Page 1

Combiboard „QC08“

Item no.: 20 89 44

Version 06/11

Page 2

Table of Contents

1. Introduction .................................................................................................................... 3

2. Intended Use ................................................................................................................. 4

3. Scope of Delivery ........................................................................................................... 4

4. Explanation of Symbols ................................................................................................. 4

5. Product Description ....................................................................................................... 5

6. Safety Information .......................................................................................................... 6

a) General Information ................................................................................................ 6

b) Before Operation .................................................................................................... 7

c) During Operation .................................................................................................... 7

7. Notes on Batteries and Rechargeable Batteries ........................................................... 8

8. Connections and Displays ........................................................................................... 10

9. Connection Options ..................................................................................................... 11

a) Power Supply ........................................................................................................ 11

b) Connecting the Receiver ...................................................................................... 12

c) Composite Output Signal ...................................................................................... 13

d) LED Status Display ............................................................................................... 14

e) Interface Connection ............................................................................................. 15

f) Combiboard Commissioning ................................................................................ 15

g) Servo Connection ................................................................................................. 16

10. Light & Sound Function ............................................................................................... 17

a) Basic Information .................................................................................................. 17

b) Selecting the Light Mode ...................................................................................... 19

c) Selecting the RC Input .......................................................................................... 20

d) Connecting the LED Strips/LEDs ......................................................................... 21

e) Buzzer Configuration ............................................................................................ 23

11. PC Connection ............................................................................................................. 24

12. Maintenance and Care ................................................................................................ 25

13. Disposal ....................................................................................................................... 25

a) General Information .............................................................................................. 25

b) Batteries and Rechargeable Batteries .................................................................. 25

14. Technical Data ............................................................................................................. 26

Page

2

Page 3

1. Introduction

Dear Customer,

Thank you for purchasing this product.

This product complies with the applicable statutory, national and European specifications.

To maintain this status and to ensure safe operation, you as the user must observe these oper-

ating instructions!

These operating instructions are part of this product. They contain important

information concerning operation and handling. Please bear this in mind in

case you pass on the product to any third party.

Therefore, keep these operating instructions for future reference!

All company names and product names are trademarks of the respective owners. All rights

reserved.

In case of any technical questions, contact or consult:

Tel. no.: +49 9604 / 40 88 80

Fax. no.: +49 9604 / 40 88 48

E-mail: tkb@conrad.de

Mon. to Thur. 8.00am to 4.30pm

Fri. 8.00am to 2.00pm

3

Page 4

2. Intended Use

The “QC08” combiboard is solely designed for private use in the model construction area and for

the operating times associated with it.

The product must not become damp or wet. The electronics are designed for use at an operating

temperature from 0°C to +40°C.

This product is not suitable for other types of use. Any other use may damage the product.

Moreover, it would involve dangers such as short-circuit, fire, electric shock, etc. Observe the

safety instructions under all circumstances!

Observe all safety notes in these operating instructions. They contain important information regarding the handling of the product.

You are solely responsible for the safe operation of the model with composite signal

converter!

3. Scope of Delivery

• Combiboard “QC08”

• Receiver connection cable

• Interface foil cable

• Operating instructions

4. Explanation of Symbols

The symbol with the exclamation mark points out particular dangers associated with

handling, function or operation.

The “arrow” symbol indicates special advice and operating information.

4

Page 5

5. Product Description

The electronics are not protected from moisture and other environmental influences

and must only be used inside the model. The inputs and outputs are provided by

common plug connections or to be connected via the included cables.

The “QC08” combiboard is an electronics PCB ready for operation that enables different functions in a model.

1. Use of a common RC receiver for composite signal-controlled models such as the

QuadroCopter.

With a common receiver, a separate control signal is generated for each servo and sent to the

respective servo plug contact at the receiver. The composite signal converter on the combiboard

reassembles the different servo impulses and outputs them as a serial composite signal. Up to

8 channels can be used for formation of the composite signal.

The combiboard can be connected directly to the LiPo flight battery (3s1p) and then supplies the

receiver connected to the composite signal converter with a direct voltage of 5 V/DC.

2.Control of light effects and displays.

• Connection of up to 8 LEDs or LED strips

• Output of different light patterns via the connected LEDs or LED strips

• Control of the light patterns by channels 5 - 8

• Output of acoustic (warning) signals by a buzzer

3.Servo connection

Up to 4 servos (channels 5 – 8) can be connected to the combiboard and are then directly

controlled by the main control of the “QuadroCopter 450”.

5

Page 6

6. Safety Information

In case of damage caused by non-compliance with these safety instructions

the warranty / guarantee will become void. We do not assume any responsibility for consequential damage!

We do not assume any liability for damage to property or personal injury caused

by improper use or the failure to observe the safety instructions! In such cases

the warranty/guarantee is void.

Dear Customer,

These safety instructions are not only for the protection of the product but also for

your own safety and the safety of others. Therefore, read this chapter very carefully

before putting the product into operation!

a) General Information

Caution, important note!

Operating the model may cause damage to property and/or persons. Therefore, make

sure that you are properly insured when using the model, e.g. by taking out private

liability insurance. If you already have private liability insurance, inquire about whether

the operation of the model is covered before operating it.

