Page 1

Operating Instructions

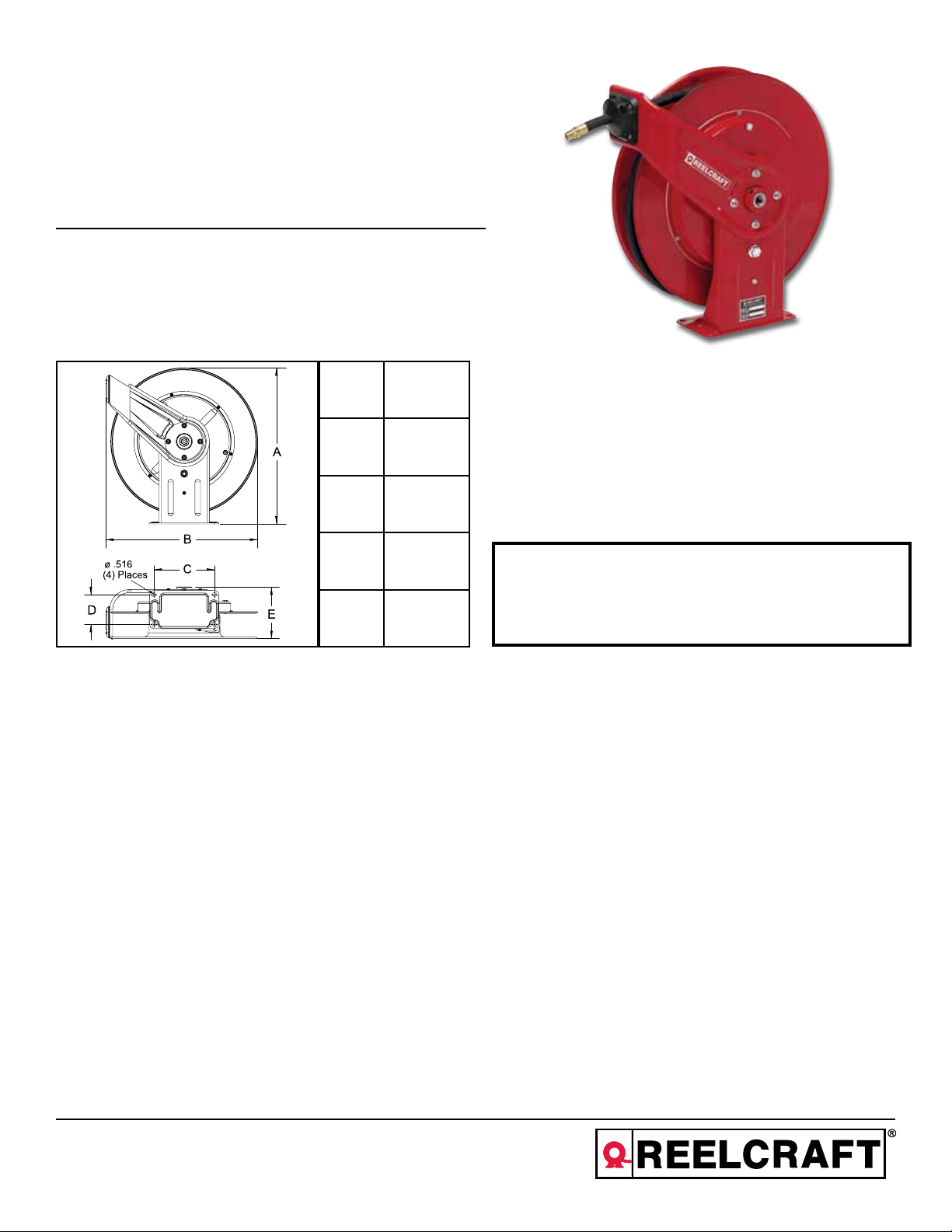

Series PW7000 Spring Driven Hose Reels

High Pressure Wash Model Numbers:

PW7600 OHP PW7650 OHP

Dimensions

A 20 1/4”

B 19 3/4”

C 7 7/8”

D 3 7/8”

E 7 3/8”

SAFETY

Personal injury and/or equipment damage may result if proper safety

precautions are not observed.

• Ensure that reel is properly installed before connecting input and

output hoses.

• Bleed fluid/gas pressure from system before servicing reel.

• Before connecting reel to supply line, ensure that pressure does

not exceed maximum working pressure rating of reel.

