description

17

3.4.2 Basic settings of the multifunction buttons

Selection takes place by pressing the required multifunction buttons [5, 6, 8 or

9]. The selection options can then be seen in a pull-down menu on the

screen.

Rotate the push and rotate knob [7] to the required setting option (e.g. TIG

points).

Press the push and rotate knob [7] to confirm the setting option.

The selection facility can be exited by pressing the relevant multifunction

button without having made a selection. If no activity takes place for 20

seconds, the selected pull down menu is exited automatically.

3.5 Welding procedure multifunction button

The welding procedure is selected by pressing the multifunction button [8], as

described in chapter 3.4.2.

3.5.1 TIG welding

The welding parameters for TIG welding are set as described in Chapter 3.4.2.

For an explanation of the TIG inert gas welding procedure, see Chapter 1.2.1 et

seq.

3.5.2 TIG points

The welding parameters for TIG spot welding are set as described in Chapter

3.4.2.

Welding in spot welding mode is recommended for welding with a fixed spot

welding time setting starting at 0,01 seconds.

The stationary welding process runs using the selected spot welding time, unless

the torch button is released prematurely during welding.

After the selected spot welding time has elapsed or the torch button has been

released during welding, the end program runs.

Because less heat is introduced into the materials that are being welded, with

TIG welding there is less distortion and only a small amount of heat tinting.

Functional description

18

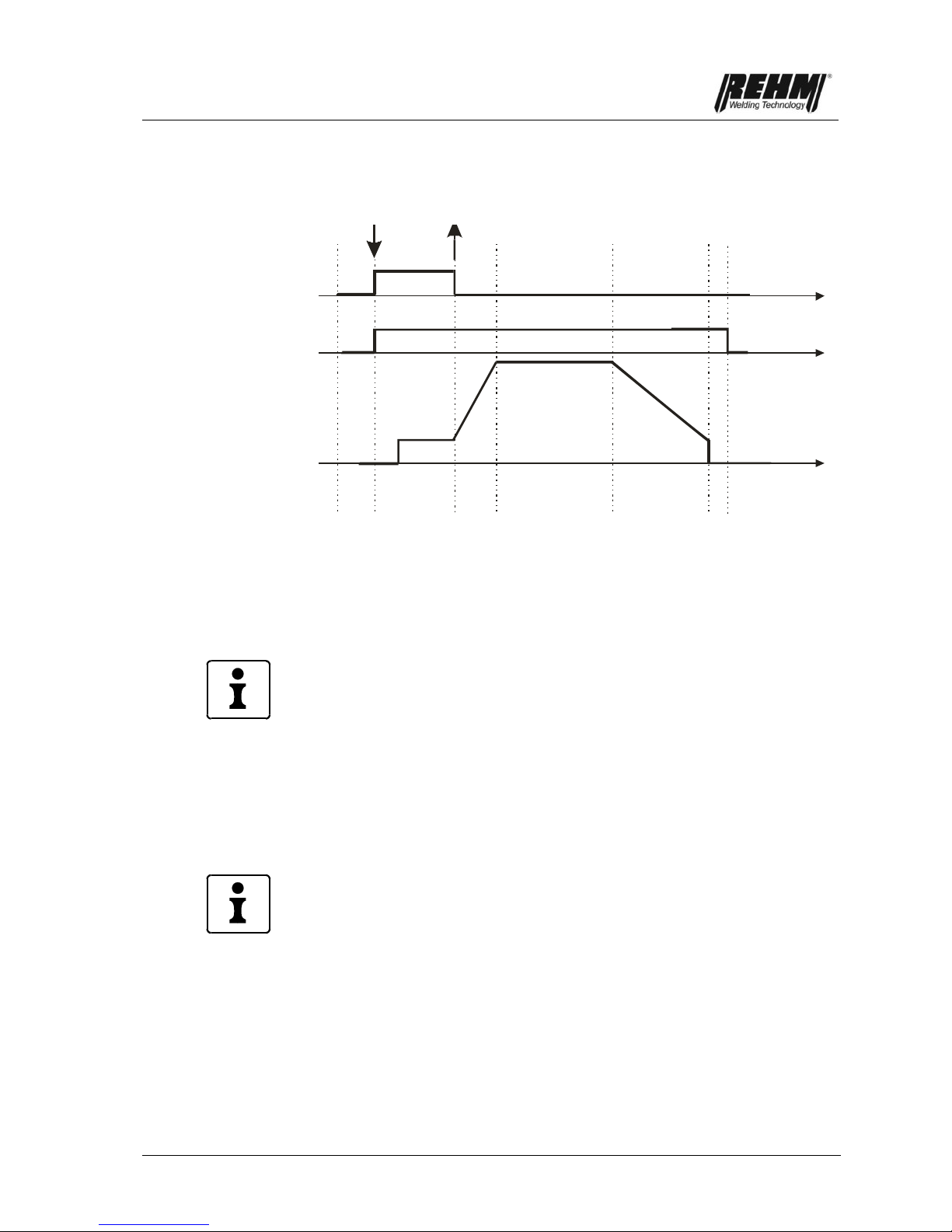

3.5.2.1 TIG spot welding, 2-step

t

t

t

2-Takt-Punkten

Brennertaster 1

Gasventil

Schweißstrom

Fig. 6: 2-step spot welding procedure

1. Press torch step button

The set gas pre-flow time starts to run and the gas valve opens. The arc is

ignited after the gas pre-flow time has elapsed. The welding current automatically

sets itself to the starting current. After the upslope time has elapsed, the welding

current reaches the preset value I1. The set spot welding time starts to run. After

the spot welding time has elapsed, the current reduces in accordance with the

preselected downslope time to the value set for the end crater current, and

switches itself off automatically after the final current time has elapsed.

2. Release torch step button

The inert gas flows in accordance with the selected gas post-flow time.

2-step spot welding

Torch Button 1

Gas valve

Welding Current

Functional description

19

3.5.2.2 TIG spot welding, 4-step

t

t

t

4-Takt-Punkten

Brennertaster 1

Gasventil

Schweißstrom

Fig. 7: 4-step spot welding procedure

1. Press torch step button

The set gas pre-flow time starts to run and the gas valve opens. The arc is

ignited after the gas pre-flow time has elapsed. The welding current automatically

sets itself to the starting current. The starting current is retained until the torch

button is pressed.

Special features:

The start and end current time cannot be adjusted for 4-step spot welding

The procedure can be aborted at any time by pressing the torch button again, the

inert gas continues to flow in accordance with the selected gas post-flow time.

2. Release torch step button

The welding current automatically sets itself to the pre-selected value after the

upslope time has elapsed. The set spot welding time starts to run. The torch

button does not have to be pressed and released again for the 3rd or 4th step,

since the welding process runs automatically after the 2nd step has been

triggered.

The procedure can be aborted by pressing the torch button again. The

downslope time starts to run, and if the torch button is released during the current

reduction time, the jump to 0A occurs and the inert gas flows in accordance with

selected gas post-flow time.

After the spot welding time has elapsed, the current reduces in accordance with

the preselected downslope time to the value set for the end crater current, and

switches itself off automatically after the final current time has elapsed. The inert

gas flows in accordance with the selected gas post-flow time.

4-step spot welding

Torch Button 1

Gas valve

Welding Current

Functional description

20

3.5.3 WIG Interval

INVERTIG.PRO digital provides TIG interval welding as an additional welding

method. Interval welding means defined spot welding with defined interval times.

The application of extremely thin fillers is possible. Interval welding is only

possible in 2-step operating mode.

Welding in interval welding mode is recommended for welding with a fixed

interval time setting starting at 0.01 seconds.

In the WIG interval the interval time between the individual intervals can be set

individually and therefore the cooling of the base material can be guaranteed

less distortion.

