Version 4 (No. 982065) 801 Series June 2019

Operating Instructions

REFUone 3K-2T ... 7K-2T

REFUone 3K-2T, 5K-2T, 7K-2T

2

Notice

This manual contains important safety instructions that must be followed during installation

and maintenance of the equipment.

Save these instructions!

This manual must be considered as an integral part of the equipment, and must be available

at all times to everyone who interacts with the equipment. The manual must always

accompany the equipment, even when it is transferred to another user or field.

Copyright Declaration

The copyright of this manual belongs to REFU Elektronik GmbH. Any corporation or individual

should not plagiarize, partially copy or fully copy it (including software, etc.), and no

reproduction or distribution of it in any form or by any means. All rights reserved.

REFU reserves the right of final interpretation. This manual is subject to change according to

user’s or customer’s feedback. Please check our website at

http://www.refu.com

for latest

version.

REFU Elektronik GmbH

Marktstraße 185

D-72793 Pfullingen

Tel.: +49 (0)7121-4332 0

Fax: +49 (0)7121–4332 140

Mail: info@refu.com

REFUone 3K-2T …7K-2T

3

Preface

Outline

Please read the product manual carefully before installation, operation or maintenance. This

manual contains important safety instructions and installation instructions that must be

followed during installation and maintenance of the equipment.

Scope

This product manual describes the installation, electrical connections, commissioning,

maintenance and troubleshooting of REFUone 3K-2T … 7K-2T inverters.

Keep this manual where it will be accessible at all times.

Target Group

This manual is intended for qualified electrical technical personnel who are responsible for

inverter installation and commissioning in the PV power system and the PV plant operator.

Symbols Used

This manual provides safety operation information and uses the symbol in order to ensure

personal and property security and use the inverter efficiently when operating the inverter.

You must understand these emphasized information to avoid the personal injury and property

loss. Please read the following symbols used in this manual carefully.

Danger indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

Danger

Warning indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

Warning

Caution indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Caution

Attention indicated potential risks which, if not avoided, may lead to equipment fault

or property damage.

Attention

Note provides tips that are valuable for the optimal operation of the product.

Note

REFUone 3K-2T, 5K-2T, 7K-2T

4

Table of Contents

1 Basic safety information ................................................................................... 5

1.1 Safety instructions ............................................................................................................................ 5

1.2 Symbols and signs ............................................................................................................................ 8

2 Product characteristics ...................................................................................... 9

2.1 Product dimensions ......................................................................................................................... 9

2.2 Function description ...................................................................................................................... 12

2.3 Efficiency curve .............................................................................................................................. 13

3 Installation ..................................................................................................... 15

3.1 Installation Process ........................................................................................................................ 15

3.2 Checking Before Installation .......................................................................................................... 15

3.3 Tools ............................................................................................................................................... 17

3.4 Determining the Installation Position ............................................................................................ 18

3.5 Moving the REFUone inverter ........................................................................................................ 20

3.6 Installing REFUone inverter ............................................................................................................ 20

4 Electrical Connections ..................................................................................... 22

4.1 Electrical connection ...................................................................................................................... 22

4.2 Connecting PGND Cables ............................................................................................................... 22

4.3 Connecting DC Input Power Cables ............................................................................................... 24

4.4 Connecting AC Output Power Cables............................................................................................. 26

4.5 Connecting Communications Cables .............................................................................................. 30

4.6 WiFi/GPRS module installation procedure ............................................................................ 34

4.7 WiFi Communication ...................................................................................................................... 35

4.8 Monitoring Portal REFUlog ............................................................................................................ 36

4.9 RS485 Communication ................................................................................................................... 37

5 Commissioning of inverter .............................................................................. 38

5.1 Safety inspection before commissioning ....................................................................................... 38

5.2 Start Inverter .................................................................................................................................. 38

6 Operation interface ........................................................................................ 39

6.1 Operation and Display Panel.......................................................................................................... 39

6.2 Standard Interface.......................................................................................................................... 40

6.3 Main Interface ................................................................................................................................ 41

6.4 Update Software online ................................................................................................................. 47

7 Trouble shooting and maintenance ................................................................. 50

7.1 Trouble shooting ............................................................................................................................. 50

7.2 Maintenance .................................................................................................................................. 55

8 Technical data ................................................................................................. 56

8.1 DC Data ........................................................................................................................................... 56

8.2 AC Data ........................................................................................................................................... 56

8.3 Efficiency, Protection and Communication ................................................................................... 56

8.4 General Data .................................................................................................................................. 57

9 Quality Assurance ........................................................................................... 58

10 Technical Support ........................................................................................... 59

REFUone 3K-2T …7K-2T

5

1

Basic safety information

If you have any question or problem when you read the following information,

please contact REFU Elektronik GmbH.

Note

Outlines of this chapter

Safety instruction

It mainly introduce the safety instruction when install and operate the equipment.

Symbols and signs

It mainly introduce the safety symbols on the inverter.

1.1

Safety instructions

Read and understand the instructions of this manual, and be familiar with relevant safety

symbols in this chapter, then start to install and troubleshoot the equipment.

According to the national and state requirements, before connecting to the electrical grid, you

must get permission from the local electrical grid operator, and the operation can only be

performed by qualified electrical engineer.

Please contact the nearest authorized service center if any maintenance or repair is needed.

Contact your distributor for the information of the nearest authorized service center. Do NOT

repair it by yourself, it may cause injury or property damage.

Before installing and maintaining the equipment, you should turn the DC switch OFF to cut off

the high voltage DC of the PV array. You can also turn the switch in the PV combiner box OFF to

cut off the high voltage DC. Otherwise, serious injury may be caused.

1.1.1

Qualified persons

The customer must make sure the operator has the necessary skill and training to do his/her

job. Staff in charge of using and maintaining the equipment must be skilled, aware and mature

for the described tasks and must have the reliability to correctly interpret what is described in

the manual. For safety reason only a qualified electrician, who has received training and / or

has demonstrated skills and knowledge in construction and in operation of this unit, can install

this inverter. REFU Elektronik GmbH does not take any responsibility for the property

destruction and personal injury because of any incorrect use.

1.1.2

Installation requirements

Please install inverter according to the following section. Fix the inverter on an appropriate

objects with enough load bearing capacity (such as walls, PV racks etc.), and ensure that

inverter is vertical placed. Choose a place suitable for installing electrical devices. Assure there

is enough fire exit space, convenient for maintenance. Maintain proper ventilation to ensure

enough air cycle to cool the inverter.

REFUone 3K-2T, 5K-2T, 7K-2T

6

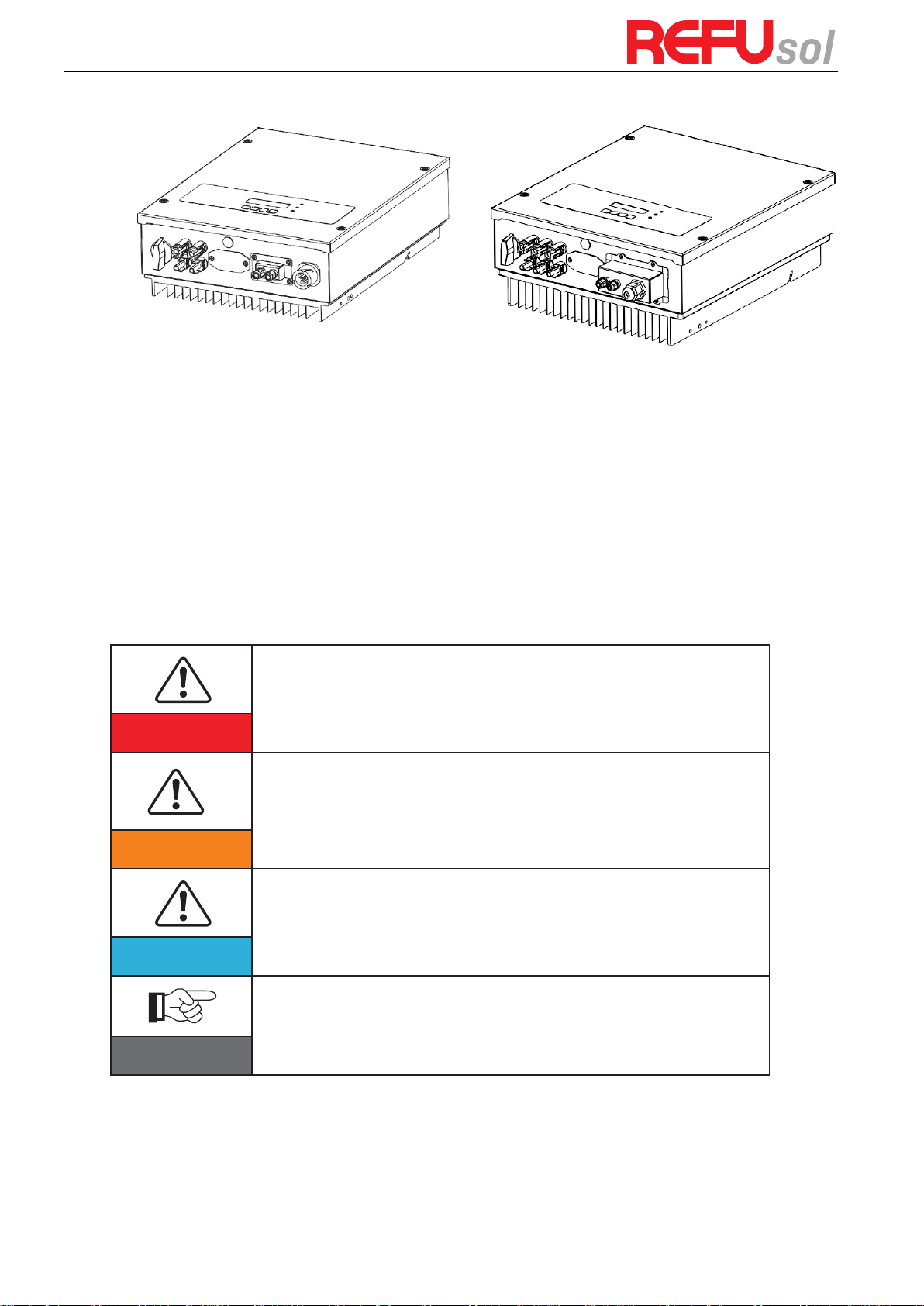

REFUone 3K-2T / 5K-2T REFUone 7K-2T

1.1.3

Transport requirements

If you find packing problems that may cause the damage of the inverter, or find any visible

damage, please immediately notice the responsible transportation company. You can ask solar

equipment installation contractor or REFU Elektronik GmbH for help if necessary. Transport of

the equipment, especially by road, must be carried out by suitable ways and means for

protecting the components (in particular, the electronic components) from violent shocks,

humidity, vibration, etc.

1.1.4

Electric connection

Please comply with all the current electrical regulations about accident prevention in dealing

with the solar inverter.

Before the electrical connection, make sure to use opaque material to cover

the PV modules or to disconnect PV array DC switch. Exposure to the sun,

PV array will produce a dangerous voltage!

Danger

All installation accomplished only by professional electrical engineer!

must be trained;

Completely read the manual operation and understand relevant

matters.

Warning

Get permission from the local electrical gird operator, complete all electrical

connections by professional electrical engineer, then connect inverter to

electrical grid.

Attention

It’s forbidden to remove the tamper evident label, or open the inverter.

Otherwise REFU will not provide warranty or maintenance!

Note

REFUone 3K-2T …7K-2T

7

1.1.5

Operation

Touching the electrical grid or the terminal of the equipment may lead to

electrocution or fire!

Don’t touch the terminal or conductor connected to the electrical grid.

Pay attention to any instructions or safety documents related to grid

connection.

Danger

Some internal components will be very hot when inverter is working.

Please wear protective gloves!

Attention

1.1.6

Maintenance and repair

Before any repair work, turn OFF the AC circuit breaker between the

inverter and electrical grid first, then turn OFF the DC switch.

After turning OFF the AC circuit breaker and DC switch, wait for 5

minutes at least before carrying out any maintenance or repair work.

Danger

Inverter should work again after removing any faults. If you need any

repair work, please contact with the local authorized service center;

Can’t open the internal components of inverter without authorized.

REFU Elektronik GmbH does not take any responsibility for the losses

from that.

Attention

1.1.7

EMC / noise level of inverter

Electromagnetic compatibility (EMC) refers to that one electrical equipment functions in a

given electromagnetic environment without any trouble or error, and impose no unacceptable

effect upon the environment. Therefore, EMC represents the quality characters of an electrical

equipment.

The inherent noise-immune character: immunity to internal electrical noise.

External noise immunity: immunity to electromagnetic noise of external system

Noise emission level: influence of electromagnetic emission upon environment.

Electromagnetic radiation from inverter may be harmful to health!

Please do not continue to stay around the inverter in less than 20 cm when

inverter is working.

Danger

REFUone 3K-2T, 5K-2T, 7K-2T

8

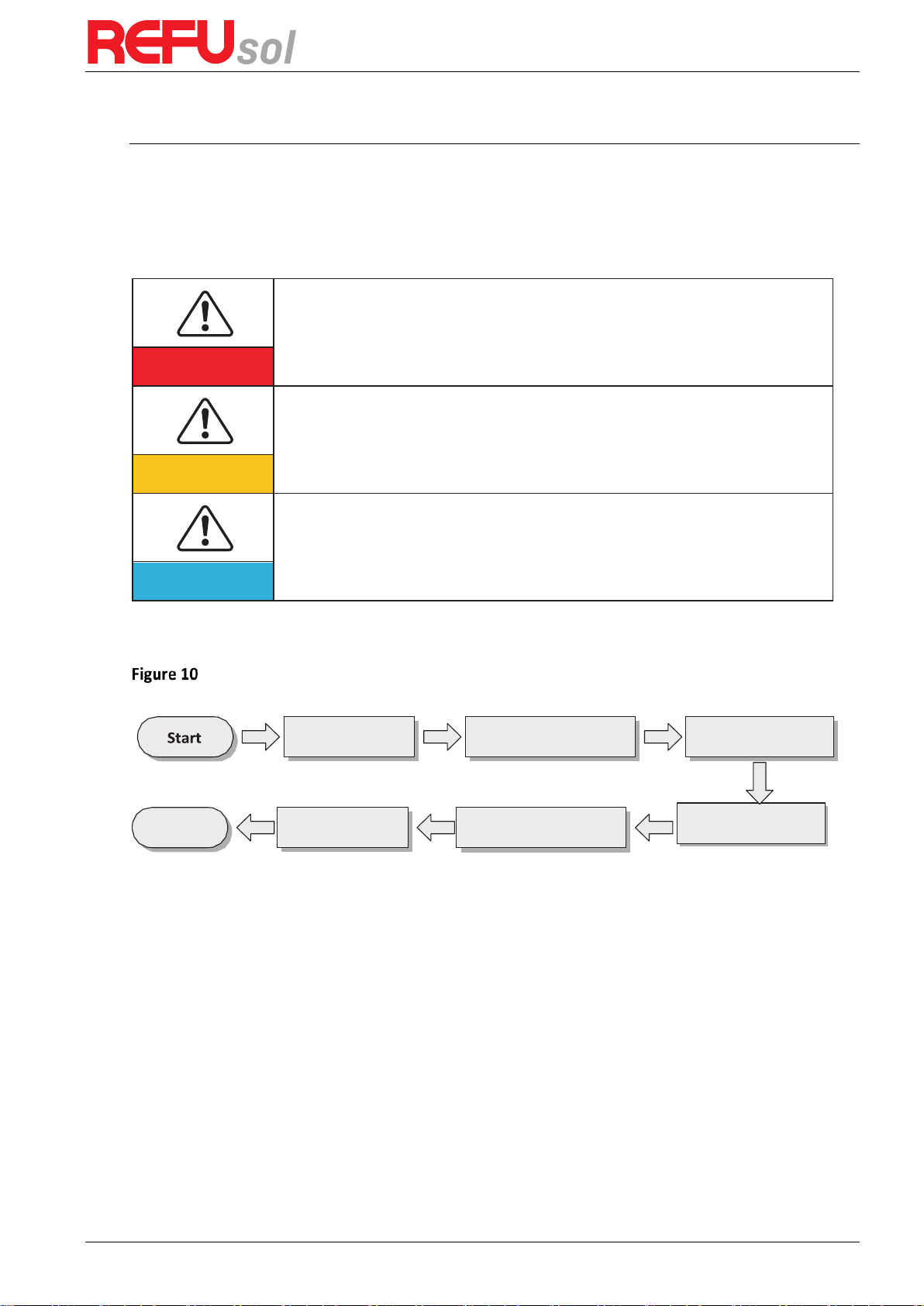

1.2

Symbols and signs

1.2.1

Safety symbols

Caution of burn injuries due to hot enclosure!

