Page 1

!

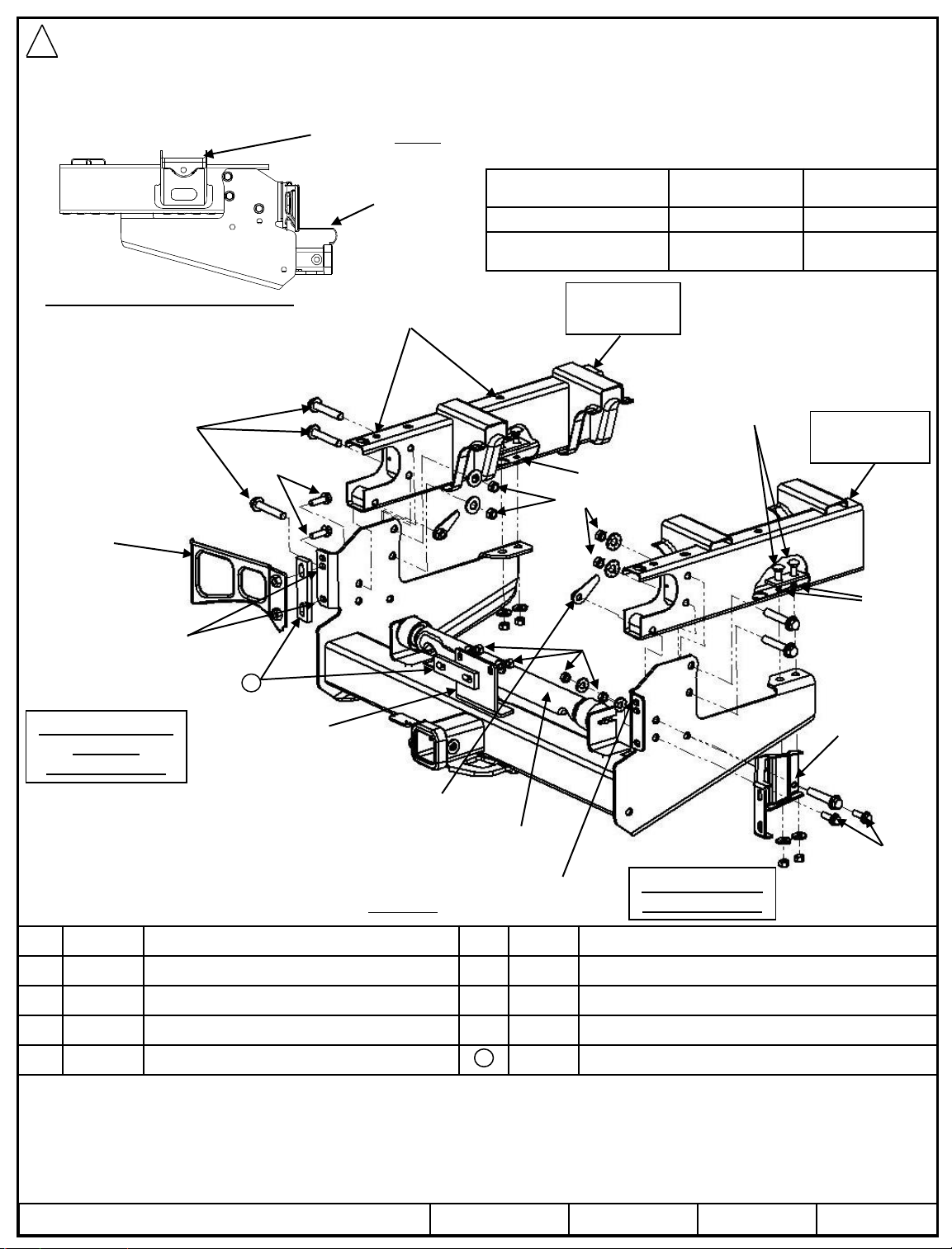

NOTE;

WITH THIS HITCH INSTALLED

THE STEP BUMPER IS NO LONGER ABLE

TO BE USED AS A TOWING POINT.

Installation Instructions

Dodge 2500/3500 Pickup

Must have pick-up chassis

Spring mount (as shown

above the frame).