• Remember, even low pressure is very dangerous and can cause

personal injury or death.

• Be aware of machinery and personnel in work area.

IMPORTANT

Read this manual carefully before installing, operating or

servicing this equipment.

• A high tension spring assembly is contained within the reel.

Exercise extreme caution.

• Pull hose from reel by grasping the hose itself, not the control

valve.

• Ensure that reel, hose, and equipment being serviced are

properly grounded. Use an ohmmeter to check ground

continuity.

• If reel ceases to unwind or rewind, remove system pressure

immediately. Do not pull or jerk on hose!

• If a leak occurs in the hose or reel, remove system pressure

immediately.

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

Customer Service: 855-634-9109 • reelcraft@reelcraft.com • www.reelcraft.com

• Treat and respect the hose reel as any other piece of machinery,

observing all common safety practices.

Form #1244-213 Rev: 4/2013

Page 2

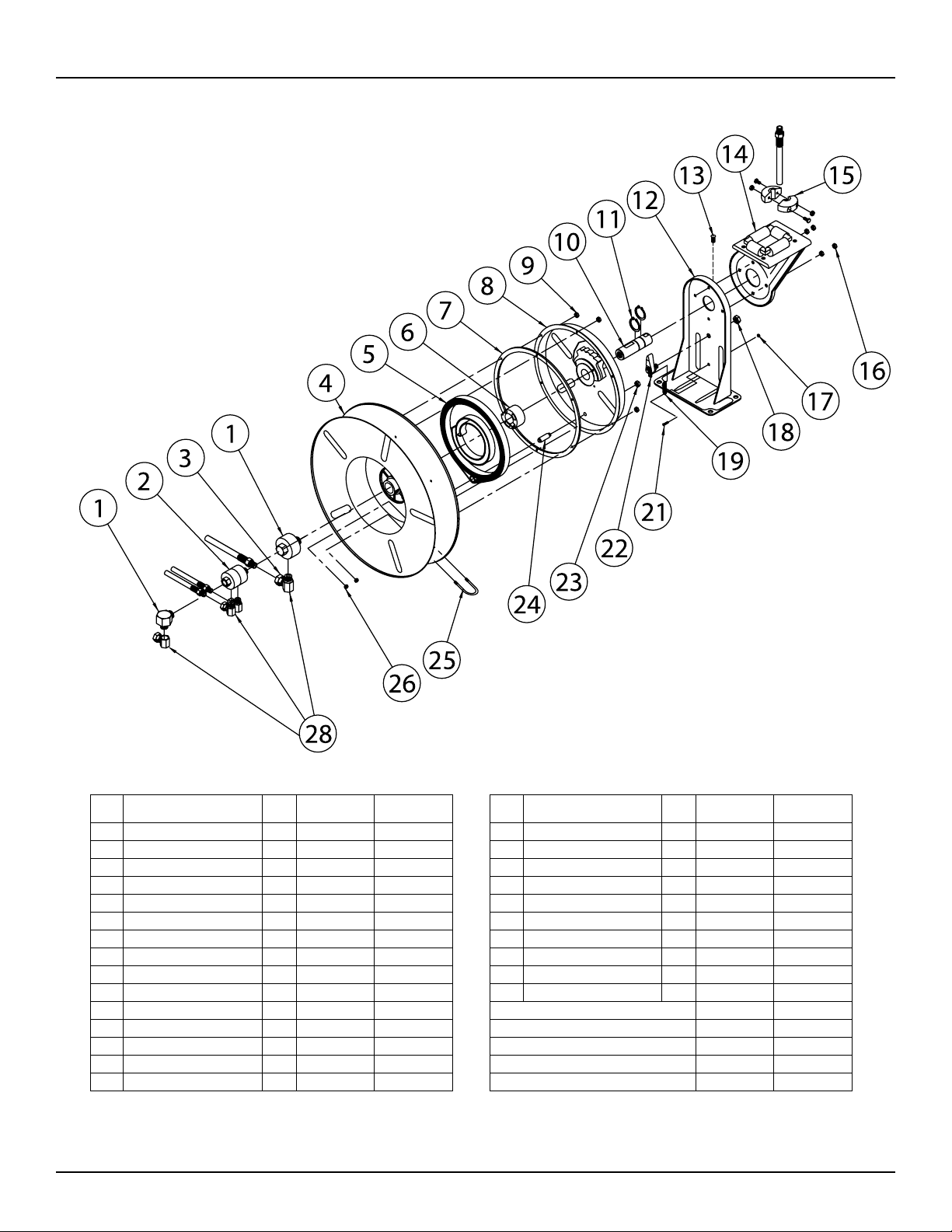

Series PW7000 Spring Driven Hose Reels

INSTALLATION INSTRUCTIONS

MOUNTING

Caution: Unless reel was specified

differently when ordering, maximum

installation height is 16 feet. Do not

exceed this distance.

