Page 1

Installation,

use and maintenance

(Copy of the original instructions)

Type 4 barrier for Access Control

with Muting functions integrated

Page 2

Introduction

SUMMARY

INTRODUCTION ...........................................................................................................................5

PURPOSE OF THIS DOCUMENT ...................................................................................................................... 5

PRODUCT DESCRIPTION ................................................................................................................................. 5

CONTENT OF THE PACKAGE ........................................................................................................................... 5

GLOSSARY ........................................................................................................................................................... 6

DISPOSAL OF MATERIALS ............................................................................................................................... 6

SAFETY ........................................................................................................................................7

SIMBOLOGY ......................................................................................................................................................... 7

PRECAUTIONS .................................................................................................................................................... 7

CAUTIONS BEFORE INSTALLATION ................................................................................................................ 8

LIST OF APPLICABLE STANDARDS ................................................................................................................. 9

EC DECLARATION OF CONFORMITY ............................................................................................................ 10

SYSTEM ARCHITECTURE ........................................................................................................11

POSSIBLE CONFIGURATIONS (VIA OPTIONAL ACCESSORIES) ............................................................. 12

THE MUTING FUNCTION ...........................................................................................................15

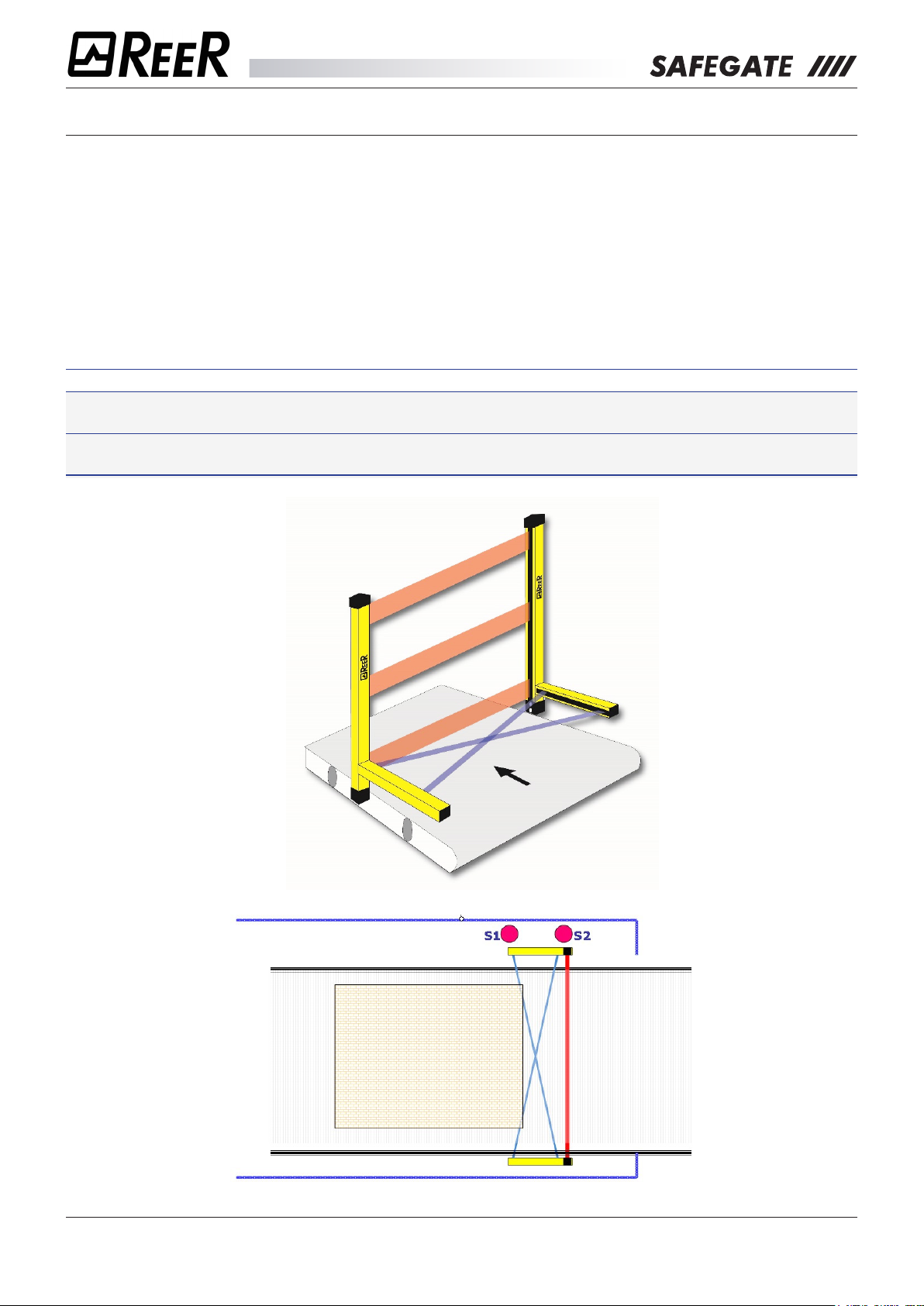

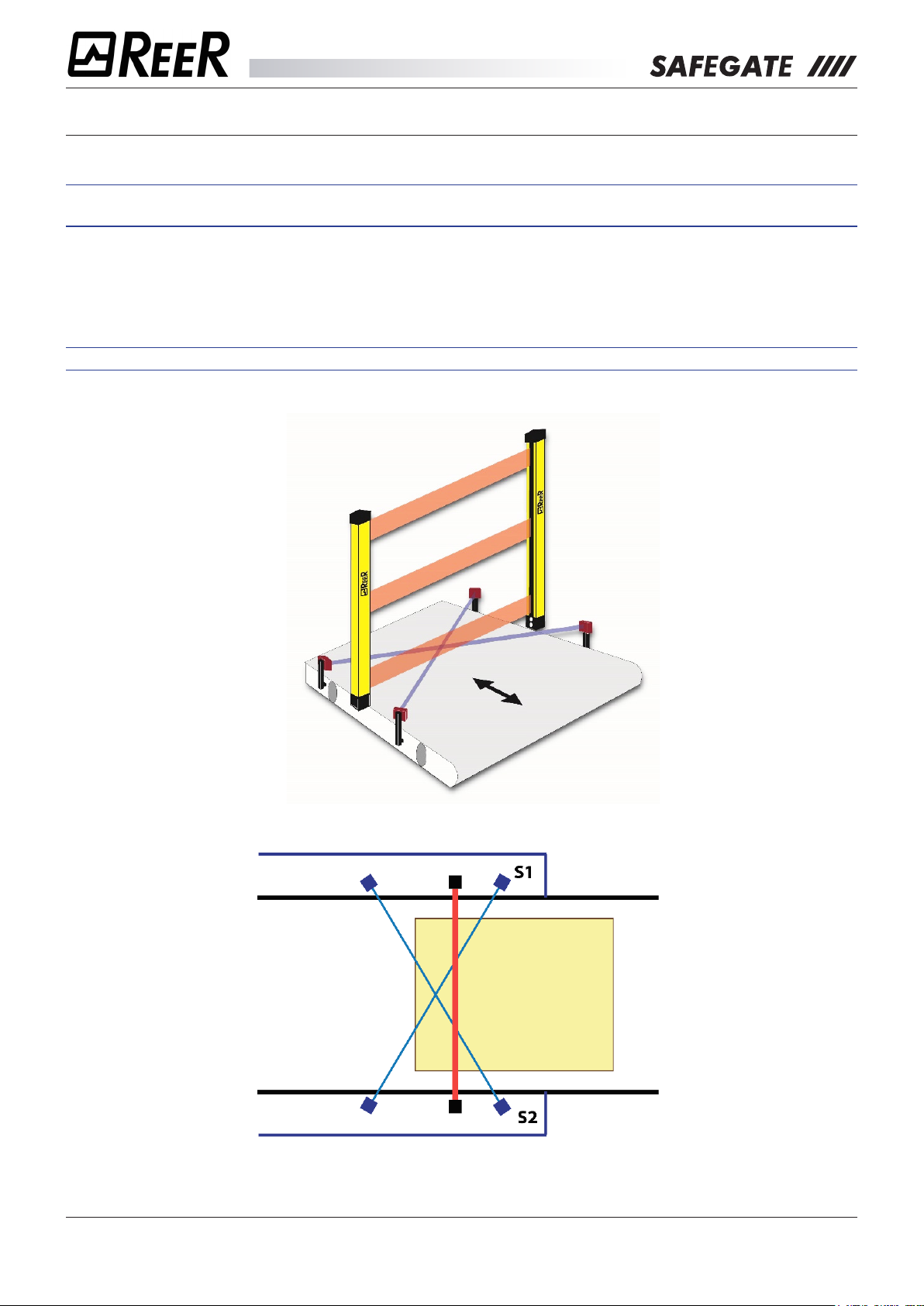

A) 2 INTEGRATED CROSS MUTING SENSORS, ONLY FOR PALLET OUTPUTS (LX) ............................. 16

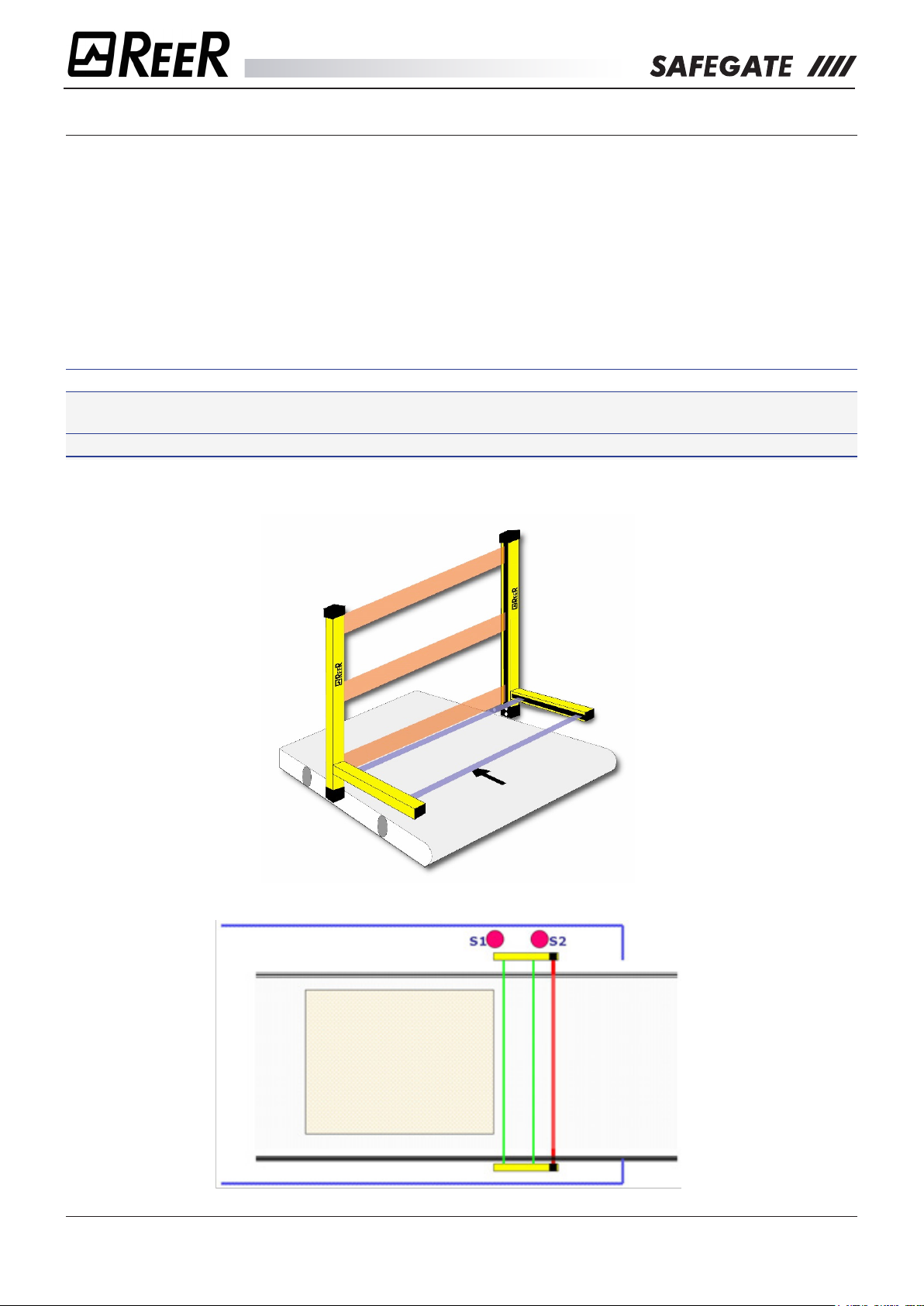

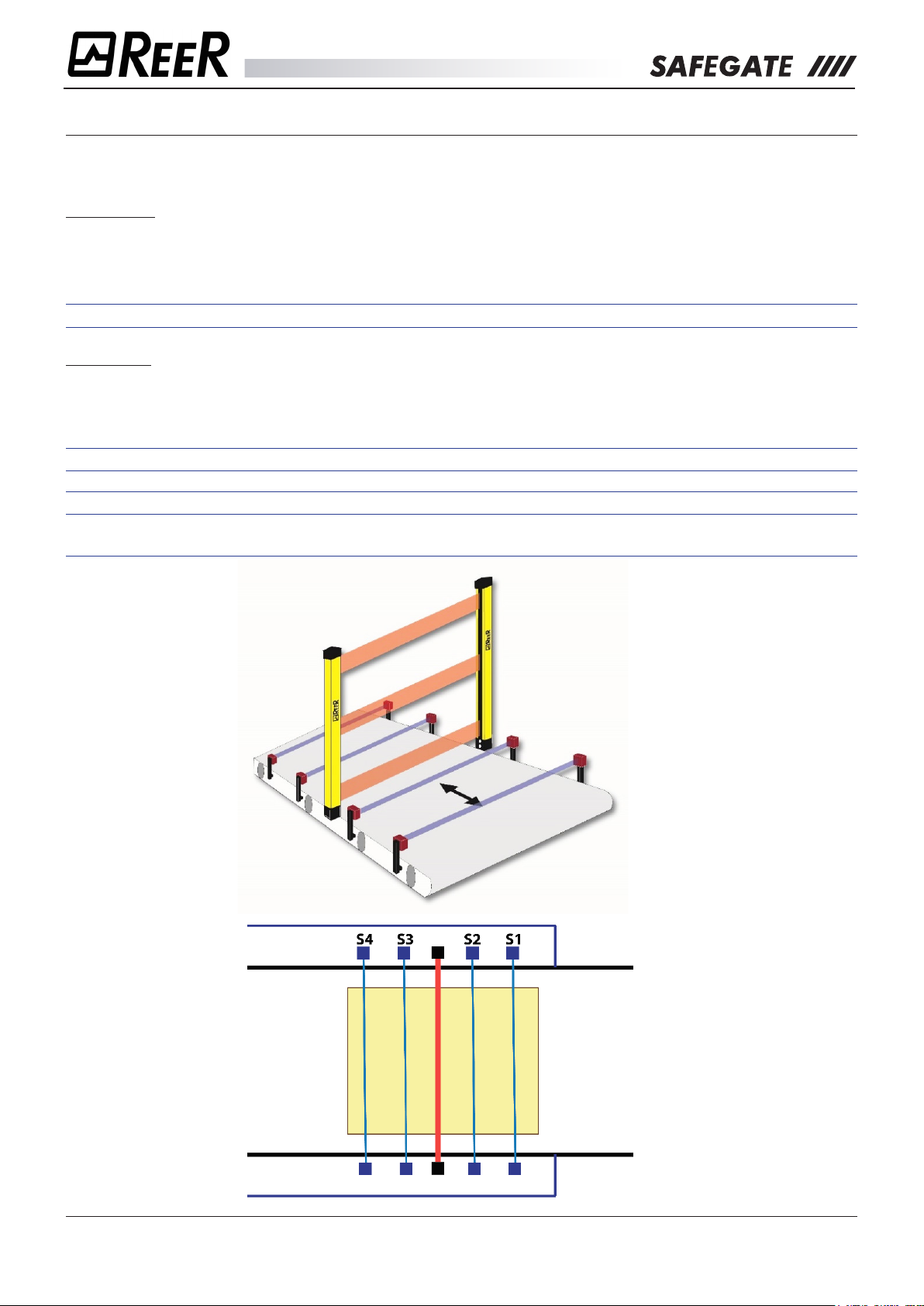

B) 2 INTEGRATED PARALLEL MUTING SENSORS, ONLY FOR PALLET OUTPUTS (L2) ........................ 17

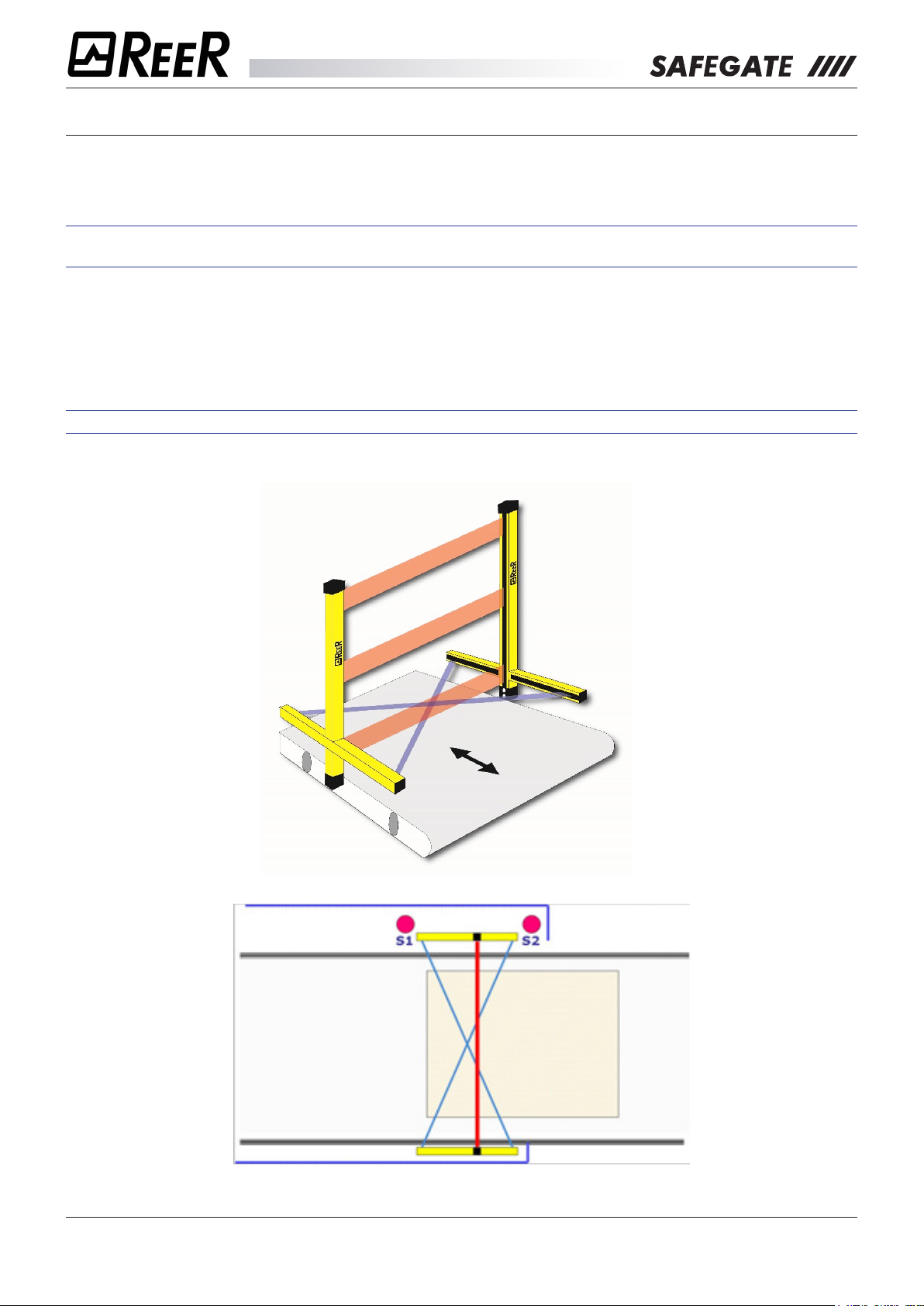

C) 2 INTEGRATED CROSS MUTING SENSORS, FOR BI-DIRECTIONAL GATES (TX) ............................ 18

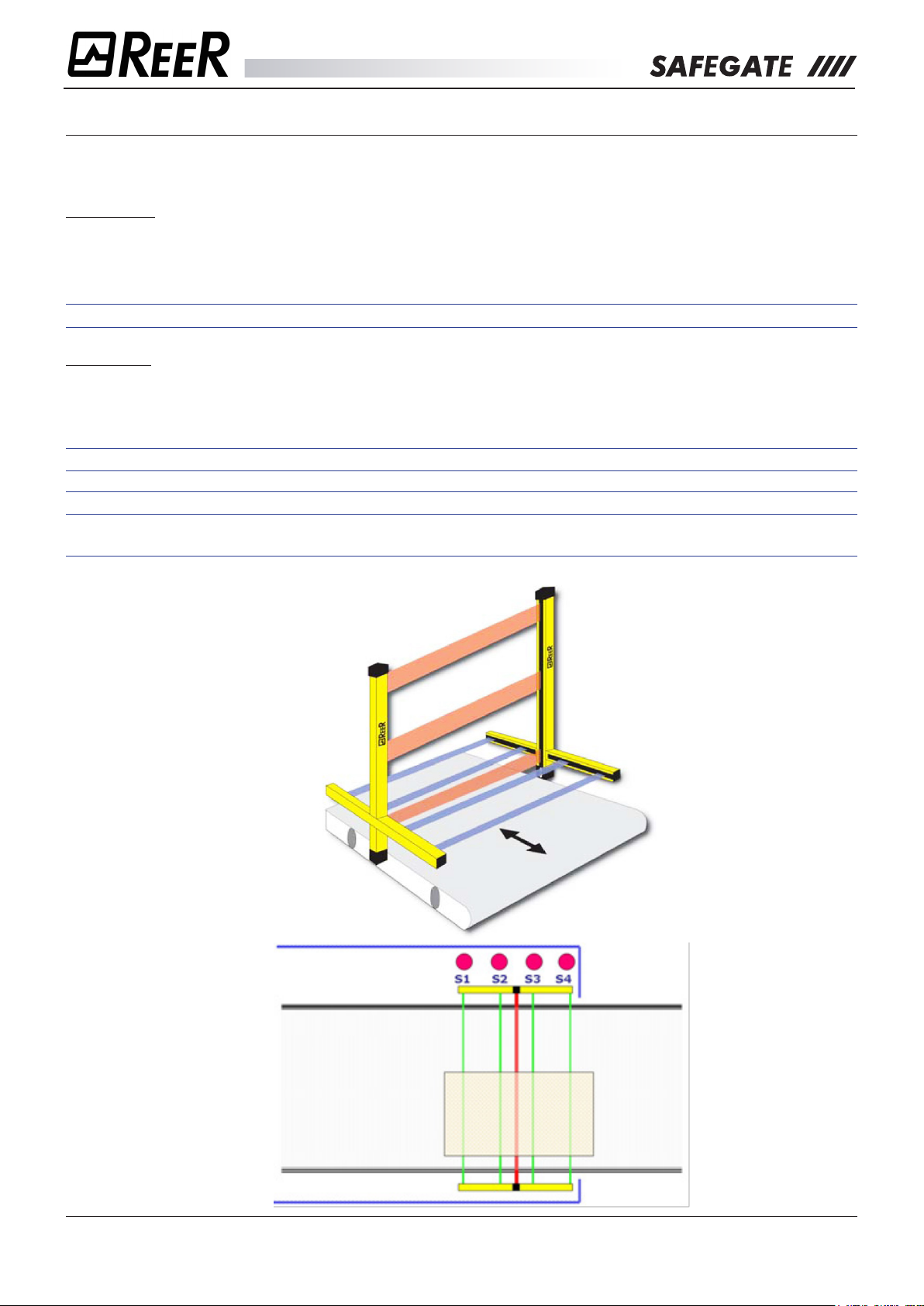

D) 4 INTEGRATED PARALLEL MUTING SENSORS, FOR BI-DIRECTIONAL GATES (T4) ....................... 19

Concurrent ..............................................................................................................................................................19

E) 2 EXTERNAL CROSS INTEGRATED MUTING SENSORS, FOR BI-DIRECTIONAL GATES (TX).

F) 4 EXTERNAL PARALLEL MUTING SENSORS, FOR BI-DIRECTIONAL GATES (T4). .......................... 21

Concurrent ..............................................................................................................................................................21

PARTIAL MUTING .............................................................................................................................................. 22

Partial Muting with Enable .......................................................................................................................................22

Partial Muting with Disable ......................................................................................................................................22

MUTING OVERRIDE .......................................................................................................................................... 23

Override with spring return key ................................................................................................................................23

Override with pushbutton .........................................................................................................................................23

INSTALLATION ...........................................................................................................................24

CALCULATION OF THE SAFETY DISTANCE ................................................................................................. 24

GENERAL FORMULA FOR CALCULATING THE SAFETY DISTANCE ........................................................ 24

MODELS WITH RESOLUTION 30 MM – 40 MM .............................................................................................. 25

MODELS WITH 2/3/4 BEAMS............................................................................................................................ 25

MULTIPLE SYSTEMS ........................................................................................................................................ 27

USE OF DEFLECTING MIRRORS ................................................................................................................... 28

DISTANCE FROM REFLECTING SURFACES ................................................................................................ 29

MECHANICAL ASSEMBLY AND OPTICAL ALIGNMENT ............................................................................... 30

SM - SMO MODELS ELECTRICAL CONNECTIONS ................................................................31

PRECAUTIONS ................................................................................................................................................. 31

WARNINGS ON CONNECTION CABLES ........................................................................................................ 31

EMITTER CONNECTIONS ............................................................................................................................... 31

RECEIVER CONNECTIONS ............................................................................................................................. 33

TEST FUNCTION ............................................................................................................................................... 34

SELECTION OF OPERATING MODES ............................................................................................................ 35

EDM ..................................................................................................................................................................... 36

