Hardness Tester

R9030

Instruction

Manual

www.GlobalTestSupply.com

Table of Contents

Introduction ................................................................................................ 3

Product Quality ........................................................................................... 4

Safety ......................................................................................................... 4

Features ...................................................................................................... 4

Included ...................................................................................................... 4

Specications ............................................................................................. 5

Instrument Description ............................................................................... 6

Display Description .................................................................................7-8

Hardness Testing Principle ..................................................................... 8

Operating Instructions ........................................................................... 8-18

Power On/Off ......................................................................................... 8

Preparation of Test Piece ....................................................................... 8

Prior to First Measurement .................................................................... 9

Loading Impact Device .......................................................................... 9

Taking Measurements ............................................................................ 9

Viewing Measurement Values .............................................................. 10

Storing Average Value .......................................................................... 10

Auto Power OFF .................................................................................. 10

Menu Navigation/Setup Mode ........................................................ 10-16

Test Set........................................................................................11-13

Impact Direction .......................................................................... 11

Average ........................................................................................ 11

Material ........................................................................................ 12

Hardness Scale ............................................................................ 12

Tolerance Limit ............................................................................. 12

Hard/

b (Hardness/Strength Testing) .......................................... 13

Probe Type ................................................................................... 13

Standard ...................................................................................... 13

Memory Manager ........................................................................ 13-15

continued...

www.GlobalTestSupply.com

2

View from No.1/View from End .................................................... 14

View from No. ............................................................................... 14

Transfer ........................................................................................ 14

Delete by No. ..........................................................................14-15

Delete All ...................................................................................... 15

System Set .................................................................................. 15-16

Enabling/Disabling Auto Save ...................................................... 15

Enabling/Disabling Auto Delete.................................................... 15

Enabling/Disabling Auto Transfer ................................................. 15

Enabling/Disabling Auto Shutoff .................................................. 16

Setting the Time and Date ........................................................... 16

Quick Setup Mode .......................................................................... 16-17

Calibration Procedure .......................................................................... 17

Connecting to a Computer .................................................................. 17

Launching the R9030 Software............................................................ 18

Battery Charging and Replacement ......................................................... 18

Applications .............................................................................................. 19

Appendix A: Hardness Scale Tables ...................................................19-22

Accessories and Replacement Parts ....................................................... 22

Product Care .......................................................................................22-23

Product Warranty ..................................................................................... 23

Product Disposal and Recycling .............................................................. 23

Product Support ....................................................................................... 23

Introduction

Thank you for purchasing your REED R9030 Hardness Tester. Please

read the following instructions carefully before using your instrument. By

following the steps outlined in this manual your meter will provide years of

reliable service.

www.GlobalTestSupply.com

3

Product Quality

This product has been manufactured in an ISO9001 facility and has been

calibrated during the manufacturing process to meet stated product

specications. If a certicate of calibration is required please contact the

nearest authorized REED distributor or authorized Service Center. Please

note an additional fee for this service will apply.

Safety

Never attempt to repair or modify your instrument. Dismantling your

product, other than for the purpose of replacing batteries, may cause

damage that will not be covered under the manufacturer's warranty.

Servicing should only be provided by an authorized service center.

Features

• Measures a wide range of materials including; cast steel, alloy steel,

stainless steel, aluminum, bronze, copper and cast irons

• Measures 7 types of hardness scales; Rockwell (HRC, HRB, HRA),

Brinell (HB), Leeb (HL), Vickers (HV) and Shore (HS)

• Compact pen style design

• Bright OLED display

• Real-time clock and internal memory stores up to 350 measurements

• USB connectivity and software allows for further measurement analysis

• Rechargeable lithium battery

• Low battery indicator

Included

• D Impact Device

• Leeb Test Block

• Small Supporting Ring

• Nylon Brush

• AC Adapter

• USB Cable

• Software

• Hard Carrying Case

www.GlobalTestSupply.com

4

Specifications

Hardness Scales: Rockwell (HRA, HRB, HRC)

