Page 1

QuadroCopter „650“ ARF

Item no.: 20 93 00

Operating Instructions

¨

¨

Version 11/10

Page 2

1. Introduction .......................................................................................................................................................... 4

2. Intended Use ....................................................................................................................................................... 5

3. Product Description ............................................................................................................................................. 5

4. Scope of Delivery ................................................................................................................................................ 6

5. Explanation of Symbols ....................................................................................................................................... 7

6. Safety Information ............................................................................................................................................... 7

7. Notes on Batteries and Rechargeable Batteries .............................................................................................. 10

8. Final Assembly of the QuadroCopter ................................................................................................................ 12

9. Checking the Configuration ............................................................................................................................... 18

10. Before Each Use ............................................................................................................................................... 25

11. Safety Devices................................................................................................................................................... 27

Table of Contents

a) General Information ...................................................................................................................................... 7

b) Before Operation ........................................................................................................................................... 8

c) During Operation ........................................................................................................................................... 8

a) Transmitter .................................................................................................................................................. 10

b) Flight Battery ............................................................................................................................................... 11

a) Assembly of the Landing Legs .................................................................................................................... 12

b) Assembly of the Rotors ............................................................................................................................... 14

c) Connecting the Receiver ............................................................................................................................. 15

d) Installing the Flight Battery ..........................................................................................................................16

e) Assembly of the Upper Cover Hood ........................................................................................................... 17

a) General Information .................................................................................................................................... 18

b) Programming of Transmitter Channels (General) ...................................................................................... 19

c) Programming of “Throttle” ........................................................................................................................... 20

d) Programming of “Yaw” ................................................................................................................................ 20

e) Programming of “Pitch” ............................................................................................................................... 20

f) Programming of “Roll” ................................................................................................................................. 21

g) Setting the Flight Mode ............................................................................................................................... 22

h) Configuration with PC Software .................................................................................................................. 23

i) Possible Flight Modes ................................................................................................................................. 24

a) Checking the Connections .......................................................................................................................... 25

b) Checking Movable Parts ............................................................................................................................. 25

c) Adjustment of the Neutral Position ............................................................................................................. 25

a) Motor Protection .......................................................................................................................................... 27

b) Emergency Landing .................................................................................................................................... 27

c) Low Voltage Monitoring............................................................................................................................... 27

d) Finder function ............................................................................................................................................ 27

Page

2

Page 3

Page

12. LED Displays ..................................................................................................................................................... 28

a) Ready to Fly ................................................................................................................................................ 28

b) Starting the QuadroCopter .......................................................................................................................... 28

c) Configuration Mode ..................................................................................................................................... 28

d) RC Offset Adjustment.................................................................................................................................. 28

e) Adjustment of the Neutral Position ............................................................................................................. 28

f) Impaired Radio Link before Take-Off .......................................................................................................... 28

g) Impaired Radio Link during Flight Operation .............................................................................................. 29

h) Emergency Landing Function ..................................................................................................................... 29

i) Low Voltage Monitoring............................................................................................................................... 29

13. Combiboard “QC08” Information....................................................................................................................... 30

a) Connection Contacts or Jumper of the Combiboard .................................................................................. 30

b) Composite Signal Output ............................................................................................................................ 31

c) LED Status Display ..................................................................................................................................... 31

d) Interface Connection ................................................................................................................................... 32

e) Servo Connection........................................................................................................................................ 33

14. Light & Sound Function..................................................................................................................................... 34

a) General Information .................................................................................................................................... 34

b) Selecting the Light Mode ............................................................................................................................ 36

c) Selecting the RC Input ................................................................................................................................ 37

d) Connecting the LED Strips/LEDs................................................................................................................ 38

e) Buzzer Configuration................................................................................................................................... 39

15. Combiboard PC Connection: ............................................................................................................................ 40

16. Information for First Take-Off............................................................................................................................. 41

a) General Handling ........................................................................................................................................ 41

b) Starting the Motor ........................................................................................................................................ 41

c) Cutting the Motor ......................................................................................................................................... 41

d) Hover Flight ................................................................................................................................................. 42

e) Yaw .............................................................................................................................................................. 42

f) Pitch............................................................................................................................................................. 42

g) Roll .............................................................................................................................................................. 43

17. The First Flight................................................................................................................................................... 44

18. Maintenance, Care and Repair ......................................................................................................................... 45

a) Regular Cleaning ........................................................................................................................................ 45

b) Replacing the Rotors................................................................................................................................... 45

c) Replacing a Motor ....................................................................................................................................... 45

d) Replacing a Radial Arm .............................................................................................................................. 46

e) Replacing the Complete Frame .................................................................................................................. 46

f) Replacing the Stabiliser Plate ..................................................................................................................... 46

19. Disposal .............................................................................................................................................................47

a) General Information .................................................................................................................................... 47

b) Batteries and Rechargeable Batteries ........................................................................................................47

20. Technical Data ................................................................................................................................................... 48

3

Page 4

1. Introduction

Dear Customer,

Thank you for purchasing this product.

This product complies with the applicable statutory, national and European specifications.

To maintain this status and to ensure safe operation, you as the user must observe these operating instructions!

These operating instructions are part of this product. They contain important information concerning operation and handling. Please bear this in mind in case you pass on the product to any

third party.

Therefore, retain these operating instructions for reference!

All company names and product names are trademarks of their respective owners. All rights reserved.

In case of any technical questions, contact or consult:

Tel. no.: +49 9604 / 40 88 80

Fax. no.: +49 9604 / 40 88 48

E-mail: tkb@conrad.de

Mon. to Thur. 8.00am to 4.30pm, Fri. 8.00am to 2.00pm

Mon to Fri 8.00 am -12.00 pm, 1.00 pm - 5.00 pm

4

Page 5

2. Intended Use

The “QuadroCopter 650 ARF” is a flight model; solely designed for private use in the model making area and the

operating times associated with this.

This system is not suitable for other types of use. Any use other than the one described above may damage the

product. Moreover, it would involve dangers such as short-circuit, fire, electric shock, etc. Observe the safety instructions under all circumstances! The product must not get damp or wet!

The product is not a toy and should be kept out of reach of children under 14 years of age.

Observe all safety notes in these operating instructions. They contain important information regarding the

handling of the product.

You alone are responsible for the safe operation of the model! The chassis is assembled ready for use.

3. Product Description

The electric flight model “QuadroCopter 650 ARF” is pre-assembled as far as possible. In the professional field, such

flight devices are already used for the most diverse of tasks. The latest micro processor controlled electronics with

position control and acceleration sensor stabilise the QuadroCopter.

High quality brushless DC motors paired with a specially developed drive enable long and powerful flight operation

while still providing reserve for transporting loads such as cameras, etc. The novel steering and the electronic selfstabilisation result in excellent flight handling characteristics. Different flying programmes ensure that both beginners

and experts will be able to have their fun.

The QuadroCopter can be used both indoors and outdoors. The in-built electronic controls can balance out small

undesired changes to the flight altitude, but cannot remove them completely. The QuadroCopter weighs relatively little

and this is sensitive to wind. Therefore, ideal flying conditions are complete lack of wind to very gentle and even wind.

The lightweight aluminium designer frame and synthetic components are sturdy and enable excellent flight handling

characteristics. The frame is collapsible and therefore space-saving and easy to transport. The designer frame contains the complete set of electronics and has space for expansion plates. The grid construction makes for good

stability and good protection of the electronics at a low weight.

Due to its construction, the QuadroCopter is designed for experienced model helicopter pilots who do not just want to

carry out helicopter-like, but also sensational moves.

However, this extremely manoeuvrable model is also suitable for beginners! However, before the first flight, we recommend that beginners follow an appropriate training program in a flight simulator for helicopters and/or seek active

assistance from an experienced model helicopter pilot.

The model can be expanded by additional electronics (expansion interface available on the control unit) and the

mounting of several mechanisms on the platform mount fixture on the underside of the grid frame