1. Unpack and inspect reel for damage.

Turn by hand to check for smooth

operation. Check for completeness.

2. Configure reel for top, side or

bottom-wind hose dispensing by

removing nuts (1) securing guide arm

bracket (2). Position guide arm bracket

to desired location, and replace nuts.

Caution: When changing guide arm

positions, the U-bolt must be placed in

the proper location as instructed in

figure A below. The reel can

“latch out” during use if this

instruction is not adhered to.

3. Position reel on floor, wall, or ceiling.

Secure into place using four (customer

supplied) bolts (3).

INSTALLING THE INPUT HOSE(S)

Warning: Ensure that supply line

pressure does not exceed maximum

working pressure rating of reel. Apply

pipe thread sealant to all threads.

Caution: Use flexible hose connection at

input. Do not use rigid plumbing.

1. Connect supply line hose (4) to main

shaft input (5) as indicated in

illustration.

INSTALLING THE OUTPUT HOSE(S)

Warning: Use extreme caution; reel

under tension. Avoid releasing latch

mechanism. Apply pipe thread sealant to

all threads.

1. Manually turn sheave (10) until spring

is tight, back off 3 turns, then latch.

2. Route output hose(s) (11) through

guide arm bracket (2), U-bolts (12),

then through cutout (13) in spool as

indicated in illustration.

3. Connect output hose(s) (11) to swivel

(14) as indicated in illustration.

4. Tighten U-bolts (12).

5. Charge hose(s). Momentarily open

control valve to purge hose(s) of gases.

When fluid appears at control valve,

close valve. With hose(s) fully charged,

release latch and wind output hose(s)

onto reel.

ADJUSTMENTS

Warning: Use extreme caution; reel

under tension. Avoid releasing latch

mechanism. If necessary, adjust spring

tension on reel by adding or removing

wraps of hose from spool, one wrap at a

time, until desired tension is obtained.

Add wraps to increase tension. Remove

wraps to decrease tension.

SERVICE INSTRUCTIONS

User servicing of the reel is limited to

replacing input/output hoses only. Refer

all other repairs to an authorized service

person or directly to Reelcraft. Failure to

do so can result in personal injury and/or

equipment damage and may void the

warranty. Warning: Rewind hose on

reel, then bleed pressure from system

before performing the following procedures.

1. Replace hoses in accordance with

procedures given in “Installation

Instructions” section of this manual.

Caution: When replacing drive spring,

hold the center of the spring down as the

hub is pulled out. If the center is allowed

to raise up, the spring may escape from

it’s container with enough force to cause

injuries.

When disposing of old or broken spring

assemblies, the coils should be welded or

wired together to prevent possible injury

to scrap handling personnel.

2. All mating moving parts are to be

lubricated with Perma Bond or Loctite

anti-seize compound.

Page 2

Figure A

www.reelcraft.com

Page 3

Series PW7000 Spring Driven Hose Reels

Item

#

1 Swivel Assembly 1 S602033 S602033

3 90° Ell 1 None None

4 Sheave Assembly 1 S260011 S260011

5 Drive Spring Assembly 1 S260053 S260053

6 Spring Arbor Assembly 1 S600621 S600621

7 Gasket 1 S260069 S260069

8 Spring Case Assembly 1 S260074 S260074

9 10-32 Hex Locknut 6 S300011 S300011

10 Main Shaft 1 S260095 S260095

11 1 1/4” Snap Ring 2 300007 300007

12 Base Assembly 1 S600016 S600016

13 1/2-13 Set Screw 1 S35-84 S35-84

14 Guide arm with Rollers 1 S600017 S600017

15 Hose Bumper Assembly 1 None A1-HR1004-3

16 5/16-18 Locknut 4 300107 300107

Description

#

PW7600 OHP PW7650 OHP

Req.