Hitch type

Bumper

Weight Distributing

Weight Carrying

Ball Mount

Part Numbers:

45299

Do Not Exceed Lower of Towing Vehicle

Manufacturer’s Rating or

Max Gross

Trailer WT (LB)

18000 (8172 kg) 2500 (1135 kg)

18000 (8172kg) 2000 (908 kg)

Max Tongue

WT (LB)

Hitch Shown In Proper Position

Equipment Required: WOOD BLOCKS

Fastener Kit: 45299F

Wrenches: m16,m18,m21, 3/8”

Drill Bits: 9/16”

EXISTING

M14 BOLTS

r

m

2010 MODEL

EXISTING

BUMPER

CORNER

BRACE

BUMPER

ATTACHMENT

(NOT REQUIRED ON 03-09)

2010 – CURRENT

MODEL

ATTACHMENT

10

CENTER BUMPER

ATTACHMENT

BED ATTACHMENT

HOLE

#4

#3

LONG BED

FRAME

DRILL ONE HOLE

k

j

l

m

Wiring Access Location: PU3, PU4

n

o

m

p

SHORT BED

FRAME

DRILL 2

HOLES

03-09 MODEL

EXISTING

BUMPER

CORNER

BRACE

EXISTING M14 HANDLE NUT (03-09 MODEL)

M14 FLANGED NUT (2010 MODEL)

VIBRATION DAMPENER

(ON CERTAIN MODELS ONLY)

FIGURE 1

j

k

l

m

n

Tighten M12 hitch fasteners with torque wrench to 75 Lb.-Ft. (102 N*M)

Tighten M14 and 1/2” fasteners with torque wrench to 100 Lb.-Ft. (136 N*M)

Note: check hitch frequently, making sure all fasteners and ball are properly tightened. If hitch is removed, plug all holes in trunk pan or other body panels to prevent entry

of water and exhaust fumes. A hitch or ball which has been damaged should be removed and replaced. Observe safety precautions when working beneath a vehicle and

wear eye protection. Do not cut access or attachment holes with a torch.

This product complies with safety specifications and requirements for connecting devices and towing systems of the state of New York, V.E.S.C. Regulation V-5 and SAE

J684.

© 2010, 2011 Cequent Performance Products

Qty. (4) HEX NUT – M14 X 2.00

Qty. (4) CONICAL WASHER – 5/8”

Qty. (6) HEX NUT – M12 X 1.75

Qty. (14) CONICAL WASHER – 1/2”

Qty. (4) CARRIAGE BOLT – 1/2”-13 X 1-3/4” GR 8

TOP HOLE – BUMPER

ATTACHMENT

Qty. (2) BLOCK – 1-1/2 X 3-1/2 X 1/4”

o

Qty. (4) HEX NUT – ½-13 GR 2H

p

Qty. (2) FISH WIRE – 1/2”

q

Qty. (4) HEX BOLT – M12 X 1.75 X 45mm CL 10.9

r

10

Qty. (3) BLOCK – SPACER 1/2 X 1-1/2 X 5-3/4

Tighten M12 bed fasteners with torque wrench to 85 Lb.-Ft. (115 N*M)

Tighten all M10 fasteners with torque wrench to 42 Lb.-Ft. (57 N*M)

