BARRACUDA RTC 60 / 100 / 150

OPERATING INSTRUCTIONS

Plasma arc cutting

GB

Product Identification

Product Identification

Plasma cutting equipment

BARRACUDA RTC 60

BARRACUDA RTC 100

BARRACUDA RTC 150

Rehm GmbH u. Co. KG

Ottostr. 2

73066 Uhingen, Germany

Telephone: +49 (0)7161/3007-0

Fax: +49 (0)7161/3007-20

e-mail: rehm@rehm-online.de

Internet: http://www.rehm-online.de

Doc. no.: 730 1200

Issue date: 06/2013

Rehm GmbH u. Co. KG, Uhingen, Germany 2005

The content of this specification is the sole property of the Rehm GmbH u. Co.

KG company.

Dissemination and/or duplication of this document and use and/or communication

of its content are forbidden except where expressly permitted.

Compensation shall be payable in the event of contraventions. All rights reserved

in the event of registration of a patent, utility model or design.

Manufacture using this documentation is not permitted.

We reserve the right to alter the specification without notice.

Designation

Type

Manufacturer

Table of Contents

3

Table of Contents

Product Identification 2

1 Introduction 5

1.1 Foreword 5

1.2 General Description 7

1.2.1 Performance features of BARRACUDA cutting equipment 8

1.2.2 Principle of plasma arc cutting 8

1.2.3 Area of application of plasma cutting equipment 9

1.2.4 Function principle of REHM BARRACUDA cutting equipment 9

1.2.5 Proper use 9

1.3 Symbols used 10

2. Safety Instructions 11

2.1 Safety symbols in these operating instructions 11

2.2 Warning symbols on the equipment 11

2.3 General 12

3 Description of Function 13

3.1 Preparations for cutting 13

3.1.1 Mains connection and power-up 13

3.1.2 Adjustment of compressed air – gas test 13

3.1.3 Operating modes 13

3.1.3.1 2-step operating mode 13

3.1.3.2 4-step operating mode 13

3.1.4 Choosing the cutting current 13

3.1.5 Nozzle selection 14

3.2 Cutting operation 14

3.2.1 General description 14

3.2.2 The REHM control panel 15

3.2.3 Symbols and their meanings 16

3.2.4 Operating modes 17

3.2.4.1 2-step function sequence 17

3.2.4.2 4-step function sequence 17

3.3 Possible applications 18

3.3.1 Cutting of perforated sheets 18

3.3.2 Hole-piercing 18

3.3.3 Gouging 18

3.3.4 Weld preparation 18

3.3.5 Circle cutting 18

3.4 Machine Functions 19

3.4.1 Gas pre-flow 19

3.4.2 Soft start 19

3.4.3 Quick start 19

3.4.4 Safety shut-down 19

3.4.5 Post-purge gas flow time 19

3.4.6 Safety contact in plasma torch 19

3.4.7 Detection of phase failure 19

4 Accessories 20

4.1 Standard Accessories 20

4.2 Options 20

4.2.1 80A torch for RTC 100 and RTC 150 20

4.2.2 Automatic torch 20

4.2.3 Torch accessories 20

4.2.4 Air filter attachment 20

4.2.5 Mechanised interlock 20

4.2.6 Special voltages 21

Table of Contents

4

4.3 Torches and accessories 21

4.3.1 RTC 60 machine configuration 21

4.3.1.1 Standard accessories for RTC 60 21

4.3.1.2 Plasma torches A80 and P80 Aut 22

4.3.2 Machine configuration RTC 100 / RTC 150 23

4.3.2.1 Standard accessories RTC 100 / RTC 150 23

4.3.2.2 Plasma torches R145 and R145P 23

4.3.2.3 Accessories for torch R145 25

4.3.3 Circle cutting equipment and magnet clamps 26

5 Commissioning 27

5.1 Safety instructions 27

5.2 Working under increased electrical danger in accordance with the provisions

of IEC 974, EN 60974-1 and VBG 15 (S) 27

5.3 Transport and set-up of the plasma cutting equipment 27

5.4 Connection of the plasma cutting equipment 28

5.5 Cooling of the plasma cutting equipment 28

5.6 Compressed air supply 28

5.7 Guidelines for working with cutting current sources 28

5.8 Connection of workpiece return cables/torch 29

5.9 Recommended cross-sections of welding power supply cables 29

5.10 Connection to jigs 29

6 Operation 30

6.1 Safety instructions 30

6.2 Electrical Hazards 30

6.3 Information for your personal safety 31

6.4 Fire Protection 31

6.5 Ventilation 32

6.6 Checks before switching on 32

6.7 Connection of the earthing cable 33

7 Faults 34

7.1 Safety instructions 34

7.2 Troubleshooting Table 35

8 Maintenance Work 38

8.1 Safety instructions 38

8.2 Maintenance table 38

8.3 Cleaning of equipment interior 39

8.4 Proper waste disposal 39

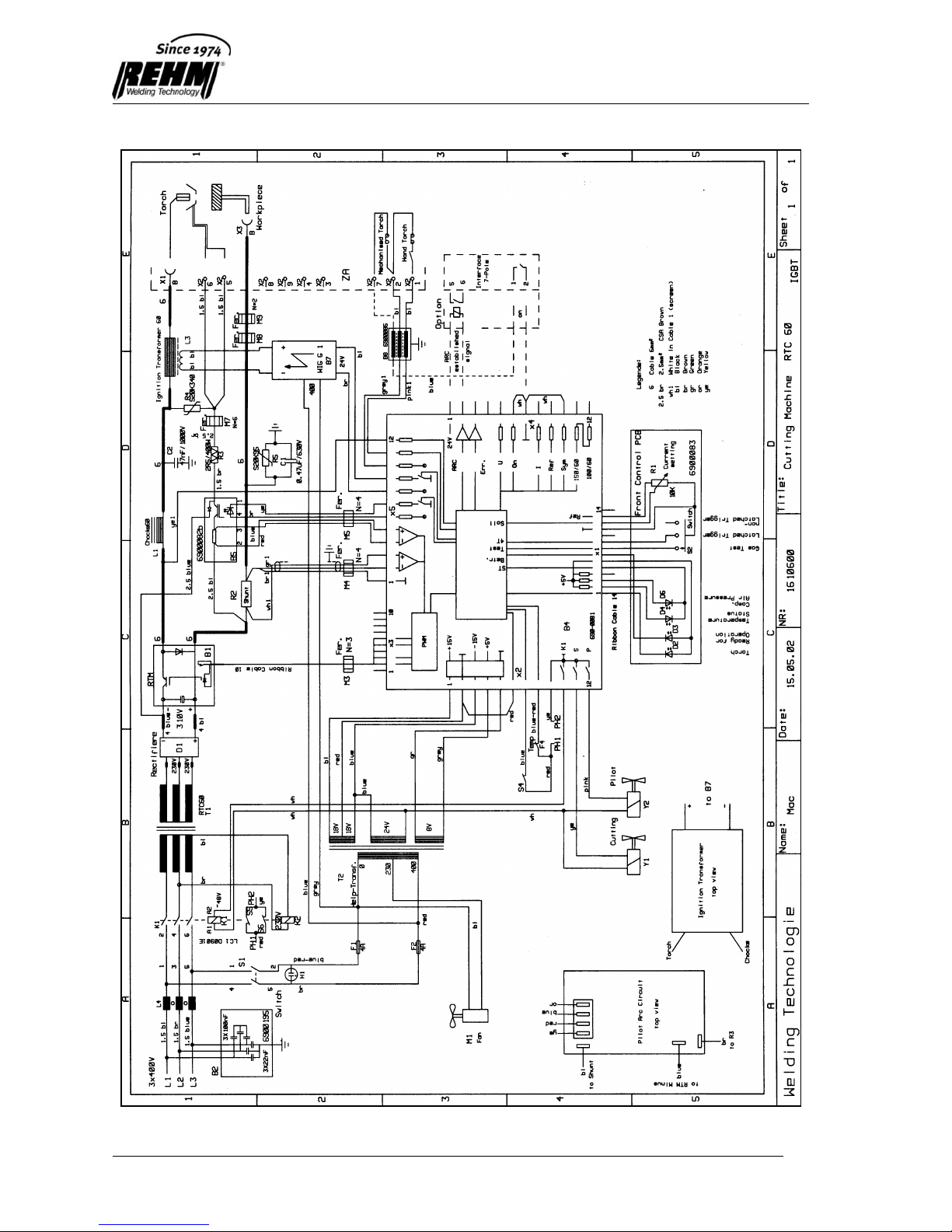

9 Circuit diagrams 40

10 List of Components 43

10.1 Sparepart list REHM RTC 43

11 Mechanised interlocks 48

11.1 RTC units with 7-pin interface (only for RTC 100 and RTC 150) 48

11.2 RTC units with 17-pin interface (only for RTC 100 and RTC 150) 48

11.3 Connection schematic for 7-Pole mechanised cutting interface 49

11.4 Connection schematic for A-pole mechanised cutting interface 50

12 Technical Data 51

13 Index 52

Introduction

5

1 Introduction

1.1 Foreword

Dear customer,

You have purchased a REHM plasma cutting machine, a brand-name

German product. We would like to thank you for the confidence you have

placed in our high quality products.

