Page 1

Operating Instructions

Series LP80000 / LPD80000

Spring Driven Hose Reels

LP82000 OLP LP83000 OLP

LPD83000 OLP LPD84000 OLP

IMPORTANT

Read this manual carefully before installing,

operating or servicing this equipment.

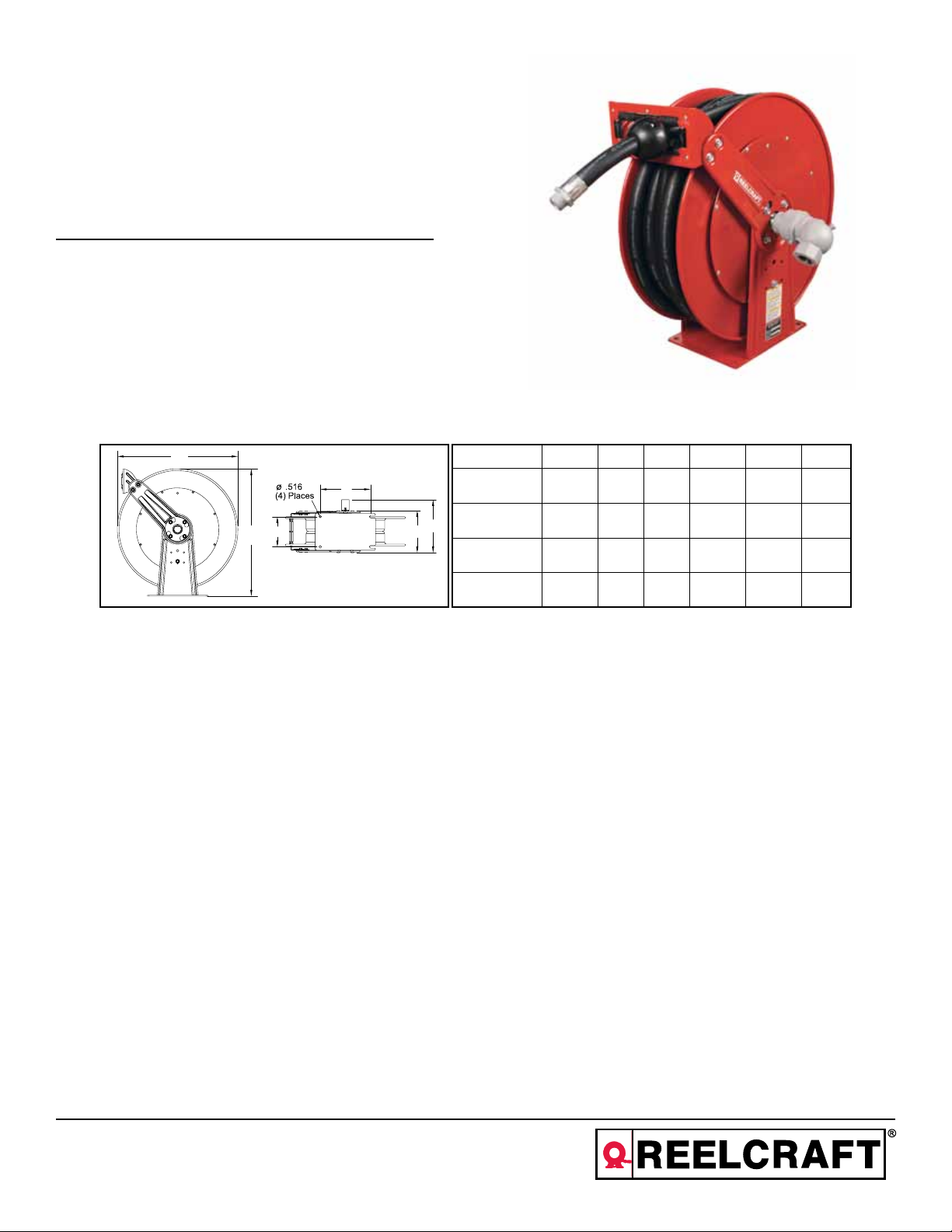

Dimensional Data

B

Part # A B C D E F

D

A

Personal Safety

Personal injury and/or equipment damage

may result if proper safety precautions are

not observed.

• Ensure that reel is properly installed

before connecting input and output

hoses.

• Bleed fluid/gas pressure from system

before servicing reel.

• Before connecting reel to supply line,

ensure that pressure does not exceed

maximum working pressure rating of

reel.

C

• Remember, even low pressure is very

dangerous and can cause personal in-

jury or death.

• Be aware of machinery and personnel

in work area.

• If a leak occurs in the hose or reel, remove system pressure immediately.

• A high tension spring assembly is contained within the reel. Exercise extreme

caution.

LP82000 OLP 25.375” 24” 10 6” 15.375” 9.375”

LP83000 OLP 25.375” 24” 10 6” 15.375” 9.375”

E

F

LPD83000 OLP 25.375” 24” 10.5” 7.875” 17.75” 9.375”

LPD84000 OLP 25.375” 24” 10.5” 7.875” 17.75” 9.375”

• Pull hose from reel by grasping the

hose itself, not the control valve.

• If reel ceases to unwind or rewind,

remove system pressure immediately.

