BOT-3000E DIGITAL TRIBOMETER

OPERATING MANUAL

PLEASE READ BEFORE OPERATING THE DEVICE!

www.regansci.com

Ver. 1.52 (for use with device firmware revision 3.00.08)

“BOT-3000” (and any model derivative) is a registered trademark of Regan Scientific

Instruments, Inc. Southlake, Texas USA

TABLE OF CONTENTS

INTRODUCTION / GETTING STARTED 1

SAFETY AND CARE 2-3

THE MULTI-LEVEL OPERATING MENU 3-4

DEVICE VERIFICATION 5

BASIC OPERATION 6-9

ADDITIONAL TESTING FEATURES 9-11

SENSOR (SLIDER) CHECKING 11-13

PRINTING FUNCTION 14

MAINTENANCE AND CALIBRATION 15-16

GENERAL NOTES 16-17

TEST RESULTS REPORTING 18-20

ON-SCREEN MESSAGES 21-22

TECHNICAL DATA 23

FREQUENTLY ASKED QUESTIONS 24-25

WARRANTY AND DISCLAIMER 26-27

INTRODUCTION

The Regan Scientific Instruments BOT-3000E is the third

generation design of the most recognized, advanced, and

portable digital tribometer in the world today. It has been carefully

designed to avoid the use of springs, actuators, dials, heavy

weights, or other components that can lead to premature wear or

mechanical fatigue. It can also export collected test results within

a secure pdf file format that includes a numerical input traceability

mechanism.

The tribometer can accurately measure static coefficient of friction

(SCOF) and dynamic coefficient of friction (DCOF), wet or dry.

The device is designed primarily for use on common hardsurfaced interior space flooring however it has also been used to

determine the slip-resistance of other materials such as paints,

waxes, and other coatings on flat metal, plastic, wood, laminate,

concrete and stone surfaces.

GETTING STARTED

We strongly encourage you to first read, print, and fully

comprehend the contents of this manual before attempting to use

this instrument. The tribometer is often used as one of many tools

utilized within an overall floor safety program. Decisions and

conclusions reached regarding the safety of employees or the

general public must be made with a high degree of care and

diligence.

Wherever STANDARD TEST METHODS exist and are

applicable, they should be regarded as the primary source of test

methodology and test result analysis. Various publications and

walkway safety training classes exist, which often focus upon the

complex causes of slip and fall incidents and their prevention.

1

SAFETY AND CARE

Personal Protective Equipment (PPE)

Latex or nitrile gloves should be worn to protect hands from

repeated exposure to surfactant solution.

A dust filter mask should be worn when sanding sensor

materials.

The following precautions, coupled with prudence and general

common sense, will help avoid damage to the device as well as

potential injury to you or others in the general vicinity:

Keep the tribometer clean, calibrated, and properly

maintained. Never open the tribometer or the battery case.

Use cones, flags or distinct barriers to prevent people from

walking into your test area and possibly slipping or tripping

on test equipment and testing items.

Immediately wipe up any wet testing spots once testing has

been completed in that area. Never leave a wet testing spot

or spill unattended!

Do not operate the device in the immediate vicinity of

motorized vehicles such as forklifts or other motor vehicles.

Do not allow the device to run into objects or people.

Do not operate near flammable gasses or liquids.

Keep hands and feet clear of the unit once a test run has

been initiated.

Do not allow liquids or dust contamination to enter the

bottom opening of the unit.

Battery pack charging should take place in an open area free

from excessive dust or flammable gasses or liquids.

Battery packs should never be stored where metallic objects

or liquids could come in contact with the connection interface

or they could potentially short circuit and catch fire.

The tribometer or any of the included accessories must not

be modified except by Regan Scientific Instruments Inc. (the

manufacturer.)

2

The LCD display is made of thin glass covered by a

protective layer of polycarbonate. Excessive force or

pressure may crack the display and void the product

warranty. The protective plastic may become scratched if not

carefully cleaned with a soft damp cloth only.

When the tribometer is being packed inside the transport

case, be careful not to place anything on top of it. If the lid is

closed with an object resting atop the unit, it could damage

the display or control switches.

Always ship the device in the approved transport case with

batteries stowed in their foam slot only. Shipping or

transporting the device in any other container will void the

factory warranty.

Each unit contains an internal shock monitoring device which

indicates if the unit has been dropped or subjected to an

extreme sudden force. Activation of this monitor will void the

factory warranty.

