Page 1

Operating Instructions

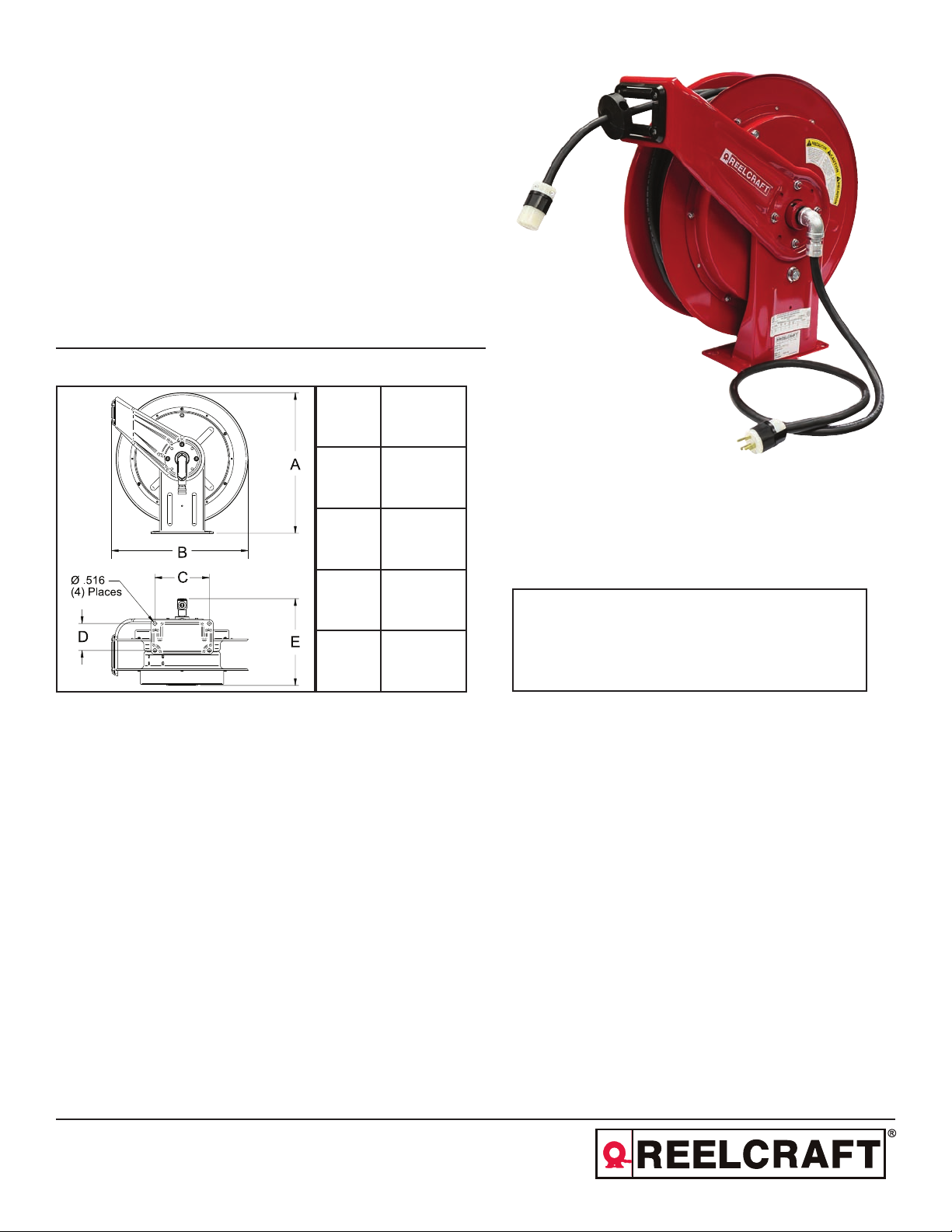

Series L 70000 Spring Driven Cord Reels

Model Numbers:

L 70075 123 3 L 70100 123 7 L 70075 123 X

L 70100 123 3 L 70075 123 7A L 70075

L 70075 123 3A L 70100 123 7A L 70100 123 X

L 70100 123 3A L 70075 123 9 L 70100

L 70075 123 3B L 70100 123 9 L 70100 124 X

L 70100 123 3B L 70075 123 9G L 70100 124

L 70075 123 7 L 70100 123 9G

Dimensions

A 20 1/4”

B 19 3/4”

C 7 7/8”

D 3 7/8”

E 12 1/2”

SAFETY

Personal injury and/or equipment damage may result if proper safety

precautions are not observed.

