Page 1

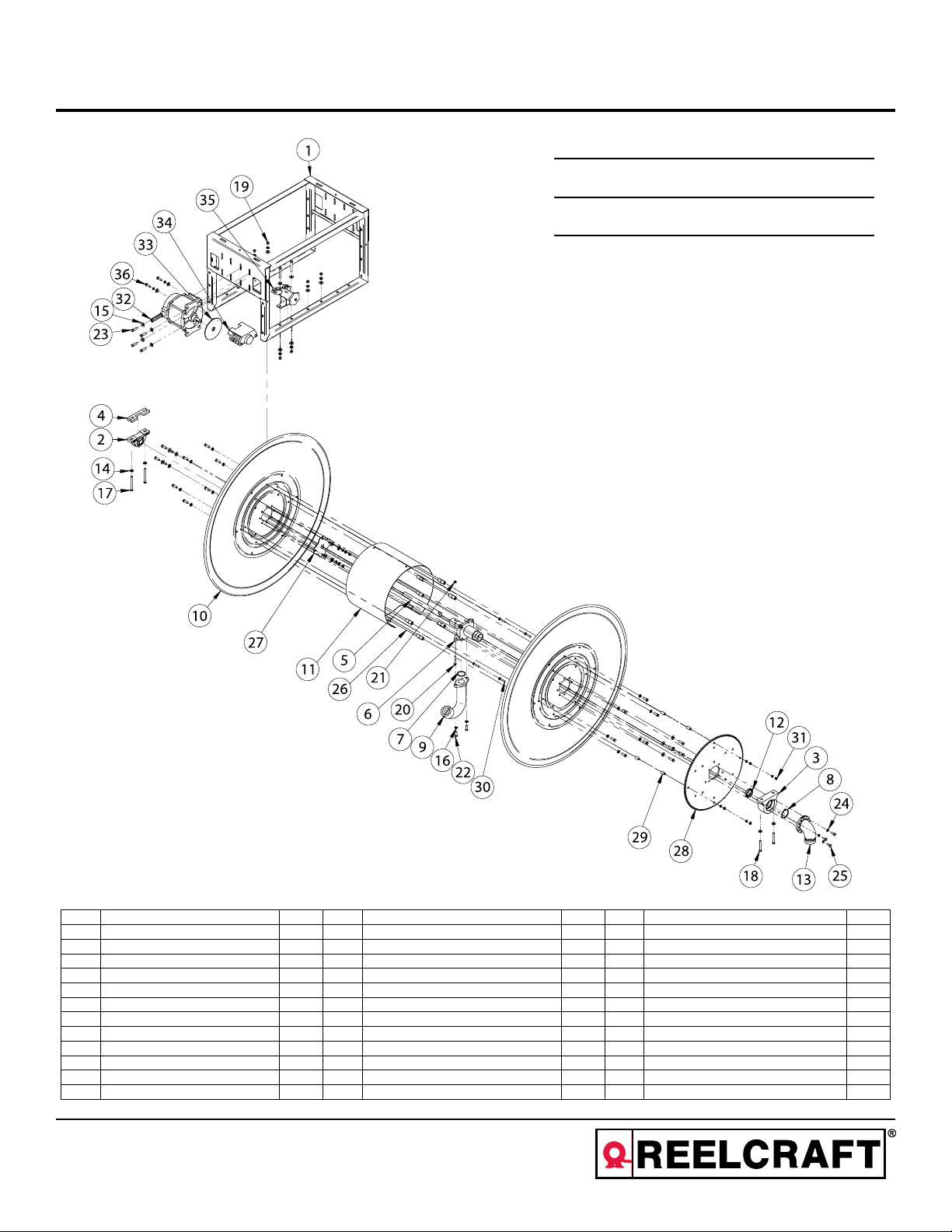

3800 SERIES

Hose Reel Operations Manual

ORDER #:

MODEL #:

SERIAL #:

IMPORTANT

Read this manual carefully before installing,

operating or servicing this equipment.

PERSONAL SAFETY

Personal injury and/or equipment damage may result

if proper safety precautions are not observed.

WARNING: Even low pressure can

cause irreparable damage or death.

Exercise extreme caution while

operating or servicing this equipment.