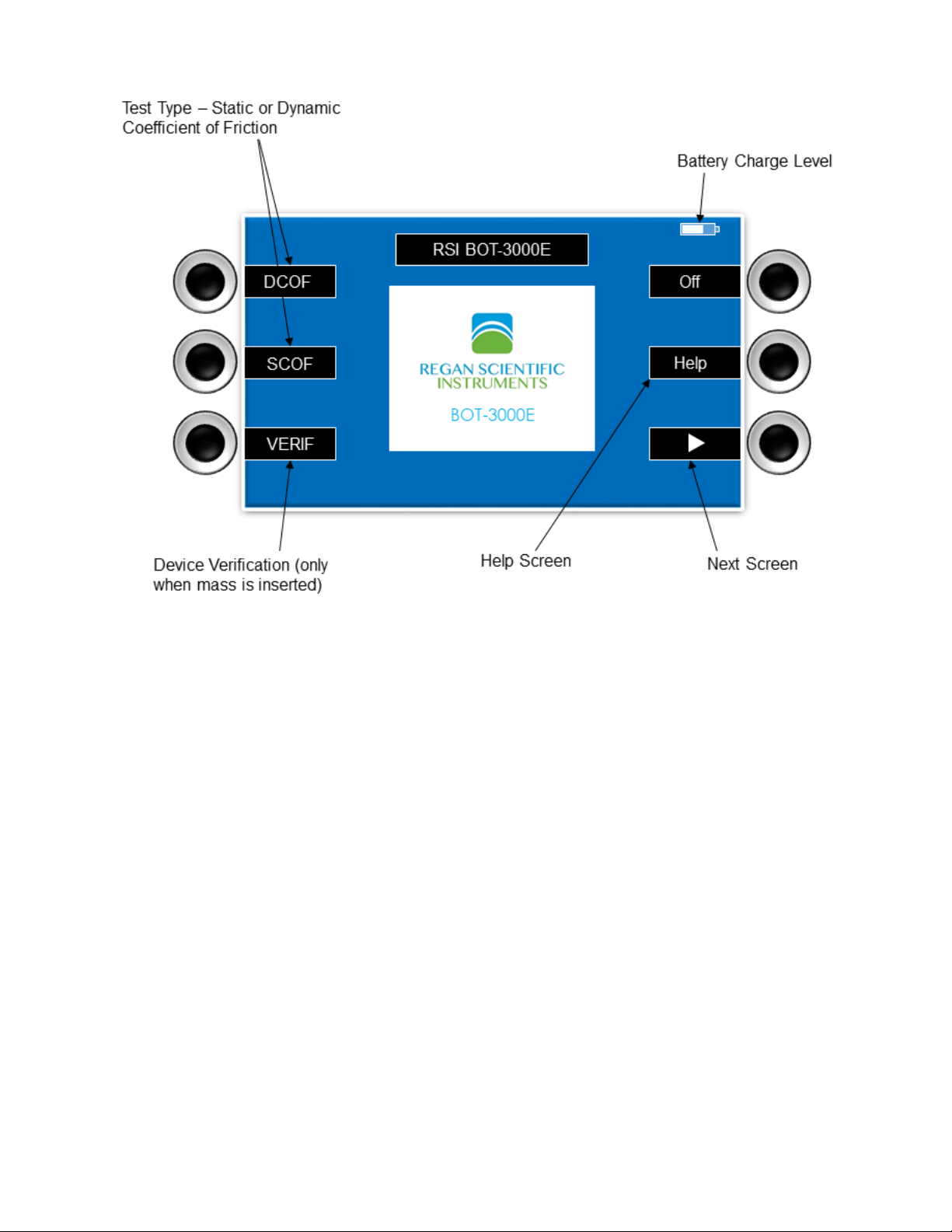

THE MULTI-LEVEL OPERATING MENU

The BOT-3000E menu system (Fig.1) has been designed to be

intuitive for the new operator. This type of man-machine interface

tends to greatly reduce the “learning curve” while providing a

more efficient data collection experience for all users. Standard

Test Methods such as ANSI A326.3 can be selected within the

menu and the device will help automate the entire testing

procedure, performing the necessary calculations and formatting

the results into an easy to understand summary or report. This

saves time and reduces the possibility of operator errors. As new

test methods are developed and introduced, they can be easily

integrated into the menu system via the firmware update process.