• Ensure that only a qualified electrician installs/services this

equipment.

•

• Ensure that power supply voltage does not exceed maximum

voltage rating of reel.

•

• Ensure that all electrical power is removed from reel before

servicing.

•

• A high-tension spring assembly is contained within the reel.

Exercise extreme caution.

•

• Check for frayed and/or broken wires before each use. Pull

electrical cord from reel by grasping the electrical cord itself,

not the work device.

•

• If an electrical malfunction should occur, remove power from

reel immediately.

IMPORTANT

Read this manual carefully before installing,

operating or servicing this equipment.

• Ensure that reel, electrical cord, and equipment being serviced

are properly grounded. Use an ohmmeter to check ground

continuity.

•

• If reel ceases to unwind or rewind, remove power immediately.

Do not pull or jerk on electrical cord!

•

• Treat and respect the reel as any other piece of machinery,

observing all common safety practices.

•

• All cord reels with flying leads must be hard wired into the

electrical circuit to ensure proper function.

•

WARNING: Even low voltage can cause irreparable damage or

death! Exercise extreme caution while operating or servicing this

equipment.

Form# 1287-916 Rev: 4/2017

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

Customer Service: 855-634-9109 • reelcraft@reelcraft.com • www.reelcraft.com

Page 2

Series L 70000 Spring Driven Cord Reels

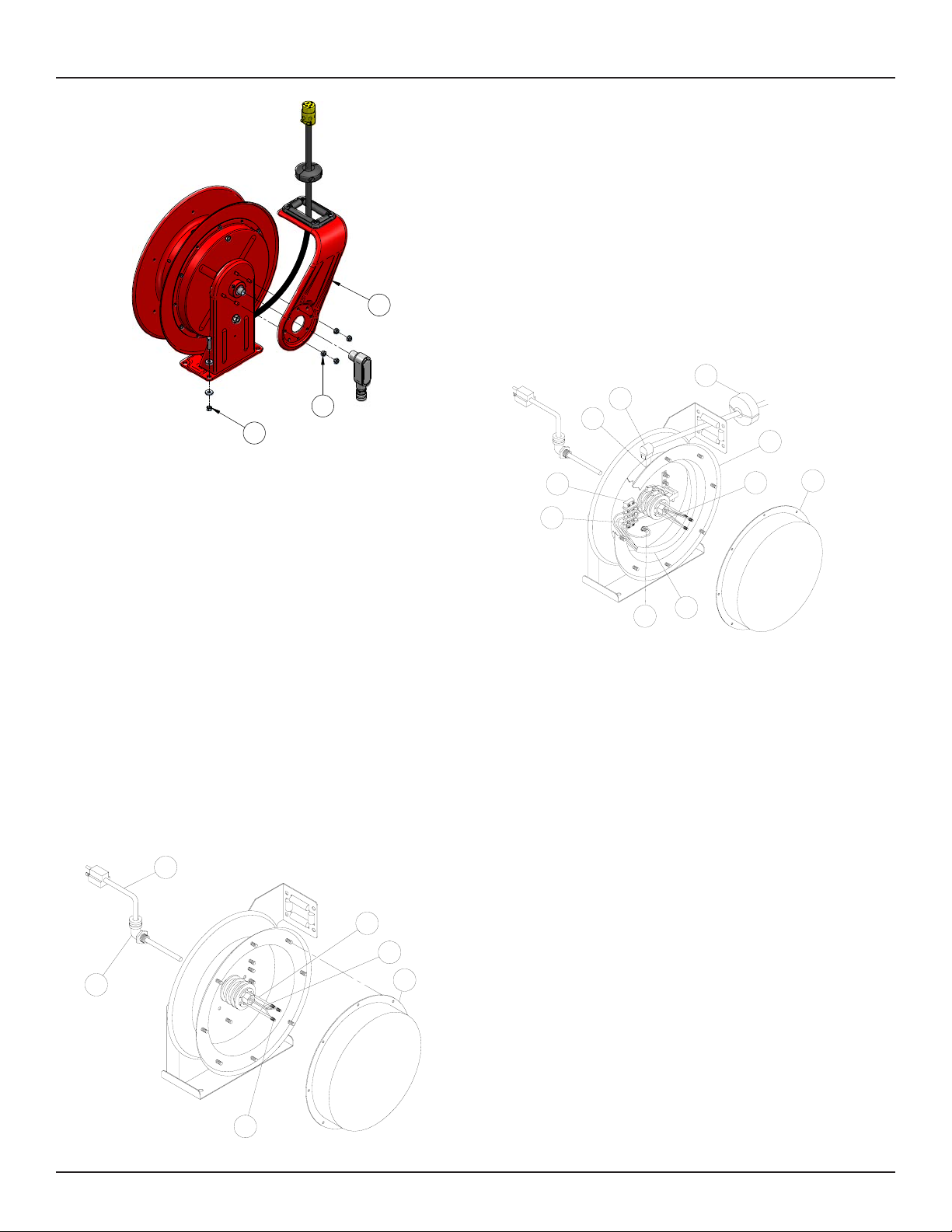

Installation Instructions

Mounting

CAUTION:

Unless reel was specified differently when ordering, maximum installation height is 16 feet. Do not exceed this distance. Ensure that only

a qualified electrician installs/services this equipment. Observe applicable NEC, OSHA, and local codes when installing this equipment.

Installation of GFCI cord reels should be performed by a qualified and

licensed professional in accordance with local building codes and

applicable NEC standards.

WARNING:

Use only 12/3 or 12/4 SEOOW cable for input wiring. Ensure that application does not exceed electrical rating of reel.

1. Feed input cable (1) through elbow (2) and main shaft.

2. Screw elbow (2) onto reel.

3. Connect input wires (3) and collector ring wires (4) together using

wire nuts (5).

4. Take the provided zip tie (not pictured) and zip tie the input cable

wires together closest to the slip ring.

5. Assemble cover (6) to reel.

Installing the Output Electrical Cable:

15 and 20 AMP Models

10

6

7

1

8

4

5

2

1. Unpack and inspect the reel for damage. Turn by hand to check for

smooth operation. Check for completeness.

2. Configure reel for top, side or bottom-wind (bottom-wind for constant tension reels only) electrical cable dispensing by removing

bolts (1) securing guide arm bracket (2).

3. Determine new guide arm bracket location and remove corresponding bolts. Position guide arm bracket to reel and replace

bolts.

4. Position reel on floor, wall or ceiling. Secure into place using four

(customer supplied) screws or bolts (3).

Installing the Input Electrical Cable:

15 and 20 AMP Models

1

4

3

2

6

3

9

WARNING:

Select output cable in accordance with power requirement of apparatus

to be supplied. Ensure that application does not exceed electrical rating

of reel. Use extreme caution, reel under tension. Avoid releasing latch

mechanism.

1. Manually turn sheave (1) until spring is tight, back off 2 turns and

latch.

2. Remove access cover (2).

3. Remove 6” of output cable outer jacket (3) and add fork terminals

(4) to ends.

4. Route cable through strain relief (6), then through cut out in spool

(7).

5. Pull enough cable through hole for roughly a 1/2 an inner wrap

shown.

6. Connect output wires to terminal block (8) as shown.

7. Connect ground wire to grounding stud (9) as shown.

8. Using an ohmmeter check for ground faults.

9. Take the provided cable clamp (not pictured) and attach it to the

wire. Then take the cable clamp and screw it down to the rightmost screw on the brush assembly (with the brush assembly facing upward).