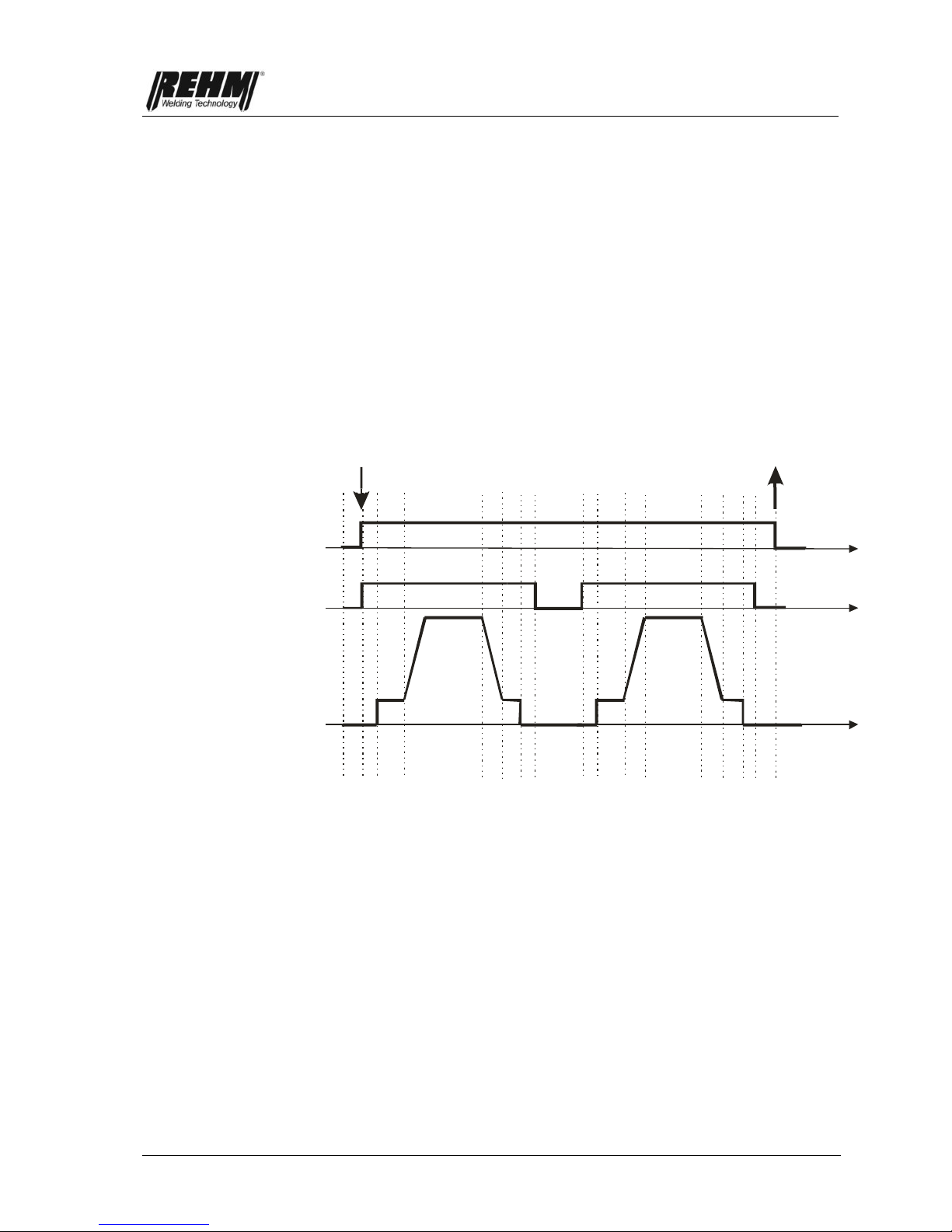

3.5.3.1 TIG interval, 2-step

t

t

2-Takt-Intervall

Brennertaster 1

Gasventil

Schweißstrom

t

Fig. 8: 2-step interval procedure

1. Press torch step button

The set gas pre-flow time starts to run and the gas valve opens. The arc is

ignited after the gas pre-flow time has elapsed. The welding current automatically

sets itself to the starting current. After the upslope time has elapsed, the welding

current reaches the preset value I1. The set interval time starts to run. After the

interval time has elapsed, the current reduces in accordance with the preselected

downslope time to the value set for the end crater current, and switches itself off

automatically after the final current time has elapsed, i.e. the welding current

goes to 0A. The inert gas continues to flow in accordance with the selected gas

post-flow time and the interval time runs down. Once the interval time has

elapsed, the welding current sets itself to the pre-selected start current again and

the welding process runs again as described.

2. Release torch step button

Interval welding stops.

2-step interval

Torch Button 1

Gas valve

Welding Current

Functional description

21

3.5.4 Electrode welding

The welding parameters for electrode welding are described in chapter 3.10.

The electrode is both an arc carrier and additional material at the same time. It

consists of an alloyed or non-alloyed core wire and a sheathing. The sheathing

has the job of protecting the melt bath from the damaging introduction of air, and

stabilising the arc. It also forms a slag that protects and shapes the seam. Almost

any metal can be welded using electrode welding. Electrode welding is a welding

method that is popular and easy to do.

3.6 The welding parameters

The welding parameters that are assigned in the welding curve that is shown are

selected using the push and rotate knob [7]. The setting facilities are always

selected and adjusted using the same principle.

3.6.1 Basic setting of welding parameters.

Rotate the push and rotate knob [7] to the required setting option (e.g. current

I1). The currently selected setting facility is displayed at the bottom centre of

the screen [12] and the associated value appears at the top centre of the

screen. A selected parameter is marked in orange.

Press the push and rotate knob [7] to select the setting option. The parameter

that is to be modified appears in blue text.

Rotate the push and rotate knob [7] until the required value is set.

Press the push and rotate knob [7] to confirm the setting option.

If no activity takes place for 20 seconds, the selected welding parameter is

exited automatically.

.

Functional description

22

Fig. 9: INVERTIG.PRO digital control panel

Welding parameter display

Push and rotate knob for selecting the welding parameters

The welding parameters are described in the following in the order shown in fig.

9.

3.6.2 Gas preflow time

The gas preflow time is set as described in Chapter 3.6.1.

The gas preflow time is the time in which the inert gas valve is opened after the

torch button 1 has been pressed in order to start a welding procedure, before the

arc is ignited. This causes the arc to be lit with an inert gas shielding layer, which

protects the electrode and the workpiece from burning out.

If the welding procedure is restarted during the gas post-flow time, the gas

preflow time is automatically set to 0 seconds by the processor controller. This

speeds up re-ignition, which saves time when tacking, for example.

3.6.3 Ignition energy

The ignition energy is set as described in Chapter 3.6.1.

The ignition energy can be adjusted to a value of between 10 and 100% when

igniting with high frequency or Lift Arc (infinitely variable).

Depending on the selected value for the ignition energy, the processor controller

defines a preselection for the required ignition process. This preselection can

now be adapted to the selected electrode (type, diameter), the gas type and the

respective welding task depending on the polarity by adjusting the ignition

energy.

During welding work with thin materials and small electrode diameters, less

ignition energy should be selected.

In AC welding systems "power ignition" is carried out with an ignition energy

setting of 90% or above, which makes ignition easier in harsh environments.

Functional description

23

3.6.4 Start current

The ignition energy is set as described in Chapter 3.6.1.

The starting current is the initial welding current that is set after the ignition

process. The setting is infinitely variable. Selecting a suitable starting current

makes the following possible:

Less stress on the electrode due to increasing current

Search arc during 4-step welding for moving to the start of the seam

Welding with reduced current at the beginning of the seam in the event of

edges or heat accumulation.

Fast heat introduction with values of greater than 100%. The starting current

can be set in percent or as a fixed value. The setting is made in the System

application.

3.6.5 Upslope time

The upslope time is set as described in Chapter 3.6.1.

The upslope time is the time during which the welding current undergoes a linear

increase from the starting current to the preselected current I1. During 2-step

welding the upslope time starts immediately after igniting the arc. During 4-step

welding the increase time starts after releasing the torch button 1 with the start

current flowing.

3.6.6 Welding current I1

The welding current I1 is set as described in Chapter 3.6.1.

The adjustable range for welding current I1 depends on the selected operating

mode and the machine model.

The following values can be set using the push and rotate knob [7] depending on

the selecting welding method:

INVERTIG.PRO

digital

240 DC / AC/DC

INVERTIG.PRO

digital

280 DC / AC/DC

INVERTIG.PRO

digital

350 DC / AC/DC

INVERTIG.PRO

digital

450 DC / AC/DC

TIG

3 A … 240 A

3 A … 280 A

3 A … 350 A

3 A … 450 A

Functional description

24

3.6.7 Welding current I2

Welding current I2 is set as described in Chapter 3.6.1.

The use of welding current I2 is only meaningful for TIG welding, and is therefore

only displayed if TIG welding is taking place. Welding current I2 is used when

pulsing (see chapter 3.9.1) and when two-current control is being used:

Two-current control:

General method of operation:

The use of two-current control allows the user to work with 2 different preset

currents when using a 2-button torch. In other words, you can switch between the

two values I1 and I2 when welding.

The changeover to I2 takes place for as long as torch button 2 is pressed. When

torch button 2 is released, a changeover to I1 occurs immediately. This setting

can be modified in the System application, see chapter 3.14.3 (torch function,

locking I2).

Examples of changeovers:

From high current to low current or vice-versa, e.g. due to a change of

welding position

Manual pulsing (see chapter 3.6.8)

Starting with high current I1 to warm up the workpiece, then welding with

lower current I2.

Starting with lower current I1 at workpiece edges, then welding with higher

current I2.

Changing over is possible during 2-step and 4-step operation without pulsing.

The following ranges can be set in accordance with welding current I1.

INVERTIG.PRO

digital

240 DC / AC/DC

INVERTIG.PRO

digital

280 DC / AC/DC

INVERTIG.PRO

digital

350 DC / AC/DC

INVERTIG.PRO

digital

450 DC / AC/DC

TIG

3 A … 240 A

3 A … 280 A

3 A … 350 A

3 A … 450 A

Current I2 setting takes place either by activating the I2 setting facility, and/or

extremely quickly and easily by pressing torch button 2 before the welding

procedure.

