Page 1

Operating Instructions

Series BA34000 M Hand Crank Reels

Twin Hydraulic Model Numbers:

BA34106 M BA34118 M BA34128 M

BA34112 M BA34122 M

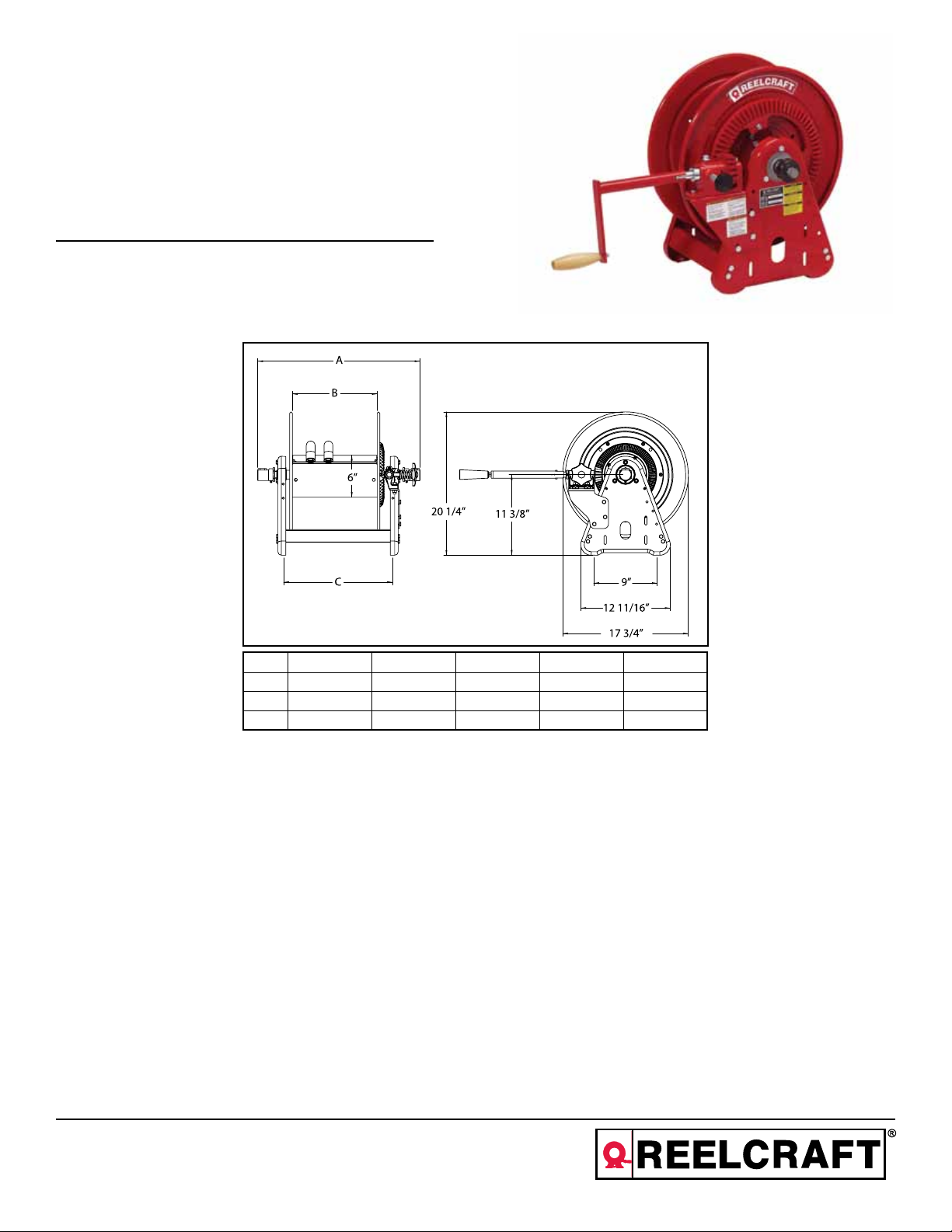

Dimensional Data

BA34106 M BA34112 M BA34118 M BA34122 M BA34128 M

A 17” 23” 29” 35” 41”

B 6” 12” 18” 22” 28”

C 9.75” 15.75” 21.75” 25.75” 30.75”

Safety Precautions

Personal injury and/or equipment damage may result if proper safety precautions are not observed.

• Ensure that the reel has been properly installed before connecting supply line (see installation instructions).

• Before connecting reel to supply line ensure that supply line pressure does not exceed maximum rated working pressure of reel.

• Bleed fluid/gas pressure from system before servicing reel.

• Do not play pranks on other personnel. Even low pressure is very dangerous and can cause irreparable damage or death.

• Do not wear loose fitting clothing while operating reel.

• Be aware of other personnel in work area.

• Be aware of other machinery in work area.

• If a leak occurs in the hose or reel, remove supply line pressure immediately.

• If the reel is power driven check for loose, frayed, and/or broken wires before operating.

