Reelcraft Hose Electrical Reel Cabinets User Manual

Operating Instructions

Hose / Electrical Reel Cabinets

1 Bank = #600367 2 Bank = #600178

APPLICATIONS

The Reelcraft 7000 Cabinet is designed for use

with Reelcraft 7000 C Series hose reels. By

using special adapter, part number 600230, the

7000 cabinet may be modified for use with 4000

and 5000 series reels.

INSTALLATION

The following installation procedure is applicable

for all 7000 Cabinet installations. If 4000 or

5000 Series hose reels are to be installed in

conjunction with the cabinet, perform all steps

of the following procedure (adapter, part number

600230, required). If 4000 Series cord reels are

to be installed in conjunction with the cabinet,

omit steps 6, 7, 9, and 11 of the following procedure. Before beginning, inspect packed materials

for shipping damage and completeness. Report

any discrepancies immediately.

CAUTION: Unless reel was specified differently

when ordering, maximum installation height

is 16 feet. Do not exceed this distance. Prior

to performing electrical maintenance (such

as removing and replacing the work device to

facilitate routing of the cord through the guide

roller assembly), ensure that all power has been

removed from reel. Consult manual of instructions accompanying reel for details.

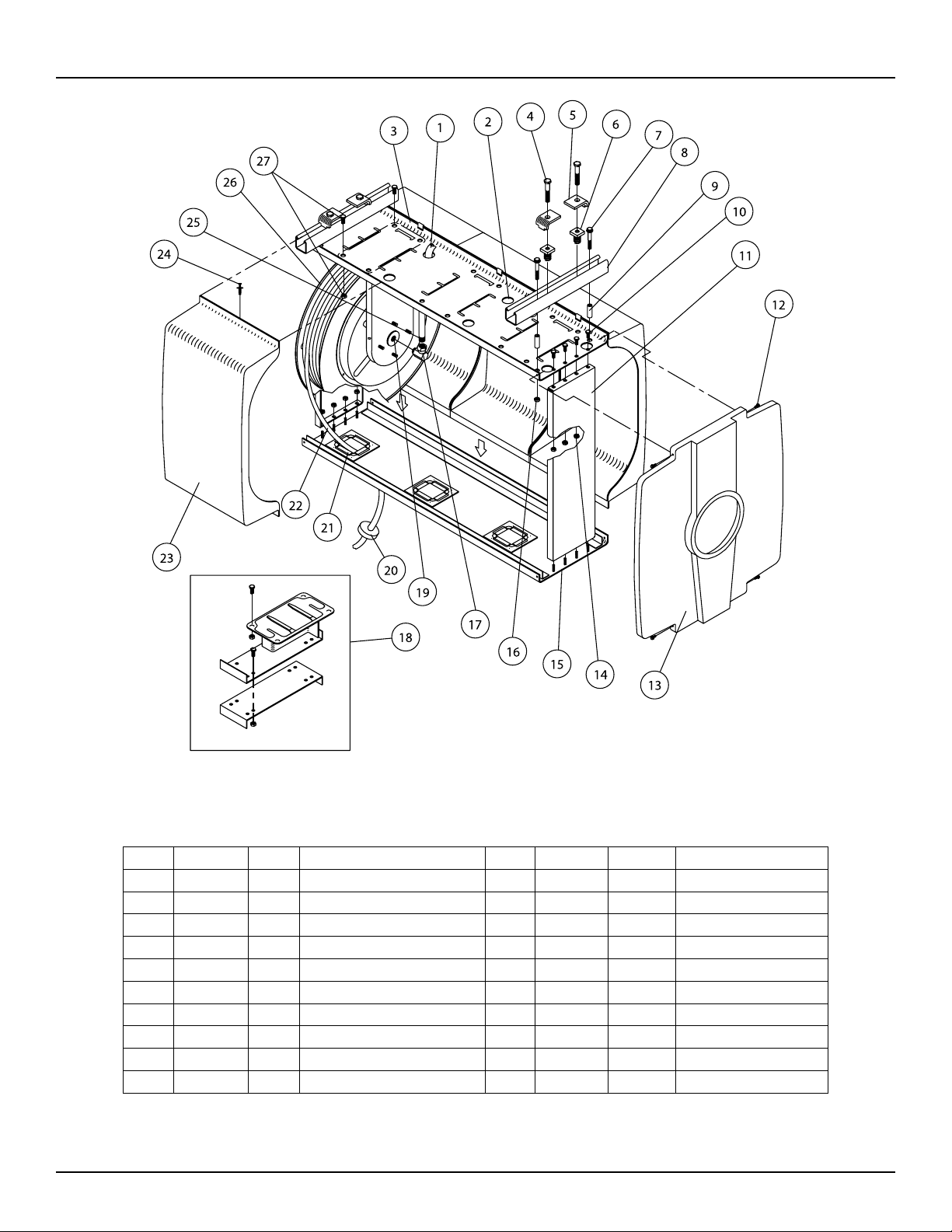

1. Assemble beam clamp assembly by inserting spring nuts (6) into channel support

(8). Position beam clamps (5) and secure

into place with 1/2” bolts (4). Repeat this

step for each beam clamp assembly before

proceeding to next step.

