- 1 -

-

HR 30W , HR 100 W

Single-Room Heat Recovery V entilation Units

V 1.1

Installation and Operation Manual

EN

- 2 -

1. HR30W and HR100W Heat Recovery Units work under pressure balance, i.e. they supply almost as much air into

a room as they extract.

2. The twin impeller and heat exchanger

arrangement simultaneously supplies and extracts

air while transferring heat from the stale exhaust

airflow to the fresh intake airflow. This provides up

to 70% heat recovery from the stale extracted air.

For situations when the air exchange needs to be

increased immediately, boost mode is available.

3. Installation and maintenance are identical

for both the unit models (HR30W and HR100W)..

CONTENTS

1.0 Introduction .............................................................................................................................. 2

1.1 Description ................................................................................................................. 2

2.0 Installation Conditions ............................................................................................................. 3

3.0 Installation ............................................................................................................................... 4

3.1 Initial preparation ........................................................................................................ 4

3.2 Installing the Appliance ............................................................................................... 5

4.0 Electric Wiring ......................................................................................................................... 6

4.1 Wiring to the mains ..................................................................................................... 6

4.2 Electrical wiring and output switching ......................................................................... 7

5.0 Maintenance ............................................................................................................................ 8

5.1 Cleaning ..................................................................................................................... 8

6.0 EXT 100 Extension .................................................................................................................. 9

