ReelCraft L 4050 163 1, L 4035 163 3, L 4050 162 2, L 4035 162 2, L 4035 163 3-RP Operating Instructions Manual

...

Operating Instructions

Series L 4000 Spring Driven Cord Reels

L 4035 163 1 L 4545 123 3 L 4545 123 7A L 4050 163 10

L 4050 163 1 L 4545 123 3-RP L 4545 123 7B L 4050 163 X

L 4035 162 2 L 4545 123 3A L 4035 163 8 L 4545 123 X

L 4050 162 2 L 4545 123 3A-RP L 4050 163 8 L 4000

L 4035 163 3 L 4545 123 3B L 4050 163 9 L 4100

L 4035 163 3-RP L 4035 A 163 5 L 4545 123 9 L 4500

L 4050 163 3 L 4050 A 163 5 L 4545 123 9G

L 4050 163 3-RP L 4545 123 7 L 4035 163 10

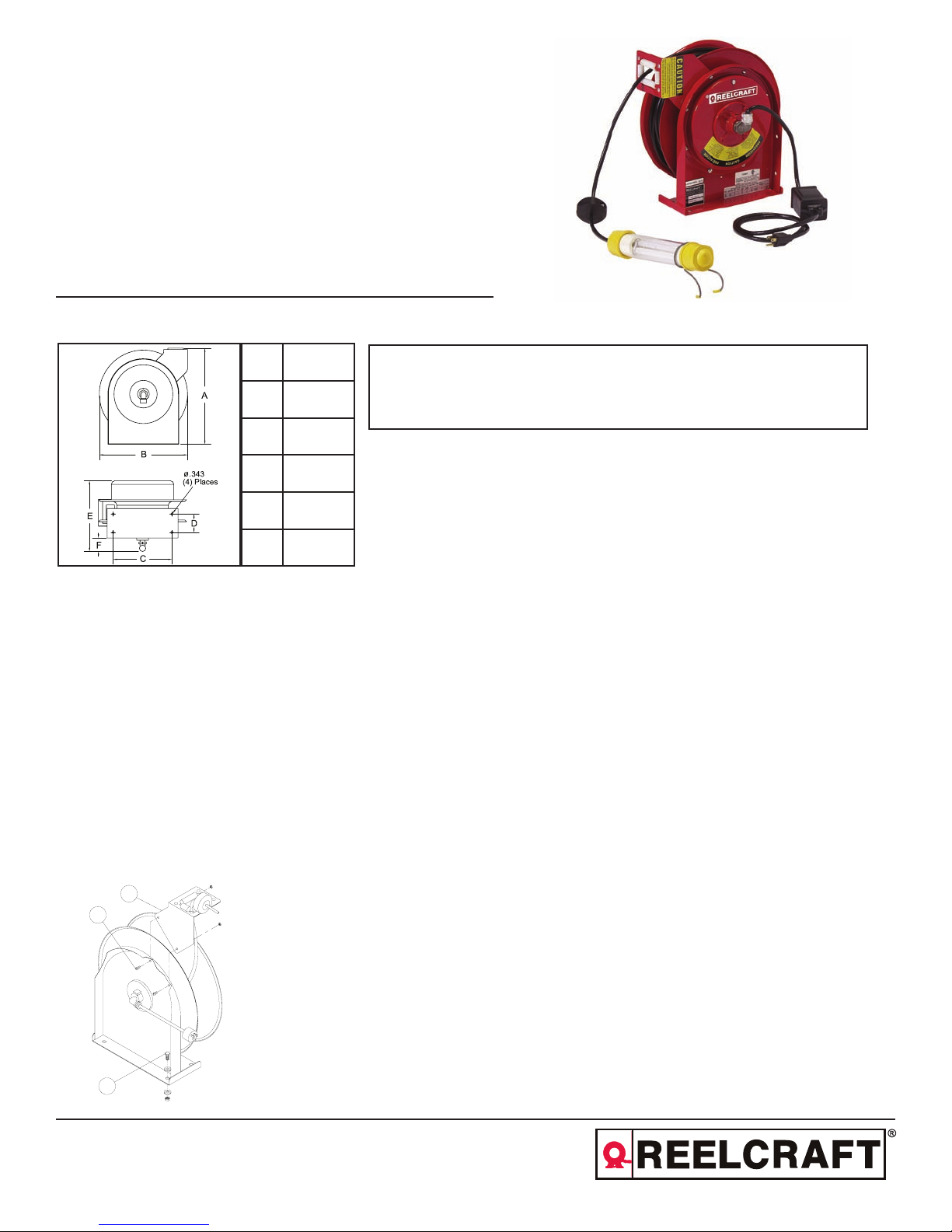

Dimensions

A 13 1/4”

B 12 5/8”

C 8”

D 2 1/2”

E 9 3/8”

F 1 3/4”

Safety Precautions

Personal injury and/or equipment damage may

result if proper safety precautions are not

observed.