• The unauthorized conversion and/or modification of the product is prohibited for safety and

approval reasons (CE).

• The product is not a toy and should be kept out of reach of children under 14 years of age.

• The product must not become damp or wet. The electronics are designed for use at an operating temperature from 0°C to +40°C.

• If you do not have sufficient knowledge yet of how to operate remote-controlled models and

RC systems, please contact an experienced model sportsman or a model construction club.

• Do not leave packaging material unattended. It may become a dangerous toy for children.

• Should questions arise that are not answered by this operating manual, contact us (for contact

information, see chapter 1) or another expert.

6

Page 7

b) Before Operation

• Make sure that no other models are operated within the range of the remote control on the

same remote control channel (transmitter frequency). Otherwise, you will lose control of the

remote-controlled models! Always use different channels if you wish to operate two or several

models in direct proximity of each other simultaneously.

• Always switch on the transmitter first and then connect the model’s drive battery at once.

• Check the functional reliability of your model and of the remote control system. Watch out for

any visible damage such as defective plug connections, loose screws or damaged cables.

• Charge the drive battery, which is necessary for operation, as well as the rechargeable battery

needed in the remote control according the instructions indicated by the manufacturer.

• When connecting LEDs, servos or connection lines, ensure secure contact. Loose or loosened plug connections may cause interferences leading to loss of the model.

c) During Operation

• Do not take any risks when operating the product! Your own safety and that of your environment is solely down to you being responsible when dealing with the model.

• Improper operation can cause serious damage to people and property! Therefore make sure

to keep a sufficiently safe distance to persons, animals or objects during operation.

• Fly your model only if your ability to respond is unrestricted. The influence of tiredness, alcohol or medication can cause incorrect responses.

• Never switch off the remote control (transmitter) while the model is in use. After landing, always disconnect the drive battery from the model first. It is only after this that the remote

control may be turned off. Never switch off the transmitter during operation.

• Never expose your model or the remote control to direct sunlight or excessive heat for an

extended period of time.

7

Page 8

7. Notes on Batteries and Rechargeable Batteries

Despite the fact that handling batteries and rechargeable batteries in daily life nowadays is a matter of fact, there are still numerous dangers and problems involved. For

LiPo/Lion rechargeable batteries in particular, various regulations must be observed

under any circumstances due to their high energy content (in comparison to conventional NiCd or NiMH rechargeable batteries), because otherwise there is danger of

explosion and fire.

Ensure that you observe the following information and safety measures when handling batteries and rechargeable batteries.

• Keep batteries/rechargeable batteries out of the reach of children.

• Do not leave any batteries/rechargeable batteries lying around openly. There is a risk of batteries being swallowed by children or pets. If swallowed, consult a doctor immediately!

• Batteries/rechargeable batteries must never be short-circuited, disassembled or thrown into

fire. There is a danger of explosion!

• Leaking or damaged batteries/rechargeable batteries can cause chemical burns to skin when

touched without the use of adequate protective gloves.

• Do not recharge normal batteries. There is a risk of fire and explosion!

Only charge rechargeable batteries intended for this purpose. Use suitable battery chargers.

Batteries (1.5 V) are meant to be used once only and must be properly disposed of when

empty.

• Please observe correct polarity (plus/+ and minus/-)of a battery pack when connecting the

rechargeable battery. Wrong polarity may not only damage the flight model and the rechargeable batteries. There also is a risk of fire and explosion.

• Never charge the enclosed drive battery immediately after use. Always leave the drive battery

to cool off first (at least 10 - 15 minutes).

• Only charge intact and undamaged batteries. If the external insulation of the LiPo battery is

damaged or if the rechargeable battery is deformed or bloated, it must not be charged. In this

case there is serious danger of fire and explosion.

• Never damage the outer cover of a drive battery, do not cut the foil cover, and do not prick the

LiPo battery with sharp objects. There is a risk of fire and explosion!

8

Page 9

• Always remove the drive battery that is to be charged from the model and place it on a fireproof support. Keep distance to flammable objects and never cover the rechargeable battery

or the charger.

• Never charge rechargeable batteries without supervision and only use chargers suitable for

the battery.

• Disconnect the batteries from the charger when they are fully charged.