OVERRIDE .......................................................................................................................................................... 37

OVERRIDE WITH KEY WITH SPRING RETURN KEY ................................................................................... 37

OVERRIDE WITH PUSHBUTTON ................................................................................................................... 37

RESTART (MANUAL OPERATION) .................................................................................................................. 38

AUTOMATIC OPERATION ................................................................................................................................ 38

MUTING ENABLE............................................................................................................................................... 39

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

Muting Enable active: correct Muting sequence ......................................................................................................39

20

2

Page 3

Introduction

APPENDIX A: SM - SMO MODELS WIRING SAMPLES ..........................................................40

SMP - SMPO MODELS ELECTRICAL CONNECTIONS ...........................................................44

PRECAUTIONS ...................................................................................................................................... 44

WARNINGS ON CONNECTION CABLES ............................................................................................ 44

EMITTER CONNECTIONS ............................................................................................................................... 44

RECEIVER CONNECTIONS ............................................................................................................................. 46

Available congurations. ..........................................................................................................................................46

TEST FUNCTION ............................................................................................................................................... 48

SELECTION OF OPERATING MODES ............................................................................................................ 49

EDM ..................................................................................................................................................................... 49

OVERRIDE (PC PROGRAMMING) ................................................................................................................... 50

OVERRIDE WITH SPRING RETURN KEY ...................................................................................................... 50

OVERRIDE WITH PUSHBUTTON ................................................................................................................... 50

RESTART (MANUAL OPERATION) .................................................................................................................. 51

AUTOMATIC OPERATION ................................................................................................................................ 51

MUTING ENABLE............................................................................................................................................... 52

Muting Enable active: correct Muting sequence ......................................................................................................52

MUTING ENABLE/DISABLE ............................................................................................................................. 52

Muting Enable/Disable active: Correct Muting sequence ........................................................................................52

PARTIAL MUTING .............................................................................................................................................. 53

1) Partial Muting with Enable ...................................................................................................................................53

2) Partial Muting with Disable ..................................................................................................................................53

APPENDIX B: SMP - SMPO MODELS WIRING SAMPLE ........................................................54

S MODELS ELECTRICAL CONNECTIONS ..............................................................................55

PRECAUTIONS ................................................................................................................................................. 55

WARNINGS ON CONNECTION CABLES ....................................................................................................... 55

TEST FUNCTION ............................................................................................................................................... 57

APPENDIX C: S MODELS WIRING SAMPLES .........................................................................57

LIGHT SIGNALS .........................................................................................................................58

EMITTER SIGNALS .......................................................................................................................................... 58

RECEIVER SIGNALS......................................................................................................................................... 59

RECEIVER SIGNALS (INTEGRATED LAMP) .................................................................................................. 60

FAULT DIAGNOSIS - EMITTER ........................................................................................................................ 61

FAULT DIAGNOSIS - RECEIVER ..................................................................................................................... 62

TECHNICAL SPECIFICATIONS .................................................................................................63

MECHANICAL DIMENSIONS .....................................................................................................66

CURTAIN DIMENSIONS .................................................................................................................................... 66

ACCESSORY DIMENSIONS ............................................................................................................................. 68

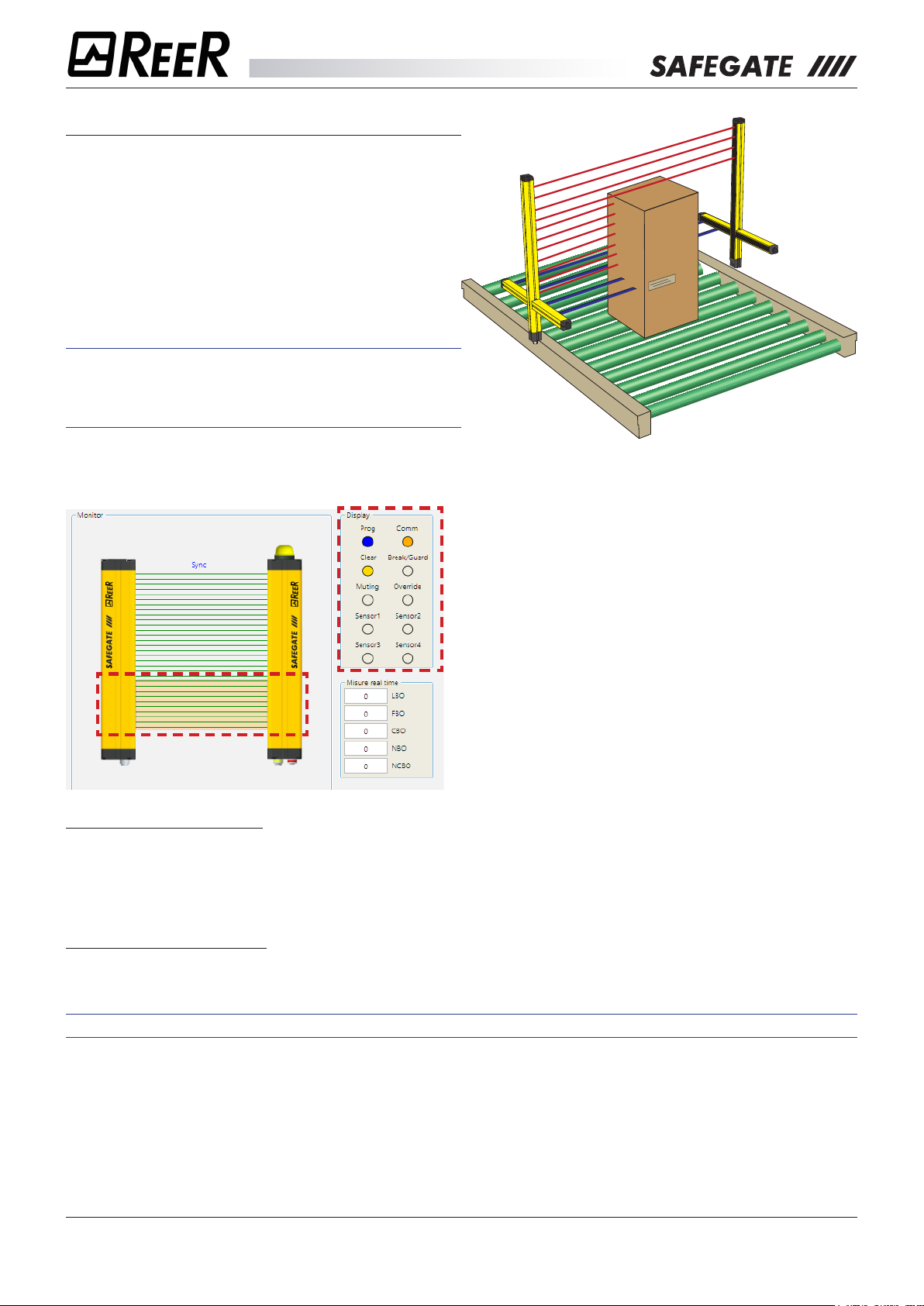

SOFTWARE SAFEGATE CONFIGURATOR ..............................................................................71

SOFWARE INSTALLATION ................................................................................................................... 71