3.6.8 Downslope time

The downslope time is set as described in Chapter 3.6.1.

The downslope time is the time during which the welding current is linearly

reduced to the end crater current. The downslope time starts immediately after

releasing torch button 1 during 2-step welding. During 4-step welding the

reduction time is started by pressing torch button 1. Slowly reducing the welding

current prevents end craters and the associated cracks from forming. Reduction

stops immediately as soon as the torch button is released in 4-step operation.

Functional description

25

Manual pulsing:

If torch button 1 is pressed during the downslope time with the TIG 2-step

function, the welding current immediately jumps to the value used during welding.

Depending on the point in time during the downslope time the torch button is

pressed, the energy mid-point can be selected directly and is infinitely variable.

t

t

t

Fig. 10: Manual pulsing procedure

3.6.9 End crater current

The end crater current is set as described in Chapter 3.6.1.

The end crater current is the welding current to which the system is reduced at

the end of the welding procedure. The setting can be made between 10% and

100% of the selected current I1 (infinitely variable). Example: End crater current

40% and welding current I1 100 A -> end crater current 40A). The percentage

ratio can be set to a fixed value in the System application. Selecting a suitable

end crater current makes the following possible:

Prevents notches and end crater cracks at end of seam due to the melt

cooling too quickly.

Manual pulsing (see chapter 3.6.8)

Welding with reduced current at the beginning of the seam in the event of

edges or heat accumulation.

3.6.10 Gas post-flow time

The gas post-flow time is set as described in Chapter 3.6.1.

The gas post-flow time is the period of time after the arc has been extinguished

before the inert gas valve is closed. The post-flow of inert gas protects the

workpiece and the tungsten needle from the oxygen in the air until they have

cooled. However, the preselected gas post-flow time only takes effect if welding

has taken place previously. Accidentally pressing the button will not start the gas

post-flow timer running. This gas management function reduces gas

consumption.

Gas valve

Welding current

Torch button 1

Functional description

26

3.7 Polarity multifunction button

Pressing the multifunction button [9] selects the AC current polarity (AC), the DC

current positive terminal (DC +), the DC current negative terminal (DC -) and

Dual Wave. The setting facilities are always selected and set using the same

principle, see chapter 3.4.2.

During electrode welding, it must be ensured that the upper output connector is

always the negative terminal in all INVERTIG.PRO digital DC welding systems

3.7.1 AC current (AC)

With AC current welding, the polarity at the output connectors switches

continuously between positive and negative polarity. With TIG pulsing, TIG

interval and TIG and electrode welding, the torch and the electrode holder are

normally connected to the upper output connector. The use of AC current makes

it possible to weld aluminium and aluminium alloys. Electrode welding with AC

current has the advantage that the blowing effect is avoided.

As far as AC current polarity is concerned, the balance, frequency and the sine

wave, triangle, square wave and AC-Matic curve shape can be selected on the

basis of a graphical display.

Fig. 11: INVERTIG.PRO digital / Classic application control panel

Graphical display of sine wave curve and AC balance 65%

Functional description

27

3.7.1.1 AC balance (%)

The balance is set as described in Chapter 3.4.2.

The balance setting can only be made in connection with AC current welding in

the case of TIG. It ranges from -80% to +80% and makes it possible to influence

the arc shape, penetration and cleaning when welding aluminium within an

extremely broad range. The negative and positive welding current is extremely

evenly distributed in the centre position (50%). With increasing negative values

the proportion of the negative welding current increases (up to -80%) and the

positive proportion decreases. This makes the arc narrower and generates

deeper penetration with less electrode loading. With increasing positive values

the proportion of positive welding current is increased (up to +80%) and the

negative proportion decreases. The cleaning of the melt bath is improved by the

positive proportion. The arc becomes wider and the penetration is less deep. The

use of a negative value that is as high as possible with a sufficient cleaning effect

is recommended (factory setting - 65%).

Fig. 12: INVERTIG.PRO digital / Classic application control panel

Graphical display of AC balance

Functional description

28

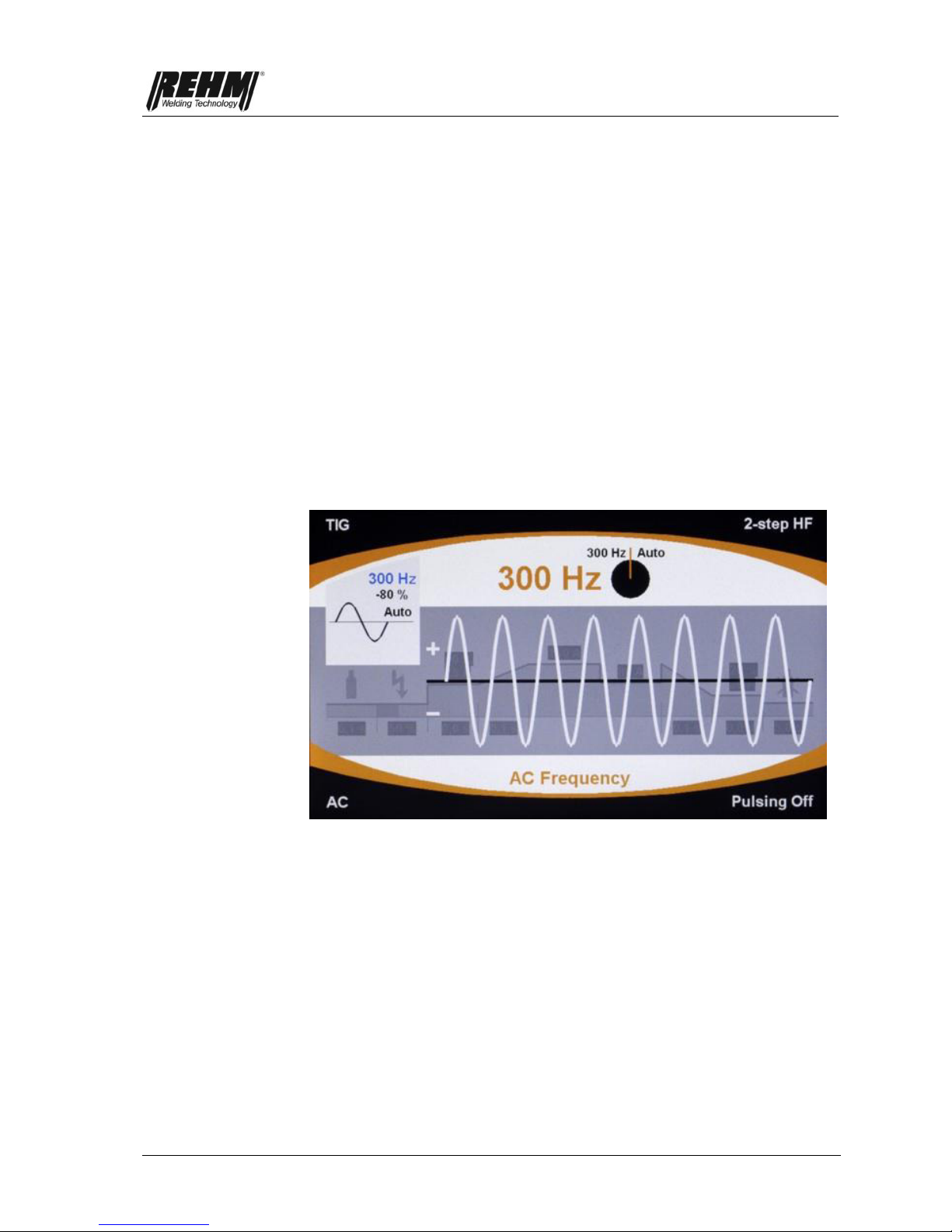

3.7.1.2 AC frequency Hz

The frequency Hz is set as described in Chapter 3.4.2.

The frequency setting can only be made in connection with AC current welding in

the case of TIG. The value for the frequency defines how frequently the output

polarity changes. The adjusting range ranges from 30 Hz to 300 Hz. For

example, at a frequency of 200 Hz the polarity change at the output connection

from plus to minus and back again takes place every 5 ms (=0.005 seconds).

The welding current is reduced to a value of zero whenever a polarity change

takes place, is re-ignited in the opposite direction and increased to the selected

welding current again. The sine wave shape that is used in this processcontrolled procedure leads to a considerable reduction in the amount of noise,

and has technical welding advantages in AC current welding.

REHM recommends setting to the automatic frequency system that has been

patented by REHM . The automatic frequency system automatically adapts the

AC frequency to the current strength. At low welding currents the AC arc is

focussed. This provides reliable root formation, e.g. in fillet welds in thin sheets of

metal. At higher currents the tungsten electrode load is reduced. A long service

life and optimum cost-effectiveness are the result. The automatic frequency

system has particular advantage when working with the iSystem P1 remote foot

controller.

