Page 1

Operating Instructions

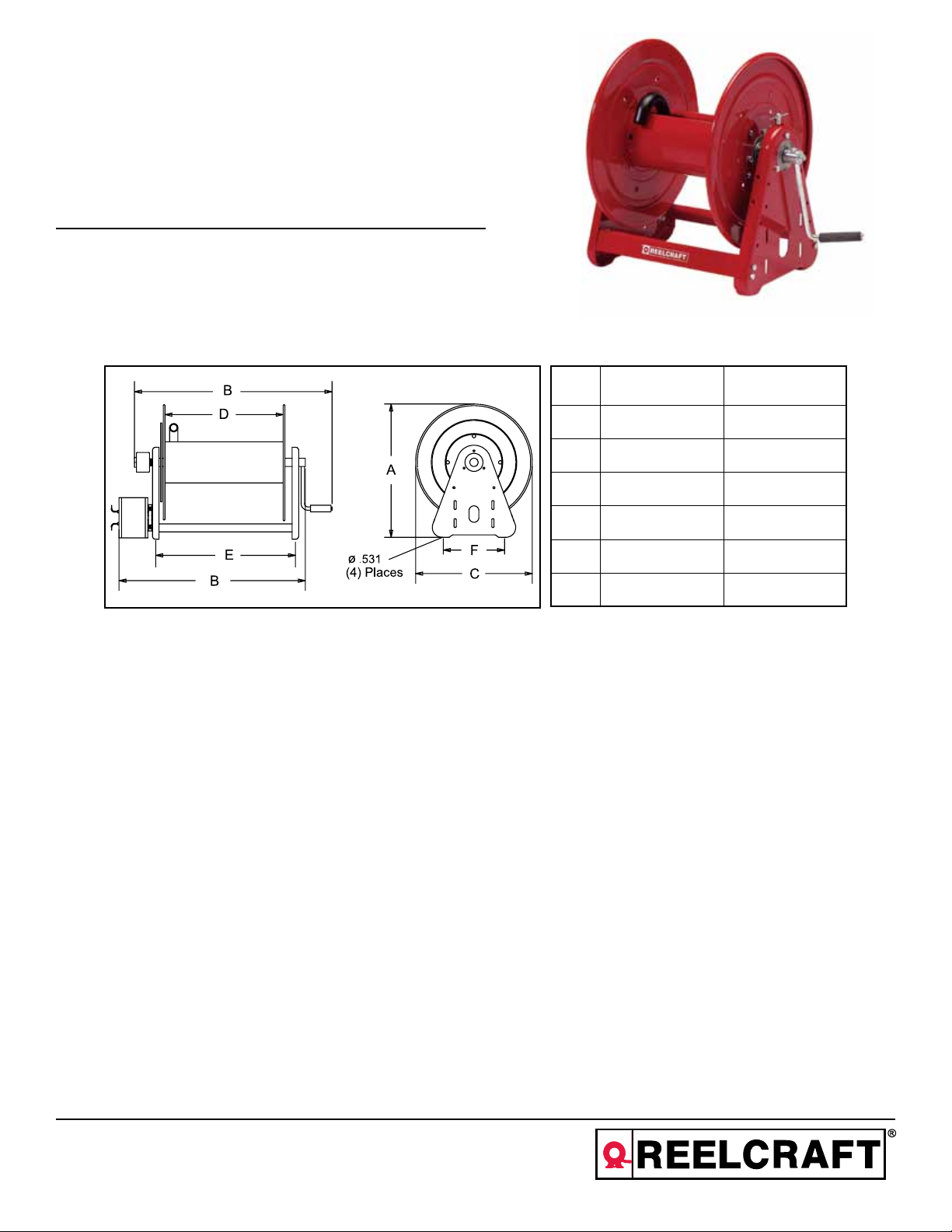

Series 30000 Hand Crank Hose Reels

High Pressure Wash Model Numbers:

CA38106 M CA38112 M

Dimensional Data

CA38106 M CA38112 M

A 20 1/4” 20 1/4”

B 19 3/4” 25 3/4”

C 17 3/4” 17 3/4”

D 6” 12”

Safety Precautions

Personal injury and/or equipment

damage may result if proper safety

precautions are not observed.

