Page 1

Operating Instructions

Series M80000 Spring Driven Hose Reels

M82000 OMP118 M83000 OMP118 M81000 OHP118

IMPORTANT

Read this manual carefully before installing,

operating or servicing this equipment.

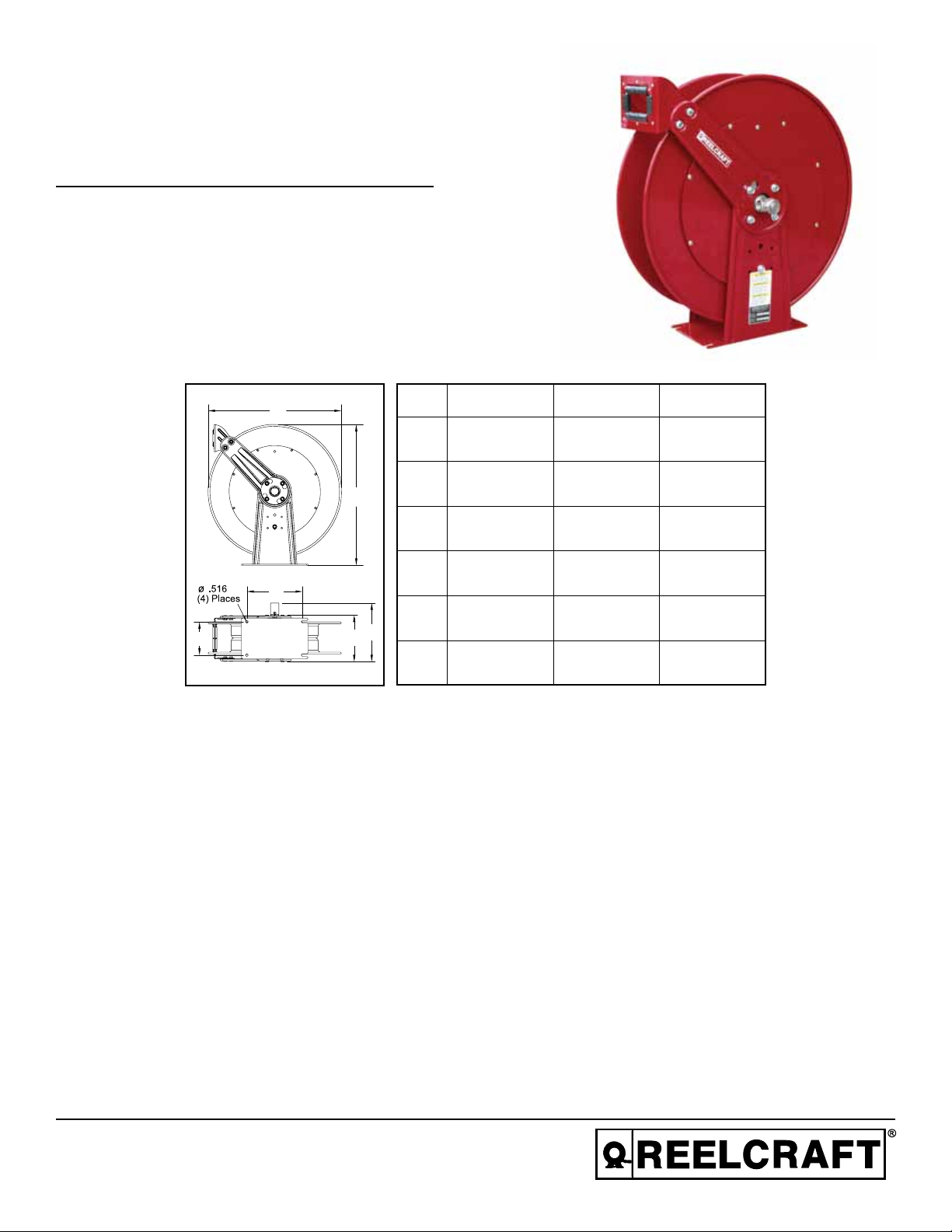

Dimensional Data

B

C

D

Personal Safety

Personal injury and/or equipment damage

may result if proper safety precautions are

not observed.

• Ensure that reel is properly installed

before connecting input and output

hoses.

• Bleed fluid/gas pressure from system

before servicing reel.

• Before connecting reel to supply line,

ensure that pressure does not exceed

maximum working pressure rating of

reel.

Part # M82000 OMP118 M83000 OMP118 M81000 OHP118

A

A

E

F

B

C

D

E

F

25.375” 25.375” 25.375”

24” 24” 24”

10” 10” 10”

6” 6” 6”

10.5” 10.5” 10.5”

8.375” 8.375” 8.375”

• Remember, even low pressure is very

dangerous and can cause personal in-

jury or death.