10. Replace cover (2).

11. Replace latch and wind cable onto reel.

12. Install bumper stop (10).

Page 2

5

www.reelcraft.com

Page 3

Series L 70000 Spring Driven Cord Reels

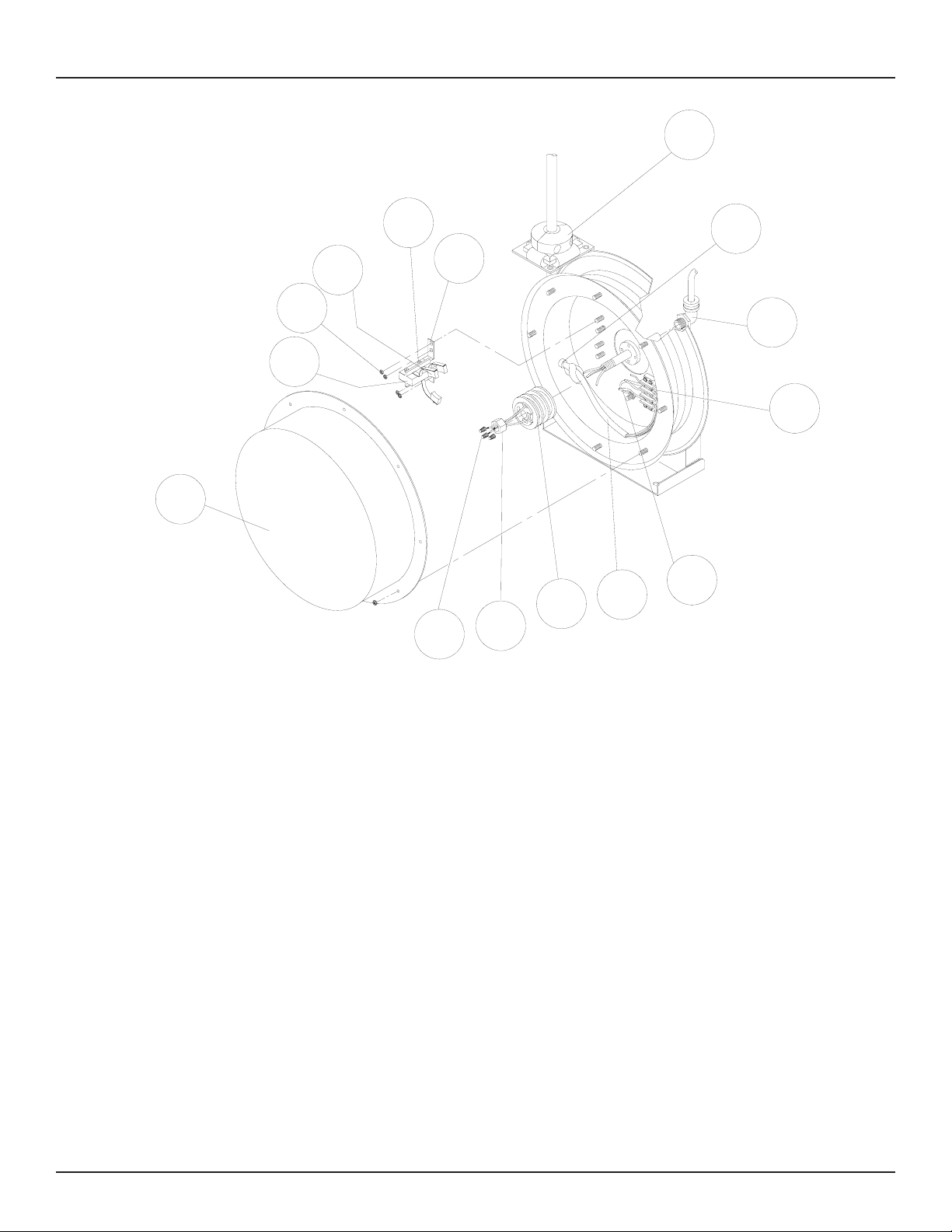

Figure A

3

12

13

11

5

10

8

14

2

1

9

4

6

7

15

Replacing the Output Cord/Work Device (figure A)

WARNING:

Remove power from reel before performing any of the following procedures. Use extreme caution, reel under tension. Avoid releasing latch

mechanism.