5

Page 6

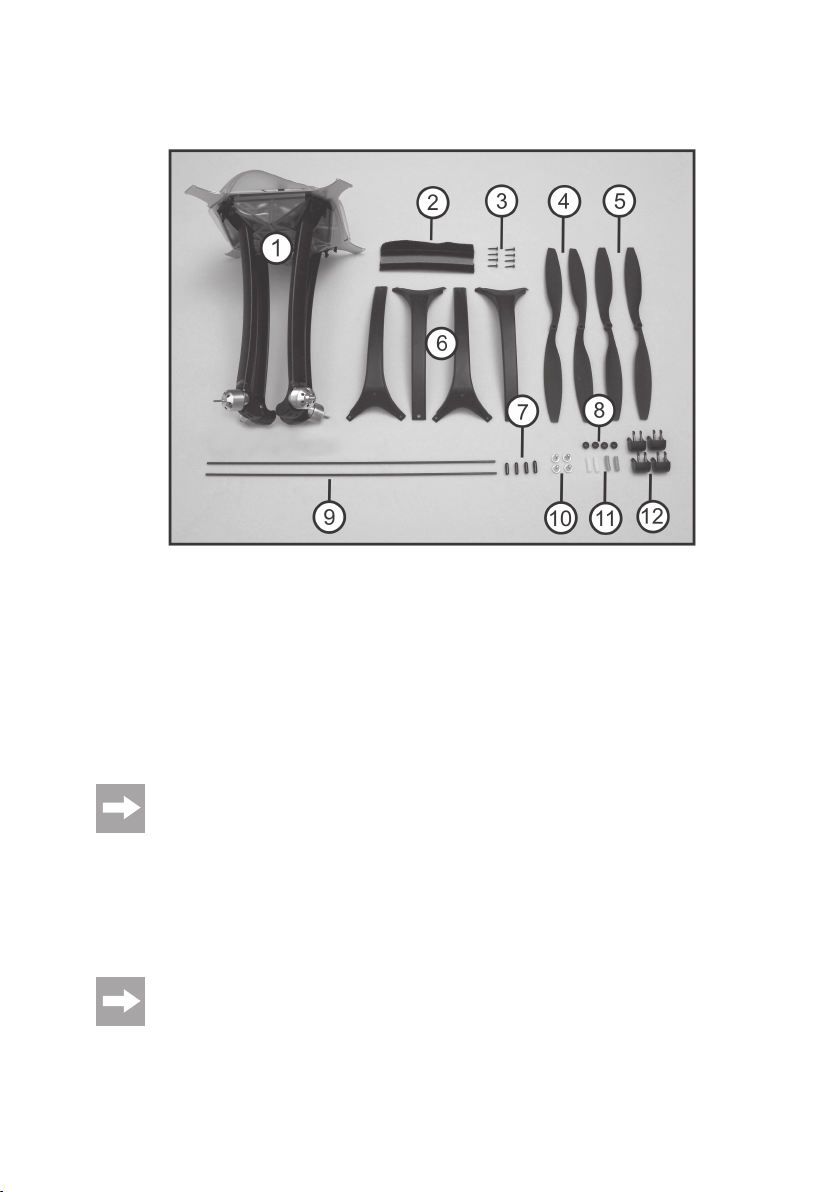

4. Scope of Delivery

Figure 1

1) Pre-assembled QuadroCopter

2) Hook and loop tapes (4 pcs)

3) Screws (8 pcs)

4) Rotors 2x left

5) Rotors 2x right

6) Landing legs (4 pcs)

7) Landing skid end caps (4 pcs)

8) Rubber sleeves (4 pcs)

9) Landing skids (2 pcs)

10) Rotor tips (4 pcs)

11) Silicon hoses (4 pcs)

12) End caps for radial arms (4 pcs)

Not displayed: Operating instruction in German (manual), operat-

ing instructions in English, French and Dutch on CD, aerial tubes,

jumpers (2) high-current plugs for battery connection, hook and

loop tapes for rechargeable battery installation (2) circlips (4) for

rotor tips, self-adhesive rubber buffers (4) and rubber for hood fastening.

The spare parts list is located on our website www.conrad.com in the download section for the respective

product. You can also order the replacement parts list by phone. For contact information, please refer to

the top of these instructions in the chapter “Introduction”.

The following components not included in delivery are required for assembly and operation:

Assembly: Soldering iron and the necessary kit.

Operation:To operate the model, a simple 6 channel remote control system, a 3-cell LiPo flight battery with a mini-

mum capacity of 2500 mAh and a discharge rate of 25 C, as well as a compatible LiPo charging device with LiPo

balance charger are required.

See our catalogues or our website at www.conrad.com for tried and tested accessories.

6

Page 7

5. Explanation of Symbols

The symbol with the exclamation mark points out particular dangers associated with handling, function or

operation.

The “arrow” symbol indicates special advice and operating information.

6. Safety Information

In case of damage caused by non-compliance with these safety instructions, the warranty/guarantee will become void. We do not assume any responsibility for consequential damage!

We do not assume any liability for damage to property or personal injury caused by improper use

or the failure to observe the safety instructions! In such cases the warranty/guarantee is void.

Normal wear caused during normal operation or a crash (e.g. broken rotors or frame) are excluded from

the warranty and guarantee.

Dear customer, these safety instructions are not only for the protection of the product but also for your own

safety and that of other people. Therefore, read this Chapter very carefully before putting the product into

operation!

a) General Information

Caution, important note!

Operating the model may cause damage to property and/or persons. Therefore, make sure that you are

properly insured when using the model, e.g. by taking out private liability insurance. If you already have

private liability insurance, inquire about whether the operation of the model is covered before operating it.

Please note: In some EU countries, you are required to have insurance for any flying models!

• The unauthorized conversion and/or modification of the product or its components is inadmissible for safety and

approval reasons (CE).

• The product is not a toy and should be kept out of reach of children under 14 years of age.

• The product must not become damp or wet. As delicate control electronics are used in the QuadroCopter which are

also sensitive to temperature fluctuations and are optimised for a particular temperature range, operation below

10°C is to be avoided.

• If you do not have sufficient knowledge yet of how to fly remote-controlled helicopters, please contact an experi-

enced model sportsman or a model construction club. Alternatively, it is recommended that you practice on a suitable flight simulator before first use.

7

Page 8

• Do not leave packaging material unattended. It may become dangerous playing material for children!

• The product has been designed for operation in an ambient temperature of between 10°C und 40°C and under

normal air humidity conditions in Central Europe in dry weather. Operation under different conditions can lead to

changed (material) properties and damage to the product as a result.

• The maximum permissible take-off weight of 2,000g must not be exceeded. A take-off weight in excess of this could

lead to damage to the rotors during operation and may cause a crash!

• Should questions arise that are not answered by this operating manual, contact us (for contact information, see

Chapter 1) or another expert.

b) Before Operation

• Observe the operating instructions for the remote control system used by you.

• Regularly check the functional safety of your model and of the remote control system. Watch out for visible damage

such as defective plug connections or damaged cables.

• All moving parts of the model must run smoothly, but should not have any play in their bearings.

• Check before each operation the correct and secure position of the rotors.

• Charge the flight battery, which is necessary for operation, as well as the rechargeable battery that may be inserted

in the remote control according the manufacturer’s instructions.

• If batteries are used as a transmitter power supply, make sure that they have sufficient remaining capacity (battery

checker). If the batteries are empty, always replace the complete set, never individual cells only.

• Always switch on the transmitter first. Please ensure that when you turn on the transmitter the throttle control is set

to the lowest setting (motors off)! Then the flight battery of the model may be connected. Otherwise, unexpected

reactions of the model may occur and the rotors might run unintentionally!

• When the rotors are running, make sure that neither objects nor body parts are in the rotating and suction area of the

rotors.

c) During Operation

• Do not take any risks when operating the model. Your own safety and that of your environment is solely down to you

being responsible when dealing with the model.

• Improper operation can cause serious damage to people and property! Therefore make sure to keep a sufficiently

safe distance to persons, animals or objects during operation.

• Select suitable ground to operate your model.

• Fly your model only if your ability to respond is unrestricted. The influence of tiredness, alcohol or medication can

cause incorrect responses.

• Do not direct your model towards spectators or towards yourself.

• Motor, flight control system and flight battery may heat up during operation of the model. For this reason, please take

a break of 10 to 15 minutes after flying for a maximum of 20 minutes before recharging the flight battery or restarting

with a possible spare battery. The drive motors must have cooled down to ambient temperature.

• Never switch off the remote control (transmitter) while the model is in use. After landing, always disconnect the flight

battery first or switch the model off. Only then may the remote control be switched off.

• In case of a defect or a malfunction, remove the problem before using the model again.

8

Page 9

• Never expose your model or the remote control to direct sunlight or excessive heat for an extended period of time.

• In the case of a severe crash (e.g. from a high altitude). the electric gyro sensors can be damaged and/or misadjusted.

Therefore, full functionality must be tested before flying again without fail. We recommend adjustment to the neutral

position.

• In the event of a crash, the throttle should be immediately reduced to zero. Rotating rotors may be damaged if they

come into contact with obstacles e.g. overcharging. Before flying again, these should be checked for possible tears

or breakages!

• To avoid damage to the QuadroCopter through crashing due to low voltage of the rechargeable battery through total

discharge, we recommend that you respect the low voltage light signals without fail. As the integrated LEDs only

flash in one direction, we recommend that you additionally fit LiPo Saver order no. 230327. The Lipo Saver forewarns you of impending low voltage by light signal. Place the Lipo Saver on the appropriate place of the QuadroCopter.

As an alternative, the integrated combiboard can also be used to display undervoltage via the connected LEDs. For

this, observe the notes in these operating instructions, chapter 14 “Light & Sound Function”

9

Page 10

7. Notes on Batteries and Rechargeable Batteries

Despite the fact that handling batteries and rechargeable batteries in daily life nowadays is a matter of fact,

there are still numerous dangers and problems involved. For LiPo/LiIon rechargeable batteries in particular, various regulations must be observed under any circumstances due to their high energy content (in

comparison to conventional NiCd or NiMH rechargeable batteries), because otherwise there is danger of

explosion and fire.

The QuadroCopter is delivered without remote control, batteries and charging device. Nevertheless, we

are including extensive information on handling batteries for safety reasons. Also observe all documents

and information included with the accessories used (e.g. remote control, rechargeable batteries, charger)!

a) Transmitter

• Keep batteries/rechargeable batteries out of the reach of children.

• Do not leave any batteries/rechargeable batteries lying around openly. There is a risk of batteries being swallowed

by children or pets. If swallowed, consult a doctor immediately!

• Batteries/rechargeable batteries must never be short-circuited, disassembled or thrown into fire. There is a danger

of explosion!

• Leaking or damaged batteries/rechargeable batteries can cause chemical burns to skin when touched without the

use of adequate protective gloves.

• Do not recharge normal batteries. There is a risk of fire and explosion! Only charge rechargeable batteries intended

for this purpose. Use suitable battery chargers.

• When inserting batteries/rechargeable batteries or when connecting a battery pack observe correct polarity

(observe plus/+ and minus/-).

• If the device is not used for an extended period of time (e.g. storage), remove the inserted batteries (or rechargeable

batteries) from the remote control to avoid damage from leaking batteries/rechargeable batteries.