2. Position beam clamp assembly to upper

mounting channel (1). Secure into place

with 1/2” bolts (7), spacers (9), and

locknuts (16). Repeat step for each beam

clamp assembly before proceeding to next

step.

3. Position upper mounting channel (1) to “I”

beam. Push beam clamps (5) inward until

they fully engage “I” beam flange. Tighten

1/2” bolts (4) to secure.

4. Position vertical channel (11) to upper

mounting channel (1) and secure into

place with four 5/16” bolts (10) and locknuts (10). Repeat step for opposite end of

bank.

NOTE: 4 bank models employ a vertical channel

in the center.

5. Position lower channel (15) to vertical

channels (11) and secure into place with

5/16” locknuts (14).

6. Apply pipe thread sealant to elbow swivel

union (17). Thread elbow swivel union

into inlet main shaft (19) of reel. Repeat

step for each reel before proceeding to next

step.

7. Thread connecting hose fitting (25) into

elbow swivel union (17). Tighten securely.

Repeat step for each reel before proceeding

to next step.

NOTE: If 4000 or 5000 Series reels are

being installed, special adapter 600230 must be

installed to reel before proceeding to next step.

Perform special adapter installation in accordance with diagram.

8. Position reel (26) to upper mounting channel (1). Secure into place with 3/8” bolts

and locknuts (27). Route 2’ connecting

hose (2) (or power cord in the case of

4000 cord reels) through upper mounting

channel (1) via 1-14” cutout (3). Repeat

step for each reel before proceeding to next

step.

9. Adjust spring tension of reel by pulling

hose from reel sheave until sheave has

turned three complete turns and then latch

reel in position. While reel is still latched,

manually rewrap hose on reel. Do not

release latch until step 10 of this procedure

has been completed. Repeat step for each

reel before proceeding to next step.

*See note below.

NOTE: In the following step, if a 4000 cord

reel is being installed, the output device and

bumper must be removed to facilitate routing

of the cord through the guide roller assembly.

Consult manual that accompanies each reel for

removing these items. *See note.

10. Route reel output hose (22) (or cord

in the case of 4000 cord reels)

through guide roller assembly (21) in

lower channel (15). When desired

length protrudes from lower channel,

install bumper (20) (do not install

output control device at this time).

Repeat step for each reel in bank

before proceeding to next step.

NOTE: For servicing, it is recommended that a

shut-off device be installed between the reel and

supply.

11. Flush piping system of contaminants.

Connect supply side plumbing, then pressurize system. Check system for leaks.

Shut off ball valves and relieve pressure.

Repeat step for each reel in bank before

proceeding to next step.

12. Install output control device.

13. Position wrapper (23) to assembly and

secure into place with clip (24). Repeat

step for each wrapper before proceeding to

next step.

14. Position end panel (13) to assembly and

secure into place using four 8-32 self-tapping screws (12). Repeat step for opposite

end of bank.

* If needed, adjust spring tension of reel

by adding or removing wrap of hose

from the spool, one wrap at a time,

until desired tension is obtained. Add

wraps to increase tension. Remove

wraps to decrease tension.

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

Customer Service: 855-634-9109 • reelcraft@reelcraft.com • www.reelcraft.com

Form# 1181-1205 Rev: 8/2014

Hose / Electrical Reel Cabinets

Page 2

Item # Part # # Req. Description Item # Part # # Req. Description

1 262017 1 Upper Channel (1 bank) 13 260471 2 End Panel

1 262018 1 Upper Channel (2 bank) 14 S85-7 16 5/16-18 Nyloc Nut

4 S2-87 4 1/2-13 x 1 1/2” Hex Cap Screw 15 600369 1 Lower Channel (1 bank)

5 260477 4 Beam Clamp 15 600176 1 Lower Channel (2 bank)

6 260478 4 Spring Clamp Nut 16 S281-8 4 1/2-13 Hex Nut

7 S2-88 4 1/2-13 x 1 3/4” Hex Cap Screw 18 600230 2 (1 bank) Adapter

8 260476 2 Support Channel 23 260473 2 (1 bank) Wrapper

10 S2-52 8 5/16-18 x 5/8” Hex Cap Screw 23 260473 4 (2 bank) Wrapper

11 260549 2 Vertical Channel 24 S282-88 4 (1 bank) Self-Tapping Screw

12 S282-88 8 Self-Tapping Screw 24 S282-88 8 (2 bank) Self-Tapping Screw

www.reelcraft.com

Loading...

Loading...