Page 1

•

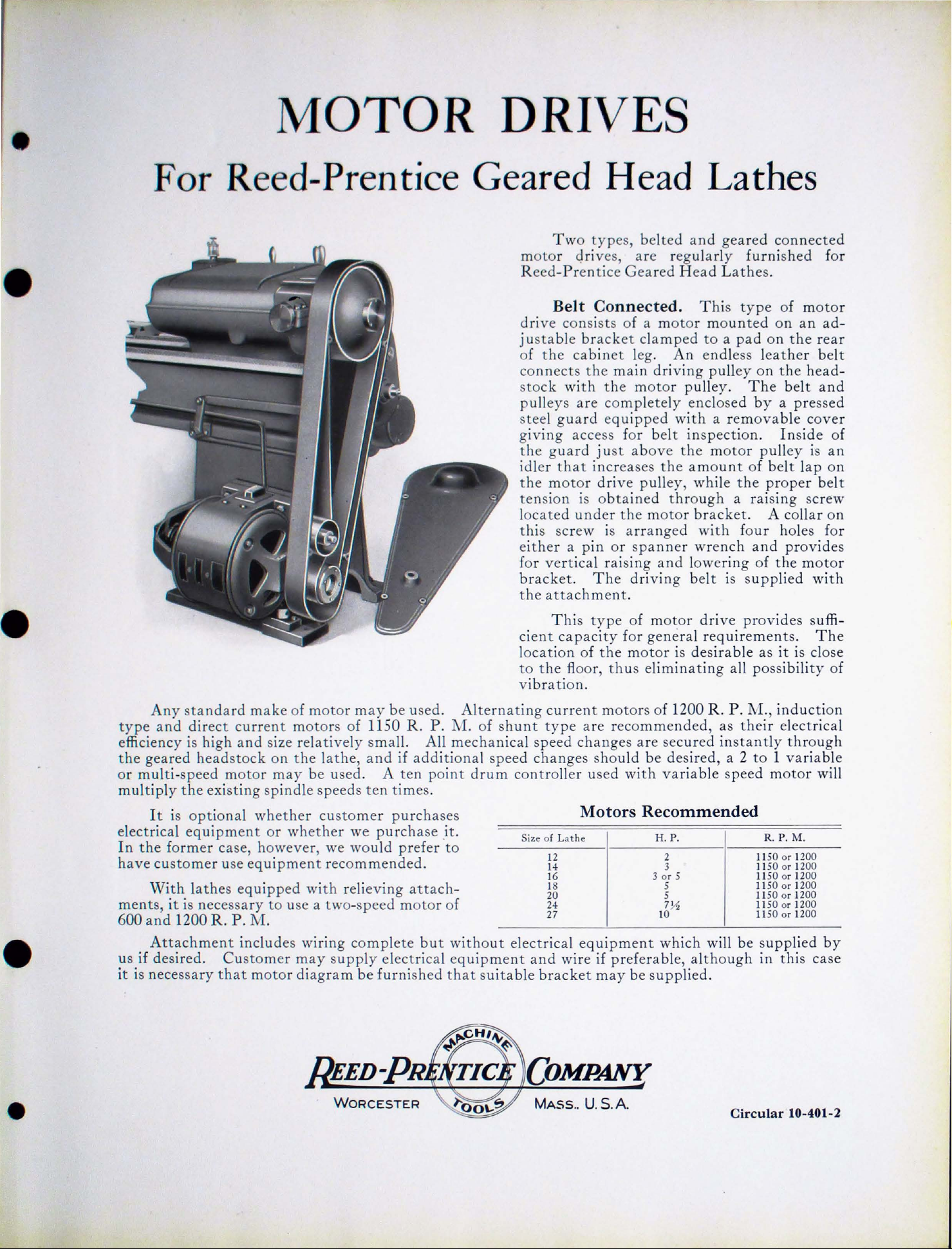

MOTOR DRIVES

For Reed-Prentice Geared Head Lathes

•

Two

motor

Reed-Prentice

Belt

drive

justable

of

the

connects

s

tock

pulleys

steel

giving

the

guard

idler

the

motor

tension

located

this

either a pin

for

vertical raising

bracket.

the

attachment

types,

qrives,

Connected.

consists

bracket

cabinet

the

with

are

guard

access

just

that

increases

drive

is

obtained

under

screw

The

the

complete

equipped

is

belted

are

Geared

of a motor

clamped

leg.

main

motor

for

above

pulley,

the

motor

arranged

or

spanner

driving belt is suppli

.

and

geared

regularly

Head

An

driving

ly

with

belt

the

the

through a raising

and

Lathes.

This

mounted

to a pad

endless leather belt

pull

ey

pulley. T

enclosed

a r

emovable

inspectio

motor

amount

whi

le

the

bracket.

with

wrench

lowe

ring

connected

furnished

type

four holes for

of

on

on

on

the

he

belt and

by a pressed

n.

