Page 1

Operating Instructions

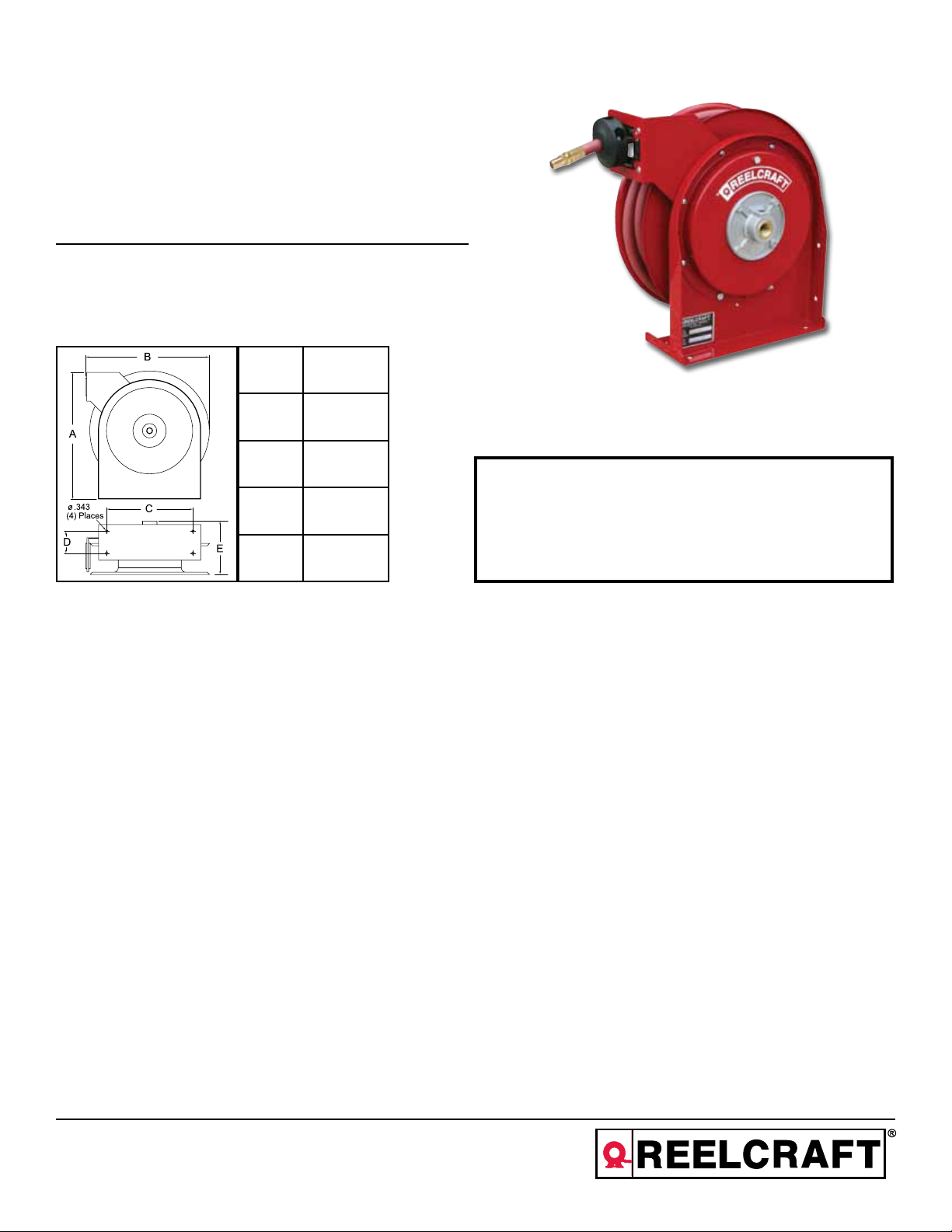

Series 4000 Spring Driven Hose Reels

Low Pressure Model Numbers:

4400 OLP 4430 OLP 4615 OLP 4620 OLP

4420 OLP 4435 OLP 4617 OLP 4625 OLP

4425 OLP 4600 OLP

Dimensions

A 12 7/8”

B 12 3/8”

C 8”

SAFETY

INSTALLATION:

MOUNTING:

LUBRICATION:

REPLACING HOSE:

D 2 1/2”

E 5 5/8”

A flexible hose connection must be used between the hose reel inlet and the source of supply to prevent possible

misalignment and binding.