• Ensure that only a qualified electrician

installs/services this equipment.

• Ensure that power supply voltage does not

exceed maximum voltage rating of reel.

• Ensure that reel is properly installed before

connecting to power supply.

• All cord reels with flying leads must be hard

wired to ensure proper function.

IMPORTANT

Read this manual carefully before installing, operating or

servicing this equipment.

WARNING: Even low voltage can cause irreparable damage or death!

Exercise extreme caution while operating or servicing this equipment.

• Ensure that all electrical power is removed

from reel before servicing.

• A high-tension spring assembly is

contained within the reel. Exercise extreme

caution.

• Check for frayed and/or broken wires before

each use. Pull electrical cord from reel by

grasping the electrical cord itself, not the

work device.

• If an electrical malfunction should occur,

remove power from reel immediately.

• Ensure that reel, electrical cord, and

equipment being serviced are properly

grounded. Use an ohmmeter to check

ground continuity.

• If reel ceases to unwind or rewind, remove

power immediately. Do not pull or jerk on

electrical cord!

• Treat and respect the reel as any other piece

of machinery, observing all common safety

practices.

Installation Instructions

2

1

3

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

Customer Service: 855-634-9109 • reelcraft@reelcraft.com • www.reelcraft.com

Mounting

CAUTION: Unless reel was specified differ-

ently when ordering, maximum installation

height is 16 feet. Do not exceed this distance.

Ensure that only a qualified electrician installs/

services this equipment. Installation of GFCI

cord reels should be performed by a qualified

and licensed professional in accordance with

building codes and applicable NEC standards.

1. Unpack and inspect reel for damage.

Turn by hand to check for smooth operation. Check for completeness.

2. Configure reel for top, side or bottomwind (bottom-wind for constant tension

reels only) electrical cord dispensing by

removing bolts (1), securing guide arm

bracket (2). Determine new guide arm

location and remove corresponding bolts.

Position guide arm bracket to reel and

replace bolts.

3. Position reel on floor, wall, or ceiling.

Secure into place, using four (customer

supplied) screws or bolts (3).