• Recharge the NiCd or NiMH rechargeable batteries about every 3 months, as otherwise there may be a total dis-

charge due to self-discharge, which renders the rechargeable batteries useless.

• Always replace the entire set of batteries or rechargeable batteries. Never mix fully charged batteries/rechargeable

batteries with partially discharged ones. Always use batteries or rechargeable batteries of the same type and manufacturer.

• Never mix batteries and rechargeable batteries!

10

Page 11

b) Flight Battery

Attention!

After the flight, the LiPo flight battery must be disconnected from the electronics system of the QuadroCopter.

Do not leave the LiPo flight battery connected to the electronic system when you do not use it (e.g. during

transport or storage). Otherwise the LiPo flight battery may be fully discharged. This would destroy it and

render it unusable! There is also a danger of malfunction due to interferences. The rotors could start up

inadvertently and cause damage or injury.

• Never charge the LiPo flight battery immediately after use. Always leave the LiPo flight battery to cool off first (at

least 10-15 minutes).

• To charge LiPo rechargeable batteries, always use a LiPo charger and a LiPo equalizer / balancer.

• Only charge intact and undamaged batteries. If the external insulation of the rechargeable battery is damaged or if

the rechargeable battery is deformed or bloated, it must not be charged. In this case there is serious danger of fire

and explosion!

• Never damage the exterior of a LiPo flight battery. Never cut the covering foil. Never stab any LiPo flight batteries

with pointed objects. There is a risk of fire and explosion!

• Remove the LiPo flight battery that is to be charged from the model and place it on a fire-proof support. Keep a

distance to flammable objects.

• As the charger and the rechargeable LiPo flight battery both heat up during the charging procedure, it is necessary

to ensure sufficient ventilation. Never cover the charger or the LiPo flight battery! Of course, this also applies for all

other chargers and rechargeable batteries.

• Never leave LiPo batteries unattended while charging them.

• Disconnect the LiPo flight battery from the charger when it is fully charged.

• Chargers may only be operated in dry rooms. The charger and the LiPo flight battery must not get damp or wet.

There is danger to life from electric shock. There is also the risk of fire or explosion by the rechargeable

battery. Rechargeable LiPo batteries in particular are very susceptible to moisture due to the chemicals

they contain! Do not expose the charger or LiPo flight battery to high/low temperatures or to direct solar

radiation. When handling LiPo batteries, observe the special safety notices of the battery manufacturer.

11

Page 12

8. Final Assembly of the QuadroCopter

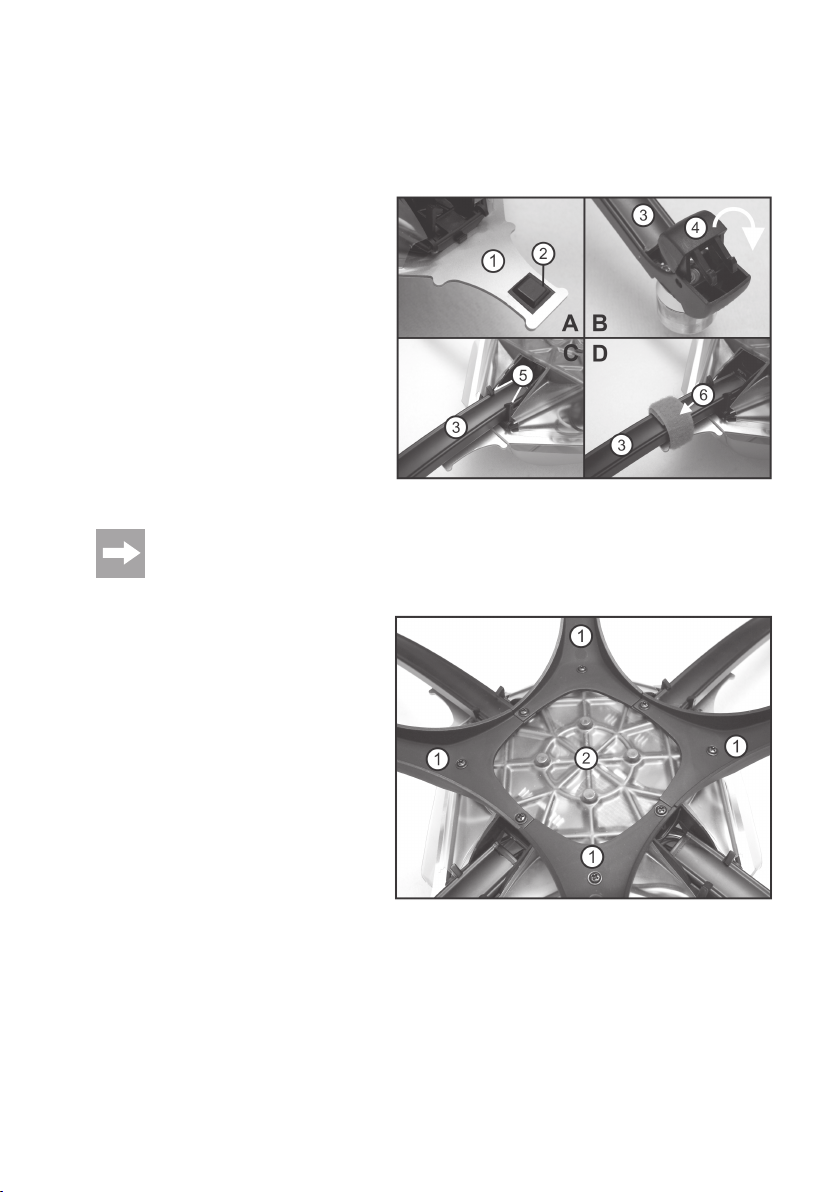

a) Assembly of the Landing Legs

Attach one self-adhesive rubber buffer (2) each to

the four ends of the chassis reinforcement plate

(1) as displayed in figure 2a, item “A”. These rubber buffers are used as stop buffers for the radial

arm (3).

Install the end pieces (4) to the four radial arms (3)

as displayed in figure 2a, item “B” and let the end

pieces catch in the locks.

Completely extend the four radial arms (3) and let

them catch in the locks (5), see figure 2a, item “C”.

Wind the hook and loop tapes (6) firmly around the

radial arm, see figure 2a, item “D”. The red hook

and loop tape must be installed on the radial arm

with a “direction arrow” and thus additionally indicates the “front” of the Quadrocopter.

By installing the rubber buffers (figure 2a, item “A”) and the hook and loop tapes (figure 2a, item “D”), the

connection between radial arms and body is additionally stabilised. At the same time, this type of attachment is sufficiently elastic for dampening harder landings. The measures shown also improve flight characteristics.

Place the Quadrocopter upside-down on a suitable

basis. Install the four landing legs (1) on the bottom of the chassis (2) as indicated in figure 2b. For

this purpose, use the eight screws from the delivery.

The bores in the plastic hood of the chassis must

be carefully drilled with a small drill before installation.

During installation, observe hat the landing legs

have an “upside” on the outsides and a “downside”

on the opposite side, where the hole for the attachment screw is supposed to go.

Figure 2a

12

Figure 2b

Page 13

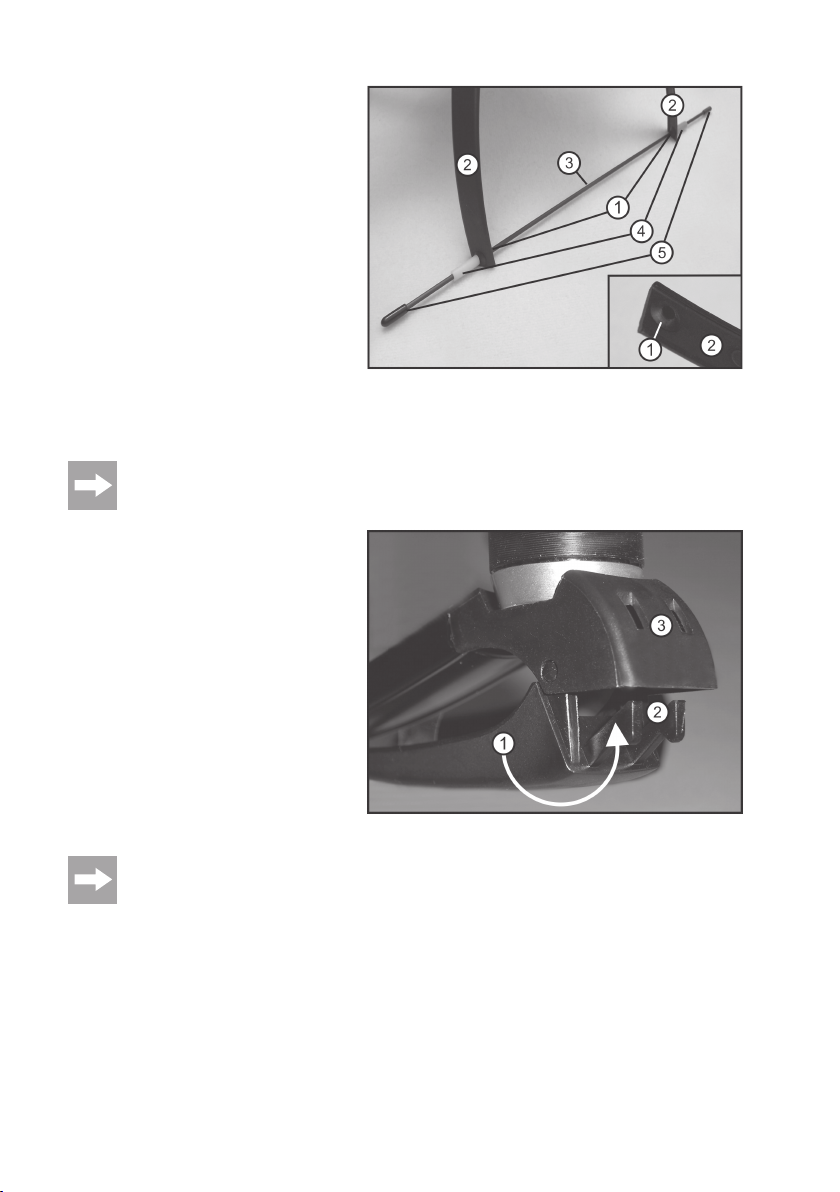

Assemble the four rubber sleeves (1) in the landing leg holes (2). Then push the landing skids (3)

on the rubber sleeves centrally (1).