Sheet 1 of 6 45299N 12-9-11 Rev. B

2003-09 MODEL

ATTACHMENT

Form: F205 Rev A 5-6-05

EXISTING

M12 BOLTS

Page 2

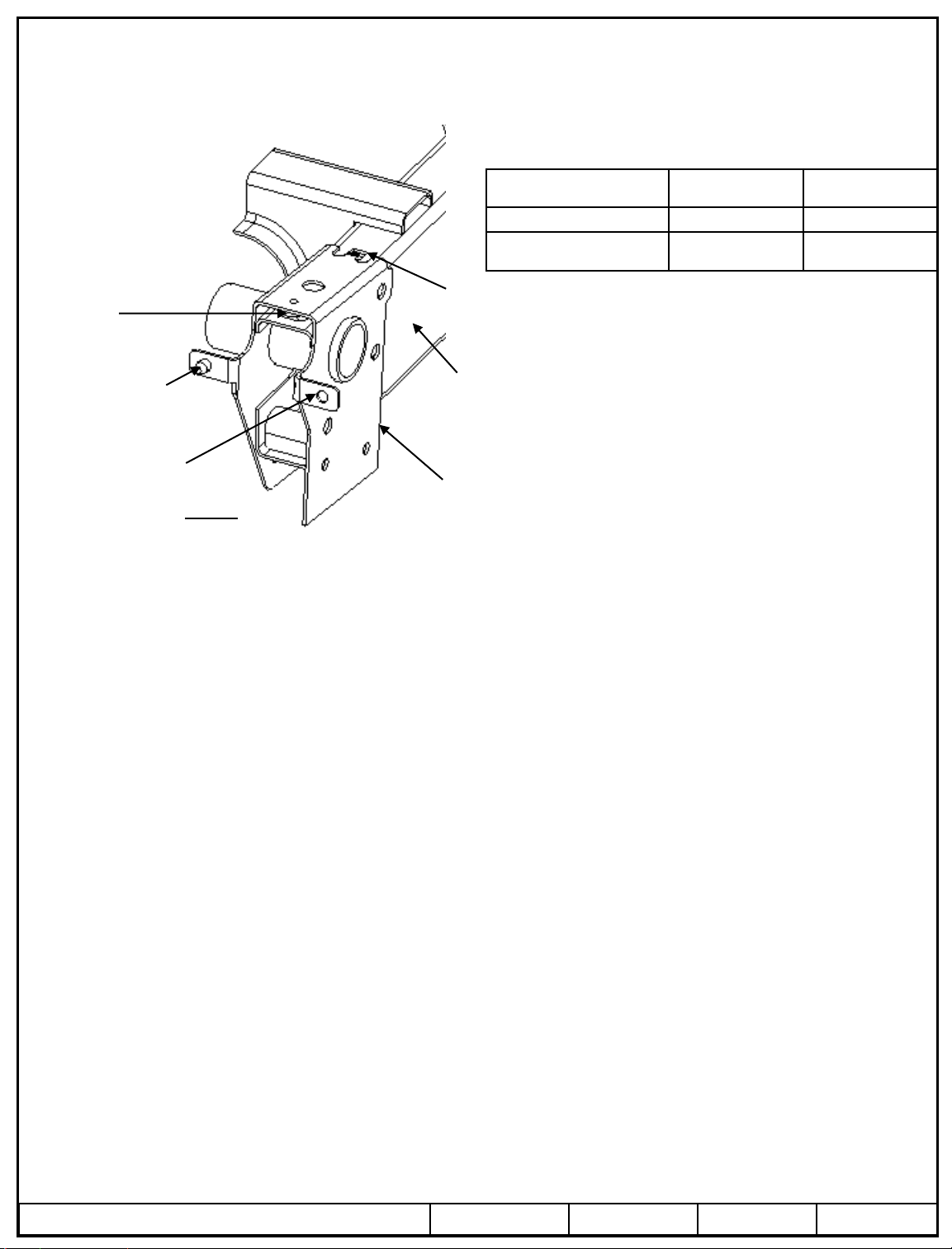

BOSS

Installation Instructions

Dodge 2500/3500 Pickup

Do Not Exceed Lower of Towing Vehicle

Hitch type

Weight Distributing

Weight Carrying

Ball Mount

TAB / SLOT

Manufacturer’s Rating or

Max Gross

Trailer WT (LB)

18000 (8172 kg) 2500 (1135 kg)

18000 (8172kg) 2000 (908 kg)

Part Numbers:

45299

Max Tongue

WT (LB)

BUMPER

ALIGNMENT PEG

FRAME RAIL

BUMPER

ATTACHMENT

Figure 2

(2003-2009 model shown)

1. Lower spare tire for ease of installation.

2. Remove 6 of the rear most bed attachment bolts. These can be accessed thru large holes in bottom of frame or suspension mounts.