These updates may performed by simply loading a file provided

by Regan Scientific Instruments into the unit using a common

USB flash drive.

When the tribometer is first powered on, the main screen will be

visible. From here you can make various selections by simply

pressing the switch adjacent to the desired menu item. Within the

3

various sublevel menus, you can make adjustments, print or

Figure 1

download test results, perform a system verification*, etc. Once

changes to settings are made (e.g. time and date), be certain to

store or save them as required.

4

THE DEVICE VERIFICATION PROCEDURE

The verification operation is intended to determine if the internal force

measurement system is within specification. It is NOT a calibration

procedure.

1. Allow the tribometer to acclimate to the ambient

temperature of the test area.

2. Press any one of the six panel switches momentarily to

power up the device.

3. Place the device onto a very stable and level surface.

4. Stand the device on the aft (printer) end, and then carefully

insert the verification mass into the sensor port.

5. The VERIFY option indicator will appear (Fig.2, lower left

screen).

6. Press the switch adjacent to “VERIFY”. NOTE: Near the

screen bottom, there are two tilt indicators. These should

indicate 90 +/- 2 degrees and 0 +/- 2 degrees in order for

the device to verify accurately, otherwise a more level

surface must be found.

7. Press the “START” switch; the device will now begin the

verification process. Be certain that the device remains

level and stable during this process, otherwise the device

may fail. Once the device has completed the verification

process, it will indicate a “PASS” or a “FAIL” status. You

may press the “PRINT” or “DONE” switch at this time. If the

device fails, the procedure may be repeated after rechecking the level or moving to a more level location. The

mass may require removing and replacing or be checked

for free movement. If the device passes verification, the

force measurement system is within factory specifications.

8. Wait several seconds before removing the verification

mass so the device can reset.

9. If the device cannot be verified because of an internal fault,

it must be returned to Regan Scientific Instruments for

service.

5

Figure 2

BASIC OPERATION

1. Insert a fully charged battery pack into the battery

compartment located at the front of the device. The latch

should engage to secure the battery pack to the device.

2. Tip the device onto either side or back panel and fully

insert the desired sensor (slider) into the receiver located in

the bottom of the device. Return the device to its operating

position (wheels down).

3. Center the device directly over the test area, noting the

approximate location of the sensor (side arrow labels).

When performing wet tests, be certain the sensor touches

down onto the applied liquid film. Avoid getting the wheels

wet, which could induce a wheel slip condition. Press any

switch momentarily to power up the device. There will be a

slight delay before the display illuminates.

6

4. Press the DCOF or SCOF switch according to the desired

test type (Fig. 2).

5. In DCOF mode, you may select “SINGLE” to perform one

test, otherwise select one of the Standard Test Methods

(Fig. 3).

USER TIP; It is often helpful to first perform a single pre-test

run which will help acclimate the sensor material to the surface

being tested.

Figure 3

6. Use the navigation switches (arrows, + and -) to adjust the

test run distance (DCOF ONLY), area, and location codes.

7. Press the “GO” switch to begin testing (Fig 4). The unit will

emit a beep alert, lower the sensor, and then move

forward. CAUTION: To protect the internal mechanism, do

not lift or move the instrument from the test surface until

the beep alert stops!

7

Figure 4

8. After each individual test run, a visual graph may be

displayed by pressing the “GRAPH” switch. Press the

switch again to return to the previous screen. NOTE: A

graph for each test run will be included in the pdf test result

file. These may be printed in hardcopy form from any PC or

MAC computer with a pdf (portable document file) reader

application.

9. Orient the device to each test starting position and

direction, then press the “GO” switch again. Repeat until all

fields are completed and the final result is indicated.

10. Press the “PRINT” switch to create a test result hardcopy

(data only).

11. The internally stored test data (with graphs and photos)

may be transferred to a USB flash drive by navigating to

“OPTIONS/USB”. To save download time, you may elect to

transfer only the test data collected since the LAST

download, or ALL of the stored test data. This may require

several minutes if there is a large amount of data stored.

You may also elect to DELETE all internally stored records

8

if desired. CAUTION: Do not remove the flash drive until all

data is transferred and a “DONE” message is indicated!

12. The maximum USB flash drive permitted is 8 GB. NOTE:

USB flash drives that do not conform to the strict USB

technical specifications may not be properly recognized by

the device.