You can only touch the screen and pressing key of the inverter while it’s

working.

Caution

PV array should be grounded in accordance to the requirements of the local

electrical grid operator!

We suggest that all PV module frames and inverter are reliably grounded to

protect the PV system and personnel security.

Attention

Ensure input DC voltage < Max. DC voltage .Over voltage may cause

permanent damage to inverter or other losses, which will not be included in

warranty!

Warning

1.2.2

Signs on the inverter

There are some symbols, which are related to security on the inverter. Please read and

understand the content of the symbols, and then start the installation.

There is a residual voltage in the inverter! Before opening the

equipment, operator should wait for five minutes to ensure the

capacitor is discharged completely.

Caution, risk of electric shock.

Caution, hot surface.

Comply with the Conformite Europeenne (CE) certification.

Grounding point.

Please read this manual before install REFUone inverters.

IP65

This indicates the degree of protection of the equipment according to

IEC standard 70-1 (EN 60529 June 1997).

Positive pole and negative pole of the input voltage (DC).

REFUone 3K-2T …7K-2T

9

2

Product characteristics

Outlines of this chapter

Product dimensions

It introduces the field of use, and the overall dimensions of the REFUone inverters.

Function description

It introduces how REFUone inverters work and the function modules inside.

Efficiency curves

It introduces the efficiency curves of in the inverter.

2.1

Product dimensions

2.1.1

Field of use

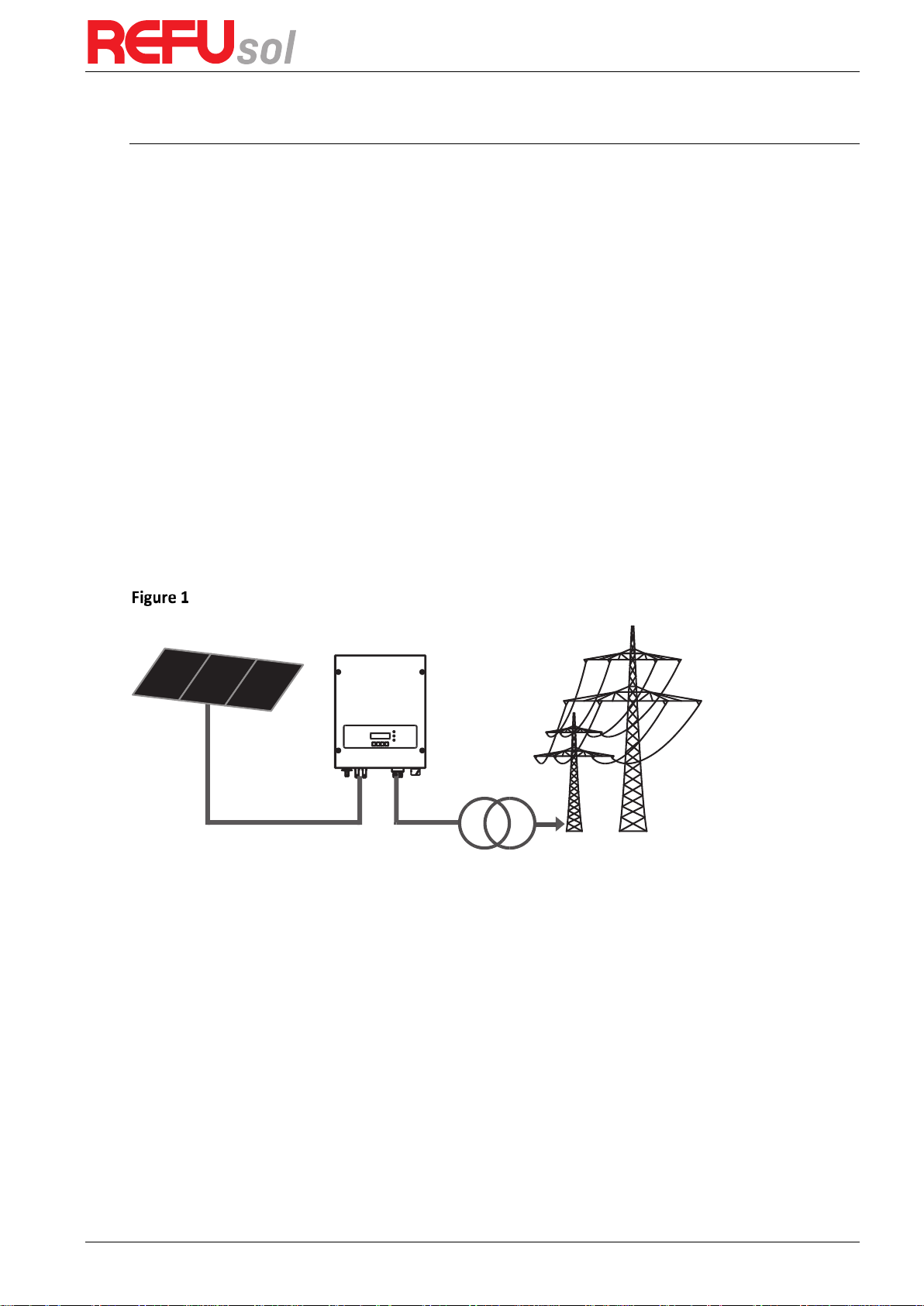

REFUone inverters are Dual MPPT grid-tied PV inverters which converts the DC power

generated by PV arrays into sine wave single-phase AC power and feeds it to the public

electrical grid, AC circuit breaker (refer to Section 4.4) and DC switch used as disconnect

device, and the disconnect device shall be easily accessible.

PV Grid-tied System

REFUone inverters can only be used with photovoltaic modules that do not require one of the

poles to be grounded. The operating current during normal operation must not exceed the

limits specified in the technical specifications. Only the photovoltaic modules can be connected

to the input of the inverter (do not connect batteries or other sources of power supply).

The choice of optional parts of inverter should be made by a qualified technician who knows

the installation conditions clearly.

Overall dimensions REFUone 3K-2T and 5K-2T (L×W×H): 437 mm×324 mm×130 mm.

Overall dimensions REFUone 7K-2T (L×W×H): 467 mm×352 mm×157 mm.

REFUone 3K-2T, 5K-2T, 7K-2T

10

352.0 mm

467.0 mm

157.0 mm

Front view and left view dimensions of REFUone 3K-2T and 5K-2T

Front view and left view dimensions of REFUone 7K-2T

324.0 mm

437.0 mm

130.0 mm

4

6

7

.

0

m

m

REFUone 3K-2T …7K-2T

11

Back view and Bracket dimensions REFUone 3K-2T and 5K-2T

Back view and Bracket dimensions REFUone 7K-2T

291.0 mm

110.0 mm

110.0 mm

130.5 mm

170.3 mm

160.0 mm

28.5 mm

9.0 mm

314.0 mm

258.7 mm

87.5 mm 87.5 mm

90.0 mm

265.0 mm

177.0 mm

85.0 mm

85.0 mm

86.0 mm

87.5 mm

REFUone 3K-2T, 5K-2T, 7K-2T

12

2.1.2

Labels on the equipment

The labels must NOT be hidden with

objects and extraneous parts (rags,

boxes, equipment, etc.); they must

be cleaned regularly and kept

visible at all times.

2.2

Function description

DC power generated by PV array is filtered through Input Board before entering into Power

Board. Input Board also offer functions such as insulation impedance detection and input DC

voltage / current detection. DC power is converted to AC power by Power Board. AC power is

filtered through Output Board then AC power is fed into the grid. Output Board also offer

functions such as grid voltage / output current detection, GFCI and output isolation relay.

Control Board provides the auxiliary power, controls the operation state of inverter and shows

the operation status by Display Board. Display Board displays fault code when inverter is in

abnormal operation conditions. At the same time, Control Board can trigger the relay so as to

protect the internal components.

Function module

1. Energy management unit

This control can be used to switch the inverter on/off through an external (remote) control.

2. Feeding reactive power into the grid

The inverter is able to produce reactive power and can therefore feed it into the grid through

the setting of the phase shift factor. Feed-in management can be controlled directly by the

grid company through a dedicated RS485 serial interface.

3. Limiting the active power fed into the grid

The inverter, if enabled can limit the amount of active power fed into the grid by the inverter

to the desired value (Expressed as a percentage).

4. Self power reduction when grid is over frequency

When the grid frequency is higher than the limited value, inverter will reduce output power

which is necessary for the grid stability.

5. Data transmission

The inverter or a group of inverters may be monitored remotely through an advanced

communication system based on RS-485 serial interface, or remotely via the WiFi.

6. Software update

SD card is used for updating the firmware.

Máx. tensão Entrada CC (Vmax)

Faixa de voltagem do MPPT

Máx. corrente entrada CC (Iop)

Máx. corrente de curto entrada CC (Icc)

Tensão CA nominal da rede

Corrente CA nominal de saída

Potência nominal de saída

Frequência nominal da rede

Fator de potência

Grau de proteção

Faixa de temperatura de operação

Classe de proteção

2x11 A

2x13.2 A

22.8 A

50 Hz

5000 W

90~580 V

220 V

IP65

Inversor Solar

Grid-Tied

Topologia do inversor

Não isolado

600 V

1 (ajustável +/-0.8)

-25°C a +65°C

Classe 1

Modelo: REFUone 5K-2T

fabricados na República Popular da China

REFU Elektronik GmbH, Marktstrasse 185

72793 Pfullingen, Alemanha

www.refu.com

Tipo: 801P005.200

REFUone 3K-2T …7K-2T

13

Electrical block diagram

Electrical block diagram

2.3

Efficiency curve

Efficiency Curve REFUone 3K-2T

82%

84%

86%

88%

90%

92%

94%

96%

98%

100%

5% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

Efficiency [%]

% of Rated Output Power

Vpv=250V

Vpv=365V

Vpv=450V

REFUone 3K-2T, 5K-2T, 7K-2T

14

Efficiency Curve REFUone 5K-2T

Efficiency Curve REFUone 7K-2T

82%

84%

86%

88%

90%

92%

94%

96%

98%

100%

5% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

Efficiency [%]

% of Rated Output Power

Vpv=300V

Vpv=365V

Vpv=450V

REFUone 3K-2T …7K-2T

15

Moving the

Inverter

3

Installation

Outlines of this chapter

This topic describes how to install the REFUone inverters.

Installation notes

Do NOT install the REFUone inverter on flammable material.

Do NOT install the REFUone inverter in an area used to store flammable or

explosive materials.

Danger

The enclosure and heat sink are very hot while the inverter is working, therefore

do NOT install the REFUone inverter in places where you might touch them

inadvertently.

Caution

Consider the weight of the inverter when transporting and moving.

Choose an appropriate mounting position and surface.

Assign at least two persons to install the inverter.

Attention

3.1

Installation Process

Installation flowchart

3.2

Checking Before Installation

3.2.1

Checking Outer Packing Materials

Packing materials and components may be damaged during transportation. Therefore, check

the outer packing materials before installing the inverter. Check the outer packing materials

for damage, such as holes and cracks. If any damage is found, do not unpack the REFUone

inverter and contact the dealer as soon as possible. You are advised to remove the packing

materials within 24 hours before installing the REFUone inverter.

3.2.2

Checking Deliverables

After unpacking the inverter, check whether deliverables are intact and complete. If any

damage is found or any component is missing, contact the dealer.

End

Install the

Inverter

Install the rear panel

Check before

installation

Prepare installation

tools

Determine the

installation position

REFUone 3K-2T, 5K-2T, 7K-2T

16

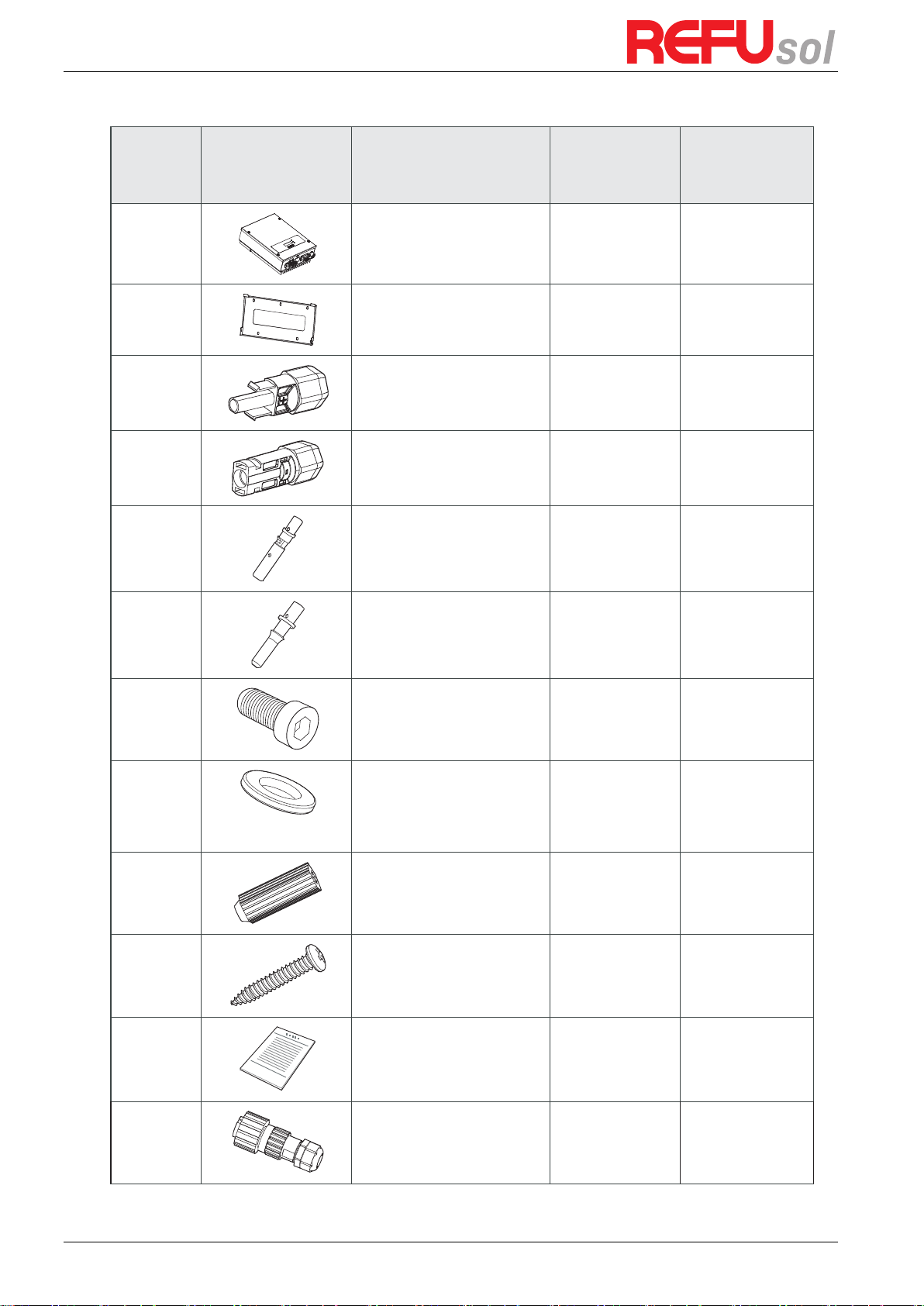

Table 1 shows the components and mechanical parts that should be delivered

No. Pictures

Description

Quantity

REFUone 3K2T, 5K-2T

Quantity

REFUone 7K-2T

1

REFUone inverter

1 pcs

1 pcs

2

Rear panel

1 pcs

1 pcs

3

PV+ input terminal

2 pcs

3 pcs

4

PV-input terminal

2 pcs

3 pcs

5

Metal terminals secured

to PV+ input power cables

2 pcs

3 pcs

6

Metal terminals secured

to PV- input power cables

2 pcs

3 pcs

7

M5 Hexagon screws

3 pcs

3 pcs

8

M6 flat washer

7 pcs

10 pcs

9

Expansion bolts

7 pcs

10 pcs

10

Self-tapping screw

5 pcs

8 pcs

11

Manual

(English and Portugese)

1 pcs

1 pcs

12 AC output terminal

1 pcs

-

REFUone 3K-2T …7K-2T

17

13 485 terminal (2pin)

1 pcs

-

14 AC connection housing

-

1 pcs

3.3

Tools

Prepare tools required for installation and electrical connections.