• Ensure that the reel has been properly

installed before connecting supply line

(see installation instructions).

• Bleed fluid/gas pressure from system

before servicing reel.

• Before connecting reel to supply line

ensure that supply line pressure does

not exceed maximum rated working

pressure of reel.

E 9 3/4” 15 3/4”

F 9” 9”

• Do not play pranks on other personnel.

Even low pressure is very dangerous

and can cause irrepairable damage or

death.

• Do not wear loose fitting clothing while

operating reel.

• Be aware of other personnel in work

area.

• Be aware of other machinery in work

area.

• If a leak occurs in the hose or reel,

remove supply line pressure

immediately.

• If the reel is power driven check for

loose, frayed, and/or broken wires before

operating.

• Treat and respect a hose reel as any

other piece of machinery, observing all

common safety practices.

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

Customer Service: 855-634-9109 • reelcraft@reelcraft.com • www.reelcraft.com

Form #1245-213 Rev: 3/2013

Page 2

Series 30000 Hand Crank Reels

INSTALLATION INSTRUCTIONS

Inspection

Unpack and inspect the reel for damage.

Turn the reel by hand to check for smooth

operation. Check for completeness.

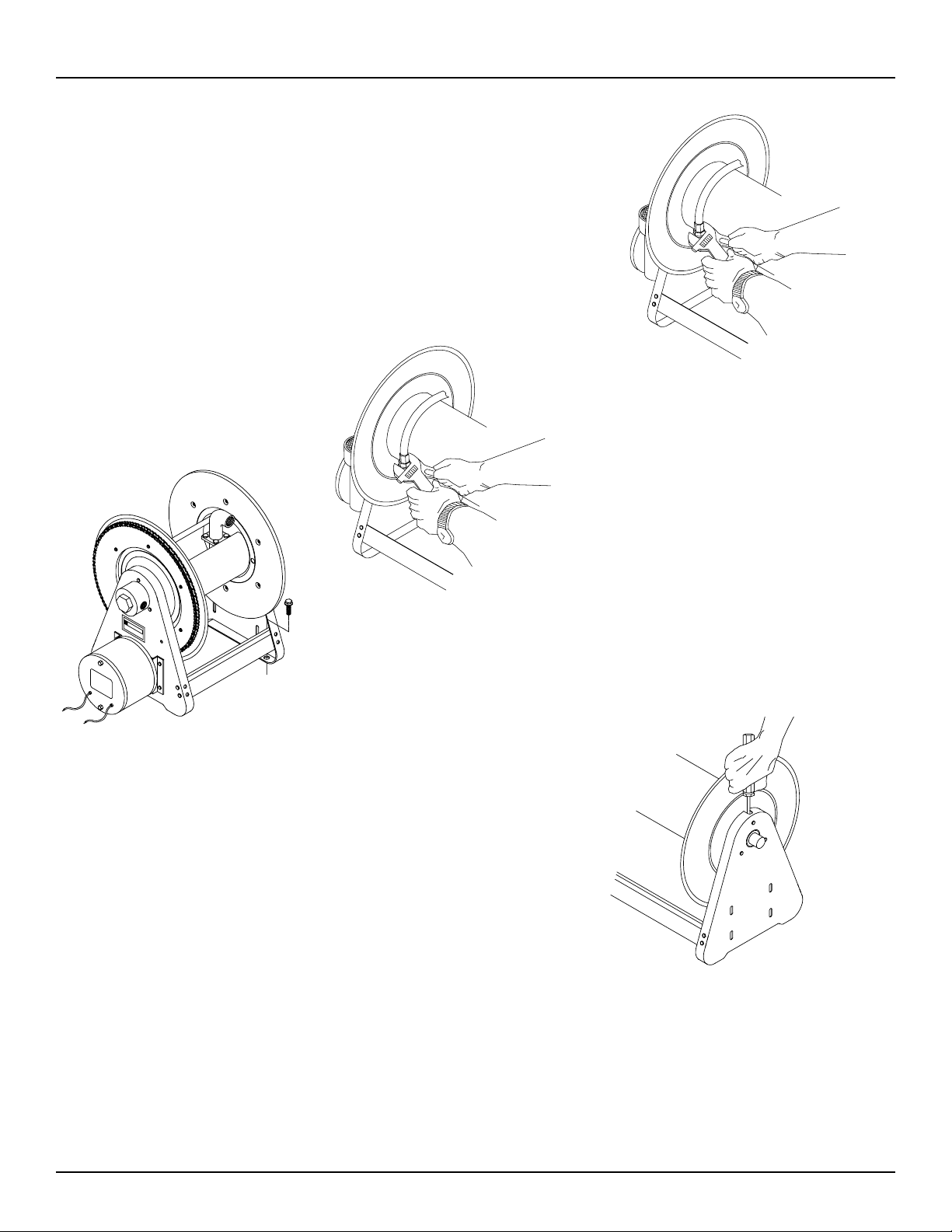

Mounting of all hose reels

NOTE: Ensure that mounting surface is

flat to prevent binding on reel after it is

mounted.

1. Two 1/2” diameter mounting holes are

located at the base of each side

support panel (2 each). Mount reel

using four (customer supplied) bolts;

tightening them securely to ensure a

solid, rigid attachment.

When fluid appears at control valve, close

valve. This prevents flattening of the hose

and excessive pressure on the drum when

fluid supply is reinitialized at a later time.

1. Apply thread compound to all threads.

2. Hand thread male hose connector into

connecting tube assembly.

3. Using a wrench, firmly hold onto

connecting tube assembly while

tightening hose connector.

Replacing the swivel

CAUTION: Remove supply line pressure

