Page 1

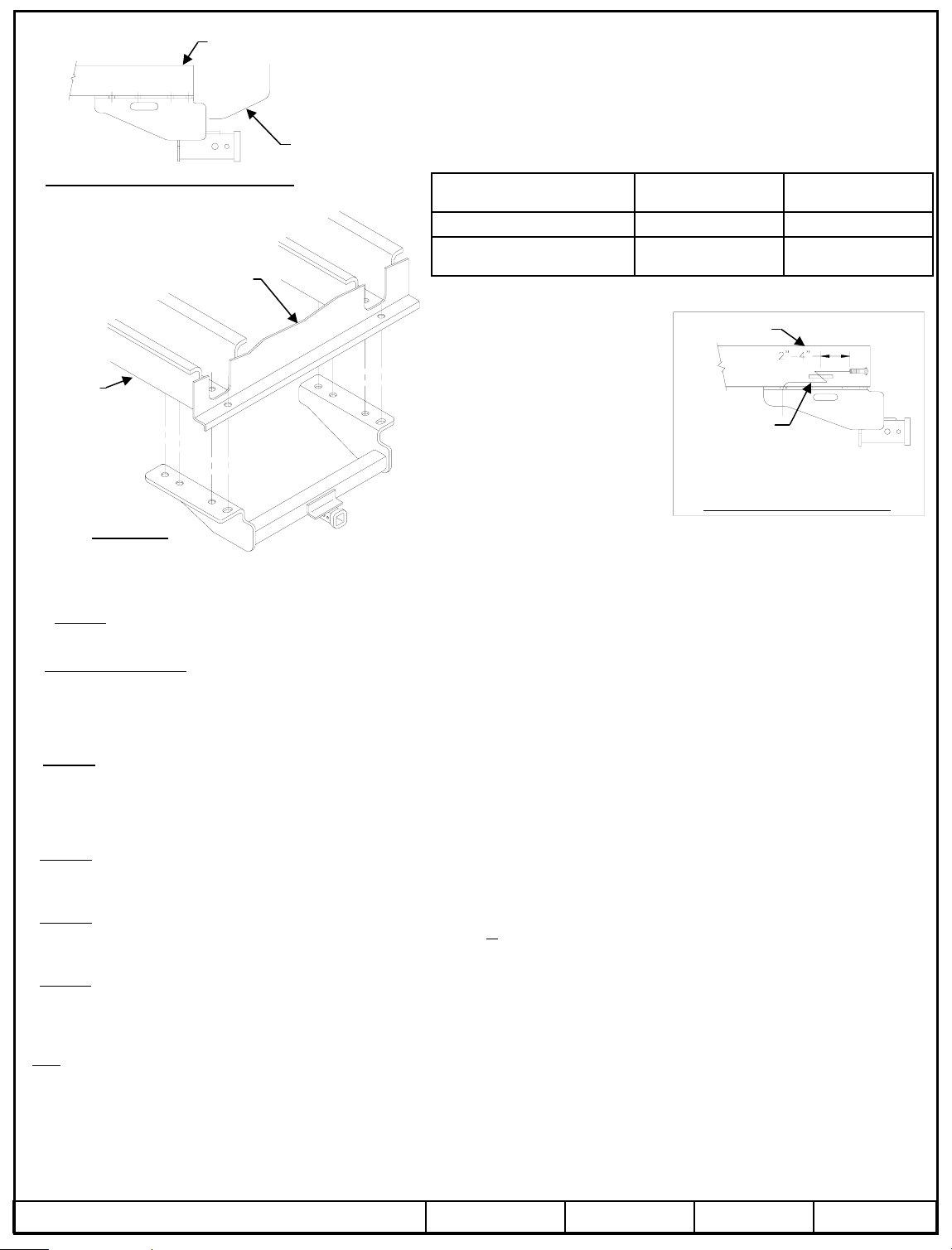

SERIES 51®

Frame rail

Installation Instructions

Jeep Cherokee

Part Numbers:

51001

Jeep Wagoneer (Downsized Model)

Fascia

Do Not Exceed Lower of Towing Vehicle

44088

Manufacturer’s Rating or

Hitch Shown In Proper Position

Equipment Required: Chisel, Pullwire (provided)

Fastener Kit: 51001-051

Wrenches: 18mm, 3/4, 13/16, 7/8

Drill Bits: None

Impact bar

Hitch type

Weight Distributing

Weight Carrying

Ball Mount

Trailer WT (LB)

Wiring Access Location: SUV1, SUV2

Max Gross

Max Tongue

WT (LB)

500 (227 Kg)5000 (2270 Kg)

300 (136 Kg)3500 (1589 Kg)

Frame

See Figures 2, 3, 4 & 5 for

Frame rail

proper fastener combinations

Kink pullwire

to keep block

independent

of bolt

Example of Pullwire Procedure

Figure 1.

Note: Five (5) installation options are possible depending on vehicle configuration refer to Figures 2, 3, 4 and 5.