Measuring Ranges: HRA: 59 to 85

Measuring Direction: 360°

Sampling Time: Less than 1 second (when triggered)

Display: Dot Matrix OLED

Battery Life: Approx. 40 hours

Low Battery Indicator: Yes

Power Supply: Rechargeable Lithium Ion Battery

Charge Time: Approx. 2 hours

Internal Memory: Yes (up to 350 readings)

Product Certications: CE

Operating Temperature: 32 to 104°F (0 to 40°C)

Storage Temperature: -4 to 140°F (-20 to 60°C)

Operating Humidity Range: 0 to 90%

Dimensions: 5.7 x 1.3 x 1" (146 x 32 x 26mm)

Weight: 5.6oz (160g)

Brinell (HB)

Leeb (HLD)

Vickers (HV)

Shore (HS)

HRB: 13 to 100

HRC: 20 to 68

HB: 19 to 651

HLD: 170 to 960

HV: 80 to 967

HS: 30 to 100

www.GlobalTestSupply.com

5

Instrument Description

1 2

4

3

5 6

7

8 9

1. Support Ring

2. LCD Display

3. POWER/Exit Button

4. Menu/Enter Button

5. Measurement set up shortcut/Right/Down/Increase Button

6. Scan/Delete/Left/Up/Decrease Button

7. Micro USB Port

8. Impact Device

9. Coding Sheath

10. Release Button

10

www.GlobalTestSupply.com

6

Display Description

Measured Value Hardness Scale Battery Indicator

HL

Connection Flag

(Cast) Steel

Battery Indicator: Displays battery capacity and charge status when

plugged in.

Impact Direction: Set impact direction.

Hardness Scale: Set hardness scale.

Measured Value: Current measured value (without average value

indicator), or current average value (with average value indicator).

Material: Set material.

Impact Times: The total number of impact times will be displayed. Impact

times set through the menu will also be displayed here.

Connection Flag: The connection ag will blink when the instrument is

trying to connect to the PC. A solid ag means successful connection.

03

Impact DirectionImpact TimesMaterial

continued...

7

www.GlobalTestSupply.com

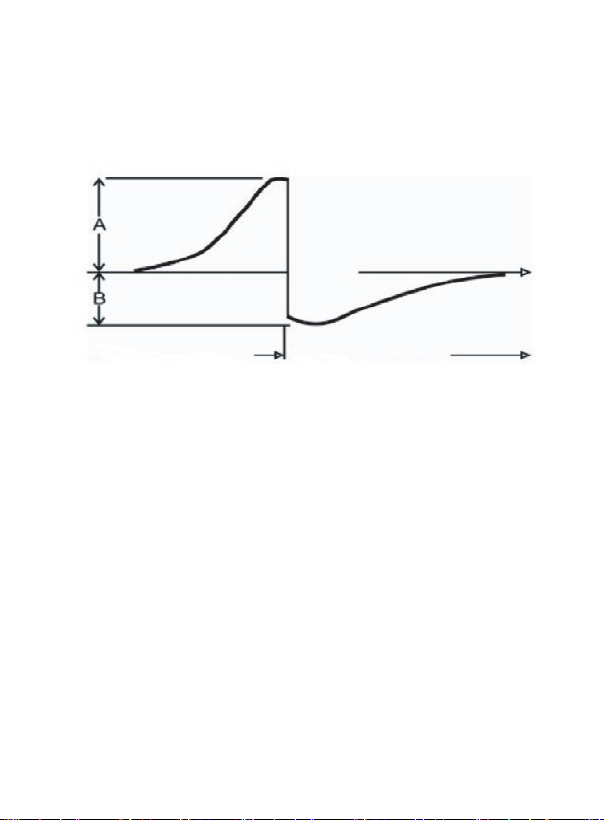

Hardness Testing Principle

The hardness value comes from the rate of rebound velocity and impact

velocity at 1mm distance from the testing surface. Using the Leeb

hardness scale as an example, the following calculation is used to

calculate the hardness value:

HL = 1000 × VB / VA

Time

Impact Phase Rebound Phase

Operating Instructions

Power On/Off

Turn the meter on by pressing the POWER button. To turn the meter off,

press and hold the POWER button for 2 seconds.