before performing the following procedure.

1. Remove supply line from swivel.

2. Remove swivel assembly from inlet

shaft.

3. Install swivel assembly to inlet shaft by

reversing steps 1 and 2. Apply thread

compound to all threads.

2. Perform the following steps only after

all other installation steps, pertaining

to your particular reel, are

accomplished. Refer to page 4 for

special instructions.

NOTE: A flexible hose connection must be

used to compensate for any offset between

the supply line and the reel swivel.

3. Apply thread compound to all threads.

4. Thread male connector of supply line

into swivel. Tighten securely.

Connecting the hose

CAUTION: Do not connect the hose to the

connecting tube assembly until after hose

reel has been installed. Fully extend and

charge hose before winding on ot reel.

Momentarily open control valve, when

initially charging, to purge hose of gases.

OPERATING INSTRUCTIONS

WARNING-PREVENT STATIC

SPARKING: When working around flam-

mable liquids such as solvents, paints,

chemicals or petroleum products, ensure

that the hose reel, hose and the equipment

being serviced are properly grounded.

Use grounded hose(s) (static wire). Use

an ohmmeter to check continuity of the

ground circuit. Fire and/or explosion can

result if proper grounding is not achieved.

If reel is power or air driven, be careful of

chain/sprocket drive system. Keep hands

clear. Do not wear loose fitting clothing. Pull hose from the reel by grasping

the hose itself, not the control handle or

swivel.

SERVICE INSTRUCTIONS

Replacing the hose

1. Using a wrench, firmly hold onto the

connecting tube assembly while

removing hose connector.

2. Follow procedures for “Connecting the

hose” (refer to installation

instructions).

ADJUSTMENT PROCEDURES

Adjusting the reel

1. Adjust reel drag by loosening or

tightening set screw on hub casting on

manual driven reel.

Hand crank to motor driven

conversion

It is possible to convert a manual driven

hose reel to a power or air driven type.

Contact Reelcraft customer service for

information.