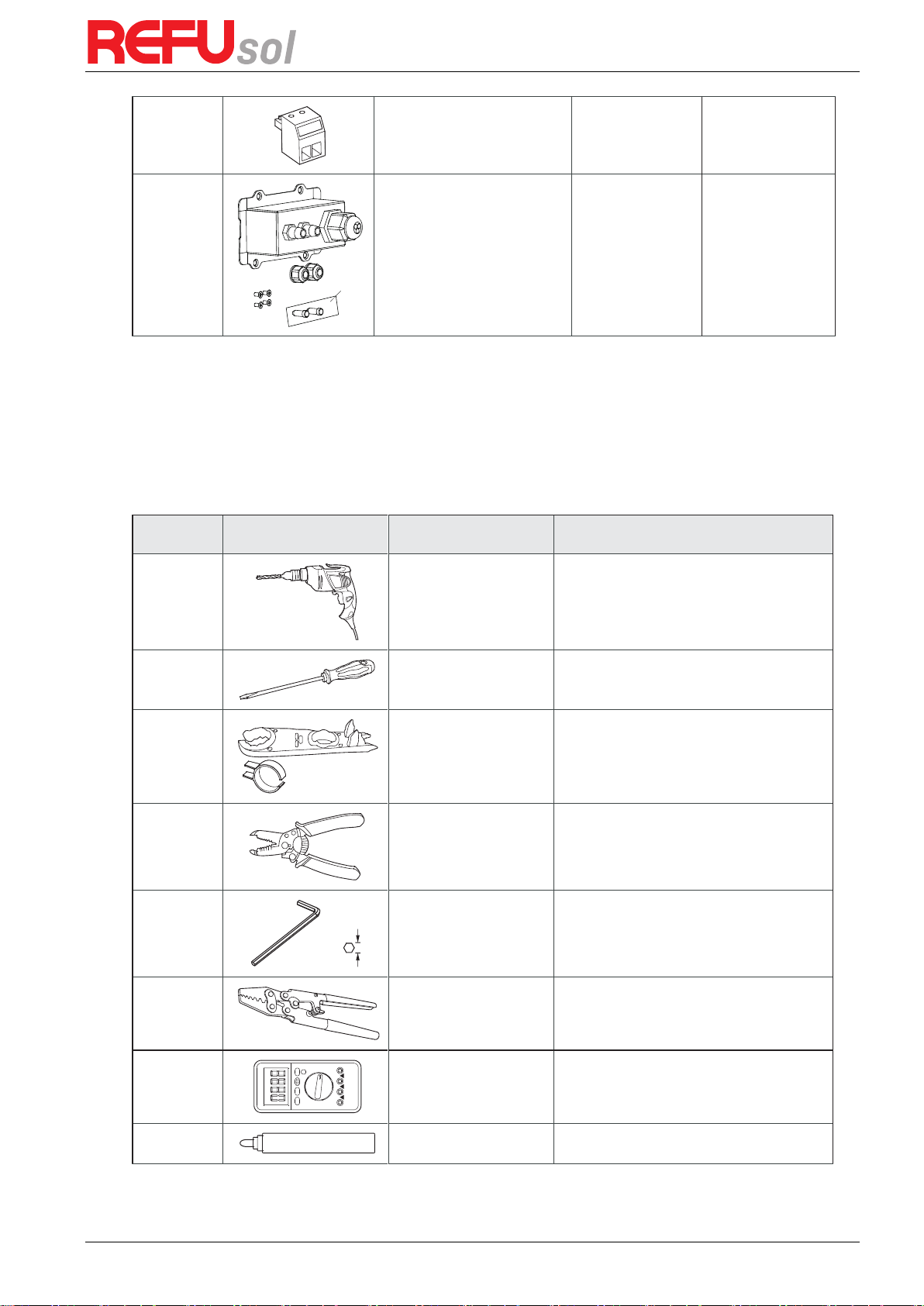

Table 2 shows the tools required for installation and electrical connections.

No.

Tool

Model

Function

1

Hammer drill

Recommend drill dia.

6mm

Used to drill holes on the wall

2

Screwdriver

wiring

3

Removal tool

Remove PV terminal

4

Wire stripper

Strip wire

5

4mm Allen Wrench

Turn the screw to connect rear panel

with inverter

6

Crimping tools

Used to crimp power cables

7

Multi-meter

Used to check grounding

8

Marker

Used to mark signs

A1

4.0

REFUone 3K-2T, 5K-2T, 7K-2T

18

9

Measuring tape

Used to measure distances

10

Level

Used to ensure that the rear panel is

properly installed

11

ESD gloves

Operators wear

12

Safety goggles

Operators wear

13

Anti-dust respirator

Operators wear

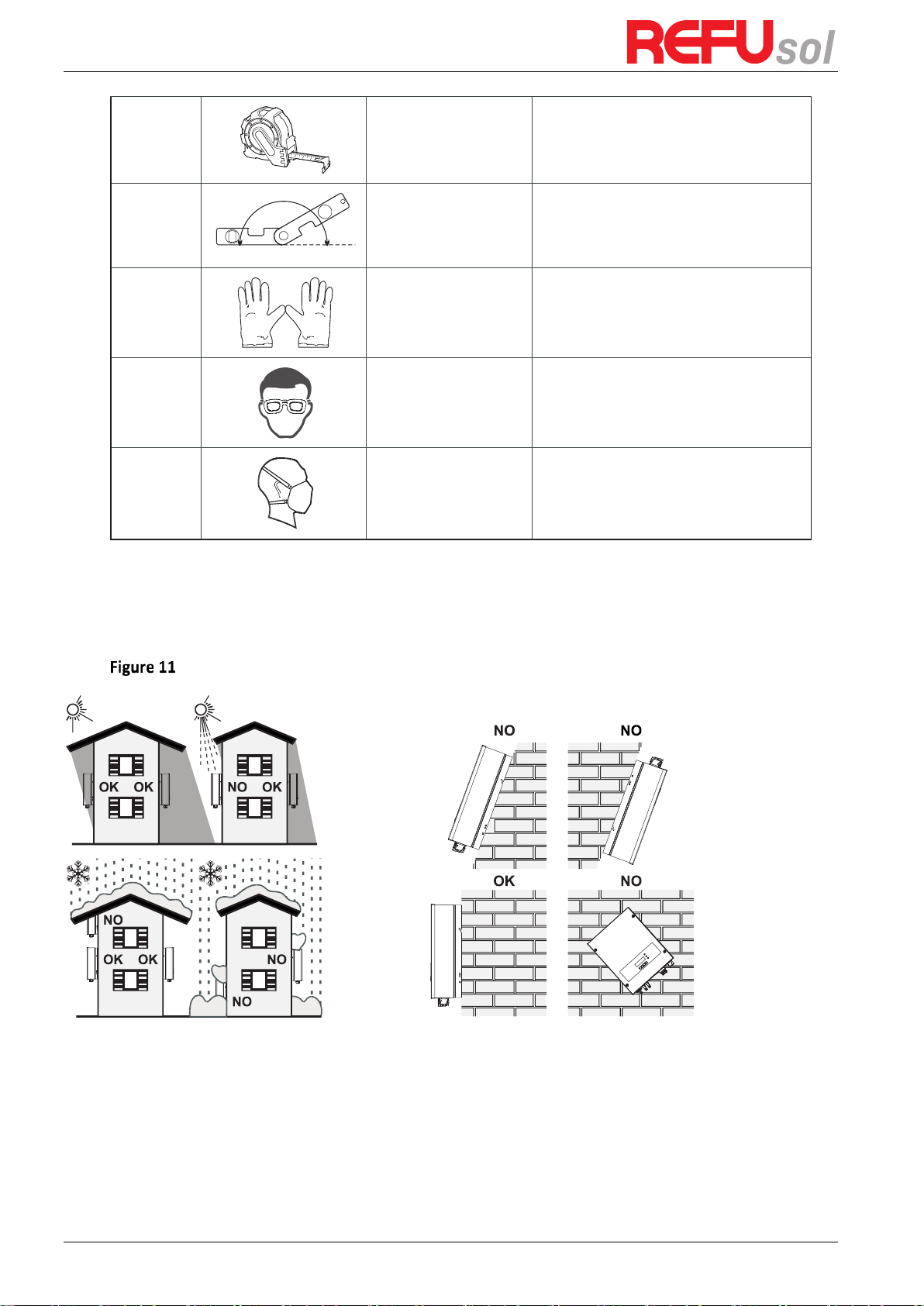

3.4

Determining the Installation Position

Determine an appropriate position for installing the REFUone inverter. Comply with the

following requirements when determining the installation position:

Installation Requirements

0-180º

REFUone 3K-2T …7K-2T

19

clearance for single REFUone inverter

Installation of multiple REFUone inverters

REFUone 3K-2T, 5K-2T, 7K-2T

20

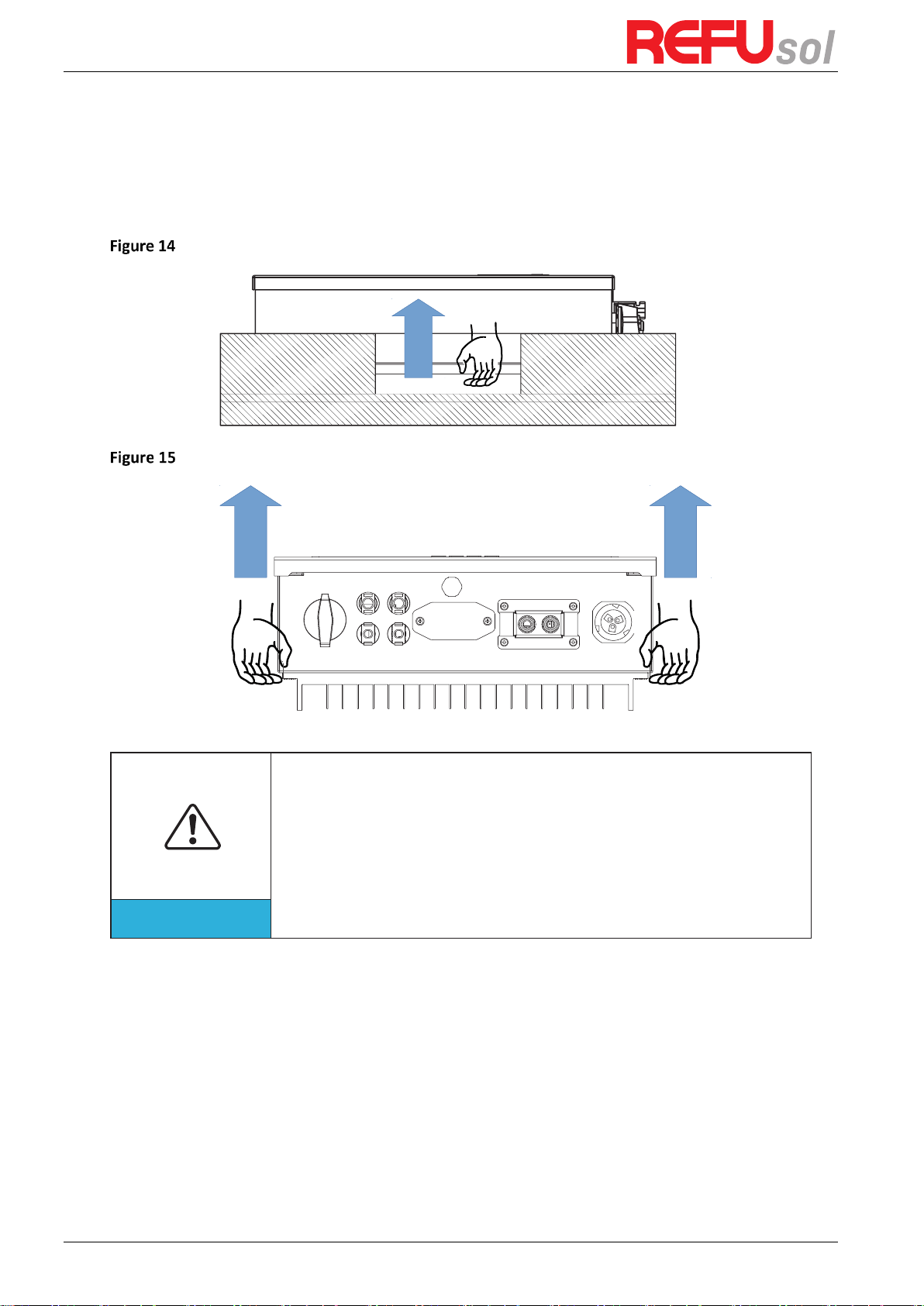

3.5

Moving the REFUone inverter

This topic describes how to move the REFUone horizontally to the installation position

Step 1

Open the packaging, insert hands into the slots on both sides of the inverter and hold

the handles, as shown in Figure 14and Figure 15.

Moving the inverter (1)

Moving the REFUone inverter (2)

Step 2

Lift the REFUone from the packing case and move it to the installation position.

To prevent device damage and personal injury, keep balance when moving the

inverter because the inverter is heavy.

Do not put the inverter with its wiring terminals contacting the floor because

the power ports and signal ports are not designed to support the weight of the

inverter. Place the inverter horizontally.

When placing the inverter on the floor, put foam or paper under the inverter to

protect its shell

Attention

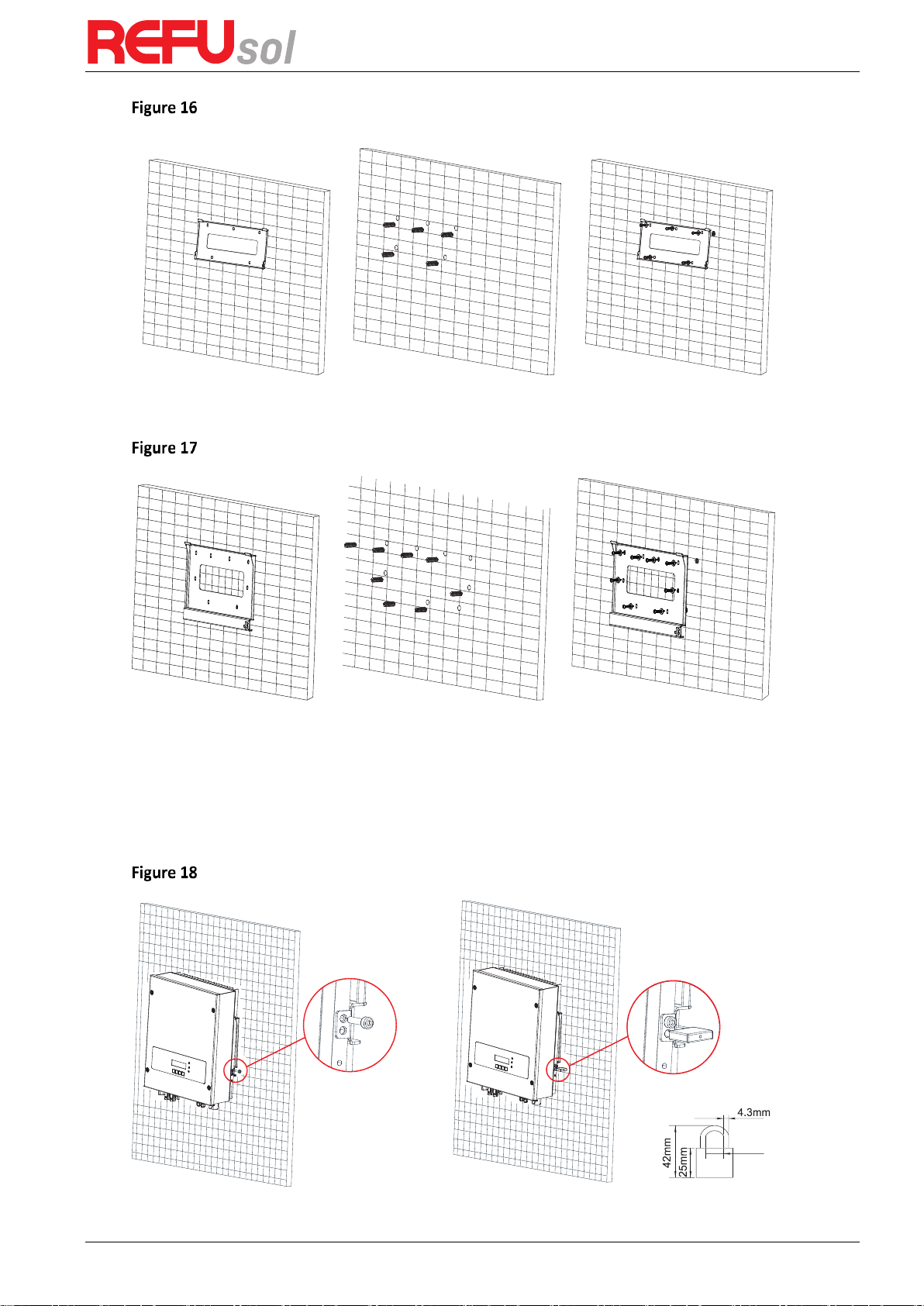

3.6

Installing REFUone inverter

Step 1

Determine the positions for drilling holes, ensure the hole positions are level, then mark

the hole positions using a marker pen, use the hammer drill to drill holes on the wall. Keep the

hammer drill perpendicular to the wall, do not shake when drilling, so as not to damage the

wall. If the error of the hole positions is too big, you need to reposition.