HARDWARE characteristics requested by the PC for connection...........................................................................71

SOFTWARE characteristics requested by the PC for connection ...........................................................................71

How to install SAFEGATE CONFIGURATOR ..........................................................................................................71

CONFIGURATION PHASES.............................................................................................................................. 71

THE TOOLBAR ................................................................................................................................................... 72

GRAPHICAL INTERFACE ................................................................................................................................. 73

Level 1 password .....................................................................................................................................................73

Level 2 password .....................................................................................................................................................73

CONNECTION WITH SAFEGATE .................................................................................................................... 74

DOWNLOAD CONFIGURATION ...................................................................................................................... 74

CURTAIN PROGRAMMING .............................................................................................................................. 75

Level 2 password .....................................................................................................................................................75

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

3

Page 4

Introduction

CONFIGURATION VALIDATION AND LOADING ............................................................................................ 75

PRINT REPORT CONFIGURATION ................................................................................................................ 76

CONFIGURATION HISTORY ............................................................................................................................ 76

ERRORS DOWNLOAD ...................................................................................................................................... 76

SAFEGATE ACTIVATION .................................................................................................................................. 77

CURTAIN CONDITION MONITORING ............................................................................................................ 77

SETTING CURTAIN GENERAL PARAMETERS .............................................................................................. 77

SETTING MUTING PARAMETERS .................................................................................................................. 78

“Concurrent” Muting .................................................................................................................................................78

“Sequential” Muting ..................................................................................................................................................79

“L” Muting .................................................................................................................................................................80

“T” Muting ................................................................................................................................................................81

PARTIAL MUTING .............................................................................................................................................. 82

Partial Muting with Enable .......................................................................................................................................82

Partial Muting with Disable ......................................................................................................................................82

Partial Muting: MONITOR ........................................................................................................................................82

MUTING OVERRIDE .......................................................................................................................................... 83

Override with spring return key ...............................................................................................................................83

Impulse override ......................................................................................................................................................83

SAFEGATE DIAGNOSTIC - ERRORS ............................................................................................................. 84

CONTROLS, CARE AND MAINTENANCE ................................................................................85

PRE-ACTIVATION CHECKLIST ........................................................................................................................ 85

PERIODIC CONTROL ....................................................................................................................................... 85

CARE AND MAINTENANCE .............................................................................................................................. 86

WARRANTY ................................................................................................................................87

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

4

Page 5

Introduction

INTRODUCTION

Dear customer, REER congratulates you on purchasing this product.

Refer to this manual before using SAFEGATE; keep the CD-ROM and the Quick Installation Guide in a

place easy to be found in order to be able to refer to them when needed.

PURPOSE OF THIS DOCUMENT

This manual illustrates the operation of the programmable access curtain with Muting integrate SAFEGATE

functions. It shows specically:

¾ a general description of the SAFEGATE world;

¾ the characteristics of the muting function;

¾ the dierent types of muting and their application;

¾ the list of SAFEGATE models;

¾ the mechanical installation;

¾ the electrical connections;

¾ the mode of operation;

¾ the Muting, Override modes and their activation;

¾ SAFEGATE programming through dedicated software.

PRODUCT DESCRIPTION

The SAFEGATE light curtain is an optoelectronic multi-beam safety system belonging to the category of

Type 4 electro-sensitive devices (in accordance with EN 61496-1,2), equipped with the Muting function, for

the protection of persons exposed to dangerous machines or plants.

SAFEGATE ensures a perfect integration of the Muting sensors that are connected directly to the connectors

on the safety curtain.

In the hardware conguration models (SM and SMO) the Muting logic and the operating parameters are

fully dened by the connections of the main connector.

The SMPO programmable models retain all the features of SM and SMO models allowing also the

conguration of various parameters and additional features via the SCS software (SAFEGATE Conguration

Software).

The main features of SAFEGATE are as follows:

¾ Resolution: 30 and 40 mm – 2, 3 and 4 beams.

¾ Integration of the main safety functions, including self-monitoring of static outputs, EDM and Start/

Restart Interlock.

¾ Outline dimensions: 55 x 50 mm.

¾ Protected height: 300 to 2200 mm.

¾ Degree of protection: IP65 e IP67.

¾ Operating temperature: -30 ... +55 ° C (no condensation).

¾ Muting lamp and integrated curtain status indication (SMO/SMPO).

CONTENT OF THE PACKAGE

¾ SAFEGATE emitter and receiver

¾ CD-ROM (Containing conguration software and this Manual)

¾ Quick Installation Guide

¾ Mounting accessories bag

¾ Sealing caps for unused connectors

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

5

Page 6

Introduction

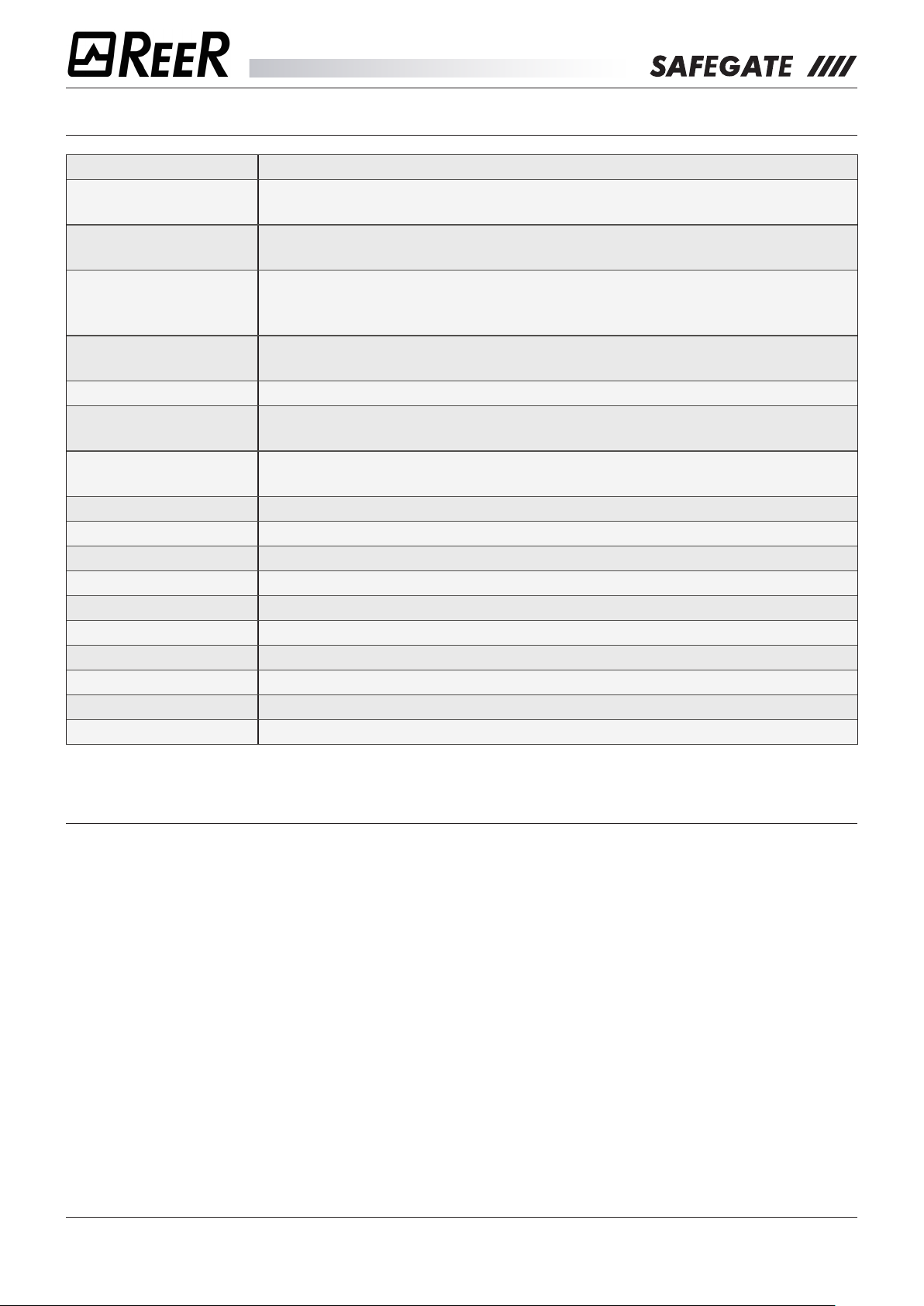

GLOSSARY

PROTECTED HEIGHT A measure that indicates the height controlled by the curtain.

SAFETY DISTANCE

EDM

MUTING

OVERRIDE

RANGE Maximum operating distance: between emitter and receiver

RESOLUTION

START/RESTART

INTERLOCK

RESPONSE TIME Time: between interruption of the gate and disabling of outputs

LX Muting Logic with 2 mono-directional cross-sensors

L2 Muting Logic with 2 mono-directional parallel sensors

TX Muting Logic with 2 bi-directional cross-sensors

T4 Muting Logic with 4 bi-directional parallel sensors

S Model without Muting

SM Model with Muting and Hardware conguration on main connector

SMO SM model with integrated Muting lamp

SMP Model with Muting Programmable with SCS software

SMPO SMP model with integrated Muting lamp

Minimum distance that must exist between the protected gate and the

dangerous area

External Device Monitoring: control of external contactors switching through

the feedback input.

Function of temporary suspension of the safety function: temporary exclusion

of the safety curtain, automatically and safely carried out based on the

machine cycle.

Forced activation of OSSD outputs: during the muting cycle for material

removal

Minimum detectable object size: to ensure the arrest of the dangerous

machine

Interlock function (manual reset required): when starting or restarting the

machine

DISPOSAL OF MATERIALS

Learn the regulations for collecting electrical and electronic products in force in the country where you want

to dispose of your product.

Observe local regulations for waste disposal and do not throw away old products with normal domestic

waste.

A proper disposal of non-usable products prevents potential negative consequences for the environment

and the population.

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

6

Page 7

Safety

SAFETY

SIMBOLOGY

This symbol indicates an important warning for personal safety. Failure to comply with this warning

may result in high level risk for exposed personnel.

Î This symbol indicates an important warning for the proper operation of the curtain.

PRECAUTIONS

The operations indicated in this document must only be carried out by qualied personnel. Such

personnel must have the necessary requirements to be able to operate on the electronic equipment

to be installed in order to avoid any risky situation.

REER declines any liability for malfunctioning of equipment installed by unqualied sta.

Any use other than those indicated in this manual may be considered as potentially dangerous for

the installer and the machine operator.

For safety reasons, please contact your country’s safety authorities or the relevant industry

association if necessary.

For applications in the food industry, consult the manufacturer to verify compatibility between

curtain materials and chemical agents used.

The protective function of optoelectronic safety devices is not eective in cases where:

¾ The machine stopping device cannot be actuated electrically and it is not possible to stop all dangerous

machine movements immediately and at any time during the operating cycle.

¾ The hazardous condition is associated with the falling of objects from above or ejection of these from

the machine.

¾ Anomalous forms of light radiation are present (for example, use of cablelless control devices on cranes,

radiation from weld spatter, etc). In this case additional measures may be necessary to ensure that the

ESPE does not fail to danger.

Î The strict and complete observance of all the standards, indications and prohibitions set forth in this

manual is a prerequisite for its proper operation.

REER S.p.A. therefore, declines any liability in case of non-respect, even partial, of these indications.

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

7

Page 8

Safety

CAUTIONS BEFORE INSTALLATION

Before installing the SAFEGATE safety system, you must verify all of the conditions listed below:

The protection level (Type4, SIL3, SILCL3, PLe) of the SAFEGATE system must be compatible with

the danger level of the system to be controlled.

The safety system should only be used as a stop device and not as a device for controlling the

machine.

The machine control must be electrically actuated.

It must be possible to immediately stop any dangerous operation of the machine.

In particular, the machine stopping times must be known and, if necessary, measured.

The machine must not generate hazardous situations due to projection or fall of materials from

above; otherwise it is necessary to provide additional mechanical protections.

The minimum size of any object to be intercepted must be greater than or equal to the resolution of

the selected model.

The knowledge of the shape and size of the hazardous area allows an estimation of the width and the

height of its access area:

Compare these dimensions with the maximum working range and the height of the area guarded by

the model used.

Before placing the safety device, it is important to consider the following general guidelines:

Verify that the temperature of the environment where the system is installed is compatible with the

temperature operating parameters indicated on the product label and in the technical data.

Avoid positioning the Emitter and Receiver near intense or ashing high-intensity light sources.

Specic environmental conditions may aect the level of detection of photoelectric devices.

In environments where fog, rain, smoke or dust may be present, it is advisable to use suitable Fc

correction factors at the maximum useful values of the working range to ensure the correct operation

of the equipment. In these cases:

Pu = Pm x Fc

where Pu and Pm are respectively the working range and maximum range in metres.

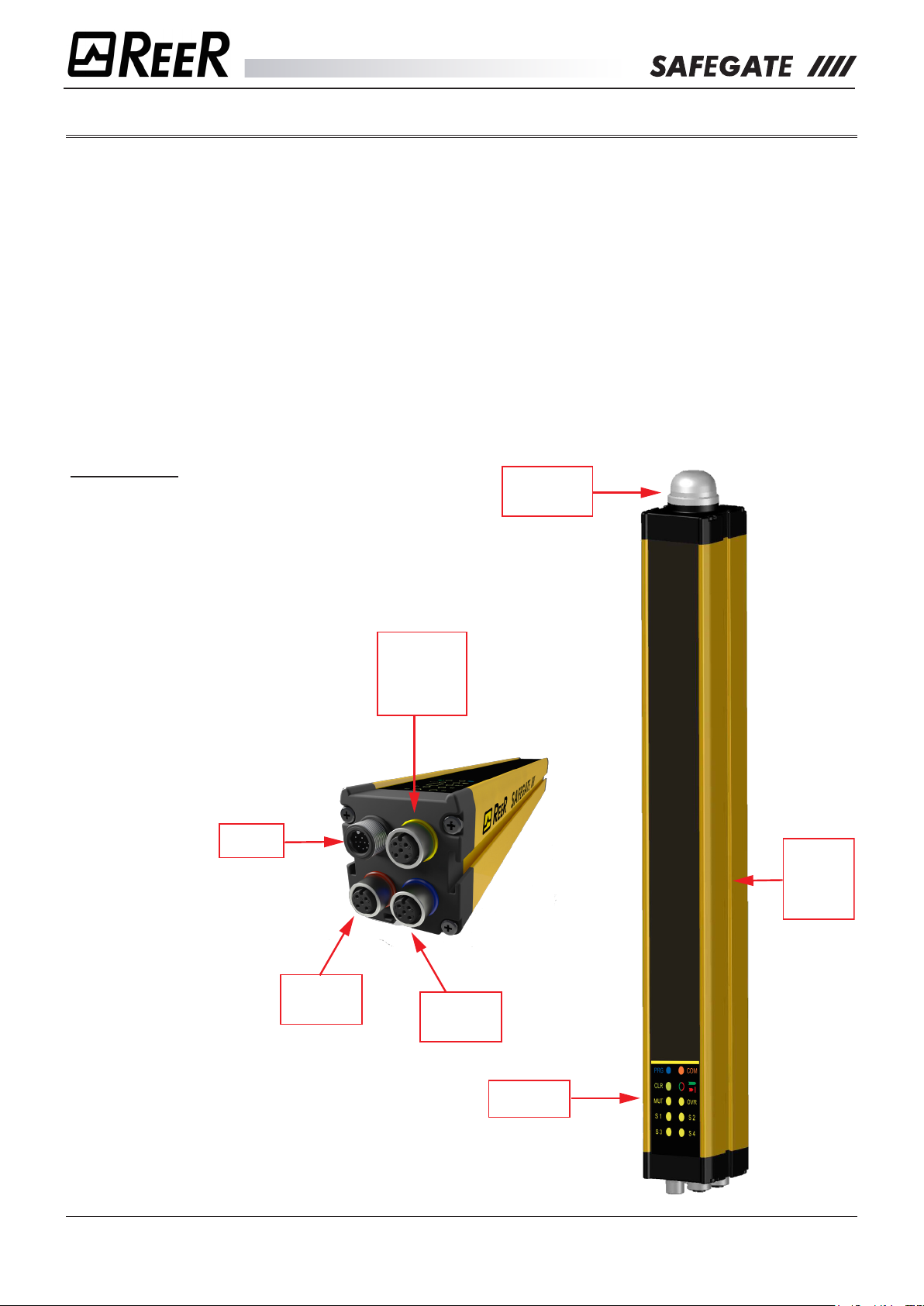

Recommended Fc factors are shown in the following table.