Page 2

www.reelcraft.com

Page 3

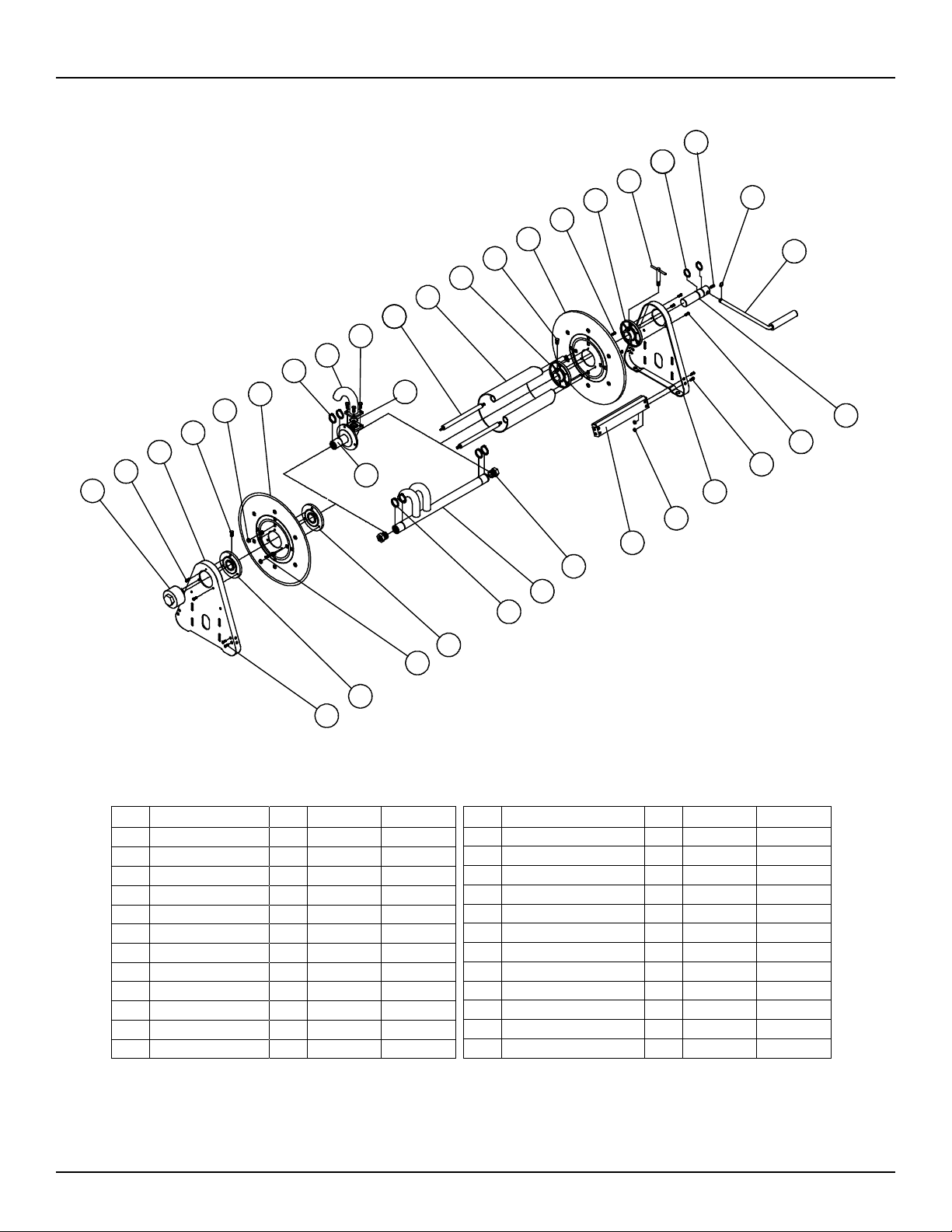

Series 30000 Hand Crank Reels

6

5

4

3

2

1

16

7

15

13

17

2

6

14

18

13

12

11

10

8

7

9

19

2

8

20

3

24

13

20

ITEM DESCRIPTION QTY. CA38106 M CA38112 M

1 Swivel assembly 1 S602033 S602033

2 Screw, 5/16-12 x 5/8” 9 S317-31 S317-31

3 Side frame 2 260403 260403

4 Set screw 3/8 brass 1 300099 300099

5 Nut, 5/16-18 8 S85-7 S85-7

6 Spool flange 2 S260399-3 S260399-3

7 Snap ring 3 300007 300007

8 Inlet assembly 1 600327-1 600327-1

9 O-ring 1 S211-120 S211-120

10 Screw, 5/16-18 x 3/4” 4 S7-51 S7-51

11 Tie rod 4 260402-100 260402-200

12 Spacer 1 260401-1 260401-2

21

22

23

8

7

13

ITEM DESCRIPTION QTY. CA38106 M CA38112 M

13 Hub & bushing assembly 3 S600640 S600640

14 Set screw 1 300006 300006

15 Lock handle assembly 1 S280109 S280109

16 Set screw 3/8 square head 1 300089 300089

17 Snap ring 1 S137-4 S137-4

18 Crank handle assembly 1 S600102 S600102

19 Shaft & snap ring assembly 1 602242 602242

20 Screw, 5/16-18 x 1/2” 8 S2-51 S2-51

21 Nut, 5/16-18 8 300107 300107

22 Cross brace 2 261501-1 261501-2

23 Reducer bushing --- None None

24 Screw, 1/4-20 x 5/8” 3 S2-42 S2-42

www.reelcraft.com

Page 3

Page 4

Instrucciones de Operacion

Series 30000 Accionado Manualmente Carreteles

Números de lavado de alta presión modelo:

CA38106 M CA38112 M

Dimensiones

CA38106 M CA38112 M

A 20 1/4” 20 1/4”

B 19 3/4” 25 3/4”

C 17 3/4” 17 3/4”

D 6” 12”

Serguridad Personal

Acidentes personales y/o equipos dandados

pueden resultar si una de las seguridades

apropiadas y percausiones no son

obervadas.

• Asegurese que el carretel este apropiadamente instalado antes de conectar la

linea de provision (leas instrucciones

de instalacion).

•

• Desaloje la presion del fluido/gas del

el sistema antes de darle servicio al

carretel.

•

• Antes de conectar el carretel a la linea

de provision asegurese que la presion

de esta linea de provision ne exeda el

maximo de capacidad de presion del

carretel.

E 9 3/4” 15 3/4”

F 9” 9”

• No jeugue o haga bromas con otra

personas. Tambien los gases abaja persion son perligrosos y pueden causar

danos inreparables o la muerte.

•

• No use ropa o vestidos sueltos cuando

este operando el carretel.