Preparation of Test Piece

Please note that measurement values may be affected if the material

under test is exposed to extreme temperatures.

If the tested material is too rough, a measuring error will appear. The

surface of the sample must have metallic luster and the surface must be

at and smooth. No oil or dirt should be present.

Curved surface: It is better that the testing surface of the test piece is

at. When the curvature radius (R) of the curved surface to be tested is

less than 30mm (for D and DL type impact device), a small support ring

(included with the R9030) should be used.

Self-magnetism of the test piece should be less than 30 Gauss.

continued...

www.GlobalTestSupply.com

8

Prior to First Measurement

Before rst use or if unused for an extended period of time,

5 measurements should be performed using the included test block.

If the average values from the charts at the end of this manual are

exceeded, the internal calibration is required (see Calibration Procedure

section for details).

Loading Impact Device

Push down the loading sheath to load and lock the impact body in place.

Taking Measurements

1. Press down on the release button located at the top of the impact

device to take a measurement.

The reading will appear on the display matching the selected material,

hardness or strength testing and impact direction (see Menu Navigation/

Setup Mode section for details).

Note: While taking a measurement, the test piece, impact device and

operator are all required to be stable.

2. Five measurements should be performed of the test piece. The

divergence of data should be not exceed ±15HL of the

required value.

3. The distance between any two impact points, or from the center of

any impact point to the edge of the test piece should be in

accordance with the following specications:

Type of

impact device

D, DC, DL, D+15 No less than: 3mm No less than: 5mm

C No less than: 2mm No less than: 4mm

The distance of two

indentations center

The distance between

indentation center and

edge of test piece

www.GlobalTestSupply.com

continued...

9

Viewing Measurement Values

1. When testing is complete, press the button to enter the recorded

data mode.

2. Press the button to scroll through the recorded data taking during

the measurement process.

3. To delete the displayed data, press the button.

4. Press the or buttons to select between Yes or No.

5. Press the button to conrm selection, or press the button to

exit and resume normal operation.

Storing Average Value

1. When testing is complete, the meter displays the average value

taken during the measurement process.

2. Press the button to enter storing average value mode.

3. Press the or buttons to select between Save & Exit or Quit.

4. Press the button to conrm selection, or press the button to

exit and resume normal operation.

Auto Power OFF

To preserve battery life, the meter is programmed to turn itself off after

5 minutes of inactivity. Prior to shutting off, the display will begin a 10

second countdown that can be cancelled by pressing the

disable this feature, see Enabling/Disabling Auto Shutoff in Menu

Navigation/Setup Mode section for details.

button. To

Menu Navigation/Setup Mode

1. Press the button to enter the menu screen.

2. Press the

following parameters.

Memory Manager View/Delete/Transfer Data

and buttons to scroll through the

Parameter Description

Test Set Setting up your meter

www.GlobalTestSupply.com

continued...

10

Parameter Description

System Set Setting automatic preferences

About View Firmware Version/Serial Number

3. Press the

button to enter the appropriate parameter and follow

the setup instructions below.

Note: At any time, you can press the

button to exit the Menu Screen/

Setup mode and resume normal operation.

Test Set

While in the Test Set function, press the and buttons to scroll

through the following list of sub parameters:

a) Impact Direction

b) Average

c) Material

d) Hardness Scale

e) Tolerance Limit

f) Hard/

b

g) Probe Type

h) Standard

Follow the instructions below to adjust each setting.

a) Impact Direction

1. Press the button when "Impact Direction" is highlighted.

2. Press the

and buttons to scroll through the 360° measuring

direction list.