Form# 542-290 Rev: 6/2016

Series L 4000 Spring Driven Cord Reels

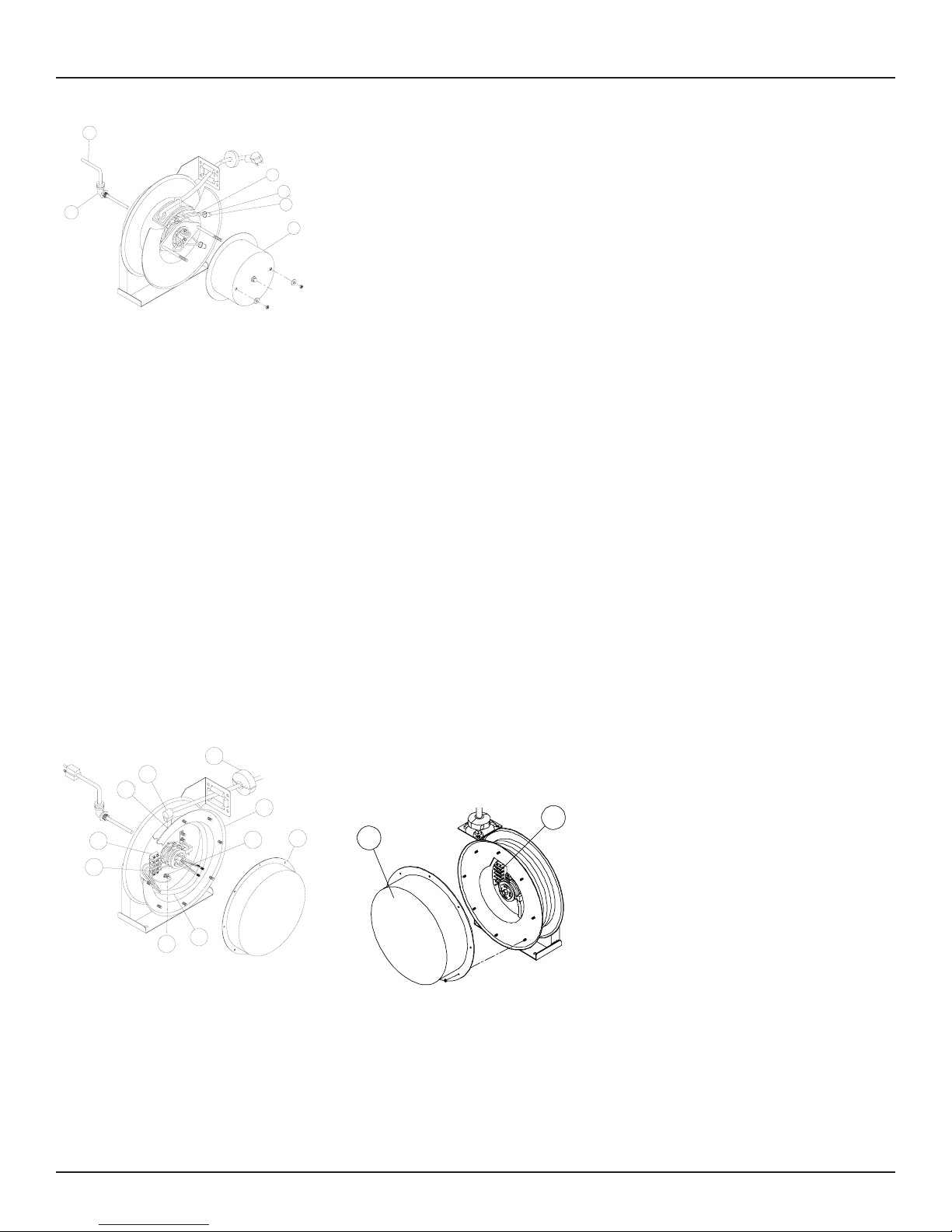

Installing the Input Electrical Cable

1

3

4

2

5

6

WARNING: Use only 12/3 or 16/3 cable for

input wiring. Ensure that application does

not exceed electrical rating of reel (refer to

page 1 of this manual). All cord reels with

GFCI receptacles must be hard wired into the

electrical circuit. Use of 2 or 3 prong plugs

may cause a potential malfunction of the GFCI

receptacle.

1. Feed input cable (1) through elbow (2)

and main shaft. Make sure that input

cable extends 6” from collector.

2. Screw elbow (2) into reel.

3. Connect input wires (3) and collector

ring wires (4) together using wire nuts

(5).

4. Take the provided zip tie (not pictured)

and zip tie the input cable wires together

closest to the slip ring.

5. Assemble cover (6) to reel.

Installing the Output

Electrical Cable

10

6

7

1

2

8

4

3

9

WARNING: Select output cable in accordance

with power requirement of apparatus to be

supplied. Ensure that application does not

exceed electrical rating of reel (refer to page

1 of this manual). Use extreme caution, reel

under tension. Avoid releasing latch mechanism.

1. Manually turn sheave (1) until spring is

tight, back off 2 turns, and latch.

5

2. Remove access cover (2).

3. Remove 6” of output cable outer jacket

(3) and add fork terminals (4) to ends.

4. Route cable through strain relief (6), then

through cut out in spool (7).

5. Pull enough cable through for roughly

1/2 an inner wrap as shown in the diagram.

6. Connect output wires to terminal block

(8) as shown.

7. Connect ground wire to grounding stud

(9) as shown.

8. Using Ohmmeter check for ground faults.

9. Take provided cable clamp (not pictured)

and attach it to the wire. Then take the

cable clamp and screw it down to the

brush assembly on the reel.

10. Replace cover (2).

11. Release latch and wind cable onto reel.

12. Install bumper stop (10).

Adjustments - Spring Tension

If necessary, adjust spring tension on reel by

adding or removing wraps of electrical cord

from spool, one wrap at a time, until desired

tension is obtained. Add wraps to increase

tension. Remove wraps to decrease tension.

WARNING: When adding wraps of electrical

cord, be careful not to exceed the winding

mechanism’s spring capacity. Add just enough

wraps of cord to achieve the desired tension.

Damage to the winding mechanism will result

if spring is over-tensioned. Always be aware

of spring tension on reel. Exercise extreme

caution.