1. Pull output electrical cord from reel until fully extended, then latch.

2. Remove output bumper stop (3).

3. Remove access cover (1).

4. Disconnect output electrical cord/work device (4) at terminal strip

(2).

5. Remove cable clamp.

6. Remove strain relief (5). Remove output electrical cord/work

device.

7. Install replacement electrical cord/work device by reversing steps

2 through 5.

8. Release latch and rewind electrical cord on reel.

9. Replace access cover (1) and bumper stop (3).

Replacing the Input Cord (figure A)

WARNING:

All cord reels with GFCI receptacles must be hard wired into the electrical circuits. Use of 2 or 3 prong plugs may cause a potential

malfunction of the GFCI receptacle.

1. Remove access cover (1).

2. Remove wire nuts (6) securing input electrical cord to collector

assembly (7).

3. Remove zip tie (not pictured), being careful to not damage wires.

4. Remove 90 degree elbow (8).

5. Remove input electrical cord.

6. Remove 11” of outer jacket from replacement input electrical cord

(input electrical cord wires must protrude a minimum of 6” from

center of collector assembly).

7. Install replacement input electrical cord by reversing steps 1

through 4.

8. Replace access cover (1).

Replacing the Brush Holder/Brushes (figure A)

1. At terminal strip (2), remove wires connecting brushes (9) to terminal strip.

2. Remove lock nuts (10) securing brush holder (11) to reel. Relocate

cable clamp temporarily and remove brush holder.

3. Remove brushes (12) from brush holder (11).

4. Install replacement brush holder/brushes by reversing steps 1

through Upon completion of installation, adjust brush-to-ring

alignment by loosening nuts (13) and sliding finger assembly

(14).

www.reelcraft.com

Page 3

Page 4

Series L 70000 Spring Driven Cord Reels

Replacing the Collector Assembly (figure A)

1. Remove access cover (1).

2. Remove wire nuts (6) securing input electrical cord to collector

assembly.

3. Remove zip tie (not pictured), being careful to not damage wires.

4. At terminal strip (2), disconnect wires (9) connecting brushes (12)

to terminal strip.

5. Remove lock nuts (10) securing brush holder (11) to reel. Relocate

cable clamp temporarily and remove brush holder.

6. Remove coupling nut (15).

7. Remove collector assembly.

8. Install replacement collector assembly by reversing steps 1

through 5. Upon completion of installation, adjust brush-to-ring

alignment by loosening nuts (13) and sliding finger assembly

(14).

9. Replace access cover (1).

Troubleshooting Instructions (figure A)

Troubleshooting of the reel consists of isolating a problem to a defective electrical cord/work device, brush holder/brushes, or collector

assembly. Refer any other discrepancies only to an authorized service

person or directly to Reelcraft.

WARNING:

The following procedure directs the technician to take voltage measurements. Remember, even low voltage is dangerous and can cause

personal injury or death. Exercise extreme caution! Ensure that only a

qualified electrican installs or services this equipment.

1. If work device is either an incandescent or fluorescent light,

replace bulb with a known good bulb. If this does not correct the

problem, proceed to step 2. If work device is an electrical receptable, ensure that tool or fixture connected to it is in good working

order. If it is, proceed to step 2.

2. Remove power from reel.

3. Remove access cover (1).

4. Reapply power to reel.

5. Check for correct voltage (120 vac) at a terminal strip (2). If voltage reading is correct, replace output electrical device (refer to

page 3). If voltage reading is incorrect, proceed to step 6.

6. Remove power from reel.

7. Using ohmmeter, check continuity of input electrical cord. If cord

checks good, proceed to step 8. If cord is faulty, replace it (refer to

page 3). Remove brush holder/brushes from reel and inspect (refer

to page 3). Replace defective components then proceed to step 9.

8. Reapply power to reel.

9. Check for correct voltage (120 vac) at terminal strip (2).

10. If voltage reading is still incorrect, replace defective collector

assembly (refer to page 4).