13. The device may be powered down by pressing the “OFF”

switch located in the main menu screen.

ADDITIONAL TESTING FEATURES:

TEST TRACEABILITY CODES

Before testing, it is often useful to enter unique location

identification codes within an area that correspond to particular

test locations. These numerically coded identifiers can help

provide traceability to previously site-mapped areas, and will

appear on test results and reports.

Area Identification (AID) codes are used to help identify

physical buildings, facilities, or work sites, etc.

Location Identification (LID) codes are used to identify test

locations within each AID.

NOTE: You should change the AID or LID numbers periodically

so the system can properly store the maximum number of test

results (500 pdf reports). Internal memory should be deleted

periodically to maintain peak operating efficiency.

The fictitious “site map” example in Fig. 5 illustrates a simple

diagram of a small commercial kitchen area containing multiple

areas that are regularly tested. These test locations are identified

on the site map with text labels. Before running each test, the

screen will display the last AID and LID entered. These can be

easily adjusted using the up/down and +/- keys. There can be up

to 999 Area IDs, and 999 Location IDs within each AID.

9

Figure 5

Assigning unique AIDs and LIDs can be quite helpful in the

organization and monitoring of test results. Trends may be

tracked and potential remediations applied as needed. Site maps

can be sketched onto graph paper by hand or easy-to-use CAD

drawing programs such as Smart Draw™ can be used to create

impressive reports.

TEST LOCATION PHOTOGRAPHS

Photographic evidence of test location presence can be

provided within each saved test result file.

By default, a forward-facing photograph is taken in each 90

degree orientation when using a programmed test method.

Single run tests will have only one photo documented.

The camera may be disabled in the Device Settings menu.

10

SENSORS

The sensor, sometimes called a slider, is a key component of the

friction measurement system and must be maintained properly to

provide reliable test results.

Sensors must be kept clean, properly conditioned, and free of

damage. Flat spots and deep scratches in the lining material

must be avoided. A sensor reconditioning (sanding) tool is

available from Regan Scientific Instruments. This tool helps

maintain the radius of the sensor while removing scratches and

surface contamination. NOTE: Before using new sensors, they

must be sanded and checked until the reference surface target

value is reached. See Sensor Checking Procedure below.

Leather sensor material should always be kept dry, as moisture

may cause the leather to swell and become ruined.

Sensors can be relined with new material by Regan Scientific

Instruments for a nominal fee if ruined or when worn to less

than 2mm in thickness.

STANDARD SENSOR TYPES AND COLORS

LEATHER – RED COLORED BODY

SBR RUBBER – BLACK COLORED BODY

NEOLITE – YELLOW OR GOLD COLORED BODY

CUSTOM – BLUE OR GRAY COLORED BODY*

*Custom sensors can be fabricated by Regan Scientific Instruments for a

nominal fee. The material provided must be at least 28mm X 28mm in size

and between 2mm and 5mm in thickness.

SENSOR SANDING PROCEDURE

1. Use fresh sandpaper with each new test location. Thoroughly

brush the sandpaper to remove any loose sand particles from

the paper.

2. Insert the sensor and sand until any noticeable wear pattern

or flat spot has been removed.

11

3. Remove sensor and wipe off debris with a clean, lint free, oil

free paper towel or clean brush.

4. Thoroughly brush all the debris from the sand paper.

5. Re-insert the sensor and sand for 10 more revolutions.

SENSOR CHECKING PROCEDURE

1. Tip the device onto either side or back panel and fully insert a

freshly sanded and cleaned sensor into the sensor receiver

located in the bottom opening of the device. NOTE: When

sanding or reconditioning the sensor material, it is highly

recommended to wear a filtered mask to avoid breathing in

any fine dust or particles generated during the process.

2. Using a small clean paint brush, apply a continuous film of the

appropriate lubricant completely down the center of the

reference surface approximately 3 inches wide. The reference

surface label (bottom) should indicate the type of lubricant

(e.g. distilled water) for each sensor as well as the expected

result.

NOTE: The optional leather sensor should never become

dampened or wet. It should be run only on completely dry

surfaces or they may become permanently ruined.

3. Return the device to its operating position (wheels down)

centered over the reference surface, with the rear edge

approximately even with back edge of the tile as shown below

(Fig.6). Arrows on the sides of the device indicate the

approximate front-to-back location of the sensor. NOTE: This

operation should be conducted on a hard, level, flat surface

and never over carpet.