Troubleshooting Instructions

2

1

Troubleshooting of the reel consists of isolating a problem to a defective electrical cord/

work device, brush holder/brushes, or collector assembly. Refer any other discrepancies only to an authorized service person or

directly to Reelcraft.

WARNING: The following procedure directs

the technician to take voltage measurements.

Remember, even low voltage is dangerous and

can cause personal injury or death. Exercise

extreme caution! Ensure that only a qualified

electrician installs/services this equipment.

1. If work device is either an incandescent

or fluorescent light, replace bulb with a

known good bulb. If this does not correct the problem, proceed to step 2. If

work device is an electrical receptacle,

ensure that tool or fixture connected to

it is in good working order. If it is, proceed to step 2.

2. Remove power from reel.

3. Remove access cover (1).

4. Reapply power to reel.

5. Check for correct voltage (120 V AC)

at terminal strip (2). If voltage reading is correct, replace output electrical cord/work device (refer to Service

Instructions). If voltage reading is incorrect, proceed to step 6.

6. Remove power from reel.

7. Using ohmmeter, check continuity of

input electrical cord. If cord checks

good, proceed to step 8. If cord is faulty,

replace it (refer to Service Instructions).

8. Remove brush holder/brushes from

reel and inspect (refer to Service

Instructions). Replace defective components then proceed to step 9.

9. Reapply power to reel.

10. Check for correct voltage (120 V AC) at

terminal strip (2). If voltage reading is

still incorrect, replace defective collector

assembly (refer to Service Instructions).

11. Replace access cover (1).

Service Instructions

Maintain reel by following the service instructions given below. Refer all other repairs,

other than those listed, only to an authorized

service person or directly to Reelcraft. Failure

to do so can result in personal injury and/or

equipment damage and may void the warranty

(refer to page 5 when referencing parts).

WARNING: Remove power from reel

before performing any of the following

procedures.