9

Page 10

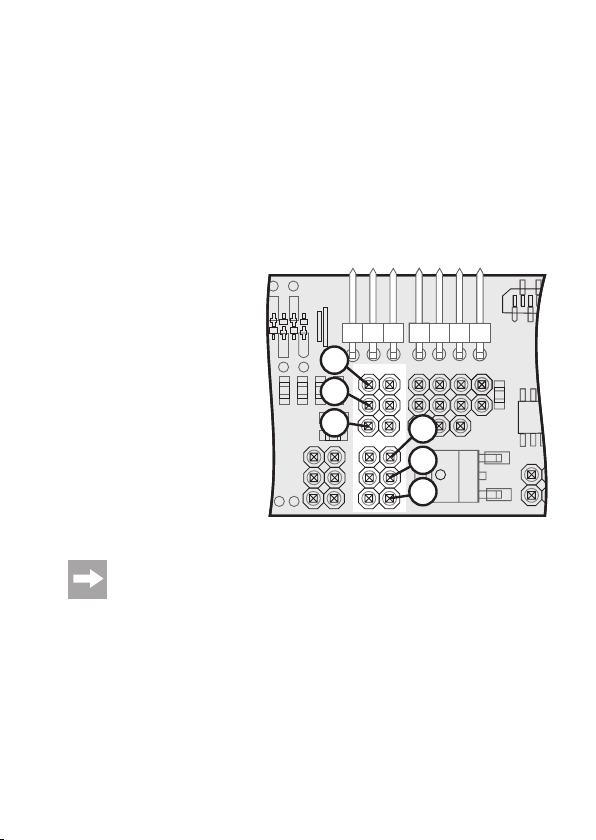

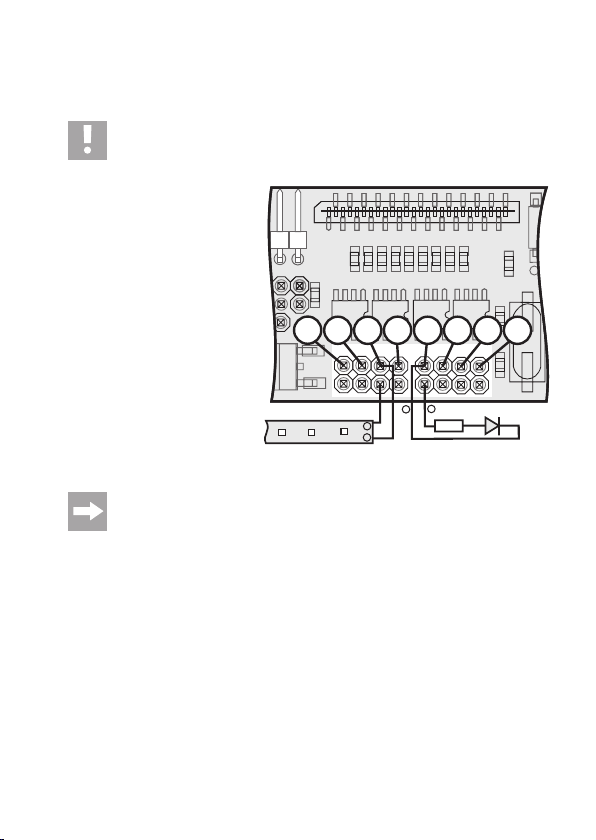

8. Connections and Displays

The combiboard has the following connection contacts

or jumper plugs:

PAD1: Plus soldering connection for supply voltage

(+)

PAD2: Minus soldering connection for supply voltage

(-)

LD1: Green LED indicator

LD2: Red LED indicator

X1: Jumper for buzzer

X2: Jumper for light mode

X3: Connection contacts for LED or LED-

strips 1 - 4

X4: Connection contacts for LED or LED-

strips 5 - 8

X5: Connection contacts for servo 1 (channel 5)

X6: Connection contacts for servo 2 (channel 6)

X7: Connection contacts for servo 3 (channel 7)

X8: Connection contacts for servo 4 (channel 8)

X9: Connection contacts for an external RC input

signal

X10: Connection strip for the broad interface cable

X11: Jumper for the interface selection

X12: Serial interface

X13: Connection sockets for the receiver cable

X14: Connection contacts for the composite signal

X15: Programming plug for production-related set-

tings

SW1: Jumper for the RC input selection

SW2: Reset button

BUZ1: Buzzer

For a detailed description of the different

contacts and the connection options, see the

following sections.

Figure 1

X1

BUZ1

SW2

C14

C14

C15

C15

C12

C12

C13

C13

C8

C8

C9

C9

C10

C10

C11

C11

C16

C16

X10

X10

X12

X11

X13

D1

+

X2

R6

R7

R3

R44

R45

R1

R23

R23

SW1

X7

X8

LD2

R43

C4

X14

PAD1

IC1

C1

Q1

Q1

C2

T3

T3

X3

T2

T2

T5

T5

X4

T4

T4

R2

R2

X9

IC2

X5

X6

R21

R22

X15

R41

R42

IC3

LD1

C17

R40

Q2

C18

C19

-

PAD2

C3

10

Page 11

9. Connection Options

Caution, important!

To use the full scope of functions of the combiboard, the QuadroCopter must have

firmware 2.1 or newer. Older QuadroCopter models can be updated to the current

software using the optional configuration sets. The respectively current firmware is

available online for download at conrad.de for the combiboard and QuadroCopter.

If you need more information on the current firmware, contact us (for contact information, see chapter 1).

a) Power Supply

For proper function, the combiboard must be used with the drive battery. For this, solder two

connection lines to the left side of the board, at the solder points “PAD1 (+)” and “PAD2 (-)”. For

the QuadroCopter, you can then lead the lines to the battery connection of one of the two motor

driver PCBs and attach them to the solder connections there.

There also is the option of supplying the combiboard via the balancer plug of the drive battery. In

this case, the 12 V connection lines of the combiboard must be equipped with a suitable plug

connector (like on the balancer connection of the charger). Only the respective outer contacts

are used for this.

Always ensure correct polarity of the connection lines.

Red = positive (+), black =

negative (-).

Attention!