Do not pull or jerk on hose!

• Treat and respect the hose reel as any

other piece of machinery, observing all

common safety practices.

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

Customer Service: 855-634-9109 • reelcraft@reelcraft.com • www.reelcraft.com

Form# 1161-1004 Rev: 5/2013

Page 2

Series LP80000 / LPD80000 Spring Driven Hose Reels

INSTALLATION INSTRUCTIONS

WARNING: Ensure that reel, hose, and

equipment are properly grounded. Use an

ohmmeter to check ground continuity.

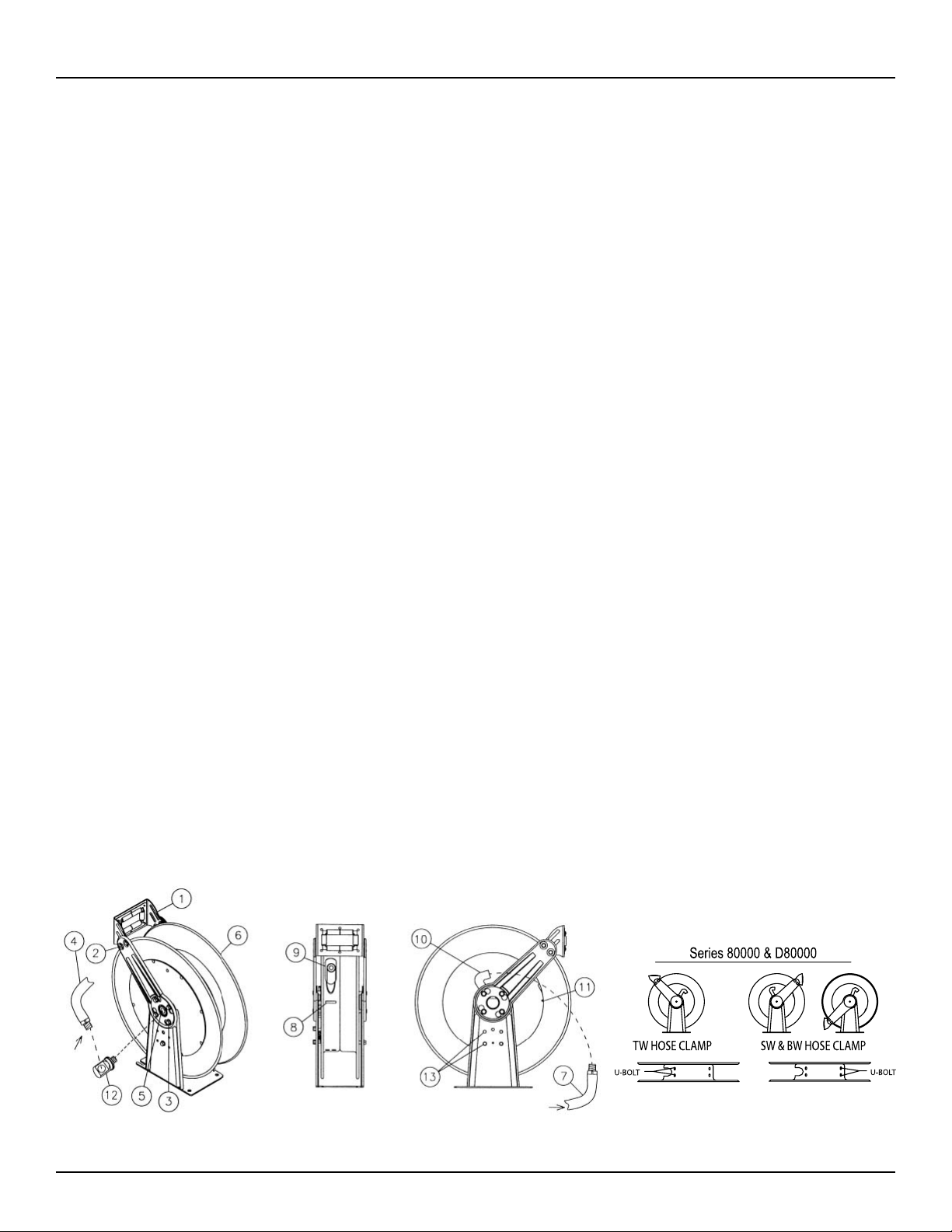

Mounting

CAUTION: Unless reel was specified different-

ly when ordering, maximum installation height

is 16 feet. Do not exceed this distance.

Maximum Operating Temperature:

Low pressure (300 psi) = 150°F (66°C)

1. Unpack and inspect reel for damage.

Turn by hand to check for smooth operation. Check for completeness.

2. Configure reel for top, side or bottom

hose dispensing by removing the bolts

(2) from one side of the guide roller

bracket and loosening the four guide arm

bolts (3) on each side of the hose reel.

Rotate and remove each guide arm then

reinstall in the desired configuration. If

bottom wind is desired, bolts (13) and

bolts (2) must be removed and replaced

after the guide arm is in position.

CAUTION: When changing guide arm

positions, the U-bolt must be placed in the

proper location as instructed in figure A. The

reel can “latch out” during use if this instruction is not adhered to.

3. Position reel on floor, wall, or ceiling.

Secure into place using four (customer

supplied) bolts.