1. Remove all but a thin layer of undercoating from attaching surfaces. Also, grind or chisel off small aluminum rivet heads if present on attaching

surfaces. This will ensure side brackets will sit flat against the frame.

2. Option A

1996 and earlier vehicles equipped with frame mounted, closed sides, steel skid shield.

A. Remove rear skid shield mounting bolt and loosen the forward skid shield mounting bolt, each side so that the skid shield is lowered about 1/4”.

Note: DO NOT REMOVE

B. Raise hitch into position, putting the receiver flange between the frame and the skid shield.

C. Install four (4) M12 bolts with lock washers provided (the rearmost attachment has a hardened flat washer between receiver flange and lock

D. At this time, remove forward skid shield mounting bolts. Place two (2) 1/2” flat washers as spacers between frame and skid shield and reinstall

Option B

1997 and later vehicles equipped with frame mounted, closed sided, steel skid shield:

A. Remove the rear skid shield bolts on each side. Drill hole thru skid shield being careful not to damage weldnut in frame.

B. Raise hitch into position placing the hitch over the skid shield flanges.

C. Install four (4) M12 bolts with conical washers provided (the rearmost attachment has a hardened flat washer between receiver flange and lock

Option C

Vehicles equipped with frame mounted tow hook on driver’s side:

A. Remove tow hook and tow hook bracket; Return component to vehicle owner. Mount driver’s side of receiver using M12 bolts as shown in

Option D

Vehicles not equipped with frame mounted, closed sided, steel skid shield or frame mounted tow hook:

A. Using pullwire feed 1/4 X 1-1/2 X 2 blocks (Item 9 & 10) and carriage bolts through end of frame and into existing holes. Raise hitch into position

Option E

Vehicles with passenger side exhaust hanger studs;

A. Remove (2) nuts from exhaust hanger . Rubber hanger in front of rear axel can be detached to allow exhaust pipe to drop further.

B. Install hitch using M12 bolts to existing weld nuts or 1/2-13 bolts with blocks to open holes as shown.

C. Attach exhaust hanger to studs with original nuts.

Note

: Use pullwire to feed blocks through end of frame in orientation shown in Figure 4. Removal of bumper (4 bolts per side) may ease process.

3. Install all remaining fasteners as shown.

Note: check hitch frequently, making sure all fasteners and ball are properly tightened. If hitch is removed, plug all holes in trunk pan or other body panels to

prevent entry of water and exhaust fumes. A hitch or ball which has been damaged should be removed and replaced. Observe safety precautions when working

beneath a vehicle and wear eye protection. Do not cut access or attachment holes with a torch.

This product complies with safety specifications and requirements for connecting devices and towing systems of the state of New York, V.E.S.C. Regulation V-5

and SAE J684.

– See Figure 2.

forward mounting bolt at this time or skid shield will come off:

washer). Each side as shown is Figure 1.

existing M12 fastener.

– See Figure 5

washers), each side as shown in Figure 5.

– See Figures 2 & 3

Figure 1. Mount passenger side of receiver as shown in Figure 3.

– See Figure 3

and attach per Figure 3.

– See Figure 4

Tighten 1/2 GR5 fasteners with torque wrench to 75 Lb.-Ft. (102 N*M)

Tighten 1/2 Handle Nut fasteners with torque wrench to 50 Lb.-Ft. (68 N*M)

Tighten M12 CL 8.8 fasteners with torque wrench to 68 Lb.-Ft. (92 N*M)