www.reelcraft.com

Item

#

17 10-32 x 3/8” Nyloc Nut 1 S82-15 S82-15

18 1/2-20 x 5/8” Hex Nut 1 S280-8 S280-8

19 Latch Spring 1 S260067-1 S260067-1

21 10-32 Shoulder Screw 1 S393-2 S393-2

22 Latch Pawl Assembly 1 S600018 S600018

23 3/8-24 Jam Nut 1 S76-106 S76-106

24 Spring Case Stud 1 S260031 S260031

25 U-bolt 1 3-117440 3-117440

26 1/4-20 x 3/8” Locknut 2 261650-1 261650-1

28 Swivel Union 1 S257-72 S257-72

Hose Assembly None 5-260044

Hose I.D. x Length None 3/8” x 50’

Reel Inlet Connection 1/2” (F)NPTF 1/2” (F)NPTF

Max. Operating Pressure 5000 PSI 4800 PSI

Max. Operating Temperature 400° F 400° F

Description

#

PW7600 OHP PW7650 OHP

Req.

Page 3

Page 4

Instrucciones de Operacion

Series PW7000 Carreteles para Mangueras

Números de lavado de alta presión modelo:

PW7600 OHP PW7650 OHP

Dimensiones

A 20 1/4”

B 19 3/4”

C 7 7/8”

D 3 7/8”

E 7 3/8”

Seguridad

Podrían ocurrir lesiones personales y/o daños en el equipo si no se

siguen las instrucciones de seguridad adecuadas.

• Asegúrese de que el carretel esté instalado apropiadamente

antes de conectar las mangueras de entrada y de salida.

• Purgue la presión de fluidos/gases del sistema antes de suministrar servicio al carretel.

• Antes de conectar el carretel a la línea de suministro,

asegúrese de que la presión no exceda la clasificación máxima

de la presión operativa del carretel.

• Recuerde que aún la presión baja es muy peligrosa y podría

causar lesiones personales o la muerte.

• Esté atento y fíjese si hay maquinaria o

personas en el área de trabajo.

IMPORTANTE

Lea este manual detenidamente antes de

instalar, operar o dar servicio a este equipo.

• Hay un ensamblaje de resorte de tensión alta en el interior del

carretel. Sea extremadamente precavido.

• Jale la manguera del carretel sujetando la manguera, y no la

válvula de control.

• Si el carretel deja de desenrollarse o enrollarse, elimine

inmediatamente la presión del sistema. ¡No jale ni sacuda la

manguera!

• Trate y utilice el carretel de manguera como lo haría con

cualquier otra máquina, siguiendo todas las pautas de seguridad generales.

• Si existe una fuga en la manguera o en el carretel, elimine

inmediatamente la presión del sistema.

Page 4

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

Customer Service: 855-634-9109 • reelcraft@reelcraft.com • www.reelcraft.com

Form #1244-213 Rev: 4/2013

Page 5

Series PW7000 Carreteles para Mangueras

INSTRUCCIONES DE INSTALACIÓN

Montaje

PRECAUCIÓN: A menos de que el car-

retel haya sido suministrado con características diferentes al ordenarlo, la altura

máxima de instalación es de 16 pies. No

exceda esta altura.

1. Déballez l’enrouleur et inspectez-le

pour déceler le dommage. Faites

tournez à la main pour vérifier le bon

fonctionnement. Vérifiez l’enrouleur

pour voir s’il est complet.

2. Agencez l’enrouleur en prévision

d’une sortie laterale, par le haut, ou

par le bas en enlevantles écrous qui

correspondent au support. Fixez le

support guide la position désirée, et

remplacez les écrous.

ATENCIÓN: Al cambiar las posiciones del

brazo guía, el perno en U debe colocarse

en la posición correcta, como se indica

en la figura A. Si no se cumple con esta

instrucción, el carrete puede bloquearse

durante el uso.

3. Positionnez l’enrouleur au sol, au

mur, ou au plafond. Fixez-le solidement en utilisant 4 boulons (fournis

par le client).

INSTALACIÓN DE LA MANGUERA DE

ENTRADA

ADVERTENCIA: Asegurece que la linea

de abastecimiento de presion no exeda el

maximo rango de trabajo de presion de el

carretel. Aplique sellante de roscas para

tuberia. PRECAUCION: Use conecciones

de manguera flexible en la entrada. No

use tuberia rigida.

1. Conecte la linea de abastecimiento de

la manguera (4) a la entrada principal

del canal del eje giratorio (5) como

se indica en la ilustracion.