Only components of the highest quality are used in the development and

manufacture of REHM plasma cutting equipment. In order to achieve a

long life-span even in heavy-duty use, only parts which fulfil REHM’s

stringent quality requirements are used for REHM plasma cutting

equipment. BARRACUDA plasma cutting equipment has been developed

and manufactured in accordance with generally recognised safety and

technical regulations. All the relevant legal requirements have been

observed, and the equipment is supplied with a declaration of conformity

as well as the CE symbol.

REHM plasma cutting equipment is produced in Germany and carries the

"Made in Germany" quality mark.

As REHM tries to make immediate use of technical advances, we reserve

the right to adapt and modify the design of this plasma cutting equipment

to conform with the latest technical requirements.

Introduction

6

except where expressly stated otherwise in writing by REHM, REHM plasma

cutting equipment is only intended for sale to commercial or industrial users and

only for use by such users.

BARRACUDA plasma cutting equipment should only be used

a) for the purpose intended and

b) in a safe condition

REHM plasma cutting equipment may only be operated by personnel trained and

instructed in the use and maintenance of plasma cutting equipment. Only

qualified, authorised and trained staff may work on and with the equipment.

These operating instructions contain important information on the safe, correct

and economic operation of the equipment. A copy of the instructions must be kept

at all times in an appropriate place where the equipment is being used.. Please

make sure that you read the information summarised in this operating manual

before using the equipment. You will gain important information regarding the use

of the equipment which will enable you to use the technical advantages of your

REHM equipment to the full. In addition, you will find details regarding

maintenance and upkeep, as well as operating and functional safety.

These operating instructions are no substitute for training given by REHM service

staff.

The documentation relating to any optional accessories installed must also be

noted.

No alterations to the equipment are permitted, nor are the attachment or

installation of any additional equipment. Such actions will result in cancellation of

any right to make warranty and liability claims.

Warranty rights will also be forfeited if any work is performed on the unit by third

parties or if any safety devices are deactivated.

Areas of

application

Qualifications of

operating

personnel

Purpose of the

document

Alterations to the

equipment

Introduction

7

1.2 General Description

Fig.1 BARRACUDA

Introduction

8

1.2.1 Performance features of BARRACUDA cutting

equipment

Housing in REHM design

Improved ergonomics thanks to systematic and continuing enhancement of

the REHM design. The protected and well thought-out design means that

protection class IP23 is achieved. The equipment can therefore be used for

cutting outdoors.

REHM high-performance transformers

High-performance transformer with double enamelled wire, insulation class H

(180°C).

High-quality enamelled copper wire is used for all transformers.

All transformer windings are wound in layers, with inter-layer insulation.

REHM thermal protection

All REHM equipment is protected against overheating by thermal sensors.

REHM transistor heavy-duty circuit breaker

The patented REHM transistor heavy-duty circuit breaker, proved in tens of

thousands of instances, permits fine control of the cutting current, which is

continuously adjustable. Precise control with voltage compensation means

that cutting current can be held constant for maximum cut quality. The high

duty cycle values of 60% (10 mins.) are achieved safely through use of only

high-grade service components.

REHM safety system

With the monitoring of torches and wearing parts, with active early warning

and automatic safety shutdown aimed at damage prevention, the logic control

system offers the maximum safety for man and equipment.

REHM cost-effectiveness

Because the controlled pilot current is switched off during cutting and a soft

start function is standard, service life is longer and wear and tear is reduced.

Dependable ignition using REHM Zetronik is possible both for contact and

distant cutting. The quick start function permits immediate ignition, even

during the post-purge gas flow time. The post-purge gas flow time is demandoriented. Changing a torch on the central connector is simple and quick.

Material-oriented regulation of high-speed pilot and cutting current allows

uninterrupted cutting of perforated sheets.

1.2.2 Principle of plasma arc cutting

In plasma arc cutting operations, the material is melted using a high-energy arc.

In the plasma torch, air or gas is heated to such high temperatures that an

electrically conductive plasma is produced. The plasma issues from a nozzle as a

concentrated jet at high speed and thus forms the contact between electrode and

workpiece. The high energy density of the jet melts the material to be cut and

simultaneously blows it out of the kerf.

Introduction

9

1.2.3 Area of application of plasma cutting equipment

BARRACUDA cutting machines are direct-current sources. All conductive metals

can be cut using plasma arc cutting. The maximum material thickness to be cut in

each case depends on the arc power of the current source, the type of material

and the cutting speed used.

1.2.4 Function principle of REHM BARRACUDA cutting

equipment

All REHM BARRACUDA cutting equipment is continuously adjustable. This

means that it is possible for the user to quickly adapt it to the specific cutting

tasks. The cutting arc is extremely stable within broad limits thanks to internal

regulation of current. Fluctuations in the power supply are compensated in the

range between +6% and -10%.

High performance reserves guarantee the optimum material penetration and

constant cutting performance even under extreme requirements.

With REHM BARRACUDA cutting equipment both contact and distant cutting is

possible. In the case of contact cutting, however, the cutting current should not

exceed 50A.

In the development and design of this equipment, the priorities were the best

cutting characteristics, high efficiency, low wear and tear and simple operation

and handling.

All the components were tested extensively under practical conditions for heavyduty and industrial usage.

1.2.5 Proper use

REHM plasma cutting equipment is designed to cut all conductive metals. Please

note also any special regulations which may apply to your application. Please

contact your safety officer or REHM Customer Service if you have any queries.

Except where expressly stated otherwise in writing by REHM, REHM plasma

cutting equipment is only intended for sale to commercial or industrial users and

only for use by such users. It must be operated only by people who have been

trained and are qualified in the use and maintenance of plasma cutting

equipment.

Cutting current sources must not be positioned in areas where there is a

significant electrical hazard

see Chapter 5, Commissioning.

These operating instructions contain rules and guidelines for the proper use of

your equipment. Only use in accordance with these operating instructions will be

deemed to be proper use. Any risks which arise from other forms of use are the

responsibility of the operator. For special requirements, it may be necessary to

observe special additional conditions as well.

Please contact your safety officer or REHM Customer Service if you have any

queries.

Attention should be paid to the specific directions regarding proper use referred to

in the delivery documentation.

Any national regulations which are more stringent than the requirements of these

operating instructions also apply.

Introduction

10

Proper use also includes compliance with the specified conditions for installation,

dismantling, re-installation, commissioning, operation, maintenance and disposal

measures. Please heed in particular the information in the chapter on safety.

The equipment may be operated only under the above-mentioned conditions. Any

other form of use is deemed as not being proper use. The operator will be liable

for any consequences arising from improper use of the equipment.

1.3 Symbols used

Lists preceded by bullet point: general list

Lists preceded by square: working or operating steps which must be carried

out in the order listed.

Section 2.2, Warning symbols on the equipment

Cross-reference: in this case to Section 2.2, Warning symbols on the

equipment

Bold type is used for emphasis

Note:

... Indicates user tips and other particularly useful information.

For the safety symbols used in this manual,

Section 2.1.

Typographical

conventions

Safety symbols

Safety Instructions

11

2. Safety Instructions

2.1 Safety symbols in these operating instructions

You will find this symbol or one which specifies the danger more precisely

by all safety instructions in these operating instructions where there is a

risk to life and limb.

One of the following words (Danger!, Warning!, Caution!) indicates the

extent of the hazard:

Danger! ... There is an immediate danger.

If the hazard is not avoided, then death or serious injury will occur.

Warning! ... There is the possibility of a dangerous situation.

If the danger is not avoided, then death or serious injury could occur.

Caution! ... There is the possibility of a harmful situation.

If this is not avoided, light or minor injury could occur and damage could

be caused to property.

Important!

Reference to a possibly harmful situation. If it is not avoided, then the

product or something in the vicinity may be damaged.

Substances which are injurious to health and/or the environment. Materials

/ fuels which have to be handled and/or disposed of in accordance with

legislation.

2.2 Warning symbols on the equipment

indicate hazards and sources of danger on the equipment.

Danger!

Dangerous electrical voltage!

Disregarding the danger can lead to death or injury.

Warnings and

symbols

Safety Instructions

12

2.3 General

The equipment was designed and manufactured in accordance with generally

recognised technical regulations.

Nevertheless, risks of personal injury to the user or third parties or damage to the

equipment or to other material assets could arise during use.

Under no circumstances may any safety mechanisms be dismantled or taken out

of service, as this will result in exposure to danger and proper use of the

equipment is no longer guaranteed.

Dismantling of safety mechanisms during set-up, repair and maintenance is

described separately. Immediately after this work has been completed, the safety

mechanisms must be re-installed.

The operator of the equipment must ensure its safety during the use of external

agents (e.g. solvents for cleaning).

All safety and warning notices and the nameplate on the equipment must be kept

in a legible condition and must be heeded.

Safety instructions are intended to promote occupational health and safety and

prevent accidents. They must be observed.

It is important to observe not only the safety instructions listed in this chapter but

also the special safety instructions given throughout these operating instructions.