Now slide the short silicon hoses (4) onto the landing skids (3) from the outside to the rubber sleeves

(1). The rubber sleeves prevent the landing skids

from slipping.

Slide on one end cap (5) each onto the ends of the

landing skids (3).

For normal flight operation, the indicated type of

skid assembly is fully sufficient. For hard flight operation, we recommend additionally securing the

skids and rubber sleeves with a few drops of

superglue.

Optional use of the “QuadroCopter 450” landing legs:

Instead of the landing gear used for the “QuadroCopter 650”, the landing legs of the “QuadroCopter 450”

may also be used. They are not included with the delivery of the “QuadroCopter 650”, but can be ordered

as a spare part (see spare part list of “QuadroCopter 450”).

Figure 2d shows the landing legs of the “QuadroCopter 450”.

Extend the landing legs (1) into flying position. The

retaining clips (2) must catch clearly noticeably in

the slots (3).

For folding in, slightly push the retaining clips (2)

into the slots (3) with a small screw driver in order

to avoid breaking the plastic parts.

A red direction indicator is mounted to one of the

landing legs. This direction indicator should always

be considered as “forwards” when flying.

Figure 2c

Figure 2d

In harder landings, the landing legs will fold in. This is normal and desired. Should you wish to avoid this

effect or if you no longer wish to fold away the landing legs for transportation, you can also permanently

affix the landing legs using superglue.

13

Page 14

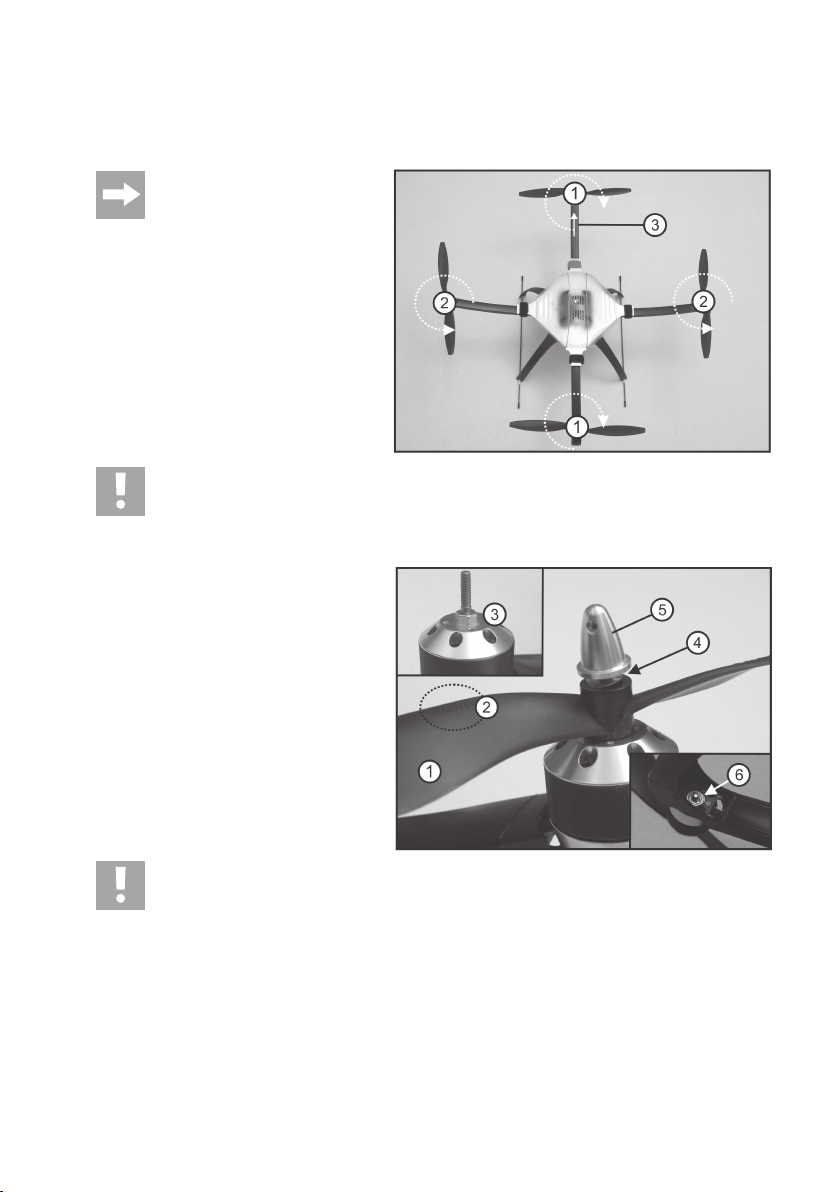

b) Assembly of the Rotors

The rotating direction of the rotors can be seen in the adjacent figure (bird’s eye view). The arrow on the radial arm is

to be used as the indication for the direction of the model and is deemed to be “front”.

Attention!

As the motors are pre-assembled, the

rotating direction of the rotors on the

basis of the flight direction should be

carefully observed (figure 3)!

The rotors in the centre line (1) turn clockwise (right

rotating) and must be marked with the inscription

“RIGHT”.

The rotors on the cross axis (2) turn anticlockwise

(left rotating) and must be marked with the inscription “LEFT”.

The arrow at the radial arm (3) indicates “front”.

Attention!

If the rotors are not installed as described, the programmed rotating directions will no longer be in line with

the rotating directions of the rotors. The QuadroCopter is therefore no longer able to fly and can no longer

be operated! Loss of guarantee/warranty!

Rotors and motor shafts are provided with a hexagonal bolt (3).

Place the rotors (1) on the motor shafts (3) so that

they lock into place in the hexagonal bolt. Observe

the indication of “RIGHT” and “LEFT” on the rotors

(2).

Now insert one of the provided spring washers (4)

at a time between the rotor and rotor tip (5), as

otherwise the rotors may become loose during

flight.

Tightly screw the rotor tips to the motor shafts using a small pen or screw driver.

Figure 3

14

Attention!

Tightening the screws too much can damage the motors. The shafts may tear or be pulled from the

bearings. The motors operate sluggishly, which may have a negative effect on the flight characteristics.

Therefore, please verify that all of the rotors can turn easily after tightening the rotors. The snap ring shown

in figure 4, item 6, on the underside of the motors must be able to move and must not jam.

Please ensure before each operation that the rotors are firmly screwed in place on the motors. It is recommended that you are careful when handling work tools.

Figure 4

Page 15

c) Connecting the Receiver

The receiver is connected to the “X13” connection socket of the combiboard (1). A suitable connection cable (2) is

supplied with QuadroCopter. The connection socket “X13” has 10 contacts that are numbered from the right to the left.

Contact 10 is on the left, contact 1 on the right.

The contacts are assigned as follows:

R41

X15

R43

1

LD2

Figure 5

Contact 10 = Channel 1

Contact 9 = Channel 2

Contact 8 = Channel 3

Contact 7 = Channel 4

Contact 6 = Channel 5

Contact 5 = Channel 6

Contact 4 = Channel 7

Contact 3 = Channel 8

Contact 2 = 5 V/DC/Plus (+)

+

PAD1

X14

-

PAD2

C18

C19

Q2

D1

10

X13

C4

R40

C17

LD1

R42

IC3

Contact 1 = GND/Minus (-)

The signals of the 8 inputs (channels 1 – 8) are measured and processed by the composite signal converter. All

available signals are combined into a composite signal pursuant to the specifications for RC remote control systems

(pulse width between 1 and 2 ms). Due to measuring of the signals and signal processing, there will be a delay of one

frame length. However, this has no effect during operation and is therefore only mentioned for the sake of completeness.

The measured servo signals may appear in any order, parallel, in sequence or overlapping. There is no limitation, so

that the composite signal converter can be used for all common systems. A synch break between the different signals

is also not required.

For the receiver’s power supply, it is sufficient to connect the contacts 1 (minus/-) and 2 (plus/+) to a single servo

connection cable.

Important!

Observe that the composite signal converter are assigned without gaps! In a 6-channel system, this means

inputs 1 - 6 and not 1 - 4 and then 6 and 7. With this assignment, the electronics would not recognised

channels 6 and 7!

Due to the many remote control receiver sizes and builds on the market, we cannot give any concrete

installation notes for the receiver. Depending on the receiver used, you may either install it between the

PCBs in the grid frame of on the reinforcement plate.

If the PCBs in the grid frame must be repositioned for installation of the receiver, we recommend installing

the main PCB of the gyro precisely at the centre for best flight characteristics (it is located on the small,

protruding PCB).