12

Figure 6

4. Adjust the test run distance to 8 inches (20 cm), run two

DCOF tests in opposing directions, then average both results.

Compare the averaged result to the reference surface label

target value. If the value falls within the stated tolerance band,

the sensor is conditioned and ready to perform testing.

5. If the resulting averaged value falls outside the stated

tolerance band, the reference surface may require additional

cleaning, or the sensor may require further reconditioning with

new sandpaper. The reference surface should be polished

periodically with 12 micron lapping film to remove invisible

contamination buildup.

6. As an optional feature, a sensor may be programmed to

incorporate a limited positive or negative offset value to

compensate for minute differences in the sensor material,

determined by a known reference surface value. The default

setting for this feature is disabled. NOTE: If an offset value is

used, the value will be included in the test result data printout.

13

PRINTING

Hardcopies of the most recent test results, calibrations, and

verifications may be obtained from the “PRINT” screen, or

immediately following a test run (Fig.7).

When the thermal paper roll becomes depleted, it may be

easily replaced by gently squeezing the plastic tabs located

on each side of the access cover, and then gently pulling the

hinged cover open. Be sure to remove the plastic core from

the depleted paper roll. A new roll may be dropped in with

the loose end facing up and outward. Allow a small amount

of paper to protrude from the printer while gently closing the

access cover until it snaps closed.

Extra thermal paper may be obtained from Regan Scientific

Instruments, online retailers, or from various office supply

stores. The paper roll must be 2 ¼” wide, and less than 50 ft.

in total length to fit the printer. Larger diameters rolls may

damage the printer! NOTE: Most thermal printer paper

printouts will fade or darken over time.

Figure 7

14

DEVICE MAINTENANCE

The BOT-3000E requires a minimum amount of maintenance as a

function of design, however there are several items that should be

noted:

BATTERIES:

Battery packs should never be transported or stored where

metallic objects or liquids may contact the connection interface

or it could arc and ignite any surrounding material.

Leaving a battery pack inside the device or the charger when

not in use will drain the pack to an unusable state.

Battery packs should be maintained on a rotating charging

schedule to prevent premature failure.

Battery pack charging should take place in an open area free

from excessive heat, dust, and flammable gasses or liquids.

Batteries may become quite warm during charging, and must

be allowed to cool completely before using.

WHEELS:

Wheels may be removed for cleaning by pushing the hub

inward and turning 90 degrees. The wheel should now be

easily separated from the axle. The wheels should be cleaned

with isopropyl alcohol, using a toothbrush, followed by a clean

water rinse. Dry wheels completely before reinstallation.

CALIBRATION:

The user may not calibrate the device; it MUST be returned

to Regan Scientific Instruments to receive an authorized

factory calibration on a specially designed calibration fixture.

The device will indicate the last calibration date with the

printed test results. The calibration cycle is on an annual

basis, regardless of the usage amount. Please make note of

15

the last calibration date, as it will become due exactly one

year from that date.

GENERAL NOTES

Each switch press may be followed by a short delay before

the desired action is initiated.

When the device is inactive for a certain time period, the

display will dim. A press of any switch will awaken the

device. After an extended period of inactivity the device will

beep several times, then power down to conserve battery

pack life. Previous test results will be saved.

It is recommended that one dedicated flash drive be used

per each BOT device, to avoid the possibility of overwriting

files created by another device.

The battery pack charger indicator illuminates red during the

charging cycle, and will change to green once the battery

pack is fully charged. The charger may fault if a battery pack

becomes overheated. In this situation, remove the battery

pack from the charger and allow it to cool down completely

before charging again.

Many types of textured or profiled floors can be tested

without problems; however there may be occasional

surfaces that can be quite challenging. These may be in the

form of grates, embossed metal plates, mosaic tiles, random

or patterned textured surfaces often found near pools, spas,

patios, ramps, etc. See Fig. 8 for examples of limitations.

Reconditioning the sensor material manually is not generally

recommended. Using the Regan Scientific Instruments

sensor reconditioning tool may greatly reduce irregular

sanding patterns or techniques.

16

Figure 8

NOTE: If a third party reference surface was provided for use

with a specific standard test method, then the procedure from

the provider should be followed.