ENVIRONMENTAL CONDITION CORRECTION FACTOR Fc

Fog 0,25

Steam 0,50

Powders 0,50

Dense smoke 0,25

If the device is placed in environments subject to sudden temperature uctuations, it is imperative

to take the appropriate steps to avoid condensation on the lenses, which may impair the detection

capability.

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

8

Page 9

Safety

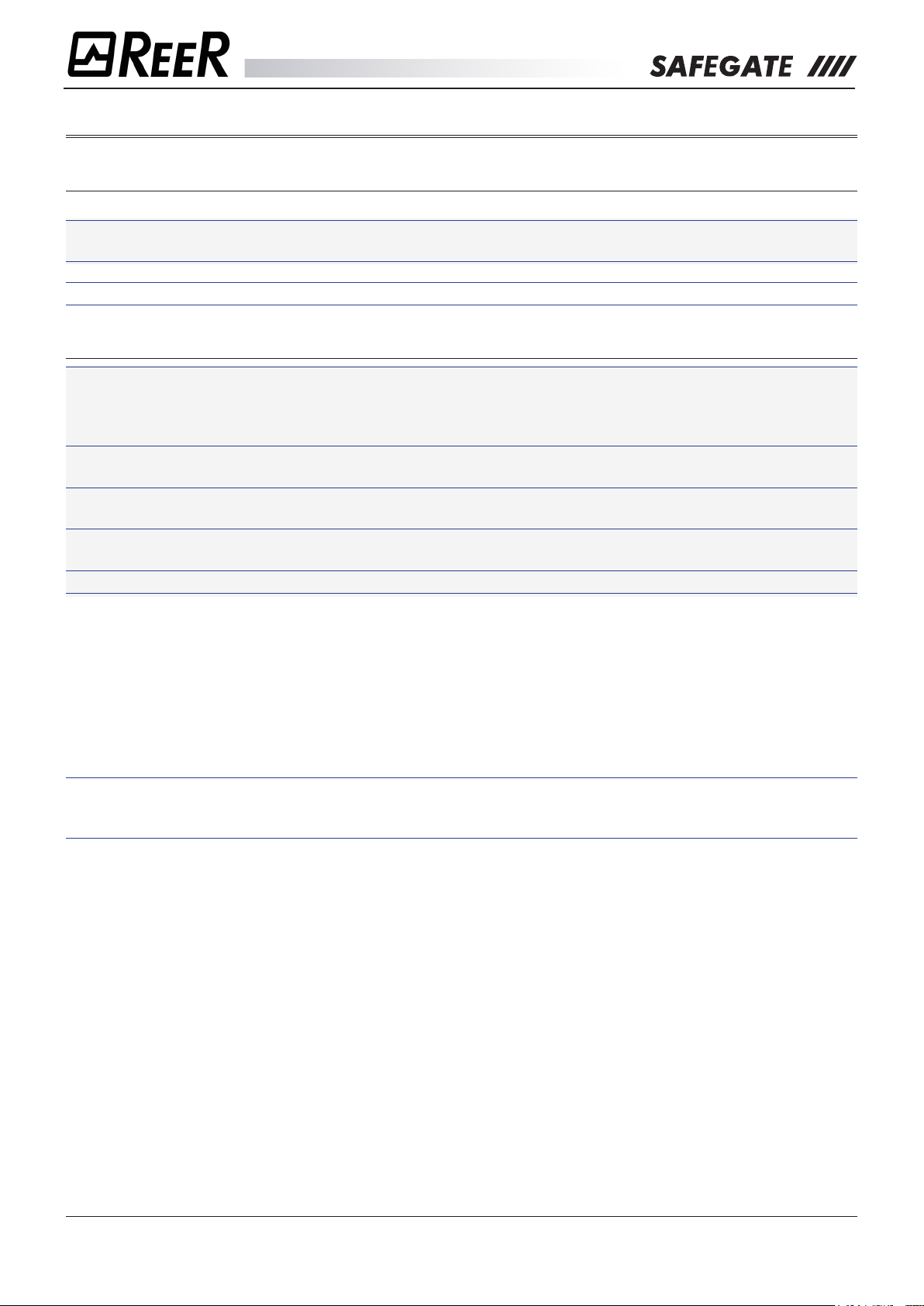

LIST OF APPLICABLE STANDARDS

SAFEGATE is manufactured in compliance with the following European Directives:

2006/42/EC “Machinery Directive”

2014/30/EU “Electromagnetic Compatibility Directive”

And it complies with the following Standards:

Safety level

Tipo 4

¾ EN 61496-1:2013

¾ EN 61496-2:2013

¾ IEC 61508-1:(ed.2)

SIL 3

¾ IEC 61508-2:(ed.2)

¾ IEC 61508-3:(ed.2)

¾ IEC 61508-4:(ed.2)

SILCL 3 ¾ IEC 62061:2005/A2:2015

PL e - Cat. 4 ¾ EN ISO 13849-1: 2015

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

9

Page 10

Safety

EC DECLARATION OF CONFORMITY

Dichiarazione CE di conformità

EC declaration of conformity

REER SpA

via Carcano 32

10153 – Torino

Italy

dichiara che le barriere fotoelettriche SAFEGATE sono Dispositivi Elettrosensibili di Sicurezza (ESPE) di :

Tipo 4 (secondo la Norma EN 61496-1:2013; EN 61496-2:2013)

SIL 3 (secondo la Norma EN 61508-1:2010; EN 61508-2:2010; EN 61508-3:2010; EN 61508-4:2010)

SILCL 3 (secondo la Norma EN 62061:2005/A2:2015)

Cat.4 - PL e (secondo la Norma EN ISO 13849-1:2015)

declares that the SAFEGATE photoelectric safety barr

Type 4 (according the Standard EN 61496-1:2013; EN 61496-2:2013)

SIL 3 (according the Standard EN 61508-1:2010; EN 61508-2:2010; EN 61508-3:2010; EN 61508-4:2010)

SILCL 3 (according the Standard EN 62061:2005/A2:2015)

Cat.4 - PL e (according the Standard EN ISO 13849-1:2015)

Electro-sensitive Protective Equipments (ESPE)

realizzati in conformità alle se

guenti Direttive Europee:

complying with the following European Directives:

2006/42/EC "Direttiva Macchine"

"Machine Directive"

2014/30/EU "Direttiva Compatibilità Elettromagnetica"

"Electromagnetic Compatibility Directive"

e alle seguenti Norme: /and to the following Standards:

EN 50178: 1997

EN 55022: 2006

EN 61000-6-2: 2005

e sono identiche all'esemplare esaminato ed approvato con esame di tipo CE da:

and are identical to the specimen examined and approved with a CE - type approval by:

TÜV SÜD Product Service GmbH – Zertifizierstelle – Ridlerstraße 65 – 80339 – München – Germany

N.B

. number: 0123 - Certificate No: Z10 17 05 24820 071

Carlo Pautasso Simone Scaravelli

Direttore Tecnico Amministratore Delegato

Technical Director Managing director

iers are :

Torino, 15/06/2017

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

10

Page 11

System architecture

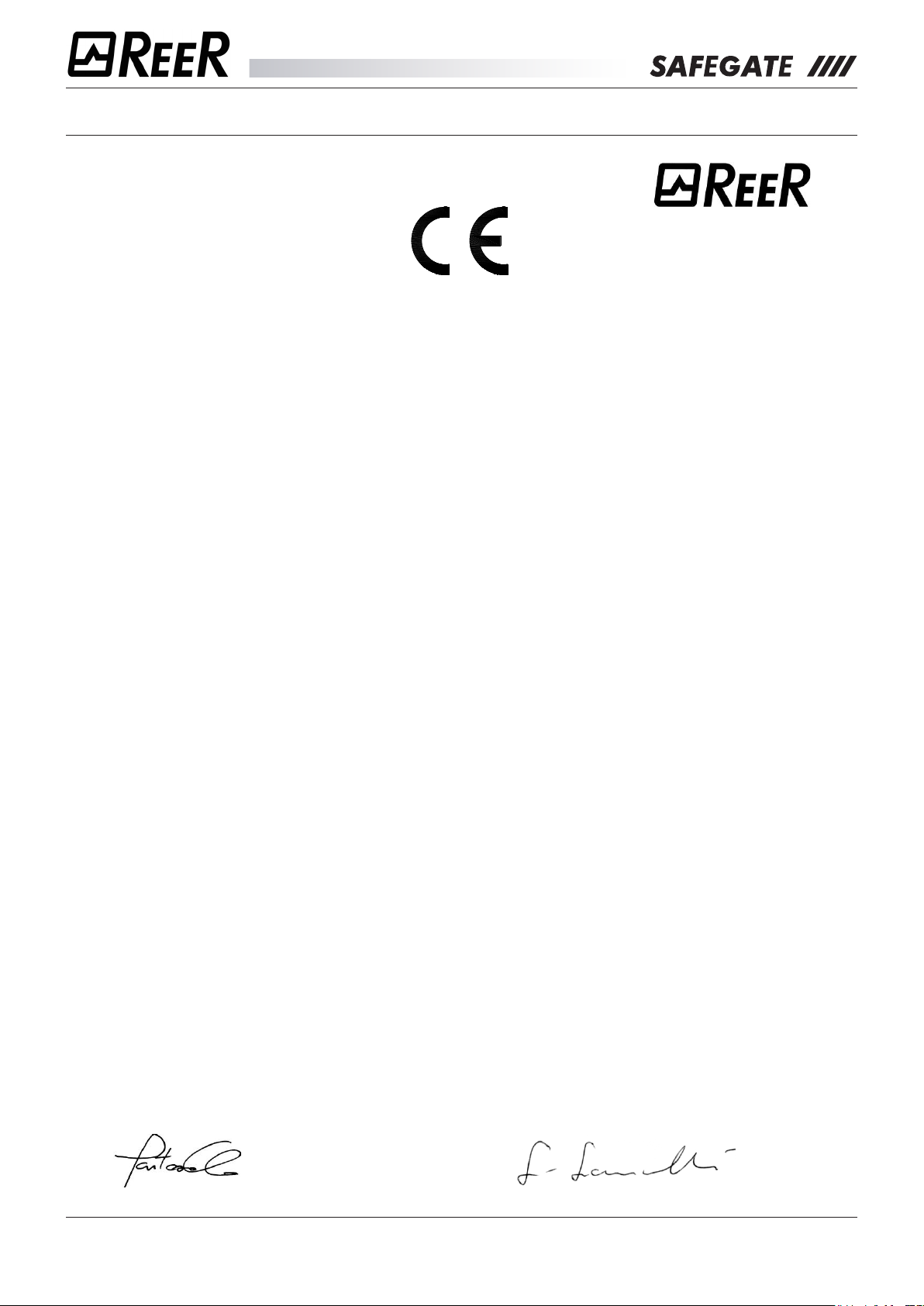

SYSTEM ARCHITECTURE

SAFEGATE is supplied as a pair (Emitter/Receiver) and allows integration with external Muting sensors

that are directly connected to the connectors installed on the curtain.

¾ Each curtain can be congured as LX, L2, TX and T4 (see the dierent Muting types in the section

“MUTING FUNCTION”) through the wiring of the main connector. This conguration can be changed

at any time.

¾ SAFEGATE can be used with (pre-aligned and pre-congured) Muting arms, with M5 multibeam

photocells (available as accessories) or any other Muting sensor.

¾

S models integrate the functions of “START/RESTART INTERLOCK” and ”EDM” but do not allow the

Muting function.

¾

SM models allow the Muting function, but have no integrated signal lamp.

¾ Programmable

problems in complex application scenarios.

¾

SMO-SMPO models with Integrated signalling lamp allow the immediate viewing of the curtain status

even at a distance.

SMP-SMPO models allow an ideal use of further conguration options to solve potential

PLEASE NOTE

The sample gure represents the Receiver

of a SMPO model.

This model comes with integrated signal

lamp.

Additionally, the conguration connector

allows the USB connection to a PC with

the conguration software installed.

Main

connector

Integrated

Signalling

Lamp

Configuration

connector

and auxiliary

signal lamp

Seat for

anchorage

of any

Muting

arms

Sensor 3-4

Muting

connector

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

Sensor 1-2

Muting

connector

Signals

label

11

Page 12

System architecture

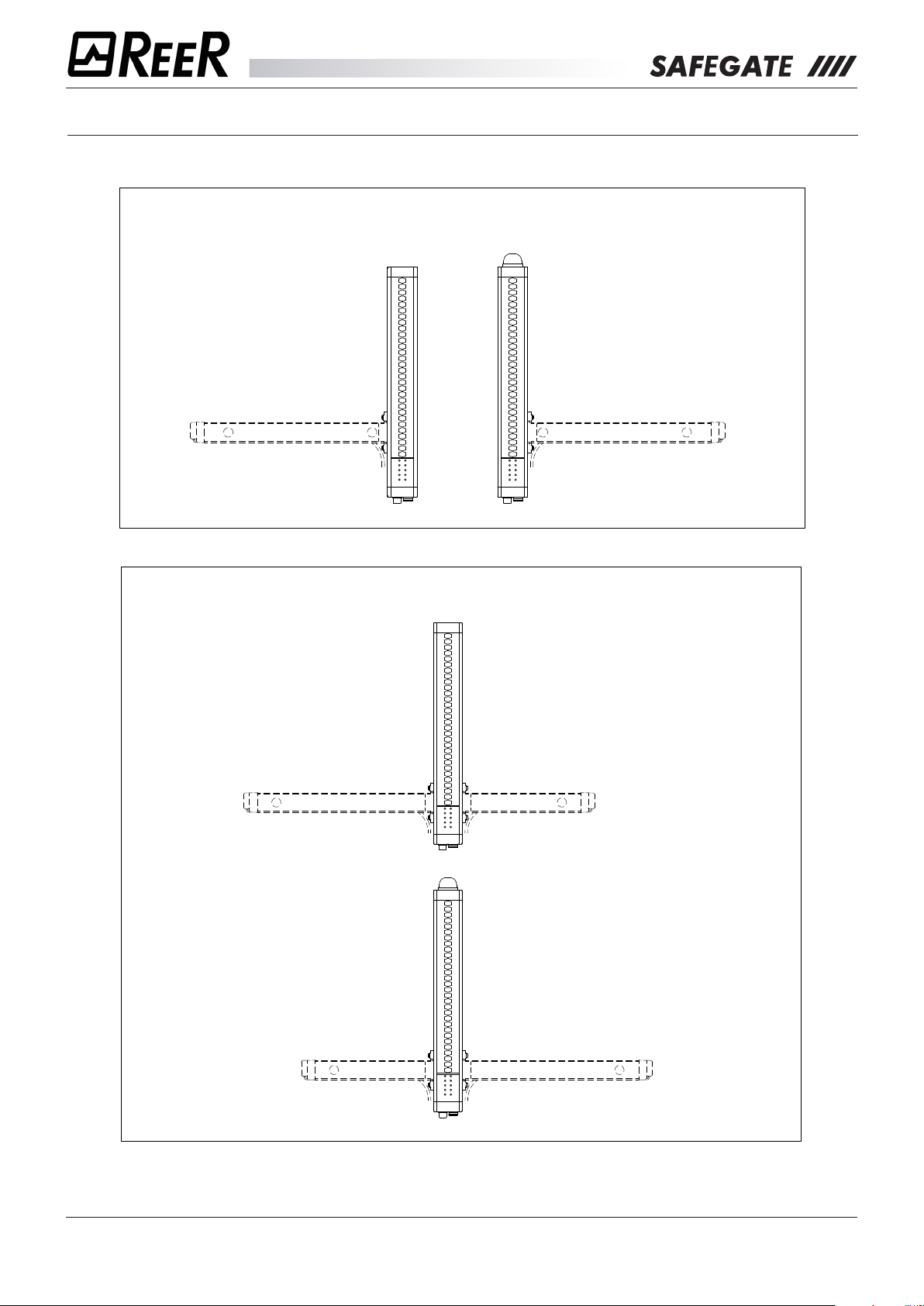

POSSIBLE CONFIGURATIONS (via optional accessories)

