Page 1

PHOTOELECTRIC

SAFETY BARRIER

EOS2

IINNSSTTAALLLLAAZZIIOONNEE,, UUSSOO EE MMAANNUUTTEENNZZIIOONNEE

IINNSSTTAALLLLAATTIIOONN,, UUSSEE AANNDD MMAAIINNTTEENNAANNCCEE

IINNSSTTAALLLLAATTIIOONN,, UUTTIILLIISSAATTIIOONN EETT MMAAIINNTTEENNAANNCCEE

IINNSSTTAALLLLAATTIIOONN,, BBEEDDIIEENNUUNNGG UUNNDD WWAARRTTUUNNGG

IINNSSTTAALLAACCIIÓÓNN,, UUSSOO YY MMAANNTTEENNIIMMIIEENNTTO

O

www.reer.it

Page 2

EOS2 SAFETY LIGHT CURTAIN

8540738 • 05/12/2017 • Rev.20

1

Eng

lish

Page 3

EOS2 SAFETY LIGHT CURTAIN

2 8540738 • 05/12/2017 • Rev.20

English

Page 4

EOS2 SAFETY LIGHT CURTAIN

8540738 • 05/12/2017 • Rev.20 3

English

INTRODUCTION

Page 5

EOS2 SAFETY LIGHT CURTAIN

4 8540738 • 05/12/2017 • Rev.20

English

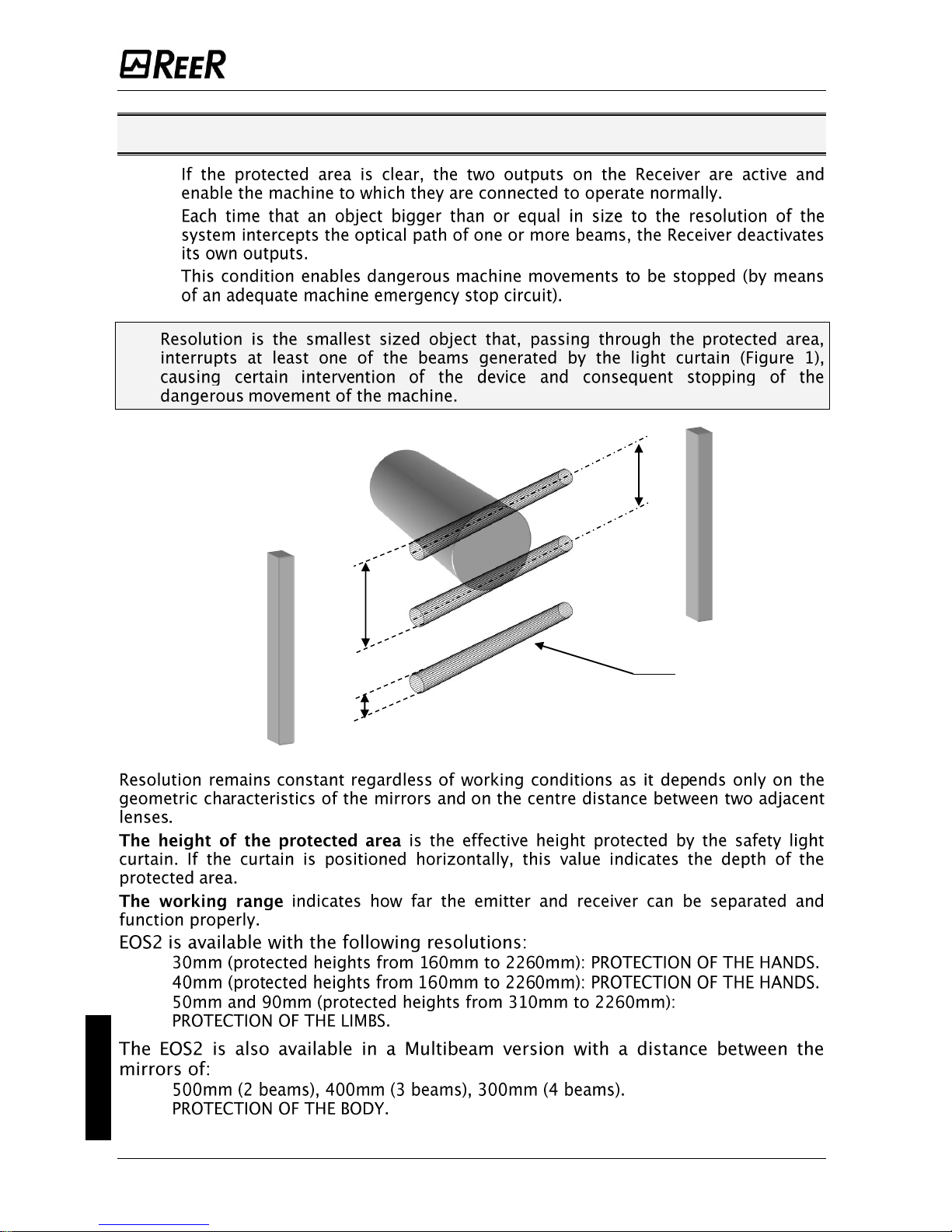

PRINCIPLE OF OPERATION

Figure 1 - Resolution

P = Pitch between two lenses

D = Diameter of a lens

R = Resolution = P+D