3. Press the button to conrm selection.

b) Average

1. Press the button when "Average" is highlighted.

2. Press the and buttons to select the number of measurements

to be used to calculate the average value between 1 and 32.

3. Press the button to conrm selection.

continued...

11

www.GlobalTestSupply.com

c) Material

1. Press the button when "Material" is highlighted.

2. Press the and buttons to select the appropriate material

being tested.

For hardness testing, you can select between the following

materials: Cast Steel, Cold Work Tool Steel, Stainless Steel, Gray Cast

Iron, Nodular Cast Iron, Cast Aluminum Alloys, Copper-Zinc Alloys

Copper-Aluminum Alloys, Wrought Copper and Wrought Steel.

For strength testing, you can select between the following materials:

Mild Steel, High-Carbon Steel, Cr Steel, Cr-V Steel, Cr-Ni Steel, Cr-Mo

Steel, Cr-Ni-Mo Steel, Cr-Mn-Si Steel, Super Strength Steeland

Stainless Steel.

3. Press the

d) Hardness Scale

button to conrm selection.

1. Press the button when "Hardness Scale" is highlighted.

2. Press the

and buttons to select the appropriate hardness

scale for the material under test.

Note: The material under test must rst be selected before selecting the

hardness scale.

3. Press the

e) Tolerance Limit

button to conrm selection.

1. Press the button when "Tolerance Limit" is highlighted.

Note: In this function, the Min/Max Tolerance Limits must be set according

the meters measuring range capabilities for each available scale.

2. Press the button to skip to the required digit.

3. Press the

and buttons until the desired value is reached.

4. Press the button to conrm and skip to the next digit.

5. After each value has been selected and conrmed, it will

automatically exit the "Tolerance Limit setup" screen.

www.GlobalTestSupply.com

continued...

12

f) Hard/ b (Hardness/Strength Testing)

1. Press the button when "Hard or b" is highlighted between hard

(hardness testing) or b (strength testing).

2. Press the

or buttons to skip to the next function

when complete.

g) Probe Type

1. Press the button when "Probe Type" is highlighted to select the

appropriate probe.

2. Press the

or buttons to skip to the next function

when complete.

h) Standard

1. Press the button when "Standard" is highlighted to select the

appropriate standard.

2. Press the

or buttons to skip to the next function

when complete.

Memory Manager

This function allows a user to view, transfer, and delete a le/group

previously saved in memory.

Press the and buttons to scroll through the following parameters

within the Memory Manager function.

a) View From No.1

b) View From End

c) View From No.

d) Transfer

e) Delete By No.

f) Delete All

Follow the instructions below to adjust each setting.

Note: If there is no data in the memory, it will display "No Memory!", and

return to the menu screen.

www.GlobalTestSupply.com

continued...

13

a,b) View from No.1/View from End

The data group displays test results, average result, sample material and

impact direction.

1. Press the

2. Press the

3. Press the

button to enter the selected parameter.

button again to activate les to view.

and buttons to scroll the list of saved les.

4. Press the button see details of the measurement data.

5. Press the and buttons to scroll through the details of the

measurement data.

6. Press the button to return to the previous screen at any time.

c) View from No.

This function allows a user to search within a specic group of data les.

1. Press the

2. Press the

3. Press the

button to enter the selected parameter.

button again to skip to the required digit.

and buttons until the desired value is reached.

4. Press the button to conrm and skip to the next digit.

5. After each value has been selected and conrmed, it will

automatically search for the data les matching the search criteria.

d) Transfer

Allows a user to transfer saved data les to the included software by

pressing the button.

e) Delete by No.

This function allows a user to delete les within a specic group.

1. Press the

2. Press the

3. Press the

button to enter the selected parameter.

button again to skip to the required digit.

and buttons until the desired value is reached.

4. Press the button to conrm and skip to the next digit.

5. After each value has been selected and conrmed, the meter will ask

to conrm deletion of the specic groups.

www.GlobalTestSupply.com

continued...

