Page 1

Operating Instructions

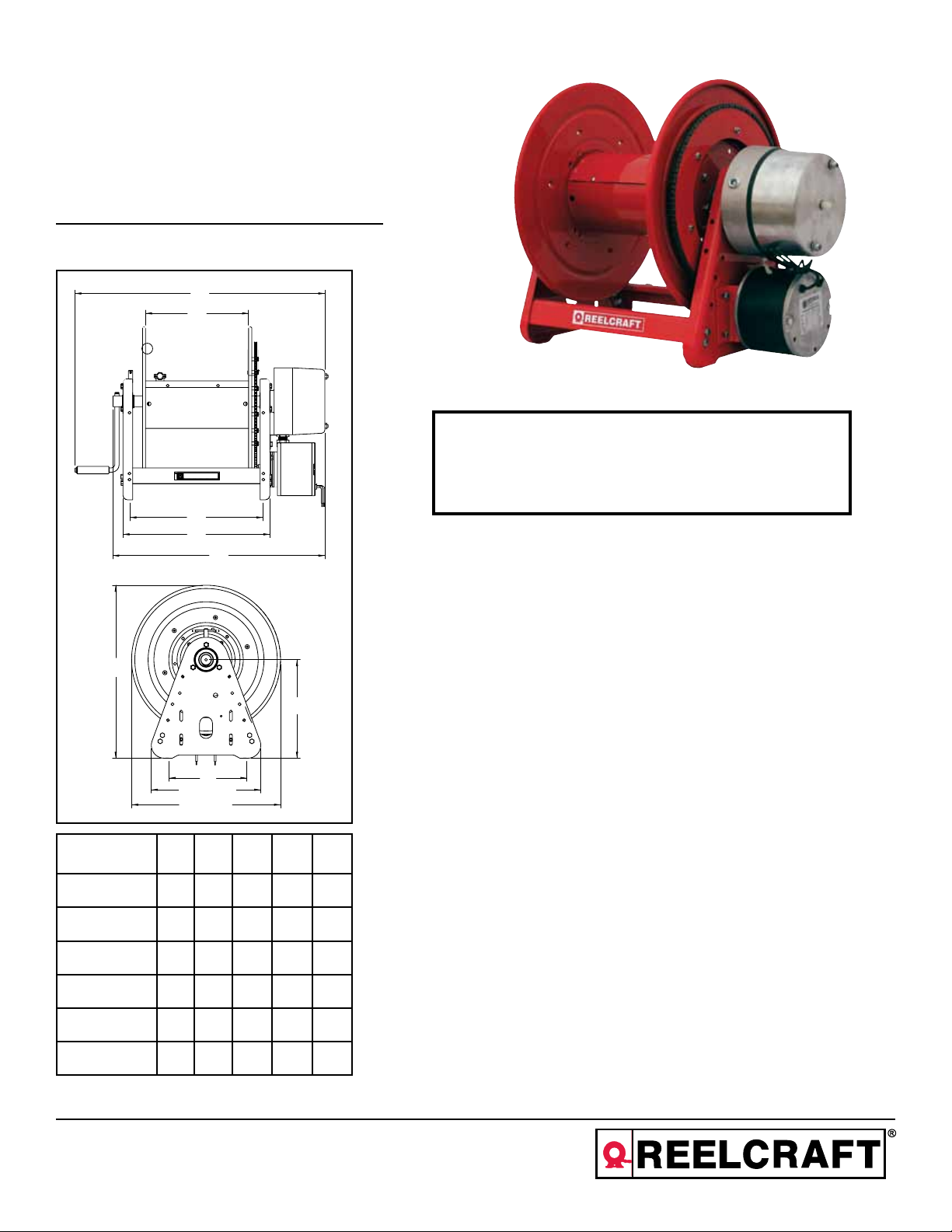

20 1/4"

11 3/8"

9"

12 11/16"