Fig. 13: INVERTIG.PRO digital / Classic application control panel

Graphical display of frequency

Functional description

29

3.7.1.3 AC curve shape selection facility

Sine wave

Fig. 14: INVERTIG.PRO digital / Classic application control panel

Graphical display of sine wave curve

Triangle

Fig. 15: INVERTIG.PRO digital / Classic application control panel

Graphical display of triangle curve shape

Square wave

Fig. 16: INVERTIG.PRO digital / Classic application control panel

Graphical display of rectangle curve shape

AC-Matic

Fig. 17: INVERTIG.PRO digital / Classic application control panel

Graphical display of AC-Matic

Noise-optimised

Better penetration than

sine wave shape

Best penetration, low

electrode loading and even

better arc stability.

AC curve shape is automatically

adapted to current strength: With low

currents (< 180A) a sine wave curve

shape is automatically selected, and

higher currents (> 180A) the square

wave curve shape is used.

Functional description

30

3.7.2 DC current positive terminal

During TIG welding, TIG spot welding and TIG interval welding with DC current

positive terminal, the positive terminal is applied to the upper output connector

for the TIG torch.

During TIG welding, TIG spot welding and TIG interval welding with DC positive

terminal, the electrode is under extremely high thermal stress which can make

the electrode melt, even with small currents, and can cause damage. Welding

with DC current positive terminal is only possible using a REHM INVERTIG.PRO

digital AC/DC welding system.

During electrode welding the electrode holder is also connected to the upper

output connector. With the DC current positive terminal setting, the electrode is

welded with positive terminal. Electrode welding with DC current positive terminal

is only possible using a REHM INVERTIG.PRO digital AC/DC welding system.

With electrode welding, the polarity for the electrode is selected depending on

the type of electrode that is used (pay attention to electrode manufacturer

information).

3.7.3 DC current negative terminal

During TIG welding and TIG spot welding with DC current negative terminal, the

negative terminal is applied to the upper output connector for the TIG torch.

During TIG welding or TIG spot welding with DC current, welding usually takes

place with this setting.

During electrode welding the electrode holder is also connected to the upper

output connector. The electrode is welded with negative terminal with the DC

current negative terminal setting. During electrode welding with an

INVERTIG.PRO digital DC welding system at the positive terminal, the electrode

holder must be plugged into the lower connector, since the polarity is not

selectable. With electrode welding, the polarity for the electrode is selected

depending on the type of electrode that is used (pay attention to electrode

manufacturer information).

3.7.4 Dual Wave

The Dual Wave process from REHM is a combination of AC and DC welding.

The AC and DC times can be adjusted independently of each other The selected

values for welding current I1 and I2, the frequency and the balance are taken

into consideration in the same way as they are in DC-only or AC-only welding.

AC time DC time

Fig. 18: Individual AC and DC time settings

The Dual Wave process reduces the excess AC part in the arc to the necessary

minimum. The reduced heat introduction that this causes makes it easier to

control the welding bath and produces less pore formation, and is used in difficult

welding situations, when welding workpieces of different thickness and when

processing thin plates made from aluminium and aluminium alloys.

Functional description

31

Fig. 19: INVERTIG.PRO digital / Classic application control panel

Dual Wave time AC setting

When selecting the Dual Wave polarity, a graphical display of the selected

setting appears at the top left of the screen: The AC and DC times can also be

individually set between 0.1 and 10.0 seconds using the graphic.

Fig. 20: INVERTIG.PRO digital / Classic application control panel

Graphical display top left, AC frequency (auto), AC balance view

(65%), AC curve shape, Dual Wave AC and DC time (2.5 s and 0.5 s)

3.8 Multifunction button 2- / 4-step and high

frequency

By pressing the multifunction button [5] you can select 2-step with high

frequency, 4-step with high frequency, 2-step with Lift Arc or 4-step with Lift-Arc.

The setting options are always selected and set using the same principle, see

chapter 3.4.2.

Functional description

32

3.8.1 2-step function

2-step welding is recommended for fast, controlled tacking and manual spot

welding.

1st step: Press torch button

Solenoid valve for inert gas is opened.

The arc is ignited after the set gas pre-flow time has elapsed.

The welding current sets itself automatically to the preselected value for I1 during

the selected increase time starting with the selected start current.

2nd step: Release torch button

The current reduces with the preselected downslope time to the value set for the

end crater current, and then switches itself off automatically.

The inert gas flows in accordance with the selected gas post-flow time.

Fig. 21: Procedure for 2-step welding

Special features:

Re. 2nd step By pressing the torch button again during current reduction, the

welding current can be abruptly reset to I1. This procedure is

known as manual pulsing (see chapter 3.6.8). Pressing torch

button 2 (BT2) extinguishes the arc.

3.8.2 4-step function

Continuous button pressing is not required with 4-step welding, which means that

the torch can be guided for a longer time without fatigue.

4-step function procedure:

1st step: Press torch button

Solenoid valve for inert gas is opened.

The arc is ignited after the set gas pre-flow time has elapsed.

The welding current has the value set for the starting current.

2nd step: Release torch button

The welding current automatically sets itself to the pre-selected value for I1

during the preselected upslope time.

Gas valve

Welding current

Torch button 1

t

t

t

Functional description

33

3rd step: Press torch button

The current reduces with the preselected downslope time to the value set for the

end crater current.

The welding current flows with the value set for the end crater.

4th step: Release torch button

The arc is extinguished.

The inert gas flows in accordance with the selected gas post-flow time.

Fig. 22: Procedure for 4-step welding

Special features:

re. 2nd step Pressing the torch button again during the upslope time causes the

arc to be extinguished and the inert gas flows in accordance with

the selected gas post-flow time.

re. 3rd step The arc can be switched off during the downslope time. Releasing

the torch button before reaching the end crater current causes the

arc to be extinguished and the inert gas flows in accordance with

the selected gas post-flow time.

3.8.3 Welding with high frequency (HF)

The REHM TIG welding systems are equipped with HF ignition devices as

standard. In the "Electrode" setting, HF ignition is automatically switched off.

The HF ignition device makes contact-free ignition of the arc possible between

the electrode and the workpiece by pre-ionising the air gap during DC and DC

current welding, whereby tungsten inclusions and therefore welding errors are

prevented. In both cases the HF ignition device is switched off again after ignition

has taken place. The re-ignition of the arc that is described in chapter 3.7.1 takes

place without using the HF ignition device. This reduces the radiation of electrical

interference fields and even makes it possible to carry out AC current welding

without HF ignition, as is already known from DC current welding (see chapter

3.8.4).

With the high frequency setting the HF ignition device is ready for operation. In

order to ignite the arc, the electrode is held about 3-5 mm above the workpiece.

When the torch button is pressed, the gap is ionised by a high-voltage pulse and

the arc is created. The contactless ignition prevents tungsten inclusions in the

weld seam. During welding, the HF ignition device is automatically switched off

again after ignition has taken place.

Torch button 1

Gas valve

Welding current

t

t

t

Functional description

34

3.8.4 Welding with Lift-Arc

When welding with DC or AC current, contact ignition (Lift-Arc) can be carried

out. The high frequency is switched off when doing this. In order to ignite the arc,

the electrode is applied and the torch button is pressed. When the electrode is

raised, the arc ignites under program control and without wearing the sharpened

electrode. This facility may be advantageous when working on sensitive

electronic devices (e.g. in hospitals, when carrying out repair welding on CNCcontrolled machinery), if there is a risk of interference from high-voltage pulses.

3.9 Pulsing multifunction button

The multifunction button [6] is pressed to select time pulsing, hyper pulsing® and

no pulsing (pulsing off). The setting options are always selected and set using

the same principle, see chapter 3.4.2.

3.9.1 I1 pulsing time t1

The I1 pulse time t1 is set as described in Chapter 3.4.2. TIG welding, TIG spot

welding and TIG interval welding with pulse function can basically be divided into

two areas:

1. Time pulsing with pulse times between 0.1 and 5.0 seconds

2. Hyper-pulse with pulse frequencies between 10 Hz and 15 kHz

During TIG pulse welding, automatic switching between currents I1 and I2 takes

place continuously. When doing this you have free choice of which current is the

bigger high current and which is the smaller low current.