Item # Description Quantity Item # Description Quantity Item # Description Quantity

1 FRAME WELDMENT ASSEMBLY 1 13 INLET 1 25 S347-53 HEX CAP SCREW 5/16”-18 X 3/4” 3

2 BEARING SUPPORT SIDE 1 14 S350-41 WASHER SMALL 3/8” 4 26 TIE ROD 6

3 BEARING HOUSING ASSEMBLY 1 15 S350-6 WASHER 3/8” 34 27 390610-35 HEAD INSERT 1

4 BEARING SPACER 1 16 S339-616 LOCK WASHER 3/8” 32 28 SPROCKET, LARGE 1

5 SUPPORT SHAFT 1 17

6 SPINDLE 1 18

7 O-RING 1 19 S338-6 HEX NUT 3/8”-16 UNC 18 31 S338-5 HEX NUT 4

8 SNAP RING 1 20 S2-59 HEX CAP SCREW (5/16-18 X 2) 1 32 MOTOR 1

9 GOOSENECK 1 21 S85-7 NYLOC NUT (5/16-18) 1 33 BRAKE DISC ASSEMBLY 1

10 HEAD 2 22 S347-65 HEX CAP SCREW 3/8”-16 UNC X 1” 18 34 BRAKE ASSEMBLY 1

11 DRUM 1 23

12 SEAL AND RING ASSEMBLY 1 24 S339-516 LOCK WASHER 9 36 S347-56 HEX CAP SCREW 5/16-18 X 1.25”LG 2

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

Customer Service: 855-634-9109 • reelcraft@reelcraft.com • www.reelcraft.com

S347-615 HEX CAP SCREW 3/8”-16 UNC X 3.5”

S347-611 HEX CAP SCREW 3/8”-16 UNC X 2.5”

S347-66 HEX CAP SCREW 3/8”-16 UNC X 1.25”

2 29 390030-4 SPACER 3/8” X 1”LG 4

4 30 S344-15 BOLT, CARRIAGE 4

8 35 360421 FRICTION BRAKE ASSEMBLY 1

Page 2

Hose Reel Operations Manual

PERSONAL SAFETY

• Ensure that reel is properly installed before connecting supply line (see instructions).

• Before connecting supply line to reel, ensure that supply line pressure does not exceed maximum rated working pressure of the

reel.

• Do not wear loose fitting clothing while operating reel.

• Be aware of other personnel / machinery in work area.

• If a leak occurs in hose or reel, remove supply line pressure immediately.

• Treat and respect a hose reel as any other piece of machinery, observing all common safety practices.

WARNINGS & TIPS

Prevent static sparking

• Pull hose by grasping the hose itself not by the control valve swivel.

• When working around flammable liquids such as solvents, paints, chemicals or petroleum products, ensure that the hose reel

and the equipment being serviced is properly grounded. Use a grounding hose (static wire).

• Use an ohmmeter to check continuity of the grounding circuit. Fire and/or explosion can result if proper grounding is not

achieved.

• If reel is electric, air or hydraulic driven, be careful of chain / sprocket drive system. Keep hands clear and do not wear loose

fitting clothing while operating reel.

• If reel ceases to unwind or rewind properly, remove power immediately. Do not pull or jerk on hose. Find and remedy problem

before continuing.