Installing the Input Hose

WARNING: Ensure that supply line pressure

does not exceed maximum working pressure

rating of reel. Apply pipe thread sealant to all

threads on standard reels. Do not overtighten

connection. Recommended torque not to

exceed 70 ft. lb.

CAUTION

input. Do not use rigid plumbing. The use of

rigid plumbing may void the warranty.

1. Apply thread sealant as directed and con-

2. For standard shaft and swivel reels, con-

: Use flexible hose connection at

nect swivel (12) to main shaft input (5).

nect customer supplied inlet hose (4) to

swivel input as indicated in illustration.

Installing the Output Hose

WARNING: Use extreme caution; reel under

tension. Avoid releasing latch mechanism.

CAUTION: Apply pipe thread sealant to all

threads on standard reels. Do not overtighten

connection. Recommended torque not to

exceed 70 ft. lb.

1. Manually turn sheave (6) until spring is

tight, back off 3 turns, then latch.

2. Route output hose (7) through roller

bracket (1), U-bolts (8), then through

cutout (9) in spool as indicated in illustration.

3. Connect output hose (7) to gooseneck

(10) as indicated in illustration.

4. Verify U-bolt position conforms with

guide arm position using label inside

spool. Tighten nuts (11) on U-bolt (8).

5. Charge hose. Momentarily open control

valve to purge hose of gases. When fluid

appears at control valve, close valve.

With hose fully charged, release latch and

wind output hose onto reel.

6. Install hose bumper assembly.

ADJUSTMENTS

WARNING: Use extreme caution; reel under

tension. Avoid releasing latch mechanism.

If necessary, adjust spring tension on reel by

manually adding or removing wraps of hose

from spool, one wrap at a time, until desired

tension is obtained. Manually add wraps to

increase tension. Remove wraps to decrease

tension.

CAUTION: When adding wraps of hose, add

just enough wraps to achieve the desired

tension without exceeding the winding mechanism’s spring capacity. Properly tensioned

reels allow all hose to be freely removed from

the spool until the point of U-bolt contact.

Damage to the winding mechanism will result

if spring is over-tensioned.

SERVICE INSTRUCTIONS

User servicing of the reel is limited to replacing input/output hoses only. Refer all other

repairs to an authorized service person or

directly to Reelcraft. Failure to do so may

result in personal injury and/or equipment

damage and may void the warranty.

WARNING: Rewind hose on reel, then bleed

pressure from system before performing the

following procedures.

CAUTION: Remove all spring tension before

disassembling the hose reel. Do not attempt to

open the riveted spring case assembly.

1. Replace hoses in accordance with procedures given in “Installation Instructions”

section of this manual.

