Page 1

•

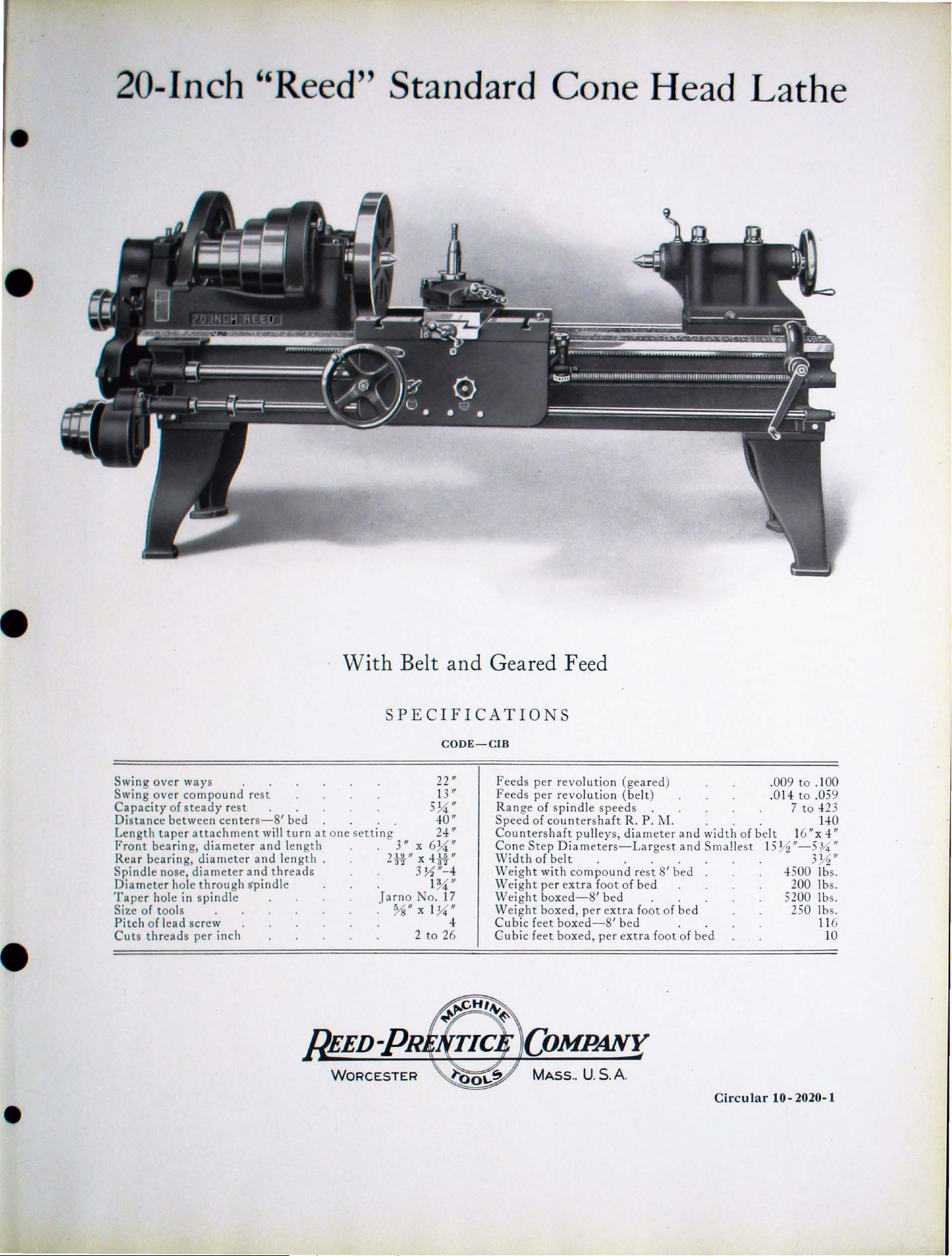

20-Inch ''Reed'' Standard Cone Head Lathe

:•

I

D

fti3

II

tJi.iiiiiiii.-------=/'~

[

•

=~~==

FallJ

~

ii&ii&W

•

.-

..

- / \

. v.