PRE-INSPECTION

1. Check reel for shipping damages.

2. Insured all parts are supplied as ordered.

3. Record model number and serial number for future reference.

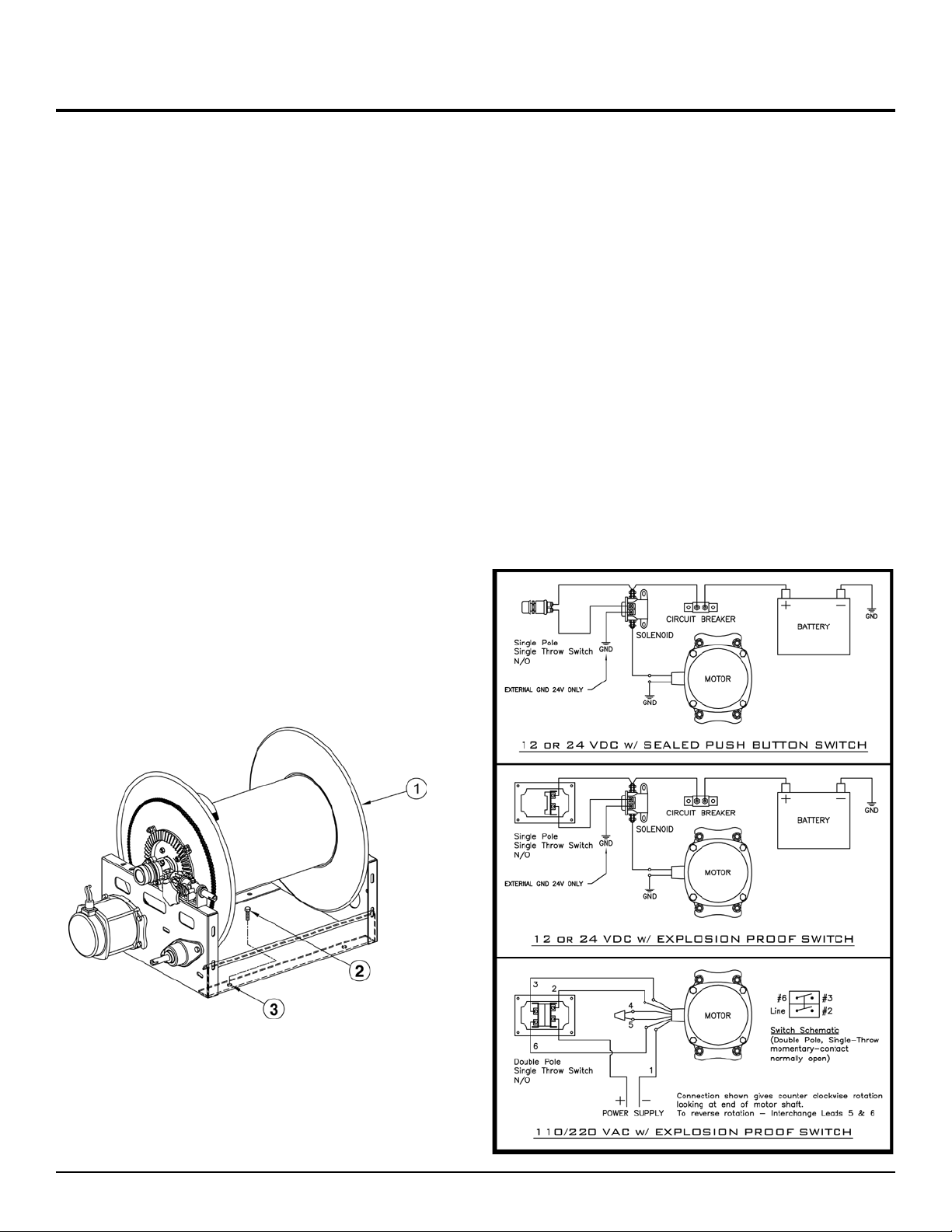

MOUNTING

1. Unpack and inspect reel - rotating spool (1) to check for

smooth operation.

2. Ensure that mounting surface is rigid and flat to prevent

binding of reel after it is installed. This is important to ensure proper alignment.

3. Drill four mounting holes in reel frame. Secure reel to

mounting surface by inserting four bolts (2) through the

four mounting holes (3) just drilled into the reel frame.

Tighten securely to ensure a solid, rigid attachment.

1. Ensure that all supply and motor electrical ratings are compatible.

2. Wire power to the motor following applicable wiring diagram.

3. Switch reel on to insure proper wiring procedures were followed. Check alignment of heads, motor, chain and sprocket

while the hose reel turns.

ELECTRIC DRIVEN REELS

WARNING: Remove all electrical power when wiring. DO NOT

“HOT WIRE”. Observe all applicable NEC, OSHA, and local codes.

NOTE: It is not proper to connect either power lead to any part of

the motor, or to any part attached to the motor, such as the

terminal box, as that would make the motor an integral part of the

electrical power circuit.

Page 2

www.reelcraft.com

Page 3

Hose Reel Operations Manual

AIR DRIVEN REELS

1. Apply thread compound to

inlet air line fitting (1) and

pneumatic motor (2) inlet

threads.

2. Connect inlet air line

(1) to motor (2).