•

• Este prevenido de otro personal en el

area de trabajo.

•

• Este prevenido de orta maquinaria en el

area de trabajo.

•

• Si una gotera ocurre en la manguera o

en el carretel remueva la linead deprovision de presion de presion inmediatamente.

•

•

• Si el carretel es de poder motorizado

revise por cables sueltos, gastados

antes de operar.

•

• Trate y respete el carretel de mangueracomo otra pieza de maquinaria, observando todas las practicas comunes de

seguirdad.

Page 4

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

Customer Service: 855-634-9109 • reelcraft@reelcraft.com • www.reelcraft.com

Form #1245-213 Rev: 3/2013

Page 5

Series 30000 Accionado Manualmente Carreteles

INSTRUCCIONES DE INSTALACION

Inspeccion

Desempaque el carretel y inspeccione por

cualquier dano. Gire el carretel con la

mano para chequear una operacion suave.

Chequee completamente.

Montaje de todos los carreteles de

manguera

NOTA: Asegurese de que la superficie

donde se monta es lisa para prevenir el

doblamiento del carretel despues de la

montura.

1. Dos de los orificios de ensamblaje d

1/2” de diametro estan hubicados a

cada lado de el panel de soporte(dos).

Monte el carretel usando cuatro tornil

los (proveidos al cliente). Aptietelos

para asegurar una solida y rigida

union.

que el carretel de la manguera sea instalado. Extienda completamente y cargue la

manguera antes de enrrollarla en el

carretel. Momentaneamente habra el

control de la valvula cuando cargue

inicialmente, para purgar la manguera de

gases. Cuando el fluido aparece en la

valvula de control, cierre la valvula. Esto

previne el aplanamiento de la anguera y

execiva presion en el tambor curando el

abastecimiento de fluidos son reiniziados

tiempo mas tarde.

1. Aplique el compuesto para tuercas a

todas las tuercas.

2. Inserte manualmente la tuerca al conector macho de la manguera dentro

del tubo de coneccion de montaje.

3. Usando una llave de tuercas, sostenga

firmemente sobre el tubo de coneccion de montaje cuando apriete el

conector de la manguera.

con la cadena dentada manejada presion.

Mantenga las manos libres, no use

ropa o vestidos sueltos. Hale la

mangueras del carretel agarrandola de la

misma y no de el control o de el eje

giratorio.

