Reer EOS4, EOS4 Series, EOS4 A, EOS4 X, EOS4 XM Installation, Use And Maintenance Manual

...Page 1

PHOTOELECTRIC

SAFETY BARRIER

EOS4

IINNSSTTAALLLLAAZZIIOONNEE,, UUSSOO EE MMAANNUUTTEENNZZIIOONNEE

IINNSSTTAALLLLAATTIIOONN,, UUSSEE AANNDD MMAAIINNTTEENNAANNCCEE

IINNSSTTAALLLLAATTIIOONN,, UUTTIILLIISSAATTIIOONN EETT MMAAIINNTTEENNAANNCCEE

IINNSSTTAALLLLAATTIIOONN,, BBEEDDIIEENNUUNNGG UUNNDD WWAARRTTUUNNGG

IINNSSTTAALLAACCIIÓÓNN,, UUSSOO YY MMAANNTTEENNIIMMIIEENNTTO

O

www.reer.it

Page 2

EOS4 SAFETY LIGHT CURTAIN

8540733 • 23/03/2016 • Rev.17

1

English

Positioning ...................................................................................................... 6

Master/Slave Positioning .................................................................................. 7

Calculation of safety distance .......................................................................... 8

Multiple systems ............................................................................................. 9

Use of deflecting mirrors ............................................................................... 10

Distance from reflective surfaces ................................................................... 11

Mechanical assembly and optical alignment ................................................... 12

Vertical positioning of the light curtain .......................................................... 13

Models with 14, 20mm resolution ............................................................... 13

Models with 30, 40mm resolution ............................................................... 13

Models with 50, 90mm resolution ............................................................... 13

Multibeam Models ...................................................................................... 14

Horizontal positioning of the light curtain ...................................................... 14

Electrical connections .................................................................................... 15

Layout of the connectors on MASTER/SLAVE light curtain ............................ 15

Emitter connections .................................................................................... 16

Receiver connections .................................................................................. 17

Warnings regarding connection cables ........................................................ 18

Configuration and operating modes (Master Models / With integrated control

functions) ...................................................................................................... 19

Automatic operation ................................................................................... 19

Manual operation ....................................................................................... 19

Connection of external contactors K1 and K2 .............................................. 20

Examples of connection with REER safety modules ...................................... 21

Light signals .................................................................................................. 24

Emitter light signals ................................................................................... 24

Receiver light signals .................................................................................. 24

TEST function ................................................................................................ 25

Status of the outputs ..................................................................................... 25

Technical specifications ................................................................................. 26

Dimensions ................................................................................................... 31

Checking of light curtain efficiency ................................................................ 33

Troubleshooting ............................................................................................ 34

Accessories/Spares ........................................................................................ 36

Page 3

EOS4 SAFETY LIGHT CURTAIN

2 8540733 • 23/03/2016 • Rev.17

English

Functional earth (earth connection)

Master/Slave System

Output Signal Switching Device = Light curtain’s solid state safety outputs

= Safety light curtain emitter.

= Safety light curtain receiver.

Hand protection light curtains

Arm and leg protection light curtains.

Full body protection light grids.

This symbol indicates an important warning for Failure to comply

with this warning may result in high level risk for exposed personnel.

This symbol indicates an important warning.

Page 4

EOS4 SAFETY LIGHT CURTAIN

8540733 • 23/03/2016 • Rev.17 3

English

INTRODUCTION

The EOS4 light curtain is an optoelectronic safety device belonging to the category of

Type 4 electro-sensitive protective equipment for the protection of personnel exposed to

risks inherent in the use of hazardous machines or plants, complying with the

EN 61496-1 and IEC 61496-2 standards. The EOS4 is available in three different versions:

Type 4 light curtain consisting of Emitter plus Receiver with automatic reset.

Type 4 light curtain consisting of Emitter plus Receiver with integration of additional

functions such as control of feedback from any external contactors and management of

manual/automatic operation.

Type 4 light curtain (with integrated control functions) comprising two (or three) TX/RX

pairs (connected in series), one of which comprising the MASTER light curtain (with

integrated functions) and one (or two) the SLAVE light curtain.

A set of indicator leds on the Emitter and Receiver provide the information needed for a

correct use of the device and for the assessment of any malfunction. The automatic fault

sensing system permits independent detection by the EOS4 light curtain of any

dangerous fault in a time equal to the light curtain response time.

For any safety problem, if necessary, consult the safety authorities of the country of

use or the competent industrial association.

For applications in the food industry, consult the manufacturer to verify compatibility

of light curtain materials with the chemical agents used.

The protection capability of optoelectronic safety devices is not effective in cases in

which:

- The machine stopping device cannot be actuated electrically and it is not possible

to stop all dangerous machine movements immediately and at any time during the

operating cycle.

- The hazardous condition is associated with the falling of objects from above or

ejection of these from the machine.

- Anomalous forms of light radiation are present (for example, use of cablelless

control devices on cranes, radiation from weld spatter, etc).

In this case additional measures may be necessary to ensure that the ESPE does not

fail to danger.

Page 5

EOS4 SAFETY LIGHT CURTAIN

4 8540733 • 23/03/2016 • Rev.17

English

PRINCIPLE OF OPERATION

If the protected area is clear, the two outputs on the Receiver are active and enable

the machine to which they are connected to operate normally.

Each time that an object bigger than or equal in size to the resolution of the

system intercepts the optical path of one or more beams, the Receiver deactivates

its own outputs. This condition enables hazardous machine movements to be

stopped (by means of an adequate machine emergency stop circuit).

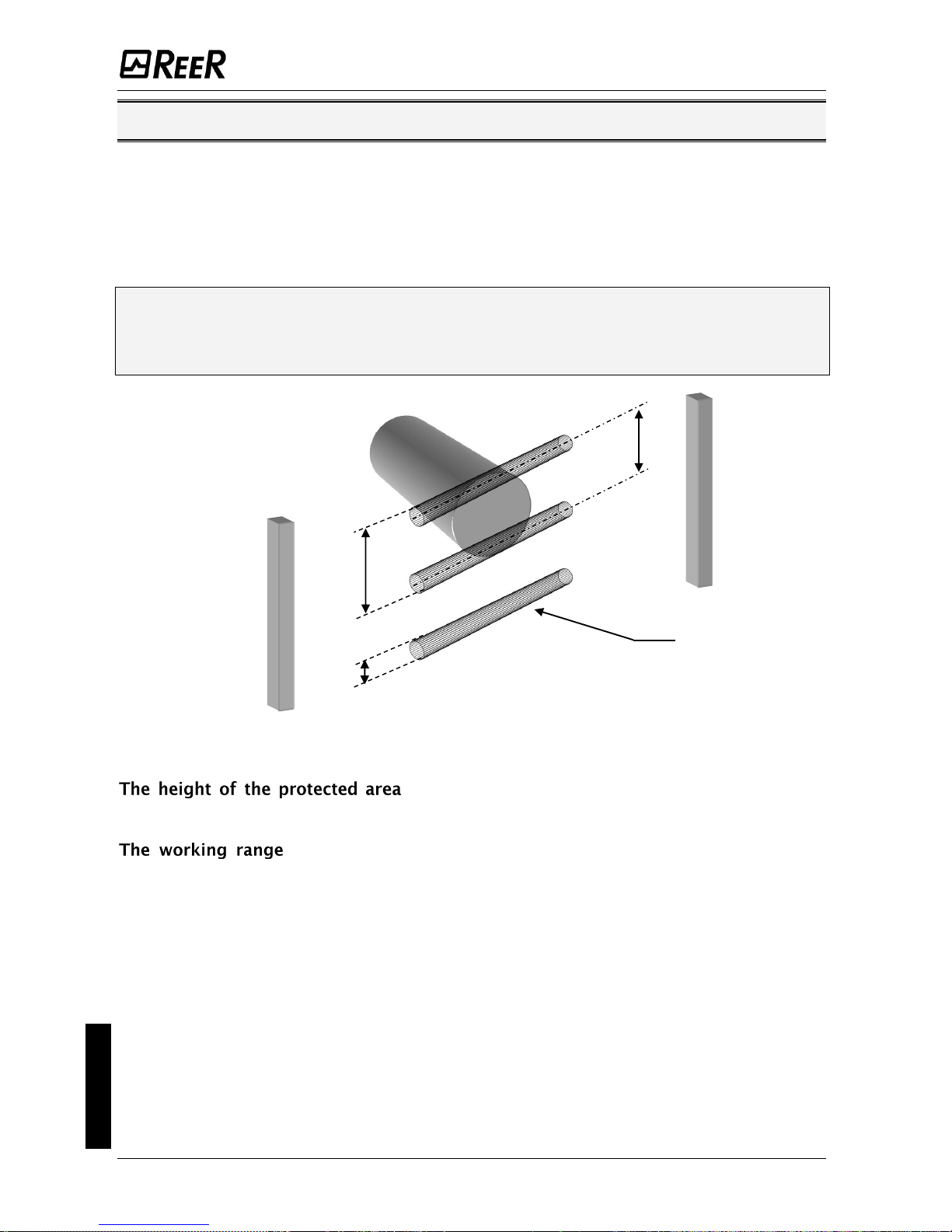

Resolution is the smallest sized object that, passing through the protected area,

interrupts at least one of the beams generated by the light curtain (Figure 1),

causing certain intervention of the device and consequent stopping of the

hazardous movement of the machine.

Figure 1 - Resolution

Resolution remains constant regardless of working conditions as it depends only on the geometric

characteristics of the mirrors and on the centre distance between two adjacent lenses.

is the effective height protected by the safety light

curtain. If the curtain is positioned horizontally, this value indicates the depth of the

protected area.

indicates how far the emitter and receiver can be separated and

function properly.

EOS4 is available with the following resolutions:

14mm (protected heights from 160mm to 1810mm): PROTECTION OF THE FINGERS.

20mm (protected heights from 160mm to 1810mm): PROTECTION OF THE FINGERS.

30mm (protected heights from 160mm to 1810mm): PROTECTION OF THE HANDS.

40mm (protected heights from 310mm to 1810mm): PROTECTION OF THE HANDS.

50mm and 90mm (protected heights from 310mm to 1810mm):

PROTECTION OF THE LIMBS.

The EOS4 is also available in a Multibeam version with a distance between the

mirrors of:

500mm (2 beams), 400mm (3 beams), 300mm (4 beams).

PROTECTION OF THE BODY.

P = Pitch between two lenses

D = Diameter of a lens

R = Resolution = P+D

P

R

D

Receiver

Emitter

Beam

Page 6

EOS4 SAFETY LIGHT CURTAIN

8540733 • 23/03/2016 • Rev.17 5

English

INSTALLATION

Before installing the EOS4 safety system, check all the conditions listed below:

The level of protection of EOS4 (Type 4, SIL3, SILCL3 PLe) must be compatible with

the level of danger of the system to be protected.

The safety system is used only as a stopping device and not to control the machine.