Leave the two forward most bed bolts tight. (Total of eight bed bolts)

3. Raise back of bed up and place a 2” thick wooden block between frame and #3 bed attachment location.

4. Remove license plate to access two bolts for next step.

5. Protect and then remove the bumper by removing 6 to12 bolts (depending on model year).

• (03-09) Two M12 bolts and one M14 bolt from the inner bumper corner brace to the bumper / hitch attachment - per side.

• (03-09) One M12 bolt from the frame rail bumper attachment to the bumper – per side.

• (2010) Two M12 bolt from the frame rail bumper attachment to the bumper – per side.

• (all years) Two M12 bolt at the license plate area – uncovered in step 4.

6. Set bumper aside for re-installation later.

7. Remove the bumper / hitch structure.

• (03-09) Remove the last two M14 bolts at the frame rail.

• (2010) Remove three M14 bolts at the frame rail.

• The structure will need to be rotated up and pulled back to clear boss and tab / slot engagements. See figure 2.

8. Lower bed and reinstall the bed bolts.

9. Raise hitch into position and use two forward most M14 bolt (2 per side) to hold it in place.

10. Using the hitch as a template, mark and drill 9/16” holes in bottom of frame.

11. Fish wire the ½” carriage bolts and block into place thru the end of the frame. Attach 1/2” washers and nuts finger tight.

12. If equipped, remove the vibration dampener from OEM unit and install on this unit (as shown in figure 1).

13. To ease the installation of the bumper, loosen the two bolts per side at the inner and outer corner brace (03-09 model only).

14. Raise bumper into position and attach with bolts from step 5.

15. Install the remaining fasteners per figure 1.

16. Measure the gap between bumper and tail gate and adjust for even gap. Tighten fasteners.

17. Raise spare tire.

18. Give the OEM bumper / hitch structure to customer in case hitch is removed.

Note: check hitch frequently, making sure all fasteners and ball are properly tightened. If hitch is removed, plug all holes in trunk pan or other body panels to

prevent entry of water and exhaust fumes. A hitch or ball which has been damaged should be removed and replaced. Observe safety precautions when working

beneath a vehicle and wear eye protection. Do not cut access or attachment holes with a torch.

This product complies with safety specifications and requirements for connecting devices and towing systems of the state of New York, V.E.S.C. Regulation V-5

and SAE J684.

© 2010, 2011 Cequent Performance Products

EXISTING BUMPER / HITCH

STRUCTURE

FRAME RAIL

Sheet 2 of 6 45299N 12-9-11 Rev. B

Form: F205 Rev A 5-6-05

Page 3

!

REMARQUE : LORSQUE CET ATTELAGE

EST MONTÉ, LE PARE-CHOCS

MARCHEPIEDS NE PEUT PLUS ÊTRE

UTILISÉ COMME POINT DE REMORQUAGE

Attelage montré dans la position appropriée

Équipement requis : BLOCS DE BOIS

Visserie : 45299F

Clés : m16, m18, m21, 3/8”

Mèches : 9/16 po

BOULONS M14

EXISTANTS

r

RENFORT D’ANGLE

POUR LE PARE-CHOCS –

MODÈLE 2010

BRACE

Doit avoir pick-up châssis

Mont de printemps (comme le

montre situé au-dessus du

frame).

m

Instructions d’installation

Camionnette Dodge 2500/3500

Ne pas dépasser les spécifications du fabricant du

véhicule de remorquage, ni

Type d’attelage

Pare-chocs

Répartition des charge

TROU DE FIXATION

DU PLATEAU

#4

#3

Capacité de charge Montage

sur boule

CHASSIS DE

PLATEAU LONG

PERCER UN TROU

k

j

Numéros de pièces :

45299

Poids brut max. de la

remorque (livres)

18000 (8172 kg) 2500 (1135 kg)

18000 (8172kg) 2000 (908 kg)

Points d’accès au câblage : PU3, PU4

Poids maximal à la

flèche d’attelage

(livres))

n

o

m

p

CHASSIS DE

PLATEAU

COURT

FIXATION DU

PARE-CHOCS

(NON REQUIS SUR 03-09)

2010 – FIXATION

POUR LE

MODÈLE ACTUEL

ÉCROU LEVIER M14 EXISTANT (MODÈLE 03-09)