INSTALACIÓN DE LA SALIDA DE

LA(S) MANGUERA(S)

ADVERTENCIA: Use extrema precaucion;

carretel bajo tension. Aplique sellante de

roscas para tuberia a todas las roscas

estandar.

1. Manualmente gire la rueda exentrica

o riel (10) hasta que el resorte este

apretado, devuelvalo 3 giros y entonces asegurelo.

2. Encamine la(s) salida(s) de la

manguera(s) (11) hasta la guia de

soporte de el brazo (2), tornillos-U

(12) entonces saquelos atravez (13)

del carretel como se indica en la

ilustracion.

3. Conecte la(s) salida(s) de la(s) (11)

a el eje giratorio (14) como se indica

en la ilustracion.

4. Aprite los tornillos-U (12).

5. Cargue las mangueras.

Momentaneamente abra la valvula de

control para purgar la mangueras de

los gases cuando el fluido aparesca

en el control de las valvulas, cierre

la valvula, Con las mangueras total

mente cardas, suelte el seguro y

enrrolle la(s) manguera(s) sobre el

carretel.

AJUSTAMIENTOS

ADVERTENCIA: Use extrema precaucion,

carretel bajo tension. Evite soltar el seguro mecanico. Si es necesario, ajuste el

resorte de tencion de el carretel poiniendo

ó quitando vueltas de la manguera del

carretel una vuelta a la vez hasta que la

tension deseada es obtenida. Adicione

vueltas para incrementar la tension. Quite

vueltas para decrecer la tension.

INSTRUCCIONES DE SERVICIO

El suministro de servicio por parte del

usuario se limita únicamente a reemplazar mangueras de entrada/salida. Remita

cualquier otra reparación a un técnico

de servicio autorizado o directamente a

Reelcraft. El no hacerlo podría resultar

en lesiones personales y/o daños del

equipo que podrían anular la garantía.

Advertencia: Enrolle la manguera en el

carretel, y después purgue la presión del

sistema antes de efectuar los siguientes

procedimientos. Precaución: Elimine

toda la tensión del resorte antes de

desensamblar el carretel de manguera. No

trate de abrir el ensamblaje remachado de

la caja de resorte.

1. Reemplace la manguera de acuerdo

con los procedimientos de la sección

Instrucciones de Instalación de este

manual.

2. Todas las partes móviles correspondientes han sido lubricadas adecuadamente en la fábrica.

Page 5

Figura A

www.reelcraft.com

Page 6

Series PW7000 Carreteles para Mangueras

ART.

NO.

1 Eje giratorio emsamblado 1 S602033 S602033

3 Codo de 90 grados 1 Ninguno Ninguno

4 Polea ensamblada 1 S260011 S260011

5 Resorte ensamblado de propulcion 1 S260053 S260053

6 Resorte del arbol 1 S600621 S600621

7 Empaque 1 S260069 S260069

8 Resorte de la caja ensamblada 1 S260074 S260074

9 10-32 Tuerca hexagonal 6 S300011 S300011

10 Columna principal 1 S260095 S260095

11 1 1/4” Anillo de resorte 2 300007 300007

12 Base ensamblada 1 S600016 S600016

13 1/2-13 T ornillo 1 S35-84 S35-84

14 Guia del brazo con rodillos 1 S600017 S600017

Manguera del parachoque ensamblada

15

16 5/16-18 Contre écrou 4 300107 300107

Descripción

NO.

PW7600 OHP PW7650 OHP

REQ.

1 Ninguno A1-HR1004-3

www.reelcraft.com

ART.

NO.

17 10-32 x 3/8” écrou Nyloc 1 S82-15 S82-15

18 1/2-20 x 5/8” écrou hexagonal 1 S280-8 S280-8

19 Ressort de loquet 1 S260067-1 S260067-1

21 10-32 tornillo de hombro 1 S393-2 S393-2

22 Assemblage de cliquet 1 S600018 S600018

23 3/8-24 contre-écrou 1 S76-106 S76-106

24

25 Tornillo “u” 1 3-117440 3-117440

26 1/4-20 x 3/8” contre-écrou 2 261650-1 261650-1

28 Union del eje giratorio 1 S257-72 S257-72

Manguera del ensamblada Ninguno 5-260044

Manguera I.D. y Medida Ninguno 3/8” x 50’

Coneccion de Entrada al Carretel 1/2” (F)NPTF 1/2” (F)NPTF

Max. Presion de Operacion 5000 PSI 4800 PSI

Max. Temperatura de Operacion 400° F 400° F

Descripción

Boulon de boîtier de ressort

NO.