• Be aware of machinery and personnel

in work area.

• If a leak occurs in the hose or reel, remove system pressure immediately.

• A high tension spring assembly is contained within the reel. Exercise extreme

caution.

• Pull hose from reel by grasping the

hose itself, not the control valve.

• If reel ceases to unwind or rewind,

remove system pressure immediately.

Do not pull or jerk on hose!

• Treat and respect the hose reel as any

other piece of machinery, observing all

common safety practices.

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

Customer Service: 855-634-9109 • reelcraft@reelcraft.com • www.reelcraft.com

Form# 1224-816 Rev: 3/2013

Page 2

Series M80000 Spring Driven Hose Reels

INSTALLATION INSTRUCTIONS

WARNING: Ensure that reel, hose, and

equipment are properly grounded. Use an

ohmmeter to check ground continuity.

Mounting

CAUTION: Unless reel was specified different-

ly when ordering, maximum installation height

is 16 feet. Do not exceed this distance.

1. Unpack and inspect reel for damage.

Turn by hand to check for smooth operation. Check for completeness.

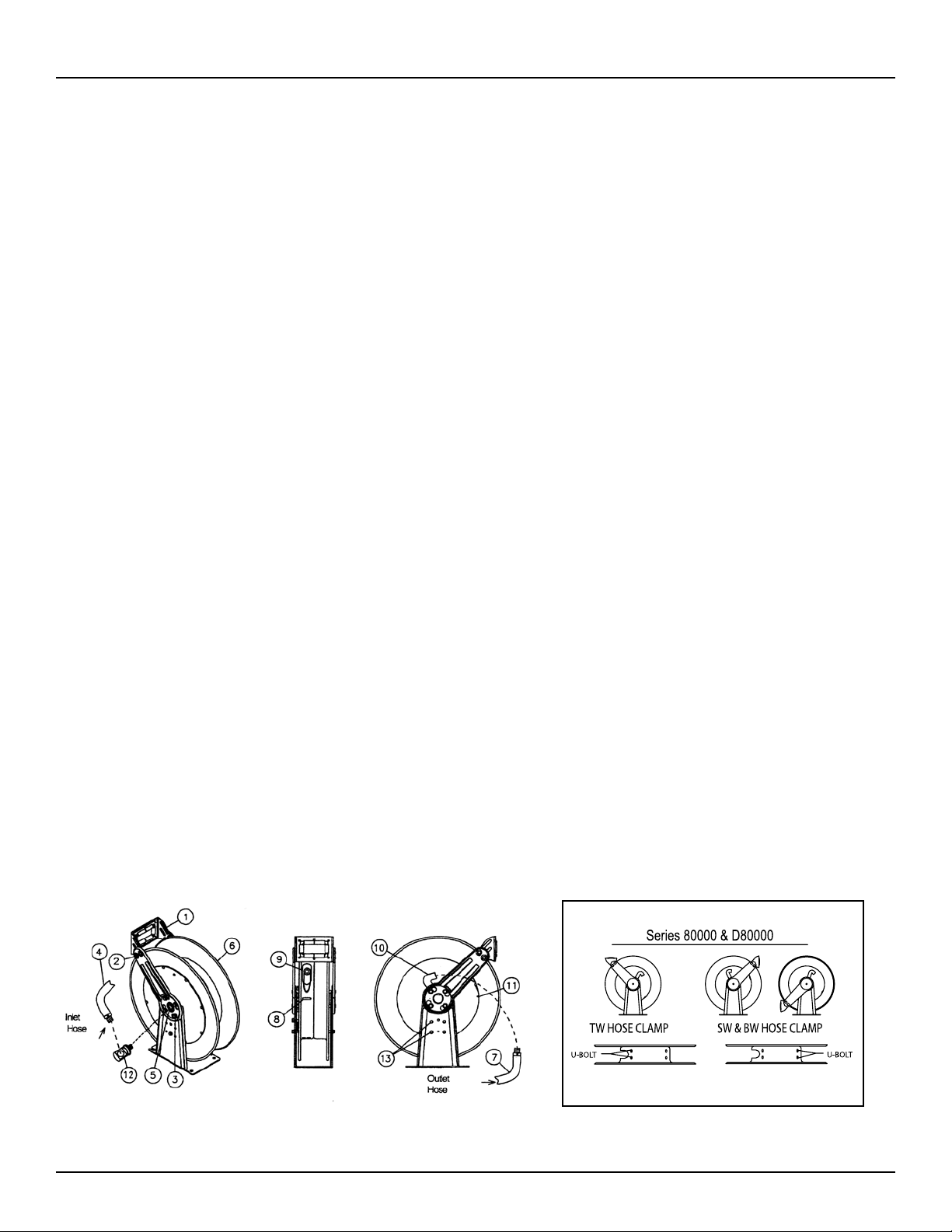

2. Configure reel for top, side or bottom

hose dispensing by removing the bolts

(2) from one side of the guide roller

bracket and loosening the four guide arm

bolts (3) on each side of the hose reel.