Inside

pulley

of b

elt

proper

A collar

and

prov

of

the motor

motor

an ad

the

head

cover

lap

screw

ed

for

rea

is

an

on

belt

on

ides

with

of

r

-

•

Any

standard

type

and

direct

efficiency is high

the

geared

or

multi-speed

multiply

It

electrical equ

In

the

have

customer

With

ments,

600

and

Attachment

us

if desired.

it

is

necessary

headstock

the

is

optional

former

lathes

it

is

necessary

1200

existing

ipment

case,

use

R.P.M.

Customer

that motor diagram

make

current

and

size

motor

spindle

whether

or

however,

equipment

equipped

to

includes

of

motor

motors

relatively

on

the

lathe, and

may

be

used . A

speeds

customer

whether

we

recommended.

with

relieving

use a

two-speed

wiring complete

may

supply

may

be

of

1150

small.

ten

times

purchases

we

purchase _it.

would

electrical

be

furnished

used.

R.

if

additional speed

ten

prefer

attach

motor

but

Alternating

P.

l\,L

of

All

mechanical speed

point

.

drum

to

-

of

without

equipment

that

suitable

cient

location

to

the

vibration

shunt

changes

controller

Size of L

electrical

and

bracket

T his

current

type

12

14 3

16

18 5

20 5

24

27 10 1150

type

capacity

of

the

floor,

thus

.

motors

are

changes

should

used

Motors

athe

equipment

wire

if

may

of

motor dri

for

general requireme

motor

recommended,

with

is

desira

eliminating

of

1200 R. P. l\lI., i

are

secured

be

desired, a 2

varia

ble

Recommended

H.P.

2

3

or

5

7½

which

preferable,

be

supp

although

lied .

ve

provides

ble

as

all

poss

as

their electrica

ins t

antly

to 1 va

speed

11

1150 o

11

1150

11

1150 or 1200

will be

supplied

in

R.

50

50

50

suffi-

nts. T

it

is close

ibili

ty

nduction

through

riable

motor

P.M.

or 1200

rl200

or 1200

or

1200

or 1200

or

1200

this

he

of

l

will

by

case

•

WORCESTER

COMPANY

MASS

..

U.S.A.

Circula

r 10-401-2

Page 2

7CE

•

i

nstantly

a 2

to 1 variable

speed

motor

through

will

the

geared

or

multi-speed

multiply

headstock

the

existing

motor

spindle

on

the lathe,

may

be

used.

speeds

and

ten

Gear

ment

clamped

leg.

driving

bakalite

The

otherwise

on

proper

train

iron

cover.

heavy

is

the

is close

possibility

used. Alternating

1

current

type

efficiency is

All

if

additional

A

ten

times.

the

The

fabroil

an

eccent

meshing

is

guard, equipped

When

work,

recommended.

location

Any

200

R.

motors

are

mechanical

point

drum controller

Connected.

motor

to a pad

motor

shaft

or

specified.

completely

a l

to

the

of

standa

P.

recommended

speed

is

on

is

through

rawhide

intermediate

ric

stud

of

athe

this

geared

of

the

floor,

vibration.

rd

l'vI.,

induction

of

1150

high

and

speed

changes

With

mounted

the

rear

geared

intermediate

is

Th

is

which

the

gears

enclosed

with

is

to

type

Like

motor

make

the

thus

of

current

R .

, as

size

changes

should

used

this

on a bracket

of

the

to

the

a

large

supplied

gear

is

provides

and

by

a

removab

be

used

of

motor drive

belted

is

desirable,

eliminating

motor

motors

type

P.

relatively

and

M .,

their

are

be

with

arrange

cabinet

main

fabroil,

gear

unless

mounted

for

the

gear

a

cast

le

fo r very

types,

as

it

all

may

be

of

direct

of

shunt

electrical

small.

secured

desired,

va-riable

-

.

•

•

With lathes

and

1200 R .

The

motors

Attachment

us

if

desired. Customer may supply electrical equipment

it

is

necessary

equipped with relieving

P.

1\I.

recommended

includes

that

motor

wiri

ng

diagram

are

in

complete

be

attachments,

accordance

but

furnished

that

it

is

necessary

with

the

tabulations

without

electr

suitable

ical

and

wire

bracket

equipment

may

Spindle

All R

equipped

starting,

spind

le.

right

hand

apron

operato

control and eliminates

troller.

eed-Prentice

with a patented

stopping

The

con

portion

it

is

always

r.

This

feature

trol

of

to

use a two-speed

on

the

previous

which

if

preferable,

be

supplied

although

Control

Geared

mechanical

and

reversing

handle

the

apron,

in a convenient

insures

the

T""4

1r Da

v,• 11t11tC••

is

need

w o

..

cit

aTS"

located

and

ease

of a reversing

page.

will

be

.

Head

apron

of

the

traveling

position

and

M.-.

••• u •

.ti

motor

supplied

in

this

Lathes

contro

headstock

in

the

with

for

rapidity

2M

12--15-25

of

600

by

case

are

l for

lower

the

the

con-

•

of

•

Loading...

Loading...