R21

R22

X6

R21

X6

15

Page 16

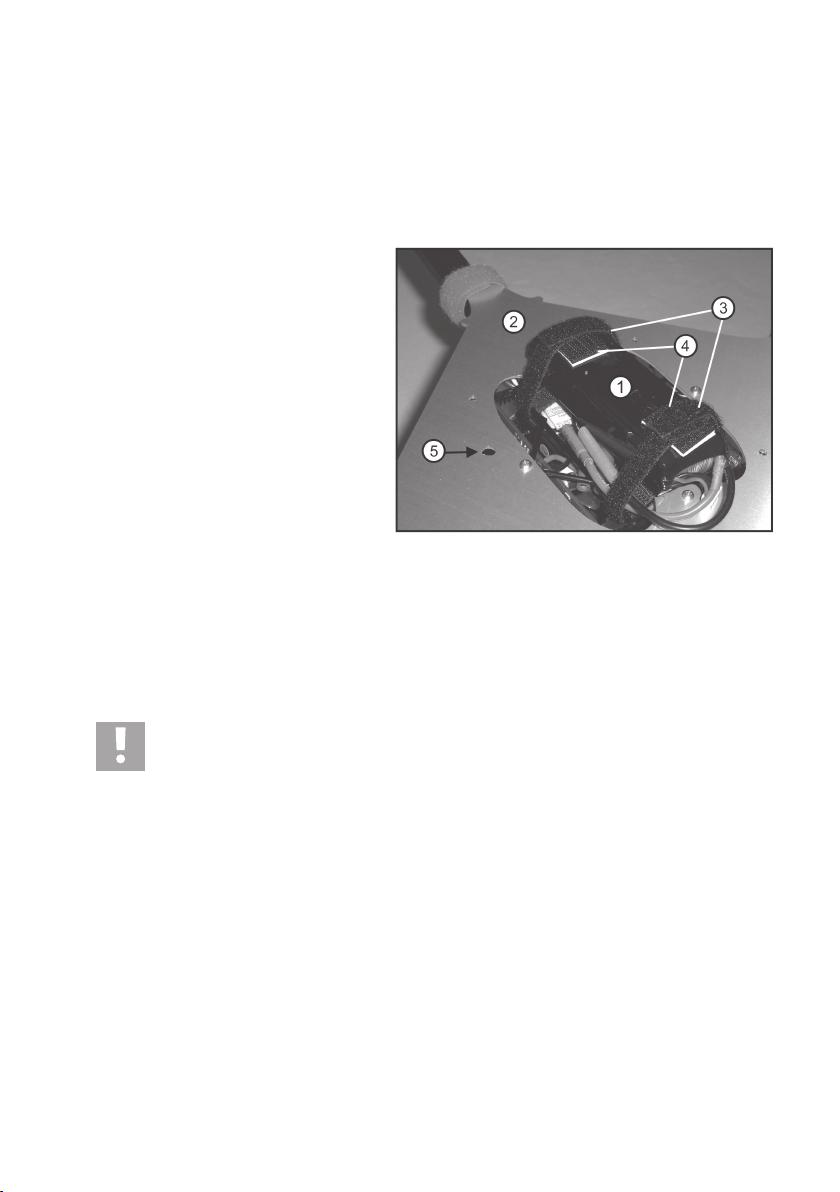

d) Installing the Flight Battery

The flight battery is not included. Take the following steps to install the flight battery:

Solder the supplied high power loading system to the connecting cable of the rechargeable battery. Always ensure

correct polarity.

The red electronics system cable of the QuadroCopter must be connected to the positive cable of the rechargeable

battery and the black cable to the negative cable of the rechargeable battery.

Install the rechargeable battery (1) in the frame (2)

and attach it with hook and loop tapes (3).

In addition to the indicated hook and loop tape, also

attach a strip of hook and loop tape to the surface

of the battery (4 - as supplied) to prevent it from

slipping forwards or backwards. The connecting

cables can also be fixed under the hook and loop

tape (3) as shown in the figure.

The rechargeable battery must be placed in the

centre so that the QuadroCopter is not tailheavy, top-heavy or side-heavy.

The reinforcement plate of the chassis (2) has a

bore intended for an aerial tube (5). You can use

the aerial tube to guide a receiver aerial outside.

The upper covering hood also has a hole in this

position.

The QuadroCopter’s electronics system has a safety device to prevent inadvertent engine start-up. When contact is

made with the rechargeable battery although the transmitter is not switched on or the speed/pitch control stick was not

set to zero, the control electronics in the model will not cause the engines to start.

When the transmitter is switched on and the speed/pitch control stick is set to zero once, the control electronics in the

model clears normal operating state.

Caution:

To prevent inadvertent engine start-up if the safety device fails, the transmitter should be switched on. The

speed/pitch control stick must be set to zero so that no acceleration command is sent.

Figure 6

16

Page 17

e) Assembly of the Upper Cover Hood

Due to the position of the aerial pipe and the predrilled hole in the upper hood, the hood can only

be mounted in one position.

Attach the upper cover hood (1) with a rubber band

(2) as shown in figure 7.

The rubber bands must be slid under the radial

arms of the reinforcement plate at the front and

back.

The hood must be attached so that the hole for the

aerial tube (3) is above the hole in the reinforcement plate (see previous chapter).

Figure 7

17

Page 18

9. Checking the Configuration

a) General Information

Please carry out the configuration of the QuadroCopter as described in this chapter. Programming of the channels is

essential, since otherwise the QuadroCopter will not recognise your transmitting equipment. When you have carried

this out, your QuadroCopter is ready to fly.

If you are using a computer remote control, programme it without using a mixer in the standard program.

To correctly align the pilot stick for the desired control commands, it is necessary to programme the QuadroCopter with

the transmitter used. In the process, the QuadroCopter’s electronics system memorises the channel on which each

control command is broadcast. Generally, you can freely choose the configuration of the control lever (according to

your habits), however, it is recommended that beginners follow the recommended examples.

Ex factory, the QuadroCopter is configured to “mode 2”. The examples are for a common assignment used by many

model pilots.

Decide which configuration you wish to program and programme the channels correspondingly. Further possibilities

for control modes 1, 3 or 4 (modes 1, 3 or 4) can be found in the instructions in this chapter under the heading

“Possible Flight Modes”.

For monitoring the configuration, indicating malfunction or operating status, a red and a green LED are installed on the

control board. The respective indications can be seen in the table in the following chapter “safety devices” in this

instruction manual.

When using multiplex remote controls, the servo protocols must be adapted for all four functions (throttle,

roll, pitch and yaw) from “MPX” to “UNI”.

If the QuadroCopter cannot be programmed onto your remote control, this may be due to the reverse

function of your remote control. We recommend pressing the reverse switch for the throttle function and retrying programming.

18

Page 19

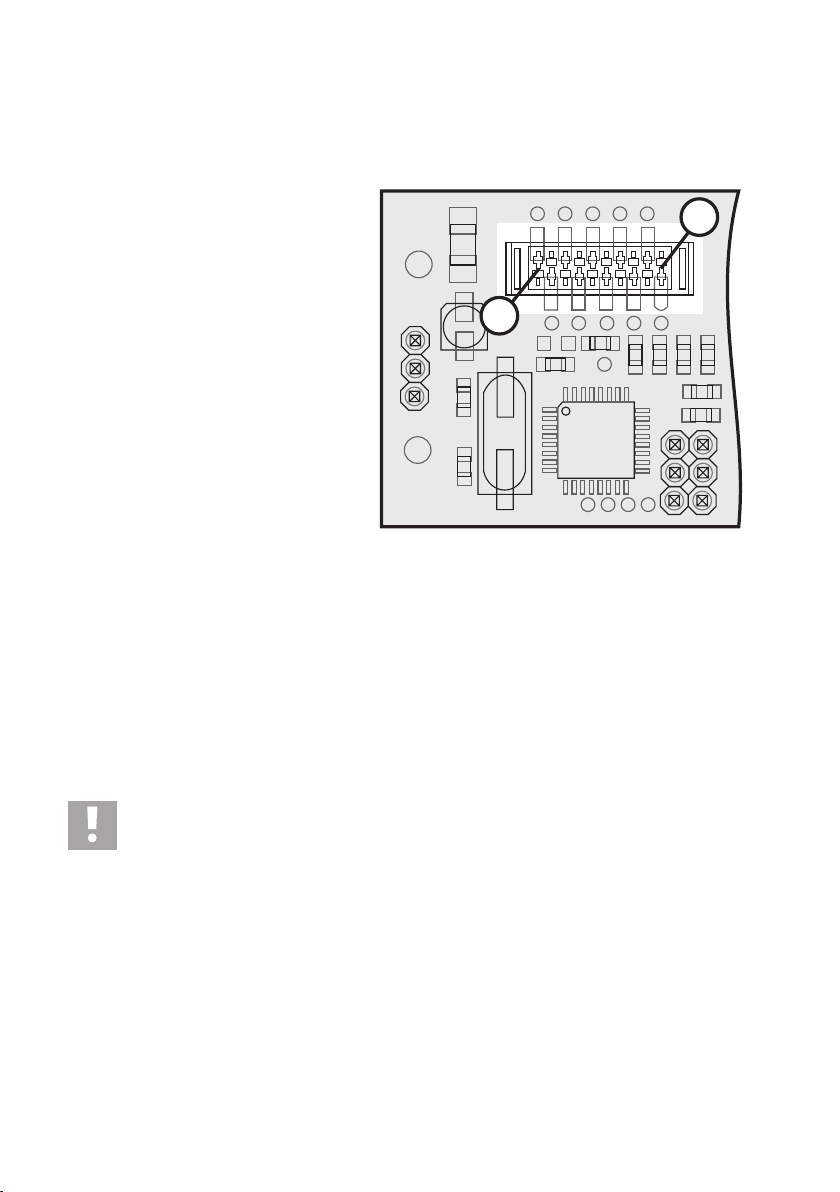

b) Programming of Transmitter Channels (General)

Before you begin programming, unplug the rechargeable battery, if connected, from the

QuadroCopter. Also disconnect the connection cable to the PC, if connected, from the QuadroCopter.