Step 2

Insert the expansion bolt vertically into the hole, pay attention to the insertion depth

of the expanding bolt (should be deep enough).

Step 3

Align the rear panel with hole positions, fix the rear panel on the wall by tightening the

expansion bolt with the nuts.

REFUone 3K-2T …7K-2T

21

Wall mounting 3K-2T, 5K-2T

Step 1 Step 2 Step 3

Wall mounting 7K-2T

Step 1 Step 2 Step 3

Step 4

Hook the inverter to the rear panel. Using an M5 screw to secure the inverter to the

rear panel to ensure safety.

Step 5

You can secure the inverter to the rear panel and protect it from stealing by installing

an anti-theft lock (this action is optional).

Securing the REFUone inverter

Step 4 Step 5

REFUone 3K-2T, 5K-2T, 7K-2T

22

Connect AC Output power

Cables

4

Electrical Connections

Outlines of this chapter

This topic describes the REFUone inverter electrical connections. Read this part carefully

before connecting cables.

NOTE:

Before performing electrical connections, ensure that the DC switch is OFF. Since the stored

electrical charge remains in a capacitor after the DC switch is turned OFF. So it’s necessary to

wait for at least 5 minutes for the capacitor to be electrically discharged.

Installation and maintenance of inverter, must be operated by professional

electrical engineer.

Attention

PV modules generate electric energy when exposed to sunlight and can create an

electrical shock hazard. Therefore, before connecting DC input power cable, cover

PV modules using opaque cloth.

Danger

In Germany, the PV array maximum voltage must be ≤ 600V, max output of

single inverter is 4.6KVA and max output of PV system is 13.8KVA.

The REFUone inverter has 2 MPP trackers, all PV modules connected to the

same MPPT should have similar rated electrical characteristics (including Isc,

Voc, Im, Vm, Pm and temperature coefficients), have the same number of

series connected PV modules and be all in the same orientation (azimuth and

tilt angle).

Note

4.1

Electrical connection

Shows the flowchart for connecting cables to the inverter

4.2

Connecting PGND Cables

Connect the inverter to the grounding electrode using protection ground (PGND) cables for

grounding purposes.

The inverter is transformer-less, requires the positive pole and negative pole of

the PV array are NOT grounded. Otherwise it will cause inverter failure. In the PV

power system, all non current carrying metal parts (such as: PV module frame, PV

rack, combiner box enclosure, inverter enclosure) should be connected to earth.

Attention

End

Connect Communication

Cables (not mandatory)

Start

Connect PGND Cables

Connect DC Input power

Cables

REFUone 3K-2T …7K-2T

23

Prerequisites:

The PGND cables are prepared (≥6mm² outdoor power cables are recommended for grounding

purposes), the color of cable should be yellow-green.

Procedure:

Step 1

Remove the insulation layer with an appropriate length using a wire stripper, as shown

in Figure 20.

Preparing a ground cable (1)

Step 2

Insert the exposed core wires into the OT terminal and crimp them by using a crimping

tool, as shown in Figure 21.

Preparing a ground cable (2)

Note 1:

L3 is the length between the insulation layer of the ground cable and the crimped

part.L4 is the distance between the crimped part and core wires protruding from the

crimped part.

Note 2:

The cavity formed after crimping the conductor crimp strip shall wrap the core wires

completely. The core wires shall contact the terminal closely.

Step 3

Install the crimped OT terminal, flat washer using M5 screw, and tighten the screw to a

torque of 3 Nm using an Allen wrench.

Ground terminal composition

L2=L1+(2-3)mm

L1

L3<2mm

L4<1.5mm

1. M5 screw

2. Flat washer

3. OT Terminal

REFUone 3K-2T, 5K-2T, 7K-2T

24

4.3

Connecting DC Input Power Cables

The REFUone 3K-2T … 7K-2T has 2 MPP Trackers. The MPPT 1 and MPPT 2

input is marked with PV1 and PV2 respectively at the connectors.

The maximum power for each MPPT is limited (see chapter 8.1 DC Data)!

If you want to use the full power of the inverter, both inputs need to be

connected.

If you want to use one string of solar panels only, you need to connect it to

both inputs PV1 and PV2 in parallel, and set the inverter input mode to

“parallel mode” (see chapter 6.3 Main Interface at (A) 9. Set Input mode).

Attention

Correct string connections with 1 String on 3K/5K-2T, and 2 Strings on 7K-2T

Table 3 Recommended DC input cable specifications

Cross-Sectional Area (mm2)

External Cable Diameter (mm)

Range

Recommended Value

4.0 … 6.0

4.0

4.5 … 7.8

Procedure

Step 1

Remove cable glands from the positive and negative connectors.

Step 2

Remove the insulation layer with an appropriate length from the positive and negative

power cables by using a wire stripper as show in Figure 24.

REFUone 3K/5K-2T

1 String - correct

1 to 2 Adapter

PV 1

PV 2

MPPT 2

MPPT 1

...

REFUone 7K-2T

2 Strings - correct

PV 1

PV 1

PV 2

MPPT 1

MPPT 2

...

...

REFUone 3K-2T …7K-2T

25

Connecting DC input power cables

Step 3

Insert the positive and negative power cables into corresponding cable glands.

Step 4

Insert the stripped positive and negative power cables into the positive and negative

metal terminals respectively and crimp them using a clamping tool. Ensure that the cables are

crimped until they cannot be pulled out by force less than 400 N, as shown in Figure 25:

Connecting DC input power cables

1.

Positive power cable

2.

Negative power cable

Step 5

Insert crimped power cables into corresponding housings until you hear a "click" sound.

The power cables snap into place.

Step 6

Reinstall cable glands on positive and negative connectors and rotate them against the

insulation covers.

Step 7

Insert the positive and negative connectors into corresponding DC input terminals of

the inverter until you hear a "click" sound, as shown in Figure 26:

Connecting DC input power cables

1. Bayonet

Note: Insert the stoppers into the unused DC connectors.

1. Positive power cable

2. Negative power cable

Note

L2 is 2 to 3 mm longer than L1.

REFUone 3K-2T, 5K-2T, 7K-2T

26

Follow-up Procedure

To remove the positive and negative connectors from the inverter, insert a removal wrench

into the bayonet and press the wrench with an appropriate strength, as shown in Figure 27

Before removing the positive and negative connectors, ensure that the DC SWITCH

is OFF.

Caution

Removing a DC input connector

4.4

Connecting AC Output Power Cables

Connect the REFUone to the AC power distribution frame (PDF) or power grid using AC output

power cables.

It is not allowed for several inverters to use the same circuit breaker

It is not allowed to connect loads between inverter and circuit breaker

AC breaker used as disconnect device, and the disconnect device shall remain

readily operable.

In Italy, any solar system bigger than 6kW should be connected to grid via an

external SPI.

Caution

Context

All the AC output cables used for the inverters are outdoor three-core cables. To facilitate the

installation, use flexible cables. Table 4-2 lists the recommended specifications for the cables.

NOT allowed: connect loads between inverter and circuit breaker

TV

REFUone 3K-2T …7K-2T

27

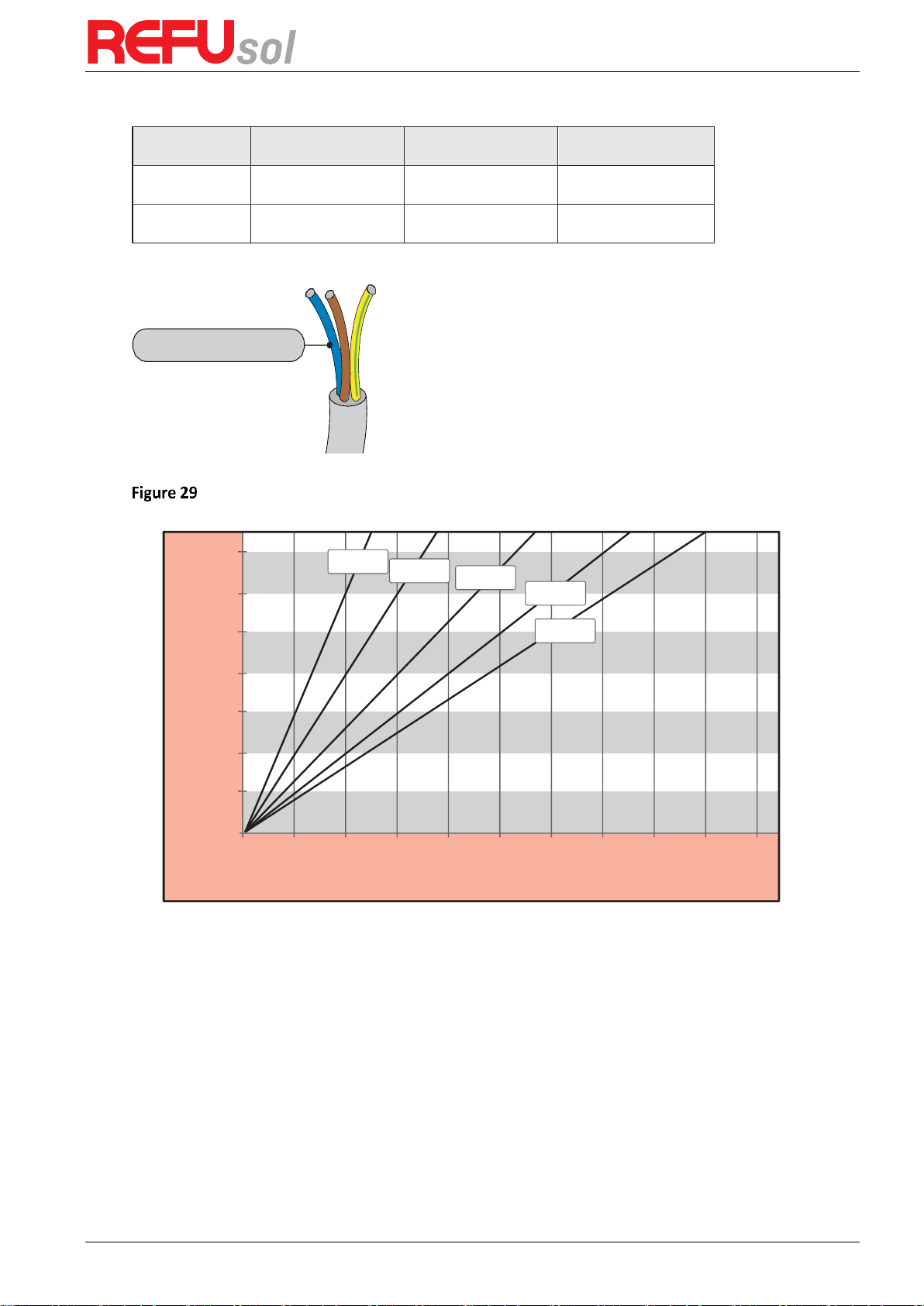

Table 4 Recommended AC output cable specifications

Model

REFUone 3K-2T

REFUone 5K-2T

REFUone 7K-2T

Cable (Copper)

≥ 4mm²

≥ 6mm²

≥ 6mm²

Circuit Breaker

20A/230V/2P/0.1A

32A/230V/2P/0.1A

40A/230V/2P/0.1A

Multi core copper wire

AC cable should be correctly sized to ensure the power loss

in AC cable is less than 1% of the rated power. If the

resistance of the AC cable is too high, it will cause a huge

increase in the AC voltage, which may lead to a

disconnection of the inverter from the electrical grid. The

relationship between power loss in AC cable and wire

length, wire cross sectional area is shown in the following

figure:

wire length, wire cross sectional area and wire power loss:

REFUone 3K-2T, 5K-2T AC wire connections procedure:

Step 1

Select appropriate cables according to Table 4-2, Remove the insulation layer of the AC

output cable using a wire stripper according to the figure shown below:

0m 10m 20m 30m 40m 50m 60m 70m 80m 90m 100m

1.4%

1.2%

1.0%

0.8%

0.6%

0.4%

0.2%

0.0%

Loss

Length

2.5mm²

4.0mm²

6.0mm²

8.0mm²

10.0mm²

Multi core copper wire

REFUone 3K-2T, 5K-2T, 7K-2T

28

A: 30 … 50mm B: 6 … 8mm;

Step 2

Disassemble the AC connector according to the figure shown below: insert the AC

output cable (with its insulation layer stripped according to step 1) through the waterproof

locking cable gland;

Step 3

Connect AC output cable as per the following requirements:

Connect the yellow-green wire to the hole labeled ‘PE’, fasten the wire using an Allen wrench;

Connect the brown wire to the hole labeled ‘L’, fasten the wire using an Allen wrench;

Connect the blue wire to the hole labeled ‘N’, fasten the wire using an Allen wrench;

L--brown, N--blue, PE--yellow/green

Step 4

Secure the locking cable gland clockwise, shown as below: make sure that all the wires

are securely connected;

Step 5

Connect the AC output connector to the output wiring terminal of inverter, rotate the

AC connector clockwise until the fastener reaches its designated position, as shown below:

A

B

REFUone 3K-2T …7K-2T

29

Step 4 Step 5

REFUone 7K-2T: AC wire connections procedure:

Step 1:

As shown in Figure 34to make the output line, the wire ends need to use tube-type

terminals. It is recommended to use tube-type terminals KST model: E6012 (10 AWG)

A1: recommendation: Tube type terminal KST model: E6012 (10AWG)

Step 2:

As shown in Figure 35, remove the waterproof cover with the cross screwdriver.

Step 3:

As shown in Figure 36, remove the waterproof plug, put the finished output cable

through the waterproof lock nut, Connect AC output cable as per the following requirements:

A1

REFUone 3K-2T, 5K-2T, 7K-2T

30

A2: waterproof plug

Connect the yellow and green cable to the lock hole of AC terminal marked with

identification;

Connect the red line to the lock hole of the terminal with L identification AC; connect the

black line to the lock hole of the terminal with N identification AC;

Step 4:

as shown in Figure 37, tighten

the

waterproof lock nut, cover and tighten it.

install the waterproof

4.5

Connecting Communications Cables

The wiring methods are the same for RS485, DRM0 and CT, this part describes their wiring

methods all together:

Table 5 Recommended communication cable sizes are shown below

Communication function

RS485

DRM0

(External Contact)

CT

(Current Transformer)

Cable size

0.5 … 1.5 mm²

0.5 ... 1.5 mm²

0.5 … 1.5 mm²

Outside diameter

2.5 … 6 mm

2.5 … 6 mm

2.5 … 6 mm

Step 1:

Remove the communication waterproof cover using a screwdriver;

L

N

A2

REFUone 3K-2T …7K-2T

31

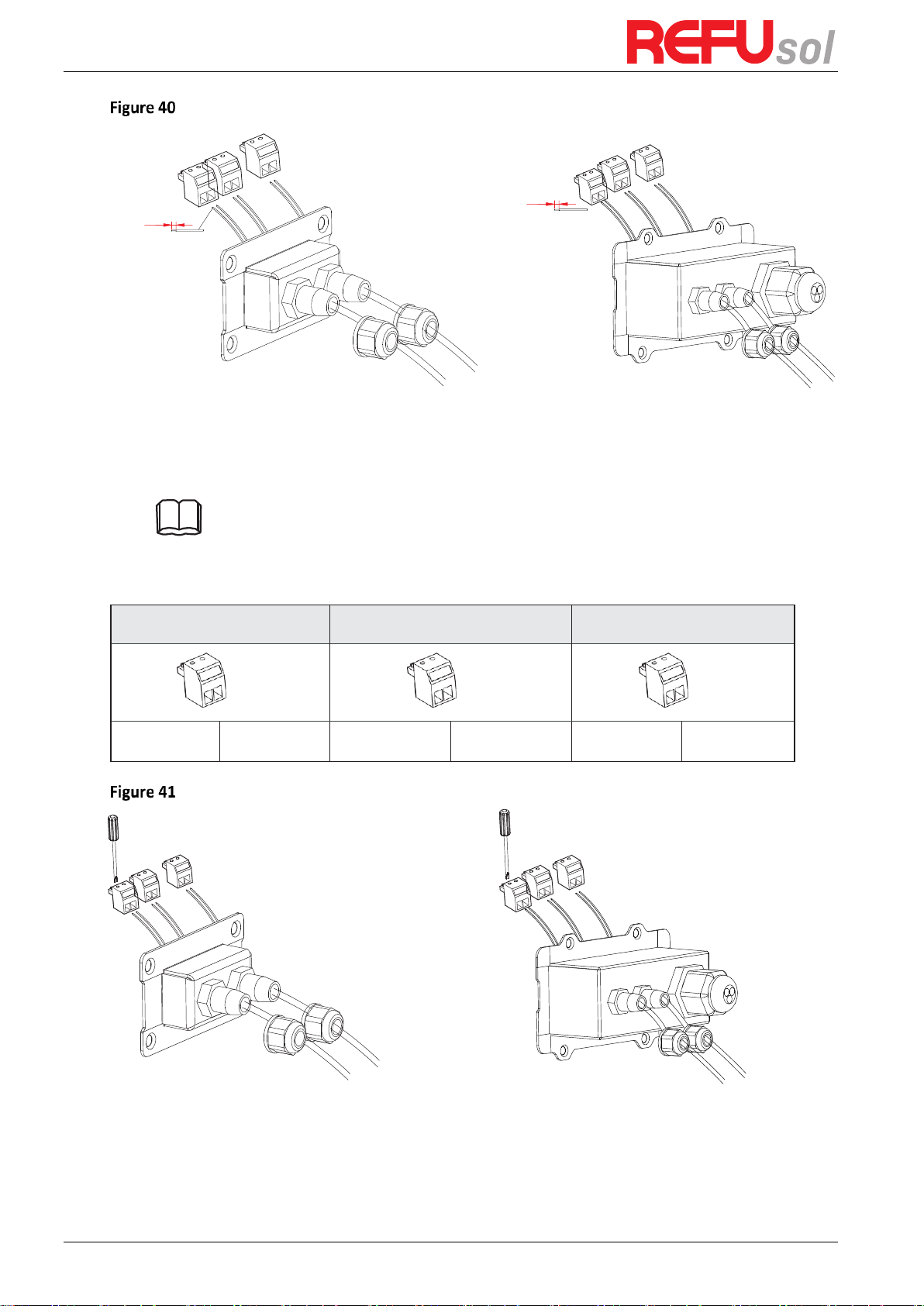

A1

Cable Gland

REFUone 3K-2T, 5K-2T REFUone 7K-2T

Step 2:

Unlock the waterproof cable gland, remove the stopper in the waterproof connector

Cable Gland

REFUone 3K-2T, 5K-2T REFUone 7K-2T

Note: The waterproof connectors correspond to: I/O, dry contact, RS485 from left to

right. Unlock the waterproof connectors according to the communication functions you

are using. Do NOT unlock the unused connectors.