• Pull hose from reel by grasping the hose itself, not the control valve.

• If reel ceases to unwind or rewind, remove system pressure immediately. Do not pull or jerk on hose!

• Treat and respect a hose reel as any other piece of machinery, observing all common safety practices.

Form# 1242-612 Rev: 5/2013

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

Customer Service: 855-634-9109 • reelcraft@reelcraft.com • www.reelcraft.com

Page 2

Series BA34000 M Hand Crank Reels

INSTALLATION INSTRUCTIONS

Inspection

Unpack and inspect the reel for damage.

Turn the reel by hand to check for smooth

operation. Check for completeness.

WARNING-PREVENT STATIC

SPARKING: When working around flam-

mable liquids such as solvents, paints,

chemicals or petroleum products, ensure

that the hose reel, hose and the equipment

being serviced are properly grounded.

Use grounded hose(s) (static wire). Use

an ohmmeter to check continuity of the

ground circuit. Fire and/or explosion can

result if proper grounding is not achieved.

If reel is power or air driven, be careful of

chain/sprocket drive system. Keep hands

clear. Do not wear loose fitting clothing. Pull hose from the reel by grasping

the hose itself, not the control handle or

swivel.

Maximum Operating Temperature

Low pressure (300 PSI) = 150°F (66°C)

Medium pressure (3000 PSI) = 210°F (99°C)

High pressure (4800 PSI) = 210°F (99°C)

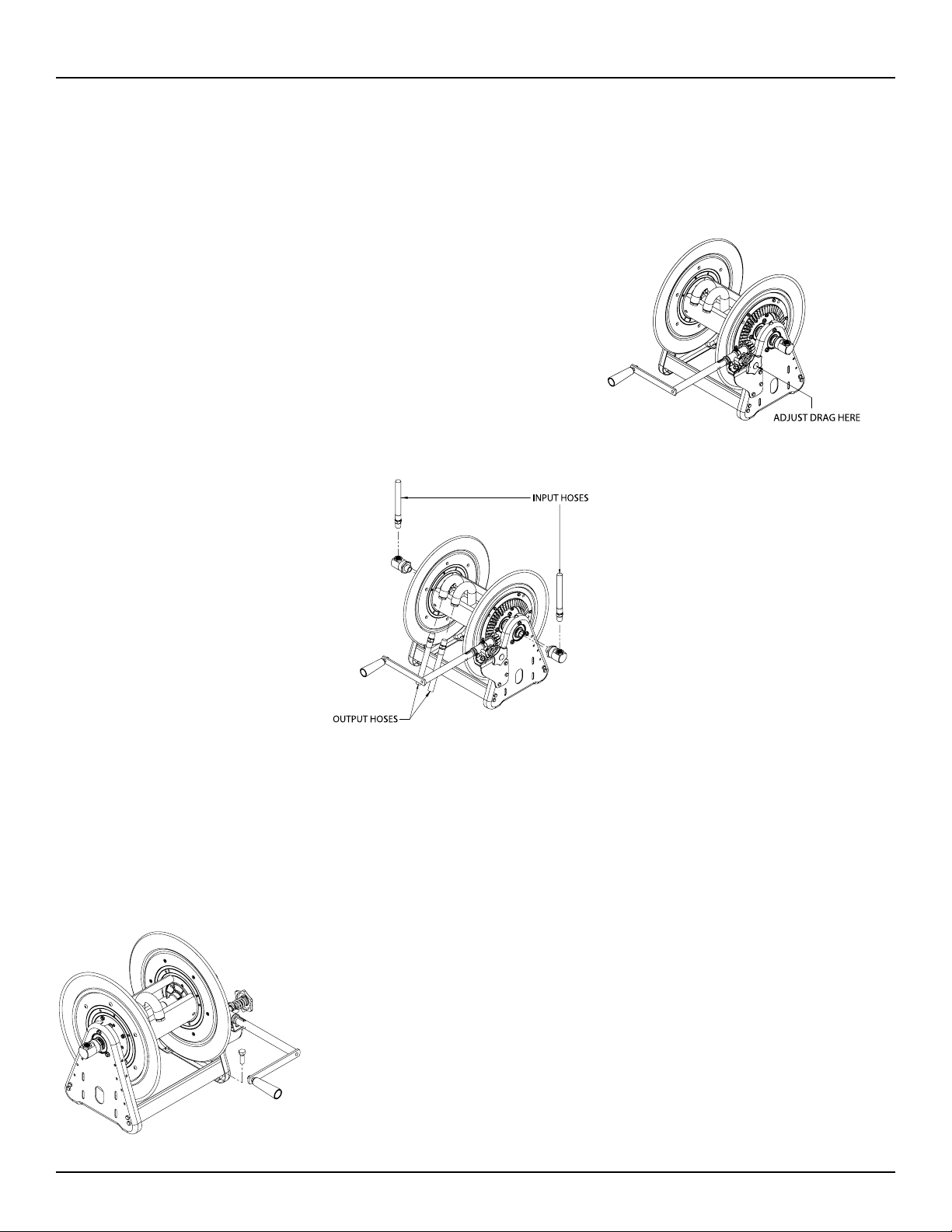

Installing the Input Hose(s)

WARNING: Ensure that supply line pres-

sure does not exceed maximum working

pressure rating of reel. Apply pipe thread

sealant where applicable to all threads on

standard reels. Do not over-tighten connection.