\_,(::)_. \ ·

~x - V u

.

-::;

-·

Fee

.

• •

0

,.,1

t-,.r;.

__,

,~

IJ.

-••• . ••• ..

ft

~,,

.

!ttiIJS

ru

111111111111111

• •

tllll I lltl

111fl

tflll

llfl1 I

•·•

In

1111U111111111111

ltj

-J

• " ' ~--..

·-.O•<•.-.

•M

uumuu,

~ "T

111111111111

,. ' -

~

h~

'-

111.'l

I

Swing

Swing

Capacity

Distance

Length

Front

Spindle

Diameter

Tape

Size

Pitch

Cuts

over

over

taper

bearing,

Rear bear

nose,

r hole in spindl

of too

of l

threads

· Wi

th

Belt

SPEC

ways

compound

of

steady rest

between

attachment

diameter

ing,

diameter and length

diameter

hole

through

ls . %

ead

screw 4

per

. . 22

rest

centers-8'

. .

bed . . .

will

turn

and

at

length

one se

ttin

g

3"

2H

and

threads

s'p

indle . l

e J

inch 2

arno

x 6¼

11

x

3 ½

No.

11

x I

I F I

CODE-C

13

5¼

40

2-!

4#"

11

-4

¾"

17

¼"

to

26

and

CA

11

11

11

11

11

11

Geared Feed

TI

ONS

IB

Feeds

per

Feeds

Range of spindle

Speed

Count

Cone

Width

Weight

Wei

ght

Weight

Wei

ght

Cubic feet boxedCubic

revolut

per

revolution

of

countershaft R.P.M

ers

haft

Step

Diam

of

belt

with

per

boxed-8'

boxed,

feet

boxe

ion

spee

pulleys,

eters-Largest

. . . . 3 ½

compound rest

extra

foot

bed

per extra

d,

per

(geared

(belt) .

ds . 7 to -!23

diameter and

of

8'

bed

extra

) .009 to .100

. . . . H O

width

and

Smallest

8'

bed

bed

. . 5200 lb s.

foot

of

bed

. .

foot

of

bed

014

of

belt

15½11- 5¾ "

-!500 lbs.

2

25

to

l611x

00

0 lbs.

.059

-!

lbs.

11

10

11

11

6

•

WORCESTER

COMPANY

MASS

..

U.S.

A.

C

ircul

ar 10-2020-1

Page 2

7CE

HE

T

of face,

a

dapted

Head

in

the

or

B.

Spindle

Rest

The ca

"Reed"

for a wide

Spindle

spindle is a modified J

& S.

:

rri age

20"

which

tapers

in

range

at

Bearings.

Lathe

has long

i·s regul

Feed: Powe r cross feed

stop

motion

arranged

from .014

with

intermediat

per

revo

St

from r

ack,

Screw

2, 3,

-!

, 5, 6, 7, 8, 9, 10,

set

consisting

cut:

1

12

mm. lead.

. ·

that lower

to

luti

on are

eel

rack

thus

Cutting

,

11

, 10, 9.5, 9, 8

with

.059

per revo

e gear.

obtained.

and

pini

preventing

of double

Standa,rd

conjunction

of

work,

is

made from

arno

a sl

ight extra

These

arly

bearin

combined

feed

: S

gs

cone

lution.

Th

on

gea

rotat

teel lead

11, 11

int

.5

, 8, 7.5,

en: by

r for

½,

ermed

Engine Lathe

with wide

both

light

a steel forging wi

17

.

charge.

are

made

made with

and

is

securely

with both

belt

and

can

be

When

changing

moving carriage. Rack

ion

of

screw

12

, 13, 14, 16, 18, 20, 72, 24

iates and

7; 6.5

has

four

face

gearing

and

heav

An

adapter

of

bronze,

compound rest,

gibbed

sty

les

of

gear

feeds, feed cones lar

moved

handle

cut 4 threads

to tighten

gea

red

gears

and

three

, 6, 5.5, 5, 4.5,

step

cone,

of suit

y.

th

journals,

can

be

bored

to

outside

rest. Independent

feed

feed is

on

gears

change

feed

per

4,

desired,

stud

gear

when

inch,

gea

with

able·pitches

hardened

furni

shed

and

hand-

but

plain

of

bed

ge

belt.