The machine movement is actuated electrically.

All dangerous movements of the machine can be interrupted immediately. In

particular, the machine stopping times must be known and, if necessary, measured.

The machine must not generate hazards due to projection or falling of materials from

above; otherwise, additional mechanical guarding must be provided.

The smallest size object to be detected must be greater than or equal to the

resolution of the selected model.

Knowing the shape and dimensions of the dangerous area, it is possible to calculate the

width and height of the related access area :

Compare these dimensions with the maximum working range and the height of the

protected area of the model used.

Before positioning the safety device, comply with the following general indications:

Check that the temperature of the environment in which the system is installed is

compatible with the operating temperature parameters indicated on the product label

and in the technical data.

Do not position the Emitter and the Receiver close to very bright or flashing sources

of light.

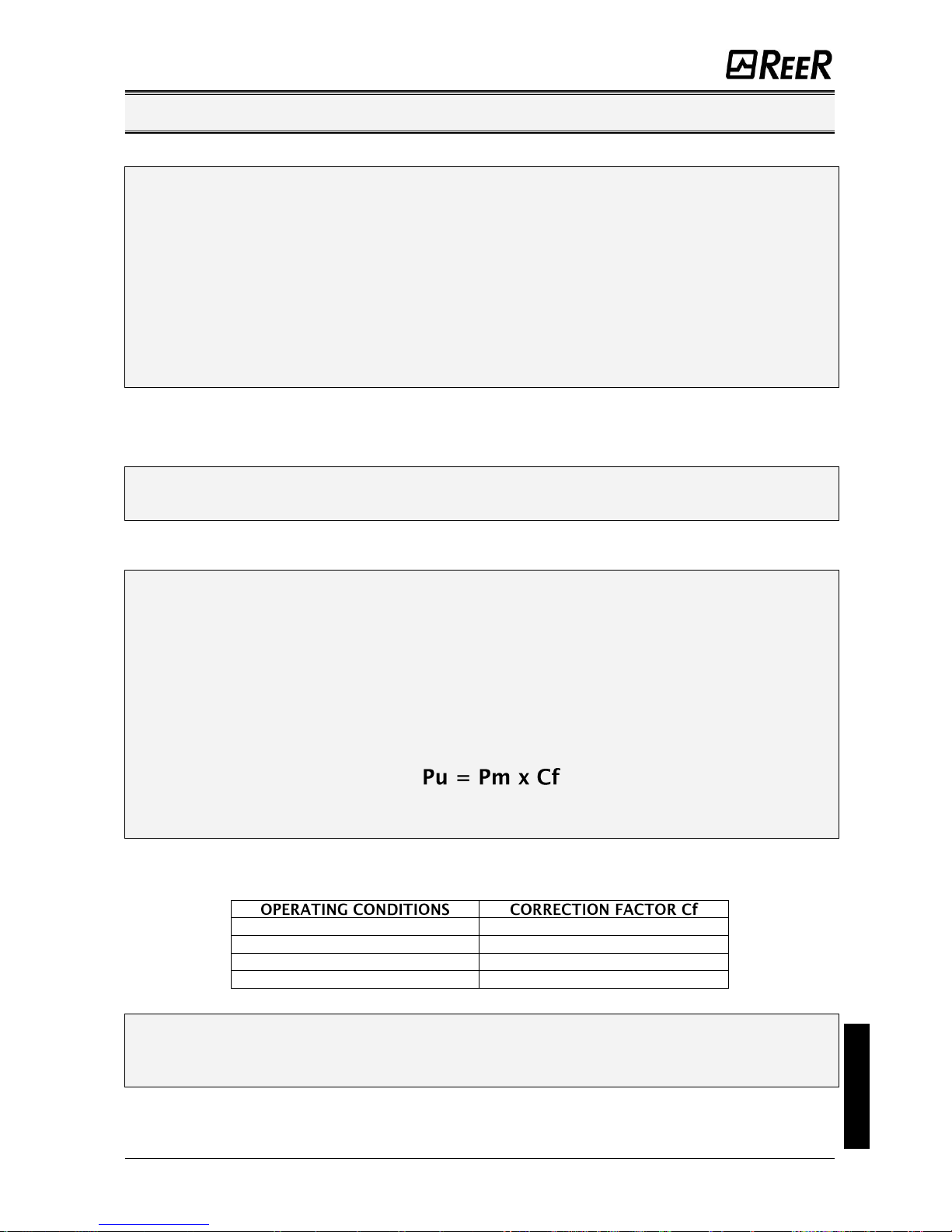

Particular operating conditions may affect the sensing level of photo-electric devices.

In environments characterised by fog, rain, fumes or dust, to always guarantee

correct operation of the appliance, it is advisable to apply suitable correction factors

Cf so as to maximum working range values. In these cases:

where Pu and Pm are, respectively, the working and maximum range expressed in

metres.

The recommended correction factors CF are indicated in the table below.

Fog

0.25

Vapours

0.50

Dust

0.50

Dense fumes

0.25

Table 1 – CF correction factors

If the device is installed in environments characterised by sudden changes in

temperature, suitable precautions must be taken to prevent the formation of

condensation on the mirrors, which could impair detection capability.

Page 7

EOS4 SAFETY LIGHT CURTAIN

6 8540733 • 23/03/2016 • Rev.17

English

Positioning

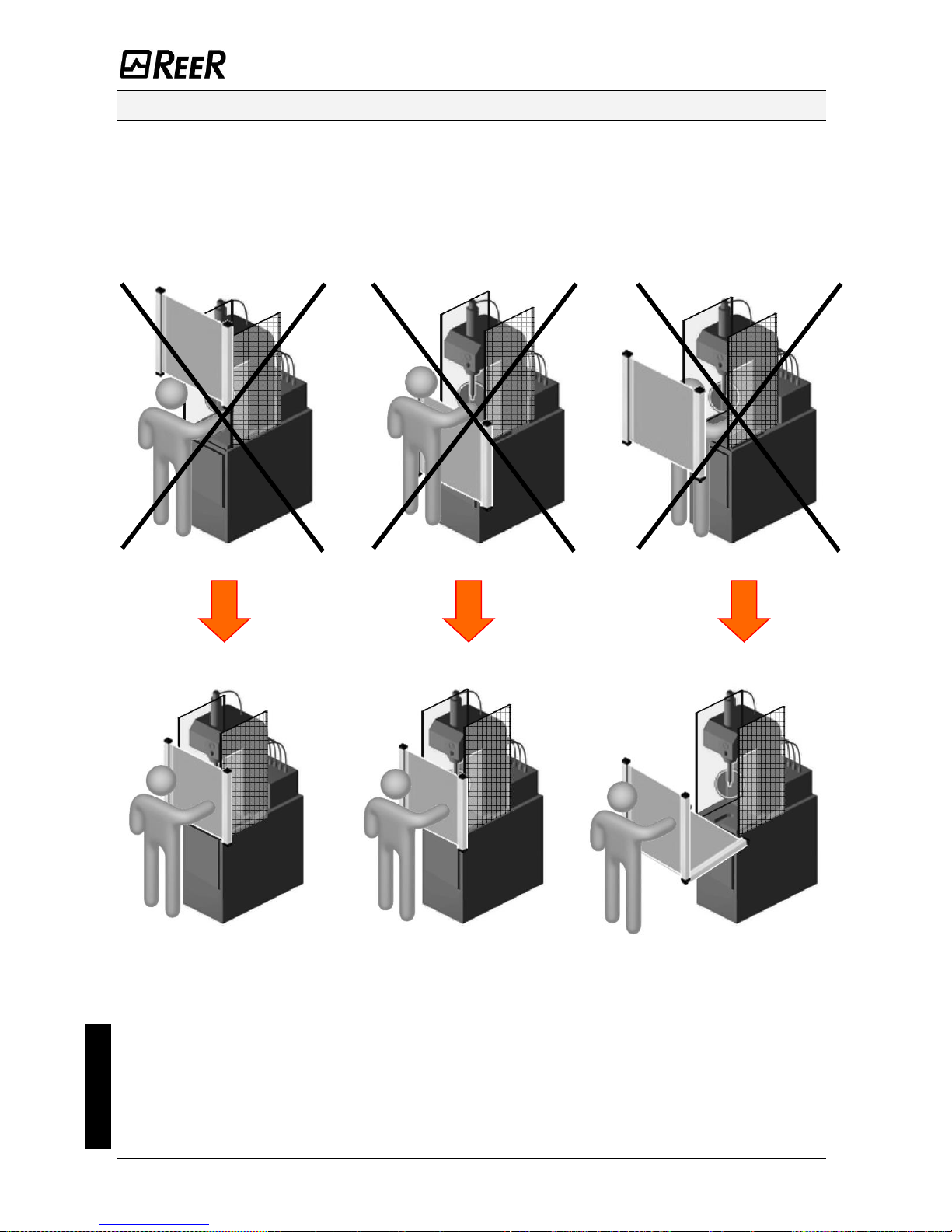

The Emitter EOS4E and the Receiver EOS4R must be positioned so that it is

impossible to access the dangerous area from above, from below and from the

sides without intercepting one of the beams. Useful indications for correct

positioning of the light curtain are provided in the figure below.