1.0 Introduction

1.1 Description

HR30W outside air intake indoor air extraction power input noise level

low speed

boost speed

30 m3/h

40 m3/h

35 m3/h

50 m3/h

10 W

23 W

-

28 dB(A)@3m

HR100W outside air intake indoor air extraction power input noise level

low speed

boost speed

38 m

3

/h

69 m3/h

43 m3/h

77 m3/h

12 W

31 W

20 dB(A)@3m

30 dB(A)@3m

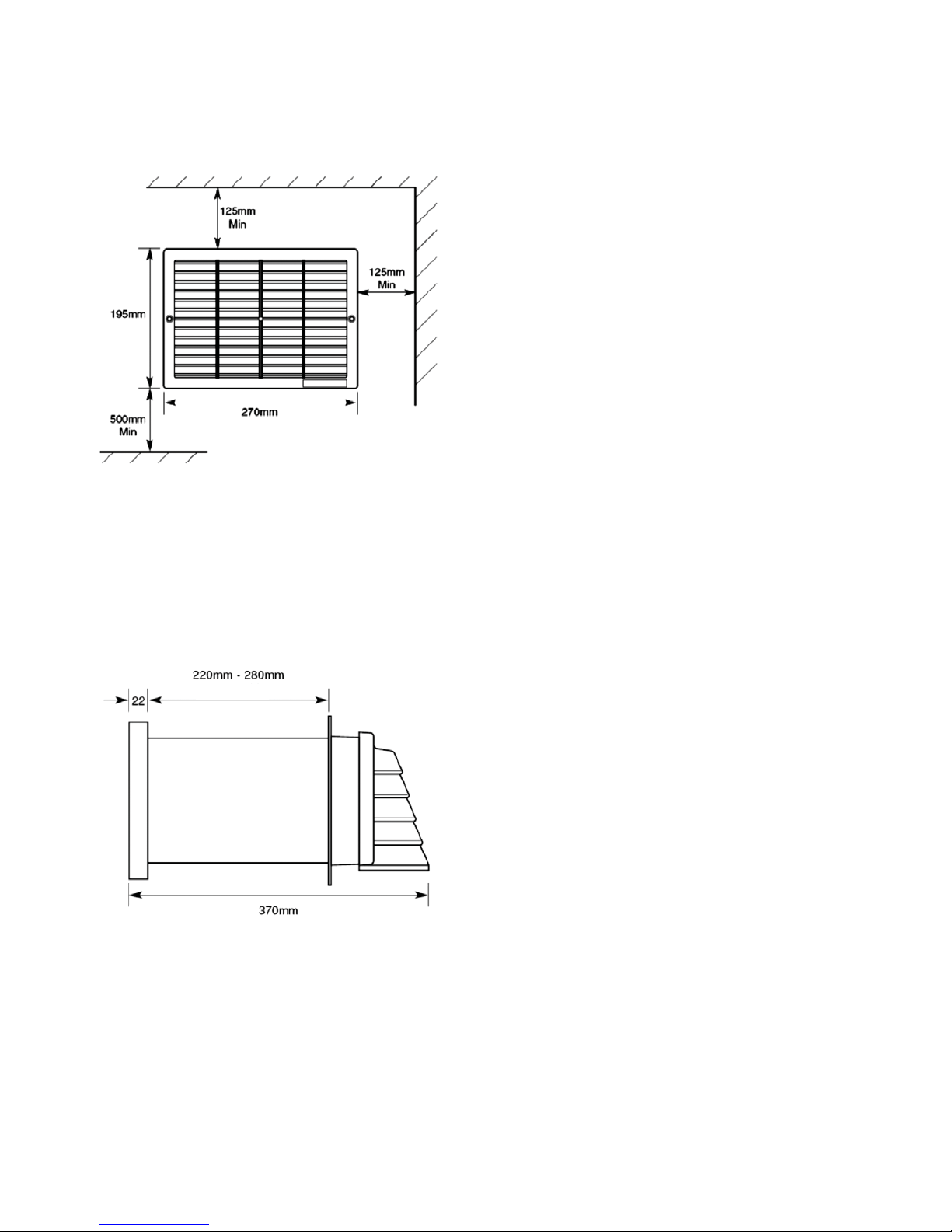

Fig. 1

- 3 -

1. The unit is designed for installation in external walls with a thickness up to 280 mm. For wall thicknesses up to

500 mm an extension kit is available (EXT100).

2. The unit must be located so that the ambient temperature will

not exceed 40° C.

3. Do not install the appliance in the vicinity of excessive levels

of airborne oil or grease.

4. If the unit is installed in a room containing a fuel burning

appliance, sufficient air replacement shall be ensured for both

appliances.

5. The grille frame shall not be located less than 125 mm away

from any wall or projecting surface (Fig. 2).

6. The external grille of the unit must be placed at least

500 mm away from any flue of gas or solid fuel appliances.

This is to avoid back flow of gases entering the room.

7. All safety regulations and requirements must be strictly followed to prevent hazards to life and property both during

and after installation and during subsequent maintenance or servicing.

8. Ensure the mains electrical supply is switched off before commencing installation or maintenance.

2.0 Installation Conditions

Fig. 2

Fig. 3

adjustable

- 4 -

3.0 Installation

3.1 Initial preparation

1. After considering the site requirements (Section 2.0), select a suitable site for the unit and controllers.

Before deciding on the final position for the unit, check there are no buried cables, pipes or obstructions

in the wall.

Cable requirements:

A 3-core cable for single-speed operation, a 4-core cable for two-speed operation. See wiring.

2. Cut out the template from the rear page of this

Manual. Mark the position of the mounting hole, 240

mm wide and 160 mm high, using this template.

3. Carefully cut the holes in the inner and outer

walls to form a suitable aperture to receive the

unit. Ensure that the unit is positioned with a slight

outward inclination (Fig. 4).