Whenever squared edge type surfaces (e.g. mosaic tiles),

are to be tested, a best practice is to orient the device to

traverse the edges at or near 45 degrees. This will make the

transition between tiles smoother.

The supplied reference surface can eventually become worn

or soiled with sensor material, minute particles, dried SLS, or

fingerprints. It is advisable to clean it occasionally with

Bona™ Stone, Tile and Laminate floor cleaner, which is

available from many retail stores. Dry the surface with plain

white paper towels ONLY, as some paper towel products are

treated with lint reduction agents, and could affect the

measurement results of the surface. The reference surface

should be polished periodically with 12 micron lapping film to

remove invisible contamination buildup.

17

TEST RESULTS REPORTING

Fig. 9 (next page) illustrates a typical device-generated report for

the ANSI A326.3 Standard Test Method (field/dry, sheet one of

three only). The report lists the four required measurements (per

the test method.) The photos are often helpful for positive

identification of particular test areas (e.g. in front of a doorway or

staircase). Each graph represents one measurement of the set.

Graphs can be useful in determining the degree of surface

variation for a given area. The average DCOF value for each

measurement is the recorded result. The median of the four

averages is the final test result. Single SCOF or DCOF tests will

display one measurement per report. Other test method reports

may be formatted differently than the illustrated example. Test

report folders are created first by the device serial number, the

test date, and then the area ID. The pdf files are arranged by

Date/AID/LID/test sequence. The DATA.LOG test data files are

stored in a folder created under the test date/area ID. These data

files may be renamed to DATA.TXT or DATA.CSV for importing

into various spreadsheet programs.

18

Figure 9

19

NOTE: The camera may be disabled in DEVICE SETTINGS if

photos are not desired in the report, however the graphs will

always remain visible as part of the test results report.

MORE ABOUT DATA.LOG FILES

Stored data files (not pdf files) contain test information in text

format which can be imported into spreadsheets or other text

input programs. This can be useful for tracking events or

analyzing trends. The structure of the logged data is

demonstrated below:

08/21/17, 8:34AM,001,002, ,DCOF ,,,0.35,,,,,

08/17/17, 2:52PM,004,001,3,A326.3,Field/Wet,Prevailing,0.38,0.36,0.42,0.34,0.41

08/17/17, 2:48PM,003,001, ,A137.1,,,0.42,0.43,0.44,0.40,0.41

The DATA.LOG file structure is as follows:

Date, Time, Area, Location, [Sample no.], Standard / Test

method, Test type, Condition, Average, Meas.1, [Meas. 2], [Meas.

3], [Meas. 4], PDF filename

NOTE: Items in brackets above are not included with single

DCOF or SCOF tests.

The PDF file naming convention is MMDDCCCC.pdf where MM is

the month, DD is the day of the month, and CCCC is the counter.

The various data log files may be viewed directly on the device

data screen, or be transferred to a USB flash drive and then

loaded into a PC for archiving or analysis. NOTE: A limited

number of data log files may reside in the device memory after

the pdf test files have been transferred or deleted.

20

BOT3000E On-Screen Messages

"ABORTED BY USER" - Measurement stopped by user.

"ARCHIVE DELETED" - Deleting of archive complete.

"ARCHIVE xxx of yyy" - Archiving files that have been transfered to USB.

"BLUETOOTH TRANSFER" - Transfering data or files via bluetooth.

"CALIB. DUE IN xxx DAYS" - Calibration expiration approaching.

"CALIB. PAST DUE xxx DAYS" - Calibration past due.

"CAMERA COMM FAILURE" - Unable to communicate with camera.

Return to factory for repair

"COMMAND FAILED" - Couldn't communicate with slider crypto chip.

"CREATING REPORT" - Creating A326.3 PDF report.

"DEAD BATTERY" - Battery is essentially dead. Unit will turn itself off.

"DELETING ARCHIVE" - Deleting files from archive.

"DELETING xxx of yyy" - Deleting files from archive.

"DETACHING USB" - Un-installing USB stick after removal.

"DO NOT REMOVE USB" - USB in use, do not remove.

"ERROR: DELTA > 0.06" - Slider offset out of range.

"FILE ERROR" - Unable to create the PDF.

"INCOMPLETE xxx of yyy" - Error in the transfering of files to USB.

"INSERT SLIDER" - Tried to take a measurement without a sensor inserted.