Incorrect positioning of the light curtain

Correct positioning of the light curtain

Figure 2 - Positioning

Page 8

EOS4 SAFETY LIGHT CURTAIN

8540733 • 23/03/2016 • Rev.17 7

English

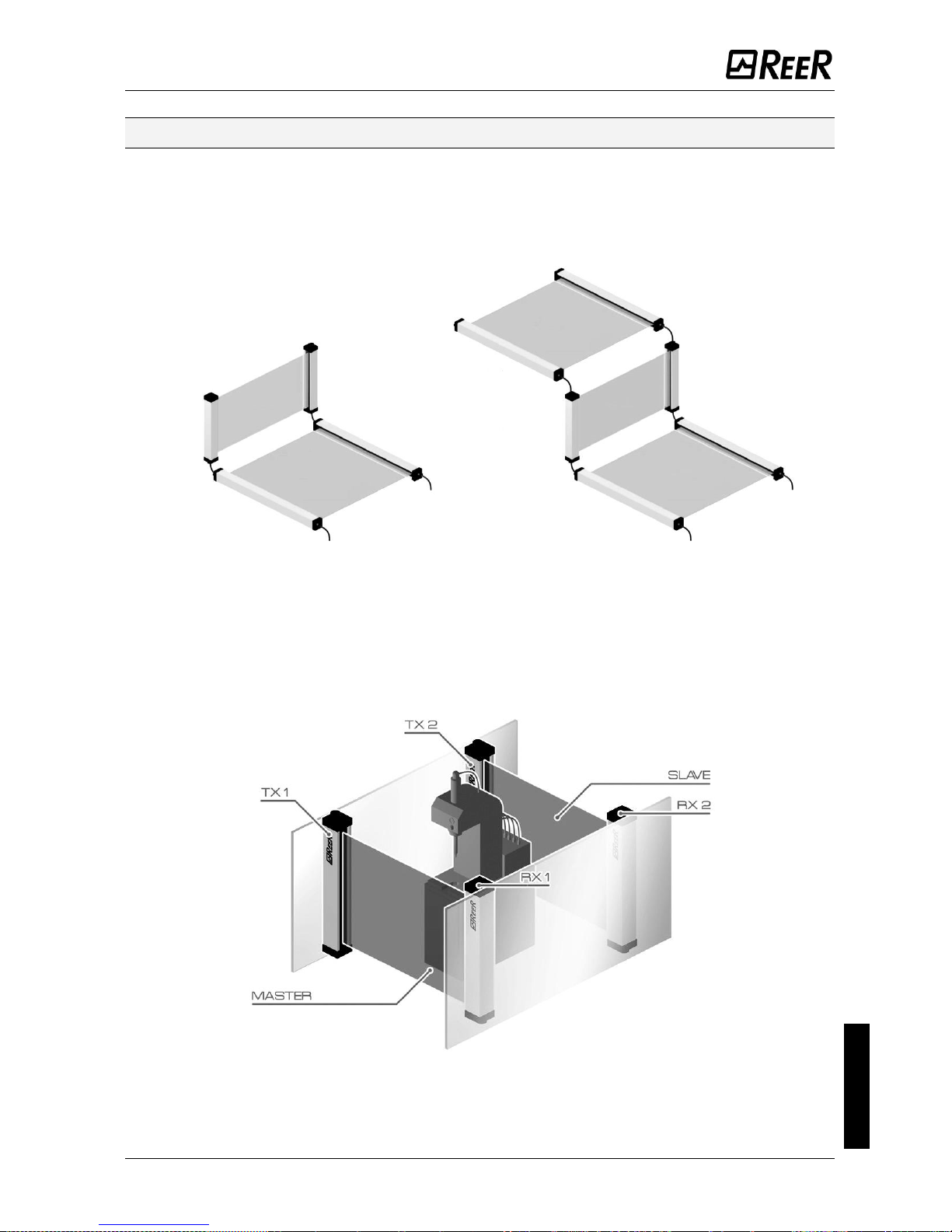

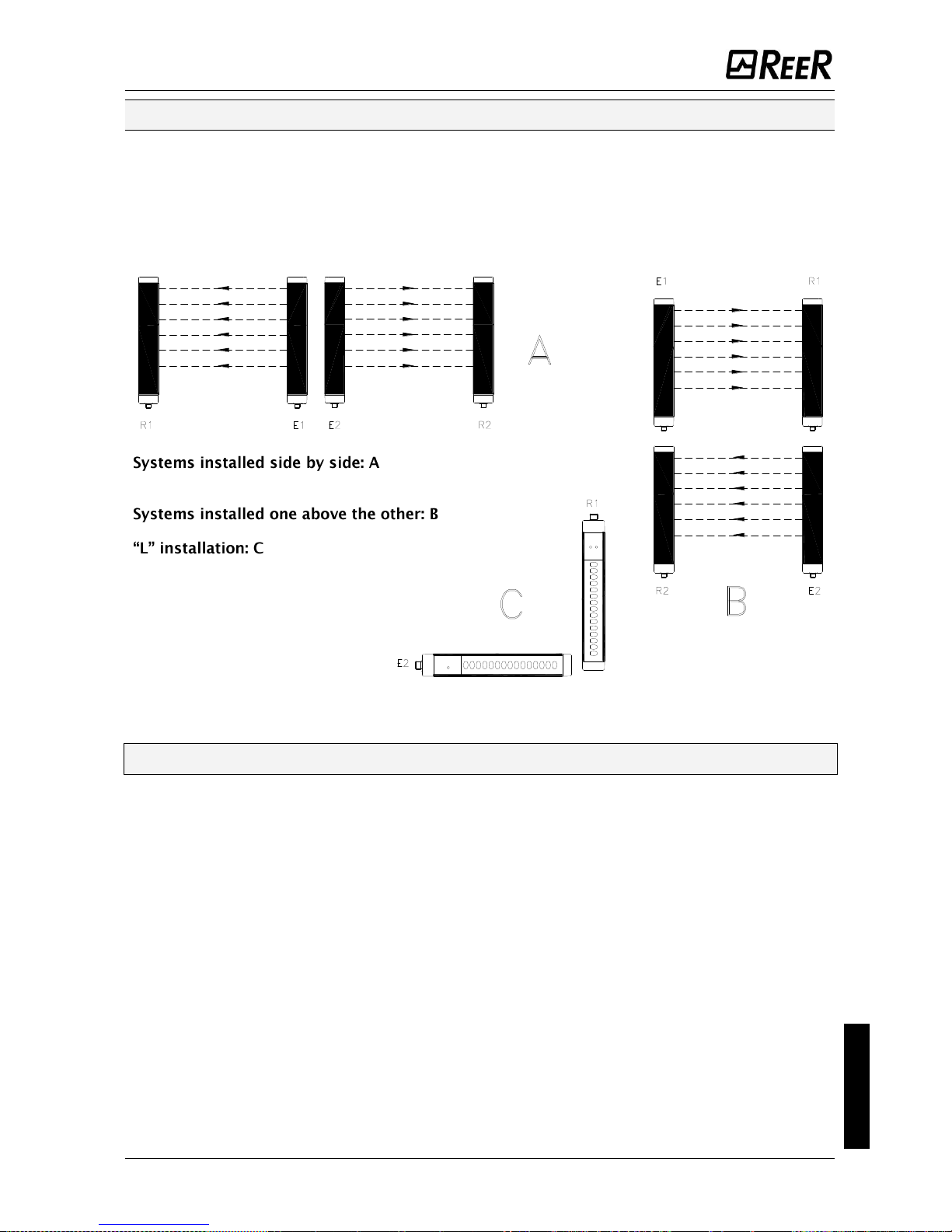

Master/Slave Positioning

In addition to standard models (that can be positioned either horizontally or vertically),

EOS4 can be purchased in a MASTER/SLAVE configuration. This configuration comprises

two (or three) pairs of light curtains in which the two (or three) Emitters and the two (or

three) Receivers are connected in series.

Figure 3 – Examples of Master/Slave configurations

The connection cable between the master and slave may be up to 50 metres in length.

This characteristic permits configuration of an application with two light curtains

positioned one at the front and one at the rear of the dangerous machine, with a single

connection towards the machine power and control circuits (Figure 4).

Figure 4 - Example of Master/Slave application with mechanical guards

MASTER

MASTER

SLAVE

SLAVE2

SLAVE

Page 9

EOS4 SAFETY LIGHT CURTAIN

8 8540733 • 23/03/2016 • Rev.17

English

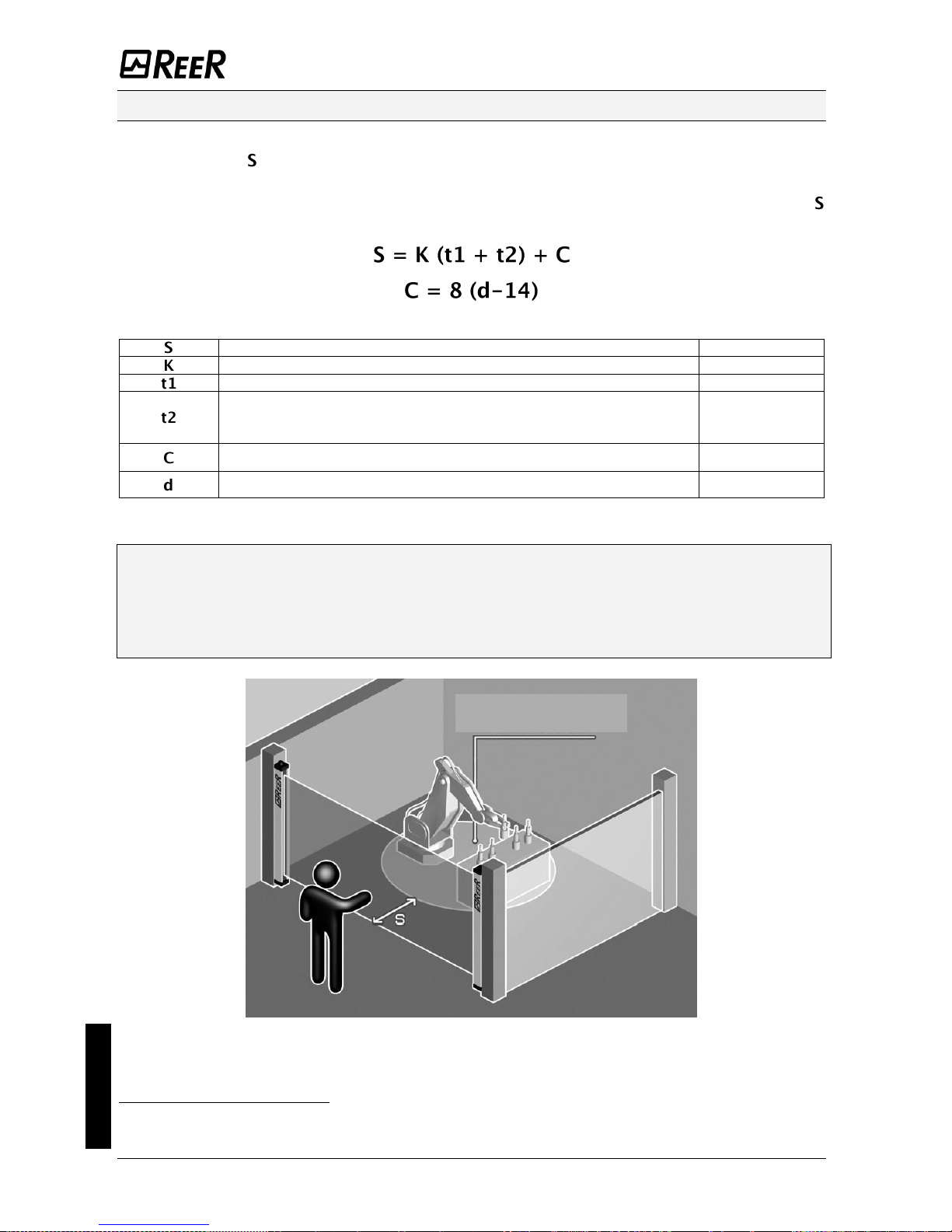

Calculation of safety distance

The light curtain must be positioned at a distance equal to or greater than the minimum

safety distance so that the dangerous point can be reached only after stopping the

dangerous movement of the machine (Figure 5).

According to the EN13855:2010 European standards, the minimum safety distance

must be calculated using the following formula :

where:

Minimum safety distance

mm

Operator approach speed to the dangerous area

mm/sec

Total response time of the light curtain, in seconds

sec

Response time of the machine in seconds, i.e. the time taken by

the machine to stop the dangerous movement from the moment

in which the stop signal is transmitted

sec

Additional distance that varies according to the application

1

mm

Resolution

mm

Table 2 – Safety distance

Failure to comply with the safety distance reduces or impairs the protection function

of the light curtain.

