Page 1

Operating Instructions

Static Discharge Reels

Model Number:

G 3050 G 3050 Y G 3050 N

INSTALLATION

CAUTION

Be sure reel base is securely grounded to mounting surface. Check for continuity following installation.

On painted surfaces, remove paint at bolt location, use external tooth lockwashers or run ground wire from reel

base to grounded object. Failure to ground will prevent reel from performing its intended function and could result

in personal injury.

Mount reel to grounded, metal surface using four holes in mounting base. To minimize wear on cable and cable

guide, reel should be mounted in direct line with work so that cable is pulled out as straight as possible during use.

See figures 1 & 2.

TENSION ADJUSTMENT

Never add / remove tension when the cable is extended from the reel. The cable must always be fully wound

on the reel.

1. Hold shaft securely with wrench and remove 2 screws from hub.

2. Turn shaft clockwise / counter-clockwise to add / remove tension (one full turn at a time).

3. When desired tension is achieved, replace the 2 screws.

RATCHET LOCK USE

Engage ratchet lock by pulling cable out to desired position and letting it retract SLOWLY until lock engages.

To release lock, quickly pull cable out a short distance and allow it to begin to retract-it operates like a window

shade. Locking feature may be turned off by turning knob on side of reel.

DANGER

DO NOT allow cable to retract in an uncontrolled manner. Always guide cable back to reel. Failure to do so can

result in damage to reel or personal injury.

Rev: 7/2014

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

Customer Service: 855-634-9109 • reelcraft@reelcraft.com • www.reelcraft.com

Page 2

Grounding Reels

REGULAR MAINTENANCE

1. Reel is factory lubricated for life. No additional lubrication required.

2. Periodically check cable for wear. If wear is detected, cable should be replaced immediately. If cable replacement is required, order cable assembly kit no. 5 which contains cable and related parts, hardware and instructions. See parts list for details.

SPRING REPLACEMENT

DANGER

DO NOT attempt to remove spring motor from its canister. Doing so can result in damage to reel or

personal injury.

Spring motors are self-contained for safe and easy handling. If spring motor replacement is required, it should be

replaced as a unit by ordering spring motor kit no. 1 which contains the spring motor, spool, shaft and bushings in

a sealed canister. See parts list for details.

RATCHET LOCK REPLACEMENT

For your convenience, the ratchet lock assembly has been included in two separate replacement kits. Order either

the hardware assembly kit no. 6, or the RH housing assembly kit no. 2. See parts list for details.

CABLE OPTIONS

(Number 5)

“Y” cable assembly (two clips),

add -Y to the part number.

EXAMPLE: G 3050-K05-Y

Nylon covered cable, add -N to

the part number.

EXAMPLE: G 3050-K05-N

RH housing assembly (no. 2)

includes ratchet lock assembly

and ground shoe attached

NOTE:

to housing.

Item

Number

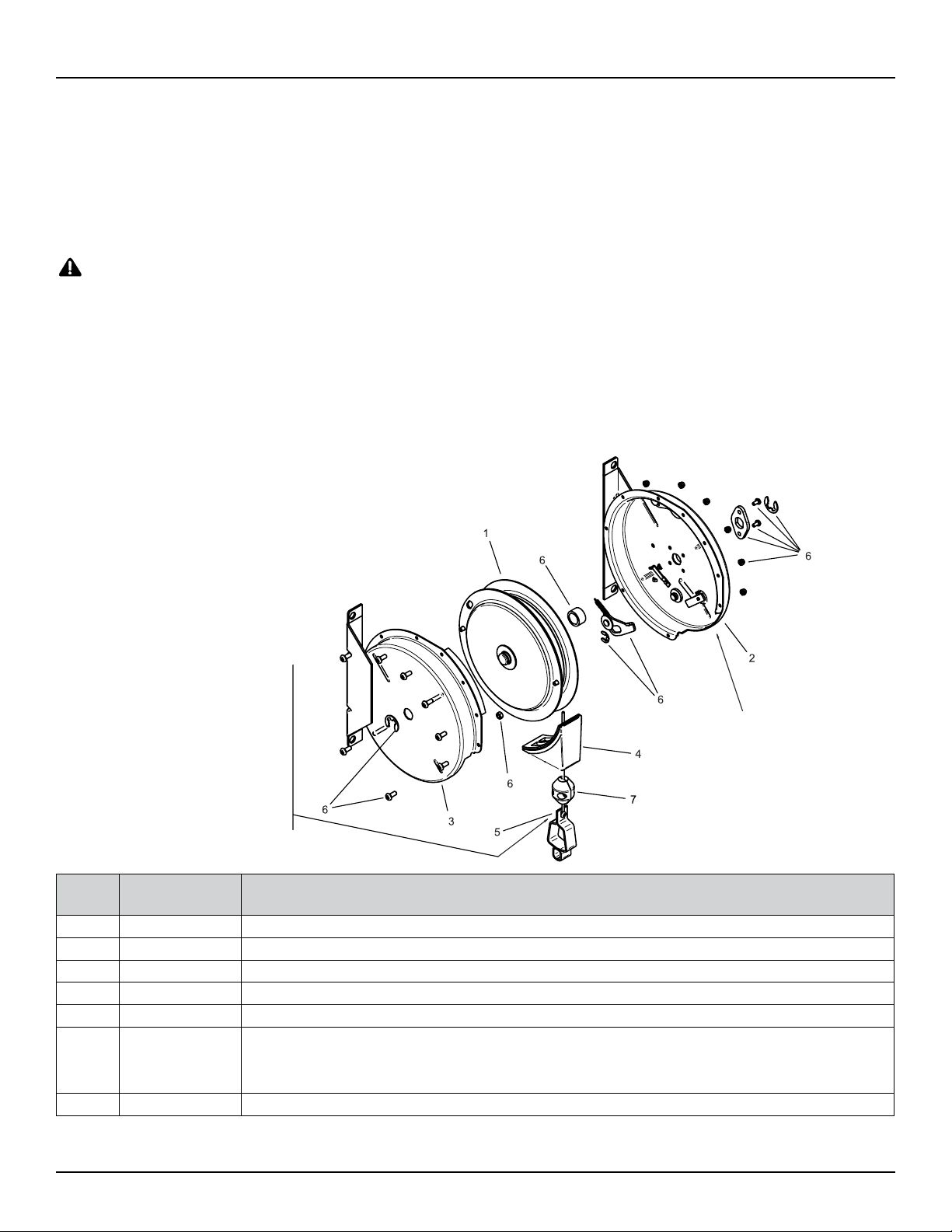

1 G 3050-K01 Spring motor assembly: spring motor, shaft and bushings in sealed container

2 G 3050-K02 RH housing assembly: RH housing half, ratchet lock assembly (attached to housing)

3 G 3050-K03 LH housing assembly: LH housing half, nameplate

4 G 3050-K04 Cable guide

5 G 3050-K05 Cable assembly: cable, grounding clamp(s), lockwasher-M4, hex nut-m4 (see notes below)

6 G 3050-K06

7 602413 Cable stop

*For G 3050 Y models with “Y” cable (two grounding clamps), order part number G 3050-K05-Y.

For G 3050 N models with nylon covered cable, order part number G 3050-K05-N.

Page 2

Part Number Description

Hardware package: spacer, torsion spring, slotted machine screws M4 x 14mm (3), slotted machine screws M4 x 8mm (6), lockwasher-M4 (10), hex nut-M4 (10), retaining ring (3), extension

spring, ratchet lock assembly

www.reelcraft.com

Loading...

Loading...