P

R

D

Receiver

Emitter

Beam

Page 6

EOS2 SAFETY LIGHT CURTAIN

8540738 • 05/12/2017 • Rev.20 5

English

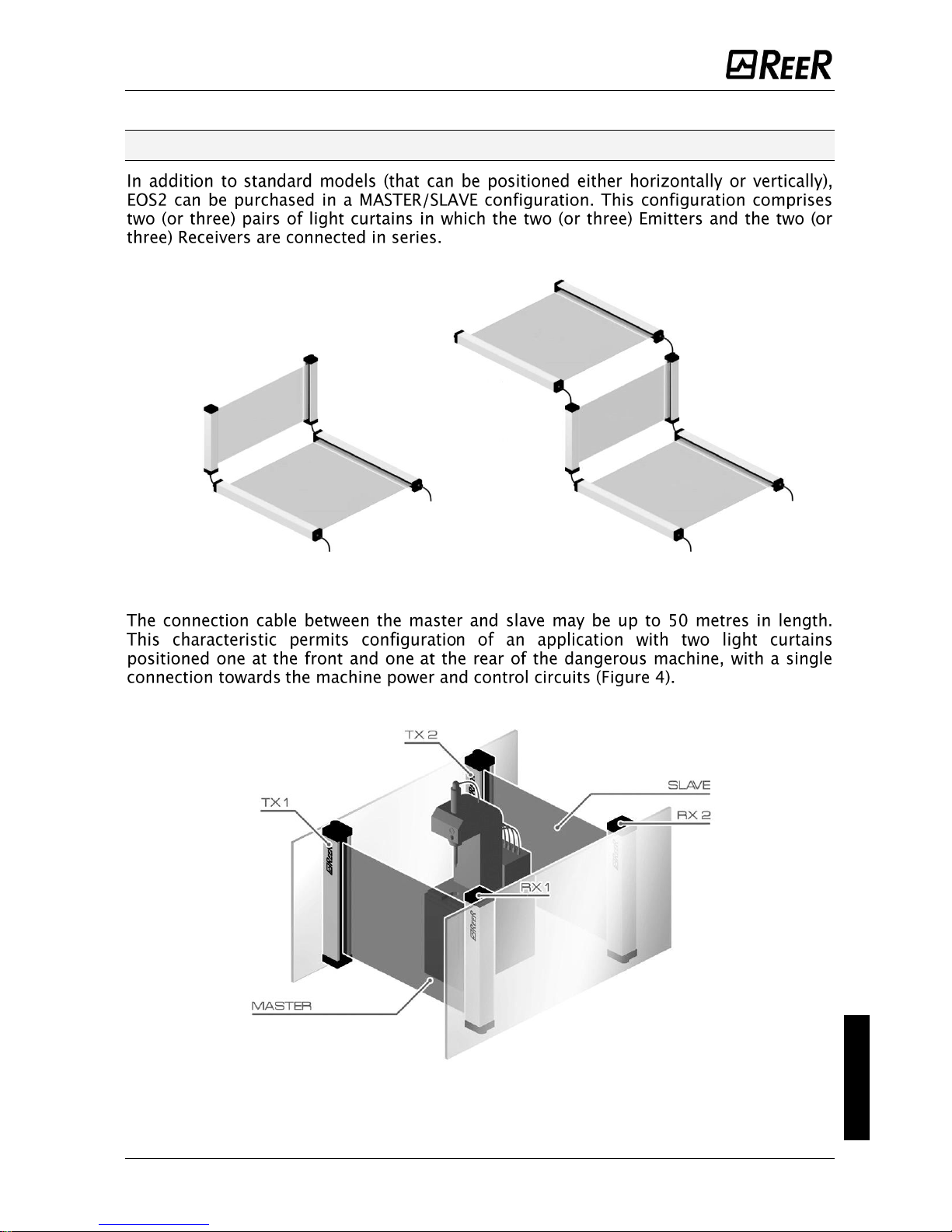

INSTALLATION

Table 1 – CF correction factors

Page 7

EOS2 SAFETY LIGHT CURTAIN

6 8540738 • 05/12/2017 • Rev.20

English

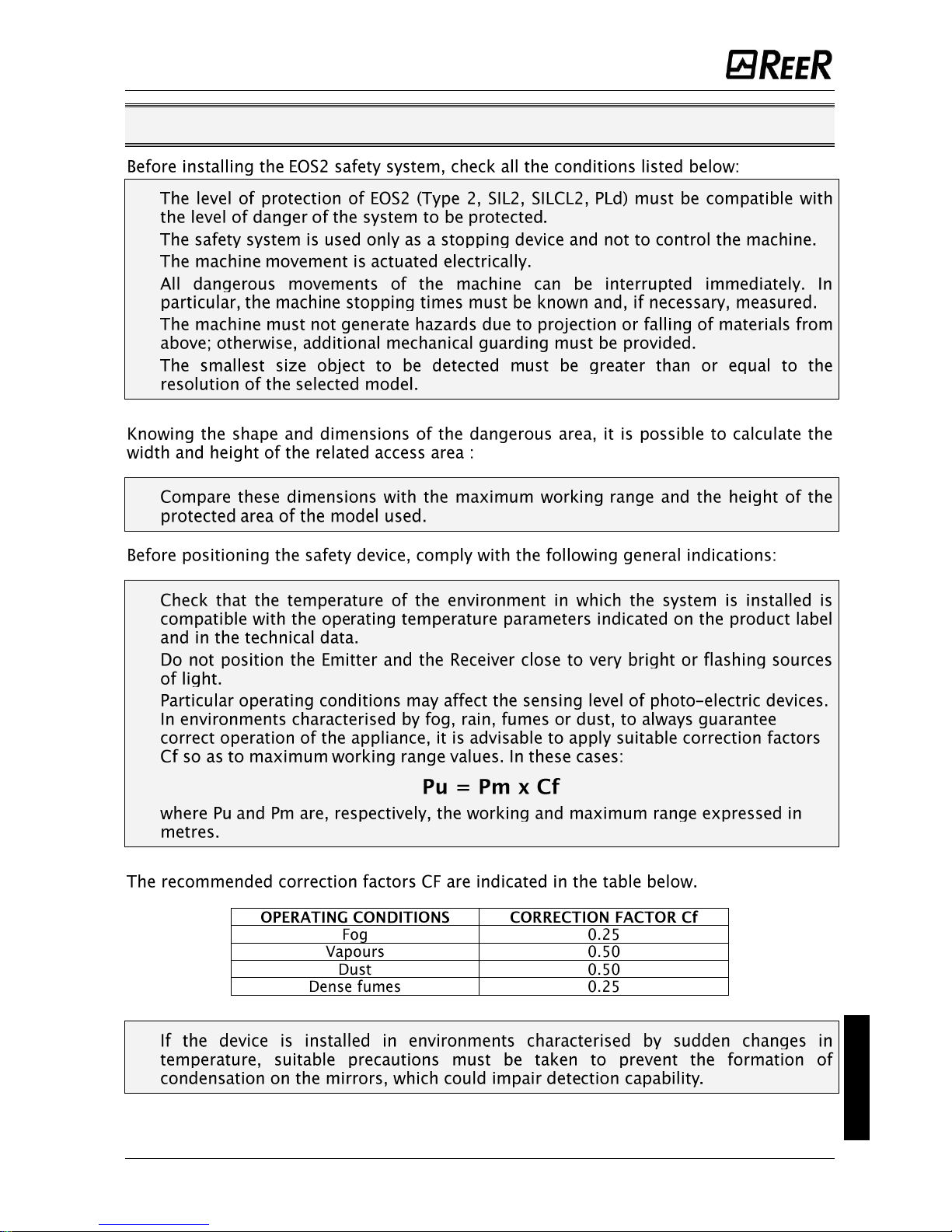

Positioning

EOS2E EOS2R

Incorrect positioning of the light curtain

Correct positioning of the light curtain

Figure 2 - Positioning

Page 8

EOS2 SAFETY LIGHT CURTAIN

8540738 • 05/12/2017 • Rev.20 7

English

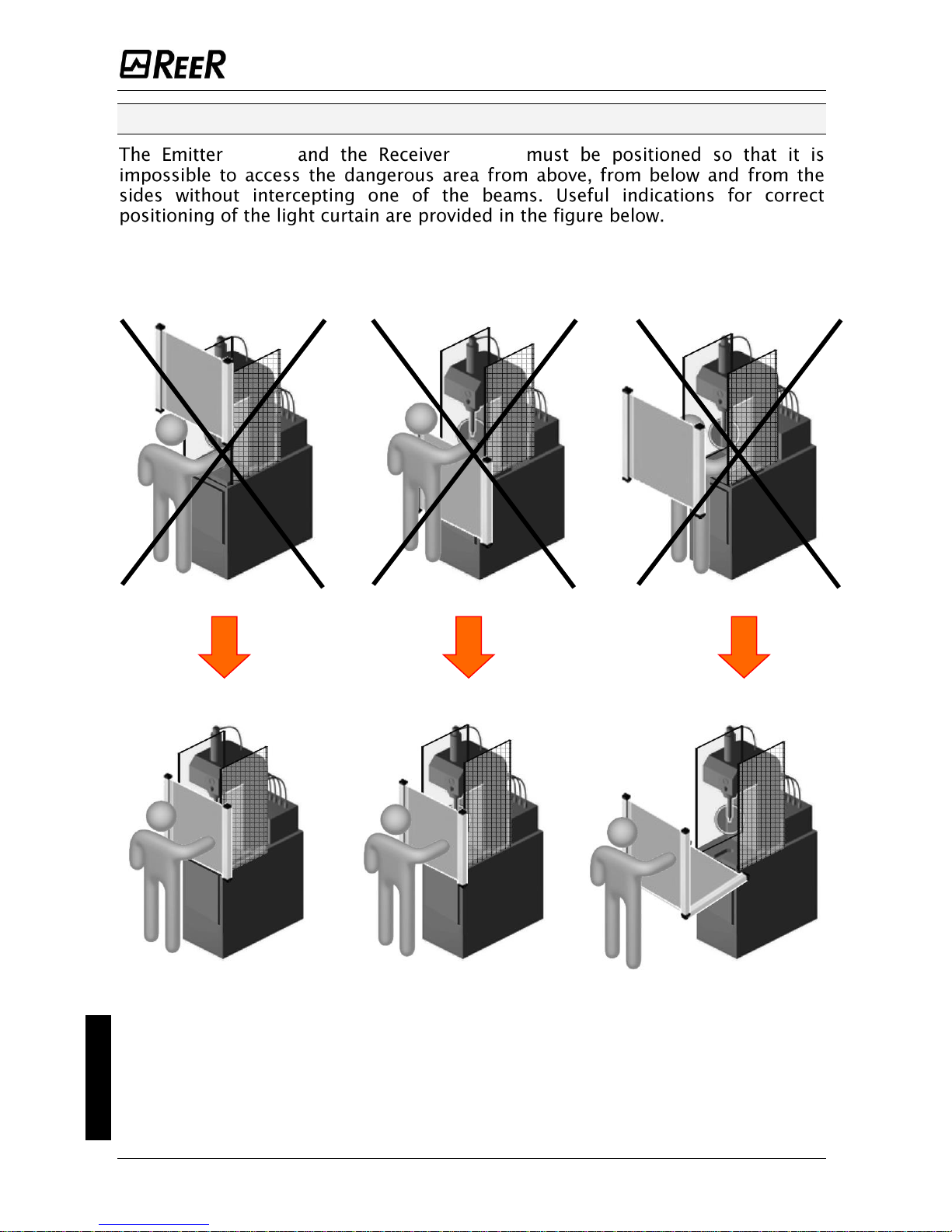

Master/Slave Positioning

Figure 3 – Examples of Master/Slave configurations

Figure 4 - Example of Master/Slave application with mechanical guards

MASTER

MASTER

SLAVE

SLAVE2

SLAVE

Page 9

EOS2 SAFETY LIGHT CURTAIN

8 8540738 • 05/12/2017 • Rev.20

English

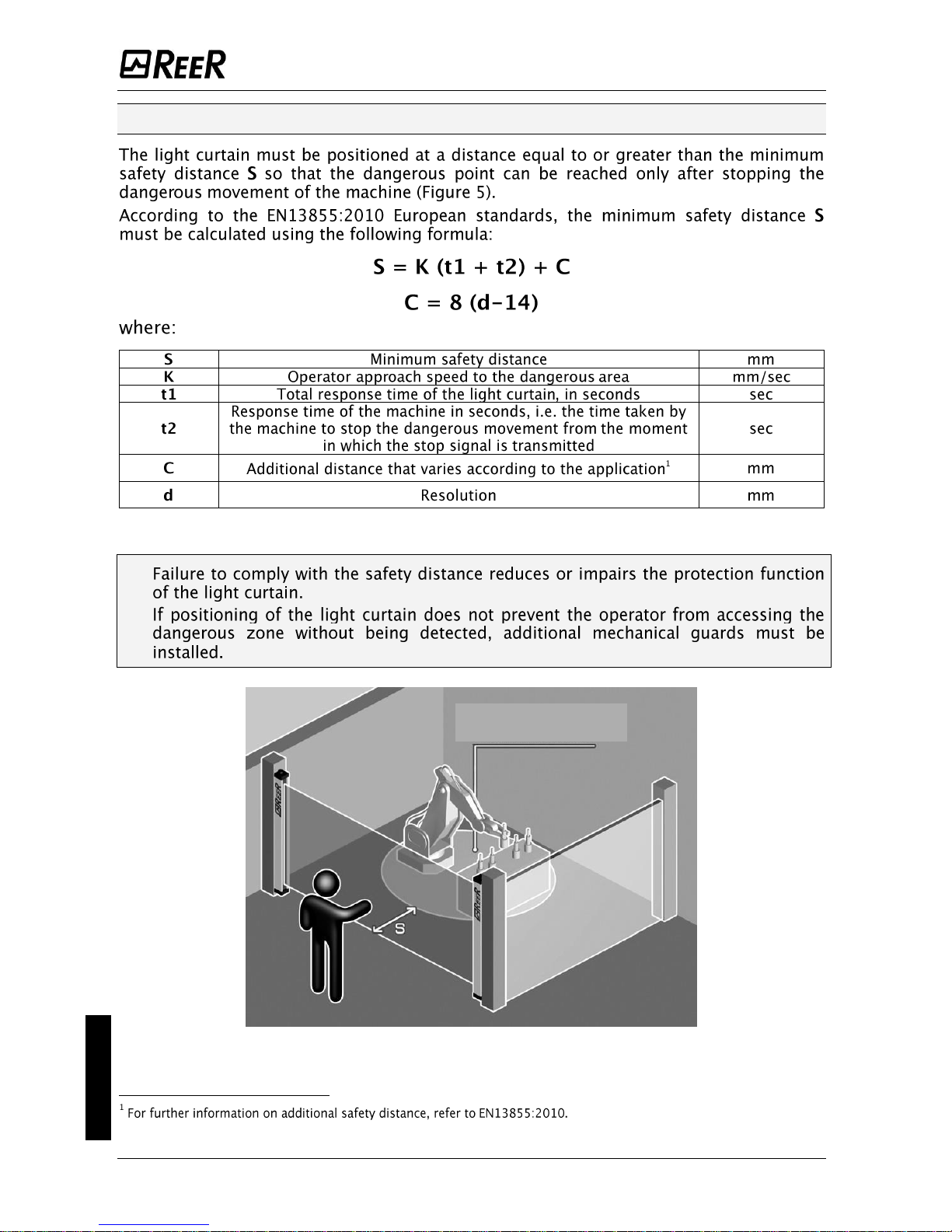