CAUTION: A flexible hose connection

must be used to compensate for any offset between the supply line and the reel

swivel. Do not use rigid plumbing.

1. Apply thread sealant as directed and

connect swivels to main shaft inputs

on opposite sides of the reel.

2. Connect customer supplied supply

line hose to swivel input as indicated

in illustration.

ADJUSTMENT PROCEDURES

Adjusting the reel

1. Adjust reel drag by loosening or

tightening the knob on the side of the

hand rewind assembly.

SERVICE INSTRUCTIONS

User servicing of the reel is limited to

replacing input/output hoses only. Refer

all other repairs to an authorized service

person or directly to Reelcraft. Failure to

do so can result in personal injury and/

or equipment damage and may void the

warranty.

WARNING: Bleed pressure from system

before servicing reel.

Mounting of All Hose Reels

NOTE: Ensure that mounting surface is

flat to prevent binding on reel after it is

mounted.

1. Two 1/2” diameter mounting holes are

located at the base of each side

support panel (2 each). Mount reel

using four (customer supplied) bolts;

tightening them securely to ensure a

solid, rigid attachment.

Installing the Output Hose(s)

WARNING: Ensure that supply line pres-

sure does not exceed maximum working

pressure rating of reel.

CAUTION: Apply pipe thread sealant

where applicable to all threads on standard

reels. Do not over-tighten connection.

1. Connect output hoses to goosenecks

paying special attention to which

gooseneck should be used depending

on application. The left inlet is connected to the left gooseneck and the

right inlet to the right gooseneck.

2. Charge hoses. Momentarily open

control valve to purge hose of gases.

When fluid appears at control valve,

close valve. With hose fully charged,

wind output hoses onto reel.

1. Replace hoses in accordance with

procedures given in “Installation Instructions” section of this manual.

2. All mating moving parts have been

factory lubricated as required.

Page 2

www.reelcraft.com

Page 3

Series BA34000 M Hand Crank Reels

ITEM DESCRIPTION QTY. BA34106 M BA34112 M BA34118 M BA34122 M BA34128 M

1 TIE ROD 4 260402-100 260402-200 260402-300 260402-400 260402-500

2 CROSS BRACE 2 261501-1 261501-2 261501-3 261501-4 261501-5

3 LOCK NUT 11 300107 300107 300107 300107 300107

4 HUB & BUSHING ASSEMBLY 4 S600640 S600640 S600640 S600640 S600640

5 SELF TAPPING SCREW 12 S317-31 S317-31 S317-31 S317-31 S317-31

6 MACHINE SCREW 8 S2-51 S2-51 S2-51 S2-51 S2-51

7 SWIVEL ASSEMBLY 2 S602026 S602026 S602026 S602026 S602026

8 SIDE FRAME 2 260403 260403 260403 260403 260403

9 NYLOC NUT 8 S85-7 S85-7 S85-7 S85-7 S85-7

10 SPOOL FLANGE 2 S260399-3 S260399-3 S260399-3 S260399-3 S260399-3

11 SET SCREW 1 300006 300006 300006 300006 300006

12 SHAFT ASSEMBLY 1 600189-1 600189-1 600189-3 600189-4 600189-5

13 SNAP RING 4 300007 300007 300007 300007 300007

14 CAP SCREW 6 S27-108 S27-108 S27-108 S27-108 S27-108

15 CRANK HANDLE 1 S390838-10-35 S390838-10-35 S390838-10-35 S390838-10-35 S390838-10-35

16 HEX FLANGE NUT 2 S281-6 S281-6 S281-6 S281-6 S281-6

17 CRANK SUPPORT 1 262344-35 262344-35 262344-35 262344-35 262344-35

18 MACHINE SCREW 3 S2-52 S2-52 S2-52 S2-52 S2-52

19 HAND REWIND ASSEMBLY 1 S390843-2-ANZ S390843-2-ANZ S390843-2-ANZ S390843-2-ANZ S390843-2-ANZ

20 MACHINE SCREW 2 S44-6 S44-6 S44-6 S44-6 S44-6

21 HEX FLANGE NUT 6 S79-3 S79-3 S79-3 S79-3 S79-3

22 CROWN GEAR 1 S323058M-ANZ S323058M-ANZ S323058M-ANZ S323058M-ANZ S323058M-ANZ

23 SPOOL SPACER 1 260401-1 260401-2 S260401-3 260401-4 260401-5

www.reelcraft.com

Page 3

Loading...

Loading...