The drive battery voltage is

at the same time supplied to

the combiboard through the

26-core broad cable. The

plug connections are, however, not intended for the

high power loads appearing

when using many LEDs.

+

PAD1

X14

-

PAD2

X13

D1

LD2

C4

R40

Q2

C18

C19

LD1

C17

IC3

R43

R42

R41

X15

R21

R22

X6

Figure 2

11

Page 12

b) Receiver Connection

The receiver is connected to the socket “X13”. A suitable connection cable for this is supplied

with the combiboard. The connection socket “X13” has 10 contacts that are numbered from the

right to the left. Contact 10 is on the left, contact 1 on the right.

The contacts are assigned as follows:

Contact 10 = Channel 1

Contact 9 = Channel 2

Contact 8 = Channel 3

Contact 7 = Channel 4

Contact 6 = Channel 5

Contact 5 = Channel 6

Contact 4 = Channel 7

Contact 3 = Channel 8

Contact 2 = 5 V/DC/Plus (+)

Contact 1 = GND/Minus (-)

+

PAD1

X14

-

PAD2

X13

D1

10

C4

R40

Q2

C18

C19

LD1

C17

IC3

The signals of the 8 inputs (channels 1 – 8) are measured and processed by the composite

signal converter. All available signals are combined into a composite signal pursuant to the

specifications for RC remote control systems (pulse width between 1 and 2 ms). Due to measuring of the signals and signal processing, there will be a delay of one frame length. However, this

has no effect during operation and is therefore only mentioned for the same of completeness.

The measured servo signals may appear in any order, parallel, in sequence or overlapping.

There are no limitations, so that the composite signal converter can be used for all common

systems. A synch break between the different signals is also not required.

To connect the receiver to the included connection cable, best use a servo connection cable.

Shorten it to the required length and then solder it to the open ends of the included receiver

connection cable. The soldering connections are then insulated with a shrink hose.

1

LD2

R43

R42

R41

X15

Figure 3

R21

R21

R22

X6

X6

12

Page 13

For the receiver’s power supply, it is sufficient to solder on the contacts 1 (minus/-)

and 2 (plus/+) to a single servo connection cable.

Important!

Observe that the composite signal converter inputs are assigned without gaps! In a

6-channel system, this means inputs 1 - 6 and not 1 - 4 and then 6 and 7. With this

assignment, the electronics would not recognised channels 6 and 7!

c) Composite Output Signal

The composite signal converter outputs the formed composite signal (SuS) at the upper contact

of the “X14” connection. This composite signal consists of so many single signals as measured

at the inputs. For example, if a 6-channel receiver is used, the composite signal also has 6

channels. Channel number recognition is performed via the valid signal measurement at the

inputs.

After removing the 35 MHz receiver from the QuadroCopter, connect the composite signal cable

to the connection “X14”. The impulse line must be connected to the upper contact of the “X14”

plug.

The "SuS", "+5V" and "GND" are to be connected to the corresponding connections of

the main PCB (Figure 4b) in the QuadroCopter. Observe connection of the two pin

bars with the correct polarity!

PAD1

X14

PAD2

+

-

SuS

+5V

GND

X13

D1

LD2

C4

R40

Q2

C18

C19

LD1

C17

R43

R42

R41

X15

IC3

Figure 4a

R21

R22

X6

Figure 4b

13

Page 14

d) LED Status Display

The composite signal converter has a green and a red LED for status display.

A green LED (LD1) indicates that the

electronics are in normal operation.

This means that servo signals can be

measured and if required a composite

signal can be generated. When the

greed LED goes out, there is a basic in-

+

PAD1

X14

terference in the electronics.

A red LED (LD2) shows that no servo

signals are present. The reasons fort his

may be receipt interference, missing

power supply of the receiver , switchedoff transmitter of contact errors in the

connection lines.

-

PAD2

Behaviour in case of receipt interferences

The composite signal converter measures the signal quality and thus also recognises receipt

interferences. Since channels 1 - 4 are mainly used for general control of models, they are

mainly targeted.

Interferences on channels 1 - 4

For these channels, verification of a valid pulse width (between 1 and 2 ms) is performed. If an

error is recognised, the composite signal is generated with the last valid value.

When the error rate exceeds the measure for proper receipt, the composite signal converter

does not output any composite signal anymore and activates the red LED. Now the receipt

problem can be recognised by the downstream logic and no receipt problems are concealed.

If the input signal is valid again, the red LED goes out and a composite signal is generated.

Interferences on channels 5 - 8

If the receipt interference only acts on channels 5 - 8, a composite signal continues to be generated for channels 1 - 4 and channels 5 - 8 are output with an invalid pulse length.

Thus, it is possible to continue to control the model, but the interference can be recognised by a

downstream logic at channels 5 - 8.

When the input signal is valid again, a regular composite signal is output.