2. All mating moving parts have been factory lubricated as required.

Page 2

Figure A

www.reelcraft.com

Page 3

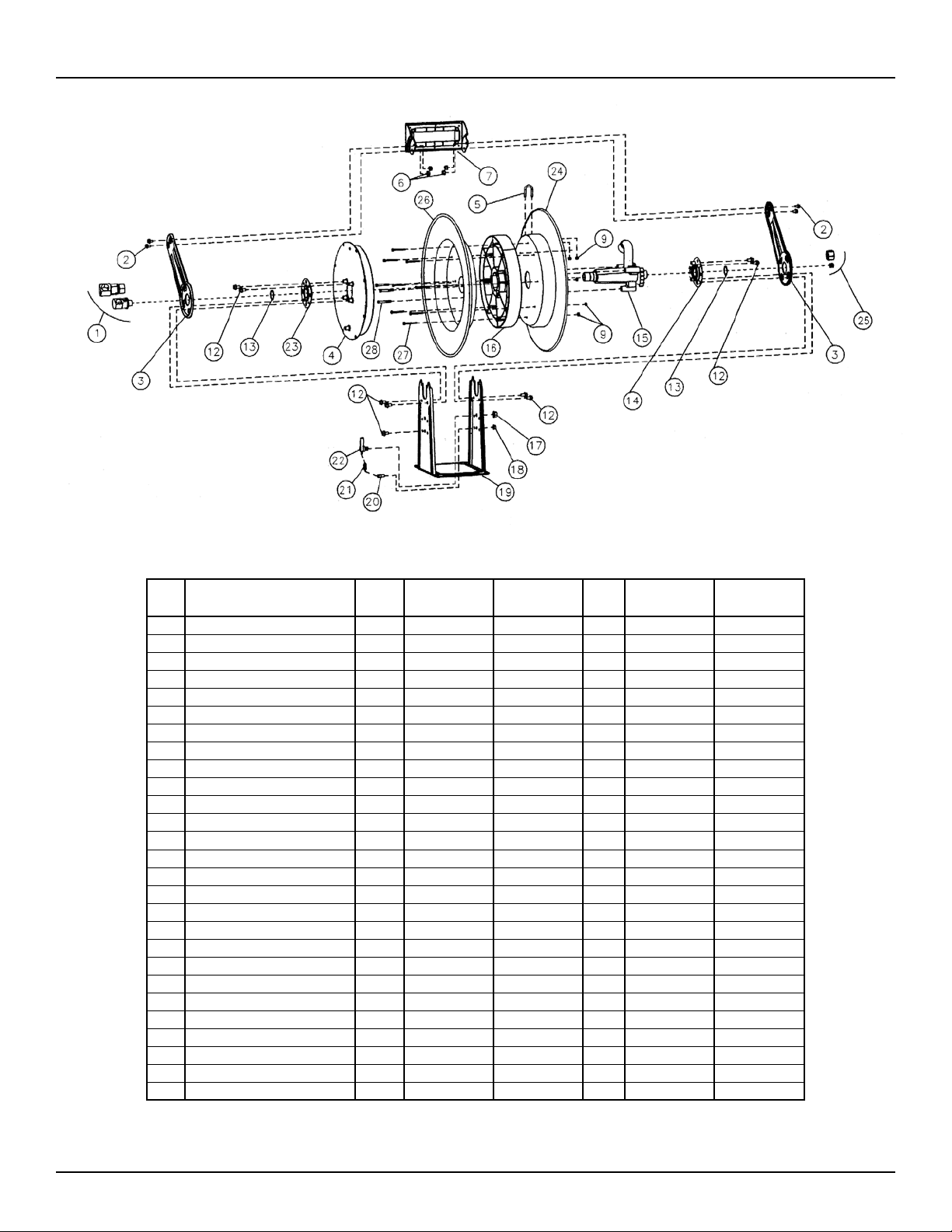

Series LP80000 / LPD80000 Spring Driven Hose Reels

ITEM DESCRIPTION

1 Swivel assembly 1 S600979-1 S600979-1 1 S600979-1 S600979-1

2 5/16-18 x 1/2” hex flange screw 4 S2-51 S2-51 4 S44-10 S44-10

3 Guide arm 2 261299 261299 2 261299 261299

4 Spring & case assembly 1 S600645-2 6006945-1 1 S600645-3 S600645-3

5 U-bolt 1 3-117440 5-117440 1 5-117440 261395

6 5/16-18 locknut 8 300107 300107 4 300107 300107

7 Roller bracket assembly 1 S600642 S600642 1 S600642 S600705

9 1/4-20 locknut 2 300070 300070 8 300070 300070

12 3/8-16 x 5/8” screw 9 S44-2 S44-2 9 S44-2 S44-2

13 1 3/8” snap ring 2 S140-34 S140-34 2 S140-34 S140-34

14 Bearing & nut-sert assembly 1 S600651 S600651 1 S600651 S600651

15 Ratchet, flow casting 1 261306-2 261306-2 1 S261590-1 S261591-1

16 Spool spacer --- None None 1 261393 261393

17 1/2-20 x 5/8” hex nut 1 S280-8 S280-8 1 S280-8 S280-8

18 3/8-16 hex nut ** --- None None 1 S281-6 S281-6

18 10-32 Nyloc nut --- None None 1 S82-15 S82-15

19 Base & upright assembly 1 600641 600641 1 600704 600704

20 Latch spring stud ** --- None None 1 261351 261351

20 Shoulder screw --- None None 1 S393-2 S393-2

21 Latch spring 1 S260067 S260067 1 S260067 S260067

22 Latch pawl assembly 1 S600018 S600018 1 S600018 S600018

23 Bearing & flange assembly 1 S600644 S600644 1 S600644 S600644

24 Sheave, hose opening 1 600649 600649 1 261307 261307

25 Pipe plug 1 S183-53 S183-54 1 S183-54 261396

26 Sheave, springcase --- None None 1 261308 261308

27 Screw, 1/4-20 x 2 1/2” --- None None 8 S2-411 S2-411

28 Screw, 5/16-18 x 2 1/2” --- None None 3 S2-511 S2-511

QTY

LP82000 OLP LP83000 OLP

(LP)

QTY

LPD83000 OLP LPD84000 OLP

(LPD)

www.reelcraft.com

**Prior to March 2012

Page 3

Page 4

Instrucciones de Operacion

Series LP80000 / LPD80000

Carreteles para Mangueras

LP82000 OLP LP83000 OLP

LPD83000 OLP LPD84000 OLP

IMPORTANTE

Lea este manual detenidamente antes de

instalar, operar o dar servicio a este equipo.

Data Dimensional

B

Part # A B C D E F

D

A

Seguridad Personal

Podrían ocurrir lesiones personales y/o

daños en el equipo si no se siguen las instrucciones de seguridad adecuadas.

• Asegúrese de que el carretel esté instalado apropiadamente antes de conectar

las mangueras de entrada y de salida.

• Purgue la presión de fluidos/gases del

sistema antes de suministrar servicio al

carretel.

• Antes de conectar el carretel a la línea

de suministro, asegúrese de que la presión no exceda la clasificación máxima

de la presión operativa del carretel.

C

• Recuerde que aún la presión baja es

muy peligrosa y podría causar lesiones

personales o la muerte.

• Esté atento y fíjese si hay maquinaria o

personas en el área de trabajo.

• Si existe una fuga en la manguera o en

el carretel, elimine inmediatamente la

presión del sistema.

• Hay un ensamblaje de resorte de tensión alta en el interior del carretel. Sea

extremadamente precavido.

• Jale la manguera del carretel sujetando

la manguera, y no la válvula de control.