"INSTALLING USB" - USB was detected and is being initialized.

"INVALID SLIDER" - Wrong sensor type for selected standard.

Insert the correct sensor for the desired test method

"LOADING DATA" - Loading previously saved A326.3 data.

"LOW BATTERY" - Battery is low but will still take a measurement.

"MAIN DETECT ERROR" - Unable to communicate with crypto on main board.

"MEAS. TIMEOUT" - Measurement did not complete in time (likely because unit did not drive

forward)

"NO DATA TO PRINT" - No measurements have been taken to print.

"NO FILE SYSTEM" - Unable to detect internal file system.

"NO USB STICK" - No USB stick inserted.

"OUT OF PAPER" - Printer out of paper.

"PRINTER ERROR" - Unable to communicate with printer.

21

"PRINTING" - Printer is currently printing.

"RE-INSERT SLIDER" - Unit detects slider but cannot read crypto chip.

Remove sensor and clean contacts, cycle power off/ on. Replace sensor if needed

"RECHARGE BATTERY" - Battery is too low to take a measurement or print

"REMOVE MASS" - Alert to remove verification mass

"ROTATE 90 DEGREES" - Instruction during standard testing

"RTC CLOCK FAILURE" - Real time clock is malfunctioning

Cycle power off and on; Return to factory if condition does not resolve itself

"SERVICE NEEDED" - Lift sensor malfunctioned

"SET DATE/TIME" - Clock is set to date prior to software compile date

Set time / date in “Device Settings”

"SHUTTING DOWN" - Warning that the unit is about to turn itself off

"SYSTEM NOT READY" - System is busy and cannot currently process user request

Pause for 1 second before switching functions

"TURNING OFF" - Off button pressed, unit about to turn off

"TXFRING xxx of yyy" - Transfering files to USB

"UNIT NOT LEVEL" - Unit not level during verification

Move device to level surface

"USB INSTALL FAILED" - Could not initialize USB stick

Replace USB flash drive

"WARNING xxx mm/s" - Measured speed out of range

Test surface too steep

"WHEELSPIN" – Wheel spin detected during measurement

Remove, clean, and dry wheels / tires – check orientation on hub

Surface friction too high to overcome

22

TECHNICAL DATA

Device dimensions: 29 x 20 x 17cm

Weight: 6.8 Kg

Measurement velocity (DCOF): 20cm/s ± 5%

Measurement range: 0.01 to 1.00 DCOF

Measurement normal force: 22.4N ± 2%

Contact patch: approx. 3mm X 28mm

Measurement system tolerance: 3%

DCOF measurement distance: 10 to 50cm, incremental by 5cm

(displays 4” to 20”)

Ramp angle: 9.6 degrees maximum (declination)

Verification Mass: 1.36 Kg

Operating/Storage Temp: 5 - 40 deg. C

Operating/Storage Humidity: 5 - 90% RH (non-condensing)

Internal Memory: 1000+ measurements

Display: 480 x 272 LCD TFT display with 262K colors, LED backlit

Test data storage/transfer: USB flash drive, 8MB max.

Transferred file formats: PDF, TXT/CSV (.LOG files)

Printer: Thermal, 48 mm wide, 8 dots/mm

Processor type: ARM Cortex M4 32 bit processor, 120 MHz

Sampling rate: 1000 samples / sec

Protection class: IP20

Power source: RSI battery pack (NiMH battery, 12V nominal,

3.8Ah)

Battery pack charger: 120-240VAC 50/60 Hz input, UL listed

23

WARNING: There are no user serviceable components

inside the tribometer, battery pack, or charging unit, and

they should NEVER be opened for any reason, except by

Regan Scientific Instruments or an authorized agent.

FREQUENTLY ASKED QUESTIONS

Q – Why does the device require annual calibration when

we hardly use it?

A – Any laboratory-grade measurement instrument should

be calibrated on a regular period determined by the

instrument manufacturer. ISO 9001:2008 promotes this

policy. Most manufacturers of this type of measurement

instrument require calibration on a frequency of at least

once per year, regardless of the usage amount.

Q – Why can’t the device be shipped with a battery pack

installed?

A – Air Transportation agencies have ruled that electronic

devices should have the batteries removed so they cannot

activate during shipment and potentially cause

interference with navigation or communication equipment.

Also, when a battery pack is installed in a device or a

charger, a small amount of energy is constantly drained.