11. Replace access cover (1).

Service Instructions

Maintain reel by following the service instructions given in this manual.

Refer all other repairs, other than those listed, only to an authorized

service person or directly to Reelcraft. Failure to do so can result in

personal injury and/or equipment damage and may void the warranty.

Page 4

www.reelcraft.com

Page 5

Series L 70000 Spring Driven Cord Reels

www.reelcraft.com

Figure B

Page 5

Page 6

Series L 70000 Spring Driven Cord Reels

Item # Description # Req'd L 70075 123 3 L 70100 123 3 L 70075 123 3A L 70100 123 3A L 70075 123 3B

1 Snap Ring 5 300007 300007 300007 300007 300007

2 Lock Nut 2 261650-1 261650-1 261650-1 261650-1 261650-1

3 U-Bolt 1 3-117440 3-117440 3-117440 3-117440 3-117440

4 Nyloc Nut 21 S82-15 S82-15 S82-15 S82-15 S82-15

5 Latch Pawl Assembly 1 S602694 S602694 S602694 S602694 S602694

6 Set Screw 1 S35-84 S35-84 S35-84 S35-84 S35-84

7 Inlet Cord Assembly 1 602714 602714 602716 602716 602716

8 Strain Relief 1 261082 261082 261082 261082 261082

9 Pipe Fitting 90 Deg. Elbow 1 S159-14 S159-14 S159-14 S159-14 S159-14

10 Conduit Box Cover 1 None None None None None

11 Conduit Box 1 None None None None None

12 Lock Nut 4 300107 300107 300107 300107 300107

13 Bumper Stop Assembly 1 1-HR1004 1-HR1004 1-HR1004 1-HR1004 1-HR1004

14 Guide Arm & Roller Assy 1 S602697 S602697 S602697 S602697 S602697

15 Main Shaft 1 262947 262947 262947 262947 262947

16 Containerized Drive Spring 1 602718-80 602718-80 602718-80

17 Spring Arbor 1 261275 261275 261275 261275 261275

18 Arbor Key 1 261274 261274 261274 261274 261274

19 Strain Relief 1 260697-R 260697-R 260697-R 260697-R 260697-R

20 Spool & Hub Assembly 1 602703 602703 602703 602703 602703

21 Snap Ring 1 S140-13 S140-13 S140-13 S140-13 S140-13

22 Collector Ring Assembly 1 S602296 602296 602296 602296 602296

23 Hex Lock Nut 3 S300011 S300011 S300011 S300011 S300011

24 Cable Clamp 1 262371-1 262371-1 262371-1 262371-1 262371-1

25 Grounding Cord Assembly 1 600283 600283 600283 600283 600283

26 Terminal Block Assembly 1 600205 600205 600205 600205 600205

27 Outlet Cord Assembly 1 602709-75 602709-100 602710-75 602710-100 602711-75

28 Slip Ring Bracket & Stud Assy 1 602696-1-35 602696-1-35 602696-1-35 602696-1-35 602696-1-35

29 Split Lock Washer 1 902016 902016 902016 902016 902016

30 Adapter Plate 1 261577 261577 261577 261577 261577

31 Spacing Washer 1 262422 262422 262422 262422 262422

32 Collector Ring Cover 1 262938 262938 262938 262938 262938

Voltage 125 125 125

AMPS 15 15 20 20 20

602718-80 602718-80

125 125

Item # Description # Req'd L 70100 123 3B L 70075 123 7 L 70100 123 7 L 70075 123 7A L 70100 123 7A