Calculation of safety distance

Table 2 – Safety distance

Figure 5 – Safety distance S

DANGEROUS ZONE

Page 10

EOS2 SAFETY LIGHT CURTAIN

8540738 • 05/12/2017 • Rev.20 9

English

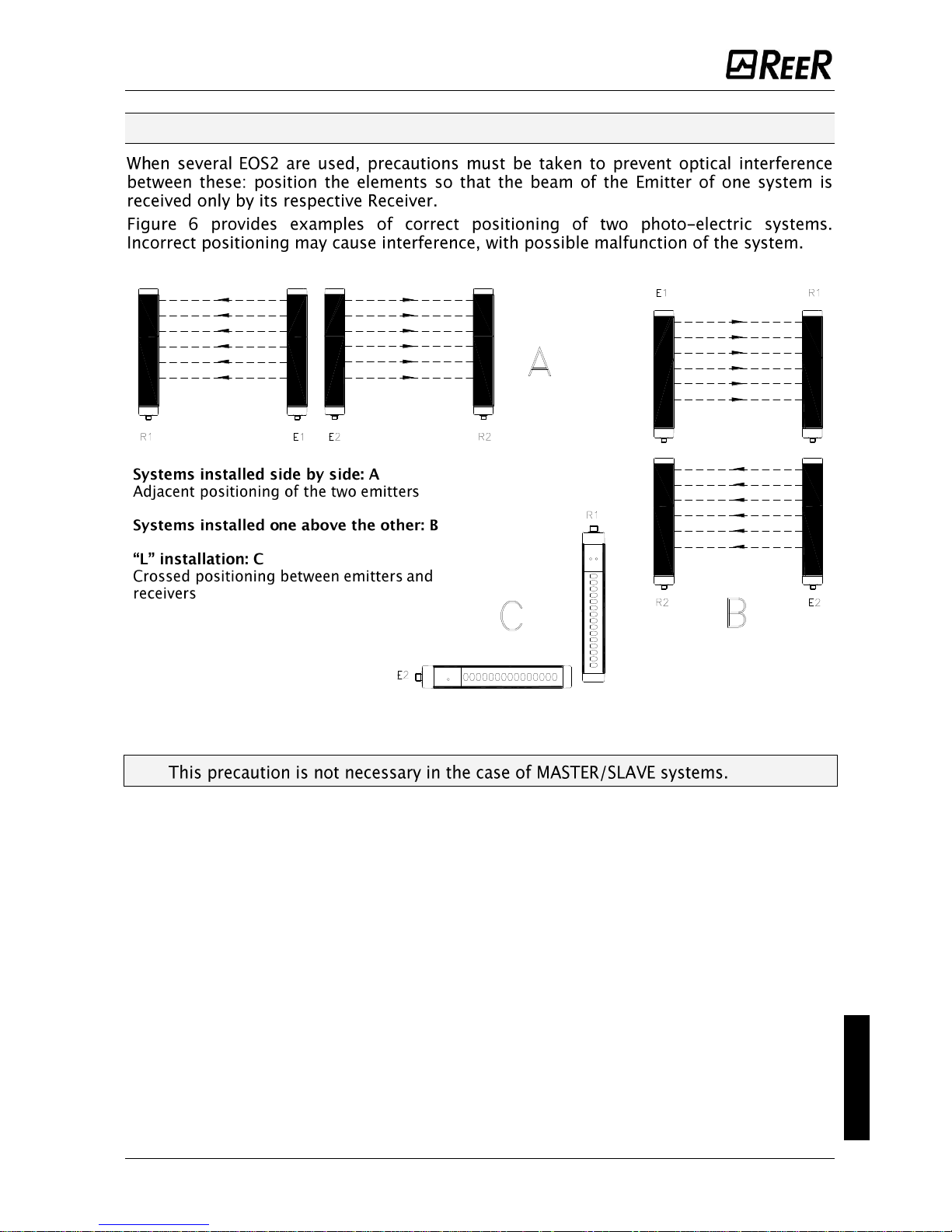

Multiple systems

Figure 6 – Multiple systems

Page 11

EOS2 SAFETY LIGHT CURTAIN

10 8540738 • 05/12/2017 • Rev.20

English

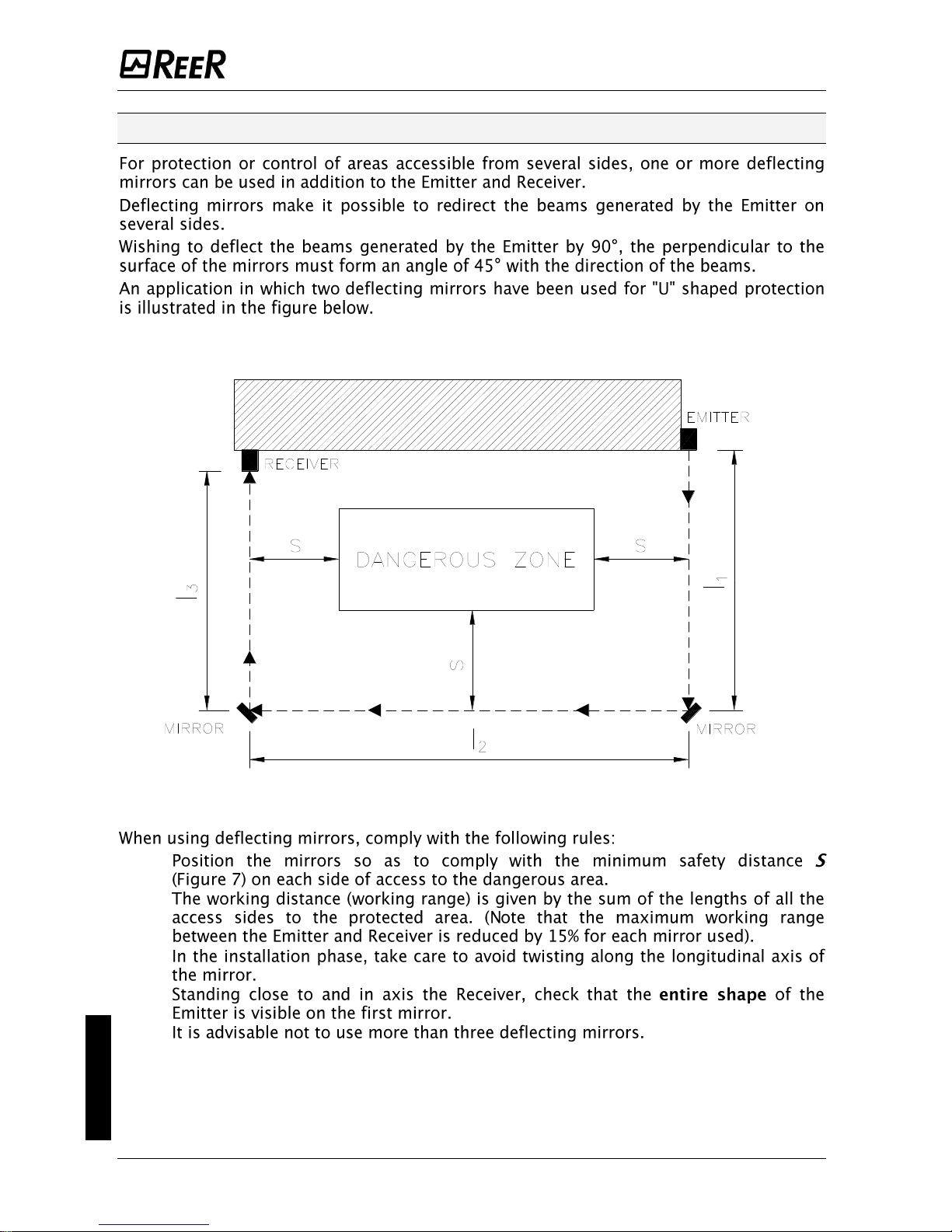

Use of deflecting mirrors

Figure 7 – Deflecting mirrors

Page 12

EOS2 SAFETY LIGHT CURTAIN

8540738 • 05/12/2017 • Rev.20 11

English

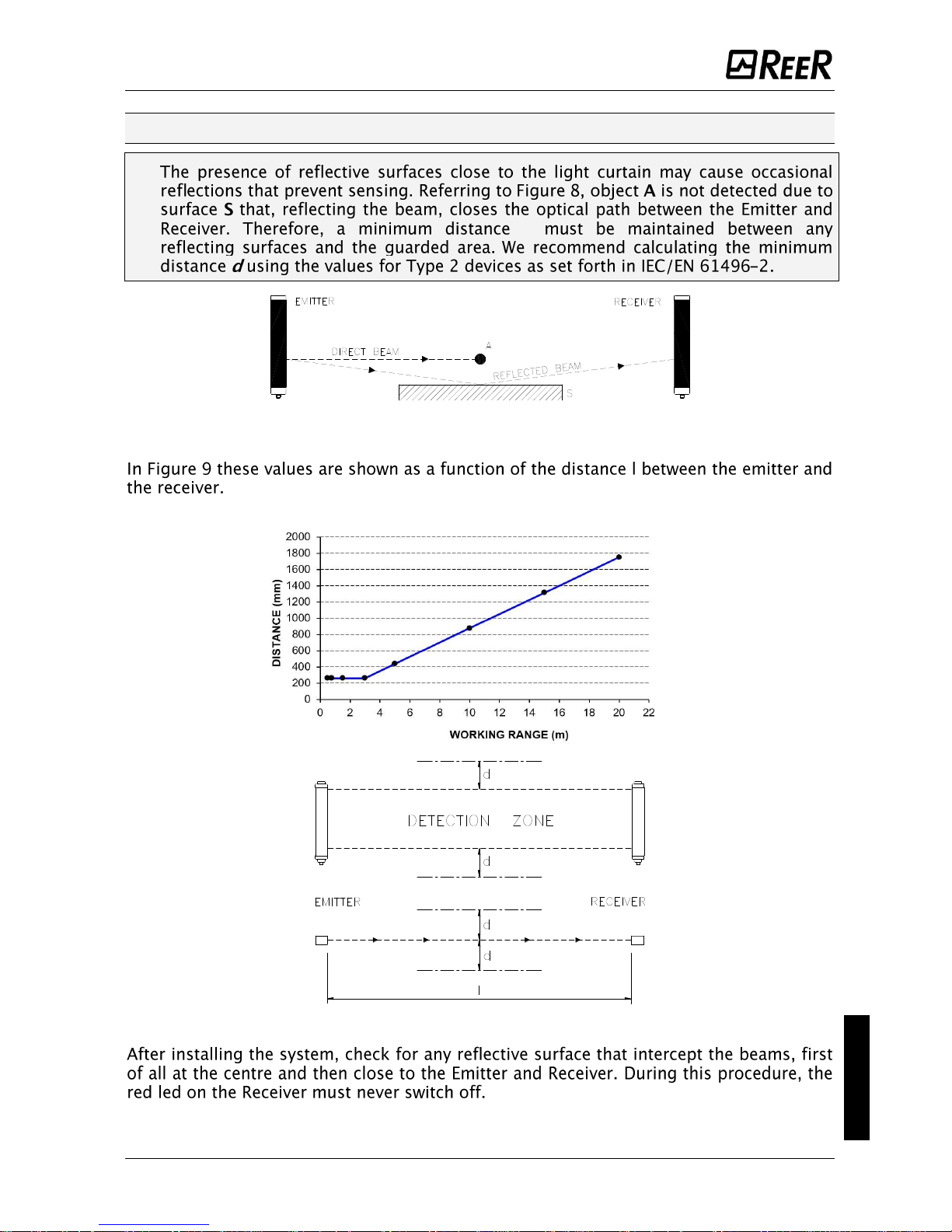

Distance from reflective surfaces

d

Figure 8 - Reflective surfaces

Figure 9 - Minimum distance d

d

l

Page 13

EOS2 SAFETY LIGHT CURTAIN

12 8540738 • 05/12/2017 • Rev.20

English

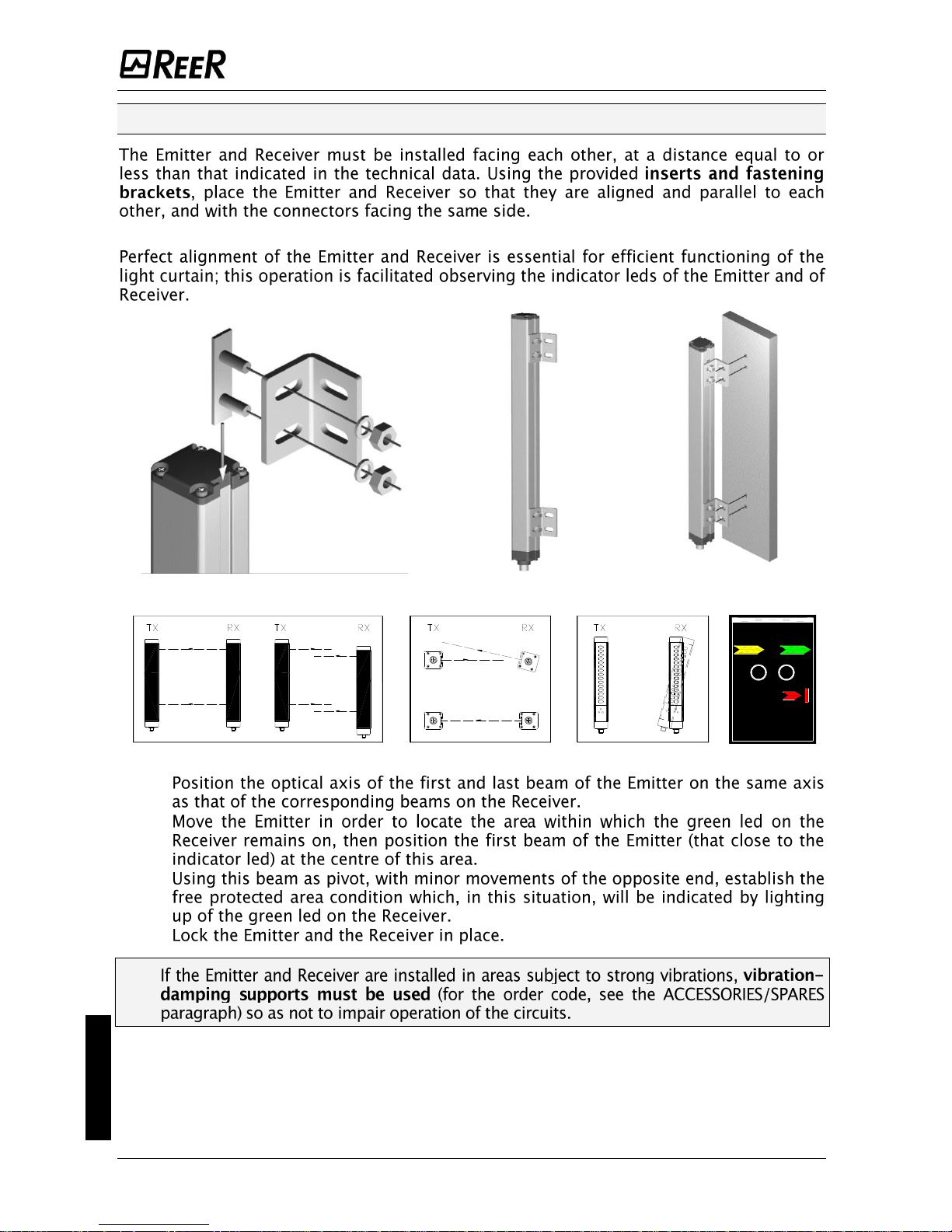

Mechanical assembly and optical alignment

Figure 10 – Mechanical assembly

Figure 11 – Optical alignment

Page 14

EOS2 SAFETY LIGHT CURTAIN

8540738 • 05/12/2017 • Rev.20 13

English

Vertical positioning of the light curtain

Models with 30, 40mm resolution

S = 2000 (t1 + t2) + 8(D-14)

(D=resolution)

S = 1600 (t1 + t2) + 8(D-14)

EN 13855 Standard.

Figure 12 -

Vertical positioning

30mm, 40mm

Models with 50, 90mm resolution

S = 1600 (t1 + t2) + 850

(EN 13855 Standard).

Figure 13 - 50mm, 90mm

Light curtain

point of

danger

direction

of

approach

reference plane

Light curtain

point of

danger

direction

of

approach

reference plane

Page 15

EOS2 SAFETY LIGHT CURTAIN

14 8540738 • 05/12/2017 • Rev.20

English

Multibeam Models

S = 1600 (t1 + t2) + 850

(EN 13855 Standard)

Figure 14 - Multibeam

Table 3 - Height H of Multibeam models

Horizontal positioning of the light curtain

S = 1600(t1 + t2) + 1200 – 0.4H

H = 15(D-50)

(D=resolution)

(EN 13855 Standard)