If positioning of the light curtain does not prevent the operator from accessing the

dangerous zone without being detected, additional mechanical guards must be

installed.

Figure 5 – Safety distance S

1

For further information on additional safety distance, refer to EN13855:2010.

DANGEROUS ZONE

Page 10

EOS4 SAFETY LIGHT CURTAIN

8540733 • 23/03/2016 • Rev.17 9

English

Multiple systems

When several EOS4 are used, precautions must be taken to prevent optical interference

between these: position the elements so that the beam of the Emitter of one system is

received only by its respective Receiver.

Figure 6 provides examples of correct positioning of two photo-electric systems. Incorrect

positioning may cause interference, with possible malfunction of the system.

Figure 6 – Multiple systems

This precaution is not necessary in the case of MASTER/SLAVE systems.

Adjacent positioning of the two emitters

Crossed positioning between emitters and

receivers

Page 11

EOS4 SAFETY LIGHT CURTAIN

10 8540733 • 23/03/2016 • Rev.17

English

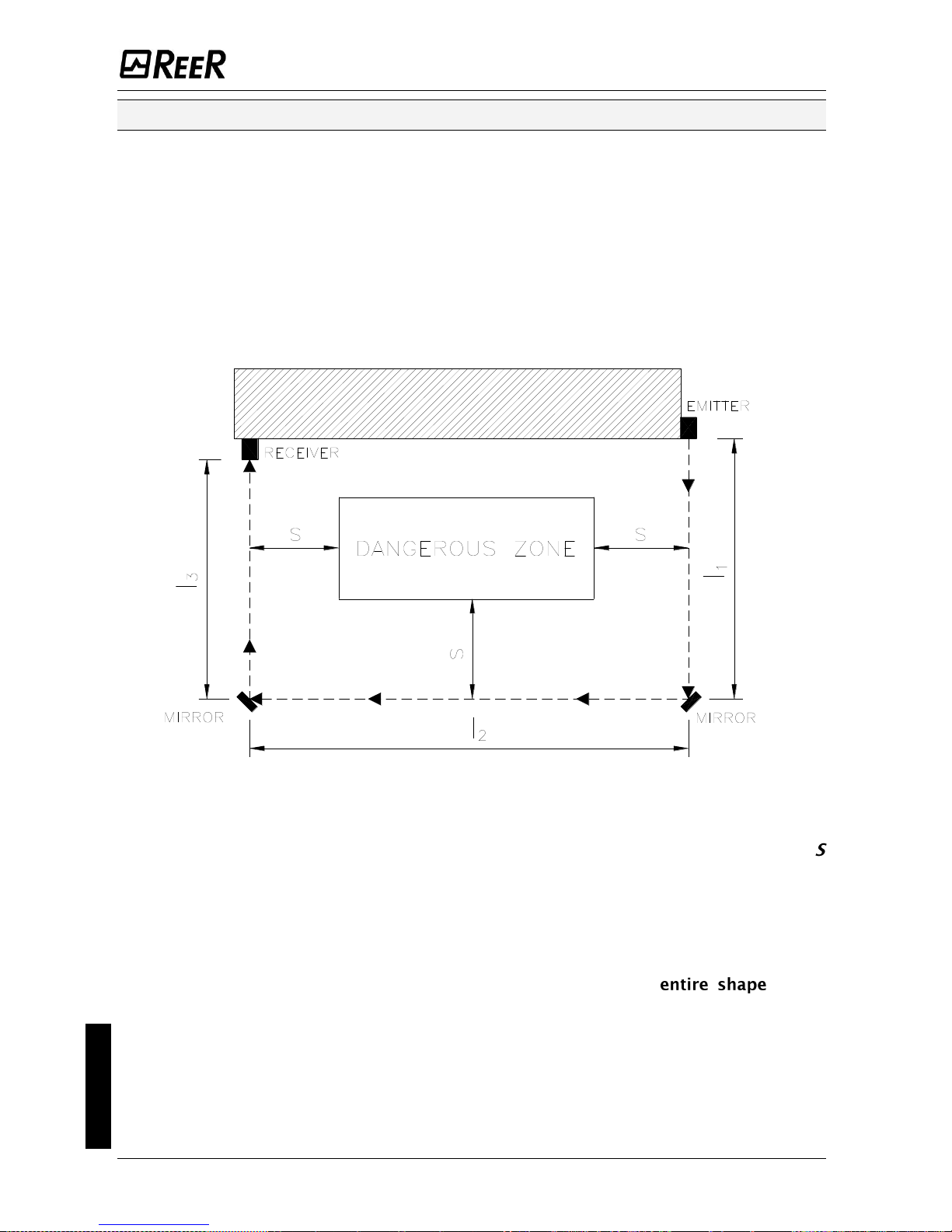

Use of deflecting mirrors

For protection or control of areas accessible from several sides, one or more deflecting

mirrors can be used in addition to the Emitter and Receiver.

Deflecting mirrors make it possible to redirect the beams generated by the Emitter on

several sides.

Wishing to deflect the beams generated by the Emitter by 90°, the perpendicular to the

surface of the mirrors must form an angle of 45° with the direction of the beams.

An application in which two deflecting mirrors have been used for "U" shaped protection

is illustrated in the figure below.

Figure 7 – Deflecting mirrors

When using deflecting mirrors, comply with the following rules:

Position the mirrors so as to comply with the minimum safety distance

(Figure 7) on each side of access to the dangerous area.

The working distance (working range) is given by the sum of the lengths of all the

access sides to the protected area. (Note that the maximum working range

between the Emitter and Receiver is reduced by 15% for each mirror used).

In the installation phase, take care to avoid twisting along the longitudinal axis of

the mirror.

Standing close to and in axis the Receiver, check that the of the

Emitter is visible on the first mirror.

It is advisable not to use more than three deflecting mirrors.

Page 12

EOS4 SAFETY LIGHT CURTAIN

8540733 • 23/03/2016 • Rev.17 11

English

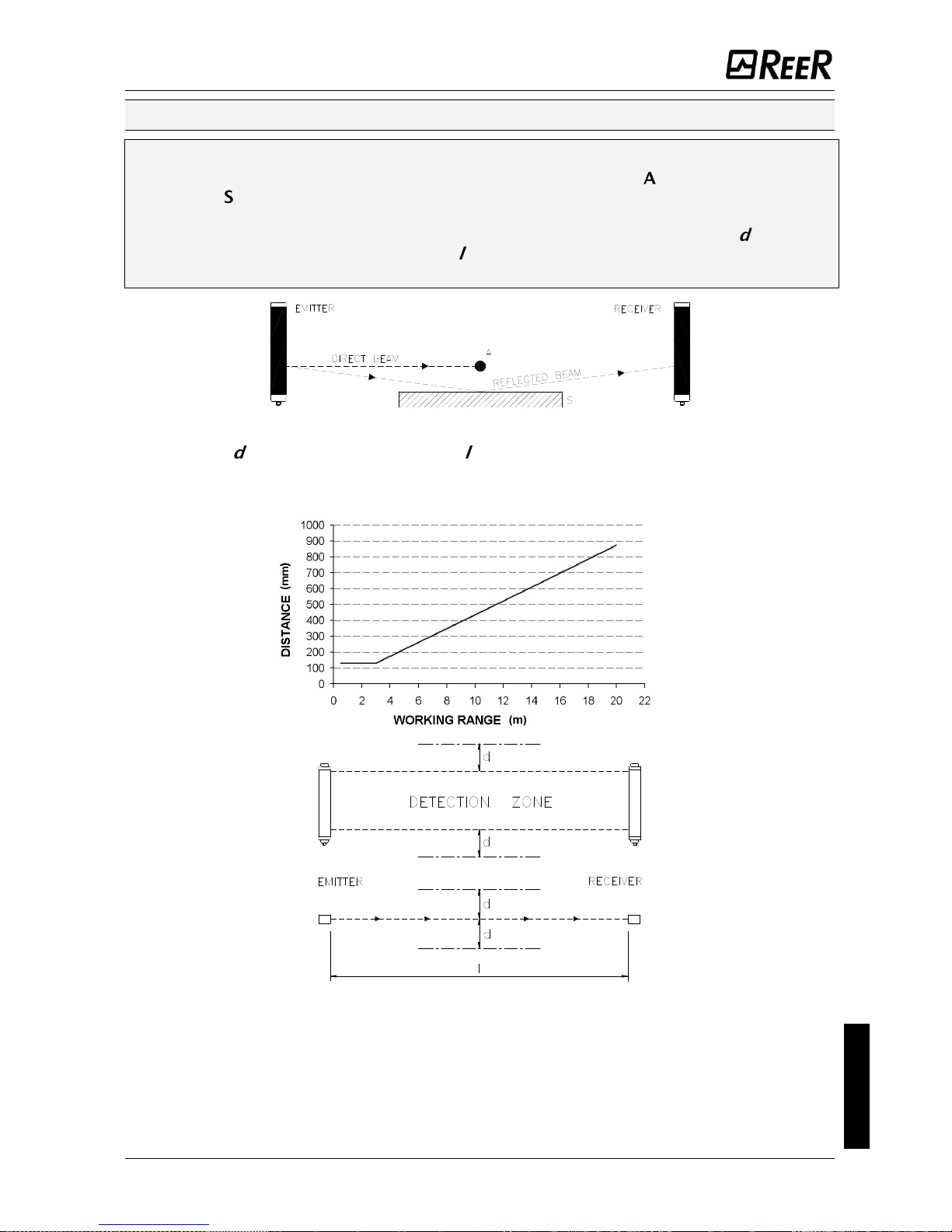

Distance from reflective surfaces

The presence of reflective surfaces close to the light curtain may cause occasional

reflections that prevent sensing. Referring to Figure 8, object is not detected due to

surface that, reflecting the beam, closes the optical path between the Emitter and

Receiver. Therefore, a minimum distance d must be maintained between any

reflecting surfaces and the guarded area. The minimum distance must be

calculated according to the distance between the Emitter and Receiver and taking

into account that the angle of projection and reception is 4°.

Figure 8 - Reflective surfaces

The distance to be kept as the distance between Emitter and Receiver varies is shown

in Picture 9.

Figure 9 - Minimum distance d

After installing the system, check for any reflective surface that intercept the beams, first

of all at the centre and then close to the Emitter and Receiver. During this procedure, the

red led on the Receiver must never switch off.

d

l

Page 13

EOS4 SAFETY LIGHT CURTAIN

12 8540733 • 23/03/2016 • Rev.17

English

Mechanical assembly and optical alignment

The Emitter and Receiver must be installed facing each other, at a distance equal to or

less than that indicated in the technical data. Using the provided

, place the Emitter and Receiver so that they are aligned and parallel to each

other, and with the connectors facing the same side.