The hose reel is equipped with a universal mounting bracket so that it can be mounted on the floor, wall or

ceiling; whichever place is convenient. The hose guide arm can be moved to the position desired by removing

the screws fastening the guide bracket to the reel base. Shift the guide arm bracket so the hose comes off the

reel at the desired position and replace the screws. NOTE: For proper installation in wall mount applications, ensure

reel is mounted with inlet on the right as you are facing the reel. Failing to do so could cause latching issues.

Hose reel spring and bearings are factory lubricated and require no further lubrication.

1. Wind spool flange clockwise-facing swivel-until spring is tight.

2. Back off three turns and latch.

3. Insert hose through roller guide.

4. Connect hose fitting to swivel joint and secure hose with clamps.

1. Do not use reel at higher pressures or temperatures than listed on

the back of this bulletin.

2. Remove all spring tension before beginning dissassembly process.

ADJUSTMENTS:

REPAIRS:

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

Customer Service: 855-634-9109 • reelcraft@reelcraft.com • www.reelcraft.com

To adjust spring tension, add or remove wraps of hose from the spool, one wrap at a time until desired tension is

obtained.

Extensive repairs should be performed only by an authorized serviceman or factory to avoid damage which may

void your warranty. Remove all spring tension before beginning disassembly process.

Form# 828-696 Rev: 4/2013

Page 2

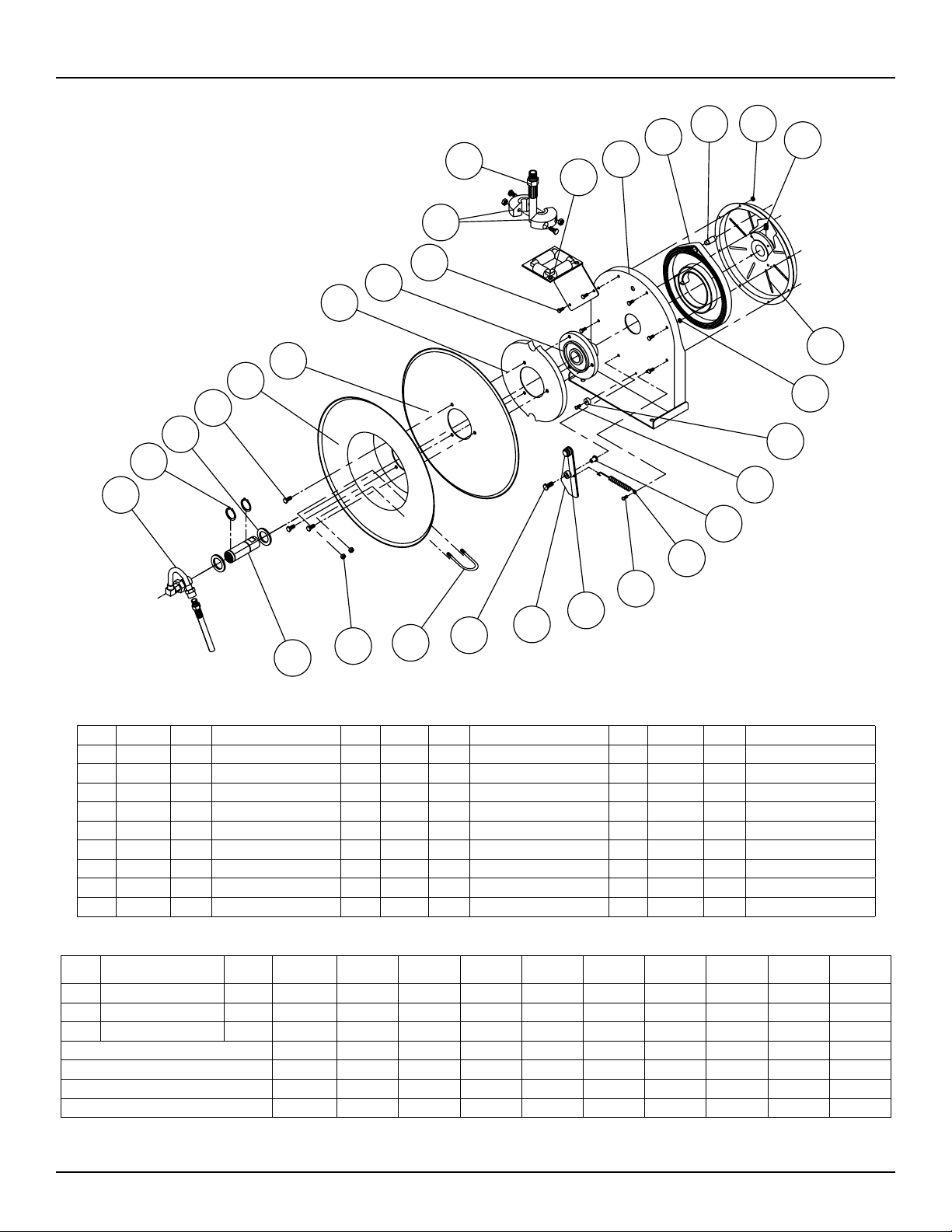

Series 4000 Spring Driven Hose Reels

1

2

3