LP82000 OLP 25.375” 24” 10 6” 15.375” 9.375”

LP83000 OLP 25.375” 24” 10 6” 15.375” 9.375”

E

F

LPD83000 OLP 25.375” 24” 10.5” 7.875” 17.75” 9.375”

LPD84000 OLP 25.375” 24” 10.5” 7.875” 17.75” 9.375”

• Si el carretel deja de desenrollarse o

enrollarse, elimine inmediatamente la

presión del sistema. ¡No jale ni sacuda

la manguera!

• Trate y utilice el carretel de manguera

como lo haría con cualquier otra máquina, siguiendo todas las pautas de

seguridad generales.

Page 4

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

Customer Service: 855-634-9109 • reelcraft@reelcraft.com • www.reelcraft.com

Form# 1161-1004 Rev: 5/2013

Page 5

Series LP80000 / LPD80000 Carreteles para Mangueras

INSTRUCCIONES DE INSTALACIÓN

ADVERTENCIA: Asegúrese de que el carretel,

la manguera y el equipo estén conectados a

tierra apropiadamente. Use un ohmiómetro para

revisar la continuidad de la conexión a tierra.

Montaje

PRECAUCIÓN: A menos de que el carretel

haya sido suministrado con características

diferentes al ordenarlo, la altura máxima de

instalación es de 16 pies. No exceda esta altura.

Temperatura Máxima de Operación:

Presión Baja (300 p.s.i.) = 150°F, (21,10 kg/cm2 /

300 p.s.i.) = 65,5° C (150° F)

1. Desempaque e inspeccione el carretel para ver si

se ha dañado. Hágalo girar a mano para cerciorarse de que gira suavemente. Asegúrese de que

todas las piezas estén incluidas.

2. Configure el carretel para poder jalar la manguera

desde arriba, abajo o lateralmente quitando los

pernos (2) a un lado de la abrazadera guía de rodillo y aflojando los cuatro pernos de brazo guía

(3) a cada lado del carretel de manguera. Gire y

quite cada brazo guía e instálelo nuevamente en

la

configuración deseada. Si desea poder jalar la

manguera desde abajo, tiene que remover y reemplacer los pernos (13) y (2) después de brazo

guía está a la posición deseada.

ATENCIÓN: Al cambiar las posiciones del brazo

guía, el perno en U debe colocarse en la posición

correcta, como se indica en la figura A. Si no se

cumple con esta instrucción, el carrete puede

bloquearse durante el uso.

3. Coloque el carretel en el piso, pared o cielo raso.

Fíjelo en su lugar usando cuatro

pernos (proporcionados por el cliente).

Instalación de la manguera de entrada

ADVERTENCIA: Asegúrese de que la presión

de la línea de suministro no exceda la

clasificación máxima de presión operativa

indicada en el carretel. Aplique sellador para

roscas de tubería en todas las roscas de los

carreteles estándar. No apriete excesivamente la

conexión. La torsión recomendada no debe exceder

70 pies libra.

PRECAUCIÓN: Use una conexión de

manguera flexible en el punto de entrada. No

use tubería rígida. El uso de fontaneria rigida

puede anular la garantia.

1. Aplique el sellador para roscas tal como se

indica y conecte el eslabón giratorio (12) a la

entrada del eje principal (5).

2. Para los carreteles de eje y eslabón giratorio

estándar, conecte una manguera de entrada proporcionada por el cliente (4) al punto de entrada

del eslabón giratorio, tal como se indica en la

ilustración.

Instalación de la manguera de salida

ADVERTENCIA: Sea extremadamente

precavido; el carretel se encuentra bajo

tensión. Evite desenganchar el mecanismo de

aldaba.

PRECAUCIÓN: Aplique sellador para roscas de tubería en todas las roscas de los carreteles estándar.

No apriete excesivamente la conexión. La torsión

recomendada no debe exceder 70 pies libra.

1. Gire manualmente la polea acanalada (6) hasta

que el resorte esté apretado, gírela hacia atrás

tres veces, y después fíjela.

2. Oriente la manguera de salida (7) a través de la

abrazadera de rodillo (1) y los pernos en U (8),

y después a través del orificio en el molinete, tal

como se indica en la ilustración.

3. Conecte la manguera de salida (7) al cuello de

cisne (10), tal como se indica en la

ilustración.

4. Verifique que la posición de los pernos en U

armonizan con el posicionamiento del brazo guía,

usando la etiqueta en el interior del molinete.

5. Cargue la manguera. Abra momentáneamente la

válvula de control para purgar los gases en la

manguera. Cierre la válvula cuando el fluido aparezca en la válvula de control. Con la manguera

completamente cargada, suelte la aldaba y enrolle

la manguera de salida alrededor del carretel.

6. Instale el ensamblaje de paragolpes.

AJUSTES

ADVERTENCIA: Sea extremadamente

precavido: el carretel se encuentra bajo

tensión. Evite desenganchar el mecanismo de

aldaba. Si es necesario, ajuste la tensión del

resorte en el carretel agregando o quitando

manualmente envolturas de manguera del

molinete una a la vez, hasta obtener la tensión

deseada. Agregue manualmente dichas

envolturas para aumentar la tensión, y quítelas

para disminuirla.