In addition to the instructions in these operating instructions, general safety and

accident prevention regulations (in Germany among others UVV VGB15 on

welding, cutting and associated processes, especially the references to arc

welding and cutting, or the appropriate national regulations) must also be

observed.

Please observe the safety notices in the operator’s workshop as well.

Dangers of

disregarding safety

instructions

Safety

instructions

Description of Function

13

3 Description of Function

3.1 Preparations for cutting

3.1.1 Mains connection and power-up

REHM cutting equipment is fitted with a Euro CEE plug for 3x400V three-phase

alternating current. The equipment is connected to the power supply voltage via

the main switch on the front side. The control lamp MAINS ON shows that the

equipment is ready for operation.

3.1.2 Adjustment of compressed air – gas test

The pressure and the flow rates for cooling and cutting air must in each case be

appropriately adjusted to the torch used. If the gas pressure is incorrectly set,

cutting quality will be reduced, wear and tear will be higher and, under extreme

conditions, the torch could be destroyed. The necessary air pressure must be

adjusted using the adjustment knob provided for this purpose on the control

panel.

To do so, turn the function selection switch to the “GAS TEST” position and pull

the blue adjustment knob upwards. Continue turning in this position until the

pressure displayed on the pressure gauge corresponds exactly to the required air

pressure. Then push the rotary knob back down to lock it. The setting is now

protected against inadvertent adjustment. After that, to begin cutting operation,

switch the function selection switch back to 2-step or 4-step operating mode.

3.1.3 Operating modes

3.1.3.1 2-step operating mode

In this operating mode, the torch button is kept pressed down throughout cutting

until cutting is terminated. Releasing the torch button terminates the cutting

operation, just as does extinguishing of the arc.

This operating mode is recommended for short, alternating cutting operations.

3.1.3.2 4-step operating mode

After ignition of the cutting arc, the torch button can be released. Reactivation and

release of the torch button terminates the cutting operation, just as does

extinguishing of the arc.

In this operating mode, it is possible to operate the torch effortlessly for extended

periods.

3.1.4 Choosing the cutting current

The current required depends essentially on the type of material to be cut and on

the material thickness Continuous adjustment of the cutting current supplied to

REHM BARRACUDA cutting equipment permits optimum adjustment to particular

cutting tasks.

If the current is set too high, this will lead to higher wear and tear of nozzle and

torch electrode. If the current is set too low, then either no material penetration

occurs or else this is too slow.

Description of Function

14

3.1.5 Nozzle selection

A plasma nozzle that is appropriate to the cutting current setting must be

selected. If the nozzle is too big, cutting performance is impeded, while too small

a nozzle will cause thermal overload and hence higher wear and tear.

To make the correct choice of nozzle, the areas of application of the various

nozzle diameters are shown on the cutting current adjustment dial.

Only replace parts with original REHM spare parts (see Chapter 4).

3.2 Cutting operation

3.2.1 General description

To achieve an optimal cutting quality, the choice of cutting current, nozzle and

cutting speed must take into account the type of material to be machined and the

thickness of the work piece.

Where light gauge sheet metal is to be cut, better cutting quality is achieved when

the torch is in contact with the material.

If thick sheets are to be cut, higher cutting performance is needed. Therefore

cutting must be performed with the torch held at a distance. The relevant spacer

elements will be found in the appendix entitled “Torches and accessories”.

In hand cutting operations, the quality of the cut and the amount of wear and

tear sustained by the torch components depends not only on the factors already

mentioned, but also on the skill of the user in handling the plasma torch.

Press torch button and move torch with pilot arc to the point at which the cut is to

start.

Following ignition of the cutting arc, draw the torch across the work piece at a

constant speed. The optimal cutting speed is achieved when the cutting jet is

facing towards the direction of cut and is inclined at approx. 10º from the kerf.

The pilot arc should not be ignited unnecessarily, as this will result in higher wear

and tear of the torch components.

With straight cuts, it is recommended using a stop rail to guide lateral movement

of the torch. To obtain even and stick-slip free movement of the torch, we

recommend using a torch carriage (see Chapter 4).

Description of Function

15

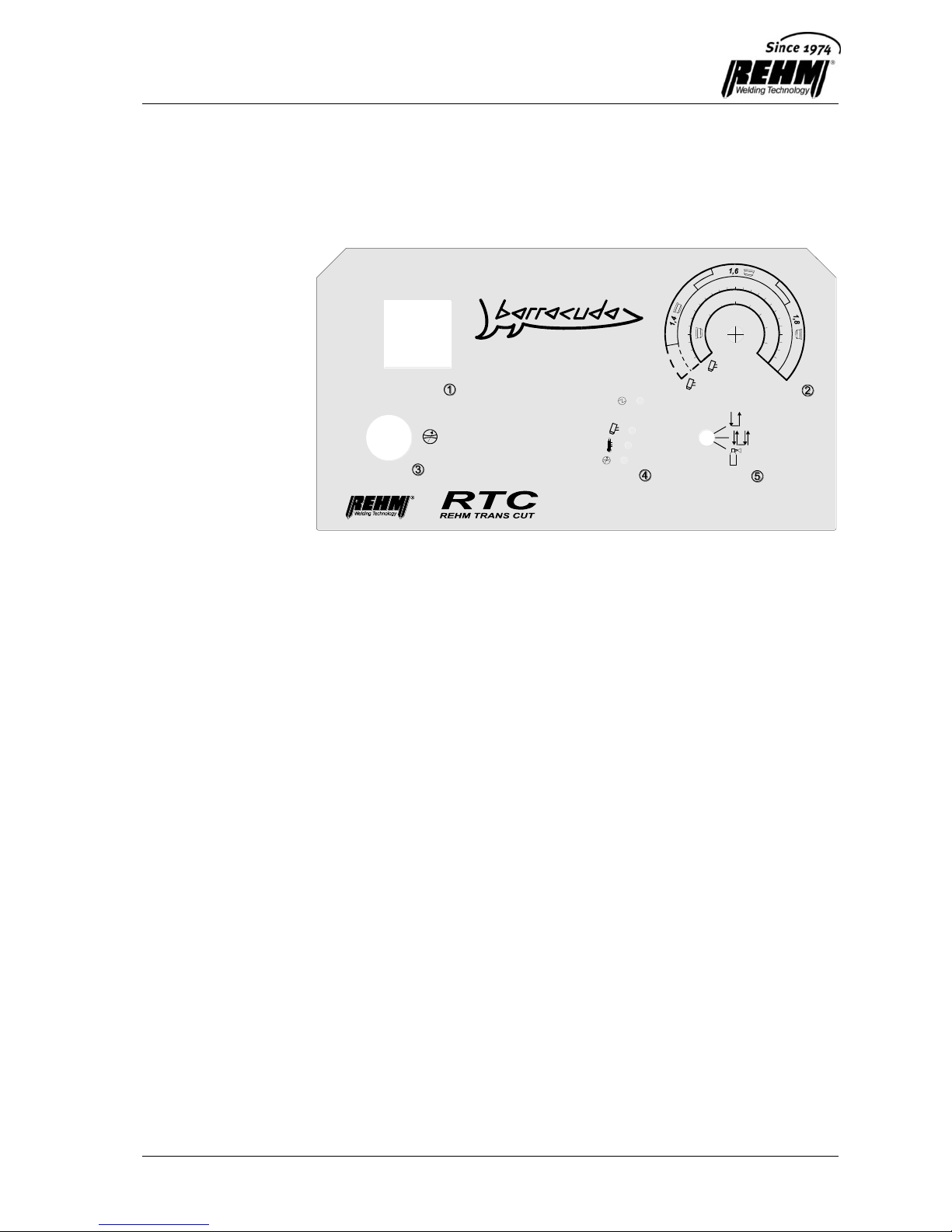

3.2.2 The REHM control panel

The plasma cutting equipment is operated using the REHM control panel shown

in Fig. 3.1.

Figure 3.1 Control panel on the BARRACUDA RTC 150 (RTC 60 and RTC 100

layouts are similar)

The control panel is divided into the following areas:

Measuring instruments for the compressed air setting

Cutting current selection knob

Rotary knob for compressed air setting

Control lamps

Function selection switch 2-step, 4-step, gas test

730 0178

1,

2

40

50

60

70

80

90

100

110

120

130

140

150

30

25

60

50

40

30

25

R145

A80

5,0-5,5 BAR ( A80 / R145 )

72,5-79,75 psi

150

Accessories

16

3.2.3 Symbols and their meanings

The symbols used on the control panel have the following meanings:

The cutting equipment is currently in 2-step cutting mode (see Section 3.2.4.1).

The cutting equipment is currently in 4-step cutting mode (see Section 3.2.4.2).

The cutting equipment is set to gas test. By pulling upwards and then turning

the blue adjustment knob, it is possible to set the required air pressure using

the pressure gauge (see Section 3.1.2).

Blue adjustment knob used to set the required air pressure. To do so, pull the

adjustment knob upwards and continue turning in this position until the

pressure displayed on the pressure gauge corresponds exactly to the required

air pressure (see Section 3.1.2).