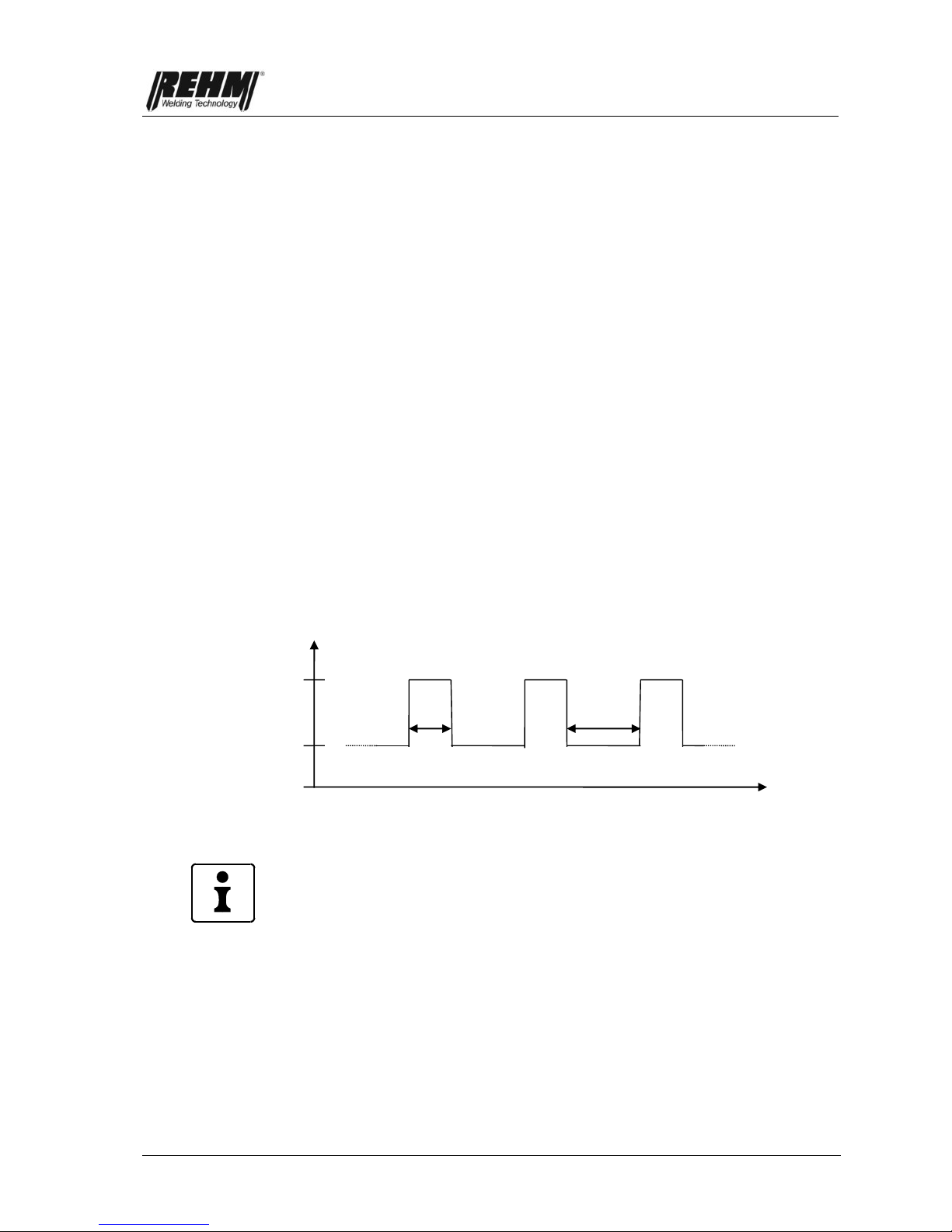

Fig. 23: Welding current when pulsing

Pulsing can be switched off and on again during welding by pressing torch button

2. If torch button 2 is pressed with a pulsing welding current, pulsing is switched

off and welding continues with welding current I2. Welding can continue with

welding current I2 until a new filler is taken, for example, and welding is

continued with a pulsing welding current by pressing torch button 2 again.

Time pulsing: Pulsing with pulse times of 0.1 to 5.0 seconds

The settings for I1 pulsing time t1 and I2 pulsing time t2 determine the length of

time for which currents I1 and I2 should be active until switching over to the other

current. Both pulse times can be set independently of each other

The times and the welding current levels should be coordinated in such a way

that the base material is melted during the high current phase and solidifies again

during the low current phase. Because of TIG pulse welding, the weld pool is

easier to control in difficult situations (particularly in dilemmas and with large

gaps to bridge) and when welding thin sheets of metal than with a constant

welding current.

Current I1

Current I2

I1 pulse time t1

I2 pulse time t2

Time

0

Functional description

35

Hyperpulse: with pulse frequencies of 10 Hz to 15 kHz

The course of the welding current corresponds to conventional pulsing. However,

the periods of time for which currents I1 and I2 respectively are active are always

the same. Since these time periods are extremely short, it is meaningful and

normal to refer to them as pulse frequencies.

The following relationships apply for converting the pulse frequency into the

respective pulse times t1 and t2:

Total pulse time = I1 pulse time t1 + I2 pulse time t2 = 1 / pulse frequency

I1 pulse time t1 = I2 pulse time t2 = 0.5 * total pulse time

Example:

Pulse frequency = 50 Hz

Total pulse time = I1 pulse time t1 + I2 pulse time t2 = 1 / 50 Hz = 20 ms = 0.02 s

I1 pulse time t1 = 0.5 * total pulse time = 0.01s

I2 pulse time t2 = 0.5 * total pulse time = 0.01s

This means that the current has the value of current I1 for 0.01 s (=10 ms) during

welding, then the value of current I2 for 0.01 s (=10 ms), then the value of current

I2 again for 0.01 s (=10 ms) etc.

Pulsing with such short times results in a narrower and more concentrated arc

and deeper penetration.

3.9.2 I2 pulse time t2

The settings are made in accordance with I1 pulse time t1 (see chapter 3.9.1).