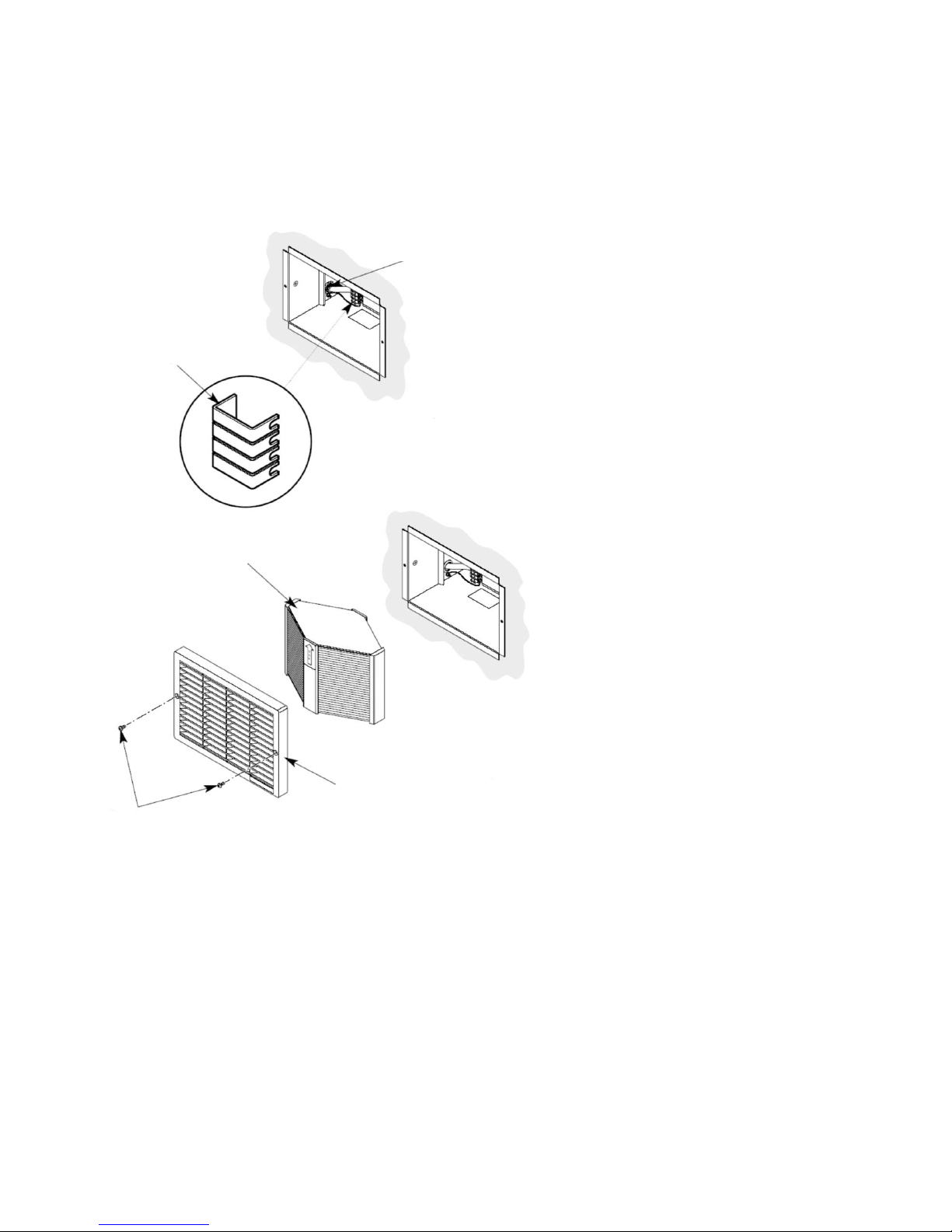

4. Remove the grille, take out heat exchanger, outer

frame and the outer louvre (Fig. 5).

Fig. 4

Fig. 5

louvre

frame

heat exchanger

grille

cable grommet

indoors

angle for

condensate

drain = 1°

outdoors

- 5 -

3.2 Installing the Appliance

From inside

1. Slide the unit into the mounting hole and ensure that the

rear part of the mounting flange is flush with the inner wall

(Fig. 6 and 7).

NOTE: The HR100W and HR30W units require an external

overhang of 60 mm. If this overhang is bigger, the unit shall

be shifted inside until the right overhang is reached.