MAL2X - braccetti L a 2 raggi incrociati TX/RX

MAL2X - L-arms with 2 crossed TX/RX beams

MAL2XE

EMITTER

Optional

Accessorio

Accessory

opzionale

MAT2X - T-arms with 2 crossed TX/RX beams

MAT2X - braccetti T a 2 raggi incrociati TX/RX

MAT2XE SX

EMITTER

Optional

Accessorio

opzionale

Accessory

SAFEGATE - EMITTER

SAFEGATE - RECEIVER

SAFEGATE - EMITTER

MAT2XE DX

EMITTER

Optional

Accessorio

Accessory

opzionale

MAL2XR

RECEIVER

Optional

Accessorio

Accessory

opzionale

SAFEGATE - RECEIVER

MAT2XR SX

RECEIVER

Optional

Accessorio

opzionale

Accessory

MAT2XR DX

RECEIVER

Accessorio

Accessory

opzionale

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

Optional

12

Page 13

System architecture

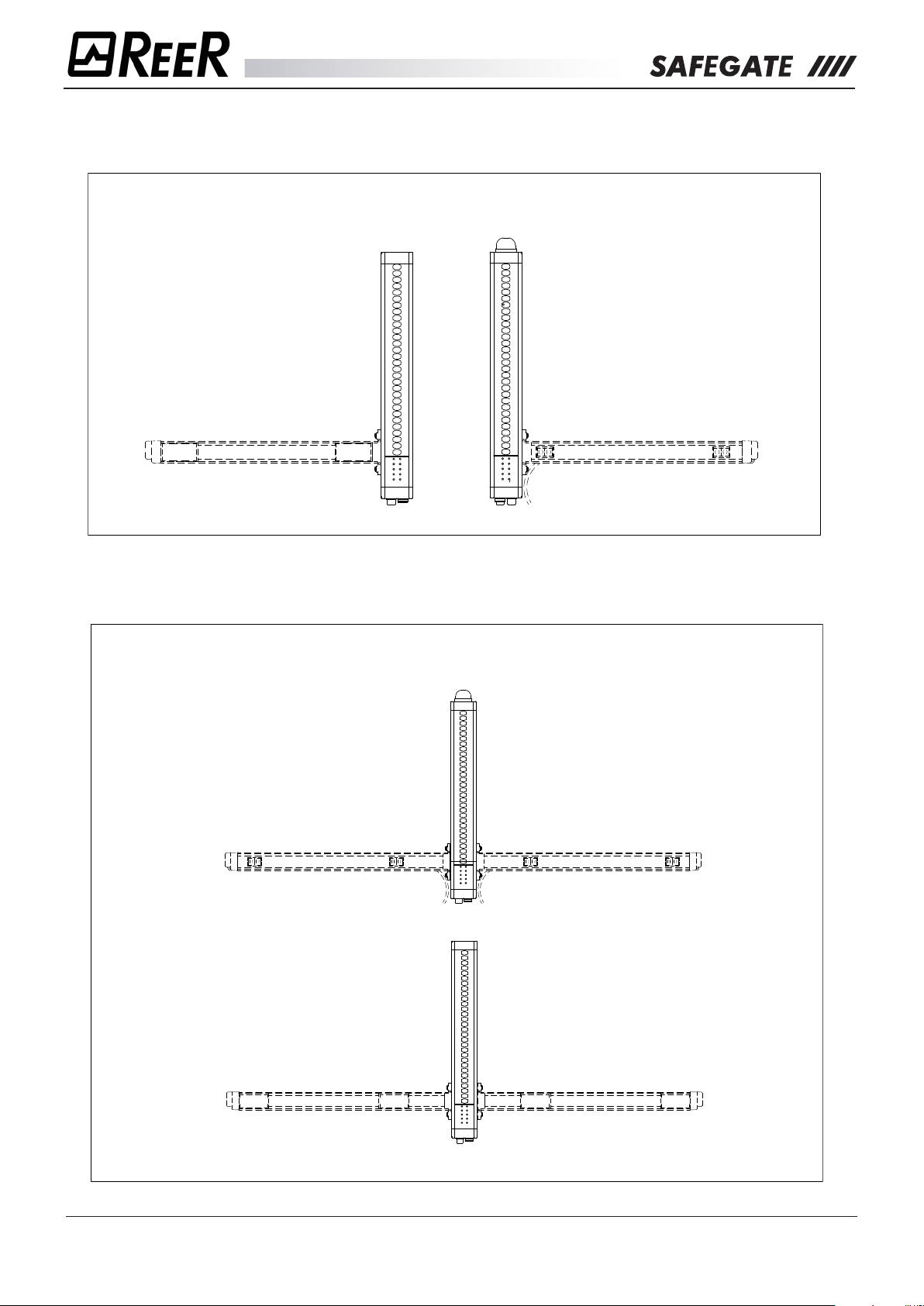

MAL2P TRX - L-arms with 2 parallel beams with reector

MAL2P TRX - braccetti L a 2 raggi paralleli con riflettore

MA2P SX 2R

REFLECTOR

Optional

Accessorio

Accessory

opzionale

MAT4P TRX - T arms with 4 parallel beams with reectors

MAT4P TRX - braccet. T a 4 raggi paralleli con riflettore

MA2P SX 2B

EMITTER / RECEIVER EMITTER / RECEIVER

Optional

Accessorio

Accessory

opzionale

SAFEGATE - EMITTER

SAFEGATE - RECEIVER

SAFEGATE - RECEIVER

MA2P DX 2B

EMITTER / RECEIVER

Optional

Accessorio

Accessory

opzionale

MA2P DX 2B

Optional

Accessorio

Accessory

opzionale

MA2P SX 2R

Optional

Accessorio

Accessory

opzionale

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

SAFEGATE - EMITTER

MA2P DX 2R

REFLECTORREFLECTOR

Optional

Accessorio

Accessory

opzionale

13

Page 14

System architecture

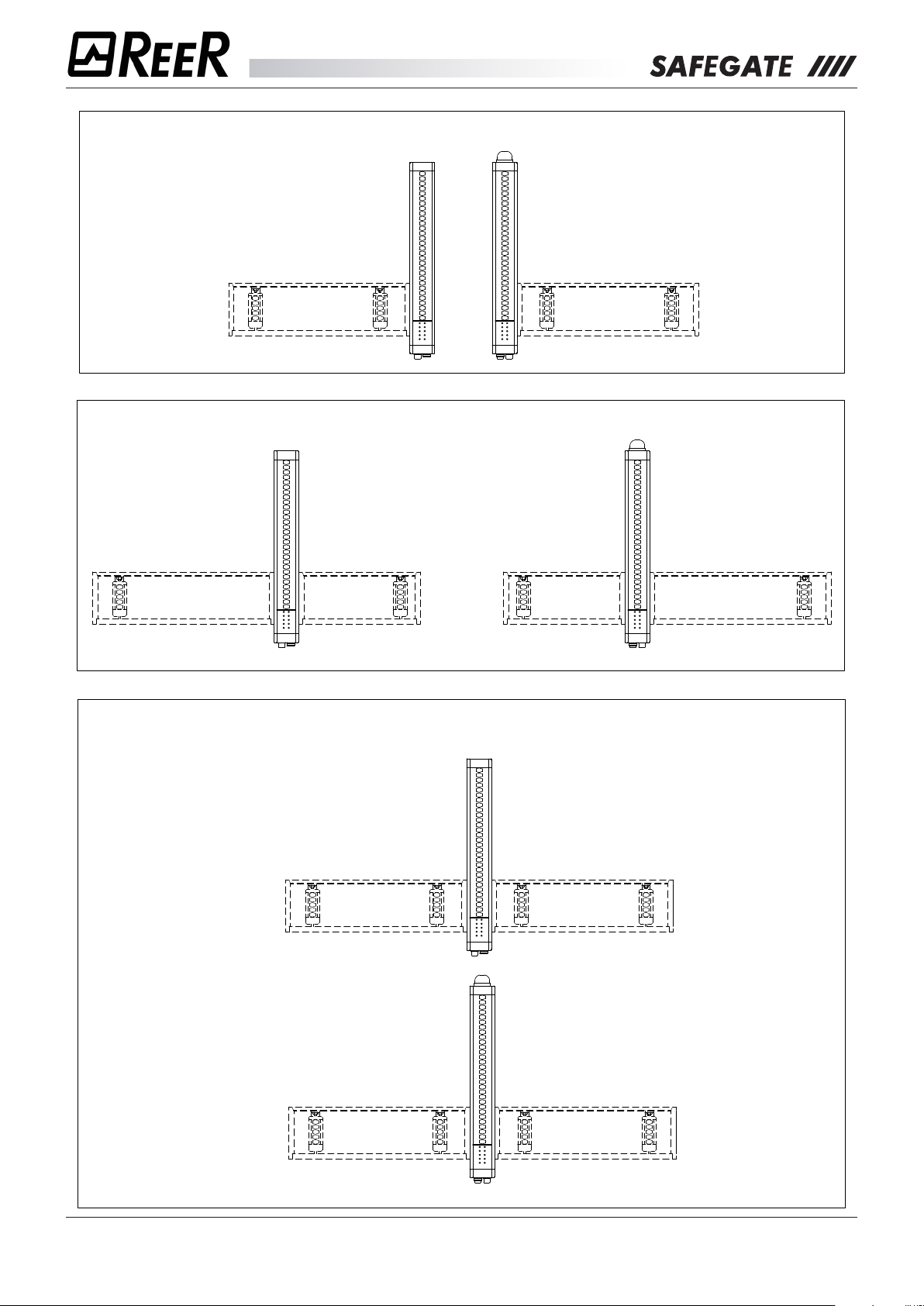

MZL2XP arms with 2 cross-linked/parallel adjustable M5 beams

MZL2XP - braccetti L a 2 raggi incrociati/paralleli regolabili M5

MZL2XPE MZL2XPR

EMITTER RECEIVER

Optional

Accessorio

Accessory

opzionale

MZT2X - T-arms with 2 adjustable M5 cross beams

MZT2X - braccetti T a 2 raggi incrociati regolabili M5

SAFEGATE - EMITTER

SAFEGATE - RECEIVER

Optional

Accessorio

Accessory

opzionale

MZT2XE SX

EMITTER RECEIVEREMITTER RECEIVER

Optional

Accessorio

Accessory

opzionale

SAFEGATE - EMITTER

MZT4P - T-arms with 4 adjustable M5 parallel beams

MZT4P - braccetti T a 4 raggi paralleli regolabili M5

MZT2XE DX

Optional

Accessorio

Accessory

opzionale

MZT4PE SX MZT4PE DX

EMITTER

Optional

Accessorio

Accessory

opzionale

SAFEGATE - EMITTER

MZT2XR SX

Optional

Accessorio

Accessory

opzionale

EMITTER

Optional

Accessorio

Accessory

opzionale

SAFEGATE - RECEIVER

MZT2XR DX

Optional

Accessorio

Accessory

opzionale

MZT4PR SX MZT4PR DX

RECEIVER

Optional

Accessorio

Accessory

opzionale

SAFEGATE - RECEIVER

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

RECEIVER

Optional

Accessorio

Accessory

opzionale

14

Page 15

The Muting function

THE MUTING FUNCTION

The Muting function is the temporary exclusion of the safety curtain, automatically and safely carried out

based on the machine cycle.

ÎÎ Carefully verify your risk analysis to make sure the Muting function is compatible with your

application and what additional measures should be taken.