X13

D1

Rot

LD1

C4

R40

Q2

C17

C18

C19

LD1

IC3

R42

Rot

LD2

R41

X15

LD2

R43

Figure 5

R21

R22

X6

14

Page 15

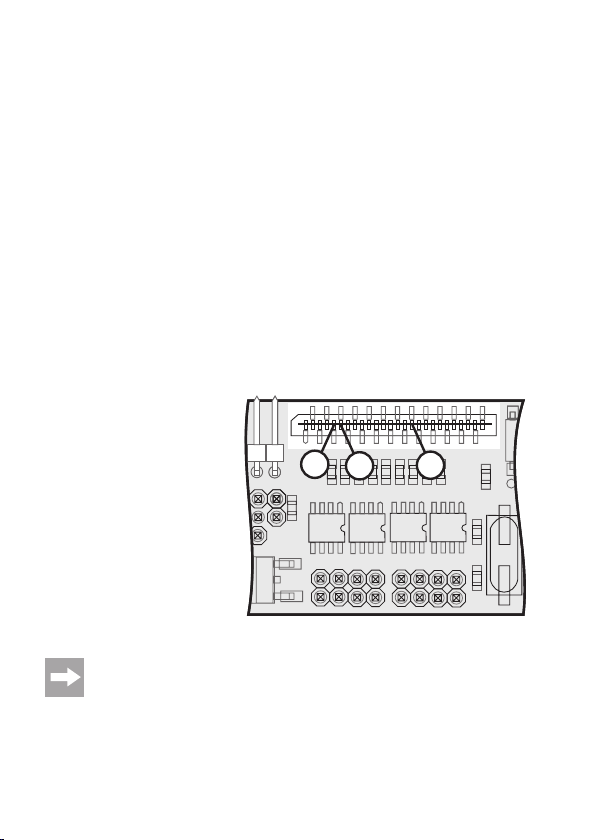

e) Interface Connection

For a connection of the combiboard

to the control board of the QuadroCopter, the combiboard comes with a

26-wire foil cable that must be connected to the connection strip for the

broad interface cable (“X10”).

Later when installing the combiboard

into the QuadroCopter, observe that

the two connection strips for the broad

interface cable (combiboard and control board) are exactly across from

each other.

Connection is performed in the same

way as a connection between the two

motor driver boards and the control

board.

X10

X10

C16

C9

C8

C16

C9

C8

C13

C13

C11

C11

1

R2

R2

T4

T4

X9

IC2

X4

C12

C12

C10

C10

T5

T5

C15

C15

C14

C14

R23

R23

26

T3

T3

T2

T2

X3

Q1

Q1

C2

C3

Figure 6

f) Combiboard Commissioning

When the combiboard is connected to the receiver and the composite signal cable, the supply

voltage and interface foil cable are connected to the QuadroCopter , it is required that you teach

in the channel assignment of the remote control in the QuadroCopter.

The precise approach can be taken from the QuadroCopter operating instructions.

15

Page 16

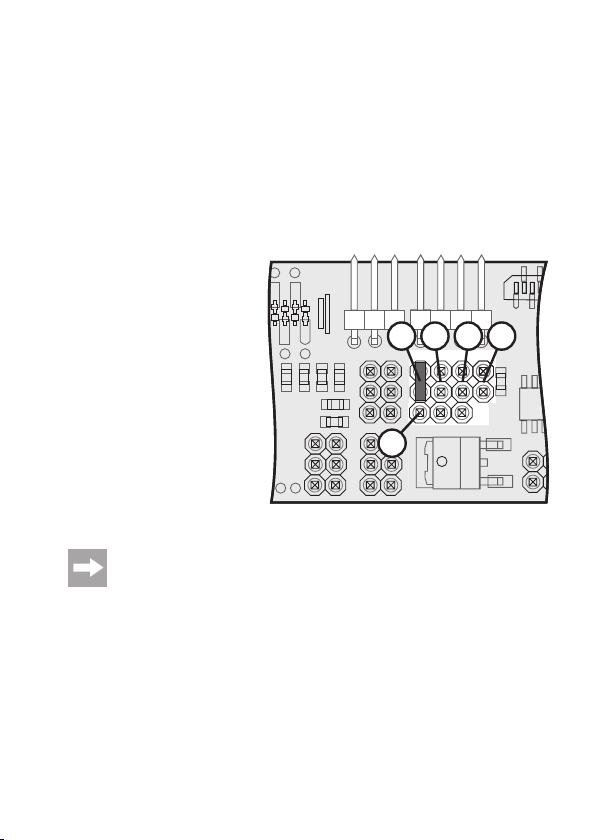

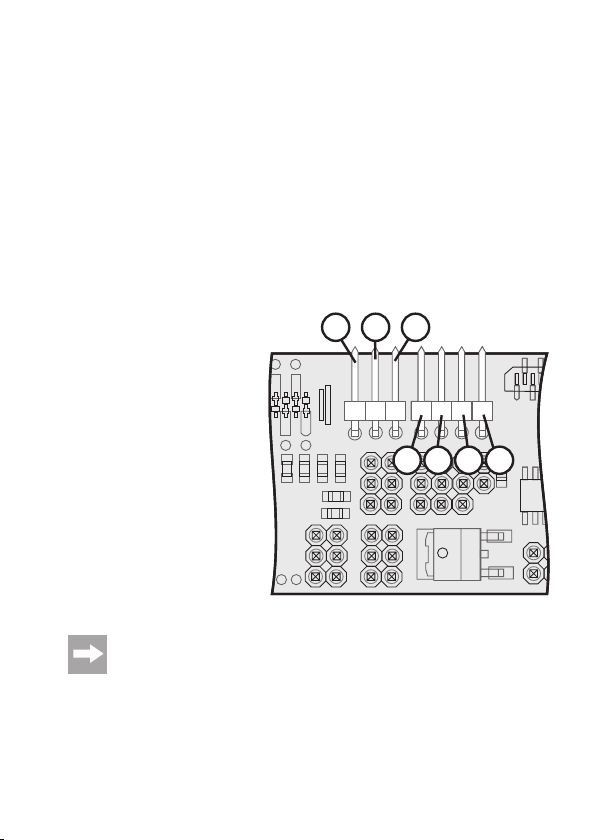

g) Servo Connection

When the combiboard is installed in the QuadroCopter and the remote control was taught in, up