2. Run the power cable through the grommet (Fig. 6).

3. Ensure that the unit is square and true with the outside

wall face. If firmer fixings are required, secure the unit in

place with the two fixing screws provided (Fig. 7).

4. Make good around the case.

From outside

1. With the outer louvre removed, slide the panel frame

(flange first) on to the unit and press the flange firm against

the outer wall (Fig. 8 and 9).

2.If necessary, mark and cut off an excessive section of the

plastic collar.

3. Seal the space between the flange face and wall using

suitable weather-resistant putty.

4. If necessary the frame flange can be secured to the wall

using dowels and screws (Fig. 8).

5. Put the outer louvre to its place and secure it with the two

enclosed screws (Fig. 9).

cable grommet

power cable

Fig. 7

fixing screws

mounting flange

Fig. 6

louvre

Fig. 9

collar

Fig. 8

fixing screws

flange

screws

- 6 -

4. Electric Wiring

Voltage: 230 V/50 Hz

Power input (normal speed) 12 W

Power input (boost speed) 31 W

4.1 Wiring to the mains

1. HR100W and HR30W units are equipped

with a two-speed motor.

2. Wiring must be via a 3A circuit breaker

min.

3. Ensure that the mains power supply is

isolated prior to installation.

4. Remove the terminal board cover

(Fig. 10) and connect incoming wires to

the appropriate terminals, see the wiring

diagram.

5. Replace the terminal board cover and fit

the grommet (Fig. 10).

6. Push the heat exchanger into the unit

so that the TOP mark points forward and

upwards (Fig. 11).

7.Put the grille onto the front of the unit and

fasten it with the two screws provided (Fig.

11).

8. Switch on the electrical mains and check

the operation of the unit.

terminal board cover

Fig. 11

Fig. 10

cable grommet

screws

grille

heat exchanger

- 7 -

4.2 Electrical wiring and output switching

1. basic wiring

3. wiring with a light switch (a relay shall be used)

2. wiring with a hygrostat

HR100W continuous normal speed

HR100W continuous boost speed

live

neutral

ground

live

neutral

ground

live

neutral

ground

switch

switch wiring (normal / boost

speed)

live

ground

terminal

These units shall not be wired

to lighting circuit!

live

neutral

(ground)

(ground)

(ground)

(ground)

Relay

light

- 8 -

5. Maintenance

5.1 Cleaning

1. In addition to removing odours, providing fresh

air and recovering heat, this unit extracts airborne

impurities such as dust, dirt and grease. These

gradually build up and detract from the efficiency

and appearance of the unit.

2. To ensure optimum performance, the unit

should be cleaned every 3 to 6 months or at

periods determined by the level of contamination

experienced.

3. Isolate the mains power supply.

4. Undo the two grille securing screws and remove

the grille (Fig. 12).

5. Pull out the four cylindrical inserts from behind

the grille and remove the filter (Fig. 13).

6. Slide out the heat exchanger (Fig. 14).

7. Wash the grille, filter and heat exchanger in warm

water using a mild detergent and dry thoroughly.

CAUTION: Keep water away from all electrical

components and wiring within the unit.

If the filter cannot be cleaned, a replacement

is necessary.

8. Reassemble in reverse order ensuring the filter

and heat exchanger are seated correctly. The heat

exchanger shall be positioned with the TOP mark

pinpointing to the front and upwards.

9. Switch power supply on and check the operation

of the unit.

HR30W

HR30W is fitted with an extra fine pollen filter (Art.