3.10 Electrode welding parameters

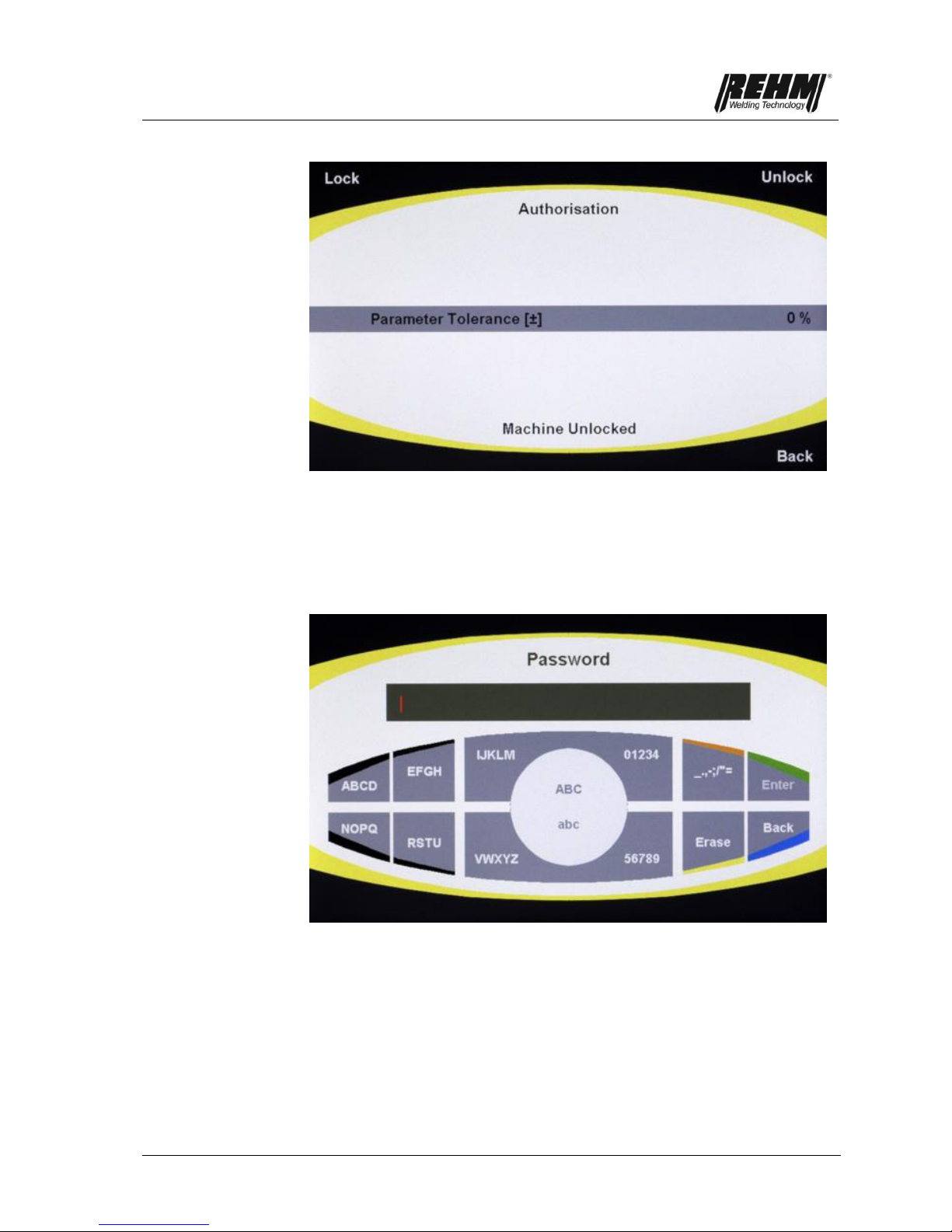

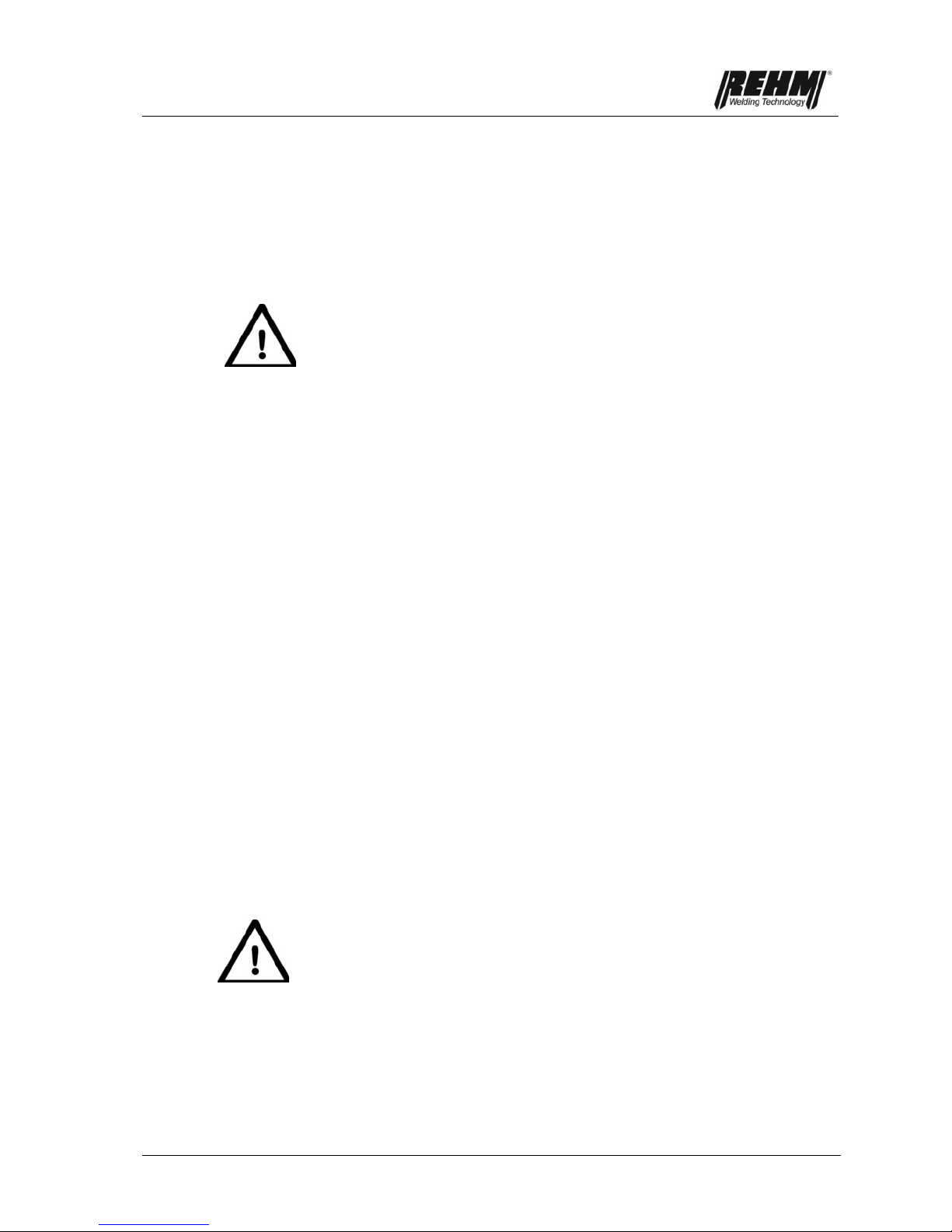

The electrode welding procedure is selected using the multifunction button [8].

The setting of electrode welding parameter welding current I1, Arc Force, Hot

Start and Hot Start Time is carried out as described in Chapter 3.4.2.

When making the settings for electrode welding, please ensure that no TIG torch

is connected. Failure to do this will result in error number "E021" being displayed

on the screen (see Chapter 7.3).

3.10.1 Welding current I1 during electrode welding

Welding current I1 can be set using the push and rotate knob [7] (infinitely

variable).

The Dual Wave procedure enables better control of the welding bath and,

particularly in difficult welding positions, when welding work pieces of differing

thicknesses, and is used for processing thin sheet like aluminium and aluminium

alloys.

Functional description

36

INVERTIG.PRO

digital

240 DC / AC/DC

INVERTIG.PRO

digital

280 DC / AC/DC

INVERTIG.PRO

digital

350 DC / AC/DC

INVERTIG.PRO

digital

450 DC / AC/DC

Electrode

3 A … 240 A

3 A … 280 A

3 A … 350 A

3 A … 450 A

3.10.2 Arc Force

In order to have a stable arc during electrode welding, it is important to make the

drip-shaped material transitions easier by adding extremely short current pulses

to the selected welding current I1. The magnitude of these current pulses is

determined by the Arc Force that is selected. The Arc Force can be set to a value

between 0% and 300% (infinitely variable) using the push and rotate knob [7]

with the Rutil and Basic electrode type selected, and between 100% and 300% of

the selected current I1 with cellulose electrode type selected (but a maximum of

Imax, e.g.: Arc Force 50% and welding current I1=100A -> ArcForce 150A)

3.10.3 Hot Start

For better ignition of the electrode during electrode welding, a higher current than

the selected welding current I1 is briefly used at the start of welding. The

magnitude thereof is determined by the Hotstart setting. The setting can be made

between 0% and 200% of the selected current I1 (infinitely variable) using the

push and rotate knob [7] (but max. Imax, e.g.: Hotstart 30% and welding current

I1=100A -> Hotstart 130A). The Hotstart time can be set to between 0.1 and 10

sec. (infinitely variable).

3.10.4 Anti-Stick Function

If a permanent short circuit occurs during electrode welding, the anti-stick

function is activated after about 0.3 sec., which limits the current to approx. 20 A.

This prevents the electrode from wearing out and the permanent short circuit can

be easily remedied by stripping.

3.11 Quick setting P1 and P2 (Quick Choice buttons)

Pushbuttons P1 [10] and P2 [11] allow the user to load and save two programs

quickly.

In order to load program 1 or program 2, briefly press the multifunction button P1

or P2.

To save the machine settings that have been made, press and hold down

pushbutton P1 [10] or P2 [11] for approx. 2 seconds in the Classic application.

When the program has been saved, P1 or P2 appears at the top right of the

screen.

Program P1 or P2 can also be called up using Up/Down torch (see Chapter

3.14).

3.12 Programs application (Progr.)

The Programs application (Progr.) allows up to 1000 programs to be loaded,

saved and managed in up to 100 folders. The programs can be saved and

Functional description

37

loaded under a freely selectable name (e.g. name of an employee, customer

and/or material) in a freely selectable folder. The values for all setting options

provided by the machine are saved and loaded for each program.

This means that device settings that have been determined for repeated welding

tasks can be set again on the welding device within seconds. This saves time

and provides consistent quality.

Also, the individual basic settings of the welding device such as start and end

crater current, ignition energy etc. can be saved and quickly retrieved again for

each person if the equipment is being used by several persons.

As a special feature, the INVERTIG.PRO digital welding system provides quick

loading and saving of 2 programs, P1 [10] and P2 [11], see chapter 3.11. In the

Progr. application [2] P1 and P2 can be selected, but the saved settings cannot

be modified or deleted.

The green border colour indicates that you are in the Programs application.

Fig. 24: INVERTIG.PRO digital / Programs application (Progr.) control panel

Functional description

38

3.12.1 Managing folders

Creating a new folder

If you press the Progr. application button [2] you will be taken to the Programs

application (Progr.)

Rotate the push and rotate knob [7] to "New Folder"

Pushing the push and rotate knob [7] allocates a default name for this folder.

Fig. 25: INVERTIG.PRO digital / Programs application (Progr.) control panel

New folder

Managing existing folders

If you press the Progr. application button [2] you will be taken to the Programs

application (Progr.)

Rotate the push and rotate knob [7] to the required folder

Press the multifunction button [9] to edit the folder. The following options are

available: Name, Rename, Delete, Move.

Fig. 26: INVERTIG.PRO digital / Programs application (Progr.) control panel

Managing existing folders

Functional description

39

3.12.2 Main management settings

Pressing the "Progr." application button [2] takes you to the Programs

application (Progr.)

Pressing the multifunction button [9] takes you to the Management menu.

Rotate the push and rotate knob [7] to the required action (e.g. Name,

Rename, Delete, Move, Copy).

Press the push and rotate knob [7] to select the action.

If no activity takes place for 20 seconds, the selected menu is exited

automatically.

Fig. 27: INVERTIG.PRO digital / Programs application (Progr.) control panel

Management selection: Name, Rename, Delete, Move, Copy.

3.12.2.1 Management: Name / Text Entry

The setting options are always selected and set using the same principle, see

chapter 3.12.2.