4

5

6

7

8

10

9

11

12

13

14

23

15

16

17

18

19

20

21

22

24

25

30

Item # Part # # Req. Description Item # Part # # Req. Description Item # Part # # Req. Description

1 S600886 1 Swivel Assembly 12 S400107 1 Guide Arm Assembly 22 S400012 1 Latch Bushing

2 300031 2 1” Snap Ring 13 400101 1 Base Assembly 23 S400018 1 Latch Spring

3 300034 2 Spacing Washer 15 S261360 1 Spring Case Stud 24 300001 5 10-32 x 3/8” Screw

4 S295-102 3 1/4” Plastite Hex Screw 16 S300011 7 10-32 Hex Lock Nut 25 400020 1 O-ring

5 400005 1 Flange Assembly 17 300006 1 3/8-16 x 1/2” Set Screw 26 S400109 1 Latch Plate Assembly

6 400006 1 Sheave Disk 18 S400103 1 Spring Case Assembly 27 300035 1 10-32 x 1” Mach. Screw

7 S400019 1 Latch Cam 19 S82-15 1 10-32 x 3/8” Nyloc Nut 28 3-117440 1 U-bolt

8 S260648 1 Spring Arbor 20 S400021 1 Latch Bumper 29 261650-1 2 1/4-20 Zinc Nyloc Nut

9 300002 2 10-32 x 1/2” Screw 21 S32-136 1 10-24 x 3/8” Mach. Screw 30 S400015 1 Main Shaft

Item # Description # Req. 4400 OLP 4420 OLP 4425 OLP 4430 OLP 4435 OLP 4600 OLP 4615 OLP 4617 OLP 4620 OLP 4625 OLP

10 Hose Bumper Assembly 1 None A1-HR1004A A1-HR1004A A1-HR1004A A1-HR1004A None A1-HR1004 A1-HR1004 A1-HR1004 A1-HR1004

11 Hose Assembly 1 None 601001-20 601001-25 601000-30 601001-35 None 601013-15 601011-17 601011-20 601013-25

14 Drive Spring Assembly 1 S400030 S400030 S400030 S400030 S400030 S404230 S404230 S404230 S404230 S404230

Hose I.D. and Length None 1/4” x 20’ 1/4” x 25’ 1/4” x 30’ 1/4” x 35’ None 3/8” x 15’ 3/8” x 17’ 3/8” x 20’ 3/8” x 25’

Reel Inlet Connection 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T.