to four servos (channel 5 – 8) can be connected and operated by remote control. However, this

is only possible when the transmitter and the receiver provide these functions and the respective

receiver outputs are connected to the input plug of the composite signal converter (“X13”).

The following plug contacts are intended for the servo connection:

X5: Servo 1 (Receiver output/channel 5)

X6: Servo 2 (Receiver output/channel 6)

X7: Servo 3 (Receiver output/channel 7)

X8: Servo 4 (Receiver output/channel 8)

X10

X10

X11

PPM

X7

X8

LD2

R43

+

R42

R41

X15

R21

-

PPM

R22

+

X5

X6

-

Please observe when connecting the servos that the impulse line (PPM) always has

to be connected to the upper pin of the three contact plugs!

16

X12

SW1

IC2

R2

R2

T

X9

Figure 7

Page 17

10. Light & Sound Function

a) General Information

The combiboard has eight LED outputs (“L1” to “L8”), and three digital inputs (“IN-1”, “IN-2”,

“IN-3”) and an external RC input (“PPM”) in addition to the composite signal converter.

Targeting of the LED outputs can be configured via 7 different modes.

The electronics either generate a fixed pattern on the outputs or the outputs are switched de-

pending on the input signals. The jumpers can be used to set modes, which can also be switched

into three states by a RC signal (channels 5, 6, 7, 8 or external). Thus, it becomes possible to

switch during flight.

Digital inputs:

The digital inputs switch the respective outputs when the respective mode was selected. A high

signal (+5 V) means that an output is switched on. The connected LED or the connected LED

strip is lit.

The three digital inputs are located at the interface connection “X10” and are assigned as follows:

IN-1 = Contact 6

IN-2 = Contact 5

IN-3 = Contact 16

Through the 3 digital inputs, different status displays or error messages of the

QuadroCopter can be displayed well visibly. The function of the output signals mainly

depend on the firmware used and can change during further development of the

QuadroCopter.

X10

X10

C16

C9

C8

C16

C9

C8

C13

C13

C11

C11

IN-2

IN-1

R2

R2

T4

T4

X9

IC2

X4

C12

C12

C10

C10

T5

T5

C15

C15

C14

C14

R23

R23

IN-3

T3

T3

T2

T2

Q1

Q1

C2

X3

C3

Figure 8

17

Page 18

A more detailed description with assignment of the 3 digital inputs can be taken from the text file

r

g

g

g

g

g

g

g

g

g

g

of the respective firmware.

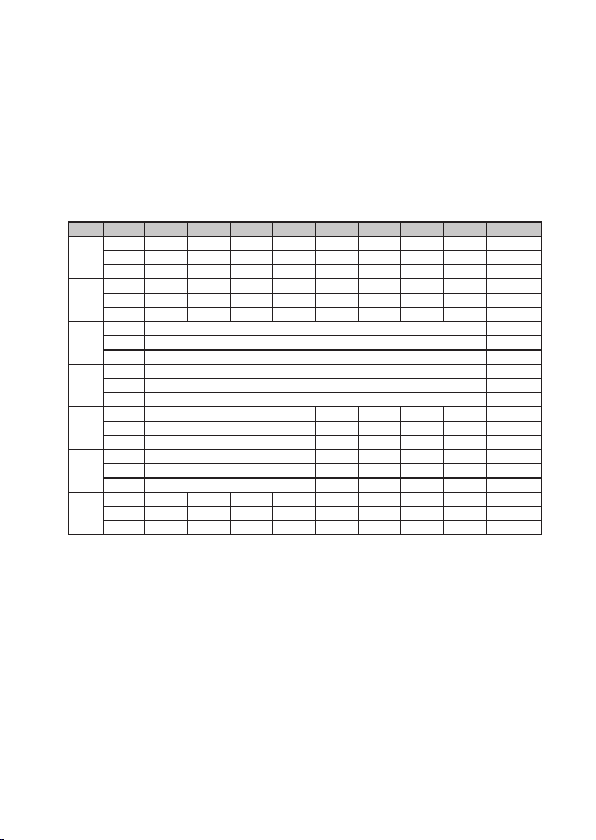

RC Input:

Using the RC input, you may switch every light mode to three different switching states. Use a

switch on the transmitter with a centre position (high, neutral, low) or a slider or rotary control.

For switching the light mode, you may use channels 5 – 8 or an externally fed servo signal

(PPM).