The letters, numbers and symbols are arranged on the screen in the same

way as they are on the control panel (see fig. 28). The letters, numbers and

symbols are selected by pressing the application and multifunction buttons on

the control panel.

The required letter, number or symbol is selected by pressing the respective

application or multifunction button several times.

Upper and lower case can be selected by pressing the push and rotate knob

[7].

Characters that have been selected by mistake can be deleted again by

pressing the application button [3].

Once the required name has been entered, saving takes place by pressing

the application button [2]. The name has been saved.

The "Name" menu can be exited again without saving by pressing the

application key [4].

Functional description

40

Fig. 28: INVERTIG.PRO digital / Programs application (Progr.) control panel

Text entry

3.12.2.2 Management: Rename

See Management: Name procedure in Chapter 3.12.2.1

3.12.2.3 Management: Move

The setting options are always selected and set using the same principle, see

chapter 3.12.2.

Rotate the push and rotate knob [7] to the folder to be moved in order to move

the selected folder or program to the required location. "Move" appears in

green text at the left-hand edge of the screen next to the folder or program to

be moved.

Press the push and rotate knob [7] to confirm.

Rotate the push and rotate knob to the new position for the folder.

Press the push and rotate knob [7] to confirm.

Functional description

41

Fig. 29: INVERTIG.PRO digital / Programs application (Progr.) control panel

"Move" appears in green text next to the folder/program.

3.12.2.4 Management: copy

Select program to be copied using the push and rotate knob [7]. The selected

program can be displayed by pressing the push and rotate knob [7]. Display

mode is exited by pressing the push and rotate knob again.

The setting options are always selected and set using the same principle, see

chapter 3.12.2.

Rotate the push and rotate knob [7] to select the position to which the

program is to be copied. "Copy" appears in green text at the left-hand edge of

the screen next to the program to be copied.

Press the push and rotate knob [7] to confirm. The copied program is saved

under the next free program number.

Fig.30: INVERTIG.PRO digital / Programs application (Progr.) control panel

"Copy" appears in green text next to the folder/program.

Functional description

42

3.12.2.5 Management: Delete

Select folder or program to be deleted using the push and rotate knob [7].

Pressing the multifunction button [9] takes you to the Management menu.

Rotate the push and rotate knob [7] to the required action, Delete.

Press the push and rotate knob [7] to select the action.

Rotate the push and rotate knob [7] to Delete "Yes" or "No".

Press the push and rotate knob [7] to confirm the selection.

Fig. 31: INVERTIG.PRO digital / Programs application (Progr.) control panel

Delete view? Yes/No

3.12.3 Loading programs

Rotate the push and rotate knob to select the required program.

The parameters of the program can be displayed on the Classic display by

pressing the push and rotate knob. No values can be modified in this view.

Pressing the push and rotate knob again takes you back to the overview.

Press the Load multifunction button [8]. The program is loaded.

The loaded program has a grey background. The program number appears in

green text on the left-hand edge of the display, next to the loaded programs.

Functional description

43

Fig. 32: INVERTIG.PRO digital / Programs application (Progr.) control panel

The loaded program has a grey background

Press the Classic application button [1]. The loaded program is displayed. The

program number appears in green text at the top right of the screen [12].

Fig. 33: INVERTIG.PRO digital / Classic application control panel

The loaded program number appears in green text at the top right.

3.12.4 Saving programs

Make the required machine settings (welding parameters) in the Classic

application [1].

Press the Progr. application button 2.

Select the required folder using the push and rotate knob [2].

Pressing the push and rotate knob [7] will cause the contents of the folder to

be displayed.

Functional description

44

Use the push and rotate knob [7] to select the required program in which the

new program will be saved. It is possible to overwrite an existing program or

create a new one.

Press Save multifunction button [5]. The program has been saved.

A new program is stored under the next free program number.

If an existing program is being overwritten, you must reply with "Yes" or "No"

to the question "Overwrite?" after pressing the multifunction button [5].

Fig. 34: INVERTIG.PRO digital / Programs application (Progr.) control panel

Overwrite? Yes/No

Functional description

45

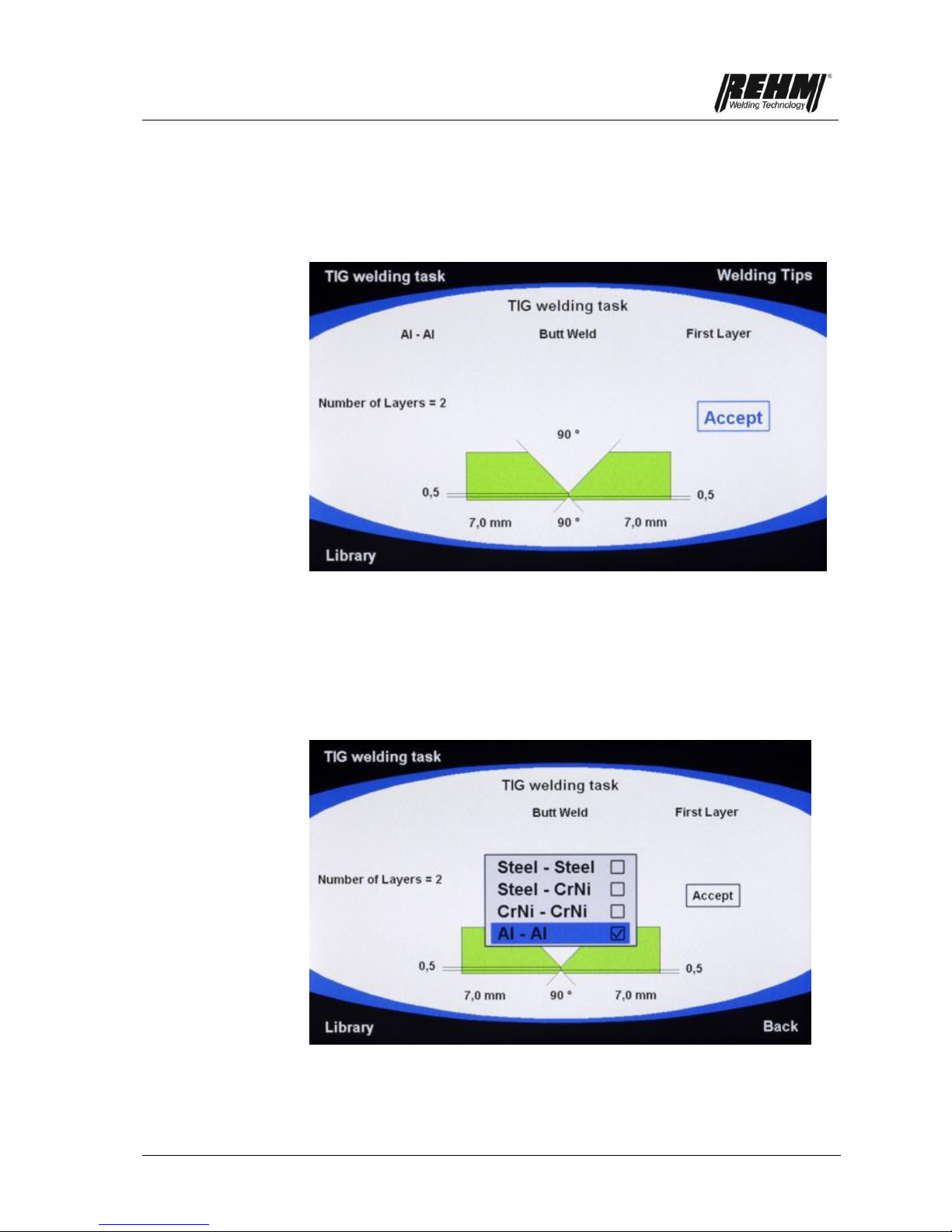

3.13 Assist Application

Pressing the Assist application button [3] takes you to the Assist application. The

Assist application [3] allows you to enter a welding task in order to obtain

suggestions for the optimum parameters for the welding task. The following

values / data can be entered.

Fig. 35: INVERTIG.PRO digital / Assist Application control panel

Data / value entry selection option

Select materials

Select weld type (butt weld / fillet weld)

Select material thickness for both components to be joined

Layer selection, first or other layers

The material thickness of the materials to be joined can be set using a graphic.

The blue border colour indicates that you are in the Assist application.

Fig. 36: INVERTIG.PRO digital / Assist application control panel

Material selection

Functional description

46

3.13.1 Setting the welding task

Rotate the push and rotate knob [7] to the specified points

You are taken to the selection by pressing the push and rotate knob [7].

Rotate the push and rotate knob [7] to the required setting.

Press the push and rotate knob [7] to confirm the setting.

Press the push and rotate knob [7] again to leave the point.

The material thickness can be set on the displayed graphic using the push and

rotate knob [7]. Note: If the material thicknesses differ considerably, the Assist

application does not calculate a suggestion. "D1-D2 too great!" appears on the

TFT display.

After entering all of the required data, select the "Accept" field using the push

and rotate knob [7]. The welding parameters are then accepted.