Perfect alignment of the Emitter and Receiver is essential for efficient functioning of the

light curtain; this operation is facilitated observing the indicator leds of the Emitter and of

Receiver.

Figure 10 – Mechanical assembly

Figure 11 – Optical alignment

Position the optical axis of the first and last beam of the Emitter on the same axis

as that of the corresponding beams on the Receiver.

Move the Emitter in order to locate the area within which the green led on the

Receiver remains on, then position the first beam of the Emitter (that close to the

indicator led) at the centre of this area.

Using this beam as pivot, with minor movements of the opposite end, establish the

free protected area condition which, in this situation, will be indicated by lighting

up of the green led on the Receiver.

Lock the Emitter and the Receiver in place.

During these operations it may be useful to check the presence of the

on the Receiver display. Upon completion of

alignment, this LED must be off.

If the Emitter and Receiver are installed in areas subject to strong vibrations,

(for the order code, see the ACCESSORIES/SPARES

paragraph) so as not to impair operation of the circuits.

Page 14

EOS4 SAFETY LIGHT CURTAIN

8540733 • 23/03/2016 • Rev.17 13

English

Vertical positioning of the light curtain

Models with 14, 20mm resolution

These models are suitable for fingers detection.

Models with 30, 40mm resolution

These models are suitable for hand detection.

The minimum safety distance is calculated according

to the following formula:

S = 2000 (t1 + t2) + 8(D-14)

(D=resolution)

This formula is valid for distances between 100 and

500 mm. If, according to the calculation, exceeds

500 mm, the distance can be reduced down to a

minimum of 500 mm using the following formula:

S = 1600 (t1 + t2) + 8(D-14)

If, in view of the particular configuration of the

machine, the dangerous zone can be reached from

above, the highest beam of the light curtain must be at

a height (from resting surface ) whose value is

determined by using the ISO 13855 Standard.

Figure 12 -

Vertical positioning

14mm, 20mm, 30mm, 40mm

Models with 50, 90mm resolution

These models are suitable for detecting the arm

or the leg and must not be used to detect

fingers or hands.

The minimum safety distance is determined

according to the following formula:

S = 1600 (t1 + t2) + 850

In every case the height of the highest beam

from resting surface must not be smaller

than 900 mm, while the height of the lowest

beam must not be bigger than 300 mm (ISO

13855 Standard).

Figure 13 - 50mm, 90mm

Light curtain

point of

danger

direction

of

approach

reference plane

Light curtain

point of

danger

direction

of

approach

reference plane

Page 15

EOS4 SAFETY LIGHT CURTAIN

14 8540733 • 23/03/2016 • Rev.17

English

Multibeam Models

These models are suitable for whole body

detection and must not be used to detect arms

or legs.

The minimum safety distance is determined

according to the following formula:

S = 1600 (t1 + t2) + 850

The recommend height H from the reference surface

(ground) is as follows (ISO 13855 Standard) :

Figure 14 - Multibeam

EOS4 2B

EOS4 3B

EOS4 4B

2

3

4

400 – 900

300 – 700 – 1100

300 – 600 – 900 - 1200

Table 3 - Height H of Multibeam models

Horizontal positioning of the light curtain

When the direction of approach of the body is parallel to

the plane of the protected area, the light curtain must be

positioned so that the distance between the far end of the

dangerous area and the outermost beam is equal to or

greater than the minimum safety distance calculated as

follows:

S = 1600(t1 + t2) + 1200 – 0.4H

where is the height of the protected surface from

the machine reference plane;

H = 15(D-50)

(D=resolution)

(ISO 13855 Standard)

Figure 15 - Horizontal positioning

Light grid

point of

danger

direction

of

approach

reference plane

Light curtain

point of

danger

direction

of approach

reference plane

Page 16

EOS4 SAFETY LIGHT CURTAIN

8540733 • 23/03/2016 • Rev.17 15

English

Electrical connections

Before making electrical connections, make sure that the mains voltage matches the one

indicated in the technical data.

The Emitter and Receiver must be powered at a 24Vdc±20% (PELV, in compliance with

the standard EN 60204-1 (Chapter 6.4)).

The electrical connections must be made according to the wiring diagrams provided in

this manual.

In particular, do not connect other devices to the connectors of the Emitter and Receiver.

To guarantee reliable operation using a diode bridge power supply unit, its output

capacity must be at least 2000F for each A absorbed.

Layout of the connectors on MASTER/SLAVE light curtain

Figure 16 - Connector layout

SLAVE primary connector

SLAVE2 secondary connector

SLAVE

SLAVE 2

SLAVE2 primary connector

MASTER secondary connector

MASTER

MASTER primary

connector

Page 17

EOS4 SAFETY LIGHT CURTAIN

16 8540733 • 23/03/2016 • Rev.17

English

Emitter connections

EOS4A - EOS4X (with integrated control functions) - EOS4XM (MASTER models)

M12 5-pin primary connectors.

1

Brown

INPUT

24VDC power supply

2

White

Light curtain configuration

complying with the EN61131-2 standard

(ref. Table 5)

3

Blue

0VDC power supply

4

Black

Light curtain configuration

complying with the EN61131-2 standard

(ref. Table 5)

5

Grey

Ground connection

Table 4 - M12, 5 pin

Master/Standard/with integrated control functions TX

24V

0V

Selection Range

0V

24V

Selection Range

0V

0V

Emitter in

24V

24V

Selection error

Table 5 – Range and TEST selection

For correct operation of the light curtain, pins 2 and 4 of the Emitter must be

connected as indicated in Table 5.

EOS4XS - EOS4XS2 (SLAVE/SLAVE2 models) - M12, 5-pin primary connector.

1

Brown

24VDC power supply

2

White

Communication

MASTER-SLAVE

3

Blue

0VDC power supply

4

Black

Communication

MASTER-SLAVE

5

Grey

Ground connection

Table 6 - M12, 5-pin Primary Slave TX

EOS4XM (MASTER models) – M12, 5-pin secondary connector.

EOS4XS2 (SLAVE2 models) – M12, 5-pin secondary connector.

1

Brown

24VDC power supply

2

White

Communication

MASTER-SLAVE

3

Blue

0VDC power supply

4

Black

Communication

MASTER-SLAVE

5

Grey

Ground connection

Table 7 - M12, 5-pin Secondary TX

Page 18

EOS4 SAFETY LIGHT CURTAIN

8540733 • 23/03/2016 • Rev.17 17

English

Receiver connections

EOS4A models - M12, 5-pin connector.

1

Brown

-

24VDC power supply

-

2

White

OUT

Static safety output 1

PNP active high

3

Blue

-

0VDC power supply

-

4

Black

OUT

Static safety output 2

PNP active high

5

Grey

-

Ground connection

-

Table 8 - M12, 5 pins Primary RX

EOS4X (models with integrated control functions) - M12, 8-pin connector.

EOS4XM (MASTER models) - M12, 8-pin primary connector.

1

White

OUTPUT

Static safety output 1

PNP active high

2

Brown - 24VDC power supply

-

3

Green

OUTPUT

Static safety output 2

PNP active high

4

Yellow

INPUT

Feedback from external

contactors

Complying with the

EN61131-2 standard

(ref. Par. "Configuration

and operating modes"

page 19)

5

Grey

INPUT

Light curtain configuration

6

Pink

INPUT 7 Blue - 0VDC power supply

-

8

Red - Ground connection

-

Table 9 - M12, 8 pins RX

Page 19

EOS4 SAFETY LIGHT CURTAIN

18 8540733 • 23/03/2016 • Rev.17

English

EOS4XS - EOS4XS2 (SLAVE/SLAVE2 models) - M12, 5-pin primary connectors.

1

Brown

24VDC power supply

2

White

Communication

MASTER-SLAVE

3

Blue

0VDC power supply

4

Black

Communication

MASTER-SLAVE

5

Grey

Ground connection

Table 10 - M12, 5 pins Primary Slave RX

EOS4XM (MASTER models) - M12, 5-pin Secondary Connector.

EOS4XS2 (SLAVE2 models) - M12, 5-pin Secondary Connector.

1

Brown

24VDC power supply

2

White

Communication

MASTER-SLAVE

3

Blue

0VDC power supply

4

Black

Communication

MASTER-SLAVE

5

Grey

Ground connection

Table 11 - M12, 5 pin Secondary RX

Warnings regarding connection cables

For connections with a length of more than 50m, use cables having a cross-section

of at least 1mm2.

It is good practice to keep the power supply of the light curtain separate from that

of other electric power equipment (electric motors, inverters, frequency variators)

or other sources of disturbance.

Connect the Emitter and Receiver to the ground outlet.

The connection cables must follow a different route from that of other power

cables.

Page 20

EOS4 SAFETY LIGHT CURTAIN

8540733 • 23/03/2016 • Rev.17 19

English

Configuration and operating modes

(Master Models / With integrated control functions)

The operating mode of the EOS4 light curtain is set by making suitable connections on

the M12 – 8-pin connector of the Receiver (Table 12).

K1_K2/restart (PIN 4)

connected to : 24VDC

SEL_A (PIN 5)

connected to :

24VDC

SEL_B (PIN 6)

connected to :

0VDC

(Figure 17)

K1_K2/restart (PIN 4)

connected to : 24VDC

(via set of NC contacts of K1K2)

SEL_A (PIN 5)

connected to :

24VDC

SEL_B (PIN 6)

connected to :

0VDC

(Figure 18)

K1_K2/restart (PIN 4)

connected to : 24VDC (via RESTART

button)

SEL_A (PIN 5)

connected to :

0VDC

SEL_B (PIN 6)

connected to :

24VDC

(Figure 19)

K1_K2/restart (PIN 4)

connected to : 24VDC

(via RESTART button and set of NC

contacts of K1K2)

SEL_A (PIN 5)

connected to :

0VDC

SEL_B (PIN 6)

connected to :

24VDC

(Figure 20)

Table 12 –Setting of manual/automatic mode

Automatic operation

If the EOS4 light curtain is used in AUTOMATIC mode, it will not be equipped with a

start/restart interlock circuit. In most applications, this safety function is compulsory.

Carefully assess the risks analysis of your own application.

In this operating mode, the OSSD1 and OSSD2 safety outputs follow the status of the light

curtain :

with guarded area free, the outputs are ON.

with guarded area occupied, they are OFF.

Manual operation

Use in manual mode (start/restart interlock ON) is compulsory if the safety device

controls an opening in order to protect a dangerous area and if a person, after

passing through the opening, can remain in the dangerous area without being

detected (use as 'trip device' according to IEC 61496). Failure to comply with this

regulation may result in very serious hazards for the persons exposed.

In this operating mode, the safety outputs OSSD1 and OSSD2 are activated in a condition

of free protected area and after having received the RESTART signal via push-button or a

specific command on the K1K2/RESTART input).

Following occupation of the protected area, the outputs will be disabled. For re-activation,

repeat the sequence described above.