ÉCROU À EMBASE M14 (MODÈLE 2010)

Qté.(4) ÉCROU HEXAGONAL – M14 X 2.00

j

Qté.(4) RONDELLE CONIQUE – 5/8 PO

k

Qté.(6) ÉCROU HEXAGONAL – M12 X 1.75

l

Qté.(14) RONDELLE CONIQUE – 1/2PO

m

n

Qté.(4)

BOULON DE CARROSSERIE 1/2PO-13 X 1-3/4

PO GR 8

10

FIXATION DU

PARE-CHOCS CENTRAL

(SUR CERTAINS MODÈLES UNIQUEMENT))

AMORTISSEUR DE VIBRATION

FIGURE 1

TROU SUPÉRIEUR –

FIXATION DU PARE–CHOCS

o

p

q

r

s

PERCER

2 TROUS

l

m

FIXATION -

MODÈLE 2003-09

ATTACHMENT

Qté.(2) BLOC - 1-1/2 X 3-1/2 X 1/4PO

Qté.(4) ÉCROU HEXAGONAL - ½-13 GR 2H

Qté.(2) CABLE DE TRACTION – 1/2PO

Qté.(4) BOULON HEXAGONAL – M12 x 1.75 x 45mm CL 10.9

Qté.(3) BLOC D’ESPACEMENT 1/2 X 1-1/2 X 5-3/4

RENFORT

D’ANGLE

EXISTANT POUR

LE

PARE-CHOCS –

MODÈLE 03-09

BOULONS

M12

EXISTANTS

Serrer toute la boulonnerie M12 à l’aide d’une clé dynamométrique en

appliquant un couple de serrage de 75 lb-pi. (102 N*M)

Serrer toute la boulonnerie M14 et ½ po à l’aide d’une clé dynamométrique en

Remarque : Vérifier l’attelage fréquemment, en s’assurant que toutes les fixations et la boule sont serrées adéquatement. Si l’attelage est enlevé, boucher tous les trous percés dans le coffre ou la carrosserie afin de prévenir

l’infiltration d’eau ou de gaz d’échappement. Un attelage ou une boule endommagés doivent être enlevés et remplacés. Observer les mesures de sécurité appropriées en travaillant sous le véhicule et porter des lunettes de

protection. Ne jamais utiliser une torche pour découper un accès ou un trou de fixation. Ce produit est conforme aux normes V-5 et SAE J684 de la V.E.S.C. (État de New York) concernant les spécifications en matière de

sécurité des systèmes d’attelage.

© 2010, 2011 Cequent Performance Products

appliquant un couple de serrage de 100 lb-pi. (136 N*M)

Serrer toute la boulonnerie M12 à l’aide d’une clé dynamométrique en

appliquant un couple de serrage de 85 lb-pi. (115 N*M)

Serrer toute la boulonnerie M10 à l’aide d’une clé dynamométrique en

appliquant un couple de serrage de 42 lb-pi. (57 N*M)N*M)

Feuillet 3 sur 6 45299N 12-9-11 Rév. B

Formulaire : F205 Rev A 5-6-05

Page 4

BOSSAGE

Instructions d’installation

Camionnette Dodge 2500/3500

Ne pas dépasser les spécifications du fabricant du

véhicule de remorquage, ni

Type d’attelage

Répartition des charges

Capacité de charge Montage

LANGUETTE/FENTE

sur boule

Numéros de pièces :

45299

Poids brut max. de

la remorque (livres)

18000 (8172 kg) 2500 (1135 kg)

18000 (8172kg) 2000 (908 kg)

Poids maximal à la

flèche d’attelage

(livres)

TAQUET D’ALIGNEMENT

LONGERON DU CHÂSSIS

DU PARE-CHOCS

FIXATION DU

PARE-CHOCS SUR LE

LONGERON DU CHÂSSIS

STRUCTURE PARE-CHOCS / ATTELAGE EXISTANTE

Figure 2

(Modèle 2003-2009)

1. Abaisser la roue de secours pour faciliter l’installation.

2. Il est possible d’y accéder par de larges ouvertures au bas du châssis ou dans les supports des suspensions. (huit boulons au total

pour le plateau)

3. Remonter le plateau et positionner un bloc en bois épais de 2 po entre le châssis et le point n°3 de la fixation du plateau.