Recommended range of adjustment on the current scale, using an electrode

diameter of 1.4 mm (the symbol is modified appropriately with other sizes).

R145

Current scale for torches R145 and R145P (see Section 4.3.2.2, “Machine

configuration”).

A80

Current scale for torch A80 (see Section 4.3.1.2, “Machine configuration”).

Control lamps

Wear and tear on the torch parts is displayed as follows:

Flashing: Early warning of increased level of wear and tear. It is

recommended that the wear parts are changed.

Continuous: Wear has exceeded permitted limits. Equipment will shut down.

The point in time at which the wear parts are changed is determined by the user.

There is a voltage at the torch. The pilot current is active, or following ignition of

the cutting arc the set cutting current is flowing.

The air pressure is no longer sufficient to supply the torch.

Equipment will shut down.

The cutting equipment has shut down due to excessive temperature. After it

has cooled down, the cutting equipment automatically reverts to operating

mode.

When heavily loaded, especially when cutting work takes place in a hot

environment, the overtemperature protection can switch off the welding current.

This is indicated by the control lamp.

Power supply voltage switch is switched on, power supply voltage is on (only

with RTC 60).

Accessories

17

3.2.4 Operating modes

3.2.4.1 2-step function sequence

Step 1 - Press torch button

Gas pre-flow time 4 seconds.

Pilot arc is ignited.

On contact with work piece, the cutting arc is ignited and the compressed air

is increased to the required throughput rate.

If contact is not made with the work piece within four seconds, the equipment

switches itself off automatically (safety shutdown).

Step 2 - Release torch button

Cutting current is interrupted, cutting voltage is switched off.

Post-purge gas flow time (demand-oriented).

If the torch button is pressed once again during the post-purge gas flow time,

no gas pre-flow will occur. Functional sequence is immediately restarted

(quick start).

3.2.4.2 4-step function sequence

Step 1 - Press torch button

Gas pre-flow time 4 seconds.

Pilot arc is ignited.

On contact with work piece, the cutting arc is ignited and the compressed air

is increased to the required throughput rate.

If contact is not made with the work piece within four seconds, the

equipment switches itself off automatically (safety shutdown).

Step 2 - Release torch button

- Prior to ignition of the cutting arc

Equipment switches to the basic setting (safety shut-down).

- After ignition of the cutting arc

Cutting operation is resumed.

If the torch is withdrawn during cutting, the arc is extinguished. This has the

effect of interrupting the cutting current and the equipment shuts down. This

function corresponds to the fourth step.

Step 3 - Press torch button

Cutting operation is resumed.

Step 4 - Release torch button

Cutting current is interrupted, cutting voltage is switched off.

Post-purge gas flow time (demand-oriented).

If the torch button is pressed once again during the post-purge gas flow time,

no gas pre-flow will occur. Functional sequence is immediately restarted

(quick start).

Accessories

18

3.3 Possible applications

3.3.1 Cutting of perforated sheets

Interrupted cuts, for example, cutting of perforated sheets, gratings etc., can only

be carried out in “2-step” operating mode. The functional sequence is identical to

the sequence involved in “2-step” mode up to beginning of the hole.

Moving towards the beginning of the hole:

Cutting current interrupted and/or cutting arc extinguished.

Compressed air is reduced.

Pilot current flowing / pilot arc active.

Moving towards the end of the hole:

W hen contact with material is resumed, the cutting arc is ignited and the

compressed air increases.

If contact is not made with the work piece within four seconds, the equipment

switches itself off automatically (safety shutdown).

3.3.2 Hole-piercing

Place torch obliquely across the work piece and ignite. Then slowly move the

torch to a vertical position until the material is penetrated.

Since during hole-piercing the molten spray can be released from the

material before the arc has penetrated the full material thickness, the

torch nozzle is particularly highly stressed due to splash back of the

material and thermal reflex reflection.

If the material is too thick, it is recommended to drill an appropriately

sized through-hole in advance so that it is possible for the material to

flow.

3.3.3 Gouging

Hold torch at an appropriate slant depending on the desired depth of penetration

and move it forwards in the direction of the molten material. This will then be

blown out of the groove as a result of the plasma pressure.

Depending on the type of seam preparation or machining desired, various

nozzles and/or torch configurations can be used for gouging (see Chapter 4).

3.3.4 Weld preparation

Move torch with appropriate nozzle (see Chapter 4) out of the vertical position

towards the side until the deviation corresponds to the desired angle of the

chamfer. Maintain position and move torch with even, adjusted speed.

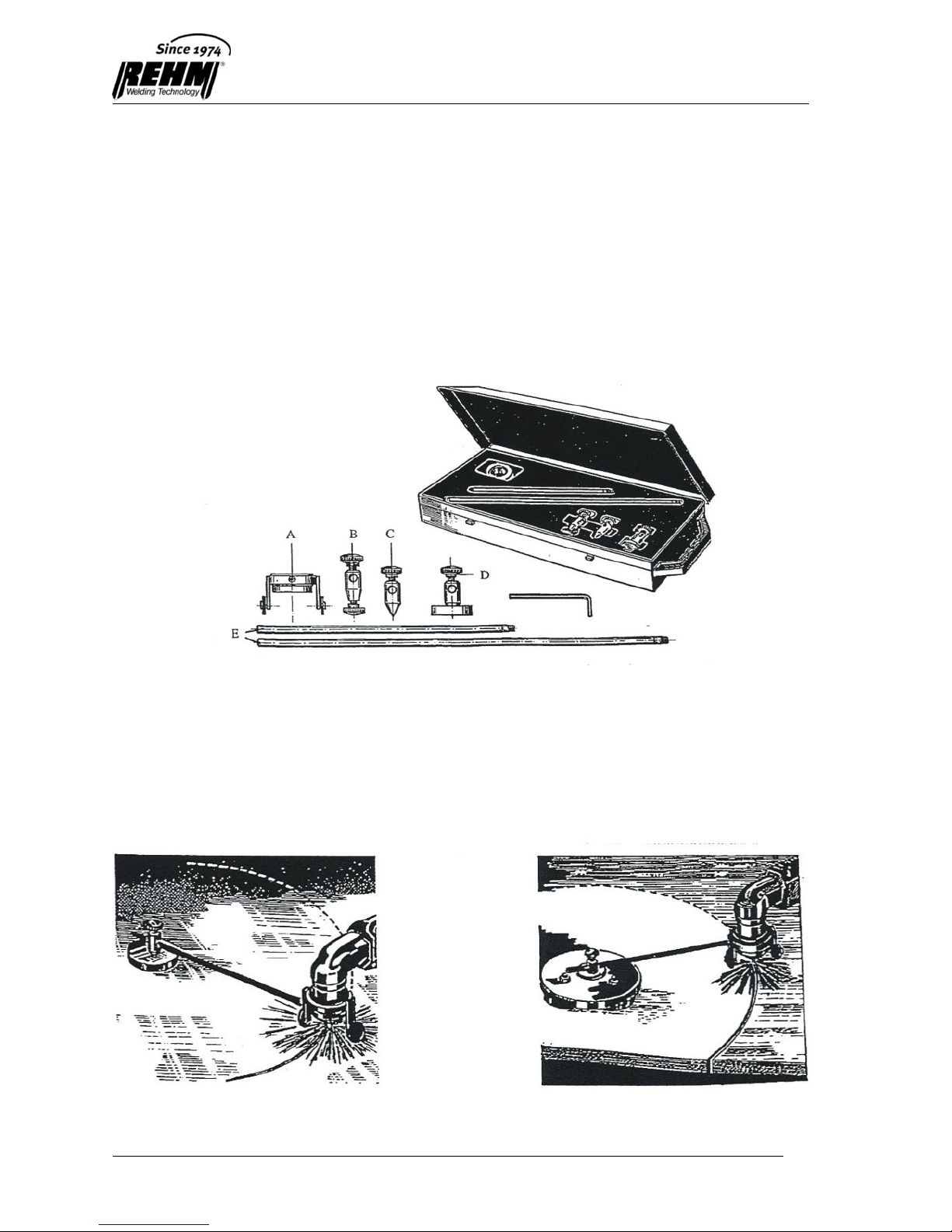

3.3.5 Circle cutting

Use of the circle cutting jig is recommended here in combination with the carriage

(see Chapter 4).

Accessories

19

3.4 Machine Functions

3.4.1 Gas pre-flow

A gas pre-flow occurs prior to the start of cutting. This avoids inadvertent ignition

of the pilot arc (safety). Moreover, it also means that the torch bundle is flushed

thoroughly and ensures even with unusually long hose bundles that the volume of

air needed for cutting is available to the torch. The predetermined time is four

seconds. This pre-flow time can be shortened using the quick start function.

3.4.2 Soft start

REHM BARRACUDA cutting equipment is equipped with a soft start function. On

ignition of the cutting arc, the cutting current is raised steadily to the pre-set value.

This increases the service life of the torch's wear parts.

3.4.3 Quick start

The gas pre-flow time can be reduced by pressing twice on the torch button. This

function makes it possible to start a work sequence rapidly. During the post-purge

gas flow time, pressing the torch button once is sufficient to interrupt the post-flow

time and immediately resume cutting operation.