Max. Operating Pressure 500 P.S.I. 300 P.S.I. 300 P.S.I. 300 P.S.I. 300 P.S.I. 500 P.S.I. 300 P.S.I. 300 P.S.I. 300 P.S.I. 300 P.S.I.

Max. Operating Temperature 210° F 150° F 150° F 150° F 150° F 210° F 150° F 150° F 150° F 150° F

29

28

27

26

Page 2

www.reelcraft.com

Page 3

Instrucciones de Operacion

Series 4000 Carreteles para Mangueras

Baja presion modelos y numeros:

4400 OLP 4430 OLP 4615 OLP 4620 OLP

4420 OLP 4435 OLP 4617 OLP 4625 OLP

4425 OLP 4600 OLP

Dimensiones

A 12 7/8”

B 12 3/8”

C 8”

SEGURIDAD

INSTALACION:

MONTAJE:

LUBRICACION:

REMPLAZO DE LA

MANGUERA:

D 2 1/2”

E 5 5/8”

Una manguera flexible de coneccion tiene que ser usada entre la entrada de la manguera de el carretel y la fuente

de abastecimiento para prevenir un posible desalineamiento y enlazamiento.

El riel de manguera esta equipado con un soporte de montaje universal para que esta pueda ser montada en el

piso, pared o techo; cualquier sitio es conveniente. El brazo guia de la manguera puede ser movido a la posicion

deseada removiendo los tornillos firmemente de la guia de soporte de la base de el carretel. Posicione la guia de

soporte del brazo abra que la manguera quede afuera del carretel a la posicion deseada; y reemplaze los tornillos.

NOTA: Para la instalación apropiada en usos del montaje de la pared, asegúrese que el carrete esté montado con

la entrada a la derecha mientras que usted está haciendo frente al carrete. El no poder hacer tan podía causar el

enganche de ediciones.

El resorte del carretel de la manguera y el cojinete estan empacado con grasa y no requiere futura lubricacion.

1. De vueltas a la palanca giratoria hacia la derecha hasta que el resorte este apretado.

2. Devuelva 3 giros y asegure.

3. Inserte la manguera atravez de la guia del rodillo.

4. Conecte y encaje la manguera a la salida hembra de el codo de tuberia.

1. No use carreteles a presiones o temperaturas altas que no se

mencionan en este boletin.

2. Remueva la tencion antes de empezar el proceso de desarme.

AJUSTAMIENTO:

REPARACION:

Page 3

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

Customer Service: 855-634-9109 • reelcraft@reelcraft.com • www.reelcraft.com

Para ajustar la tension del resorte en el carretel, agrege o quite vueltas hasta que la tension deseada es obtenidad.

Extensivas reparaciones deberan ser realizadas por una persona de servicio autorizada o por la fabrica para evitar

daños que eliminen su garantia. Remueva todos los resortes de tension antes del proceso de desmontaje.

Form# 828-696 Rev: 4/2013

Page 4

Series 4000 Carreteles para Mangueras

1

2

3

4

5

6

7

8

10

9

11

12

13

14

23

15

16

17

18

19

20

21

22

24

25

30

Arti

Part #

culo

1 S600886 1 Eje giratorio ensamblado 12 S400107 1

2 300031 2 1" Aro de resorte 13 400101 1 Base para ensamblar 23 S400018 1 Seguro del resorte

3 300034 2 Arandela espaciadora 15 S261360 1 Perno de la caja de resorte 24 300001 5 10-32 x 3/8" Tornillo

4 S295-102 3 1/4" Tornillo Hexagonal 16 S300011 7 10-32 Tuerca Hexagonal 25 400020 1 Arandela O

5 400005 1 Platillo ensamblado 17 300006 1 3/8-16 x 1/2" Tornillo 26 S400109 1 Serguro Ensamblado del plato

6 400006 1 Rueda exentrica del disco 18 S400103 1 Caja de resorte ensamblado 27 300035 1 10-32 x 1" Tornillo