1 Snap Ring 5 300007 300007 300007 300007 300007

2 Lock Nut 2 261650-1 261650-1 261650-1 261650-1 261650-1

3 U-Bolt 1 3-117440 3-117440 3-117440 3-117440 3-117440

4 Nyloc Nut 21 S82-15 S82-15 S82-15 S82-15 S82-15

5 Latch Pawl Assembly 1 S602694 S602694 S602694 S602694 S602694

6 Set Screw 1 S35-84 S35-84 S35-84 S35-84 S35-84

7 Inlet Cord Assembly 1 602716 602715 602715 602716 602716

8 Strain Relief 1 261082 261082 261082 261082 261082

9 Pipe Fitting 90 Deg. Elbow 1 S159-14 S159-14 S159-14 S159-14 S159-14

10 Conduit Box Cover 1 None None None None None

11 Conduit Box 1 None None None None None

12 Lock Nut 4 300107 300107 300107 300107 300107

13 Bumper Stop Assembly 1 1-HR1004 1-HR1004 1-HR1004 1-HR1004 1-HR1004

14 Guide Arm & Roller Assy 1 S602697 S602697 S602697 S602697 S602697

15 Main Shaft 1 262947 262947 262947 262947 262947

16 Containerized Drive Spring 1 602718-80 602718-80 602718-80

17 Spring Arbor 1 261275 261275 261275 261275 261275

18 Arbor Key 1 261274 261274 261274 261274 261274

19 Strain Relief 1 260697-R 260697-R 260697-R 260697-R 260697-R

20 Spool & Hub Assembly 1 602703 602703 602703 602703 602703

21 Snap Ring 1 S140-13 S140-13 S140-13 S140-13 S140-13

22 Collector Ring Assembly 1 602296 602296 602296 602296 602296

23 Hex Lock Nut 3 S300011 S300011 S300011 S300011 S300011

24 Cable Clamp 1 262371-1 262371-1 262371-1 262371-1 262371-1

25 Grounding Cord Assembly 1 600283 600283 600283 600283 600283

26 Terminal Block Assembly 1 600205 600205 600205 600205 600205

27 Outlet Cord Assembly 1 602711-100 602332-75 602332-100 602333-75 602333-100

28 Slip Ring Bracket & Stud Assy 1 602696-1-35 602696-1-35 602696-1-35 602696-1-35 602696-1-35

29 Split Lock Washer 1 902016 902016 902016 902016 902016

30 Adapter Plate 1 261577 261577 261577 261577 261577

31 Spacing Washer 1 262422 262422 262422 262422 262422

32 Collector Ring Cover 1 262938 262938 262938 262938 262938

Voltage 125 125 125

AMPS 20 15 15 20 20

602718-80 602718-80

125 125

Page 6

www.reelcraft.com

Page 7

Series L 70000 Spring Driven Cord Reels

Item # Description # Req'd L 70075 123 9 L 70100 123 9 L 70075 123 9G L 70100 123 9G L 70075 123 X