Step 3:

Select appropriate cable according to Table 5, remove the insulation layer using a wire

stripper, the length of the wire core is about 6 mm, insert the cable through the cable gland

and waterproof cover, as shown in the figure below:

A1: Waterproof stopper

REFUone 3K-2T, 5K-2T, 7K-2T

32

cut

6 mm

REFUone 3K-2T, 5K-2T REFUone 7K-2T

Step 4:

Choose the terminal according to Table 6, connect the wires as per the labels, and

secure the wires using a slotted screwdriver.

Note: keep the unused terminals for future use.

Table 6 functional description of the communication terminals

RS485

DRM0

CT

(2 pin)

(2 pin)

(2 pin)

TX-

TX+

DRM0

GND

CT-

CT+

REFUone 3K-2T, 5K-2T REFUone 7K-2T

Step 5:

Insert the terminal as per the printed label, and then tighten the screws to fix the

waterproof cover, rotate the cable gland clockwise to fasten it securely.

6 mm

cut

REFUone 3K-2T …7K-2T

33

cut

Connected in parallel

6 mm

REFUone 3K-2T, REFUone 5K-2T REFUone 7K-2T

If users need to connect multiple inverters via RS485 wires, refer to the figure shown below:

RS485 wires are connected in parallel, so 4 wires may be required. First connect the two 485+

(TX+) wires in parallel, then connect the two 485- (TX-) wires in parallel, then insert them into

the terminal and tighten the screws using a slotted screwdriver.

Note: We recommend using two different colors of wires to connect TX- (485-) and TX+ (485+).

Wires of the same color are connected together to avoid wrong wire connections.

REFUone 3K-2T, 5K-2T REFUone 7K-2T

REFUone 3K-2T, 5K-2T, 7K-2T

34

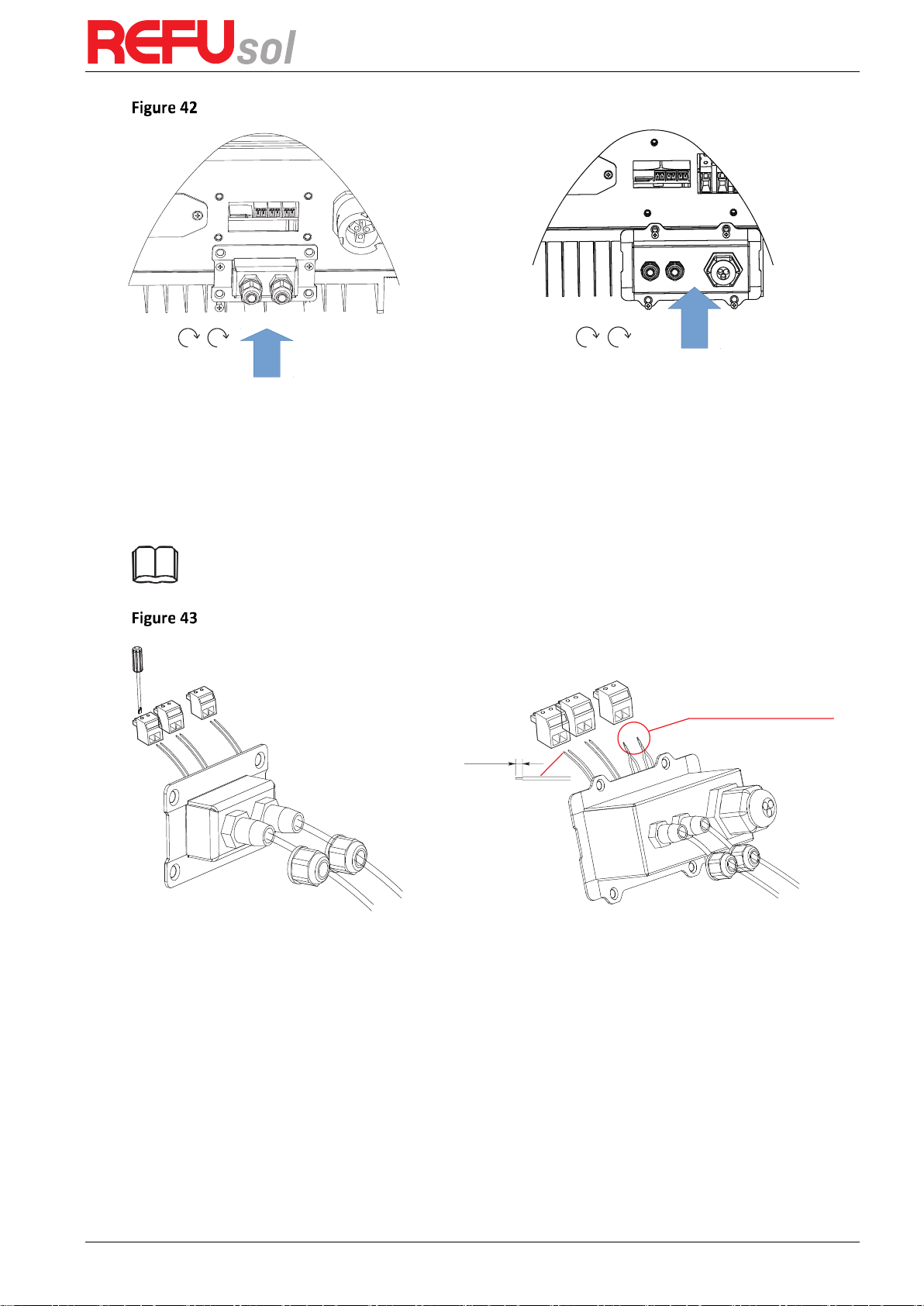

4.6

WiFi/GPRS module installation procedure

Step 1

: remove WiFi/GPRS waterproof cover using screw driver

Step 2

: Assemble logger to the inverter communication interface as shown in the diagram.

Step 3

: fasten WiFi/GPRS module using screws.

REFUone 3K-2T …7K-2T

35

4.7

WiFi Communication

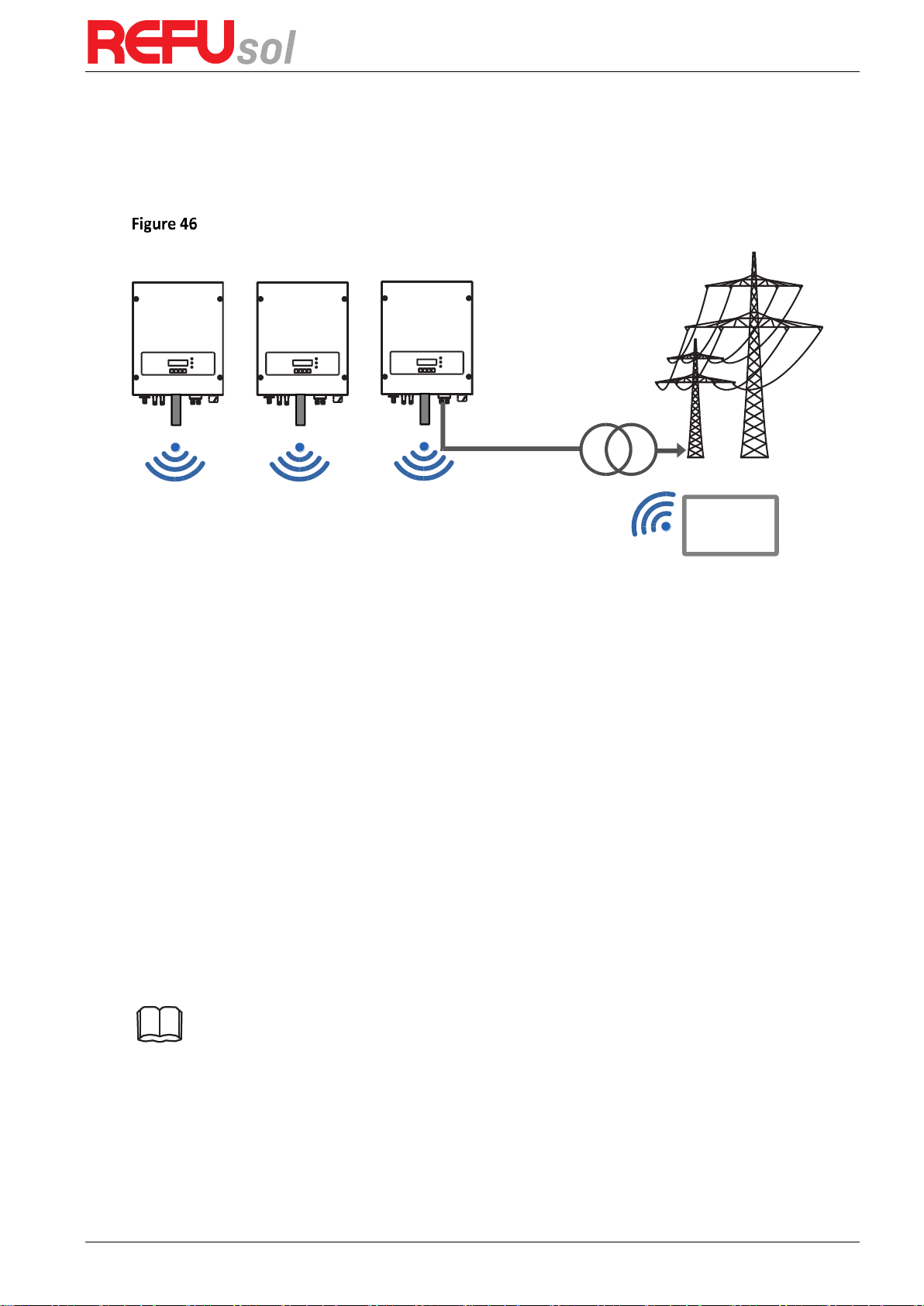

The REFUone grid-connected inverters offer Wi-Fi communication modes as standard.

Refer to the figure shown below:

The operation information (generated energy, alert, operation status) of the inverter can be

transferred to the REFUlog monitoring portal via WiFi.

4.7.1

Configuration of WiFi Stick with PC

Preparation:

The WiFi Stick is installed according to section 4.6 and the REFUone Inverter must

be running.

Follow the following steps to configure the WiFi stick:

Step 1

: connect your PC with WiFi network to the Access Point of the WiFi stick. The name of

the WiFi is “AP” followed by the serial number of the WiFi Stick (see type label)

If you are asked for a password, read it from the WiFi Stick label at PWD

Step 2

: Open an internet browser, and enter the address

10.10.100.254

Recommended browsers: Internet Explorer 8+, Google Chrome 15+, Firefox 10+

Step 3

: Fill in username and password, both of which are “admin” as default. The Status page

opens

Step 4

: Click “Wizard” to configure how the WiFi Stick can access your internet gateway.

Result: the WiFi Stick will start to send monitoring data to REFUlog.

Note: Please refer to the detailed instructions delivered with the WiFi stick.

Internet

Gateway

REFUone 3K-2T, 5K-2T, 7K-2T

36

4.7.2

Configuration of WiFi Stick with App

To download the App for iPhone, search "REFUone Set" in Apple Store.

To download the App for Android, search "REFUone Set" in Google Play Store.

WiFi Connection Configuration

1) The App will automatically get your WiFi network, so you need to enter your WiFi password

to continue the configuration. If the network is not correct, select [switch network], then

find or manually enter the network ID.

2) On iPhone, go to [Network Settings] interface, and select the stick logger's network with

the name AP _XXXXX (Serial Number of the WiFi Stick without leading 0). Then return to

the App, the WiFi Stick will start to configure.

3) The connection will automatically start after connect the network.

Note: If it is unable to find an AP_XXXXX (Serial number without leading 0) in

wireless network list, please make sure to shorten the distance between WiFi

routers and Stick to under 10 meters. The connection or setting may appear

problem, if you have repeat the above steps and still cannot find the AP _XXXXX.

Please follow the WiFi Stick Manual for troubleshooting or contact our Customer

Center.

4.8

Monitoring Portal REFUlog

The REFUone inverter are sending the operating data to the REFUlog monitoring portal, when

the WiFi connection is established.

Once an internet connection is established, the inverter will automatically start to send data

to REFUlog every 5 minutes.

To view the inverter data, open

www.refu-log.com

with your browser and login with your

existing username and password or register as a new user.

You can use the activation code provided on the inverter to assign one or more inverter to a

PV system in your account.

REFUlog Monitoring Portal

REFUone 3K-2T …7K-2T

37

4.9

RS485 Communication

4.9.1

Communication between one inverter and one PC with RS485

Refer to the figure shown below, connect the TX+ and TX- of the inverter to the TX+ and TX- of

the RS485 to USB adapter, and connect the USB port of the adapter to the computer. (Note 1)

1: Radio ripple control receiver 2: RS485 to USB Adapter

4.9.2

Communication between multiple inverters and one PC with RS485

Refer to the following figure: RS485 wires are connected in parallel between inverters, refer to

section 4.5 of this manual for wire connection methods. Connect the TX+ and TX- of the

inverter to the TX+ and TX- of the RS485→USB adapter; connect the USB port of the adapter

to the computer. A maximum of 31 inverters can be connected in one daisy chain. (Note 2)

1: Radio ripple control receiver 2: RS485 to USB Adapter

Note 1:

The length of the RS485 communication cable should be less than 1000 m.

Note 2:

When multiple inverters are connected via RS485 wires, set mod-bus

address to differentiate the inverters.

1

2

PC

1

2

PC

REFUone 3K-2T, 5K-2T, 7K-2T

38

5

Commissioning of inverter

5.1

Safety inspection before commissioning

5.2

Start Inverter

Step 1:

Turn ON the DC switch.

Step 2:

Turn ON the AC circuit breaker.

When the DC power generated by the solar array is adequate, the REFUone inverter will start

automatically. Screen showing „normal” indicates correct operation.

Step 3:

Choose the correct country code. (Refer to section 6.3 of this manual)

Notice: Different distribution network operators in different countries have different

requirements regarding grid connections of PV grid connected inverters.

Therefore, it is very important to make sure that you have selected the correct country code

according to requirements of local authority.

Please consult qualified electrical engineer or personnel from electrical safety authorities

about this.

REFU Elektronik GmbH is not responsible for any consequences arising out of incorrect country

code selection.

If the inverter indicates any fault, please refer to of this manual trouble shooting for help.

Ensure that DC and AC voltages are within the acceptable range of the inverter.