Figure 15 - Horizontal positioning

Light grid

point of

danger

direction

of

approach

reference plane

Light curtain

point of

danger

direction

of approach

reference plane

Page 16

EOS2 SAFETY LIGHT CURTAIN

8540738 • 05/12/2017 • Rev.20 15

English

Electrical connections

Layout of the connectors on MASTER/SLAVE light curtain

Figure 16 - Connector layout

SLAVE primary connector

SLAVE2 secondary connector

SLAVE

SLAVE 2

SLAVE2 primary connector

MASTER secondary connector

MASTER

MASTER primary

connector

Page 17

EOS2 SAFETY LIGHT CURTAIN

16 8540738 • 05/12/2017 • Rev.20

English

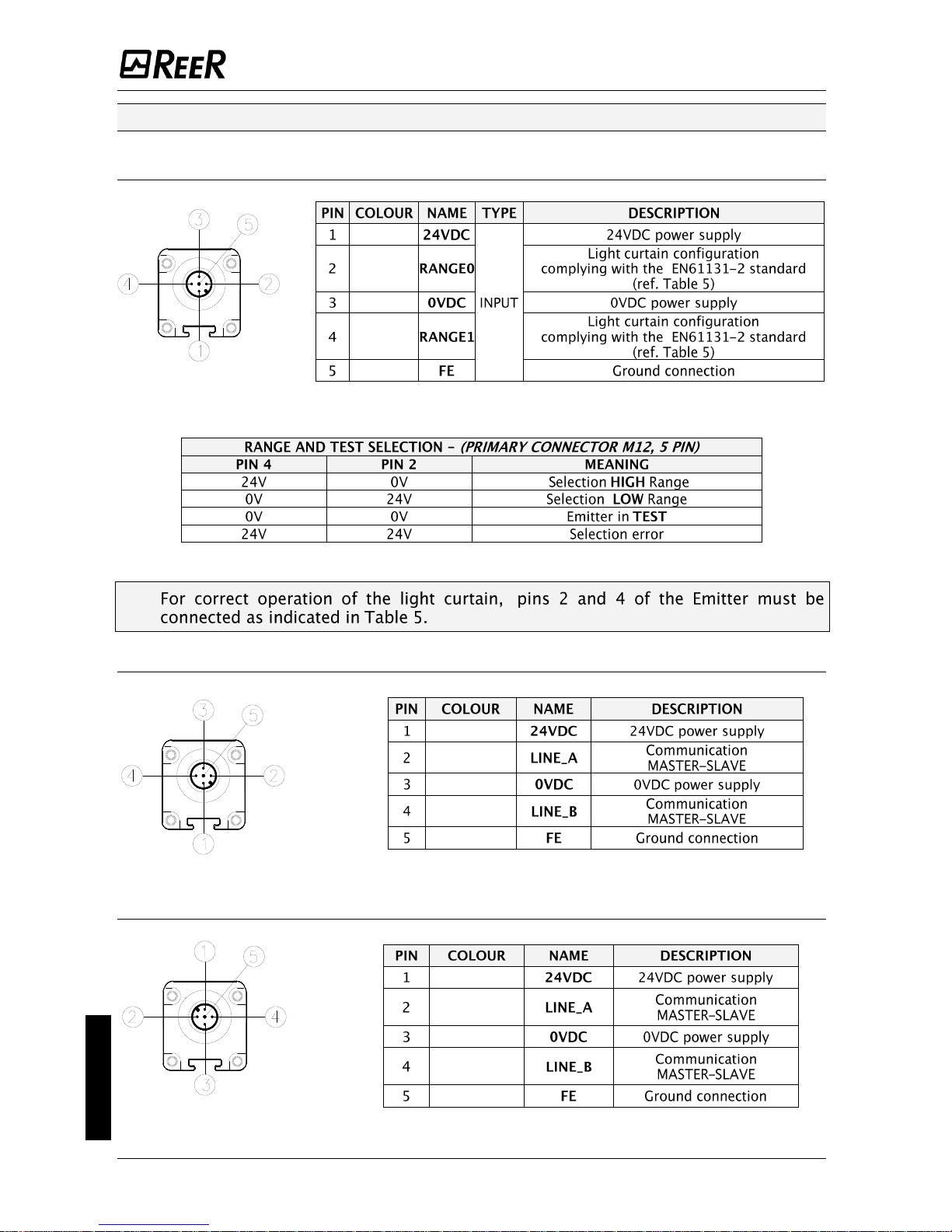

Emitter connections

EOS2A - EOS2X (with integrated control functions) - EOS4XM (MASTER models)

M12 5-pin primary connectors.

Brown

White

Blue

Black

Grey

Table 4 - M12, 5 pin

Master/Standard/with integrated control functions TX

Table 5 – Range and TEST selection

EOS2XS - EOS2XS2 (SLAVE/SLAVE2 models) - M12, 5-pin primary connector.

Brown

White

Blue

Black

Grey

Table 6 - M12, 5-pin Primary Slave TX

EOS2XM (MASTER models) – M12, 5-pin secondary connector.

EOS2XS2 (SLAVE2 models) – M12, 5-pin secondary connector.

Brown

White

Blue

Black

Grey

Table 7 - M12, 5-pin Secondary TX

Page 18

EOS2 SAFETY LIGHT CURTAIN

8540738 • 05/12/2017 • Rev.20 17

English

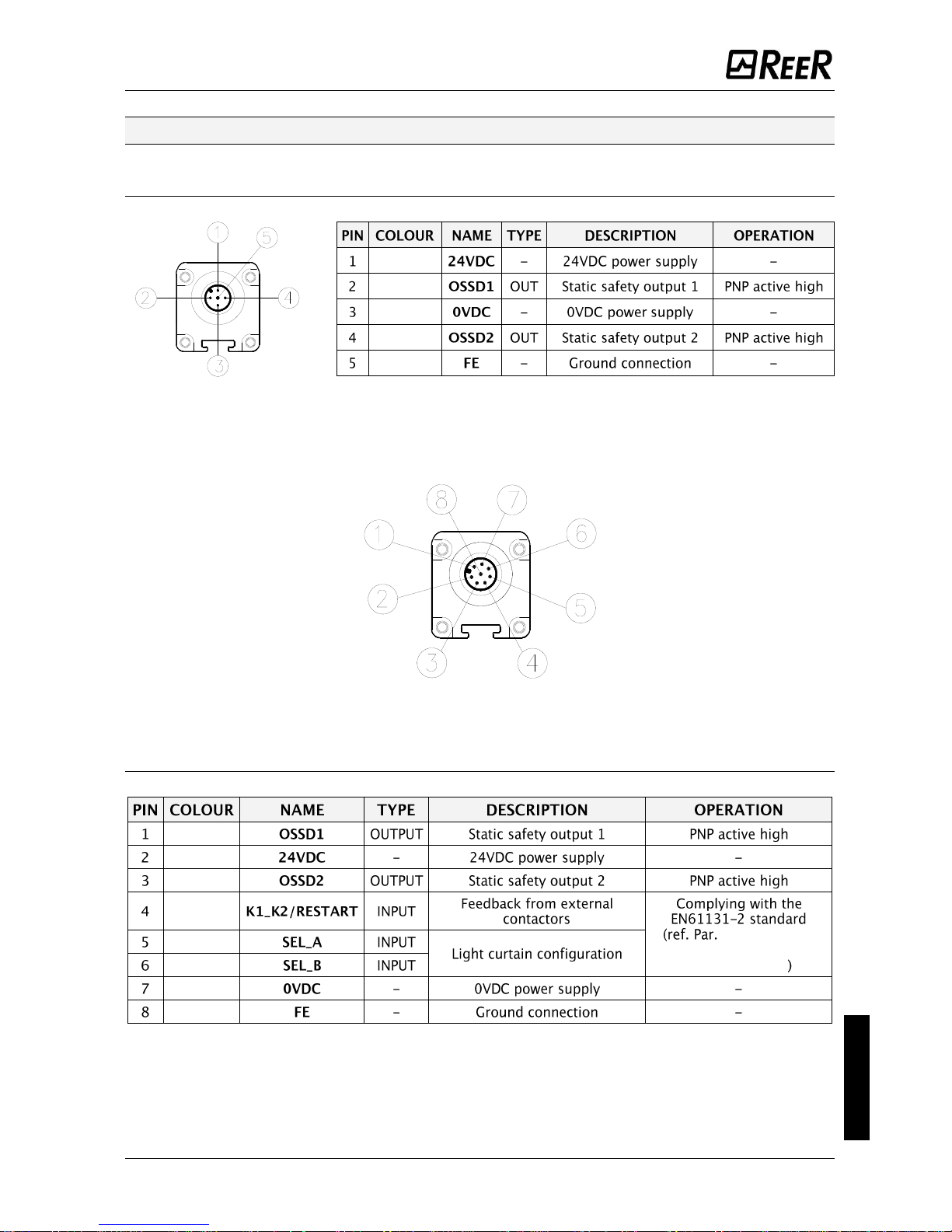

Receiver connections

EOS2A models - M12, 5-pin connector.

Brown

White

Blue

Black

Grey

Table 8 - M12, 5 pins Primary RX

EOS2X (models with integrated control functions) - M12, 8-pin connector.

EOS2XM (MASTER models) - M12, 8-pin primary connector.

White

Brown

Green

Yellow

"Configuration

and operating

modes" page 19

Grey

Pink

Blue

Red

Table 9 - M12, 8 pins RX

Page 19

EOS2 SAFETY LIGHT CURTAIN

18 8540738 • 05/12/2017 • Rev.20

English

EOS2XS - EOS2XS2 (SLAVE/SLAVE2 models) - M12, 5-pin primary connectors.

Brown

White

Blue

Black

Grey

Table 10 - M12, 5 pins Primary Slave RX

EOS2XM (MASTER models) - M12, 5-pin Secondary Connector.

EOS2XS2 (SLAVE2 models) - M12, 5-pin Secondary Connector.

Brown

White

Blue

Black

Grey

Table 11 - M12, 5 pin Secondary RX

Warnings regarding connection cables

Page 20

EOS2 SAFETY LIGHT CURTAIN

8540738 • 05/12/2017 • Rev.20 19

English

Configuration and operating modes

(Master Models / With integrated control functions)

( )

(via set of NC contacts of K1K2)

( )

(via RESTART

button)

( )

(via RESTART button and set of NC

contacts of K1K2)

( )