In connection with the 7 different modes, the following light patterns result:

Mode PPM L1 L2 L3 L4 L5 L6 L7 L8 Buzze

High IN-1 IN-2 IN-3 DF SF SB DF Bat Bat

1 Neutral IN-1 IN-2 IN-3 DF SF SB OFF Bat Bat

Low IN-1 IN-2 IN-3 DF SF SB ON Bat Bat

Hi

h IN-1 IN-2 IN-3 DF SF SB DF Bat IN-3

2 Neutral IN-1 IN-2 IN-3 DF SF SB OFF Bat IN-3

Low IN-1 IN-2 IN-3 DF SF SB ON Bat IN-3

Hi

h Running light L1 to L8 IN-3

3 Neutral OFF IN-3

Low Runnin

Hi

h Inverted running light L1 to L8 IN-3

4 Neutral OFF IN-3

Low Inverted runnin

Hi

h Running light L1 to L4 IN-1 IN-3 SB Bat IN-3

5 Neutral OFF IN-1 IN-3 SB Bat IN-3

Low Runnin

Hi

h Inverted running light L1 to L4 IN-1 IN-3 SB Bat IN-3

6 Neutral OFF IN-1 IN-3 SB Bat IN-3

Low Inverted runnin

Hi

h WB1 WB2 IN-1 IN-2 IN-3 SF DF Bat IN-3

7 Neutral WB1 WB2 IN-1 IN-2 IN-3 SF OFF Bat IN-3

Low WB1 WB2 IN-1 IN-2 IN-3 SF ON Bat IN-3

light L4 to L1 IN-1 IN-3 SB Bat IN-3

light L4 to L1 IN-1 IN-3 SB Bat IN-3

light L8 to L1 IN-3

light L8 to L1 IN-3

Meaning of the abbreviations:

SB: Slow Blink (400 ms on, 400 ms off)

FB: Fast Blink (200 ms on, 200 ms off)

SF: Single Flash (50 ms, 1 s pause)

DF: Double Flash (50 ms, 50 ms, 1 s pause)

Bat: Battery warning in 5 stages

(>9.4 V = OFF; <9.4 V = SF; <9.2 V = DF; <9.0 V = SB; <8.8 V = FB)

WB1, WB2: Alternative flashing (alternation every 100 ms)

Running light speed: Alternation every 100 ms

18

Page 19

b) Selecting the Light Mode

You can now set 7 light modes using the jumper plug (“X2”). Depending on the desired mode,

the different contacts must be connected with a jumper. Set the following jumpers for the following modes:

Mode 1: No jumper

Mode 2: Jumper 1 - 2

Mode 3: Jumper 3 - 4

Mode 4: Jumper 1 - 2 and Jumper 3 - 4

Mode 5: Jumper 2 - 4

Mode 6: Jumper 1 - 3

Mode 7: Jumper 1 - 3 and Jumper 2 - 4

SW2

C12

C12

C15

C15

C14

C14

R23

R23

T3

T3

Q1

Q1

C2

X3

BUZ1

X1

R7

R45

R1

C1

R44

IC1

R6

R3

1

3

2

X2

4

C3

5

6

Figure 9

19

Page 20

c) Selecting the RC Input

The desired RC input for switching the light effect can be set using the jumper SW1. Always

connect the upper and lower contacts with the jumper. Assignment is as follows:

Servo selection 1 = channel 8

Servo selection 2 = channel 7

Servo selection 3 = channel 6

Servo selection 4 = channel 5

In the illustration on the side, the jumper is set to servo selection 1. You can now switch the set

light mode at the transmitter via channel 5.

X10

X10

X11

1

X7

X8

LD2

R43

R42

R41

R21

R22

X15

PPM

X5

X6

Control via channels 5, 6, 7 or 8 is only possible where they are also generated by

the main control. Signal generation is independent from the composite signal converter!

If this is not the case, you are able to directly feed an external servo signal (PPM) into

the left connection contact of the “X9” plug of an unassigned receiver output (e.g.

channel 9).

If you do not use any RC input and thus waive the possibility of switching, PPM

switching state “high” will always be active!

20

X12

3

SW1

IC2

4

R2

R2

T

X9

2

Figure 10

Page 21

d) Connecting the LED Strips/LEDs

The combiboard offers the possibility of connecting up to eight LED strips with an operating

voltage of 12 V and a maximum power intake of 1 A/per strip. Even if the MOSFET switching

outputs (FDS6890A) can resist up to 7.5 A, it is recommended not to load the separate outputs

with more than 1 A due to the board layout and cooling.

If you want to connect individual LEDs with a lower operational voltage of only 2 – 3 V, a suitable

dropping resistor (Rv) must be calculated. For calculation of the dropping resistor, you should

use an operational voltage of 12 V, since a freshly charged 3-cell LiPo battery may have far more

than 12 V instead of 11.1 V.

Example calculation:

Assuming that the light diode used has a supply voltage of 2.6 V and a power intake of 20 mA,

first the dropping resistor voltage must be calculated:

12 V – 2.6 V = 9.4 V

If you want to switch two same light diodes in sequence, 2 x 2.6 V = 5.2 V must be

subtracted from the operating voltage of 12 V (12 V – 5.2 V = 6.8 V)

For three same diodes, this is 3 x 2.6 V = 7.8V to be subtracted from the operating

voltage of 12 V (12 V - 7.8 V = 4.2 V).