z 2001, 2002, 2006 Cequent Towing Products

Rev. B8-15-06N51001Sheet 1 of 2

Form: F205 Rev A 5-6-05

Page 2

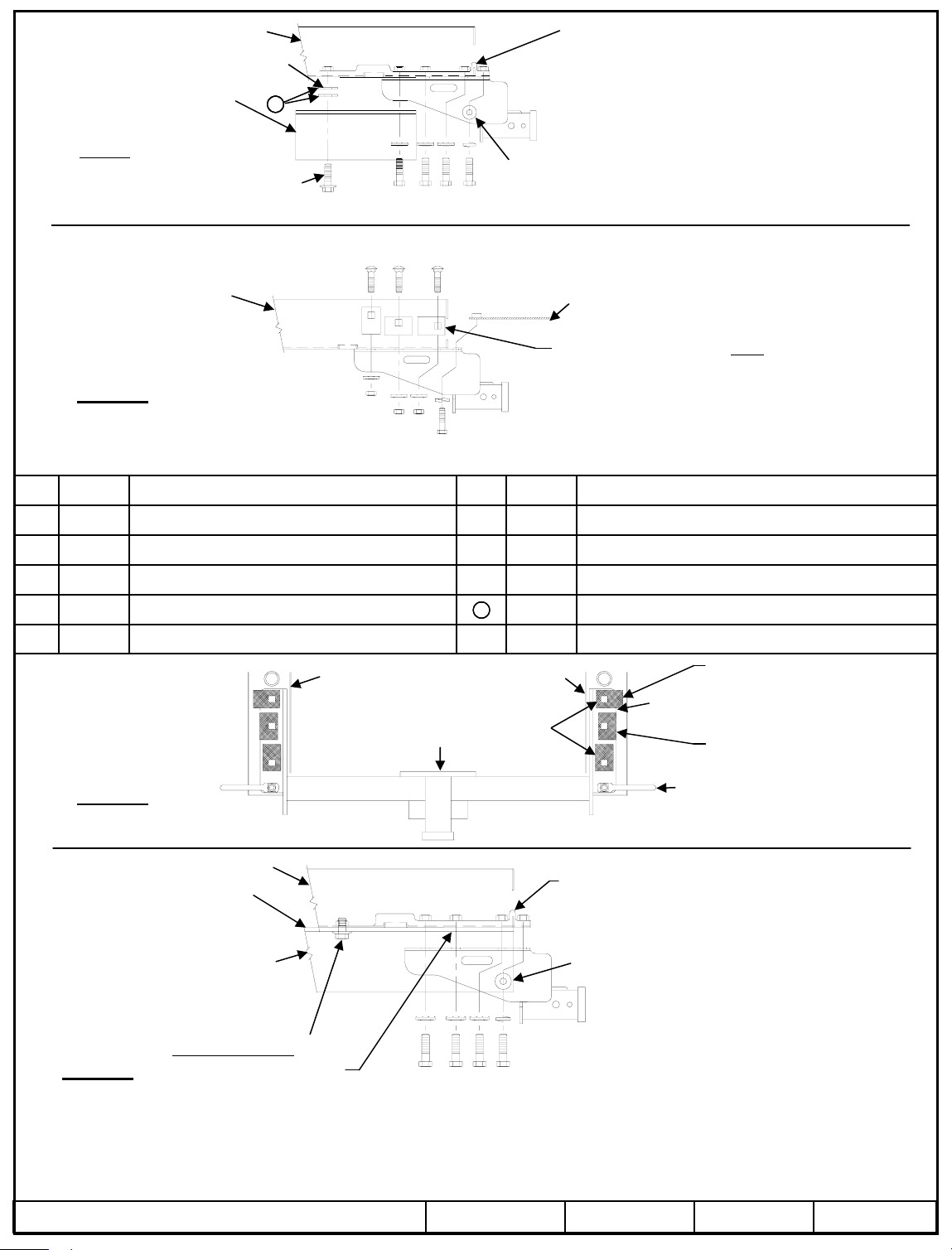

Closed sided steel skid shield

1996 and earlier vehicles

Figure 2

Option A

Option B Driver’s side

only

Frame rail

Used as spacers

Existing M12

bolt

Existing weld nut bar both sides

with closed sided skid shield.

Existing driver’s side only with

tow hook.

11

7

2

2

2

1

9

6

1

6

1

9

6

5

6

Frame rail

Figure 3

Option C Passenger only

Option D

1

2

3

4

Carriage Bolt 1/2-13 X 1.75Qty. (6)

Conical Washer 1/2Qty. (6)

Hex Nut 1/2-13Qty. (6)

Hex Bolt 1/2-13 X 1.50Qty. (2)

5

6

Hex Bolt M12 X 1.75 X 40Qty. (8)

Figure 4

Viewed from under vehicle

looking up

2

2

3

2

3

3

Passenger’s side

frame rail

5

4

Rear

of

vehicle

7

8

9

11

Driver’s side

frame rail

8

Insert through end of frame. Note: Leave

pullwires attached to carriage bolts until lock

washers and nuts are installed. This will

allow bolts to be pulled through receiver after

receiver is positioned around fuel tank.

Flat Washer (Hardened)Qty. (2)

Nut Assy-Handle 1/2-13Qty. (2)

Block 1/4 X 1-1/2 X 2Qty. (4)

Block 1/4 X 1-1/2Qty. (2)

Flat Washer 1/2 (Used as a Spacer)Qty. (4)Lock Washer 1/2Qty. (2)

Option D –

Exhaust hanger

8

stud and nut. Typical

Option E –

Exhaust hanger

stud and nut. Typical

9

Typical

Note: Proper orientation of blocks is

necessary to insure fastener alignment

Frame rail

Note: Closed sided steel skid

shield is between frame rail

and receiver.

Closed sided steel

skid shield 1997

and later vehicles

Existing M12 bolt

DO NOT REMOVE

Figure 5

Option B

Note: check hitch frequently, making sure all fasteners and ball are properly tightened. If hitch is removed, plug all holes in trunk pan or other body panels to

prevent entry of water and exhaust fumes. A hitch or ball which has been damaged should be removed and replaced. Observe safety precautions when working

beneath a vehicle and wear eye protection. Do not cut access or attachment holes with a torch.

This product complies with safety specifications and requirements for connecting devices and towing systems of the state of New York, V.E.S.C. Regulation V-5

and SAE J684.

z 2001, 2002, 2006 Cequent Towing Products

Skid shield must be drilled.

Do Not damage weldnut

2

6

2

6

2

6

5

6

Existing weld nut bar both sides

with closed skid shield.

7

Form: F205 Rev A 5-6-05

Rev. B8-15-06N51001Sheet 2 of 2

Loading...

Loading...