Table 12 –Setting of manual/automatic mode

Automatic operation

Manual operation

Page 21

EOS2 SAFETY LIGHT CURTAIN

20 8540738 • 05/12/2017 • Rev.20

English

Connection of external contactors K1 and K2

Figure 17 - Automatic

Figure 18 – Automatic with K1K2 feedback

Figure 19 - Manual

Figure 20 – Manual with K1K2 feedback

Page 22

EOS2 SAFETY LIGHT CURTAIN

8540738 • 05/12/2017 • Rev.20 21

English

Examples of connection with REER safety modules

Figure 21 - EOS2 A: Manual operation with AD SR1 module

Figure 22 - EOS2 X: Automatic operation with AD SR0 module

Page 23

EOS2 SAFETY LIGHT CURTAIN

22 8540738 • 05/12/2017 • Rev.20

English

Figure 23 - EOS2 X: Connection examples

Page 24

EOS2 SAFETY LIGHT CURTAIN

8540738 • 05/12/2017 • Rev.20 23

English

Figure 24 - EOS2 A: Connection examples

Page 25

EOS2 SAFETY LIGHT CURTAIN

24 8540738 • 05/12/2017 • Rev.20

English

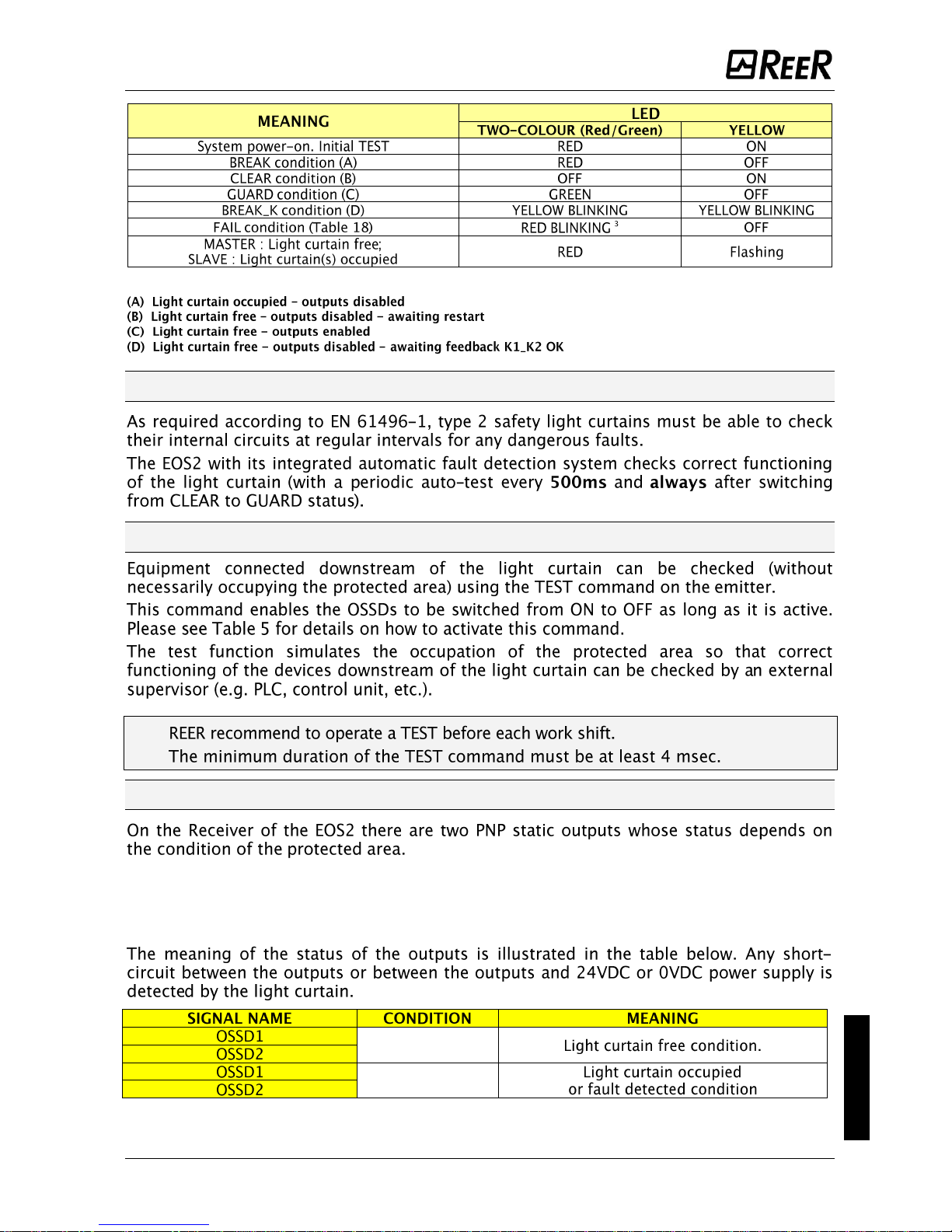

OPERATION AND TECHNICAL DATA

Light signals

Figure 25 - Light signals

Emitter light signals

Table 13 – TX light signals

Receiver light signals

Table 14 – RX light signals EOS2 A / EOS2 Slave

Table 15 – RX light signals EOS2 X (With integrated control functions)

chapter

Page 26

EOS2 SAFETY LIGHT CURTAIN

8540738 • 05/12/2017 • Rev.20 25

English

Table 16 – RX light signals EOS2 (Master)

Internal TEST function

Periodical system TEST

Status of the outputs

The maximum permissible load for each output is 400mA@24VDC, corresponding to a resistive load of 60

.

The maximum OFF-state voltage is < 0,5VDC.

The maximum output current in OFF-state (leakage current) is <2mA.

The maximum load capacity corresponds to 0.82

F@24VDC.

24VDC

0VDC

Table 17 - Status of the outputs

Page 27

EOS2 SAFETY LIGHT CURTAIN

26 8540738 • 05/12/2017 • Rev.20

English

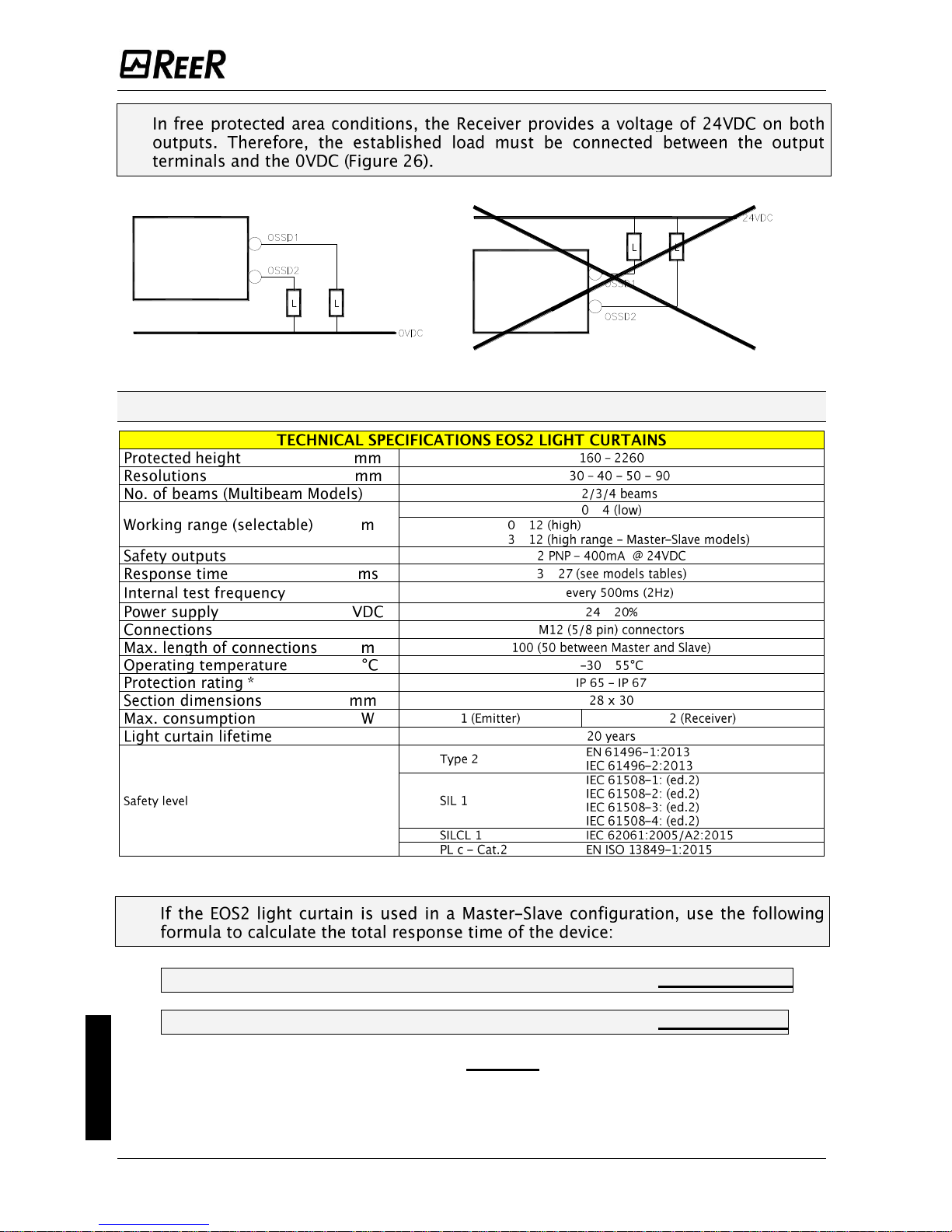

Figure 26 – Correct load connection on the outputs

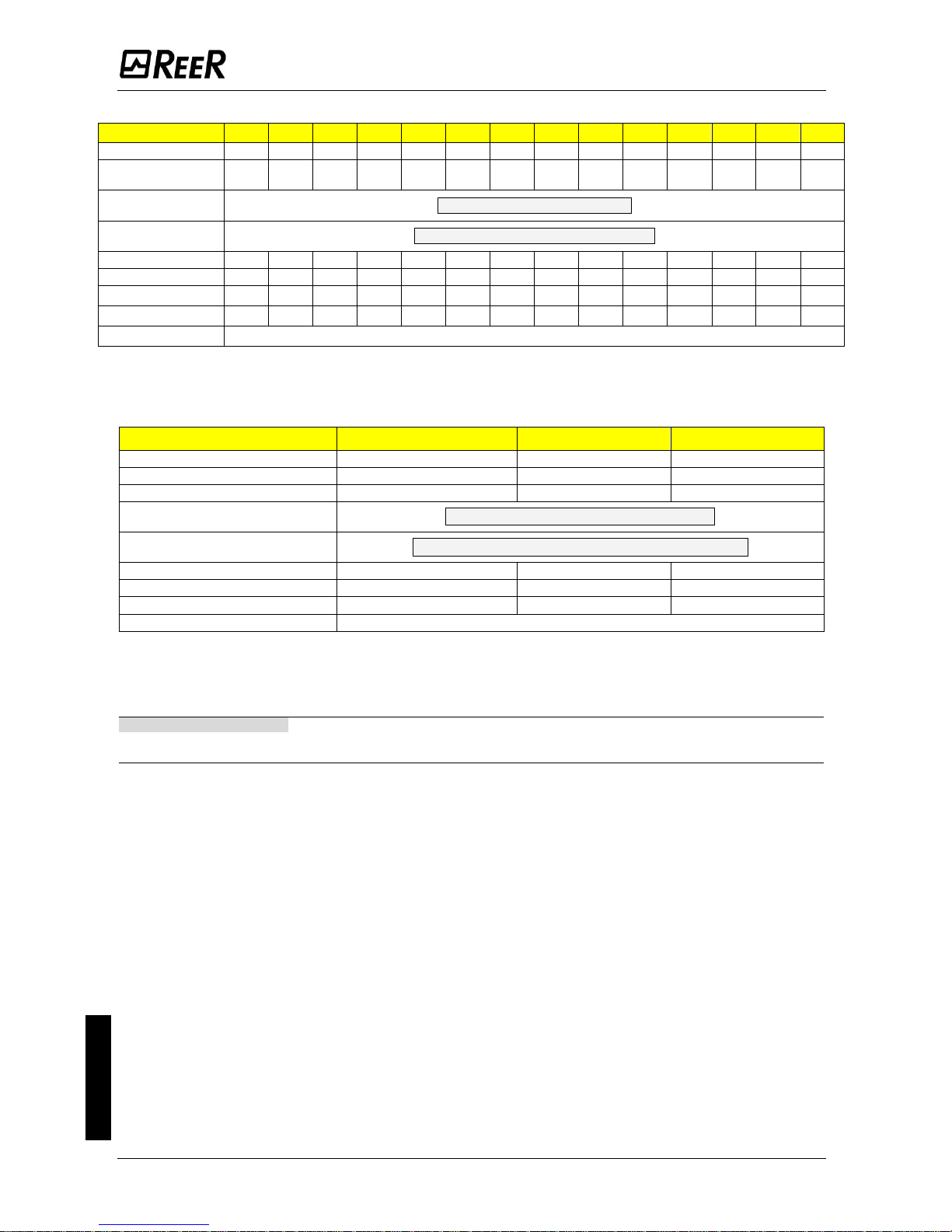

Technical specifications

*) Devices are not suitable for outdoor use without supplementary measures

t

tot

= [0,1104 * (Nr

slave1

+ Nr

master

) + 1,1044] * 2 (Master + 1 slave)

t

tot

= [0,1104 * (Nr

slave1

+ Nr

slave2

+ Nr

master

) + 1,3228] * 2 (Master +2 slave)