Use a jumper for the RC configuration setting “R2”

for “remote setting” (5). You will find the plug connectors for the jumper in the right upper area on

the reverse of the control board of the

QuadroCopter.

On one side of the board (1), both of the LEDs (2)

indicate particular operating statuses. On the opposite side of the board (3), the plug connectors

“S1, S2, R1, R2” (4) for the jumpers are to be seen.

Figure 8

To operate the QuadroCopter in “remote setting” mode, affix the jumper “R2” (5) as shown in figure 8. This setting is

independent from other affixed jumpers.

Important!

Before switching the transmitter on, please set the throttle stick to “motors off” and all trim levers / trim

sliding controllers of the pilot stick to the neutral position. Otherwise, the QuadroCopter may not recognise

the transmitter after the battery is connected.

Now switch on the transmitter and pull out the telescopic aerial of 27-/40 MHz remote control systems completely.

Please ensure that all levers and trims of the transmitter are in neutral position. The examples given show the procedure using a remote control in mode 2. If you prefer to use another mode, the used axes may differ (see chapter

“Possible Flight Modes”)!

Please also ensure that the sliding controller for the trim is set to neutral position! Otherwise correct recognition of the

channels will not be possible!

Please also ensure that lever movements are made

in the right direction, otherwise the signals will be

memorised in reverse! Computer remote controls

should always be operated without mixer!

Move the throttle lever (see figure 9) backwards to

the neutral position (motor off), all other control

devices should be set to neutral.

Do you want to try out “pitch reverse”? (during “motor off” the pilot stick for throttle is pulled away from

the body), then bring the throttle lever forwards into

the max. position before you connect the rechargeable battery.

Figure 9

19

Page 20

c) Programming of “Throttle”

Connect the charged battery to the QuadroCopter. The model starts with a self-test and directly continues with programming of the channels. On the basis of the throttle setting, the QuadroCopter automatically recognises which

channel you would like to use for the throttle.

As a confirmation, the red LED of the QuadroCopter flashes in groups of 2 (2 short flashes, then a longer pause, then

2 short flashes again etc.)

d) Programming of “Yaw”

Now move the yaw lever (see figure 10) to the left

to full deflection and hold it there for at least one

second.

The QuadroCopter thus recognises the YAW channel and memorises this.

Move the YAW lever back to neutral position with

the THROTTLE still on zero.

As confirmation, the QuadroCopter’s red LED

flashes in a cycle of 3s (3 short flashes, then a pause

etc.)

During the respective configuration

step, the green LED shows the channel as long as the lever is still being

pushed! However, only the red LED is

important for the progress indicator!

During the programming process, please ensure that you only move the required lever, otherwise the setting will not

be recognised!

Figure 10

e) Programming of “Pitch”

Move the PITCH lever (see figure 11) to full deflection for GIVE PITCH upwards and hold it there for

at least one second.

The QuadroCopter thus recognises the PITCH

channel and memorises this. Move the PITCH lever back to neutral position, continue to leave the

THROTTLE on zero.

As confirmation, the QuadroCopter’s

red LED flashes in a cycle of 4s (4x

short flashes, then a pause etc.).

20

Figure 11

Page 21

f) Programming of “Roll”

Move the ROLL lever (see figure 12) to full deflection for ROLL LEFT and hold it there for at least

one second.

The QuadroCopter thus recognises the ROLL channel and memorises this. Move the ROLL lever back

to neutral position, continue to leave the THROTTLE on zero.

As confirmation, the QuadroCopter’s red LED goes

off and the green LED is lit permanently. This is the

end of the training process.

Disconnect the rechargeable battery from the

QuadroCopter and remove jumper “R2”.

Other possibly connected jumpers may be left

plugged in. This is the end of the programming process for the channels.

Figure 12

21

Page 22

g) Setting the Flight Mode

The QuadroCopter offers three different flight modes.

• Beginner (suitable for novices)

• Sport (suitable for proficient QuadroCopter pilots; lower axis limits and higher dynamics)

• User (flight parameters adjustable with PC software, see chapter “configuration with PC software”)

The flight mode is configured before switch-on by setting the jumpers “S1” and “S2” and cannot be altered during

operation. The positions for the jumpers are on the control board (also see figure 8 in chapter “Programming of

Transmitter Channels”)

Practical advice:

Beginners in particular are urgently advised to reduce the directness of the control command with which

the QuadroCopter performs the commands from the remote control around the centre detent (negative

exponential “expo”).

To illustrate:

Normally, the QuadroCopter responds linearly. This means that the pilot stick deflection and the reaction are synchronous. With negative expo, the QuadroCopter will respond relatively sluggishly at the start of the controlling motion. In

the case of stronger control deflections, however, it responds much more strongly to the control command. This is

particularly beneficial for beginners who initially tend to oversteer, i.e. move the control stick of the remote control more

intensely than necessary. This effect is, of course, only desired for the three control axes (roll, pitch and yaw) and not,

however, for throttle. Thus: Do not configure expo on throttle!

In other words: With negative expo, slow behaviour of the flying device is achieved on the controlling motions in the

area of the centre detent of the pilot stick. This takes place either via the optionally available software, via the

QuadroCopter’s jumpers (see “beginner mode”) or via the existing “expo function” of the remote control. Only computerised remote controls can set “expo”. However, care must be taken, since the higher the negative expo selected, the

more aggressively the QuadroCopter reacts when the control stick is moved in the area of full deflection.

The following table illustrates the different settings of the jumper. Jumpers are not set ex factory and the QuadroCopter

is set to beginner mode. The jumpers “S1” and “S2” are independent from the other jumpers!

Beginner Sport User

22

For the “user” flight mode, you must configure your own setting with the optionally available configuration

software. For this, you can use either the beginner or sport modes as a basis and customise your own

personal requirements. Please observe the operating instructions for the configuration sets.

Page 23

h) Configuration with PC Software

To fly the QuadroCopter with your own settings, you may connect the electronics system of the QuadroCopter to a PC

via an interface cable (serial TTL on USB).

An optional PC configuration set is available for this. This contains a connection cable, a detailed description and the

software on CD. This kit may be used with Microsoft® Windows XP®*, Windows Vista®* and Windows 7®* (* Microsoft,

Windows XP, Windows Vista and Windows 7 are registered trademarks of the Microsoft Cooperation in the U.S. and

other countries).

As it is not necessary to carry out configuration with a PC for normal flight operation, this is only mentioned here as a

side note. More information on the configuration can be found in the software operating instructions.

When jumper “R1” is set, the QuadroCopter is in PC configuration mode (PC mode) and cannot be flown. Remove this

jumper for normal flight operation!

On the control board below the LEDs, a micro push button is mounted which can be used to reset the

control electronics. For this, press the micro push button with the rechargeable battery connected for

around 1 second. Then the electronics will restart and start in the status set according to each jumper. The

effect is the same as for “unplug flight battery”.

The micro push button (1) and the interface (2) are

on the control board (3). For photo-technical reasons, the circuit board of the control board was

uninstalled for figure 13.

Figure 13

23

Page 24

i) Possible Flight Modes

Mode Throttle Yaw Pitch Roll

1

2

3

4

24

Page 25

10. Before Each Use

a) Checking the Connections

Check all screws for tightness before transport and flights. Vibration during transport and flight may cause screws to

loosen. Due to this, you need to conduct a thorough pre-flight check just as for a real helicopter.

b) Checking Movable Parts

Always check all movable parts and all parts with bearings for unobstructed movement before flying. They must be

easy to move, but without play.

c) Adjustment of the Neutral Position

For the stabilisation of the QuadroCopter to work correctly, the neutral position must be set. This is the position that the

QuadroCopter tries to stabilise as long as no other flying manoeuvre is desired.

Proceed in the following sequence:

1) Switch on the transmitter.

2) Set THROTTLE to zero and all other levers and trims to the neutral position.

3) Place the QuadroCopter on a level, even surface!

4) Connect the rechargeable battery to the QuadroCopter.

5) The QuadroCopter’s red LED must be OFF and the green LED must be ON.

6) Move THROTTLE to full deflection and YAW to full deflection

on the right (figure 14).

7) The QuadroCopter’s green LED flashes as confirmation and the neutral position is memorised.

8) Move the THROTTLE back to zero, move YAW, PITCH, and ROLL into the neutral position.

9) The red LED is OFF and the green LED in ON –> the QuadroCopter is now ready to fly!

Figure 14

25

Page 26

If you do not set the neutral position , the QuadroCopter will use either the factory settings or the last saved value!

It is very important that you set the neutral position of the QuadroCopter as precisely as possible. For this,

it is necessary to set the neutral position on a completely horizontal base. Ideally, this should be measured

with a spirit level.

Due to different environmental conditions than in the factory and/or at the actual place of flight operation, the factory

settings may not be ideal! It is therefore urgently recommended that you set the neutral position before first flight.

If the QuadroCopter still swerves in one direction despite the relevant trims to the transmitter, the neutral position must

be stored again by slightly lifting up the QuadroCopter on the side to which it swerves. This way, the (changed) position

is saved as the new centre position.