INSTRUCCIONES DE SERVICIO

Reemplazo De La Manguera

1. Usando un llave de tuercas, firmemente sugete el tubo de conecicon de

montaje por untiempo removiendo el

conector de manguera.

2. Siga el proceso para “Conecciones

de manguera” (mire intrucciones de

instalacion).

Reemplazando El Eje Giratorio

PRECAUCION: Remueva la linea de

abastecimiento de presion minetras realiza

el siguiente procedimiento.

1. Remueva la linea de abastecimiento

del eje giratorio.

2. Remueva el eje de montaje del eje giratorio la entrada de el tunel o hueco

origicio del eje.

3. Instale el montaje del eje firatorio

dentro de el tunel del eje devolviendose por os pasos 2,1. Aplique

compnente de tuercas a todas las

tuercas.

2. Realize los siguientes pasos solamente depues de todos los otros

pasos de instalacion pertenecientes a

asu carretel en particular, sean realizados.

NOTA: Una coneccion de manguera flexible debe de ser para compensar cualquier

balance entre la linea de abastesi, iento o

provision y el carretel giratorio.

3. Aplique el compuesto para tuercas

atodas las tuercas.

4. Inserte la tuerca al conector macho de

la linea de abastecimiento dentro del

torniquete, apriete seguramente.

Conecte La Manguera

PRECAUCION: No conecte la manguera al

tubo de coneccion montado hasta despues

Page 5

INSTRUCCIONES DE

OPERAMIENTO

PRECAUCIONES-PREVENCIONES DE

CHISPA ESTATICA: Cuando este trabaja-

ndo alrededor de liquidos inflamables

como solventes, pinturas, quimicos o productos de petroleo, asegurece que el carretel de la manguera, manguera y equipo

esten devidamente conectados a tierra.

Use la(s) manguera(s) conectadas a tierra

(calbes electrico(s) estatico(s)). Use un

ohmetro medidor de resistencia electrica

para revisar la continuidad del circuito de

coneccion a tierra. Fuego y/o explocion

pueden resultar si una propia coneccion

a tierra no es realizada. Si el carretel es

operado con aire a presion tenga cuidado

PROCEDIMIENTO DE

AJUSTAMIENTO

Ajustamiento del carretel

1. Ajustar el dispositivo de seguridad

del carretel desagustando y ajustando

el conjunto de tornillos en la cubierta,

en los carreteles conducidos manualmente.

Palanca De Codo Operada A Motor O

Transmission

Esposible convertir un motor de manguera

manual a uno electrico o aire. Contacte la

compania Reelcraft para imformacion.

www.reelcraft.com

Page 6

Series 30000 Accionado Manualmente Carreteles

11

10

8

7

6

5

4

3

2

1

9

8

12

13

14

16

7

15

13

17

2

6

18

19

2

20

3

13

20

ARTICULO

1 Ensamblaje del eje giratoria 1 S602033 S602033

2 Tornillo, 5/16-12 x 5/8” 9 S317-31 S317-31

3 Lado el marco 2 260403 260403

4 Juego de tornillo de bronce 3/8 1 300099 300099

5 Tuerca, 5/16-18 8 S85-7 S85-7

6 Platillo del carretel 2 S260399-3 S260399-3

7 Aro de resorte 3 300007 300007

8 Ensamblaje de entrada 1 600327-1 600327-1

9 Arendela 1 S211-120 S211-120

10 Tornilla, 5/16-18 x 3/4” 4 S7-51 S7-51

11 Separador 4 260402-100 260402-200

12 Espaciador 1 260401-1 260401-2

DESCRIPCION CTD CA33106 M CA33112 M

24

21

22

23

8

7

13

ARTICULO

13 Ensamblaje de la campana y boquilla 3 S600640 S600640

14 Juego de tornillo 2 300006 300006

15 Ensamblaje del sequro de la manija 1 S280109 S280109

16 Juego de tornillo 3/8 1 300089 300089

17 Aro de resorte 1 S137-4 S137-4

18 Ensamblaje de la manija 1 S600102 S600102

19 Eje y montaje para anillo elástico 1 602242 602242

20 Tornillo, 5/16-18 x 1/2” 8 S2-51 S2-51

21 Tuerca, 5/16-18 8 300107 300107

22 Miembro cruzado 2 261501-1 261501-2

23 Reducido de la boquilla --- ---------- ---------24 Tornillo, 1/4-20 x 5/8” 3 S2-42 S2-42

DESCRIPCION CTD CA33106 M CA33112 M

www.reelcraft.com

Page 6

Page 7

Instructions D’Opération

Série 30000 Manuels Enrouleurs

Haute pression chiffres laver modèle:

CA38106 M CA38112 M

Dimensional Data

CA38106 M CA38112 M

A 20 1/4” 20 1/4”

B 19 3/4” 25 3/4”

C 17 3/4” 17 3/4”

D 6” 12”

La Sécurité du Personnel

Blessure personnel et/ou le dommage

d’équipement peut résulter si les précautions de sécurité ne sont pas observées.

• Assurez-vous que l’enrouleur est installé comme il faut avant de connecter

le tuyau d’alimentation (voyez les instructions d’installation).

•

• Évacuez du système la pression de

fluide/ combustible avant de faire le

service.

•

• Avant de connecter l’enrouleur au tuyau

d’alimentation, assurez-vous que la

pression ne dépasse pas la pression

maximum pour l’enrouleur.

E 9 3/4” 15 3/4”

F 9” 9”

• Ne jouez pas un tour aux autres personnel. Même la basse pression est

trés dangereuse et elle peut causer le

dommage irréparable ou le mort.

•

• Ne portez pas des vêtements amples en

utilisant l’enrouleur.

•

• Soyez conscient d’autres personnels au

travaille.

•

• Soyez conscient d’autres machines au

travaille.

•

• Si le tuyau ou l’enrouleur se met à fuir,

évacuez la pression du système immédiatement.

• Si l’enrouleur fonctionne à l’électricité,

vérifiez que les fils ne sont pas effilochés ou cassés avant chaque utilisation.

•

• Comme tout d’autres machines,

repectez et utilisez avec soin

l’enrouleur. Observez tous les practiques de sécurité.

Page 7

Reelcraft Industries, Inc. • 2842 E Business Hwy 30, Columbia City, IN 46725

Ph: 800-444-3134 / 260-248-8188 • Fax: 800-444-4587 / 260-248-2605

Customer Service: 855-634-9109 • reelcraft@reelcraft.com • www.reelcraft.com

Form #1245-213 Rev: 3/2013

Page 8

Série 30000 Manuels Enrouleurs

INSTRUCTIONS D’INSTALLATION

Inspection

Déballez et inspectez l’enrouleur pour

déceler le dommage s’il existe. Faites

tourner l’enrouleur à la main pour vérifier

le bon fonctionnement.

Montage de tous enrouleurs

NOTEZ: Assurez-vous que la surface de

montage est plate pour éviter le coincement du tuyau après l’enrouleur est monté.

1. Deux trous de montage du diamètre

1/2” se trouvent au base de chaquesupport de côté (2 pour chaque).Montez l’enrouleur avec 4 boulons (fournis

par le cliènt). Serrez-les biens pour

assurer une fixation solide.

2. Faites les étapes suivantes

après toutes autres instructions

d’installations sont faites pour votre

enrouleur en particulier.

NOTEZ: Un racord flexible doit être utilisé

pour compenser entre le tuyau et le pivot.

3. Appliquez du matériau d’étanchéité à

tous les filets.

4. Enfilez le raccord mâle de la ligne

d’alimentatin au pivot. Serrez bien.

Connection du tuyau

PRÉCAUTION: Ne connectez pas le tuyau

à l’assemblage du tubulure de raccord

avant d’installer l’enrouleur de tuyau.

Étendez entièrenment le tuyau et remplissez-le avant d’enrouler sur l’enrouleur.

Ouvrez momentanément la vanne de

régulation, fermez-la. Cela évite

l’aplatissage du tuyau et la pression exces-

sive quand vous utilisez l’enrouleur plus

tard.

1. Appliques du matériau d’étanchéité à

tous les filets.

2. Enfilez le raccord mâle à l’assemblage

de tubulure de raccord.