7 S400019 1 Seguro de leva 19 S82-15 1 10-32 x 3/8" Tuerca 28 3-117440 1 Tornillo “U”

8 S260648 1 Resorte de tambor 20 S400021 1 Seguro del parachoque 29 261650-1 2 1/4-20 Tuerca de zinc

9 300002 2 10-32 x 1/2" Tornillo 21 S32-136 1 10-24 x 3/8" Tornillo 30 S400015 1 Columna principal

Arti

culo

Parachoques Ensamblados Para

10

La Manguera

11 Manguera ensamblada 1 None 601001-20 601001-25 601000-30 601001-35 None 601013-15 601011-17 601011-20 601013-25

Resorte ensamblado de propulsion

14

Identificacion de la manguera y largo None 1/4” x 20’ 1/4” x 25’ 1/4” x 30’ 1/4” x 35’ None 3/8” x 15’ 3/8” x 17’ 3/8” x 20’ 3/8” x 25’

Coneccion de entrada del carretel 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T.

Maxima presion de operacion 500 P.S.I. 300 P.S.I. 300 P.S.I. 300 P.S.I. 300 P.S.I. 500 P.S.I. 300 P.S.I. 300 P.S.I. 300 P.S.I. 300 P.S.I.

Maxima temperatura de presion 210° F 150° F 150° F 150° F 150° F 210° F 150° F 150° F 150° F 150° F

No

Req.

Descripcion

Descripcion

No

4400 OLP 4420 OLP 4425 OLP 4430 OLP 4435 OLP 4600 OLP 4615 OLP 4617 OLP 4620 OLP 4625 OLP

Req.

1 None A1-HR1004A A1-HR1004A A1-HR1004A A1-HR1004A None A1-HR1004 A1-HR1004 A1-HR1004 A1-HR1004

1 S400030 S400030 S400030 S400030 S400030 S404230 S404230 S404230 S404230 S404230

29

Arti

culo

28

Part #

27

No

Req.

Guia del brazo y rodillos

ensamblados

26

Descripcion

Arti

Part #

culo

22 S400012 1 Seguro del casquillo

No

Req.

Descripcion

Page 4

www.reelcraft.com

Page 5

Instructions D’Opération

Série 4000 Enrouleurs de Tuyau Manuels

Basse pression numéros de modèle:

4400 OLP 4430 OLP 4615 OLP 4620 OLP

4420 OLP 4435 OLP 4617 OLP 4625 OLP

4425 OLP 4600 OLP

Dimensions

A 12 7/8”

B 12 3/8”

C 8”

LA SÉCURITÉ

INSTALLATION:

MONTAGE:

LUBRIFICATION:

REMPLACEMENT

DE TUYAU:

D 2 1/2”

E 5 5/8”

Un raccord de tuyau flexible doit être utilisé entre l’entrée d’enrouleur et la source d’alimentation pour prévenir le

défaut d’alignment ou le coincement.

L’enrouleur de tuyau est équipé d’un support de montage universal pour être monté au plancher, au mur, ou au

plafond, quel que soit la position que vous désiriez. Le guide de tuyau peut être mis au position désiré en enlevant

les vis attachant le support guide au base de l’enrouleur. Positionez le support guide pour que le tuyau puis

enrouler de l’enrouleur comme désiré et remplacez les vis. NOTE : Pour l’installation appropriée dans des applications de bâti de mur, assurez que l’enrouleur est montée avec l’admission du côté droit pendant que vous faites

face à l’enrouleur. Ne pas faire ainsi a pu causer verrouiller des issues.

Le ressort de l’enrouleur et les pailers sont lubrifiés à vie en usine.

1. Enroulez la piéce d’espacement bridée dans le sens des aiguilles d’une montre (face au pivot) jusqu’ au ressort

est bien serré.

2. Faites marche arriére 3 tours, et puis fermez au loquet le mécanisme.

3. Insérez le tuyau à travers le guide et le trou de la pièce d’espacement bridée.

4. Connectez le raccord de tuyau au joint de pivot, et fixez le tuyau avec des crampons.

1. N’utillisez pas les enrouleurs à pression plus haut ou aux

températures plus hauts que ce qui est noté sur le dos de ce

bulletin.