26

Page 27

11. Safety Devices

The QuadroCopter has a range of safety devices which protect the model from damage and/or should reduce possible

damage to a minimum. The protection mechanisms are identified by LED indicators. For this, please observe the

following chapter 12 “LED Displays”.

a) Motor Protection

The control electronics has a motor protection which immediately switches off all motors if one rotor is blocked (e.g.

after a crash). After possible damage has been checked for, the motors can be restarted using the normal control

command “starting the motors”.

b) Emergency Landing

If the control electronics of the QuadroCopter detects too great interferences, it tries to realign the QuadroCopter in a

level position.

If interference of the receiver continues, the throttle is set to a value just under hovering (without rear weight) and the

QuadroCopter begins its descent.

When the interference of the receiver is over, the model pilot can give another control command and the emergency

landing programme is terminated.

c) Low Voltage Monitoring

The QuadroCopter constantly monitors the voltage of the connected battery. If it falls below a critical level over a

particular period of time, this will be indicated by the LEDs.

In this case, the red LED flashes and the green LED will be permanently lit. This indicator can only be switched off by

disconnecting the battery.

In order to detect a low rechargeable battery during flight, it is recommended that strong throttle thrusts be carried out

from time to time. If the QuadroCopter responds slowly and weakly, it should be landed and the rechargeable battery

should be checked. Due to the performance, this test is, however, difficult to realize.

In the case of a long, uninterrupted flight operation, it is recommended to also test the LED indictors through time to

time landing.

Practical advice: To avoid damage to the QuadroCopter from crashing due to undervoltage and/or to the rechargeable battery due to total discharge, we recommend that you always observe the low voltage light signals. As the

integrated LEDs only flash in one direction, we also recommend installing the LiPo Saver (Conrad item no. 230327).

The Lipo Saver warns you of impending low voltage by light signal. Place the LiPo Saver on the appropriate position

on the QuadroCopter and connect it to the battery via, e.g., the balancing connector.

d) Finder function

When there is no transmitter signal or when the transmitter is off, the activated QuadroCopter automatically emits an

acoustic signal (beeps).

In case of landing outside in high grass or in a grain or corn field, it can thus be easily recovered.

27

Page 28

12. LED Displays

The following LED display options are not safety indicators, but only indicate particular operating statuses. You will find

the LEDs for the displays described in the following on the control board (see figure 8).

a) Ready to Fly

After you have plugged in the flight battery and before starting the motors, the green LED lights up and the red LED is

off. Your QuadroCopter is ready to operate. If this is not the case, there is an interference. Please observe the following

operating instructions in this chapter.

b) Starting the QuadroCopter

Rev the motors. The red LED now lights up permanently and the green LED flashes. After approx. two seconds, the

green LED also lights up permanently. If this is not the case, there is an interference. Please observe the following

operating instructions in this chapter.

c) Configuration Mode

During the configuration of the remote control, the red LED indicates the programme step and the green LED indicates

the channel to be programmed through corresponding flashing with pauses.

d) RC Offset Adjustment

After the flight battery is connected, the red and green LEDs flash quickly and indicate the alignment of the transmitter

and electronic system of the QuadroCopter . After successful alignment has taken place, the red LED goes off and the

green LED is permanently lit.

e) Adjustment of the Neutral Position

If an adjustment to the neutral position is carried out, the green LED flashes quickly. The red LED is off.

The following LED display options are safety indicators. The causes for this must be explored and resolved.

f) Impaired Radio Link before Take-Off

You want to take off and the engines are still off. The red and the green LEDs flash slowly at the same time and

indicate a faulty radio link.

Possible causes: Receiver crystal has fallen out of the base, receiver crystal is defective, receiver aerial has broken

off. Transmitter aerial not pulled out, second transmitter with the same transmitter channel switched on/ batteries from

transmitter empty. Check the possible causes and restart.

If there is any permanent radio interference during flight, the QuadroCopter will start an emergency landing and the

LEDs will also indicate an impaired radio link here by simultaneous flashing.

28

Page 29

g) Impaired Radio Link during Flight Operation

You want to take off and the engines are already switched on or during flight operation. The red and the green LEDs

flash slowly at the same time and indicate a faulty radio link.

Possible causes: Receiver crystal has fallen out of the base, receiver crystal is defective, receiver aerial has broken

off. Transmitter aerial not pulled out, second transmitter with the same transmitter channel switched on/ batteries from

transmitter empty. Check the possible cause and restart.

If there is any permanent radio interference during flight, the QuadroCopter will start an emergency landing and the

LEDs will also indicate an impaired radio link here by simultaneous flashing.

h) Emergency Landing Function

During operation, a permanent radio interference prevails. The QuadroCopter starts an emergency landing independently. The red and green LEDs flash slowly and simultaneously. Look for possible error causes on the basis of the

previously illustrated examples.

i) Low Voltage Monitoring

The battery voltage is permanently monitored. If a certain battery voltage is exceeded (threshold approx. 9.4 V), the

red LED starts to flash quickly. The green LED is permanently lit. This indicator can only be reset by disconnecting the

flight battery. If the red LED flashes, you should carry out a landing as quickly as possible and adjust the flight operation.

If the QuadroCopter is connected to a non-fully charged battery, this can also lead to undervoltage detection. In this case, fully charge the flight battery first of all and then try the take-off once again.

29

Page 30

13. Combiboard “QC08” Information

a) Connection Contacts or Jumper of the Combiboard

PAD1: Plus soldering connection for supply voltage (+)

PAD2: Minus soldering connection for supply voltage (-)

LD1: Green LED indicator

LD2: Red LED indicator

X1: Jumper for buzzer

X2: Jumper for light mode

X3: Connection contacts for LED or LED-strips 1 - 4

X4: Connection contacts for LED or LED-strips 5 - 8

X5: Connection contacts for servo 1 (channel 5)

X6: Connection contacts for servo 2 (channel 6)

X7: Connection contacts for servo 3 (channel 7)

X8: Connection contacts for servo 4 (channel 8)

X9: Connection contacts for an external RC input signal

X10: Connection strip for the broad interface cable

X11: Jumper for the interface selection

X12: Serial interface

X13: Connection sockets for the receiver cable

X14: Connection contacts for the composite signal

X15: Programming plug for production-related settings

SW1: Jumper for the RC input selection

SW2: Reset button

BUZ1: Buzzer

X10

X10

BUZ1

SW2

X1

R23

R23

C14

C14

C15

C15

C12

C12

C13

C13

C8

C8

C9

C9

C10

C10

C11

C11

C16

C16

X12

X11

R7

R45

R1

R2

R2

SW1

X7

X8

LD2

R43

X2

R6

R3

R44

IC1

C1

Q1

Q1

C2

T3

T3

X3

T2

T2

T5

T5

T4

T4

LD1

R41

R42

R21

X4

X9

IC2

X5

X6

R22

X15

IC3

C3

30

X13

C17

R40

D1

C4

Q2

C18

C19

+

X14

PAD1

-

PAD2

Figure 15

Page 31

b) Composite Signal Output

The composite signal converter outputs the formed

composite signal (SuS) at the upper contact of the

“X14” connection.

This composite signal consists of so many single

signals as measured at the inputs.

For example, if a 6-channel receiver is used, the

composite signal also has 6 channels.

Channel number recognition is performed via the

valid signal measurement at the inputs.

The connections “SuS”, “+5V” and “GND” must be

connected to the respective connections of the main

PCB (figure 16b) in the QuadroCopter.

Ensure correct polarity for the connection of the

two pin contact strips.

c) LED Status Display

The composite signal converter has a green and a

red LED for status display.

A green LED (LD1) indicates that the electronics

are in normal operation. This means that servo signals can be measured, and if required a composite

signal can be generated.

When the green LED goes out, there is a basic

interference in the electronics.

A red LED (LD2) shows that no servo signals are

present. The reasons fort his may be reception interference, lack of power supply to the receiver ,

switched-off transmitter of contact errors in the connection lines.

+

PAD1

X14

-

PAD2

+

PAD1

X14

-

PAD2

SuS

+5V

C18

GND

C19

C18

C19

X13

D1

LD2

R42

R41

X15

R43

R21

R22

X6

C4

R40

Q2

C17

LD1

IC3

Figure 16a

Figure 16b

X13

D1

Rot

LD1

C4

R40

Q2

C17

LD1

IC3

Rot

LD2

R42

R41

X15

R43

LD2

R21

R22

X6

Figure 17

31

Page 32

Behaviour in case of reception interferences

The composite signal converter measures the signal quality and thus also recognises reception interferences.

Since channels 1 - 4 are mainly used for general control of models, they are specifically described.

Interferences on channels 1 - 4

For these channels, verification of a valid pulse width (between 1 and 2 ms) is performed. If an error is recognised, the

composite signal is generated with the last valid value.

When the error rate exceeds the measure for proper reception, the composite signal converter does not output any

composite signal anymore and activates the red LED. Now the reception problem can be recognised by the downstream logic and no reception problems are concealed.

If the input signal is valid again, the red LED goes out and a composite signal is generated.

Interferences on channels 5 - 8

If the reception interference only acts on channels 5 - 8, a composite signal continues to be generated for channels

1 - 4 and channels 5 - 8 are output with an invalid pulse length.

Thus, it is possible to continue to control the model, but the interference can be recognised by a downstream logic at

channels 5 - 8.

When the input signal is valid again, a regular composite signal is output.

d) Interface Connection

For a connection of the combiboard to the control

board of the QuadroCopter, the combiboard comes

with a 26-wire foil cable that must be connected to

the connection strip for the broad interface cable

(“X10”).

Late, when installing the combiboard in the

QuadroCopter, observe that the two connection

strips for the broad interface cable (combiboard and

control board) are exactly across from each other.