No. FR30RF4). Its maintenance is the same as that

of the standard filter, see Cleaning (section 5.1).

grille

grille

screws

screws

heat exchanger

heat exchanger

spacers

spacers

filter

filter

grille

grille

Fig. 13

Fig. 13

Fig. 12

Fig. 12

Fig. 14

Fig. 14

- 9 -

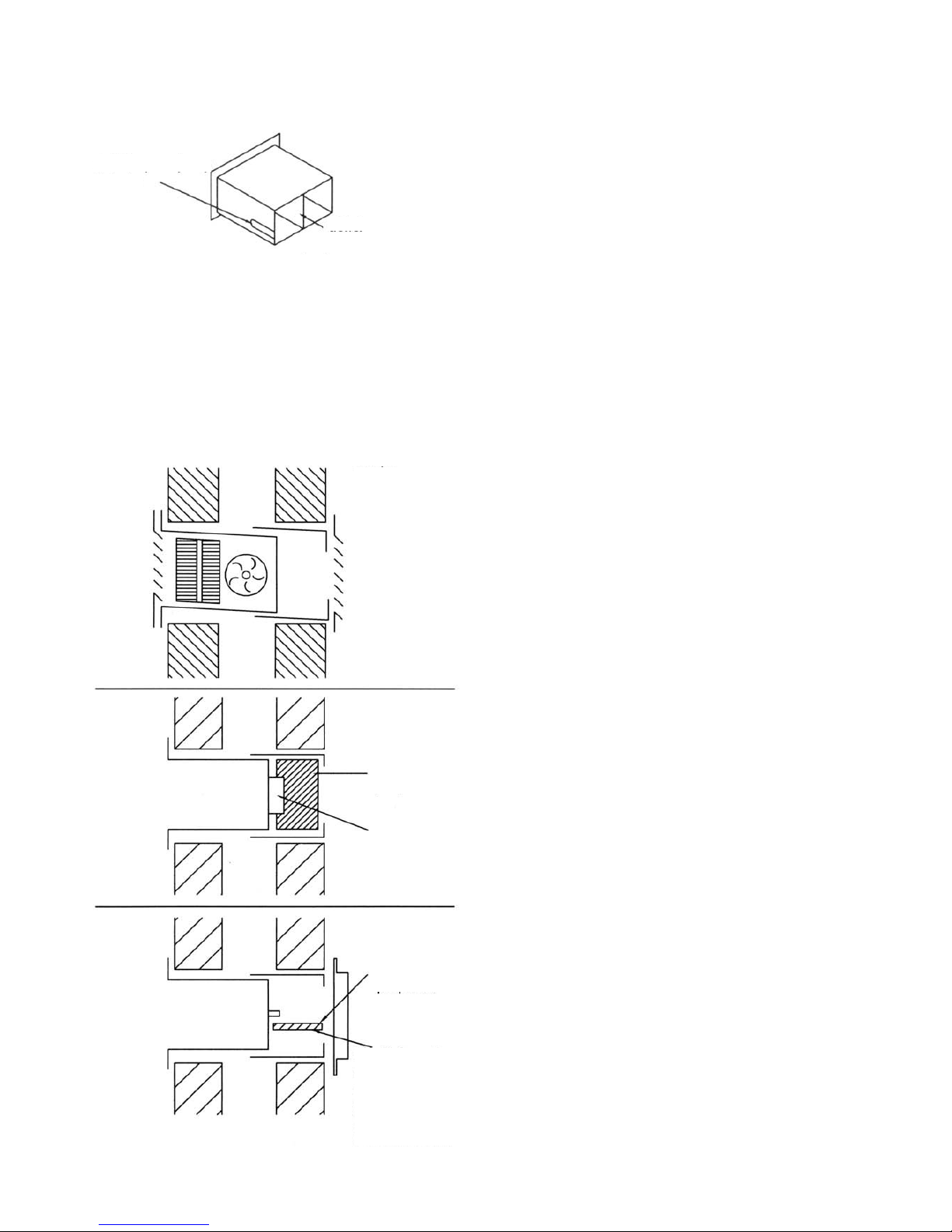

6. EXT 100 Extension

Extension for HR100W or HR30W is needed for 280-500 mm thick walls. It comes with the ABS outer louvre already

mounted that forms a collar overlapping by 15 mm, making good around the installation opening, helping to seal off the

opening with a water-resistant putty.