14

6. Press the and buttons to select between "Yes" or "No".

7. Press the button to conrm selection.

f) Delete All

1. Press the button to enter the selected parameter.

2. Press the

and buttons to select between "Yes" or "No".

3. Press the button to conrm selection.

System Set

Press the and buttons to scroll through the following

setup parameters.

1. Auto Save: Off/On

2. Auto Delete: Off/On

3. Auto Transfer: On/Off

4. Auto Off: On/Off

5. Time Date Set

Follow the instructions below to adjust each setting.

Enabling/Disabling Auto Save

1. Press the

2. Press the or buttons to skip to the next parameter

when complete.

Enabling/Disabling Auto Delete

1. Press the

2. Press the

when complete.

Enabling/Disabling Auto Transfer

1. Press the

2. Press the or buttons to skip to the next parameter

when complete.

button to turn Auto Save On or Off.

button to turn Auto Delete On or Off.

or buttons to skip to the next parameter

button to turn Auto Transfer On or Off.

www.GlobalTestSupply.com

continued...

15

Enabling/Disabling Auto Shutoff

1. Press the button to turn Auto Shutoff On or Off.

2. Press the or buttons to skip to the next parameter

when complete.

Setting the Time and Date

1. Press the

button to enter the selected parameter.

2. Press the and buttons to adjust the month as

indicated by "mm."

3. Press the button to conrm and skip to the next digit.

4. Repeat steps 2 and 3 to set the day, year, hour and minutes as

indicated by (dd/yyyy/h/m).

5. After each value has been selected and conrmed, it will

automatically exit the Setting the time and date setup screen.

Quick Setup Mode

1. While in normal operation, press the button to enter the Quick

Measurement Setup Mode.

2. The meter will automatically default to the previously selected

Hardness Scale preset.

3. Press the

material under test.

4. Press the button to conrm selection and jump to the next

parameter (Impact Direction).

Press the button to scroll through the 360° measuring direction list.

5.

6. Press the button to conrm selection and jump to the next

parameter (Material).

7. Press the

8. Press the

parameter (Average).

9. Press the

used to calculate the average value between 1 and 32.

button to select the appropriate hardness scale for the

button to select the appropriate material being tested.

button to conrm selection and jump to the next

button to select the number of measurements to be

www.GlobalTestSupply.com

continued...

16

10. Press the button to exit Quick Setup Mode and resume

normal operation.

Calibration Procedure

1. While the meter is off, press and hold the button while turning the

meter on.

2. Release the button until the meter enters the calibration mode as

indicated on-screen by "Calibration 0/5 times".

3. The required number of measurements to be used to complete

calibration is automatically set to 5.

Note: The selected impact direction should be vertically down on the

Leeb hardness test block.

4. The average value will appear on the screen at the end of

the 5 measurements.

5. If the value exceeds the standard value, press the

buttons to adjust the nominal value.

6. Press the key to nish calibration and resume normal operation.

Note: Calibration range is ±15HL.

and

Connecting to a Computer

The instrument is equipped with a micro-usb port. Using the included

cable, the hardness tester has the ability to connect to a computer, or

external storage device/mini-printer. Measurement data stored in the

memory of the gauge can be transferred to the computer through the

micro-usb port.

www.GlobalTestSupply.com

continued...

17

Launching the R9030 Software

1. Visit www.REEDInstruments.com/software & drivers to download the

R9030 software.

2. Double click on the software labeled DV-R9030 located in the REED

Hardness Tester Dataview folder to launch.

3. If the meter fails to connect, it may require that the driver be

installed separately.

4. The application can be saved to your computer by Extracting all the

les to a specic folder.

Full specications and Operating System compatibility can be found on

the product page at www.REEDInstruments.com. If you have specic

questions related to your application and/or questions related to software

setup and functionality please contact the nearest authorized distributor

or Customer Service at info@REEDInstruments.com or 1-877-849-2127.