17 3/4"

Series L 30000 Cable Reels

Model Numbers:

LC312 103 LE312 103 12D LB312 103

LC312 123 LE312 123 12D LB312 123

Dimensions

E

B

IMPORTANT

R

REELCRAFT

D

A

C

20 1/4"

11 3/8"

9"

12 11/16"

17 3/4"

Part Number A B C D E

LC312 103 17” 12” X 15¾” 30¼”

LC312 123 17” 12” X 15¾” 30¼”

LE312 103 12D 17” 12” 24½” 15¾” X

LE312 123 1D 17” 12” 24½” 15¾” X

Read this manual carefully before installing, operating or

servicing this equipment.

Safety

Injury and/or equipment damage may result if proper safety precautions are not

observed.

• Ensure that only a qualified electrician installs/services this equipment.

• Ensure that power supply voltage does not exceed maximum voltage rating of

reel.

• Ensure that reel is properly installed before connecting to power supply.

• Ensure that all electrical power is removed from reel before servicing.

• Check for frayed/broken wires before each use.

• Pull electrical cord from reel by grasping the electrical cord itself, not the

work device.

• If an electrical malfunction should occur, remove power from reel immediately.

• Ensure that reel, electrical cable, and equipment being serviced are properly

grounded. Use an ohmmeter to check ground continuity.

• If reel ceases to unwind or rewind, remove power immediately. Do not pull

or jerk on electrical cable

• Treat and respect the hose reel as any other piece of machinery, observing all

common safety practices.

WARNING:

This reel is to be used for cable storage only! The entire length of cable must be

unwound before use. Severe damage to the reel will result if the cable is energized

while fully wound on the reel.

LB312 103 17” 12” X 15¾” 29¼”

LB312 123 17” 12” X 15¾” 29¼”

Four 1/2” diameter mounting holes

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

Customer Service: 855-634-9109 • reelcraft@reelcraft.com • www.reelcraft.com

WARNING:

Even low voltage can cause irreparable damage or death! Exercise extreme caution

while operating or servicing this equipment.

Form# 1175-1005 Rev: 5/2013

Page 2

Series L 30000 Cable Reels

Inspection

Unpack and inspect reel for damage. Turn the

reel by hand to check for smooth operation.

Check for completeness.

Mounting of all Hose Reels

NOTE: Ensure that mounting surface is flat to

prevent binding on reel after it is mounted.

1. Two 1/2” diameter mounting holes are

located at the base of each side support

panel (2 each). Mount reel using four

(customer supplied) bolts’ tightening them

securely to ensure a solid, rigid

attachment.

Installation Instructions

Ensure that only a qualified electrician install/

services this equipment. Observe

applicable NEC, OSHA, and local codes when

installing this equipment.

NOTE: make center harness connections as

short as possible to prevent rubbing on slip

ring cover.