CAPTION

t

tot

= Total response time Nr = number of beams (of the model selected)

RECEIVER

RECEIVER

Max. load

400mA

Max. load

400mA

Page 28

EOS2 SAFETY LIGHT CURTAIN

8540738 • 05/12/2017 • Rev.20 27

English

30 mm Resolution Models

153

253

303

453

603

753

903

1053

1203

1353

1503

1653

1803

1953

2103

2253

Number of beams

8

13

16

23

31

38

46

53

61

68

76

83

91

98

106

113

Response time

(EOS models)

ms

4,5

5,5 6 8

10

11

13

14,5

16

17,5

19,5

21

22,5

24

25,5

27

Response time

(Master + 1 slave)

ms

t

tot

= [0,1104 * (Nr

slave1

+ Nr

master

) + 1,1044] * 2

Response time

(Master + 2 slaves)

ms

t

tot

= [0,1104 * (Nr

slave1

+ Nr

slave2

+ Nr

master

) + 1,3228] * 2

Protected height

mm

160

260

310

460

610

760

910

1060

1210

1360

1510

1660

1810

1960

2110

2260

PFHd *

2,05E-08

2,56E-08

2,67E-08

3,31E-08

3,93E-08

4,58E-08

5,19E-08

5,84E-08

6,46E-08

7,10E-08

7,72E-08

8,37E-08

8,98E-08

9,63E-08

1,02E-07

1,09E-07

DCavg #

91,3%

91,1%

91,0%

90,9%

90,7%

90,6%

90,6%

90,5%

90,5%

90,4%

90,4%

90,4%

90,3%

90,3%

90,3%

90,3%

MTTFd #

years

485,1

399,1

384,3

315,6

269,6

233,9

207,6

185,8

168,8

154,1

142,3

131,7

122,9

114,9

108,2

102,0

CCF #

80%

40 mm Resolution Models

154

254

304

454

604

754

904

1054

1204

1354

1504

1654

1804

1954

2104

2254

Number of beams

6 9 11

16

21

26

31

36

41

46

51

56

61

66

71

76

Response time

(EOS models)

ms

4

4,5 5 6

7,5

8,5

9,5

10,5

11,5

13

14

15

16

17

18

19

Response time

(Master + 1 slave)

ms

t

tot

= [0,1104 * (Nr

slave1

+ Nr

master

) + 1,1044] * 2

Response time

(Master + 2 slaves)

ms

t

tot

= [0,1104 * (Nr

slave1

+ Nr

slave2

+ Nr

master

) + 1,3228] * 2

Protected height

mm

160

260

310

460

610

760

910

1060

1210

1360

1510

1660

1810

1960

2110

2260

PFHd *

1,84E-08

2,29E-08

2,30E-08

2,75E-08

3,22E-08

3,67E-08

4,13E-08

4,58E-08

5,05E-08

5,50E-08

5,96E-08

6,41E-08

6,88E-08

7,33E-08

7,79E-08

8,24E-08

DCavg #

91,5%

91,2%

91,2%

91,0%

90,9%

90,8%

90,7%

90,6%

90,6%

90,5%

90,5%

90,5%

90,4%

90,4%

90,4%

90,4%

MTTFd #

years

532,9

440,1

438,1

373,4

324,3

287,4

257,4

233,6

213,4

196,8

182,2

170,0

159,0

149,6

141,0

133,6

CCF #

80%

50 mm Resolution Models

155

305

455

605

755

905

1055

1205

1355

1505

1655

1805

1955

2105

2255

Number of beams

4 8 12

16

20

24

28

32

36

40

44

48

52

56

60

Response time

(EOS models)

ms

3,5

4,5

5,5 6 7 8 9

10

10,5

11,5

12

13

14

15

16

Response time

(Master + 1 slave)

ms

t

tot

= [0,1104 * (Nr

slave1

+ Nr

master

) + 1,1044] * 2

Response time

(Master + 2 slaves)

ms

t

tot

= [0,1104 * (Nr

slave1

+ Nr

slave2

+ Nr

master

) + 1,3228] * 2

Protected height

mm

160

310

460

610

760

910

1060

1210

1360

1510

1660

1810

1960

2110

2260

PFHd *

1,76E-08

2,13E-08

2,48E-08

2,85E-08

3,20E-08

3,58E-08

3,92E-08

4,30E-08

4,64E-08

5,02E-08

5,36E-08

5,74E-08

6,08E-08

6,46E-08

6,80E-08

DCavg #

91,5%

91,3%

91,1%

91,0%

90,9%

90,8%

90,7%

90,7%

90,6%

90,6%

90,6%

90,5%

90,5%

90,5%

90,4%

MTTFd #

years

553,7

468,4

410,2

361,5

325,8

294,3

270,2

248,2

230,8

214,5

201,5

188,9

178,7

168,8

160,6

CCF #

80%

WITH:

N

rslave1

= number of beams of slave1

N

rslave2

= number of beams of slave2

N

rmaster

= number of beams of master

* IEC 61508

#

EN ISO 13849-1

t

tot

= total response time

Page 29

EOS2 SAFETY LIGHT CURTAIN

28 8540738 • 05/12/2017 • Rev.20

English

90 mm Resolution Models

309

459

609

759

909

1059

1209

1359

1509

1659

1809

1959

2109

2259

Number of beams

4 6 8

10

12

14

16

18

20

22

24

26

28

30

Response time

(EOS models)

ms

3,5 4 4,5 5 5,5 6 6

6,5 7 7 8 8 9 9

Response time

(Master + 1 slave)

ms

t

tot

= [0,1104 * (Nr

slave1

+ Nr

master

) + 1,1044] * 2

Response time

(Master + 2 slaves)

ms

t

tot

= [0,1104 * (Nr

slave1

+ Nr

slave2

+ Nr

master

) + 1,3228] * 2

Protected height

mm

310

460

610

760

910

1060

1210

1360

1510

1660

1810

1960

2110

2260

PFHd *

1,83E-08

2,06E-08

2,28E-08

2,51E-08

2,73E-08

2,96E-08

3,18E-08

3,42E-08

3,64E-08

3,87E-08

4,09E-08

4,32E-08

4,54E-08

4,77E-08

DCavg #

91,5%

91,3%

91,2%

91,1%

91,0%

91,0%

90,9%

90,8%

90,8%

90,7%

90,7%

90,7%

90,6%

90,6%

MTTFd #

years

536,2

483,6

442,2

405,7

376,2

349,5

327,3

306,9

289,7

273,6

259,8

246,8

235,5

224,8

CCF #

80%

Multibeam Models

2B

3B

4B

Number of beams 2 3

4

Distance between the beams mm

500

400

300

Response time ms

3

3,5

3,5

Response time

(Master +1 slave) ms

t

tot

= [0,1104 * (Nr

slave1

+ Nr

master

) + 1,1044] * 2

Response time

(Master + 2 slaves) ms

t

tot

= [0,1104 * (Nr

slave1

+ Nr

slave2

+ Nr

master

) + 1,3228] * 2

PFHd *

1,72E-08

1,87E-08

2,03E-08

DCavg

#

91,5%

91,4%

91,3%

MTTFd

#

years

564,8

524,1

488,9

CCF

#

80%

WITH:

N

rslave1

= number of beams of slave1

N

rslave2

= number of beams of slave2

N

rmaster

= number of beams of master

* IEC 61508

#

EN ISO 13849-1

t

tot

= total response time

Page 30

EOS2 SAFETY LIGHT CURTAIN

8540738 • 05/12/2017 • Rev.20 29

English

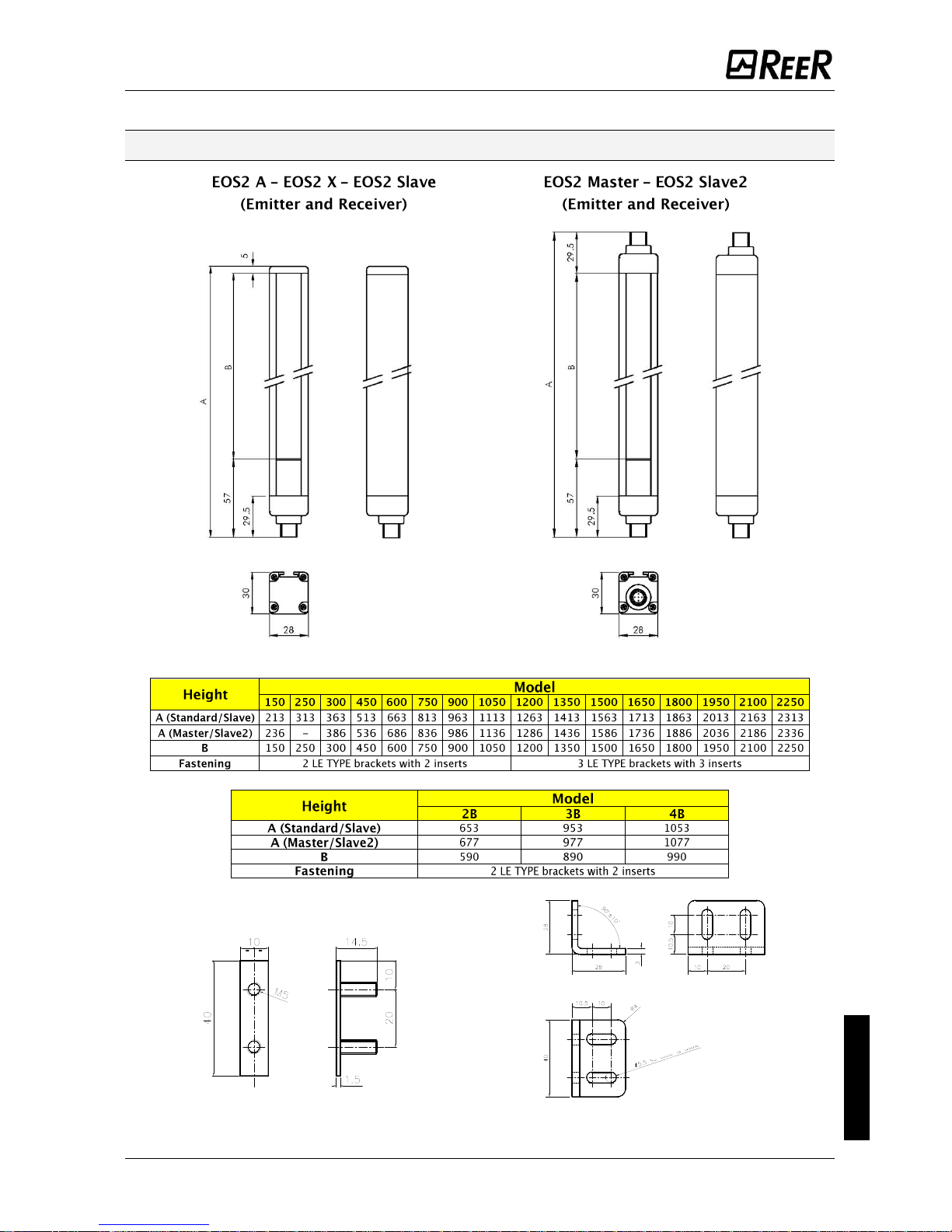

Dimensions

Figure 27 - Emitter and Receiver

Figure 28 - FIE inserts and LE fastening brackets (provided)

Page 31

EOS2 SAFETY LIGHT CURTAIN

30 8540738 • 05/12/2017 • Rev.20

English

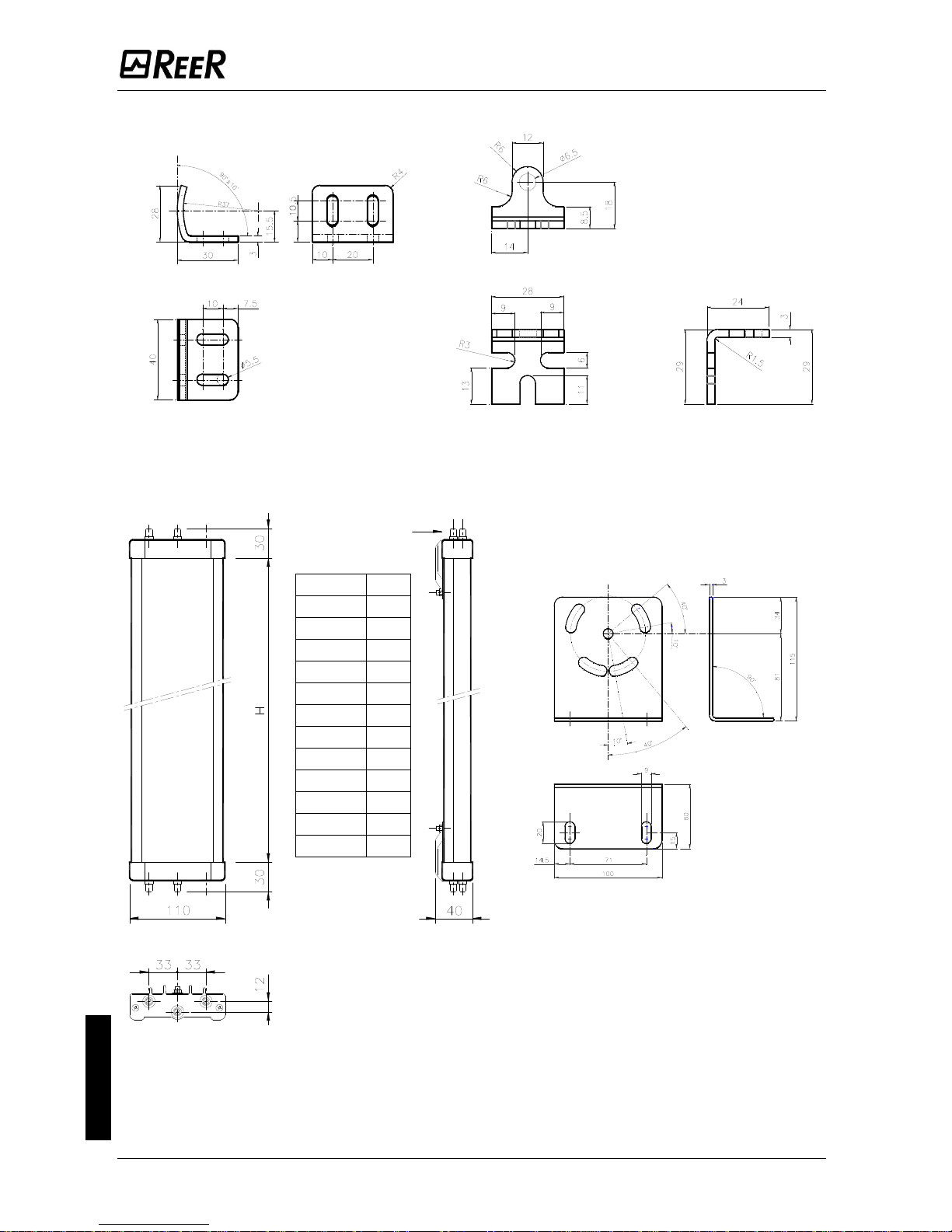

Figure 29 - Fastening brackets SFBE

Figure 30 - Fastening brackets SFB180E

Figure 31 - Deflection mirrors

Figure 32 - Fastening brackets for mirrors

Model

H

SP100S

250

SP300S

400

SP400S

540

SP600S

715

SP700S

885

SP900S

1060

SP1100S

1230

SP1200S

1400

SP1300S

1450

SP1500S

1600

SP1600S

1750

SP1800S

1900

M8 Inserts

Page 32

EOS2 SAFETY LIGHT CURTAIN

8540738 • 05/12/2017 • Rev.20 31

English

CHECKOUTS AND MAINTENANCE

Functional checks

chapter

Figure 33 – Efficiency check

Page 33

EOS2 SAFETY LIGHT CURTAIN

32 8540738 • 05/12/2017 • Rev.20

English

Troubleshooting

Check connections of pins 2 & 4.

Send to REER for repair.

Check model compatibility

Check condition of the Master.

If in FAIL condition, check the type of

fault.

If the fault persists, send the device to

ReeR laboratories for repair.

Check Master/Slave connections.

Reset of the system.

If the fault persists, send Master and

Slave to ReeR laboratories for repair

Check connections.

Carefully locate the interfering Emitter and

take action in one of the following ways:

Reduce the range of the interfering

Emitter from High to Low

Swap over the position of Emitter and

Receiver

Move the interfering Emitter so that it

does not illuminate the Receiver

Shield the beams emitted by the

interfering Emitter using opaque

protections

Check connections.

If the fault persists, send to REER for

repair.

Check Master/Slave connections

If the fault persists, send the device to

ReeR laboratories for repair.

Send the device to ReeR laboratories for

repair

Table 18 - Troubleshooting

Page 34

EOS2 SAFETY LIGHT CURTAIN

8540738 • 05/12/2017 • Rev.20 33

English

Page 35

EOS2 SAFETY LIGHT CURTAIN

34 8540738 • 05/12/2017 • Rev.20

English

Accessories/Spares

Page 36

EOS2 SAFETY LIGHT CURTAIN

8540738 • 05/12/2017 • Rev.20 35

English

GUARANTEE

Characteristics liable to modifications without prior notice. Complete or partial reproduction is forbidden without REER’s prior authorisation.

Page 37

Dichiarazione CE di conformità

EC declaration of conformity

Torino, 05/12/2017

REER SpA

via Carcano 32

10153 – Torino

Italy

dichiara che le barriere fotoelettriche EOS2 sono Dispositivi Elettrosensibili di Sicurezza (ESPE) di :

Tipo 2 (secondo la Norma EN 61496-1:2013; EN 61496-2:2013)

SIL 1 (secondo la Norma IEC 61508-1(ed.2); IEC 61508-2: (ed.2); IEC 61508-3: (ed.2); IEC 61508-4: (ed.2))

SILCL 1 (secondo la Norma IEC 62061:2005/A2:2015)

Cat.2 - PL c (secondo la Norma EN ISO 13849-1:2015)

declares that the EOS2 photoelectric safety barriers are :

Type 2 (according the Standard EN 61496-1:2013; EN 61496-2:2013)

SIL 1 (according the Standard IEC 61508-1(ed.2); IEC 61508-2: (ed.2); IEC 61508-3: (ed.2); IEC 61508-4: (ed.2))

SILCL 1 (according the Standard IEC 62061:2005/A2:2015)

Cat.2 - PL c (according the Standard EN ISO 13849-1:2015)

Electro-sensitive Protective Equipments (ESPE)

realizzati in conformità alle seguenti Direttive Europee:

complying with the following European Directives:

2006/42/EC "Direttiva Macchine"

"Machine Directive"

2014/30/EU "Direttiva Compatibilità Elettromagnetica"

"Electromagnetic Compatibility Directive"

e alle seguenti Norme: /and to the following Standards:

EN 50178: 1997

EN 55022: 2006

EN 61000-6-2: 2005

e sono identiche all'esemplare esaminato ed approvato con esame di tipo CE da:

and are identical to the specimen examined and approved with a CE - type approval by:

TÜV SÜD Product Service GmbH – Zertifizierstelle – Ridlerstraße 65 – 80339 – München – Germany

N.B. number: 0123 – Certificate No. Z10 16 05 24820 065

Carlo Pautasso Simone Scaravelli

Direttore Tecnico Amministratore Delegato

Technical Director Managing director

Page 38

REER S.p.A.

32 via Carcano

10153 Torino Italia

Tel. +39/0112482215 r.a.

Fax +39/011859867

Internet: www.reer.it

e-mail: info@reer.it

Loading...

Loading...