Battery Charging and Replacement

When the battery is empty, recharge the Lithium rechargeable battery.

Connect the USB battery cable to the micro USB port and then connect

the other end of the cable to an AC source or computer.

Battery life expectancy with regular use is 3 years. Should you require a

new battery please contact the nearest authorized distributor or Customer

Service at info@REEDInstruments.com or 1-877-849-2127.

www.GlobalTestSupply.com

18

Applications

• Ideal for hardness testing of large and heavy objects

• In production lines of mass produced components

• Materials identication in stores and warehouses

• In locations with difcult access, or in conned spaces

Appendix A: Hardness Scale Tables

The R9030 includes D impact device. Please note that impact devices DL,

DC, D+15 and C can be ordered seperately. For more information please

contact us at 1-877-849-2127 or info@REEDinstruments.com.

Non conventional impact devices DC(D)/DL D+15 C

Impacting energy 11mJ 11mJ 2.7mJ

Mass of impact body

Test tip Hardness 1600HV 1600HV 1600HV

Diameter of test tip 3mm 3mm 3mm

Material of test tip Tungsten

Impact device Diameter 20mm 20mm 20mm

Impact device Length 86(147)/

Impact device Weight

Max. hardness of workpiece 940HV 940HV 1000HV

Mean roughness of workpiece surface

of the Ra

Min. weight of sample:

Measure directly

Need support rmly

Need coupling tightly

Min. thickness of sample:

Coupling tightly

Min.layer thickness for surface harden

Hardness 300HV Indentation diameter 0.54mm 0.54mm 0.38mm

Indentation depth 24μm 24μm 12μm

Hardness 600HV Indentation diameter 0.54mm 0.54mm 0.32mm

Indentation depth 17μm 17μm 8μm

5.5g/7.2g 7.8g 3.0g

carbide

75mm

50g 80g 75g

1.6μm 1.6μm 0.4μm

>5kg >5kg >1.5kg

2-5kg 2 to 5kg 0.5 to 1.5kg

0.05-2kg 0.05 to 2kg 0.02 to 0.5kg

5mm 5mm 1mm

≥0.8mm ≥0.8mm ≥0.2mm

Tungsten

carbide

162mm 141mm

Tungsten

carbide

www.GlobalTestSupply.com

continued...

19

Non conventional impact devices DC(D)/DL D+15 C

Hardness 800HV Indentation diameter 0.35mm 0.35mm 0.35mm

Available type of

impact device

Indentation depth 10μm 10μm 7μm

D: General test

DC: Hole or hollow-cylindrical test

DL: Slender narrow groove

or hole test

D+15:

groove or

reentrant

surface

C: small,

light, thin

parts or

surface of

hardened

layer

Type of

impact device

D (included)

DC (optional)

DL (optional)

D+15 (optional)

C (optional)

Hardness value

of standard Leeb

hardness block

760±30HLD ±6HLD 6HLD

530±40HLD ±10HLD 10HLD

760±30HLDC ±6HLDC 6HLD

530±40HLDC ±10HLDC 10HLD

878±30HLDL

736±40HLDL

766±30HLD+15

544±40HLD+15

822±30HLC

590±40HLC

www.GlobalTestSupply.com

Error of

displayed value

±12HLDL 12HLDL

±12HLD+15 12HLD+15

±12HLC 12HLC

Repeatability of

displayed value

continued...