Rotate and remove each guide arm then

reinstall in the desired configuration. If

bottom wind is desired, bolts (13) and

bolts (2) must be removed and replaced

after the guide arm is in position.

CAUTION: When changing guide arm

positions, the U-bolt must be placed in the

proper location as instructed in figure A. The

reel can “latch out” during use if this instruction is not adhered to.

3. Position reel on floor, wall, or ceiling.

Secure into place using four (customer

supplied) bolts.

Installing the Input Hose

WARNING: Ensure that supply line pressure

does not exceed maximum working pressure

rating of reel. Apply pipe thread sealant to all

threads on standard reels. Do not overtighten

connection. Recommended torque not to

exceed 70 ft. lb.

CAUTION: Use flexible hose connection at

input. Do not use rigid plumbing.

1. Apply thread sealant as directed and connect swivel (12) to main shaft input (5).

2. For standard shaft and swivel reels, connect customer supplied inlet hose (4) to

swivel input as indicated in illustration.

Installing the Output Hose

WARNING: Use extreme caution; reel under

tension. Avoid releasing latch mechanism.

CAUTION: Apply pipe thread sealant to all

threads on standard reels. Do not overtighten

connection. Recommended torque not to

exceed 70 ft. lb.

1. Manually turn sheave (6) until spring is

tight, back off 3 turns, then latch.

2. Route output hose (7) through roller

bracket (1), U-bolts (8), then through

cutout (9) in spool as indicated in illustration.

3. Connect output hose (7) to gooseneck

(10) as indicated in illustration.

4. Verify U-bolt position conforms with

guide arm position using label inside

spool. Then tighten nuts (11) on U-bolt

(8).

5. Charge hose. Momentarily open control

valve to purge hose of gases. When fluid

appears at control valve, close valve.

With hose fully charged, release latch and

wind output hose onto reel.

6. Install hose bumper assembly.

ADJUSTMENTS

WARNING: Use extreme caution; reel under

tension. Avoid releasing latch mechanism.

If necessary, adjust spring tension on reel by

manually adding or removing wraps of hose

from spool, one wrap at a time, until desired

tension is obtained. Manually add wraps to

increase tension. Remove wraps to decrease

tension.

WARNING: Rewind hose on reel, then bleed

pressure from system before performing the

following procedures.

CAUTION: Remove all spring tension before

disassembling the hose reel. Do not attempt to

open the riveted spring case assembly.

1. Replace hoses in accordance with procedures given in “Installation Instructions”

section of this manual.

2. All mating moving parts have been factory lubricated as required.

Page 2

Figure A

www.reelcraft.com

Page 3

Series M80000 Spring Driven Hose Reels

ITEM DESCRIPTION QTY. M82000 OMP118 M83000 OMP118 M81000 OHP118

1 Pipe Plug 1 * * *

2 5/16-18 x 1/2” Screw 9 602487 602487 602487

3 Guide Arm 2 261299 261299 261299

4 5/16-18 Lock Nut 8 * * *

5 Spring & Case Assembly 1 600653-2-35 600653-1-35 600645-2-35

6 Roller Bracket Assembly 1 S600642 S600642 S600642

7 U-bolt 1 3-117440 5-117440 3-117440

8 1/4-20 Lock Nut 2 261650-1 261650-1 261650-1

9 Sheave Assembly 1 600649-35 600649-35 600649-35

10 Ratchet, Flow Casting 1 261306-4 261306-4 600667-5

11 Adapter 2 S382-19 None None

12 Swivel Assembly 1 602487 602487 602487

13 3/8-16 x 5/8” Screw 9 * * *

14 1 3/8” Snap Ring 2 * * *

Flange W/Bearing & Nut-Sert

15

Assembly

16 Machine Screw 5/16-18 x 1/2 7 S44-10 S44-10 S44-10

17 Bearing & Flange Assembly 1 S600644 S600644 S600644

18 Latch Pawl Assembly 1 S600018 S600018 S600675

19 Latch Mounting Bracket 1 261303 261303 None

20 Latch Spring 1 S260067 S260067 S260067

21 Base & Upright Assembly 1 600641 600641 600641

22 Shoulder Screw 1 S393-2 S393-2 S393-2

23 Nyloc Nut 1 S82-15 S82-15 S82-15

Latch Pawl & Mounting Bracket

Assembly - Items 18/19/20/22/23

1 S600651 S600651 S600651

1 S600643 S600643 None

www.reelcraft.com

*Included in hardware kit part number 602504

Page 3

Loading...

Loading...