3.4.4 Safety shut-down

If no cutting current arrives within four seconds when the pilot arc is on, the

equipment shuts down automatically. This avoids undue wear and tear on the

torch.

3.4.5 Post-purge gas flow time

To cool the torch sufficiently, the gas continues to flow after the end of cutting.

The post-purge gas flow time is based in a demand-oriented manner on the

cutting performance available during the cutting operation, divided into stages of

32, 64 or 96 seconds. If the torch button has been activated, but no cutting

operation occurred, the post-purge gas flow time is set to 12 seconds.

Important!

Under no circumstances should the equipment be shut down before the

post-purge gas flow time has finished, as otherwise the torch components

will not be adequately cooled.

3.4.6 Safety contact in plasma torch

All torches are fitted with a safety contact which only permits functioning to

commence if the torch is assembled in the proper manner. W hen wear parts are

changed, the contact is automatically interrupted for safety reasons so that cutting

operations cannot resume.

3.4.7 Detection of phase failure

REHM BARRACUDA cutting equipment is provided with automatic phase failure

detection. This prevents the equipment from being overloaded as a result of the

failure of one phase of the supply voltage. Depending on which phase fails, either

the green MAINS ON control lamp goes out and the equipment cannot be made

to work, or else, on ignition of the pilot arc, the power component switches off

again immediately (one can tell that this has occurred because the power

contactor pulls in and is then immediately released).

Accessories

20

4 Accessories

4.1 Standard Accessories

1 earthing cable with terminal (4m)

1 mains cable with connector (5m)

1 mono-gas plasma torch with central connector and safety switch (6m)

1 set of operating and functional instructions

1 set of wear parts (see appendix, “Torches and accessories”)

4.2 Options

4.2.1 80A torch for RTC 100 and RTC 150

Optional 60A torches enabling cutting of light gauge sheet metal with a smaller

nozzle are also available for the RTC 100 and RTC 150 units. From the coding of

the torch, the equipment can tell that an 80A torch has been connected. The

cutting current is automatically limited to 60A. The inside scale then applies to the

cutting current settings.

The permitted equipment duty cycle is based under this combination on the

maximum duty cycle of the 80A torch (see Section 4.3).

4.2.2 Automatic torch

Appropriate automatic torches can be employed for automated operations, e.g.

on cutting machines. The specification details will be found in Section 4.3.

When an automatic torch is used, a mechanised interlock may be necessary.

Please contact your supplier for further information about this.

4.2.3 Torch accessories

Details of accessories for the various types of torch will be found in Section 4.3.

4.2.4 Air filter attachment

If the REHM BARRACUDA cutting equipment is used in an environment in which

the air is heavily polluted, then use of an air filter attachment is recommended.

This consists of a protective frame and a filter unit which is very easy to replace

when heavily clogged. The air filter attachment can be retrofitted without difficulty.

4.2.5 Mechanised interlock

For automated use of the BARRACUDA equipment, an interface can be provided,

the signals of which are metallically separated.

Outputs: - Current-flowing message (CFL) for message “Cutting arc on”

- Group alarm

- Arc voltage (U) (e.g. for arc voltage height control)

Accessories

21

Inputs: - Cutting on (external contact instead of torch button)

- Cutting current (Iset)

Your supplier will be able to tell you about the various options for automated use

of REHM plasma cutting equipment.

4.2.6 Special voltages

REHM BARRACUDA cutting equipment can be supplied with a variety of power

supply voltages.

Please ask your supplier for further details.

4.3 Torches and accessories

All plasma torches for the BARRACUDA series are fitted with a special REHM pin

configuration on the central connector.

4.3.1 RTC 60 machine configuration

4.3.1.1 Standard accessories for RTC 60

Description

Order no.

Earthing clamp with terminal

360 0004

Mains cable with connector

360 0110

Plasma torch A80

766 0806

Set of wear parts

750 0727

Set of operating and functional instructions

730 0275

Accessories

22

4.3.1.2 Plasma torches A80 and P80 Aut

Torch: Plasma torch A80 (order no. 766 0806)

Plasma torch P80 Aut (order no. 766 0816)

Mono-gas plasma torch 6m with central connector and safety switch

Technical data for A80 torch

Maximum cutting current: 60A

Duty cycle at I

max

: 60%

Air pressure: 5-5.5 bar

Air flow rate: 105 l/min

Nozzle diameter: 1.2 mm for current range 10-60A

Set of wear parts: 2 nozzles diameter 1.2mm

1 double electrode

Item

Description

Order no.

Suitable for torch

A60

A80

1

Torch body A80

776 0507

x

x

1a

Gripper tube A80

776 0607

x

Torch body A80 Aut

776 0508

x

Torch sleeve A80 Aut

776 0608

x

2

O-ring A60/80

776 3501

x

x

4

Diffuser A60/80

776 6120

x

x

5

Double electrode A60/80

776 6003

x

x

7

Nozzle 1.2mm A60/80

776 6110

x

x

8

Electrode long A60/80

776 6004

x

x

9

Plasma nozzle long A60/80

776 6111

x

10

External protective nozzle A80

776 6312

x

18

Switch for A80

776 0606

x

19

Spacer spring A60/80

776 6404

x

x

20

Spacer with 4 castellations

776 6405

x

x

Adapter to adapt A60 to A80

776 0614

x

21

Carriage A80

776 7013

x

Circle cutting unit, complete

776 7009

x

Accessories

23

4.3.2 Machine configuration RTC 100 / RTC 150

4.3.2.1 Standard accessories RTC 100 / RTC 150

Description

Order no.

RTC 100

Order no.

RTC 150

Earthing clamp with terminal

360 0004

360 0111

Mains cable with connector

360 0134

360 0135

Plasma torch A80

766 1456

766 1456

Set of wear parts

750 0728

750 0729

Set of operating and functional

instructions

730 0275

730 0275

4.3.2.2 Plasma torches R145 and R145P

Torch: Plasma torch R145 (order no. 766 1456)

Plasma torch R145 automatic torch (order no. 766 1466)

Mono-gas plasma torch 6 m with central connector and safety switch

Technical Data

(Technical data for R145P is the same as for torch type R145)

Maximum cutting current: 150A

Duty cycle at I

max

: 100%

Air pressure: 5-5.5 bar

Air flow rate: 230 l/min

Nozzle diameter: 1.4mm for current range 40-60A

1.6mm for current range 70-120A

1.8mm for current range 110-150A

3.0mm for gouging

Set of wear parts: Nozzle diameter 1.4 mm

(RTC 100 / RTC 150)

1 nozzle diameter 1.6mm

(RTC 100 / RTC 150)

1 nozzle diameter 1.8mm (RTC 150)

2 electrodes (RTC 100)

3 electrodes (RTC 150)

Accessories

24

Torch R145 Automatic torch R145P

Item

Description

Order no.

Plasma torch R145

6m with central connector

766 1456

Automatic torch R145P 6m with central connector

766 6119

1

Torch body R145

766 0505

3

Torch body R145P

766 0506

2

O-ring

776 3502

4

Electrode

776 6005

4 A

Electrode, long

776 6006

5

Insulator

776 3503

6

Nozzle, 1.4mm

776 6112

Nozzle, 1.6mm

776 6113

Nozzle, 1.8mm

776 6114

Nozzle 3.0mm (for gouging)

776 6116

6 A

Plasma nozzle, long

776 6119

7

External protective nozzle (tapered)

776 6301

8

Spacer – contact plate

776 6406

8 A

Spacer (rounded)

776 6302

9

Spacer – contact plate

776 6407

9 A

Spacer (straight)

776 6303

10

Spring retainer support for no. 7 with two spacer rings

776 6413

10 A

Spacer spring

776 6409

Carriage

776 7016

Accessories

25

4.3.2.3 Accessories for torch R145

No.:

Description

Article no.:

4 A

Electrode, long

776 6006

6 A

Plasma nozzle, long

776 6119

7 A

External protective nozzle (cylindrical)

776 6304

10 A

Spacer spring

776 6409

11

Spacer for gouging and weld preparation

776 6410

12

Spacer with 2 castellations

776 6411

13

Spacer with 4 castellations

776 6412

Accessories

26

4.3.3 Circle cutting equipment and magnet clamps

Circle cutting equipment, complete, consisting of:

– Carriage (A)

– Threaded bracket (B)

– Centrepoint (C)

– Magnet clamp standard (D)

– Extendable compass bar (250mm and 400mm) (E)

Order number for RTC 60: 776 7010

for RTC 100 / RTC 150: 776 7015

Magnet clamp:

Standard (D) included in circle cutting equipment.

Diameter: 40mm

Maximagnet: article number 776 7017

Diameter: 75mm

Commissioning

27

5 Commissioning

5.1 Safety instructions

Please read the operating instructions carefully, especially

Chapter 2, Safety

Instructions, prior to commissioning of the equipment and before you begin

working on this cutting current source.

Warning!

REHM plasma cutting equipment may only be operated by personnel

trained and instructed in the use, maintenance and safety provisions of

plasma cutting equipment.

Always wear protective clothing during cutting and ensure that other

people who are in the vicinity are not endangered by UV radiation from the

arc.