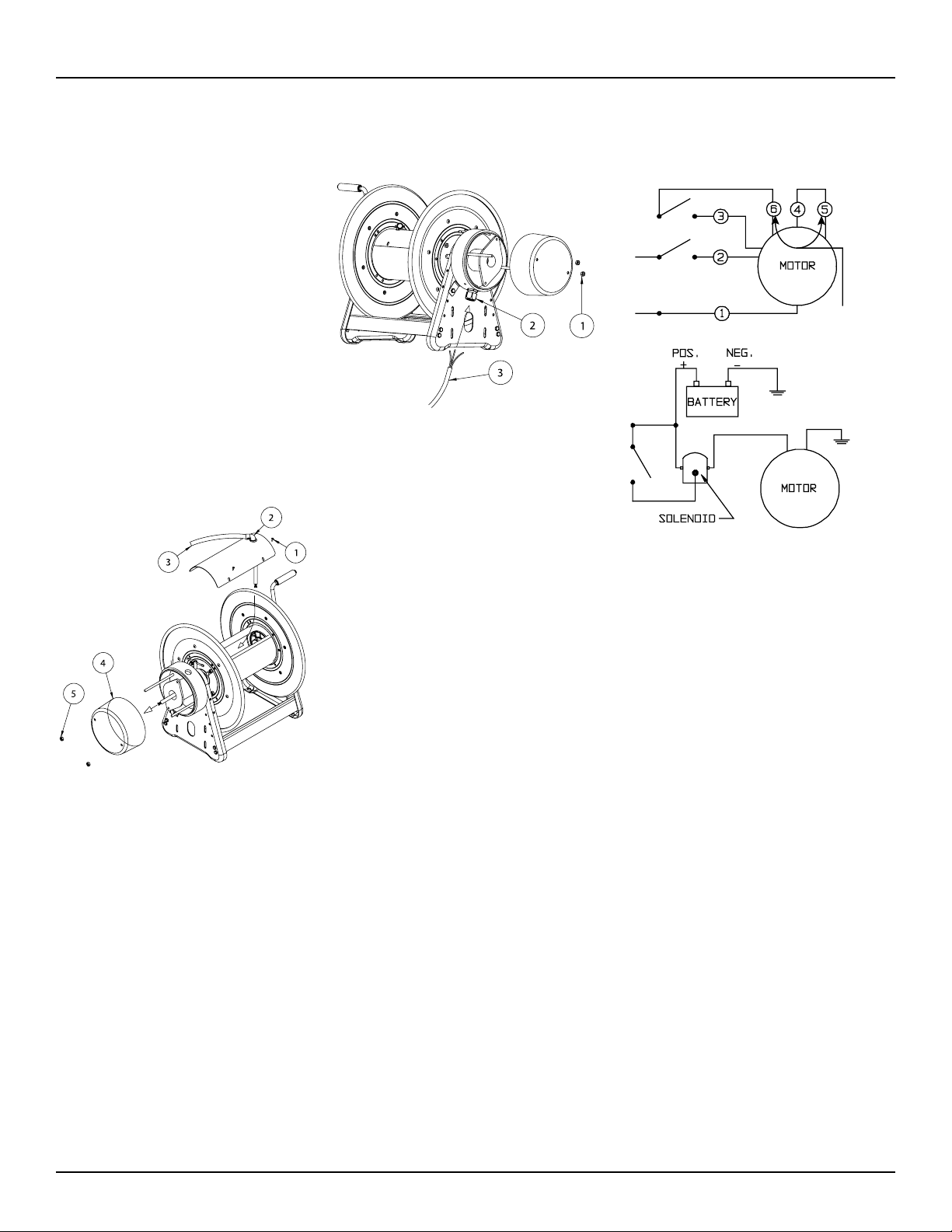

Installing the Inlet Cable

1. Remove the 2 nuts holding collector ring

cover (1).

2. Feed inlet cord thru grommet (2) in

collector ring base approximately 6-8”.

Tighten grommet.

3. Slide protective sleeve over each inlet wire.

4. Attach supplied knife disconnects to inlet

wires (3) & crimp.

5. Make knife connection & slide protective

sleeve over knife connections.

DOUBLE POLE

SINGLE-THROW

SWITCH

SINGLE POLE

SINGLE-THROW

Hot

Neutral

Connection shown

gives counterclockwise rotation

looking at end of

motor shaft. To

reverse rotation

interchange Leads

5, 6.

12/24 VOLT

D.C.

Installing the Output Cable

1. Remove the 4 screws holding spool cover

(1).

2. Loosen screws on 90° strain relief (2) and

feed approximately 18” thru. Tighten

screws.

3. Feed cord thru shaft and replace spool

cover.

4. Connect output wire (3) to collector ring

wire leads per NEC recommendations.

(Not knife disconnects).

5. Replace collector ring cover (4) and tighten

nuts (5).