Attention

REFUone 3K-2T …7K-2T

39

6

Operation interface

Outlines of this chapter

This section introduces the display, operation, buttons and LED indicator lights of REFUone

Inverter.

6.1

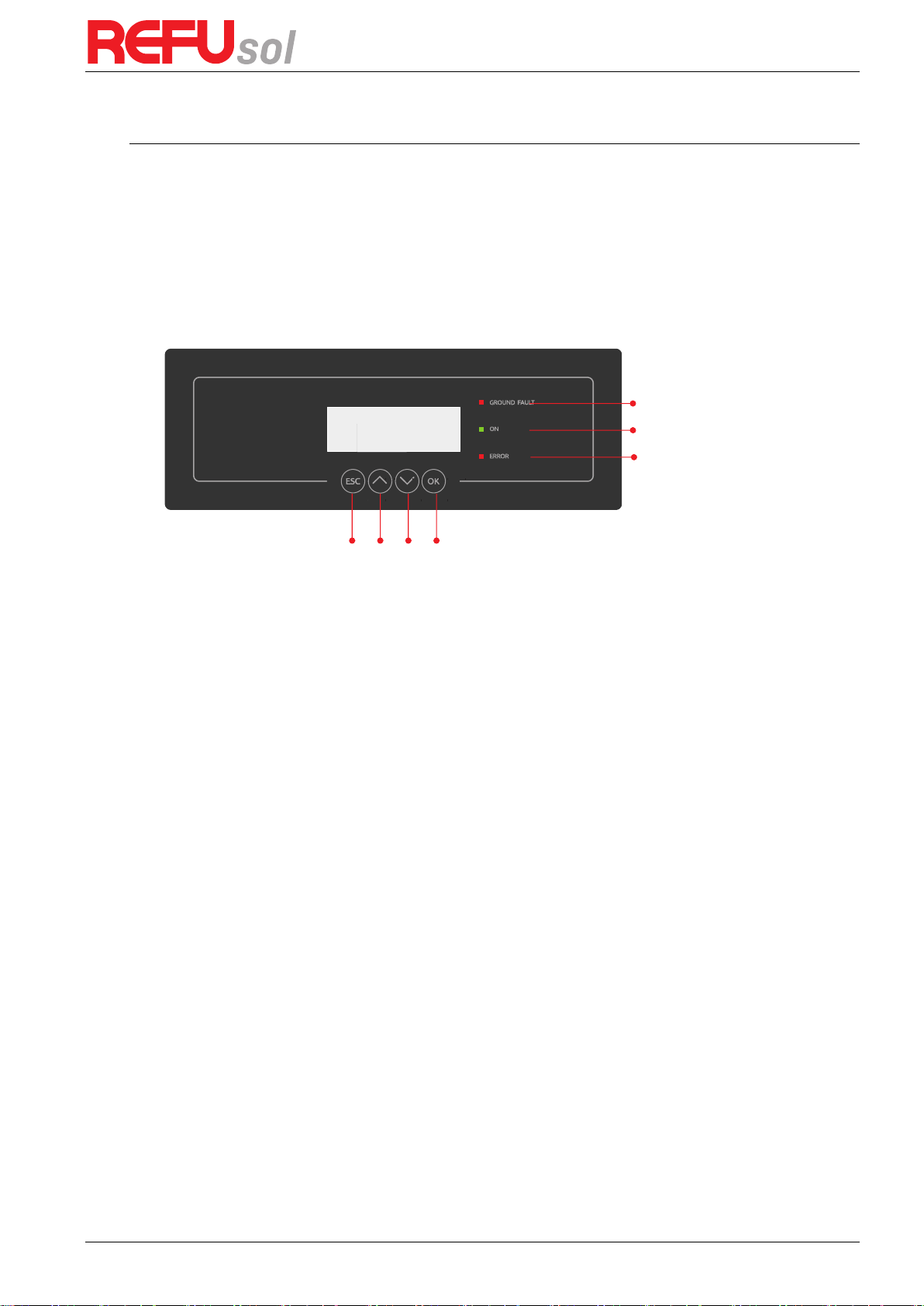

Operation and Display Panel

Buttons and Indicator lights

Ground Fault Warning Light

Inverter Status Light

Warning Light

Key buttons

(A) Key buttons

Back

: to return to previous menu or enter into main menu from the standard interface.

Up

: to move up or increase value

Down

: to move down or decrease value

OK

: to confirm selection

(B) Indicator Lights

Inverter States Light(GREEN)

o Flashing: ‘Wait’ or ‘Check’ state

o ON: ‘Normal’ state

o OFF: ‘Fault’ or ‘Permanent’ state

Warning Light (RED)

o ON: ‘Fault’ or ‘Permanent’ state

o OFF: ‘Normal’ state

GFCI Warning Light (RED)

o ON: ‘ID12: GFCIFault’ or ‘ID20: GFCIDeviceFault’

o OFF: GFCI normal

REFUone 3K-2T, 5K-2T, 7K-2T

40

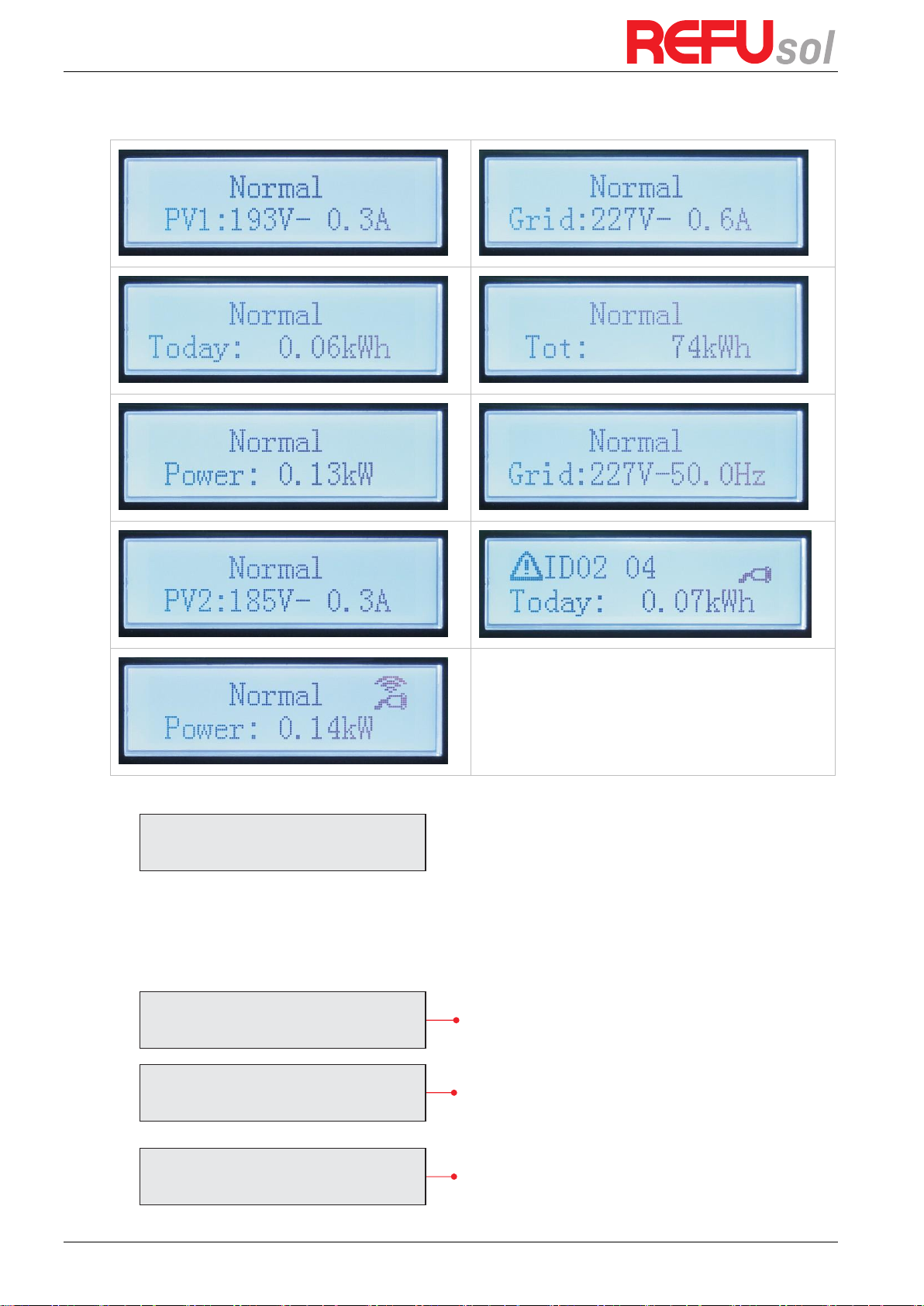

6.2

Standard Interface

When power-on, LCD interface displays INITIALIZING, refer below picture.

When control board successfully connected with communication board, the LCD display the

current state of the inverter, display as shown in the figure below.

Waiting States, Countdown 10S

(depends country code, some are 60s)

Checking

Normal Power Generation

Initializing…

Wait 10s

Check

Normal

REFUone 3K-2T …7K-2T

41

Regular error state

Unrecoverable error state

(C) Inverter states includes: wait, check, normal, fault and permanent

Wait:

Inverter is waiting to Check State at the end of reconnection time. In this state,

grid voltage value is between the max and min limits and so on; If not, Inverter

will go to Fault State or Permanent State.

Check:

Inverter is checking isolation resistor, relays, and other safety requirements. It

also does self-test to ensure inverter software and hardware are functional.

Inverter will go to Fault State or Permanent State if any error or fault occurs.

Normal:

Inverter enter to Normal State, it is feeding power to the grid; inverter will go

to Fault State or Permanent state if any error or fault occurs.

Fault:

Fault State: Inverter has encountered recoverable error. It should recover if the

errors disappear. If Fault State continues, please check the inverter according

error code.

Permanent:

Inverter has encountered unrecoverable error, we need maintainer debug this

kind of error according to error code.

When the control board and communication board connection fails, the LCD display interface

as shown in the figure below.

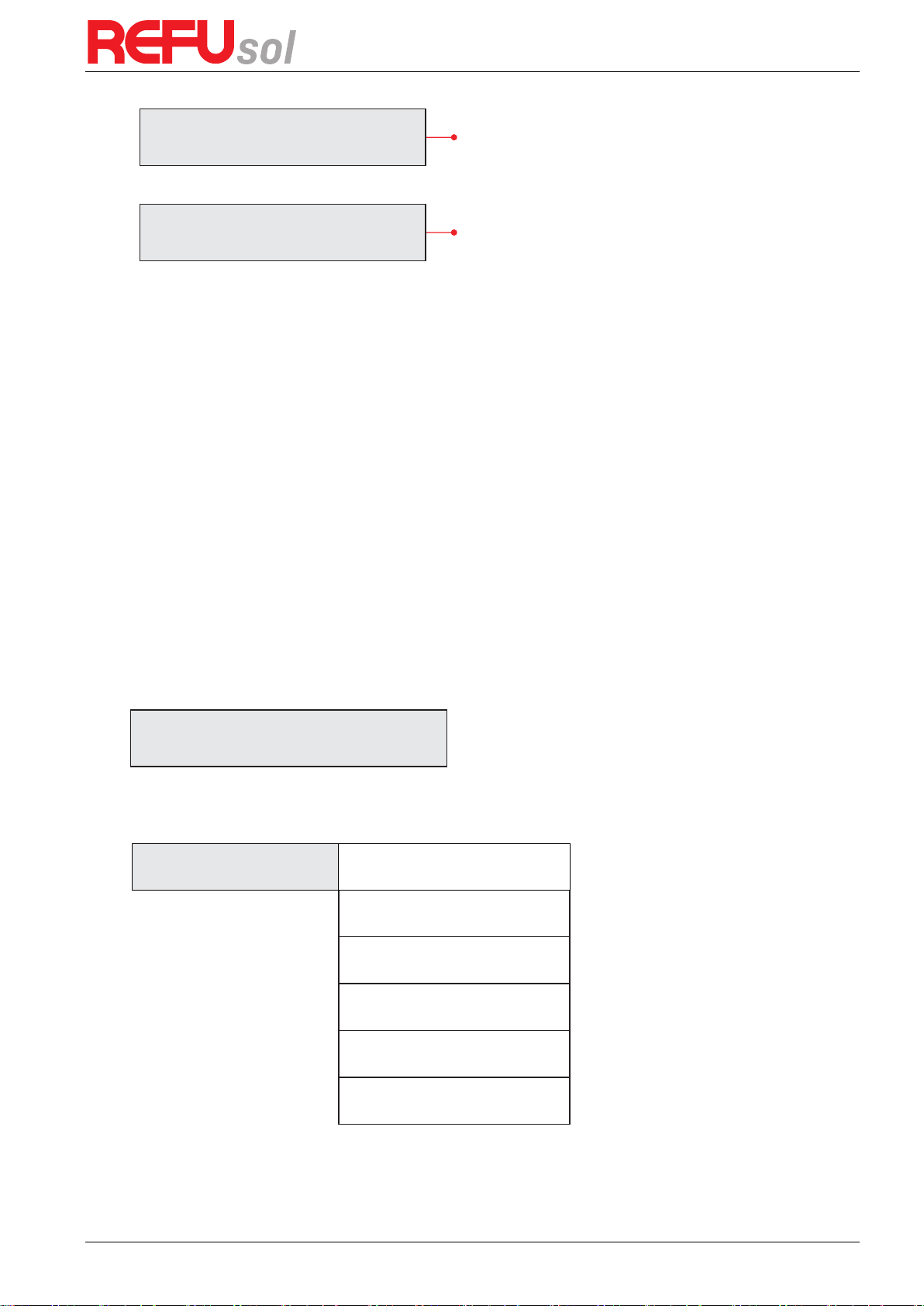

6.3

Main Interface

Press „ESC” button under standard interface to enter into main interface, including:

Normal

1. Enter Setting

2. Event List

3. SystemInfo

4. System Time

5. Software Update

Fault

Permanent

DSP communicate fail

REFUone 3K-2T, 5K-2T, 7K-2T

42

(A) “Enter Setting” Interface as below:

1.Enter Setting

1. Set Time

11. Set Start Parameter

2. Clear Energy

12. Set Safety Voltage

3. Clear Events

13. Set Safety Frequency

4. Set Country

14. Insulation Resistance

5. On-Off Control

15. Set Reactive Power

6. Enable Set Country

16. Set Power Derate

7. Set Energy

17. Reflux Power

8. Set Address

18. MPPT Scan

9. Set Input mode

19. DRM0 Control

10. Set Language

1. Set Time

Users press „ESC” button to enter „Enter Setting” interface, Press „OK” button to enter main

setting interface. Enter „ Set Time” by pressing „Up” button or „Down” button, then press ”OK“

button and start to set up time.

Time set from year, month, day, minutes, and seconds in turns, „Up” button or „Down” button

to choose different value to set each date. Set each value is need to press „OK” button to

confirm setting. „success” is displayed if the setting time is correct, „fail” means failure

settings.

2. Clear Energy

Users press „ESC” button to enter „Enter Setting” interface, Press OK button to enter main

setting interface. Then Enter „Clear Energy” by pressing „Up” button or „Down” button, press

„OK” to enter password 001 by pressing „Up” and „Down” button and then press „Enter” to

start to clear produce. „success” is displayed after settings.

3. Clear Events

Users press „ESC” button to enter „Enter Setting” interface, Press „OK” button to enter main

setting interface. Enter „Clear Events” by pressing „Up” button or „Down” button. Press „OK”

button and start to clear events. „success” is displayed after settings.

4. Set Country

Users press „ESC” button to enter „Enter setting” interface, Press OK button to enter main

setting interface. Enter „Set Country Code” by pressing „Up” button or „Down” button, press

„OK” button. If it shows “set disable” on the screen, then you can NOT choose the operating

country, you should enable country setting through "Enable Set Country" interface. If it shows

"set Country code?" on the screen, then press “OK” button to start country setting. "Success"

will be shown on the screen after a successful country setting.

REFUone 3K-2T …7K-2T

43

Table 7 Country code setting

Code

Country

Code

Country

Code

Country

00 Germany VDE AR-N4105

12 Poland

24 Cyprus

01 CEI0-21 Internal

13 Germany BDEW

25 India

02

Australia

14 Germany VDE 0126

26 Philippines

03 Spain RD1699

15 Italy CEI0-16

27 NewZealand

04 Turkey

16 UK-G83

28 Brazil

05 Denmark

17 Greece island

29 Slovakia VSD

06 Greece Continent

18 EU EN50438

30 Slovakia SSE

07 Netherland

19 IEC EN61727

31 Slovakia ZSD

08 Belgium

20 Korea

32

CEI0-21 In Areti

09 UK-G59t

21 Sweden

10 China

22

Europe General

11 France

23 CEI0-21 External

5. Remote Control

Users press „ESC” button to enter „Enter setting” interface, Press OK button to enter main

setting interface. Enter „Remote Control” by pressing „Up” button or „Down” button. Press „OK”

button and enter Remote Control Switch on and off interface. Choose „Enable” or „Disable”

by pressing „Up” button or „Down” button, press „OK” button, then communication board

start to transmit control signals to control board. „Success” is displayed after setting success;

otherwise it will show „fail”.