Now use Ohm’s law R = U : I to calculate the dropping resistance Rv:

Rv = 9.4 V: 0.02 A = 470 Ohm

Use the formula P = U x I to also calculate the output the dropping resistor must be able to

withstand:

9.4 V x 0.02 A = 0.188 W

A resistor with an output of ¼ W (0.25 W) would therefore be sufficient.

The respective upper connection contacts of the plugs “X3” (“L1” to “L4”) and “X4” (“L5” to “L8”)

are intended for the LEDs or LED strip connection. The lower connection contacts are connected to the plus connection (+) of the drive battery (11.1 V of the LiPo battery).

21

Page 22

Connection pattern

Image 11 shows the scheme for the connection of a LED with dropping resistor at the output „L1“

and the connection of a 12 V light strip at the output „L7“.

Important!

When connecting LEDs and LED light strips, observe correct polarity of the connection

lines.

X10

X10

C16

C11

C10C9C8

C13

C12

C15

L1

C14

C13

C12

C15

C14

R23

R23

T3

T3

T2

T2

+

Rv

L2

Q1

Q1

L3

L4

C2

X3

C3

LED

C16

C11

C10C9C8

R2

R2

X9

L5

IC2

L6

T5

T5

T4

T4

L8

L7

X4

-

+

12 V

-

Figure 11

In practice, pre-manufactured BEC sockets with open cable-ends have proven well

suitable for LED connection.

22

Page 23

e) Buzzer Configuration

The buzzer can be switched on or off with the jumper („X1“).

When the contacts 1 and 2 are connected with a jumper, the buzzer is off.

When the contacts 2 and 3 are connected with a jumper, the buzzer is on and outputs signals

according to the modes table.

SW2

C12

C12

C15

C15

C14

C14

R23

R23

T3

T3

Q1

Q1

C2

X3

C3

BUZ1

3

X1

2

R7

R45

R1

C1

IC1

1

R6

R44

R3

X2

Figure 12

23

Page 24

11. PC Connection

The Combiboard has a serial interface like the control board of the QuadroCopter. The electronics can communicate with a computer via those interfaces.

Using the jumper „X11“, the serial interface of the combiboard can either communicate with the

control board of the QuadroCopter (2nd internal interface) via the 26-core interface cable or be

switched to the interface connection „X12“. This function is used for future expansions and is

currently without function.

When the contacts 1 and 2 are connected with a jumper, the interface at the control board of the

QuadroCopter is active. When the contacts 2 and 3 are connected with a jumper, the interface at

the Combiboard („X12“) is active.

For the pin assignment of the interface plug „X12“, see figure 13.

3

2

1

X10

X10

X11

X7

X8

LD2

R43

R42

R41

X15

GND

R21

R22

X5

X6

If the computer interface in the computer does not have sufficient power supply for

the electronics in the QuadroCopter, the drive battery must be connected to the

QuadroCopter.

24

X12

SW1

TXD RXD

IC2

X9

R2

R2

+5V

Figure 13

T

Page 25

12. Maintenance and Care

The electronics do not require any maintenance or care but should be protected from outside

influences such as moisture or wetness.

13. Disposal

a) General Information

At the end of its service life, dispose of the product according to the relevant statutory

regulations.

b) Batteries and Rechargeable Batteries

You as the end user are required by law (Battery Ordinance) to return all used batteries/rechargeable batteries. Disposing of them in the household waste is prohibited!

Batteries/rechargeable batteries that include hazardous substances are labelled with

these icons to indicate that disposal in domestic waste is forbidden. The descriptions

for the respective heavy metal are: Cd = cadmium, Hg = mercury, Pb = lead (the

names are indicated on the battery/rechargeable battery e.g. below the rubbish bin

icons shown to the left).

You may return used batteries/rechargeable batteries free of charge to any collecting

point in your local community, in our stores or everywhere else where batteries/

rechargeable batteries are sold.

You thus fulfil your statutory obligations and contribute to the protection of the environment.

25

Page 26

14. Technical Data

Power supply: LiPo rechargeable battery (3s1p) ... 11.1 V

Channel number of composite signal converter ..... max. 8

Servo connections .................................................. 4

Digital inputs ........................................................... 3

LED ports ................................................................ 8

Power resistance per LED output ........................... 1,000 mA

PPM Inputs ............................................................. 1

Dimensions (LxWxH) .............................................. 100 x 30 x 20 mm

PCB weight without cable and plug ........................ Approx. 20 g

Working temperature range .................................... 0 °C to +40 °C

26

Page 27

27

Page 28

Legal Notice

These operating instructions are a publication by Conrad Electronic SE, Klaus-Conrad-Str. 1, D-92240 Hirschau (www.conrad.com).

All rights including translation reserved. Reproduction by any method, e.g. photocopy, microfilming, or the capture in electronic

data processing systems require the prior written approval by the editor. Reprinting, also in part, is prohibited.

These operating instructions represent the technical status at the time of printing. Changes in technology and equipment reserved.

© Copyright 2011 by Conrad Electronic SE.

V3_0611_01

Loading...

Loading...