4. Retirer la plaque d’immatriculation pour accéder aux deux boulons de l’étape suivante.

5. Protéger, puis enlever le pare-chocs en retirant 6 à 12 boulons (le nombre dépend de l’année du modèle).

• (03-09) Deux boulons M12 et un boulon M14 du renfort d’angle interne du pare-chocs et de la fixation de l’attelage au parechocs – de chaque côté

• (03-09) Un boulon M12 de la fixation entre le longeron du châssis et le pare-chocs –de chaque côté.

• (2010) Deux boulons M12 de la fixation entre le longeron du châssis et le pare-chocs –de chaque côté.

• (tous les modèles) Deux boulons M12 de la zone de la plaque d’immatriculation –retirée à l’étape 4.

6. Mettre le pare-chocs de côté en attendant de le réinstaller plus tard.

7. Retirer la structure de fixation pare-chocs / attelage.

• (03-09) Retirer les deux derniers boulons M14 sur le longeron du châssis.

• (2010) Retirer trois boulons M14 sur le longeron du châssis.

• Il sera nécessaire de faire tourner la structure puis de la tirer pour dégager le bossage et les engagements de la

languette/fente. Voir figure 2.

8. Abaisser le plateau puis réinstaller les boulons du plateau.

9. Lever l’attelage jusqu’à la position requise et utiliser les boulons M14 les plus à l’avant (2 de chaque côté) pour le maintenir en

place.

10. En utilisant l’attelage comme gabarit, marquer et percer deux trous de 9/16 po dans le bas du châssis.

11. Tirer les boulons de carrosserie d’½ po à l’aide d’un câble de tirage et les bloquer en position à travers l’extrémité du châssis. Fixer

les rondelles et les écrous d’½ po et les serrer à la main.

12. Si le système comprend un amortisseur de vibration, le retirer et l’installer sur ce système (comme indiqué en figure 1).

13. Pour faciliter l’installation du pare-chocs, desserrer les deux boulons des renforts d’angle internes et externes de chaque côté

(uniquement pour les modèles 03-09).

14. Lever le pare-chocs jusqu’à la position requise et l’attacher avec les boulons de l’étape 5.

15. Installer les autres fixations comme indiqué en figure 1.

16. Mesurer l’écartement entre le pare-chocs et le hayon et l’ajuster. Serrer les vis.

17. Relever la roue de secours.

18. Donner le manuel d’utilisation de la structure pare-chocs / attelage au client à consulter en cas de retrait de l’attelage.

Remarque : Vérifier fréquemment l’attelage, en s’assurant que toute la visserie et la boule d’attelage sont serrées adéquatement. Si l’attelage est enlevé, boucher tous les trous percés

dans le coffre ou la carrosserie afin de prévenir l’infiltration d’eau ou de gaz d’échappement. Un attelage ou une boule d’a ttelage endommagé doit être enlevé et remplacé. Respecter

les mesures de sécurité appropriées en travaillant sous le véhicule et porter des lunettes de protection. Ne jamais utiliser un chalumeau pour découper un accès ou un trou de fixation.

Ce produit est conforme aux normes V-5 et SAE J684 de la V.E.S.C. de l’état de New York concernant les spécifications en matière de sécurité des systèmes et dispositifs d’attelage.

© 2010, 2011 Cequent Performance Products

Feuillet 4 sur 6 45299N 12-9-11 Rév. B

Formulaire : F205 Rev A 5-6-05

Page 5

!

NOTA:

CON ESTE ENGANCHE INSTALADO

EL PARACHOQUES DE ESCALÓN YA NO SE

PODRÁ USAR COMO PUNTO DE REMOLQUE.

Instrucciones de instalación

Dodge 2500/3500 tipo Pickup

Deben tener chasis de Pick-up

primavera Monte (como se

muestra por encima de la

trama).