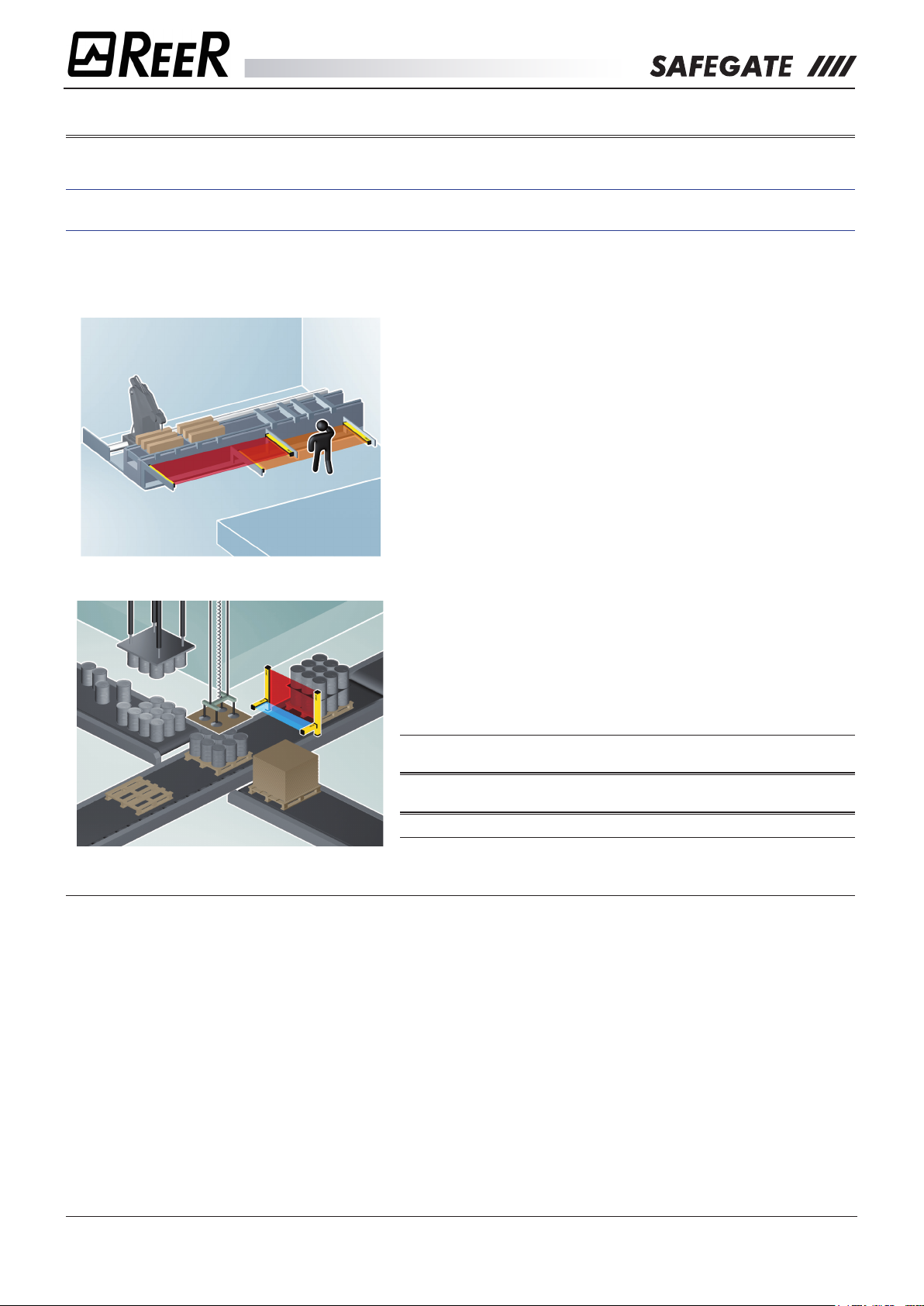

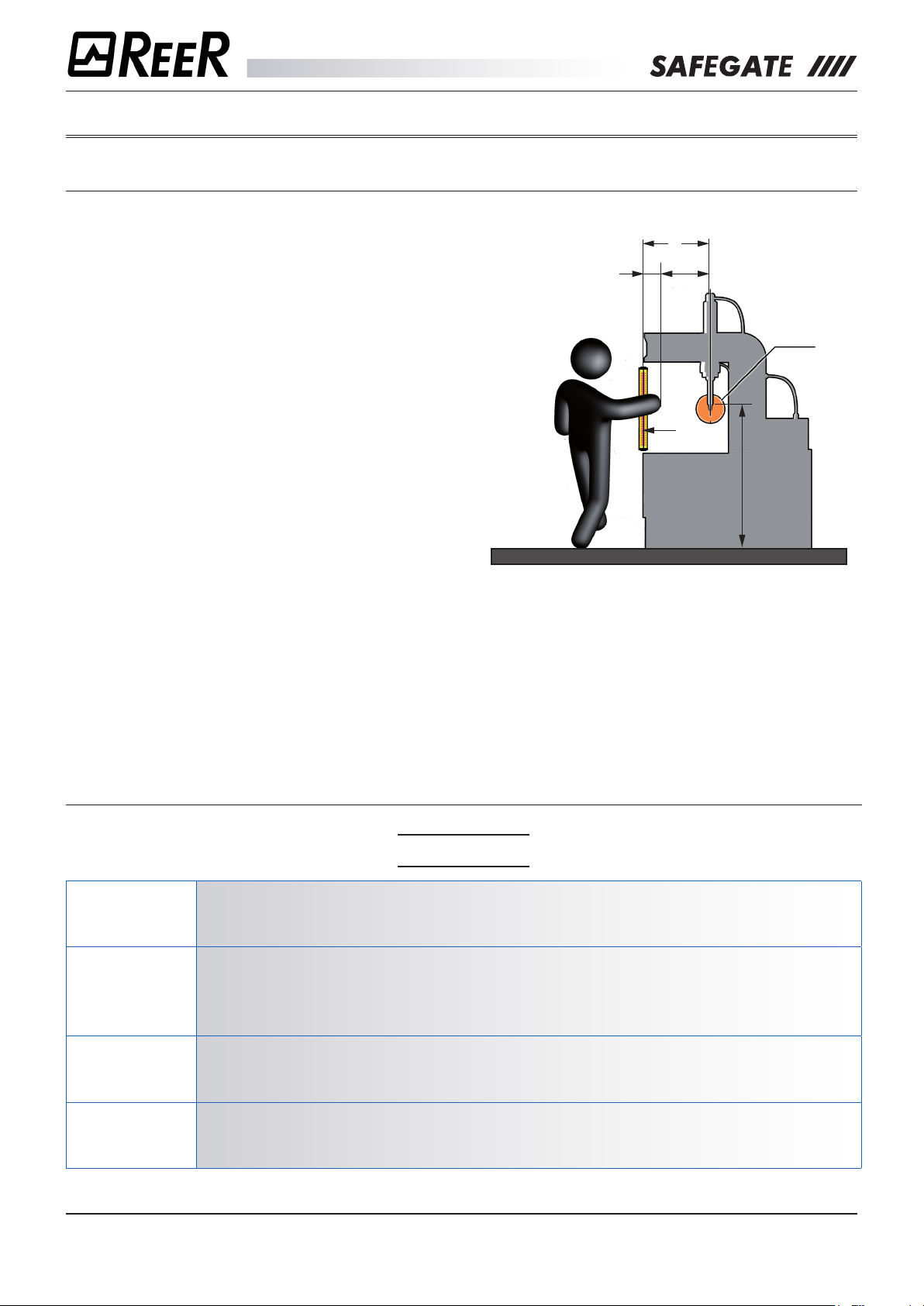

There are basically two types of applications:

1. Those allowing people to enter the dangerous area during the non-dangerous part of the machine

cycle.

Example:

Positioning or Removing the workpiece

Depending on the position of the tool, which is the hazardous

element, one of the two curtains (the one facing the tool

work area) is active while the other is in Muting condition

to allow the operator loading/unloading the workpiece. The

Muting condition of the two curtains will then be reversed

when the tool is to work on the opposite side of the machine.

2. Those who allow material transit and prevent access to the people.

Example: Pallet exit from the hazardous area

The safety curtain is equipped with Muting sensors able to

eectively discriminate between the person and the material

allowed to get through the controlled gate. The essential

requirements concerning the Muting function are described

in the following Standards:

ÎÎ IEC TS 62046 - “Application of protection devices for people

detection”.

ÎÎ EN 415-4 - “Safety on packaging machines – Palletizers and

Unpalletizers”.

ÎÎ IEC 61496-1 - “Electro-sensitive protective devices”.

General requirements:

¾ The Muting function is a temporary suspension of the safety function that needs to be activated and

deactivated automatically.

¾ The activation and subsequent deactivation of the Muting function must take place only through the use

of two or more wired and independent signals activated by a correct timing or spatial sequence. This

means that a stand-alone failure cannot activate the Muting function.

¾ It should not be possible to activate the Muting function when SAFEGATE has deactivated the safety

outputs.

¾ It should not be possible to start a Muting function by switching o and then restarting the device.

¾ Muting must be activated at an appropriate point of the machine cycle, i.e. only when there are no risks

for the operator.

¾ Muting sensors must be mechanically protected so that any impact does not modify their alignment.

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

15

Page 16

The Muting function

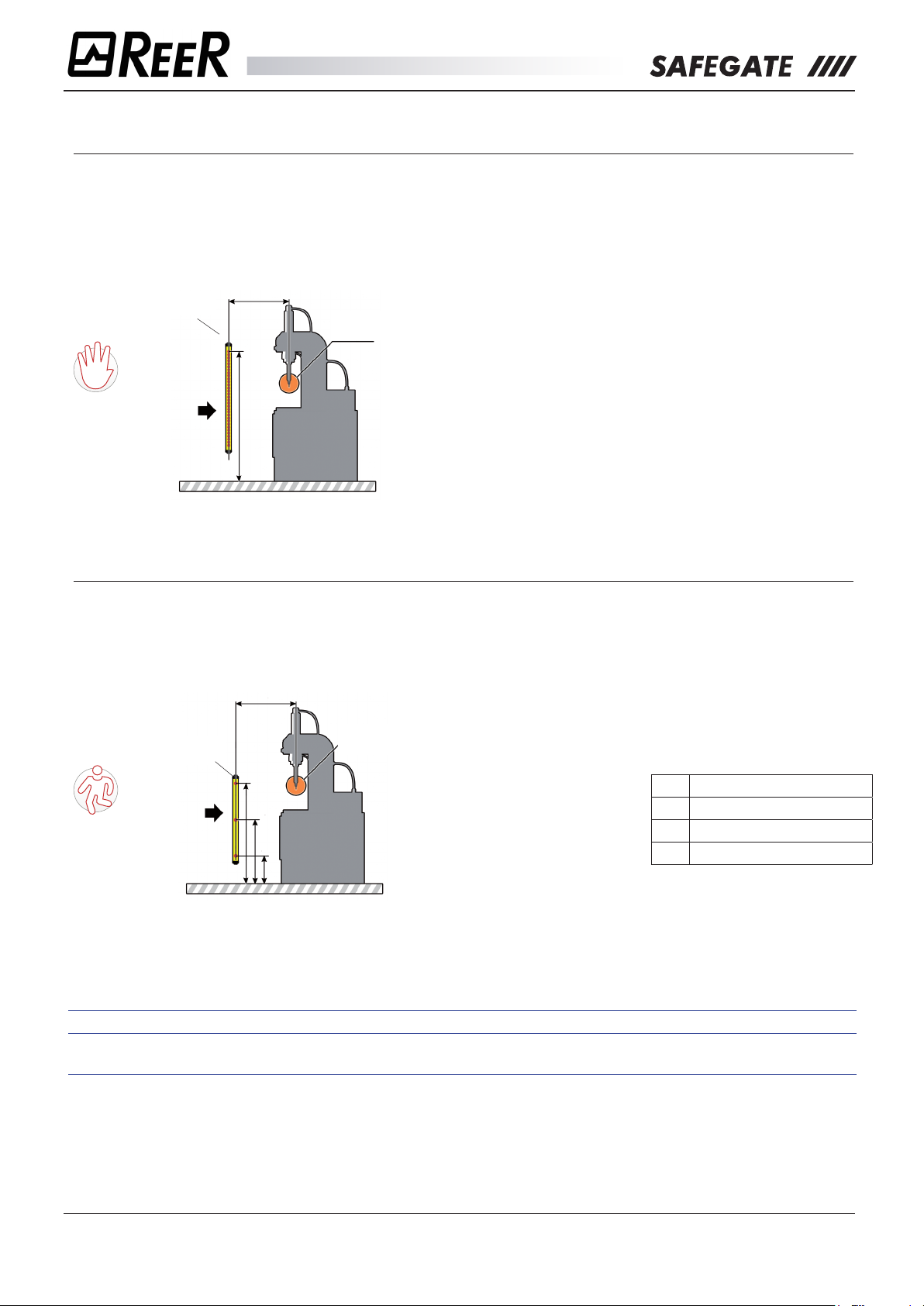

A) 2 INTEGRATED CROSS MUTING SENSORS, ONLY FOR PALLET OUTPUTS (LX)

In this way sensors 1 and 2 are on the same side as the vertical curtain and are placed in front of the

dangerous gate. This mode is unidirectional and is useful for protecting gates with pallet output.

The activation of the Muting function occurs after the simultaneous interruption (within 4 sec maximum) of

S1 and S2 sensors. As long as both sensors remain busy, the Muting function continues. When the rst of

the 2 sensors is released, the material will still have 4 seconds to leave the protected area limited by the

curtain. The Muting condition will be disabled as soon as the protected area is released.

At the end of 4 seconds, if the curtain is still busy, the OSSD outputs are disabled by interrupting the

operation of the machine. This allows selecting the maximum duration of the Muting condition (timeout) as

30 seconds or 9 hours.

ÎÎ Other timings are available with programmable programs.

Î For the safe operation of the LX conguration, it is absolutely essential that the horizontal Muting

sensor elements are located within the hazardous area.

Î The minimum distance between two consecutive pallets must be less than 10 cm or greater than

32cm.

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

16

Page 17

The Muting function

B) 2 INTEGRATED PARALLEL MUTING SENSORS, ONLY FOR PALLET OUTPUTS (L2)

In this way sensors 1 and 2 are on the same side as the vertical curtain and are placed in front of the

dangerous gate. This mode is unidirectional and is useful for protecting gates with pallet output.

The activation of the Muting function occurs after the simultaneous interruption (within max 4 sec) of

sensors S1 and S2. As long as both sensors remain busy, the Muting function continues. When the rst

of the 2 sensors is released, the material will still have 4 seconds to leave the protected area limited by

the curtain. The Muting condition will be disabled as soon as the protected area is released. At the end of

4 seconds, if the curtain is still busy, the OSSD outputs are disabled by interrupting the operation of the

machine.

This allows selecting the maximum duration of the Muting condition (timeout) as 30 seconds or 9 hours.

ÎÎ Other timings are available with programmable programs.

Î For the safe operation of the L2 conguration, it is imperative that horizontal Muting sensors are

located within the hazardous area.

Î The minimum distance between two consecutive pallets must be greater than 40 cm.

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

17

Page 18

The Muting function

C) 2 INTEGRATED CROSS MUTING SENSORS, FOR BI-DIRECTIONAL GATES (TX)

In this way, the two Muting sensors are each rst on a dierent side of the vertical curtain.

This mode is unidirectional and is useful for protecting gates with pallet output.

ÎÎ The crossing point of the two Muting sensors must be placed inside the hazardous area to avoid

undesirable and dangerous activations of the Muting function.

The activation of the Muting function occurs after the simultaneous interruption (within max 4 sec) of

sensors S1 and S2. As long as both sensors remain busy, the Muting function continues. By releasing the

rst of the two sensors, the Muting function is disabled.

This mode also allows selecting the maximum duration of the Muting condition (timeout) as 30 seconds or

9 hours.

ÎÎ Other timings are available with programmable programs.

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

18

Page 19

The Muting function

D) 4 INTEGRATED PARALLEL MUTING SENSORS, FOR BI-DIRECTIONAL GATES (T4)

This mode is bidirectional and is useful for protecting gates with pallet output.

Using this mode, two dierent modes of operation are outlined:

Concurrent

The activation of the Muting function occurs after the sensors S1 and S2 are interrupted (within max 4sec)

(or S4 and S3 with material moving in the opposite direction).

The Muting state ends after the release of the gate, and of the S3 sensor (or S2 with material moving in

the opposite direction).

ÎÎ For the T4 models (concurrent operation), there are two available timeouts: 1) 30 sec; 2) 9 hours.

Sequential

The activation of the Muting function occurs after the sequential interruption of sensors S1 and S2 (or S4

and S3 with material moving in the opposite direction) without time limitations.

The Muting state ends after the release of the gate, and of the S3 sensor (or S2 with material moving in

the opposite direction).

ÎÎ For the T4 models (sequential operation), there are two available timeouts: 1) 30 sec; 2) innite.

ÎÎ Other timings are available with programmable programs.

ÎÎ In both modes of operation, the minimum pallet length must be 70 cm (to ensure simultaneous

occupancy of all four sensors).

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

19

Page 20

The Muting function

E) 2 EXTERNAL CROSS INTEGRATED MUTING SENSORS, FOR BI-DIRECTIONAL GATES (TX).

This mode is bidirectional and is useful for protecting gates with pallet output.

ÎÎ The crossing point of the two Muting sensors must be placed inside the hazardous area to avoid

undesirable and dangerous activations of the Muting function.

The activation of the Muting function occurs after the simultaneous interruption (within max 4 sec) of

sensors S1 and S2. As long as both sensors remain busy, the Muting function continues. When the rst

of the two sensors is released, the Muting function is disabled. In this mode of operation the maximum

duration of the Muting condition (timeout) can be selected in 30 seconds or 9 hours.

ÎÎ Other timings are available with programmable programs.

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

20

Page 21

The Muting function

F) 4 EXTERNAL PARALLEL MUTING SENSORS, FOR BI-DIRECTIONAL GATES (T4).

This mode is bidirectional and is useful for protecting gates with pallet output.

Using this mode, two dierent modes of operation are outlined:

Concurrent

The activation of the Muting function occurs after the sensors S1 and S2 are interrupted (within max 4

sec) (or S4 and S3 with material moving in the opposite direction).

The Muting state ends after the release of the gate, and of the S3 sensor (or S2 with material moving in

the opposite direction).

ÎÎ For the T4 models (concurrent operation), there are two available timeouts: 1) 30 sec; 2) 9 hours.

Sequential

The activation of the Muting function occurs after the sequential interruption of sensors S1 and S2 (or S4

and S3 with material moving in the opposite direction).

The Muting state ends after the release of the gate, and of the S3 sensor (or S2 with material moving in

the opposite direction).

ÎÎ For the T4 models (sequential operation), there are two available timeouts: 1) 30 sec; 2) innite.

ÎÎ Other timings are available with programmable programs.

ÎÎ In both modes of operation, the minimum pallet length must be 70 cm (to ensure simultaneous

occupancy of all four sensors).

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

21

Page 22

The Muting function

PARTIAL MUTING

The Partial Muting feature allows you to limit the

Muting function to a number of well-dened beams.

By this function, you can enable the Muting function

only for those beams that will be interrupted by the

passage of the material (e.g. lower pallets at the end

of the product cycle). The remaining beams, however,

can be kept active to protect the dangerous gate.

ÎÎ This function is only available on SMP/SMPO

models and must be managed through the

Safegate Congurator software (select “Partial

Muting Enabling”).

The software should then select the number of beams aected by Partial Muting, taking into account that

the rst Partial Muting beam always starts from the bottom (connectors side).

For this operation, it may be useful to verify the

Monitor software function (free beams are indicated

by dierent colouring than the busy ones) and the

various numerical information on the side (LBO,

FBO, etc.).

Only one value can be entered when programming

the number of beams aected by this function.

There are two types of partial Muting and, for both,

the “Partial Muting” input pin (pin 6 of M12 12-pin

connector on the receiver) must be used.

Partial Muting with Enable

With this option, the Partial Muting function is normally deactivated. To activate this function, the input

signal (pin 6 of the receiver) must switch from LO to HI (rising edge) before starting the Muting cycle.

Partial Muting with Disable

With this option the Partial Muting function is normally active. To activate this function, the input signal (pin

6 of the receiver) must switch from LO to HI (rising edge) before starting the Muting cycle.

ÎÎ Refer to the “OPERATING MODES” section to correctly set this function.