remove

of

hea

is

arranged

scr

ew

with

and

26

rs,

the

3.5, 3, 2.75, 2.5, 2.25, 2, 1.75, 1.5, 1.25,

steps

in

There are

cutting.

open and

per

following

large

makes

and

to

accommodate

scraped

rest

can

at front

rod,

friction

diameter

belt

dstock,

so

inch.

in

diameter

this

lathe

ground. The

either

to

fit spindle.

be

furnished

and

back.

feed

and

and wide

six

belt

feeds

and

connect

feeds from

that

it

shut

nut.

By

metric

can

the

.009"

be

Cuts

use

threads

and

wide

especially

taper

if

automatic

of

withdrawn

of

hole

Morse

desired

face, so

ranging

feed

rod

to

.100"

threads

an extra

can

be

and

•

.

•

Me

tric Lead Screw

charge

5.5,

consis

cut

. L

5,

4.5, 4, 3.5,

ting

: 2,

3,

Quick

co

mbined

parts

possible. (See cir

Tool

Countershaft

Hangers

Taper

cha

rge.

in

position

poi

nt

the

provides

for

Standard

be

lt

and

gear

Addi

coll

et

attachment

center

s,

microm

athe

so

equipped

3,

2.75, 2.5, 2.25, 2, 1.75 , 1.5, 1.25,

of

double intermediates

4, 5, 6,

Change

belt and

Posts

have

Attachme

This Attachment

for work

tool begins its

turning

7,

gea

will

take

has two fricti

large oil

at

tapers up

8, 9, 10,

Gear: L

red

cular

reservoirs.

nt.

any desired place on the bed,

cut

Equipment

ed

feed,

thread

tional

Equipment

and

collets, reliev

eter bed

stop, Eur

cut 6 mm.

will

cut

11, 11

athe can

feeds if des i

of 20" R

turn

ing

tools%"

on

Taper

is rigid

. Bar is gr

:

chas

and complete

to

3"

St

eady rest,

ing

.

Taper

opean

lead

can

the

followi

and eight

½ ,

12

, 13, 14, 16, 18

be

equipped

red.

pulleys

Attachm

to

dial,

This mechanism

eed

Quick

x 1¼ ".

ent

aduated

the

foot,

lar

doubl e

attachment, foll

ing atta

tool post,

be

supplied

ng

metric

change

with

Change

1

6"

diameter

can

be

furnished with either

in itself.

and

on one

24" in

ge

and

-fr

chment, carri

sma

iction

and

othe

end

length.

ow rest, oil

in place

threads:

and 1 mm.

gea

rs,

the

and

20

quick

is

very

Gear

it always

ll

pulley

Lathe.

for

4"

Simply

in

inch

face plates,

countershaft,

age

or

r l

ength

of

regular

lead

screw

without

extra

12, 11, 10, 9.5, 9, 8.5, 8, 7.5, 7, 6.5, 6,

lead.

following

per

inch

change

simple

)

be

lt,

tightening

gives

es, on

pan,

bed

s of

By

the

English

.

gear

and

and

the

the

compound

oil

turrets, chuck

bed

than listed in

mechanism

is

should

style

one

correct

other

and

pump

use

of

threads can

made

screw

rest,

up

run

at

of

rest

makes

taper

end

in degrees,

regular

necessary

and

piping,

an

extra

instead

of

the

fewest

140

R.

at

an ext

it

secure

at

whateYer

tool

wrenches

draw

plates

, special

specificati

set

P.

}VI.

and

post,

-in

ons

be

of

ra

•

.

.

•

Motor Drive.

direct

Driv

current

es for R eed

Thi

adjustable

Lathes.)

s l

athe

can

be su

speed, or alternati

pplied

ng curr

at

an

ent

ext

ra

charge

mu

lti-speed

with motor drive heads

motor

s. (See

'"

' ••"•• "•• •• ••"'•••1••

Circular

""""•••..,

tock,

of

•,.

using

l'vlotor

3M,l

•l..tt

•

Loading...

Loading...