Page 2

www.reelcraft.com

Series L 4000 Spring Driven Cord Reels

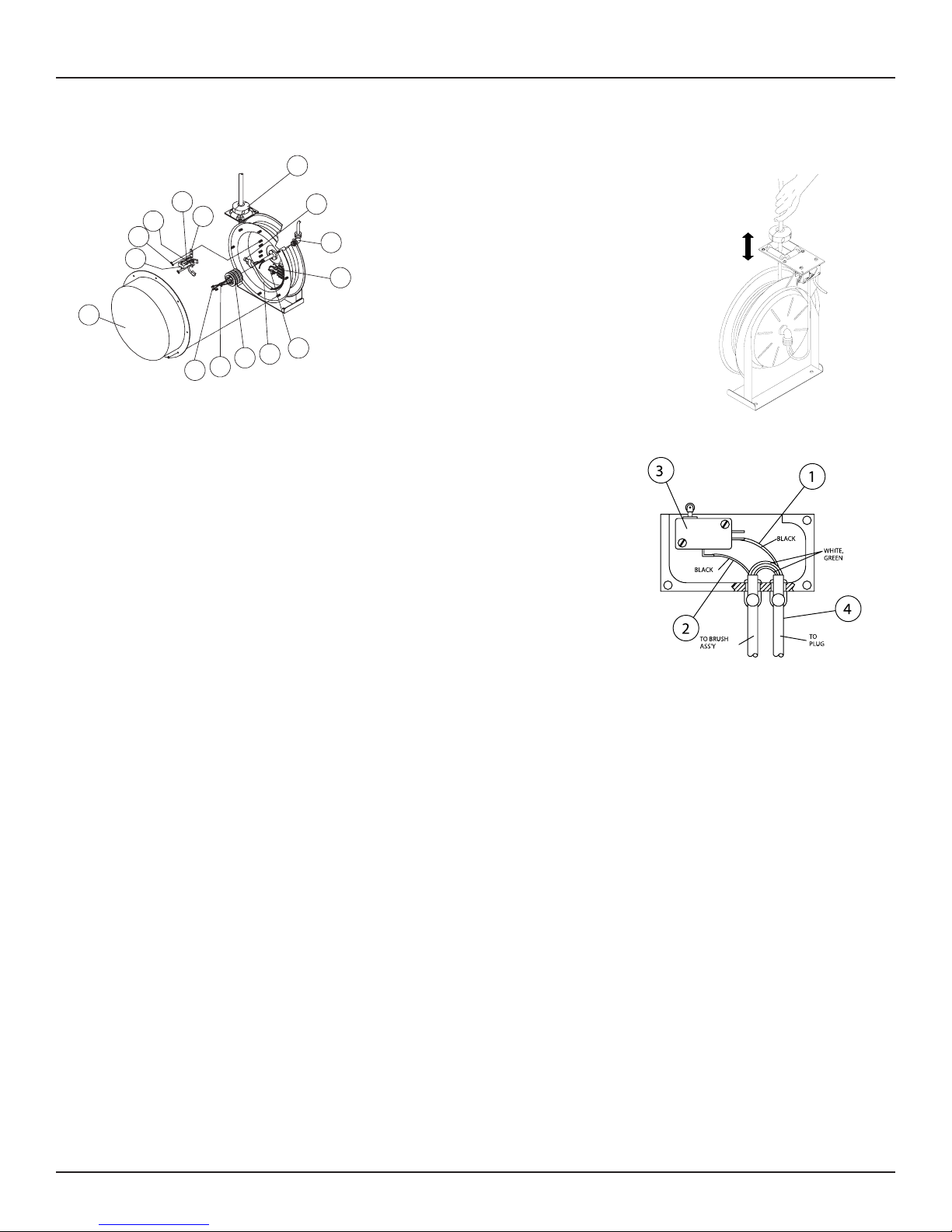

Replacing the Output Electrical

Cord/Work Device

7

5

15

6

12

13

14

4

3

2

1

WARNING: Use extreme caution, reel under

tension. Avoid releasing latch mechanism.

1. Pull output electrical cord from reel until

fully extended, then latch.

2. Remove output electrical bumper stop

(7).

3. Disconnect output electrical cord/work

device (12) at terminal strip (10).

4. Remove strain relief (8). Remove output

electrical cord/work device.

5. Install replacement electrical cord/work

device by reversing steps 2 through 4.

6. Release latch and rewind electrical cord

on reel.

7. Replace access cover (1).

8

9

11

Replacing the Input Electrical Cord

WARNING: Use of 2 or 3 prong plugs on

cord reels equiped with GFCI receptacles may

cause a potential malfunction of the GFCI

receptacle.

1. Remove wire nuts (15) securing input

electrical cord to collector assembly (13).

2. Remove 90 degree elbow (9).

3. Remove input electrical cord.

4. Remove 11” of outer jacket from replacement input electrical cord (input electrical

cord wires must protrude a minimum of

6” from center of collector assembly).

5. Install replacement input electrical cord

by reversing steps 1 through 3.

6. Replace access cover (1).

Replacing the Brush

Holder/Brushes

1. At terminal strip (10), remove wires connecting brushes (11) to terminal strip.

2. Remove lock nuts (3) securing brush

holder (6) to reel. Relocate cable clamp

temporarily and remove brush holder.

3. Remove brushes (4) from brush holder

(6).

4. Install replacement brush holder/brushes

by reversing steps 1 through 3. Upon

completion of installation, adjust brush-

10

to-ring alignment by loosening nuts (5)

and sliding finger assembly (2).

Replacing the Collector Assembly

1. Remove wire nuts (15) securing input

electrical cord to collector assembly.

2. At terminal strip (10), disconnect wires

(11)connecting brushes (4) to terminal

strip.

3. Remove lock nuts (3) securing brush

holder (6) to reel. Relocate cable clamp

temporarily and remove brush holder.

4. Remove snap ring (14).

5. Remove collector assembly (13).

6. Install replacement collector assembly

by reversing steps 1 through 5. Upon

completion of installation, adjust brushto-ring alignment by loosening nuts (5)

and sliding finger assembly (2).

7. Replace access cover (1).

Autoswitch Operating Instructions

To operate Autoswitch reels, pull out and

retract cable as shown in the above diagram.

When cable is fully retracted, the reel is in the

“Off” position. As the cable is pulled out, the

guide arm pivots upward and the reel switches

to the “On” position.

Autoswitch Troubleshooting

Service Instructions

Maintain reel by following the service instructions given below. Refer all other repairs,

other than those listed, only to an authorized

service person or directly to Reelcraft. Failure

to do so can result in personal injury and/

or equipment damage and may void the warranty. If reel fails to operate electrically, refer

to troubleshooting instructions on page 2. If

problem persists, check switch using the following steps.

1. Using a ohmmeter, check for continuity

between lines (1) and (2), while switch is

in the “On” or “Up” position.

2. If continuity test fails, replace switch (3).

3. If continuity test passes, check for inlet

cord (4) damage.

ON

OFF

www.reelcraft.com

Page 3

Loading...

Loading...