5.2 Working under increased electrical danger in

accordance with the provisions of IEC 974, EN

60974-1 and VBG 15 (S)

REHM plasma cutting equipment complies with the above regulations.

Care should be taken that the cutting current source is not set up in this area

when working under increased electrical danger. Please observe regulations EN

60974-1 and VBG 15.

5.3 Transport and set-up of the plasma cutting

equipment

Set up the REHM plasma cutting equipment so that the user has sufficient room

in front of the equipment to monitor and operate the controls.

Set up the REHM plasma cutting equipment so that there are no obstructions of

the air intake and outlet. The stated duty cycle of the equipment can only be

achieved if there is adequate air throughput.

When transporting the unit, always comply with the applicable accident prevention

regulations. When transporting the unit with a crane, use the lifting rings attached

to the housing.

Danger! Electric voltage

Do not use the plasma cutting equipment in the open air when it is raining!

Commissioning

28

5.4 Connection of the plasma cutting equipment

Connect the REHM cutting current source to the power mains in accordance with

the current provisions of VDE (Association of German Electrical Engineers) and

also observe the regulations of the appropriate safety authorities.

REHM cutting equipment is fitted with a Euro CEE plug for 3x400V three-phase

alternating current. When connecting the unit, observe the information regarding

the supply voltage and fuse protection. Automatic circuit breakers and fuses must

always be rated for the current indicated. You will find the necessary details in

Chapter 12, Technical Data.

Always switch off the equipment when it is not in use.

Where shielding gas cylinders are used, set these up separately and secure them

against falling over. Screw the cylinder pressure regulator onto the cylinder thread

and check the connection for tightness. Always close the cylinder valve after

working. Observe the appropriate regulations of the competent safety authorities.

5.5 Cooling of the plasma cutting equipment

Set up the REHM plasma cutting equipment so that there are no obstructions of

the air intake and air outlet. The stated duty cycle of the power components can

only be achieved if there is adequate ventilation (see “Technical Data”). Ensure

that no grindings, dust, metal parts or other foreign matter can get into the

equipment.

5.6 Compressed air supply

The rapid plug-and-socket connection for the compressed air supply is located on

the back of the equipment. The pressure must be at least 7 bar to ensure that the

cutting equipment has a sufficient supply.

The compressed air line must be adequately dimensioned. Where compressed

air lines are relatively long, the next higher cross-section should be chosen.

The compressed air provided must be clean, dry and oil-free. If the compressed

air is significantly contaminated, the unit should also be fitted with a fine mesh

microfilter (see REHM catalogue of accessories).

5.7 Guidelines for working with cutting current

sources

Only skilled workers or operators who have received appropriate instruction in the

equipment and procedures should be entrusted with cutting work. Always wear

protective clothing during cutting work and make sure that no one else who is

close by is exposed to any hazard. Following completion of the cutting work, you

should leave the equipment switched on for a few more minutes to allow the fan

to continue to run and the heat in the unit to be dissipated.

Commissioning

29

5.8 Connection of work piece return cables/torch

Connection of the earthing cable

The appropriate cable is inserted into the socket on the front side and locked in

position. The earthing clamp must be attached at an exposed place on the

workpiece or on the cutting table. Take care to ensure that the current can be

transferred smoothly.

Connection of the torch

REHM-RTC cutting equipment is fitted with rapid plug-and-socket connections

(central connector with REHM inscription) for connection of the plasma torch. The

torch is inserted and must then be connected securely by manually tightening the

coupling nut. This entails pressing the safety pin on the central connector with the

patent key. The patent key is fastened above the central connector and must be

used both to connect and to disconnect the torch.

Important!

To avoid unnecessary energy losses during cutting, take care to ensure that all

work piece return cable connections are properly tightened and well insulated.

5.9 Recommended cross-sections of welding power

supply cables

Cross-sections of copper cables:

With lengths

up to 5m

up to 10m

up to 15m

up to 60A

16 mm2

25 mm2

25 mm2

up to 100A

25 mm2

25 mm2

35 mm2

up to 150A

35 mm2

35 mm2

50 mm2

5.10 Connection to jigs

With the optional mechanised interlock, all REHM plasma cutting equipment can

be connected easily to a cutting machine or automatic fixture via the built-in

remote control socket. For further information on this point, see Section 4.2.6.If

you have any further questions, please contact your REHM dealer.

Important!

Please use the cover provided to protect the remote control socket from dirt when

not in use.

Operation

30

6 Operation

6.1 Safety instructions

Please read the operating instructions carefully, especially

Chapter 2, Safety

Instructions, prior to commissioning of the equipment and before you begin

working on this welding current source.

Warning!

REHM plasma cutting equipment may only be operated by persons who

have been trained and instructed in the use and maintenance of plasma

cutting equipment and in the safety provisions that apply thereto.

Working on and servicing electrical plasma cutting equipment is always

potentially hazardous. Personnel not familiar with such equipment and machinery

could hurt themselves or others. For this reason, operators must be told of the

potential hazards outlined below and of the safety measures that are necessary to

avoid possible injury. Irrespective of this, anyone operating plasma cutting

equipment must familiarise himself with the safety regulations that apply in the

relevant working area prior to starting work.

6.2 Electrical Hazards

Connection of and maintenance work on plasma cutting equipment and its

accessories may only be carried out in compliance with current VDE (association

of German electrical engineers) provisions and the regulations issued by the

appropriate safety authority. Ignition of the arc and cutting require a very high

voltage.

Warning!

The no-load voltage with plasma cutting equipment is over 100V.

- Never touch any live metal parts with the bare skin or with wet clothing.

- When cutting, always wear gloves and protective hoods fitted with approved

protective filters.

- Take care to ensure that all parts which you have to touch during your work,

such as your clothing, your working area, the welding torch, the electrode

holder and the plasma cutting equipment, are always dry.

- Take care to ensure that there is good insulation by only wearing dry gloves

and boots with rubber soles, and by standing on a dry, insulated base,

especially if you have to stand on metal during your work or are working in

areas with significant electrical hazards.

- Avoid using any power cables that are worn or damaged. Ensure that power

cables are not overloaded. Use only equipment that has no faults.

- Switch off the plasma cutting equipment whenever work is interrupted for any

length of time.

- Do not wind the cutting cable around any part of the housing and do not let it

lie wound up in coils.

- Never leave the plasma cutting equipment switched on and unsupervised.

- Only ignite the pilot arc against the work piece.

Operation

31

- Take careful note of the performance data relating to the torch and cutting

equipment. If the permitted values are exceeded, this could lead to

irreparable damage.

- Do not touch any current-carrying parts. Do not hold the work piece tightly.

- Do not move the hose bundle into the splash zone of the material.

- Avoid damaging the hose bundle on sharp edges.

- Do not perform any cutting in wet or moist surroundings.

- Replace defective parts immediately.

- Do not repair damaged torches and hose bundles, but replace them instead.

- Always switch the equipment off before replacing torches, wear parts or

damaged parts.

- Use only original REHM spare parts.

- Repair work may only be carried out by qualified technicians who have been

trained by REHM. Before opening the housing of the plasma cutting

equipment, it must have been disconnected from the power supply, e.g. by

pulling out the plug. When the housing is open, the device must not be

operated and must be disconnected from the power supply.

6.3 Information for your personal safety

Extremely high temperatures, infra-red and ultraviolet radiation can occur during

plasma arc cutting. Radiation from the electrical arc and hot metal can cause

serious burns to unprotected skin and eyes.

- To protect the eyes and body from sparks and radiation from the arc, please

use only welders’ protective hoods that are free of defects and are fitted with

approved protective filters (protection level 11-13), leather gloves and a

welding helmet (see VBG 15, §27). Wear the same protective clothing even

when you are only supervising the cutting work.

- Inform anyone in the vicinity of the hazards of arc radiation and hot metal

splashes, and protect them with non-flammable shielding.

- Never point the cutting jet at persons or objects.

- Compressed gas cylinders constitute a potential hazard. Therefore comply

strictly with the safety regulations issued by the relevant safety authorities and

suppliers. Safeguard shielding gas cylinders against falling over.

- Use appropriate protective clothing such as welding aprons, gloves, headgear

and safety shoes. Make sure that your clothing cannot catch sparks or

cinders. For example, wear trousers without turn-ups.

- Do not wear contact lenses during work, (there is a danger that the lens could

burn onto the cornea).

- Take care to ensure that reflection and transmission of radiation are not

possible in the cutting area. Use dark surfaces, for example, to reduce

reflections, and use guard shields and safety partition panels.

6.4 Fire Protection

- Hot cinders or sparks can trigger fires if they come into contact with

flammable materials, liquids or gases. Remove all inflammable and explosive

materials from the cutting area and have a fire extinguisher to hand.

- Never perform cutting work on containers used to hold fuel, lubricants or

other combustible materials, even if they are empty.

Operation

32

- Where the ambient air contains high concentrations of inflammable vapours,

combustible gases or dust, cutting work may only be performed if the area is

properly ventilated.

- If hydrogen is used or is present, it should be noted that it is an inflammable

gas and that there is a potential danger of explosion.