The plastic baffle comes together with the EXT100 extension piece and

shall be cut as necessary to divide the fresh incoming air from the outgoing

stale air along its entire length.

INSTALLATION

1. Cut an opening in the wall, 245 mm wide and 165 mm high, to accommodate the HR100W or HR30W unit and the

extension (the opening is bigger by 5 mm than that intended for the HR100W unit alone).

2. Remove the louvre from the extension, notice how it is mounted.

3.Slide the HR100W (HR30W) into the mounting hole from

inside and the extension from outside. Shift the two items

into one another in such a manner that the mounting flange

is flush with the inner wall and the edge of the extension

with the outer wall. Align the assembly in order to reach

a uniform outward inclination of about 1°.

4. Measure the distance from the rear of HR unit to the end

of the extension.

5. Cut the baffle to this length. The baffle shall fit tightly

between the rear section of HR unit and the extension’s

outer collar.

6. Wire the unit as described in the Electric Wiring chapter.

7. Verify there is a slight outward inclination of the assembly,

and if necessary, the extension can be secured in this

position using dowels and screws.

8. Slide the baffle in its place and fasten it to the HR rear

using the self-adhesive stripe provided. Make sure the

baffle is placed in the middle and straight, and that there

are no gaps between the two airways. Possible leaks shall

be sealed off with a duct tape.

9. Screw the outer louvre to its place using the enclosed

screws. At the same time make a watertight seal between

the outer louvre collar and the outer wall surface using

silicone or another suitable putty.

10. Finish the installation following instructions in the

Installation Manual for HR100W/HR30W.

cable groove

baffle

inside

seal between

the baffle and

extension

(self-adhesive,

if necessary)

baffle

outside

baffle

- 10 -

template for HR100W, HR100WH and HR30W

this side up

at least 125 mm from a ceiling

cable

at least 500 mm from a floor

- 11 -

EC DECLARATION OF CONFORMITY

Manufacturer:

Vent-Axia Limited

Fleming Way, Crawley

GB-RH109YX West Sussex

UK

Product:

Single-Room Heat Recovery Ventilation Units,

models:

HR 25; HR 25 L; HR 25 XXL

HR 30 ; HR 30 W

HR 100 W; HR 100 WH; HR 100 S

Relevant harmonized standards:

EN 60335-1:1995; EN 60335-2-80:1997;

EN 55014-1:1997; EN 55014-2:1997;

EN 61000-3-2:1995; EN 61000-3-3:1995;

EN ISO 9001:2000

Relevant Directives:

Directive 2006/95/C- Low Voltage Directive (LVD)

Directive 2004/108/C - Electromagnetic Compatibility Directive (EMC)

Last two digits of the year in which the CE marking was affixed

07

Date and place of issue, name and position of the responsible person:

…………………………..

West Sussex 03.07.2007 Lee Austin, Managing Director

HR 100 R; HR 100 RS;

- 12 -

2014

REGULUS, spol. s r.o.

Do Koutů 1897/3 http://www.regulus.eu

143 00 Praha 4 E-mail: sales@regulus.cz

CZECH REPUBLIC

WARRANTY CERTIFICATE

Model: .......................................................................................

Serial number: .......................................................................

Seller: .......................................................... Date of purchase: ...............................

WARRANTY CONDITIONS

1. The Seller grants the Buyer a guarantee period of 24 months from the date

of purchase.

2. When claiming warranty, this Warranty Certificate must be submitted together with

the purchase receipt.

3. The warranty is valid only when the technical conditions set by the Manufacturer,

installation manual and instructions in the documentation and on the product itself

are maintained.

4. The warranty does not cover defects caused by external conditions or improper

working conditions, defects caused by normal wear and tear, further when the

product is not used in compliance with its purpose and when the defect was caused

by mechanical damage to the product, improper handling, tampering by a third

person, improper installation, improper stocking, natural disaster etc.

HR 30W, HR 100 W Single-Room Heat Recovery Ventilation Unit

Loading...

Loading...