The RESTART command is active with transition

The duration of the command must be within

The Restart command must be installed outside the danger area in a position where

the danger area and the entire work area concerned are clearly visible.

It must not be possible to reach the control from inside the danger area.

Page 21

EOS4 SAFETY LIGHT CURTAIN

20 8540733 • 23/03/2016 • Rev.17

English

Connection of external contactors K1 and K2

In both operating modes, it is possible to activate control of the external contactors

K1/K2 (series of contacts). If this control is to be used, it is necessary to connect pin 4 of

the M12 8-pin connector of the Receiver with the power supply (24VDC) via a set of NC

contacts (feedback) of the external contactors.

In the case of manual operation, the RESTART button in series with the NC contacts

(feedback) of the external contactors K1/K2 (Figure 20) must also be present.

If the application requires it, the response time of the external contactors must be

verified by an additional device.

Figure 17 - Automatic

Figure 18 – Automatic with K1K2 feedback

Figure 19 - Manual

Figure 20 – Manual with K1K2 feedback

Page 22

EOS4 SAFETY LIGHT CURTAIN

8540733 • 23/03/2016 • Rev.17 21

English

Examples of connection with REER safety modules

Figure 21 - EOS4 A: Manual operation with AD SR1 module

Figure 22 - EOS4 X: Automatic operation with AD SR0 module

Page 23

EOS4 SAFETY LIGHT CURTAIN

22 8540733 • 23/03/2016 • Rev.17

English

Figure 23 - EOS4 X: Connection examples

Page 24

EOS4 SAFETY LIGHT CURTAIN

8540733 • 23/03/2016 • Rev.17 23

English

Figure 24 - EOS4 A: Connection examples

Page 25

EOS4 SAFETY LIGHT CURTAIN

24 8540733 • 23/03/2016 • Rev.17

English

OPERATION AND TECHNICAL DATA

Light signals

The leds on the Emitter and Receiver light up according to system operating conditions.

Refer to the tables below to identify the various indications (ref. Figure 25).

Figure 25 - Light signals

Emitter light signals

System power-on. Initial TEST.

RED

System power-on. HIGH working range selected.

2 GREEN BLINKINGS

FAIL condition (Table 19)

RED BLINKING 2

TEST condition

ORANGE

Normal operating condition

GREEN

Table 13 – TX light signals

Receiver light signals

System power-on. Initial TEST.

RED

ON

BREAK condition (A)

RED

OFF

GUARD condition (C)

GREEN

OFF

FAIL condition (Table 19)

RED BLINKING 2

OFF

Table 14 – RX light signals EOS4 A / EOS4 Slave

System power-on. Initial TEST

RED

ON

BREAK condition (A)

RED

OFF

CLEAR condition (B)

OFF

ON

GUARD condition (C)

GREEN

OFF

BREAK_K condition (D)

YELLOW BLINKING

YELLOW BLINKING

FAIL condition (Table 19)

RED BLINKING 2

OFF

Table 15 – RX light signals EOS4 X (With integrated control functions)

2

The type of fault is identified by the number of flashes (see chapter)

Page 26

EOS4 SAFETY LIGHT CURTAIN

8540733 • 23/03/2016 • Rev.17 25

English

System power-on. Initial TEST

RED

YELLOW

BREAK condition (A)

RED

OFF

CLEAR condition (B)

OFF

YELLOW

GUARD condition (C)

GREEN

OFF

BREAK_K condition (D)

YELLOW BLINKING

YELLOW BLINKING

FAIL condition (Table 19)

RED BLINKING 3

OFF

GUARD condition with weak signal

GREEN

BLUE

CLEAR condition with weak signal

-

YELLOW /BLUE

BREAK condition with weak signal

RED

BLUE

BREAK_K condition with weak signal

YELLOW

YELLOW

OFF

BLUE

Table 16 - RX light signals EOS4 14mm and H (20m)

System power-on. Initial TEST

RED

ON

BREAK condition (A)

RED

OFF

CLEAR condition (B)

OFF

ON

GUARD condition (C)

GREEN

OFF

BREAK_K condition (D)

YELLOW BLINKING

YELLOW BLINKING

FAIL condition (Table 19)

RED BLINKING 4

OFF

MASTER : Light curtain free;

SLAVE : Light curtain(s) occupied

RED

Blinking

Table 17 – RX light signals EOS4 (Master)

TEST function

The test function simulates the occupation of the protected area, allowing checking by an

external supervisor (e.g. PLC, control module, etc.) of the correct operation of the entire

system. Via an automatic fault detection system, the EOS4 light curtain is able to verify

occurrence of a fault independently within the response time (declared for each model).

This fault detection system is always active and does not require any external

intervention. The TEST command is available in the case in which the user wishes to

check the devices connected downstream of the light curtain (without physically

intervening inside the guarded area). This command interrupts emission of the beams on

the emitter and makes it possible to switch the OSSD from ON to OFF status as long as

the command is active.

The minimum duration of the TEST command must be at least 4 msec.

Status of the outputs

On the Receiver of the EOS4 there are two PNP static outputs whose status depends on

the condition of the protected area.

The maximum permissible load for each output is 400mA@24VDC, corresponding to a resistive load of 60

.

The maximum OFF-state voltage is < 0,5VDC.

The maximum output current in OFF-state (leakage current) is <2mA.

The maximum load capacity corresponds to 0.82

F@24VDC.

3

The type of fault is identified by the number of flashes (see chapter)

Page 27

EOS4 SAFETY LIGHT CURTAIN

26 8540733 • 23/03/2016 • Rev.17

English

The meaning of the status of the outputs is illustrated in the table below. Any shortcircuit between the outputs or between the outputs and 24VDC or 0VDC power supply is

detected by the light curtain.

OSSD1

24VDC

Light curtain free condition.

OSSD2

OSSD1

0VDC

Light curtain occupied

or fault detected condition

OSSD2

Table 18 - Status of the outputs

In free protected area conditions, the Receiver provides a voltage of 24VDC on both

outputs. Therefore, the established load must be connected between the output

terminals and the 0VDC (Figure 26).

Figure 26 – Correct load connection on the outputs

Technical specifications

Protected height mm

160 – 1810

Resolutions mm

14 - 20 - 30 – 40 - 50 - 90

No. of beams (Multibeam Models)

2/3/4 beams

Working range (selectable)

m

14mm Models

0 3 (low) / 1 6 (high)

30-40-50-90-Multibeam Models

0 4 (low) / 0 12 (high)

20-30-40-50-90-Multibeam Models

0 10 (low) / 3 20 (high)

Safety outputs

2 PNP – 400mA @ 24VDC

Response time ms

2,5 20 (see models tables)

Power supply VDC

24 20%

Connections

M12 (5/8 pin) connectors

Max. length of connections m

100 (50 between Master and Slave)

Operating temperature °C

-10 55°C

Protection rating *

IP 65 - IP 67

Section dimensions mm2

28 x 30

Max. consumption W

1 (Emitter)

2 (Receiver)

Light curtain lifetime

20 years

Safety level

Type 4

EN 61496-1/A1:2008;

IEC 61496-2:2006

SIL 3

IEC 61508-1:1998

IEC 61508-2:2000

IEC 61508-3:1998

IEC 61508-4:1998

SILCL 3

IEC 62061:2005

PL e - Category 4

ISO 13849-1:2006

*) Devices are not suitable for outdoor use without supplementary measures

RECEIVER

RECEIVER

Max. load

400mA

Max. load

400mA

Page 28

EOS4 SAFETY LIGHT CURTAIN

8540733 • 23/03/2016 • Rev.17 27

English

14 mm Resolution Models

151

301

451

601

751

901

1051

1201

1351

1501

1651

1801

Number of beams

15

30

45

60

75

90

105

120

135

150

165

180

Response time

ms 4 5,5

7,5 9 11

13

14,5

16,5

18

20

22

23,5

Response time

(Master + 1 slave)

ms

t

tot

= [0,06 * (N

rslave1

+ N

rmaster

) + 0,9636] * 2

Response time

(Master + 2 slaves)

ms

t

tot

= [0,06 * (N

rslave1

+ N

rslave2

+ N

rmaster

) + 1,0036] * 2

Protected height

mm

160

310

460

610

760

910

1060

1210

1360

1510

1660

1810

PFHd * 1,03E-08

1,27E-08

1,52E-08

1,75E-08

2,00E-08

2,24E-08

2,49E-08

2,73E-08

2,98E-08

3,22E-08

3,48E-08

3,71E-08

DCavg #

95,4%

94,9%

94,5%

94,1%

93,8%

93,6%

93,3%

93,1%

92,9%

92,8%

92,7%

92,6%

MTTFd

#

years

100

CCF #

80%

30 mm Resolution Models

153

253

303

453

603

753

903

1053

1203

1353

1503

1653

1803

Number of beams

8 13

16

23

31

38

46

53

61

68

76

83

91

Response time

ms 4 5

5,5

7,5 9 10,5

12,5

14

15,5

17

19

20,5

22

Response time

(Master + 1 slave)

ms

t

tot

= [0,11 * (Nr

slave1

+ Nr

master

) + 0,9376] * 2

Response time

(Master + 2 slaves)

ms

t

tot

= [0,11 * (Nr

slave1

+ Nr

slave2

+ Nr

master

) + 1,0508] * 2

Protected height

mm

160

260

310

460

610

760

910

1060

1210

1360

1510

1660

1810

PFHd * 7,08E-09

8,06E-09

8,20E-09

9,47E-09

1,06E-08

1,19E-08

1,30E-08

1,43E-08

1,54E-08

1,67E-08

1,78E-08

1,90E-08

2,02E-08

DCavg #

96,6%

96,9%

97,0%

97,2%

97,3%

97,4%

97,5%

97,6%

97,6%

97,7%

97,7%

97,7%

97,8%

MTTFd #

years

100

CCF #

80%

40 mm Resolution Models

154

254

304

454

604

754

904

1054

1204

1354

1504

1654

1804

Number of beams

6 9

11

16

21

26

31

36

41

46

51

56

61

Response time

ms

3,5 4 4,5

5,5 7 8 9 10

11

12,5

13,5

14,5

15,5

Response time

(Master + 1 slave)

ms

t

tot

= [0,11 * (Nr

slave1

+ Nr

master

) + 0,9376] * 2

Response time

(Master + 2 slaves)

ms

t

tot

= [0,11 * (Nr

slave1

+ Nr

slave2

+ Nr

master

) + 1,0508] * 2

Protected height

mm

160

260

310

460

610

760

910

1060

1210

1360

1510

1660

1810

PFHd * 6,82E-09

7,73-09

7,76E-09

8,58E-09

9,52E-09

1,03E-08

1,13E-08

1,21E-08

1,30E-08

1,38E-08

1,48E-08

1,56E-08

1,65E-08

DCavg #

96,4%

96,7%

96,7%

96,9%

97,1%

97,2%

97,3%

97,4%

97,4%

97,5%

97,5%

97,6%

97,6%

MTTFd #

years

100

CCF #

80%

50 mm Resolution Models

155

305

455

605

755

905

1055

1205

1355

1505

1655

1805

Number of beams

4 8

12

16

20

24

28

32

36

40

44

48

Response time

ms 3 4

4,5

5,5

6,5

7,5

8,5 9 10

11

12

13

Response time

(Master + 1 slave)

ms

t

tot

= [0,11 * (Nr

slave1

+ Nr

master

) + 0,9376] * 2

Response time

(Master + 2 slaves)

ms

t

tot

= [0,11 * (Nr

slave1

+ Nr

slave2

+ Nr

master

) + 1,0508] * 2

Protected height

mm

160

310

460

610

760

910

1060

1210

1360

1510

1660

1810

PFHd *

6,53E-09

7,16E-09

7,85E-09

8,48E-09

9,17E-09

9,80E-09

1,05E-08

1,11E-08

1,18E-08

1,24E-08

1,31E-08

1,37E-08

DCavg #

96,5%

96,8%

96,9%

97,1%

97,2%

97,3%

97,4%

97,5%

97,5%

97,6%

97,6%

97,6%

MTTFd #

years

100

CCF #

80%

WITH:

N

rslave1

= number of beams of slave1

N

rslave2

= number of beams of slave2

N

rmaster

= number of beams of master

* IEC 61508

#

ISO 13849-1

t

tot

= total response time

Page 29

EOS4 SAFETY LIGHT CURTAIN

28 8540733 • 23/03/2016 • Rev.17

English

90 mm Resolution Models

309

459

609

759

909

1059

1209

1359

1509

1659

1809

Number of beams

4 6 8 10

12

14

16

18

20

22

24

Response time

ms

3

3,5 4 4,5 5 5,5

5,5 6 6,5

7

7,5

Response time

(Master + 1 slave)

ms

t

tot

= [0,11 * (Nr

slave1

+ Nr

master

) + 0,9376] * 2

Response time

(Master + 2 slaves)

ms

t

tot

= [0,11 * (Nr

slave1

+ Nr

slave2

+ Nr

master

) + 1,0508] * 2

Protected height

mm

310

460

610

760

910

1060

1210

1360

1510

1660

1810

PFHd *

6,79E-09

7,34E-09

7,78E-09

8,33E-09

8,77E-09

9,32E-09

9,76E-09

1,03E-08

1,07E-08

1,13E-08

1,17E-08

DCavg #

96,5%

96,6%

96,7%

96,8%

96,9%

96,9%

97,0%

97,1%

97,1%

97,1%

97,2%

MTTFd #

years

100

CCF #

80%

Multibeam Models

2B

3B

4B

Number of beams 2 3

4

Distance between

the beams mm

500

400

300

Response time ms

2,5 3 3

Response time

(Master +1 slave) ms

t

tot

= [0,11 * (Nr

slave1

+ Nr

master

) + 0,9376] * 2

Response time

(Master + 2 slaves) ms

t

tot

= [0,11 * (Nr

slave1

+ Nr

slave2

+ Nr

master

) + 1,0508] * 2

PFHd *

6,89E-09

7,55E-09

8,21E-09

DCavg #

96,2%

96,2%

96,1%

MTTFd

#

years

100

CCF #

80%

WITH:

N

rslave1

= number of beams of slave1

N

rslave2

= number of beams of slave2

N

rmaster

= number of beams of master

* IEC 61508

#

ISO 13849-1

t

tot

= total response time

Page 30

EOS4 SAFETY LIGHT CURTAIN

8540733 • 23/03/2016 • Rev.17 29

English

20m MODELS

20 mm H Resolution Models

152

302

452

602

752

902

1052

1202

1352

1502

1652

1802

Number of beams

15

30

45

60

75

90

105

120

135

150

165

180

Response time

ms 4 5,5

7,5 9 11

13

14,5

16,5

18

20

22

23,5

Response time

(Master + 1 slave)

ms

t

tot

= [0,06 * (N

rslave1

+ N

rmaster

) + 0,9636] * 2

Response time

(Master + 2 slaves)

ms

t

tot

= [0,06 * (N

rslave1

+ N

rslave2

+ N

rmaster

) + 1,0036] * 2

Protected height

mm

160

310

460

610

760

910

1060

1210

1360

1510

1660

1810

PFHd *

1,03E-08

1,27E-08

1,52E-08

1,75E-08

2,00E-08

2,24E-08

2,49E-08

2,73E-08

2,98E-08

3,22E-08

3,48E-08

3,71E-08

DCavg #

95,4%

94,9%

94,5%

94,1%

93,8%

93,6%

93,3%

93,1%

92,9%

92,8%

92,7%

92,6%

MTTFd #

years

100

CCF #

80%

30 mm H Resolution Models

153

303

453

603

753

903

1053

1203

1353

1503

1653

1803

Number of beams

8 16

23

31

38

46

53

61

68

76

83

91

Response time

ms 3 4 5 6

6,5

7,5

8,5

9,5

10

11

12

13

Response time

(Master + 1 slave)

ms

t

tot

= [0,06 * (N

rslave1

+ N

rmaster

) + 0,9636] * 2

Response time

(Master + 2 slaves)

ms

t

tot

= [0,06 * (N

rslave1

+ N

rslave2

+ N

rmaster

) + 1,0036] * 2

Protected height

mm

160

310

460

610

760

910

1060

1210

1360

1510

1660

1810

PFHd *

9,13E-09

1,04E-08

1,16E-08

1,28E-08

1,41E-08

1,53E-08

1,66E-08

1,78E-08

1,91E-08

2,03E-08

2,16E-08

2,29E-08

DCavg #

95,7%

95,4%

95,1%

94,9%

94,7%

94,5%

94,3%

94,1%

93,9%

93,8%

93,7%

93,6%

MTTFd #

years

100

CCF #

80%

40 mm H Resolution Models

154

304

454

604

754

904

1054

1204

1354

1504

1654

1804

Number of beams

6 11

16

21

26

31

36

41

46

51

56

61

Response time

ms

3

3,5 4 4,5 5 6

6,5 7 7,5 8 8,5

9,5

Response time

(Master + 1 slave)

ms

t

tot

= [0,06 * (N

rslave1

+ N

rmaster

) + 0,9636] * 2

Response time

(Master + 2 slaves)

ms

t

tot

= [0,06 * (N

rslave1

+ N

rslave2

+ N

rmaster

) + 1,0036] * 2

Protected height

mm

160

310

460

610

760

910

1060

1210

1360

1510

1660

1810

PFHd *

8,84E-09

9,85E-09

1,06E-08

1,16E-08

1,23E-08

1,34E-08

1,41E-08

1,51E-08

1,59E-08

1,69E-08

1,77E-08

1,87E-08

DCavg #

95,8%

95,5%

95,3%

95,1%

95,0%

94,8%

94,7%

94,5%

94,4%

94,2%

94,2%

94%

MTTFd #

years

100

CCF #

80%

50 mm H Resolution Models

155

305

455

605

755

905

1055

1205

1355

1505

1655

1805

Number of beams

4 8

12

16

20

24

28

32

36

40

44

48

Response time

ms

2,5 3 3,5 4 4,5 5 5,5 6 6,5 7 7

8

Response time

(Master + 1 slave)

ms

t

tot

= [0,06 * (N

rslave1

+ N

rmaster

) + 0,9636] * 2

Response time

(Master + 2 slaves)

ms

t

tot

= [0,06 * (N

rslave1

+ N

rslave2

+ N

rmaster

) + 1,0036] * 2

Protected height

mm

160

310

460

610

760

910

1060

1210

1360

1510

1660

1810

PFHd *

8,50E-09

9,11E-09

9,82E-09

1,04E-08

1,11E-08

1,18E-08

1,25E-08

1,31E-08

1,38E-08

1,44E-08

1,52E-08

1,58E-08

DCavg #

95,9%

95,7%

95,5%

95,4%

95,2%

95,1%

94,9%

94,8%

94,7%

94,6%

94,5%

94,5%

MTTFd

#

years

100

CCF #

80%

WITH:

N

rslave1

= number of beams of slave1

N

rslave2

= number of beams of slave2

N

rmaster

= number of beams of master

* IEC 61508

#

ISO 13849-1

t

tot

= total response time

Page 31

EOS4 SAFETY LIGHT CURTAIN

30 8540733 • 23/03/2016 • Rev.17

English

90 mm H Resolution Models

309

459

609

759

909

1059

1209

1359

1509

1659

1809

Number of beams

4 6 8 10

12

14

16

18

20

22

24

Response time

ms

2,5 3 3

3,5

3,5

3,5 4 4

4,5

4,5

5

Response time

(Master + 1 slave)

ms

t

tot

= [0,06 * (N

rslave1

+ N

rmaster

) + 0,9636] * 2

Response time

(Master + 2 slaves)

ms

t

tot

= [0,06 * (N

rslave1

+ N

rslave2

+ N

rmaster

) + 1,0036] * 2

Protected height

mm

310

460

610

760

910

1060

1210

1360

1510

1660

1810

PFHd * 8,71E-09

9,23E-09

9,64E-09

1,02E-08

1,06E-08

1,11E-08

1,15E-08

1,20E-08

1,24E-08

1,30E-08

1,34E-08

DCavg #

95,8%

95,7%

95,6%

95,4%

95,3%

95,2%

95,1%

95,0%

95,0%

94,9%

94,8%

MTTFd

#

years

100

CCF #

80%

Multibeam H Models

2B

3B

4B

Number of beams 2 3

4

Distance betweenthe beams mm

500

400

300

Response time

ms

2,5

2,5

2,5

Response time

(Master +1 slave) ms

t

tot

= [0,06 * (N

rslave1

+ N

rmaster

) + 0,9836] * 2

Response time

(Master + 2 slaves) ms

t

tot

= [0,06 * (N

rslave1

+ N

rslave2

+ N

rmaster

) + 1,0336] * 2

PFHd *

9,15E-09

9,99E-09

1,08E-08

DCavg #

95,8%

95,6%

95,4%

MTTFd

#

years

100

CCF #

80%

WITH:

N

rslave1

= number of beams of slave1

N

rslave2

= number of beams of slave2

N

rmaster

= number of beams of master

* IEC 61508

#

ISO 13849-1

t

tot

= total response time

Page 32

EOS4 SAFETY LIGHT CURTAIN

8540733 • 23/03/2016 • Rev.17 31

English

Dimensions

Figure 27 - Emitter and Receiver

213

313

363

513

663

813

963

1113

1263

1413

1563

1713

1863

236 - 386

536

686

836

986

1136

1286

1436

1586

1736

1886

150

250

300

450

600

750

900

1050

1200

1350

1500

1650

1800

2 LE TYPE brackets with 2 inserts

3 LE TYPE brackets with 3 inserts

653

953

1053

677

977

1077

590

890

990

2 LE TYPE brackets with 2 inserts

Figure 28 - FIE inserts and LE fastening brackets (provided)

Page 33

EOS4 SAFETY LIGHT CURTAIN

32 8540733 • 23/03/2016 • Rev.17

English

Figure 29 - Fastening brackets SFBE

Figure 30 - Fastening brackets SFB180E

Figure 31 - Deflection mirrors

Figure 32 - Fastening brackets for mirrors

Model

H

SP100S

250

SP300S

400

SP400S

540

SP600S

715

SP700S

885

SP900S

1060

SP1100S

1230

SP1200S

1400

SP1300S

1450

SP1500S

1600

SP1600S

1750

SP1800S

1900

M8 Inserts

Page 34

EOS4 SAFETY LIGHT CURTAIN

8540733 • 23/03/2016 • Rev.17 33

English

CHECKOUTS AND MAINTENANCE

Checking of light curtain efficiency

Before each shift or at power-on, check the correct operation of the light curtain.