- If aluminium is cut underwater or directly on water, the high temperature of

the plasma can trigger decomposition of the water into oxygen and hydrogen.

The combination of oxygen with hot aluminium can result in dangerously high

concentrations of the remaining hydrogen. This concentration of hydrogen

can be avoided by using suitably designed air agitation units on the table

bottom.

- Only use pressure regulators that are in good condition and only for the

gases for which they are intended. Never lubricate pressure regulators with

grease or oil.

6.5 Ventilation

- During cutting work, poisonous gases can be given off as a result of melting

of the material. Wear protective masks!

- Workstations must be designed taking into account the methods, materials

and conditions of use, so that the air inhaled by the user can be kept free of

substances harmful to health (see VBG 15, 4 and 29).

- Take care to ensure that the cutting area is ventilated either by natural

ventilation or by appropriate technical devices.

- Do not perform any cutting work on workpieces that are painted or treated

with degreasing agents, which can cause poisonous vapours to be given off.

The material to be cut must be cleaned of any solvent or degreasing agent.

- Solvents containing chlorine or materials containing lead, graphite cadmium,

zinc, mercury or beryllium or are coated with these can give off poisonous

fumes that could be a health hazard.

6.6 Checks before switching on

It is assumed that:

- the unit was set up properly in accordance with Chapter 5,

Commissioning;

- all connections (shielding gas, torch connection) were established in the

proper fashion in accordance with Chapter 5, Commissioning;

- maintenance work has been carried out at the due intervals Chapter 8,

Maintenance;

- the safety devices and equipment components (especially the torch

connection hoses) have been checked by the operator and are in proper

working order;

- the operator and other persons involved have put on the appropriate

protective clothing, and the working area has been shielded so that no

bystanders are at risk.

Operation

33

6.7 Connection of the earthing cable

Warning!

Section 6.2 Electrical Hazards. Take care to ensure that the welding

current cannot flow through hoist chains, crane ropes or other components

that conduct electricity.

Section 6.2, Electrical Hazards. Ensure that the earthing cable is

connected to the work piece as close to the welding location as possible. If

the earthing cable is not connected to the work piece near to the welding

location, the effectiveness of earthing will be reduced and the risk of

electric shock and stray currents will be increased.

Safety Instructions

34

7 Faults

7.1 Safety instructions

Warning!

In the event of a fault which constitutes a danger to persons, equipment

and/or the surroundings, switch off the equipment immediately and ensure

that it cannot be switched back on.

Do not resume operation of the equipment until the cause of the

malfunction has been eliminated and there is no longer any hazard to

persons, equipment and/or the environment.

Faults should be rectified only by qualified staff observing all safety

instructions.

Chapter 2.

The equipment must be inspected and approved by qualified staff before it

is used again

Troubleshooting Table.

If the equipment is properly set up and handled, plasma cutting using the REHM

BARRACUDA cutting equipment will become a simple, reliable separation

process. If nevertheless any faults should occur, we would like to give you the

following practical advice and tips on how to eliminate them. If you are unable to

solve the problem using this information, we would ask you to contact your

supplier, who will be happy to help you further.

General information:

Different metals, especially non-ferrous metals, have quite different heat

conduction properties, which have an effect on the appearance of the cut

surface/cutting results. In such cases, you should check whether alteration of the

current setting, the nozzle, the distance from the work piece or the speed at which

the torch is moved could produce better results.

Trouble-Shooting Table

35

7.2 Troubleshooting Table

Control lamp MAINS ON (green) has gone out – not working

Cause Remedy

Mains or phase voltage missing Check fuses and voltages

Fault in mains cable or plug Check these

Equipment will not switch on – control lamp OPERATION (green) has gone out

Cause Remedy

Operation blocked by one of the yellow See “Control lamps”

control lamps

Faulty torch button or hose bundle Service required!

Torch not properly assembled after Check this

replacement of wear parts

Control lamp OPERATION (green) is on steadily

Cause Remedy

Torch button faulty (short-circuit) Check torch button

Control defective Service required!

Control lamp TORCH (yellow) is lit

Cause Remedy

Torch parts are worn Change wear parts

Control lamp TEMPERATURE (yellow) is lit

Cause Remedy

Maximum duty cycle exceeded Allow equipment to cool down, and clean it if

necessary

The air inlet or air outlet is clogged or Clean, make sure air can circulate freely,

blocked if necessary fit air filter attachment

Control lamp AIR PRESSURE (yellow) is lit

Cause Remedy

Air pressure too low Provide the required air pressure

WATER control lamp (yellow) is lit (only with water cooling option)

Cause Remedy

Water pressure too low, not enough water Replenish water

Water pump fuse has blown Check fuse and replace if appropriate

Water pump defective Service required!

Trouble-Shooting Table

36

Fans do not operate

Cause Remedy

Fuse has blown Change fuse

Fan defective Service required!

Pilot arc difficult to ignite or will not ignite

Cause Remedy

Plasma nozzle or electrode worn Replace wear parts

Water in compressed air Check and if necessary insert fine mesh

micro filter

Failure of one phase of the power supply voltage Check fuse

No cutting current available

Cause Remedy

Workpiece too far from nozzle Check out

Torch faulty Replace torch

Failure of one phase of the power supply voltage Check fuse

Workpiece not connected Check earthing cable and earthing clamp

Weak cutting performance

Cause Remedy

Wrong nozzle Change nozzle

Wrong distance from workpiece Correct

Wrong current setting Correct

One phase of power supply voltage missing Check fuse

Poor earth connection Check out

Cutting arc is extinguished

Cause Remedy

Cutting speed too high Reduce speed

Torch too far away Move closer

Plasma jet is a green colour

Cause Remedy

Torch electrode or nozzle faulty Check and if necessary replace

Trouble-Shooting Table

37

High consumption of wear parts

Cause Remedy

Wrong nozzle being used Check and if necessary correct

Air is moist or dirty Check

if necessary, fit fine mesh micro filter

Original REHM spare parts not in use Check out

Cutting performance too high for Check handling

workpiece contact

Pilot arc ignites too often in the air Check handling

Insufficient penetration

Cause Remedy

Cutting speed too high Reduce speed

Torch inclined at too great an angle Correct torch angle

Material too thick Check cutting current setting

Maintenance and Repair Work

38

8 Maintenance Work

8.1 Safety instructions

Warning!

Repair and maintenance may only be carried out by persons who have

received appropriate training from REHM. Please contact your REHM

dealer. When replacing parts, use only original REHM spare parts.

If maintenance or repairs are undertaken by persons who have not been

trained by REHM and are not authorised for this work, then REHM will not

accept any liability or warranty claims.

The plasma cutting equipment must be switched off and disconnected from

the mains supply before cleaning commences!

Before maintenance is carried out, the welding unit must be switched off

and disconnected from the mains supply and protected against being

switched back on inadvertently.

Supply hoses must be blocked off and depressurised.

The warnings contained in

Chap.2 "Safety Instructions" must be

observed.

The welding equipment and its components must be maintained in accordance

with the specifications in the operating and maintenance instructions.

Inadequate or inappropriate maintenance or repair work can lead to technical

faults during operation. Regular maintenance of the equipment is therefore

essential. No structural modifications or additions to the equipment may be

undertaken.

Before maintenance is carried out, the welding unit must be switched off

and disconnected from the mains supply and protected against being

switched back on inadvertently.

.

8.2 Maintenance table

The maintenance intervals are recommended by REHM for normal standard

requirements (e.g. one-shift operation, use in clean, dry surroundings). The

precise intervals will be determined by your safety officer.

Activity

Chap.

Interval

Cleaning of equipment interior

8.3

Depends on conditions of

use

Function testing of safety devices by

operating staff

Daily

Visual checking of the unit, especially

the torch hoses

Daily

Maintenance and Repair Work

39

Activity

Chap.

Interval

Checking that fault-current circuit

breaker is working.

Daily

(with unsupported work)

Otherwise monthly

Have supply cables and torch hoses

inspected by qualified staff; inspection

noted in the appropriate test book.

Inspection to be carried out more

frequently if required by national

legislation.

Every 6 months

Have entire welding equipment

inspected by qualified staff; inspection

noted in the appropriate test book.

Inspection to be carried out more

frequently if required by national

legislation.

Once a year

8.3 Cleaning of equipment interior

If the REHM plasma cutting equipment is used in a dusty environment, the interior

of the unit must be cleaned regularly by blowing-out or suction.

The frequency with which this cleaning has to be performed depends on the

conditions of use. Use only clean, dry air for blowing-out or use a vacuum

cleaner.

8.4 Proper waste disposal

Only for EU countries!

Do not dispose of electric tools together with household waste material!

In observance of European Directive 2002/96/EC on waste electrical and

electronic equipment and its implementation in accordance with national law,

electric tools that have reached the end of their life time must be collected

separately and returned to an environmentally compatible recycling facility.

Circuit Diagrams

40

9 Circuit diagrams

Circuit Diagrams

41

Circuit Diagrams

42

List of Components

43

10 List of Components

10.1 Sparepart list REHM RTC

Drawing No.