3. Avec une clef, serrez bien ce raccord pendant que vous tenez bien

l’assemblage de tubulure de raccord.

INSTRUCTIONS D’OPÉRATION

AVERTISSEMENT - ÉVITEZ LA

CHARGE STATIQUE: Quand vous tra-

vaillez près des liquides combustibles

come des dissolvants, des penitures, des

produits chimiques, ou des produits

de pétroles, assurez-vous que l’enrouleur,

le tuyau, et l’equipement sont tous mis à

terre. Utilisez des tuyaux mis à terre.

Utilisez un ohmètre pour vérifier la continuité du circuit. Si l’enrouleur n’est pas

correctement mis à terre, un feu ou une

explosion peur résulter. Si l’enrouleur

fonctionne à l’air ou à l’électicité, soyez

prudent du système de chaîne/de pignon.

Tenez vos mains loin du système. Ne

portez pas des vêtements amples. Tirez le

tuyau de l’enrouleur en empoignant le

tuyau, et non pas la poignée de régulation

ni le pivot.

INSTRUCTIONS D’ENTRETIEN

Remplacement des tuyaux

1. Avec une clef, tenez bien l’assemblage

de tubulure de raccord pendant que

vous enlevez le raccord.

2. Suivez les procédés pour “La raccordement de Tuyau” (Voyez les Instructions d’Installation).

Remplacement de Pivot

PRÉCAUTION: Enlevez la pression du

tuyau avant de faire le procédé suivant.

1. Enlevez le tuyau du pivot.

2. Enlevez l’assemblage du pivot de

l’arbre d’entré.

3. IInstallez l’assemblage de pivot à

l’arbre d’entré enfaisant les étapes 1 à

2 par ordre inverse. Appliquéz du matériau d’étanchéité à tous les filets.

PROCÉDÉS DE RÉGLAGES

Réglage de l’Enrouleur

1. Réglez la résistance en serrant ou

en désserrant la vis sans tête qui se

trouve sur le moyeu sur les enrouleurs manuels.

Changement de l’enrouleur manuel à

l’enrouleur à moteur.

Il est possible de modifier un enrouleur

manuel à un enrouleur électrique ou

pneumatique. Téléphonez ou écrivez à

l’usine de Reelcraft pour avoir de

l’information.

Page 8

www.reelcraft.com

Page 9

Série 30000 Manuels Enrouleurs

6

5

4

3

2

1

16

7

15

13

17

2

6

14

18

13

12

11

10

8

7

9

19

2

8

20

3

24

13

20

Article DESCRIPTION Quantité CA33106 M CA33112 L

1 Assemblage de pivot 1 S602033 S602033

2 Vis, 5/16-12 x 5/8” 9 S317-31 S317-31

3 Cadre Latéral 2 260403 260403

4 Vis sans tête 3/8 en laiton 1 300099 300099

5 Écrou, 5/16-18 8 S85-7 S85-7

6 Tambour bridé 2 S260399-3 S260399-3

7 Dispositif de retenue 3 300007 300007

8 Assemblage d’entrée 1 600327-1 600327-1

9 Anneau en “O” 1 S211-120 S211-120

10 Vis, 5/16-18 x 3/4” 4 S7-51 S7-51

11 Farre d’accouplement 4 260402-100 260402-200

12 Pièce d’espacement 1 260401-1 260401-2

21

22

23

8

7

13

Article DESCRIPTION Quantité CA33106 M CA33112 L

13 Assemblage de moyeu et manchon 3 S600640 S600640

14 Vis sans tête 1 300006 300006

15 Assemblage de manche loquant 1 S280109 S280109

16 Vis sans tête 3/8 1 300089 300089

17 Dispositif de retenue 1 S137-4 S137-4

18 Assemblage de poignée de manivelle 1 S600102 S600102

19 Arbre et montage circlip 1 602242 602242

20 Vis, 5/16-18 x 1/2” 8 S2-51 S2-51

21 Écrou, 5/16-18 8 300107 300107

22 Traverse 2 261501-1 261501-2

23 Manchon de re’duction --- --------- --------24 Vis, 1/4-20 x 5/8” 3 S2-42 S2-42

www.reelcraft.com

Page 9

Loading...

Loading...