1 Snap Ring 5 300007 300007 300007 300007 300007

2 Lock Nut 2 261650-1 261650-1 261650-1 261650-1 261650-1

3 U-Bolt 1 3-117440 3-117440 3-117440 3-117440 3-117440

4 Nyloc Nut 21 S82-15 S82-15 S82-15 S82-15 S82-15

5 Latch Pawl Assembly 1 S602694 S602694 S602694 S602694 S602694

6 Set Screw 1 S35-84 S35-84 S35-84 S35-84 S35-84

7 Inlet Cord Assembly 1 602714 602714 602714 602714 262958

8 Strain Relief 1 261082 261082 261082 261082 261082

9 Pipe Fitting 90 Deg. Elbow 1 S159-14 S159-14 S159-14 S159-14 None

10 Conduit Box Cover 1 None None None None 262294

11 Conduit Box 1 None None None None 262293

12 Lock Nut 4 300107 300107 300107 300107 300107

13 Bumper Stop Assembly 1 1-HR1004 1-HR1004 1-HR1004 1-HR1004 1-HR1004

14 Guide Arm & Roller Assy 1 S602697 S602697 S602697 S602697 S602697

15 Main Shaft 1 262947 262947 262947 262947 262947

16 Containerized Drive Spring 1 602718-80 602718-80 602718-80

17 Spring Arbor 1 261275 261275 261275 261275 261275

18 Arbor Key 1 261274 261274 261274 261274 261274

19 Strain Relief 1 260697-R 260697-R 260697-R 260697-R 260697-R

20 Spool & Hub Assembly 1 602703 602703 602703 602703 602703

21 Snap Ring 1 S140-13 S140-13 S140-13 S140-13 S140-13

22 Collector Ring Assembly 1 602296 602296 602296 602296 602296

23 Hex Lock Nut 3 S300011 S300011 S300011 S300011 S300011

24 Cable Clamp 1 262371-1 262371-1 262371-1 262371-1 262371-1

25 Grounding Cord Assembly 1 600283 600283 600283 600283 600283

26 Terminal Block Assembly 1 600205 600205 600205 600205 600205

27 Outlet Cord Assembly 1 602712-75 602712-100 602713-75 602713-100 602707-75

28 Slip Ring Bracket & Stud Assy 1 602696-1-35 602696-1-35 602696-1-35 602696-1-35 602696-1-35

29 Split Lock Washer 1 902016 902016 902016 902016 902016

30 Adapter Plate 1 261577 261577 261577 261577 261577

31 Spacing Washer 1 262422 262422 262422 262422 262422

32 Collector Ring Cover 1 262938 262938 262938 262938 262938

Voltage 125 125 125

AMPS 15 15 15 15 20

602718-80 602718-80

125 125

Item # Description # Req'd L 70075 L 70100 123 X L 70100 L 70100 124 X L 70100 124

1 Snap Ring 5 300007 300007 300007 300007 300007

2 Lock Nut 2 261650-1 261650-1 261650-1 261650-1 261650-1

3 U-Bolt 1 3-117440 3-117440 3-117440 3-117440 3-117440

4 Nyloc Nut 21 S82-15 S82-15 S82-15 S82-15 S82-15

5 Latch Pawl Assembly 1 S602694 S602694 S602694 S602694 S602694

6 Set Screw 1 S35-84 S35-84 S35-84 S35-84 S35-84

7 Inlet Cord Assembly 1 262958 262958 262958 262966 262966

8 Strain Relief 1 261082 261082 261082 261082 261082

9 Pipe Fitting 90 Deg. Elbow 1 None None None None None

10 Conduit Box Cover 1 262294 262294 262294 262294 262294

11 Conduit Box 1 262293 262293 262293 262293 262293

12 Lock Nut 4 300107 300107 300107 300107 300107

13 Bumper Stop Assembly 1 1-HR1004 1-HR1004 1-HR1004 1-HR1004 1-HR1004

14 Guide Arm & Roller Assy 1 S602697 S602697 S602697 S602697 S602697

15 Main Shaft 1 262947 262947 262947 262947 262947

16 Containerized Drive Spring 1 602718-80 602718-80 602718-80

17 Spring Arbor 1 261275 261275 261275 261275 261275

18 Arbor Key 1 261274 261274 261274 261274 261274

19 Strain Relief 1 260697-R 260697-R 260697-R 260697-R 260697-R

20 Spool & Hub Assembly 1 602703 602703 602703 602703 602703

21 Snap Ring 1 S140-13 S140-13 S140-13 S140-13 S140-13

22 Collector Ring Assembly 1 602296 602296 602296 602297 602297

23 Hex Lock Nut 3 S300011 S300011 S300011 S300011 S300011

24 Cable Clamp 1 262371-1 262371-1 262371-1 262371-1 262371-1

25 Grounding Cord Assembly 1 600283 600283 600283 600283 600283

26 Terminal Block Assembly 1 600205 600205 600205 600280 600280

27 Outlet Cord Assembly 1 None 602707-100 None 602475-100 None

28 Slip Ring Bracket & Stud Assy 1 602696-1-35 602696-1-35 602696-1-35 602696-2-35 602696-2-35

29 Split Lock Washer 1 902016 902016 902016 902016 902016

30 Adapter Plate 1 261577 261577 261577 261577 261577

31 Spacing Washer 1 262422 262422 262422 262422 262422

32 Collector Ring Cover 1 262938 262938 262938 262938 262938

Voltage 125 125 125

AMPS 20 20 20 16 16

602718-80 602718-80

600 600

www.reelcraft.com

Page 7

Loading...

Loading...