Name

RTC 60

RTC 100

RTC 150

1

Suspension

2000757

2000757

2

Nipple

3100014

3100014

3100014

3

Compressed air filter

3100076

3100076

3100076

4

Control panel foil

7300176

7300177

7300178

5

Insulating bolt

3400108

3400108

3400108

6

Compressed air unit

2200286

2200287

2200287

7

Pressure gauge

3100049

3100049

3100049

8

Earth socket

4300023

4300023

4300023

9

ground cable

7810100

7810100

7810101

10

Torch suspension

7560102

7560102

7560102

11

Plasma torch

7660806

7661456

7661456

12

Pilot resistor

5100008

5100008

5100008

13

HF unit

6900020

6900020

6900020

14

Fan

4100008

4100008

4100008

15

Main rectifier

5300054

5300040

5300040

16

Main transformer

2200270

2200271

2200272

17

Choke unit

2200406

2200338

18

Welding chocke

2200273

19

HF chocke

2200283

20

Side panel left

2000734

2000734

21

Front panel

2000611

22

Front panel

2000729

2000729

23

Handle

2100534

2500061

2500061

24

Cover 3300165

3300165

25

Surge filter

6900085

6900085

6900085

26

Rotary knob

2600055

2600055

2600055

27

Rotary knob

2600053

2600053

2600053

28

Power line switch

4200051

4200051

4200051

29

Capacitor

5200087

30

Pilot switch

6900082

6900082

6900082

31

Chopper

2200276

2200278

2200278

32

Shunt

6700019

6700020

6700021

33

Control panel

6900083

6900083

6900083

34

Main control panel

6900115

6900115

6900115

35

Side panel left

2000732

2000732

36

Block roller

2500011

2500006

2500006

37

Caster wheel

2500005

2500005

38

Mains cable

3600110

3600134

3600135

39

Thermostat

6600021

6600021

6600021

40

Interference suppressor

6900102

6900185

6900185

41

Instruction manual

7300275

7300275

7300275

42

Fan cable

3600069

3600069

3600069

List of Components

44

Drawing No.

Name

RTC 60

RTC 100

RTC 150

Compressed air unit

2200286

2200287

2200287

44

Solenoid Valve

4200113

4200113

4200113

45

Pressure switch

6600022

6600022

6600022

46

Pressure regulator

3100079

3100079

3100079

47

Threaded connector

3100085

3100085

3100085

48

Tee

3100016

3100016

3100016

49

Threaded connector

3100073

3100073

3100073

50

Quick-screw joint

3100007

3100007

3100007

51

Tee

3100034

3100034

3100034

52

Hose line f. compr. Air

3200003

3200003

3200003

E-box

53

Main contactor

4200151

4200152

4200152

54

Control transformer

4700052

4700052

4700052

55

Fuse socket

4300170

4300170

4300170

56

Power-line filter

6900195

6900195

6900195

57

Relays

4200153

4200153

4200153

58

Relays socket

4200154

4200154

4200154

59

Mounting support

4200158

4200158

4200158

60

Protection key

2101260

2101260

2101260

Fuse F1 4A

6600043

6600043

6600043

Fuse F2 4A

6600043

6600043

6600043

Fuse F3 1A

6600043

6600043

6600043

Fuse F5 4A

6600043

6600043

6600043

List of Components

45

1

2

3

6

7

4

8

9

10

11

12

13

14

15

42

16

39

17

20

22

5

List of Components

46

38

23

24

25

26

27

60

28

29

30

31

34

E-Box

33

35

36

37

32

40

F3, F5

List of Components

47

54

57

55(F1, F2)

56

53

59

58

44

47

45

46

52

51

50

48

49

Compressed air unit

E-Box

Mechanised Interlocks

48

11 Mechanised interlocks

Mechanised interlocks with metallic separation are only available factory

fitted.

11.1 RTC units with 7-pin interface (only for RTC 100

and RTC 150)

Input: – “Cutting on/off” closing contact, always required.

Output:– “Current-flow” message contactless for “Cutting arc on” Can be used for

external further processing, e.g. as precondition to starting control or

similar.

Article number: 756 1152

Standard: 5m cable

11.2 RTC units with 17-pin interface (only for RTC 100

and RTC 150)

Inputs: – Current set point for the range l

min

to l

max

linear 0-10V or connection of

potentiometer (< = 10 kOhm)

– “Cutting on/off” closing contact or “On” if U>18V

Outputs: – “Current-flow” message contactless for “Cutting arc on” Can be used

for external further processing, e.g. as precondition to starting

control or similar.

– Group alarm “RTC unit fault” by closing contact. Can be used for

external further processing, e.g. as error message on control or

similar.

- Actual value of cutting voltage 0-5V linear for 0-500V.Can be used

for external further processing, e.g. for arc voltage height control or

similar.

Article number: 756 1010

Standard: 5m cable

Mechanised Interlocks

49

11.3 Connection schematic for 7-Pole mechanised

cutting interface

Control

A1

white

brown

grey

pink

Plug Socket

Interference

protection

PCB A8

On/Off

signal

Arc

established

signal

Mechanised Interlocks

50

11.4 Connection schematic for A-pole mechanised

cutting interface

Technical data

51

12 Technical Data

Model RTC 60

RTC 100

RTC 150

Continuous range of adjustment

[A]

10 - 60

15 - 100

25 - 150

Duty cycle at

I

max.

(10 min)

[%]

60

60

60

Current / voltage at 60% duty

cycle

[A / V]

60 / 95

100 / 115

150 / 140

Current / voltage at 100 % duty

cycle

[A / V]

50 / 90

80 / 105

130 /130

Max. cutting performance

[kW]

5.7

11.5

21

No-load voltage

[V]

310

310

310

Power consumption at I

max.

[kVA]

7.5

13.5

24.5

Current consumption at I

max.

[A]

11

19

35

Power supply voltage

[V]

3 x 400

3 x 400

3 x 400

Power frequency

[Hz]

50

50

50

Mains voltage compensation

-10% +6%

-10% +6%

-10% +6%

Fuse protection

[A]

16

20

35

Power factor

cos

0.97

0.97

0.97

Protection class

IP 23

IP 23

IP 23

Insulation class

H H

H

Type of cooling

Fan

Fan

Fan

Torch cooling

Mono-gas/air

Mono-gas/air

Mono-gas/air

Compressed air supply

[bar]

min 7 – max 10

min 7 – max 10

min 7 – max 10

Dimensions L/W/H

[mm]

345/460/885

655/375/885

655/375/885

Weight

[kg]

54

95

129

Index

52

13 Index

A

accessories 20

accident prevention 12

alterations to the equipment 6

areas of application 6

C

checks before switching on 32

circuit diagrams 40

cleaning of equipment interior 39

commissioning 27

connect earthing cable 33

connection of the earthing cable 33

connection of the welding equipment 28

control panel 15

H

health and safety 12

L

list of components 43

M

machine description 2

maintenance work 38

manufacturer 2

O

operation, checks before switching on 32

other applicable regulations 9

P

performance features of TIG welding equipment 8

product identification 2

machine description 2

type number 2

proper use 10

purpose of the document 6

Q

qualifications, staff 6

R

residual risks 12

S

safekeeping of instructions 6

safety, dangers of disregarding safety instructions 12

safety instructions 5, 11, 12

safety regulations 30, 31

safety symbols 5, 11

symbols 10

Index

53

T

table of contents 3

technical data 51

TIG welding 8

type number 2

typographical conventions 10

W

warning symbols on the equipment 11

warnings and symbols, presentation 11

EC Declaration of Conformity

We hereby confirm that the following products

Plasma Cutting Equipment

BARRACUDA RTC 60

BARRACUDA RTC 100

BARRACUDA RTC 150

meet all the major protection requirements laid down in the Council Directive 2004/108/EC (EMC directive)

on the approximation of the laws of the Member States relating to electromagnetic compatibility and

stipulated in the Directive 2006/95/EC relating to electrical equipment designed for use within certain

voltage limits.

The aforementioned products comply with the provisions of this Directive and meet the safety requirements

applicable to equipment for arc welding in accordance with the following product standards:

EN 60 974-1: 2006-07

Arc welding equipment – Part 1: Welding power sources

EN 60 974-2: 2003-09

Arc welding equipment – Part 2: Liquid cooling systems

EN 60 974-3: 2004-04

Arc welding equipment – Part 3: Arc striking and stabilizing devices

EN 60 974-8: 2004-12

Arc welding equipment – Part 8: Gas consoles for welding and plasma cutting systems

EN 60974-10: 2004-01

Arc welding equipment – Part 10: Electromagnetic compatibility (EMC) requirements

According to EC Directive 2006/42/EG Article 1, para. 2, the above products come exclusively within the

scope of Directive 2006/95/EEC relating to electrical equipment designed for use within certain voltage

limits.

This declaration is made on behalf of the manufacturer:

REHM GmbH u. Co. KG Schweißtechnik

Ottostr. 2

73066 Uhingen Germany

Uhingen, 24 April 2007

Declaration made by

R. Stumpp

Managing Director

by REHM, Printed in Germany

No: 730 1200 06 / 2013

GB

Loading...

Loading...