PRECAUCIÓN: Al agregar envolturas de

manguera, agregue únicamente el número

suficiente para obtener la tensión deseada sin

exceder la capacidad del resorte del

mecanismo de devanado. Los carreteles con

una tensión adecuada permiten sacar toda la

manguera del molinete hasta llegar al punto de

contacto con el perno en U. La tensión

excesiva del resorte dañará el mecanismo de

devanado.

INSTURCCIONES DE SERVICIO

El suministro de servicio por parte del usuario

se limita únicamente a reemplazar mangueras

de entrada/salida. Remita cualquier otra

reparación a un técnico de servicio autorizado

o directamente a Reelcraft. El no hacerlo podría

resultar en lesiones personales y/o daños del

equipo que podrían anular la garantía.

ADVERTENCIA: Enrolle la manguera en el

carretel, y después purgue la presión del

sistema antes de efectuar los siguientes

procedimientos.

PRECAUCIÓN: Elimine toda la tensión del

resorte antes de desensamblar el carretel de

manguera. No trate de abrir el ensamblaje

remachado de la caja de resorte.

1. Reemplace la manguera de acuerdo con los

procedimientos de la sección “Instrucciones de

Instalación” de este manual.

2. Todas las partes móviles correspondientes han

sido lubricadas adecuadamente en la

www.reelcraft.com

Figure A

Page 5

Page 6

Series LP80000 / LPD80000 Carreteles para Mangueras

ART.

NO.

1 Ensamblaje del eje giratoria 1 S600979-1 S600979-1 1 S600979-1 S600979-1

2 5/16-18 x 1/2” tornillo 4 S2-51 S2-51 4 S44-10 S44-10

3 Brazo Guía 2 261299 261299 2 261299 261299

4 Ensamblaje de Resorte y Caja 1 S600645-2 6006945-1 1 S600645-3 S600645-3

5 Perno en U 1 3-117440 5-117440 1 5-117440 261395

6 Tuerca de Sujeción 5/16-18 8 300107 300107 4 300107 300107

7 Ensamblaje de Abrazadera de Rodillo 1 S600642 S600642 1 S600642 S600705

9 1/4-20 Tuerca de Sujeción 2 300070 300070 8 300070 300070

12 3/8-16 x 5/8” tornillo 9 S44-2 S44-2 9 S44-2 S44-2

13 1 3/8” Aro de Resorte 2 S140-34 S140-34 2 S140-34 S140-34

14 Brida con Cojinete y Ensamblaje Nut-Sert 1 S600651 S600651 1 S600651 S600651

15 Trinquete, Bastidor Del Flujo 1 261306-2 261306-2 1 S261590-1 S261591-1

16 Espaciador Del Carrete --- -------- -------- 1 261393 261393

17 Tuerca de hexagonal 1/2-20 x 5/8” 1 S280-8 S280-8 1 S280-8 S280-8

18 3/8-16 Tuerca de hexagonal ** --- -------- -------- 1 S281-6 S281-6

18 10-32 Tuerca de Nyloc --- -------- -------- 1 S82-15 S82-15

19 Ensamblaje de Bajo Y Vertical 1 600641 600641 1 600704 600704

20 Perno prisionero del resorte de cierre ** --- -------- -------- 1 261351 261351

20 Tornillo de hombro --- -------- -------- 1 S393-2 S393-2

21 Resorte de cierre 1 S260067 S260067 1 S260067 S260067

22 Ensamblaje del gatillo del cierre 1 S600018 S600018 1 S600018 S600018

23 Ensamblaje del cojinete y del reborde 1 S600644 S600644 1 S600644 S600644

24 Polea acanalada, abertura de la Manguera 1 600649 600649 1 261307 261307

25 Tapón de tuberia 1 S183-53 S183-54 1 S183-54 261396

26 Polea acanalada, springcase --- -------- -------- 1 261308 261308

27 Tornillo, 1/4-20 x 2 1/2” --- -------- -------- 8 S2-411 S2-411

28 Tornillo, 5/16-18 x 2 1/2” --- -------- -------- 3 S2-511 S2-511

Descripción

NO.

REQ.

LP82000 OLP LP83000 OLP

(LP)

NO.

REQ.

LPD83000 OLP LPD84000 OLP

(LPD)

Page 6

** Antes del marzo de 2012

www.reelcraft.com

Page 7

Instructions D’Opération

Série LP80000 / LPD80000

Enrouleurs de Tuyau

LP82000 OLP LP83000 OLP

LPD83000 OLP LPD84000 OLP

IMPORTANT

Lisez ce manuel soigneusement avant

d’installer, actionner, ou entretenir cet

èquipment.

Dimensions

B

Part # A B C D E F

D

A

Sécurité

Podrían ocurrir lesiones personales y/o

daños en el equipo si no se siguen las instrucciones de seguridad adecuadas.

• Assurez-vous que l’enrouleur est correctement installé avant de raccorder

les tuyaux d’entrée et de sortie.

• Evacuez tout liquide/gaz sous pression du système avant d’entreprendre

l’entretien de l’enrouleur.

• Avant de raccorder l’enrouleur à la

ligne d’alimentation, assurez-vous que

la pression n’excède pas la pression de

fonctionnement nominale maximum de

l’enrouleur.