Parachoques

No supere la calificación inferior entre el

fabricante del vehículo de remolque o

Tipo de enganche

Distribución de peso

Carga de peso

Montaje de bola

Números de partes:

45299

Peso bruto máximo

del remolque (LB)

18000 (8172 kg) 2500 (1135 kg)

18000 (8172kg) 2000 (908 kg)

Peso máximo de la

horquilla (LB)

El enganche se muestra en la posición correcta

Equipo necesario: BLOQUES DE MADERA

Kit de tornillos: 45299F

Llaves: m16,m18,m21, 3/8”

Brocas de taladro: 9/16”

PERNOS EXISTENTES

M14

MODELO 2010

ABRAZADERA ESQUINERA

DE PARACHOQUES

EXISTENTE

UNIÓN DEL

PARACHOQUES

(NO SE REQUIERE PARA03-09)

2010 – ACTUAL

INSTALACIÓN

CENTRE LA UNION

DEL PARACHOQUES

r

m

10

MODELO

TUERCA DE MANIJA M14 EXISTENTE (MODELO 03-09)

TUERCA CON REBORDE M14 (MODELO 2010)

(EN CIERTOS MODELOS ÚNICAMENTE)

ORIFICIO PARA UNIÓN DE

LA BASE

AMORTIGUADOR DE VIBRACIÓN

FIGURA 1

#4

#3

ORIFICIO SUPERIOR –

UNIÓN DEL PARACHOQUES

Ubicación de acceso al cableado: PU3, PU4

BASTIDOR DE

BASE LARGA

PERFORE UN ORIFICIO

k

j

l

m

2003-09

INSTALACIÓN

MODELO

n

o

m

p

BASTIDOR DE

BASE CORTA

PERFORE 2

ORIFICIOS

MODELO 03-09

ABRAZADERA

ESQUINERA

DE

PARACHOQUES

EXISTENTE

PERNOS

M12

EXISTENTES

j

k

l

m

n

Apriete los tornillos M12 del enganche con una llave de torsión a 75 Lb.-pies (102 N*M)

Apriete los tornillos M14 y 1/2” con una llave de torsión a 100 Lb.-pies (136 N*M)

Nota: Revise el enganche con frecuencia, verificando que todos los tornillos y la bola estén correctamente apretados. Si se quita el enganche tape todos los orificios en el

colector del baúl u otros paneles de la carrocería para evitar la entrada del agua y los gases del escape. Se debe retirar y reemplazar un enganche o bola que se haya dañado.

Observe las precauciones de seguridad al trabajar por debajo del vehículo y use protección visual. No corte los orificios de acceso o accesorios con soplete.

Este producto cumple con las especificaciones y requisitos de seguridad para conectar dispositivos y sistemas de remolque del estado de Nueva York, V.E.S.C. Regulación

V-5 y SAE J684.

© 2010, 2011 Cequent Performance Products

Cant. (4) TUERCA HEXAGONAL – M14 X 2.00

Cant. (4) ARANDELA CÓNICA – 5/8”

Cant. (6) TUERCA HEXAGONAL – M12 X 1.75

Cant. (14) ARANDELA CÓNICA – 1/2”

Cant. (4) PERNO DE CARRUAJE – 1/2”-13 X 1-3/4” GR 8

Hoja 5 def 6 45299N 12-9-11 Rev. B

Cant. (2) BLOQUE – 1-1/2 X 3-1/2 X 1/4”

o

Cant. (4) TUERCA HEXAGONAL – ½-13 GR 2H

p

Cant. (2) CABLE PARA INSERTAR – 1/2”

q

Cant. (4) PERNO HEXAGONAL – M12 X 1.75 X 45mm CL 10.9

r

10

Cant. (3) BLOQUE – ESPACIADOR 1/2 X 1-1/2 X 5-3/4

Apriete los tornillos M12 de la base con una llave de torsión a 85 Lb.-pies (115 N*M)

Apriete todos los tornillos M10 con una llave de torsión a 42 Lb.-pies (57 N*M)

Form: F205 Rev A 5-6-05

Page 6

Instrucciones de instalación

Dodge 2500/3500 tipo Pickup

Números de partes:

45299

No supere la calificación inferior entre el

fabricante del vehículo de remolque o

Tipo de enganche

Distribución de peso

Carga de peso

Montaje de bola

Peso bruto máximo

del remolque (LB)