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

22

Page 23

The Muting function

MUTING OVERRIDE

The OVERRIDE function becomes necessary when, after incorrect Muting activation sequences, the

machine stops leaving the material in the dangerous gate.

In this situation, the OSSD outputs are inactive because the curtain and/or at least one Muting sensor are

busy. In this condition, the OVERRIDE request LED ashes.

Î This operation activates the OSSD outputs to remove the material obstructing the gate.

Î During the entire phase in which the OVERRIDE function is active, the Override/Muting lamp ashes.

You should periodically verify the eciency of this lamp (during Muting or Override phases).

Î The Pulse Override command automatically activates the curtain outputs until both the curtain and

the Muting sensors are again free of obstacles. During this period the curtain is not able to protect

access to the dangerous gate. It is therefore necessary that all operations be conducted under close

supervision of experienced personnel.

The user will use the type of Override previously congured:

1. Override with spring return key

2. Override with pushbutton

Override with spring return key

Activation of this function must be done by bringing both receiver pins 9 and 10 to + 24VDC (within a 400

ms time window), for example by using a 2-way key switch with spring return.

Override has a maximum duration of 15 minutes; it can end due to two dierent causes.

1. When the selector is released or the 15 minutes expire, the override ends, bringing the outputs to

OFF, turning o the lamp, and returning the display to normal. However, it is still possible to start a

new override, releasing the selector and reactivating it.

2. At the release of the curtain and sensors (clear gate) the override ends and the GUARD condition is

reactivated (the curtain is working properly) without additional commands.

Override with pushbutton

The activation of this function must occur inverting (within a time window of 400 ms) the condition of pins

9 and 10 of the receiver through the use of a 2-way switch.

When override is active the condition of pins 9 and 10 is no longer veried.

MAXIMUM OVERRIDE TIME (MODELS WITH HARDWARE CONFIGURATION)

The override has a maximum duration of 15 minutes (repeatable).

The function can only restart if the button is pushed again (complying with the following conditions):

1. Maximum OVERRIDE time (after n consecutive requests) = 60 min

2. Maximum number of consecutive OVERRIDE requests = 30.

MAXIMUM OVERRIDE TIME (MODELS WITH SOFTWARE CONFIGURATION)

The function can only restart if the button is pushed again (complying with the following conditions):

1. Maximum OVERRIDE time (after n consecutive requests) = 4 x timeout override

2. Maximum number of consecutive OVERRIDE requests = 30.

At the release of the curtain and sensors (clear gate) the override ends and the GUARD condition is

reactivated (the curtain is working properly) without additional commands.

The timer (point 1) and the counter (point 2) are reset if one of the following conditions occurs:

¾ A proper sequence of Muting.

¾ A system reset (turning it o and on).

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

23

Page 24

Mechanical installation

INSTALLATION

CALCULATION OF THE SAFETY DISTANCE

The eectiveness of the protection heavily depends

on the correct positioning of the curtain according

to the danger. The curtain must be positioned at a

distance greater than or equal to the minimum safety

distance S so that reaching the dangerous point can

only be achieved after the dangerous operation of the

machine has stopped.

The positioning shall be such that:

• Reaching the dangerous point is avoided without

crossing the area controlled by the curtain.

• No person is allowed in the dangerous area

without this being detected. For this case,

additional safety devices (e.g. horizontal light

curtains) may be required.

S

C KxT

1

2

a

The ISO 13855 standard provides the elements for

3

calculating the safety distance.

1. Dangerous point

If the machine under consideration is subject to a type

C specic standard, reference should be made to this

rule.

2. Protected plane

3. Reference plane

a. Height of dangerous point

S. Safety distance

If the S distance calculated appears to be excessive,

it is necessary:

• to reduce the total time the machine is o

• to improve the resolution of the curtain.

GENERAL FORMULA FOR CALCULATING THE SAFETY DISTANCE

S = K x T + C

S

K

minimum safety distance between the protection and the dangerous point, expressed in mm.

advance speed of the body or parts of the body, expressed in mm per second.

K values can be:

K = 2000 mm per second for safety distances up to 500 mm

K = 1600 mm per second for safety distances over 500 mm

Total machine stopping time including:

T

C

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

T1 response time of the protection device in seconds

T2 machine reaction time to stop the hazardous operation, in seconds.

additional distance expressed in mm.

24

Page 25

Mechanical installation

MODELS WITH RESOLUTION 30 mm – 40 mm

Curtains with resolution

for arms detection.

Curtain resolution (d) 30 - 40 mm

S

Protected

plane

H

MODELS WITH 2/3/4 beams

Body detection curtains.

Curtain with 2/3/4 beams

Dangerous

point

Calculating the minimum

safety distance (S)

Refer to the general formula

for the safety distance

calculation.

S = K x T + C

S = 2000xT + 8x(d-14)

If the formula provides as a

result: S>500 it’s possible to

use

K=1600

S = 1600xT + 8x(d-14)

(with C = 8x(d-14))

• The S distance must

not be less than

100mm

• If the resulting

distance S is greater

than 500 mm, you

can recalculate the

distance using K =

1600.

• In this case the

distance must still not

be less than 500 mm.

S

Recommended height

according to the number

of beams

N° Recommended height

2 400 - 900 mm

3 300 - 700 - 1100 mm

4 300 - 600 - 900 - 1200 mm

Protected

plane

H≥1100

H≥700

H≤300

Dangerous

point

Refer to the general formula

for the safety distance

calculation.

S = K x T + C

S = 1600xT + 850

ÎÎ The S distance must not be less than 100 mm

ÎÎ If the resulting distance S is greater than 500 mm, it is possible to recalculate the distance using

K = 1600 but in this case the distance must still not be less than 500 mm

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

25

Page 26

Mechanical installation

ÎÎ For applications on packaging machines (palletizers and unpalletizers), follow the instructions in

European standard EN 415-4, which are repeated here.

From low level (oor)

Device with 3 beams at least

Dimensions in m

Above the conveyor (rollers)

Device with 2 beams at least

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

26

Page 27

Mechanical installation

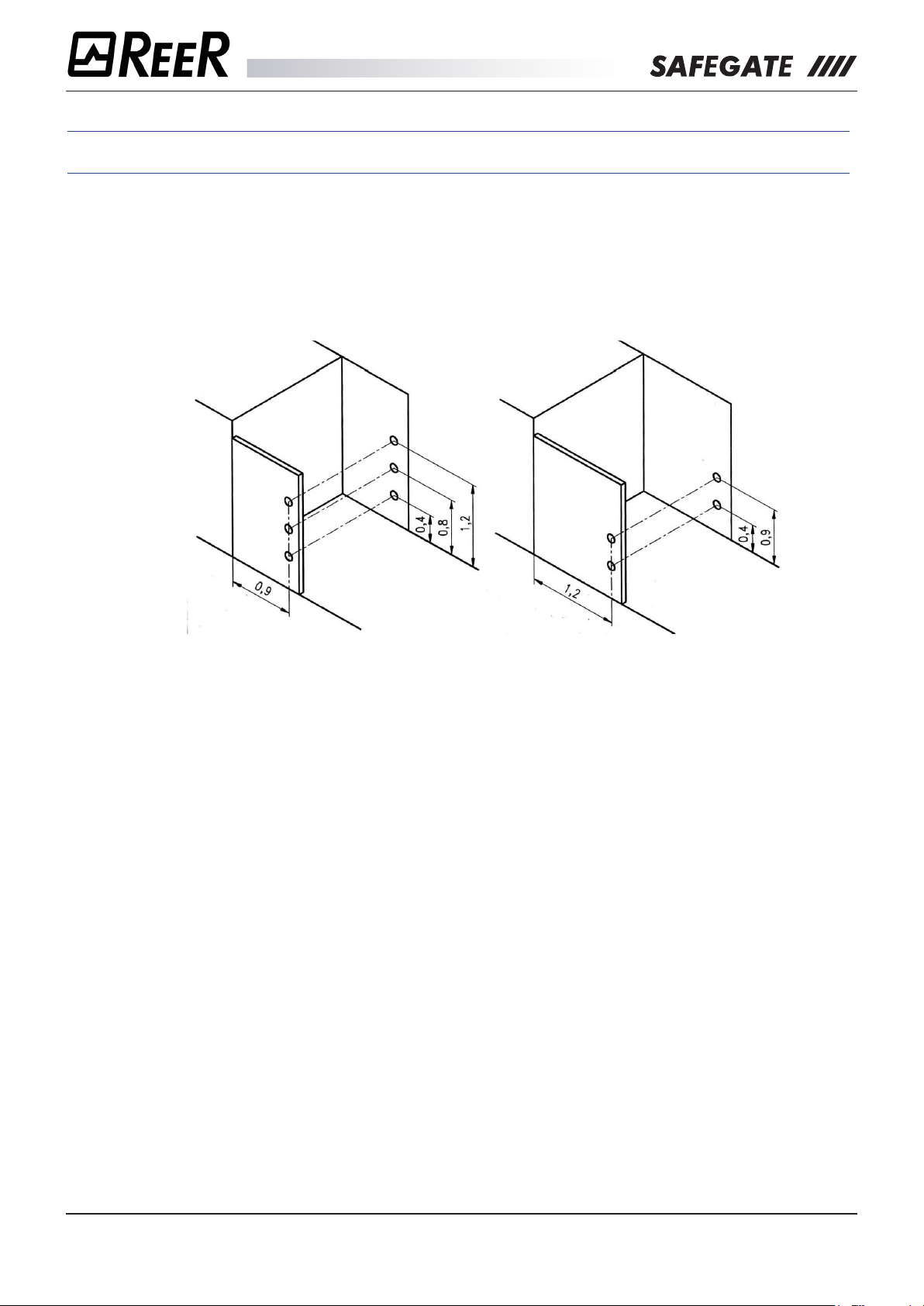

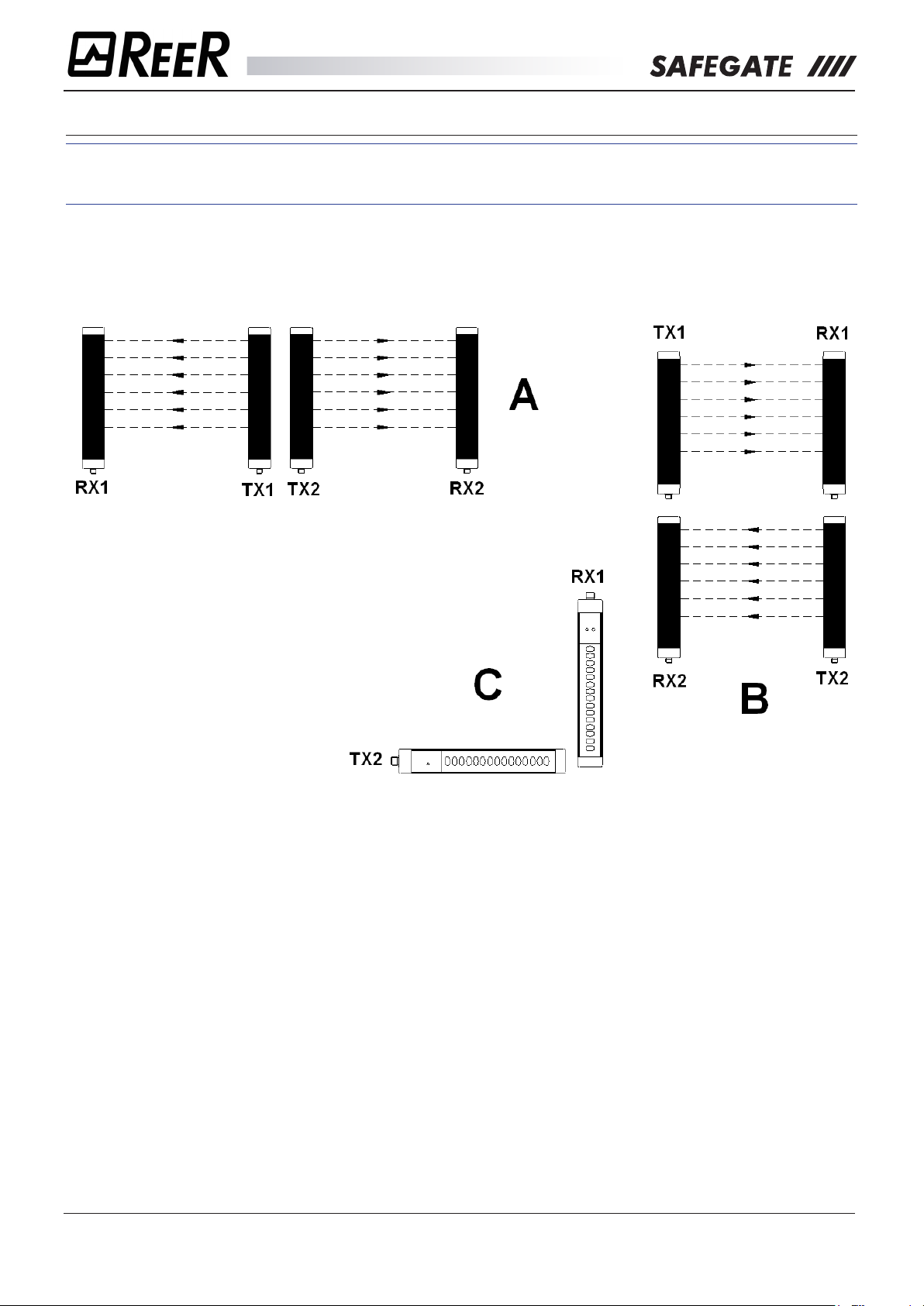

MULTIPLE SYSTEMS

ÎÎ When using multiple SAFEGATE systems, it is necessary to avoid them interfering optically with one

another: position the elements so that the beam emitted by the system Emitter is received only by

the respective Receiver.

The following gure shows some examples of correct positioning between the two photoelectric systems.

An incorrect positioning may cause interference, leading to an abnormal operation.

Systems side by side: A

Adjacent positioning of the two projectors

Overlapping systems: B

“L” combination: C

Cross-positioning between

projectors and receivers

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

27

Page 28

Mechanical installation

USE OF DEFLECTING MIRRORS

For the protection or control of multiple accessed areas, one or more deecting mirrors can be used in

addition to the Emitter and the Receiver.

The deecting mirrors allow in fact returning the optical beams generated by the Emitter on

multiple sides.

If you want to deect by 90° the beams emitted by the Emitter, the perpendicular to the surface of the

mirror should make a 45° angle with the direction of the beams.

The following gure shows an application in which two deecting mirrors are used to make a “U” protection.

Dangerous zone

S

S

When making use of deecting mirrors consider the following rules:

¾ Position the mirrors so that the minimum safety distance S is kept on each of the sides to access the

hazardous area.

¾ The working distance (range) is the sum of the lengths of all sides accessing the guarded area.

(Please note that the maximum working range between Emitter and Receiver is reduced by 15% for

each mirror used).

¾ When installing, pay particular attention to not to twist along the longitudinal axis of the mirror.

¾ Verify, by positioning near and on the Receiver axis, that in the rst mirror you see the whole shape of

the Emitter.

¾ It is recommended that you use no more than three deecting mirrors.

S

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

28

Page 29

DISTANCE FROM REFLECTING SURFACES

Î The presence of reective surfaces located near the light curtain

can cause spurious reections preventing the detection. Referring to the

S

A

following Figure object A is not detected due to the plane S reecting the

beam and thus closing the optical path between the Emitter and Receiver.

It is therefore necessary to keep a minimum distance d between any

reecting surfaces and the protected area. For calculating the minimum

distance d, it is recommended to use the values set for Type 4 devices

according to IEC/EN 61496-2.

The following gure shows the above-mentioned values of the distance d

based on the distance between the Emitter and the Receiver.

Mechanical installation

DISTANCE (mm)

RANGE (m)

ÎÎ Once the system is installed, verify any reective surfaces which may intercept the beams, rst

in the centre and then near the Emitter and Receiver. During this procedure, the red LED on the

Receiver must never go o.

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

29

Page 30

Mechanical installation

MECHANICAL ASSEMBLY AND OPTICAL ALIGNMENT

Î The following operations must only be carried out by qualied personnel, otherwise you may lose

the machine safety function.