C

• Souvenez-vous, même les pressions

basses sont dangereuses et peuvent

provoquer des blessures ou la mort.

• Ayez conscience des machines et des

personnes se trouvant dans la zone de

travail.

• Si une fuite apparaît dans le tuyau ou

l’enrouleur, décompressez le système

immédiatement.

• L’enrouleur comporte un assemblage

à ressort de haute tension. Observez la

plus grande prudence.

LP82000 OLP 25.375” 24” 10 6” 15.375” 9.375”

LP83000 OLP 25.375” 24” 10 6” 15.375” 9.375”

E

F

LPD83000 OLP 25.375” 24” 10.5” 7.875” 17.75” 9.375”

LPD84000 OLP 25.375” 24” 10.5” 7.875” 17.75” 9.375”

• Sortez le tuyau de l’enrouleur en tirant sur le tuyau lui-même, pas sur

l’embout.

• Si l’enrouleur arrête d’enrouler ou de

dérouler, décompressez le système immédiatement. Ne pas tirer ou secouer le

tuyau !

• Comme avec toute autre machine,

traitez l’enrouleur de tuyau avec respect, en observant les consignes de

sécurité habituelles.

Page 7

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

Customer Service: 855-634-9109 • reelcraft@reelcraft.com • www.reelcraft.com

Form# 1161-1004 Rev: 5/2013

Page 8

Série LP80000 / LPD80000 Enrouleurs de Tuyau

CONSIGNES D’INSTALLATION

AVERTISSEMENT : Assurez-vous que l’enrouleur,

le tuyau et l’équipement sont correctement mis à la

terre. Utilisez un ohmmètre pour vous assurer de la

continuité du circuit de mise à la terre.

Montage

ATTENTION : A moins de spécifications différentes

lors de la commande, la hauteur d’installation maximum de l’enrouleur est de 4,90 m (16 pieds). Ne

dépassez pas cette hauteur.

Température de fonctionnement maximum :

Basse pression (21,10 kg/cm2 / 300 p.s.i.) =

65,5° C (150° F)

Pression moyenne (140,65 kg/cm2 / 2000 p.s.i.)

= 98,9° C (210° F)

1. Déballez l’enrouleur et assurez-vous qu’il n’est

pas endommagé. Faites-le tourner à la main

pour vous assurer de son bon fonctionnement.

Assurez-vous qu’il est complet.

2. Configurez l’enrouleur pour une distribution

supérieure, latérale ou inférieure du tuyau en

retirant les vis (2) d’un côté du support du guide

à molette et en desserrant les quatre vis du bras

de guidage (3) de chaque côté de l’enrouleur de

tuyau. Pivotez et enlevez chaque bras de guidage, puis remettez-les en place dans la position

voulue. Pour une distribution inférieure, enlevez

et remplacez les vis (13) et (2) après le bras de

guidage est à la position désirée.

ATTENTION: Lorsque vous changez la position

du bras de guidage, le boulon en U doit se trouver dans l’emplacement indiqué sur la figure A.

L’enrouleur peut se débloquer en cours d’utilisation

si cesinstructions ne sont pas respectées.

3. Placez l’enrouleur sur le sol, le mur ou le plafond. Fixez en place à l’aide de quatre vis (non

fournies).

Installation du tuyau d’entrée

AVERTISSEMENT : Assurez-vous que la

pression de la ligne d’alimentation n’excède pas la

pression de fonctionnement nominale maximum de

l’enrouleur. Appliquez un produit d’étanchéité sur le

filetage de tous les tuyaux des enrouleurs standard.

Ne serrez pas excessivement les raccords. Le moment de torsion recommandé ne doit pas dépasser

98 Nm (70 ft.lb).

ATTENTION : Utilisez des raccords de tuyau flexibles à l’entrée. N’utilisez pas de tuyauterie rigide.

1. Appliquez le produit d’étanchéité comme indiqué

et raccordez le pivot (12) à l’entrée de l’axe principal (5).

2. Pour les enrouleurs à pivot et axe standard, raccordez le tuyau d’entrée (4) (non fourni) à l’entrée

du pivot comme indiqué dans

l’illustration.

Installation du tuyau de sortie

AVERTISSEMENT : Observez une extrême pru-

dence ; l’enrouleur est sous la tension d’un ressort.

Evitez de relâcher le mécanisme de verrouillage.

ATTENTION : Appliquez du produit d’étanchéité sur

tous les filetages des enrouleurs standard.Ne pas

serrer excessivement les raccords. Le moment de

torsion recommandé ne doit pas dépasser 98 Nm (70

ft.lb). Ne pas serrer excessivement les raccords.

Le moment de torsion recommandé ne doit pas dépasser 98 Nm (70 ft.lb).

1. Tournez manuellement la poulie (6) jusqu’à ce

que le ressort soit tendu, relâchez de trois tours,

puis verrouillez.

2. Faites passer le tuyau (7) par le support à molette

(1), l’étrier de serrage (8), puis par la découpe du

tambour (9), comme indiqué dans l’illustration.

3. Raccordez le tuyau de sortie (7) au col de cygne

(10), comme indiqué dans l’illustration.

4. Assurez-vous que la position de l’étrier de serrage est conforme à celle du bras de guidage en

utilisant les inscriptions situées à l’intérieur du

tambour.