6. Enable Set Country

Users press Back button to enter „Enter setting” interface, Press OK button to enter main

setting interface. Enter „Enable Set Country” by pressing „Up” button or „Down” button, press

„OK” button and enter „Input Password” Setting interface. Press „ESC” button to set

passwords (default: 0001), increase or decrease value though pressing „Up” button or „Down”

button, press „OK” button to next value setting. „Error!” Try again” will be displayed for wrong

passwords. Press „ESC” button and rekey in the correct passwords. „ Success” will be displayed

if setting successfully.

Attention: when inverter working for power generation over 24h, country setting is forbidden,

it can only be set after LCD setting. Key in passwords for country setting through LCD (default:

0001), country setting can be set in 24h after keying in the correct passwords, over 24h, set

through LCD again.

7. Set Energy

Users press Back button to enter „Enter setting” interface, Press OK button to enter main

setting interface. Enter „Set Total Energy” by pressing „Up” button or „Down” button , then press

„OK” button and enter „Input Password” Setting interface. Press „OK” button to set passwords

(default: 0001), increase or decrease value though pressing „Up” button or „Down” button,

REFUone 3K-2T, 5K-2T, 7K-2T

44

press „OK” button to confirm the value and to next value setting. „Error! Try again” will be

displayed for wrong passwords. Press „ESC” button and rekey in the correct passwords then

set total energy. „Success” or „fail” is displayed after setting.

8. Set address

Users press „ESC” button to enter „Enter setting” interface, press ”OK“ button to enter main

setting interface. Enter „ Set address” by pressing „Up” button or ”Down“ button. Press „OK”

button and enter setting interface. Choose corresponding setting items by pressing „Up”

button or „Down” button, then press „OK” button. „Success” or „fail” is displayed after setting.

9. Set Input mode

Input mode selection: the inverter has 2 MPPT channels, the 2 MPPT can operate independently, also can operate in parallel. If the PV strings are connected in parallel outside the

inverter, you should choose the "in parallel mode", otherwise use the default setting. Press

„ESC” button to enter „Enter setting” interface, press ”OK“ button to enter main setting

interface. Enter „Set inputmode” by pressing „Up” or ”Down“ buttons. Press „OK” button to

enter setting interface. Choose „In parallel Mode?” or „Independent Mode?” by pressing „Up”

or „Down” buttons, then press „OK” button. „Success” or „fail” is displayed after setting.

10. Set Language

Users press „ESC” button to enter „Enter setting” interface, Press ”OK“ button to enter main

setting interface. Enter „Set Language” by pressing „Up” button or ”Down“ button. Press „OK”

button and enter setting interface. Choose corresponded setting items by pressing „Up” button

or „Down” button, then press „OK” button. „Success” or „fail” is displayed after setting.

11. Start Parameter

User can change the start parameter by the LCD. First the User need to copy the TXT file which

is used to change the start parameter to the SD card.

Users press Back button to enter „Enter setting” interface, Press OK button to enter main

setting interface. Enter „Set StartPara” by pressing „Up” button Or „Down” button, press „OK”

button and enter „Input Password” Setting interface. Press „ESC” button to set passwords

(default: 0001), increase or decrease value though pressing „Up” button or „Down” button,

press „OK” button to next value setting. „Error!” Try again” will be displayed for wrong

passwords. Press „ESC” button and rekey in the correct passwords. „ Success” will be displayed

if setting successfully.

12. Safety Voltage

User can change the Voltage protection point by the LCD. First the User need to copy the TXT

file which is used to change the Voltage protection point to the SD card.

Users press Back button to enter „Enter setting” interface, Press OK button to enter main

setting interface. Enter „Set SafetyVolt” by pressing „Up” button Or „Down” button, press

„OK” button and enter „Input Password” Setting interface. Press „ESC” button to set

passwords (default: 0001), increase or decrease value though pressing „Up” button or „Down”

button, press „OK” button to next value setting. „Error!” Try again” will be displayed for wrong

passwords. Press „ESC” button and rekey in the correct passwords. „Success” will be displayed

if setting successfully.

13. Safety Frequency

User can change the Frequency protection point by the LCD. First the User need to copy the.

TXT file which is used to change the Frequency protection point to the SD card .

Users press Back button to enter „Enter setting” interface, Press OK button to enter main

REFUone 3K-2T …7K-2T

45

setting interface. Enter „Set SafetyFreq” by pressing „Up” button Or „Down” button, press „OK”

button and enter „Input Password” Setting interface. Press „ESC” button to set passwords

(default: 0001), increase or decrease value though pressing „Up” button or „Down” button,

press „OK” button to next value setting. „Error!” Try again” will be displayed for wrong

passwords. Press „ESC” button and rekey in the correct passwords. „ Success” will be displayed

if setting successfully.

14. Insulation Resistance

User can change the Insulation protection point by the LCD. First the User need to copy the.

TXT file which is used to change the Insulation protection point to the SD card.

Users press Back button to enter „Enter setting” interface, Press OK button to enter main

setting interface. Enter „Set Insulation” by pressing „Up” button Or „Down” button, press „OK”

button and enter „Input Password” Setting interface. Press „ESC” button to set passwords

(default: 0001), increase or decrease value though pressing „Up” button or „Down” button,

press „OK” button to next value setting. „Error!” Try again” will be displayed for wrong

passwords. Press „ESC” button and rekey in the correct passwords. „ Success” will be displayed

if setting successfully.

15. Reactive Power

Users press „ESC” button to enter „Enter Setting” interface, Press „OK” button to enter main

setting interface. Enter „Set Reactive” by pressing „Up” button or „Down”button, press „OK”

button and enter „Input Password” Setting interface.

Press „ESC” button to set passwords (default: 0001), increase or decrease value though

pressing „Up” button or „Down” button, press „OK” button to next value setting. „Error! Try

again” will be displayed for wrong passwords. Press „ESC” button and rekey in the correct

passwords. „success” will be displayed if setting successfully,

16. Power Derate

Users press „ESC” button to enter „Enter Setting” interface, Press „OK” button to enter

main setting interface. Enter „Set PowerDerate” by pressing „Up” button or „Down”button,

press „OK” button and enter „Input Password” Setting interface.

Press „ESC” button to set passwords (default: 0001), increase or decrease value though

pressing „Up” button or „Down” button, press „OK” button to next value setting. „Error! Try

again” will be displayed for wrong passwords. Press „ESC” button and rekey in the correct

passwords. „success” will be displayed if setting successfully,

17. Reflux Power

Users press „ESC” button to enter „Enter Setting” interface, Press „OK” button to enter main

setting interface. Enter „Set RefluxP” by pressing „Up” button or „Down” button, press „OK”

button and enter „Input Password” Setting interface.

Press „OK” button to set passwords (default: 0001), increase or decrease value though

pressing „Up” button or „Down” button, press „OK” button to next value setting. „Error! Try

again” will be displayed for wrong passwords. Press „ESC” button and rekey in the correct

passwords. „success” will be displayed if setting successfully.

18. MPPT Scan

Users press „ESC” button to enter „Enter setting” interface, Press „OK” button to enter main

setting interface. Enter „MPPT Scan” by pressing „Up” button or „Down” button, press „OK”

button and enter „Input Password” Setting interface. Press „ESC” button to set passwords

REFUone 3K-2T, 5K-2T, 7K-2T

46

(default: 0001), increase or decrease value though pressing „Up” button or „Down” button,

press „OK” button to next value setting. „Error! Try again” will be displayed for wrong

passwords. Press „ESC” button and rekey in the correct passwords. „Success” will be displayed

if setting successfully.

19. DRM0 Control

Users press Back button to enter „Enter setting” interface, Press „OK” button to enter main

setting interface. Enter „DRM0 Control” by pressing „Up” button Or „Down” button, press

„OK” button and enter „Input Password” Setting interface. Press „ESC” button to set

passwords (default: 0001), increase or decrease value though pressing „Up” button or „ Down”

button, press „OK” button to next value setting. Error! Try again will be displayed for wrong

passwords. „Press Back” button and rekey in the correct passwords. „Success” will be

displayed if setting successfully.

(B) “Event List” Interface

Event List is used to display the real-time event records, including the total number of events

and each specific ID No. and happening time. User can enter Event List interface through main

interface to check details of real-time event records, Event will be listed by the happening time,

and recent events will be listed in the front. Please refer to below picture: Users press „ESC”

button and „Down” button in standard interface, then enter into „2.EventList” interface.

Press „OK”

Total number of events

Press „OK”

Event ID.

Press „OK”

Time of occurance

ID91

Events TotalNum:02

2.EventList

2013-10-31 16:42:16

REFUone 3K-2T …7K-2T

47

(C) “SystemInfo” Interface as below:

3.SystemInfo

1. Inverter Type

7. Input Mode

2. Serial Number

8. Power Factor

3. SoftVersion

9. Reflux Power

4. HardVersion

10. Safety Paras

5. Country

11. MPPT Scan

6. Modbus Address

(D) Display Time

Press the „ESC” button and „Up” button or „Down” key in the standard user interface to enter

into „4.Display Time”, then press „OK ” button to display the current system time.

(E) Software Update

Press the „ESC” button and „Up” button or „Down” button in the standard user interface to

enter into „5. Software Update”, then press „OK” button to enter into the ” input password ”

interface, now press the „OK” button to input the password(initial passwords is 0715),Press

the „Up” and „Down” button to change the value, then press „OK” button to confirm the

current value of input and enter the next set of value. When set over, if the password is wrong,

the LCD will display „Error! Try again”, at this time, you should re-enter your password .If the

password is correct, then begin the update process.

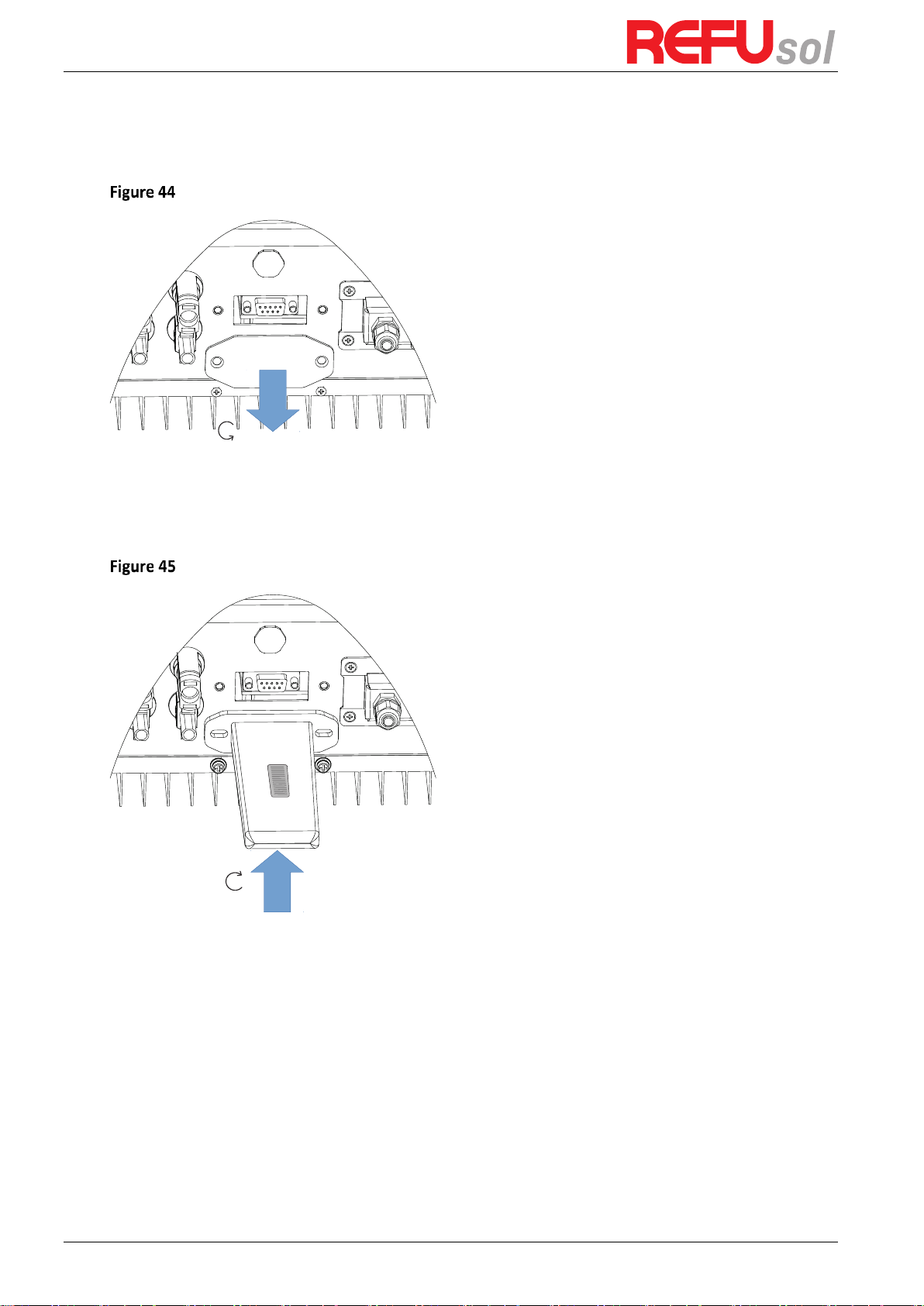

6.4

Update Software online

The REFUone inverters offer software upgrade via SD card to maximize inverter performance

and avoid inverter operation error caused by software bugs.

(A) Procedure

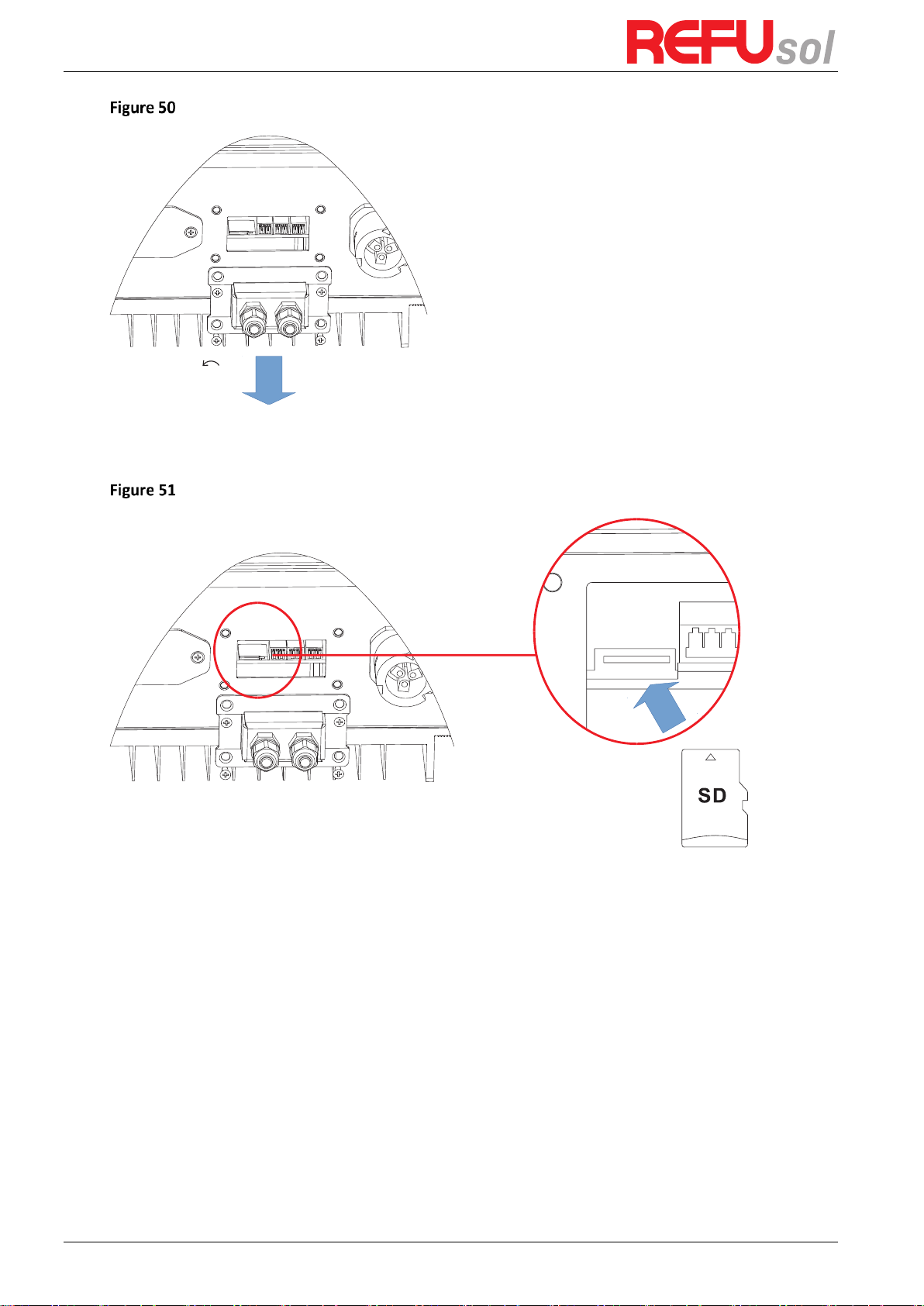

Step 1

first, turn off the DC and AC breaker, and then remove the communication waterproof

cover as the following picture. If the communication lines (RS485, Relays, I/O) has been

connected, Be sure to release the waterproof nut, Make sure the communication line is no

longer the force. Then remove the waterproof cover, In order to avoid loosening the

communication plug, which has been connected.