¾ The Emitter and the Receiver must be mounted one in front of the other at a distance equal to or less

than that indicated in the technical data; Using the supplied inserts and brackets, position the Emitter

and the Receiver so that they are aligned and parallel to each other and with the connectors facing the

same side.

¾ The perfect alignment between Emitter and Receiver is essential for the smooth operation of the curtain;

this operation is facilitated by observing the Emitter and Receiver signalling LEDs.

¾ Make electrical connections according to the directions of the dedicated chapter.

ÎÎ Pay particular attention to the SAFEGATE model you are connecting.

Connections may vary depending on the model.

¾ Place the optical axis of the rst and last beams of the Emitter on the same axis as that of the

corresponding beams on the Receiver.

¾ Move the Emitter to nd the area within which the green LED on the Receiver stays on, then place the

rst transmitter beam (the one near the signal LED) at the centre of this area.

¾ Using this beam as a pivot, with small lateral displacements of the opposite end, move to the free

guarded area condition, which in this situation will be indicated by turning on the green LED on the

Receiver.

¾ Firmly tighten the Emitter and the Receiver.

ÎÎ If the Emitter and the Receiver are mounted in areas subject to strong vibrations, in order not to

compromise the operation of the circuits, it is necessary to use anti-vibration dampers.

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

30

Page 31

Electrical connections/Operating modes

Modelli SM, SMO, SMP, SMPO

(3) 0VDC

CONNESSIONI EMETTITORE

SM - SMO MODELS ELECTRICAL CONNECTIONS

Before proceeding to the electrical connections make sure that the available power supply voltage is in

accordance with the data specied in the technical data.

The Emitter and the Receiver must be powered with a voltage of 24Vdc ± 20%.

The external power supply must comply with EN 60204-1.

In order to ensure the declared Environmental Protection Degree (IP65-IP67), it is mandatory to

protect the unused connectors with the provided protection caps.

PRECAUTIONS

• Make the connection to earth before making any other connections.

• Connect Safegate before energizing.

• The ground connection (0VDC) must be common to all system components.

WARNINGS ON CONNECTION CABLES

• Conductor Size: 0,25÷2,5 mm2.

• It is recommended to keep SAFEGATE’s power supply separate from that of other electrical power equipment

(electric motors, inverters, frequency changers) or other sources of disturbance.

• For cables more than 20 m long, cables with a section of at least 0.5 mm

length over 50 m).

2

must be used (AWG16), (1 mm2 with a

EMITTER CONNECTIONS

0VDC (3)

(1) 24VDC

(4) 0VDC

(1) 24VDC

(5) PE

(4) RANGE1

(2) SYNC

(“Table 1”, page 32)

(“Table 2”, page 32)

(2) SYNC

(1) 24VDC

PE

(3) 0VDC

(“Table 3”, page 32)

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

(5) PE

(4) 0VDC

(“Table 4”, page 32)

31

Page 32

Electrical connections/Operating modes

Table 1

RANGE/TEST SELECTION MALE CONNECTOR - M12 - 5-PIN

PIN COLOUR SIGNAL IN/OUT DESCRIPTION ELECTRICAL LEVEL

1 Brown 24VDC - Power supply 24 VDC Positive

2 White RANGE0 Input Range selection (see table “RANGE AND TEST SELECTION”)

3 Blue 0VDC - Power supply 0VDC Negative

4 Black RANGE1 Input Range selection (see table “RANGE AND TEST SELECTION”)

5 Grey PE - Earth connection -

Table 2

RANGE AND TEST SELECTION - M12 - 5-PIN

PIN 2 PIN 4 FUNCTION

24VDC 0VDC LOW range

0VDC 24VDC HIGH range

(For range values, refer to the Technical Features table)

0VDC 0VDC Curtain under TEST (Refer to paragraph “TEST FUNCTION”)

24VDC 24VDC - Condition not allowed

Table 3

FEMALE CONNECTOR POWER SUPPLY SENSORS MUTING 1 - 2 - M12 - 5-PIN

PIN COLOUR SIGNAL IN/OUT DESCRIPTION ELECTRICAL LEVEL

1 Brown 24VDC - Sensor Power Supply 24VDC Positivoe

2 White SYNC Output Synchronization with M5 arms LL0->0Vdc; LL1->24Vdc

3 Blue 0VDC - Sensor Power Supply 0VDC Negative

4 Black 0VDC - Sensor Power Supply 0VDC Negative

5 Grey PE - EARTH CONNECTION -

Table 4

FEMALE CONNECTOR POWER SUPPLY SENSORS MUTING 3 - 4 - M12 - 5-PIN

PIN COLOUR SIGNAL IN/OUT DESCRIPTION ELECTRICAL LEVEL

1 Brown 24VDC - Sensor Power Supply 24VDC Positivoe

2 White SYNC Output Synchronization with M5 arms LL0->0Vdc; LL1->24Vdc

3 Blue 0VDC - Sensor Power Supply 0VDC Negative

4 Black 0VDC - Sensor Power Supply 0VDC Negative

5 Grey PE - EARTH CONNECTION -

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

32

Page 33

Electrical connections/Operating modes

Modelli SM, SMO

(4) SENSOR3

(3) 0VDC

RECEIVER CONNECTIONS

0VDC (2)

OSSD1 (3)

OSSD2 (4)

PE (5)

SEL_B (11)

(“Table 5”, page 33)

(1) 24VDC

(3) 0VDC

(“Table 8”, page 34)

(2) SENSOR4

(5) PE

(10) OVER1_RESTART

(1) 24VDC

(9) OVERRIDE2

(8) EDM

(7) MUTING_ENABLE

(12) STATUS

(6) SEL_A

(2) N.C.

MUT_LAMP (1)

(5) N.C.

N.C. (4)

(“Table 6”, page 34)

(2) SENSOR2

(3) 0VDC

(1) 24VDC

(5) PE

(4) SENSOR1

(“Table 7”, page 34)

Table 5

MAIN MALE CONNECTOR - M12 - 12 PIN

PIN COLOUR SIGNAL IN/OUT DESCRIPTION ELECTRICAL LEVEL

1 Brown 24VDC - POWER SUPPLY 24 VDC -

2 Blue 0VDC - POWER SUPPLY 0VDC -

3 White OSSD1 Output STATIC SAFETY OUTPUTS PNP active high

4 Green OSSD2 Output

5 Pink PE - EARTH CONNECTION -

6 Yellow SEL_A Input MUTING CONFIGURATION

7 Black MUT_ENABLE Input

8 Grey EDM Input FEEDBACK K1/K2

9 Red OVERRIDE2 Input OVERRIDE REQUEST

10 Violet

11 Grey/ Pink SEL_B Input MUTING CONFIGURATION

12 Red/Blue STATUS Output SYSTEM STATUS PNP active high

EXTERNAL MUTING

ENABLE

OVERRIDE1

Input

RESTART RESTART INTERLOCK

OVERRIDE REQUEST

Refer to “SELECTION OF OPERATING

MODES”, page 35

Safegate considers the muting cycle correct if it

detects a “MUTING ENABLE” signal rising edge

before the use of the sensors

External contactors feedback ”EDM”, page 36

Refer to the section “OVERRIDE”, page 37

Refer to the section “OVERRIDE”, page 37

Refer to the table “RESTART (MANUAL

OPERATION)”, page 38

Refer to the section “SELECTION OF

OPERATING MODES”, page 35

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

33

Page 34

Electrical connections/Operating modes

Table 6

MUTING LAMP FEMALE CONNECTOR, CURTAIN PROGRAMMING

PIN COLOUR SIGNAL IN/OUT DESCRIPTION ELECTRICAL LEVEL

1 Brown MUT_LAMP Output Muting Lamp activation command Active Muting 24VDC

2 White n.c. - - 3 Blue 0VDC - Muting Lamp 0VDC 0VDC

4 Black n.c. - 5 Grey n.c. - - -

Table 7

FEMALE CONNECTOR POWER SUPPLY SENSORS MUTING 1 - 2 - M12 - 5-PIN

PIN COLOUR SIGNAL IN/OUT DESCRIPTION ELECTRICAL LEVEL

1 Brown 24VDC - Sensor Power Supply 24VDC Positive

2 White SENSOR2 Input SENSOR 2 Status

3 Blue 0VDC - Sensor Power Supply 0VDC Negative

4 Black SENSOR1 Input SENSOR 1 Status

5 Grey PE - EARTH CONNECTION -

< 5VDC : CLEAR SENSOR

11÷30 VDC : ACTUATED SENSOR

< 5VDC : CLEAR SENSOR

11÷30 VDC : ACTUATED SENSOR

Table 8

FEMALE CONNECTOR POWER SUPPLY/SENSORS MUTING 3 - 4 - M12 - 5-PIN

PIN COLOUR SIGNAL IN/OUT DESCRIPTION ELECTRICAL LEVEL

1 Brown 24VDC - Sensor Power Supply 24VDC Positive

2 White SENSOR4 Input SENSOR 4 Status

3 Blue 0VDC - Sensor Power Supply 0VDC Negative

4 Black SENSOR3 Input SENSOR 3 Status

5 Grey PE - EARTH CONNECTION -

< 5VDC : CLEAR SENSOR

11÷30 VDC : ACTUATED SENSOR

< 5VDC : CLEAR SENSOR

11÷30 VDC : ACTUATED SENSOR

Î Using LX or TX conguration with 2 sensors: SENSOR1 wiring is mandatory, while the position of the

second muting sensor is the operator’s choice between SENSOR2 and SENSOR3.

TEST FUNCTION

By means of the test function, which simulates occupation of the protected area, it possible to verify the

operation of the entire system by means of an external supervisor (e.g. PLC, control module, etc.). The

SAFEGATE barrier system features an automatic self-diagnosis function that enables it to detect response

time malfunctions (this time is declared for each model).

This safety system is permanently active and does not require any interventions from the outside.

The TEST function is available should the user wish to check equipment connected downstream of the

barrier (without physically entering the protected area). By means of this function the OSSDs can be

switched from ON to OFF as long as the function remains active.

Î The minimum duration of the TEST function must be 40 msec.

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

34

Page 35

Electrical connections/Operating modes

SELECTION OF OPERATING MODES

The inputs available to the SAFEGATE receiver (main male connector - M12 - 12pin) allow the conguration

of the various operating modes.

It is therefore necessary, when switching on, to properly connect the SAFEGATE receiver inputs for proper

operation, as shown below.

The following tables allow the user to congure the type of Muting to be adopted in terms of: MUTING

MODE, TIMEOUT MUTING, OVERRIDE TYPOLOGY.

SEL_A (pin 6) SEL_B (pin 11) MODALITÀ MUTING MUTING TIMEOUT

24VDC (1) OSSD1 (3) 4 SENSORS, SEQUENTIAL 30 s

24VDC (1) OSSD2 (4) 4 SENSORS, SEQUENTIAL ∞

OSSD2 (4) OSSD1 (3) 2 SENSORS, “TX” MODE 30 s

OSSD1 (3) OSSD2 (4) 2 SENSORS, “TX” MODE 9 hours

OSSD1 (3) 24VDC (1) 2 SENSORS, “L” MODE 30 s

OSSD2 (4) 24VDC (1) 2 SENSORS, “L” MODE 9 hours

MANUAL MODE

OSSD2 (4) OSSD2 (4) 4 SENSORS CONCURRENT 30 s

OSSD1 (3) OSSD1 (3) 4 SENSORS CONCURRENT 9 hours

n.c. / 0VDC n.c. / 0VDC Conguration error

n.c. / 0VDC n.c. / 0VDC SPM/SPMO models: programming needed

SEL_A (pin 6) SEL_B (pin 11) MODALITÀ MUTING MUTING TIMEOUT

24VDC (1) 24VDC (1) 4 SENSORS, SEQUENTIAL 30 s

STATUS (12) STATUS (12) 4 SENSORS, SEQUENTIAL ∞

24VDC (1) STATUS (12) 2 SENSORS, “TX” MODE 30 s

STATUS (12) 24VDC (1) 2 SENSORS, “TX” MODE 9 ore

STATUS (12) OSSD1 (3) 2 SENSORS, “L” MODE 30 s

OSSD1 (3) STATUS (12) 2 SENSORS, “L” MODE 9 ore

STATUS (12) OSSD2 (4) 4 SENSORS CONCURRENT 30 s

AUTOMATIC MODE

OSSD2 (4) STATUS (12) 4 SENSORS CONCURRENT 9 ore

n.c. / 0VDC n.c. / 0VDC Conguration error

n.c. / 0VDC n.c. / 0VDC SPM/SPMO models: programming needed

Î To program SMP / SMPO models it is mandatory that pin 6 and 11 of the 12 pin connector on the

receiver detect 0VDC (or open circuit).

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

35

Page 36

Electrical connections/Operating modes

Hardware configuration

EDM (8)

OSSD2 (12)

SAFEGATE

RECEIVER

EDM enabled

EDM (8)

OSSD2 (12)

SAFEGATE

RECEIVER

EDM disabled

+24VDC

FBK K1 FBK K2

EDM

The EDM function (external K1 / K2 control) can be enabled / disabled via hardware:

EDM ACTIVATED

SAFEGATE awaits a signal with inverse logic to the condition of the external contactors:

¾ OSSD1 / OSSD ON: External contacts K1/K2 closed: EDM = OPEN CIRCUIT

¾ OSSD1 / OSSD OFF: External contacts K1/K2 open: EDM = CLOSED CIRCUIT

Connect the pin 8 of the 12 poles connector to the Receiver as shown above.

Î The time allowed to elapse from the activation of the OSSD outputs and the opening of the FBK

contacts must be t <500ms.

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

36

Page 37

Electrical connections/Operating modes

OVERRIDE

SAFEGATE allows you to congure two dierent types of override; (See paragraph “MUTING OVERRIDE”,

page 23 for the description of the following function).

OVERRIDE1 (pin 10) OVERRIDE2 (pin 9) SELEZIONE

0 0 Override with spring return key

0 1 Override with button

1 0 Wrong conguration

1 1

OVERRIDE WITH KEY WITH SPRING RETURN KEY

The function starts with the simultaneous activation of the two OVERRIDE inputs according to the following

table:

OVERRIDE1 (pin 10) OVERRIDE2 (Pin 9)

0 0

1 1

Both signals are active at 24VDC and the function only starts if they are activated at the same time (within

a maximum delay of 400 ms) and the key is kept active for at least 400 ms.

OVERRIDE WITH PUSHBUTTON

The function starts with the simultaneous activation of the two OVERRIDE inputs according to the following

table:

OVERRIDE1 (pin 10) OVERRIDE2 (Pin 9)

0 1

1 0

The function starts only if the signals are activated at the same time (within a maximum delay of 400 ms)

and the button is held pressed for at least 400 ms.

8541150 - rev.1 - 10/07/2017

REER S.p.A. - 32 via Carcano - 10153 Torino Italia Internet: www.reer.it - e-mail: info@reer.it

37

Page 38

Electrical connections/Operating modes

SAFEGATE

RECEIVER

AUTOMATIC

SAFEGATE

RECEIVER

MANUAL

OVERRIDE1

RESTART (10)

24Vdc

RESTART

SAFEGATE

RECEIVER

MANUAL

24Vdc

RESTART (MANUAL OPERATION)

Pin 10 has RESTART function. As a result of occupation of the protected area, outputs will be deactivated

(Manual mode - start/restart interlock enabled). To reactivate them you will need to repeat the sequence:

¾ “0Vdc” → “24Vdc” → “0Vdc”.

¾ The high level (24Vdc) must be between 100 ms and 5 s.

OVERRIDE1

RESTART (10)

RESTART

Use in manual mode (start/restart interlock enabled) is mandatory in case the safety device

controls a gate to protect a dangerous area and a person, once crossed the gate, can stay

in the hazardous area without being detected (use as a ‘trip device’ according to IEC 61496).

The Restart command must be located outside the hazardous area, at a point where the

hazardous area and the entire working area concerned are clearly visible.

It must not be possible to reach the command from inside the hazardous area.

AUTOMATIC OPERATION

Thanks to the connection of the pin 10 on the main receiver connector, the operator can choose to enable

the AUTOMATIC operation.

In Automatic operating mode, the OSSD1 and OSSD2 safety outputs follow the status of the light curtain:

¾ with guarded area free, the outputs are ON.

¾ with guarded area occupied, they are OFF.

OVERRIDE1

RESTART (10)

If the SAFEGATE light curtain is used in AUTOMATIC mode, it will not be equipped with