Press the push and rotate knob [7] to accept the data.

The colour of the "Accept" text will be red whilst the data is being loaded.

Fig. 37: INVERTIG.PRO digital / Assist application control panel

Accept loading procedure

When loading is complete, "Accepted" is displayed black. Note: The device is

now ready for welding. There is no need to switch to the Classic application.

Functional description

47

Fig. 38: INVERTIG.PRO digital / Assist application control panel

Welding task accepted

If you press the Classic application button [1], the optimum parameters for the

welding task will be displayed on the Classic screen. "Assist" appears in blue

text at the top right of the screen [12].

Fig. 39: INVERTIG.PRO digital / Classic application control panel

Display optimum welding parameters for welding task

3.13.2 Welding tip

The welding tip is called up by pressing the multifunction button [5]. As well as

the parameters, additional practical information for the welding task is suggested

in the welding tip such as the gas nozzle size, the preheating temperature, the

electrode type etc.

The information in the welding tip cannot be modified or overwritten.

The welding tip cannot be called up until the entered Assist values for the

welding task have been determined.

Functional description

48

Fig. 40: INVERTIG.PRO digital / Assist application welding tip

3.13.3 Library

The library is called up by pressing the multifunction button [9]. The library is a

comprehensive technical database to do with welding, and provides information

about gas, fillers, electrodes, types of seam and welding position.

Fig. 41: INVERTIG.PRO digital / Assist application control panel

Library view

Fig. 42: INVERTIG.PRO digital / Assist application control panel

Library view WIG electrodes and welding position

Functional description

49

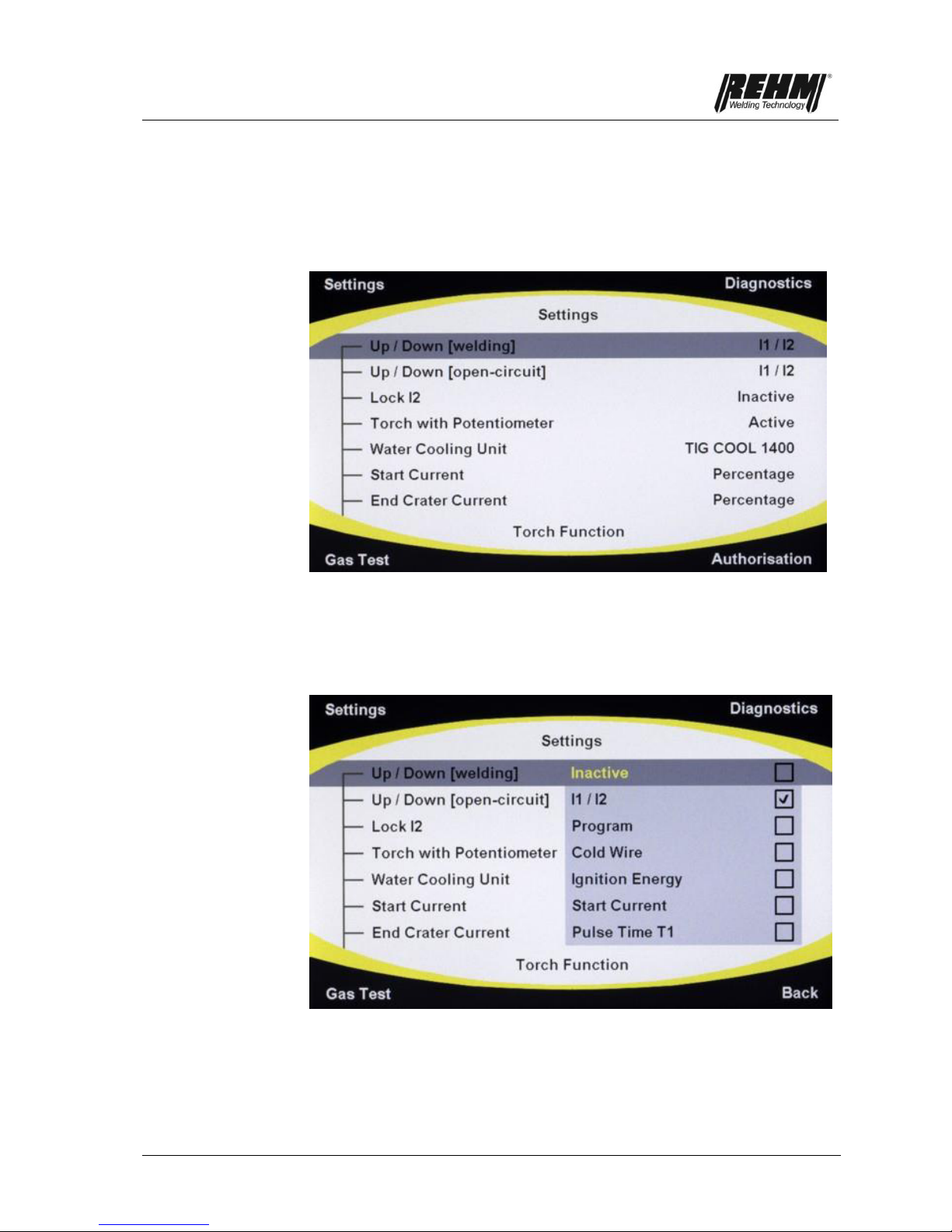

3.14 System application button

Pressing the application button [4] takes you to the System application. System is

the application with which functions and procedures can be defined in an

extremely convenient and clear way.

The yellow border colour indicates that you are in the System application.

Fig. 43: INVERTIG.PRO digital / Assist application control panel

Settings view

3.14.1 System overview

Pull-down menus provide clarity and allow you to make quick changes.

Fig. 44: Overview of System application and pull-down menu

Functional description

50

3.14.2 Basic selection of machine settings

Rotate the push and rotate knob [7] to the required setting.

Press the push and rotate knob [7] to display the selection of the setting to be

modified.

Rotate the push and rotate knob [7] to the required point.

Press the push and rotate knob [7] to confirm the selection.

The settings in the System application are described in the following.

3.14.3 Explanation of system settings

Torch Up/Down welding function

This setting is provided for the use of an Up/Down torch The following settings

can therefore be made for the Up/Down torch for welding operation.

Inactive

→ Up-/Down torch is inactive, i.e. Up-Down function not present

I1/I2

→ Welding current I1 or I2 can be modified for the Up/Down torch. The I1/I2

relationship is maintained when pulsing.

Program

→ With the Up/Down torch, all programs can be called up within a program

sequence.

Other setting options:

Cold wire, only when using the REHM APUS series cold wire device (start

and end of wire feed is carried out using the Up button; cold wire retraction is

carried out using the Down button), ignition energy, start current, pulse time

t1, Pulse time t2, pulse frequency, end crater current, AC balance, AC

frequency, current I1, Current I2, gas pre-flow time, start current time, upslope

time, downslope time, end crater current time, gas post-flow time, AC time,

DC time, pulse type, AC curve type, spot welding time, interval time

Torch idling Up/Down function

The Up/Down function of the torch can be set in the following ways during

standby operation, i.e. not during welding operation.

Inactive. I1/I2, cold wire (start and end of wire positioning in 2nd step), ignition

energy, start current, pulse time t1, Pulse time t2, pulse frequency, end crater

current, AC balance, AC frequency, current I1, Current I2, gas pre-flow time,

start current time, upslope time, downslope time, end crater current time, gas

post-flow time, ignition, operating mode, polarity, AC time, DC time, pulse

type, AC curve type, spot welding type, welding procedure, interval time

Torch I2 locking function

Inactive

→ I2 locking is inactive, i.e. I2 is only active for as long as torch button 2 is

pressed.

Active

→ I2 locking is active, i.e. the changeover from I1 to I2 during welding takes

place in such a way that pressing torch button 2 provides a constant

changeover to the other current. Pressing torch button 2 again switches

back to I1.

Functional description

51

Torch poti-torch function

This setting is intended for the use of a torch with a potentiometer.

Inactive

→ Torch potentiometer is inactive, i.e. the potentiometer at the torch is not

evaluated

Active

→ Torch potentiometer is active, i.e. the value set at the potentiometer is

evaluated

Water cooling device

TIG COOL 1400

→ Welding with a water-cooled torch is possible without a water cooling

device being detected by the welding system, e.g.: TIG -COOL CART

1400, or other water cooling device without a communication interface.

TIG COOL 2000

→ Welding with water-cooled torch is only allowed if the wending system

detects the use of a functioning water cooling device, e.g. TIG-COOL

CART 2000. Otherwise an error message occurs, which prevents

damage to the welding torch if no water cooling device is present.

Classic application start current

Percentage or absolute

→ Start current is set percentage-wise to I1 or can be set to an absolute

value

Classic application end crater current

Percentage or absolute

→ End crater current is set percentage-wise to I1 or can be set to an

absolute value

Classic E-manual polarity function

Manual or auto (automatic changeover of torch connector polarity –

depending on the selected electrode type): Note: The Auto function can only