This can eventually lead to a dead battery pack.

Q – Why is my reference surface reading too low?

A – This may be caused by using worn sandpaper, or a

reference surface that has accumulated surfactant levels

(SLS build-up) over time. Replace the sandpaper often

and clean the reference surface properly.

Q – Can you replace worn or damaged sensors?

24

A – Yes, we can replace the sensor material for

approximately half the cost of a new sensor. Please visit

our website (see cover) for pricing, availability, shipping,

and other information.

Q – What does “Wheel Slip Error” on the display indicate?

A – The wheels should be kept dry during operation to

provide adequate traction. They may need to be removed

and cleaned if they have picked up contamination.

Q – Can the device run across tile grout joints during a

DCOF test?

A – Most properly installed tile floors will have grouted

joints between flat level tiles, and are traversable, as long

as the device crosses the joints at an angle of

approximately 45 degrees. The test run distance may be

adjusted to fit within most single tiles. Avoid running

across uneven, raised tile edges that protrude above the

normal surface plane, as the sensor could catch on the

raised edge.

Q – Why should I utilize a Standard Test Method?

A – Different testing methodologies often produce quite

different results due to the number and degree of

variables. Standard Test Methods are designed to apply

controls and limits, therefore allowing test results to be

used within a context or framework of acceptable and

unacceptable levels of risk.

The current time and date, along with other device settings,

may be edited by navigating to OPTIONS/DEVICE/ DEVICE

SETTINGS. The “SAVE” switch must be pressed when

completed.

25

Product Warranty and Disclaimer

One year parts and labor, excluding normal wear and tear parts

such as sensors, batteries, tires or any physical damage. Any

warranty exclusion is solely determined by Regan Scientific

Instruments, Inc. Defective products or materials may be repaired

or replaced at our discretion. We reserve the right to make

changes to product designs and specifications without providing

notice.

Limitations on Liability

BUYER SHALL NOT IN ANY EVENT BE ENTITLED TO, AND

SELLER SHALL NOT BE LIABLE FOR INDIRECT, SPECIAL,

INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY

NATURE INCLUDING, WITHOUT LIMITATION, BUSINESS

INTERRUPTION COSTS, REMOVAL AND/OR

REINSTALLATION COSTS, REPROCUREMENT COSTS, LOSS

OF PROFIT OR REVENUE, LOSS OF DATA, PROMOTIONAL

OR MANUFACTURING EXPENSES, OVERHEAD, INJURY TO

REPUTATION OR LOSS OF CUSTOMERS, EVEN IF SELLER

HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES. BUYER'S RECOVERY FROM SELLER FOR ANY

CLAIM SHALL NOT EXCEED BUYER'S PURCHASE PRICE

FOR THE PRODUCT GIVING RISE TO SUCH CLAIM

IRRESPECTIVE OF THE NATURE OF THE CLAIM, WHETHER

IN CONTRACT, TORT, WARRANTY, OR OTHERWISE.

SELLER SHALL NOT BE LIABLE FOR AND BUYER SHALL

INDEMNIFY, DEFEND AND HOLD SELLER HARMLESS FROM

ANY CLAIMS BASED ON SELLER'S COMPLIANCE WITH

BUYER'S DESIGNS, SPECIFICATIONS OR INSTRUCTIONS,

OR MODIFICATION OF ANY PRODUCTS BY PARTIES OTHER

THAN SELLER, OR USE IN COMBINATION WITH OTHER

PRODUCTS.

26

Warranty Disclaimer

We (seller) make no representations about the suitability of

the products for any purpose. In no event shall we be liable

for any special, indirect or consequential damages or any

damages whatsoever resulting from loss of use, data or

profits, whether in an action of contract, negligence or other

tortuous action, arising out of or in connection with the use

or performance of the products it sells. We assume no

responsibility for errors or omissions in this publication or

other documents which are referenced or linked to this

publication; nor do we make any commitment to update the

information contained herein. This publication and other

documents, and prices are subject to change without notice.

We are not responsible or liable for any injuries, damages, or

death caused by the use, misuse or failure of products

purchased from us, nor from the use of any other materials,

articles, or other published information.

© 2008 - 2018 Regan Scientific Instruments Inc.

1628 Valwood Parkway Suite 200

Carrollton, Texas 75006 USA

All rights reserved

27

Loading...

Loading...