20

Material

Steel and

Cast Steel

Hammered Steel HB 143~650

Hardness

Test

Method

HRC 17.9~68.5

HRB 59.6~99.6 37.0~99.9

HRA 59.1~85.8

HB 127~651 80~638 80~638 81~646

HV 83~976 80~937 80~996 80~950

HS 32.2~99.5

D/DC D+15 C DL

Impact Device

19.3~67.9

33.3~99.3

20.0~68.2 20.6~68.2

31.8~102.1 30.6~96.8

Cold Work

Tool Steel

Stainless Steel

Gray Cast Iron HB 93~334

Nodular Cast

Iron

Cast Aluminum

Alloys

Brass (Copper-

Zinc Alloys)

Bronze

(Copper-Aluminum/

Copper-Tin Alloys)

Wrought Copper

Alloys

HRC 20.4~67.1

HV 80~898 80~935 100~941

HRB 46.5~101.7

HB 85~655

HV 85~802

HB 131~387

HB 19~164 23~210

HRB 23.8~84.6 22.7~85.0

HB 40~173

HRB 13.5~95.3

HB 60~290

HB 45~315

www.GlobalTestSupply.com

19.8~68.2

20.7~68.2

continued...

21

No. Material HLD Strength b

1 Mild Steel 350~522 374~780

2 High-Carbon Steel 500~710 737~1670

3 Cr Steel 500~730 707~1829

4 Cr-V Steel 500~750 704~1980

5 Cr-Ni Steel 500~750 763~2007

6 Cr-Mo Steel 500~738 721~1875

7 Cr-Ni-Mo Steel 540~738 844~1933

8 Cr-Mn-Si Steel 500~750 755~1993

9 Super strength Steel 630~800 1180~2652

10 Stainless Steel 500~710 703~1676

Accessories and Replacement Parts

• R8888 Medium Hard Carrying Case

Don't see your part listed here? For a complete list of all accessories and

replacement parts visit your product page on www.REEDInstruments.com.

Product Care

To keep your instrument in good working order we recommend the following:

• Store your product in a clean, dry place.

• Change the battery as needed.

• If your instrument isn't being used for a period of one month or longer

please remove the battery.

• Clean your product and accessories with biodegradable cleaner. Do not

spray the cleaner directly on the instrument. Use on external parts only.

• After using the impact device 1000 times, it is recommended to use the

nylon brush provided to clean the guide tube and the impact body of

the impact device. To clean the guide tube, unscrew the support ring

and then take out the impact body. Use the nylon brush to clean in a

counter-clock direction. Repeat this 5 times and remount the impact

body and the support ring.

continued...

22

www.GlobalTestSupply.com

• Remember to release the impact body after use.

• It is strongly recommended to not use any lubricant agent to clean the

impact device.

• The tester should be stored at room temperature, away from vibration,

strong magnetic eld, corrosive medium, dampness and dust.

Product Warranty

REED Instruments guarantees this instrument to be free of defects in

material or workmanship for a period of one (1) year from date of shipment.

During the warranty period, REED Instruments will repair or replace, at no

charge, products or parts of a product that proves to be defective because

of improper material or workmanship, under normal use and maintenance.

REED Instruments total liability is limited to repair or replacement of the

product. REED Instruments shall not be liable for damages to goods,

property, or persons due to improper use or through attempts to utilize the

instrument under conditions which exceed the designed capabilities. In

order to begin the warranty service process, please contact us by phone

at 1-877-849-2127 or by email at info@REEDInstruments.com to discuss

the claim and determine the appropriate steps to process the warranty.

Product Disposal and Recycling

Please follow local laws and regulations when disposing or recycling your

instrument. Your product contains electronic components and must be

disposed of separately from standard waste products.

Product Support

If you have any questions on your product, please contact your authorized

REED distributor or REED Instruments Customer Service by phone at

1-877-849-2127 or by email at info@REEDInstruments.com.

Please visit www.REEDInstruments.com for the most

up-to-date manuals, datasheets, product guides and software.

Product specifications subject to change without notice.

All rights reserved. Any unauthorized copying or reproduction of

this manual is strictly prohibited without prior written permission

from REED Instruments.

www.GlobalTestSupply.com

23

TEST & MEASURE

WITH CONFIDENCE

Access our

Product Catalog

Over 200 portable test and

measurement instruments

www.GlobalTestSupply.com

Loading...

Loading...