To do this, comply with the following procedure which uses a test object to intercept the

beams.

The correct test object must be used for the test, depending on light curtain

resolution. Refer to the chapter for the correct

ordering code.

Referring to Figure 33:

Introduce the test object in the protected area and move it slowly up and down,

first at the centre and then close to both the Emitter and Receiver.

For models: using an opaque object, interrupt the beams one by one,

first of all at the centre and then close to the Emitter and Receiver.

Check that, in each phase of test object movement, the red led on the Receiver

always remains ON.

Figure 33 – Efficiency check

The EOS4 light curtain does not require any specific maintenance; however, it is good

practice to clean the front protective surfaces of the mirrors of the Emitter and Receiver.

Clean with a damp cloth; in very dusty environments, after cleaning the front surface,

spray with an anti-stat product.

that could damage the

part to be cleaned or wool cloths in order to prevent electrifying the front surface.

Even very fine scratching of the front plastic surfaces may increase the width of the

beam emitted by the light curtain, thereby impairing its efficiency in the presence of

reflecting side surfaces.

Therefore, during cleaning, it is essential to dedicate particular attention to the front

window of the light curtain, in particular in environments characterised by abrasive

powders (e.g. cement works etc).

Page 35

EOS4 SAFETY LIGHT CURTAIN

34 8540733 • 23/03/2016 • Rev.17

English

Troubleshooting

The indications provided by the leds on the Emitter and Receiver make it possible to trace

the cause of any system malfunction. As indicated in the “LIGHT SIGNALS” paragraph of

this manual, in the case of a fault, the system switches to stop status and the leds of each

unit indicate the type of fault that has occurred. (See the tables below). The numbers of

the leds are referred to Figure 25.

RED

2 consecutive flashes

Check connections of pins 2 & 4.

RED

3/4 consecutive flashes

Send to REER for repair.

RED

5 consecutive flashes

Check model compatibility

ORANGE

Flashing

Check condition of the Master.

If in FAIL condition, check the type

of fault.

If the fault persists, send the

device to ReeR laboratories for repair.

ORANGE

2 consecutive flashes

Check Master/Slave connections.

Reset of the system.

If the fault persists, send Master

and Slave to ReeR laboratories for repair

RED

2 consecutive flashes

Check connections.

RED

4 consecutive flashes

Carefully locate the interfering Emitter and

take action in one of the following ways:

Reduce the range of the

interfering Emitter from High to Low

Swap over the position of Emitter

and Receiver

Move the interfering Emitter so

that it does not illuminate the Receiver

Shield the beams emitted by the

interfering Emitter using opaque

protections

RED

5 consecutive flashes

Check connections.

If the fault persists, send to REER

for repair.

RED

6/7 consecutive

flashes

Send the device to ReeR

laboratories for repair

RED

8 consecutive flashes

Check Master/Slave connections

If the fault persists, send the

device to ReeR laboratories for repair.

Table 19 - Troubleshooting

In any case, if a system stoppage occurs, switch the system off and on again to check

whether the incorrect behaviour of the system is to be ascribed to transitory

electromagnetic disturbances.

If the malfunction persists:

Check that electrical connections are correct and undamaged;

Check that supply voltage levels comply with those indicated in the technical data.

4

Indication present only on Slave light curtains

5

Indication present only on Master and Slave light curtains

6

Indication present only on Master and Slave2 light curtain

Page 36

EOS4 SAFETY LIGHT CURTAIN

8540733 • 23/03/2016 • Rev.17 35

English

Check that the Emitter and the Receiver are correctly aligned and that front

surfaces are perfectly clean.

It is advisable to keep the power supply of the light curtain separate from that of

other electric power equipments (electric motors, inverters, frequency variators) or

other sources of disturbance.

If it is not possible to trace the cause of the malfunction and eliminate this, stop the

machine and contact the Reer assistance service.

If the checks suggested are not sufficient to restore the correct operation of the system,

please send the device, with all its parts, to the REER laboratories, clearly indicating:

product code number (P/N field shown in the product label);

serial number (S/N field shown in the product label);

date of purchase;

period of operation;

type of application;

detected fault.

Page 37

EOS4 SAFETY LIGHT CURTAIN

36 8540733 • 23/03/2016 • Rev.17

English

Accessories/Spares

ADMIRAL AD SR1 safety module

1330900

ADMIRAL AD SRM safety module with muting function

1330904

ADMIRAL AD SR0 safety relay

1330902

ADMIRAL AD SR0A safety relay

1330903

Straight M12 5-pin female connector with 5-m cable

1330950

90° M12 5-pin female connector with 5-m cable

1330951

Straight M12 5-pin female connector with 15-m cable

1330952

90° M12 5-pin female connector with 15-m cable

1330953

Straight M12 5-pin female connector PG9

1330954

90° M12 5-pin female connector PG9

1330955

Straight M12 8-pin female connector with 5m cable

1330980

Straight M12 8-pin female connector with 10m cable

1330981

Straight M12 8-pin female connector with 15m cable

1330982

90° M12 8-pin female connector with 5m cable

1330983

90° M12 8-pin female connector with 10m cable

1330984

90° M12 8-pin female connector with 15m cable

1330985

Straight M12 8-pin female connector PG9

1330986

90° M12 8-pin female connector PG9

1330987

0.3m cable with 2 straight M12 5-pin female connectors

1330990

3m cable with 2 straight M12 5-pin female connectors

1360960

5m cable with 2 straight M12 5-pin female connectors

1360961

10m cable with 2 straight M12 5-pin female connectors

1360962

Test rod diameter 14mm

1330960

Test rod diameter 20mm

1330961

Test rod diameter 30mm

1330962

Test rod diameter 40mm

1330963

Test rod diameter 50mm

1330964

Set of 4 fastening accessories (brackets, inserts and bolts)

for models up to 1050

1310970

Set of 6 fastening accessories(brackets, inserts and bolts)

for models from 1200

1310971

Set of 4 vibration-damping supports (for models h=150)

1310972

Set of 8 vibration-damping supports (for models h=300÷1050)

1310973

Set of 12 vibration-damping supports (for models h=1200÷1500)

1310974

Page 38

EOS4 SAFETY LIGHT CURTAIN

8540733 • 23/03/2016 • Rev.17 37

English

GUARANTEE

All new EOS4 systems are guaranteed by REER for a period of 12 (twelve) months under

normal working conditions, against defects due to faulty materials and workmanship.

During the aforesaid period, REER promises to replace faulty parts free of charge. This

guarantee covers both material and labour.

REER reserves the right to decide whether to repair equipment or replace it with

equipment of the same type or having the same characteristics.

The validity of this guarantee is subject to the following conditions:

The user must notify REER of the fault within twelve months following the date of

delivery of the product.

The equipment and all parts thereof must be in the condition in which they were

supplied by REER.

The defect or malfunction must not arise directly or indirectly from:

Improper use

Non-observance of the instructions for use;

Negligence, inexperience, improper maintenance;

Repairs, modifications and adjustments carried out by personnel not authorised by

REER, tampering, etc.;

Accidents or collisions (also during transportation or due to acts of God);

Other reasons for which REER cannot be held responsible.

Repairs will be carried out at REER’s laboratories, to which the material must be

consigned or forwarded: transport costs and any damage or loss of material during

transportation will be charged to the Customer.

All replaced products and parts are property of REER.

REER does not recognise any other form of guarantee or rights other than those expressly

stated above; no requests for compensation for damages incurred for costs, suspension

of activities or any other events or circumstances related in any way to malfunctioning of

the product or any parts thereof will be taken into consideration.

Precise, complete compliance with all the indications and warnings indicated in this

manual is essential for correct operation of the light curtain. Therefore, REER s.p.a.

declines any responsibility for defects caused by even partial non-compliance with

such indications.

Characteristics liable to modifications without prior notice. Complete or partial reproduction is forbidden without REER’s prior authorisation.

Page 39

Dichiarazione CE di conformità

EC declaration of conformity

Torino, 18/03/2016

REER SpA

via Carcano 32

10153 – Torino

Italy

dichiara che le barriere fotoelettriche EOS4 sono Dispositivi Elettrosensibili di Sicurezza (ESPE) di :

Tipo 4 (secondo la Norma EN 61496-1/A1:2008; IEC 61496-2:2006)

SIL 3 (secondo la Norma IEC 61508-1:1998; IEC 61508-2:2000; IEC 61508-3:1998; IEC 61508-4:1998)

SILCL 3 (secondo la Norma IEC 62061:2005)

Cat.4 - PL e (secondo la Norma EN ISO 13849-1:2008)

declares that the EOS4 photoelectric safety barriers are :

Type 4 (according the Standard EN 61496-1/A1:2008; IEC 61496-2:2006)

SIL 3 (according the Standard IEC 61508-1:1998; IEC 61508-2:2000; IEC 61508-3:1998; IEC 61508-4:1998)

SILCL 3 (according the Standard IEC 62061:2005)

Cat.4 - PL e (according the Standard EN ISO 13849-1:2008)

Electro-sensitive Protective Equipments (ESPE)

realizzati in conformità alle seguenti Direttive Europee:

complying with the following European Directives:

2006/42/EC "Direttiva Macchine"

"Machine Directive"

2014/30/EU "Direttiva Compatibilità Elettromagnetica"

"Electromagnetic Compatibility Directive"

2014/35/EU "Direttiva Bassa Tensione"

"Low Voltage Directive"

e alle seguenti Norme: /and to the following Standards:

EN 50178: 1997

EN 55022: 2006

e sono identiche all'esemplare esaminato ed approvato con esame di tipo CE da:

and are identical to the specimen examined and approved with a CE - type approval by:

TÜV SÜD Rail GmbH – Ridlerstrasse 65 – D-80339 – Muenchen – Germany

Carlo Pautasso Simone Scaravelli

Direttore Tecnico Amministratore Delegato

Technical Director Managing director

Page 40

REER S.p.A.

32 via Carcano

10153 Torino Italia

Tel. +39/0112482215 r.a.

Fax +39/011859867

Internet: www.reer.it

e-mail: info@reer.it

Loading...

Loading...