HYDRAULIC DRIVEN REELS

1. Apply thread compound inlet / outlet hydraulic line fittings

(1) and hydraulic motor inlet threads (2).

2. Thread hydraulic line fittings (1) into motor inlet / outlet (2)

tighten securely.

INLET CONNECTION

NOTE: Install a union fitting as near as possible to the swivel

joint inlet, so the joint can be easily removed for servicing.

VICTAULIC INLET SWIVELS

NOTE: Victaulic - Type swivel joint inlet connections must be

carefully aligned. Two victaulic connections, correctly installed,

allow adequate flexibility for smooth rotation.

1. Connect victaulic coupling onto inlet swivel fitting and inlet

supply line

2. Adjust inlet supply line to verify flexibility exists for proper

alignment.

3. With control valve open, fully extend and charge hose

to purge system of gases. When fluid appears at control

valve, close valve. This prevents flattening of hose and excessive presure on drum when fluid supply is reinitialized

at a later time.

VICTAULIC

CONNECTION

FLEXIBLE

CONNECTION

CONNECTING THE SUPPLY LINE FOR THREADED INLET

SWIVELS

NOTE: Avoid strain on swing joint at all times. Threaded type

swivel inlets must be connected to the fluid supply by using a

flexible connector.

1. Apply thread compound to the swivel (1) and connecting

hose fitting (2) threads.

2. Thread connecting hose fitting (2) into swivel (1). Tighten

securely.

3. With control valve open, fully extend and charge hose

to purge system of gases. When fluid appears at control

valve, close valve. This prevents flattening of hose and excessive pressure on drum when fluid supply is reinitialized

at a later time.

NOTE: Failure to

use flexible connector with any

live reel will void

warranty

For larger reels, gooseneck may be removed from reel to fit to

hose. Note that if the reel has a welded or threaded riser in the

fluid path assembly, it cannot be removed to attach the hose.

CAUTION: Do not connect the output hose to the gooseneck

(1) until after the reel is installed and motor connections are

complete. Fill the hose before winding on the reel to prevent

excessive pressure on the drum when hose is filled.

1. Apply thread compound

to connecting gooseneck

(1) and output hose fitting

threads (2).

2. Hand thread output hose

fi tting (2) into gooseneck

(1).

3. Using a wrench, fi rmly

hold gooseneck (1) while

tightening out put hose fitting (2).

www.reelcraft.com

Page 3

Page 4

Hose Reel Operations Manual

REPLACE THE SWIVEL

CAUTION: Remove supply line

pressure before performing the

following procedures.

1. Remove supply line (2)

from the swivel (1) or

inlet.

2. Remove swivel (1) from

inlet shaft (3).

3. Install replacement swivel

by reversing steps 1 & 2.

REPLACING “U” CUP SEALS ON NORDIC SWIVELS

NOTE: For special swivels such as food grade, Catherine style reels,

and special purpose swivels, see attached exploded drawing and

parts list for special instructions for swivel repair / replacement.

1. Remove supply line (3) from inlet adaptor (1).

2. Remove all three bolts (2).

3. Pull seal from recess inside of inlet adaptor.

4. Examine new seal (5) and ring (4) to check for damage.

5. Moisten face of seal with lubricant and replace into inlet adaptor

(1).

6. Bolt adaptor back in place and re-install supply line.

REPLACING THE CHAIN

CAUTION: Before replacing the chain, remove electrical

power and fluid pressure from reel.

1. Loosen (do not remove bolts securing motor (2) to reel.

2. Remove chain master-link.

3. Install replacement chain (1).

4. Adjust chain tension by moving motor until properly

obtained. Over tensioning results in reduced motor life.

Adjust to allow between ¼” and ½” play in chain.

HOW TO ORDER REPLACEMENT PARTS

Please provide the following information:

REPLACING THE MOTOR

CAUTION: Before replacing the motor, remove electrical power and

fluid pressure from reel.

1. Loosen (do not remove) bolts (1) securing motor (2) to reel.

2. Slide motor and remove chain.

3. Remove bolts securing motor.

4. Install replacement motor.

1. Model number

2. Serial number

3. Part description and/or balloon number listed on the

front of this manual.

*Some parts may not be shown, in this case a detailed part

description will be required.

Page 4

www.reelcraft.com

Loading...

Loading...