Power Driven Reels

1. Driven which end of reel, motor is to be

mounted on. If the original factory

configuration is not condusive to your

application see section in this manual

titled, “Modifications.”

CAUTION: Remove all electrical power when

wiring. Do not hot-wire. Observe all applicable

NEC/OSHA requirements.

2. Ensure that supply and motor voltage

ratings are compatible.

3. Consult wiring diagrams and determine

which one is applicable to your reel.

4. Perform electrical wiring following

applicable diagram.

Page 2

www.reelcraft.com

Page 3

Series L 30000 Cable Reels

1/3 HP Motorized Reels

Bevel Gear

Drive

PARTS COMMON TO 1/3 HP MOTORIZED

REELS

Item

www.reelcraft.com

Part # Qty Description

#

1 S260409 1

2 S260408 1 Motor Gear

3 S2-52 4 Screw, 5/16-18 x 5/8”

4 260405 1 Motor Bracket

5 300039 4 Washer

6 S2-52 4 Screw, 5/16-18 x 5/8”

7 S85-7 4 Lock Nut 5/16-18

8 260403 REF REF Side Frame

9 S79-3 6 Flange Nut 10-32

10 260407 1 Spool Gear

11 S260410 6 Gear Spacer

12 S27-112 6 Screw 10-32 x 1 1/8”

13 260399 REF REF Spool Flange

14 S260406 1

Drive Motor

Drive Chain #35

PARTS COMMON TO BEVEL GEAR DRIVEN REELS

Item

#

1 S390838-10-35 1

2 S281-6 2 Nut, hex flange 12 S260399-3 2 Flange, spool

3 S317-31 12 Screw, self tapping 13 S317-31 12 Screw, self tapping

4 260403 2 Frame, side 14 261102 1 Shaft, bevel support

5 S600640 4 Hub & bushing ass’y 15 S2-51 8 Screw, hex cap

6 300007 7 Ring, snap 16 S44-6 2 Screw, machine

7 S79-3 6 Nut, flange 17 S2-52 5 Screw, hex cap

8 S323058M-ANZ 1 Gear, crown 18 262344-35 1 Crank, support

9 S85-7 8 Nut, nyloc 19 S390843-2-ANZ 1 Hand rewind ass’y

10 600640 4

Part # Qty Description

Crank & handle ass’y 11 S27-108 6 Screw, cap

Hub & bushing ass’y

Item

#

Part # Qty Description

Page 3

Page 4

Series L 30000 Cable Reels

16

Item # Description Qty LB312 103 LB312 123 LC312 103 LC312 123 LE312 103 12D LE312 123 12D

14 Spool Cover 1 262011-1 262011-2 262011-1 262011-2 262011-1 262011-2

15 Strain Relief 1 262016 260697 262016 260697 262016 260697

Item

#

1 602081 1 Collector Ring Assembly 12 261555 1 Cord Grip Assembly

2 S2-51 8 Screw, 5/16-18 x ½” 13 261402-100 4 Tie Rod

3 S317-31 12 Screw, 5/16-18 x 5/8” 14 By Model 1 Spool Cover

4 260403 2 Side Frame 15 By Model 1 Strain Relief

5 261988 1 Collector Ring Shaft 16 261501-2 2 Cross Brace

6 S600640 4 Hub & Bushing Assembly 17 602242 1 Support Shaft

7 S85-7 8 Nyloc Nut 18 S600102 1 Crank & Handle Assembly

8 S280109 1 Lock Handle Assembly 19 300089 1 Set Screw 3/8-16 x 3/8”

9 S260399-3 2 Spool Flange 20 300007 5 Snap Ring

10 300006 2 Set Screw 3/8-16 x 1/2” 21 300107 9 Lock Nut 5/16-18

11 260401-2 1 Spool Spacer 22 262019 1 Housing Bracket

Page 4

Part # Qty

Description

Item

#

Part # Qty

Description

www.reelcraft.com

Loading...

Loading...