18000 (8172 kg) 2500 (1135 kg)

18000 (8172kg) 2000 (908 kg)

Peso máximo de la

horquilla (LB)

RANURA DE LENGÜETA

SALIENTE

CLAVIJA DE

ALINEACIÓN

LARGUERO DEL BASTIDOR

DEL PARACHOQUES

UNIÓN DEL

PARACHOQUES

EN LARGUERO DEL

BASTIDOR

Figura 2

ESTRUCTURA EXISTENTE DE

ENGANCHE EN EL PARACHOQUES

(modelo exhibido 2003-2009)

1. Baje la llanta de repuesto para una fácil instalación.

2. Retire de los pernos de unión de la base más posteriores. El acceso a éstos se logra a través de los orificios grandes en la base del

bastidor o montajes de suspensión. Deje apretados los dos pernos de la base más delanteros. (Total de ocho pernos base)

3. Levante la parte posterior de la base y coloque un bloque de madera de 2” de grosor entre el bastidor y la ubicación de unión de la base #3.

4. Quite la chapa del vehículo para lograr acceso a los dos pernos para el siguiente paso.

5. Proteja y luego retire el parachoques quitando 6 a12 pernos (dependiendo del año del modelo).

• (03-09) Dos pernos M12 y un perno M14 de la abrazadera esquinera del parachoques interno a la unión parachoques/enganche –

por lado.

• (03-09) Un perno M12 de la unión del parachoques del larguero del bastidor al parachoques – por lado.

• (2010) Dos pernos M12 de la unión del parachoques del larguero del bastidor al parachoques – por lado.

• (todos los años) Dos pernos M12 en el área de la chapa del vehículo – que de destapó en el paso 4.

6. Coloque el parachoques a un lado para reinstalar después.

7. Retire la estructura de parachoques/enganche.

• (03-09) Retire los últimos dos pernos M14 en el larguero del bastidor.

• (2010) Retire tres pernos M14 en el larguero del bastidor.

• La estructura se deberá rotar hacia arriba y hacia atrás para despejar la saliente y los engranajes de lengüeta/ranura. Ver figura 2.

8. Baje la base y vuelva a instalar los pernos de la base.

9. Levante el enganche a su posición y use dos de los pernos M14 más delanteros (2 por lado) para mantenerlo en su lugar.

10. Usando el enganche como plantilla, marque y perfore orificios de 9/16” en la base del bastidor.

11. Inserte los pernos de carruaje de ½” y el bloque en su lugar a través del extremo del bastidor. Instale arandelas y tuercas de ½” y apriete a

mano.

12. Si está equipado, retire el silenciador de vibración de la unidad OEM e instale en esta unidad (como se muestra en la figura 1).

13. Para facilitar la instalación del parachoques, afloje los dos pernos por lado en la abrazadera esquinera interior y exterior (modelo 03-09

únicamente).

14. Levante el parachoques a su posición e instale con pernos del paso 5.

15. Instale los tornillos restantes según la figura 1.

16. Mida la distancia entre el parachoques y la puerta trasera y ajuste para una distancia uniforme. Apriete los tornillos.

17. Levante la llanta de repuesto.

18. Entregue la estructura del parachoques/enganche OEM al cliente en caso de retirar el enganche.

Nota: Revise el enganche con frecuencia, verificando que todos los tornillos y la bola estén correctamente apretados. Si se quita el enganche tape todos los orificios en

el colector del baúl u otros paneles de la carrocería para evitar la entrada del agua y los gases del escape. Se debe retirar y reemplazar un enganche o bola que se haya

dañado. Observe las precauciones de seguridad al trabajar por debajo del vehículo y use protección visual. No corte los orificios de acceso o accesorios con soplete.

Este producto cumple con las especificaciones y requisitos de seguridad para conectar dispositivos y sistemas de remolque del estado de Nueva York, V.E.S.C.

Regulación V-5 y SAE J684.

© 2010, 2011 Cequent Performance Products

Hoja 6 de 6 45299N 12-9-11 Rev. B

Form: F205 Rev A 5-6-05

Loading...

Loading...