PW7600 OHP PW7650 OHP

REQ.

1 S260031 S260031

Page 6

Page 7

Instructions D’Opération

Série PW7000 Enrouleurs de Tuyau

Haute pression chiffres laver modèle:

PW7600 OHP PW7650 OHP

Dimensions

A 20 1/4”

B 19 3/4”

C 7 7/8”

D 3 7/8”

E 7 3/8”

Sécurité

Podrían ocurrir lesiones personales y/o daños en el equipo si no se

siguen las instrucciones de seguridad adecuadas.

• Assurez-vous que l’enrouleur est correctement installé avant de

raccorder les tuyaux d’entrée et de sortie.

• Evacuez tout liquide/gaz sous pression du système avant

d’entreprendre l’entretien de l’enrouleur.

• Avant de raccorder l’enrouleur à la ligne d’alimentation, assurezvous que la pression n’excède pas la pression de fonctionnement

nominale maximum de l’enrouleur.

• Souvenez-vous, même les pressions basses sont dangereuses et

peuvent provoquer des blessures ou la mort.

• Ayez conscience des machines et des personnes se trouvant

dans la zone de travail.

IMPORTANT

Lisez ce manuel soigneusement avant d’installer, actionner,

ou entretenir cet èquipment.

• Si une fuite apparaît dans le tuyau ou l’enrouleur, décompressez

le système immédiatement.

• L’enrouleur comporte un assemblage à ressort de haute tension.

Observez la plus grande prudence.

• Sortez le tuyau de l’enrouleur en tirant sur le tuyau lui-même,

pas sur l’embout.

• Si l’enrouleur arrête d’enrouler ou de dérouler, décompressez le

système immédiatement. Ne pas tirer ou secouer le tuyau !

• Comme avec toute autre machine, traitez l’enrouleur de tuyau

avec respect, en observant les consignes de sécurité habituelles.

Page 7

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

Customer Service: 855-634-9109 • reelcraft@reelcraft.com • www.reelcraft.com

Form #1244-213 Rev: 4/2013

Page 8

Série PW7000 Enrouleurs de Tuyau

CONSIGNES D’INSTALLATION

MONTAMIENTO

PRECAUCION: Amenos que el riel haya

sido especificado diiferentemente cuando

se ordeno, el maximo de instalacion es de

16 pies. No exeda esta distancia.

1. Desempaque e inspeccione si el riel

esta dañado. Girelo con la mano

suave y revise su integridad.

2. Configure el riel por arriba, abajo o

lados, enrrolle el dispensador de la

manguera para remover las tuercas

(1) Asegurando la guia de soporte de

el brazo para escoger el sitio, reemplaze las tuercas.

3. Posicione el carretel sobre el piso,

pared o techo. Asegurese de instalarlo usando cuatro tornillos (abastesidos al cliente) y (3) tuercas.

INSTALLATION DES TUYAUX

D’ENTRÉS

MIS EN GARDE: Assurez-vous que la

pression du tuyau d’alimentation ne

dépasse pas la pression maximum qui

est specifié pour l’enrouleur. Appliquez

du materiau d’étanchiété pour les filets de

tuyau à tous les filets uniquement sur les

enrouleurs. AVERTISSMENT: Utilisez un

raccord flexible à l’entré. N’utilisez pas les

tuyaux rigides.

1. Connectez la ligne d’alimentation (4)

à la manche d’entré principale (5)

comme indiqué.

INSTALLATION DES TUYAUX DE

SORTIES

MIS EN GARDE: Faites attention; enrou-

leur sous tension! Évitez de lâcher le

mécanisme d’accrochage. Appliquez du

matériau d’étanchéité pour les filets du

tuyau à tous les filets uniquement sur les

enrouleurs.

1. Tournez à la main la poulie (10)

jusqu’au ressort est tendu, puistournez-la 3 tours à la sense opposite, puis fermez au loquet.

2. Guidez le(s) tuyau(x) (11) à travers le

support guide, les boulons en U (12),

et puis à travers le trou (13) dans

l’entrouleur comme indiqué.