2. Enlevez toute tension du ressort avant de désassembler.

RÉGLAGES:

RÉPARATIONS:

Page 5

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

Customer Service: 855-634-9109 • reelcraft@reelcraft.com • www.reelcraft.com

Pour régler la tension du ressort, ajoutez ou enlevez des tours de câble, un tour à la fois, jusqu’à l’obtention de la

tension désirée.

Des réparations étendues doivent être fait uniquement par un homme de service authorisé ou par l’usine pour éviter

le dommage quie peut annuler votre garantie. Enlevez toute tension de ressort avant de désassembler.

Form# 828-696 Rev: 4/2013

Page 6

Série 4000 Enrouleurs de Tuyau Manuels

1

2

3

4

5

6

7

8

10

9

11

12

13

14

23

15

16

17

18

19

20

21

22

24

25

27

N°

requis.

N°

28

N°de

pièce

30

N°

d’article

N°

d’article

10 assemblage d'arrêt de câble 1 None A1-HR1004A A1-HR1004A A1-HR1004A A1-HR1004A None A1-HR1004 A1-HR1004 A1-HR1004 A1-HR1004

11 assemblage de tuyau 1 None 601001-20 601001-25 601000-30 601001-35 None 601013-15 601011-17 601011-20 601013-25

14 assemblage de ressort 1 S400030 S400030 S400030 S400030 S400030 S404230 S404230 S404230 S404230 S404230

Longuer et diametre intérieur du tuyau None 1/4” x 20’ 1/4” x 25’ 1/4” x 30’ 1/4” x 35’ None 3/8” x 15’ 3/8” x 17’ 3/8” x 20’ 3/8” x 25’

Raccord d'entré d'enrouleur 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T. 3/8” F.P.T.

Pression d'opération maximum 500 P.S.I. 300 P.S.I. 300 P.S.I. 300 P.S.I. 300 P.S.I. 500 P.S.I. 300 P.S.I. 300 P.S.I. 300 P.S.I. 300 P.S.I.

Température d'opération maximum 210° F 150° F 150° F 150° F 150° F 210° F 150° F 150° F 150° F 150° F

N°de

pièce

1 S600886 1 assemblage de pivot 12 S400107 1

2 300031 2 1" dispositif de retenue 13 400101 1 assemblage de base 23 S400018 1 ressort de loquet

3 300034 2 rondelle d'espacement 15 S261360 1 boulon de boîtier de ressort 24 300001 5 10 -32 x 3/8" vis

4 S295-102 3 1/4" vis hexagonale Plastite 16 S300011 7 10 -32 contre-écrou hexagonal 25 400020 1 anneau en O

5 400005 1 assemblage de flasque 17 300006 1 3/8 - 16 x 1/2" vis sans tête 26 S400109 1

6 400006 1 disque de poulie 18 S400103 1 assemblage de boîtier de ressort 27 300035 1 10 -32 x 1" vis à metaux

7 S400019 1 came de loquet 19 S82-15 1 10 - 32 x 3/8" écrou Nyloc 28 3-117440 1 boulon en U

8 S260648 1 mandrin de ressort 20 S400021 1 boutoir de loquet 29 261650-1 2 1/4 - 20 écrou Nyloc en zinc

9 300002 2 10 -32 x 1/2" vis 21 S32-136 1 10 -24 x 3/8" vis à métaux 30 S400015 1 arbre principal

N°

requis.

Déscription

Déscription

N°

4400 OLP 4420 OLP 4425 OLP 4430 OLP 4435 OLP 4600 OLP 4615 OLP 4617 OLP 4620 OLP 4625 OLP

requis.

29

d’article

26

Déscription

assemblage de guide à

molettes

N°

d’article

N°de

pièce

22 S400012 1 manchon de loquet

N°

requis.

assemblage deplaque de loquet

Déscription

Page 6

www.reelcraft.com

Loading...

Loading...