Connection is performed in the same way as a connection between the two motor driver boards and

the control board.

IC2

X10

X10

C16

C9

C16

1

R2

R2

T4

T4

X9

X4

C8

C9

C8

C13

C10

C10

C13

C12

C12

C15

C15

C14

C14

R23

R23

C11

C11

26

T3

T5

T5

T3

T2

T2

X3

Q1

Q1

C2

C3

32

Figure 18

Page 33

e) Servo Connection

When the combiboard is installed in the

QuadroCopter and the remote control was programmed, up to four servos (channel 5 – 8) can be

connected and operated by remote control.

However, this is only possible when the transmitter

and the receiver provide these functions and the

respective receiver outputs are connected to the

input plug of the composite signal converter (“X13”).

The following plug contacts are intended for the

servo connection:

X5: Servo 1 (Receiver output/channel 5)

X6: Servo 2 (Receiver output/channel 6)

X7: Servo 3 (Receiver output/channel 7)

X8: Servo 4 (Receiver output/channel 8)

Please observe that the impulse line (PPM) always has to be connected to the upper pin of the three

contact plugs when connecting the servos!

R42

R41

X15

R43

PPM

LD2

+

-

R21

R22

X6

X11

X8

X7

PPM

+

X5

X10

X10

X12

SW1

IC2

X9

R2

R2

T

-

Figure 19

33

Page 34

14. Light & Sound Function

a) General Information

The combiboard has eight LED outputs (“L1” to “L8”), and three digital inputs (“IN-1”, “IN-2”, “IN-3”) and an external RC

input (“PPM”) in addition to the composite signal converter.

Triggering of the LED outputs can be configured via 7 different modes.

The electronics either generate a fixed pattern on the outputs or the outputs are switched depending on the input

signals. The jumpers can be used to set modes, which can also be switched into three states by a RC signal (channels

5, 6, 7, 8 or external). Thus, it becomes possible to switch during flight.

Digital inputs:

The digital inputs switch the respective outputs when the respective mode was selected. A high signal (+5 V) means

that an output is switched on. The connected LED or the connected LED strip is lit.

The three digital inputs are located at the interface connection “X10” and are assigned as follows:

IN-1 = contact 6

IN-2 = contact 5

IN-3 = contact 16

X10

X10

C16

C9

C11

C11

IN-1

C10

C10

T5

T5

C8

C9

C8

C13

C13

C12

C12

C15

C15

C14

C14

R23

IN-3

T2

T2

R23

T3

T3

Q1

Q1

C16

IN-2

R2

R2

T4

T4

34

IC2

X9

X4

X3

C2

C3

Figure 20

Different status displays or error messages of the QuadroCopter can be displayed well visibly via the 3

digital inputs. The function of the output signals mainly depends on the firmware used and can change

during further development of the QuadroCopter. A more detailed description with assignment of the 3

digital inputs can be taken from the text file of the respective firmware.

Page 35

RC Input:

r

g

g

g

g

g

g

g

g

g

g

Using the RC input, you may switch every light mode to three different switching states. Use a switch on the transmitter

with a centre position (high, neutral, low) or a slider or rotary control. For switching the light mode, you may use

channels 5 – 8 or an externally fed servo signal (PPM).

In connection with the 7 different modes, the following light patterns result:

Mode PPM L1 L2 L3 L4 L5 L6 L7 L8 Buzze

High IN-1 IN-2 IN-3 DF SF SB DF Bat Bat

1 Neutral IN-1 IN-2 IN-3 DF SF SB OFF Bat Bat

Low IN-1 IN-2 IN-3 DF SF SB ON Bat Bat

h IN-1 IN-2 IN-3 DF SF SB DF Bat IN-3

Hi

2 Neutral IN-1 IN-2 IN-3 DF SF SB OFF Bat IN-3

Low IN-1 IN-2 IN-3 DF SF SB ON Bat IN-3

h Running light L1 to L8 IN-3

Hi

3 Neutral OFF IN-3

Low Runnin

Hi

h Inverted running light L1 to L8 IN-3

4 Neutral OFF IN-3

Low Inverted runnin

Hi

h Running light L1 to L4 IN-1 IN-3 SB Bat IN-3

5 Neutral OFF IN-1 IN-3 SB Bat IN-3

Low Runnin

Hi

h Inverted running light L1 to L4 IN-1 IN-3 SB Bat IN-3

6 Neutral OFF IN-1 IN-3 SB Bat IN-3

Low Inverted runnin

Hi

h WB1 WB2 IN-1 IN-2 IN-3 SF DF Bat IN-3

7 Neutral WB1 WB2 IN-1 IN-2 IN-3 SF OFF Bat IN-3

Low WB1 WB2 IN-1 IN-2 IN-3 SF ON Bat IN-3

light L4 to L1 IN-1 IN-3 SB Bat IN-3

light L4 to L1 IN-1 IN-3 SB Bat IN-3

light L8 to L1 IN-3

light L8 to L1 IN-3

Meaning of the abbreviations:

SB: Slow Blink (400 ms on, 400 ms off)

FB: Fast Blink (200 ms on, 200 ms off)

SF: Single Flash (50 ms, 1 s pause)

DF: Double Flash (50 ms, 50 ms, 1 s pause)

Bat: Battery warning in 5 levels (>9.4 V = OFF; <9.4 V = SF; <9.2 V = DF; <9.0 V = SB; <8.8 V = FB)

WB1, WB2: Alternative flashing (alternation every 100 ms)

Running light speed: Alternation every 100 ms

35

Page 36

b) Selecting the Light Mode

You can now set 7 light modes using the jumper (“X2”). Depending on the desired mode, the different contacts must be

connected with a jumper. Set the following jumpers for the following modes:

Mode 1: No jumper

Mode 2: Jumper 1 - 2

Mode 3: Jumper 3 - 4

Mode 4: Jumper 1 - 2 and Jumper 3 - 4

Mode 5: Jumper 1 - 3

Mode 6: Jumper 2 - 4

Mode 7: Jumper 1 - 3 and Jumper 2 - 4

C12

C12

C15

C15

C14

C14

T3

T3

R23

R23

SW2

R1

Q1

Q1

C1

R45

R44

BUZ1

1

X1

R7

R6

R3

X2

2

X3

C2

C3

IC1

3

5

4

6

Figure 21

36

Page 37

c) Selecting the RC Input

The desired RC input for switching the light effect can be set using the jumper SW1. Always connect the upper and

lower contacts with the jumper.

Assignment is as follows:

Servo selection 1 = channel 5

Servo selection 2 = channel 6

Servo selection 3 = channel 7

Servo selection 4 = channel 8

R42

R41

X15

R43

LD2

R21

R22

X6

X11

X8

X7

PPM

1

X12

2

SW1

X5

In the adjacent figure, the jumper is set to servo selection 1. You can now switch the set light mode at the transmitter

via channel 5. Control via channels 5, 6, 7 or 8 is only possible where they are also generated by the main control.

Signal generation is independent from the composite signal converter!

If this is not the case, you are able to directly feed an external servo signal (PPM) into the left connection contact of the

“X9” plug of an unassigned receiver output (e.g. channel 9). If you do not use any RC input and thus waive the

possibility of switching, PPM switching state “high” will always be active!

3

IC2

X9

X10

X10

4

R2

R2

Figure 22

T

37

Page 38

d) Connecting the LED Strips/LEDs

The combiboard offers the possibility of connecting up to eight LED strips with an operating voltage of 12 V and a

maximum power intake of 1 A/per strip. Even if the MOSFET switching outputs (FDS6890A) can resist up to 7.5 A, it

is recommended not to put more than 1 A on the individual outputs for board layout and cooling reasons.

If you want to connect individual LEDs with a lower operational voltage of only 2 – 3 V, a suitable dropping resistor (Rv)

must be calculated. For calculation of the dropping resistor, you should use an operational voltage of 12 V, since a

freshly charged 3-cell LiPo battery may have far more than 12 V instead of 11.1 V.

Example calculation:

Assuming that the light diode used has a supply voltage of 2.6 V and a power intake of 20 mA, first the dropping

resistor voltage must be calculated:

12 V – 2.6 V = 9.4 V

If you want to switch two corresponding light diodes in sequence, 2 x 2.6 V = 5.2 V must be subtracted from the

operating voltage of 12 V (12 V – 5.2 V = 6.8 V)

For three same diodes, this is 3 x 2.6 V = 7.8V to be subtracted from the operating voltage of 12 V (12 V - 7.8 V =

4.2 V).

Now use Ohm’s law R = U : I to calculate the dropping resistance Rv:

Rv = 9.4 V : 0.02 A = 470 Ohm

Use the formula P = U x I to also calculate the output the dropping resistor must be able to withstand:

9.4 V x 0.02 A = 0.188 W

A resistor with an output of ¼ W (0.25 W) would therefore be sufficient. The respective upper connection contacts of

the plugs “X3” (“L1” to “L4”) and “X4” (“L5” to “L8”) are intended for the LEDs or LED strip connection. The lower

connection contacts are connected to the plus connection (+) of the drive battery (11.1 V of the LiPo battery).

Connection pattern

Figure 23 shows the scheme for the connection of

a LED with dropping resistor at the output “L1” and

the connection of a 12 V light strip at the output

“L7”.

Important!

When connecting LEDs and LED light

strips, observe correct polarity of the

connection lines.

In practice, pre-manufactured BEC sockets with

open cable-ends have proven well suitable for LED

connection.

IC2

X10

X10

C16

C11

C10C9C8

C13

C12

C15

C16

C11

C10C9C8

R2

R2

X9

L5

L6

T5

T5

T4