REFUone 3K-2T, 5K-2T, 7K-2T

48

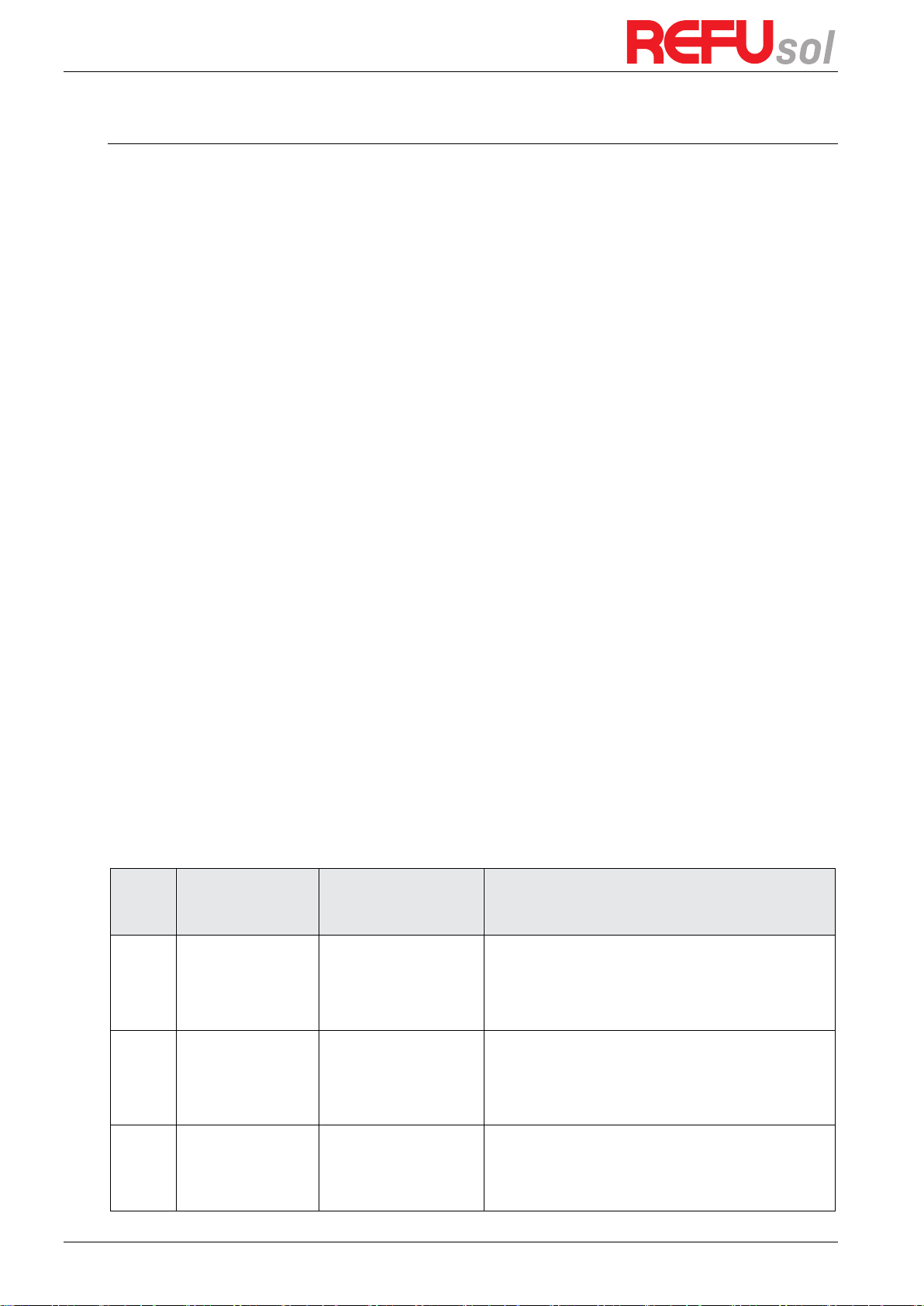

Step 2

Remove the waterproof cover, Press SD card inside in the position marked SD card.

Then the SD card will automatically pop up.

Step 3

The SD card reader must be ready by the users, so that SD card so easy to establish the

connection with the computer.

Step 4

REFU will send the Software code to the user who needs to update. After user receive

the file, please decompressing file and cover the original file in SD card.

Step 5

Insert the SD card into the SD card slot, there will be a faint clicking sound typically,

indicating that has stuck.

Step 6

Then turn on DC switch and enter into the online upgrade to the main menu „5.

Software Update” in the LCD display program [6.3(E)]. The method to enter the menu can refer

to operation interface of LCD.

Step 7

Input the password, if password is correct, the update process begins; the original

password is 0715.

Step 8

System update main DSP, slave DSP and ARM in turns. If main DSP update success,the

LCD will display „Update DSP1 Success”, otherwise display „Update DSP1 Fail”; If slave DSP

update success ,the LCD will display „Update DSP2 Success”, otherwise display „Update DSP2

REFUone 3K-2T …7K-2T

49

Fail”.

Step 9

If fail, please turn off the DC breaker, wait for the LCD screen extinguish, then turn on

the DC breaker again, then Continue to update from step 6.

Step 10

After the update is completed, turn off the DC breaker, wait for the LCD screen

extinguish, then recover the communication waterproof and then turn on the DC breaker and

AC breaker again, the inverter will enters the running state.

REFUone 3K-2T, 5K-2T, 7K-2T

50

7

Trouble shooting and maintenance

Outlines of this chapter

This topic describes how to perform daily maintenance and troubleshooting to ensure

longterm proper operation of the inverter.

7.1

Trouble shooting

This section contains information and procedures for solving possible problems with the

inverter.

This section help users to identify the inverter fault. Please read the following procedures

carefully:

Check the warning, fault messages or fault codes shown on the inverter screen, record all the

fault information.

If there is no fault information shown on the screen, check whether the following

requirements are met:

Is the inverter mounted in a clean, dry place with good ventilation?

Is the DC switch turned ON?

Are the cables adequately sized and short enough?

Are the input and output connections and wiring in good condition?

Are the configuration settings correct for the particular installation?

Are the display panel and the communication cables properly connected and undamaged?

Follow the steps below to view recorded problems:

Press „ESC” to enter the main menu from the standard interface. Select „2. Event List”, then

press „OK” to enter event list.

7.1.1

EventList information

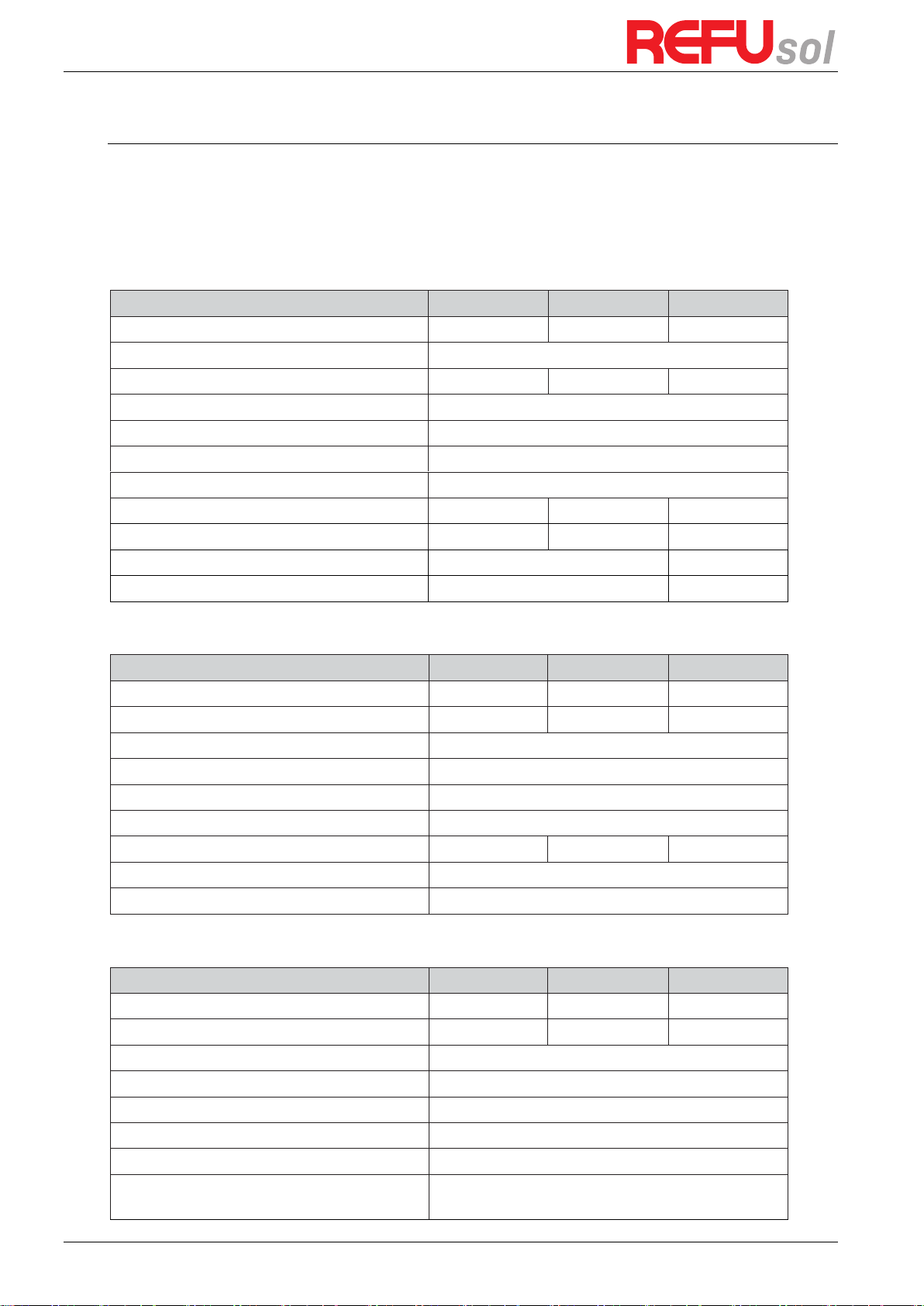

Table 8 Eventlist

Event

List No.

EventList Name

EventList description

Solution

ID01

GridOVP

The power grid voltage

is too high

If the alarm occurs occasionally, the possible cause is

that the electric grid is abnormal occasionally.

Inverter automatically returns to normal operating

status when the electric grid is back to normal.

ID02

GridUVP

The power grid voltage

is too low

If the alarm occurs frequently, check whether the grid

voltage/frequency is within the acceptable range. If

no, contact technical support. If yes, check the AC

circuit breaker and AC wiring of the inverter.

ID03

GridOFP

The power grid

frequency is too high

If the grid voltage/frequency is within the acceptable

range and AC wiring is correct, while the alarm occurs

repeatedly, contact technical support to change the

grid over-voltage, under-voltage, over- frequency,

REFUone 3K-2T …7K-2T

51

under-frequency protection points after

ID04

GridUFP

The power grid

frequency is too low

Obtaining approval from the local electrical grid

operator.

ID05

PVUVP

The input voltage is too

low

Check whether too few PV modules are series

connected in a PV string, thus the voltage (Vmp) of

the PV string is lower than the minimum operating

voltage of inverter. If yes, adjust the number of series

connected PV modules to increase the voltage of the

PV string to fit the input voltage range of inverter.

Inverter automatically returns to normal operating

status after correct adjustments.

ID09

PvOVP

The input voltage is too

high

Check whether too many PV modules are series

connected in a PV string, thus the voltage (Voc) of the

PV string is higher than the maximum input voltage of

inverter. If yes, adjust the number of series

connected PV modules to decrease the voltage of the

PV string to fit the input voltage range of inverter.

Inverter automatically returns to normal operating

status after correct adjustments.

ID10

IpvUnbalance

Input current is not

balanced

Check the input mode (parallel mode/ independent

mode) setting of inverter according to Section 0.

Input Mode of this user manual, If it’s incorrect,

change it according to Section 0. Set Input mode of

this manual.

ID11

PvConfigSetWrong

Incorrect input mode

ID12

GFCIFault

GFCI Fault

If the fault occurs occasionally, the possible cause is

that the external circuits are abnormal occasionally.

Inverter automatically returns to normal operating

status after the fault is rectified.

If the fault occurs frequently and lasts a long time,

check whether the insulation resistance between the

PV array and earth (ground) is too low, then check

the insulation conditions of PV cables.

ID14

HwBoostOCP

The input current is too

high, and h as happen

hardware protection

Check whether the input current is higher than the

maximum input current of inverters, then check the

input wiring, if both are correct, please contact

technical support.

ID15

HwAcOCP

The grid current is too

high, and has happen

hardware protection

ID15-ID24 are internal faults of inverter, turn OFF the

„DC switch”, wait for 5 minutes, then turn ON the

„DC switch”. Check whether the fault is rectified. If

no, please contact technical support.

ID16

AcRmsOCP

The grid current is too

high

ID17

HwADFaultIGrid

The grid current

sampling error

ID18

HwADFaultDCI

The DCI sampling error

ID19

HwADFaultVGrid

The grid voltage

sampling error

ID20

GFCIDeviceFault

The GFCI sampling error

REFUone 3K-2T, 5K-2T, 7K-2T

52

ID21

MChip_Fault

The master chip fault

ID22

HwAuxPowerFault

The auxiliary voltage

error

ID23

BusVoltZeroFault

The bus voltage

sampling error

ID24

IacRmsUnbalance

The Output current is

not balanced

ID25

BusUVP

The bus voltage Is too

low

If the PV array configuration is correct (no ID05 fault),

the possible cause is that the solar irradiance is too

low. Inverter automatically returns to normal

operating status after the solar irradiance returns to

normal level.

ID26

BusOVP

The bus voltage Is too

high

ID26-ID27 are internal faults of inverter, turn OFF the

„DC switch”, wait for 5 minutes, then turn ON the

„DC switch”. Check whether the fault is rectified. If

no, please contact technical support.

ID27

VbusUnbalance

The bus voltage is not

balanced

ID28

DciOCP

The Dci is too high

Check the input mode (parallel mode/ independent

mode) setting of inverter according to Section 0

(Input Mode) of this user manual, If it’s incorrect,

change it according to Section 0. Set Input mode of

this manual.

If the input mode is correct, turn OFF the „DC

switch”, wait for 5 minutes, then turn ON the „DC

switch”. Check whether the fault is rectified. If no,

please contact technical support, If it’s incorrect,

change it according to Section 6.3 (A) 10.Set Input

mode of this manual.

ID29

SwOCPInstant

The grid current is too

high

Internal faults of inverter, turn OFF the „DC switch”,

wait for 5 minutes, then turn ON the „DC switch”.

Check whether the fault is rectified. If no, please

contact technical support.

ID30

SwBOCPInstant

The input current is too

high

Check whether the input current is higher than the

maximum input current of inverters, then check the

input wiring, if both are correct, please contact

technical support.

ID49

Consistent

Fault_VGrid

The grid voltage

sampling value between

the master DSP and

slave DSP is not

consistent

ID49-ID55 are internal faults of inverter, turn OFF the

„DC switch”, wait for 5 minutes, then turn ON the

„DC switch”. Check whether the fault is rectified. If

no, please contact technical support.

ID50

Consistent

Fault_FGrid

The grid f requency

sampling value between

the master DSP and

slave DSP is not