5. Remplissez le tuyau. Ouvrez provisoirement la

valve afin de purger les gaz du tuyau. Fermez la

valve lorsque le liquide y apparaît. Une fois le

tuyau entièrement rempli, déverrouillez le loquet

et enroulez le tuyau de sortie sur l’enrouleur.

6. Installez l’assemblage du butoir.

AJUSTEMENTS

AVERTISSEMENT : Observez une extrême

prudence ; l’enrouleur est sous la tension d’un ressort. Evitez de relâcher le mécanisme de

verrouillage. Si cela est nécessaire, ajustez la tension du ressort de l’enrouleur en ajoutant ou en enlevant manuellement des tours detuyau du tambour,

un tour à la fois, jusqu’à ce que la tension désirée

soit obtenue. Ajoutez manuellement des tours pour

augmenter la tension. Enlevez manuellement des

tours pour abaisser la tension.

ATTENTION : Lors de l’ajout de tours de tuyau,

ajoutez juste assez de tours afin d’obtenir la

tension désirée sans dépasser la capacité du ressort

du mécanisme d’enroulement. Un enrouleur dont la

tension est correctement ajustée permet de dérouler

librement tout le tuyau jusqu’au point de contact

avec l’étrier de serrage. Un ressort surtendu endommagera le mécanisme d’enroulement.

CONSIGNES D’ENTRETIEN

L’entretien de l’enrouleur par l’utilisateur se limite

uniquement au remplacement des tuyaux d’entrée et

de sortie. Toute autre réparation doit être confiée à

un technicien autorisé ou directement à Reelcraft. Le

manquement à cette consigne peut conduire à des

blessures corporelles et/ou à des dommages matériels, ainsi qu’à l’annulation de la garantie.

AVERTISSEMENT : Enroulez le tuyau sur le

tambour, puis dépressurisez le système avant de

procéder aux opérations suivantes.

ATTENTION : Détendez entièrement le ressort

avant de désassembler l’enrouleur. Ne pas essayer

d’ouvrir l’assemblage riveté du boîtier de res

1. Remplacez les tuyaux en observant les instructions contenues dans la section “Consignes

d’installation” de cette notice.

2. Toutes les pièces mobiles emboîtées ont été lubrifiées à l’usine, comme requis.

sort.

Page 8

Figure A

www.reelcraft.com

Page 9

Série LP80000 / LPD80000 Enrouleurs de Tuyau

ART

N°.

1 Assemblage du pivot 1 S600979-1 S600979-1 1 S600979-1 S600979-1

2 Vis de 5/16-18 x 1/2 pouce 4 S2-51 S2-51 4 S44-10 S44-10

3 Bras de guidage 2 261299 261299 2 261299 261299

4 Ass. du ress. et du boît 1 S600645-2 6006945-1 1 S600645-3 S600645-3

5 Etrier de serrage 1 3-117440 5-117440 1 5-117440 261395

6 Contre-écrou de 5/16-18 pouce 8 300107 300107 4 300107 300107

7 Assemblage du support à molette 1 S600642 S600642 1 S600642 S600705

9 Contre-écrou de 1/4-20 pouce 2 300070 300070 8 300070 300070

12 3/8-16 x 5/8” vis 9 S44-2 S44-2 9 S44-2 S44-2

13 1 anneau ressort de 3/8” 2 S140-34 S140-34 2 S140-34 S140-34

Assemblage de l’embase avec roulement

14

et Nut-Sert

15 Rachet, Bâti D’Écoulement 1 261306-2 261306-2 1 S261590-1 S261591-1

16 Entretoise De Bobine --- None None 1 261393 261393

17 Ecrou hexagonal de 1/2-20 x 5/8 pouce 1 S280-8 S280-8 1 S280-8 S280-8

18 3/8-16 Écrou De Sortilège ** --- None None 1 S281-6 S281-6

18 10-32 Écrou de Nyloc --- None None 1 S82-15 S82-15

19 Ass. de la base et du montantl 1 600641 600641 1 600704 600704

20 Goujon de ressort de verrou ** --- None None 1 261351 261351

20 Vis d’épaule --- None None 1 S393-2 S393-2

21 Ressort de verrou 1 S260067 S260067 1 S260067 S260067

22 Assemblage de cliquet 1 S600018 S600018 1 S600018 S600018

23 Assemblage du roulement et de l’embase 1 S600644 S600644 1 S600644 S600644

24 Poulie, ouverture de tuyau 1 600649 600649 1 261307 261307

25 Bouchond’ étanchéité 1 S183-53 S183-54 1 S183-54 261396

26 Poulie, Springcase --- None None 1 261308 261308

27 Vis, 1/4-20 x 2 1/2” --- None None 8 S2-411 S2-411

28 Vis, 5/16-18 x 2 1/2” --- None None 3 S2-511 S2-511

DÉSCRIPTION

N° REQ.

LP82000 OLP LP83000 OLP

(LP)

1 S600651 S600651 1 S600651 S600651

N° REQ.

(LPD)

LPD83000 OLP LPD84000 OLP

www.reelcraft.com

** Avant le mars 2012

Page 9

Loading...

Loading...