3. Connectez le(s) tuyau(x) (11) au raccord tounant (14) comme indiqué.

4. Serrez bien le boulons en U.

5. Chargez le(s) tuyau(x). Ouvrez

momentanément la vanne de régulation pour évacuer le(s) tuyau(x) des

gaz. Quand du fluide arrive à la vanne

de régulation, fermez-la. Lorsque

le(s) tuyau(x) sont completement

chargé(s), relâchez le mécanisme

d’accorchage et enroulez le(s)

tuyau(x) de sortie sur l’enrouleur.

RÉGLAGES

MISE EN GARDE: Faites attention;

enrouleur sous tension. Évitez de relâcher

le mécanisme d’accrochage. Au besoin,

réglez la tension du ressort l’enrouleur en

ajoutant ou en enlevant un tour de câble

à la fois jusqu’à l’obtention de la tension

désirée. Ajoutez un tour de câble pour

augmenter la tension. Enlevez un

tour pour l’effet contraire.

DIRECTIVES DE MAINTENANCE

La maintenance de l’enrouleur par

l’utilisateur est limitée à la remplacement

des tuyaux d’entré et de sortie. Signalez

tout autre problème seulement à une

personne autorisée ou directement à

Reelcraft. Inobservation de le faire peut

résulter en blessure personnel et/ou

le dommage d’équipment. En plus, la

garantie peut être annulée. MISE EN

GARDE: Rebobinez le tuyau à l’enrouleur,

et puis évacuez la pression du système

avant de faire ce qui suit.

1. Remplacez les tuyaux comme

décrivé au paragraphe “Instructions

d’Installation” qui se trouve dans ce

manuel.

AVERTISSMENT: Quand vous remplacez

le ressort de mouvement, maintenezle bien en place lorsque le moyeu est

enlevé. Si le centre du ressort peut se

lever, il peut échapper de son conteneur

avec assez de force de causer des blessures. En jetant de vieux assemblages

ou des assemblages cassés, les câbles

doivent être soudés ensemble ou fixés

ensemble pour éviter des blessures possibles aux ferrailleurs.

1. Toutes les pièces qui se touchent en

mouvant doivent être lubrifiées avec

du Perma Bond ou du Loctite (composé qui empêche le grippage).

Page 8

Figure A

www.reelcraft.com

Page 9

Série PW7000 Enrouleurs de Tuyau

ART

N°.

1 Assemblage de pivot 1 S602033 S602033

3 Coude à 90° 1 Aucun Aucun

4 Assemblage de poulie 1 S260011 S260011

Assemblage de ressort de mouvement

5

6 Mandrin de ressort 1 S600621 S600621

7 Joint d’étanchéité 1 S260069 S260069

8 Assemblge de boîtier de ressort 1 S260074 S260074

9 10-32 contre-écrou Nyloc 6 S300011 S300011

10 Arbre principal 1 S260095 S260095

11 1 1/4” dispositif de retenue 2 300007 300007

12 Assemblage de base 1 S600016 S600016

13 1/2-13 vis sans tête 1 S35-84 S35-84

14 Assemblage de guide 1 S600017 S600017

15 Assemblage d’arrêt de câble 1 Aucun A1-HR1004-3

16 5/16-18 contre écrou 4 300107 300107

DÉSCRIPTION

N°

PW7600 OHP PW7650 OHP

REQ.

1 S260053 S260053

www.reelcraft.com

ART

N°.

17 10-32 x 3/8” écrou Nyloc 1 S82-15 S82-15

18 1/2-20 x 5/8” écrou hexagonal 1 S280-8 S280-8

19 Ressort de loquet 1 S260067-1 S260067-1

21 10-32 vis à épaulement 1 S393-2 S393-2

22 Assemblage de cliquet 1 S600018 S600018

23 3/8-24 contre-écrou 1 S76-106 S76-106

24

25 Boulon en U 1 3-117440 3-117440

26 1/4-20 x 3/8” contre-écrou 2 261650-1 261650-1

28 Union de pivot 1 S257-72 S257-72

Assemblage de tuyau Aucun 5-260044

Longeur et Diamètre Intérieur du Tuyau Aucun 3/8” x 50’

Raccord d’entré d’enrouleur 1/2” (F)NPTF 1/2” (F)NPTF

Pression d’opération maximum 5000 PSI 4800 PSI

Température d’opération maximum 400° F 400° F

DÉSCRIPTION

Boulon de boîtier de ressort

N°

PW7600 OHP PW7650 OHP

REQ.

1 S260031 S260031

Page 9

Loading...

Loading...